Page 1

SERVICE MANUAL

LCD COLOR MONITOR

MODEL LL-T155A

CONTENTS

NOTES TO SERVICE PERSONNEL................................................................................. 1

CAUTIONS IN SERVICING............................................................................................... 1

CHAPTER 1: OUTLINE OF THE PRODUCT AND NOMENCLATURE................................. 4

CHAPTER 2: REPLACING LAMPS....................................................................................... 6

CHAPTER 3: CONNECTION, ADJUSTMENT, OPERATION, AND FUNCTIONS................ 8

CHAPTER 4: TROUBLESHOOTING....................................................................................12

CHAPTER 5: TRIMING AND PROCESSING LEAD WIRES................................................14

CHAPTER 6: BLOCK DIAGRAM/UNIT TERMINALS ...........................................................15

CHAPTER 7: APPAEARANCE AND DISASSEMBLY DRAWINGS OF MECHANISMS......17

CHAPTER 8: PACKAGING METHOD..................................................................................18

Parts marked with " " is important for maintaining the safety of the set. Be sure to replace these parts with specified

ones for maintaining the safety and performance of the set.

This document has been published to be used

SHARP CORPORATION

for after sales service only.

The contents are subject to change without notice.

Page 2

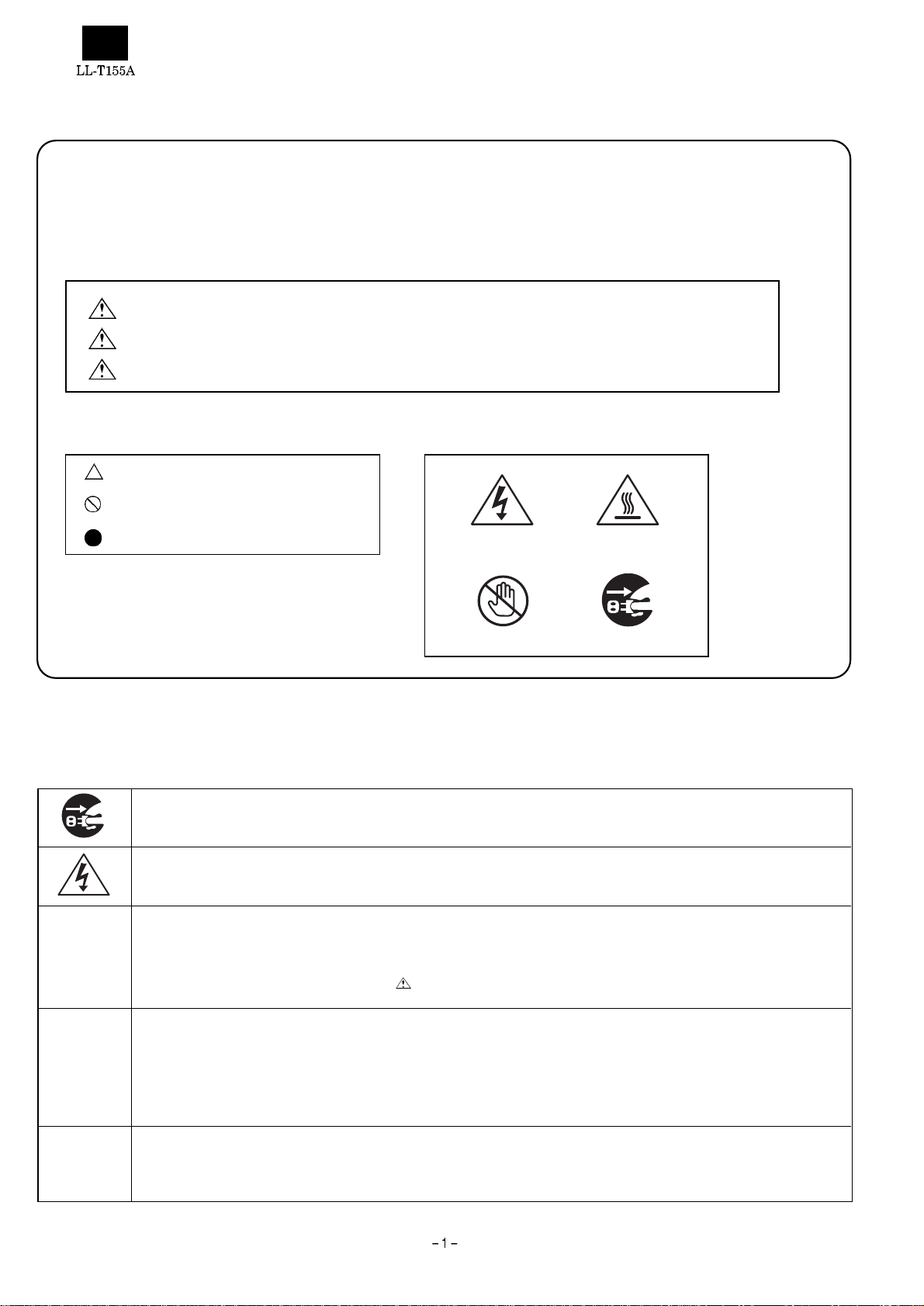

■Notes to service personnel

·Pictorials

· This servic e manual and th e product us e a variety of pic torials in or der to assure the s afety of repair op erations and of the product

repaired.

· If those pictorials are ignored in repairing, the following troub les might occur:

· Understand the meaning of those pictorials and read this manual carefully before trying to repair the product.

DANDER:

WARNING:

CAUTION:

Failure to follow the instructions in the message might cause a serious accident or death.

Failure to follow the instructions in the message might cause a serious accident or death.

Failure to follow the instructions in the message may cause personal injury or damage to the asset.

·Meaning of symbols ·Pictorial example

symbols mean the necessi t y of using caution.

symbols mean actions wh ich are prohibited.

symbols mean actions to b e required.

■Cautions in servicing

Locations which requi r e a special caution carry safety instructions using labels and stamps on the cabinet, chassis and components.

When servicing, observe t he instructions on such labels and stamps.

Electrical shock Hot surface

Don’t touch Remove power plug

Electrical shock and burn

1. Prior to servicing, make sure to remove the powe r supply plug.

Electrical shock

2. Some parts inside the unit have a high voltage. Use caution to avoid an electrical shock accident when servicing an energized

unit.

Use specified parts

3. The component pa rts of this unit have saf et y characteristics such as flam e resistance and dielectric st rength.

· Use replacement parts which have the same characteristics as those of the components parts used for this unit.

· In particular, component parts marked with in the circuit drawing parts list are important for mainta ining the safety of the

product. Make sure to use specified replacement parts.

