Page 1

TENTATIVE

TECHNICAL LITERATURE

TFT - LCD module

FOR

No.

DATE Feb. 1, 2010

LD-K22152

MODEL No.

The technical literature is subject to change without notice.

So, please contact SHARP or its representative before designing

your product based on this literature.

LK816D3LA19

MODULE DEVELOPMENT CENTER

AVC LIQUID CRYSTAL DISPLAY GROUP

SHARP CORPORATION

Page 2

LK816D3LA19

RECORDS OF REVISION

SPEC No. DATE

No. PAGE

LD-K22152 Feb. 1, 2010 - - - 1st. Issue

REVISED

SUMMARY NOTE

Page 3

LD-K22152-1

r

1. Application

This technical literature applies to the color 81.6” TFT-LCD module LK816D3LA19.

* These technical literature sheets are proprietary products of SHARP CORPORATION (“SHARP”) and include

materials protected under copyright of SHARP. Do not reproduce or cause any third party to reproduce them in any

form or by any means, electronic or mechanical, for any purpose, in whole or in part, without the express written

permission of SHARP.

* In case of using the device for applications such as control and safety equipment for transportation (aircraft, trains,

automobiles, etc.), rescue and security equipment and various safety related equipment which require higher

reliability and safety, take into consideration that appropriate measures such as fail-safe functions and redundant

system design should be taken.

* Do not use the device for equipment that requires an extreme level of reliability, such as aerospace applications,

telecommunication equipment (trunk lines), nuclear power control equipment and medical or other equipment for

life support.

* SHARP assumes no responsibility for any damage resulting from the use of the device that does not comply with

the instructions and the precautions specified in these technical literature sheets.

* Contact and consult with a SHARP sales representative for any questions about this device.

2. Overview

This module is a color active matrix LCD module incorporating amorphous silicon TFT (T

composed of a color TFT-LCD panel, driver ICs, control circuit, power supply circuit, inverter circuit and back light

system etc. Graphics and texts can be displayed on a 1080×RGB×1920 dots panel with one billion colors by

using LVDS (Low Voltage Differential Signaling) to interface, +12V of DC supply voltages.

This module also includes the DC/AC inverter to drive the CCFT. (+24V of DC supply voltage)

And in order to improve the response time of LCD, this module applies the Over Shoot driving (O/S driving)

technology for the control circuit. In the O/S driving technology, signals are being applied to the liquid crystal

according to a pre-fixed process as an image signal of the present frame when a difference is found between image

signal of the previous frame and that of the current frame after comparing them.

By using the captioned process, the image signals of this LCD module are being set so that image response can be

completed within one frame, as a result, image blur can be improved and clear image performance can be realized.

3. Mechanical Specifications

Paramete

Display size(Diagonal)

Active area 1015.74 (H) x 1805.76 (V) mm

Pixel Format

Pixel pitch 0.9405(H) x 0.9405 (V) mm

Pixel configuration R, G, B horizontal stripe

Display mode Normally black

Unit Outline Dimensions (*1) 1094 (W) x 1879 (H) x 81.9 (D) mm

Mass

Surface treatment

(*1) Outline dimensions are shown in Fig.1.

2071.83 mm

81.5683 inch

1080 (H) x 1920 (V)

(1pixel = R + G + B dot)

64.8±1.0

Anti glare, low reflection coating

Hard coating: 2H

Specifications Unit

hin Film Transistor). It is

pixel

kg

Page 4

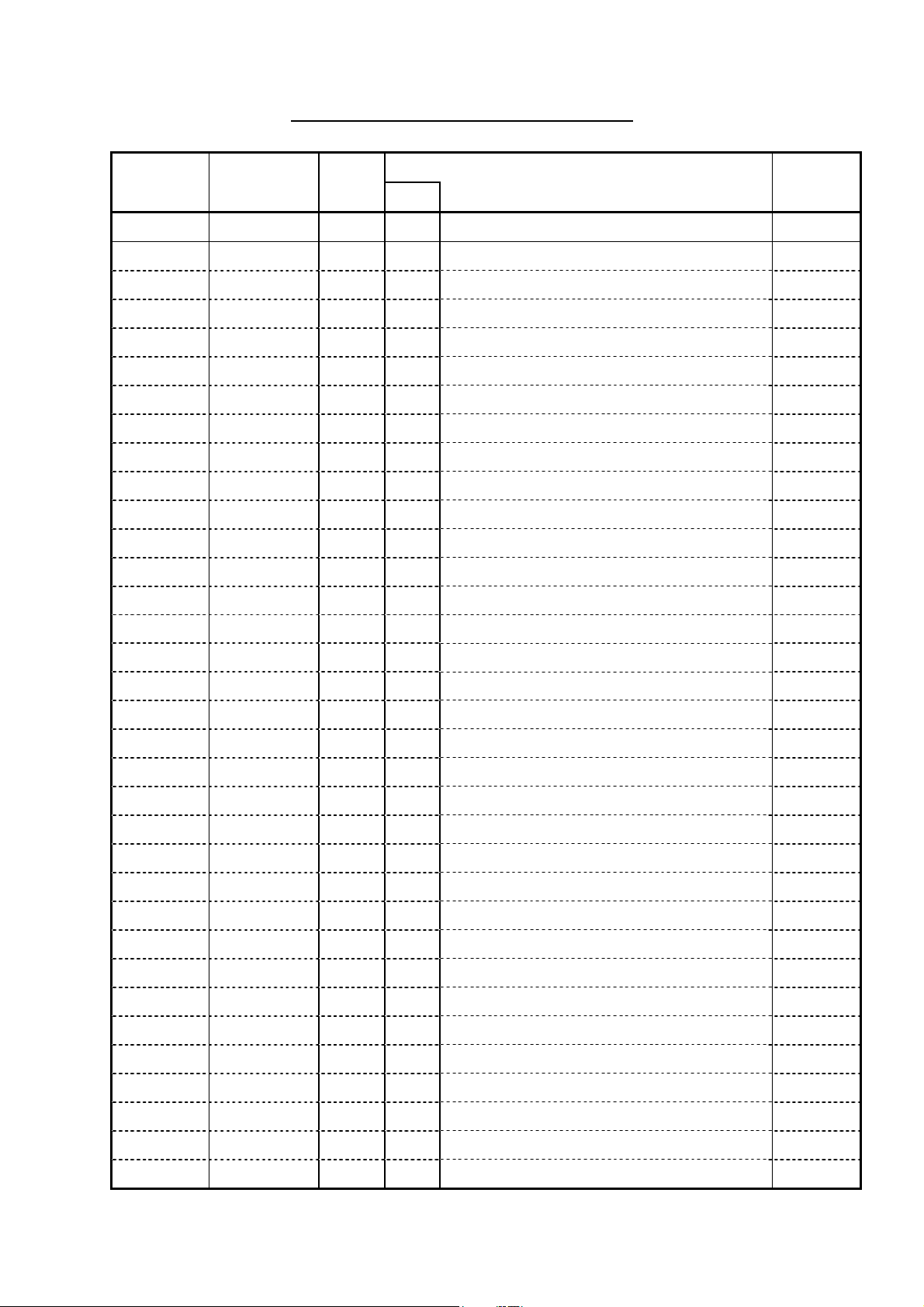

4. Input Terminals

4-1. TFT panel driving

CN1 (Interface signals) on CPWB

Using connector : FI-RE51S-VF (Japan Aviation Electronics Industry, Ltd.)

Mating connector : FI-RE51HL (Japan Aviation Electronics Industry, Ltd.)

Mating LVDS transmitter : THC63LVD1023B (THine) or equivalent device

Pin No. Symbol Function Remark

1

2

3

4

5

6

7

8 O/S_SET

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

FRAME

Reserved It is required to set non-connection (OPEN).

Reserved It is required to set non-connection (OPEN).

Reserved It is required to set non-connection (OPEN).

