Page 1

AVシステム事業本部

液晶DS第四事業部 技術部殿

LD-K23Z03 -1

納入仕様書番号

作成日 2012年 1月 6日

改訂日 年 月 日

LD-K23Z03

《新規・変更》

品名 TFT-LCDモジュール

形名 LK315T3HB00X/T/A

【受領印欄】

納 入 仕 様 書

※この仕様書は、付属書等を含めて全21頁で構成されております。

当仕様書について異議があれば発注時点までにお申し出ください。

RoHS規制対応部品

シャープ株式会社

大型液晶事業本部

液晶事業部 第二開発部

所属長 参事 副参事 係長 担当

三重県亀山市白木町幸川464番地

Page 2

MODEL No. : LK315T3HB00X/T/A

SPEC No. : LD-K23Z03

DATE

2012.1.6

NO.

LD-K23Z03

RECORDS OF REVISION

REVISED

No.

-

PAGE SUMMARY NOTE

- -

LD-K23Z03 -2

1st Issue

Page 3

LD-K23Z03 -3

1. Application

This specification applies to the color 31.5” Wide XGA TFT Open-Cell LK315T3HB00X/T/A.

* These specification sheets are proprietary products of SHARP CORPORATION (“SHARP”) and include materials

protected under copyright of SHARP. Do not reproduce or cause any third party to reproduce them in any form or by

any means, electronic or mechanical, for any purpose, in whole or in part, without the express written permission of

SHARP.

* In case of using the device for applications such as control and safety equipment for transportation (aircraft, trains,

automobiles, etc.), rescue and security equipment and various safety related equipment which require higher

reliability and safety, take into consideration that appropriate measures such as fail-safe functions and redundant

system design should be taken.

* Do not use the device for equipment that requires an extreme level of reliability, such as aerospace applications,

telecommunication equipment (trunk lines), nuclear power control equipment and medical or other equipment for

life support.

* SHARP assumes no responsibility for any damage resulting from the use of the device that does not comply with

the instructions and the precautions specified in these specification sheets.

* Contact and consult with a SHARP sales representative for any questions about this device.

2. Overview

This Open-Cell is a color active matrix LCD module incorporating amorphous silicon TFT (T

It is composed of a color TFT-LCD panel, driver ICs, control circuit, power supply circuit, inverter circuit and back

light system etc. Graphics and texts can be displayed on a 1366×RGB×768 dots panel with 16,777,216 colors by

using LVDS (L

This module also includes the LED-PWB module to drive the LED.

And in order to improve the response time of LCD, this module applies the Over Shoot driving (O/S driving)

technology for the control circuit .In the O/S driving technology, signals are being applied to the Liquid Crystal

according to a pre-fixed process as an image signal of the present frame when a difference is found between image

signal of the previous frame and that of the current frame after comparing them.

By using the captioned process, the image signals of this Open-Cell are being set so that image response can be

completed within one frame, as a result, image blur can be improved and clear image performance can be realized.

3. Mechanical Specifications

Active area 697.69 (H) × 392.26 (V) mm

Pixel Format

Pixel pitch 0.51075(H) × 0.51075 (V) mm

Pixel configuration R,G, B vertical stripe

Display mode Normally black

Unit Outline Dimensions (*1) 709.3(W) × 451.2(H) ×4.8max(D) mm

Mass 1.2 kg

Surface treatment

(*1) Outline dimensions are shown in Fig.1

ow Voltage Differential Signaling) to interface, +12V of DC supply voltages.

Parameter Specifications Unit

Display size

80.039 (Diagonal)

31.5 (Diagonal)

1366 (H) × 768 (V)

(1pixel = R + G + B dot)

Low-Haze Anti Glare

Hard coating: 2H

hin Film Transistor).

cm

inch

pixel

Page 4

4. Input Terminals

4-1. TFT panel driving

CN1 (Interface signals and +12V DC power supply) (Shown in Fig.1)

Using connector :

GT103-30S-H23-D-E2500 (LSMtron)

Matching connector :FI-X30H/FI-X30HL, FI-X30C/FI-X30C2L

or FI-X30M (Japan Aviation Electronics Ind. , Ltd.)

Matching LVDS transmitter:THC63LVDM83R (THine) or equivalent device

Pin No. Symbol Function Remark

1 VCC +12V Power Supply

2 VCC +12V Power Supply

3 VCC +12V Power Supply

4 VCC +12V Power Supply

5 GND

6 GND

7 GND

8 GND

9 SELLVDS

10 Reserved

11 GND

12 RIN013 RIN0+

14 GND

15 RIN116 RIN1+

17 GND

18 RIN219 RIN2+

20 GND

21 CLKIN22 CLKIN+

23 GND

24 RIN325 RIN3+

26 GND

27 Reserved

28 Reserved

29

30

GND

Reserved

Ground

Ground

Ground

Ground

Select LVDS data order [Note 1]

Not Available

Ground

Negative (-) LVDS differential data input

Positive (+) LVDS differential data input

Ground

Negative (-) LVDS differential data input

Positive (+) LVDS differential data input

Ground

Negative (-) LVDS differential data input

Positive (+) LVDS differential data input

Ground

Clock Signal(-)

Clock Signal(+)

Ground

Negative (-) LVDS differential data input

Positive (+) LVDS differential data input

Ground

Not Available

Not Available

Ground

Write Protect

[Note] GND of a liquid crystal panel drive part has connected with a module chassis.

LD-K23Z03 -4

Default: Pull down

(L:GND)

[Note 2]

LVDS

LVDS

LVDS

LVDS

LVDS

LVDS

LVDS

LVDS

LVDS

LVDS

Default: Pull down

Protect enable

(

)

