Page 1

TopPage

LC-65RX1H/X

SERVICE MANUAL

No. S68L7LC65RX1H

LCD COLOR TELEVISION

MODELS

LC-65RX1H

LC-65RX1X

In the interests of user safety (required by safety regulations in some countries) the set should be restor ed to its

original condition and only parts identical to those specified should be used.

OUTLINE

This model is based on the LC-65RX1M and partially modified.

For the contents not covered in this Service Manual, accordingly, please refer to the LC-65RX1M (S58K6LC65RX1M)

Service Manual.

CONTENTS

OUTLINE AND DIFFERENCES FROM BASE MODEL

OUTLINE.............................................................i

DIFFERENCES FROM BASE MODEL..............ii

CHAPTER 4. TROUBLESHOOTING TABLE

[1] TROUBLESHOOTING TABLE (for LC-

65RX1X)........................................................4-1

SAFETY PRECAUTION

IMPORTANT SAFETY PRECAUTION..............iii

Precautions for using lead-free solder ..............iv

CHAPTER 1. SPECIFICATIONS

[1] LC-65RX1H....................................................1-1

[2] LC-65RX1X....................................................1-2

CHAPTER 2. OPERATION MANUAL

[1] OPERATION MANUAL..................................2-1

CHAPTER 3. DIMENSIONS

[1] DIMENSIONS ................................................ 3-1

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with specified ones for maintaining the

safety and performance of the set.

CHAPTER 5. OVERALL WIRING DIAGRAM/BLOCK

DIAGLAM

[1] OVERALL WIRING DIAGRAM......................5-1

[2] SYSTEM BLOCK DIAGRAM (LC-65RX1X)........5-2

CHAPTER 6. PRINTED WIRING BOARD

[1] SUB UNIT (LC-65RX1X) ...............................6-1

CHAPTER 7. SCHEMATIC DIAGRAM

[1] SCHEMATIC DIAGRAM (LC-65RX1X).........7-1

Parts Guide

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Page 2

LC-65RX1H/X

LC65RX1H

OUTLINE AND DIFFERENCES FROM BASE MODEL

ServiceManual

OUTLINE

This model is based on the LC-65RX1M and partially modified.

For the contents not covered in this Service Manual, accordingly, please refer to the LC-65RX1M (S58K6LC65RX1M) Service Manual.

