.‘

i

PREPARED BY :

DATE

SHARP

SPECIFICATION

DEVICE SPECIFICATION for

Passive Matrix LCD Module

Mode 1 No.

SPEC No. L C 9 9 2 0 4

FILE No.

I SSUED FEB. 5.1999

PAGE 24 Pages

APPLICABLE DIVISION

N DUTY LCD DEVELOPMENT CENTEI

Z TFT DEVELOPMENT CENTER

iIl LCD PRODUCTS DEVELOPMEN

CENTER

i1 EL PRODUCT ION DEPT.

Cl CUSTOMER’S APPROVAL

DATE

Lid3201 921

Y. I noue

Depart d nt General Manager

Mobile LCD Department P.T Module

DUTY LCD Department Center

DUTY Liquid Crystal Display Group

SHARP Corporation

SPEC. No. MO0E.L No. .

RECORDS OF REVISION

LC99204

DOC. FIRST ISSUE

LY3201921

FEB. 5.1999

IDENT. DATA No.

DATE SPEC REVISED REF. PAGE SUMMARY CHECK

REVISED No. &

No. APPROVAL

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .............

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .............

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .............

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .............

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .............

~........___....._...................................................................................................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..--...................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ............

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..-........-...........

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ............

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ............

. . . . . . ..__......_............................*......................................................................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..---.....--.....---...

. . . . . . ..__..........................................................................................................................~

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..-.....--....----.--.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .......--....

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..-.....---.--.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..--....----....

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..-.....-......-.-....

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..*..........................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ............

. . . . . . . . . . . . . . . . . . . . . . . . . . ..-..................................................................................................-....

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ............

. . . . . . . . . . . . . . . . . . . . . . . . ..---.......-..........................................................................................-...-

. . . . . . . .._.....................................................................................................................~....

--.................---.....--.......................................................................................,...............

SHARP

OPrecautions

1) EspeciaJJy the power ON/OFF sequence shown on Page.16 shall be followed to avoid

latch-up of drive LSIs and application of OC voltage to LCD panel.

2) Industrial (Mechanical) design of the

incorporated

optimized. Please consider the optimum viewing conditions according to the purpose

when installing the module. (For the optical characteristics refer to the table .)

3) This module is installed using mounting holes at the four corners of module. When

installing the module, pay attention and handle carefully not to allow any undue

stress such as twist or bend.

A transparent acry'iic resin board or other type of protective panel should be

attached to the front of the module to protect the polarizer, LCD cells, etc.

4) Since the front polarizer is easily damaged. Please pay attention not to scratch

on its face.

5) If the surface of the LCD ceJJs needs to be cleaned, wipe it swiftly with cotton

or other soft cloth. If still not completely clear, blow on its and wipe.

6) Water droplets, etc.,

changes, staining, etc.,

7) Since LCD and TOUCH SCREEN is made of glass plates, dropping the moduJe or banging

it against hard objects may cause cracking or fragmentation.

8) Since CMOS LSIs are equipped in this module, fo'llowing countermeasures must be

taken to avoid electrostatics charge.

l.Operator

Z.Equipment

should be made.

3.Humidity

Humidity of working room may lower electrostatics generating material's

kept over 50 X because humidity less than 50 X may increase material's

electrostatic earth resistance and it become easy to electrify.

4.Transportation/storage

SPEC No.

LC99204

product

must

be made that the viewing angle characteristics of the LCD may be

must be wiped off irnnediately since they may cause color

if remained for a Jong time.

Electrostatic shielding clothes shall be use for fear that the static

electricity human body in case that operator have a insulating garment.

There is a possibility that the static electricity is charged to equipment

which have a function of peeling or mechanism of friction (EX:Conveyer,soldering

in which this LCD module wiJ7 be

MODEL No. PAGE

LM3201 92T 1

iron, working table), so the countermeasure (electrostatic earth:lXlb t2)

rasistance and have something to prevent electrifying. So,humidity shou'ld be

The measure should be made for storage materials because there is a possibility

that the static electricity, which electrify human body or storage materials

like ccntainer by friction or peeling, cause the dielectric charge.

S.Other

The laminator is attached on the surface of LCD module to prevent from

scratches, fouling and dust. It should be peeled off unhurriedly with using

static eliminator.

SHARP

SPEC No. nY)DEL No.