Reinstall component parts in their original locations and return wires which have been rerouted for servicing

purposes to their original positions.

4. Some com ponent par ts us e ins ulati ng ma terial s suc h as tu bes or tape f or sa fety pur pose s, or a re mo unted , a bit fl oated , on the

printed wiring bo ard.

· When rerouting inside wiring or clamping the wires, use caution not to bring the wires too close t o heating or high-voltage parts.

· Make sure to return inside wiring to their original locations.

Check for safety after servicing.

5. After finishing servicing, check whether the screws, parts, wires which have been removed for servicing are reinstalled properly.

In addition , chec k to see i f yo u hav e not d eter iorate d par ts a round the pa rt yo u ser vic ed, a nd als o ch eck f or in sulati on be tween

each of the attachment plug terminals and the external metal section.

Page 3

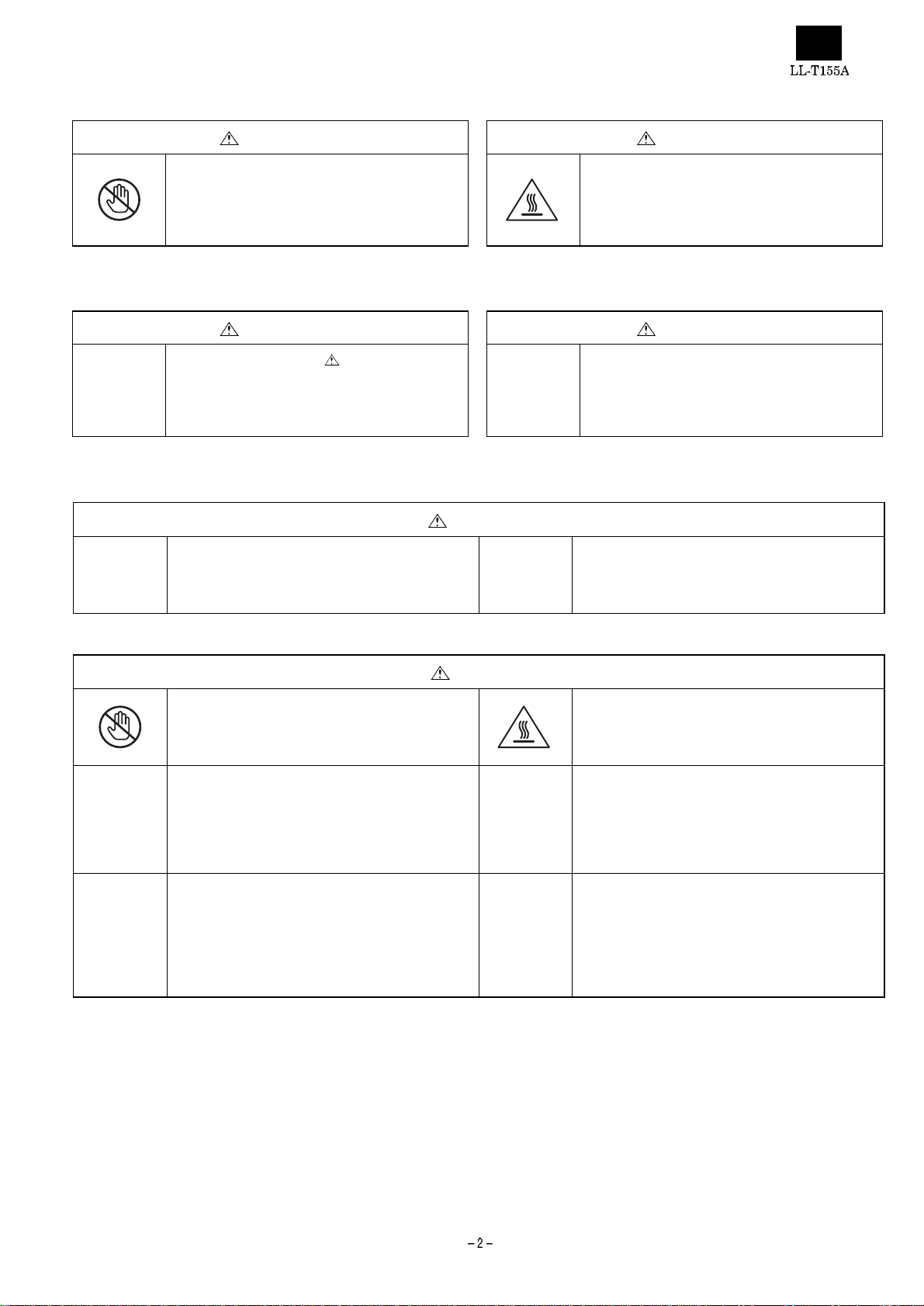

·Cautions to be taken when making adjustments

WARNING CAUTION

1. Use caution to avoid shorts due to the probe of an

oscilloscope or jigs and do not touch high-voltage

circuits directly.

(There is fear of causing a fire or your getting an

electric short accident)

·Cautions to be taken when replacing electrical parts

WARNING CAUTION

1. Parts marked with are important for

maintaining the safety of the product. Use

specified parts when replacement of such parts is

required. (There is fear of giving off smoke,

catching fire, or your getting an electric shock)

·Cautions to be taken when soldering

WARNING

1. Do not try to solder when th e parts are energized or

the unit is turned on.

(There is fear of causing fire or your getting an

electric shock.)

2. Use caution not to touch heating parts like the

radiating plate directly.

(You could get a burn.)

2. Use caution not to damage the LCD unit when

handling it.

2. Use caution not to damage peripheral parts and

lead wires (e.g., burning peeling o f coating).

(There is fear of causing a fire or your getting an

electric shock accident.)

CAUTION

1. Use caution not to touch a soldering iron directly.

(You could get a burn.)

3. Use caution not to have the wrong direction when

installing parts, if they need the installation of a

correct direction.

(There is fear of causing a fire.)

5. Some parts need to be installed at a specified

intervals or by a specified method for safety

purposes (they may be a bit floated from the board

for dissipating heat.). They mu st be reinstalled to

the original conditions.

(There is fear of causing a fire or your getting an

electrical shock accident.)

2. Make sure the radiating plate or heating parts are

cool enough not to get a burn before touching such

a part.

(You could get a burn.)

4. Use caution to avoid shorts due to an improperly

cut length of parts’ lead legs after soldering and

exercise care not to cut your finger with the edge of

cut surface.

(There is fear of causing a fire or your getting an

injury.

6. Use caution to solder in a correct manner so that

areas other than the part you want to solder are

contaminated with solder, like a solder ball or

bridge.

