Page 1

LH7A400

Preliminary Data Sheet

FEATURES

• ARM922T™ Core:

– 32-bit ARM9TDMI™ RISC Core

– 16KB Cache: 8KB Instruction Cache and

8KB Data Cache

– MMU (Windows CE Enabled)

• High Performance (200 MHz)

• 80KB On-Chip Memory

• External Bus Interface

– 100 MHz

– Asynchronous SRAM/ROM/Flash

– Synchronous DRAM/Flash

– PCMCIA

– CompactFlash

• Clock and Power Management

– 32.768 kHz and 14.7456 MHz Oscillators

– Programmable PLL

• Low Power Modes

– Run (147 mA), Halt (41 mA), Standby (42 µA)

• Programmable LCD Controller

– Up to 1,024 × 768 Resolution

– Supports STN, Color STN, AD-TFT, HR-TFT, TFT

– Up to 64,000 Colors and 15 Gray Shades

• DMA (10 Channels)

–AC97

–MMC

–USB

• USB Device Interface (USB 1.1)

• Synchronous Serial Port (SSP)

– Motorola SPI™

– Texas Instruments SSI

– National MICROWIRE™

32-Bit System-on-Chip

• Three Programmable Timers

• Three UARTs

– Classic IrDA (115 kbit/s)

• Smart Card Interface (ISO7816)

• DC-to-DC Converters

• MultiMediaCard™ Interface

• AC97 Codec Interface

• Smart Battery Monitor Interface

• Real Time Clock (RTC)

• Up to 60 General Purpose I/Os

• Programmable Interrupt Controller

• Watchdog Timer

• JTAG Debug Interface and Boundary Scan

• Operating Voltage

– 1.8 V Core

– 3.3 V Input/Output (1.8 V I/O Optional

• 5 V Tolerant Inputs (except oscillator pins

• Operating Temperature

– 0°C to +70°C Commercial

– -40°C to +85°C Industrial (With Clock Frequency

Reduction

• 256-Ball PBGA or 256-Ball CABGA Package

1

)

DESCRIPTION

The LH7A400, powered by an ARM922T, is a com-

plete System-on-Chip with a high level of integration to

satisfy a wide range of requirements and expectations.

This high degree of integration lowers overall sys-

tem costs, reduces development cycle time and accelerates product introduction.

1

)

2

)

Motorola SPI is a trademark of Motorola, Inc.

National Semiconductor MICROWIRE is a trademark of

National Semiconductor Corporation.

Windows CE is a trademark of Microsoft Corporation.

Preliminary Data Sheet 12/8/03 1

NOTES:

1. Under development. Results pending further characterization.

2. Oscillator pins R13, T13, P15, and P16 are 1.8 V ±10%

Page 2

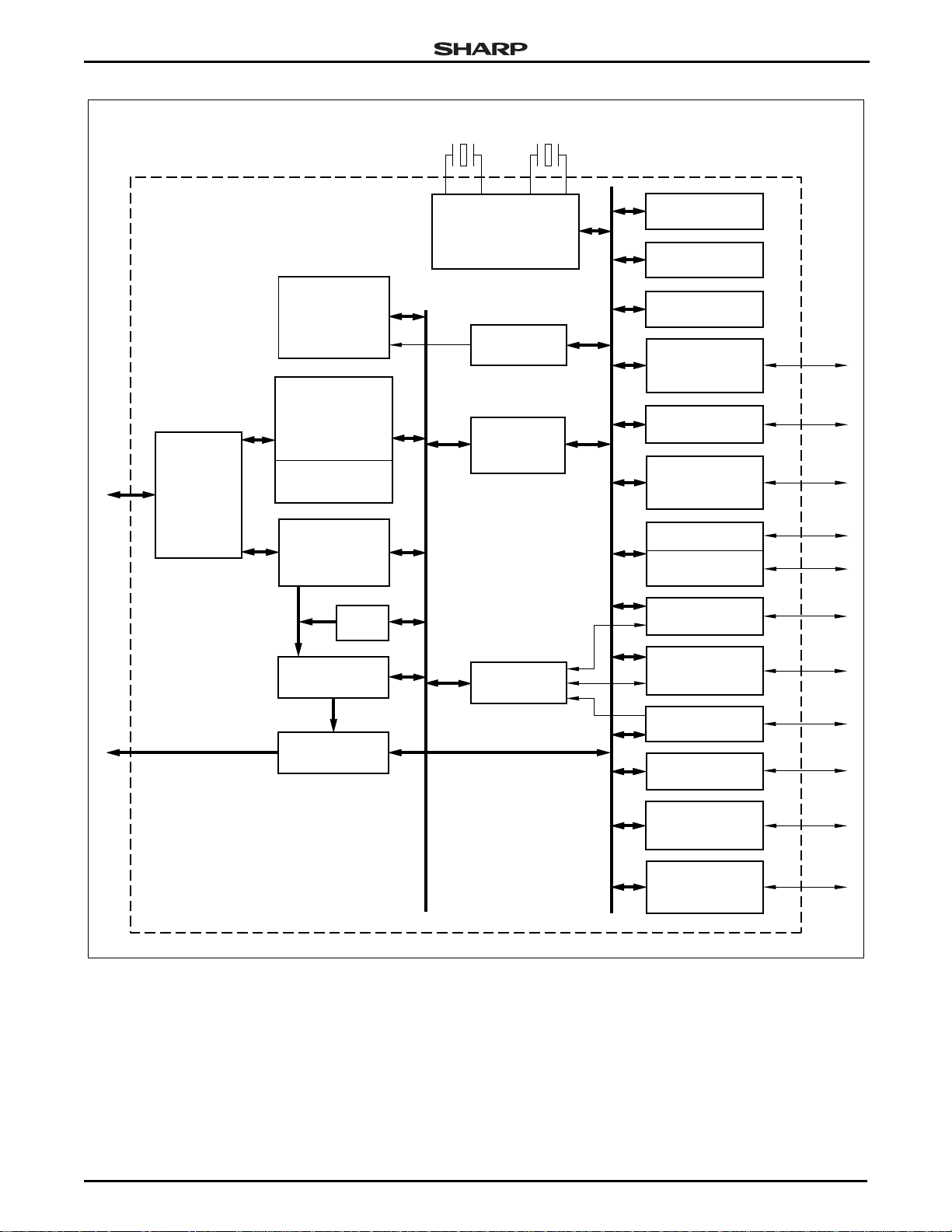

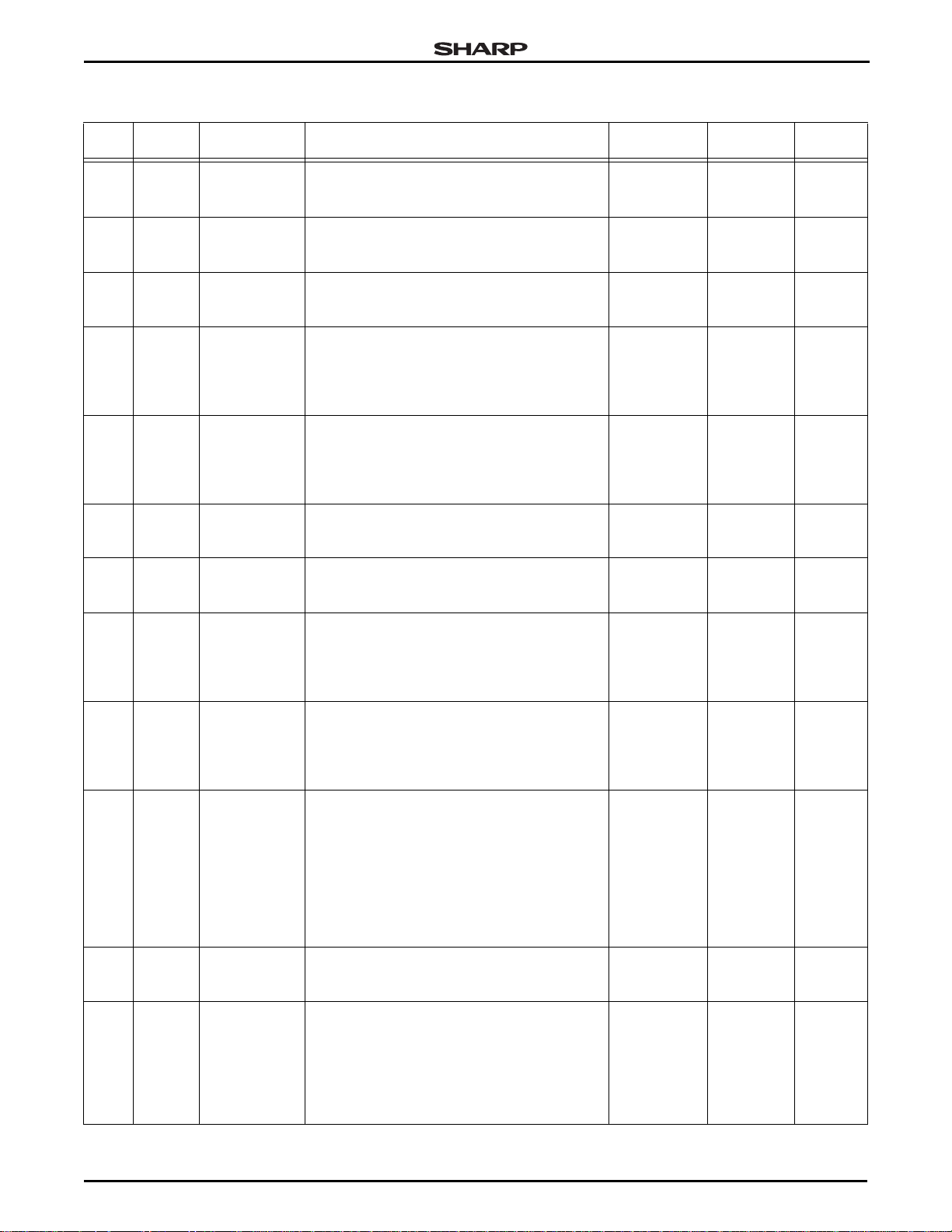

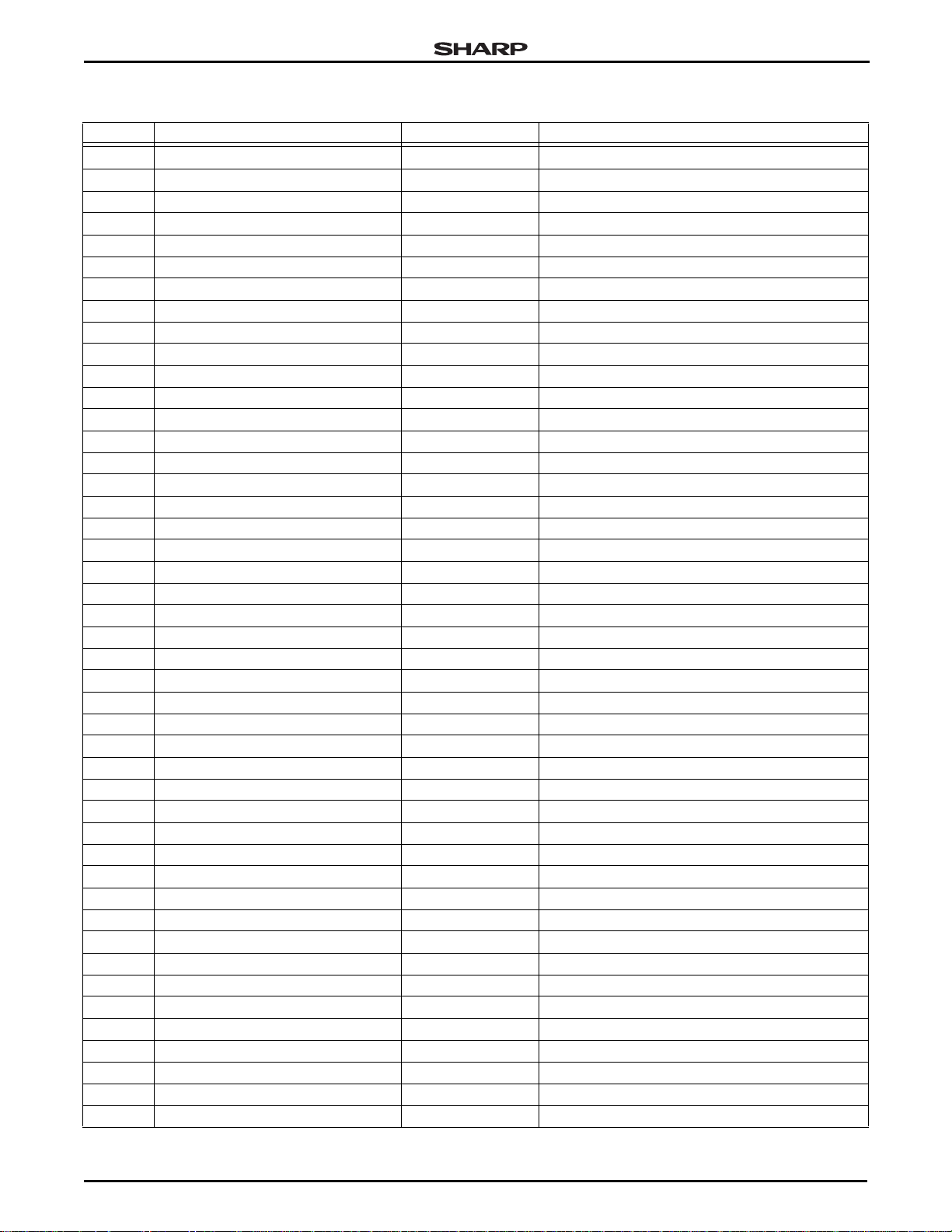

LH7A400 32-Bit System-on-Chip

14.7456 MHz 32.768 kHz

EXTERNAL

BUS

INTERFACE

(ASYNCHRONOUS)

CONTROLLER

PCMCIA/CF

CONTROLLER

SYNCHRONOUS

DYNAMIC RAM

CONTROLLER

LCD AHB

BUS

ARM922T

STATIC

MEMORY

(SMC)

(SDMC)

80KB

SRAM

OSCILLATOR,

PLL1 and PLL2, POWER

MANAGEMENT, and

RESET CONTROL

INTERRUPT

CONTROLLER

ADVANCED

PERIPHERAL

BUS BRIDGE

REAL TIME

CLOCK

WATCHDOG

TIMER

TIMER (3)

GENERAL

PURPOSE I/O

(60)

SYNCHRONOUS

SERIAL PORT

BATTERY

MONITOR

INTERFACE

UART (3)

IrDA

INTERFACE

USB DEVICE

INTERFACE

COLOR LCD

CONTROLLER

ADVANCED LCD

INTERFACE

ADVANCED

HIGH-PERFORMANCE

BUS (AHB)

Figure 1. LH7A400 Block Diagram

DMA

CONTROLLER

ADVANCED

PERPHERAL

BUS (APB)

MULTIMEDIACARD

INTERFACE

ADVANCED AUDIO

CODEC (AC97)

AUDIO CODEC

INTERFACE

SMART CARD

INTERFACE

(ISO7816)

DC to DC

INTERFACE

(2)