LC99204

LM3201921 2

PAGE

9) Avoid to expose the module to the direct sun-light, strong ultraviolet light, etc.

for a long time.

10) If stored at temperatures below specified storage temperature, the LC may freeze

and be deteriorated. If storage temperatures exceed the specified rating, the

molecular orientation of the LC may change to that of a liquid, and they may not

revert to their original state.

11) Disassembling the LCD module can cause permanent damage and should be strictly

avoided.

12) Don't use any materials that emit gas from epoxy resin (amines'herdener) and

silicone adhesive agent (dealcohol or deoxym) to prevent change polarizer color owing

to gas.

13)Since leakage current, which may ba caused by routing of CCFT cables, etc., may

affect the brightness of display, the inverter has to be designed taking the leakage

current into consideration. Thorough evaluation of the LCD module/inverter built into

its hots equipment shall be conducted, therefore, to ensure the specified brightness.

l4)This specification describes display quality in case of no gray scale. Since

display quality can be affected by gray scale methods, display quality shall be

carefully evaluated for the usability of LCD module in case gray scale is displayed

on

the LCD module.

I

I

SPEC Ho. HODEL Ho.

LC99204

OHANCLING INSTRUCTION FOR TOUCH PANEL

Following precaution should be taken on use of Touch

analog detective type and matrix detective type).