Page 4

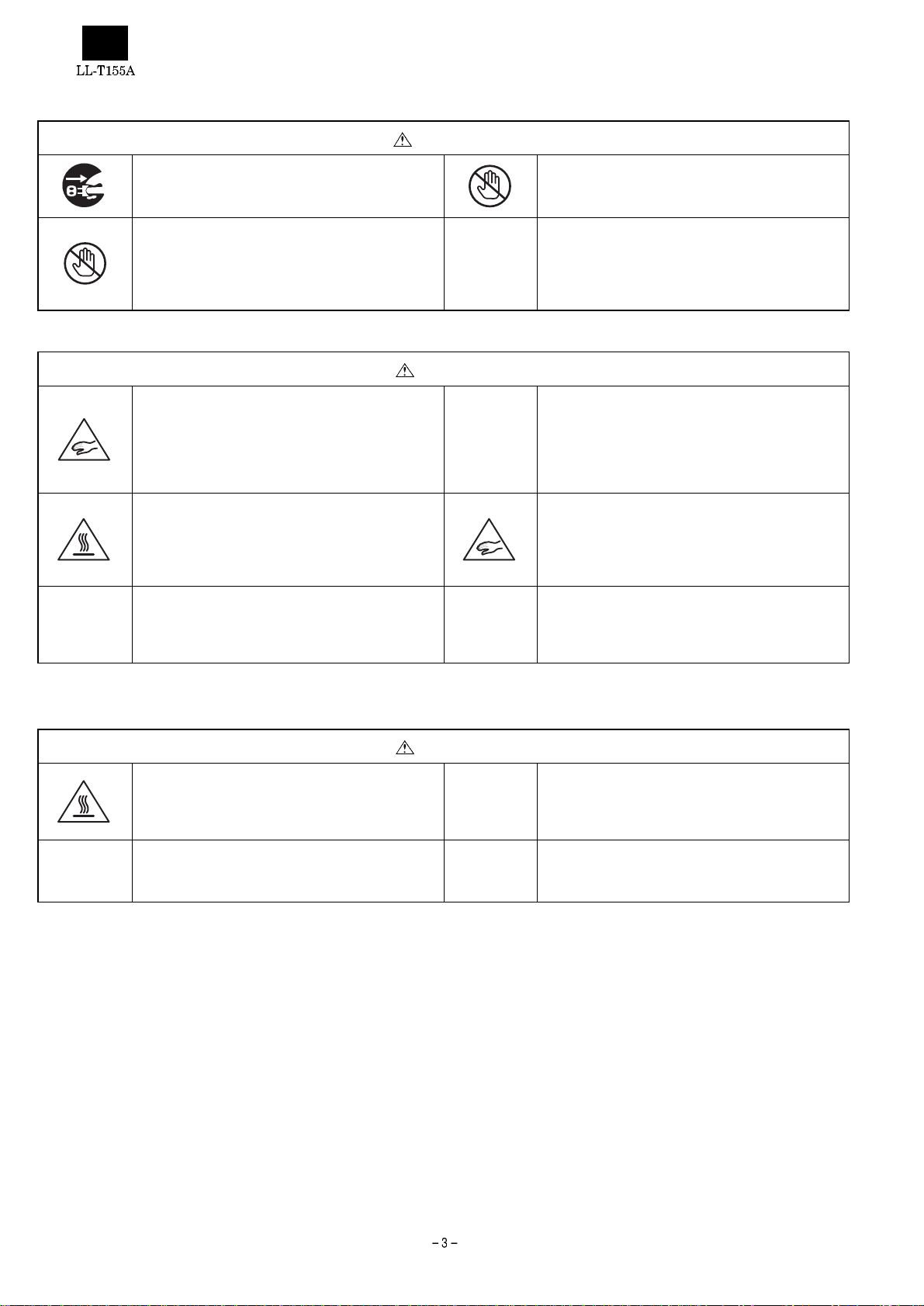

·Cautions to be taken when disassembling or reassembling the unit

WARNING

1. Prior to servicing, make sure to remove the power

supply plug.

(You could get an electrical shock accident.)

3. Before servicing, make sure you know the locations

of high-voltage p art s.

(You could get an electrical shock accident.)

CAUTION

1. When disassembling or reassembling the unit,

make sure to put the front c abinet side (LCD unit

side) downward and carry out work using caution

not to get your fingers caught.

(Since the LCD unit side is heavier, there is fear of

your getting an injury due to tipping or falling.)

3. When disassembling th e unit, use caution not to get

a burn because r adiating plates and areas around

lamps on the PWB are hot immediately after

unplugging.

(You could get a burn.)

5. Pay attention to burrs or edges of the resin (c ab inet

and PWBs) and metal (chassis and others) parts.

(You could cut your finger with them.)

2. Use caution not to touch the inside of the product

with a wet hand or foot.

(You could get an electrical shock accident.)

4. Do not work on an un stab le plac e or with the stan d

put upright. In particular, fix the cabinet before

replacing PWBs or fan.

(There is fear of your getting an injury due to

tipping or falling.

2. Use caution to avoid a reaction due to your

applying too much force when removing or

reinstalling screws.

(You could get an injury.)

4. Use caution not to get you fingers caught in the

stand pole, between the stand and angles or under

the cabinet.

(You could get an injury.)

6. Use caution to the deformation of the grounding

spring or the displacement of the ferrite core.

(There is fear of causing radio noises to other

equipment.)

·Cautions to be taken when replacing fluorescent lamp

CAUTION

1. Make sure the fluorescent lamp is cool enough not

to get a burn before you are going to touch the

lamp or areas around it .

(You could get a burn.)

3. Use caution not to break the fluorescent lamp when

handling it.

(You could get an injury.)

2. Use caution to avoid a reaction due to your

applying too much force when removing the

connector.

(You could get an injury.)

Page 5

CHAPTER1. OTLINE OF HE PRODUCT, NOMENCLATURE AND FUNCTIONS

[1] Features

· 38 cm [15 ty pe] 1024-dots x RGB x 7 68-line high-resolu tion TFT

color LCD panel

· 200 cd/m

2

high-luminance d esign

· Connectable to analog RGB output (for CRT)

Multi display mode function that supports resolutions from 640-dot

x RGB x 400-line to up to 1024-dot x RGB x 768-line

In modes l ower than 800 x 600 dots, it is possib le to enlarge the

screen that offers smooth and excellent visibility.

Supports VESA specification, PC9800 series, Power Ma cin tosh.

· Up to 16 million colors can be displayed.

· Automatic screen adjustment

· The display timing and RGB gain can be more finely adjusted due

to the OSD guide functi on, in addition to the automati c adjustment

function.

