Page 1

Page 2

Page 3

LCY-W-07201 Page 1 of 29

NOTICE

This publication is the proprietary of SHARP and is copyrighted, with all rights reserved. Under the copyright laws,

no part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical

for any purpose, in whole or in part, without the express written permission of SHARP. Express written permission

is also required before any use of this publication may be made by a third party.

The application circuit examples in this publication are provided to explain the representative applications of

SHARP's devices and are not intended to guarantee any circuit design or permit any industrial property right or

other rights to be executed. SHARP takes no responsibility for any problems related to any industrial property right

or a third party resulting from the use of SHARP's devices, except for those resulting directly from device

manufacturing processes.

In the absence of confirmation by device specification sheets, SHARP takes no responsibility for any defects that

occur in equipment using any of SHARP's devices, shown in catalogs, data books, etc. Contact SHARP in order to

obtain the latest device specification sheets before using any SHARP's device.

SHARP reserves the right to make changes in the specifications, characteristics, data, materials, structures and

other contents described herein at any time without notice in order to improve design or reliability. Contact SHARP

in order to obtain the latest specification sheets before using any SHARP's device. Manufacturing locations are

also subject to change without notice.

Observe the following points when using any device in this publication. SHARP takes no responsibility for

damage caused by improper use of the devices.

The devices in this publication are designed for use in general electronic equipment designs, such as:

Personal computers Office automation Telecommunication equipment

Test and measurement equipment Industrial control Personal Digital Assistant

Audio visual and multimedia equipment Consumer electronics

The appropriate design measures should be taken to ensure reliability and safety when SHARP's devices are

used for equipment such as:

Transportation control and safety equipment(i.e. aircraft, trains, automobiles, etc.)

Traffic signals Gas leakage sensor breakers

Alarm equipment Various safety devices etc.

SHARP's devices shall not be used for equipment that requires extremely high level of reliability, such as:

Military and space applications Nuclear power control equipment

Medical equipment for life support

Contact a SHARP representative, in advance, when intending to use SHARP's devices for any "specific"

applications other than those recommended by SHARP.

Contact and consult with a SHARP representative if there are any questions about the contents of this

publication.

Page 4

1. Applicable Scope

This specification is applicable to TFT-LCD Module “LQ035Q1DH01”.

2. General Description

LCY-W-07201 Page 2 of 29

This module is a color active matrix LCD module incorporating amorphous silicon TFT (T

hin Film Transistor).

It is composed of a color TFT-LCD panel, driver IC, Input FPC, a back light unit and a touch panel.

Graphics and texts can be displayed on a 320 × RGB × 240 dots panel with about 262k colors by supplying

18bit data signals (6bit × RGB), four timing signals, 3wires 9bit serial interface signals, logic (Typ. +3.3V),

analog (Typ. +3.3V) supply voltages for TFT-LCD panel driving and supply voltage for back light.

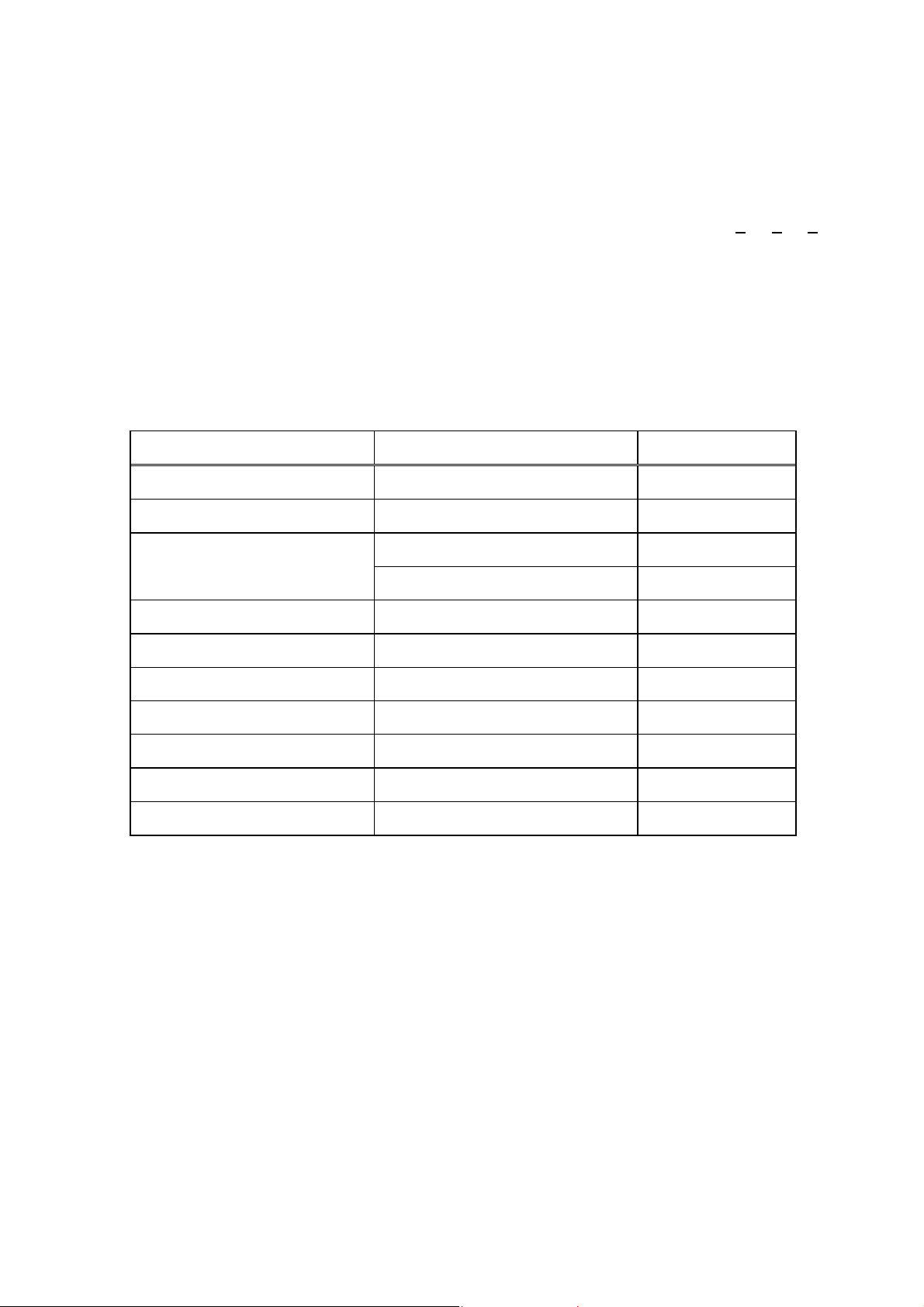

3. Mechanical (Physical) Specifications

Item Specifications Unit

Screen size 8.8 (3.5” type) diagonal cm

Active area 70.56 (H) × 52.92 (V) mm

320 (H) × 240 (V) pixel

Pixel format

1 Pixel = R+G+B dots

-

Pixel pitch 0.2205 (H) × 0.2205 (V) mm

Pixel configuration R,G,B vertical stripes -

Display mode Normally white -

Unit outline dimensions *

63.9 (W) × 76.9 (H) × 4.5 (D) mm

Mass Approx. 43 g

Surface hardness 2H -

Surface treatment Anti glare -

*The above-mentioned table indicates module sizes without some projections and FPC.