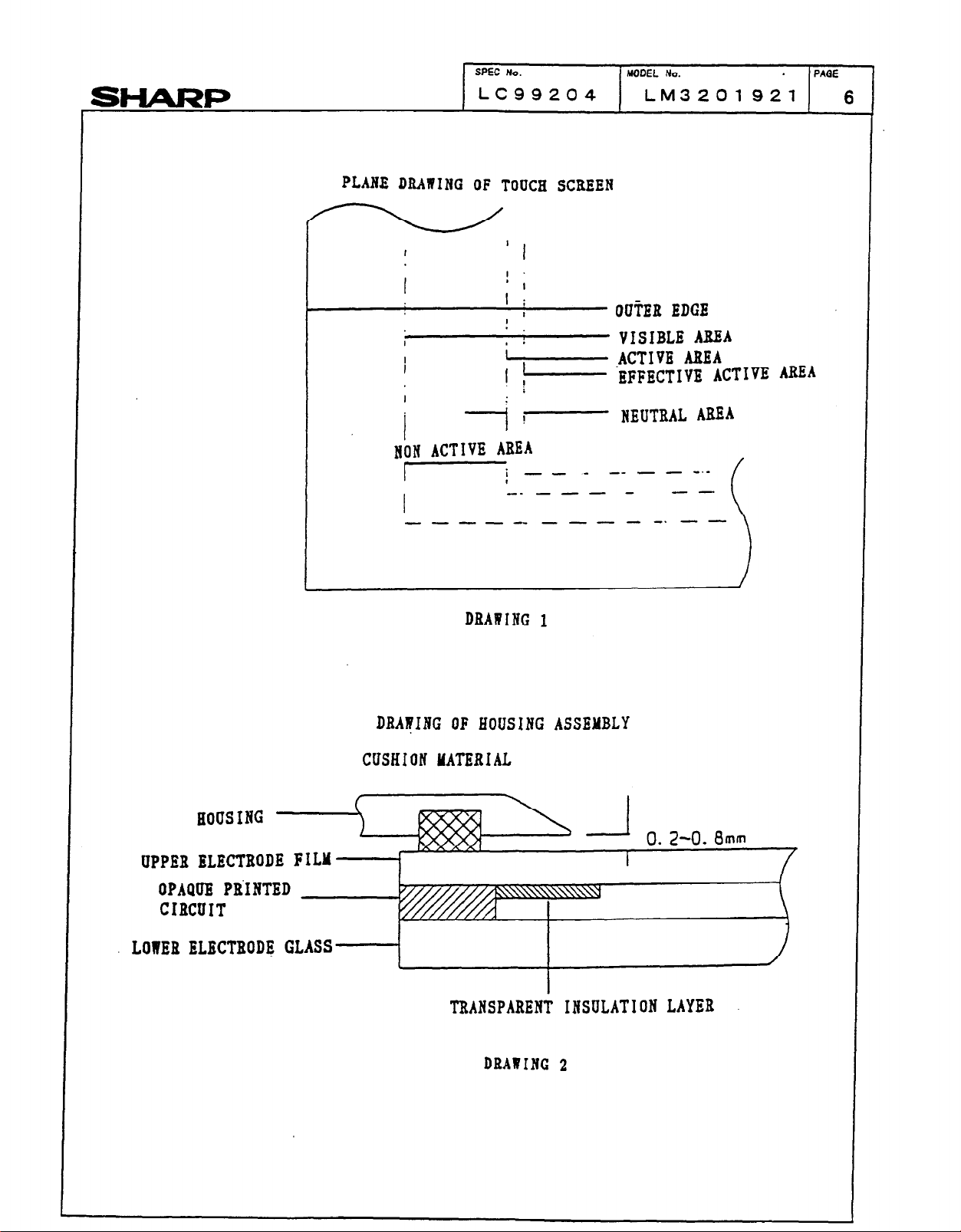

1. PRECAUTION ON DESIGNING TOUCH PANEL

(please see Touch Panel plane drawing 1.)

1) ACTIVE AREA

Active area is described as inputted area by pen or finger, which assures

quality clarified on the specifications related to input action such as

functional property. optical property and durabi I ity.

(1) For detection of coordinates and calibration. it should be always

conducted within active area. If it is conducted outside of the

act i ve area. it may cause functional error.

(2) Area which is actually inputted by pen or finger should be designed

within active area. lf it is designed outside of the active area. it

may cause functional error.

2) NEUTRAL AREA

Neutral area is located in outside of the active area by 0.2-1.011x11

(inside of non active area by 0.2 -~l.Onm~). coordinates can be detected.

but its location is in outside of the area which

clarified on specifications related to input action such as functional

property, opt i ca I property and durab i I i ty.

Neutral area detects coordinates when inputted by pen or finger, but

(1)

it

may cause functional error when it is transacted as data detected.

Si rice a role of the neutral area is to protect non active area.

(2)

hard pushing by tip of a pen, etc. may cause deterioration of its

durab i I i ty.

Screen

assures

LM3201 921.

(IT0 resistive

quality

PAGE

3

3) VIS I

BLE AREA

Thi

S

is transparent area without printed silver electrode or flexible

print circuit printed with opaque ink, it assures quality clarified on

spec if i cat ions

re

la-tad to appearance standard.

4) NON ACTIVE AREA

Upper electrode or lower electrode of the non active area is printed with

transparent insulation ink. it is located in outside of the active area.

Input by pen does not work in this area.

(1) Non active area is printed with insulation ink. hard push may cause

transformation of upper electrode film, active area located near may

contact together.

may generate conductive power.

(2) Since a role of non active area is to hold flatness of the upper

electrode film on its structure. hard pushing by pen or on housing

may cause functional error.

2. PRECAUTION ON DESIGNING PRINT CIRCUIT OR TOUCH PANEL

1) There is contact resistance between upper and

lower electrode

Touch Pane I. Setting impedance of receiving circuit high enough on

-the desien is recommended. Lower irrpedance may

cause

functional

of the

error

SHARP

2) Conduction between upper and lower electrode generates contact

res i stance. Data

contact res i stance become stab I e enough. Otherwise it may cause

functional error.

input

SPEC no.

LC99204

by pen or finger should be started after the

MGDEL No. PAGE

LM320192J

4

3) Touch Pane I picks up noise eas i I y, any measures such as earth. etc

recosxaended. Otherwise it may cause functional error.

3. PRECAUTION ON DESIGNING HOUSING (please see drawing of housing assemb

11 TO RETAIN SPACE BE-MEN UPPER ELECTRODE FILM AND HOUSING TOP.

(1) Retain 0.2-O. &mu space above the non active area not to make

pressure on upper electrode film. If there is any pressure on

It may cause functional error

electrode f i Im.

(2) Flexible material such as robber is recoaxaended for cushion materials.

It should be fixed outside of visible area.

act i ve area. it may cause functional error due to transformation of

the upper electrode film.

2) TO ASSEMBLE ON HOUSING

(1) To f i x Touch Panel on Hous i ng. supporting Touch Panel from back

side (lower electrode glass) is reconxnended.

is fixed with both sides adhesive tape, it may lead to peeling-off of

the upper electrode film due to repeated input pressure.