· Power management fu nction

· Supports Plug&Play (VESA:DDC1, DDC2B specifications)

[2] Safe servicing and safe inspection,

<When servicing or inspecting,

observe the safety instructions.>

1. Observe the cautions.

Locations which require a special caution carry safety instructions

using labels and stamps on the cabinet, chassis and components.

When servicing, observe the instructions on such labels and

stamps as well as those in the Instruction manual.

2. Exercise care not to get an electric al shock

accident.

Some parts have a high voltage inside the unit. Use caution when

handling them while they are energized.

3. Use specified parts.

The component parts of this unit have safety characteristics such

as flame resistance and dielectric strength. Use replacement parts

which have the same characteristics as those of the components

parts used for th is un it. In particular, component parts marked with

in the cir cuit dr awing parts list ar e imp ortant for m aintain ing th e

safety of the product. Make sure to use specified replacement

parts.

5. Check for safety after servicing.

After finishing servicing, check whether the screws, parts, wires

which have be en r em ove d f or serv ic ing a re r ein s talle d p rop erl y. In

addition, check to see if you have not deteriorated parts around th e

part you serviced, and also check for insulation between each of

the attachment plug terminals and the external metal section.

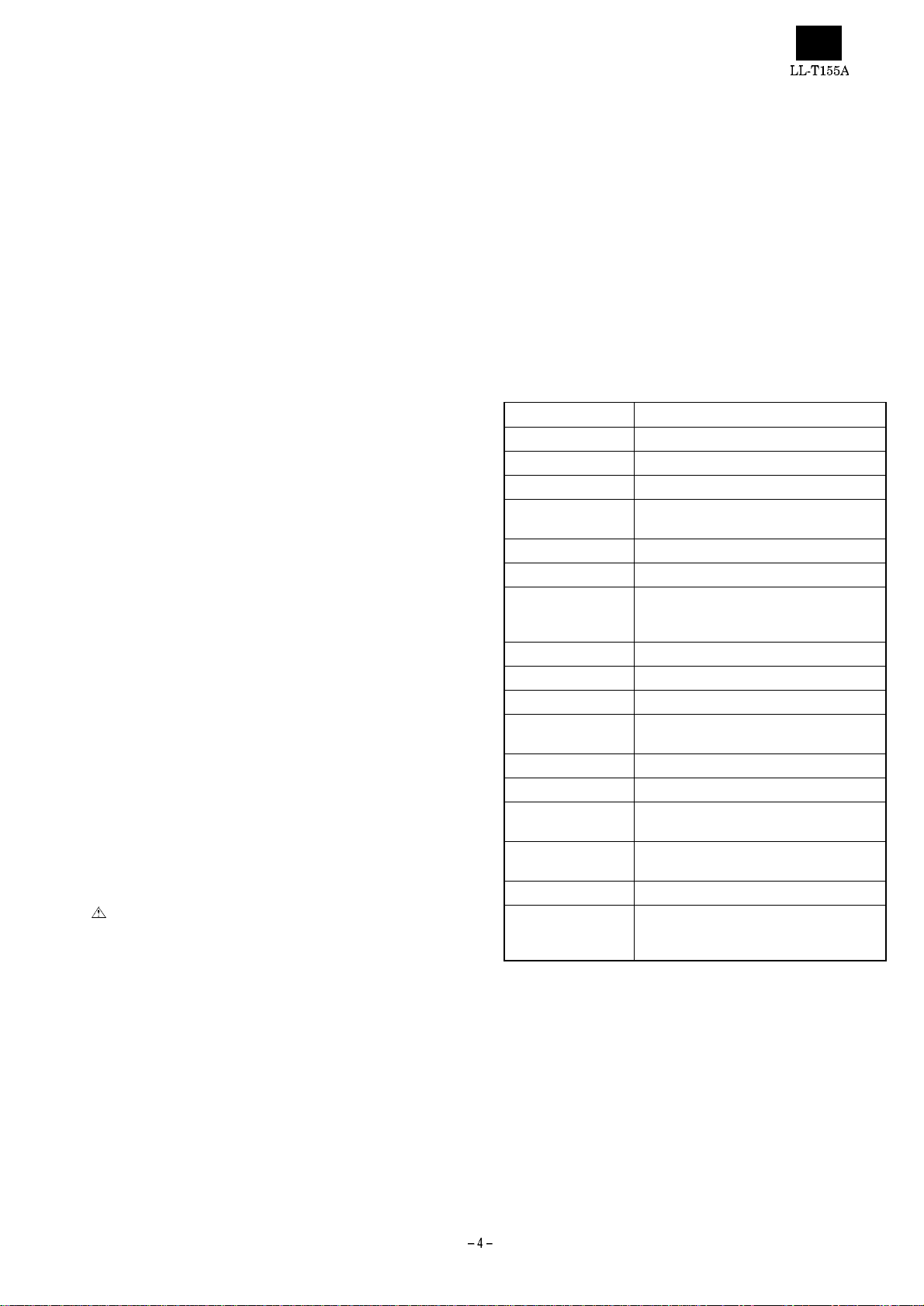

[3] Specifications

1. General specification s

Name of the product: LCD color monitor

Model: LL-T155A, LL-T155B

Item Specifications

LCD display device 38 cm (15 type) TFT color LCD

Picture element pitch 0.297 mm (horizontal) x 0.297 mm (vertical)

Display area 304.1 mm (horizontal) x 228.1 mm (vertical)

Number of picture

elements

Display color approx. 16 million colors (max.)

Input vide signal Analog RGB (0.7 Vp-p/75

Input synchronizing

signal

Input terminal 15-pin mini D-sub connector

USB USB cable relay connector

Plug&Play VESA DDC1/DDC2B

Power management

function

Working temperatu re 5 ~ 35°C

Power supply 100 V AC 50/60 Hz

Power consumption approx. 22 W/ abo ut 3 W in power sav e

Outer dimen sions about 385 mm (width) x 203 mm (depth) x

Weight approx. 6 kg

Accessories AC power supply cord (1), Instruction

1024 x RGB x 768 dots

W )

Horizontal synchronizing sign al TTL level

(positive, negative), vertical synchronizing

signal TTL level (positive, neg ative)

Compatible with VESA DPMS

mode

373 mm (height)

manual (1), warranty (1), adjustment disk

(1), USB cable (1)

4. Reinstall component parts in their original

locations and return wires which have been

rerouted for servicing purposes to their original

positions.

Some component parts use insulating materials such as tubes or

tape for safety purposes, or are mounted, a bit floated, on the

printed wiring bo ard.

When rerouting inside wiring or clamping the wires, use caution not

to bring the wires too close to heati ng or high-voltage pa rts.

Make sure to return inside wiring to their original locations.