Page 5

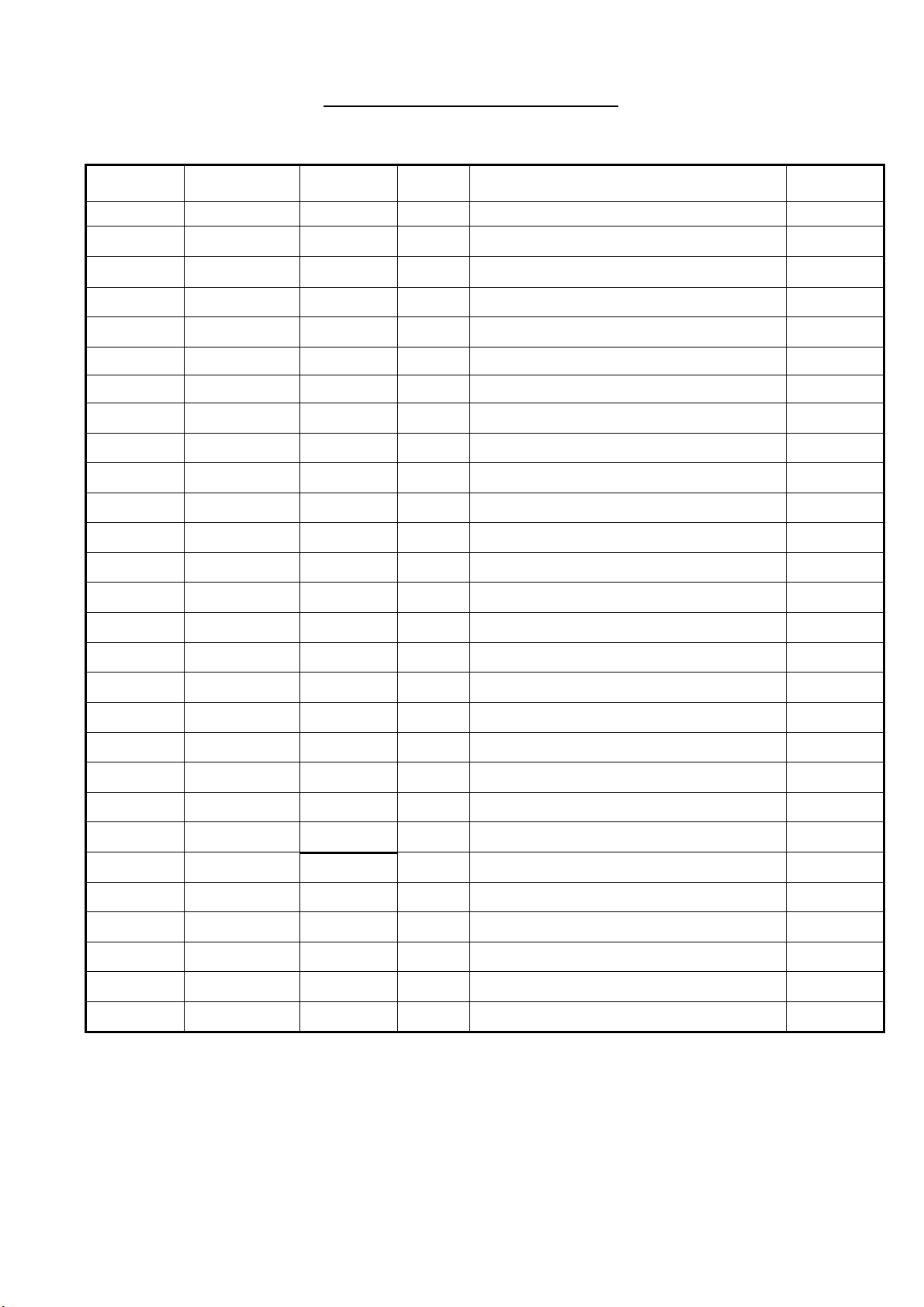

[Note1] SELLVDS

Transmitter SELLVDS

Pin No Data

51 TA0

52 TA1

54 TA2

55 TA3

56 TA4

3 TA5

4 TA6

6 TB0

7 TB1

11 TB2

12 TB3

14 TB4

15 TB5

19 TB6

20 TC0

22 TC1

23 TC2

24 TC3

27 TC4

28 TC5

30 TC6

50 TD0

2 TD1

8 TD2

10 TD3

16 TD4

18 TD5

25 TD6

= L(GND) or Open

R0(LSB)

R1

R2

R3

R4

R5

G0(LSB)

G1

G2

G3

G4

G5

B0(LSB)

B1

B2

B3

B4

B5

= H(3.3V)

R2

R3

R4

R5

R6

R7(MSB)

G2

G3

G4

G5

G6

G7(MSB)

B2

B3

B4

B5

B6

B7(MSB)

NA NA

NA NA

DE(*) DE(*)

R6 R0(LSB)

R7(MSB) R1

G6 G0(LSB)

G7(MSB) G1

B6 B0(LSB)

B7(MSB) B1

NA NA

LD-K23Z03 -5

NA: Not Available

(*) Since the display position is prescribed by the rise of DE (Display Enable) signal,

please do not fix DE signal during operation at "High."

[Note 2] The equivalent circuit figure of the terminal

Ter mina l

1.0K ohm

10K ohm

Page 6

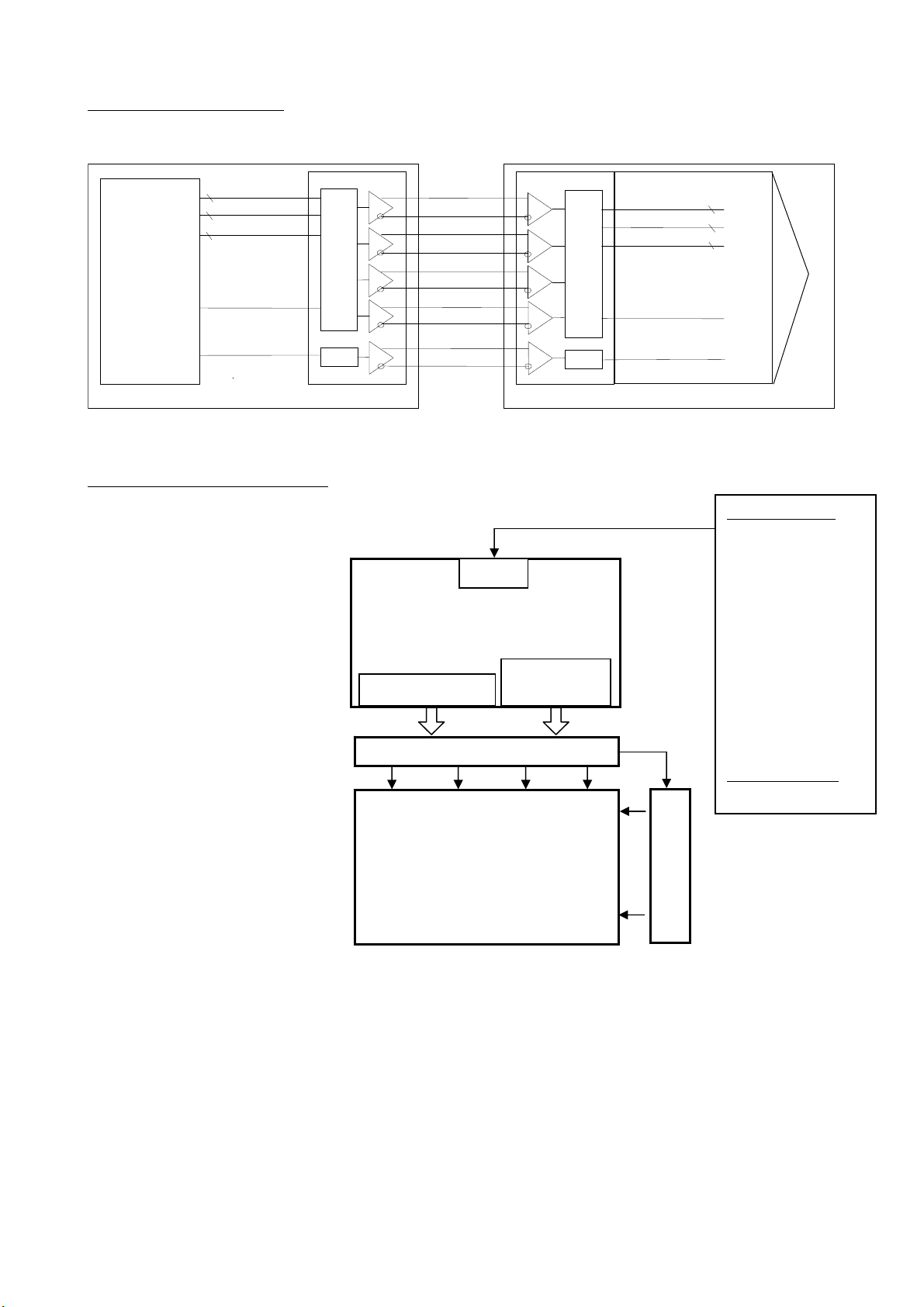

・Interface block diagram

Corresponding Transmitter: THC63LVDM83R (THine) or equivalent device

controller

G0

~

R0~R7

B0~B7

ENAB

G7

CLK

(

8

8

8

)