For detailed measurements and tolerances, please refer to 19. Outline Dimensions.

Page 5

LCY-W-07201 Page 3 of 29

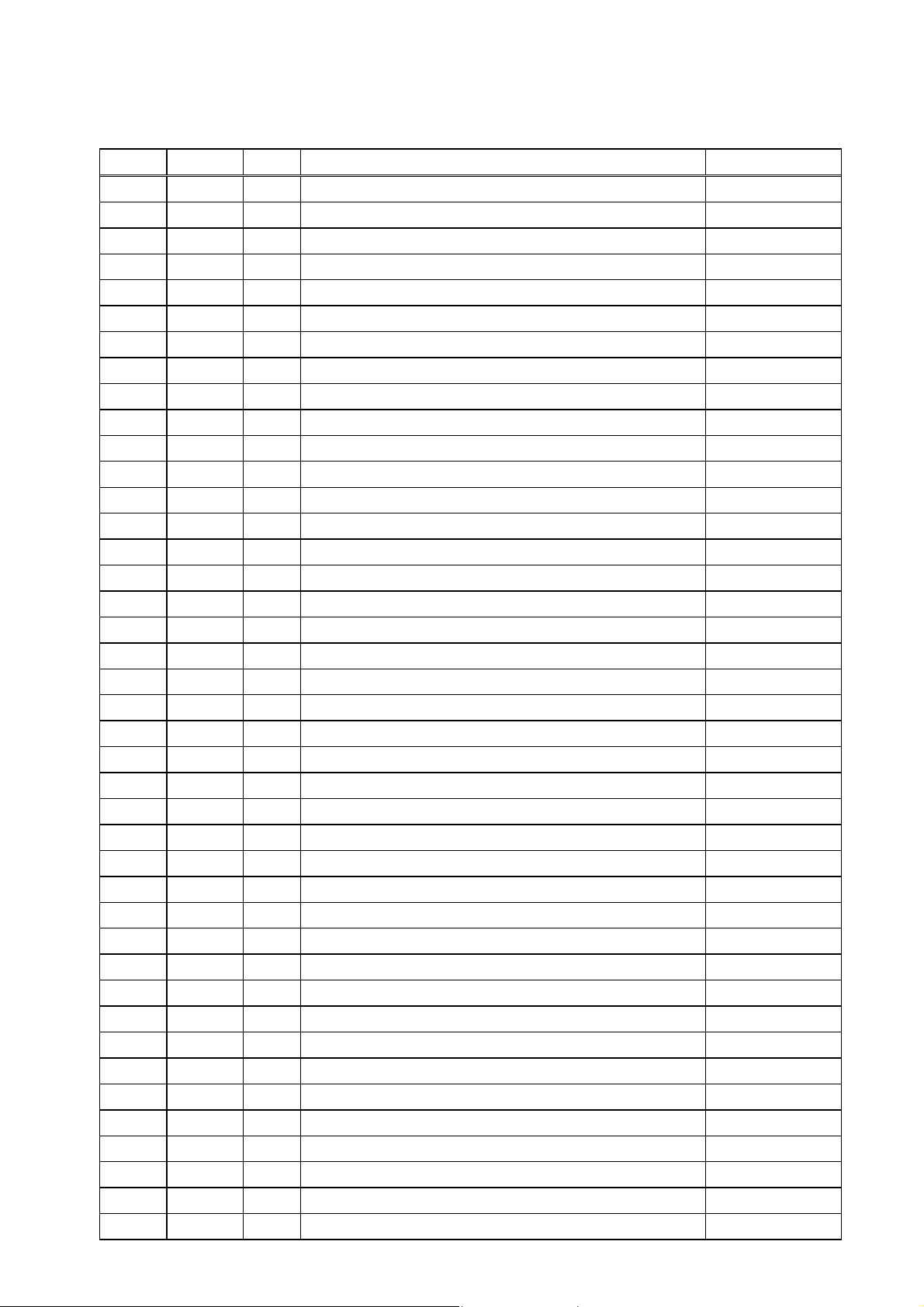

4. Input Terminal Names and Functions

Recommendation CN㧦[HIROSE] FH26G-67S-0.3SHBW(05) or [KYOCERA ELCO] 00 6281 067 2X2 829 +

