Page 1

TopPage

LCD KIT

SERVICE MANUAL

No.S83M276070G9T

LED BACKLIGHT TV

MODEL :

LC-60G9T

LC-70G9T

In the interests of user-safety (Required by safety regula tions in some countries) the set should be restored to its original condition and only parts identical to those specified should be used.

CONTENTS

SAFETY PRECAUTION

IMPORTANT SERVICE SAFETY

PRECAUTION................................................i

PRECAUTION FOR USING LEED-FREE

SOLDER.........................................................ii

OUTLINE

[1] OUTLINE...........................................iii

CHAPTER 5. ADJUSTMENT

[1] ADJUSTMENT....................................5-1

CHAPTER 6. TROUBLESHOOTING TABLE

[1] TROUBLESHOOTING T ABLE .... ............ .........6 -1

CHAPTER 7. MAJOR IC INFORMATIONS

[1] MAJOR IC INFORMATION......................... 7-1

CHAPTER 1. SPECIFICATIONS

[1] SPECIFICA TION.................................1-1

CHAPTER 2. OPERATION MANUAL

[1] OPERATION MANUAL ..................2-1

CHAPTER 3.DIMENSIONS

[1] DIMENSIONS ...............................................3-1

CHAPTER 4. REMOVING OF MAJOR PARTS

[1] REMOVING OF MAJOR PARTS...........4-1

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with specified ones for maintaining the

safety and performance of the set.

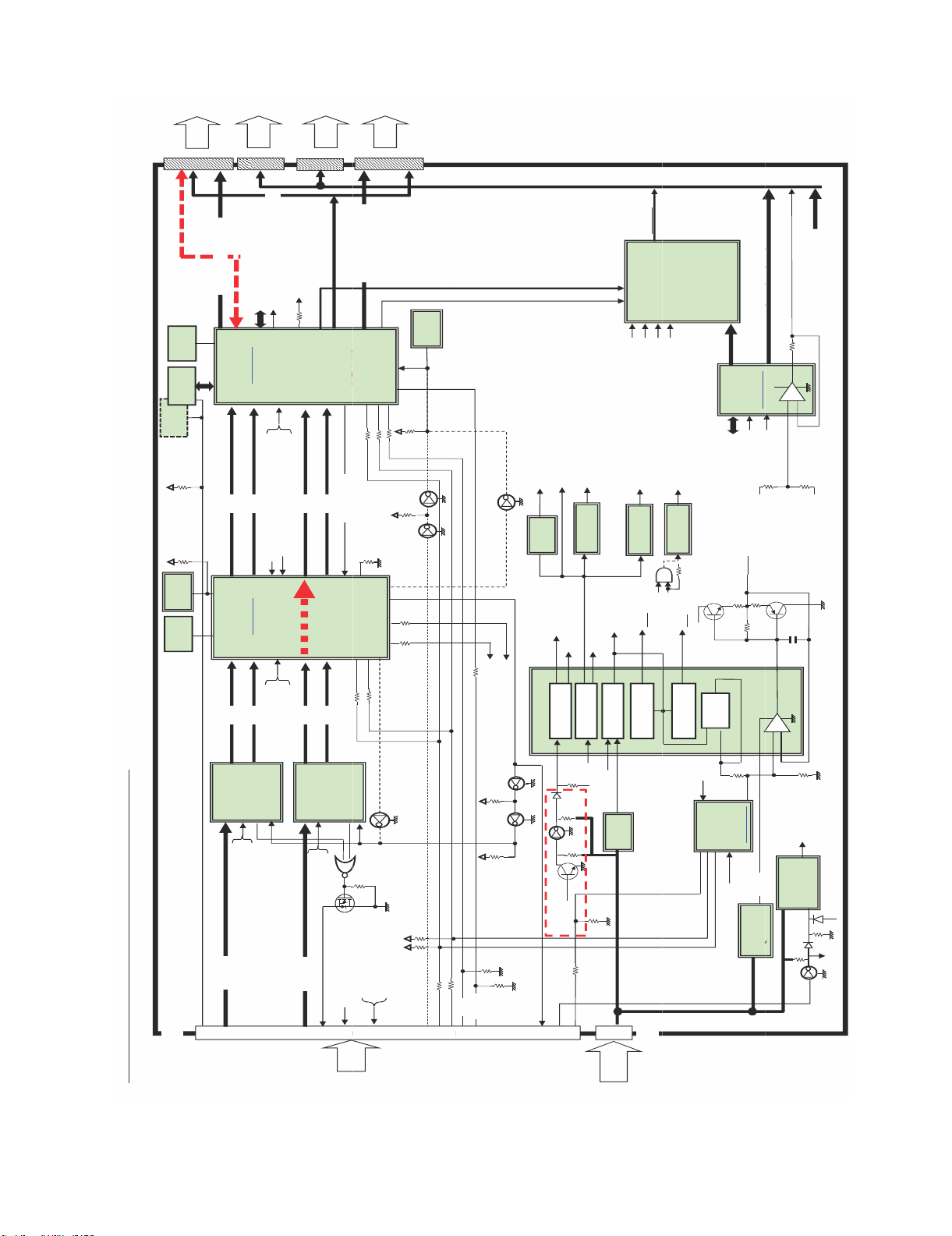

CHAPTER 8. OVERALL WIRING/BLOCK DIAGRAM

[1] SYSTEM BLOCK DIAGRAM............................8-2

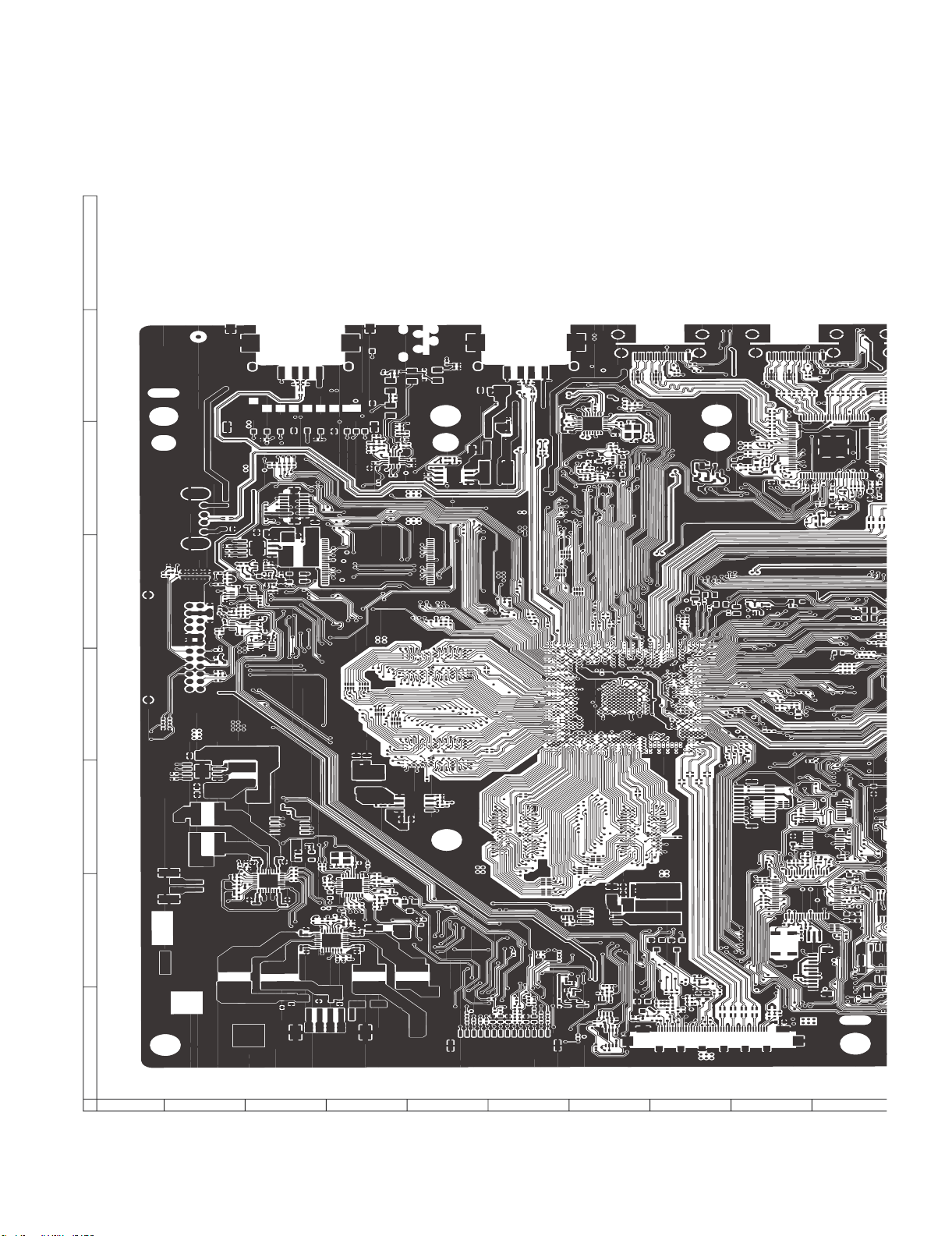

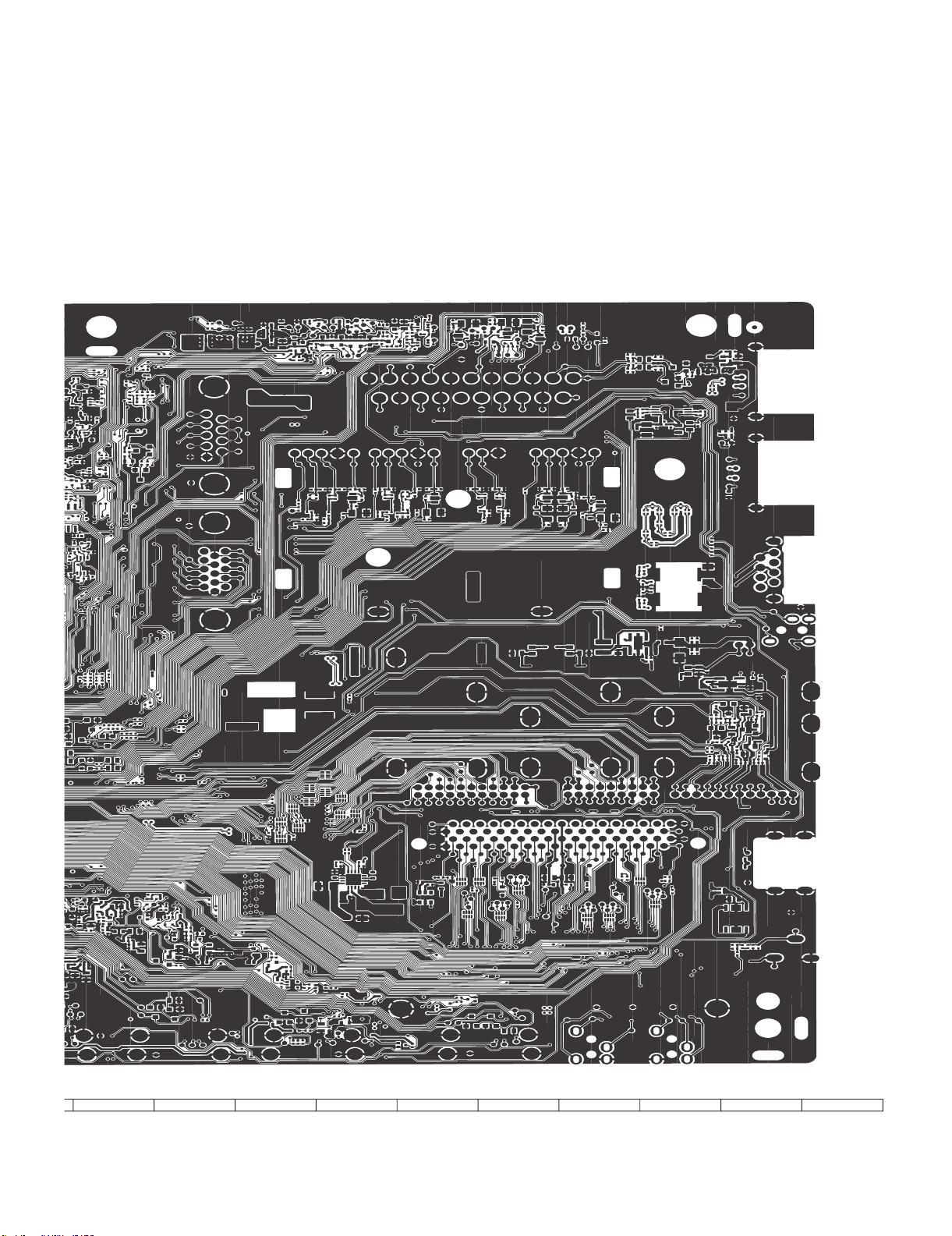

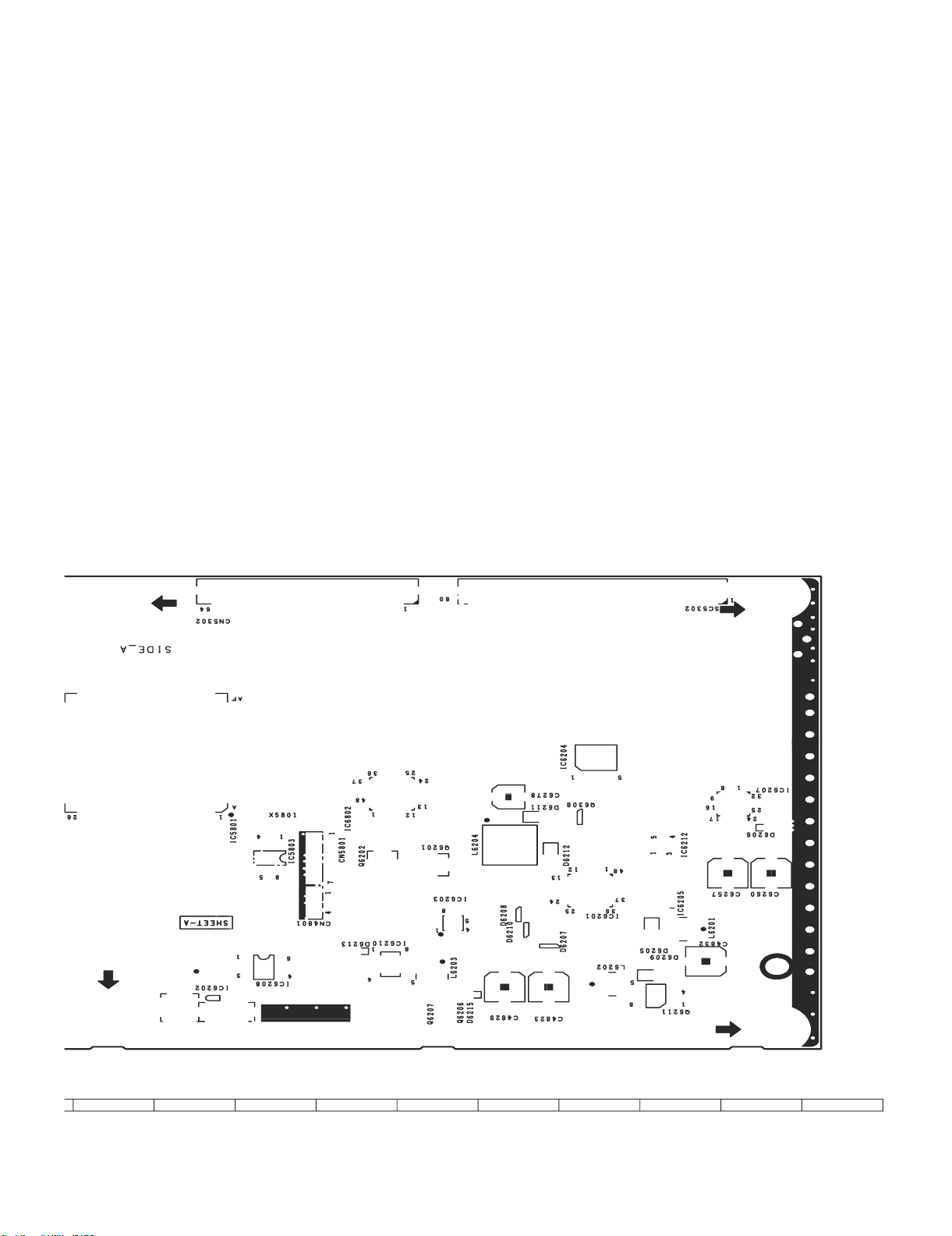

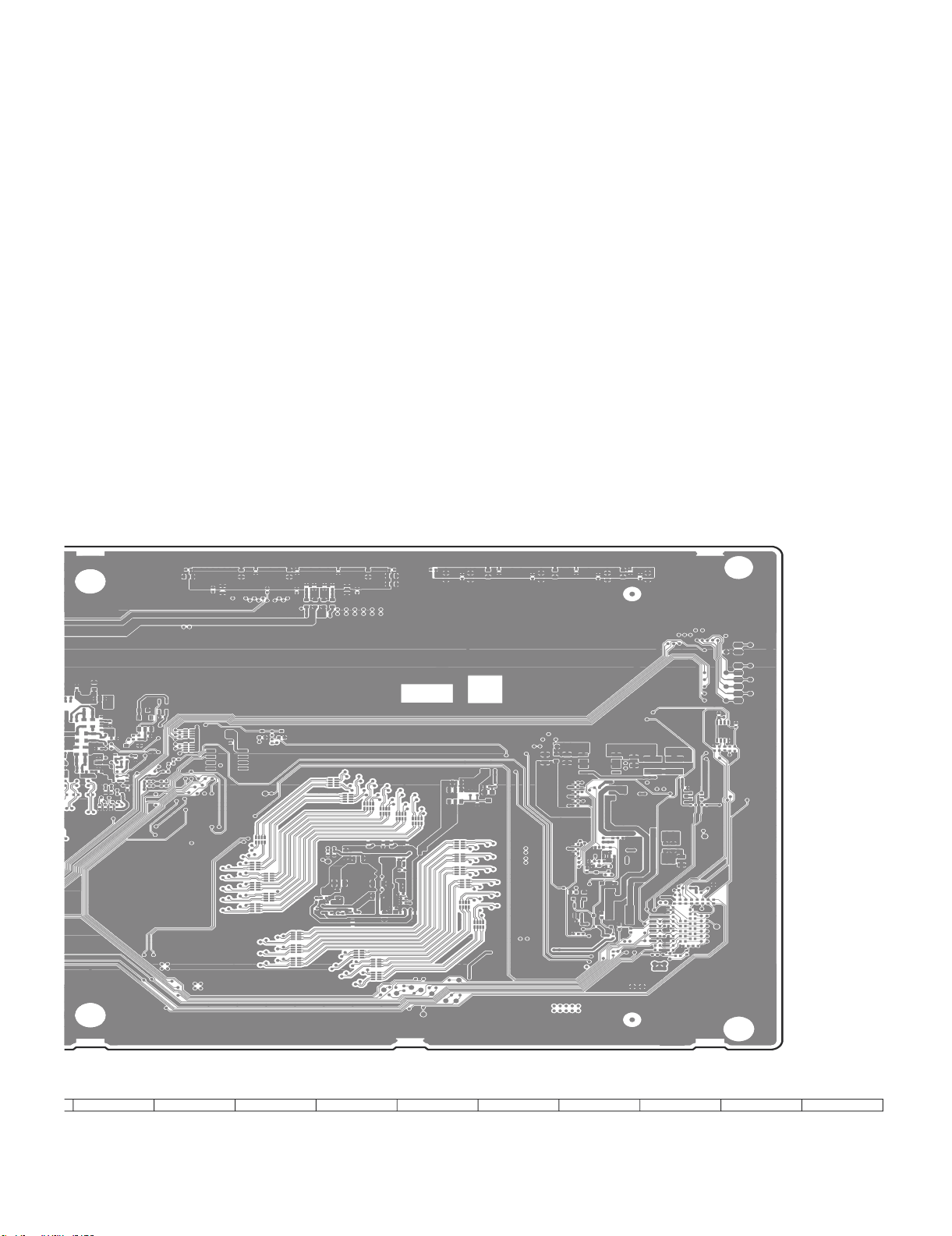

CHAPTER 9. PRINTED WIRING BOARD ASSEMBLIES

[1] Main Unit ..................... .. ... ................................9-1

CHAPTER 10. SCHEMATIC DIAGRAM

[1] DESCRIPTION OF SCHEMATIC

DIAGRAM.........................................................10-1

Parts Guide

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Page 2

LC-60G9T / LC-70G9T

SAFETY PRECAUTION

LC-60LE650U

SAFETY PRECAUTION

IMPORTANT SERVICE SAFETY PRECAUTION

Service work should be performed only by qualified service technicians who are thoroughly familiar with all safety checks and the

servicing guidelines which follow:

WARNING

1. For continued safety, no modification of any circuit should be

attempted.

2. Disconnect AC power before servicing.

CAUTION: FOR CONTINUED PROTECTION

AGAINST A RISK OF FIRE REPLACE ONLY WITH

SAME TYPE FUSE.

F7001 (250V 5A) -LC-60G9T

-LC-70G9T

SAF

ETY

PR

EC

AUT

ION

SAF

ETY

PR

EC

AUT

ION

SAF

ETY

PR

EC

AUT

ION

SAF

ETY

PR

EC

AUT

ION

SAF

ETY

PR

EC

AUT

ION

SAF

ETY

PR

EC

AUT

ION

SAF

ETY

PR

EC

AUT

ION

SAF

ETY

PR

EC

AUT

ION

Service Manual

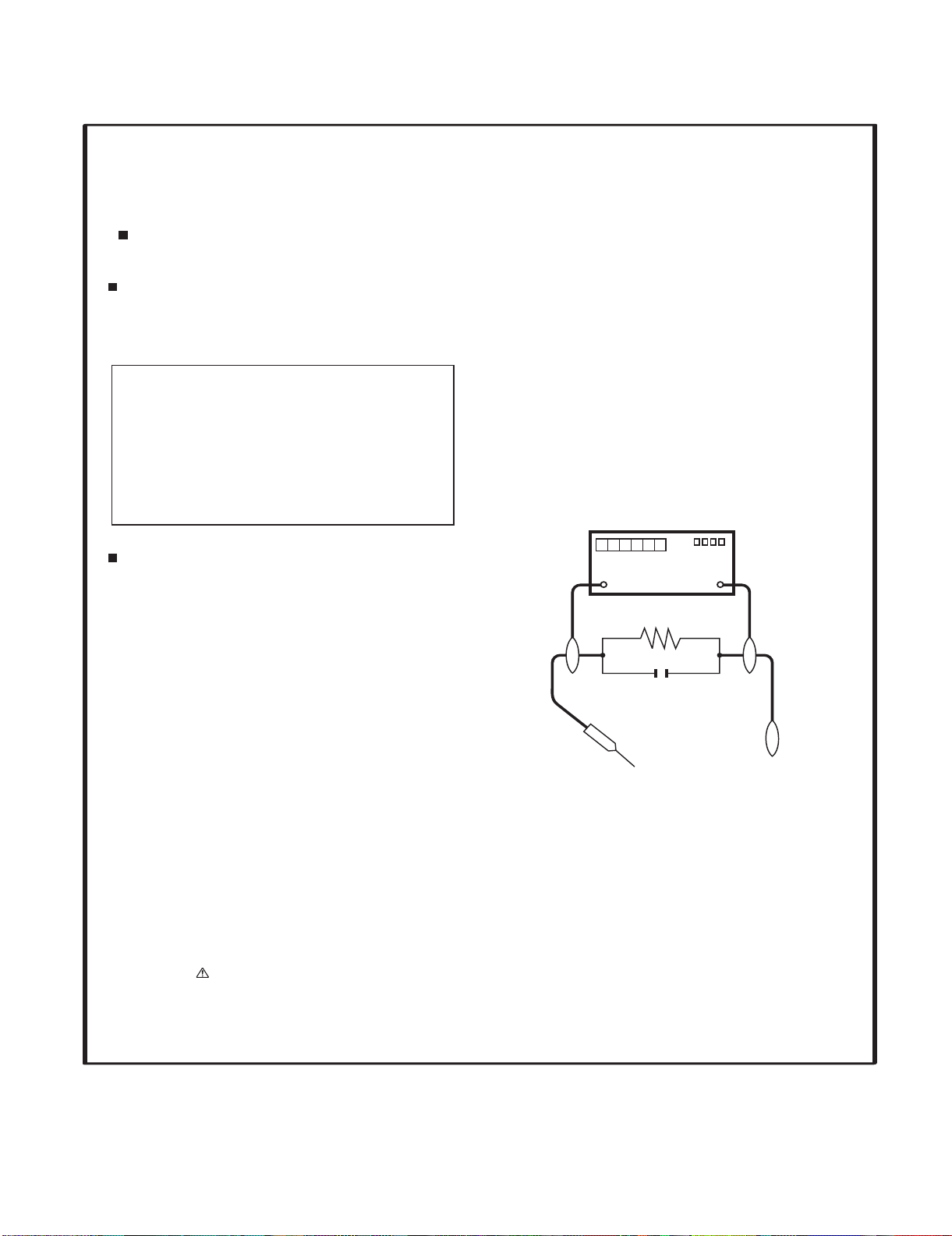

• Using two clip leads, connect a 1.5k ohm, 10 watt resistor paralleled by a 0.15PF capacitor in series with all exposed metal cabinet

parts and a known earth ground, such as electrical conduit or electrical ground connected to an earth ground.

• Use an AC voltmeter having with 5000 ohm per volt, or

sitivity or measure the AC voltage drop across the resistor.

• Connect the resistor connection to all exposed metal parts having a

return to the chassis (antenna, metal cabinet, screw heads, knobs

and control shafts, escutcheon, etc.) and measure the AC voltage

higher, sen-

drop across the resistor.

All checks must be repeated with the AC cord plug connection

reversed. (If necessary, a nonpolarized adaptor plug must be used

only for the purpose of completing these checks.)