Rx1IN0+(13)

Rx1IN0-(12)

Rx1IN1+(16)

LVD S

↑

TTL

PLL

Rx1IN1-(15)

Rx1IN2+(19)

Rx1IN2-(18)

Rx1IN3+(25)

Rx1IN3-(24)

Rx1CLKIN+(22)

Rx1CLKIN-(21)

side

TV

・Block Diagram (LCD Module)

CN1

SOURCE/CONTROL PWB

Control Signals

SOURCE DRIVER

Power Supply

LCD PANEL

1366×3(RGB)×768

Circuit

TTL

↑

LVDS

PLL

(TFT-LCD side)

LD-K23Z03 -6

8

R0~R7

8

G0

G7

~

8

B0~B7

ENAB

CK

INPUT SIGNALS

CLKIN+

CLKINRIN0+

RIN0RIN1+

RIN1RIN2+

RIN2RIN3+

RIN3SELLVDS

POWER SUPPLY

+12V DC

Internal circuit s

GATE DRIVER

Page 7

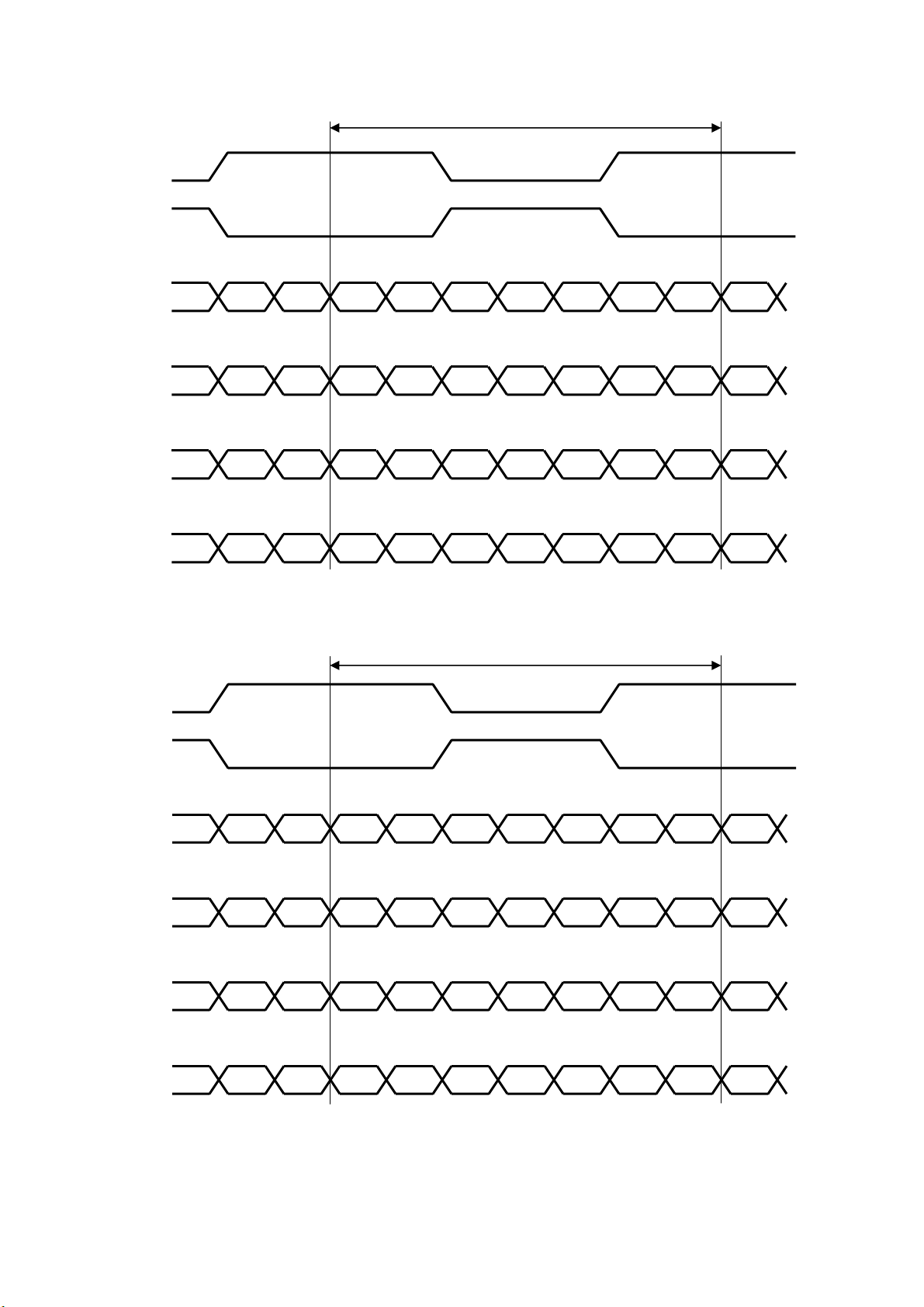

SELLVDS= High (3.3V)

CLKIN+

CLKIN-

RIN0+

RIN0-

RIN1+

RIN1-

RIN2+

RIN2-

RIN3+

RIN3-

SELLVDS= Low(GND) or Open

CLKIN+

CLKIN-

RIN0+

RIN0-

RIN1+

RIN1-

RIN2+

RIN2-

RIN3+

RIN3-

DE: Display Enable

NA: Not Available (Fixed Low)

LD-K23Z03 -7

1 cycle

G2 R7 R6 R5 R4 R3 R2 R2 R3 G2

B3 B2 G7 G6 G5 G4 G3 G3 G4 B3

DE

NA NA

B1 B0 G1 G0 R1 R0 R0 R1 NA NA

B7 B6 B5 B4 B4 B5

DE

1 cycle

G0 R5 R4 R3 R2 R1 R0 R0 R1 G0

B1 B0 G5 G4 G3 G2 G1 G1 G2 B1

DE

NA NA

B7 B6 G7 G6 R7 R6 R6 R7 NA NA

B5 B4 B3 B2 B2 B3

DE

Page 8

LD-K23Z03 -8

V

V

4

F

2

2

4

5. Absolute Maximum Ratings

Parameter Symbol Condition Ratings Unit Remark

Input voltage

(for Control)

+12V supply voltage

(for Control)

I Ta=25°C -0.3 ~ 3.6 V [Note 1]

V

VCC Ta=25°C 0 ~ +15 V

Storage temperature Tstg - -25 ~ +60 °C

Operation temperature

(Ambient)

Topa - 0 ~ +50 °C

[Note 2]

[Note 1] SELLVDS

[Note 2] Humidity 95%RH Max.(Ta ≤ 40°C)

Maximum wet-bulb temperature at 39°C or less.(Ta > 40°C), No condensation.