· Specifications and a part of the appearance are subject to change

without notice.

Page 6

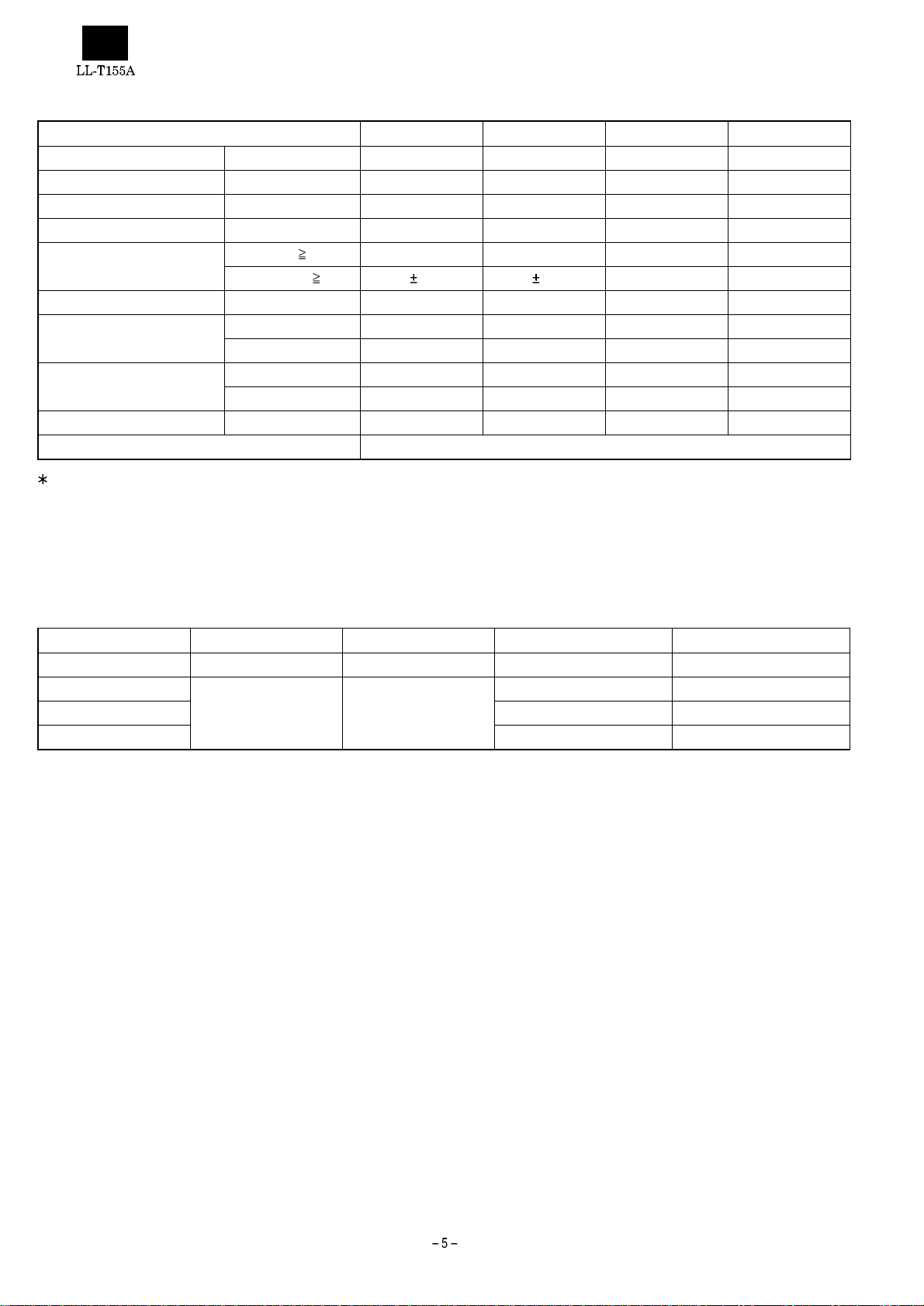

2. Technical specifications

Item MIN TYP MAX Unit

Power supply voltage AC 90 100 110 V

Working temperatur e range +5 — +35 °C

Storing temperature range -20 — +60 °C

Humidity range 20 — 85 %RH

Visual angle range Vertical (CR

Horizontal (CR

Contrast ratio(CR) (

Response speed Leading (

Screen white chromaticity (X) 0.283 0.313 0.343 —

White surface lumina nce (Y

Module model number LQ150X1DH10

Specifications and a part of the appearance are subject to change without notice.

q = 0°) 150 — — —

Trailing (

(Y) 0.299 0.329 0.359 —

) 150 200 — cd/m

L

[Power management]

This unit supports VESA*1 DPMS*2.

To use the power management funct ion of this unit, the video card and

the computer must be compatible with the DPMS specifications.

*1 VESA: Video Electronics Standards Association

*2 DPMS:Display Power Management Signaling

5) +20 ~ -50 +35 ~ -60 — Temperature

5) 50 55 — Temperature

t r) — 10 25 ms

t d) — 35 50 ms

2

DPMS mode Screen condition Power consumption Horizontal synchronizati on Vertical synchronization

ONSTATE Displayed state approx. 22 W Yes Yes

STANDBY

SUSPEND Yes No

OFFSTATE No No

No display approx. 3 W

No Yes

[DDC*3]

This unit supports VESA’s DDC specifications

DDC means a signal specification that offers Plug&Play function to the

monitor and the personal computer.

Information about resolution and others are communicated between

the monitor and the personal computer.

This function is available when the personal computer supports DDC.

There are some DDC types depending on different communication

methods.

This unit supports DDC1 and .DDC2B.

*3 DDC: Display Data Channel

Page 7

[4] Nomenclature and functions

[Front part]

1

1

2

3

Power-on lamp

Light comes on when the power supply is turned on.

The light is green in the normal display mode and orange in the

power save mode.

and buttons

1) Display the adjustment menus.

2) Switch over the adjustment menus (MAIN MANU and SUB

MENU)

3) Change the setting of the adjustment option selected.

DOWN and UP buttons

1) Display the adjustment menus

2) Select adjustment items

[Rear part]

Power supply connector

Make sure to use the AV power supply cord supplied with the unit.

Power supply switch

( | ) : The power is turned on. (T he power-on lamp comes on.)

) : The power is turned off.

(

Signal cable

This cable is used to connect the monitor to the analog RGB output

connector of the computer.

USB DOWN connector

This is sued to connect the monitor to USB devices.

USB UP connector

This is used to connect the monitor to a computer.