Any reading of 0.75 Vrms (this corresponds to 0.5 mA rms AC.) or

more is excessive and indicates a potential shock hazard which

must be corrected before returning the monitor to the owner.

BEFORE RETURNING THE RECEIVER (Fire &

Shock Hazard)

Before returning the receiver to the user, perform the following

safety checks:

3. Inspect all lead dress to make certain that leads are not pinched,

DVM

AC SCALE

1.5k ohm

10W

and check that hardware is not lodged between the chassis and

other metal parts in the receiver.

4. Inspect all protective devices such as non-metallic control knobs,

insulation materials, cabinet backs, adjustment and compartment

covers or shields, isolation resistor-capacitor networks, mechanical

insulators, etc.

0.15µF

TEST PROBE

5. To be sure that no shock hazard exists, check for leakage current

in the following manner.

• Plug the AC cord directly into a 120 volt AC outlet.

TO EXPOSED

METAL PARTS

CONNECT TO

KNOWN EARTH

GROUND

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

SAFETY NOTICE

Many electrical and mechanical parts in LCD color television have

special safety-related characteristics.

These characteristics are often not evident from visual inspection, nor

can protection afforded by them be necessarily increased by using

replacement components rated for higher voltage, wattage, etc.

Replacement parts which have these special safety characteristics are

identified in this manual; electrical components having such features

are identified by " " and shaded areas in the Replacement Parts List

and Schematic Diagrams.

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

For continued protection, replacement parts must be identical to those

used in the original circuit.

The use of a substitute replacement parts which do not have the same

safety characteristics as the factory recommended replacement parts

shown in this service manual, may create shock, fire or other hazards.

i

Page 3

LC-60G9T / LC-70G9T

PRECAUTIONS FOR USING LEAD-FREE SOLDER

Employing lead-free solder

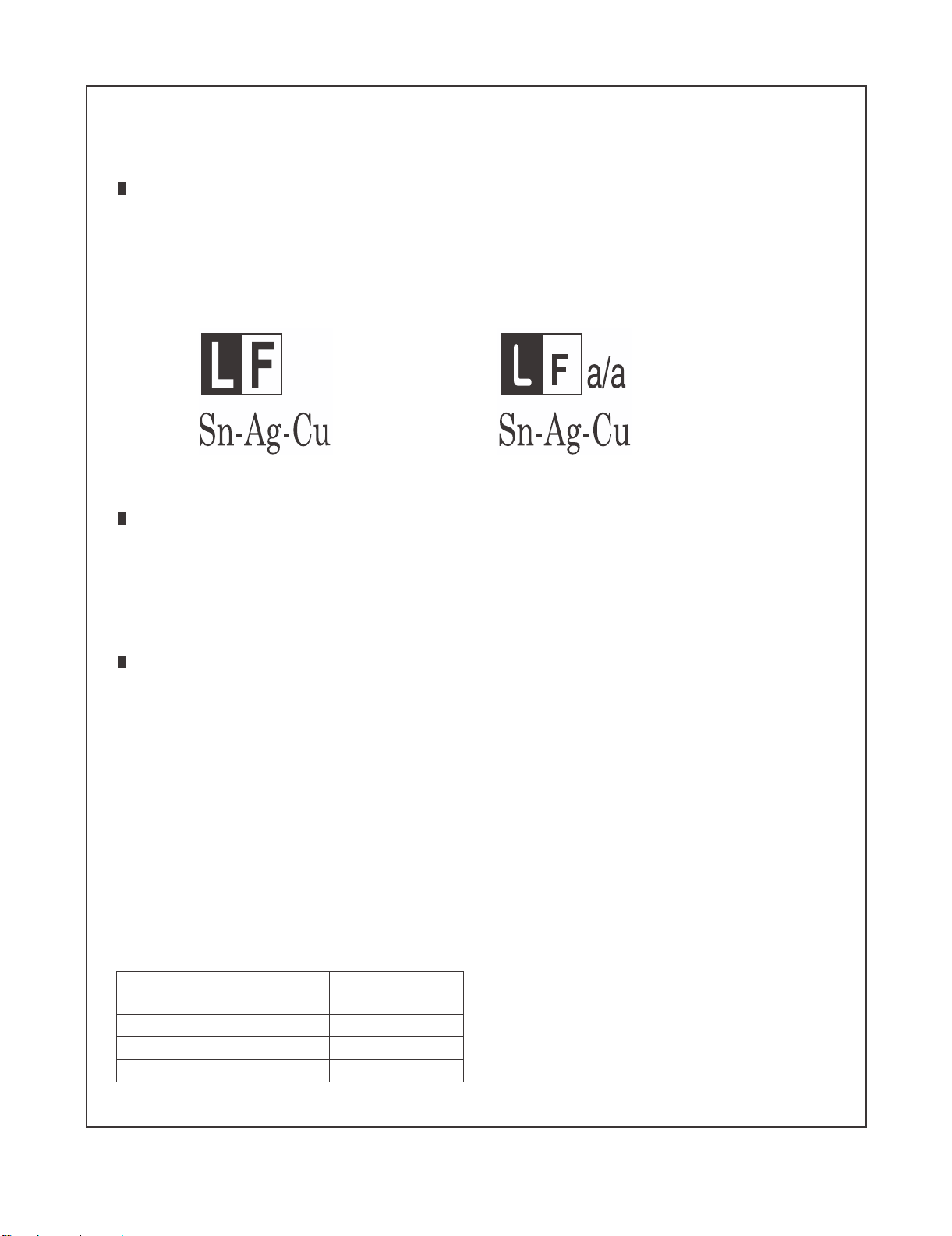

• “PWBs” of this model employs lead-free solder. The LF symbol indicates lead-free solder, and is attached on the PWBs and service manuals. The

alphabetical character following LF shows the type of lead-free solder.

Example:

Indicates lead-free solder of tin, silver and copper. Indicates lead-free solder of tin, silver and copper.

Using lead-free wire solder

• When fixing the PWB soldered with the lead-free solder, apply lead-free wire solder. Repairing with conventional lead wire solder may cause damage or accident due to cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40 qC, we recommend you to use a dedicated soldering

bit, if you are not familiar with how to obtain lead-free wire solder or soldering bit, contact our service station or service branch in your area.

Soldering

• As the melting point of lead-free solder (Sn-Ag-Cu) is about 220 qC which is higher than the conventional lead solder by 40 qC, and as it has poor

solder wettability, you may be apt to keep the soldering bit in contact with the PWB for extended period of time. However, Since the land may be

peeled off or the maximum heat-resistance temperature of parts may be exceeded, remove the bit from the PWB as soon as you confirm the

steady soldering condition.

Lead-free solder contains more tin, and the end of the soldering bit may be easily corroded. Make sure to turn on and off the power of the bit as

required.

If a different type of solder stays on the tip of the soldering bit, it is alloyed with lead-free solder. Clean the bit after every use of it.

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sandpaper.

• Be careful when replacing parts with polarity indication on the PWB silk.

Lead-free wire solder for servicing

PARTS CODE

ZHNDAi123250E BL J I0.3mm 250g (1roll)

ZHNDAi126500E BK J I0.6mm 500g (1roll)

ZHNDAi12801KE BM J I1.0mm 1kg (1roll)

PRICE

RANK

PART

DELIVERY

DESCRIPTION

ii

Page 4

LC-60G9T / LC-70G9T

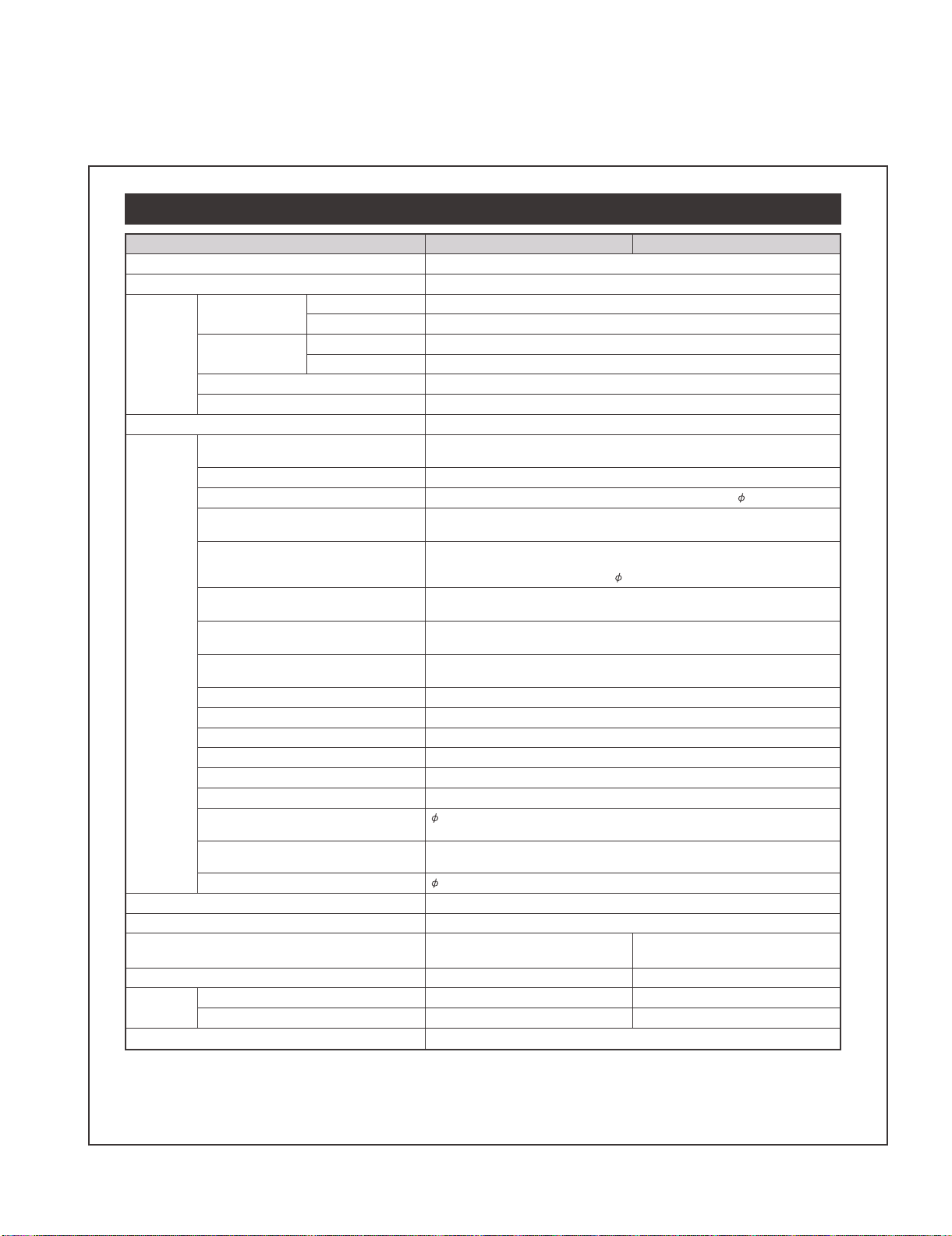

OUTLINE

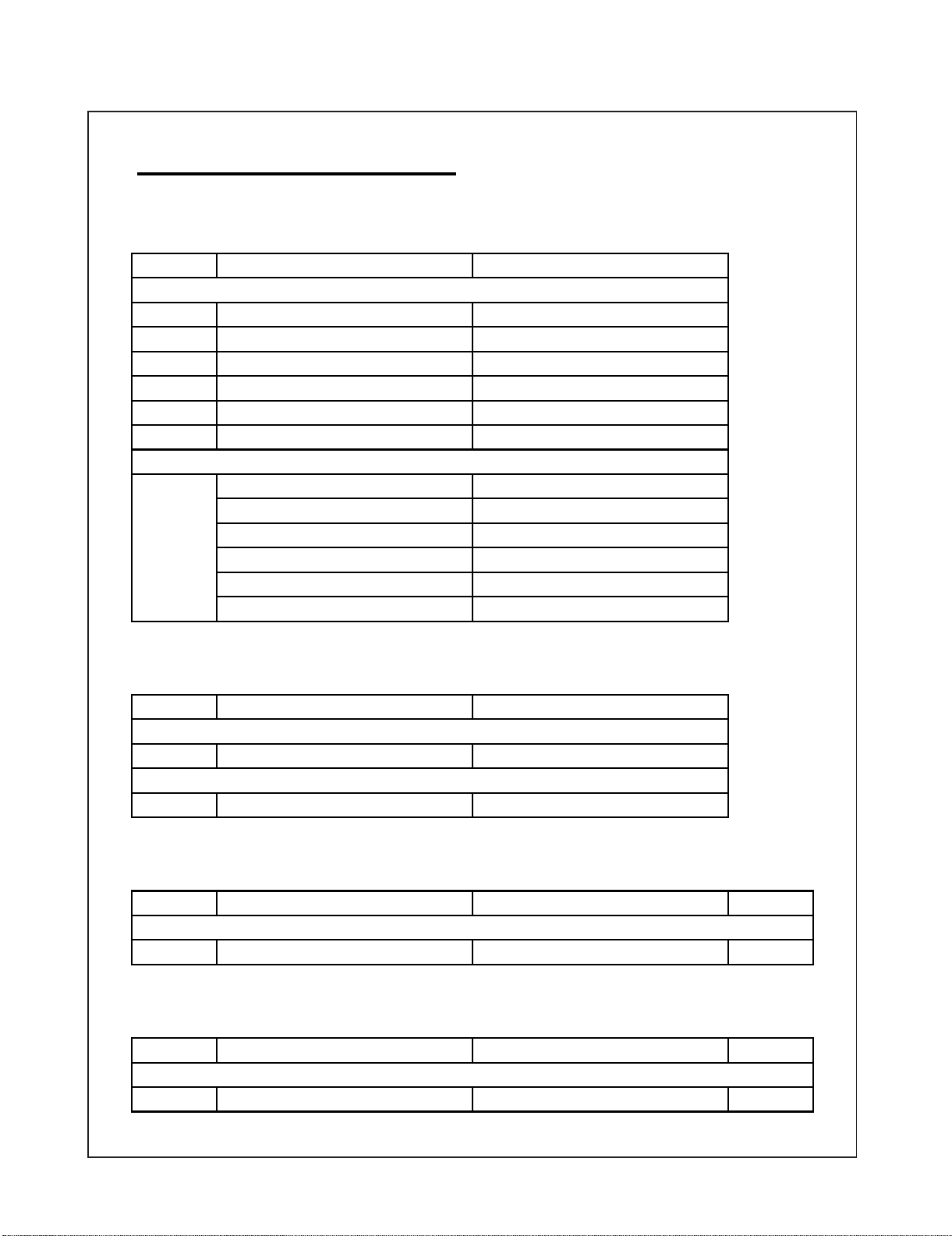

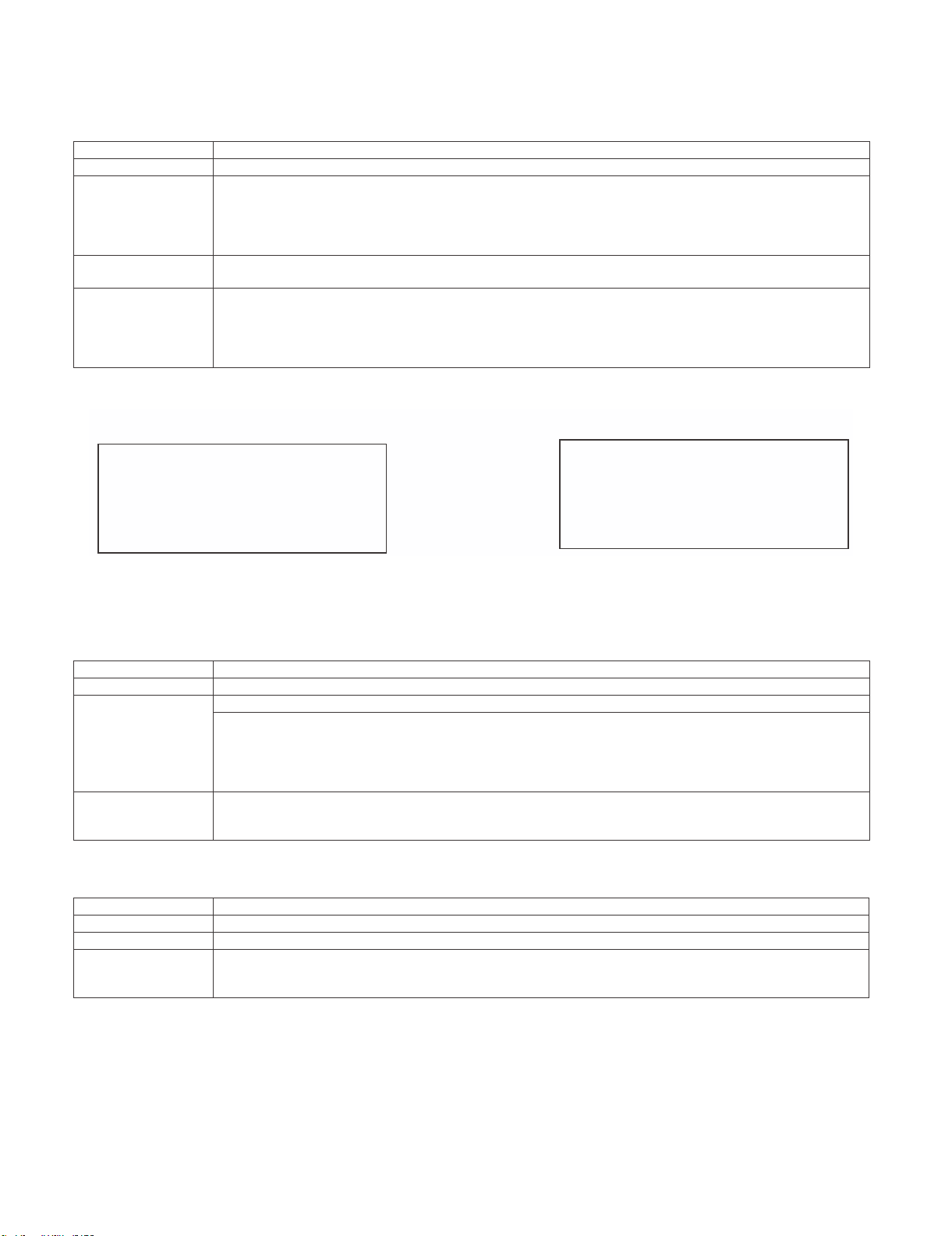

MAJOR SERVICE PARTS

PWB Unit

Ref NO.

LC-60G9T

DKEYFM216FMG3

RUNTKB116WJQZ

DUNTKG016FMG1

DUNTKF800FMF8

DUNTKG017FMF7

DUNTKG215FMG2

LC-70G9T

DKEYFM216FMG4

RUNTKB118WJQZ

DUNTKG016FMG1

DUNTKF800FMF8

DUNTKG017FMF7

DUNTKG215FMG2

OTHER unit

Ref NO.

LC-60G9T

R1JE600D3HD60W

LC-70G9T

R1JE695D3HB10W

PARTS CODE DESCRIPTION

tinUniaMN

tinurewoP06N

tinUCRDELN

tinUyeKN

tinUD3N

TN -Con Unit

tinUniaMN

tinurewoP07N

tinUCRDELN

tinUyeKN

tinUD3N

TN -Con Unit

PARTS CODE DESCRIPTION

06N -Inch Panel

07N -Inch Panel

IC For Exclusive Use of the Service

PARTS CODE DESCRIPTION

LC-60/70G9T

IC2004 RH-IXD515WJN8Q IC (Monitor Microprocessor) 1

Service Jigs

PARTS CODE DESCRIPTION

LC-60/70G9T

N QCNW-M539WJQZ

PD Main-Power + TCON 100cm

iii

YtQ.ONfeR

YtQ.ONfeR

1

Page 5

CHAPTER 1. SPECIFICATIONS

[1] SPECIFICATIONS

Specifications

LC-60G9T / LC-70G9T

Item

080,1x029,1noituloseR

06LAP/34.4CSTN/85.3CSTN/MACES/LAPmetsysruolocoediV

TV function TV-standard Analogue NTSC: M

Digital DVB - T

Receiving channel Analogue VHF/UHF 44.25-863.25 MHz

Digital VHF 470-806 MHz

hc531teserpotuAmetsysgninutVT

STEREO/BILINGUAL BTSC system

)refooW(1xW51,2xW01reifilpmaoiduA

Terminals

Power consumption (method IEC62087) 217 W

Operating temperature

*1

The HDMI 2 and 電腦(PC) terminals can both use the same audio input terminal.

• As a part of our policy of continuous improvement, SHARP reserves the right to make design and specification changes for product

improvement without prior notice. The performance specification figures indicated are nominal values of production units. There

may be some deviations from these values in individual units.

(無線電視/有線電視)

(Antenna input)

電腦

(PC) 15 pin mini D-sub, AUDIO in (shared usage with HDMI2) (

輸

入1 (INPUT 1) (ARC) HDMI HDMI (HDMI input) (480I, 576I, 480P, 576P, 720P/50Hz, 720P/60Hz,

輸

入2 (INPUT 2) HDMI HDMI (HDMI input) (480I, 576I, 480P, 576P, 720P/50Hz, 720P/60Hz,

輸

入3 (INPUT 3) HDMI HDMI (HDMI input) (480I, 576I, 480P, 576P, 720P/50Hz, 720P/60Hz,

輸

入 4 (MHL) HDMI HDMI (HDMI input) (480I, 576I, 480P, 576P, 720P/50Hz, 720P/60Hz,

輸

入 ,zH05/P027,P675,P084,I675,I084(niTNENOPMOC,niOIDUA)5TUPNI(5

輸

入 niOIDUA,niOEDIV)6TUPNI(6

輸

入 niOIDUA,niOEDIV)7TUPNI(7

USB 2 (無線網絡) (WIRELESS LAN) USB

(硬碟)

USB 3

乙太網絡ETHERNET (10/100 BASE-T) Network connector

聲音輸入(HDMI 2/電腦)

AUDIO IN (HDMI 2/PC)

數位聲音輸出

(DIGITAL AUDIO OUTPUT)

輸出(OUTPUT)/Headphones

ANT

(HDD) USB

UHF/VHF/CATV 75 q F type

1080I/50Hz, 1080I/60Hz, 1080P/50Hz, 1080P/60Hz, 1080P/24Hz)

1080I/50Hz, 1080I/60Hz, 1080P/50Hz, 1080P/60Hz, 1080P/24Hz),

AUDIO in (shared usage with PC) (

1080I/50Hz, 1080I/60Hz, 1080P/50Hz, 1080P/60Hz, 1080P/24Hz)

1080I/50Hz, 1080I/60Hz, 1080P/50Hz, 1080P/60Hz, 1080P/24Hz)

720P/60Hz, 1080I/50Hz, 1080I/60Hz)

3.5 mm jack*

Optical S/PDIF digital audio output

3.5 mm jack (audio output)

(0.3 W Standby)

0 °C to e 40 °C

rotcennocelamnip9buS-DC232-SR

3.5 mm jack)

BSU1BSU

1

esenihClanoitidarT/hsilgnEegaugnalDSO

zH06,V011CAtnemeriuqerrewoP

161 W

(0.3 W Standby)

W04W74edomrepapllawgnirudnoitpmusnocrewoP

gk93gk5.94dnatShtiWthgieW

gk23gk5.24dnatStuohtiW

T9G06-CLT9G07-CL

3.5 mm jack)

1 – 1

Page 6

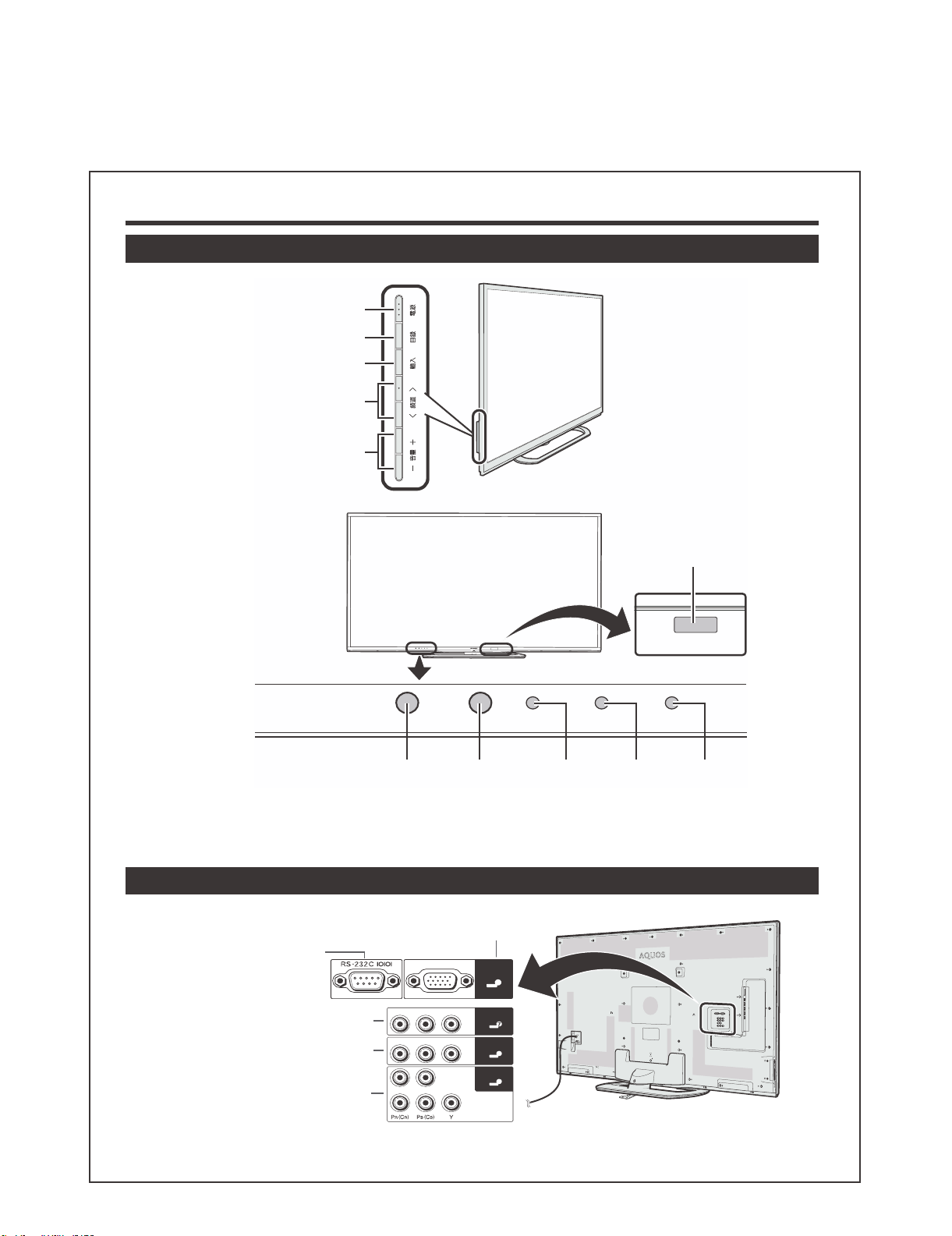

LC-60G9T / LC-70G9T

CHAPTER 2. OPERATION MANUAL

[1] OPERATION MANUAL

Part names and functions

TV (front view)

電源(POWER)

目錄(MENU)

輸入(INPUT)

頻道

r/s

(CH

音量

(VOL

r/s

e/f

e/f

)

)

REC

1

*

3Dinfraredemitter

POWER

Remotecontrol

sensor

*1

This panel emits infrared signal towards the 3D glasses you wear when viewing 3D images. Do not place anything between the 3D infrared emitter on

the TV and the infrared receiver on the 3D glasses.