i

Page 3

LC-65RX1H/X

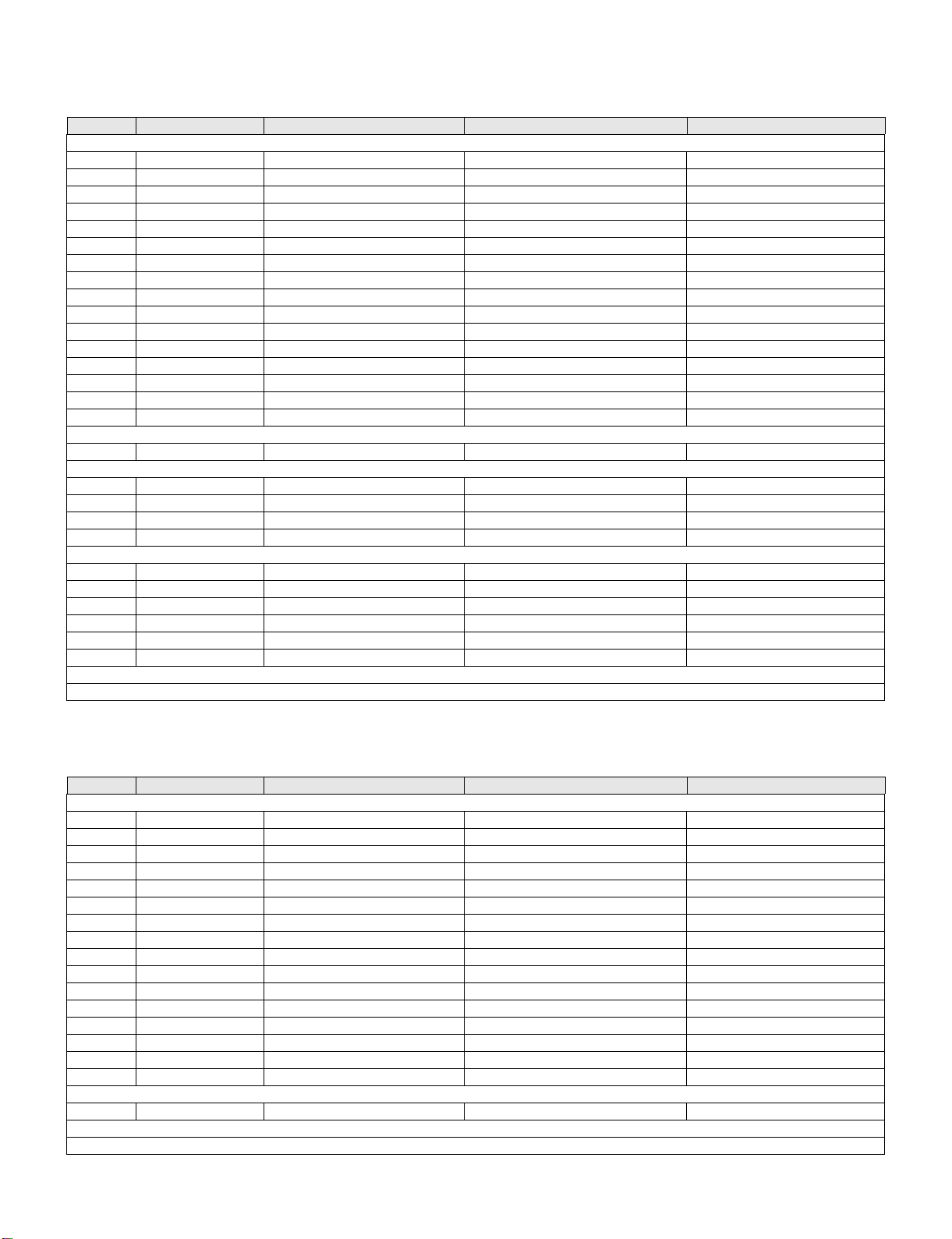

