Page 1

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 2

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 3

Parameter

Specifications

Unit

80.039 (Diagonal)

cm

31.5 (Diagonal)

inch

Active area

697.69 (H) × 392.26 (V)

mm

1366 (H) × 768 (V)

(1pixel = R + G + B dot)

pixel

Pixel pitch

0.51075(H) × 0.51075 (V)

mm

Pixel configuration

R,G, B vertical stripe

Display mode

Normally black

Unit Outline Dimensions

mm

Mass

1.15s0.1

kg

Low-Haze Anti Glare, Hard coating

<6B: TFT side (Rear)

A

Global LCD Panel Exchange Center

1. Application

This specification applies to the color 31.5” Wide XGA TFT Open-Cell LK315T3HB94.

* These specification sheets are proprietary products of SHARP CORPORATION (“SHARP”) and include materials

protected under copyright of SHARP. Do not reproduce or cause any third party to reproduce them in any form or by

any means, electronic or mechanical, for any purpose, in whole or in part, without the express written permission of

SHARP.

* In case of using the device for applications such as control and safety equipment for transportation (aircraft, trains,

automobiles, etc.), rescue and security equipment and various safety related equipment which require higher

reliability and safety, take into consideration that appropriate measures such as fail-safe functions and redundant

system design should be taken.

* Do not use the device for equipment that requires an extreme level of reliability, such as aerospace applications,

telecommunication equipment (trunk lines), nuclear power control equipment and medical or other equipment for

life support.

* SHARP assumes no responsibility for any damage resulting from the use of the device that does not comply with

the instructions and the precautions specified in these specification sheets.

* Contact and consult with a SHARP sales representative for any questions about this device.

2. Overview

This Open-Cell is a color active matrix LCD module incorporating amorphous silicon TFT (T

It is composed of a color TFT-LCD panel, driver ICs, control circuit, power supply circuit, inverter circuit and back

light system etc. Graphics and texts can be displayed on a 1366×RGB×768 dots panel with 16,777,216 colors by

using LVDS (L

And in order to improve the response time of LCD, this module applies the Over Shoot driving (O/S driving)

technology for the control circuit .In the O/S driving technology, signals are being applied to the Liquid Crystal

according to a pre-fixed process as an image signal of the present frame when a difference is found between image

signal of the previous frame and that of the current frame after comparing them.

By using the captioned process, the image signals of this Open-Cell are being set so that image response can be

completed within one frame, as a result, image blur can be improved and clear image performance can be realized.

3. Mechanical Specifications

ow Voltage Differential Signaling) to interface, +12V of DC supply voltages.

www.panelook.com

LD-K24Z13C-1

hin Film Transistor).

Display size

Pixel Format

[Note 2]

Surface treatment

[Note 1]

[Note 1] Without the protection film.

[Note 2] The Outline dimensions are shown in P17.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

715.59(W) × 446.45(H) ×1.8(D)

Surface Hardness;

2H: CF side (Front)

ڸ

www.panelook.com

Page 4

Pin No.

Symbol

Function

Remark

1

VCC

+12VPower Supply

2

VCC

+12VPower Supply

3

VCC

+12VPower Supply

4

VCC

+12VPower Supply

5

GND

Ground

6

GND

Ground

7

GND

Ground

8

GND

Ground

SELLVDS

Default: Pull down

[Note 2]

10

Reserved

Not Available

11

GND

Ground

12

RIN0-

Negative (-) LVDS differential data input

LVDS

13

RIN0+

Positive (+) LVDS differential data input

LVDS

14

GND

Ground

15

RIN1-

Negative (-) LVDS differential data input

LVDS

16

RIN1+

Positive (+) LVDS differential data input

LVDS

17

GND

Ground

18

RIN2-

Negative (-) LVDS differential data input

LVDS

19

RIN2+

Positive (+) LVDS differential data input

LVDS

20

GND

Ground

21

CLKIN-

Clock Signal(-)

LVDS

22

CLKIN+

Clock Signal(+)

LVDS

23

GND

Ground

24

RIN3-

Negative (-) LVDS differential data input

LVDS

25

RIN3+

Positive (+) LVDS differential data input

LVDS

26

GND

Ground

27

Reserved

No Connection

28

Reserved

No Connection

29

GND

Ground

30

Reserved

No Connection

Global LCD Panel Exchange Center

4. Input Terminals

4-1. TFT panel driving

CN1 (Interface signals and +12V DC power supply) (Shown in Fig.1)

Using connector 㸸

Matching connector 㸸FI-X30H/FI-X30HL, FI-X30C/FI-X30C2L

Matching LVDS transmitter㸸THC63LVDM83R (THine) or equivalent device

FI-X30SSL-HF-R2500 (JAE) 䕦C

or FI-X30M (Japan Aviation Electronics Ind. , Ltd.)