CHAPTER2. REPLACING LAMPS

(Removing LCD module)

1. Replacing lamps

· After removi ng the LCD module from the unit according to 2. Re-

moving the LCD modu le, replace the lamp units.

· Replace the lam p units using the following replacemen t procedur e,

referring to Fig.1 (enlarged view) and Fig. 2 (overall view).

· There are two lamp units at the top and bottom of the monitor.

· Wear finger sacks when doing this work, not to contaminate or

damage the LCD panel. Use caut i on prevent the entr an c e of dirt

or dust into the module.

[Replacement procedure]

Turn the module over and remove the screw s A in F igs. 1. (1 screw

for each unit). Put a finger on the concave B and remove the lamp

unit in a straight line.

· Use caution not to apply undue force on the lamp.

Replace the lamp unit with a new one.

Reinstall in the reverse order of disassembly.

· Tighten the screw and make sure the lamp unit won’t move.

Drawing

direction

4

5

21

3

B

Fluorescent

lamp lead wire

Screw A

Fig. 1

Page 8

2. Removing LCD module

Procedure

· Disassembly

1. Remove the 4 screws in

cabinet).

· Use caution not to break the latches in when removing the

front cabinet.

2. Remove the 4 screws in

· Use caution not to drop the LCD module.

3. Remove the 2 screws in

from the module.

· Reassembly

Reassemble the LCD module using the steps from 1 to 3 in reverse.

· Use caution not to get the cables caught in the cabinet when

reassembling.

and remove the display mask (front

and remove the module.

and remove the LCD cable connec tor

1

3

2

4

Page 9

Upper fluorescent lamp lead wire

Screw A (upper)

CN2

CN2

Lower fluorescent lamp

lead wire

Cover

Cover

Tape

Screw A (lower)

Fig. 2

CHAPTER3. CONNECTION, ADJUSTMENT, OPERATION AND FUNCTIONS

Connection to the power supply and the

computer

[Rear part]

· Make sure the computer and the monitor are turned off ( ).

Connect the signal cab le to th e compu ter. Make su re to tig hten the

connector screws.

Connect the AC power supply cord to the monitor. Connect the

other end of the cord to the wall outlet.

Turn the power supply switch on ( | ) to turn on the monitor. Then,

turn on the computer.

When adjustment of the monitor’s picture quality is required, refer to

Paragraph [Adjusting the screen].

Note: Make sure that both the monitor an d compute r are turn ed off

before conn ecting or d isconnecti ng the cord or c able. When

connecting or disconnecting the cord and cable, make sure

1

2

3

to hold their plug, not the cord or cable.

Page 10

Connecting USB cable

[Rear part]

USB DOWN

3

connector

2

USB UP

connector

to computer

USB

device

The monitor has a USB cable relay connector.

The following requirements need to be satisfied in order to use the

USB cable relay connector of this monitor.

· The computer to be connected and its OS (operating system) sup-

ports USB.

· Or a USB hub connected to a computer (and OS) that supports

USB.

When connecting a USB device to the monitor, use the USB cable

supplied with the monitor and follow the steps given below.

Connect the connector at one en d of the USB cable to the USB

DOWN connector of the computer.

Connect the connector at the other end to the USB UP connector

of the monitor.

Connect the cable connected to the USB device to the USB DOWN

connector of the monitor.

1

Press the or button to change the setting of the adjustment

option you selected.

To store the adjustment setting, wait for a while until the adjustment

menu automatically disappear, in the screen mode (resolution, refresh rate or others) for the adjustment.

If any adjustment operation is not carried out for about more than

10 seconds , the adjus tment menu autom atical ly d isapp ear an d the

setting is stored in memory.

If you want to adjust the screen, make an automatic screen adjustment as follows:

Select AUTO ADJUSTMENT from the MAIN MENU and press

or button. The automatic adjustment fu nction starts to

either

automatically adjust the CLOCK, PHASE, HO-POSITION, V-POSITION to the optimal states.

It is necessary to adjust the screen for every screen mode (RESOLUTION, REFRESH RAT, but th e setting is automatic ally stored in

memory and is v alid even after the power is turned off. Once the

adjustment is made, there is no need to adjust thereafter.

If a fine adjus tment of the screen is requi red, use the adjustment

disk (for Windows) supplied with the monitor to make such an adjustment m an ually. If you use an OS other than Windows, you need

to make a fine adjustment of the screen, observing the actual

screen.

How to use the adjustment program

In this manual, the de scriptions are wr itten on the assumption that

you use Windows 95/98.

In addition, it is assumed that the floppy disk drive is drive A.

Insert the attached "Adjustment disk" into drive A.

Open "3.5 inch FD (A):" in "My computer".

(In the case of Windows 3.1, open "File manager" and select drive

A.)

Double click "Adj_uty.exe" to start the adjustment program.

When the adjustment program starts up, the adjustment pattern

shown on the next appears on the screen. Make an adjustment

according to the instructions on the screen.

Note: Some USB device s might not work properly with the com-

puter, OS or per ipheral equipment use d. For the USB support of devices and OS’s, please ask their respective manufacturers or suppliers. The USB device connected to the USB

cable relay connector is operative even if the monit or is in the

power save mode or it is turned off.

Adjustment

In the case of setting up for the first time, or in the case of changin g

the setting of the computer used, it is necessary to adjust the screen.

Adjust the screen in the following manner.

Adjusting procedure:

Press any of the DOWN/ UP/ / buttons to display the MAIN

MENU shown on the ne xt page.

Switch over the two menus (MAIN and SUB) by pr essing the or

button.

Press the DOWN or UP button to select the adjustment item you

want to adjust.

Color pattern

Display frame

White and black

lines alternate.

Screen showing the adjustment program

You can exit the adjustment program by pressing the [Esc] key on

the keyboard of the computer.

When the di spl ay mod e of the co mpu ter us ed is in t he 6 5,0 00- col or

mode, you might see different tones of each color of the color

pattern or a colored gray scale. This is a specificatio n of the input

signal, not a trouble.

Page 11

Adjustment options

Adjustment option 1: MAIN MENU

TO SUB MENU (switching to SUB MENU)

Press the or button to switch over to SUB MENU.

AUTO ADJUSTMENT

Press the or button to start the AUTO ADJUSMENT function, thus

adjusting CLOCK, PHASE, H-POSITION, and V-POSITION to their

respective optimal stat es.

CLOCK

Use the or button to adjust the CLOCK so that you cannot see

vertical stripes-like noses in the pattern where white and black lines

alternate. (See the sketches on the right.)

Vertical stripe-like noise

PHASE

Use the or button to adjust the PHASE so that you can see a clear

white and blac k pattern on the scr een with the horizontal stripes-like

noises minimized.