*2

OPC: Optional Picture Control

OPC

sensor*

2

POWER

indicator

TIMER

TIMER

indicator

REC

indicator

TV (rear view)

電腦 (PC)terminal

RS-232Cterminal

電腦

8

輸入7( 影像 / 聲音 ( 左 / 右 ))

terminal(INPUT7)

輸入6( 影像 / 聲音 ( 左 / 右 ))

terminal(INPUT6)

輸入5( 色差端子 / 聲音 ( 左 / 右 ))

terminal(INPUT5)

右 聲音 左 影像

右 聲音 左 影像

右 聲音 左

色差端子

2 – 1

輸入7

輸入6

輸入5

6

5

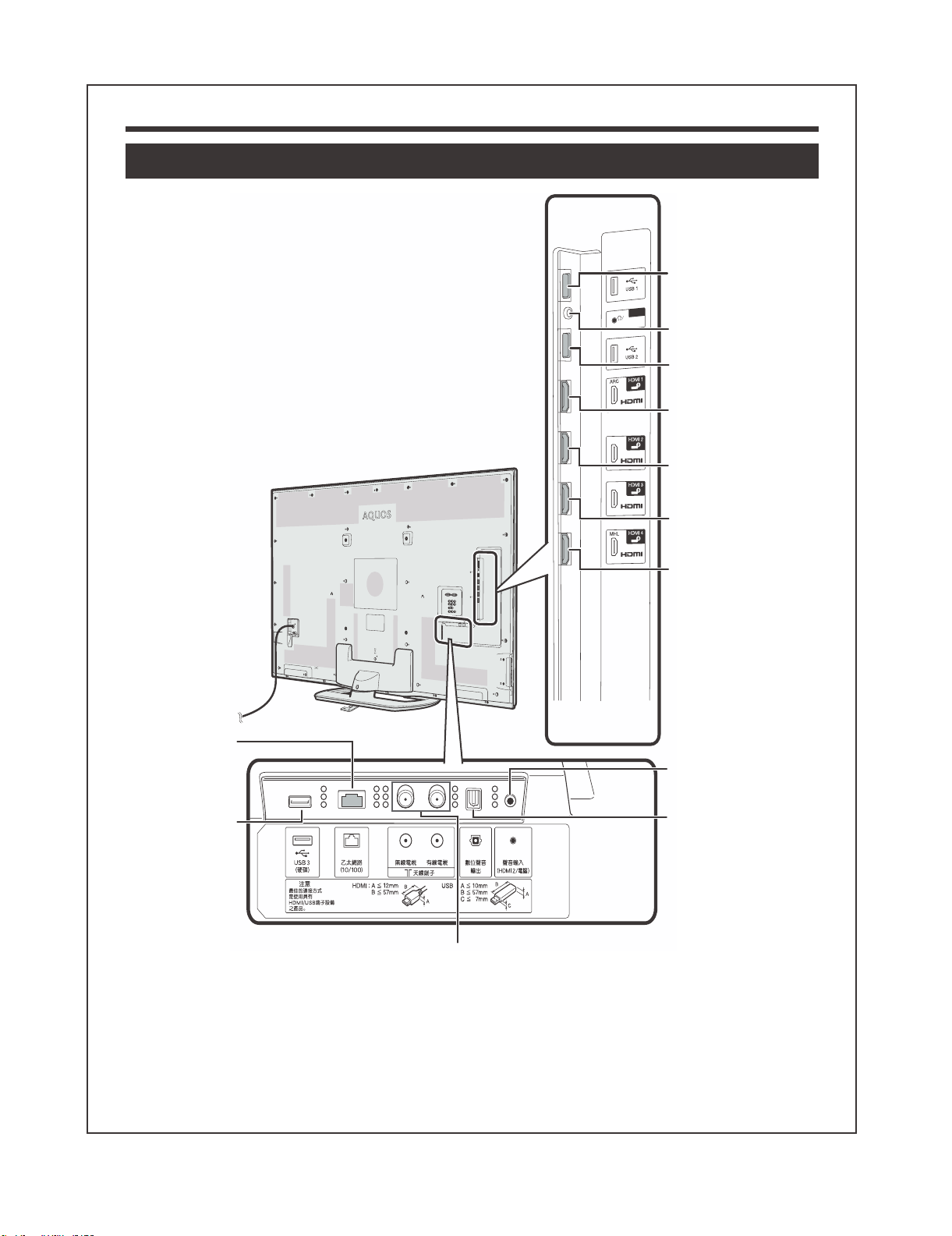

Page 7

Part names and functions

TV (rear view) (continued)

USB1port

輸出

輸出(Headphones/

)右/左(音聲

聲音(左/右))

terminal

USB2port

(WIRELESSLAN)

HDMI1(HDMI/ARC)

terminal(INPUT1)

HDMI2(HDMI)

terminal(INPUT2)

LC-60G9T / LC-70G9T

*1

乙太網絡

(ETHERNET)

(10/100)terminal

USB3(硬碟)

(HDD)port

Antennaterminals(無線電視/有線電視)

(DC5V900mA)

HDMI3(HDMI)

terminal(INPUT3)

HDMI4(HDMI/MHL)

terminal(INPUT4)

聲音輸入(HDMI2/電腦)

(AUDIOIN(HDMI2/PC))

*2

jack

數位聲音輸出

(DIGITALAUDIO

OUTPUT)terminal

Regarding details of Skype, visit the following website.

skype: http://www.skype.com or Sharp: http://www.aquos-world.com

*1

The HDMI 2 and 電腦 terminals can both use the same audio input terminal(聲音輸入 (HDMI 2/電腦) (AUDIO IN) (HDMI 2/PC)). However, the proper

item must be selected in the “Audio select” menu .

WARNING

• Excessive sound pressure from earphones and headphones can cause hearing loss.

• Do not set the volume at a high level. Hearing experts advise against extended listening at high volume levels.

2 – 2

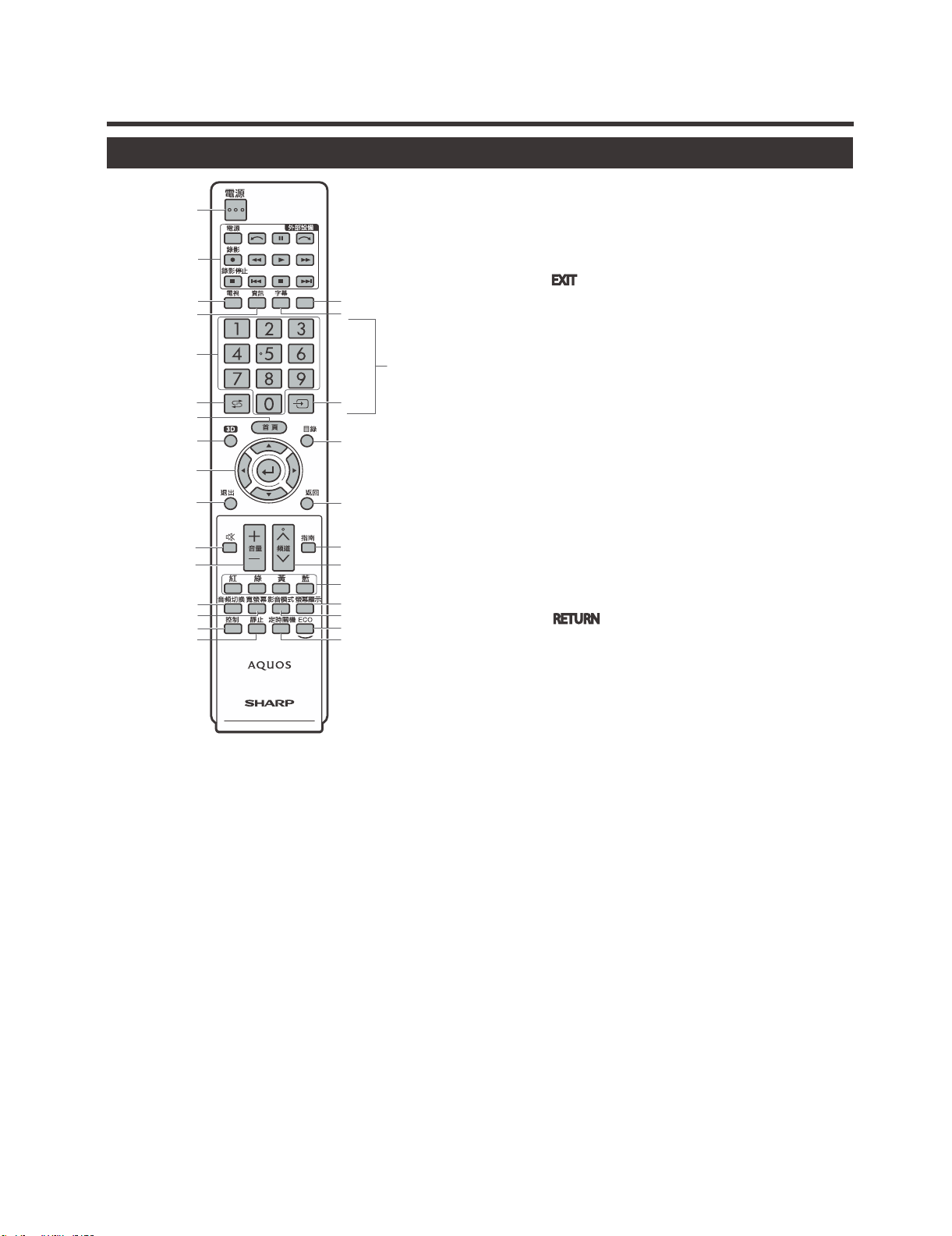

Page 8

LC-60G9T / LC-70G9T

Part names and functions

Remote control unit

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

1 電源(<) (Standby/On)

To switch the power on and off .

2 外部設備 (EXT MEDIA) buttons

AQUOS LINK

If external equipment such as a AQUOS BD player

is connected via HDMI cables and is AQUOS LINK

compatible, you can use these EXT MEDIA buttons.

USB-recording

Record a programme you are watching.

3 電視 (>)

Press to access analogue and digital TV mode.

4 資訊(INFO)

DTV : Display the programme information .

ATV : Display the channel information.

50–9*

Set the channel .

6 A (Flashback)*

Press to return to the previously selected channel or

external input.

7 首頁 (HOME)

Display the “HOME” screen to enjoy Internet connection

and Home network function and to perform settings for the

TV .

**

17

18

19

20

21

22

23

24

25

26

27

83D

Select between 3D and 2D image viewing .

9 a/b/c/d (Cursor)

Select a desired item on the setting screen.

? (ENTER)

Execute a command.

10 退出( EXIT

Turn off the On-Screen Display .

11 e (Mute)

Mute the sound.

12 音

*

Set the volume.

13 音

頻切換 (MPX)

Select a sound multiplex mode .

14 寬螢幕 (WIDE)

Change a wide image mode .

15 控制 (CONTROL)

Press to display the panel to operate some functions on the

screen.

16 靜止 (FREEZE)

Freeze a motion picture on the screen.

17 字幕(Subtitle)

Switch subtitle languages on/off .

18 b (INPUT SOURCE)*

Select an input source .

19 目錄 (@)

Displays the menu screen .

20 返回 ( RETURN

Menu mode: Return to the previous menu screen .

21 指南(GUIDE)

DTV : To display EPG (Electronic Programme Guide) screen

ATV : Display the channel list.

22 頻道r/s (CHr/s)

TV input mode: Select the channel .

AQUOS.NET: Select the page .

23 紅/綠/黃/藍 (R/G/Y/B) (Colour) buttons

The coloured buttons are correspondingly used to select

the coloured items on the screen (e.g., AQUOS LINK, USB

media, Home network).

24 螢幕顯示 (DISPLAY)

Display the channel or input information.

Reveal/hide the guide display for USB media mode.

25 影音模式(#)

Select audio/video settings .

26 ECO

Select “Energy save” setting .

27 定時關機 (SLEEP)

Set the sleep timer.

+/‒

)

(Y+/‒)

)

NOTE

* “0 − 9”, “A”, “b” are used by string input like a mobile

phone.

** This button does not work on this model.

2 – 3

Page 9

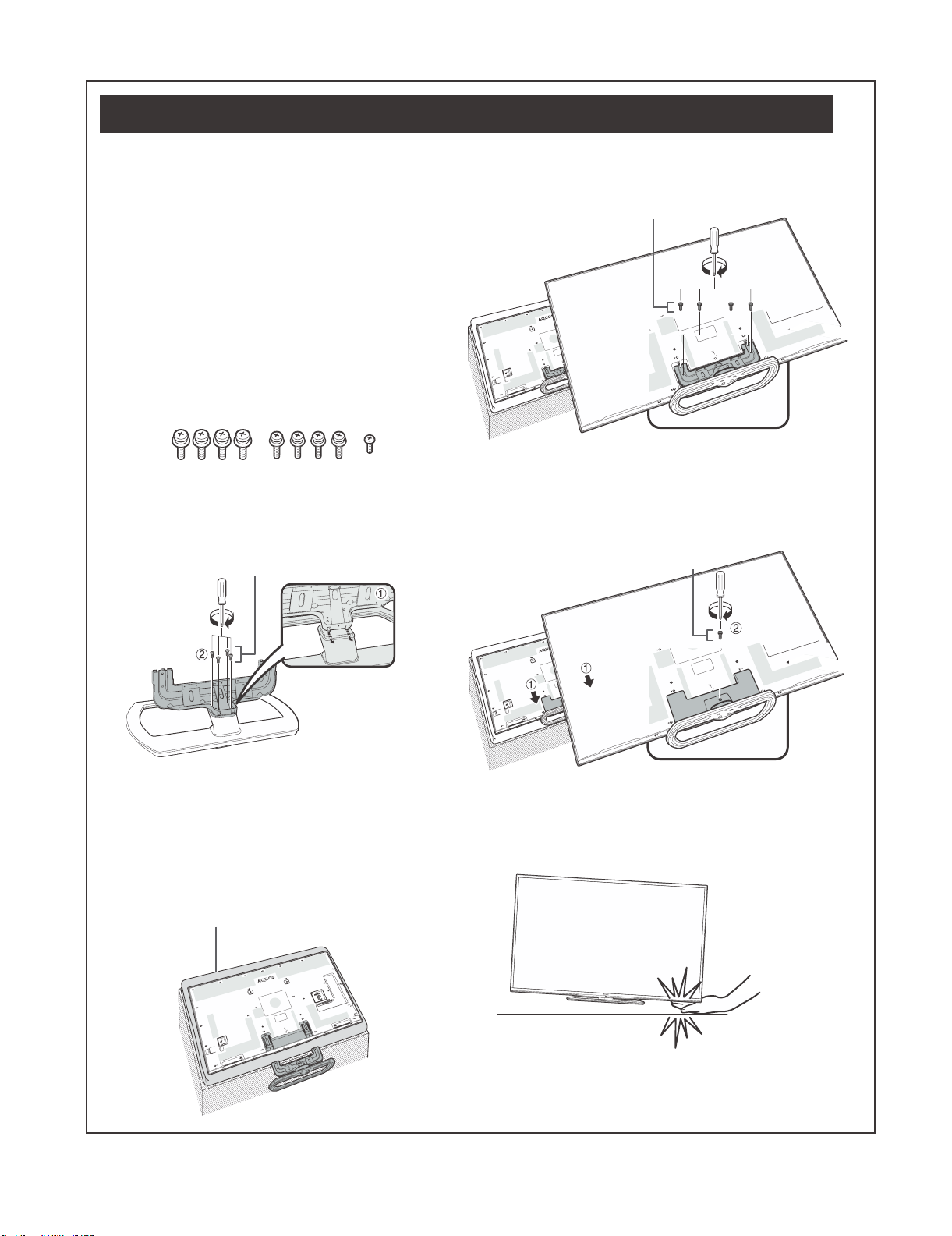

Attaching the stand unit

LC-60G9T / LC-70G9T

• Before attaching (or detaching) the stand, unplug the AC

cord.

• Before performing work, spread cushioning over the surface

on which you will be laying the TV. This will prevent it from

being damaged.

• Be sure that two or more persons attach the stand.

CAUTION

• Attach the stand in the correct direction.

• Be sure to follow the instructions. Incorrect installation

of the stand may result in the TV falling over.

• After attaching the stand to the TV, do not hold the

stand when you put up, set up, move or lay down the

TV.

• Do not remove the stand from the TV unless using a

wall mount bracket to mount it.

1

Confirmthatthereare9screws(fourM6screws,

fourM5screwsandoneM4screw)suppliedwith

thestandunit.

2

Attachthesupportingposttothestandbase.

1

Insert the claws of the supporting post into the stand

base.

2

Secure the post and the base using the M6 screws

(length: 60" (10 mm / 70" (20 mm)) and a screwdriver.

M6 screws

4

InsertandtightentheM5screws(length:14mm)

intotheholesontherearoftheTV.

M5 screws

5

Attachingthestandcover.

1

Insert the stand cover.

2

Insert and tighten the M4 screw (length: 8 mm) into the

holes of the stand cover.

• Tighten the screw by pressing the bottom of the

stand base to the TV side.

M4 screw

NOTE

• Tighten the screws to the holes of the mark “b”.

3

Insertthestandintotheopeningsonthebottom

oftheTV(holdthestandsoitwillnotdropfrom

theedgeofthebasearea).

• Make sure that the stand is firmly inserted into the TV.

Improper installation may result in tilting of the TV set.

Soft cushion

NOTE

• To detach the stand unit, perform the steps in reverse order.

• A screwdriver is not supplied with this product.

• In the installation procedure, be careful not to catch your

fingers between the TV set and the floor.

2 – 4

Page 10

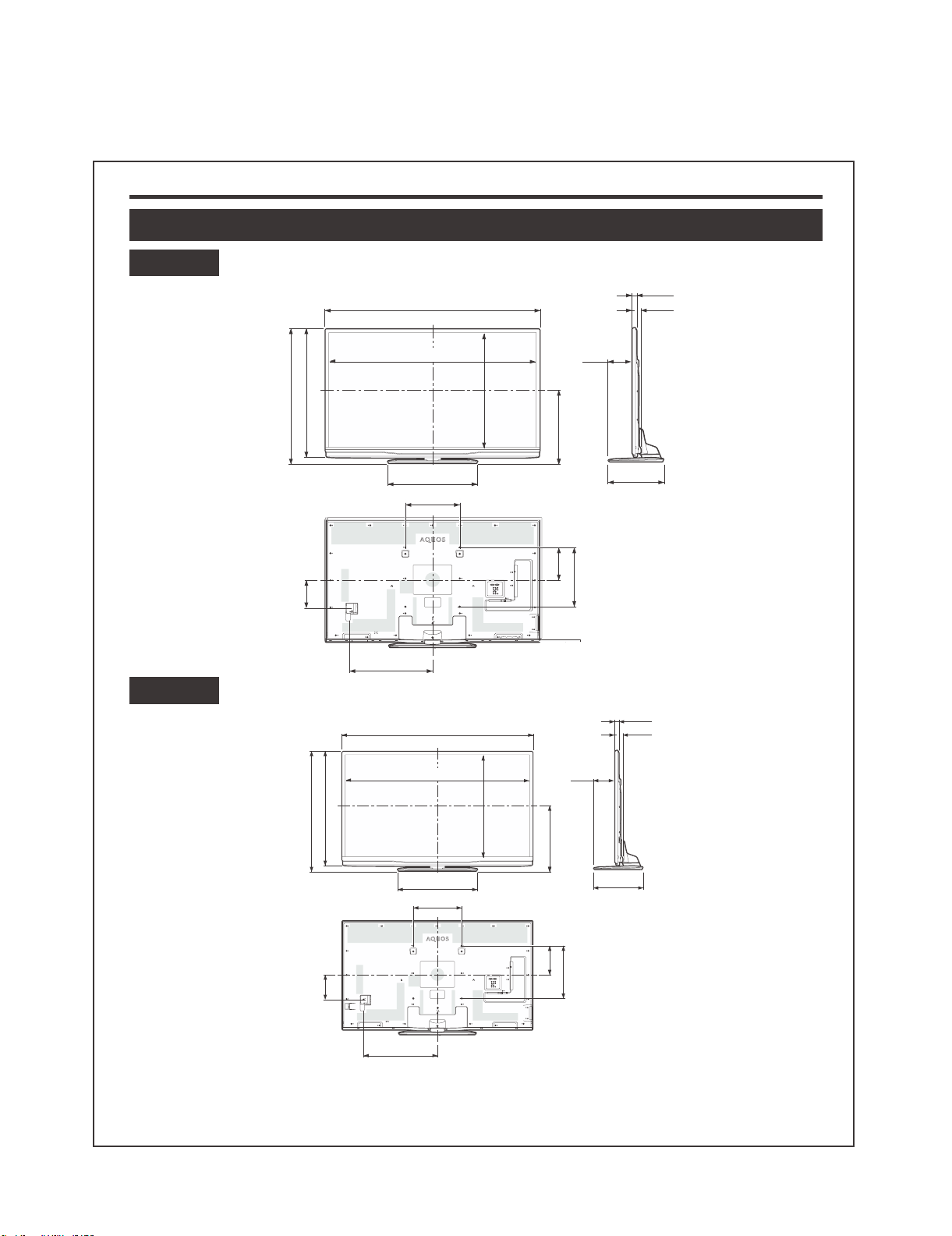

CHAPTER 3. DIMENSIONS

[1] DIMENSIONS

Dimensional drawings

LC-70G9T

(971)

(932)

(1539)

LC-60G9T / LC-70G9T

*2

(28)

(1578)

*1

*1

(866)

(178)

(513)

(58)

LC-60G9T

(251)

(848)

(810)

(1329)

(621)

*1

(640)

(400)

(1378)

(640)

(400)

*1

(748)

(451)

(200)

(400)

(178)

(385)

(385)

(28)

(58)

*2

(176)

*1

Active area

*2

Thinnest part (except of terminal height)

(575)

NOTE

• Dimensions do not include protrusions such as screws and some parts.