www.panelook.com

LD-K24Z13C-2

9

Select LVDS data order [Note 1]

(L:GND)

[Note] GND of a liquid crystal panel drive part has connected with a module chassis.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 5

Transmitter

SELLVDS

Pin No

Data

= L(GND) or Open

= H(3.3V)

51

TA0

R0(LSB)

R2

52

TA1

R1

R3

54

TA2

R2

R4

55

TA3

R3

R5

56

TA4

R4

R6

3

TA5

R5

R7(MSB)

4

TA6

G0(LSB)

G2

6

TB0

G1

G3

7

TB1

G2

G4

11

TB2

G3

G5

12

TB3

G4

G6

14

TB4

G5

G7(MSB)

15

TB5

B0(LSB)

B2

19

TB6

B1

B3

20

TC0

B2

B4

22

TC1

B3

B5

23

TC2

B4

B6

24

TC3

B5

B7(MSB)

27

TC4

NA

NA

28

TC5

NA

NA

30

TC6

DE(*)

DE(*)

50

TD0

R6

R0(LSB)

2

TD1

R7(MSB)

R1

8

TD2

G6

G0(LSB)

10

TD3

G7(MSB)

G1

16

TD4

B6

B0(LSB)

18

TD5

B7(MSB)

B1

25

TD6

NA

NA

Terminal

1.0K ohm

10K ohm

Global LCD Panel Exchange Center

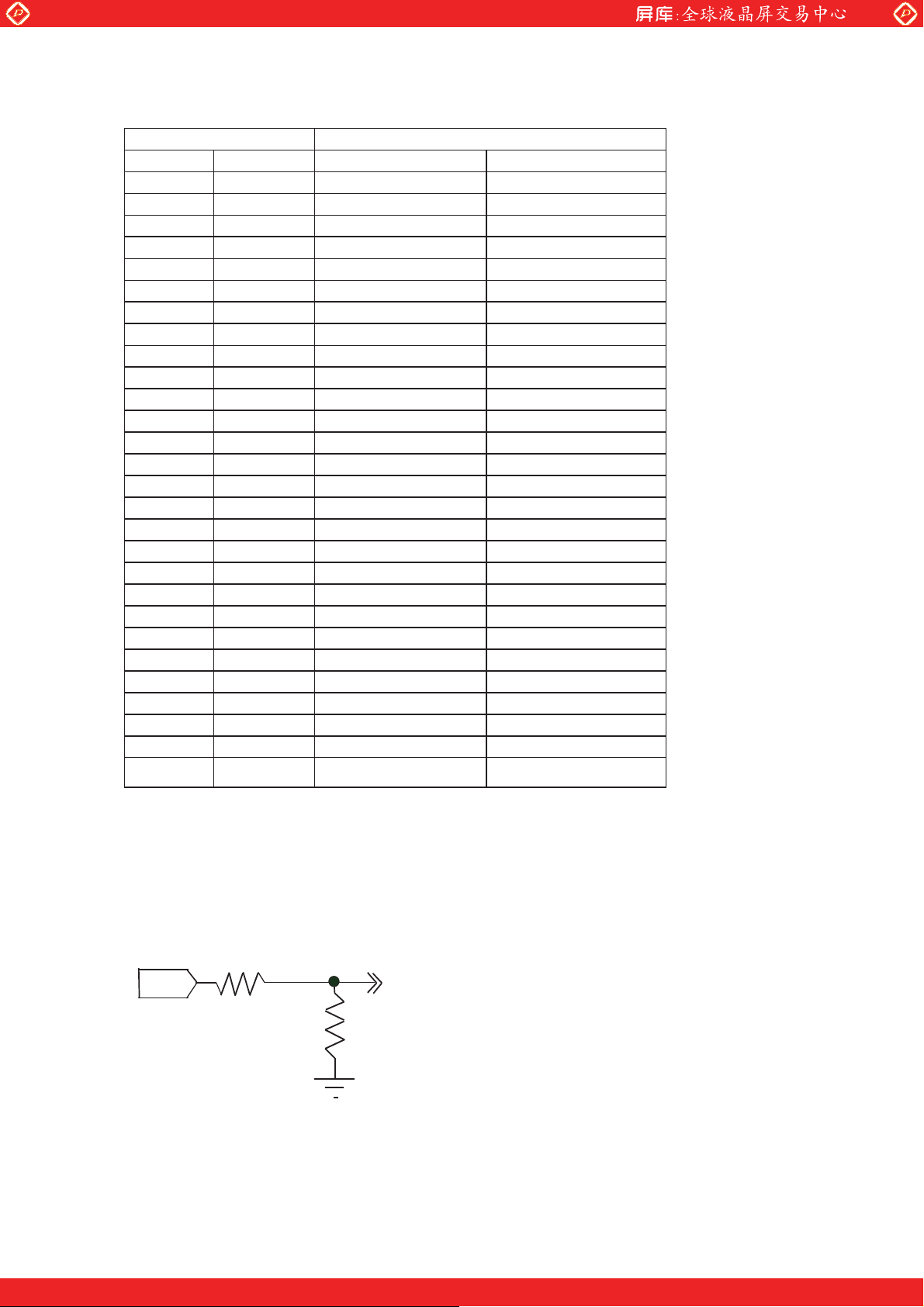

[Note1] SELLVDS

www.panelook.com

LD-K24Z13C-3

NA: Not Available

(*) Since the display position is prescribed by the rise of DE (Display Enable) signal,

please do not fix DE signal during operation at "High."