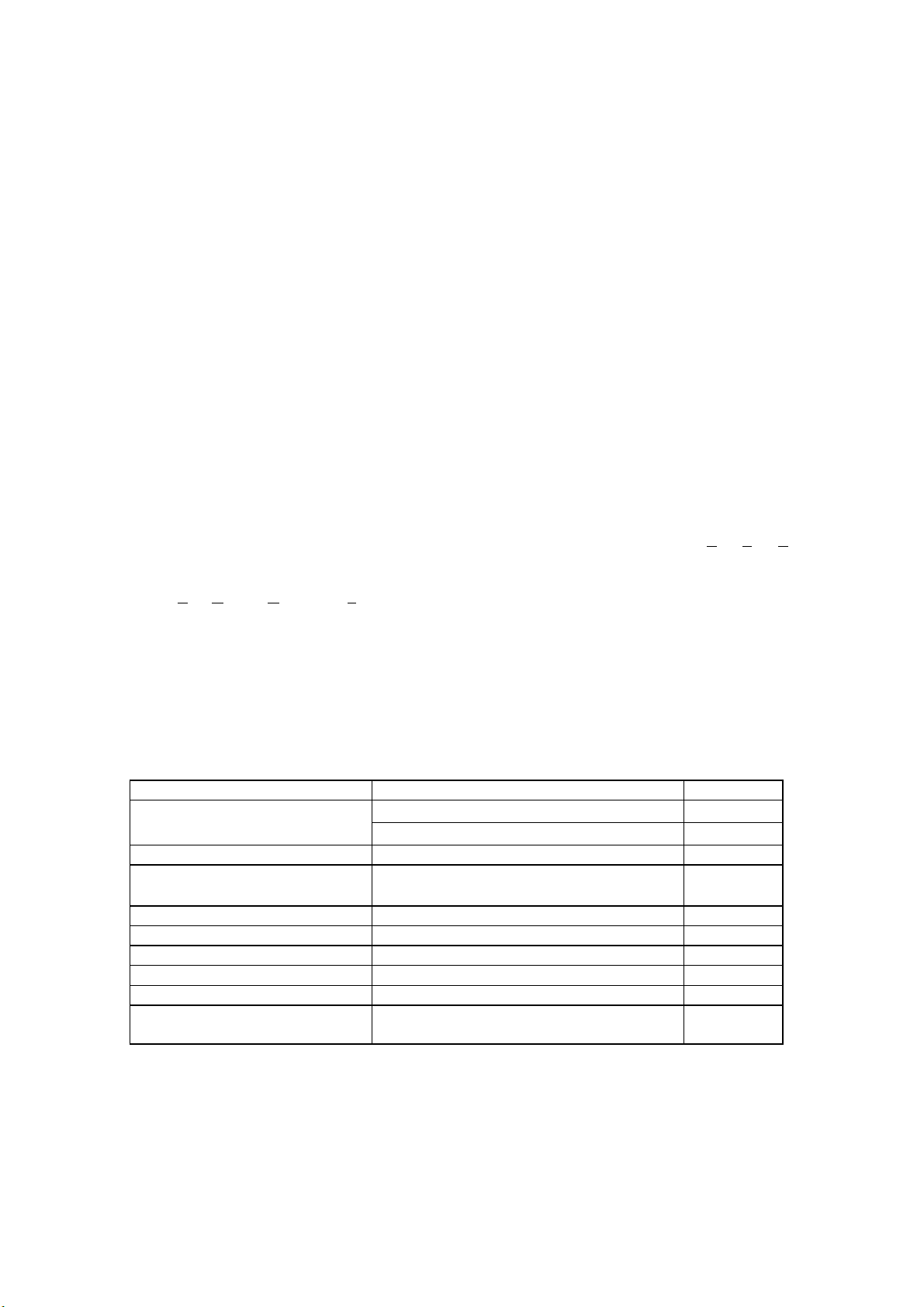

6. Electrical Characteristics

6-1. Control circuit driving Ta=25°C

Parameter Symbol Min. Typ. Max. Uniit Remark

Supply voltage VCC +11.4 +12.0 +13.7 V [Note 1]

+12V supply

voltage

Current dissipation

ICC - 350 600 mA [Note 2]

I

- 1500 2500 mA [Note 5]

RUSH

T

RUSH

- 0.5 - ms [Note 5]

Permissible input ripple voltage VRP - - 100 mVP-P Vcc = +12.0V

High VTH - - 100 mV Differential input

threshold voltage

Low V

-100 - - mV

TL

Input Low voltage VIL 0 - 0.7 V

Input High voltage VIH 2.6 - 3.3 V

Input leak current (Low) IIL - - 400 µA

Input leak current (High) IIH - - 100 µA

V

CM = +1.2V

[Note 4]

[Note 3]

I = 0V

V

[Note 3]

I =3.3V

V

[Note 3]

Termi n al r e s i s t o r RT - 100 - Ω Differential input

[Note] VCM: Common mode voltage of LVDS driver.

[Note 1]

Input voltage sequences Dip conditions for supply voltage

50μs < t1 ≤ 20ms a) 9.1V ≤ V

< 10.8V

CC

20ms< t2-1 ≤ 5s td ≤ 10ms

20ms< t2-2 ≤ 5s b) V

< 9.1V

CC

0 < t3 ≤ 1s Dip conditions for supply voltage is

t4 ≥ 1s based on input voltage sequence.

t5 ≥ 300ms

0.9V

0.1VCC

CC

Data1

Data

Back light:

CC

t2-1

t1

t2-

t5

ON

INV

OFF

0.9 V

CC

0.1 VCC

t3

0.1V

t

OF

CC

V

9

.

7

1

.

V

2

td

Vcc

1

V

0

.

5

8

V

.

Page 9

LD-K23Z03 -9

※ Data1: CLKIN±,RIN0±,RIN1±, RIN2±, RIN3±

※ Data2: SELLVDS

※ About the relation between data input and back light lighting, please base on the above-mentioned input

sequence.

When back light is switched on before panel operation or after a panel operation stop, it may not display

normally. But this phenomenon is not based on change of an incoming signal, and does not give damage to a

liquid crystal display.

[Note 2]Typical current situation: 256 gray-bar pattern (V

= +12.0V)

CC

The explanation of RGB gray scale is seen in section 8.

RGB

GS0

RGB

GS1

RGB

GS2

....

RGB

GS254

RGB

GS255

V

= +12.0V

CC

CK = 82.0MHz

Th = 20.68μs

[Note 3] SELLVDS

[Note 4] CLKIN+/CLKIN-, RIN0+/RIN0-, RIN1+/RIN1-, RIN2+/RIN2-, RIN3+/RIN3-

[Note 5] The Rush current corrugation at the time of power on

Page 10

LD-K23Z03 -10

7. Timing characteristics of input signals

7-1. Timing characteristics

Timing diagrams of input signal are shown in Fig.2

Parameter Symbol Min.

Typ.