3 – 1

(200)

(400)

Page 11

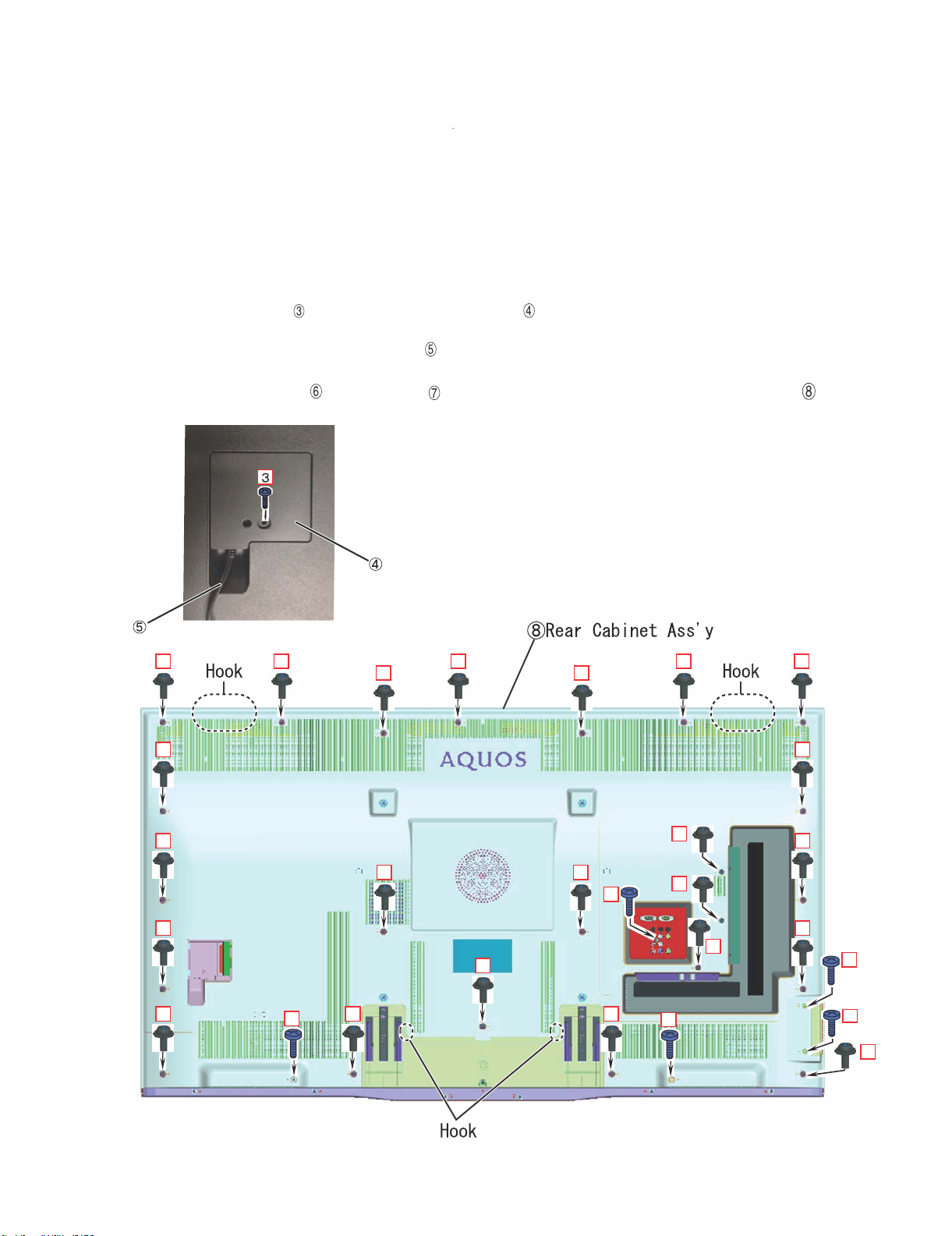

LC-60G9T / LC-70G9T

CHAPTER 4. REMOVING OF MAJOR

PARTS

R

E

M

O

V

I

N

G

O

F

M

A

1. Removing of Stand Unit and Rear Cabinet Ass'y. (LC-60G9T/ LC-70G9T)

1. Remove the 1 lock screw and detach the Stand Safety Cover Ass'y.

2. Remove the 4 lock screws and detach the Stand Unit.

3. Remove the 1 lock screw and detach the AC Cord Cover .

4. Disconnect AC Wire and detach the AC Cord .

5. Remove the 23 lock screws , 5 lock screws and the 4 Hooks and detach the Rear Cabinet Ass'y .

AC Cord Cover

AC Cord

J

O

R

P

A

R

T

R

E

M

O

V

I

N

G

O

F

M

A

J

O

R

P

A

R

T

R

E

M

O

V

I

N

G

O

F

M

A

J

O

R

P

A

R

T

R

E

M

O

V

I

N

G

O

F

M

A

J

O

R

P

A

R

T

R

E

M

O

V

I

N

G

O

F

M

A

J

O

R

P

A

R

T

4 – 1

Page 12

2. Removing of Speaker (L/R) and KEY Unit. ( LC-60G9T )

1. Remove the 1 lock screw and the 4 Hooks and detach the Bottom Cover Ass’y .

2. Detach the Speaker (L) , Speaker (R) .

3. Detach the KEY Unit Ass'y .

4. Remove the 2 Hooks and detach the Key Button from the Key Button Cover .

5. Disconnect the KM wire.

6. Detach the KEY Unit from Key Button .

LC-60G9T / LC-70G9T

Speaker (R)

Bottom Cover Ass'y

SP

Speaker (L)

4 – 2

Page 13

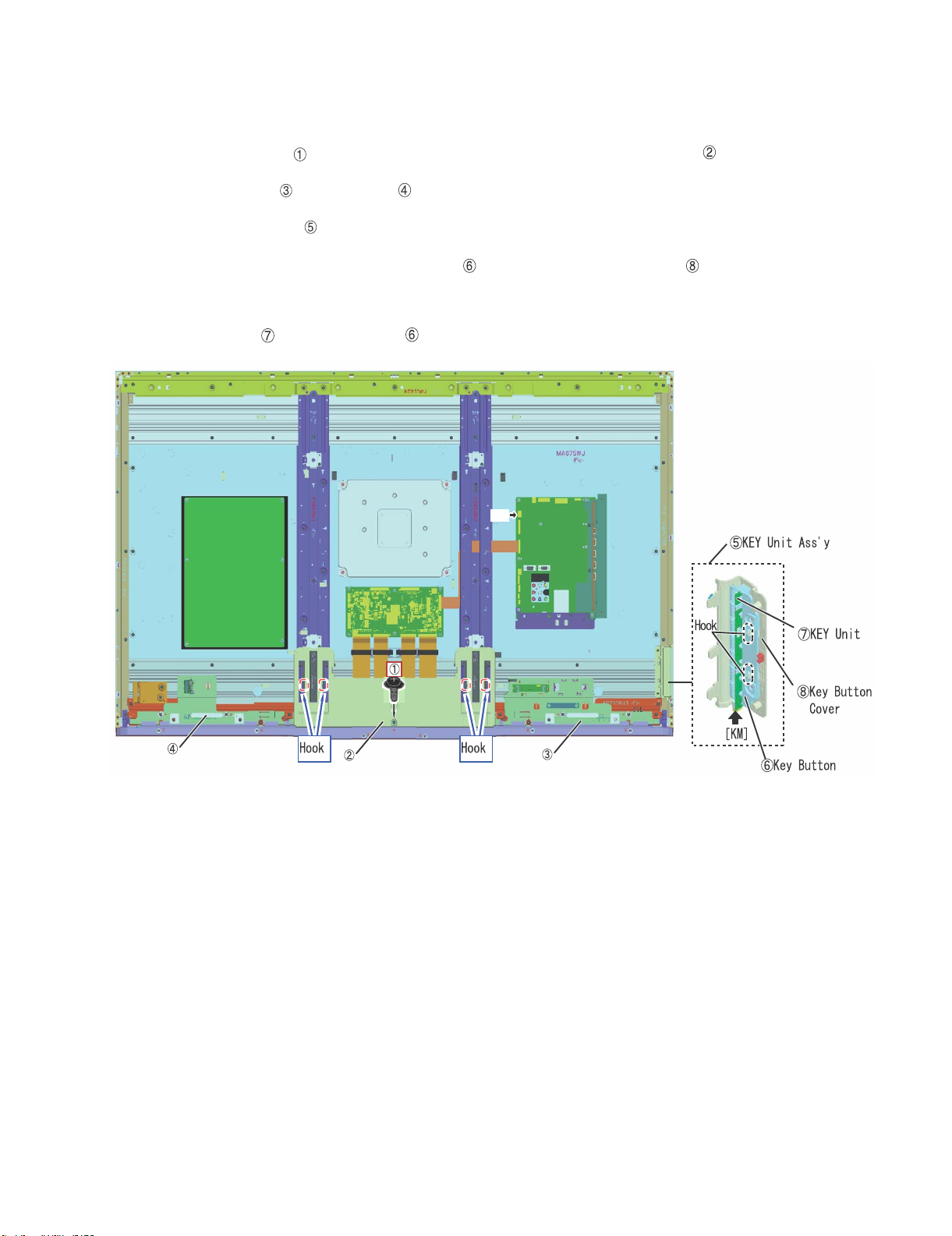

LC-60G9T / LC-70G9T

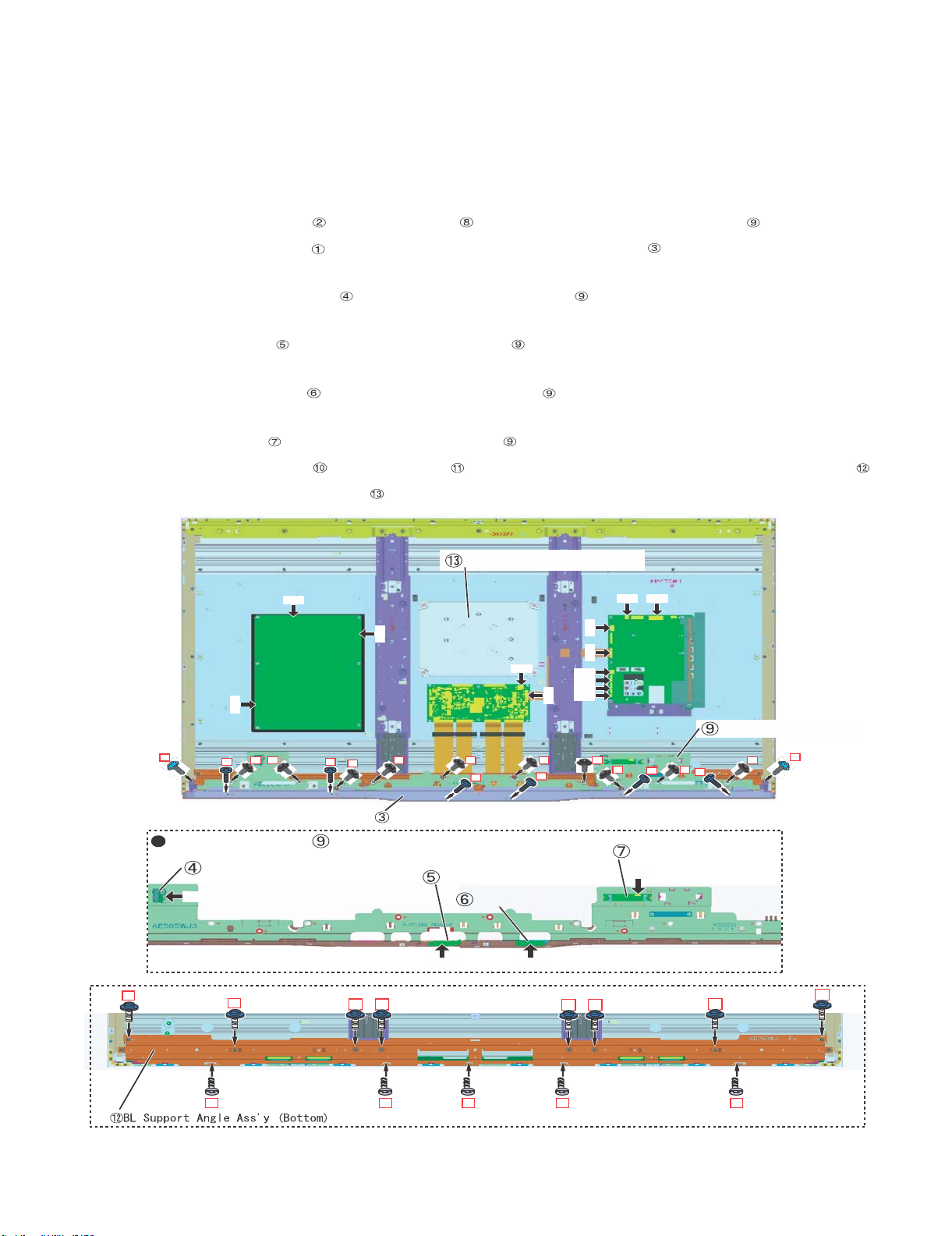

3. Removeing of Connectors and Decoration Cover, Front Cover Ass'y and Back Light Support Angle Bottom

Ass'y. ( LC-60G9T )

1. Disconnect the following connectors from MAIN Unit. (SB,PD,LV)

2. Disconnect the following connectors from POWER/DRIVE Unit. (L1,PD)

3. Disconnect the following connectors from LCD CONTROL Unit. (PL,LV)

4. Remove the 2 lock screws , 10 lock screws and detach the Front Cover Ass'y .

5. Remove the 6 lock screws and detach the Decoration Cover (Rear) .

6. Disconnect the following connector from BLUETOOTH Unit. (BT)

7. Detach the BLUETOOTH Unit from the Front Cover Ass'y .

8. Disconnect the following connector from ICON Unit. (CI)

9. Detach the ICON Unit from the Front Cover Ass'y .

10.Disconnect the following connector from R/C OPC Unit. (RA)

11.Detach the R/C OPC Unit from the Front Cover Ass'y .

12.Disconnect the following connector from WiFi Unit. (UB)

13.Detach the WiFi Unit from the Front Cover Ass'y .

14.Remove the 8 lock screws , 5 lock screws and detach the BL Support Angle Ass'y (Bottom) .

15.Detach the Speaker Unit (Woofer) .

2

Front Cover Ass'y

BLUETOOTH UNIT

BT

10

Speaker Unit (Woofer)

L1

PD

LV SP

PL

AC

8 8 8 8 8 8 8

11

8

1

RC

BT

LV

IR

UB

1

Decoration Cover (Rear)

PDSB

8 8

1

1

WiFi UNIT

ICON UNIT

UB

R/C OPC UNIT

CI RA

10

1010

10 10

Front Cover Ass'y

2

10

10

11

11

11

11

11

4 – 3

Page 14

LC-60G9T / LC-70G9T

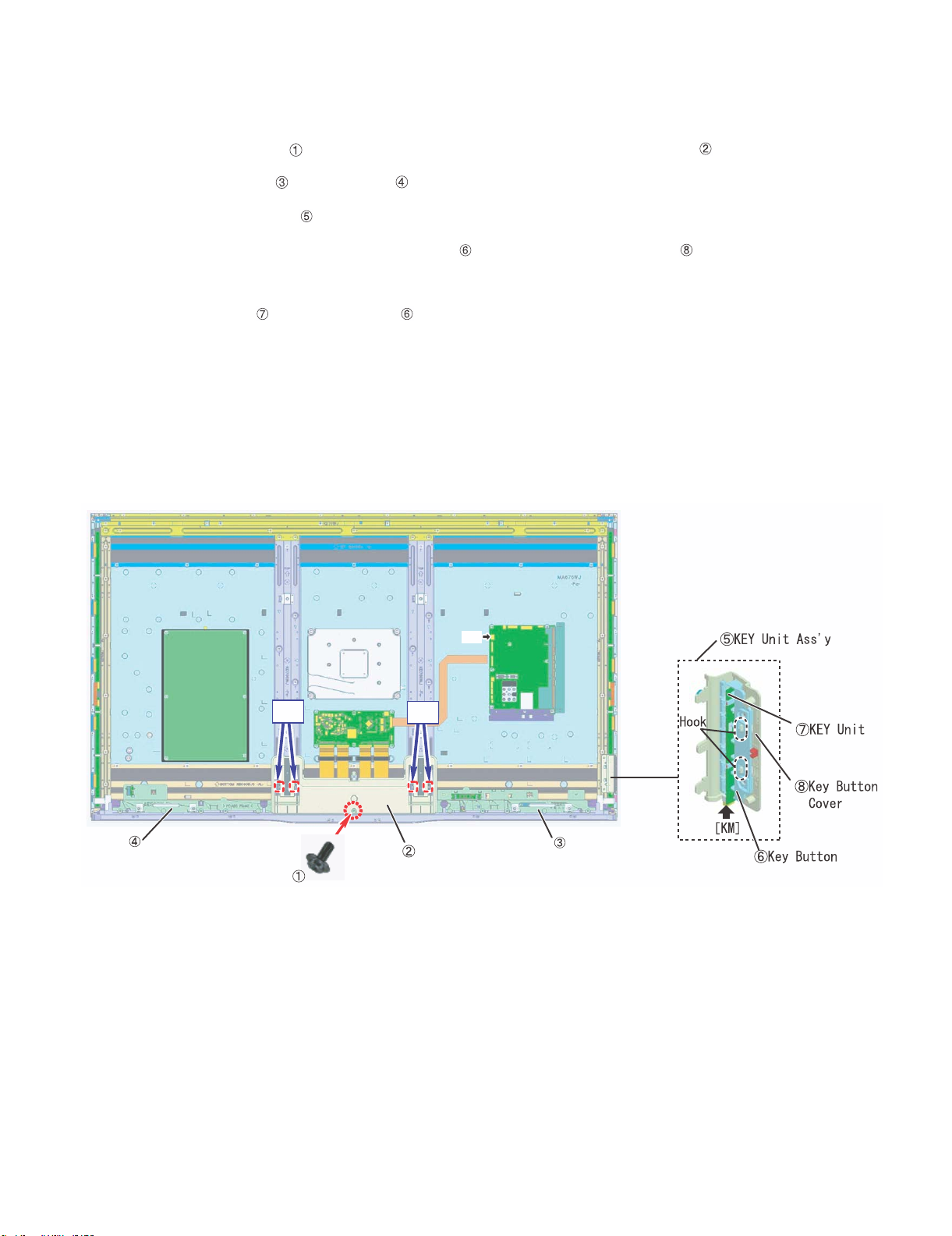

2. Removing of Bottom cover, Speaker(L/R), KEY Unit Ass'y.( LC-70G9T )

1. Remove the 1 lock screw and the 4 Hooks and detach the Bottom Cover Ass’y .

2. Detach the Speaker (L) , Speaker (R) .

3. Detach the KEY Unit Ass'y .

4. Remove the 2 Hooks and detach the Key Button from the Key Button Cover .

5. Disconnect the KM wire.

6. Detach the KEY Unit from Key Button .

Speaker (R)

Hook Hook

Bottom Cover Ass'y

SP

Speaker (L)

4 – 4

Page 15

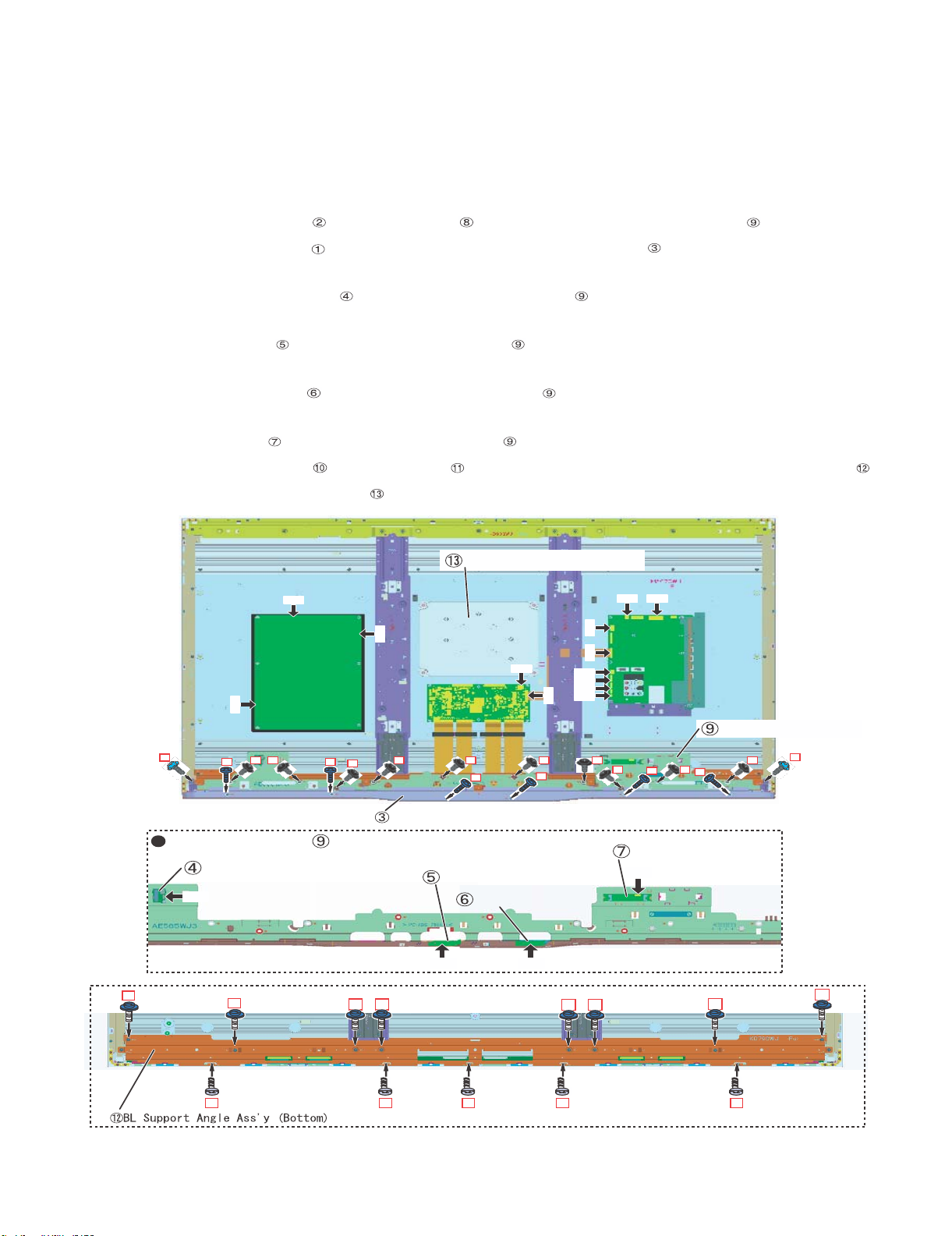

LC-60G9T / LC-70G9T

3. Removeing of Connectors and Decoration Cover, Front Cover Ass'y and Back Light Support Angle Bottom

Ass'y. ( LC-60G9T )

1. Disconnect the following connectors from MAIN Unit. (SB,PD,LV)

2. Disconnect the following connectors from POWER/DRIVE Unit. (L1,PD)

3. Disconnect the following connectors from LCD CONTROL Unit. (PL,LV)

4. Remove the 2 lock screws , 10 lock screws and detach the Front Cover Ass'y .

5. Remove the 6 lock screws and detach the Decoration Cover (Rear) .

6. Disconnect the following connector from BLUETOOTH Unit. (BT)

7. Detach the BLUETOOTH Unit from the Front Cover Ass'y .

8. Disconnect the following connector from ICON Unit. (CI)

9. Detach the ICON Unit from the Front Cover Ass'y .

10.Disconnect the following connector from R/C OPC Unit. (RA)

11.Detach the R/C OPC Unit from the Front Cover Ass'y .

12.Disconnect the following connector from WiFi Unit. (UB)

13.Detach the WiFi Unit from the Front Cover Ass'y .

14.Remove the 8 lock screws , 5 lock screws and detach the BL Support Angle Ass'y (Bottom) .

15.Detach the Speaker Unit (Woofer) .

2

Front Cover Ass'y

BLUETOOTH UNIT

BT

10

Speaker Unit (Woofer)

L1

PD

LV SP

PL

AC

8 8 8 8 8 8 8

11

8

1

RC

BT

LV

IR

UB

1

Decoration Cover (Rear)

PDSB

8 8

1

1

WiFi UNIT

ICON UNIT

UB

R/C OPC UNIT

CI RA

10

1010

10 10

Front Cover Ass'y

2

10

10

11

11

11

11

11

4 – 5

Page 16

LC-60G9T / LC-70G9T

CHAPTER 5. ADJUSTMENT

[1] ADJUSTMENT

[1] ADJUSTMENT PROCEDURE

Main unit supplied as service unit was adjusted on some item.

However, W/B adj is not finished because it needs to be done by final set condition. So the main unit is in the adjustment condition when it is supplied

and K mark is shown up in display when you use it. After finishing Factory setting, K -mark disappear so please do it as following ADJUSTMENT

PROCUDURE.

The adjustment values are set to the optimum conditions at the factory before shipping. If a value should become improper or an adjustment is

required due to part replacement, make an adjustment according to the following procedure.

1. After replacement of any PWB unit and/or IC for repair, please note the following.

x When replacing the following units, make sure to prepare the new units loaded with updated software.

MAIN Unit: DKEYMF216FMG3: LC-60G9T

DKEYMF216FMG4: LC-70G9T

x When replacing the LCD control PWB, perform the VCOM adjustment.

2. Upgrading of each microprocessor software

CAUTION: Never “POWER OFF” the unit when software upgrade is ongoing.

Otherwise the system may be damaged beyond recovery.

2.1. Software version upgrade

The model employs the following software.

• Main software LC-60/70G9T (please use a software version after XIAN_G9T_XXX.USB)

• Monitor microprocessor software (please use a software version XIANSUBXXX-SMB)

The main software, monitor microprocessor software can be upgraded by using a general-purpose USB Memory.

The followings are the procedures for upgrading, explained separately for the main software, monitor microprocessor software.

2.2. Main software version upgrade

2.2.1 Get ready before you start

• USB Memory of 128MB or higher capacity.

• PC running on Windows 98/98SE/ME/2000/XP operating system.

• USB Memory reader/writer or PC with a USB port.

• The file system of a USB memory is FAT. (FAT32 supports)

• Use the USB memory without other functions. (lock and memory reader...etc)

2.2.2 Preparations

To upgrade the main software, it is necessary to get ready the USB Memory for version upgrade before you start.

Follow the steps below and create the USB Memory for version upgrade.

1. Copy the file XIAN_G9T-XXX.USB for version upgrade to the root directory (folder) of the USB Memory.

NOTE: In the USB Memory drive, do not store other folders or unrelated files, or more than one file for version upgrade.

Now the USB Memory for version upgrade is ready.