H-POSITION

The screen moves to the left by pressing the button and to the right

by pressing the

both the frame lines at the right and left edges of the adjustment

pattern.

button. Adjust the H-POSITION so that you can see

V-POSITION

The screen mov e s d ownw ard by pr ess ing th e button an d upw ard by

pressing th e

both the fr ame lines at the to p and bottom edges o f the adjustment

pattern.

button. Adjust the V-POSITION so that you can see

720 x 400 LINE (switching over resolutions)

Use the or button to set the horizontal resolution of the 400-line

screen of PC98 series, US TEXT and other machines.

640 x 400: PC98 series

720 x 400: US TEXT and others

You can switch over the horizontal resolutions of 720 x 400 LINE and

640 x 400 LINE only t hose two modes.

OSD WINDOW LOCATION (movement of adjustment

menu window)

Press the or button to move the adjustment menu on the screen.

RESET

Press the or button to return the screen se ttings to the default

state.

Horizontal stripes-like noise

Adjust the CLOCK first, and then proceed with the adjustment of the

PHASE.

Page 12

Adjustment option 2: SUB MENU

TO MAIN MENU (switching to MAIN MENU)

Press the or button to switch over to MAIN MENU.

AUTO BALANCE

Press or button to function AUTO BALANCE so that the contrast is

automatically optimized. The monitor is factory adjusted for the optimal

condition. However, the adjustment of the contrast may be required

depending on the type of the computer connected. If contrast adjustment is required, use the color pattern in the adjustment program.

Note: There is a possibility that you cannot optimize the contrast

depending on the video output level of the computer used.

COLOR

Use the or button to set the maxi mum number of colors that can

be displayed (approx. 16 million or approx. 260 thousand co lors)

16M: approx. 16 million colors

260K: approx. 260 thousand colors

BRIGHTNESS

Use the or button to adjust the brightness of the entire screen.

Press the

CONTRAST

Press the or butto n to adjust the contrast of the entir e s c re en . U s e

the color pa ttern of the adjustme nt program so that al l tones can be

displayed. Press button to make it weaker and the button to make

stronger.

button to darken and the button to brighten.

RED, GREEN, BLUE

Press the or button to adjust the brightness of each of the

red, green and blue colors.

RED, GREEN, BLUE

Press the or button to adjust the contrast of each of the red,

green and blue colors.

1. Signal timing list

Display mode

31.5 kHz 60 Hz 25.175 MHz

640 x 480

VESA

(IBM AT

compatible

machines and

PC9800 series)

PC-9800 series

640 x 400

US TEXT

720 x 400 31.5 kHz 70 Hz 28.3 MHz

Power Macintosh

640 x 480 35.0 kHz 67 Hz 30.5 MHz

382 x 624 49.7 kHz 74.6 Hz 57.3 MHz

1024 x 768 60.2 kHz 75 Hz 80.0 MHz

The frequencies listed for Power Macintosh are reference values.

For connecting this monitor to Power Macintosh, the conversion

adapter is required.

However, Power Macintosh G3 (Blue & White) model does not

require any conversion adapter.

If a signal timing that is not supported by this monitor is entered, the

message "OUT OF RANGE" appears on the screen for about 5

seconds. In this case, set the computer for any of the signal timings

that are supported by this monitor, referring to the Instruction manual of the computer used.

800 x 600

1024 x 768

37.9 kHz 72 Hz 31.5 MHz

37.5 kHz 75 Hz 31.5 MHz

35.1 kHz 56 Hz 36.0 MHz

37.9 kHz 60 Hz 40.0 MHz

48.1 kHz 72 Hz 50.0 MHz

46.9 kHz 75 Hz 49.5 MHz

48.4 kHz 60 Hz 65.0 MHz

56.5 kHz 70 Hz 75.0 MHz

60.0 kHz 75 Hz 78.75 MHz

24.8 kHz 56 Hz 21.053 MHz

31.5 kHz 70 Hz 25.175 MHz

Non-interlace support only.

2. Connector pin layout

15-pin mini D-sub conn ector

Input connector

Pin No. Function

1 Red video signal input

2 Green video signal input

3 Blue video signal input

4GND

5GND

6 GND for red video signal

7 GND for green video signal

8 GND for blue video signal

9N.C.

10 GND for synchronizing signal

11 GND

12 DDC data

13 Horizontal synchronizing signal input

14 Vertical synchronizing signal input

15 DDC clock

Page 13

CHAPTER4. TROUBLESHOOTING

No power supply

LED comes on in green when

power switch is turned on?

Yes

LED comes on in red.

LED comes on in orange.

Backlight comes on?

Yes

No

No

No

No

Yes

Yes

Is LED in key switch unit normal?

(Check for disconnected cable.)

Is the unit in power save mode (No synchronizing

signal input)

Check if personal computer is turned on?

Check if RGB cable is connected.

Check if synchronizing signal is applied.

Is voltage output to key

switch unit connector

terminal (J4)?

+12 V/+5 V output at power

No

unit connector terminal

CN-JP5) ?

No

Yes

Yes

Key switch unit

defective

Defective

interface unit

No

100 V AC input to power unit

1

Yes

High voltage

*1 output to inverter PWB output

terminal?

Yes

Check LCD module lamp.

Note 1: Note that up to about 1.4 kVrms is applied when the inverter is started or in normal operation.

+12 V and On signal "H" at

inverter terminal (JP5)?

No

input connector?

No

Defective inverter unit

Yes

Check AC

switch and cord.

Defective

power unit

Page 14

Screen is not normal

Check the screen condition by changing the display modes.

Reset the microprocessor to check to see if the screen condition changes.

1

Screen stays in black. Screen stays in white

Check the following signals

(LCD signal input terminals):

+5V power check for LCD

Clock signal

DE signal

H sync/ V sync signal

Jittering screen and

flickering characters

Are OSD adjustment PHASE,

CLOCK settings appropriate?

(If not, adjust according to

Instruction manual.)

Normal

Normal

Abnormal

Abnormal color

Is RGB setting in OSD

adjustment appropriate?

Check LCD signal input terminal

corresponding to the color

condition on screen.

Abnormal

Backlight system normal

LED lights in green

Brighten screen condition.

Under the above conditions,

check LCD signal input terminal.

Abnormal

Normal

Defective interface unit Defective LCD module

Page 15

CHAPTER5. TRIMING AND PROCESSING LEAD WIRES

Step 1

Put the CCF T cable and LCD cab le into shield plate bu shings to

prevent them from getting caught when installing the shield plate.

(Figs. 1 and 2)

Put the CCFT cable at the back of the LCD module to prevent it

from getting cau ght when installing the LCD module.