Pin No. Symbol I/O Description Remarks

1 LED_C (-) - Power supply for LED (Low voltage)

2 LED_A(+) - Power supply for LED (High voltage)

3 DGND1 - Digital Ground

4 X1 O Touch Panel Right Electrode

5 Y2 O Touch Panel Bottom Electrode

6 X2 O Touch Panel Left Electrode

7 Y1 O Touch Panel Top Electrode

8 AGND1 - Analog Ground

9 VGH - Connect to a Stabilizing capacitor Note 4

10 C2P - Connect a Booster capacitor to C2N Note 3

11 C2N - Connect a Booster capacitor to C2P Note 3

12 C1P - Connect a Booster capacitor to C1N Note 3

13 C1N - Connect a Booster capacitor to C1P Note 3

14 VGL - Connect a Stabilizing capacitor to GND Note 4

15 C3P - Connect a Booster capacitor to C3N Note 3

16 C3N - Connect a Booster capacitor to C3P Note 3

17 AGND2 - Analog Ground

18 V

- Connect a Stabilizing capacitor to GND Note 4

CIX2

19 CYP - Connect a Booster capacitor to CYN Note 3

20 CYN - Connect a Booster capacitor to CYP Note 3

21 VCI - Booster input voltage pin Note 4

22 NC - Not connected Note 1

23 AGND3 - Analog Ground

24 V

- Connect a Stabilizing capacitor to GND Note 4

CIM

25 CXP - Connect a Booster capacitor to CXN Note 3

26 CXN - Connect a Booster capacitor to CXP Note 3

27 ID O MFG ID pin Note 2

28 RESB I System reset

29 DGND2 - Digital Ground

30 V

31 V

- Voltage input pin for logic I/O

DDIO

- Connect a Stabilizing capacitor to GND Note 4

CORE

32 DGND3 - Digital Ground

33 SHUT I Sleep mode control

34 CSB I Chip select pin of serial interface

35 SDI I Data input pin in serial mode

36 SCK I Clock input pin in serial mode

37 V

- Connect a Stabilizing capacitor

DROP

38 DEN I Display enable

39 B5 I BLUE data signal(MSB)

40 B4 I BLUE data signal

41 B3 I BLUE data signal

Page 6

LCY-W-07201 Page 4 of 29

Pin No. Symbol I/O Description Remarks

42 B2 I BLUE data signal

43 B1 I BLUE data signal

44 B0 I BLUE data signal(LSB)

45 G5 I GREEN data signal(MSB)

46 G4 I GREEN data signal

47 G3 I GREEN data signal

48 G2 I GREEN data signal

49 G1 I GREEN data signal

50 G0 I GREEN data signal(LSB)

51 R5 I RED data signal(MSB)

52 R4 I RED data signal

53 R3 I RED data signal

54 R2 I RED data signal

55 R1 I RED data signal

56 R0 I RED data signal(LSB)

57 VSYNC I Frame synchronization signal

58 HSYNC I Line synchronization signal

59 DOTCLK I Dot-clock signal

60 CDUM0 - Connect a Stabilizing capacitor to GND Note 4

61 DGND4 - Digital Ground

62 V

63 V

64 V

- Connect a Stabilizing capacitor to GND Note 4

LCD63

- Connect a Stabilizing capacitor to GND Note 4

COMH

- Connect a Stabilizing capacitor to GND Note 4

COML

65 DGND5 - Digital Ground

66 CSVCMP - Connect a Stabilizing capacitor to CSVCMN Note 4

67 CSVCMN - Connect a Stabilizing capacitor to CSVCMP Note 4

Note 1) this pin should be opened.

Note 2) ID is connected to V

via FPC.