TEMP_Error Error output at the ultra high temperature [Note 5]

SELLVDS

INV_duty Inverter Brightness Control [Note 4]

INV_ON/OFF

Frame frequency setting

L: Normal operation

U/D Vertical shift direction [Note 3]

GND

AIN0-

AIN0+

AIN1-

AIN1+

AIN2-

AIN2+

GND

ACK-

ACK+

GND

AIN3-

AIN3+

AIN4-

AIN4+

GND

GND

BIN0-

BIN0+

BIN1-

BIN1+

BIN2-

BIN2+

GND

BCK-

BCK+

GND

BIN3-

BIN3+

BIN4-

H:60Hz, L:50Hz

H: Protection function operates

Select LVDS data order [Note 2]

O/S operation setting

H: O/S driving ON, L: O/S driving OFF

Inverter ON/OFF setting

H:ON, L:OFF

A port (-)LVDS CH0 differential data input

A port (+)LVDS CH0 differential data input

A port (-)LVDS CH1 differential data input

A port (+)LVDS CH1 differential data input

A port (-)LVDS CH2 differential data input

A port (+)LVDS CH2 differential data input

A port LVDS Clock signal(-)

A port LVDS Clock signal(+)

A port (-)LVDS CH3 differential data input

A port (+)LVDS CH3 differential data input

A port (-)LVDS CH4 differential data input

A port (+)LVDS CH4 differential data input

B port (-)LVDS CH0 differential data input

B port (+)LVDS CH0 differential data input

B port (-)LVDS CH1 differential data input

B port (+)LVDS CH1 differential data input

B port (-)LVDS CH2 differential data input

B port (+)LVDS CH2 differential data input

B port LVDS Clock signal(-)

B port LVDS Clock signal(+)

B port (-)LVDS CH3 differential data input

B port (+)LVDS CH3 differential data input

B port (-)LVDS CH4 differential data input

Pull up 3.3V(by 2.0kΩ)

[Note 1]

Pull down GND(by2.0kΩ)

[Note 1]

Pull up 3.3V(by 2.0kΩ)

[Note 1]

Pull up 3.3V(by 2.0kΩ)

[Note 1]

LD-K22152-2

Page 5

41

42

43

44

45

46

47

48

49

50

51

BIN4+ B port (+)LVDS CH4 differential data input

GND

GND

GND

GND

GND

NC

NC

NC

NC

NC

It is required to set non-connection (OPEN).

It is required to set non-connection (OPEN).

It is required to set non-connection (OPEN).

It is required to set non-connection (OPEN).

It is required to set non-connection (OPEN).

* L: Low level voltage (GND). H: High level voltage (3.3V)

*Connect the GND of the liquid crystal panel drive part to the chassis of the module.

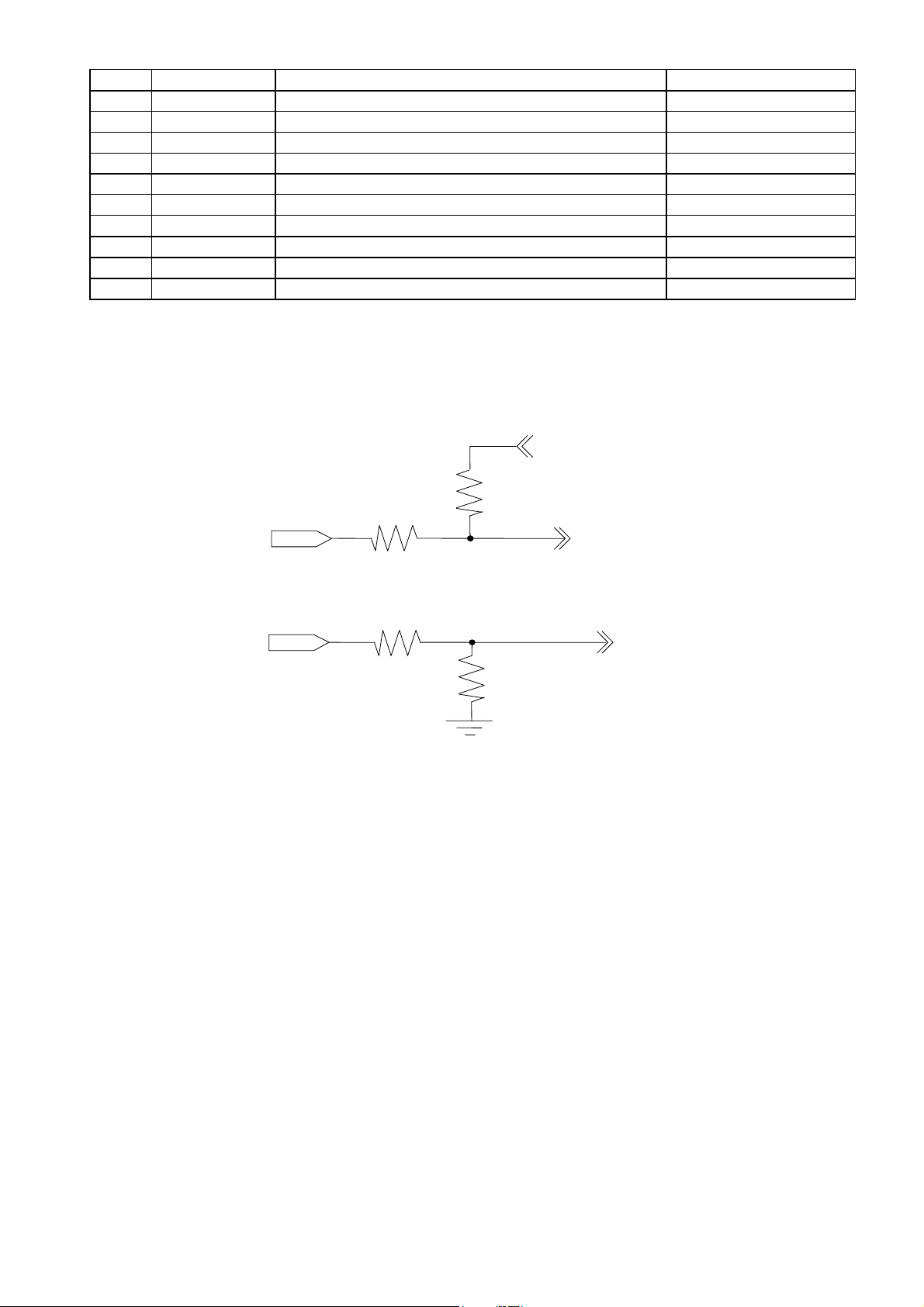

[Note1] The equivalent circuit figure of the terminal

3.3V

FRAME,SELLVDS, O/S_SET

Te rm in al

100Ω

(2.0KΩ)

U/D

Te rm in al

100Ω

(2.0KΩ)

LD-K22152-3

Page 6

[Note2] LVDS data order (SELLVDS=H:JEIDA Mode, L:VESA Mode)

Transmitter

Data

SELLVDS = “L”(GND)

LVDS data

SELLVDS = “H”(3.3V) or Open

LVDS data

TA0 R0(LSB) R4

TA1 R1 R5

TA2 R2 R6

TA3 R3 R7

TA4 R4 R8

TA5 R5 R9(MSB)

TA6 G0(LSB) G4

TB0 G1 G5

TB1 G2 G6

TB2 G3 G7

TB3 G4 G8

TB4 G5 G9(MSB)

TB5 B0(LSB) B4

TB6 B1 B5

TC0 B2 B6

TC1 B3 B7

TC2 B4 B8

TC3 B5 B9(MSB)

TC4 HSYNC HSYNC

TC5 VSYNC VSYNC

TC6 DE DE

TD0 R6 R2

TD1 R7 R3

TD2 G6 G2

TD3 G7 G3

TD4 B6 B2

TD5 B7 B3

TD6 N/A N/A

TE0 R8 R0(LSB)

TE1 R9(MSB) R1

TE2 G8 G0(LSB)

TE3 G9(MSB) G1

TE4 B8 B0(LSB)

TE5 B9(MSB) B1

TE6 N/A N/A

NA: Not Available

*Since the display position is prescribed by the rise of DE (Display Enable) signal,

please do not fix DE signal during operation at “High”.