LH7A400-1

2 12/8/03 Preliminary Data Sheet

Page 3

32-Bit System-on-Chip LH7A400

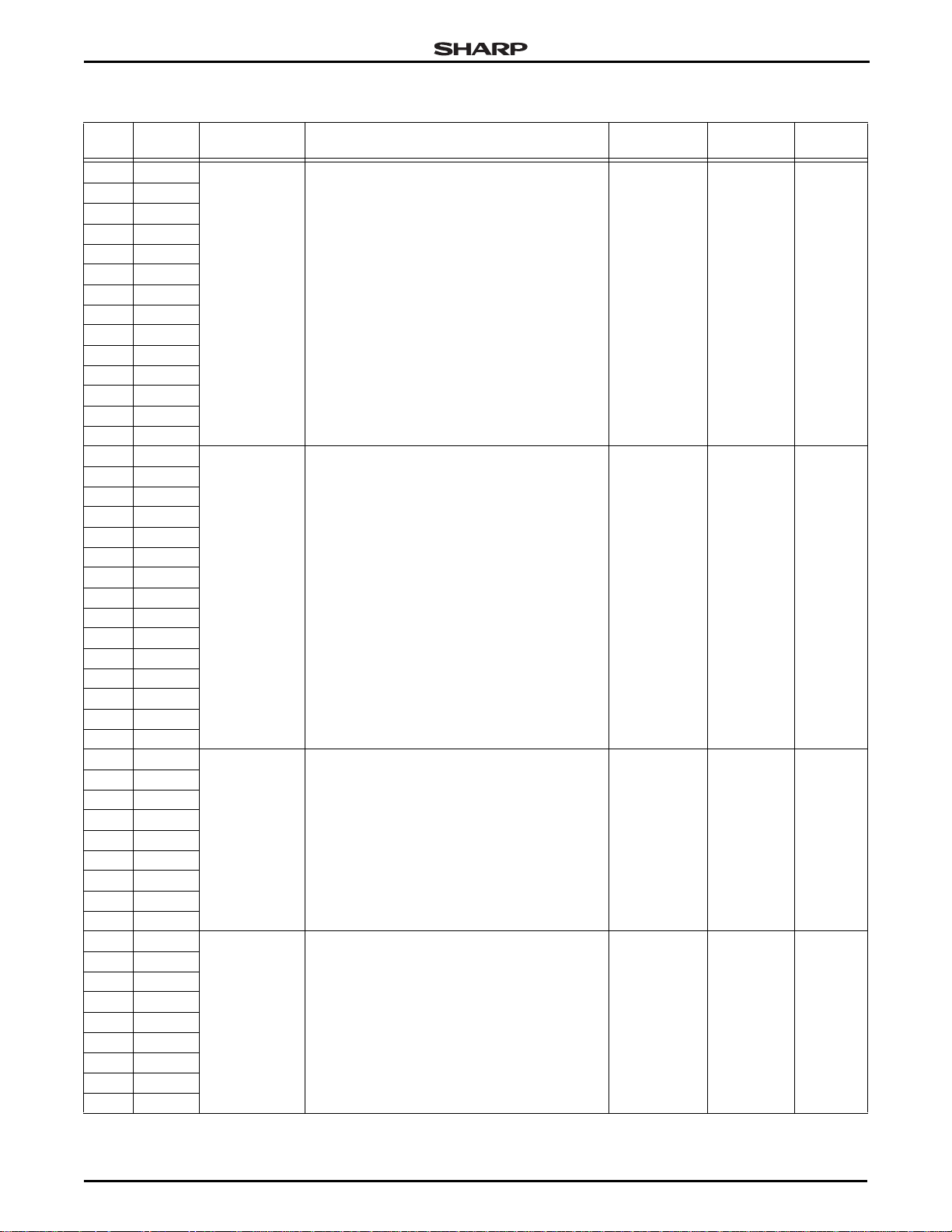

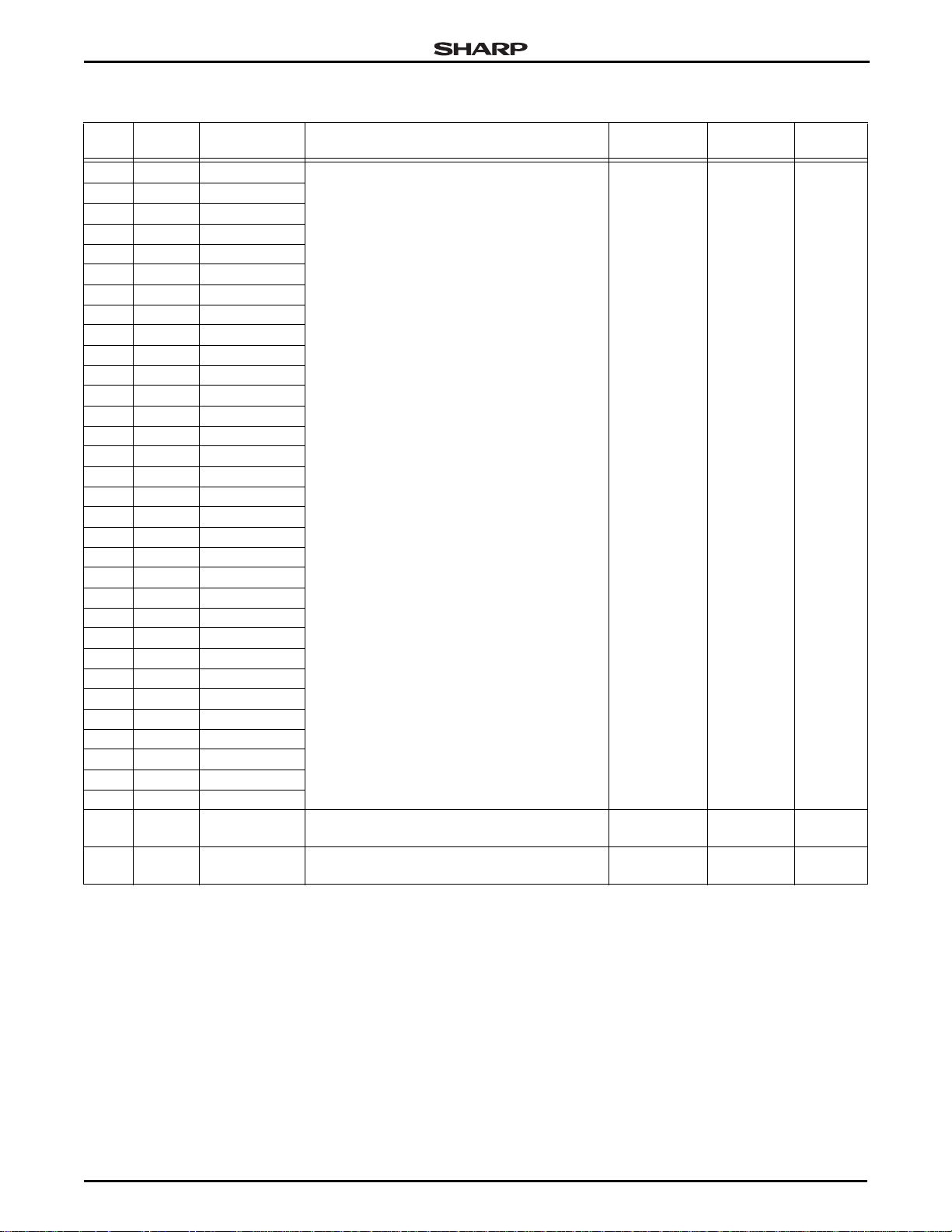

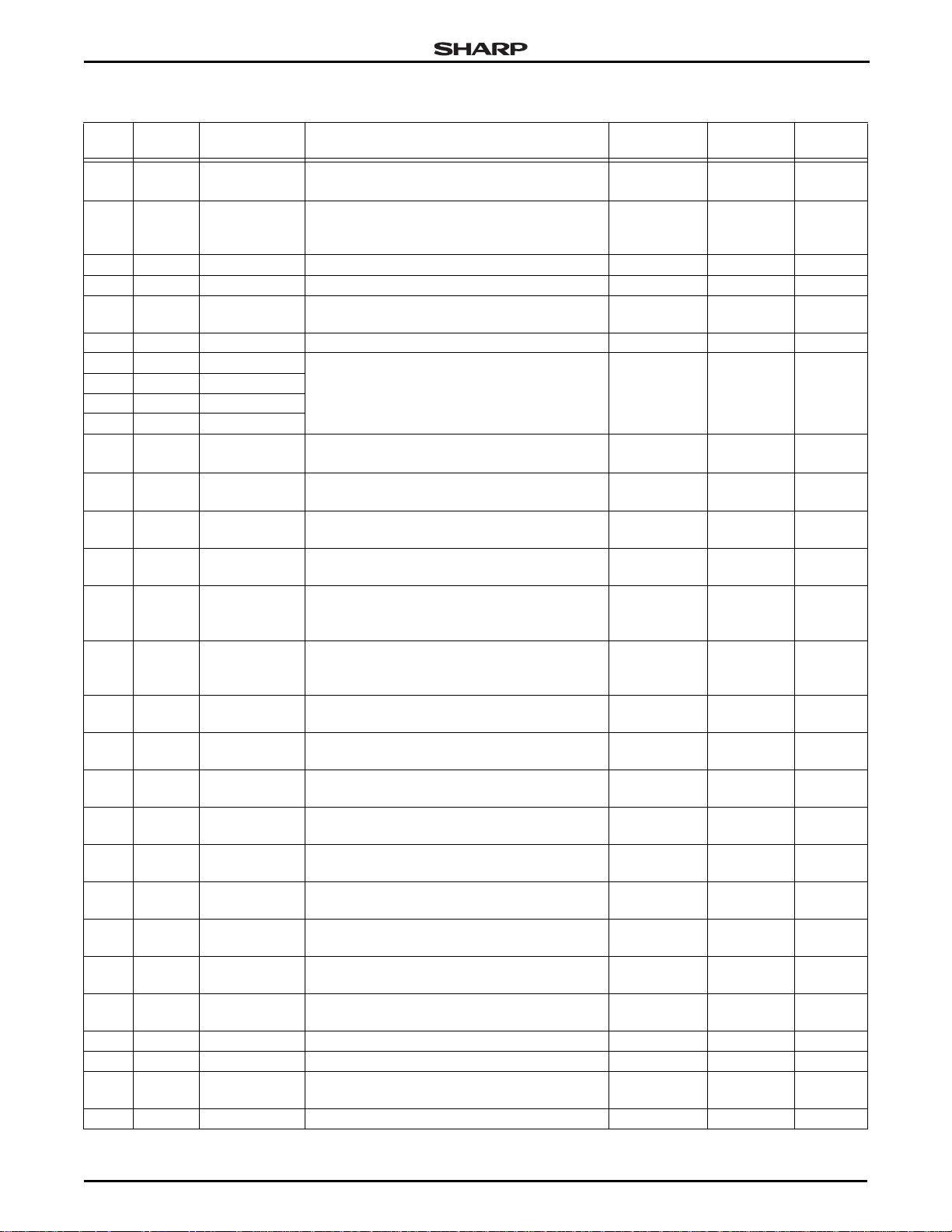

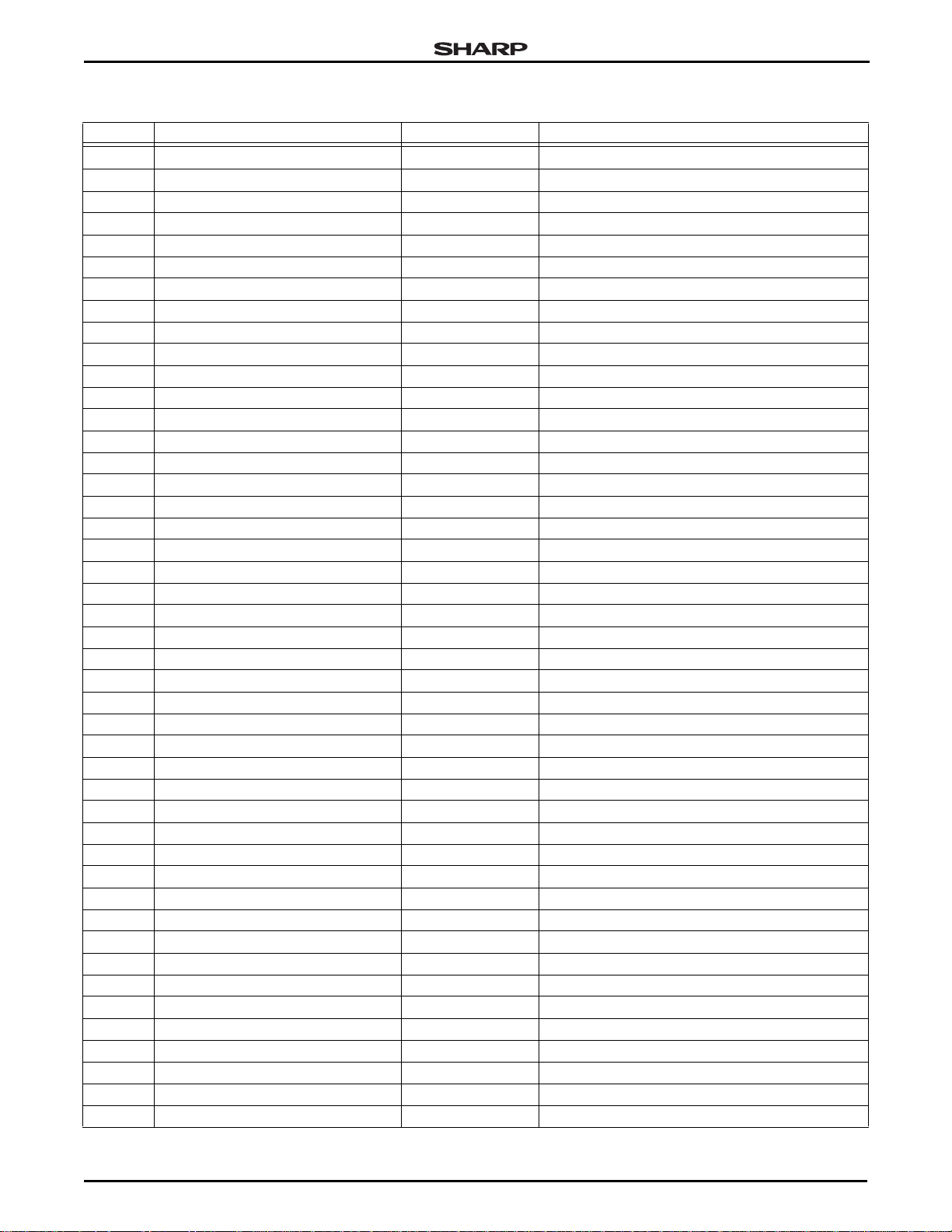

Table 1. Functional Pin List

PBGA

CABGA

PIN

G7 C10

F1 F9

K7 F11

M1 F14

M5 G8

T6 H13

R14 J9

M14 K15

J11 L7

J12 N6

F13 N8

B14 N12

E10 N13

B8 P11

H7 B8

G3 C6

K4 D5

N5 D13

P6 E8

T14 F7

R16 G13

N16 H9

K13 J14

H9 K7

C15 L8

A11 L10

E8 L12

A5 M11

F7 M14

E1 C4

J4 D7

P3 D10

T8 F4

K9 F10

L13 J4

E15 J8

D12 K8

A7 L6

H5 G7

M3 H4

L9 H8

T10 L4

N15 L9

H12 N3

B15 N7

C9 N10

G6 R5

PIN

SIGNAL DESCRIPTION

VDD I/O Ring Power

VSS I/O Ring Ground

VDDC Core Power

VSSC Core Ground

RESET

STATE

STANDBY

STATE

OUTPUT

DRIVE

Preliminary Data Sheet 12/8/03 3

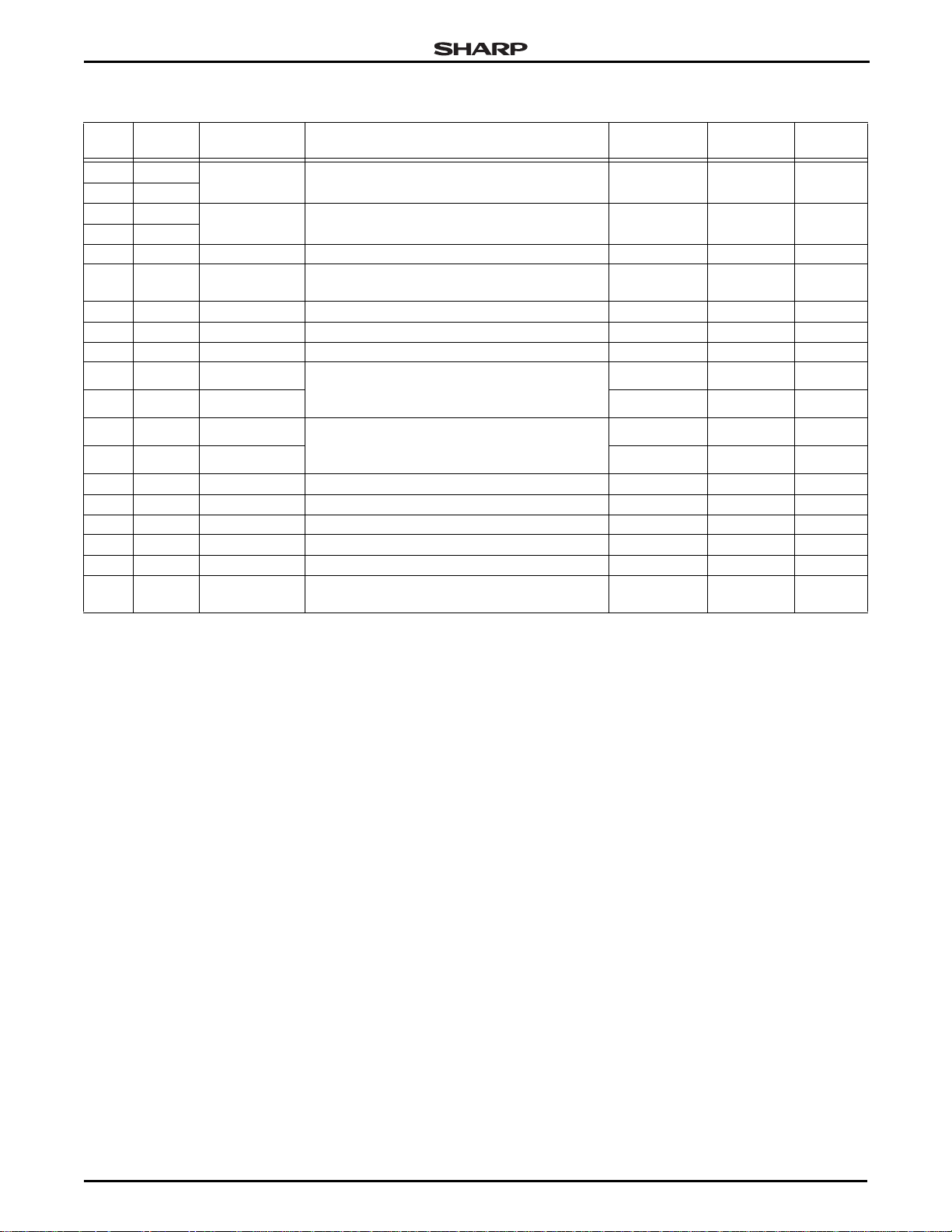

Page 4

LH7A400 32-Bit System-on-Chip

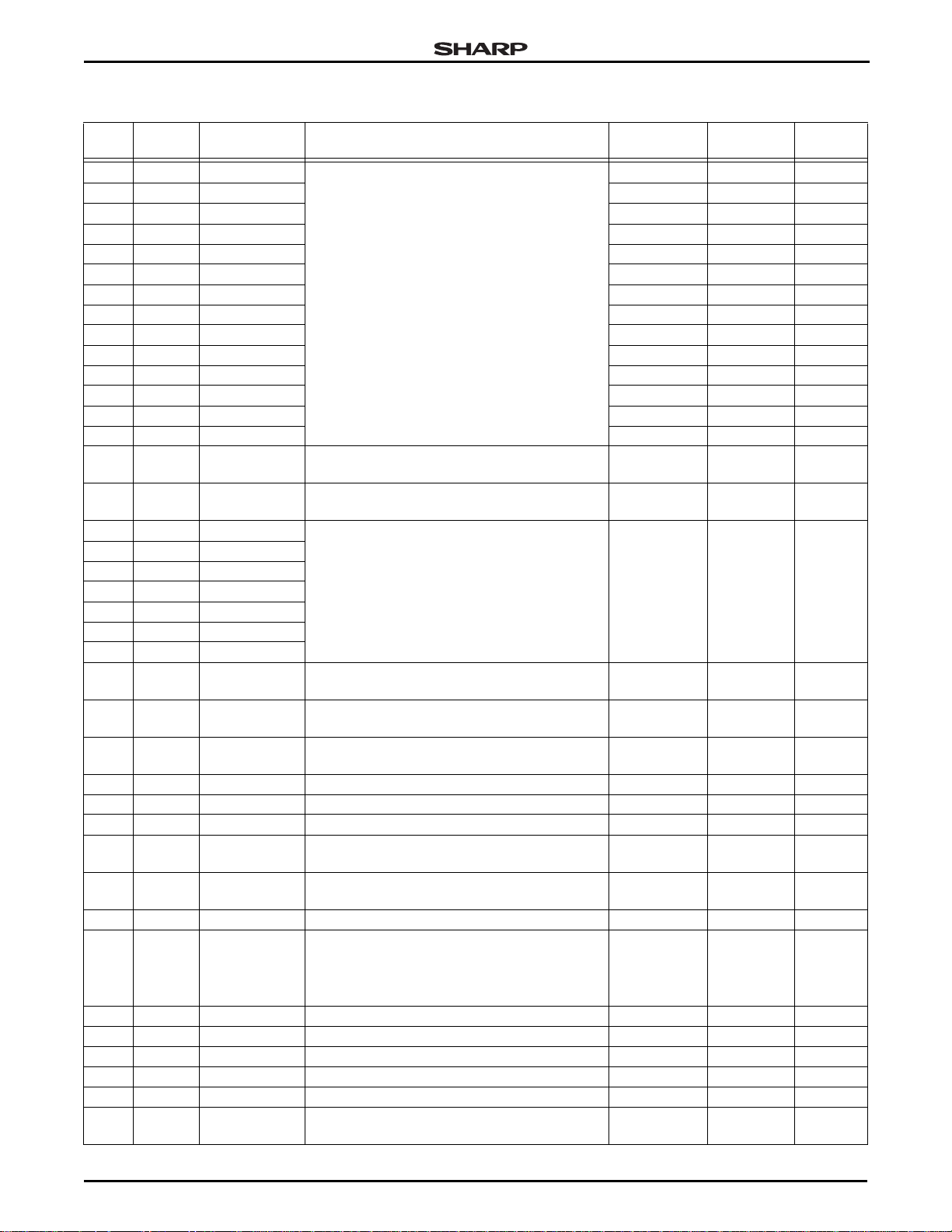

Table 1. Functional Pin List (Cont’d)

PBGA

CABGA

PIN

R11 P12

N12 M10

P12 R13

T11 N11

D3 E4 nPOR Power On Reset Input Input

H6 D1 nURESET

D4 E2 WAKEUP Wake Up Input (Sch mitt) Input

E4 F2 nPWRFL Power Fail Signal Input (Schmitt) Input

C2 D2 nEXTPWR External Power Input (Schmitt) Input

R13 R14 XTALIN

T13 R15 XTALOUT LOW LOW

P16 N14 XTAL32IN

P15 M13 XTAL32OUT Output Output

P14 M12 CLKEN External Oscillator Clock Enable Output LOW LOW 8 mA

J6 J5 PGMCLK Programmable Clock (14.7456 MHz MAX.) LOW LOW 8 mA

K11 P14 nCS0 Asynchronous Memory Chip Select 0 HIGH HIGH 12 mA

K10 P16 nCS1 Asynchronous Memory Chip Select 1 HIGH HIGH 12 mA

P13 N15 nCS2 Asynchronous Memory Chip Select 2 HIGH HIGH 12 mA

M12 N16

PIN

SIGNAL DESCRIPTION

VDDA Analog Power for PLL

VSSA Analog Ground for PLL

User Reset; should be pulled HIGH for normal or

JTAG operation.

14.7456 MHz Crystal Oscillator pins. An external

clock source can be connected to XTALIN leaving XTALOUT open.

32.768 kHz Real Time Clock Crystal Oscillator

pins. An external clock source can be connected

to XTAL32IN leaving XTAL32OUT open.

nCS3/

nMMSPICS

• Asynchronous Memory Chip Select 3

• MultiMediaCard SPI Mode Chip Select

RESET

STATE

Input (Schmitt) Input

Input Input

Input Input

HIGH: nCS3 HIGH 12 mA

STANDBY

STATE

OUTPUT

DRIVE

4 12/8/03 Preliminary Data Sheet

Page 5

32-Bit System-on-Chip LH7A400

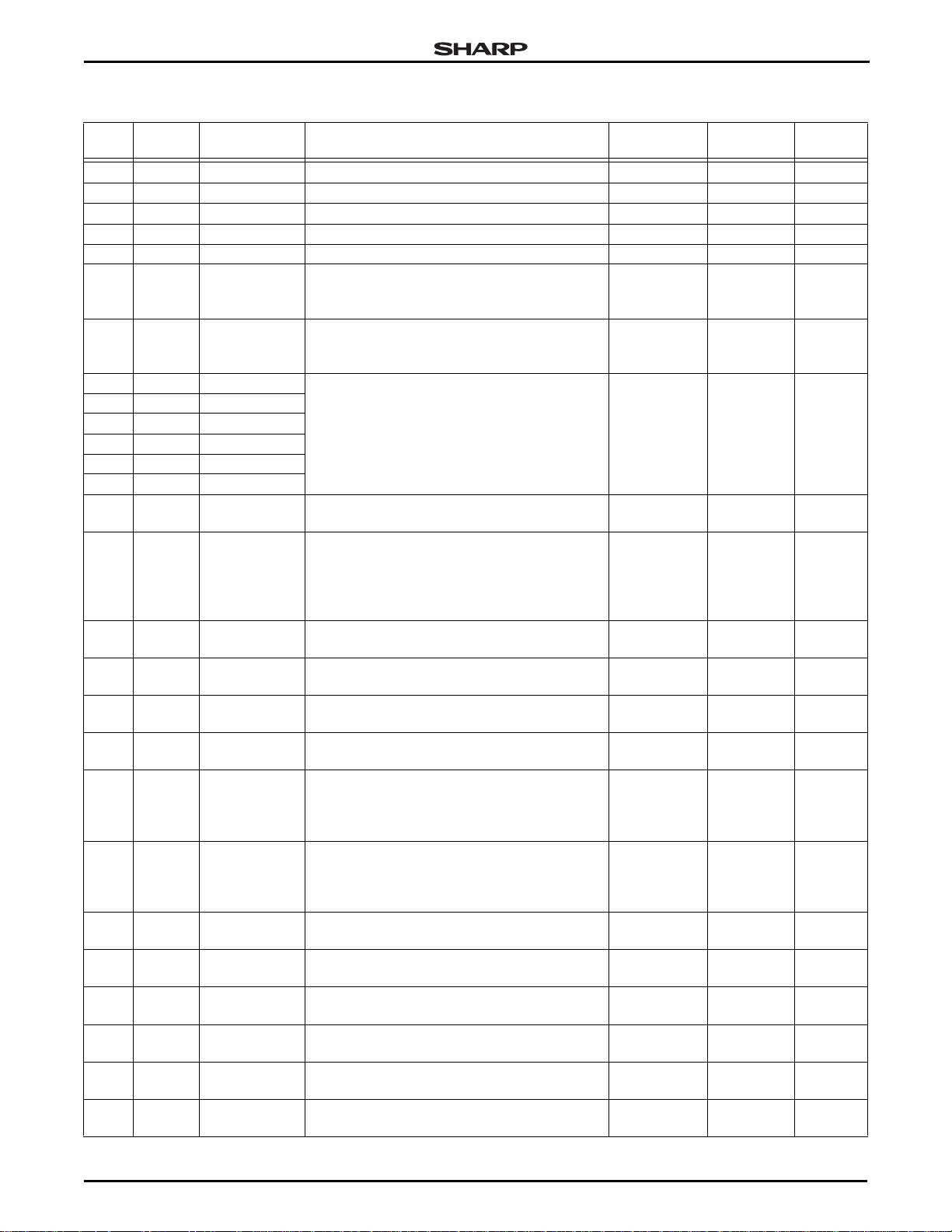

Table 1. Functional Pin List (Cont’d)

PBGA

CABGA

PIN

L12 L11 D0

M15 L13 D1

N13 L14 D2

L16 K11 D3

L15 L16 D4

L14 K14 D5

H11 J15 D6

K12 J12 D7

J15 J10 D8

J13 H16 D9

J10 H14 D10

H15 H11 D11

H13 G16 D12

G15 G9 D13

G11 G14 D14

G12 G12 D15

F15 F15 D16

F12 E15 D17

E14 D16 D18

D16 F12 D19

H10 E13 D20

D14 D14 D21

F10 E12 D22

A16 B16 D23

A14 D12 D24

B13 A16 D25

C13 B13 D26

E12 B14 D27

G10 C12 D28

B12 A14 D29

B11 B12 D30

D11 A12 D31

M16 M15 A0/nWE1

N14 M16 A1/nWE2

PIN

SIGNAL DESCRIPTION

RESET

STATE

Data Bus LOW LOW 12 mA

• Asynchronous Address Bus

• Asynchronous Memory Write Byte Enable 1

• Asynchronous Address Bus

• Asynchronous Memory Write Byte Enable 2

HIGH: nWE1 HIGH 12 mA

HIGH: nWE2 HIGH 12 mA

STANDBY

STATE

OUTPUT