DDIO

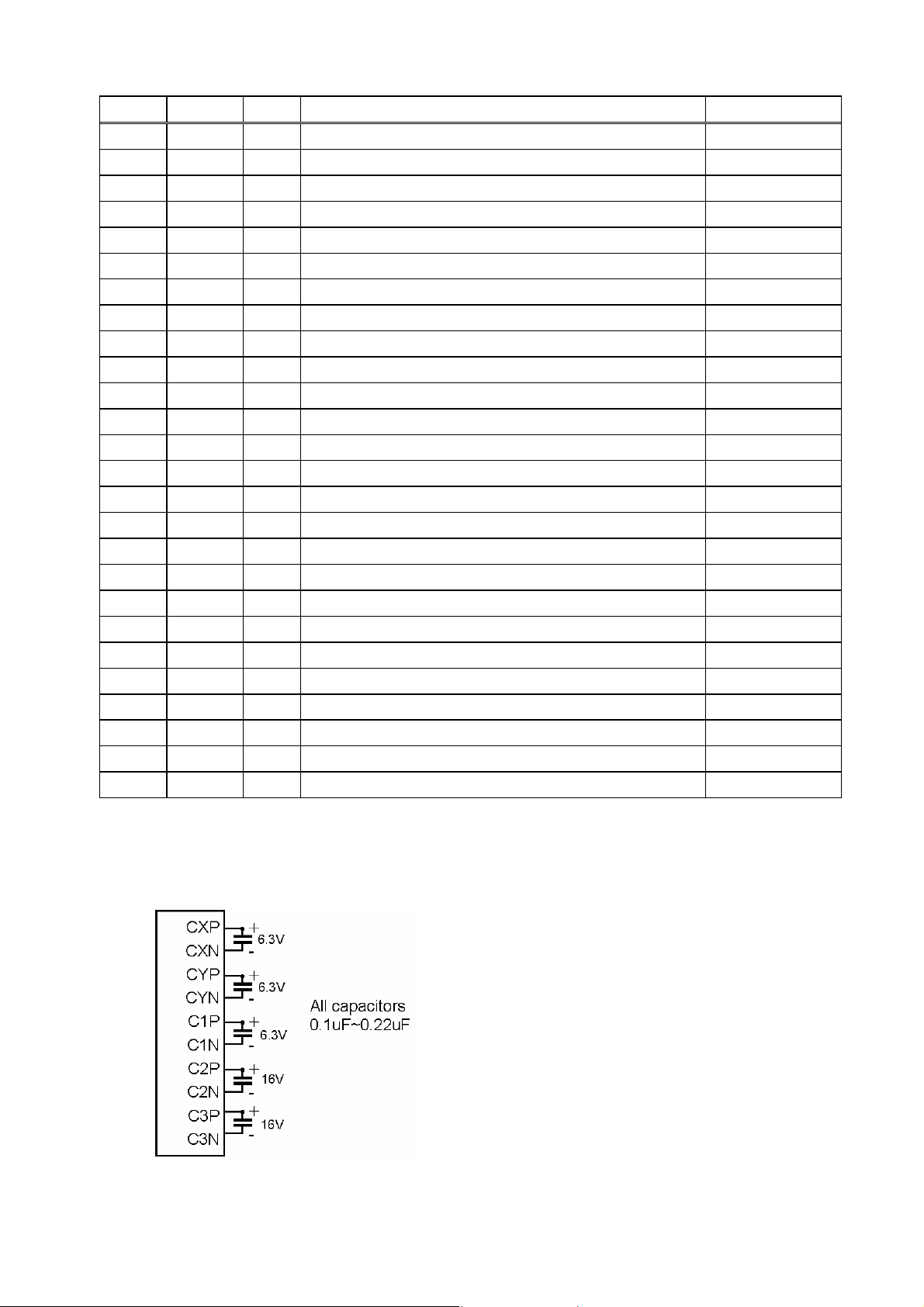

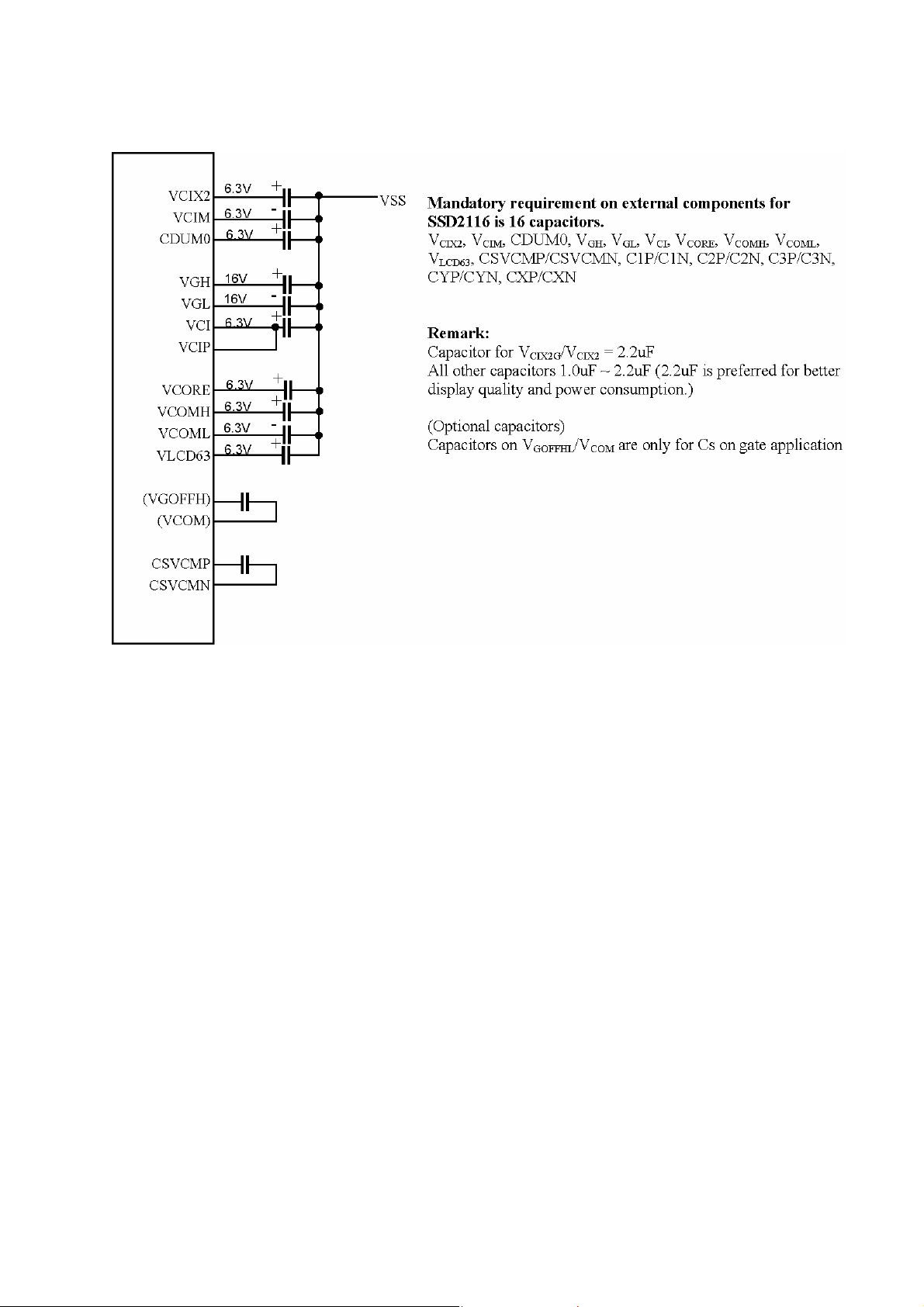

Note 3) Booster Capacitors

Page 7

Note 4) Stabilization and charge sharing Capacitors

LCY-W-07201 Page 5 of 29

Page 8

5. Absolute Maximum Ratings

LCY-W-07201 Page 6 of 29

Item Symbol

Input voltage

Logic I/O power supply voltage

Analog power supply voltage

Temperature for storage

Temperature for operation

LED input electric current

LED electricity consumption

V

V

Tstg - -30 ~ +85

Topr - -10 ~ +70

I

P

Conditions Rated value

VI

DDIO

CI

LED

LED

Ta = 25qC

Ta = 25qC

Ta = 25qC

Ta = 25qC

Ta = 25qC

-0.3 ~ V

AGND-0.3 ~ +5.0

+0.3

DDIO

-0.3 ~ +4.0

35

123

Unit Remarks

V

Note 1

V

V

q

C

q

C

Note 2

Note 3

mA

mW

Note 1) RESB, SHUT, CSB, SDI, SCK, DEN, B5~B0, G5~G0, R5~R0, VSYNC, HSYNC, DOTCLK

Note 2) Humidity: 80%RH Max. (Ta҇40qC)

Maximum bulb temperature under 39qC (Ta>40qC) See to it that no dew will be condensed.

Note 3) Panel surface temperature prescribes.

(Reliability is examined at ambient temperature of 50qC.)

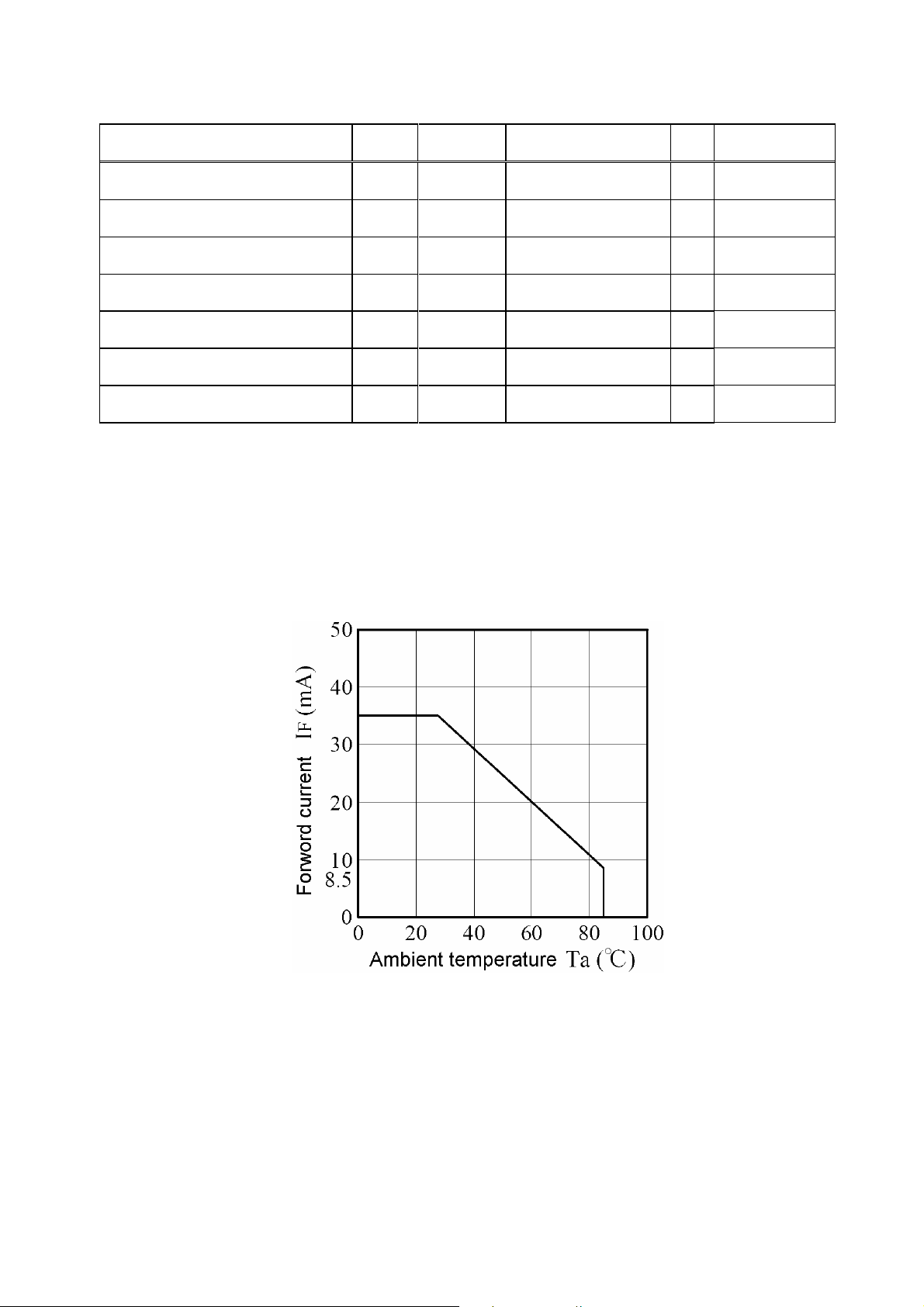

Note 4) Power consumption of one LED (Ta = 25qC). (use 7 pieces LED)

Ambient temperature and the maximum input are fulfilling the following operating conditions.