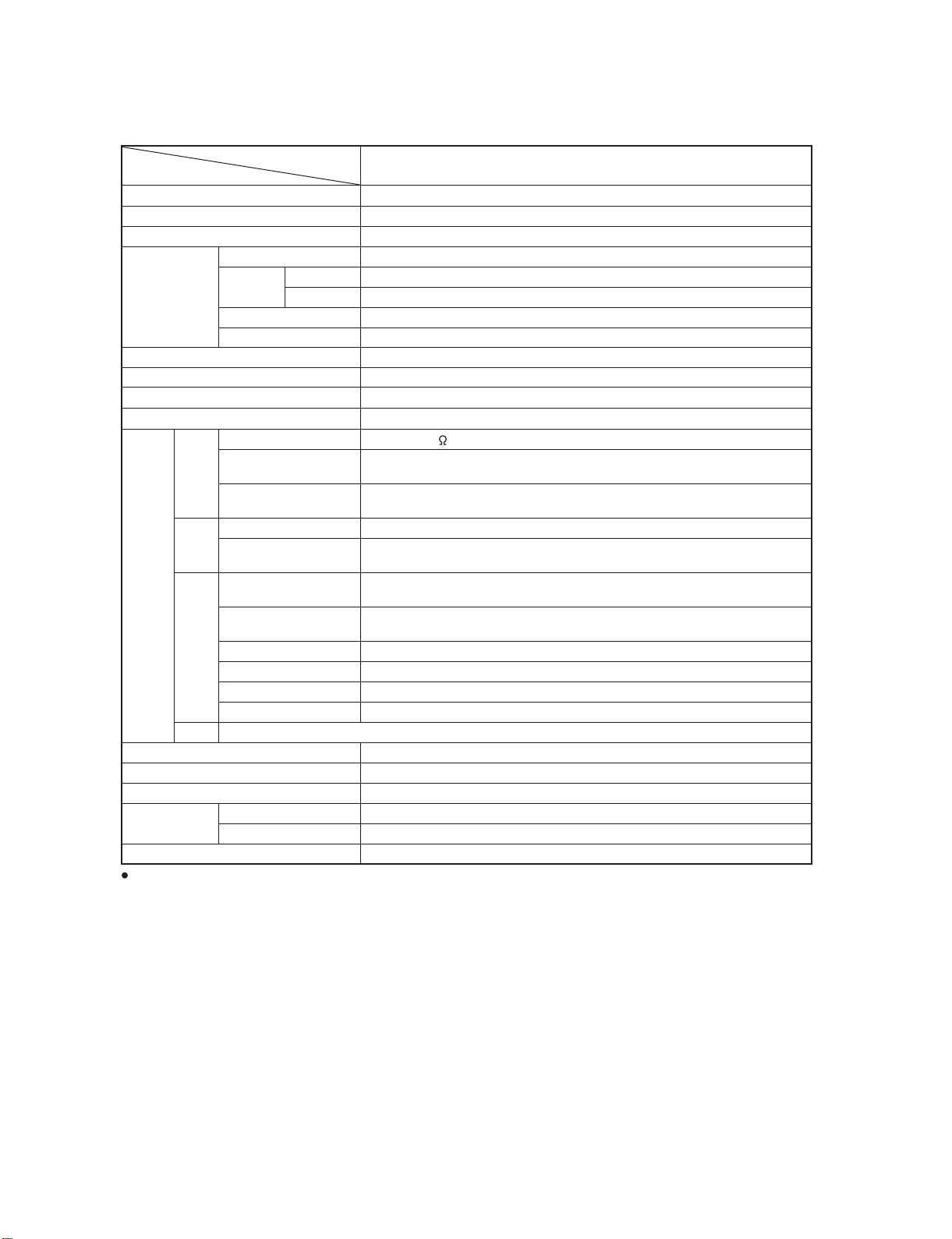