DRIVE

Preliminary Data Sheet 12/8/03 5

Page 6

LH7A400 32-Bit System-on-Chip

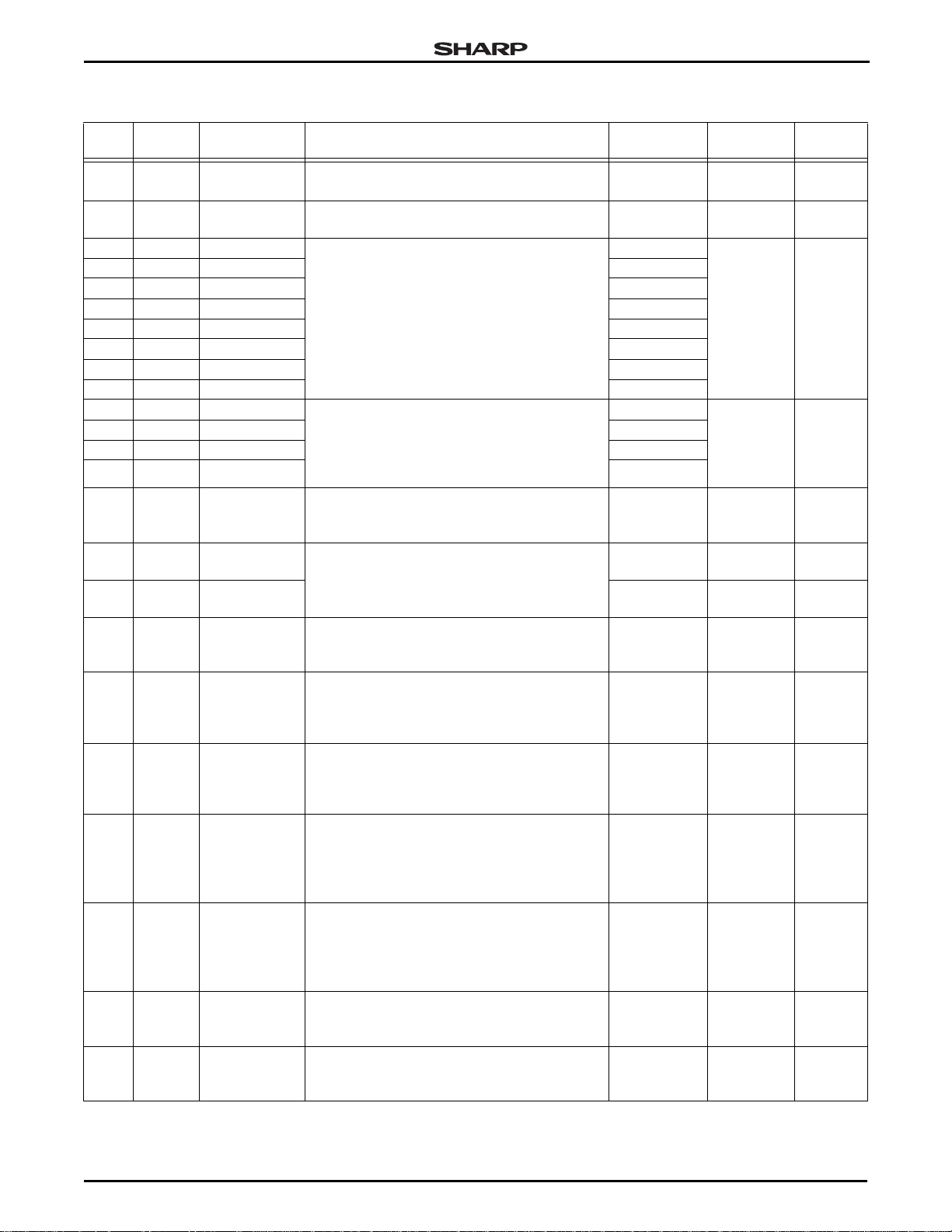

Table 1. Functional Pin List (Cont’d)

PBGA

CABGA

PIN

M13 L15 A2/SA0

K16 K12 A3/SA1 LOW LOW 12 mA

K15 K13 A4/SA2 LOW LOW 12 mA

K14 K16 A5/SA3 LOW LOW 12 mA

J8 J13 A6/SA4 LOW LOW 12 mA

J16 J11 A7/SA5 LOW LOW 12 mA

J14 J16 A8/SA6 LOW LOW 12 mA

J9 H15 A9/SA7 LOW LOW 12 mA

H16 H10 A10/SA8 LOW LOW 12 mA

H14 H12 A11/SA9 LOW LOW 12 mA

G16 G15 A12/SA10 LOW LOW 12 mA

G14 G10 A13/SA11 LOW LOW 12 mA

G13 G11 A14/SA12 LOW LOW 12 mA

F16 F16 A15/SA13 LOW LOW 12 mA

F14 E16 A16/SB0

E16 F13 A17/SB1

E13 E14 A18

F11 D15 A19

D15 C16 A20

C16 C15 A21

B16 C14 A22

A15 B15 A23

A13 E11 A24

G8 D8 A25/SCIO

F8 B7 A26/SCCLK

A8 A7 A27/SCRST

D8 C8 nOE Asynchronous Memory Output Enable HIGH HIGH 12 mA

C8 F8 nWE0 Asynchronous Memory Write Byte Enable 0 HIGH HIGH 12 mA

D10 D9 nWE3 Asynchronous Memory Write Byte Enable 3 HIGH HIGH 8 mA

B10 E9 CS6/SCKE1_2

C10 A10 CS7/SCKE0

G9 A11 SCKE3 Synchronous Memory Clock Enable 3 LOW LOW 12 mA

A10 B10 SCLK Synchronous Memory Clock LOW LOW

C14 C13 nSCS0 Synchronous Memory Chip Select 0 HIGH HIGH 12 mA

D13 A15 nSCS1 Synchronous Memory Chip Select 1 HIGH HIGH 12 mA

E11 D11 nSCS2 Synchronous Memory Chip Select 2 HIGH HIGH 12 mA

A12 E10 nSCS3 Synchronous Memory Chip Select 3 HIGH HIGH 12 mA

C12 A13 nSWE Synchronous Memory Write Enable HIGH HIGH 12 mA

C11 B11 nCAS

PIN

SIGNAL DESCRIPTION

• Asynchronous Address Bus

• Synchronous Address Bus

• Asynchronous Address Bus

• Synchronous Device Bank Address 0

• Asynchronous Address Bus

• Synchronous Device Bank Address 1

Asynchronous Address Bus LOW LOW 12 mA

• Asynchronous Memory Address Bus

• Smart Card Interface I/O (Data)

• Asynchronous Memory Address Bus

• Smart Card Interface Clock

• Asynchronous Memory Address Bus

• Smart Card Interface Reset

• Asynchronous Memory Chip Select 6

• Synchronous Memory Clock Enable 1 OR 2

• Asynchronous Memory Chip Select 7

• Synchronous Memory Clock Enable 0

Synchronous Memory Column Address

Strobe Signal

RESET

STATE

LOW LOW 12 mA

LOW LOW 12 mA

LOW LOW 12 mA

LOW: A25 LOW 12 mA

LOW: A26 LOW 12 mA

LOW: A27 LOW 12 mA

LOW: CS6 LOW 12 mA

LOW: CS7 LOW 12 mA

HIGH HIGH 12 mA

STANDBY

STATE

OUTPUT

DRIVE

20 mA

(sink)

12 mA

(source)

6 12/8/03 Preliminary Data Sheet

Page 7

32-Bit System-on-Chip LH7A400

Table 1. Functional Pin List (Cont’d)

PBGA

CABGA

PIN

F9 C11 nRAS Synchronous Memory Row Address Strobe Signal HIGH HIGH 12 mA

A9 C9 DQM0 Synchronous Memory Data Mask 0 HIGH HIGH 12 mA

B9 A9 DQM1 Synchronous Memory Data Mask 1 HIGH HIGH 12 mA

D9 B9 DQM2 Synchronous Memory Data Mask 2 HIGH HIGH 12 mA

E9 A8 DQM3 Synchronous Memory Data Mask 3 HIGH HIGH 12 mA

J5 K1 PA0/LCDVD16

K1 K2 PA1/LCDVD17

K2 K3 PA2

K3 K4 PA3

K5 K6 PA4

L1 K5 PA5

L2 L1 PA6

L3 L2 PA7

L4 L3 PB0/UARTRX1

L5 M1 PB1/UARTTX3

L7 M2 PB2/UARTRX3

M2 M3

M4 L5

N1 N1

N2 N2

N3 M4 PB7/SMBCLK

P1 P1 PC0/UARTTX1

P2 P2 PC1/LCDPS

R1 R1

K6 M5 PC3/LCDREV

L8 P3 PC4/LCDSPS

T1 N4 PC5/LCDCLS

PIN

SIGNAL DESCRIPTION

• GPIO Port A

• LCD Data bit 16. This CLCDC output signal is

always LOW.

