LPREPARED BY: DATE

APPROVED BY:

DATE

SHARP

LIQUID CRYSTAL DISPLAY GROUP

SHARP CORPORATION

SPEC No. LC99908

FILE No.

ISSU OCT. 1.1999

PAGE 23 Pages

REPRENTATIVE DMSION

Model No.

LM057QCTT03

SPECIFICATION

DEVICE SPECIFICATION for

Passive Matrix LCD Module

ENGINEERING DEPARTMENT

DUTY

LCD DEVELOPMENT

CENTER

DUTY LIQUID CRYSTAL

DISPLAY GROUP

1

q

CUST~MER’S USE ONLY

DATE

BY

PRESENTED _

M.Ise

DEPARTMENT GENERAL

ENGINEERING DEPARTMENT 1

DUTY LCD DEVELOPMENT CENTER

DUTY LIQUID CRYSTAL DISPLAY GROUP

/

MANAGER

RECORDS OF REVISION

SPEC.No.

MODEL No.

LC99908 LM057QCTT03

DOC.

FIRST ISSUE

OCT. 1.1999

IDENT. DATA No.

IATE SPEC REVISED REF. PAGE SUIWARY

REVISED No.

No.

-----._--------..----------.----.---------------.-------------------------------------------------------.------------.--------------

---------------..--.--------.----.---------------.----------------.----------------------------------------~----------.--------------

------______---.____------------.---------------.--------------------------------------------------------------------.--------------

------____-__--..___------------.---------------.----------------.-------------------------------------------------.-.--------------

-----__________.________________________--------.--------------~-----------------------------------------------------.---------~.--.-----_________.____------------.---------------.--------------------------------------------------------------------.-------------.------__------_____------------.---------------.--------------------------------------------------------------------.-------------.-----____-----.____------------.---------------.--------------------------------------------------------------------.--------------.

.-----_-____---.-_______________________--------.--------------------------------------------------------------------.--------------.

-___-_________._____-----------.---------------.----------------.---------------------------------------------------.---------------

-----________-.-____-----------.---------------.--------------------------------------------------------------------.--------------.

-----_________._____-----------.---------------.----------------.---------------------------------------------------.---------------

CHECK

?l

APPROVAL

-_---_______________-----------.---------------.----------------.---------------------------------------------------.--------------

-----________-.-________________________-------.--------------------------------------------------------------------.-------------______________._____-----------.---------------.----------------.-----------------.---------------------------------.--------------

__--__________._____-----------.---------------.----------------.-----------------.---------------------------------.-------------______________._____-----------.---------------.----------------.-----------------.---------------------------------.-------------________________________________________-------.----------------------------------.---------------------------------.-------------.___-_________._____-----------.---------------.----------------.---------------------------------------------------.-------------.___________________-----------.---------------.-------~------------------------------------------------------------.-------------._______________________________________-------.--------------------------------------------------------------------.-------------.--___________._________________________-------.--------------------------------------------------------------------.--------------

---_________________----------.---------------.-___________________-------------------------------________________________________________------.----------------.-------------------------------------

____.___________________________________------.--------------------------------------------------------------------

-----_______-.-_________________________------.-------------------------------------------------------------------- ----------_---.

-----________.-_________________________------.________________________________________---------------------------- .--------_------

________________.__------------

_______,_____---------

_-_-me-

.___---_---____

,_.