[Note 2] The equivalent circuit figure of the terminal

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 6

INPUT SIGNALS

POWER SUPPLY

+12V DC

Control Signals

CN1

Power Supply

Circuit

SOURCE㻌㻌 DRIVER

GATE DRIVER

Global LCD Panel Exchange Center

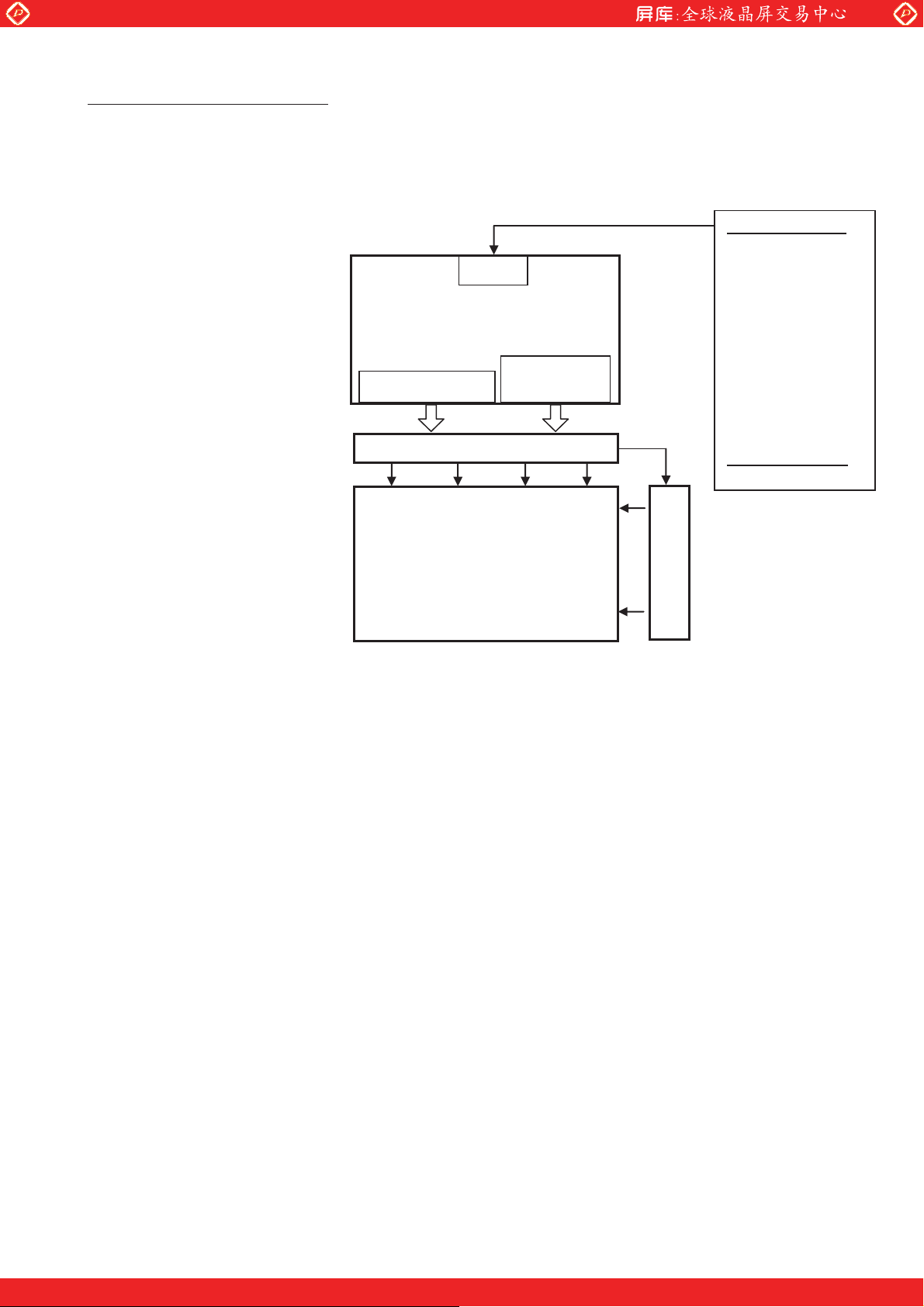

࣭Block Diagram (LCD Module)