• GPIO Port A

• LCD Data bit 17. This CLCDC output signal is

always LOW.

GPIO Port A Input No Change 8 mA

• GPIO Port B

• UART1 Receive Data Input

• GPIO Port B

• UART3 Transmit Data Out

• GPIO Port B

• UART3 Receive Data In

PB3/

UARTCTS3

PB4/

UARTDCD3

PB5/

UARTDSR3

PB6/SWID/

SMBD

PC2/

LCDVDDEN

• GPIO Port B

• UART3 Clear to Send

• GPIO Port B

• UART3 Data Carrier Detect

• GPIO Port B

• UART3 Data Set Ready

• GPIO Port B

• Single Wire Data

• Smart Battery Data

• GPIO Port B

• Smart Battery Clock

• GPIO Port C

• UART1 Transmit Data Output

• GPIO Port C

• HR-TFT Power Save

• GPIO Port C

• HR-TFT Power Sequence Control

• GPIO Port C

• HR-TFT Gray Scale Voltage Reverse

• GPIO Port C

• HR-TFT Reset Row Driver Counter

• GPIO Port C

• HR-TFT Row Driver Clock

RESET

STATE

Input: PA0 No Change 8 mA

Input: PA1 No Change 8 mA

Input: PB0 No Change 8 mA

Input: PB1

Input: PB2 No Change 8 mA

Input: PB3 No Change 8 mA

Input: PB4 No Change 8 mA

Input: PB5 No Change 8 mA

Input: PB6

Input: PB7

LOW: PC0 No Change 12 mA

LOW: PC1 No Change 12 mA

LOW: PC2 No Change 12 mA

LOW: PC3 No Change 12 mA

LOW: PC4 No Change 12 mA

LOW: PC5 No Change 12 mA

STANDBY

STATE

LOW if

UART3 is

Enabled,

otherwise

No Change

Input if SMB

is Enabled,

otherwise

No Change

Input if SMB

is Enabled,

otherwise

No Change

OUTPUT

DRIVE

8 mA

8 mA

8 mA

Preliminary Data Sheet 12/8/03 7

Page 8

LH7A400 32-Bit System-on-Chip

Table 1. Functional Pin List (Cont’d)

PBGA

CABGA

PIN

T2 R2 PC6/LCDHRLP

R2 N5 PC7/LCDSPL

M11 M9 PD0/LCDVD8

L11 K10 PD1/LCDVD9 LOW: PD1

K8 P10 PD2/LCDVD10 LOW: PD2

N11 T11 PD3/LCDVD11 LOW: PD3

R9 T12 PD4/LCDVD12 LOW: PD4

T9 R11 PD5/LCDVD13 LOW: PD5

P10 R12 PD6/LCDVD14 LOW: PD6

R10 T13 PD7/LCDVD15 LOW: PD7

L10 T9 PE0/LCDVD4

N10 K9 PE1/LCDVD5 Input: PE1

M9 T10 PE2/LCDVD6 Input: PE2

M10 R10 PE3/LCDVD7 Input: PE3

A6 A5 PF0/INT0

B6 B4 PF1/INT1

C6 E7 PF2/INT2

H8 B3 PF3/INT3

B5 C5

D6 D6

E6 A4

C5 A3

R3 M6 PG0/nPCOE

T3 T1 PG1/nPCWE

PIN

SIGNAL DESCRIPTION

• GPIO Port C

• LCD Latch Pulse

• GPIO Port C

• LCD Start Pulse Left

• GPIO Port D

• LCD Video Data Bus

• GPIO Port E

• LCD Video Data Bus

• GPIO Port F

• External FIQ Interrupt. Interrupts can be level or

edge triggered and are internally debounced.

• GPIO Port F

• External IRQ Interrupts. Interrupts can be level

or edge triggered and are internally debounced.

• GPIO Port F

• External IRQ Interrupt. Interrupts can be level or

edge triggered and are internally debounced.

• GPIO Port F

PF4/INT4/

SCVCCEN

PF5/INT5/

SCDETECT

PF6/INT6/

PCRDY1

PF7/INT7/

PCRDY2

• External IRQ Interrupt. Interrupts can be level or

edge triggered and are internally debounced.

• Smart Card Supply Voltage Enable

• GPIO Port F

• External IRQ Interrupt. Interrupts can be level or

edge triggered and are internally debounced.

• Smart Card Detection

• GPIO Port F

• External IRQ Interrupt. Interrupts can be level or

edge triggered and are internally debounced.

• Ready for Card 1 for PC Card (PCMCIA or

CompactFlash) in single or dual card mode

• GPIO Port F

• External IRQ Interrupt. Interrupts can be level or

edge triggered and are internally debounced.

• Ready for Card 2 for PC Card (PCMCIA or

CompactFlash) in single or dual card mode

• GPIO Port G

• Output Enable for PC Card (PCMCIA or

CompactFlash) in single or dual card mode

• GPIO Port G

• Write Enable for PC Card (PCMCIA or

CompactFlash) in single or dual card mode

RESET

STATE

LOW: PC6 No Change 12 mA

LOW: PC7 No Change 12 mA

LOW: PD0

Input: PE0 LOW if 8-bit

Input: PF0

(Schmitt)

Input: PF1

(Schmitt)

Input: PF2

(Schmitt)

Input: PF3

(Schmitt)

Input: PF4

(Schmitt)

Input: PF5

(Schmitt)

Input: PF6

(Schmitt)

Input: PF7

(Schmitt)

LOW: PG0 No Change 8 mA

LOW: PG1 No Change 8 mA

STANDBY

STATE

LOW if

Dual-Panel

LCD is

Enabled;

otherwise,

No Change

LCD is

Enabled,

otherwise

No Change

No Change 8 mA

No Change 8 mA

No Change 8 mA

No Change 8 mA

LOW if SCI

is Enabled;

otherwise,

No Change

No Change 8 mA

No Change 8 mA

No Change 8 mA

OUTPUT

DRIVE

12 mA

12 mA

8 mA

8 12/8/03 Preliminary Data Sheet

Page 9

32-Bit System-on-Chip LH7A400

Table 1. Functional Pin List (Cont’d)

PBGA

CABGA

PIN

L6 P4 PG2/nPCIOR

M6 R3 PG3/nPCIOW

N6 T2 PG4/nPCREG

M7 P5 PG5/nPCCE1

M8 R4 PG6/nPCCE2

N4 T3 PG7/PCDIR

P4 P6

R4 T4

T4 M7

N7 T5

P8 R6

P5 R7

PIN

SIGNAL DESCRIPTION

PH0/

PCRESET1

PH1/CFA8/

PCRESET2

PH2/

nPCSLOTE1

PH3/CFA9/

PCMCIAA25/

nPCSLOTE2

PH4/

nPCWAIT1

PH5/CFA10/

PCMCIAA24/

nPCWAIT2

• GPIO Port G

• I/O Read Strobe for PC Card (PCMCIA or

CompactFlash) in single or dual card mode

• GPIO Port G

• I/O Write Strobe for PC Card (PCMCIA or

CompactFlash) in single or dual card mode

• GPIO Port G

• Register Memory Access for PC Card (PCMCIA

or CompactFlash) in single or dual card mode

• GPIO Port G

• Card Enable 1 for PC Card (PCMCIA or

CompactFlash) in single or dual card mode.

This signal and nPCCE2 are used by the PC

Card for decoding low and high byte accesses.

• GPIO Port G

• Card Enable 2 for PC Card (PCMCIA or

CompactFlash) in single or dual card mode.

This signal and nPCCE1 are used by the PC

Card for decoding low and high byte accesses.

• GPIO Port G

• Direction for PC Card (PCMCIA or

CompactFlash) in single or dual card mode

• GPIO Port H

• Reset Card 1 for PC Card (PCMCIA or

CompactFlash) in single or dual card mode

• GPIO Port H

• Address Bit 8 for PC Card (CompactFlash) in

single card mode

• Reset Card 2 for PC Card (PCMCIA or

CompactFlash) in dual card mode

• GPIO Port H

• Enable Card 1 for PC Card (PCMCIA or

CompactFlash) in single or dual card mode.

This signal is used for gating other control signals to the appropriate PC Card.

• GPIO Port H

• Address Bit 9 for PC Card (CompactFlash) in

single card mode

• Address Bit 25 for PC Card (PCMCIA) in single

card mode

• Enable Card 2 for PC Card (PCMCIA or

CompactFlash) in dual card mode. This signal

is used for gating other control signals to the

appropriate PC Card.

• GPIO Port H

• WAIT Signal for Card 1 for PC Card (PCMCIA

or CompactFlash) in single or dual card mode

• GPIO Port H

• Address Bit 10 for PC Card (CompactFlash) in

single card mode

• Address Bit 24 for PC Card (PCMCIA) in single

card mode

• WAIT Signal f o r Ca r d 2 for PC Card (PCMCIA

or CompactFlash) in dual card mode

RESET

STATE

LOW: PG2 No Change 8 mA

LOW: PG3 No Change 8 mA

LOW: PG4 No Change 8 mA

LOW: PG5 No Change 8 mA

LOW: PG6 No Change 8 mA

LOW: PG7 No Change 8 mA

Input: PH0 No Change 8 mA

Input: PH1 No Change 8 mA

Input: PH2 No Change 8 mA

Input: PH3 No Change 8 mA

Input: PH4 No Change 8 mA

Input: PH5 No Change 8 mA

STANDBY

STATE

OUTPUT

DRIVE

Preliminary Data Sheet 12/8/03 9

Page 10

LH7A400 32-Bit System-on-Chip

Table 1. Functional Pin List (Cont’d)

PBGA

CABGA

PIN

R5 P7

T5 T6

R6 T7 LCDFP LCD Frame Synchronization pulse LOW LOW 12 mA

R8 R9 LCDLP LCD Line Synchronization pulse LOW LOW 12 mA

P9 P9

N9 N9 LCDDCLK LCD Data Clock LOW LOW 12 mA

P7 M8 LCDVD0

R7 P8 LCDVD1

T7 R8 LCDVD2

N8 T8 LCDVD3

T15 T16 USBDP USB Data Positive (Differential Pair) Input Input

T16 R16 USBDN USB Data Negative (Differential Pair) Input Input

E7 C7 nPWME0

D7 A6 nPWME1

C7 B6 PWM0

B7 B5 PWM1

C4 A2 ACBITCLK

D5 A1 ACOUT

B4 B2 ACSYNC

A4 E6 ACIN

A3 C3

B3 B1

A2 D4

E2 E1 UARTCTS2

E3 F3 UARTDCD2

E5 G4 UARTDSR2 UART2 Data Set Ready Signal Input Input

F2 G5 UARTIRTX1 IrDA Transmit LOW LOW 8 mA

F3 G6 UARTIRRX1

F4 F1 UARTTX2 UART2 Transmit Data Output HIGH HIGH 8 mA

PIN

SIGNAL DESCRIPTION

PH6/

AC97RESET

PH7/nPCSTATRE

LCDENAB/

LCDM

MMCCLK/

MMSPICLK

MMCCMD/

MMSPIDIN

MMCDATA/

MMSPIDOUT

• GPIO Port H

• Audio Codec (AC97) Reset

• GPIO Port H

• Status Read Enable for PC Card (PCMCIA or

CompactFlash) in single or dual card mode

• LCD TFT Data Enable

• LCD STN AC Bias

LCD Video Data Bus LOW LOW 12 mA

DC-DC Converter Pulse Width

Modulator 0 Enable

DC-DC Converter Pulse Width

Modulator 1 Enable

DC-DC Converter Pulse Width

Modulator 0 Output during normal operation and

Polarity Selection input at reset

DC-DC Converter Pulse Width

Modulator 1 Output during normal operation and

Polarity Selection input at reset

• Audio Codec (AC97) Clock

• Audio Codec (ACI) Clock

• Audio Codec (AC97) Output

• Audio Codec (ACI) Output

• Audio Codec (AC97) Synchronization

• Audio Codec (ACI) Synchronization

• Audio Codec (AC97) Input

• Audio Codec (ACI) Input

• MultiMediaCard Clock (20 MHz MAX.)

• MultiMediaCard SPI Mode Clock

• MultiMediaCard Command

• MultiMediaCard SPI Mode Data Input

• MultiMediaCard Data

• MultiMediaCard SPI Mode Data Output

UART2 Clear to Send Signal. This pin is an output for JTAG boundary scan only.

UART2 Data Carrier Detect Signal. This pin is output for JTAG boundary scan only.

IrDA Receive. This pin is an output for JTAG

boundary scan only.

RESET

STATE

Input: PH6 No Change 8 mA

Input: PH7 No Change 8 mA

LOW:

LCDENAB

Input Input

Input Input

Input Input 8 mA

Input Input 8 mA

Input Input

LOW LOW 8 mA

LOW LOW 8 mA

Input Input

LOW:

MMCCLK

Input:

MMCCMD

Input:

MMCDATA

Input Input

Input Input

Input Input

STANDBY

STATE

LOW 12 mA

LOW 8 mA

Input 8 mA

Input 8 mA

OUTPUT

DRIVE

75 mA

(NOM.)

75 mA

(NOM.)

10 12/8/03 Preliminary Data Sheet

Page 11

32-Bit System-on-Chip LH7A400

Table 1. Functional Pin List (Cont’d)

PBGA

CABGA

PIN

J7 G3 UARTRX2

H4 J3 SSPCLK Synchronous Serial Port Clock LOW LOW 8 mA

J1 J6 SSPRX Synchronous Serial Port Receive Input Input

J2 J7 SSPTX Synchronous Serial Port Transmit LOW LOW 8 mA

J3 J2

F6 G2 COL0

F5 G1 COL1

G1 H3 COL2

G2 H5 COL3

G4 H6 COL4

G5 H7 COL5

H1 H2 COL6

H2 H1 COL7

H3 J1 TBUZ Timer Buzzer (254 kHz MAX.) LOW LOW 8 mA

C3 F5 MEDCHG

P11 T14 WIDTH0

R12 T15 WIDTH1

D1 E3 BATOK Battery OK Input (Schmitt) Input

D2 F6 nBATCHG Battery Change Input (Schmitt) Input

A1 E5 TDI

B1 C2 TCK

B2 D3 TDO

C1 C1 TMS

T12 P15 nTEST0

R15 P13 nTEST1

PIN

SIGNAL DESCRIPTION

UART2 Receive Data Input. This pin is an output

for JTAG boundary scan only.

SSPFRM/

nSSPFRM

Synchronous Serial Port Frame Sync

Keyboard Interface HIGH HIGH 8 mA

Boot Device Media Change. Used with the

WIDTH0 and WIDTH1 pins to specify boot memory device.

External Memory Width Pins. Also, used with

MEDCHG to specify the boot memory device size.

JTAG Data In. This signal is internally pulled-up

to VDD.

JTAG Clock. This signal should be externally

pulled-up to VDD.

JTAG Data Out. This signal should be externally

pulled up to VDD with a 33 k

JTAG Test Mode select. This signal is internally

pulled-up to VDD.

Test Pin 0. Internally pulled up to VDD. For Normal

mode, leave open. For JTAG mode, tie to GND.

See Table 2.

Test Pin 1. internally pulled up to VDD. For Normal

and JTAG mode, leave open. See Table 2.

Ω resistor.

RESET

STATE

Input Input

Input:

nSSPFRM

Input (Schmitt) Input

Input (Schmitt) Input

Input with

Pull-up

Input Input

Input No Change 4 mA

Input with

Pull-up

Input with

Pull-up

Input with

Pull-up

STANDBY

STATE

Input 8 mA

Input with

Pull-up

Input with

Pull-up

Input with

Pull-up

Input with

Pull-up

OUTPUT

DRIVE

NOTES: *Signals beginning with ‘n’ are Active LOW.