SHARP

Precautions

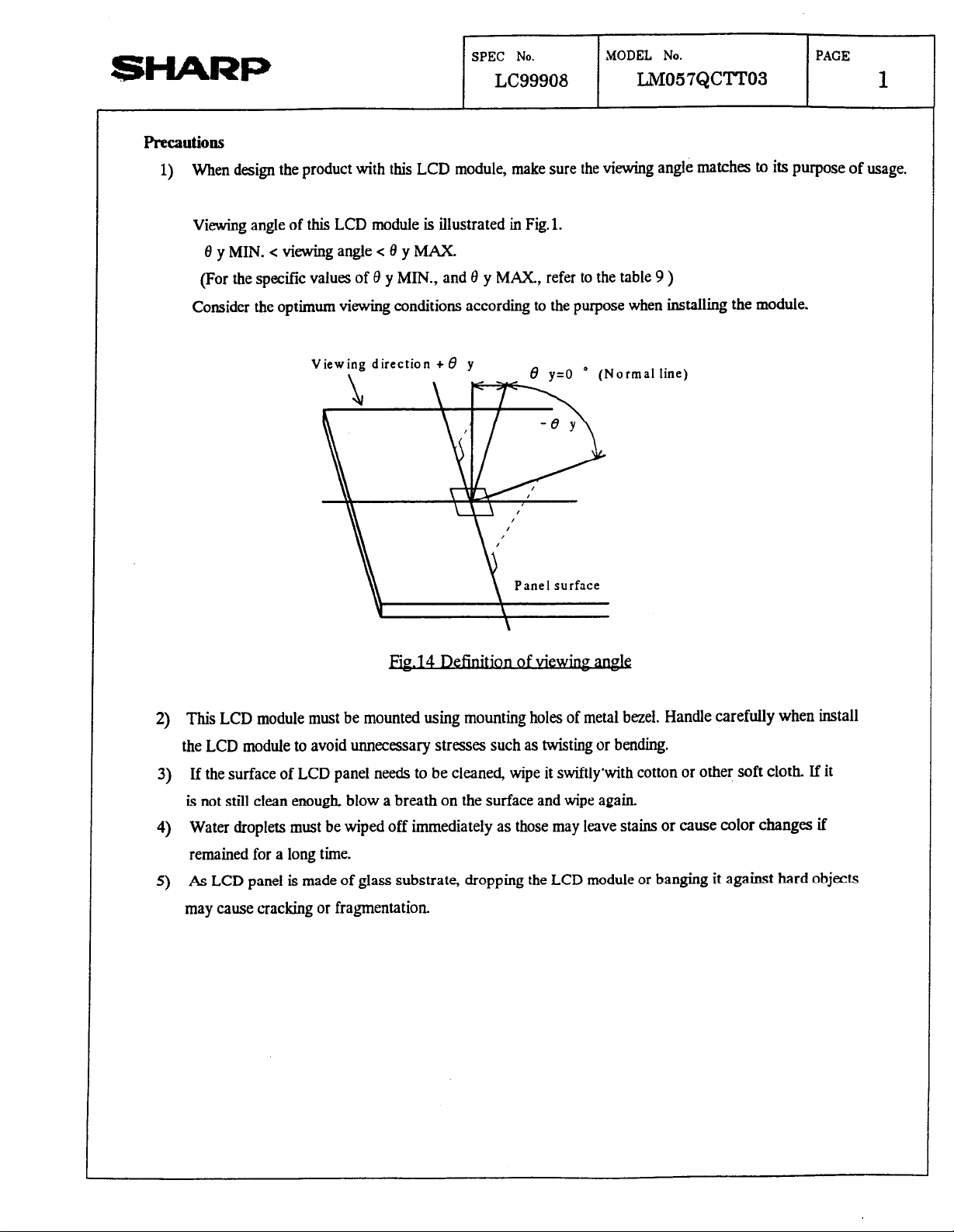

1) When design the product with this LCD module, make sure the viewing angle matches to its purpose of usage.

Viewing angle of this LCD module is illustrated in Fig. 1.

8yMIN.<viewingangle<OyMAX.

(For the specific values of 6 y MIN., and 8 y MAX., refer to the table 9 )

Consider the optimum viewing conditions according to the purpose when installing the module.

SPEC No.

LC99908

MODEL No.

LM057QClT03

I

PAGE

1

I

Viewing direction + 6

Ei~-14 Definttlonofwe~

2) This LCD module must be mounted using mounting holes of metal bezel. Handle carefully when install

the LCD module to avoid unnecessary stresses such as twisting or bending.

3) If the surface of LCD panel needs to be cleaned, wipe it swiftly’with cotton or other soft cloth If it

is not still clean enough, blow a breath on the surface and wipe again

y

Panel surface

. . . .

ormal line)

4) Water droplets must be wiped off immediately as those may leave stains or cause color changes if

remained for a long time.

5)

As LCD panel is made of glass substrate, dropping the LCD module or banging it against hard objects

may cause cracking or fragmentation.