www.panelook.com

LD-K24Z13C-4

CLKIN+

CLKINRIN0+

RIN0-

SOURCE/CONTROL PWB

RIN1+

RIN1RIN2+

RIN2RIN3+

RIN3SELLVDS

LCD PANEL

1366×3(RGB)×768

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 7

G0

R5

R4

R3

R2

R1

R0

R0

R1

G0

B1

B0

G5

G4

G3

G2

G1

G1

G2

B1

DE

B5

B4

B3

B2

B2

B3 DENA

NA

B7

B6

G7

G6

R7

R6

R6

R7

NA

NA

1 cycle

G2

R7

R6

R5

R4

R3

R2

R2

R3

G2

B3

B2

G7

G6

G5

G4

G3

G3

G4

B3

DE

B7

B6

B5

B4

B4

B5 DENA

NA

B1

B0

G1

G0

R1

R0

R0

R1

NA

NA

1 cycle

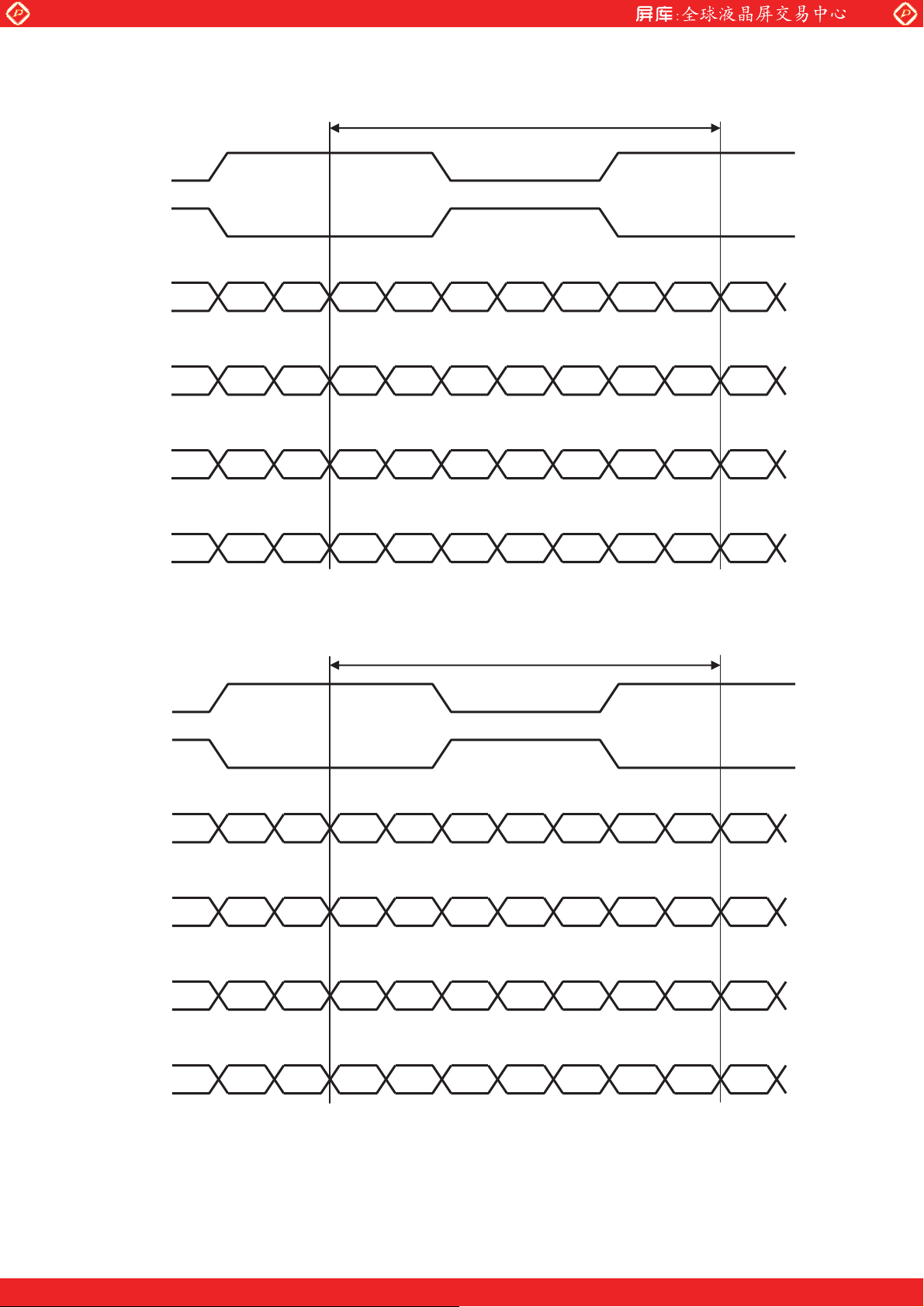

Global LCD Panel Exchange Center

SELLVDS= High (3.3V)