CCFT cable

Fig. 1 Fig. 2

Step 2

Use caution to prevent the power supply cable and switch cable

from getting caugh t when installing arm rear cover (Fig. 3).

Use caution to prevent the power supply and switch cable from

getting caught when installing the base metal.

Power supply cable

Inverter cable

Power supply cable

Switch cable

LCD cable

Power supply cable

Switch cable

Fig. 3 Fig. 4

Page 16

CHAPTER6. BLOCK DIAGRAM/UNIT TERMINSL

LCD UNIT

LANP

1 LCD SIGNAL INPUT

RGB, H/V

IN PUT

15 inch LCD

LANP

INTERFACE

UNIT

5J1

KEY-SWITCH UNIT

INVERTER

2JP5

4 CN-JP5

3J4

AC 100V

INPUT

POWER UNIT

AC SW

1 5 Connector Symbol Function

AC SOKET

Page 17

Unit terminals

LCD SIGNAL INPUT

Used connector : FX8-60P-SV (HIROSE)

Pin No. Symbol Function

1 GND GND

2 RB0 RED Even-number picture

element signal

3RB1RED

4RB2RED

5RB3RED

6RB4RED

7 RB5 RED (MSB)

8 GND GND

9 GB0 GREEN Even-numb er picture

element signal

10 GB1 GREEN

11 GB2 GREEN

12 GB3 GREEN

13 GB4 GREEN

14 GB5 GREEN (MSB)

15 GND GND

16 BB0 BLUE Even-number picture

element signal

17 BB1 BLUE

18 BB2 BLUE

19 BB3 BLUE

20 BB4 BLUE

21 BB5 BLUE (MSB)

22 GND GND

23 RA0 RED Odd-number picture

element signal

24 RA1 RED

25 RA2 RED

26 RA3 RED

27 RA4 RED

28 RA5 RED (MSB)

29 GND GND

30 GA0 GREEN O dd-number pi cture

element signal

31 GA1 GREEN

32 GA2 GREEN

33 GA3 GREEN

34 GA4 GREEN

35 GA5 GREEN (MSB)

36 GND GND

37 BA0 BLUE Odd-number picture

element signal

38 BA1 BLUE

39 BA2 BLUE

40 BA3 BLUE

41 BA4 BLUE

42 BA5 BLUE (MSB)

43 GND GND

44 REV1 (GND)

45 GND GND

46 Vsync Vertical synchronizing signal

47 Hsync Horizontal synchronizing signal

48 DE Data enable signal

49 GND GND

50 GND GND

51 CKB Sampling clock

(LSB)

(LSB)

(LSB)

(LSB)

(LSB)

(LSB)

Pin No. Symbol Function

52 CKA Sampling clock

53 GND GND

54 GND GND

55 REV2 (GND)

56 REV3 (GND)

57 Vcc +5V power supply

58 Vcc +5V power supply

59 Vcc +5V power supply

60 Vcc +5V power supply

JP5 (To Inver ter Terminal)

Used connector : PH5PS (JST)

Pin No. Symbol Functi on

1 ON / OFF HIGH = ON, LOW = OFF

2NC

3 BRIGHT Brightness control of inverter

4 GND GND

5 +12V B + of inverter

JP4 (To Key Switch Board Termin a l )

Used connector : PH8PS (JST)

Pin No. Symbol Functi on

1NC

2 GND

3LED 1

4LED 2

5DOWN

6 +

7

8UP

–

CN-JP5 (Power Supply Input Terminal)

Used connector : PH6PS (JST)

Pin No. Symbol Functi on

1 +12V +12V supply from power BD

2 +12V +12V supply from power BD

3 GND GND

4 GND GND

5NC

6 Vcc +5V supply from power BD

J1 (Signal Input Terminal)

Used connector : PH12PS (JST)

Pin No. Symbol Functi on

1 SCL DDC

2SDADDC

35VDDC

4 V-SYNC5 H-SYNC

6 GND

7BLUE

8 GND

9 GREEN

10 GND

11 RED

12 GND

Page 18

CHAPTER7. APPEARANCE AND DISASSEMBLY DRAWING OF MECHANISMS

86

24

21

3

31

44

57

32

23

56

85

29

56

29

36

90

26

67

44

51

61

70

60

63

50

59

41

49

20

53

67

44

62

51

33

63

35

52

46

34

91

3733

58

19

84

22

17

77

33

33

33

87

33

6

44

5

43

87

19

33

78

87

79

33

10

33

45

43

2

TP000005

1

36

89

70

4

35

No. Part name Part code New/Conti.

1 Panel, front

2 Panel, rear

3 Base cover

4 Arm, front

5 Arm, rear

New

New

New

New

New

6 Wire ass’y

10 LCD metal ass’y New

17 Interface PWB

New

19 Screw

20 Power PWB New

21 Base controller PWB

22 Wire ass’y New

23 LCD unit

24 Key frame

New

New

26 Rubber, base

29 T-screw

31 Switch, tact

32 LED

33 Screw

34 Connector

35 Connector

36 Screw

37 PCB ass’y New

41 Connector

43 Screw

44 T-screw

45 Cable ass’y New

No. Part name Part code New/Conti.

46 VR

49 Heat sink-1

50 Heat sink-2

51 T-screw

52 Connector

53 Connector

56 T-screw

57 LED holder

58 Switch, locker

59 Connector

60 Wire ass’y

61 Wire ass’y New

62 Wire ass’y

63 Shrink tube

67 Screw

70 Screw New

77 USB A and B

78 Connector

79 Connector

84 Conductive tape

85 Conductive tape

86 Gasket

87 Tape

89 Bracket

90 Bracket

New

New

New

New

New

New

New

New

New

91 Screw

Page 19

CHAPTER8. PACKAGING METHOD

21

3

1

5

ON LCD METAL

13

4

15

11

16

2

8

6

TP000006

No. Part name Part code New/Conti.

1 Power cord

2 End cap R

3 End cap L

4 PE bag

5 PE bag

6Carton New

8 Label, bar code

11 Label, rating

13 Label, bar code

15 Manual New

16 End cap

21 Cable ass’y

New

New

New

New

New

New

New

New

Page 20

COPYRIGHT ã 1999 BY SHARP CORPORATION

All rights reserved.

Printed in Japan.

No part of this publication may be reproduced,

stored in a retrieval system, or transmitted.

In any form or by any means,

electronic, mechanical, photocopying, recording, or otherwise,

without prior written permission of the publisher.

SHARP CORPORATION

Information Systems Group

Quality & Reliability Control Center

Yamatokoriyama, Nara 639-1186, Japan

1999 July Printed in Ja pan

Loading...

Loading...