Ambient temperature and the maximum input

Page 9

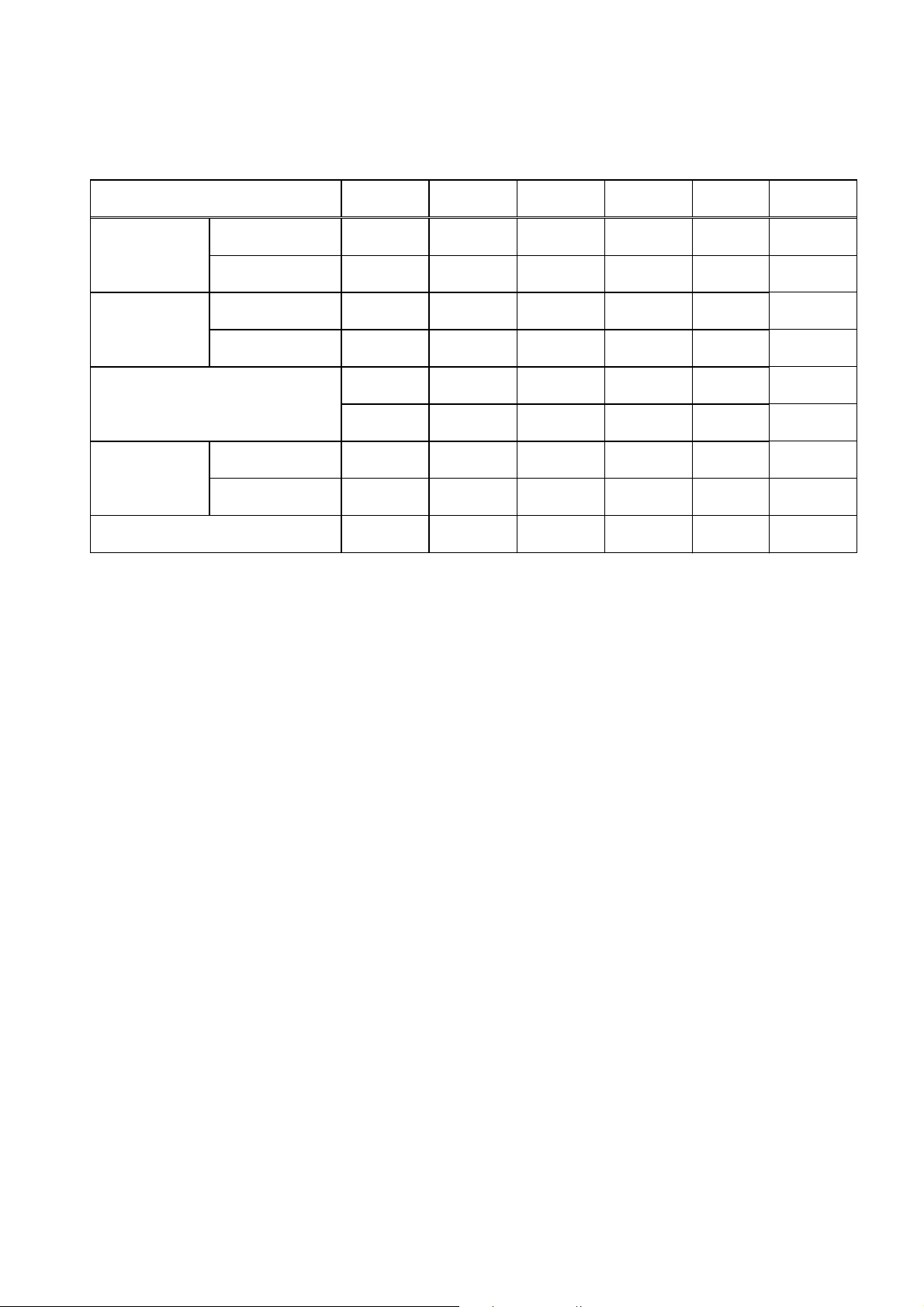

6. Electrical Characteristics

6-1. TFT LCD Panel Driving

LCY-W-07201 Page 7 of 29

Ta = 25qC

Item Symbol

Logic I/O

power supply

Analog

power supply

DC voltage

DC Current

DC voltage

DC Current

Permissive input

Ripple voltage

Logic

Input Voltage

High

Low

Logic input Current IIH / IIL -1 - 1

Note 1) V

= VCI = +3.3V

DDIO

Current situation for I

Current situation for I

Min. Typ. Max.

+2.5 +3.3 +3.6

V

DDIO

- 0.35 0.50

I

VDDIO

V

CI

I

VCI

V

RFVDDIO

V

RFVCI

V

IH

V

IL

: Black & White checker flag pattern

VDDIO

: All black pattern

CI

+2.5 or V

DDIO

- 8.5 12.0

- - (100)

- - (100)