*HSYNC and VSYNC are not necessary

LD-K22152-4

Page 7

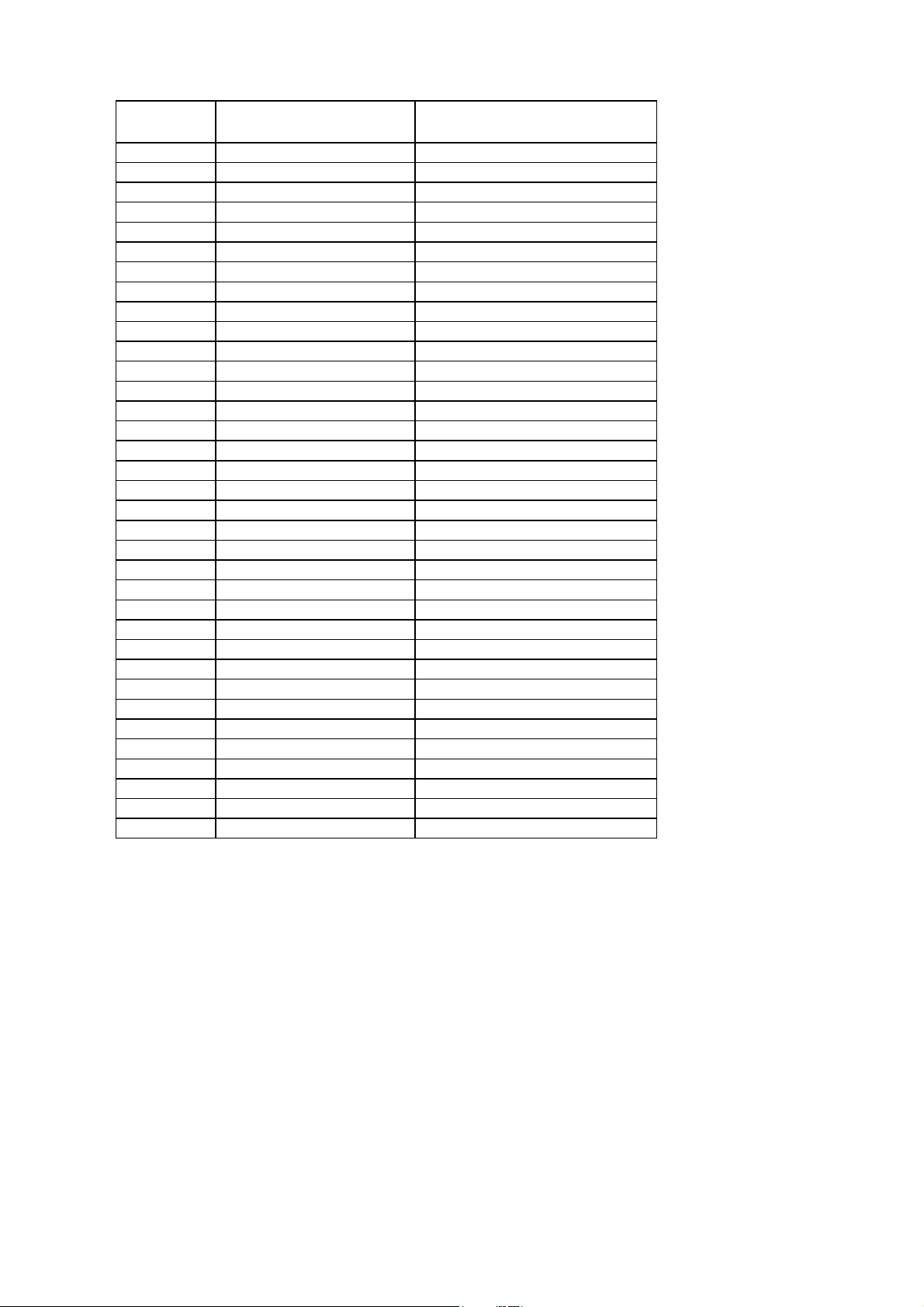

・LVDS da ta order (SELLVDS = “L”)

ACK+, BCK+

ACK-, BCK-

AIN0+, BIN0+

AIN0-, BIN0-

AIN1+,BIN1+

AIN1-,BIN1-

AIN2+,BIN2+

AIN2-,BIN2-

G0 R5 R4 R3 R2 R1 R0 R0 R1 G0

B1 B0 G5 G4 G3 G2 G1 G1 G2 B1

DE

NA

AIN3+,BIN3+

AIN3-,BIN3-

B7 B6 G7 G6 R7 R6 R6 R7 NA NA

AIN4+,BIN4+

AIN4-,BIN4-

B9 B8 G9 G8 R9 R8 R8 R9 NA NA

・LVDS da ta order (SELLVDS = “H”)

ACK+,BCK+

ACK-,BCK-

AIN0+,BIN0+

AIN0-,BIN0-

G4 R9 R8 R7 R6 R5 R4 R4 R5 G4

AIN1+,BIN1+

AIN1-,BIN1-

B5 B4 G9 G8 G7 G6 G5 G5 G6 B5

AIN2+,BIN2+

AIN2-,BIN2-

AIN3+,BIN3+

AIN3-,BIN3-

DE

NA NA

B3 B2 G3 G2 R3 R2 R2 R3 NA NA

AIN4+,BIN4+

AIN4-,BIN4-

B1 B0 G1 G0 R1 R0 R0 R1 NA NA

DE: Display Enable, NA: Not Available (Fixed Low)