NTSC PAL

Max. Unit

Clock Frequency 1/Tc 72 82 82 85 MHz

Horizontal period TH

Data enable

signal

Horizontal period (High) THd 1366 1366 1366 1366 clock

Vertical period TV 778 806 967 972 line

Vertical period (High) TVd 768 768 768 768 line

[Note] When vertical period is very long, flicker may occur.

Please turn off the module after it shows the black screen.

Please make sure that length of vertical period should become of an integral multiple of horizontal length of

period. Otherwise, the screen may not display properly.

As for your final setting of driving timing, we will conduct operation check test at our side, please inform

your final setting.

Vertical period must change less than 1 line each flames.

TH

THd

DE

DATA

(R,G,B)

1366

1 2

Tc

1 2 768

DE

TV

Fig.2 Timing characteristics of input signals

1540 1696 1696 1940 clock

19.84 20.68 20.68 - µs

1366

767

TVd

Page 11

7-2. Input data signal and display position on the screen

R1 G1 B1 R2 G2 B2

(1、1) (1,2)

1・1 1・2 1・3

2・1 2・2

3・1

R G B

768・1

Display Position of Data (V,H)

1・1366

768・1366

LD-K23Z03 -11

Page 12

8. Input Signal, Basic Display Colors and Gray Scale of Each Color

Colors &

Gray scale

Gray

R0 R1 R2 R3 R4 R5 R6 R7 G0 G1 G2 G3 G4 G5 G6 G7 B0 B1 B2 B3 B4 B5 B6 B7

Scale

Data signal

LD-K23Z03 -12

Black

Blue

Green

Cyan

Red

Basic Color

Magenta

Yellow

White

Black GS0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

GS1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

×

Darker GS2 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

×

Ø

Brighter GS253 1 0 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Gray Scale of Red

GS254 0 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Ø

Red GS255 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Black GS0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

GS1 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

×

Darker GS2 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0

×

Ø

Brighter GS253 0 0 0 0 0 0 0 0 1 0 1 1 1 1 1 1 0 0 0 0 0 0 0 0

Gray Scale of Green

GS254 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0

Ø

Green GS255 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

-

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1

-

0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0

-

0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

-

1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

-

1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1

-

1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0

-

1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

-

È

È

È

È

È

È

È

È

È

È

È

È

È

È

È

È

Black GS0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

GS1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0

×

Darker GS2 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0

×

Ø

Brighter GS253 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 1 1 1 1 1 1

È

È

È

È

È

È

È

È

Gray Scale of Blue

GS254 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1

Ø

Blue GS255 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1

0 : Low level voltage, 1 : High level voltage.

Each basic color can be displayed in 256 gray scales from 8 bit data signals. According to the combination of total

24 bit data signals, the 16,777,216 colors display can be achieved on the screen.

Page 13

9. Optical characteristics

Parameter Symbol Condition Min. Typ. Max. Unit Remark

θ21

θ22

θ11

θ12

CR ≥ 10

70 88 - Deg.

70 88 - Deg.

Viewing angle

range

Horizontal

Vertical

Contrast ratio CRn 3750 5000 - -

Response time

Chromaticity of white

Chromaticity of red

Chromaticity of green

Chromaticity of blue

Luminance of white YL 320 400 - cd/m2

τ

DRV

x 0.252

y 0.258

x 0.604

θ=0 deg.

y 0.323

x 0.279

y 0.601

x 0.123

y

Luminance uniformity δW

- 7 - ms

0.031

0.282

0.288

0.634

0.353

0.309

0.631

0.153

0.061

0.312 -

0.318 -

0.664 -

0.383 -

0.339 -

0.661 -

0.183 -

0.091 -

- - 1.54 - [Note 6]

Measurement condition : Back Light Unit is used for LK315T3LWD0X.

*The measurement shall be executed 60 minutes after lighting at rating.

[Note] The optical characteristics are measured using the following equipment.

Detector (EZ-CONTRAST, Photo Diode)

400mm

Detector (SR-3)

Field=1°

Center of the screen (θ = 0°)

Center of the screen (θ = 0°)

TFT-LCD Module

TFT-LCD Module

Fig.3-1 Measurement of viewing angle range

and response time.

(Viewing angle range: EZ-CONTRAST

Response time: Photo Diode)

Fig.3-2 Measurement of Contrast,

Luminance, and Chromaticity.

LD-K23Z03 -13

Ta = 25°C, Vcc = +12V

[Note1,4]

[Note2,4]

[Note3,4,5]

[Note 4]

[Note 4]

Page 14

[Note 1] Definitions of viewing angle range :

LD-K23Z03 -14

Normal

θ11

θ21

θ12

θ22

6 o’clock direction

[Note 2] Definition of contrast ratio :

The contrast ratio is defined as the following.

Luminance (brightness) with all pixels white

Contrast Ratio

=

Luminance (brightness) with all pixels black

[Note 3] Definition of response time

The response time (τ

) is defined as the following figure and shall be measured by switching the input

DRV

signal for “any level of gray (0%, 25%, 50%, 75% and 100%)” and “any level of gray (0%, 25%, 50%, 75% and

100%)” at panel surface temperature 45°C.

0%

0%

25%

50%

75%

100%

td: 25%-0%

td: 50%-0% td: 50%-25%

td: 75%-0% td: 75%-25% td: 75%-50%

td: 100%-0% td: 100%-25% td: 100%-50% td: 100%-75%

25% 50% 75%

tr: 0%-25%

tr: 0%-50% tr: 0%-75% tr: 0%-100%

tr: 25%-50% tr: 25%-75% tr: 25%-100%

tr: 50%-75% tr: 50%-100%

t*:x-y...response time from level of gray(x) to level of gray(y)

= Σ(t*:x-y)/20

τ

DRV

[Note 4] This shall be measured at center of the screen.

[Note 5] This value is valid when O/S driving is used at typical input time value .

[Note 6] Definition of white uniformity ;

White uniformity is defined as the following with five measurements. (A~I)

Maximum luminance of Nine points (brightness)

W=

δ

Minimum luminance of Nine points (brightness)

100%

227 683 1139 画素

A

B

C

tr: 75%-100%

D

E

F

pixel

G

H

I

128

384

640

Page 15

LD-K23Z03 -15

10. Handling Precautions of the module

a) Be sure to turn off the power supply when inserting or disconnecting the cable.

b) Be sure to design the cabinet so that the module can be installed without any extra stress such as warp or

twist.

c) Since the front polarizer is easily damaged, pay attention not to scratch it.

d) Since long contact with water may cause discoloration or spots, wipe off water drop immediately.

e) When the panel surface is soiled, wipe it with absorbent cotton or other soft cloth.

f) Since the panel is made of glass, it may break or crack if dropped or bumped on hard surface. Handle with

care.

g) Since CMOS LSI is used in this module, take care of static electricity and take the human earth into

consideration when handling.

h) Please consider to minimize the influence of EMI and the exogenous noise before designing the grounding of

Open-Cell.

i) The Open-Cell has some printed circuit boards (PCBs) on the side, take care to keep them form any stress or

pressure when handling or installing the module; otherwise some of electronic parts on the PCBs may be

damaged.

j) Observe all other precautionary requirements in handling components.

k) When some pressure is added onto the module from rear side constantly, it causes display non-uniformity

issue, functional defect, etc.. So, please avoid such design.

l) When handling LCD modules and assembling them into cabinets, please be noted that long-term storage in

the environment of oxidization or deoxidization gas and the use of such materials as reagent, solvent,

adhesive, resin, etc. which generate these gasses, may cause corrosion and discoloration of the LCD

modules.