@HARP

6) As CMOS LSIs are equipped in this module, following countermeasures must be taken to avoid

electrostatics charges.

1. Operator

Ware the electrostatic shielded clothes because human body may be statically charged if not ware shielded

clothes.

2. Equipment

I I

SPEC No. MODEL No.

LC99908

LM057QCTT03

I

PAGE

2

There is a possibiiity that the static electricity is charged to the equipment which have a function of

or friction action(ex: conveyer, soldering iron, working table). Earth the equipment through proper

resistance(electrostatic earth: 1 X 10” 9).

3. Floor

Floor is the important part to drain static electricity which is generated by operators or equipment.

There is a possibility that charged static electricity is not properly drained in case of insulating floor.

Set the electrostatic earth(1 X lO”S2).

4. Humidity

Proper humidity helps in reducing the chance of generating electrostatic charges. Humidity should be kept

over 50%RH.

5. Transportation/storage

The storage materials also need to be anti-static treated because there is a possibility that the human body or

storage materials such as containers may be statically charged by friction or peeling.

6. Others

The laminator@rotective film) is attached on the surface of LCD panel to prevent it from scratches or stains.

It should be peeled off slowly using static eliminator.

Static eliminator should also be installed to the work bench to prevent LCD module from static charge.

7) Do not use any materials which emit gas from epoxy resin(hardener for amine) and silicone adhesive

peeling

agent(dealcoho1 or deoxym) to prevent discoloration of polarizer due to gas.

8) The brightness of the LCD module may be affected by the routing of CCFI cables due to leakage to the

chassis through coupling effect. The inverter circuit needs to be designed taking the level of leakage current

into consideration. Thorough evaluation is needed for LCD module and inverter built into its ho& equipment

to ensure specified brightness.

9) Avoid the exposure of the module to the direct sun-light or strong ultraviolet light for a long time.

10) If the LCD module is stored at below specified temperature, the LC material may freeze and be deteriorated

If it is stored at above specified temperature, the molecular orientation of the LC material may change to

Liquid state and it may not revert to its original state. Therefore, the LCD module should always be stored

within specified temperature range.

11) Disassembling the LCD module can cause permanent damage and it should be strictly avoided

@HARP

12) Procedure to insert mating connector

SPEC No.

LC99908

MODEL No.

LM057QCTT03

PAGE

3

When the mating connector is inserted, it should be parallel to the connector on the

should be inserted horizontally. Do not leave a gap beh>een two connectors.

13) The module should be driven according to the specified ratings to avoid malfunction and permanent damage.

Applying DC voltage causes a rapid deterioration of LC material. Make sure to apply alternating waveform

by continuous application of the M signal. Espe&&& power ON/OFF sm 17 &n&l&

t to avov DC m

14) LCD retains the display pattern when it is applied for long time.(Image retention)

To prevent image retention. do not apply the flied pattern for along time.

15) Image retention is not a deterioration of LCD. It will be removed after display pattern is changed

16) CCFI’ backlight should be kept OFF during VDD is “L” level.

Precautions for touch panel

1) Designing

1. Active area

Active area is defined as input area by pen or finger. Its function, optical properties and durability

LCD

module and it

are specified in the specifications.

a) Detection of coordinates and calbration must always be conducted within active area. If those are

conducted outside of the active area, those may cause functional errors.

b) Area which is actually accessed by pen or finger must be designed within active area. If it is

designed outside of the active area, it may cause functional error.

2.Neutral area

Neutral area is located around the active area for l.Omm wide. Although the coordinates can be detected

in this area, its functionality, optical properties and durability are not assured.

a) Neutral area detects coordinates when input by pen or finger, but it may cause functional error

when it is treated as detected data.

b) As the purpose of the neutral area is to protect inactive area, pushing hardly by pen tip or others

may cause deterioration of its durability.

3.Visible area

This is transparent area where silver electrode or flex printed with opaque ink are not existing.

It assures qualities related to appearance standards defined in the specifications.

4Jnactive area

Upper electrode or lower electrode in the inactive area is printed with transparent insulation ink on it.