NA

1 cycle

B5 B4 B3 B2 B2 B3

1 cycle

B9 B8 B7 B6 B6 B7

LD-K22152-5

DE

DE

Page 8

LD-K22152-6

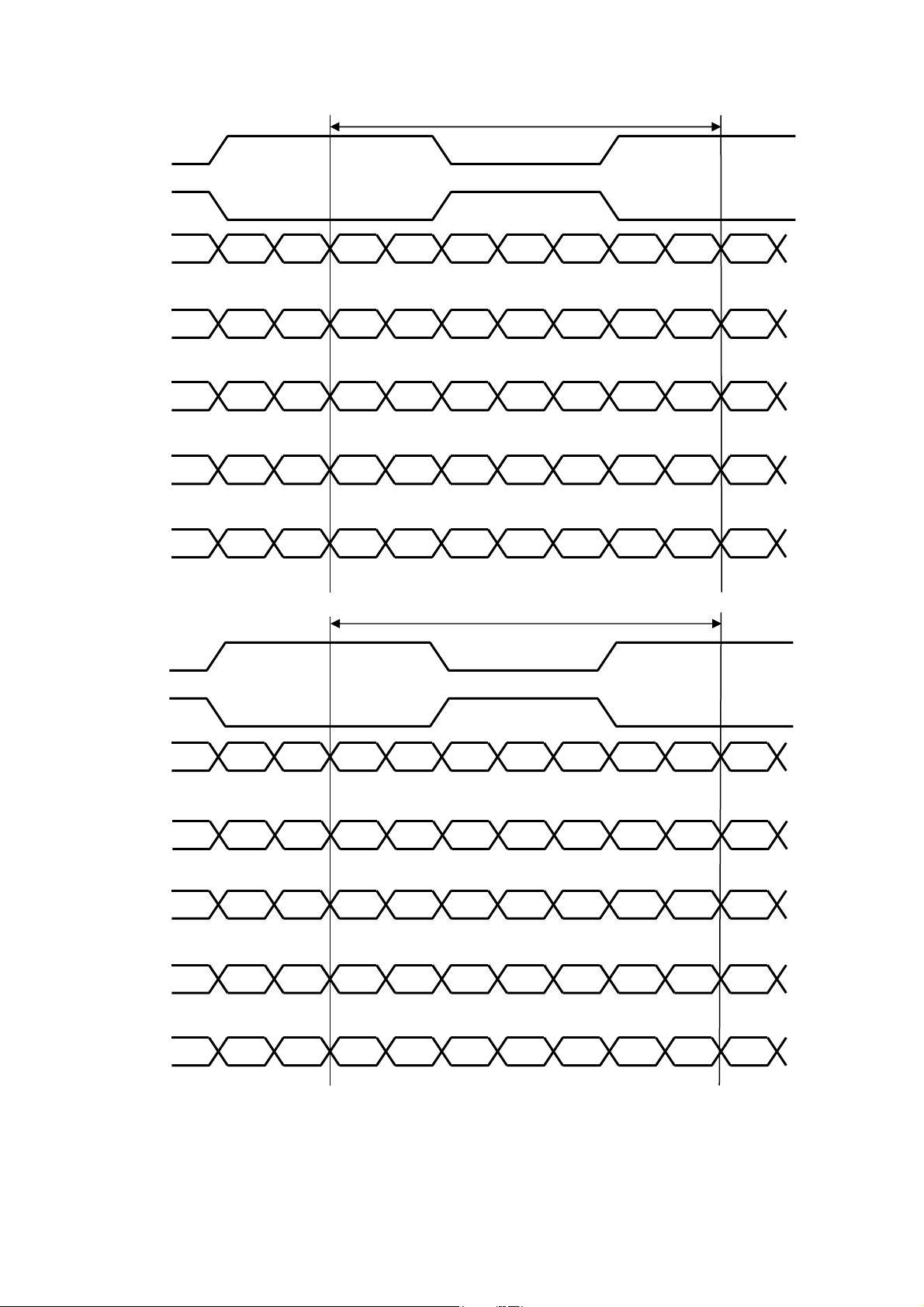

[Note 3]Display reversal function

Normal (Default)

Vertical reverse image

U/D:L (GND) U/D:H (3.3V)

CONTROL PWB

CONTROL PWB

[Note 4]Brightness Control (Pulse PWM dimming)

Pin No. 9 is used for the control of the PWM duty with input pulse.

T

T

t

t

OFL1/2

duty

Ta = 25°C

MIN TYP MAX Remark

Pulse signal [Hz] 155 165 175

DUTY (t/T) [%] 20

-

100

*There is a case that lamp mura may happen, depending on ambient temperature, in

dimming. Minimum dimming level should be set according to your evaluation of actual

display performance. (Minimum duty 60% at below 15℃)

[Note 5] Error output at the ultra high temperature

For the protection of the module C_PWB decreases DUTY of PWM of the inverter to 30% forcibly when the

temperature of the module is more than (85) ℃. Duty of PWM of the inverter returns to a normal state

afterwards when the temperature of the module is less than (55) ℃.

Error output is Low (0V) at normal state. Error output becomes High (3.3V) when protection function operates.

Page 9

LD-K22152-7

R

R

R

CN2 (+12V DC power supply) on CONTROL PWB

Using connector : SM04B-PASS-TBT (J.S.T. Mfg Co., Ltd.)

Mating connector : PAP-04V-S (J.S.T. Mfg Co., Ltd.)

Pin No.

1 VCC

2 VCC

3 GND

4 GND

Symbol Function Remark

+12V Power Supply

+12V Power Supply

GND

GND

*Current rating:3A (AWG#22)

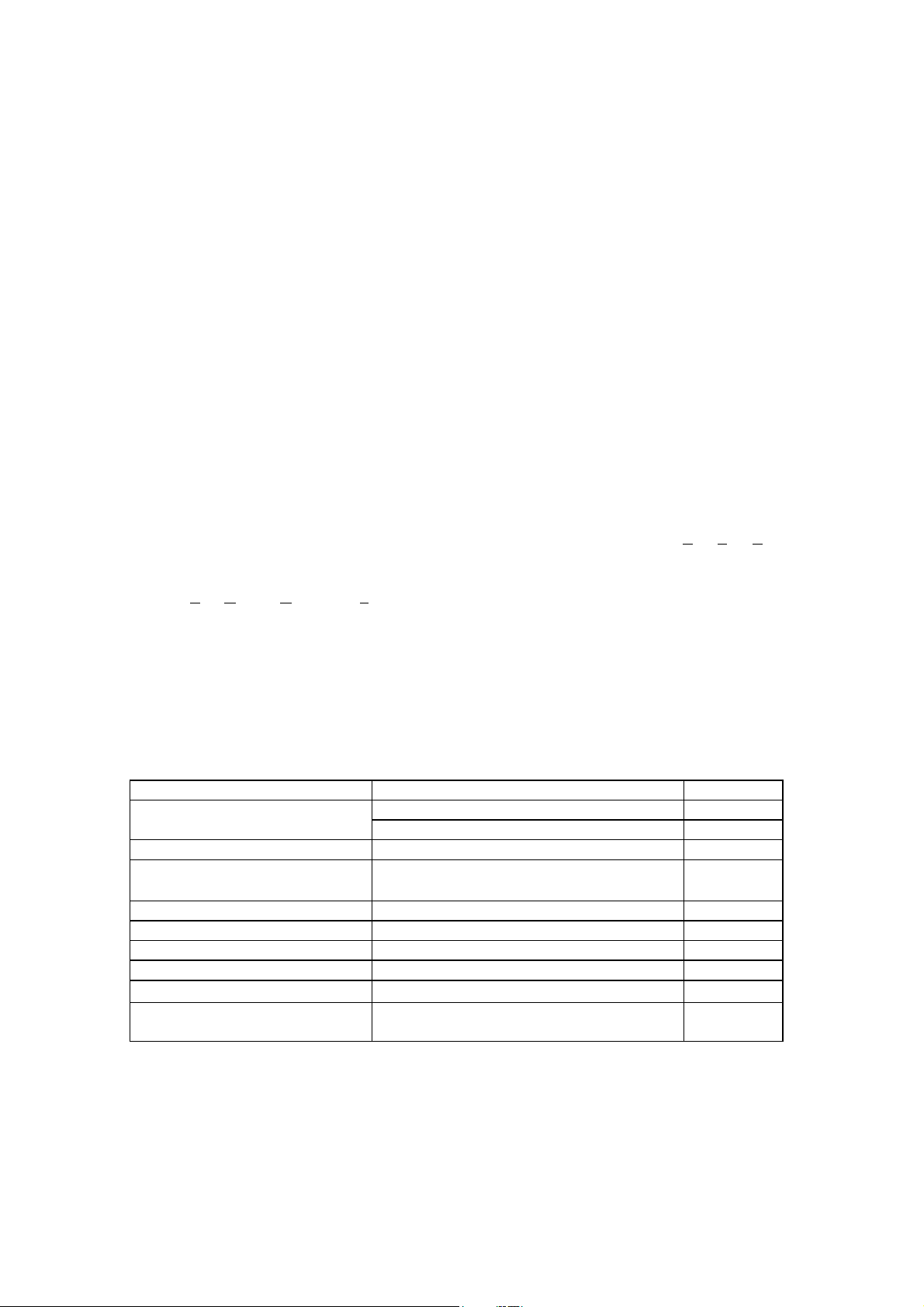

Block Diagram (LCD Module)

INPUT SIGNALS

INV_duty, INV_ON/OFF, O/S_SET, SELLVDS,

・

FRAME,

AIN0-, AIN0+, AIN1-, AIN1+, AIN2-, AIN2+

AIN3-, AIN3+, AIN4-, AIN4+, ACK-, ACK+、

BIN0-, BIN0+, BIN1-, BIN1+, BIN2-, BIN2+

BIN3-, BIN3+, BIN4-, BIN4+, BCK-, BCK+

OUTPUT SIGNALS

TEMP_Error

CN1

GATE DRIVE

BACK LIGHT(120 CCFTs )

LCD PANEL

1080X1920

POWER SUPPLY

+24V DC

GND

POWER SUPPLY

CONTROL PWB

+12V DC

GND

CN2

SOURCE DRIVE

GATE DRIVE

INVERTER PWB

CN3 ,4 ,5 ,6 ,7 ,8 CN,9,10,11,12,13,14

Page 10

0

0

A

0

0

0

L

L

0

0

9 AB0AB

9

LCD

I

l

Ci

i

A

A

A

A

A

A

A

A

A

BB9

0

0

0

0

LPLL

0

0

0

BG0 BG9 CLK

B

A

B AIN4+(25

BIN4–(

B

Interface block diagram

AG

AB

AR

AR9

AG9

AB9

Con t r o l l e r

ENAB_

Hsy n c _ A

Vsync_ A

CLKA

BR

BR9

BG0 BG9

BB0

ENAB_ B

Hs yn c_

Vs yn c_ B

CLKB

Corresponding Transmitter:

LD-K22152-8

(TV Side)

Port A

1

10

1

LVDS

TTL

PL

Port B

1

1

1

LVDS

TTL

PLL

IN0+(13)

IN0– (12)

IN1+(15)

IN1– (14)

IN2+(17)

IN2– (16)

IN3+(23)

IN3– (22)

AIN4– (24)

ACK+( 2 0)

CK– (19)

BIN0+(29)

BIN0– (28)

BIN1+(31)

BIN1– (30)

BIN2+(33)

BIN2– (32)

BIN3+(39)

BIN3– (38)

BIN4+(41)

BCK+( 36 )

BCK–(3 5)

(TFT-LCD side)

Port

TT

LVDS

)

PLL

Por t

TT

LVDS

40)

1

AR0AR

1

AG0AG9

10

1

BR0 BR9

1

1

BB0 BB9

DE_ A

Hsy nc _ A

Vsync_ A

CLKA

DE_B

Hsync_ B

Vs yn c_ B

t

rcu

nterna

THC63LVD1023B (THine) or equivalent device

Page 11

LD-K22152-9

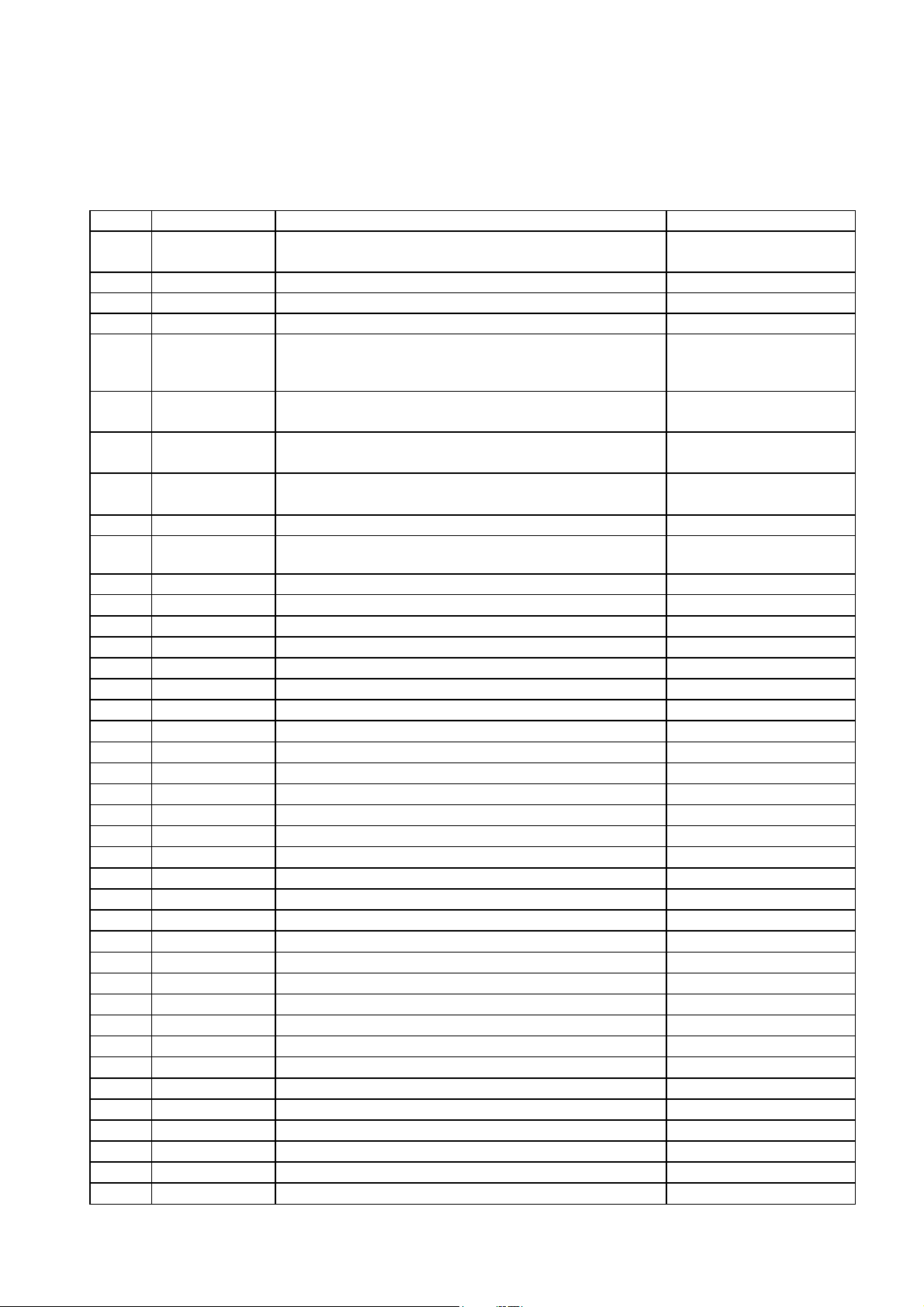

4-2. Backlight driving

Inverter connecter1 (+24V DC power supply and inverter control)

CN3, CN4, CN5, CN6, CN7, CN8 (Inverter Power input Pin layout) on INVERTER PWB

Using connector: S14B-PH-K-S (LF) (J.S.T. Mfg Co.,Ltd.)

Mating connector: PHR-14 (J.S.T. Mfg Co.,Ltd.)

Pin No. Symbol Function Remark

1 VINV +24V

2 VINV +24V

3 VINV +24V

4 VINV +24V

5 VINV +24V

6 GND GND

7 GND GND

8 GND GND

9 GND GND

10 GND GND

11 Reserved It is required to set non-connection (OPEN).

12 Reserved It is required to set non-connection (OPEN).

13 Reserved It is required to set non-connection (OPEN).

14 Reserved It is required to set non-connection (OPEN).

*Current rating:2A (AWG#24)

Inverter connecter2 (+24V DC power supply)

CN9, CN10, CN11, CN12, CN13, CN14 (Inverter Power input Pin layout) on INVERTER PWB

Using connector : S12B-PH-K-S(LF) (J.S.T. Mfg Co.,Ltd.)

Mating connector : PHR-12 (J.S.T. Mfg Co.,Ltd.)

Pin No. Symbol Function

1 VINV +24V

2 VINV +24V

3 VINV +24V

4 VINV +24V

5 VINV +24V

6 GND GND

7 GND GND

8 GND GND

9 GND GND

10 GND GND

11 Reserved It is required to set non-connection (OPEN)

12 Reserved It is required to set non-connection (OPEN)

*Current rating:2A (AWG#24)

4-3. the back light system characteristics

The back light system is direct type with 120 CCFTs (Cold Cathode Fluorescent Tube).

The characteristics of the lamp are shown in the following table.

The value mentioned below is at the case of one CCFT.

Item Symbol Min. Typ. Max. Unit Remarks

Life time TL - (60000) - Hour

[Note]・Lamp life time is defined as the time when brightness becomes 50% of the original value

in the continuous operation under the condition the Ta=25 ℃ and brightness control(duty=100%).

・Above value is applicable when the long side of LCD module is placed vertically (Portrait position).

Page 12

5. Absolute Maximum Ratings

Parameter Symbol Condition Ratings Unit Remark

Input voltage

(for Control)

12V supply voltage

(for Control)

24V supply voltage

(for Inverter)

LD-K22152-10

I

V

Ta=25 ℃

-0.3 ~ 3.6 V [Note 1]

VCC Ta=25 ℃ 0 ~ + 14 V

V

INV

Ta=25 ℃

0 ~ +27 V

Storage temperature Tstg - -25~ +60

Operation temperature

(Ambient) Topa - 0 ~ +35

℃

℃

[Note 2]

[Note 3]

[Note 4]

[Note 5]

[Note 1] FRAME, SELLVDS, O/S_SET, U/D,INV_duty,INV_ON/OFF

[Note 2] Humidity 95%RH Max.(Ta≦40℃)

Maximum wet-bulb temperature at 39 ℃ or less.(Ta>40 ℃) / No condensation.