5 – 1

Page 17

LC-60G9T / LC-70G9T

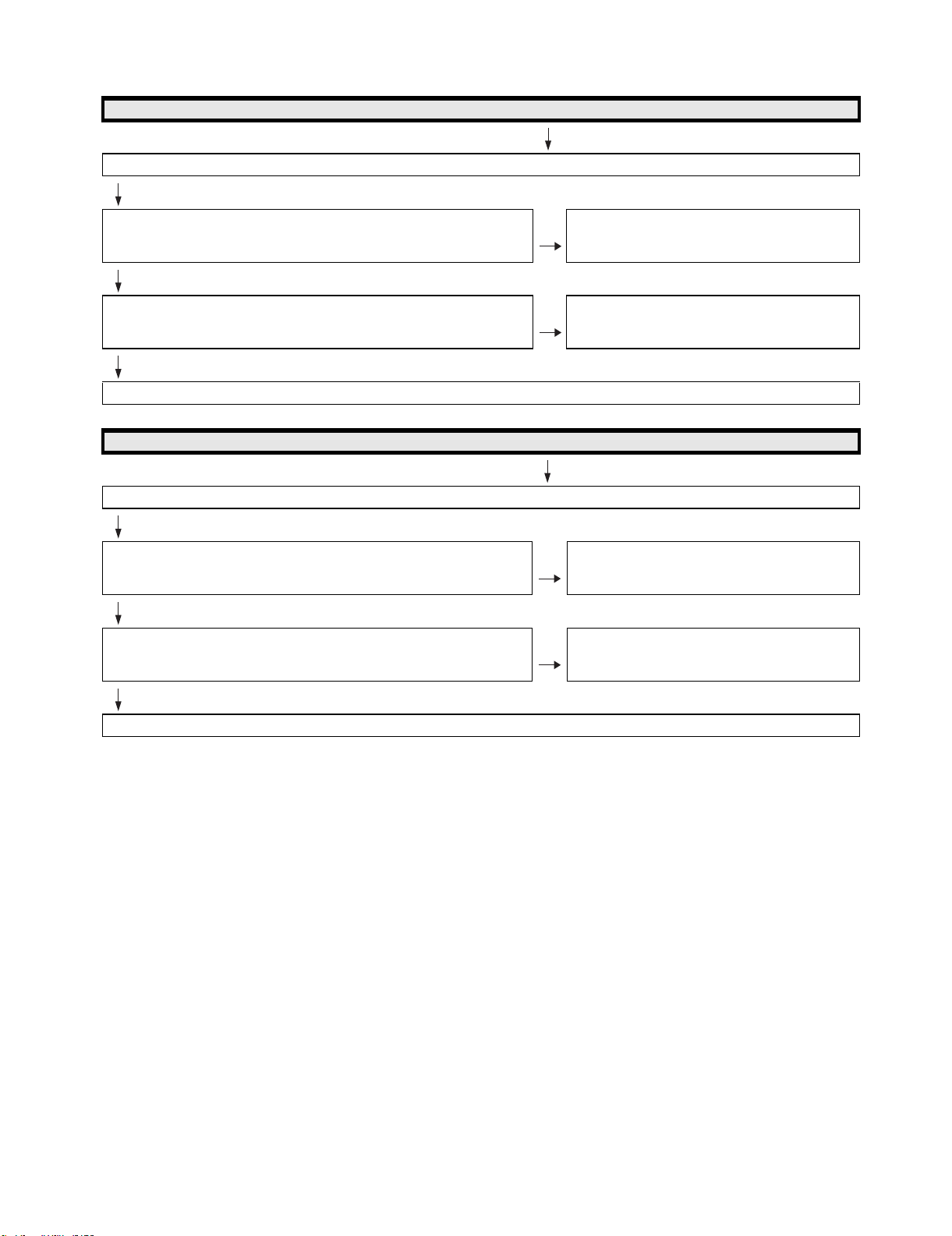

2.2.3 How to upgrade the software

1. Unplug the AC cord.

2. Insert the USB Memory for version upgrade into USB1.

3. Plug in the AC cord with power button pressed down.

4. After 5 seconds, unpress the power button.

5. After the unit startup, the system upgrade screen as shown below within 20-40 seconds.

Software Update

MAIN

SUB MICOM

PANEL EEPROM

3D IR MICOM

MAIN Version

SUB MICOM Version

PANEL EEPROM

3D IR MICOM Version

6. Even a single failure in the process will trigger the upgrade failure screen.

Software Update

UPGRADE FAILURE

MAIN

SUB MICOM

PANEL EEPROM

3D IR MICOM

MAIN Version

SUB MICOM Version

PANEL EEPROM

3D IR MICOM Version

60/70G9T

26%

NO DATA

NO DATA

095X1307021

60/70G9T

Project ID

NO DATA

NO DATA

NOTE: In the event of a failure, repeat the upgrade process. If the process repeatedly fails, it is likely that the hardware need fixing.

7. Upon completion of the whole process, the upgrade success screen as shown below appears. You can check the new software version on this

screen. The version information appears after the upgrade is complete.

Software Update

MAIN Version

SUB MICOM Version

PANEL EEPROM

3D IR MICOM Version

UPGRADE SUCCESS

MAIN

SUB MICOM

PANEL EEPROM

3D IR MICOM

100%

NO DATA

NO DATA

095X1307021

60/70G9T

8. Unplug the AC cord and remove the USB Memory for version upgrade.

9. Now the software version upgrade is complete.

NOTE: When you are done with the software version upgrade, start the set, go to the top page of the adjustment process screen and check the main

software version information.

If you upgrade the software version of 60/70G9T the model name is upgrade screen is displayed as 60/70G9T.

5 – 2

Page 18

LC-60G9T / LC-70G9T

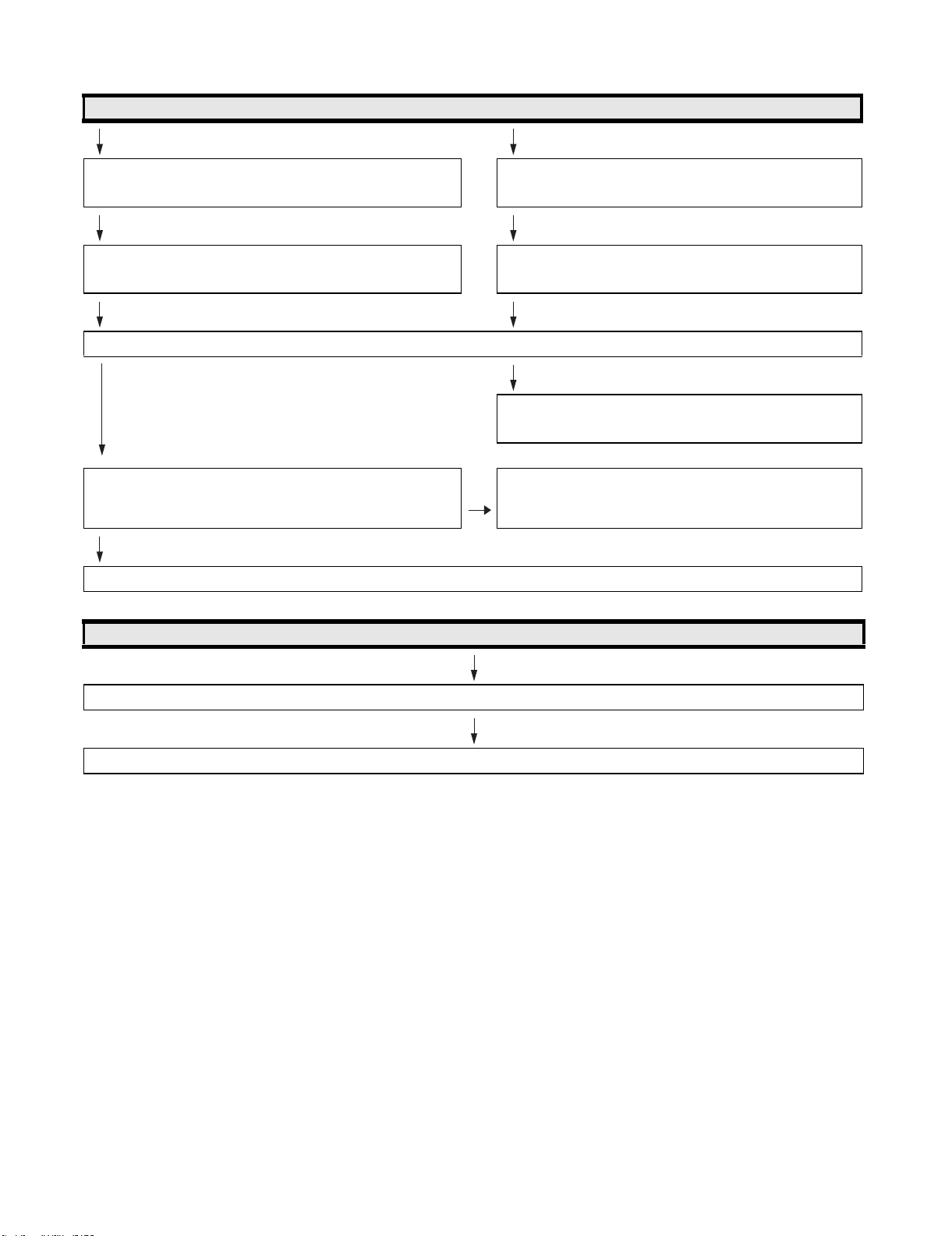

2.3. Monitor microprocessor software version upgrade

Create the USB memory for monitor microprocessor software version upgrade in the same manner as explained in the “Main software version

upgrade”.

Copy the file XIAN_G9T_XXX.USB and XIANSUBxxx.SMB. (named temporarily) for monitor microprocessor software version upgrade to the

USB memory.

2.3.1 How to upgrade the software

1. Unplug the AC cord.

2. Insert the USB Memory for version upgrade into USB1.

3. Plug in the AC cord with power button pressed down.

4. After 5 seconds, unpress the power button.

CAUTION: • The moment this operation is done, the upgrading of the monitor microprocessor software starts. While the upgrade is ongoing, never

5. After the unit startup, the upgrade starts. The power led will blink co

power off the unit. Otherwise the upgrade will fail and the system may be serious damaged beyond recovery (inability to start).

• After the monitor microprocessor software is upgraded, also perform the 'Industry Init'.

ntinuously. Also, an upgrade screen will be shown during a minor upgrade.

Software Update

MAIN Version

SUB MICOM Version

PANEL EEPROM

3D IR MICOM Version

MAIN

SUB MICOM

PANEL EEPROM

3D IR MICOM

NO DATA

50%

NO DATA

0.820

60/70G9T

6. If the upgrade fails, power led will stop blinking. Also, the upgrade failure screen will be shown if upgrade screen was shown at 5.

Software Update

MAIN Version

SUB MICOM Version

PANEL EEPROM

3D IR MICOM Version

UPGRADE FAILURE

MAIN

SUB MICOM

PANEL EEPROM

3D IR MICOM

NO DATA

SAME VERSION

NO DATA

60/70G9T

NOTE: In the event of a transient failure, upgrade will be automatically retried up to three times. If the process repeatedly fails, hardware may be the

cause.

7. The upgrade success screen will be shown if upgrade screen was shown at 5.

Software Update

MAIN Version

SUB MICOM Version

PANEL EEPROM

3D IR MICOM Version

UPGRADE SUCCESS

MAIN

SUB MICOM

PANEL EEPROM

3D IR MICOM

NO DATA

100%

NO DATA

0.820

60/70G9T

8. Unplug the AC cord and remove the USB Memory for version upgrade.

9. Now the software version upgrade is complete.

NOTE: When you are done with the software version upgrade, start the set, go to the top page of the adjustment process screen and check the mon-

itor microprocessor software version information and panel size information.

If you upgrade the software version of 60/70G9T, the model name in upgrade screen is displayed as 60/70G9T.

5 – 3

Page 19

LC-60G9T / LC-70G9T

3. Entering and exiting the adjustment process mode

1) Before entering the adjustment process mode, the AV position RESET in the video adjustment menu.

2) While holding down the “VOL(-)” and “INPUT” keys at a time, plug in the AC cord of the main unit to turn on the power.

The letter “<K>” appears on the screen.

3) Next, hold down the “VOL(-)” and “CH( )” keys at a time.

(The “VOL (—)” and “CH ( )” keys should be pressed and held until the display appears.)

Multiple lines of blue characters appearing on the display indicate that the unit is now in the adjustment process mode.

When you fail to enter the adjustment process mode (the display is the same as normal startup), retry the procedure.

4) To exit the adjustment process mode after the adjustment is done, unplug the AC cord from the outlet to make a forced shutdown. (When the

power was turned off with the remote controller, once unplug the AC cord and plug it again. In this case, wait 10 seconds or so before plugging.)

CAUTION: Use due care in handling the information described here lest your users should know how to enter the adjustment process mode. If the

4. Remote controller key operation and description of display in adjustment process mode

1) Key operation

CH ( / )

VOL (+/–) VOL (+/–) Changing a selected item setting (+1/ –1)

Cursor (UP/DOWN) ————— Turing a page (PREVIOUS/NEXT)

Cursor (LEFT/RIGHT) ————— Changing a selected line setting (+10/ –10)

2) Description of display

settings are tampered in this mode, unrecoverable system damage may result.

noitcnuFyektinuniaMyekrellortnocetomeR

CH ( / )

Moving an item (line) by one (UP/DOWN)

)gnihctiwselggot(gnihctiwstupnI—————TUPNI

noitcnufagnitucexE—————RETNE

*Input mode is switched automatically when relevant adjustment is started so far as the necessary input signal is available.

(1) Current page/

Total pages

(2) Current selected input

(3) Current color system

(4) Inducing display

(5) LCD Panel size/Speaker type

MAIN Version

BOOT Version

Monitor Version

T-CON Version / LED CON Version

NET TV KEY / MAC

CI+INFO/SECURE BOOT

MARLIN

FRC Version

VMDRM

LAMP ERROR

MONITOR ERR CAUSE

NORMAL STANDBY CAUSE

ERROR STANDBY CAUSE

(6) Item name

AILARTSUAOTUAVTD02/1

1.00 (X 2012/XX/XX)

PRAHA 100

1.00

XXXXXXX / XX

----/XX-XX-XX-XX-XX-XX

----/No

0

1) XXXXX 2) XXXXX

3) XXXXX 4) XXXXX

0

00000

G9T

(7) Parameters

noitacificepsyalpsiDnoitpircseD.oN

(1) Present page/number of total pages 2char/2char Decimal Number mark.

(2) Input that has been selected now DTV/TUNER/INPUT1/INPUT2/INPUT3/INPUT4/INPUT5/INPUT6/INPUT7

.cte05/i0801/i085/i084/MACES/LAP/344N/853N/OTUAmetsysruoloctneserP)3(

LARENEG/DNALAEZWEN/AILARTSUAyalpsidgnicudnI)4(

(5) Inch setting and Model name display Inch setting and Model name display

rahc03.xaMemanmetI)6(

rahc06.xaMretemaraP)7(

NOTE: In the case of 60G9T or 70G9T also ,the model name of ( 5 ) is displayed as G9T.

.

5 – 4

Page 20

5. List of adjustment process mode menu

The character string in brackets [ ] will appear as a page title in the adjustment process menu header.

1/20

4 T-CON Version / LED CON Version xxxxxxxx/xxxx T-CON/H.264 Version

6 CI + INFO / SECURE BOOT xxxxx/NO CI + Key Information / SECURE BOOT

7 MARLIN

8 FRC Version

9 IR Micom Version

2/20

3/20

4/20

11 MONITOR ERR CAUSE 1) xxxxxx 2) xxxxxx

4

7 TUNER ADJ (SMPTE CH57) Enter TUNER auto adjustment execution (SMPTE CH57)

8 PAL+TUNER ADJ (SMPT

10 TUNER CONTRAST D_GAIN 2048 TUNER signal level adjustment

11 TUNER CONTRAST OFFSET 256 TUNER signal level adjustment

8 SECAM CONTRAST D_GAIN 2048 SECAM contra

9 SECAM CONTRAST OFFSET 256 SECAM contrast adjustment

E CH57) Enter PAL TUNER auto adjustment execution (SMPTE CH57)

3) xxxxxx 4) xxxxxx

Last error standby cause.

(Excluding the error) Refer to 7. STANDBY CAUSE FUNCTIONS.

TIONS.

itazilaitinIretnETINIYRTSUDNI1 on to factory settings execution.

ilaitinIFFO)cilbuP-(TINIYRTSUDNI2 zation to factory settings execution.

(Public mode is excluded)

(Level appears in green on the upper right)

noisreverawtfosniaM)xxxxx(xxx1noisreVNIAM1

noisreVTOOBxxxxxxxnoisreVTOOB2

sserddACAMxxxx/xxxCAM/YEKVTTEN5

.sruohgnitareponiaM—emitucAretneC

.teserrorrepmaLFFOTESERRORREPMAL8

TESMARAPJDAretnETESMARAPJDA9

tnemtsujdaLAPretnEJDALAP1

tnemtsujdaMACESretnEJDAMACES2

tnemtsujda853NretnEJDA853N3

st adjustment

LC-60G9T / LC-70G9T

noisreverawtfosrotinoMxxxxxxxnoisreVrotinoM3

.rorrepmaloteudnoitanimretforebmuN0RORREPMAL01

.dneehttaybdnatsemacebtahtnoitasutiS0ESUACYBDNATSLAMRON21

gnittesFFO/NOedomcilbuPFFOEDOMCILBUP3

.tesersruohgnitareponiaMFFOTESER5

.sruohgnitarepothgilkcaB—emitucAthgilkcaB6

.tesersruohgnitarepothgilkcaBFFOTESER7

DAERCIVrofgnittesetanidrooc-X0SOPXCIV01

DAERCIVrofgnittesetanidrooc-Y0SOPYCIV11

DAERCIVrofgnittesepytlangiSNIAMEPYTLANGISCIV21

noitcnufnoitisiuqcalevelerutciPFFODAERCIV31

cexetnemtsujdaotuaRENUTretnEJDARENUT1

noitu

noitucexetnemtsujdaotuaRENUTLAPretnEJDARENUT+LAP2

)HC8-AC(noitucexetnemtsujdaotuaRENUTretnE)HC8-AC(JDARENUT3

)ETPMS(noitucexetnemtsujdaotuaRENUTretnE)ETPMS(JDARENUT5

tnemtsujdalevellangisRENUT41NIAG_ATSARTNOCRENUT9

tnemtsujdatsartnocLAP41NIAG_ATSARTNOCLAP4

tnemtsujdatsartnocLAP8402NIAG_DTSARTNOCLAP5

tnemtsujdatsartnocLAP652TESFFOTSARTNOCLAP6

tnemtsujdatsartnocMACES41NIAG_ATSARTNOCMACES7

tnemtsujdatsartnoc853N41NIAG_ATSARTNOC853N01

tnemtsujdatsartnoc853N8402NIAG_DTSARTNOC853N11

tnemtsujdatsartnoc853N652TESFFOTSARTNOC853N21

).cte,liatedtnemtsujda(skrameRnoitpircseDmetIeniLegaP

-CNUFESUACYBDNATS.7otrefeR.esuacybdnatsrorrE0000ESUACYBDNATSRORRE31

)HC8-AC(noitucexetnemtsujdaotuaRENUTLAPretnE)HC8-AC(JDARENUT+LAP4

)ETPMS(noitucexetnemtsujdaotuaRENUTLAPretnE)ETPMS(JDARENUT+LAP6

5 – 5

Page 21

LC-60G9T / LC-70G9T

5/20

3 INSPECT USB TERM PORT ALL : - - - - - - Reading inspection of USB memory terminal

4 MONIDATA READ [TEMP/OPC] OFF MONITOR Temperature/OPC Acquisition tool.

6/20

7/20

8/20

9/20

10/20

11/20

12/20

3 MONITOR EEP READ/WRITE WRITE MONITOR EEPROM READ/WRITE Setting/execution

13/20

1 LCD TEST PATTERN

2 LCD TEST PATTERN 1 NOT SUPPORT Pattern with built-in LCD controler display

4 LCD TEST PATTERN 3 NOT SUPPORT

5 LCD TEST PATTERN 4 NOT SUPPORT

).cte,liatedtnemtsujda(skrameRnoitpircseDmetIeniLegaP

tsetCECIMDHretnETSETCECIMDH1

GNITIRWDIDEIMDHretnEETIRWDIDEIMDH2

esuacybdnatsfoteseRretnETESERESUAC5

tnemtsujdalevelerutcipK51tnenopmoCretnEJDALLAK51PMOC1

eulavtnemtsujdaNIAGY041NIAGYNIAMK51PMOC2

eulavtnemtsujdaNIAGbC051NIAGBCNIAMK51PMOC3

eulavtnemtsujdaNIAGrC051NIAGRCNIAMK51PMOC4

eulavtnemtsujdaTESFFOY46TESFFOYK51PMOC5

eulavtnemtsujdaTESFFOBC821TESFFOBCK51PMOC6

eulavtnemtsujdaTESFFORC821TESFFORCK51PMOC7

0PMALC_AK51PMOC8

tnemtsujdaleveloedivVTDHretnEJDAVTDH1

eulavtnemtsujdaNIAGYVTDH041NIAGYVTDH2

eulavtnemtsujdaNIAGbCVTDH051NIAGBCVTDH3

eulavtnemtsujdaNIAGrCVTDH051NIAGRCVTDH4

eulavtnemtsujdaTESFFOYVTDH46TESFFOYVTDH5

eulavtnemtsujdaTESFFOBCVTDH821TESFFOBCVTDH6

eulavtnemtsujdaTESFFORCVTDH821TESFFORCVTDH7

0PMALC_AVTDH8

tnemtsujdaleveloedivGOLANAIVDretnEJDACPGOLANA1

eulavtnemtsujdaFFOTUCR46TESFFOR2

eulavtnemtsujdaFFOTUCG46TESFFOG3

eulavtnemtsujdaFFOTUCB46TESFFOB4

eulavtnemtsujdaEVIRDR44NIAGR5

eulavtnemtsujdaEVIRDG44NIAGG6

eulavtnemtsujdaEVIRDB44NIAGB7

0PMALC_ABGR8

tnemtsujdasaibnommoC46JDAMOCV1

kcehcRDDetucexEretnEKCEHC2RDD1

00x0]0:1[AB2

0000x0]0:31[RDDA3

0000x0]0:51[QD4

FFO/NOCRFetucexEretnEFFO/NOCRF5

eulavtnemtsujdaEVIRDR0)OL(NIAGR1

eulavtnemtsujdaEVIRDG0)OL(NIAGG2

eulavtnemtsujdaEVIRDB0)OL(NIAGB3

eulavtnemtsujdaEVIRDR0)IH(NIAGR4

eulavtnemtsujdaEVIRDG0)IH(NIAGG5

eulavtnemtsujdaEVIRDB0)IH(NIAGB6

gnittestuo-emitnoitacinummocniamehtdnarotinoMNOTUOEMITROTINOM1

utarepmetXAMROTINOM95PMETXAMROTINOM2

FFO2NRETTAPTSETDCL3

gnitteser

gnisserddayrartibraMORPEEROTINOM0x0RDAPEEROTINOM4

noitacificepsatadyrartibraMORPEEROTINOM0x0ATADPEEROTINOM5

5 – 6

Page 22

14/20

1 T-CON VERSION EXT.1

2 T-CON VERSION EXT.2

3 T-CON VERSION EXT.3

4 T-CON VERSION EXT.4

15/20

1 3D HDMI FPGA Version

22Do3D FPGA Version

09SSENTHGIRBDELD33

NOLORTNOCRETTIMERID34

16/20

FFOEDOMJDAKLATSSORC1

2 CROSS TALK TH1

3 CROSS TALK TH2

4 CROSS TALK TH3

5 CROSS TALK TH4

6 CROSS TALK GAIN1

7 CROSS TALK GAIN2

8 CROSS TALK GAIN3

17/20

00FAzHG4.2DISSIFIW1

05FAzHG5DISSIFIW2

05-zHG4.2ISSRIFIW3

05-zHG5ISSRIFIW4

01zHG4.2EMITIFIW5

01zHG5EMITIFIW6

RSSI(Passive)

W8

5GHz ERR - 1

18/20

0x 0

0x 0

0x 0

19/20

1 ERROR STANDBY CAUSE 1 NO RECORD ERROR STANDBY CAUSE

2 ERROR STANDBY CAUSE 2 NO RECORD

3 ERROR STANDBY CAUSE 3 NO RECORD

4 ERROR STANDBY CAUSE 4 NO RECORD

5 ERROR STANDBY CAUSE 5 NO RECORD

20/20

3 MONITOR ERROR CAUSE RESET OFF Reset of moni

NOTE: In the case of 60G9T or 70G9T also, please choose "G9T" as MODEL NAME in Page.20.

zHG5dnazHG4.2TSETISSRIFIW7

,1-RREzHG4.2TLUSERISSRIFI

retnEELBANEGALFPUREV6

NOTIMILLENAP7

032TIMILEGNARLENAP8

06TNERRUCKCEHCTROHS01

WOLWSTNERRUC11

LC-60G9T / LC-70G9T

).cte,liatedtnemtsujda(skrameRnoitpircseDmetIeniLegaP

etirW/daeRDAERETIRW/DAER1

sserddaevalS0EVALSSSERDDA/EVALS2

sserddaretsigeR0x0SSERDDARETSIGER3

atadgnitirW0x0ATADETIRW4

atadgnidaeR0x0ATADDAER5

.esuacybdnatsteseRFFOTESERESUACYBDNATS6

.MORPEEotseulavgnittesgnitirWFFOEVASPEE1

.MORPEEmorfseulavgnittesgnidaeRFFOREVOCERPEE2

tor error cause

EMANLEDOMX048ELEMANLEDOM4

.gnittesezislenaP06EZISLENAP5

thgiLkcaBDELkcehCretnEEDOMKCEHCTROHS9

)yrotcafforecudorprof(gnivresnehwhcuott'noD0x0RDAPEETCUDORP21

hwhcuott'noD0x0ATADPEETCUDORP31 en serving (for producer of factory)

)yrotcafforecudorprof(gnivresnehwhcuott'noD552YROTCAFTCUDORP41

5 – 7

Page 23

LC-60G9T / LC-70G9T

6. Special features

* STANDBY CAUSE (Page 1/20)

Display of a cause (code) of the last standby

The cause of the last standby is recorded in EEPROM whenever possible.

Checking this code will be useful in finding a problem when you repair the troubled set.

* EEP SAVE (Page 20/20)

Storage of EEP adjustment value

* EEP RECOVER (Page 20/20)

Retrieval of EEP adjustment value from storage area

7. STANDBY CAUSE FUNCTIONS

This model is equipped with a STANDBY CAUSE FUNCTIONS which stores the cause of why the unit is turned off and displays it on adjustment process mode.

1. NORMAL STANDBY CAUSE

ERROR CODE here indicates cause of standby in normal operation or Function of the Unit.

No display when the unit is turned off with R/C.

Only the latest cause is indicated.

2. ERROR STANDBY CAUSE

ERROR CODE here indicates cause of Error in the unit.

It also indicates accumulated operating times of the unit.

The last five histories are displayed.

1)-5) five histories 1) is the latest.

When there is no error, error code is ‘0’ and no characters appear.

3. MONITOR ERROR CAUSE

When the monitor micom detects an error, ERROR CODE is displayed.

The number of flashing Power LED and OPC LED indicates location of error detected.