(2) TO PREVENT SWELLING OF UPPER ELECTRODE Fl LM OF TOUCH PANEL CAUSED BY

ATMOSPHERIC PRESSURE DIFFERENCE BETWEEN INSIDE AND OUTSIDE OF THE

DEVI CE. ETC.

If

upper electrode film

difference between inside and outside of the device, etc., it may

cause deterioration of durability of Touch Panel and may cause

functional error.

(3) TO PREVENT DEW CONDENSATION ON TOUCH PANEL AND TO PREVENT ANY LICU I D

SUCH AS WATER, VAPOR FROM COMING I NT0 TOUCH SCREEN.

Upper electrode film and lower electrode glass of Touch Panel are

fixed with adhesive. and there set

shows liquid may penetrate into Touch Panel easily due to its

structure. any measures on designing the Housing to prevent the

penetration is required. Penetration of liquid may cause functional

error.

swells caused by atomospheric pressure

due

to transformation of the upper

If it is placed over non

If upper electrode fi Im

up

a vent hole between them.

y

it,

is

2.1

This

4. PRECAUTION ON UNPACKING AND ASSEMBLING TOUCH PANEL.

1) STORAGE

Store the product without unpacking in a place where temperature and

humidity is within the range clarified on spec;fications.

2) UNPACK I NG

(1) Check upper and lower side and be sure to unpack from upper side.

(2) Be careful not to hit the product when any tool such as sharp knife is

to be used for unpacking.

SHARP

(3) Do not hold and pull out flexible tail, otherwise it may cause shut

(4) Any treatment i s

3) HANDLING

(1) Pick up outside of visible area for handling. Do not pick up center

I SPEC No.

LC99204

down of the flexible print circuit.

not

made for glass edge. It may

cause any injury when handled by bare hands. Wear a fingerstall or

glove and handle with extra care.

of the visible

area and flexible tail.

1 MOOEL No. 1 PAGE

LM320192i 5

be

sharp and may

(2) Do not stack

It may cause scratch or transformation.

(3) Wipe out any dirt on the product with dried flexible cloth. If it is

heavy dirt, wipe it out with flexible cloth with some ethyl alcohol.

Upper electrode film and lower electrode glass of Touch Panel are

fixed with adhesive, and

Therefore ethyl alcohol may penetrate into Touch Panel easily from

the edge, so extra care is required. It may cause functional error.

4) PRECAUTION ON ASSEMGLY

(1) Be careful not to generate excess distortion on heat sealed area and

flexible tai I. It may cause functional error.

(2) Be careful not to scratch the product on assemb I y.

5) PRECAUTION ON HANDLING

(1) handle the product within the range of temperature and humidity

clarified on specifications.

(2) Use finger or polyacetal pen attached for input to Touch Panel.

Surface of the Touch Panel is bar-code treated, film surface may be

damaged if inputted

up

the products and do not place anything on the product.

there set up

by

ball-point pen or metal piece.

a vent hole between them.

(3) Do not expose Touch Panel to direct sunlight for long period of time.

Polyester film is used on Touch Panel, exposure to direct sunlight

for long period of time may cause discoloration.

(4) If Chemical stays on the Touch Panel for long period of time, upper

electrode film may be swelled and may cause functional error. If it

is to be used under severer circumstances. another measures for water

protection i s requi red.

5. If any other quest i on may be arised. please fee

I free to contact us.

. SHARP

SPEC No.

LC99204

PLANE DRAlING OF TOUCH SCREEN

MGDEL No. PAGE

LM3201 921

6

I

1

I

i

j ,---j !

N&i ACTIVE AREA

I-; - - - -- - - -.- f

I

------_----.

I .

I

I

I I

t

I

* .

;

!+

-.--A -

OUTER EDGE

-EFFECTIVE ACTIVE AREA

VISIBLE ABEA

ACTIVE AREA

NEUTRAL AREA

--

--

\

)

DRAWING 1

HOUS I NG

UPPER ELECTRODE FILM

OPAQUE PRiNTED

CIRCUIT

LOWER ELECTROD! GLASS--{

DRAYIJG OF HOUSING ASSEMBLY

CUSHION MATERIAL

c

)

TRANSPARENT INSULATION LAYER

DRAWING 2

I

0.2-0.8mm

I

/

L

Loading...

Loading...