[Note 3] Temperature Uniformity :10 ℃ Max.

[Note 4] Glass surface temperature : 55 ℃ Max,

[Note 5] To put out high brightness a lot of lamps are built into this module. Therefore, when this module is

operated, cooling this module is required. There is a possibility of damaging the module when a

surrounding operating temperature is exceeded.

Page 13

LD-K22152-11

,

V

6. Electrical Characteristics

6-1. Control circuit driving Ta=25 ℃

Parameter Symbol Min. Typ. Max. Unit Remark

Supply voltage Vcc 11.4 12.0 12.6

V

[Note1]

+12V supply

voltage

Current dissipation Icc - (0.9) (1.5) A [Note2]

1 -

I

RUSH

(TBD)

- A

Inrush current

I

2 -

RUSH

(TBD)

- A t1>5ms

Permissible input ripple voltage VRP - - 100 mVP-P Vcc = +12.0V

Input Low voltage VIL 0 - 0.8 V

Input High voltage VIH 2.3 - 3.6 V

Input leak current (Low) IIL - - 400 µA VI = 0V

Input leak current (High) IIH 100 µA VI=3.3V

Termin al resistor RT - 100 -

Ω

Input Differential Voltage |VID| 200 400 600 mV [Note3]

Differential Input common mode

voltage

VCM |VID|/2 1.2 2.4-|VID|/2 V

[Note]VCM: Common mode voltage of LVDS driver.

[Note 1]

Input voltage sequences Dip conditions for supply voltage

0.1 ms < t1 ≦ 20 ms a) 6.5V ≦ Vcc < 10.8V

10 ms < t2 ≦ 50 ms td ≦ 10 ms

10 ms < t3 ≦ 50 ms b) Vcc < 6.5 V

0 ms < t4 ≦ 1 s Dip conditions for supply voltage is

t5 ≧ 1 s based on input voltage sequence.

t6 ≧ 0

t7 ≧ 1 s

t8 ≧ 500 ms

t9 ≧ 1 s

t1=500us

[Note4]

Differential input

[Note3]

Data1

Data2

Back light:

INV

Back light:

V

cc

INV

on/off

0.1Vcc

INVduty

0.9 Vcc

t1

t2

t3

t8

0.9 Vcc

0.1Vcc

t4

ON

t3

t5

OFF

t6

OFF

0.1Vcc

0.1Vcc

t7

td

0.1Vcc

t9

Data1:ACK±,AIN0±,AIN1±, AIN2±, AIN3±, AIN4±, BCK±,BIN0±,BIN1±, BIN2±, BIN3±, BIN4±

Data2:SELLVDS, FRAME, O/S_SET,

V2

Vcc

V1

V1: 10.8V

V2: 6.5V

Page 14

LD-K22152-12

*About the relation between data input and back light lighting, please base on the above-mentioned input

sequence. When back light is switched on before panel operation or after a panel operation stop, it may not

display normally. But this phenomenon is not based on change of an incoming signal, and does not give

damage to a liquid crystal display.

[Note 2] Typical current situation: 1024 gray-bar patterns. (Vcc = +12.0V)

The explanation of RGB gray scale is seen in section 8.

RGB

GS1023

RGB

GS1022

....

Vcc=12.0V

CK=74.25MHz

TT=14.8μs

RGB

GS2

RGB

GS1

RGB

GS0

[Note3] ACK±,BCK±,AIN0±,AIN1±,AIN2±,AIN3±, AIN4±,BIN0±,BIN1±,BIN2±,BIN3±, BIN4±

*CK-,*IN-

*CK+,*IN+

GND

|VID|

|VID|

VCM

[Note4] SELLVDS, FRAME, O/S_SET, U/D, INV_duty,INV_ON/OFF

Page 15

LD-K22152-13

V

V

3

1

V

V

6-2. Inverter driving for back light

The back light system is

direct type with 120CCFTs (Cold Cathode Fluorescent Tube). Ta=25℃

Parameter Symbol Min. Typ. Max. Unit Remark

INV_ON/OFF=3.3V

Supply voltage VINV 23.0 24.0 25.0 V

Current dissipation1 IINV1

+24V

Current dissipation2 IINV 2

Permissible input ripple

voltage

Input voltage (Low) V

Input voltage (High) V

- (62) (70) A

- (TBD) (TBD) A

- (50) (58) A

- (65) (75) A

RF - - 300 mV

V

0 - 0.8 V

ONL

2.3 3.3 3.6 V

ONH

INV_duty = 100%

【Note1】【Note2】

VINV = 24V

INV_ON/OFF=3.3V

INV_duty = 100%

【Note1】【Note2】

VINV = 24V

INV_ON/OFF=3.3V

INV_duty = 100%

※with cooling module

【Note1】【Note2】

VINV = 24V

INV_ON/OFF=3.3V

INV_duty = 100%

【Note1】【Note2】

VINV = 24V

INV_ON/OFF=3.3V

INV_duty = 100%

※with cooling module

【Note1】【Note2】

VINV = 24V

p-p

INV_ON/OFF, INV_duty

【Note1】

【Note 1】1)VINV-turn-on condition

CC( CONTROL PWB)

0.9VCC

T1

T2

0.9VINV

T1≧500ms

T2>100s

≧1ms

T

INV

0V

0.1VINV

T3

_ON/OFF,

_on/off,

INV_duty

INV_duty

t1

0.

INVON/O FF

t1≧1ms

t2≧1ms

INV

2) V

INV-turn-off condition

INV

INV

CC(CONTROL

0.8V

PWB)

t2

0.9V

0.9V

0V

INV

0V

INV

0V

【Note 2】Current dissipation1 : Definition within 120 minutes after turn on.( Rush current Is excluded)

Current dissipation2 : Definition more than 120 minutes after turn on.

【Note】 The inverter unit is driving at the following drive frequency.