This number stores the latest four contents of the error. ‘0’ is displayed when no error.

x NORMAL STANDBY CAUSE

2 NO_OPERT in the cause of “no operation off”

3 NO_SIGNA in the cause of “no signal off”

6 SLEEP_TM in the cause of “SLEEP timer”

8 OFF_232C in the cause of command by RS-232C

x ERROR STANDBY CAUSE

1A E_MONITR in the cause of monitor trouble detected

1C E_CVICBT in the cause of driver boot error

22 E_TCNERR in the cause of software abmormality of LCD controller

48 E_MRESET in the cause of failure of resetting menu settings (Initial Setup - Reset)

50 E_TCNF_S in the cause of TCON FPGAStatus error

54 E_TCON_E in the cause of fatal error by TCON hanging up

x MONITOR ERROR CAUSE

02 Initial Communication Error 2 Cannot receive initial communication from main CPU

03 Initial Communication Error 3 Receive initial communication only

04 Initial Communication Error 4 To the communication setting reception

05 Initial Communication Error 5 To the initialization completion reception

06 Initial Communication Error 6 To the notice of version reception

07 Initial Communication Error 7

08 Initial Communication Error 8 To the start information answer reception

09 Initial Communication Error 9 To the time-out setting reception

0A Communication Error A Request Time-out

0B Communication Error B Restart Time-out

0C Communication Error C End sequence Time-out

0D Communication Error D Reserve start Time-out when End seqence

0E Communication Error E Download Start Time-out

0F Communication Error F Get Time Start Time-out

To the notice of start information reception

nosaeRrorrEyalpsiD

noitpircseDnoitacidnIedoCyalpsiD

noitpircseDnoitacidnIedoCyalpsiD

5 – 8

Page 24

nosaeRrorrEyalpsiD

11 Communication Error H Regular communication Time-out

rorrEpmaLrorrEeludoMDCL61

rorrEerutarepmeTrotinoM2rorrErehtOA1

1D Power supply Error1 PS_ON(AC_DET) Error

1E Power supply Error 2 D_POW(DET_13V) Error

1F Power supply Error 3 D_POW(DET_D3V3) Error

21 Power supply Error 5 Panel Power Error

UPCniaMmorftseuqerybdnatSrorrE3rorrErehtO32

LCD TV ADJUSTMENT ITEM

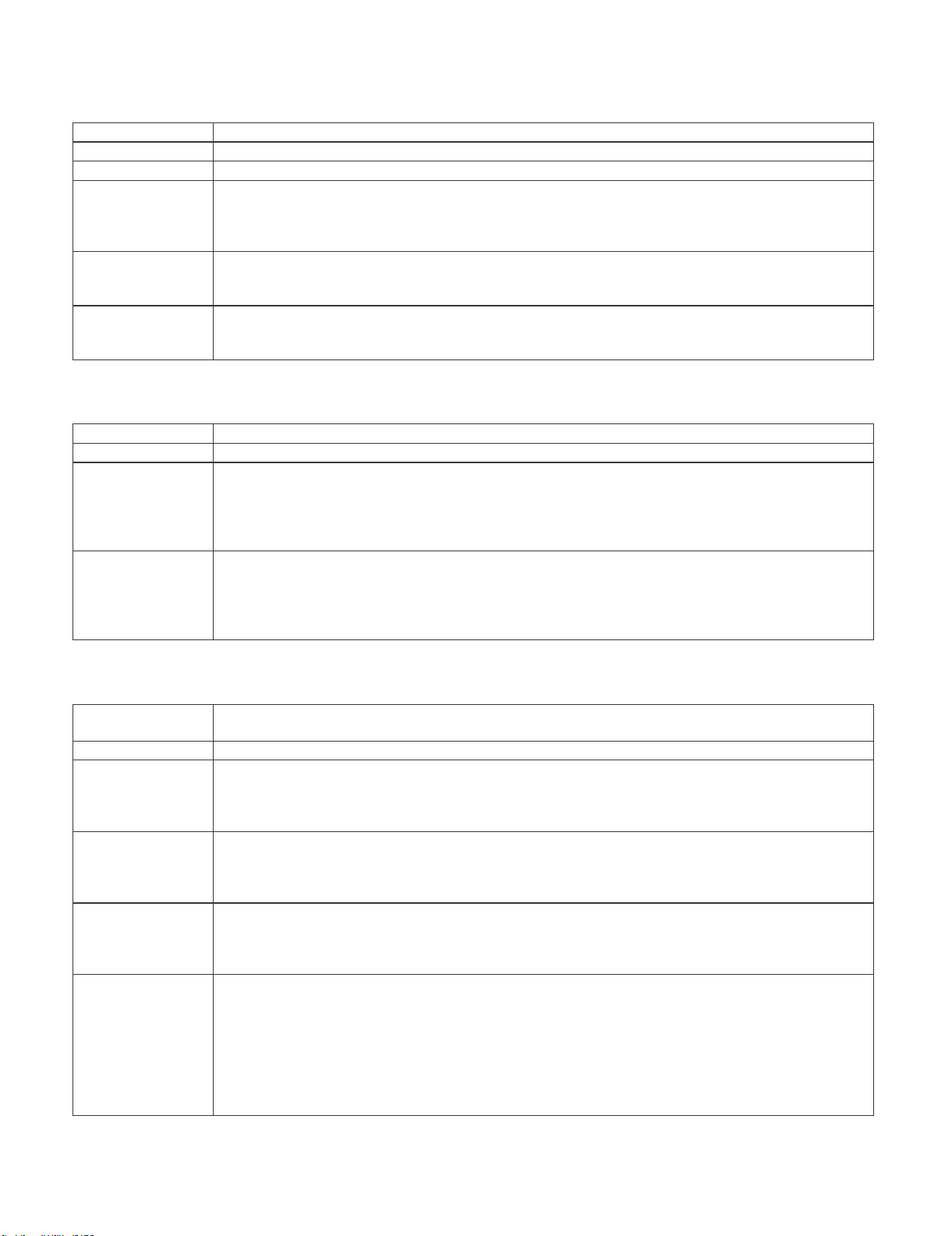

1. MICON SOFTWARE DATA INPUT

1) Main MICON/Monitor MICON Software Data Input (Main PWB : QPWBXG216WJ**)

1 Main MICON/

Monitor

MICON Data

Input

(Main PWB)

Checker

adjustment

Full version

confirmation

USB Memory

1. At checker, connect software jig at SC3101 (TL3114~3128).

2. Connect the USB memory at J9502 (TL9524~TL9527)

3. Standard voltage apply at Main PWB and from software jig, BOOT

Operation starting.

4. Software entry start command is transmitted through RS232C

5. After receive confirmation software input condition, confirm it by

reply OK and cut off the power.

Confirmation.

[ Caution item ]

If USB memory is not conne

cted or error such as cannot read data

occurs, no data will be input.

LC-60G9T / LC-70G9T

ERUDECORPNOITIDNOCMETI

2) T-CON ROM DATA INPUT (T-CON PWB : QPWBXG215WJ**)

1 T-CON Data

Input

Checker

adjustment

3. At checker, connect software jig at CN5801 (TL5801~5807).

4. Input voltage at P4804 (TL4801~TL4804) and ROM start to

input data.

(T-CON PWB)

Full version

3. Power OFF after finish data input.

confirmation

[ Caution item ]

If some error happened, ROM data is not written in at all.

Note: Please refer to below for combination of T-Con software

R1JE600D3HD60W

1

2

R1JE695D3B10W

DUNTKG215FMG1

DUNTKG215FMG2

PRIMROSE_CMB_601F8(YS2)_2012100330440002_3FAAEBD.ROM

PRIMROSE_CMB_701FC(YS2)_2012100330550004_3B59E6E.ROM

ERUDECORPNOITIDNOCMETI

ERAWTFOSNOC-TTINUNOC-TLENAPDCL

5 – 9

Page 25

LC-60G9T / LC-70G9T

C

o

m

A

9. SIGNAL ADJUSTMENT

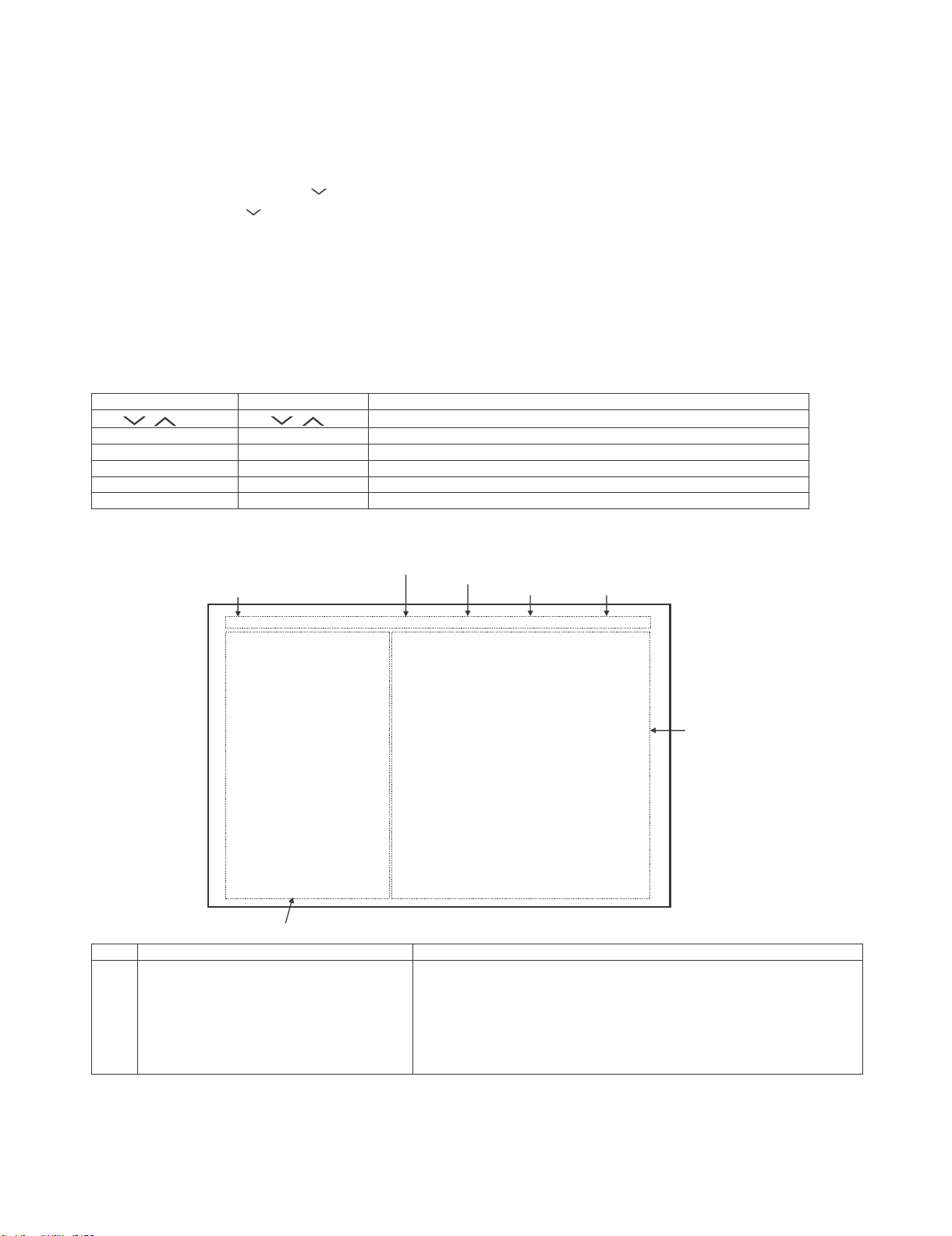

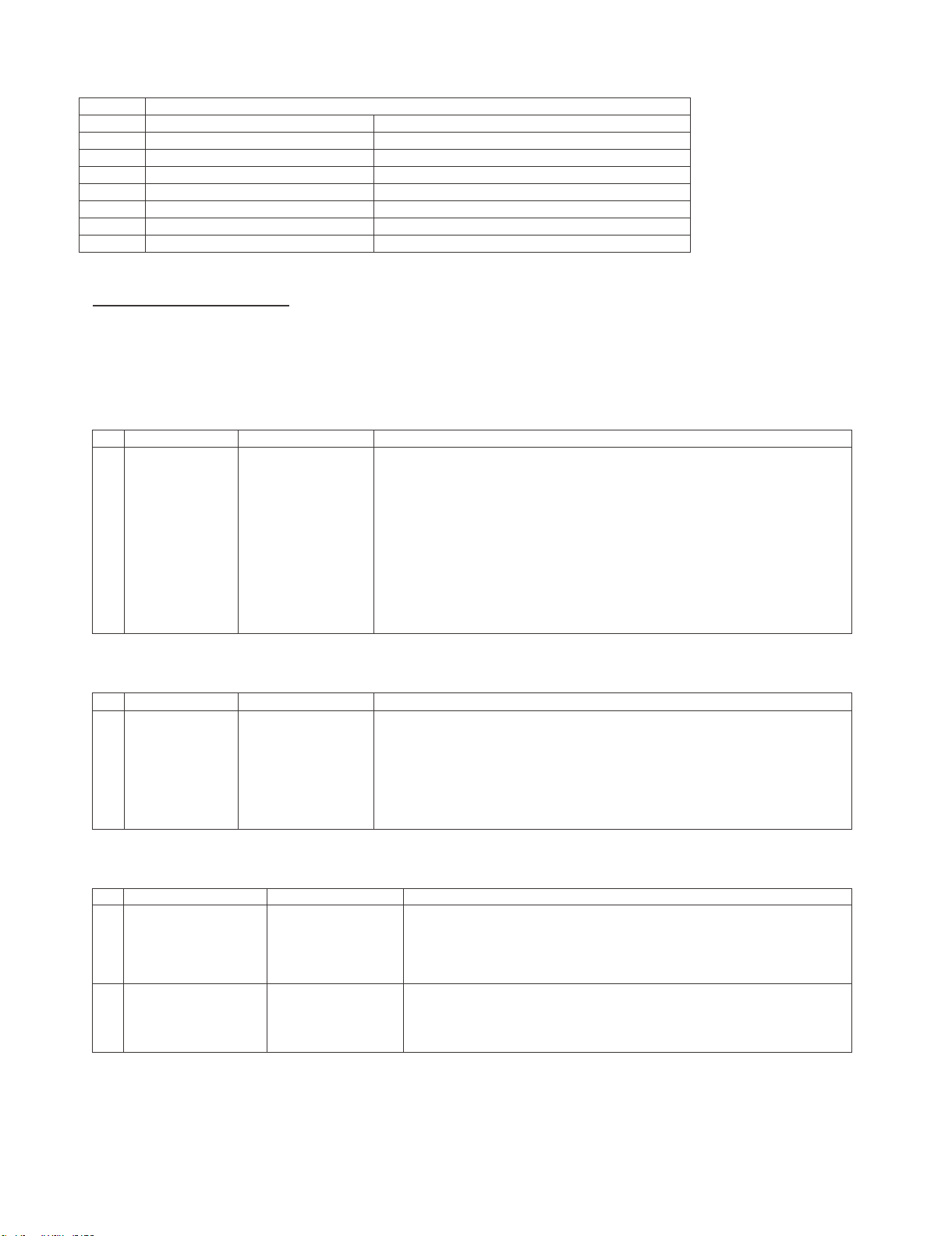

9.1 ) LCD Adjustment [ LCD Module Adjustment ]

1BIAS

adjustment

(LCD module

Adjustment

Item)

Adjustment must

be done at center

of panel

ERUDECORPNOITIDNOCMETI

1. Enter adjustment mode by using test remote control.

2. By using Remote control, press

3. After press “ENTER”, adjustment pattern will appear..

4. With key volume + / -, adjust until the flicker is minimum appear on

the center of the screen.

5. After satisfied with step 4, press “ENTER” to OFF.

[ Caution item ]

*Adjustment done during no signal from ANT (due to brightness will

change because of active backlight)

[ Adjustment Location ]

䊺䚸䊼

to select

[VCOM ADJ]

9.2) PICTURE ADJUSTMENT

(9.2.1) Equipment confirmation

Before adjustment, need to confirm that Adjustment equipment and signal generator have set to SHARP

LCD US used.

Confirmation of signal from generator (setting to spec level)

posite signal (NTSC)[For ‘T’ & ‘X’ model ] 㸸0.714Vp-p ± 0.02Vp-p (pedestal to white level)

(PAL/SECAM)[For ‘X’ model only] 㸸0.7 Vp-p ± 0.02Vp-p (pedestal to white level)

Component signal (50Hz) 㸸Y level 㸸0.7 Vp-p ± 0.02Vp-p (pedestal to white lev

Pb, Pr level 㸸0.7 Vp-p ± 0.02Vp-p

Component signal 㸸Ylevel 㸸0.7 Vp-p ± 0.02Vp-p (pedestal to white level)

Pb, Pr level 㸸0.7 Vp-p ± 0.02Vp-p

ogue RGB : RGB level 㸸0.7 Vp-p ± 0.02Vp-p (pedestal to white level)

el)

5 – 10

Page 26

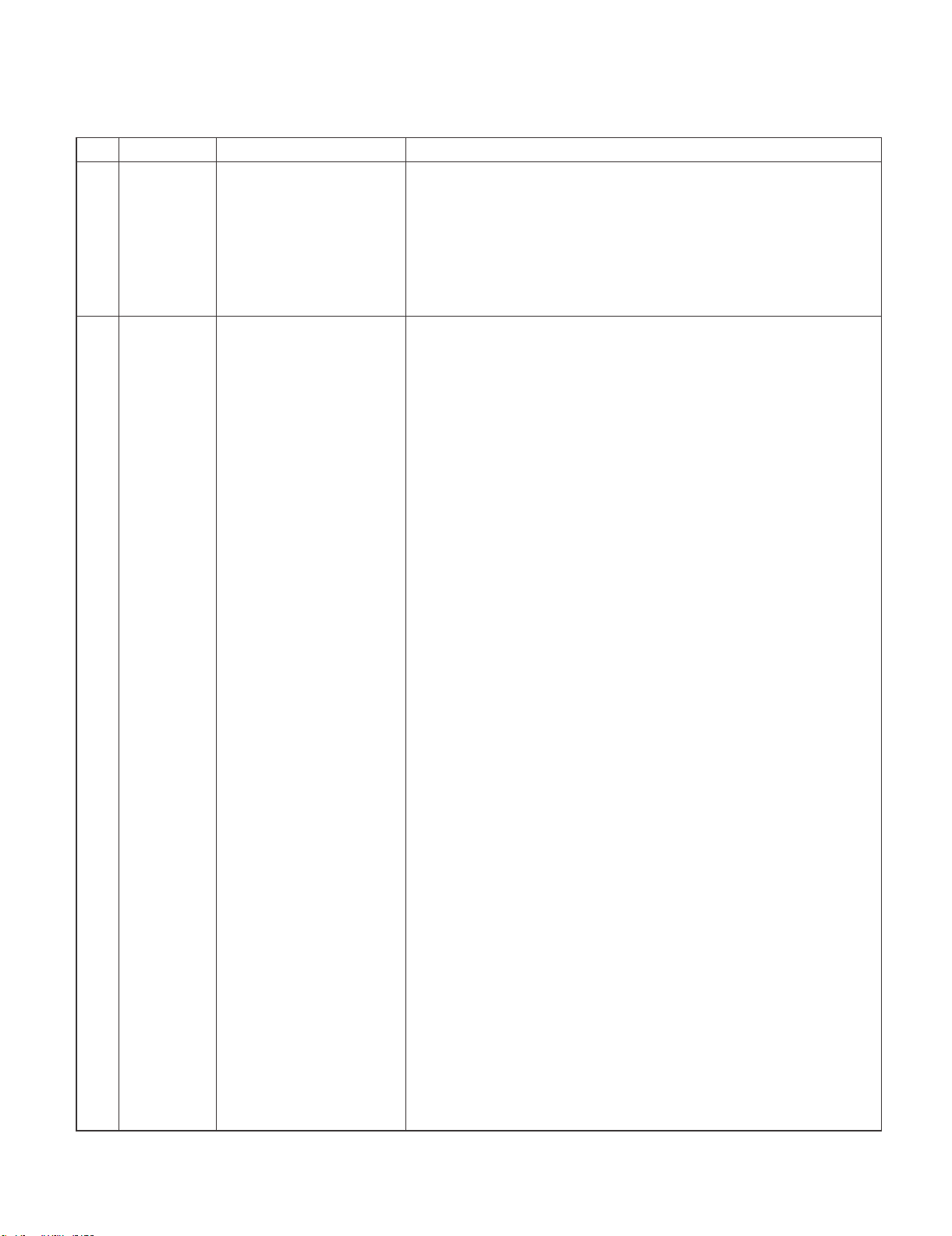

( 9.2.2 ) Adjustment Mode

ERUDECORPNOITIDNOCMETI

1 Adjustment Mode Press the test key at the test remote control

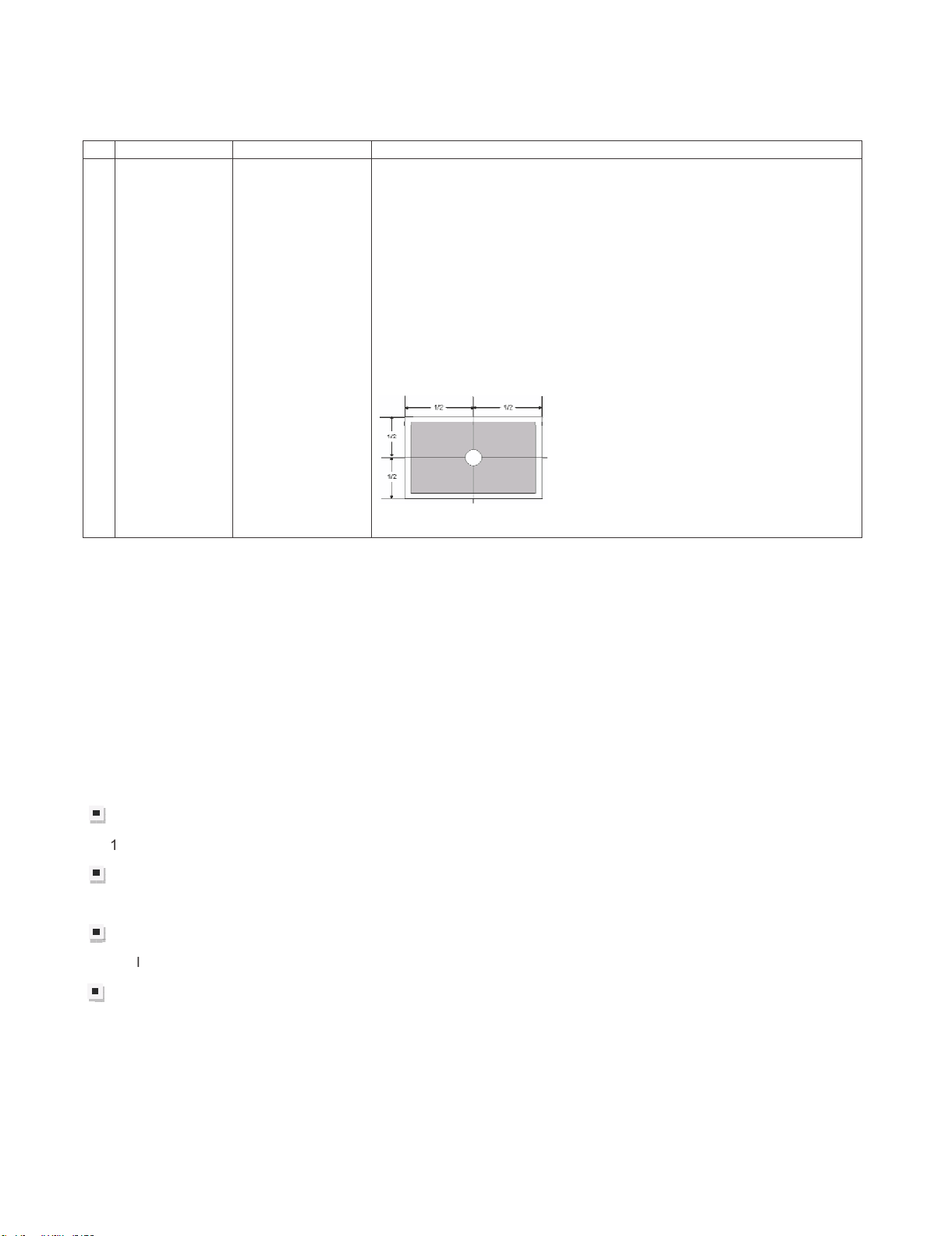

(9.2.3) PAL Signal Adjustment [For ‘X’ model ONLY. Skip for ‘T’ model]

ERUDECORPNOITIDNOCMETI

1 Setting [Signal]

PAL Full-field

࣭Feed the PAL Full-field Colour Bar signal(75% colour

saturation) to INPUT 6

Colour Bar

[Terminal]

INPUT 6

Video input

100% WhiteЍЋBlack

LC-60G9T / LC-70G9T

2 Auto Adjustment Test Mode page

[4/33]

At the related page, move cursor to [PAL ADJ], press OK.

[PAL ADJ OK] appears when finished.

*Caution: Please execute (6) TUNER adjustment afterwards when adjust PAL signal of (3) after all

adjustments are completed.