Table 2. nTest Pin Function

MODE nTEST0 nTEST1 nURESET

JTAG 0 1 1

Normal 1 1 x

Preliminary Data Sheet 12/8/03 11

Page 12

LH7A400 32-Bit System-on-Chip

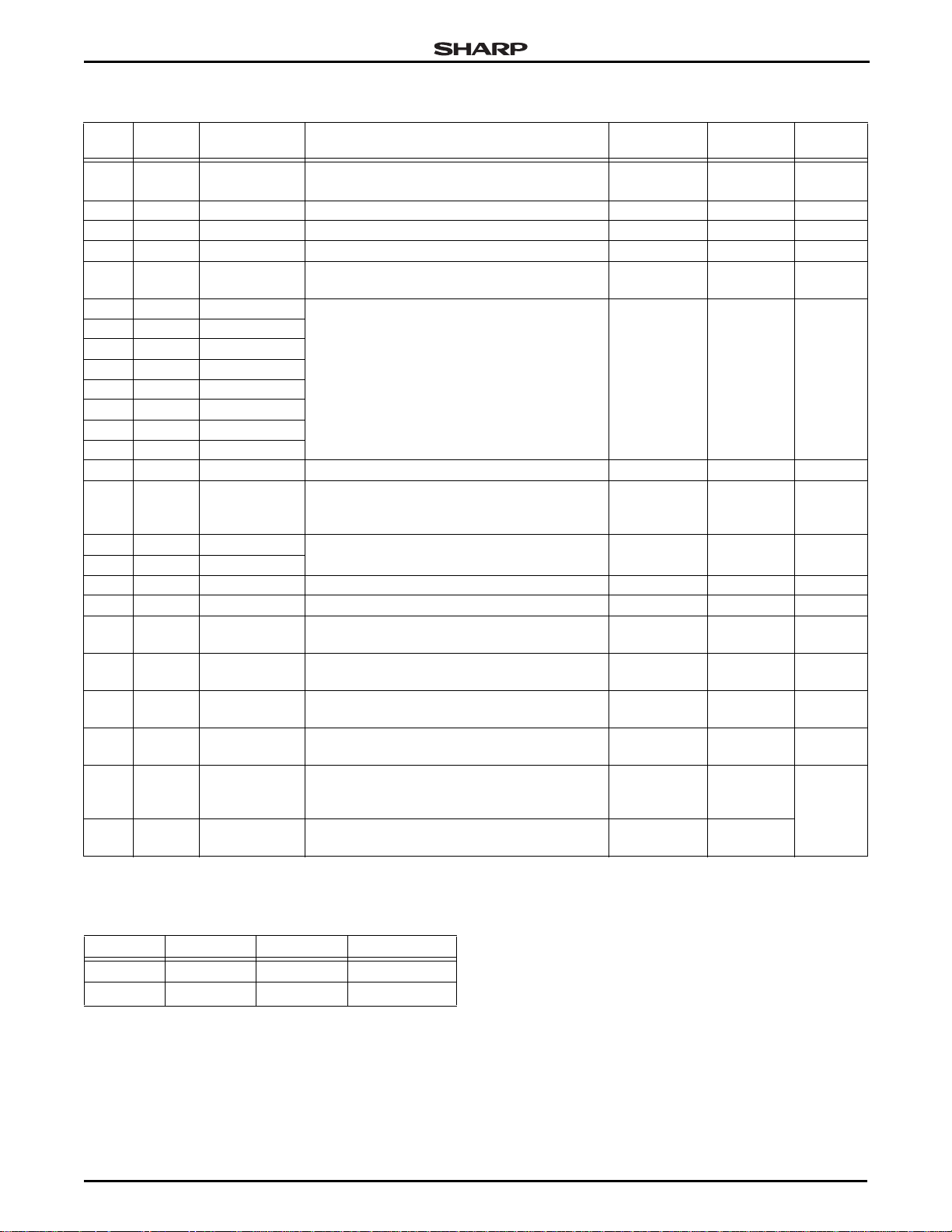

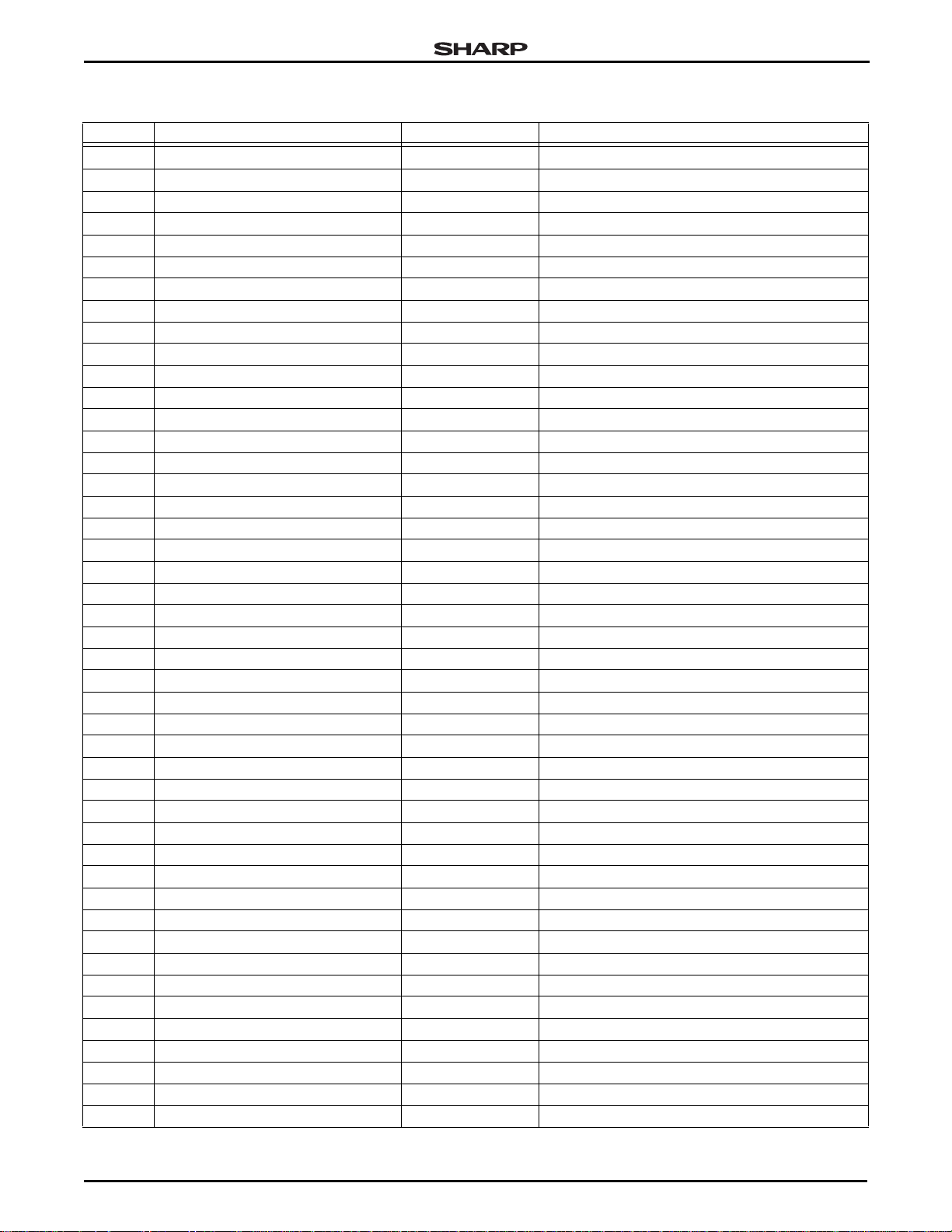

Table 3. LCD Data Multiplexing

STN

PBGA

CABGA

PIN

K1 K2 LCDVD17 LOW

J5 K1 LCDVD16 LOW

R10 T13 LCDVD15 MLSTN7 CLSTN7 Intensity Intensity

P10 R12 LCDVD14 MLSTN6 CLSTN6 BLUE4 BLUE4

T9 R11 LCDVD13 MLSTN5 CLSTN5 BLUE3 BLUE3

R9 T12 LCDVD12 MLSTN4 CLSTN4 BLUE2 BLUE2

N11 T11 LCDVD11 MLSTN3 CLSTN3 BLUE1 BLUE1

K8 P10 LCDVD10 MLSTN2 CLSTN2 BLUE0 BLUE0

L11 K10 LCDVD9 MLSTN1 CLSTN1 GREEN4 GREEN4

M11 M9 LCDVD8 MLSTN0 CLSTN0 GREEN3 GREEN3

M10 R10 LCDVD7 MLSTN3 MUSTN7 MUSTN7 CUSTN7 CUSTN7 GREEN2 GREEN2

M9 T10 LCDVD6 MLSTN2 MUSTN6 MUSTN6 CUSTN6 CUSTN6 GREEN1 GREEN1

N10 K9 LCDVD5 MLSTN1 MUSTN5 MUSTN5 CUSTN5 CUSTN5 GREEN0 GREEN0

L10 T9 LCDVD4 MLSTN0 MUSTN4 MUSTN4 CUSTN4 CUSTN4 RED4 RED4

N8 T8 LCDVD3 MUSTN3 MUSTN3 MUSTN3 MUSTN3 CUSTN3 CUSTN3 RED3 RED3

T7 R8 LCDVD2 MUSTN2 MUSTN2 MUSTN2 MUSTN2 CUSTN2 CUSTN2 RED2 RED2

R7 P8 LCDVD1 MUSTN1 MUSTN1 MUSTN1 MUSTN1 CUSTN1 CUSTN1 RED1 RED1

P7 M8 LCDVD0 MUSTN0 MUSTN0 MUSTN0 MUSTN0 CUSTN0 CUSTN0 RED0 RED0

PIN

LCD

DATA

SIGNAL

MONO 4-BIT MONO 8-BIT COLOR

SINGLE

PANEL

DUAL

PANEL

SINGLE

PANEL

DUAL

PANEL

SINGLE

PANEL

DUAL

PANEL

TFT

AD-TFT/

HR-TFT

NOTES:

1. The Intensity bit is identically generated for all three colors.

2. MU = Monochrome Upper

3. CU = Color Upper

4. CL = Color Lower

12 12/8/03 Preliminary Data Sheet

Page 13

32-Bit System-on-Chip LH7A400

Table 4. 256-Ball PBGA Package Numerical Pin List

BGA PIN SIGNAL RESET STATE STANDBY STATE

A1 TDI Input with Pull-up Input with Pull-up

A2 MMCDATA/MMSPIDOUT Input: MMSPIDOUT LOW

A3 MMCCLK/MMSPICLK LOW: MMSPICLK LOW

A4 ACIN Input Input

A5 VSS

A6 PF0/INT0 Input: PF0 No Change

A7 VDDC

A8 A27/SCRST LOW: A27 LOW

A9 DQM0 HIGH LOW

A10 SCLK LOW LOW

A11 VSS

A12 nSCS3 HIGH HIGH

A13 A24 LOW LOW

A14 D24 LOW LOW

A15 A23 LOW LOW

A16 D23 LOW LOW

B1 TCK Input Input

B2 TDO Input No Change

B3 MMCCMD/MMSPIDIN Input: MMSPIDIN LOW

B4 ACSYNC LOW LOW

B5 PF4/INT4/SCVCCEN Input: PF4 LOW if SCI is Enabled; otherwise, No Change

B6 PF1/INT1 Input: PF1 No Change

B7 PWM1 Input Input

B8 VDD

B9 DQM1 HIGH LOW

B10 CS6/SCKE1_2 LOW: CS6 LOW

B11 D30 LOW LOW

B12 D29 LOW LOW

B13 D25 LOW LOW

B14 VDD

B15 VSSC

B16 A22 LOW LOW

C1 TMS Input with Pull-up Input with Pull-up

C2 nEXTPWR Input Input

C3 MEDCHG Input Input

C4 ACBITCLK Input Input

C5 PF7/INT7/PCRDY2 Input: PF7 No Change

C6 PF2/INT2 PF2/INT2 No Change

C7 PWM0 Input Input

C8 nWE0 HIGH HIGH

C9 VSSC

C10 CS7/SCKE0 LOW: CS7 LOW

C11 nCAS HIGH HIGH

C12 nSWE HIGH HIGH

C13 D26 LOW LOW

Preliminary Data Sheet 12/8/03 13

Page 14

LH7A400 32-Bit System-on-Chip

Table 4. 256-Ball PBGA Package Numerical Pin List (Cont’d)

BGA PIN SIGNAL RESET STATE STANDBY STATE

C14 nSCS0 HIGH HIGH

C15 VSS

C16 A21 LOW LOW

D1 BATOK Input Input

D2 nBATCHG Input Input

D3 nPOR Input Input

D4 WAKEUP Input Input

D5 ACOUT LOW LOW

D6 PF5/INT5/SCDETECT Input: PF5 No Change

D7 nPWME1 Input Input

D8 nOE HIGH HIGH

D9 DQM2 HIGH LOW

D10 nWE3 HIGH HIGH

D11 D31 LOW LOW

D12 VDDC

D13 nSCS1 HIGH HIGH

D14 D21 LOW LOW

D15 A20 LOW LOW

D16 D19 LOW LOW

E1 VDDC

E2 UARTCTS2 Input Input

E3 UARTDCD2 Input Input

E4 nPWRFL Input Input

E5 UARTDSR2 Input Input

E6 PF6/INT6/PCRDY1 Input: PF6 No Change

E7 nPWME0 Input Input

E8 VSS

E9 DQM3 HIGH LOW

E10 VDD

E11 nSCS2 HIGH HIGH

E12 D27 LOW LOW

E13 A18 LOW LOW

E14 D18 LOW LOW

E15 VDDC

E16 A17/SB1 LOW: SBANK1 LOW

F1 VDD

F2 UARTIRTX1 LOW LOW

F3 UARTIRRX1 Input Input

F4 UARTTX2 HIGH HIGH

F5 COL1 HIGH HIGH

F6 COL0 HIGH HIGH

F7 VSS

F8 A26/SCCLK LOW: A26 LOW

F9 nRAS HIGH HIGH

F10 D22 LOW LOW

14 12/8/03 Preliminary Data Sheet

Page 15

32-Bit System-on-Chip LH7A400

Table 4. 256-Ball PBGA Package Numerical Pin List (Cont’d)

BGA PIN SIGNAL RESET STATE STANDBY STATE

F11 A19 LOW LOW

F12 D17 LOW LOW

F13 VDD

F14 A16/SB0 LOW: SBANK0 LOW

F15 D16 LOW LOW

F16 A15/SA13 LOW: SA13 LOW

G1 COL2 HIGH HIGH

G2 COL3 HIGH HIGH

G3 VSS

G4 COL4 HIGH HIGH

G5 COL5 HIGH HIGH

G6 VSSC

G7 VDD

G8 A25/SCIO LOW: A25 LOW

G9 SCKE3 LOW LOW

G10 D28 LOW LOW

G11 D14 LOW LOW

G12 D15 LOW LOW

G13 A14/SA12 LOW: SA12 LOW

G14 A13/SA11 LOW: SA11 LOW

G15 D13 LOW LOW

G16 A12/SA10 LOW: SA10 LOW

H1 COL6 HIGH HIGH

H2 COL7 HIGH HIGH

H3 TBUZ LOW LOW

H4 SSPCLK LOW LOW

H5 VSSC

H6 nURESET Input Input

H7 VSS

H8 PF3/INT3 Input: PF3 No Change

H9 VSS

H10 D20 LOW LOW

H11 D6 LOW LOW

H12 VSSC

H13 D12 LOW LOW

H14 A11/SA9 LOW: SA9 LOW

H15 D11 LOW LOW

H16 A10/SA8 LOW: SA8 LOW

J1 SSPRX Input Input

J2 SSPTX LOW LOW

J3 SSPFRM/nSSPFRM Input: nSSPFRM Input

J4 VDDC

J5 PA0/LCDVD16 Input: PA0 No Change

J6 PGMCLK LOW LOW

J7 UARTRX2 Input Input

Preliminary Data Sheet 12/8/03 15

Page 16

LH7A400 32-Bit System-on-Chip

Table 4. 256-Ball PBGA Package Numerical Pin List (Cont’d)

BGA PIN SIGNAL RESET STATE STANDBY STATE

J8 A6/SA4 LOW: SA4 LOW

J9 A9/SA7 LOW: SA7 LOW

J10 D10 LOW LOW

J11 VDD

J12 VDD

J13 D9 LOW LOW

J14 A8/SA6 LOW: SA6 LOW

J15 D8 LOW LOW

J16 A7/SA5 LOW: SA5 LOW

K1 PA1/LCDVD17 Input: PA1 No Change

K2 PA2 Input No Change

K3 PA3 Input No Change

K4 VSS

K5 PA4 Input No Change

K6 PC3/LCDREV LOW: PC3 No Change

K7 VDD

K8 PD2/LCDVD10 LOW: PD2

K9 VDDC

K10 nCS1 HIGH HIGH

K11 nCS0 HIGH HIGH

K12 D7 LOW LOW

K13 VSS

K14 A5/SA3 LOW: SA3 LOW

K15 A4/SA2 LOW: SA2 LOW

K16 A3/SA1 LOW: SA1 LOW

L1 PA5 Input No Change

L2 PA6 Input No Change

L3 PA7 Input No Change

L4 PB0/UARTRX1 Input: PB0 No Change

L5 PB1/UARTTX3 Input: PB1 LOW if UART3 is Enabled, otherwise No Change

L6 PG2/nPCIOR LOW: PG2 No Change

L7 PB2/UARTRX3 Input: PB2 No Change

L8 PC4/LCDSPS LOW: PC4 No Change

L9 VSSC

L10 PE0/LCDVD4 Input: PE0 LOW if 8-bit LCD is Enabled, otherwise No Change

L11 PD1/LCDVD9 LOW: PD1

L12 D0 LOW LOW

L13 VDDC

L14 D5 LOW LOW

L15 D4 LOW LOW

L16 D3 LOW LOW

M1 VDD

M2 PB3/UARTCTS3 Input: PB3 No Change

M3 VSSC

LOW if Dual-Panel LCD is Enabled; otherwise,

No Change

LOW if Dual-Panel LCD is Enabled; otherwise,

No Change

16 12/8/03 Preliminary Data Sheet

Page 17

32-Bit System-on-Chip LH7A400

Table 4. 256-Ball PBGA Package Numerical Pin List (Cont’d)