*The lamp drive frequency : 31.4 ±2.0 kHz

*The burst Brightness control drive frequency : 165 ± 10 Hz

Page 16

LD-K22152-14

r

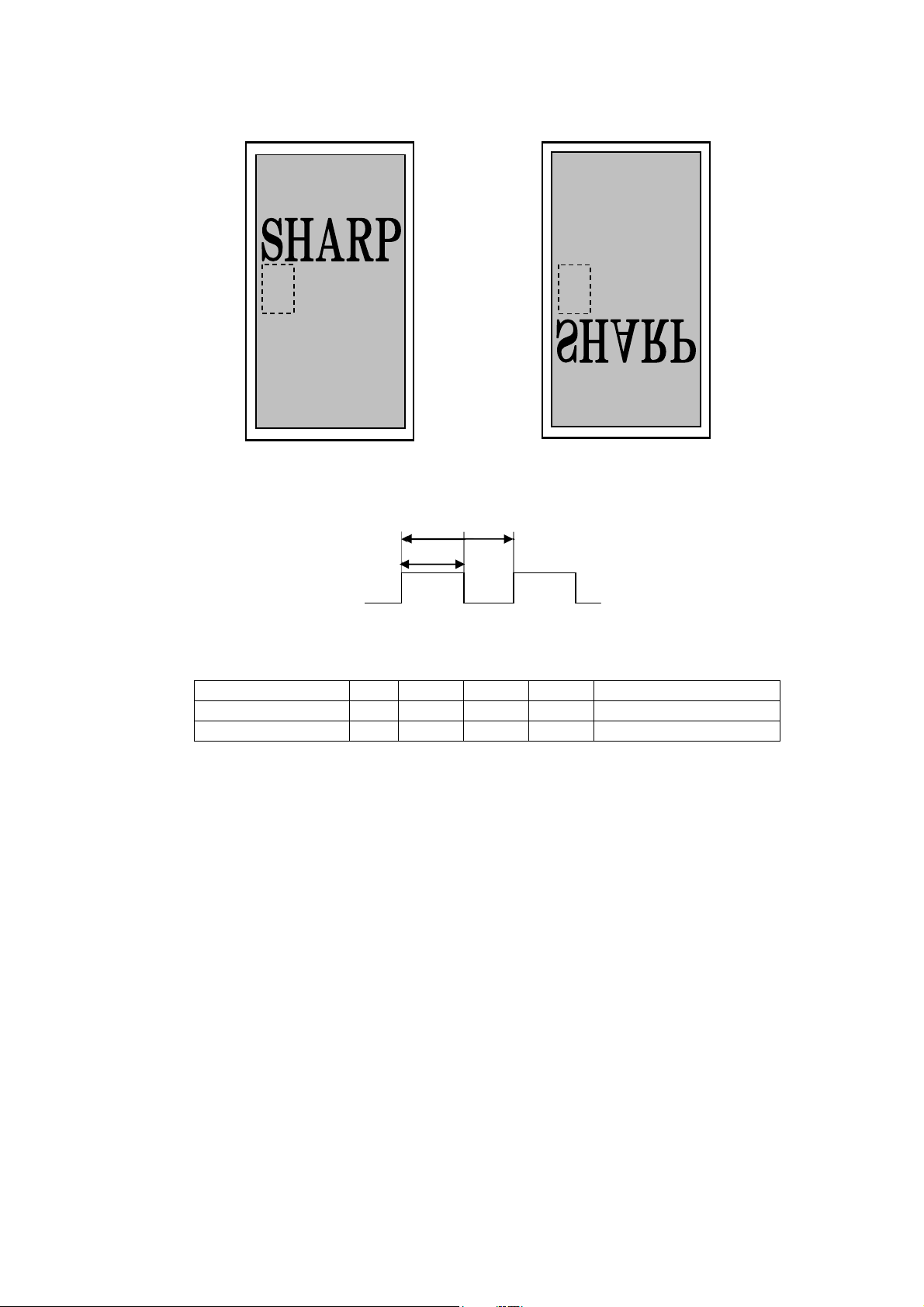

7. Timing characteristics of input signals

7-1. Timing characteristics

This LCD module is designed to be used in portrait position other than input signal.

The definition of input signal is based on landscape position. Therefore, please ensure to take it into account in

designing your set.

Timing diagrams of input signal are shown in Fig.2.

Paramete

Symbol Min. Typ. Max. Unit Remark

Clock Frequency 1/Tc 69 74.25 76 MHz

1084 1100 1200 clock

14.6 14.8 16.1 µs

1109 1125 (1400) line

47 60 63 Hz

Data enable

signal

Horizontal period TH

Horizontal period (High) THd 960 960 960 clock

Vertical period

TV

Vertical period (High) TVd 1080 1080 1080 line

【Note】*When vertical period is very long, flicker and others may occur.

*Please turn off the module after it shows the black screen.

*Please make sure that length of vertical period should become of an integral multiple

of horizontal length of period. Otherwise, the screen may not display properly.

*As for your final setting of driving timing, we will conduct operation check test at our side,

please inform your final setting.

TH

THd

DE

A port data

1919

1

3

1919

(R, G, B)

B port data

2

4 1920 1920

(R, G, B)

Tc

1 2

1079

1080

DE

TV

TVd

Fig.2 Timing characteristics of input signals

Page 17

7-2. Input data signal and display position on the screen

G

LD-K22152-15

1・1920

CONTROL PWB

Direction of H

B2

G2

R2

B1

G1

R1

( 1,2 )

B port

( 1,1 )

A port

1・3

1・2

1・1

2・2

2・1

Dire ction of V

1080・1920

B

R

1080・1

3・1

Display position of data (V,H)

Page 18

LD-K22152-16

8. Input Signal, Basic Display Colors and Gray Scale of Each Color

Colors &

Gray

scale

Black – 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Blue – 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 1 1

Green – 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0

Cyan – 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

Red – 1 1 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Basic Color

Magenta – 1 1 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 1 1

Yellow – 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0

White – 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

Black GS0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Gray

R0 R1 R2 R3 R4 R5 R6 R7 R8 R9 G0 G1 G2 G3 G4 G5 G6 G7 G8 G9 B0 B1 B2 B3 B4 B5 B6 B7 B8 B9

Scale

GS1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Darker GS2 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Brighter GS1021 1 0 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Data signal

Gray Scale of Red

GS1022 0 1 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Red GS1023 1 1 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Black GS0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

GS1 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Darker GS2 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Brighter GS1021 0 0 0 0 0 0 0 0 0 0 1 0 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0

Gray Scale of Green

GS1022 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 0 0 1 0 0 0 0 0 0 0 0 0 0

Green GS1023 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0

Black GS0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

GS1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0

Darker GS2 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0

Brighter GS1021 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 1 1 1 1 1 1 1 1

Gray Scale of Blue

GS1022 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 1

Blue GS1023 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 1 1

0: Low level voltage, 1: High level voltage.

Each basic color can be displayed in 1021 gray scales from 10 bit data signals. According to the combination of

total 30 bit data signals, the one billion-color display can be achieved on the screen.

Page 19

LD-K22152-17

p

9. Optical characteristics

Vcc = 12.0V, V

INV = 24.0V, Timing:60Hz, Ta=25℃(typ. Value)

Parameter Symbol Condition Min. Typ. Max. Unit Remark

Viewing angle

Horizontal

range

Vertical

Contrast ratio CRn

Response time

θ21

θ22

θ11

θ12

τDRV

CR≧10

70 88 - Deg.

[Note1][Note4]

70 88 - Deg.

(950) (1500) -

INV

[Note2][Note4]

INV

- (6) - ms

[Note3][Note4]

_duty

_duty

=100%

=100%

[Note5]

Chromaticity of white

Chromaticity of red

Chromaticity of green

Chromaticity of blue

Luminance of white YL1

x

y

x

y

x

θ=0 deg

y

x

y

0.257 0.287 0.317

0.265 0.295 0.325

0.564 0.594 0.624

0.302 0.332 0.362

0.259 0.289 0.319

0.531 0.561 0.591

0.117 0.147 0.177

0.066 0.096 0.126

(800) (1200) -

1200 1500 -

-

-

-

-

-

-

-

-

cd/m2

INV_

=100%

duty

[Note 4]

INV

=100%

_duty

[Note 4]

INV

_duty

=100%

with cooling module

[Note 4][Note7]

Luminance uniformity δW - - (1.25) [Note 6]

Measurement condition: Set the value of duty to maximum luminance of white.

*The measurement shall be executed 120 minutes after lighting at rating.

【Note】The optical characteristics are measured using the following equipment.

Detector(EZ-CONTRAST/Photo Diode)

2500 mm

Detector(SR-3)

Field=1°

Middle of the screen (θ=0°)

Middle of the screen (θ=0°)

TFT-LCD Module

TFT-LCD Module

Fig.3-1 Measurement of viewing angle range

and response time.

Fig.3-2 Measurement of Contrast, Luminance,Chromaticity .

Viewing angle range : EZ-CONTRAST

onse time : Photo Diode

Res

Page 20

LD-K22152-18

[Note 1]Definitions of viewing angle range:

Normal

θ11

θ22

θ21

θ12

6 o’clock direction

[Note 2]Definition of contrast ratio:

The contrast ratio is defined as the following.

Luminance (brightness) with all pixels white

Contrast Ratio

=

Luminance (brightness) with all pixels black

[Note 3]Definition of response time

The response time (

) is defined as the following figure and shall be measured by switching the input

Drv

signal for “five luminance ratio (0%, 25%, 50%, 75%, and 100%)” and “five luminance ratio (0%, 25%, 50%,

75%, and 100%)”.

0% 25% 50% 75% 100%

0% tr: 0%-25% tr: 0%-50% tr: 0%-75% tr: 0%-100%

25% td: 25%-0% tr: 25%-50% tr: 25%-75% tr: 25%-100%

50% td: 50%-0% td: 50%-25% tr: 50%-75% tr: 50%-100%

75% td: 75%-0% td: 75%-25% td: 75%-50% tr: 75%-100%

100% td: 100%-0% td: 100%-25% td: 100%-50% td: 100%-75%

t*: x-y...response time from level of gray(x) to level of gray(y)

= (t*: x-y)/20

Drv

[Note 4]This shall be measured at center of the screen.

[Note 5] Response time is the value when O/S driving is used at typical input time value.