CLKIN+

CLKIN-

RIN0+

RIN0-

RIN1+

RIN1-

RIN2+

RIN2-

RIN3+

RIN3-

SELLVDS= Low(GND) or Open

CLKIN+

CLKIN-

RIN0+

RIN0-

RIN1+

RIN1-

RIN2+

RIN2-

RIN3+

RIN3-

DE: Display Enable

NA: Not Available (Fixed Low)

www.panelook.com

LD-K24Z13C-5

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 8

Parameter

Symbol

Condition

Ratings

Unit

Remark

Input voltage

(for Control)

C

V

[Note 1]

+12V supply voltage

(for Control)

C

V

Storage temperature

Tstg

°C

[Note 2]

Operation temperature

(Ambient)

Topa

°C

Parameter

Symbol

Min.

Typ.

Max.

Uniit

Remark

+12V supply

voltage

Supply voltage

VCC

+11.4

+12.0

+13.7 V [Note 1]

Current dissipation

ICC - 350

600

mA

[Note 2]

I

RUSH

- 1500

2500

mA

[Note 5]

T

RUSH

- 0.5

-

ms

[Note 5]

Permissible input ripple voltage

VRP - -

100

mVP-P

Vcc = +12.0V

Differential input

threshold voltage

High

VTH - -

100

mV

VCM = +1.2V

[Note 4]

Low

VTL

-100 - -

mV

Input Low voltage

VIL 0 -

0.7

V

Input High voltage

VIH

2.6 - 3.3

V

ak current (Low)

- -

400

μA

VI = 0V

[Note 3]

Input leak current (High)

- -

100

μA

VI =3.3V

[Note 3]

Terminal resistor

RT - 100

- Ω Differential input

0.9VCC

Back light: V

INV

Data1

VCC

t3

t4

t1

0.1VCC

0.1VCC

0.9VCC

0.1VCC

t2-1

OFF

OFF

t5

t2-2

ON

Data2

9FF

WG

㸬

㹔

㸬

㹔

9.1V

10.8V

Global LCD Panel Exchange Center

5. Absolute Maximum Ratings

www.panelook.com

LD-K24Z13C-6

VI

V

CC

Ta=25°

Ta=25°

-0.3 ~ 3.6

0 ~ +15

- -25 ~ +60

- 0 ~ +50

[Note 1] SELLVDS

[Note 2] Humidity 95%RH Max.(Ta d 40°C)

Maximum wet-bulb temperature at 39°C or less.(Ta > 40°C), No condensation.

6. Electrical Characteristics

6-1. Control circuit driving Ta=25°C

Input le

I

IL

I

IH

[Note] VCM: Common mode voltage of LVDS driver.

[Note 1]

Input voltage sequences Dip conditions for supply voltage

50μs < t1 d 20ms a) 9.1V d V

< 10.8V

CC

20ms < t2-1 d 5s td d 10ms

20ms < t2-2 d 5s b) V

< 9.1V

CC

0 < t3 d 1s Dip conditions for supply voltage is

t4 t 1s based on input voltage sequence.

t5 t 300ms

[Note 3]

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 9

5*%

*6

5*%

*6

5*%

*6

5*%*6

5*%

*6

Global LCD Panel Exchange Center

Data1: CLKINs,RIN0s,RIN1s, RIN2s, RIN3s

Data2: SELLVDS

About the relation between data input and back light lighting, please base on the above-mentioned input

sequence.

When back light is switched on before panel operation or after a panel operation stop, it may not display

normally. But this phenomenon is not based on change of an incoming signal, and does not give damage to a

liquid crystal display.

[Note 2] Typical current situation: 256 gray-bar pattern (V

The explanation of RGB gray scale is seen in section 8.

[Note 3] SELLVDS

[Note 4] CLKIN+/CLKIN-, RIN0+/RIN0-, RIN1+/RIN1-, RIN2+/RIN2-, RIN3+/RIN3-

[Note 5] The Rush current corrugation at the time of power on

www.panelook.com

= +12.0V)

CC

V

CC

CK = 82.0MHz

Th = 20.68μs

LD-K24Z13C-7

= +12.0V

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 10

Symbol

Typ.

Max.

Unit

NTSC

PAL

Clock

Frequency

1/Tc

72

82

82

85

MHz

Data enable

signal

TH

1540

1696

1696

1940

clock

19.84

20.68

20.68

-

μs

Horizontal period (High)

THd

1366

1366

1366

1366

clock

Vertical period

TV

778

806

967

972

line

Vertical period (High)

TVd

768

768

768

768

line

1

2

1366

THd

TH

TVd

TV

Tc

1

2

768

767

1366

Global LCD Panel Exchange Center

7. Timing characteristics of input signals

7-1. Timing characteristics

Timing diagrams of input signal are shown in Fig.2

www.panelook.com

LD-K24Z13C-8

Parameter

Horizontal period

[Note] When vertical period is very long, flicker may occur.