BGA PIN SIGNAL RESET STATE STANDBY STATE

M4 PB4/UARTDCD3 Input: PB4 No Change

M5 VDD

M6 PG3/nPCIOW LOW: PG3 No Change

M7 PG5/nPCCE1 LOW: PG5 No Change

M8 PG6/nPCCE2 LOW: PG6 No Change

M9 PE2/LCDVD6 Input: PE2 LOW if 8-bit LCD is Enabled; otherwise No Change

M10 PE3/LCDVD7 Input: PE3 LOW if 8-bit LCD is Enabled; otherwise No Change

M11 PD0/LCDVD8 LOW: PD0

M12 nCS3/nMMSPICS HIGH: nCS3 HIGH

M13 A2/SA0 LOW: SA0 LOW

M14 VDD

M15 D1 LOW LOW

M16 A0/nWE1 HIGH: nWE1 HIGH

N1 PB5/UARTDSR3 Input: PB5 No Change

N2 PB6/SWID/SMBD Input: PB6 Input if SMB is Enabled; otherwise No Change

N3 PB7/SMBCLK Input: PB7 Input if SMB is Enabled; otherwise No Change

N4 PG7/PCDIR LOW: PG7 No Change

N5 VSS

N6 PG4/nPCREG LOW: PG4 No Change

N7 PH3/CFA9/PCMCIAA25/nPCSLOTE2 Input: PH3 No Change

N8 LCDVD3 LOW LOW

N9 LCDDCLK LOW LOW

N10 PE1/LCDVD5 Input: PE1 LOW if 8-bit LCD is Enabled; otherwise No Change

N11 PD3/LCDVD11 LOW: PD3

N12 VDDA

N13 D2 LOW LOW

N14 A1/nWE2 HIGH: nWE2 HIGH

N15 VSSC

N16 VSS

P1 PC0/UARTTX1 LOW: PC0 No Change

P2 PC1/LCDPS LOW: PC1 No Change

P3 VDDC

P4 PH0/PCRESET1 Input: PH0 No Change

P5 PH5/CFA10/PCMCIAA24/nPCWAIT2 Input: PH5 No Change

P6 VSS

P7 LCDVD0 LOW LOW

P8 PH4/nPCWAIT1 Input: PH4 No Change

P9 LCDENAB/LCDM LOW: LCDENAB LOW

P10 PD6/LCDVD14 LOW: PD6

P11 WIDTH0 Input Input

P12 VSSA

P13 nCS2 HIGH HIGH

P14 CLKEN LOW LOW

LOW if Dual-Panel LCD is Enabled; otherwise,

No Change

LOW if Dual-Panel LCD is Enabled; otherwise,

No Change

LOW if Dual-Panel LCD is Enabled; otherwise,

No Change

Preliminary Data Sheet 12/8/03 17

Page 18

LH7A400 32-Bit System-on-Chip

Table 4. 256-Ball PBGA Package Numerical Pin List (Cont’d)

BGA PIN SIGNAL RESET STATE STANDBY STATE

P15 XTAL32OUT Output Output

P16 XTAL32IN Input Input

R1 PC2/LCDVDDEN LOW: PC2 No Change

R2 PC7/LCDSPL LOW: PC7 No Change

R3 PG0/nPCOE LOW: PG0 No Change

R4 PH1/CFA8/PCRESET2 Input: PH1 No Change

R5 PH6/nAC97RESET Input: PH6 No Change

R6 LCDFP LOW LOW

R7 LCDVD1 LOW LOW

R8 LCDLP LOW LOW

R9 PD4/LCDVD12 LOW: PD4

R10 PD7/LCDVD15 LOW: PD7

R11 VDDA

R12 WIDTH1 Input Input

R13 XTALIN Input Input

R14 VDD

R15 nTEST1 Input with Pull-up Input with Pull-up

R16 VSS

T1 PC5/LCDCLS LOW: PC5 No Change

T2 PC6/LCDHRLP LOW: PC6 No Change

T3 PG1/nPCWE LOW: PG1 No Change

T4 PH2/nPCSLOTE1 Input: PH2 No Change

T5 PH7/nPCSTATRE Input: PH7 No Change

T6 VDD

T7 LCDVD2 LOW LOW

T8 VDDC

T9 PD5/LCDVD13 LOW: PD5

T10 VSSC

T11 VSSA

T12 nTEST0 Input with Pull-up Input with Pull-up

T13 XTALOUT LOW LOW

T14 VSS

T15 USBDP HIGH HIGH

T16 USBDN LOW LOW

LOW if Dual-Panel LCD is Enabled; otherwise,

No Change

LOW if Dual-Panel LCD is Enabled; otherwise,

No Change

LOW if Dual-Panel LCD is Enabled; otherwise,

No Change

NOTE: ‘No Change’ means the pin remains as it was programmed

prior to entering the Standby state.

18 12/8/03 Preliminary Data Sheet

Page 19

32-Bit System-on-Chip LH7A400

Table 5. 256-Ball CABGA Package Numerical Pin List

CABGA PIN SIGNAL RESET STATE STANDBY STATE

A1 ACOUT LOW LOW

A2 ACBITCLK Input Input

A3 PF7/INT7/PCRDY2 Input: PF7 (Schmitt) No Change

A4 PF6/INT6/PCRDY1 Input: PF6 (Schmitt) No Change

A5 PF0/INT0 Input: PF0 (Schmitt) No Change

A6 nPWME1 Input Input

A7 A27/SCRST LOW: A27 LOW

A8 DQM3 HIGH HIGH

A9 DQM1 HIGH HIGH

A10 CS7/SCKE0 LOW: CS7 LOW

A11 SCKE3 LOW LOW

A12 D31 LOW LOW

A13 nSWE HIGH HIGH

A14 D29 LOW LOW

A15 nSCS1 HIGH HIGH

A16 D25 LOW LOW

B1 MMCCMD/MMSPIDIN Input: MMCCMD Input

B2 ACSYNC LOW LOW

B3 PF3/INT3 Input: PF3 (Schmitt) No Change

B4 PF1/INT1 Input: PF1 (Schmitt) No Change

B5 PWM1 Input Input

B6 PWM0 Input Input

B7 A26/SCCLK LOW: A26 LOW

B8 VSS

B9 DQM2 HIGH HIGH

B10 SCLK LOW LOW

B11 nCAS HIGH HIGH

B12 D30 LOW LOW

B13 D26 LOW LOW

B14 D27 LOW LOW

B15 A23 LOW LOW

B16 D23 LOW LOW

C1 TMS Input with Pull-up Input with Pull-up

C2 TCK Input Input

C3 MMCCLK/MMSPICLK LOW: MMCCLK LOW

C4 VDDC

C5 PF4/INT4/SCVCCEN Input: PF4 (Schmitt) LOW if SCI is Enabled; otherwise, No Change