[Note 6]Definition of white uniformity;

White uniformity is defined as the following with five measurements. (A~E)

E

Pixel

1440

960

Maximum luminance of five points (brightness)

W=

δ

Minimum luminance of five points (brightness)

270 540 810

D

C

A B

480

Pixel

Page 21

LD-K22152-19

[Note 7] Fig.4 shows relation between the temperature of blowing air in the thermostatic chamber and luminance of

white and relation between the temperature of blowing air in the thermostatic chamber and power.

㏅/㎡

Luminance of white

1800

1600

1400

1200

1000

0 10203035

Environmental temperature

℃

Fig.4 the temperature of blowing air in thermostatic chamber

(TBD)

10. Handling Precautions of the module

a) Be sure to turn off the power supply when inserting or disconnecting the cable.

b) This product is using the parts (inverter, CCFT etc), which generate the high voltage.

Therefore, during operating, please don't touch these parts.

c) Brightness control voltage is switched for “ON” and “OFF”, as shown in Fig.5. Voltage difference generated

by this switching, ΔV

INV, may affect a sound output, etc. When the power supply is shared between the

inverter and its surrounding circuit. So, separate the power supply of the inverter circuit with the one of its

surrounding circuit.

ΔVINV

VINV

IINV

PWM control

signal

0V

0A

ON ON OFF

0V

Fig.5 Brightness control voltage.

d) Be sure to design the cabinet so that the module can be installed without any extra stress such as warp or

twist.

e) Since the front polarizer is easily damaged, pay attention not to scratch it.

f) Since long contact with water may cause discoloration or spots, wipe off water drop immediately.

g) When the panel surface is soiled, wipe it with absorbent cotton or other soft cloth.

Page 22

LD-K22152-20

h) Since the panel is made of glass, it may break or crack if dropped or bumped on hard surface. Handle with

care.

i) Since CMOS LSI is used in this module, take care of static electricity and take the human earth into

consideration when handling.

j) The module has some printed circuit boards (PCBs) on the back side, take care to keep them from any stress

or pressure when handling or installing the module; otherwise some of electronic parts on the PCBs may be

damaged.

k) Observe all other precautionary requirements in handling components.

l) When some pressure is added onto the module from rear side constantly, it causes display non-uniformity

issue, functional defect, etc... So, please avoid such design.

m) When giving a touch to the panel at power on supply, it may cause some kinds of degradation. In that case,

once turn off the power supply, and turn on after several seconds again, and that is disappear.

n) When handling LCD modules and assembling them into cabinets, please be noted that long-term storage in

the environment of oxidization or deoxidization gas and the use of such materials as reagent, solvent,

adhesive, resin, etc. which generate these gasses, may cause corrosion and discoloration of the LCD

modules.

o) Lamps of the backlight are placed horizontally to the short side of LCD module. The lifetime of the backlight

shortens if the module is used in landscape position.

p) Make sure that the LCD module is operated within specified temperature and humidity.

Measures against dust, water, vibration, and heat radiation, etc. are required at the cabinet or equipment side.

And image retention may occur if same fixed pattern is displayed for a long time.

In some cases, it may not disappear. It is recommended to use moving picture periodically.

After long-term static display, periodical power-off or screen saver is needed. For screen saver,

moving picture or black pattern is strongly recommended.

Avoid combination of background and image with large different luminance.

Please consider the design and operating environment.

q) Ultra-violet ray filter is necessary in outdoor environment.

r) Operation for 24 hours a day is NOT recommended.

s) Well-ventilated place is recommended to set up Information Display system.

t) Execute it at 0℃ or above when you light the module. There is a possibility of don't lighting when begin

lighting at a temperature that is lower than 0℃

u) If you control the temperature of the ambient air or the module, please equalize the temperature

of the module.

Page 23

11. Packing form

2

a) Piling number of cartons: 1 maximum. (Do not pile up.)

b) Packing quantity in one carton: 4 pcs.

c) Carton size: (1230) (W) × (1090) (D) × (2134) (H)

d) Total mass of one carton filled with full modules: (TBD)kg

e) Packing Form is shown in Fig 5. (TBD)

12. Reliability test item *only as for the module.

No. Test item Condition

High temperature storage test

1

Low temperature storage test

2

High temperature and high humidity

3

operation test

High temperature operation test

4

Low temperature operation test

5

Vibration test*

(non-operation)

6

Ta=60℃ 240h

Ta=-20℃ 240h

Ta=40℃ ; 95%RH 240h

(No condensation)

Ta=40℃ 240h

Ta= 0℃ 240h

Frequency: 10~57Hz/Vibration width (one side): 0.075mm

: 58~500Hz/Acceleration: 9.8 m/s

Sweep time: 11 minutes

Test period: 1.5 hours (0.5h for each direction of X, Y, Z)

Shock test*

7

(non-operation)

Maximum acceleration: 294m/s

Pulse width: 11ms, sinusoidal half wave

Direction: (+/-Y), once for each direction.

At the following conditions, it is a thing without incorrect

operation and destruction.

(1)Non-operation: Contact electric discharge +/-10kV

ESD

8

Non-contact electric discharge+/-20kV

(2)Operation Contact electric discharge +/-8kV

Non-contact electric discharge +/-15kV

Conditions: 150Pf,330ohm

【Note】these items apply to the single module.

【Result evaluation criteria】

Under the display quality test condition with normal operation state, there shall be no change, which may

affect practical display function.

LD-K22152-21

2

Page 24

LD-K22152-22

(

)

13. Others

1) Lot No. Label

The label that displays SHARP, product model (LK816D3LA19), a product number is stuck on the

back of the module.

LK816D3LA19

01 L50 001

MADE IN JAPAN

Module No.

Barcode

ot No.

A production year (the last figures of the Christian era)

A production month (1-9, X,Y, Z)

Identification Code

L:Kameyama Tec. Kameyama Fab.

How to express Lot No.

○ L ○ ○ ○ ○ ○ ○○

○

Serial number

Management number

2) Packing Label

社内品番:

Bar code(①)

LotNO.

Bar code(②)

Quantity:

Bar code(③)

ユーザ品番

シャープ物流用ラベルです。

4S

LK816D3LA19

(1T)201*. *.**

(Q)

pcs

4

① Management No. (LK816D3LA19)

② Lot No. (Date)

③ Quantity

3) Adjusting volume has been set optimally before shipment, so do not change any adjusted value.

If adjusted value is changed, the specification may not be satisfied.

4) Disassembling the module can cause permanent damage and should be strictly avoided.

5) Please be careful since image retention may occur when a fixed pattern is displayed for a long time.

6) The chemical compound, which causes the destruction of ozone layer, is not being used.

7) Cold cathode fluorescent lamp in LCD PANEL contains a small amount of mercury. Please follow local

ordinances or regulations for disposal. It is displaying the label in the module back.

Page 25

LD-K22152-23

8) This LCD is appropriate to UL. Below figure shows the UL label.

9) This module is corresponded to RoHS

10) The chemical compound, which causes the destruction of ozone layer, is not being used.

11) Rust on the module is not taken up a problem.

12) Appearance quality and standard are referred to the outgoing incoming inspections.

13) Rust on the module is not taken up a problem.

14. Carton storage condition

Temperature 0℃ to 40℃

Humidity 95%RH or less

Reference condition : 20℃ to 35℃ , 85%RH or less (summer)

: 5℃ to 15℃ , 85%RH or less (winter)

・the total storage time (40℃,95%RH) : 240h or less

Sunlight Be sure to shelter a product from the direct sunlight.

Atmosphere Harmful gas, such as acid and alkali which bites electronic components and/or

wires must not be detected.

Notes Be sure to put cartons on palette or base, don’t put it on floor, and store them with

removing from wall

Please take care of ventilation in storehouse and around cartons, and control

changing temperature is within limits of natural environment

Please keep LCD module in Portrait position.

(The long side of LCD module is placed vertically)

Storage life 1 year

Factory code

Page 26

ᾛᾓὼᾚᾁᾁᾀᾄᾁὼᾁᾃ

ᾕᶇᶅᵋᵏ

Loading...

Loading...