0.8 V

DDIO

0 - 0.2 V

+3.3 +3.6

mVp-p

mVp-p

- V

DDIO

DDIO

Unit Remarks

V

mA

Note 1

V

mA

Note 1

Note 2

Note 2

V

V

μA

Note 3

Note 3

Note 3

Note 2) V

= VCI = +3.3V

DDIO

Note 3) RESB, SHUT, CSB, SDI, SCK, DEN, B5~B0, G5~G0, R5~R0, VSYNC, HSYNC, DOTCLK

Page 10

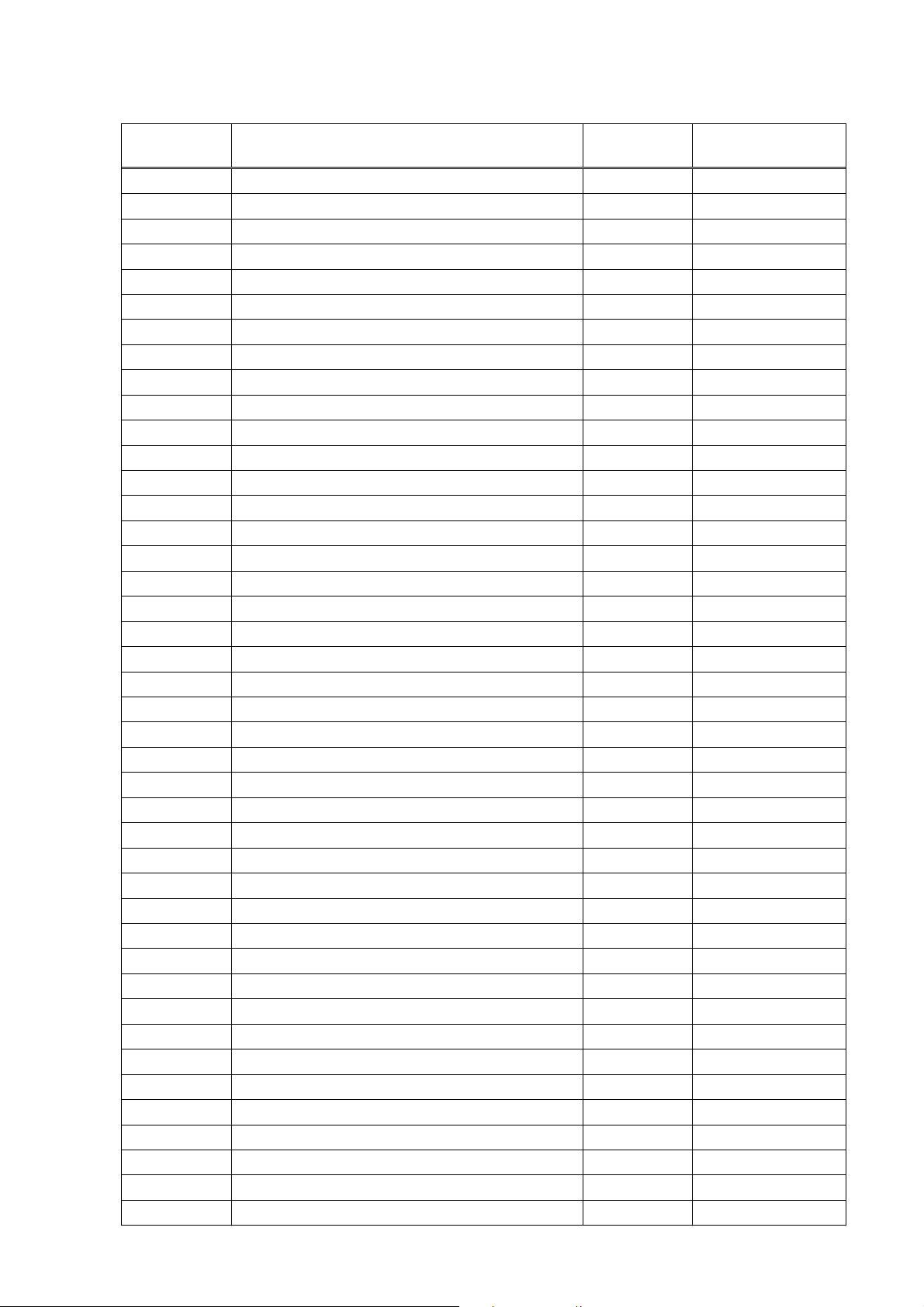

6-2. Register Setting

Reg. # Register

R01 h Driver output control 2AEF h

R02 h LCD drive AC control 0300 h

R03 h Power control (1) 7A7E h

R0B h Frame cycle control DC00 h

R0C h Power control (2) 0005 h

R0D h Power control (3) 0002 h

R0E h Power control (4) 2900 h

R0F h Gate scan starting Position 0000 h

R16 h Horizontal Porch 9F86 h Note1

R17 h Vertical Porch 0002 h Note2

R1E h Power control (5) 0000 h

R2E h 3 Gamma B945 h

R30 h Gamma control (1) 0000 h

R31 h Gamma control (1) 0707 h

R32 h Gamma control (1) 0003 h

R33 h Gamma control (1) 0401 h

R34 h Gamma control (1) 0307 h

R35 h Gamma control (1) 0000 h

R36 h Gamma control (1) 0707 h

R37 h Gamma control (1) 0204 h

R3A h Gamma control (2) 0D0B h

R3B h Gamma control (2) 0D0B h

R40 h Gamma control (3) 0000 h

R41 h Gamma control (3) 0707 h

R42 h Gamma control (3) 0003 h

R43 h Gamma control (3) 0401 h

R44 h Gamma control (3) 0307 h

R45 h Gamma control (3) 0000 h

R46 h Gamma control (3) 0707 h

R47 h Gamma control (3) 0204 h

R4A h Gamma control (4) 0D0B h

R4B h Gamma control (4) 0D0B h

R50 h Gamma control (5) 0000 h

R51 h Gamma control (5) 0707 h

R52 h Gamma control (5) 0003 h

R53 h Gamma control (5) 0401 h

R54 h Gamma control (5) 0307 h

R55 h Gamma control (5) 0000 h

R56 h Gamma control (5) 0707 h

R57 h Gamma control (5) 0204 h

R5A h Gamma control (6) 0D0B h

R5B h Gamma control (6) 0D0B h

LCY-W-07201 Page 8 of 29

Data

(Gamma 2.2)

Remark

Page 11

Note 1)

LCY-W-07201 Page 9 of 29

Page 12

Note 2)

LCY-W-07201 Page 10 of 29

6-3. Back light driving

The back light system has 7 LEDs

[NSSW020B]

Parameter Symbol Min. Typ. Max. Unit Remark

Rated Voltage

Rated Current

V

BL

I

L

- 22.4 24.5 V

- 20 - mA

Ta=25qC

Power consumption WL - 448 - mW

Page 13

7. Timing characteristics of input signals

7-1. Pixel Clock Timing

LCY-W-07201 Page 11 of 29

Pixel Clock Timing

Page 14

7-2. Data Transaction Timing in Normal Operating Mode (262k color)

LCY-W-07201 Page 12 of 29

Page 15

7-3. Synchronization Signals Timing in Power Save Mode (8 color)

LCY-W-07201 Page 13 of 29

Page 16

7-4. VGH Output against SHUT & RESB

LCY-W-07201 Page 14 of 29

Page 17

7-5. Power Up Sequence

LCY-W-07201 Page 15 of 29

Page 18

7-6. Power Down Sequence

LCY-W-07201 Page 16 of 29

Page 19

7-7. SPI Interface Timing Diagram & Transaction Example (9 bit)