C6 VSS

C7 nPWME0 Input Input

C8 nOE HIGH HIGH

C9 DQM0 HIGH HIGH

C10 VDD

C11 nRAS HIGH HIGH

Preliminary Data Sheet 12/8/03 19

Page 20

LH7A400 32-Bit System-on-Chip

Table 5. 256-Ball CABGA Package Numerical Pin List

CABGA PIN SIGNAL RESET STATE STANDBY STATE

C12 D28 LOW LOW

C13 nSCS0 HIGH HIGH

C14 A22 LOW LOW

C15 A21 LOW LOW

C16 A20 LOW LOW

D1 nURESET Input (Schmitt) Input

D2 nEXTPWR Input (Schmitt) Input

D3 TDO Input No Change

D4 MMCDATA/MMSPIDOUT Input: MMCDATA Input

D5 VSS

D6 PF5/INT5/SCDETECT Input: PF5 (Schmitt) No Change

D7 VDDC

D8 A25/SCIO LOW: A25 LOW

D9 nWE3 HIGH HIGH

D10 VDDC

D11 nSCS2 HIGH HIGH

D12 D24 LOW LOW

D13 VSS

D14 D21 LOW LOW

D15 A19 LOW LOW

D16 D18 LOW LOW

E1 UARTCTS2 Input Input

E2 WAKEUP Input (Schmitt) Input

E3 BATOK Input (Schmitt) Input

E4 nPOR Input Input

E5 TDI Input with Pull-up Input with Pull-up

E6 ACIN Input Input

E7 PF2/INT2 Input: PF2 (Schmitt) No Change

E8 VSS

E9 CS6/SCKE1_2 LOW: CS6 LOW

E10 nSCS3 HIGH HIGH

E11 A24 LOW LOW

E12 D22 LOW LOW

E13 D20 LOW LOW

E14 A18 LOW LOW

E15 D17 LOW LOW

E16 A16/SB0 LOW LOW

F1 UARTTX2 HIGH HIGH

F2 nPWRFL Input (Schmitt) Input

F3 UARTDCD2 Input Input

F4 VDDC

F5 MEDCHG Input (Schmitt) Input

F6 nBATCHG Input (Schmitt) Input

20 12/8/03 Preliminary Data Sheet

Page 21

32-Bit System-on-Chip LH7A400

Table 5. 256-Ball CABGA Package Numerical Pin List

CABGA PIN SIGNAL RESET STATE STANDBY STATE

F7 VSS

F8 nWE0 HIGH HIGH

F9 VDD

F10 VDDC

F11 VDD

F12 D19 LOW LOW

F13 A17/SB1 LOW LOW

F14 VDD

F15 D16 LOW LOW

F16 A15/SA13 LOW LOW

G1 COL1 HIGH HIGH

G2 COL0 HIGH HIGH

G3 UARTRX2 Input Input

E5 UARTDSR2 Input Input

G5 UARTIRTX1 LOW LOW

G6 UARTIRRX1 Input Input

G7 VSSC

G8 VDD

G9 D13 LOW LOW

G10 A13/SA11 LOW LOW

G11 A14/SA12 LOW LOW

G12 D15 LOW LOW

G13 VSS

G14 D14 LOW LOW

G15 A12/SA10 LOW LOW

G16 D12 LOW LOW

H1 COL7 HIGH HIGH

H2 COL6 HIGH HIGH

H3 COL2 HIGH HIGH

H4 VSSC

H5 COL3 HIGH HIGH

H6 COL4 HIGH HIGH

H7 COL5 HIGH HIGH

H8 VSSC

H9 VSS

H10 A10/SA8 LOW LOW

H11 D11 LOW LOW

H12 A11/SA9 LOW LOW

H13 VDD

H14 D10 LOW LOW

H15 A9/SA7 LOW LOW

H16 D9 LOW LOW

J1 TBUZ LOW LOW

Preliminary Data Sheet 12/8/03 21

Page 22

LH7A400 32-Bit System-on-Chip

Table 5. 256-Ball CABGA Package Numerical Pin List

CABGA PIN SIGNAL RESET STATE STANDBY STATE

J2 SSPFRM/nSSPFRM Input: nSSPFRM Input

J3 SSPCLK LOW LOW

J4 VDDC

J5 PGMCLK LOW LOW

J6 SSPRX Input Input

J7 SSPTX LOW LOW

J8 VDDC

J9 VDD

J10 D8 LOW LOW

J11 A7/SA5 LOW LOW

J12 D7 LOW LOW

J13 A6/SA4 LOW LOW

J14 VSS

J15 D6 LOW LOW

J16 A8/SA6 LOW LOW

K1 PA0/LCDVD16 Input: PA0 No Change

K2 PA1/LCDVD17 Input: PA1 No Change

K3 PA2 Input No Change

K4 PA3 Input No Change

K5 PA5 Input No Change

K6 PA4 Input No Change

K7 VSS

K8 VDDC

K9 PE1/LCDVD5 Input: PE1

K10 PD1/LCDVD9 LOW: PD1

K11 D3 LOW LOW

K12 A3/SA1 LOW LOW

K13 A4/SA2 LOW LOW

K14 D5 LOW LOW

K15 VDD

K16 A5/SA3 LOW LOW

L1 PA6 Input No Change

L2 PA7 Input No Change

L3 PB0/UARTRX1 Input: PB0 No Change

L4 VSSC

L5 PB4/UARTDCD3 Input: PB4 No Change

L6 VDDC

L7 VDD

L8 VSS

L9 VSSC

L10 VSS

L11 D0 LOW LOW

L12 VSS

22 12/8/03 Preliminary Data Sheet

Page 23

32-Bit System-on-Chip LH7A400

Table 5. 256-Ball CABGA Package Numerical Pin List

CABGA PIN SIGNAL RESET STATE STANDBY STATE

L13 D1 LOW LOW

L14 D2 LOW LOW

L15 A2/SA0 LOW LOW

L16 D4 LOW LOW

M1 PB1/UARTTX3 Input: PB1 LOW if UART3 is Enabled, otherwise No Change

M2 PB2/UARTRX3 Input: PB2 No Change

M3 PB3/UARTCTS3 Input: PB3 No Change

M4 PB7/SMBCLK Input: PB7 Input if SMB is Enabled, otherwise No Change

M5 PC3/LCDREV LOW: PC3 No Change

M6 PG0/nPCOE LOW: PG0 No Change

M7 PH2/nPCSLOTE1 Input: PH2 No Change

M8 LCDVD0 LOW LOW

M9 PD0/LCDVD8 LOW: PD0

M10 VDDA

M11 VSS

M12 CLKEN LOW LOW

M13 XTAL32OUT Output Output

M14 VSS

M15 A0/nWE1 HIGH: nWE1 HIGH

M16 A1/nWE2 HIGH: nWE2 HIGH

N1 PB5/UARTDSR3 Input: PB5 No Change

N2 PB6/SWID/SMBD Input: PB6 Input if SMB is Enabled, otherwise No Change

N3 VSSC

N4 PC5/LCDCLS LOW: PC5 No Change

N5 PC7/LCDSPL LOW: PC7 No Change

N6 VDD

N7 VSSC

N8 VDD

N9 LCDDCLK LOW LOW

N10 VSSC

N11 VSSA

N12 VDD

N13 VDD

N14 XTAL32IN Input Input

N15 nCS2 HIGH HIGH

N16 nCS3/nMMSPICS HIGH: nCS3 HIGH

P1 PC0/UARTTX1 LOW: PC0 No Change

P2 PC1/LCDPS LOW: PC1 No Change

P3 PC4/LCDSPS LOW: PC4 No Change

P4 PG2/nPCIOR LOW: PG2 No Change

P5 PG5/nPCCE1 LOW: PG5 No Change

P6 PH0/PCRESET1 Input: PH0 No Change

LOW if Dual-Panel LCD is Enabled; otherwise,

No Change

Preliminary Data Sheet 12/8/03 23

Page 24

LH7A400 32-Bit System-on-Chip

Table 5. 256-Ball CABGA Package Numerical Pin List

CABGA PIN SIGNAL RESET STATE STANDBY STATE

P7 PH6/AC97RESET Input: PH6 No Change

P8 LCDVD1 LOW LOW

P9 LCDENAB/LCDM LOW: LCDENAB LOW

P10 PD2/LCDVD10 LOW: PD2 No Change

P11 VDD No Change

P12 VDDA

P13 nTEST1 Input with Pull-up Input with Pull-up

P14 nCS0 HIGH HIGH

P15 nTEST0 Input with Pull-up Input with Pull-up

P16 nCS1 HIGH HIGH

R1 PC2/LCDVDDEN LOW: PC2 No Change

R2 PC6/LCDHRLP LOW: PC6 No Change

R3 PG3/nPCIOW LOW: PG3 No Change

R4 PG6/nPCCE2 LOW: PG6 No Change

R5 VSSC

R6 PH4/nPCWAIT1 Input: PH4 No Change

R7 PH5/CFA10/PCMCIAA24/nPCWAIT2 Input: PH5 No Change

R8 LCDVD2 LOW LOW

R9 LCDLP LOW LOW

R10 PE3/LCDVD7 Input: PE3 No Change

R11 PD5/LCDVD13 LOW: PD5 No Change

R12 PD6/LCDVD14 LOW: PD6 No Change

R13 VSSA

R14 XTALIN Input Input

R15 XTALOUT LOW LOW

R16 USBDN Input Input

T1 PG1/nPCWE LOW: PG1 No Change

T2 PG4/nPCREG LOW: PG4 No Change

T3 PG7/PCDIR LOW: PG7 No Change

T4 PH1/CFA8/PCRESET2 Input: PH1 No Change

T5 PH3/CFA9/PCMCIAA25/nPCSLOTE2 Input: PH3 No Change

T6 PH7/nPCSTATRE Input: PH7 No Change

T7 LCDFP LOW LOW

T8 LCDVD3 LOW LOW

T9 PE0/LCDVD4 Input: PE0

T10 PE2/LCDVD6 Input: PE2 No Change

T11 PD3/LCDVD11 LOW: PD3 No Change

T12 PD4/LCDVD12 LOW: PD4 No Change

T13 PD7/LCDVD15 LOW: PD7 No Change

T14 WIDTH0 Input (Schmitt) Input

T15 WIDTH1 Input (Schmitt) Input

T16 USBDP Input Input

LOW if 8-bit LCD is Enabled, otherwise

No Change

24 12/8/03 Preliminary Data Sheet

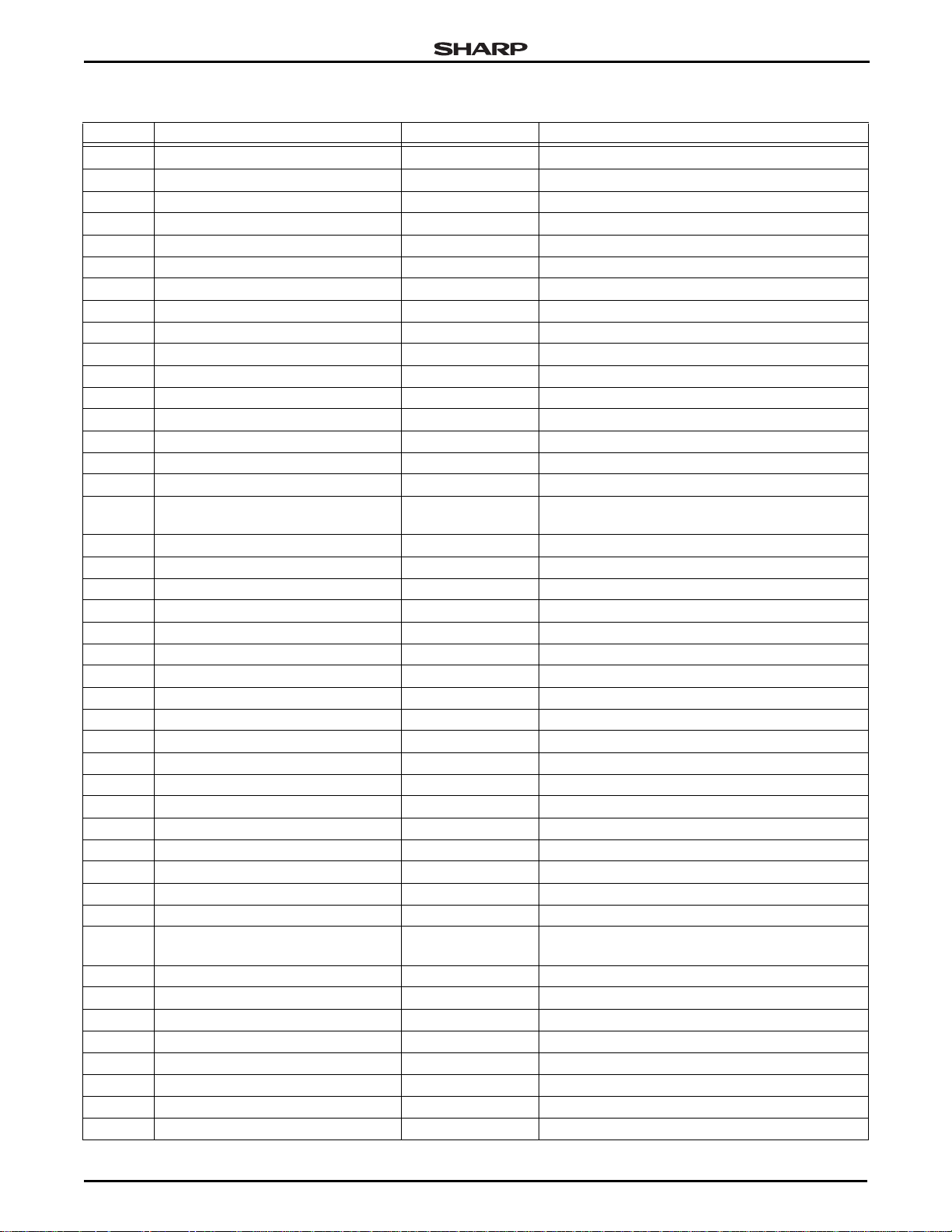

Page 25

32-Bit System-on-Chip LH7A400

TOUCH

SCREEN

CONTR.

ROM

FLASH

SRAM

SDRAM

1 2 3

4 5 6

7 8 9

*

0 #

GPIO

STN/TFT/

AD-TFT

SSP

UART

SCI

SMART

CARD

MMC

MULTIMEDIA

CARD

LH7A400

COMPACT

FLASH

PC

CARD

PCMCIA

UART

USB

Figure 2. Application Diagram

SYSTEM DESCRIPTIONS

ARM922T Processor

The LH7A400 microcontroller features the

ARM922T cached core with an Advanced High Performance Bus (AHB) interface. The processor is a member of the ARM9T family of processors. For more

information, see the ARM document, ‘ARM922T Technical Reference Manual’, available on ARM’s website

at www.arm.com.

Clock and State Controller

The clocking scheme in the LH7A400 is based

around two primary oscillator inputs. These are the

14.7456 MHz input crystal and the 32.768 kHz real time

clock oscillator. See Figure 3. The 14.7456 MHz oscillator is used to generate the main system clock

domains for the LH7A400, where as the 32.768 kHz is

used for controlling the power down operations and

real time clock peripheral. The clock and state controller provides the clock gating and frequency division

necessary, and then supplies the clocks to the processor and to the rest of the system. The amount of clock

gating that actually takes place is dependent on the

current power saving mode selected.

DMA

AC97

IR

BMI

BATTERY

CODEC

DC to DC

VOLT AGE

GENERATION

CIRCUITRY

LH7A400-3

The 32.768 kHz clock provides the source for the

Real Time Clock tree and power-down logic.This clock

is used for the power state control in the design and is

the only clock in the LH7A400 that runs permanently.

The 32.768 kHz clock is divided down to 1 Hz using a

ripple divider to save power. This generated 1 Hz clock

is used in the Real Time Clock counter.

The 14.7456 MHz source is used to generate the

main system clocks for the LH7A400. It is the source

for PLL1 and PLL2, it acts as the primary clo ck to the

peripherals and is the source clock to the Programmable clock (PGM) divider.

PLL1 provides the main clock tree for the chip, it

generates the following clocks: FCLK, HCLK and

PCLK. FCLK is the clock that drives the ARM922T

core. HCLK is the main bus (AHB) clock, as such it

clocks all memory interfaces, bus arbitrators and the

AHB peripherals. HCLK is generated by dividing FCLK

by 1, 2, 3, or 4. HCLK can be gated by the system to

enable low power operation. PCLK is the peripheral

bus (APB) clock. It is generated by dividing HCLK by

either 2, 4, or 8.

PLL2 is used to generate a fixed frequency of

48 MHz for the USB peripheral.

Preliminary Data Sheet 12/8/03 25

Page 26

LH7A400 32-Bit System-on-Chip

14.7456 MHz

MAIN OSC.

32.768 kHz

RTC OSC.

STATE CONTROLLER

DIVIDE REGISTER

HCLK

Figure 3. Clock and State Controller Block Diagram

Power Modes

The LH7A400 has three operational states: Run,

Halt, and Standby. In Run mode, all clocks are hardware-enabled and the processor is clocked. Halt mode

stops the processor clock while waiting for an event

such as a key press, but the dev ice contin ues to fu nction. Finally, Standby equates to the computer being

switched ‘off’, i.e. no display (LCD disabled) and the

main oscillator is shut down. The 32.768 kHz oscillator

operates in all three modes.

Reset Modes

There are three external signals that can generate

resets to the LH7A400; these are nPOR (power on

reset), nPWRFL (power failure) and nURESET (user

reset). If any of these are active, a system reset is generated internally. A nPOR reset performs a full system

reset. The nPWRFL and nURESET resets will perform

a full system reset except for the SDRAM refresh control, SDRAM Global Configuration, SDRAM Device

Configuration and the RTC peripheral r egisters. The

SDRAM controller will issue a self-refresh command to

external SDRAM before the system enters this reset

(the nPWRFL and nURESET resets only, not so for the

nPOR reset). This allows the system to maintain its

Real Time Clock and SDRAM contents. On coming out

of reset, the chip enters Standby mode. Once in Run

mode the PWRSR register can be interrogated to determine the nature of the reset, and the trigger source,

after which software can then take appropriate actions.

FCLK

HCLK

(TO PROCESSOR CORE)

/2, /4, /8 PCLKs

LH7A400-4

Data Paths

The data paths in the LH7A400 are:

• The AMBA AHB bus

• The AMBA APB bus

• The External Bus Interface

• The LCD AHB bus

• The DMA busses.

AMBA AHB BUS

The Advanced Microprocessor Bus Architecture

Advanced High-performance Bus (AMBA AHB) bus is a

high speed 32-bit-wide data bus. The AMBA AHB is for

high-performance, high clock frequency system modules.

Peripherals that have high bandwidth requirements

are connected to the LH7A400 core processor using

the AHB bus. These include the external and internal

memory interfaces, the LCD registers, palette RAM

and the bridge to the Advanced Peripheral Bus (APB)

interface. The APB Bridge transparently converts the

AHB access into the slower speed APB accesses. All

of the control registers for the APB peripheral s are programmed using the AHB - APB bridge interface. The

main AHB data and address lines are configured using

a multiplexed bus. This removes the need for tri-state

buffers and bus holders, and simplifies bus arbitra tio n.

26 12/8/03 Preliminary Data Sheet

Page 27

32-Bit System-on-Chip LH7A400

AMBA APB BUS

The AMBA APB bus is a lower-speed 32-bit-wide

peripheral data bus. The speed of this bus is selectable

to be a divide-by-2, divide-by-4 or divide-by-8 of the

speed of the AHB bus.

EXTERNAL BUS INTERFACE

The External Bus Interface (EBI) provides a 32-bit

wide, high speed gateway to external memory devices.

The memory devices supported include:

• Asynchronous RAM/ROM/Flash

• Synchronous DRAM/Flash

• PCMCIA interfaces

• CompactFlash interfaces.

The EBI can be controlled by either the Asynchronous memory controller or Synchronous memory controller. There is an arbiter on the EBI input, with priority

given to the Synchronous Memory Controller int erface.

LCD AHB BUS

The LCD controller has its own local memory bus

that connects it to the system’s embedded m emory and

external SDRAM. The function of this local data bus is

to allow the LCD controller to perform its video refresh

function without congesting the AHB bus. This leads to

better system performance and lower power consumption. There is an arbiter on both th e embedded memory

and the synchronous memory controller. In b oth cases

the LCD bus is given priority.

DMA BUSES

The LH7A400 has a DMA system that conn ects t he

higher speed/higher data volume APB peripherals

(MMC, USB and AC97) to the AHB bus. This enables

the efficient transfer of data between these peripherals

and external memory without the intervention of the

ARM922T core. The DMA engine d oes not support

memory to memory transfers.

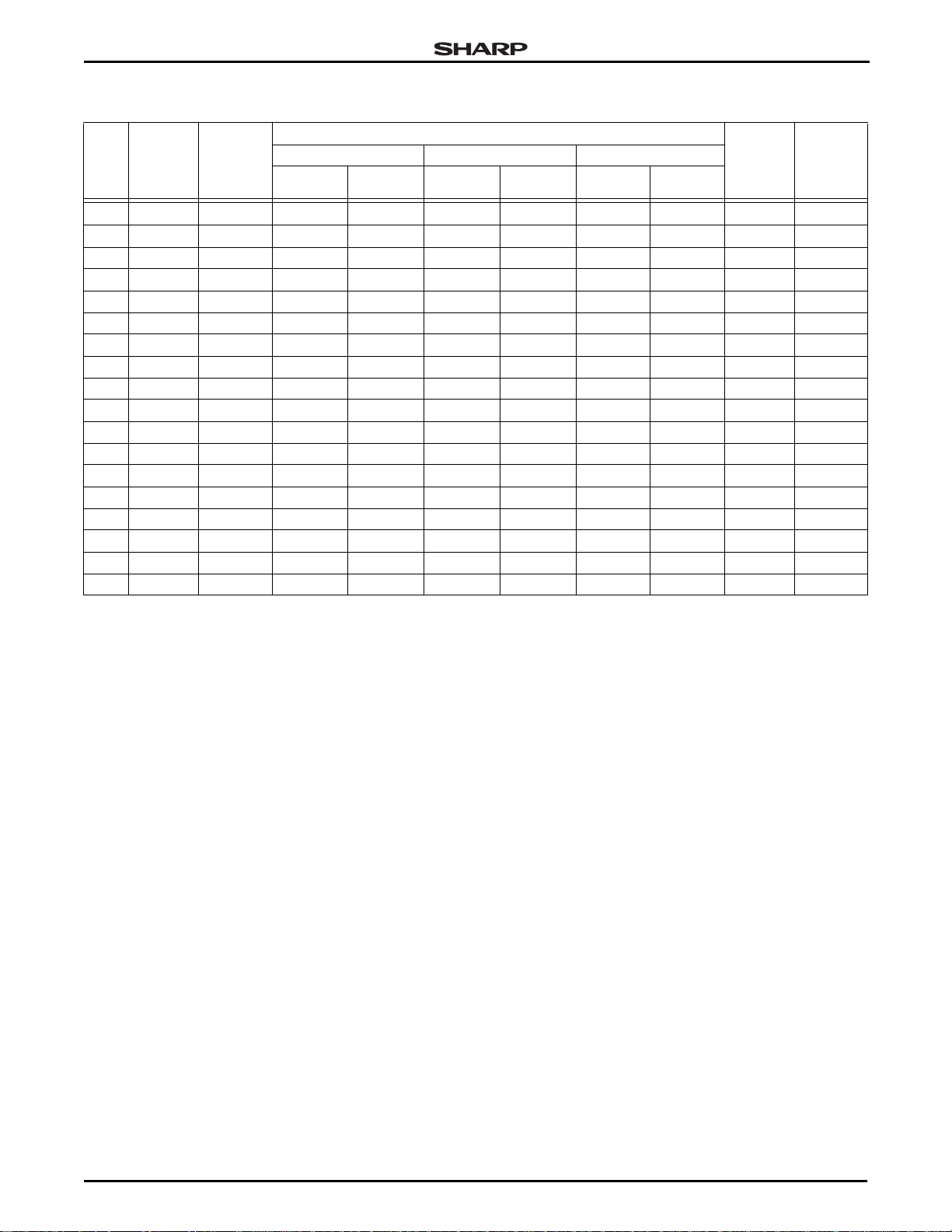

Memory Map

The LH7A400 system has a 32-bit-wide address bus.

This allows it to address up to 4GB of memory. This

memory space is subdivided into a number of memory

banks; see Figure 4. Four of these banks (each of

256MB) are allocated to the Synchronous memory controller. Eight of the banks (again, each 256MB) are allo cated to the Asynchronous memory controller. Two of

these eight banks are designed for PCMCIA systems.

Part of the remaining memory space is allocated to the

embedded SRAM, and to the control registers of the

AHB and APB. The rest is unused.

The LH7A400 can boot from either synchronous or

asynchronous ROM/Flash. The selection is determined

by the value of the MEDCHG pin at Power On Reset as

shown in Table 6. When booting from synchronous

memory, then synchronous bank 4 (nSCS3) is mapped

into memory location zero. When booting from asynchronous memory, asynchronous memory bank 0

(nSCS0) is mapped into memory location zero.

Figure 4 shows the memory map of the LH7A400

system for the two boot modes.

Once the LH7A400 has booted, the boot code can

configure the ARM922T MMU to remap the low memory space to a location in RAM. This allows the user to

set the interrupt vector table.

Table 6. Boot Modes

BOOT MODE

8-bit ROM 0 0 0

16-bit ROM 0 1 0

32-bit ROM 1 0 0

32-bit ROM 1 1 0

16-bit SFlash

(Initializes Mode Register)

16-bit SROM

(Initializes Mode Register)

32-bit SFlash

(Initializes Mode Register)

32-bit SROM

(Initializes Mode Register)

LATCHED

BOOT-

WIDTH1

0 0 1

0 1 1

1 0 1

1 1 1

LATCHED

BOOT-

WIDTH0

LATCHED

MEDCHG

Interrupt Controller

The LH7A400 interrupt controller is designed to control the interrupts from 28 different sources. Four interrupt sources are mapped to the FIQ input of the

ARM922T and 24 are mapped to the IRQ input. FIQs

have a higher priority than the IRQs. If two interrupts

with the same priority become active at the same time,

the priority must be resolved in software.

When an interrupt becomes active, the interrupt controller generates an FIQ or IRQ if the corresponding

mask bit is set. No latching of interrupts takes place in

the controller. After a Power On Reset all mask register

bits are cleared, therefore masking all interrupts.

Hence, enabling of the mask register must be done by

software after a power-on-reset.

Preliminary Data Sheet 12/8/03 27

Page 28

LH7A400 32-Bit System-on-Chip

E000.0000

D000.0000

C000.0000

B001.4000

B000.0000

8000.3800

8000.2000

8000.0000

7000.0000

6000.0000

5000.0000

4000.0000

3000.0000

2000.0000

1000.0000

0000.0000

ASYNCHRONOUS MEMORY (nCS0)F000.0000

SYNCHRONOUS MEMORY (nSCS2)

SYNCHRONOUS MEMORY (nSCS1)

SYNCHRONOUS MEMORY (nSCS0)

RESERVED

EMBEDDED SRAM

RESERVED

AHB INTERNAL REGISTERS

APB INTERNAL REGISTERS

ASYNCHRONOUS MEMORY (CS7)

ASYNCHRONOUS MEMORY (CS6)

PCMCIA/CompactFlash (nPCSLOTE2)

PCMCIA/CompactFlash (nPCSLOTE1)

ASYNCHRONOUS MEMORY (nCS3)

ASYNCHRONOUS MEMORY (nCS2)

ASYNCHRONOUS MEMORY (nCS1)

SYNCHRONOUS ROM (nSCS3)

SYNCHRONOUS MEMORY BOOT

Figure 4. Memory Mapping for Ea ch Boot Mode

SYNCHRONOUS MEMORY (nSCS3)

SYNCHRONOUS MEMORY (nSCS2)

SYNCHRONOUS MEMORY (nSCS1)

SYNCHRONOUS MEMORY (nSCS0)

RESERVED

EMBEDDED SRAM

RESERVED

AHB INTERNAL REGISTERS

APB INTERNAL REGISTERS

ASYNCHRONOUS MEMORY (CS7)

ASYNCHRONOUS MEMORY (CS6)

PCMCIA/CompactFlash (nPCSLOTE2)

PCMCIA/CompactFlash (nPCSLOTE1)

ASYNCHRONOUS MEMORY (nCS3)

ASYNCHRONOUS MEMORY (nCS2)

ASYNCHRONOUS MEMORY (nCS1)

ASYNCHRONOUS ROM (nCS0)

ASYNCHRONOUS MEMORY BOOT

256MB

256MB

256MB

256MB

80KB

256MB

256MB

256MB

256MB

256MB

256MB

256MB

256MB

LH7A400-6

External Bus Interface

The external bus interface allows the ARM922T,

LCD controller and DMA engine access to an external

memory system. The LCD controller has access to an

internal frame buffer in embedded SRAM and an extension buffer in Synchronous Memory for large displays.