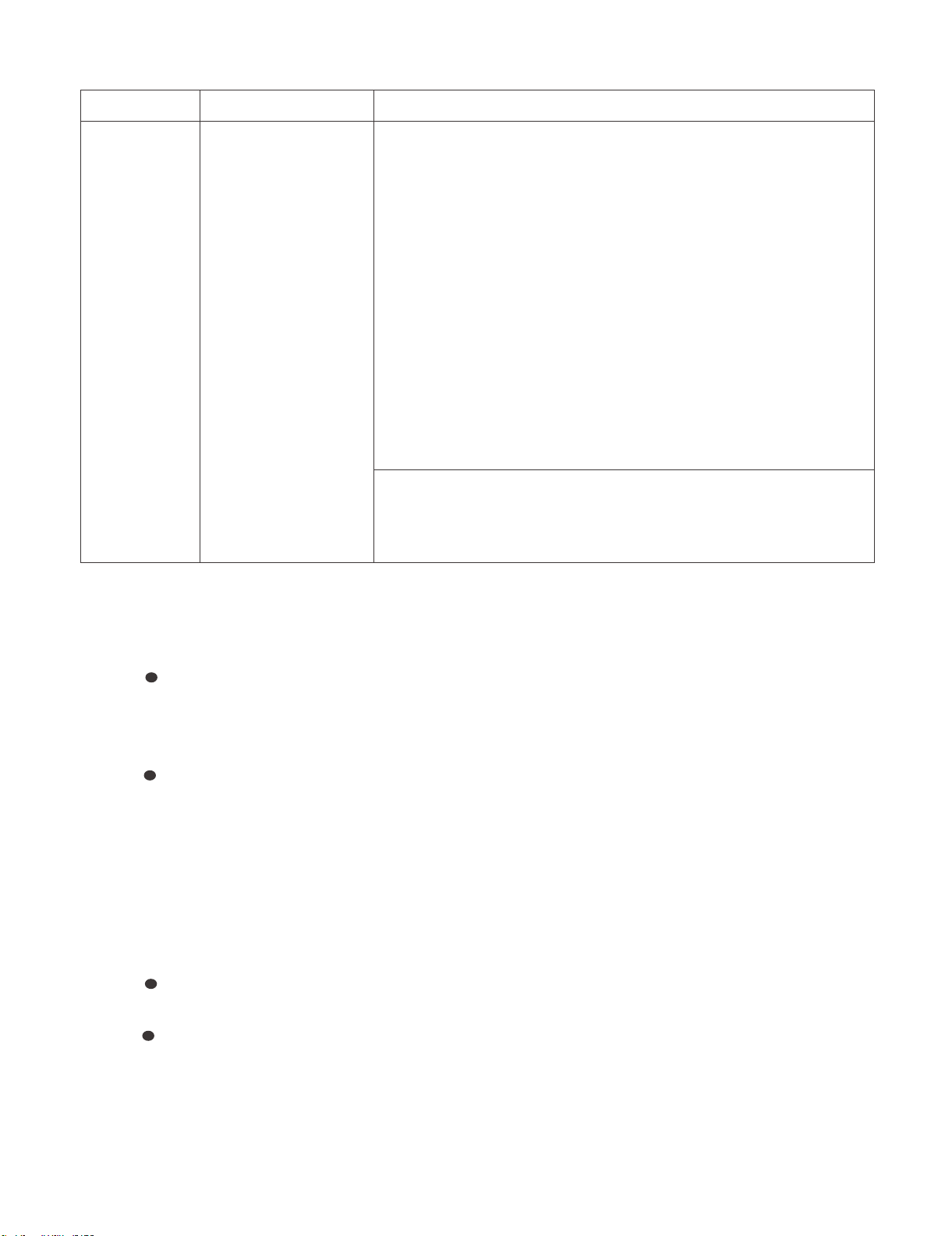

(9.2.4) NTSC Signal Adjustment [For ‘X’ and ‘T’ model]

ERUDECORPNOITIDNOCMETI

1 Setting [Signal]

N358 Full-field

࣭Feed the NTSC-J Full-field Colour Bar signal(75% colour

saturation) to INPUT 6

Colour Bar

[Terminal]

INPUT 6

Video input

100% WhiteЍЋBlack

2 Auto Adjustment Test Mode page

[4/33]

At the related page, move cursor to [N358 ADJ], press OK.

[N358 ADJ OK] appears when finished.

5 – 11

Page 27

LC-60G9T / LC-70G9T

Ќ

00%

[

]

Ќ

00%

[

]

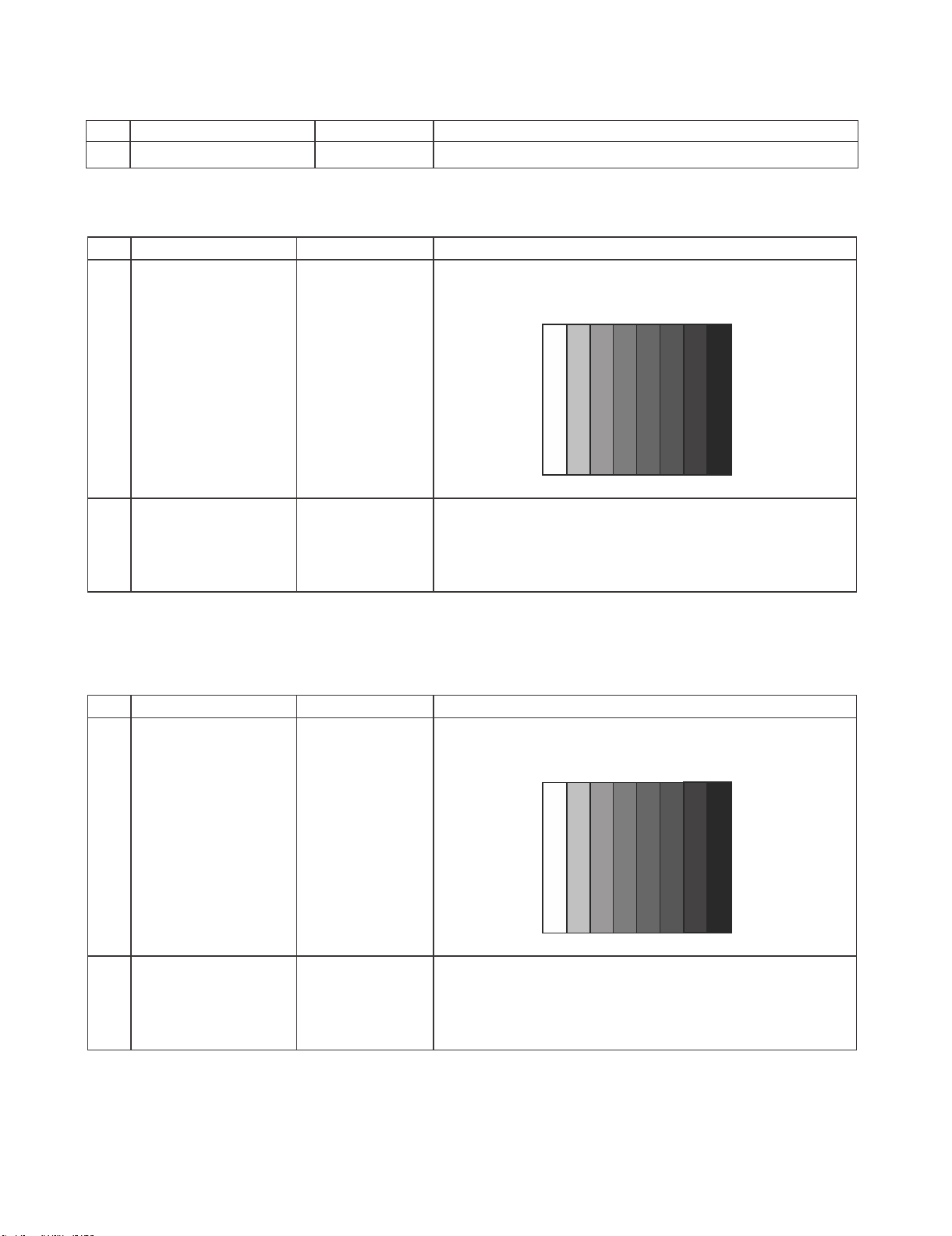

(9.2.5) SECAM Signal Adjustment [For ‘X’ model ONLY. Skip for ‘T’ model]

1 Setting [Signal]

SECAM Full-field

Colour Bar

[Terminal]

INPUT 6

Video Input

2 Auto Adjustment Test Mode page

[4/33]

(9.2.6) TUNER Signal Adjustment [For ‘X’ and ‘T’ model]

࣭Feed the SECAM Full-field Colour Bar signal(75% colour

saturation) to INPUT 6

100% White

At the related page, move cursor to [SECAM ADJ], press OK.

[SECAM ADJ OK] appears when finished.

ЍЋ

ERUDECORPNOITIDNOCMETI

Black

1 Setting [For ‘X’ model]

[Signal]

PAL split color bar

Internal UV

[Terminal]

TUNER

[For ‘T’ model]

[Signal]

NTSC split color

bar

Internal UV

[Terminal]

TUNER

ERUDECORPNOITIDNOCMETI

࣭Feed the Internal signal (PAL colour bar E-12) to tuner RF.

Picture level and Sync Level 7:3

RF CH E-12

White 1

Feed the Internal signal (NTSC colour bar US-10CH) to

tuner RF. Picture level and Sync Level 7:3

RFCH US-10

White1

2 Auto Adjustment

[For ‘X’ & ‘T’ model]

Test Mode page

[3/33]

At the related page, move cursor to [TUNER ADJ], press OK.

[TUNER ADJ OK] appears when finished.

5 – 12

Page 28

(9.2.7) Component 15K Adjustment [For ‘X’ and ‘T’ model]

1 Setting [For ‘X’ model]

[Signal]

COMP 15K 50Hz

࣭Feed the COMPONENT 15K 50Hz (576i) 100% Full-field

Colour Bar signal(100% colour saturation) to

COMPONENT INPUT 5

(576i)

100% Full-field

Colour Bar

LC-60G9T / LC-70G9T

ERUDECORPNOITIDNOCMETI

[Terminal]

100% White

ЍЋ

COMPONENT

INPUT 5

[For ‘T’ model]

[Signal]

COMP 15K 60Hz

(480i)

࣭Feed the COMPONENT 15K 60Hz (480i) 100% Full-field

Colour Bar signal(100% colour saturation) to

COMPONENT INPUT 5

100% Full-field

Colour Bar

[Terminal]

100% White

ЍЋ

COMPONENT

INPUT 5

2 Auto Adjustment

[For ‘X’ & ‘T’ model]

Test Mode page

[6/33]

At the related page, move cursor to [COMP 15K ALL ADJ],

press OK.

[COMP 15K ALL OK] appears when finished.

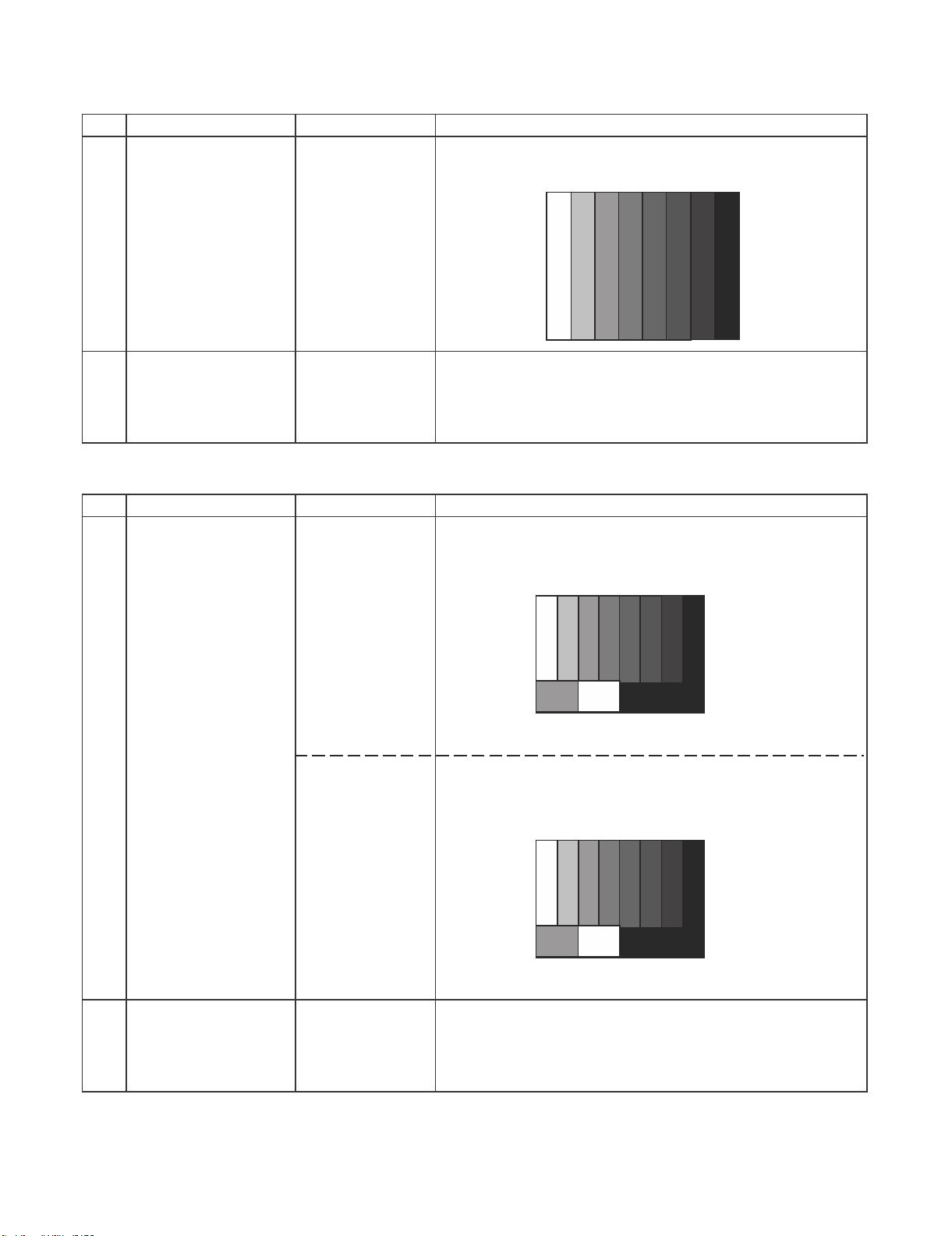

(9.2.8) HDTV Adjustment (Component 33K) [For ‘X’ and ‘T’ model]

1 Setting [For ‘X’ model]

[Signal]

COMP 33K 50Hz

(1080i/50Hz)

࣭Feed the COMPONENT 33K 50Hz (1080i) 100% Full-field

Colour Bar signal(100% colour saturation) to

COMPONENT INPUT 5

100% Full-field

Colour Bar

Black

Black

ERUDECORPNOITIDNOCMETI

[Terminal]

COMPONENT

INPUT 5

100% White

5 – 13

ЍЋ

Black

Page 29

LC-60G9T / LC-70G9T

[For ‘T’ model]

[Signal]

COMP 33K 60Hz

(1080i/60Hz)

100% Full-field

Colour Bar

࣭Feed the COMPONENT 33K 60Hz (1080i) 100% Full-field

Colour Bar signal(100% colour saturation) to

COMPONENT INPUT 5

[Terminal]

100% White

ЍЋ

COMPONENT

INPUT 5

2 Auto Adjustment

[For ‘X’ & ‘T’ model]

Test Mode page

At the related page, move cursor to [HDTV ADJ], press OK.

[7/33]

[HDTV ADJ OK] appears when finished.

(9.2.9) PC ( Analogue D-sub 15 pin) Signal adjustment [For ‘X’ and ‘T’ model]

1 Setting

[For ‘X’ & ‘T’ model]

[Signal]

࣭Feed the XGA 60Hz 100% Full field colour bar signal (100%

colour saturation) to PC INPUT

XGA 60Hz

100% Full field

Colour Bar

Black

ERUDECORPNOITIDNOCMETI

2 Auto Adjustment

[Terminal]

PC INPUT 7

[For ‘X’ & ‘T’ model]

Test Mode page

[8/33]

100% White

ЍЋ

Black

At the related page, move cursor to [ANALOG PC ADJ], press

OK.

[ANALOG PC ADJ OK] appears when finished.

5 – 14

Page 30

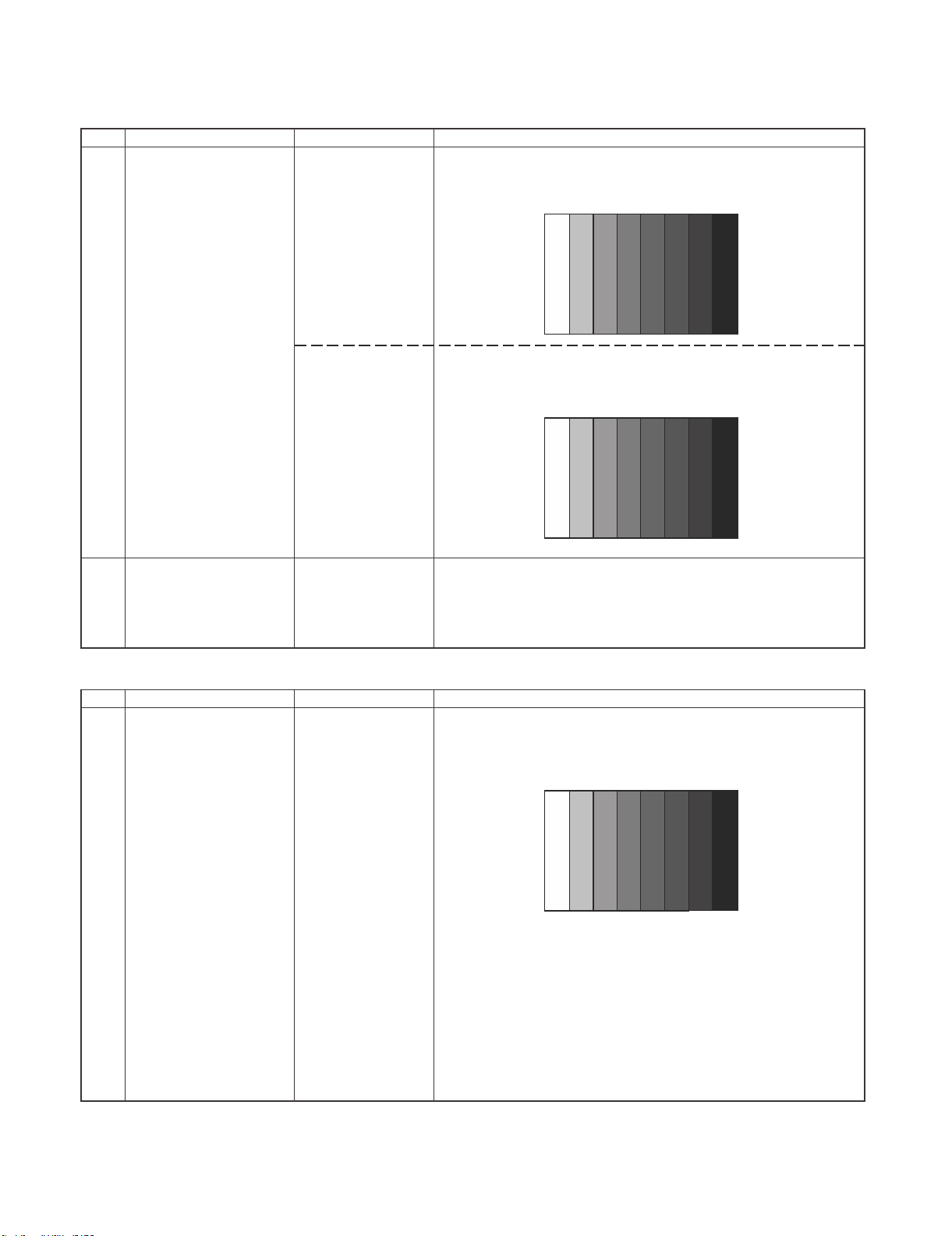

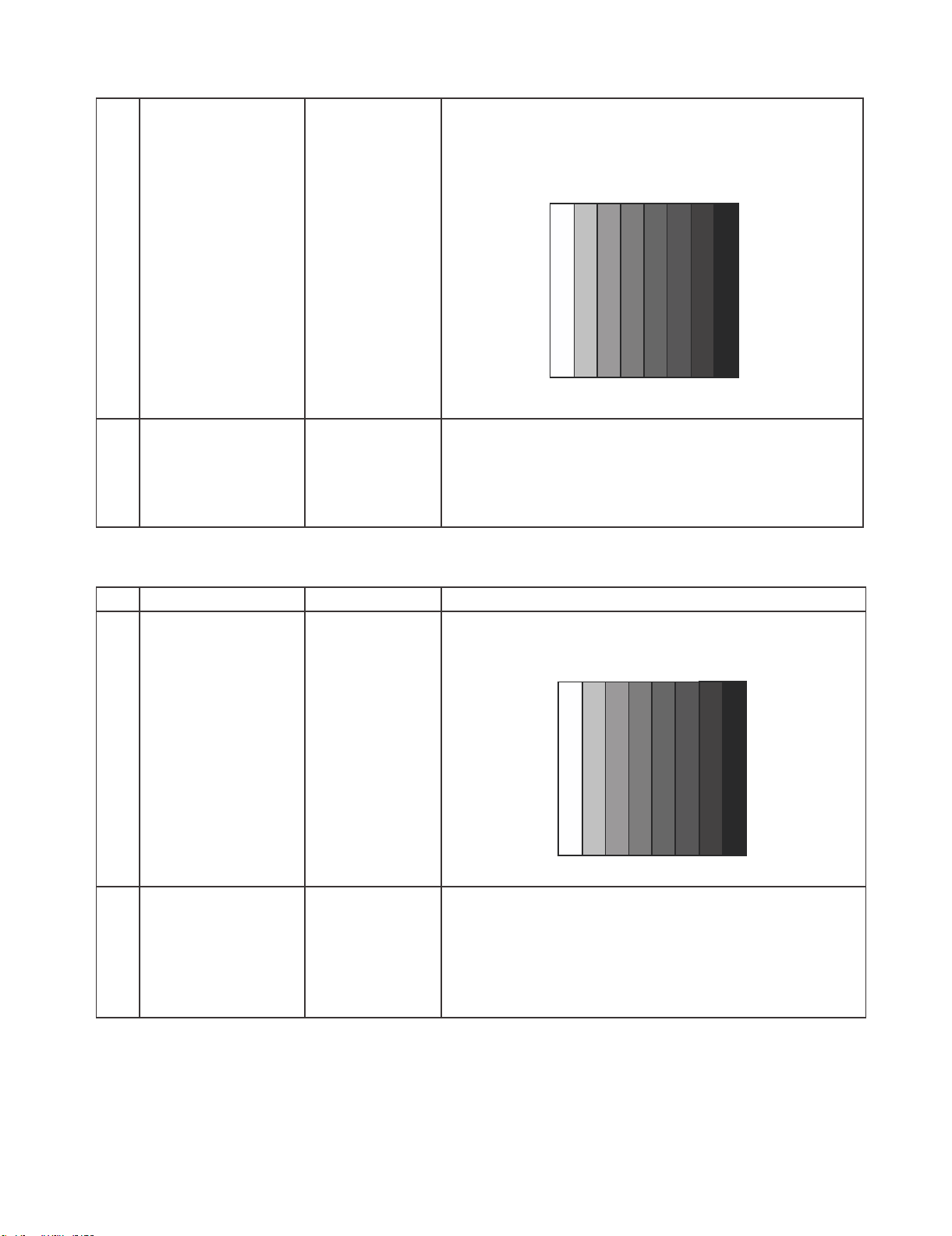

10㸧WHITE BALANCE ADJUSTMENT/ GAMMA ADJUSTMENT

4

10.1㸧White Balance Adjustment / Gamma Adjustment

㸯

㸰

Setting

Auto

Adjustment

Brightness㸸MAX㸦+16㸧

AV MODE: DYNAMIC

Active Backlight: OFF

OPC: OFF

Set the luminance

㸦

meter on the centre of the

screen

[command]

Adjustment mode

Setting

Multi point adj.

Gamma adjustment mode

setting

㸧

KRSW0001

KKT10037

KYOF0000

OSDS0001

SBSL0016

MSET0011

GC6P0011

Point 6

229

LEV60

GCC6****

MG6G****

MG6Y****

MG6B****

MG6R****

Point 5

LEV50

173

GCC5****

MG5G****

MG5Y****

MG5B****

MG5R****

Point 4

LEV40

133

GCC4****

MG4G****

MG4Y****

MG4B****

MG4R****

Point 3

LEV30116

GCC3****

MG3G****

MG3Y****

MG3B****

MG3R****

For the details of white balance adjustment procedure, please refer

to white balance adjustment spec for Kameyama model ver 1.9.