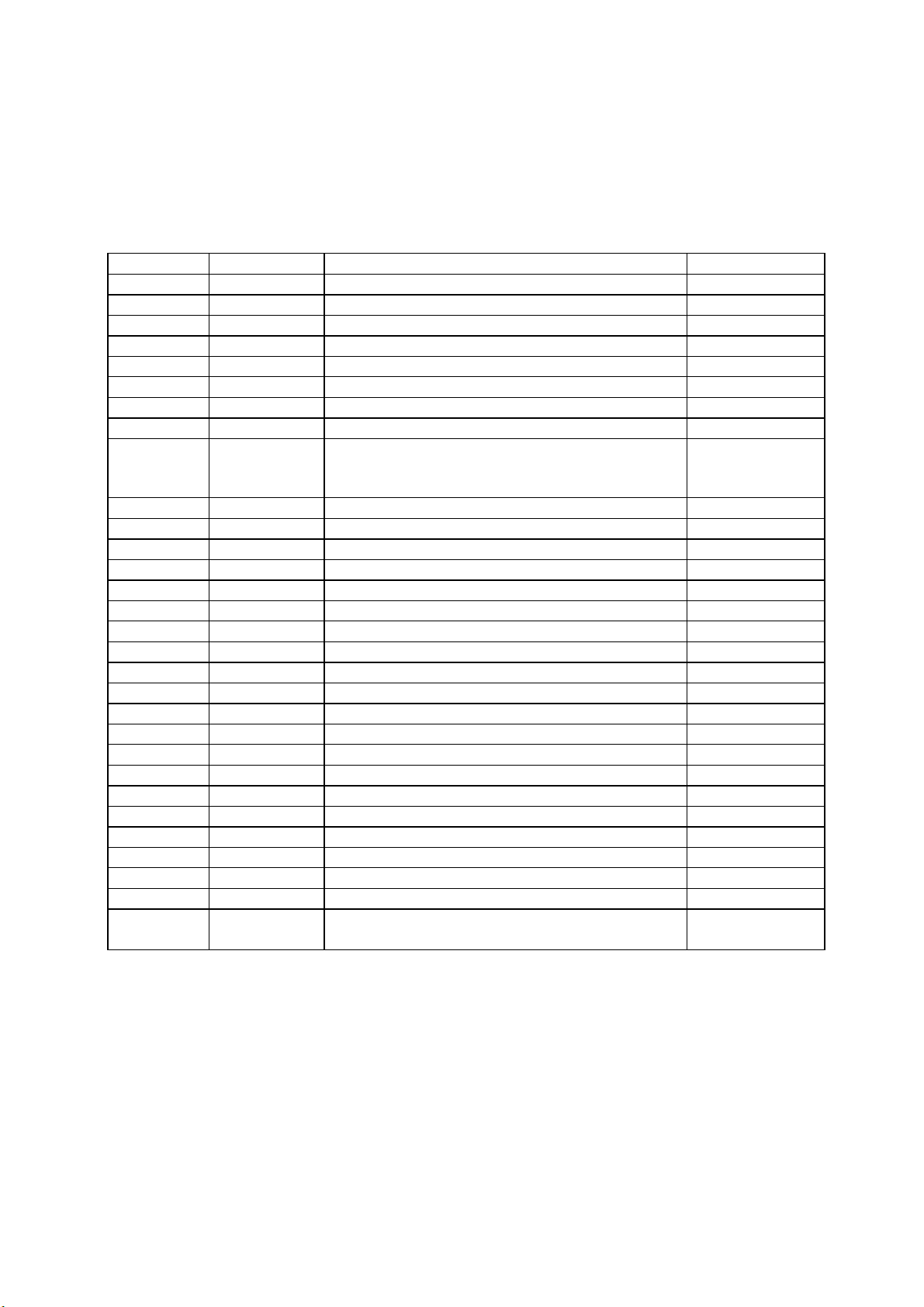

11. Reliability test item

No. Test item Condition

1 High temperature storage test Ta=60°C 500h

2 Low temperature storage test Ta=-25°C 500h

3

4

5

High temperature and high humidity

operation test

High temperature operation test Ta=50°C 500h

Low temperature operation test Ta=0°C 500h

Vibration test

6

(Cell Box with Open-Cells)

(non-operation)

Shock test

7

(Cell Box with Open-Cells)

(non-operation)

Ta=40°C ; 95%RH 500h

(No condensation)

(The panel surface temperature of this time is MAX60 ℃)

(The panel surface temperature of this time is MIN0 ℃)

X and Y direction: 15min, Z direction: 60min.

5Hz to 50Hz acceleration velocity: 1.0G

Sweeping ratio: 3min

Maximum acceleration: 490m/s

2

Pulse width: 11ms, sinusoidal half wave

Direction: +/-X, +/-Y, +/-Z, once for each direction.

Page 16

Page 17

Page 18

Page 19

Page 20

To: SHARP Corporation

pp

go.j

f

Report on Environmental Impact Substances Contained in Parts

and Materials

We guarantee the following verified results on the environmental impact substances:

1. Information on surveyed part:

1) Part Name

2) Sharp Part Code Number

3) Manufacturer’s Part Code Number

4) Part(Material) Weight (g)

TFT Open-Cell

R1LK315T3HB00X

LK315T3HB00X/T/A

1200g

Date:

Company Name:

Department:

Jan,06,2012

1/1

SHARP CORPRATION

LIQUID CRYSTAL DISPLAY GROUP

2. Ozone-depleting substances contained in the part or used in manufacturing:

No. Substances

Ozone-depleting substances(regulated by the

1

Montreal Protocol (Class I and II))(*1)

Note: When the verified results show the substances are “present”, the part or material is prohibited by the SHARP standard.

Not contained in part/materials. However, use of the refrigerant (HCFC) for

air-conditioners is considered as object exclusion.

Not used in the rinse process. (Object: PWBs, )

(Even if you select "Not use" that means you didn’t use these substances to rinse

process, you have to describe rinse solution and method of the rinse process.)

Details (Criteria)

3. Presence of banned substances in the part (material)

No. Substances

Hexavalent chromium compound Content is 1000ppm or less. Not intentionally added. (*3)

1

Bis(tri-n-butyltin) oxide

2

Tri-substiituted organostannic compounds Content is 1000ppm or less. Not intentionally added.

3

Polybrominated biphenyls (PBBs)

4

Polybrominated diphenyl ethers

5

(PBDEs)

Polychlorinated biphenyls (PCBs)

13

6

Polychlorinated naphthalene

7

Short chain chlorinated paraffin Not intentionally added. (Only C:10-13 are subject to the regulation.)

8

Asbestos Not intentionally added.