The processor and DMA engine share the main system

bus, providing access to all external memory devices

and the embedded SRAM frame buffer.

An arbitration unit ensures that control over the

External Bus Interface (EBI) is only granted when an

existing access has been completed. See Figure 5.

Embedded SRAM

The amount of Embedded SRAM contained in the

LH7A400 is 80KB. This Embedded memory is designed

to be used for storing code, data, or LCD frame data

and to be contiguous with external SDRAM. The 80KB

is large enough to store a QVGA panel (320 × 240) at 8

bits per pixel, equivalent to 70KB of information.

Containing the frame buffer on chip reduces the

overall power consumed in any application that uses

the LH7A400. Normally, the system has to perform

external accesses to acquire this data. T he LCD controller is designed to automatically use an overflo w

frame buffer in SDRAM if a larger screen size is

required. This overflow buffer can be located on any

4KB page boundary in SDRAM, allowing software to

set the MMU (in the LCD controller) page tables such

that the two memory areas appear contiguous. Byte,

Half-Word and Word accesses are permissible.

Asynchronous Memory Controller

The Asynchronous memory controller is incorporated as part of the memory controller to provide an

interface between the AMBA AHB system bus and

external (off-chip) memory devices.

The Asynchronous Memory Controller prov ides support for up to eight independently configura ble memory

banks simultaneously. Each memory bank is capable

of supporting:

•SRAM

•ROM

• Flash EPROM

• Burst ROM memory.

Each memory bank may use devices using either 8-,

16-, or 32-bit external memory dat a paths. The memory

controller can be configured to support either littleendian or big-endian operation.

The memory banks can be configured to support:

• Non-burst read and write accesses only to high-

speed CMOS static RAM.

• Non-burst write accesses, nonburst read accesses

and asynchronous page mode read accesses to

fast-boot block flash memory.

28 12/8/03 Preliminary Data Sheet

Page 29

32-Bit System-on-Chip LH7A400

SDRAM

SDRAM

EXTERNAL TO

THE LH7A400

SRAM

ROM

INTERNAL TO

THE LH7A400

DATA

ADDRESS

and

CONTROL

EXTERNAL

BUS

INTERFACE

(EBI)

LCD

AHB

ASYNCHRONOUS

ARBITER

ARM922T

STATIC

MEMORY

CONTROLLER

(SMC)

PCMCIA/CF

SUPPORT

SYNCHRONOUS

DYNAMIC

MEMORY

CONTROLLER

(SDMC)

80KB

EMBEDDED

SRAM

LCD MEMORY

MANAGEMENT

UNIT (MMU)

ARBITERARBITER

ARBITER

COLOR LCD

CONTROLLER

(CLCDC)

AD-TFT

LCD TIMING

CONTROLLER

ADVANCED

HIGH-PERFORMANCE

BUS (AHB)

Figure 5. External Bus Interface Block Diagram

DMA

CONTROLLER

LH7A400-8

Preliminary Data Sheet 12/8/03 29

Page 30

LH7A400 32-Bit System-on-Chip

The Asynchronous Memory Controller has six main

functions:

• Memory bank select

• Access sequencing

• Wait states generation

• Byte lane write control

• External bus interface

• CompactFlash or PCMCIA interfacing.

Synchronous Memory Controller

The Synchronous memory controller provides a high

speed memory interface to a wide variety of Synchronous memory devices, including SDRAM, Synchronous Flash and Synchronous ROMs.

The key features of the controller are:

• LCD DMA port for high bandwidth

• Up to four Synchronous Memory banks that can be

independently set up

• Special configuration bits for Synchronous ROM

operation

• Ability to program Synchronous Flash devices using

write and erase commands

• On booting from Synchronous ROM, (and optionally

with Synchronous Flash), a configuration sequence is

performed before releasing the processor from reset

• Data is transferred between the controller and the

SDRAM in quad-word bursts. Longer transfers withi n

the same page are concatenated, forming a seamless burst

• Programmable for 16- or 32-bit data bus size

• Two reset domains are provided to enable SDRAM

contents to be preserved over a ‘soft’ reset

• Power saving Synchronous Memory SCKE and

external clock modes provided.

MultiMediaCard (MMC)

The MMC adapter combines all of the requirements

and functions of an MMC host. The adapter supports

the full MMC bus protocol, defined by the MMC Definition Group’s specification v.2.11. The controller can

also implement the SPI interface to the cards.

INTERFACE DESCRIPTION AND MMC OVERVIEW

The MMC controller uses the three-wire serial data

bus (clock, command, and data) to transfer data to and

from the MMC card, and to configure and acquire status

information from the card’s registers.

MMC bus lines can be divided into three groups:

• Power supply: VDD and VSS

• Data Transfer: MMCCMD, MMCDATA

• Clock: MMCLK.

MULTIMEDIACARD ADAPTER

The MultiMediaCard Adapter implements MultiMediaCard specific functions, serves as the bus master for the

MultiMediacard Bus and implements the standard interface to the MultiMediaCard Cards (card initialization,

CRC generation and validation, comma nd/response

transactions, etc.).

Smart Card Interface (SCI)

The SCI (ISO7816) interfaces to an external Smart

Card reader. The SCI can autonomously control data

transfer to and from the smart ca rd. Transmit and

receive data FIFOs are provided to reduce the required

interaction between the CPU core and the peripheral.

SCI FEATURES

• Supports asynchronous T0 and T1 transmission

protocols

• Supports clock rate conversion factor F = 372, with

bit rate adjustment factors D = 1, 2, or 4 supported

• Eight-character-deep buff er ed Tx an d Rx pa th s

• Direct interrupts for Tx and Rx FIFO level monitoring

• Interrupt status register

• Hardware-initiated card deactivation sequence on

detection of card removal

• Software-initiated card deactivation sequence on

transaction complete

• Limited support for synchronous Smart Cards via

registered input/output.

PROGRAMMABLE PARAMETERS

• Smart Card clock frequency

• Communication baud rate

• Protocol convention

• Card activation/deactivation time

• Check for maximum time for first character of

Answer to Reset - ATR reception

• Check for maximum duration of ATR character

stream

• Check for maximum time of receipt of first character

of data stream

• Check for maximum time allowed between characters

• Character guard time

• Block guard time

• Transmit/receive character retry.

30 12/8/03 Preliminary Data Sheet

Page 31

32-Bit System-on-Chip LH7A400

Direct Memory Access Controller (DMA)

The DMA Controller interfaces streams from the fol-

lowing three peripherals to the system memory:

• USB (1 Tx and 1 Rx DMA Channel)

• MMC (1 Tx and 1 Rx DMA Channel)

• AC97 (3 Tx and 3 Rx DMA Channels).

Each has its own bi-directional peripheral DMA bus

capable of transferring data in both directions simultaneously. All memory transfers take place via the main

system AHB bus.

DMA Specific features are:

• Independent DMA channels for Tx and Rx

• Two Buffer Descriptors per channel to avoid poten-

tial data under/over-flows due to software introduced

latency

• No Buffer wrapping

• Buffer size may be equal to, greater than or less than

the packet size. Transfers can automatically switch

between buffers.

• Maskable interrupt generation

• Internal arbitration between DMA Channels and

external bus arbiter.

• For DMA Data transfer sizes, byte, word and quad-

word data transfers are supported.

A set of control and status registers are available to

the system processor for setting up DMA operations

and monitoring their status. A system interrupt is generated when any or all of the DMA channels wish to

inform the processor that a new buffer needs to be allocated. The DMA controller services three peripherals

using ten DMA channels, each with its own peripheral

DMA bus capable of transferring data in both directions

simultaneously.

The MMC and USB peripherals each use two DMA

channels, one for transmit and one for receive. The

AC97 peripheral uses six DMA channels (three transmit and three receive) to allow different sample frequency data queues to be handled with low software

overheads. The DMA Controller does not su pport

memory to memory transfers.

USB Device

The features of the USB are:

• Fully compliant to USB 1.1 specification

• Provides a high level interface that shields the firm-

ware from USB protocol details

• Compatible with both OpenHCI and Intel’s UHCI

standards

• Supports full-speed (12 Mbps) functions

• Supports Suspend and Resume signalling.

Color LCD Controller

The LH7A400’s LCD Controller is programmable to

support up to 1,024 × 768, 16-bit color LCD panels. It

interfaces directly to STN, color STN, TFT, AD-TFT,

and HR-TFT panels. Unlike other LCD controllers, the

LH7A400’s LCD Controller incorporates the timing conversion logic from TFT to HR-TFT, allowing a direct

interface to HR-TFT and minimizing external chip count.

The Color LCD Controller features suppo rt for:

• Up to 1,024 × 768 Resolution

• 16-bit Video Bus

• STN, Color STN, AD-TFT, HR-TFT, TFT panels

• Single and Dual Scan STN panels

• Up to 15 Gray Shades

• Up to 64,000 Colors

AC97 Advanced Audio Codec Interface

The AC97 Advanced Audio Codec controller

includes a 5-pin serial interface to an ex ternal audio

codec. The AC97 LINK is a bi-directional, fixed rate,

serial Pulse Code Modulation (PCM) digital stream,

dividing each audio frame into 12 outgoing and 12

incoming data streams (slots), each with 2 0-bit sa mple

resolution.

The AC97 controller contains logic that controls the

AC97 link to the Audio Codec and an interface to the

AMBA APB.

Its main features include:

• Serial-to-parallel conversion for data received from

the external codec

• Parallel-to-serial conversion for data transmitted to

the external codec

• Reception/Transmission of control and status infor-

mation via the AMBA APB interface

• Supports up to 4 different codec sampling rates at a

time with its 4 transmit and 4 receive channels. The

transmit and receive paths are buffered with internal

FIFO memories, allowing data to be stored independently in both transmit and receive modes. The outgoing data for the FIFOs can be written via either the

APB interface or with DMA channels 1 - 3.

Preliminary Data Sheet 12/8/03 31

Page 32

LH7A400 32-Bit System-on-Chip

Audio Codec Interface (ACI)

The ACI provides:

• A digital serial interface to an off-chip 8-bit CODEC

• All the necessary clocks and timing pulses to perform serialization or de-serialization of the data

stream to or from the CODEC device.

The interface supports full duplex operation and the

transmit and receive paths are buffered with internal

FIFO memories allowing up to 16 bytes to be stored

independently in both transmit and receive modes.

The ACI includes a programmable frequency divider

that generates a common transmit and receive bit clo ck

output from the on-chip ACI clock input (ACICLK).

Transmit data values are output synchronous with the

rising edge of the bit clock output. Receive data values

are sampled on the falling edge of the bit clock output.

The start of a data frame is indicated b y a synchronization output signal that is synchronous with the bit clock.

Synchronous Serial Port (SSP)

The LH7A400 SSP is a master-only interface for

synchronous serial communication with device peripheral devices that has either Motorola SPI, National

Semiconductor MICROWIRE or Texas Instruments

Synchronous Serial Interfaces.

The LH7A400 SSP performs serial-to-parallel conversion on data received from a peripheral device. The

transmit and receive paths are buffered with internal

FIFO memories allowing up to eight 16-bit values to be

stored independently in both transmit and receive

modes. Serial data is transmitted on SSPTXD and

received on SSPRXD.

The LH7A400 SSP includes a programmab le bit rate

clock divider and prescaler to generate the serial output

clock SCLK from the input clock SSPCLK. Bit rates are

supported to 2 MHz and beyond, subject to choice of

frequency for SSPCLK; the maximum bit rate will usually be determined by peripheral devices.

UART/IrDA

The LH7A400 contains three UARTs, UART1,

UART2, and UART3.

The UART performs:

• Serial-to-Parallel conversion on data received from

the peripheral device

• Parallel-to-Serial conversion on data transmitted to

the peripheral device.

The transmit and receive paths are buffered with internal FIFO memories allowing up to 16 bytes to be stored

independently in both transmit and receive modes.

The UART can generate:

• Four individually maskable interrupts from the

receive, transmit and modem status logic blocks

• A single combined interrupt so that the output is

asserted if any of the individual interrupts are

asserted and unmasked.

If a framing, parity or break error occurs durin g

reception, the appropriate error bit is set, and is stored

in the FIFO. If an overrun condition occurs, the overrun

register bit is set immediately and the FIFO data is pr evented from being overwritten. UART1 also supports

IrDA 1.0 (15.2 kbit/s).

The modem status input signals Clear to Send

(CTS), Data Carrier Detect (DCD) and Data Set Ready

(DSR) are supported on UART2 and UART3.

Timers

Two identical timers are integrated in the LH7A400.

Each of these timers has an associated 16-bit read/write

data register and a control register. Each timer is loaded

with the value written to the data register immediately,

this value will then be decremented on the next active

clock edge to arrive after the write. When the timer

underflows, it will immediately assert its appropriate

interrupt. The timers can be read at any time. The clock

source and mode is selectable by writing to various bits

in the system control register. Clock sources are

508 kHz and 2 kHz.

Timer 3 (TC3) has the same basic operation, but is

clocked from a single 7.3728 MHz source. It has the

same register arrangement as Timer 1 and Timer 2, providing a load, value, control and clear register. Once the

timer has been enabled and is written to, unlike the

Timer 1 and Timer 2, will decrement the timer on the

next rising edge of the 7.3728 MHz clock after the data

register has been updated. All the timers can operate in

two modes, free running mode or pre-scale mode.

FREE-RUNNING MODE

In free-running mode, the timer will wrap around to

0xFFFF when it underflows and continue counting down.

PRE-SCALE MODE

In pre-scale (periodic) mode, the value written to

each timer is automatically re-loaded when the timer

underflows. This mode can be used to produce a programmable frequency to drive the bu zzer or generate a

periodic interrupt.

32 12/8/03 Preliminary Data Sheet

Page 33

32-Bit System-on-Chip LH7A400

Real Time Clock (RTC)

The RTC can be used to provide a basic alarm function or long time-base counter. This is achieved by generating an interrupt signal after counting for a

programmed number of cycles of a real-time clock

input. Counting in one second intervals is achieved by

use of a 1 Hz clock input to the RTC.

Battery Monitor Interface (BMI)

The LH7A400 BMI is a serial communication interface specified for two types of Battery Monitors/Gas

Gauges. The first type employs a single wire interface.

The second interface employs a two-wire multi-master

bus, the Smart Battery System Specification. If both

interfaces are enabled at the same time , the Single

Wire Interface will have priority. A brief overview of

these two interface types are given here.

SINGLE WIRE INTERFACE

The Single Wire Interface performs:

• Serial-to-parallel conversion on data received from

the peripheral device

• Parallel-to-serial conversion on data transmitted to

the peripheral device

• Data packet coding/decoding on data transfers

(incorporating Start/Data/Stop data packets)

The Single Wire interface uses a command-based

protocol, in which the host initiates a data transfer by

sending a WriteData/Command word to the Battery

Monitor. This word will always contain the Command

section, which tells the Single Wire Interface device the

location for the current transaction. The most significant bit of the Command deter mines if the trans action

is Read or Write. In the case of a Write transaction,

then the word will also contain a WriteData section with

the data to be written to the peripheral.

SMART BATTERY INTERFACE

The SMBus Interface performs:

• Serial-to-Parallel conversion on data received from

the peripheral device

• Parallel-to-Serial conversion of data transmitted to

the peripheral device.

The Smart Battery Interface uses a two-wire multimaster bus (the SMBus), meaning that more than one

device capable of controlling the bus can be connected

to it. A master device initiates a bus transfer and provides

the clock signals. A slave device can receive data provided by the master or it can provide data to the master.

Since more than one device may attempt to take control

of the bus as a master, SMBus provides an arbitration

mechanism, by relying on the wired-AND connection of

all SMBus interfaces to the SMBus.

DC-to-DC Converter

The features of the DC-DC Converter interface are:

• Dual drive PWM outputs, with independent closed

loop feedback

• Software programmable configuration of one of 8

output frequencies (each being a fixed divide of the

input clock).

• Software programmable configuration of duty cycle

from 0 to 15/16, in intervals of 1/16.

• Output polarity (for positive or negative voltage generation) is hardware-configured during power-o n

reset via the polarity select inputs

• Each PWM output can be dynamically switched to

one of a pair of preprogrammed frequency/duty

cycle combinations via external pins.

Watchdog Timer (WDT)

The Watchdog Timer provides hardware protection

against malfunctions. It is a programmable timer that is

reset by software at regular intervals. Failure to reset

the timer will cause a FIQ interrupt. Failure to service

the FIQ interrupt will then generate a System Reset.

The WDT features are:

• Driven by the system clock

• 16 programmable time-out per iods: 2

clock cycles

• Generates a system reset (resets LH7A400) or a

FIQ Interrupt whenever a time-out period is reached

• Software enable, lockout, and counter-reset mecha-

nisms add security against inadvertent writes

• Protection mechanism guards against

interrupt-service-failure:

– The first WDT time-out triggers FIQ and asserts

nWDFIQ status flag

– If FIQ service routine fails to clear nWDFIQ, then

the next WDT time-out triggers a System Reset.

16

through 2

31

General Purpose I/O (GPIO)

The LH7A400 GPIO has eight ports, each with a

data register and a data direction register. It also has

added registers including Keyboard Scan, PINMUX,

GPIO Interrupt Enable, INTYPE1/2, GPIOFEOI and

PGHCON.

The data direction register determines whether a

port is configured as an input or an output while the

data register is used to read the value of the GPIO pins.

The GPIO Interrupt Enable, INTYPE1/2, and GPIOFEOI registers are used to control edge-triggered

Interrupts on Port F. The PINMUX register controls

what signals are output of Port D and Port E when they