LCY-W-07201 Page 17 of 29

Page 20

7-8. Input Data Signals and Display Position on the screen

LCY-W-07201 Page 18 of 29

Please refer to Input Terminal Names and Functions

Page 21

LCY-W-07201 Page 19 of 29

8. Input Signals, Basic Display Colors and Gray Scale of Each Color

㩷 Colors &

Gray Gray R0 R1 R2 R3 R4 R5 G0 G1 G2 G3 G4 G5 B0 B1 B2 B3 B4 B5

㩷 Scale Scale LSB MSB LSB MSB LSB MSB

Date signal

Black

Blue

Basic Color

Green

Cyan

Red

Magenta

Yellow

White

Black GS0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Gray Scale of Red

×

Darker

×

Ø

Brighter

Ø

Red GS63 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0

㧙

㧙

㧙

㧙

㧙

㧙

㧙

㧙

GS1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

GS2 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

ÈÈ È È

ÈÈ È È

GS61 1 0 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0

GS62 0 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1

0 0 0 0 0 0 1 1 1 1 1 1 0 0 0 0 0 0

0 0 0 0 0 0 1 1 1 1 1 1 1 1 1 1 1 1

1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0

1 1 1 1 1 1 0 0 0 0 0 0 1 1 1 1 1 1

1 1 1 1 1 1 1 1 1 1 1 1 0 0 0 0 0 0

1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

Black GS0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Gray Scale of Green

×

Darker

×

Ø

Brighter

Ø

Green GS63 0 0 0 0 0 0 1 1 1 1 1 1 0 0 0 0 0 0

Black GS0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Gray Scale of Blue

×

Darker

×

Ø

Brighter

Ø

Blue GS63 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1

GS1 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0

GS2 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0

ÈÈ È È

ÈÈ È È

GS61 0 0 0 0 0 0 1 0 1 1 1 1 0 0 0 0 0 0

GS62 0 0 0 0 0 0 0 1 1 1 1 1 0 0 0 0 0 0

GS1 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0

GS2 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0

ÈÈ È È

ÈÈ È È

GS61 0 0 0 0 0 0 0 0 0 0 0 0 1 0 1 1 1 1

GS62 0 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1

0: Low level voltage, 1: High level voltage

Each basic color can be displayed in 64 gray scales from 6 bit data signals.

According to the combination of 18 bit data signals, the 262k color display can be achieved on the screen.

Page 22

9. Optical Characteristics

LCY-W-07201 Page 20 of 29

Ta = 25qC, V

= +3.3V, VCI = +3.3V

DDIO

Parameter Symbol Condition Min. Typ. Max. Unit Remark

Viewing

angle

range

(Without

Wide View)

Horizontal

Vertical

ș21 - 45 - deg.

ș22 - 45 -

CR㧪10

ș11 - 20 -

ș12

- 55 -

deg.

deg.

deg.

ޣNote1,4ޤ

Optimum

Contrast ratio CR

viewing

100 300 -

ޣNote2,4ޤ

angle

Response Rise IJr - 30 45 ms

Time Decay IJ

ș=0°

d

- 30 45 ms

ޣNote3,4ޤ

x 0.26 0.31 0.36 Chromaticity of

2

ޣNote4ޤ

I

=20mA

LED

ޣNote6ޤ

ޣNote5ޤ

White

Luminance of white X

y 0.29 0.34 0.39

300 400 - cd/m

L1

Uniformity U 70 80 %

* The optical characteristics measurements are operated under a stable luminescence

= 20mA) and a dark condition. (Refer to Fig.9-1)

(I

LED

Photodetector(SR-3:TOPCON)

Field=2°

TFT-LCD module

Center of the screen

400mm

LCD panel

Fig.9-1 Optical characteristics measurement method

Page 23

ޣ

Note 1 ޤDefinitions of viewing angle range

ș

22

ș

12

6 o’clock

ޣ

Note 2 ޤDefinition of contrast ratio

The contrast ratio is defined as the following

(CR)ratioontrastC

Normal line

LCY-W-07201 Page 21 of 29

ș

11

ș

21

whitepixelsall withs)(brightnesLuminance

blackpixelsall withs)(brightnesLuminance

ޣ Note 3 ޤDefinition of response time

The response time is defined as the following figure and shall be measured

by switching the input signal for “Black” and “White”

White White

Photo detector output

(Relative value)

Black

Time

ޣ Note 4 ޤThis shall be measured at center of the screen.

Black

Page 24

ޣ

Note 5 ޤDefinition of Uniformity

LCY-W-07201 Page 22 of 29

1/6

Uniformity

BrightnessMinimum

BrightnessMaximum

The brightness should be measured on the

9-point as shown in the right figure.

ޣ

Note 6 ޤThis shall be measured

as shown in the right figure.

on the 9-point

= whiteofLuminance

(%)100u

1/6

Brightnesspoint-9theofSummation

9

Page 25

LCY-W-07201 Page 23 of 29

10. Touch panel characteristics

Parameter Min. Typ. Max. Unit Remark

Input voltage - 5.0 7.0 V

Resistor between terminals(XL-XR) 260 615 1,200 ȍ

Resistor between terminals(YU-YD) 160 400 800 ȍ

Line linearity(X direction) - - 1.5 %

Line linearity(Y direction) - - 1.5 %

Insuration resistance 20 - - Mȍ at DC25V

Minimum tension for detecting - - 0.8 N

Provisional

specification

Note) For use of finger input

11. Handling of modules

11-1. Inserting the FPC into its connector and pulling it out

1) Be sure to turn off the power supply and the signals when inserting or disconnecting the cable.

2) Please insert for too much stress not to join FPC in the case of insertion of FPC.

11-2. About handling of FPC

1) The bending radius of the FPC should be more than 1.4mm, and it should be bent evenly.

2) Do not dangle the LCD module by holding the FPC, or do not give any stress to it.

11-3. Mounting of the module

1) The module should be held on to the plain surface. Do not give any warping or twisting stress to

the module.

2) Please consider that GND can ground a modular metal portion etc. so that static electricity is not

charged to a module.

3) Design guidance for touch panel (T/P)

a) Example of housing design

(1) If a consumer will put a palm on housing in normal usage, care should be taken as follows.

(2) Keep the gap, for example 0.3 to 0.7mm, between bezel edge and T/P surface.

The reason is to avoid the bezel edge from contacting T/P surface that may cause a “short”

with bottom layer. (See Fig.11-3-1)

(3) Insertion a cushion material is recommended.

(4) The cushion material should be limited just on the busbar insulation paste area.

If it is over the transparent insulation paste area, a ”short” may be occurred.

(5) There is one where a resistance film is left in the T/P part of the end of the pole.

Design to keep insulation from the perimeter to prevent from mis-operation and so on.

Page 26

LCY-W-07201 Page 24 of 29

b) Mounting on display and housing bezel

(1) In all cases, the T/P should be supported from the backside of the Plastic.

(2) Do not to use an adhesive-tape to bond it on the front of T/P and hang it to the housing bezel.

(3) Never expand the T/P top layer (PET-film) like a balloon by internal air pressure.

The life of the T/P will be extremely short.

(4) Top layer, PET, dimension is changing with environmental temperature and humidity.

Avoid a stress from housing bezel to top layer, because it may cause “waving”.