Please turn off the module after it shows the black screen.

Please make sure that length of vertical period should become of an integral multiple of horizontal length of

period. Otherwise, the screen may not display properly.

As for your final setting of driving timing, we will conduct operation check test at our side, please inform

your final setting.

Vertical period must change less than 1 line each flames.

DE

DATA

(R,G,B)

DE

Fig.2 Timing characteristics of input signals

Min.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 11

㸯࣭㸯

㸯࣭㸰

㸯࣭㸱

㸰࣭㸯

㸰࣭㸰

㸱࣭㸯

㺃

㺃

㺃

R1

G1

B1

R2

G2

B2

RGB

Global LCD Panel Exchange Center

7-2. Input data signal and display position on the screen

㸯㺂㸯

㸯㸰

www.panelook.com

'LVSOD\3RVLWLRQRI'DWD9+

LD-K24Z13C-9

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 12

Colors &

Gray scale

Data signal

Gray

Scale

R0

R1

R2

R3

R4

R5

R6

R7

G0

G1

G2

G3

G4

G5

G6

G7

B0

B1

B2

B3

B4

B5

B6

B7

Basic Color

Black

㸫

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

0

Blue

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1

1

Green

0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0

0

Cyan

0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

1

Red

1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 Magenta

1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1

1

Yellow

1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0

0

White

1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

1

Gray Scale of Red

Black

GS0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

GS1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Darker

GS2 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

È

È È

È

È È

Brighter

GS253 1 0 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 Ø

GS254 0 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Red

GS255 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Gray Scale of Green

Black

GS0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

GS1 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Darker

GS2 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0

È

È È

È

È È

Brighter

GS253 0 0 0 0 0 0 0 0 1 0 1 1 1 1 1 1 0 0 0 0 0 0 0 0

GS254 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0

Green

GS255 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0

Gray Scale of Blue

Black

GS0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

GS1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0

Darker

GS2 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0

È

È È

È

È È

Brighter

GS253 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 1 1 1 1 1 1

GS254 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1

Blue

GS255 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1

Global LCD Panel Exchange Center

8. Input Signal, Basic Display Colors and Gray Scale of Each Color

㸫

㸫

㸫

㸫

㸫

㸫

㸫

×

www.panelook.com

LD-K24Z13C-10

×

Ø

×

×

Ø

Ø

×

×

Ø

È

È

È

È

È

È

Ø

0 : Low level voltage, 1 : High level voltage.

Each basic color can be displayed in 256 gray scales from 8 bit data signals. According to the combination of total

24 bit data signals, the 16,777,216 colors display can be achieved on the screen.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 13

Parameter

Symbol

Condition

Min.

Typ.

Max.

Unit

Remark

Viewing angle

Horizontal

θ21

θ22

10

70

88

-

Deg.

Note1,4]

Vertical

θ11

θ12

70

88

-

Deg.

CRn

0 deg.

750

5000 - -

,4]

- 7 -

ms

[Note3,4,5]

C

ڸ

A

x

0.246

0.276

0.306

-

[Note 4]

y

0.244

0.274

0.304

-

ڸ

A

x

0.603

0.633

0.663

-

y

0.324

0.354

0.384

-

C

ڸ

A

x

0.288

0.318

0.348

-

y

0.625

0.655

0.685

-

ڸ

A

x

0.115

0.145

0.175

-

y

0.021

0.051

0.081

-

20

400

-

cd/m2

[Note 4]

- -

1.25 - [Note 6]

Center of the screen (θ = 0°)

TFT-LCD Module

Center of the screen (θ = 0°)

TFT-LCD Module

400mm

Field=1r

Detector (SR-3)

Detector (EZ-CONTRAST, Photo Diode)

Fig.3-1 Measurement of viewing angle range

Fig.3-2 Measurement of Contrast,

Global LCD Panel Exchange Center

9. Optical characteristics

range

www.panelook.com

CR t

LD-K24Z13C-11

Ta = 25°C, Vcc = +12V

[

Contrast ratio

Response time

hromaticity of white

W

DRV

3

θ =

Chromaticity of red

hromaticity of green

Chromaticity of blue

Luminance of white Y

L

3

Luminance uniformity

δ

W

Measurement condition : Back Light Unit is based on SHARP standard Moudel.

*The measurement shall be executed 60 minutes after lighting at rating.

[Note] The optical characteristics are measured using the following equipment.

and response time.

(Viewing angle range: EZ-CONTRAST

Response time: Photo Diode)

Luminance, and Chromaticity.