1. Confirm the set condition.

2. Connect the white balance jig.

3. Through RS-232C command, adjustment mode screen is

displayed

ㄪᩚἲࠚ

㸯.R/C࡚ࠕࣔࢽࢱ࣮ㄪᩚᕤ⛬ࠖࢥ࣮ࢻࢆ㏦ಙࡍࡿࠋ

㸰.6 㺬㺽㺐㺻㺢┠ࢆᣦᐃࡉࢀࡓ㝵ㄪタᐃࡋࠊ࣐࢞ࣥㄪᩚࡢ 6 ࣏ࣥࢺ

┠ࡢ㍤ᗘࢆ ᐃࡋࠊྲྀᚓࡋࡓ㍤ᗘࡢ 10 ಸࢆタᐃࡍࡿࠋ୍␒ᙉ࠸

ⰍࢆᅛᐃⰍࡋ࣐ࢼࢫㄪᩚ࡛ᇶ‽್࡞ࡿࡼ࠺ RGB ࢆㄪᩚ

ࡍࡿࠋ

RGB ࡢ㝵ㄪࢆࢭࢵࢺࡋࡓᚋࠊYe ࡢ㝵ㄪࢆ⟬ฟࡍࡿࠋ

R㸼G ࡢሙྜ…Ye=G×1.05

ࡓࡔࡋࠊYe ࡢ್ࡀึᮇ್(916)ࢆ㉸࠼ࡓሙྜࡣࠊ916 ࡍࡿ

RӌG ࡢ

ሙྜ…Ye=R×1.05

ࡓࡔࡋࠊYe ࡢ್ࡀึᮇ್(916)ࢆ㉸࠼ࡓሙྜࡣࠊ916 ࡍࡿ

ୖグ᮲௳ᘧࡽ⟬ฟࡉࢀࡓ Ye ࡢ್ࢆ MG6YXXXX ࡛ࢭࢵࢺࡍ

ࡿࠋ

ᇶ‽್᮰ࡍࡿࡲ࡛⧞ࡾ㏉ࡋ RGBYe ࢆㄪᩚࡍࡿࠋ

䠏.(STEP2)6 䢊䢛䡮䢙䢀┠䛾ㄪᩚᚋ㍤ᗘ Y

ศග㍤ᗘィ(SR-LEDW,SR-3 ➼)䛻䜘䜛⿵ṇ㍤ᗘ Y

R6,G6,B6 䜢 2-1 䛻䛶ィ⟬䛧䛯 6 䢊䢛䡮䢙䢀┠䛾 R,G,B ㄪᩚ್䛸䛩䜛䚹

Y

䠘258 䛛䛴㻌 R6䠙916 䛾ሙྜ䚸௨ୗ䛾ฎ⌮䜢⾜䛖䚹

WB6-SR3

䠙(268/Y

GAIN

G6

WB6-SR3

ణ䛧䚸Y=355…440cd/m

GAIN

䠚1.10 䛾䚸GAING6=1.10 䛸䛩䜛䚹

G6

ィ⟬ᚋ䛾 6 䢊䢛䡮䢙䢀┠䛾 G 䜢 G6'䠙GAIN

ィ⟬ᚋ䛾 6 䢊䢛䡮䢙䢀┠䛾 Ye 䜢 Ye6'䠙1.05×min(R6,G6')䛸䛩䜛䚹

ィ⟬ᚋ䛾 6 䢊䢛䡮䢙䢀┠䛾 B 䜢 B6’䠙B6×G6’䠋G6 䛸䛩䜛䚹

ణ䛧䚸R6',G6',B6'䛜 916 䜢㉸䛘䜛䚸916 䛸䛩䜛䚹

.5 㺬㺽㺐㺻㺢┠ࢆᣦᐃࡉࢀࡓ㝵ㄪタᐃࡋࠊ ᐃࡋࡓ㍤ᗘ(cd/m2)ࡢ 10

ಸࢆ࣐࢞ࣥㄪᩚࡢ 5 ࣏ࣥࢺ┠タᐃࡍࡿࠋ

G ࡢ⿵ṇ್㸦692×6 㺬㺽㺐㺻㺢┠ G ್/916㸧(➃ᩘࡣᅄᤞධ)࠾ࡼࡧ

Ye ࡢ⿵ṇ್(692×6 ࣏ࣥࢺ┠Ye ್/916)(➃ᩘࡣᅄᤞධ)ࢆࢭ

ࢵࢺࡋࠊᇶ‽್࡞ࡿࡼ࠺ RB ࢆ±ࡋ࡚ㄪᩚࡍࡿࠋ

5.4 㺬㺽㺐㺻㺢┠ࢆᣦᐃࡉࢀࡓ㝵ㄪタᐃࡋࠊ ᐃࡋࡓ㍤ᗘ(cd/m

ಸࢆ࣐࢞ࣥㄪᩚࡢ 4 ࣏ࣥࢺ┠タᐃࡍࡿࠋ

G ࡢ⿵ṇ್㸦532×6 㺬㺽㺐㺻㺢┠ G ್/916㸧㸦➃ᩘࡣᅄᤞධ㸧࠾ࡼ

ࡧ Ye ࡢ⿵ṇ್(532×6 ࣏ࣥࢺ┠ Ye ್/916)(➃ᩘࡣᅄᤞධ)

ࢆ㺜㺍㺢ࡋࠊᇶ‽್࡞ࡿࡼ࠺ RB ࢆ±ࡋ࡚ㄪᩚࡍࡿࠋ

6.3 㺬㺽㺐㺻㺢┠ࢆᣦᐃࡉࢀࡓ㝵ㄪタᐃࡋࠊ ᐃࡋࡓ㍤ᗘ(cd/m

ಸࢆ࣐࢞ࣥㄪᩚࡢ 3 ࣏ࣥࢺ┠タᐃࡍࡿࠋ

ERUDECORPNOITIDNOCMETI

䜢 ᐃ䛧䚸䛭䛾⤖ᯝ䜢

WB6

)^(1/2䠅

2

┦ᙜ䚸365䞉䞉䞉453cd ┦ᙜ䚸

×G6 䛸䛩䜛䚹

G6

LC-60G9T / LC-70G9T

䛻⿵ṇ䛩䜛䚹

WB6-SR3

2

)ࡢ 10

2

)ࡢ 10

5 – 15

Page 31

LC-60G9T / LC-70G9T

Point 2

LEV20

GCC2****

MG2G****

MG2Y****

MG2B****

MG2R****

Point 1

LEV10

GCC1****

MG1G****

MG1Y****

MG1B****

MG1R****

WB adj value data input

MSET0003

MIN࣭MAX point

GCP00000

GCP70255

GCC0****

GCC7****

Adj. Value data input

GCST0001

Measure Luminance after

adjustment

CHGM1255

074

045

G ࡢ⿵ṇ್㸦464×6 㺬㺽㺐㺻㺢┠ G ್/916㸧㸦➃ᩘࡣᅄᤞධ㸧࠾ࡼ

ࡧ Ye ࡢ⿵ṇ್(464×6 ࣏ࣥࢺ┠ Ye ್/916)(➃ᩘࡣᅄᤞධ)

ࢆ㺜㺍㺢ࡋࠊᇶ‽್࡞ࡿࡼ࠺ RB ࢆ±ࡋ࡚ㄪᩚࡍࡿࠋ

7.2 㺬㺽㺐㺻㺢┠ࢆᣦᐃࡉࢀࡓ㝵ㄪタᐃࡋࠊ ᐃࡋࡓ㍤ᗘ(cd/m

2

)ࡢ 10

ಸࢆ࣐࢞ࣥㄪᩚࡢ 2 ࣏ࣥࢺ┠タᐃࡍࡿࠋ

G ࡢ⿵ṇ್㸦296×6 㺬㺽㺐㺻㺢┠ G ್/916㸧㸦➃ᩘࡣᅄᤞධ㸧࠾ࡼ

ࡧ Ye ࡢ⿵ṇ್(296×6 ࣏ࣥࢺ┠ Ye ್/916)(➃ᩘࡣᅄᤞධ)

ࢆ㺜㺍㺢ࡋࠊᇶ‽್࡞ࡿࡼ࠺ RB ࢆ±ࡋ࡚ㄪᩚࡍࡿࠋ

2

8.1 㺬㺽㺐㺻㺢┠ࢆᣦᐃࡉࢀࡓ㝵ㄪタᐃࡋࠊ ᐃࡋࡓ㍤ᗘ(cd/m

)ࡢ 10

ಸࢆ࣐࢞ࣥㄪᩚࡢ 2 ࣏ࣥࢺ┠タᐃࡍࡿࠋ

G ࡢ⿵ṇ್㸦

180×6 㺬㺽㺐㺻㺢┠ G ್/916㸧㸦➃ᩘࡣᅄᤞධ㸧࠾ࡼ

ࡧ Ye ࡢ⿵ṇ್(180×6 ࣏ࣥࢺ┠ Ye ್/916)(➃ᩘࡣᅄᤞධ)

ࢆ㺜㺍㺢ࡋࠊᇶ‽್࡞ࡿࡼ࠺ RB ࢆ±ࡋ࡚ㄪᩚࡍࡿࠋ

9㸬MSET0003 ࢥ࣐ࣥࢻ࡚ࠊㄪᩚ್ࢆ᭩ࡁ㎸ࡴࠋAC 㟁※ࢆษࡿࠋ

10㸬MIN࣭MAX ㄪᩚ㝵ㄪࢆᣦᐃࡉࢀࡓ㝵ㄪタᐃࡋࠊ࣐࢞ࣥㄪᩚࡢ

MAX ࣏ࣥࢺࡢ㍤ᗘࢆ ᐃࡍࡿࠋMAX ࡣྲྀᚓࡋࡓ MAX ㍤ᗘ

2

)ࡢ 10 ಸࢆタᐃࡍࡿࠋMIN ࡣྲྀᚓࡋࡓ MAX ㍤ᗘࣃࢿ

(cd/m

ࣝ SPEC ࡢࢥࣥࢺࣛࢫࢺẚࡽ MIN ㍤ᗘ(cd/m

ࡢ㍤ᗘࡢ 100 ಸ

ࢆタᐃࡍࡿࠋ

2

)ࢆ⟬ฟࡋࠊࡇ

11㸬GCST0001 ࢥ࣐ࣥࢻ࡚ࠊㄪᩚ್ࢆ᭩ࡁ㎸ࡳ AC 㟁※ࢆษࡿࠋ

6 㺬㺽㺐㺻㺢ࡢ RGBYe ࡢึᮇ್㸸 タᐃ㝵ㄪ 916

1㹼5 㺬㺽㺐㺻㺢ࡢ RGB ࡢึᮇ್㸸 ྛ㺬㺽㺐㺻㺢ࡢ G ࡢ⿵ṇ್

ࡓࡔࡋ 1㹼5 㺬㺽㺐㺻㺢ࡢ Ye ࡢึᮇ್㸸ྛ㺬㺽㺐㺻㺢ࡢ Ye ࡢ⿵ṇ್

ὀព㸸

ࢸࢫࢺࣃࢱ࣮ࣥฟຊࢥ࣐ࣥࢻࢆᐇ⾜ᚋࠊࣃࢱ࣮ࣥฟຊࡲ

࡛ࡢീ㐜ᘏࡀ࠶ࡿࡓࡵࠊ“OK”ࡢ㏉ࡾࡽୗグ Wait 㛫

௨ୖᚅࡗࡓᚋࠊⰍᗘ࣭㍤ᗘࢆ ᐃࡍࡿࡼ࠺ࡋ࡚ୗࡉ࠸ࠋ

ീ㐜ᘏ㔞㸸70ms

㸦࣓࣐ࣥࢥ࣭ࣥLCD ࢥࣥࢺ࣮ࣟࣛࡢࢺ࣮ࢱࣝ㐜ᘏ㔞್᭱㸧

࠙ㄪᩚ್ࠚ

ۼᢏ⾡㒊ᥦฟࡢࠕࢸ࣮ࢳࣥࢢࢭࢵࢺࠖ‽ࡎࡿࠋ

࠙ㄪᩚᇶ‽್ࠚ ᐃჾ㸸[Minolta CA-210 ] ᢏ⾡ ᐃჾ

㺸㺫㺼㺷 ᇶ‽್ ㄪᩚ㺛㺫㺽㺍㺖 ᳨ᰝ㺛㺫㺽㺍㺖

㺬㺽㺐㺻㺢 6916

㺬㺽㺐㺻㺢 5692

㺬㺽㺐㺻㺢 4

㺬㺽㺐㺻㺢 3

㺬㺽㺐㺻㺢 2

㺬㺽㺐㺻㺢 1

532

464

296

180

X= 0.272

y= 0.277

X= 0.272

y= 0.277

X= 0.272

y= 0.277

X= 0.272

y= 0.277

X= 0.272

y= 0.277

X= 0.272

y= 0.277

±0.0010 ±0.0020

±0.0010 ±0.0020

±0.0015 ±0.0030

±0.0020 ±0.0040

±0.0030 ±0.0060

±0.0040 ±0.0080

ഛ⪃ ᳨ᰝࡢࢭࢵࢺ᮲௳

AV MODE : [DYNAMIC]

Monochro : ON

Aging Time㸸 Min. 60

5 ศ

5 – 16

Page 32

11 ). KEY DATA INPUT

11.1) EDID DATA INPUT ( Main PWB : QPWBXG216WJ**)

ERUDECORPNOITIDNOCMETI

1 HDMI EDID

INPUT

ANALOG RGB

EDID INPUT

(Main PWB)

11.2)MACADDRESS DATA INPUT (Main PWB : QPWBXG216WJ**)

Please refer to Document “Caution Item for Production “.

11.3)CIPLUS KEY DATA INPUT (Main PWB : QPWBXG216WJ**) [For X Model Only]

Please refer to Document “Caution Item for Production”.

Inspection mode

Confirm the file

name/version.

1. Enter the Adjustment Mode.

2. Move cursor at [HDMI EDID WRITE] and press [ENT] key.

[OK] appear when finish.

(HDMI and Analogue RGB input data together)

[ Caution Item ]

Please execute data input after setting the model distinction.

The data based on model distinction information is recorded in

EEPROM.

LC-60G9T / LC-70G9T

11.4) WMDRM KEY DATA INPUT (Main PWB : QPWBXG216WJ**)

Please refer to Document “Caution Item for Production”.

12. CONFIRMATION ITEM

(1) HDMI-CEC Check

Confirm the operation of HDMI-CEC circuit.

(2) LAN Check

Confirm the connection and communication of PC and LAN terminal.

13. FACTORY SETTING

AC power is plug off after shipment setting is done.

Caution: Do not plug on again after shipment setting is done. If do, please re-do the shipment setting. Do not

off with remote control.

5 – 17

Page 33

LC-60G9T / LC-70G9T

ERUDECORPNOITIDNOCMETI

Factory setting AC power off to exit the

factory setting.

Go to adjustment mode page [2/33], move cursor at [INDUSTRY INIT]

and press [OK] at Remote control.

ޚFor X model, please select destination either

- AUSTRALIA for COUNTRY of AUSTRALIA

- NEWZEALAND for COUNTRY of NEW ZEALAND

- GENERAL for others ASIA COUNTRIES

Remark: GENERAL setting is for MALAYSIA/ SINGAPORE/

INDONESIA/ SINGAPORE/ VIETNAM/ PHILIPINNE/ THAI

MIDDLE EAST

ޚ For T model, just press [ENTER] at Remote Control and no

selection need to be done.

////////// appear, after that

SUCCESS --------- Destination appear after finished.

If success, background colour is GREEN , if failed, background colour

is RED

The followings are initialised to factory setting

1) User setting

2) Channel data (e.g. broadcast frequencies)

3) Manufacturer’s option settings

4) Password data

14. SOFT/ ROM VERSION

1.Main microprocessor

950X/951X

XIAN_LE950X_xxx.USB

XIAN_LE950X_xxx.UVP

XIAN_LE950X_xxx.PCC

G9T

XIAN_G9T_xxx.USB

XIAN_G9T_xxx.UVP

XIAN_G9T_xxx.PCC

2.Monitor microprocessor

XIANSUBxxx.SMB

3.T-CON ROM

LC-60LE950X/951X,LC-60G9T

PRIMEROSE_CMB_601F8(YS2)_2012100330110002_3FAAEBD.ROM

LC-70LE950X/951X,LC-70G9T

PRIMEROSE_CMB_701FC(YS2)_2012100330550004_3B59E6E.ROM

5 – 18

Page 34

[2] PUBLIC MODE SETTING PROCEDURE

1. How to start Public Mode

Starting the Public Mode

• There is one following ways to display the PUBLIC Mode setting screen.

1) Method of needing password

a) Press the "INPUT" and "VOL (+)" keys on the set at once and turn on the power.

b) Display the Pass Word input screen.

LC-60G9T / LC-70G9T

Enter password

Operation procedure

• The initial input position is the digit at the left end.

• For the numeric keys “0” to “9” of R/C, key input is accepted.

Input of the other keys is prohibited.

• Change “—” to “ * ” by inputting the numeric key at the input position, and shift the input position rightward one digit.

• When three digits are completely input, the Pass Word is judged.

c) Check the Pass Word by inputting three digits.

If the Pass Word “0” “2” “7”, it shifts to the PUBLIC Mode setting screen.

In another case, the screen is erased, and it operates in the ordinary mode.

2) In the adjustment process mode, turn on “PUBLIC MODE”. Also press the “CH ( )” or “CH ( )” and “VOL(+)” keys on the set at once and turn

on the power.

Enter password

Enter password

2. How to exit Public Mode

There are the following ways to quit the public mode setup screen.

x Turn off “PUBLIC MODE” in the adjustment process mode. ( ) m This way alone is not for quitting the setup screen, but for quitting the mode itself.

x Turn off the power with the “POWER” key. ( )

x Select “EXECUTE”. ( )

... “PUBLIC MODE” stays on in the adjustment process mode.

... The settings will be back to the factory ones.

3. Public Mode Setting Values

x With the factory settings made, the public mode settings get initialized. (The adjustment process remains intact.)

5 – 19

Page 35

LC-60G9T / LC-70G9T

4. Public Mode Menu

The guidance is not displayed on screen.

Setup procedure

x To move the cursor up and down, use the “cursor UP/DOWN” key (remote controller) and “CH ( )/( )” key (remote controller and set).

x To change the settings, use the “cursor RIGHT/LEFT” key (remote controller) and “VOL (+)/(–)” key (remote controller and set).

x To save new settings, keep the cursor at “EXECUTE” and use “ENTER” key (remote controller and set).

5 – 20

Page 36

LC-60G9T / LC-70G9T

5. On Setting Items

1) Power ON fixed [POWER ON FIXED]

Option “VARIABLE”, “FIXED_ALL”, “FIXED_BODYKEY” or “RCRESPOND” (loop enabled)

Default “VARIABLE”

Function • VARIABLE

• FIXED_ALL

• FIXED_BODYKEY

• RC RESPOND

Key disabled when set

other than default

Remarks • When selecting to “FIXED_ALL”, function related standby factors (see below) doesn’t work. and not selecting.

If the power button is pressed in the ordinary mode in setting to “FIXED_ALL” and “FIXED_BODYKEY”, the caution is displayed for 5 seconds.

• OFF TIMER (SLEEP) (*Only when setting to FIXED_ALL)

OFF TIMER (Sleep)

No operation OFF

No signal OFF (including the power management)

* These items does not exist according to the model.

: “POWER/RECEPTION” key on TV unit or remote control is enabled.

: “POWER/RECEPTION” key on TV unit or remote control is disabled.

: Only the “MAIN POWER” key on TV unit is disabled (The remote control is enabled).

: The main unit’s POWER switch toggles between ON and Standby (the same operation by the

remote control).

When power button on the main unit is pressed When power button on R/C is pressed

No Power off by power button.

* The OSD display is an example.

If another ODS is previously displayed, the status is reset (MENU or similar).

2) Instantaneous current shutdown setting in turning off the power [SHUT DOWN MODE]

Option “NORMAL” or “QUICK”

Default NORMAL

Function • This function decides whether

NORMAL

QUICK

Remarks In selecting “QUICK”, the function does not work for the following items. (selection impossible.)

• ON TIMER, QUICK START, DIGITAL FIXED, etc.

* These items does not exist according to the model.

3) Volume maximum level [MAXIMUM VOLUME]

Option 0~100 (loop disabled)

Default 100

Function The volume cannot be increased more than the adjusted value (the main unit’s speaker only).

Remarks • When setting to 59 or less, only the figure is displayed in the normal mode; the volume bar is not displayed.

• The volume of the headphones is limited.

• The setting is impossible when VOLUME FIXED is set to FIXED.

scanning digital tuner is enabled or disabled when the power is standby.

: Scanning digital tuner is enabled when the power is standby.

: Scanning digital tuner is disable.

It is possible to put into the standby state instantaneously due to power off input, when the

power is standby.

Immediately, state is a complete standby.

No Power off by remote control.

5 – 21

Page 37

LC-60G9T / LC-70G9T

4) Volume fixed [VOLUME FIXED]

Option “VARIABLE”, “FIXED”, “ACCTRL” or “AC/RCCTRL” (loop enabled)

Default “VARIABLE”

Function • VARIABLE

• FIXED

• AC CTRL

• AC/RC CTRL

Exception • In the adjustment process, the volume can be set to any level regardless of this setting.

Disabled key when

setting to FIXED

Remarks • [MAXIMUM VOLUME] has priority to [VOLUME FIXED]

• VOLUME UP/DOWN [both remote control and main unit]

•MUTE

* Main units's key is enabled for operating menu.

* When setting to FIXED, Maximum volume is fixed.

• The volume of the headphones is fixed.

• When setting to “FIXED”, the volume is not displayed in operating Disabled key.

• In menu operation, the main unit’s keys (Vol (+/-)) are enabled.

: The volume is not fixed.

: The volume is fixed to the value adjusted in the volume fixed level.

: The unit starts at the volume specified in the volume fixed level, when power is turned on in the

case of the AC-ON only.

: The unit starts at the volume specified in the volume fixed level, when power is turned on in

any case.

(ACoON, remote controloON, main utit's keyoON)

5) Volume fixed level [VOLUME FIXED LEVEL]

Option 0~100 (loop disabled)

Default 30

Function The volume is fixed to the adjuste

Exception • In the adjustment process, the volume can be set to any level regardless of this setting.

Remarks • When [VOLUME FIXED] is set to “VARIABLE”, the setting cannot be changed.

6) Remote control operation [RC BUTTON]

Option “RESPOND”, “NORESPOND” or “LIMITED” (loop enabled)

Default “RESPOND”

Function The operation of the remote control’s keys is set.

RESPOND

NO RESPOND

LIMITED

Exception • All the keys are enabled regardless of this setting while entering the adjustment process mode, inspection mode or

Public Mode setting screen.

Remarks The enable keys when setting to “LIMITED” are depended on Model.

7) Main Unit Operation [PANEL BUTTON]

Option “RESPOND” or “NO RESPOND” (loop enabled)

Default “RESPOND”

Function • RESPOND

• NO RESPOND

Exception • The start operation in the adjustment process mode, inspection mode are enabled regardless of this setting.

• All the keys are enabled regardless of this setting while entering the adjustment process mode, inspection mode or

Public Mode setting screen.

• For the models with the MENU key on the main unit, menu operation is possible regardless of the setting during the

initial setting when the power is turned on for the first time.

d value (the main unit’s speaker only).

: The remote control’s keys in the normal state are enabled.

: The remote control’s keys in the normal state are disabled.

The POWER key (RECEPTION/STANDBY key) is also disabled.

: Only a part of keys (CHANNEL, etc.) is enabled and other keys are disabled.

: The main unit’s keys are enabled.

: The main unit’s keys are disabled excluding the POWER key (RECEPTION/STANDBY key).

5 – 22

Page 38

LC-60G9T / LC-70G9T

8) Menu operation [MENU BUTTON]

Option “RESPOND” or “NO RESPOND” (loop enabled)

Default “RESPOND”

Function The MENU key on the main unit and remote control is decided whether it is enabled or disabled.

Exception • RESPOND

• NO RESPOND

Disabled key excluding

Menu key when setting

to not default

Remarks When setting to “NO RESPOND”

9) AV position fixed [AV POSITION FIXED]

Option “VARIABLE” or “FIXED” (loop enabled)

Default “VARIABLE”

Function • VARIABLE

rks • When receiving the sound select direct keys (AV POSITION key, OPC, DOLBY key, etc.), only the actual state is

Rema

All the direct transition keys to menu display. (AUTO PRESET, MANUAL MEMORY and others)

* These keys does not exist according to the model.

• For the models with the MENU key on the main unit, menu operation is possible regardless of the setting while the

initial setting when the power is turned on for the first time.

• FIXED

displayed; no setting is changed.

* These keys does not exist according to the model.

• The settings for the Public mode are retained after the personal data is initialized, each item for the AV position and

image/sound adjustment are not initialized.

: The manu key is enabled.

: The manu key is disabled.

: All the keys are enabled regardless of this setting while entering the process mode, inspection

mode or Public Mode setting screen.

: AV position is not fixed.

: AV position is fixed.

: The image/sound adjustment items in the menu are fixed in the selected state.

: When receiving “AV POSITION” of the remote control, only the actual state is displayed, and

setting is not changed.

10) OSD display [ON SCREEN DISPLAY]

Option “YES”, “NO” or “LIMITED” (loop enabled)

“LIMITED” is looped only in case of need (destination).

Default “YES”

Function • YES

•NO

•LIMITED

Key which may be

enabled

(Example of the confusing key)

Disabled key when

setting to not default

Remarks • When setting to “NO”,

• It is OK in the case that simple input select occur or the original state returns soon automatically.

• When setting to “NO”, the keys which is related to visibility of the screen and sound cannot be used.

STILL IMAGE, SCREEN DISPLAY, OFF TIMER, AV POSITION, BRIGHTNESS SENSOR, SCREEN SIZE SELECT,

AUTO PRESET, MANUAL MEMORY, IMAGE SELECT, SOUND SELECT, LANGUAGE, Closed caution

* Disabled keys dependeds on the models.

* These items does not exist according to the model.

hen setting to “NO”,

•W

: OSD is displayed.

: The following OSD is not displayed.

Registration, setting, adjustment menu, channel call, volume bar, and input select.

: Only a part of OSD (CH call: “New Information” etc...) is not displayed.

ON TIMER (Watching reservation) is cleared.

OFF TIMER “SLEEP” is cleared.

These Displays (Version-up, Public mode setting screen, Pass Word input screen of Public

Mode, the adjustment process mode, K mark of inspection mode) are enabled regardless of

this setting.

5 – 23

Page 39

LC-60G9T / LC-70G9T

11) Start mode [INPUT MODE START]

Option “NORMAL” or “Input source 1 (input selection or channel)” ... (loop enabled)

Default “NORMAL”

Function Which kinds of input source or channel is decided when the power turning on.

NORMAL : The content of the last memory is followed.

Remarks • When setting to not Normal, ON TIMER (Watching reservation) has priority.

• When setting to “NORMAL”, [INPUT MODE FIXED] is set to “VARIABLE” and [INPUT MODE FIXED] is prohibited to

select. (selection impossible.)

Example of option: “NORMAL”, “TVD (002TV)”, “INPUT1”, “INPUT2”, “INPUT3”, “HDMI1”, “HDMI2”, “HDMI3”, “HDMI4”.

12) Input fixed [INPUT MODE FIXED]

Option “VARIABLE”, “FIXED”, “ACCTRL” or “AC/RCCTRL” (loop enabled)

Default VARIABLE

Function VARIABLE

Disabled key when

setting to “FIXED”

Remarks • If [INPUT MODE START] is Normal, this function cannot be set.

FIXED

AC CTRL