(5) The input to the touch panel sometimes distorts touch panel itself.

Housing

Cushion material

(=Cushion Area)

PET Film

Insulation metal

Transparent

Insulation Paste

Glass

Key Area

Prohibition Area

Fig.11-3-1

Electrode

0.3 to 0.7mm

Layer

11-4. Cautions in assembly / Handling pre cautions

As the polarizer can be easily scratched, be most careful in handling it.

1) Work environments in assembly.

Working under the following environments is desirable:

a) Implement more than 1Mȍ conductive treatment (by placing a conductive mat or applying conductive

paint) on the floor or tiles.

b) No dusts come in to the working room. Place an adhesive, anti-dust mat at the entrance of the room.

c) Humidity of 50 to 70% and temperature of 15 to 27qC are desirable.

d) All workers wear conductive shoes, conductive clothes, conductive fingerstalls and grounding belts

without fail.

e) Use a blower for electrostatic removal. Set it in a direction slightly tilt downward so that each Module

can be well subjected to its wind. Set the blower at an optimum distance between the blower and the

module.

2) How the remove dust on the polarizer

a) Blow out dust by the use of an N2 blower with antistatic measures taken. Use of an ionized air Gun is

recommendable.

b) When the panel surface is soiled, wipe it with soft cloth.

3) In the case of the module’s metal part (shield case) is stained, wipe it with a piece of dry, soft cloth.

If rather difficult, give a breath on the metal part to clean better.

Page 27

LCY-W-07201 Page 25 of 29

4) If water dropped, etc. remains stuck on the polarizer for a long time, it is apt to get discolored or cause

stains. Wipe it immediately.

5) As a glass substrate is used for the TFT-LCD panel, if it is dropped on the floor or hit by something hard,

it may be broken or chipped off.

6) Since CMOS LSI is used in this module, take care of static electricity and take the human earth into

consideration when handling.

11-5. Others

1) Regarding storage of LCD modules, avoid storing them at direct sunlight-situation.

You are requested to store under the following conditions:

(Environmental conditions of temperature/humidity for storage)

a) Temperature: 0 to 40qC

b) Relative humidity : 95% or less

As average values of environments (temperature and humidity) for storing, use the following control

guidelines:

Summer season: 20 to 35qC, 85㧑 or less Winter season: 5 to 15qC, 85㧑 or less

If stored under the conditions of 40qC and 95% RH, cumulative time of storage must be less than 240

hours.

2) If stored at temperatures below the rated values, the inner liquid crystal may freeze, causing cell

destruction. At temperatures exceeding the rated values for storage, the liquid crystal may become

isotropic liquid, making it no longer possible to come back to its original state in some cases.

3) If the LCD is broken, do not drink liquid crystal in the mouth. If the liquid crystal adheres to a hand or

foot or to clothes, immediately cleanse it with soap.

4) If a water drop or dust adheres to the polarizer, it is apt to cause deterioration. Wipe it immediately.

5) Be sure to observe other caution items for ordinary electronic parts and components.

6) If local pressure joins T/P surface for a long time, it will become the cause of generating of Newton’s

ring.

Page 28

LCY-W-07201 Page 26 of 29

12. Reliability test items

No. Test item Conditions

High temperature storage test

1

Low temperature storage test

2

High temperature

3

& high humidity operation test

4 High temperature operation test

5 Low temperature operation test

Ta = 85qC 240h

Ta = -30qC 240h

Ta = 40qC ; 95%RH 240h

(No condensation)

Ta = 70qC 240h

(The panel temp. must be less than 50qC)

Ta = -10qC 240h

Frequency range: 10 to 55Hz

Vibration test

6

(non- operating)

Stroke: 1.5mm

Sweep time: 1minutes

Test period: 2 hours for each direction of X,Y,Z

7 Shock test

8 Thermal shock test

Point activation test

9

(Touch panel)

10

Electro static discharge test

Direction: ±X, ±Y, ±Z, Time: Third for each direction.

Impact value: 980m/s², Action time 6ms

Ta=-10qC to 70qC /10 cycles

(30 min) (30min)

Hit it 100,000 times with a silicon rubber.

Hitting force : 2.4 N

Hitting speed : 2 times per second

s

200Vy200pF(0

ȍ) to Terminals(Contact)

(1 time for each terminals)

r

4kV150pF(330

r

8kV150pF(330

ȍ) to Housing bezel or T/P(Contact)

ȍ) to Housing bezel or T/P(in Air)

ޣ

NoteޤTa = Ambient temperature, Tp = Panel temperature

ޣ

Check items

ޤ

(a)Test No.1 to No.8

In the standard condition, there shall be no practical problems that may affect the display function.

(b)Test No.9

The measurements after the tests are satisfied “10 Touch panel characteristics”.

13. Display Grade

The standard regarding the grade of color LCD displaying modules should be based on the delivery

inspection standard.

14. Delivery Form

14-1. Carton storage conditions

1) Carton piling-up: Max 8 rows

2) Environments

Temperature: 0㨪40°C

Humidity: 65% RH or less (at 40°C)

There should be no dew condensation even at a low temperature and high humidity.

3) Packing form: As shown in 16. LCD module packing carton

Cartons are weak against damp, and they are apt to be smashed easily due to the compressive

pressure applied when piled up. The above environmental conditions of temperature and humidity are

set in consideration of reasonable pile-up for storage.

Page 29

LCY-W-07201 Page 27 of 29

14-2. Packing composition

Name quantity Note

Carton size 1 575×360×225 (mm)

Tray 12 Material: Electrification prevention polypropylene

(The number of Module) 120 12 unit/tray: 120 unit/carton

Electrification prevention bag

2

Material: Electrification prevention polyethylene

680mm(length)×500mm(depth)×50μm(thin)

Carton weight (120 modules): Approx. 9.8kg

15. Lot No. marking

The lot No. will be indicated on individual labels. The location is as shown

Indication Label

LQ035Q1DH01٤ ٤٤٤٤٤٤٤٤٤ ٤

Processing place code (Q, L, etc.)

Model No + Parts code (A~H)

16. LCD module packing carton

Lot No = Production year(07~) + mouth(A~L) + Serial No(000001~)

Page 30

LCY-W-07201 Page 28 of 29

17. Others

1 Disassembling the module can cause permanent damage and you should be strictly avoided.

2 Please be careful that you don’t keep the screen displayed fixed pattern image for a long time,

since retention may occur.

3 If you pressed down a liquid crystal display screen with your finger and so on, the alignment disorder

of liquid crystal will occur. And then It will become display fault.

Therefore, be careful not to touch the screen directly, and to consider not stressing to it.

4 If any problem arises regarding the items mentioned in this specification sheet or otherwise, it should be

discussed and settled mutually in a good faith for remedy and/or improvement.

18. Sticking position of insulated tape in Soldering area

Page 31

Loading...

Loading...