[Note2

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 14

0%

25%

50%

75%

100%

0%

%

50%

75%

tr: 0%-100%

25%

%

tr: 25%-50%

75%

tr: 25%-100%

50%

%

td: 50%-25%

75%

tr: 50%-100%

75%

%

td: 75%-25%

td: 75%-50%

tr: 75%-100%

100%

td: 100%-0%

td: 100%-25%

td: 100%-50%

td: 100%-75%

Normal

θ21

θ11

θ12

θ22

6 o’clock direction

Luminance (brightness) with all pixels white

Contrast Ratio

Luminance (brightness) with all pixels black

Maximum luminance of five points (brightness)

δ

Global LCD Panel Exchange Center

[Note 1] Definitions of viewing angle range :

[Note 2] Definition of contrast ratio :

The contrast ratio is defined as the following.

[Note 3] Definition of response time

The response time (W

) is defined as the following figure and shall be measured by switching the input

DRV

signal for “any level of gray (0%, 25%, 50%, 75% and 100%)” and “any level of gray (0%, 25%, 50%, 75% and

100%)” at panel surface temperature 45°C.

㸻

www.panelook.com

LD-K24Z13C-12

tr: 0%-25

td: 25%-0

td: 50%-0

td: 75%-0

tr: 0%-

tr: 50%-

tr: 0%-

tr: 25%-

t*:x-y...response time from level of gray(x) to level of gray(y)

= 6(t*:x-y)/20

W

DRV

[Note 4] This shall be measured at center of the screen.

[Note 5] This value is valid when O/S driving is used at typical input time value .

[Note 6] Definition of white uniformity ;

White uniformity is defined as the following with five measurements. (A~E)

㹕㸻

Minimum luminance of five points (brightness)

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 15

No.

Test item

Condition

1

High temperature storage test

Ta=60°C 500h

2

Low temperature storage test

Ta=-25°C 500h

3

High temperature and high humidity

operation test

Ta=40°C ; 95%RH 500h

(No condensation)

4

Ta=50°C 500h

(The panel surface temperature of this time is MAX60°C)

5

Ta=0°C 500h

(The panel surface temperature of this time is MIN0°C)

6

Vibration test

(non-operation)

X and Y direction: 15min, Z direction: 60min.

5Hz to 50Hz

Sweeping ratio: 3min

7

Shock test

(non-operation)

Maximum acceleration: 490m/s2

Pulse

Direction: +/-X, +/-Y, +/-Z, once for each direction.

Model No.

Lot No.

2D Barcode

LK315T3HB94

XX XXXXXX L

Barcode

A production year (the last figures of the Christian Era)

A production month (1-9,X,Y,Z)

Serial No.

Last Management No.

ۑ ۑ ۑ ۑۑ ۑ ۑ

ۑ

Identification Code

K: Kameyama Plant.

L:

. Kameyama Fab.

N:NSEC

Global LCD Panel Exchange Center

10. Reliability

Reliability test item

High temperature operation test

Low temperature operation test

www.panelook.com

LD-K24Z13C-13

(Cell Box with Open-Cells)

(Cell Box with Open-Cells)

width: 11ms, sinusoidal half wave

acceleration velocity: 1.0G

11. Label

1. Lot No. label

The label stuck on a cell surface displays SHARP, product model (LK315T3HB94) and a product Lot No.

(ex.) [LK315T3HB94] JAPAN PRODUCTION

䠨䠭䠏䠓䠌䠠䠏䠨䠶䠍䠐

䠑䠕䚷䠴䠴䠴䠴䠴䠴

䠩䠝䠠䠡䚷䠥䠪䚷䠦䠝䠬䠝䠪

Kameyama Tec

ڸB

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 16

ڸ

Carton storage condition

Management No

Quantity

㸦㹏㸧

♫ෆရ␒㸸

LKK315T3HHB94㸨

㹊㹭㹲㹌㹍㸬

࣭㸦㸯㹒㸧㸨㸨㸨㸨

㹏㹳㹟㹬㹲㹧㹲㹷㸸

15

㹮㹡㹱

࣮ࣘࢨရ␒

Bar code

Bar code

Bar code

Bar code

ࢩ࣮ࣕࣉ≀ὶ⏝࡛ࣛ࣋ࣝࡍࠋ

㸦㹏㸧

♫ෆရ␒㸸

LKK315T3HHB94㸨

㹊㹭㹲㹌㹍㸬

࣭㸦㸯㹒㸧㸨㸨㸨㸨

㹏㹳㹟㹬㹲㹧㹲㹷㸸

240

㹮㹡㹱

࣮ࣘࢨရ␒

Bar code

Bar code

Bar code

Bar code

ࢩ࣮ࣕࣉ≀ὶ⏝࡛ࣛ࣋ࣝࡍࠋ

Global LCD Panel Exchange Center

2. Packing label

࣭Cell box

ձ

ղ Lot No. (Date)

ճ

Packing form

12.