9

Polychlorinated Terphenyls (PCTs)

10

Phenol,2-(2H-benzotriazol-2-yl)-4,6-

11

bis(1,1-dimethylethyl)

Tris (2-chloroethyl) phosphate

12

Hexabromocyclododecane

Diarsenic Pentoxide

14

Cobalt dichloride

15

Dimethyl fumarate

16

Refractory Ceramic Fibres,Aluminosilicate

17

Refractory Ceramic Fibres,

18

Zirconia Aluminosilicate

Note: When the verified results show the substances are “present”, the part or material is prohibited by the SHARP standard.

Content is 1000ppm or less. Not intentionally added. Not present

Content is 1000ppm or less. Not intentionally added. Not present

Content is 1000ppm or less. Not intentionally added.

Not intentionally added. Not present

Not intentionally added.(Only poly chlorinated naphthalene with

three chlorines and more is subject to the regulation.)

Not intentionally added. Not present

Not intentionally added.

Content is 1000ppm or less. Not intentionally added. Not present

Content is 1000ppm or less. Not intentionally added. Not present

Content is 1000ppm or less. Not intentionally added. Not present

Content is 1000ppm or less. Not intentionally added. Not present

Content is 1000ppm or less. Not intentionally added. Not present

Not intentionally added. Not present

Not intentionally added. Not present

Details (Criteria) (*2) Verified Result

Verified Result

Not present

Not use/Use

Rinse solution:

Rinse method:

Not present

Not present

Not present

Not present

Not present

Not present

Not present

Not present

Not present

Not present

4. Presence of banned substances depending on application

When the verified result of criteria shows the substances are "present",

please complete and return the “CONFIRMATION OF USE” form which details use of each substance.

No. Substances

Cadmium and its compound Content is 100ppm or less. Not intentionally added. (*3)

1

Lead and its compound Present

2

Mercury and its compound Content is 1000ppm or less. Not intentionally added. (*3)

3

Beryllium and its compound Content is 1000ppm or less. Not intentionally added.

4

Azo colorants Not intentionally added. Content is 30ppm or less.

5

Polyvinyl Chloride Not intentionally added.

6

Phthalates Content is 1000ppm or less. Not intentionally added.

7

Radioactive substances Not intentionally added.

8

Perfluorooctane sulfonate(PFOSs)

9

and its salt(*4)

Formaldehyde

10

Nickel

11

Perchlorates Not intentionally added.(The object of survey is only battery)

12

Diarsenic trioxide Content is 1000ppm or less. Not intentionally added.

13

Arsenic and its compound (except Diarsenic

14

Pentoxide and Diarsenic trioxide)

Boric acid Content is 1000ppm or less. Not intentionally added.

15

Disodium tetraborate,anhydrous

16

Tetraboron disodium heptaoxide, hydrate

Dibutyltin (DBT) compounds Content is 1000ppm or less of tin in a material. Not Intentionally added.

17

Dioctyltin (DOT) compounds Content is 1000ppm or less of tin in a material. Not Intentionally added.

18

*1) Regarding Ozone-depleting substances, object substances are CFC, 1,1,1-trichloroethane, Carbon tetrachloride, Bromomethane,Halon HBFC, and HCFC.

*2) Unit for calculating content rate is homogenious material.

*3) For packaging part and packaging material, the total concentration of these 4 heavy metals in part/material, ink and paint which constitute a package

is 100ppm or less each.

*4) Concerning "Perfluorooctane sulfonate(PFOSs) and its salt", please refer to the Web Site of Ministry of Economy, Trade and Industry of Japan.

URL: http://www.meti.

*5) When the verified result shows the substances are "present", please complete and return the attachment 1 “CONFIRMATION OF USE FORM” which details use of

each substance.

p/policy/chemical_management/03kanri/96list.pd

Approved:

Not intentionally added. Content in plastics is 300ppm or less.

Content in others is 1000ppm or less. (*3)

Not intentionally added, and Content in substance/preparation is 50ppm or less,

content of sub-product/article etc. except substance/preparation is

m or less, content of coating agent is 1μg/m2 or less.

1000

Wood component: atmospheric concentration is 0.1ppm or less

(by the chamber method).

Plastics/fibers: content is 75ppm or less.

Not intentionally added. Present

Content is 1000ppm or less. Not intentionally added.

Content is 1000ppm or less. Not intentionally added.

SHIGEKI TANAKA

Details (Criteria)(*2) Verified Result(*5)

Written by:

YOSHITAKE NAKAMURA

Not present

Not present

Present

Present

Not present

Not present

Not present

Not present

Not present

Not present

Not present

Not present

Not present

Not present

Not present

Not present

Not present

Not present

Not present

Not present

Not present

Not present

Signature: Signature:

Ver.5.3 Revised: June, 2011

Page 21

y

To: SHARP Corporation

Attachement 1 "CONFIRMATION OF USE FORM"

(Parts and materials which are usable or prohibited according to application)

This form is to be completed when the verified results in the form 'Report on Environmental Impact Substances Contained in Parts

and Materials' have shown the presence of banned substances with restrictions depending on application.

1. Information on survey applicable part

1) Part Name TFT Open-Cell

2) Sharp Part Code Number R1LK315T3HB00X

3) Manufacturer’s Part Code Number LK315T3HB00X/T/A

2.Detail of verified result

Please indicate with a "O" in the verified results column if an

of the restricted substances are used for the following reasons.

No. Substances Check point ( criteria )

(1) Used for electric point

Cadmium

1

and its compound

Lead

2

and its compound

Mercury

3

and its compound

Beryllium and its

4

compound

5 Azo colorants

6 Polyvinyl Chloride

7 Phthalate esters

Radioactive

8

substances

Perfluorooctane

9

sulfonate(PFOSs)

and its salt

10 Formaldehyde

11 Nickel

12 Perchlorates

13 Diarsenic trioxide

Arsenic and

14

its compound

15 Boric acid

Disodium tetraborate,

anhydrous Tetraboron

16

disodium heptaoxide,

hydrate

Dibutyltin (DBT)

17

compounds

Dioctyltin (DOT)

18

compounds

Note: When the verified results correspond to "banned", the part or material is prohibited by the SHARP standard.

(2) Used in filter glass.

(3) Used in a thermal cutoff of a one shot pellet type

(4) Battery is compliant with the EU Battery Directive (98/101/EC).

(5) Used in every application other than the above (1-4).

(1) Used in high-melting point solder (lead-based alloys containing 85 % by weight or more lead)

(2) Used in electrical and electronic components in a glass or ceramic other than dielectric ceramic in capacitors,

(3) Used less than 0.2% by weight in glass of a fluorescent tube

(4) Contained in alloy component. (Lead content should be less than 0.35 Wt%, 0.4 Wt% and 4Wt% in steel material,

aluminum material and copper material, respectively.)

(5) Used in solder consisting of more than two types of elements for connecting microprocessor pins and package containing

(6) Used in solder for connecting semiconductor dies and carriers in flip chip IC packages

(7) Used in white glass or filter glass used for an optical purpose

(8) Used in coating material for thermal conduction module C-rings

(9) Used in shell (exterior casing) or bushing (a cylindrical component fitted inside a hole) of a bearing for a compressor

(10) Used in dielectric ceramic used in a capacitor with rated voltage of 125V AC or 250V DC or larger

(11) Used in a dielectric ceramic used in a capacitor with rated voltage less than 125V AC or 250V DC

(12) Used in glass used for flat fluorescent lamps used for LCD, designing, or lighting for industrial purpose

(13) Used in finishing agents of 0.65 mm or finer pitch components other than connectors

(14) Used for stabilizer or additive for non-electrolytic gold or nickel plating

(15) Battery is compliant with the EU Battery Directive (98/101/EC).