It is located outside of the active area and a non functional area.

a) Inactive area is printed with insulation ink. Hard push action may cause a deformation of upper

electrode film and may lead to a malfunction in the active area nearby. Upper electrode may come

J

@HARP

b) As the purpose of the inactive area is to keep the flatness of the upper electrode ftirn in the touch panel

Designing print circuit

1. There is a contact resistance between upper and lower electrodes of the touch panel. It is recommended

to set the impedance of detecting circuit high enough. Low impedance detecting circuit may cause a

functional error.

2. Contact of the upper and lower electrode generates a contact resistance. Access by pen or finger to the

touch panel should be started after the contact resistance becomes stable. Otherwise, it may cause

a functional error.

3. Touch panel picks up a noise easily. It is recommended to earth or do other noise protections. Otherwise,

it may cause a functional error.

r I

SPEC No.

MODEL No. PAGE

LC99908 LM057QCTT03

in contact with lower electrode and may cause a electrical leakage.

structuie. hard push by pen or by system chassis may cause a functi&al error.

I

4

Designing system chassis

1. Retain the air gap between upper electrode film and front chassis.

a) Retain minimum of 0.3mm air gap above the inactive area so that the front chassis does not make a

pressure on upper electrode film. If there is any pressure on it, it may cause a functional error due to

the deformation of the upper electrode film.

b) Flexible material such as rubber is recommended as cushioning materials. It should be placed outside of

visible area. If it is placed onto inactive area, it may cause a functional error due to deformation of

the upper electrode film.

2. Assemble design

a) Do not glue nor tape system front chassis to the surface of touch panel(upper electrode fam) as it may

lead to peeling off of the upper electrode film

b) Make sure not to swell the upper electrode film by atmospheric pressure difference between inside and

outside of the system. If it is swelled, it may cause a deterioration of durability of the touch panel and

may cause a functional error.

c) Prevent vapor condensation to the touch panel. Do not expose the touch panel to high humidity

Atmosphere, vaporous air, or to any liquid such as water. It may cause a leakage inside the touch panel

structure:

Upper electrode film and lower electrode glass are fied by adhesive, and there is a ventilation hole

between film and glass. Liquid penetrate into touch panel easily due to this structure. Design the system

carefully so that liquid will not penetrate into touch panel.

SHARP

Assembling LCD module with touch panel

* 1. Unpacking

SPEC No.

LC99908

a) Do not hold nor pull flex cable. otherwise it may cause a breakage of the flex.

b) Glass edge of touch pane1 is not treated It is sharp edge and it may cause an injury when handled

by bare hands. Wear finger sacks or groves and handle with extra care.

2. Handling

a) Do not pick up the visible area or flexible tail.

b) Do not stack up the LCD module. Do not place anything on the LCD module. It may cause scratch,

deformation or breakage.

c) Wipe a dirt on the screen with dry soft cloth If it is still sticked, wipe it out with soft cloth with

ethyl alcohol. Upper electrode film and lower electrode glass of touch panel are fixed by adhesive

and there is a ventilation hole in between. Be careful not to have ethyl alcohol may penetrate into

touch panel. It may cause a functional error.

iMODEL No. PAGE

LM057QCTT03

5

3. Assembling

a) Be careful not to apply excessive distortion on heat sealed area of the flex cable. It may cause a

functional error.

b) Be careful not to scratch the front of touch pane1 during assembly process.

4. Operating instruction

a) Use a finger or a polyacetal pen to access to touch panel. The surface of the touch panel film

is hard coat treated. This hard coating may be damaged if it is touched by a ball-point pen or

metal piece.

b) Do not expose the LCD module to the direct sun-light for long period of time. Polyester film is

used as the front film of the touch panel, exposure to direct sun-light for long time may cause

a discoloration

c) If a chemical material stays on the touch panel for long period of time, front film may be swelled

and may cause a functional error. If it is planned to be used under severer circumstances, very

careful protection is required

SHARP

SPEC No. MODEL No. PAGE

LC99908 LM057QCTI'03

6

OContents

1. Application

2. Construction and Outline

3. Mechanical Specifications

4. Absolute Maximum Ratings

5. Electrical Specifications

6. Module driving method

7. Optical Characteristics

8. Characteristics of Backlight

Page

7

7

7

15

17

20

9. Touch panel specification

10. Supply voltage sequence condition

11. Outline dimension

21

22

23

Loading...

Loading...