C

a) Piling number of cartons: 16 cell box / 1 palette.

b) Packing quantity in one cell box: 15 pcs

c) Carton sizeձ: 1200(W) × 1000(D) × 1127(H)

Carton sizeղ: 1200(W) × 1000(D) × 1157(H)

d) Total mass of one carton filled with full modules: 330 kg(Max)

13.

a) Temperature: 0°C to 40°C

b) Humidity: 95%RH or less

Reference condition: 20°C to 35°C, 85%RH or less (summer)

: 5°C to 15°C, 85%RH or less (winter)

The total storage time (40°C, 95%RH): 240H or less

c) Sunlight:

Be sure to shelter a product from the direct sunlight.

d) Atmosphere:

Do not store in a place where exists the risk of corrosive gas (such as acid and alkali) or volatile solvents.

e) Prevent condensation:

Be sure to put cartons on a palette or base, don’t put it on the floor, and store them keeping off the wall.

Please take care of ventilation in storehouse and around cartons, and control temperature not to change abruptly

beyond the natural environment.

f) Storage life: 6 months

www.panelook.com

ձ

㸨㸨㸨ղ

ճ

࣭

LD-K24Z13C-14

Carton

ձ

㸨㸨㸨ղ

ճ

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 17

Precautions

item

Management standard value and performance standard

1

Anti-static mat(shelf)

1 to 50 [Mega ohm]

2

Anti-static mat(floor, desk)

1 to 100 [Mega ohm]

3

Ionizer

Attenuate from ±1000V to ±100V within two seconds.

4

Anti-static wrist band

0.8 to 10 [Mega ohm]

5

Anti-static wrist band entry and

ground resistance

Below 1000 [ohm]

6

Temperature

22 to 26 [qC]

7

Humidity

60 to 70 [%]

Gate-Driver

S-PWB

Fig.5 Direction of peeling off

GND

Source-Control

PWB

Source-Driver

Global LCD Panel Exchange Center

14. P

a) Because the Open-Cell is weak to static electricity, please do not touch the terminal with bare hands.

b) Since the front polarizer is easily damaged, pay attention not to scratch it.

c) Since long contact with drops of water may cause discoloration or spots, please wipe off them as soon as put

on the screen.

d) When the panel surface is soiled, wipe it with absorbent cotton or other soft cloth.

e) Since the panel is made of glass, it may break or crack if dropped or bumped on hard surface. Handle with

care.

f) Precautions of peeling off the protection film:

- Be sure to peel off slowly (recommended more than 7sec) and constant speed.

- Peeling direction shown in Fig. 5.

- Be sure to ground person with adequate methods such as the anti-static wrist band.

- Be sure to ground S-PWBs while peeling off the protection film.

- Ionized air should be blown to the surface while peeling off.

- The protection film must not touch drivers and S-PWBs.

- If adhesive may remain on the polarizer after the protection film peeled off, please remove with

isopropyl-alcohol.

g) Since the Open-Cell consists of TFT and electronic circuits with CMOS-ICs, which are very weak to

electrostatic discharge, persons who are handling a Open-Cell should be grounded through adequate methods

such as an anti-static wrist band. Connector pins should not be touched directly with bare hands.

㺃Reference: Process control standard of sharp

www.panelook.com

LD-K24Z13C-15

h) Since the Open-Cell has some PWBs, please take care to keep them off any stress or pressure when handling

or installing the Open-Cell, otherwise some of electronic parts on them may be damaged.

i) Be sure to turn off the power supply when inserting or disconnecting the cable.

j) Be sure to design the module and cabinet so that the Open-Cell can be installed without any extra stress such

as warp or twist.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 18

Global LCD Panel Exchange Center

k) When handling and assembling Open-Cells into module and cabinets, please be noted that long-term storage

in the environment of oxidization or deoxidization gas and the use of materials such as reagent, solvent,

adhesive, resin, etc. which generate these gasses, may cause corrosion and discoloration of the Open-Cell.

l) Applying too much force and stress to PWBs and drivers may cause a malfunction electrically and

mechanically.

m) The Open-Cell has high frequency circuits. Sufficient suppression to EMI should be done by system

manufactures.

n) Please be careful since image retention may occur when a fixed pattern is displayed for a long time.

o) The chemical compound, which causes the destruction of ozone layer, is not being used.

p) This Open-Cell module is corresponded to RoHS.

q) Please design the heat dissipation of the module with enough care for SC-PWB, Source-driver

and Gate-driver’s IC.

r) When any question or issue occurs, it shall be solved by mutual discussion.

www.panelook.com

LD-K24Z13C-16

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 19

Fig.6 Outline dimensions

A

Global LCD Panel Exchange Center

www.panelook.com

LD-K24Z13C-17

ڸ

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 20

Global LCD Panel Exchange Center

www.panelook.com

LD-K24Z13C-18

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 21

Global LCD Panel Exchange Center

www.panelook.com

LD-K24Z13C-19

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Loading...

Loading...