(16) Used in products for children 12 and under, containing lead exceeding 300ppm per surveying unit.

(17) Used in parts/material used in toys, containing lead above 0.009% per surface treatment layer such as coating.

(18) Used in the other than the above (1-15).

(1) Used in single-capped fluorescent lamp that does not exceed the following limitations (per burner):

(a) For general illumination less than 30W: 5mg, (b) For general illumination of 30W or higher and less than 50W: 5 mg

(c) For general illumination of 50W or higher and less than 150W: 5 mg, (d) For general illumination of 150W or higher: 15mg

(e) Having a circular or square structure, 17mm or less in tube diameter, and for general illumination: 7mg, (f) For a specific use: 5 mg

(2) Used in double-capped strip fluorescent lamp (in each lamp) for general purposes that does not exceed the following limitations:

(a) A three-wavelength phosphor of less than 9mm in tube diameter (e.g., T2) with normal lifetime: 5mg

(b) A three-wavelength phosphor of 9mm or larger and of 17mm or less in tube diameter (e.g., T5) with normal lifetime: 5mg

(c) A three-wavelength phosphor of over 17mm and 28mm or less in tube diameter (e.g., T8) with normal lifetime: 5mg

(d) A three-wavelength phosphor of over 28mm in tube diameter (e.g., T12) with normal lifetime: 5mg

(e) A three-wavelength phosphor with long lifetime (> 25,000 h) : 8mg

(3) Used in double-capped fluorescent lamp (in each individual lamp) not for general purposes under the following conditions:

(a) A linear white lamp of 28mm in tube diameter (e.g., T10 and T12): mercury that does not exceed 10mg

(b) Nonlinear white lamps of all shapes: mercury that does not exceed 15mg

(c) Mercury contained in a nonlinear three-wavelength phosphor lamp of 17mm or larger (e.g., T9)

(d) Mercury contained in a lamp for any other general illumination or specific purposes (e.g., induction lamps)

(4) Used in cold cathode fluorescent lamps and external electrode fluorescent lamps (CCFL and EEFL)

for special purposes not exceeding (per lamp):

(a)Short length (≤ 500 mm): 3.5mg, (b)Medium length (> 500 mm and ≤ 1500 mm): 5mg, (c)Long length (> 1500 mm): 13mg

(5) Used in low pressure discharge lamps (per lamp) other than the above(1-4)

(6) Used in extra-high voltage sodium (vapor) lamp for general illumination with an improved color rendering index over 60

(7) Used in extra-high voltage sodium (vapor) lamp for general illumination

(8) Used in high-pressure mercury vapor lamp (HPMV)

(9) Used in high-pressure mercury vapor lamp (HPMV)

(10) Used in metal halide lamp (MH)

(11) Battery is compliant with the EU Battery Directive (98/101/EC).

(12) Used in every application other than the above (1-11).

(1) Used in the exception items. (exception items: alloy, ceramics, glass, semiconductor)

(2) Used in the parts excluding exception items

(1) Used in a contact part with human body of a product (ex:electric carpet, earphone, strap and etc.) which is manufactured

based on the premise that the product continuously contacts human body, and may produce amine when discomposed.

(2) Used in every application other than the above (1). (Used in a part which does not continuously contact with human body.)

(1) Used in packaging material and packaging part for Sharp product.

(2) Used for the other than the above (1).

(1) Bis(2-ethylhexyl)phthalate:DEHP/DOP is used intentionally.

(2) Dibutyl phthalate:DBP, or Bis(butylbenzyl) phthalate:BBP, or Diisobutyl phthalate:DIBP is used.

(3) Dinonyl phthalate:DINP, or Diisodecyl phthalate:DIDP, or Di-n-octyl phthalate:DNOP is used

in parts/materials that is used in products for children 12 and under.

(4) Bis(2-ethylhexyl)phthalate:DEHP/DOP is contained as impurities (Not intentionally added)

(5) Used in the other than the above (1-3).

(1) Used in the magnetron of a microwave oven. (Only Thorium is subject to the regulation.)

(2) Used in the electric bulb of a LCD projector. (Only Krypton 85 is subject to the regulation.)

(3) Used in the other than the above (1-2).

(1)Used in photoresists and rantireflection coating for the photolithography process.

(2) Used in photo coating used in pringing plates, film, and documents.

(3) Used in mist suppressants for hard chrome plating, and moistening agent used in equipment for plating.

(4) Used in every application other than the above (1-3).

(1) Used in wooden parts.

(2) Used in a direct human body contact part of a product which is intended to continuously contact with human body.

(ex: electric carpet, earphone, strap and etc.)

(3) Used in every application other than the above (1-2).

(1) Used in parts which continuously contact with human skin for a long time.

(2) Used in the other than the above (1).

(1) Contained above 6ppb by weight per battery

(2) Contained less than 6ppb by weight per battery

(1) Used in the lamp of LCD projector.

(2) Used in the other than the above (1).

(1) Used for the exception items. (exception items: semiconductor, resist, magnet filter, copper foil and battery)

(2) Used in the other than the above (1).

(1) Used in the polarizers(made of PVA) of LCD panel and glass.

(2) Used in adhensive agent.

(3) Used for the other than the above (1-2).

(1) Used in the polarizers(made of PVA) of LCD panel and glass.

(3) Used for the other than the above (1-2).

(1) Used for one-component and two-component room temperature vulcanisation sealants (RTV-1 and RTV-2 sealants) and adhesives

(2) Used for paints and coatings containing DBT compounds as catalysts when applied on articles

(3) Used in stabilizer of soft polyvinyl chloride (PVC) for outdoor purpose

(4) Used in catalyst for polymerization of resin for toner. Content as a metal tin is 1000ppm or less.

(5) Used for the other than the above (1-4).

(1) Used for two-component room temperature vulcanisation moulding kits (RTV-2 moulding kits)

(2) Used for the other than the above (1).

Approved:

SHIGEKI TANAKA

less than 85wt% and more than 80wt% of lead.

containing coolant for heating,ventilation, air-conditioning, refrigeration, chilling, and HVACR

(2) Used in adhensive agent and fibers.

Signature: Signature:

e.g. piezoelectronic devices, or in a glass or ceramic matrix compoundcompounds

Written by:

Date: Jan,06,2012

Company Name:

Verified Adaptability under the

Results SHARP standard

SHARP CORPRATION

Department:

LIQUID CRYSTAL DISPLAY GROUP

○

○

○

○

○

○

○

YOSHITAKE NAKAMURA

Usable

Banned

Usable

Banned

Usable

Banned

Usable

Banned

Banned

Usable

Banned

Usable

Banned

Usable

Usable

Banned

Usable

Banned

Banned

Usable

Banned

Usable

Usable only with

statement

Usable

Usable

Banned

Usable

Banned

Usable

Banned

Usable

Banned

Usable

Banned

Banned

Usable

1/1

Ver.5.3 Revised: June, 2011

Loading...

Loading...