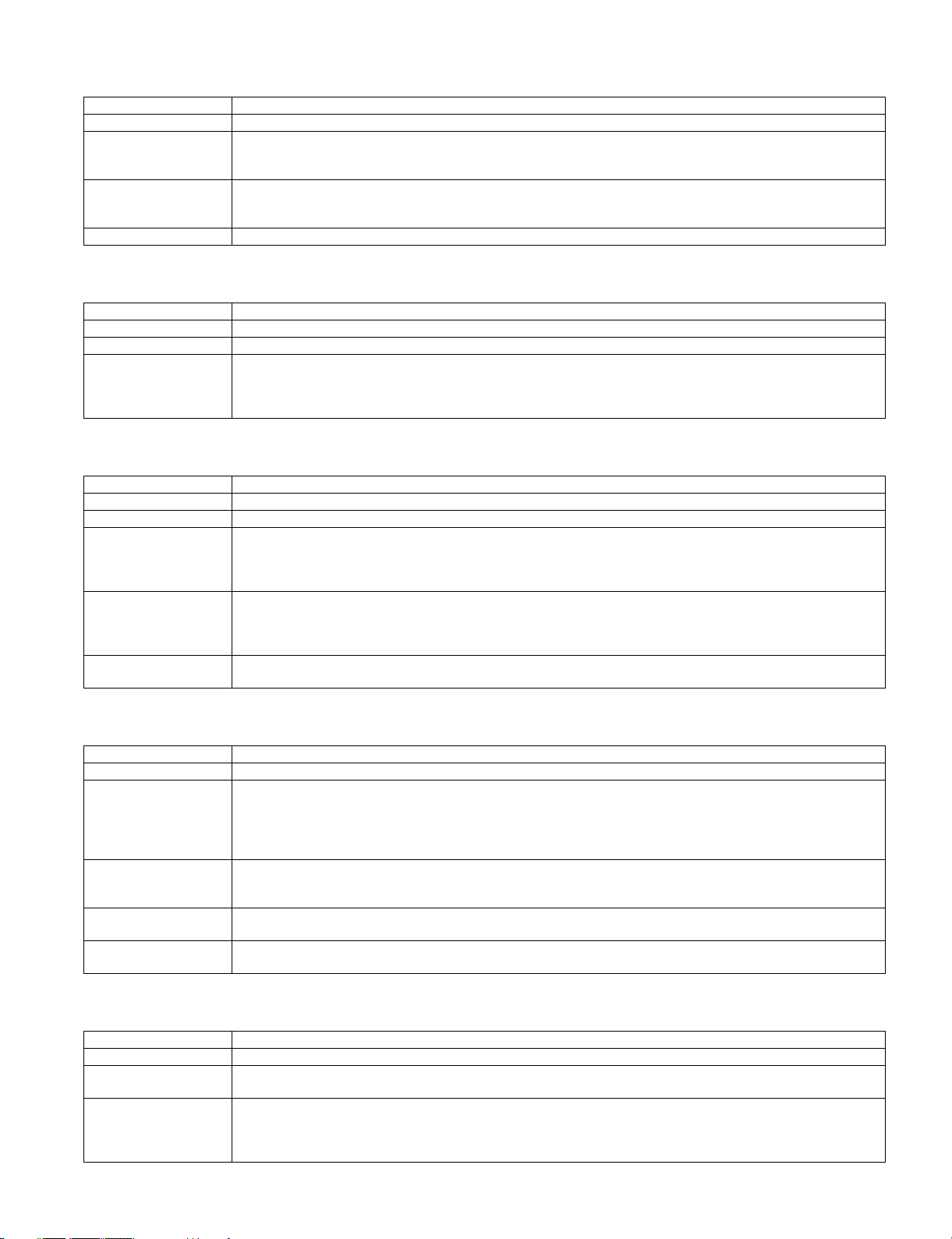

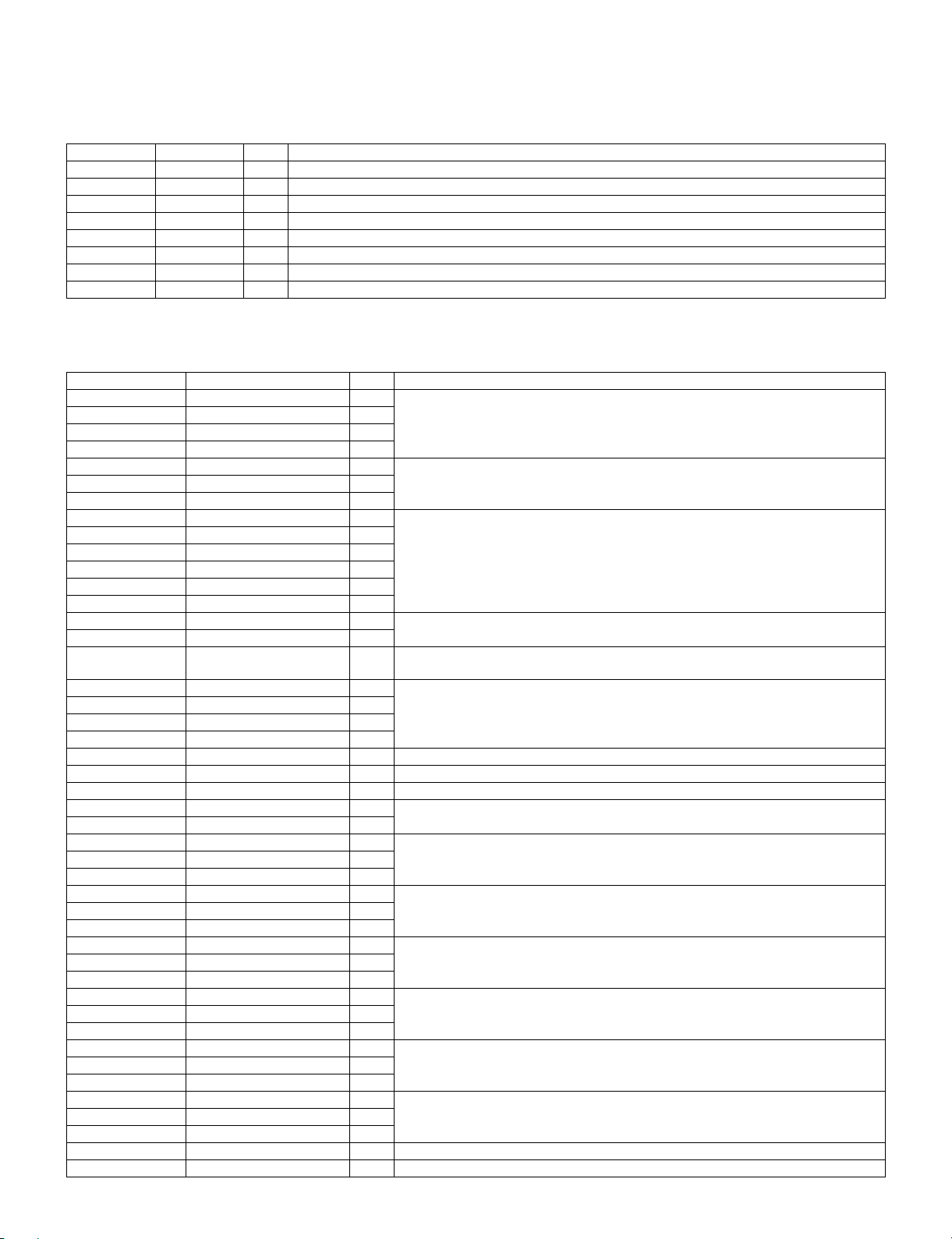

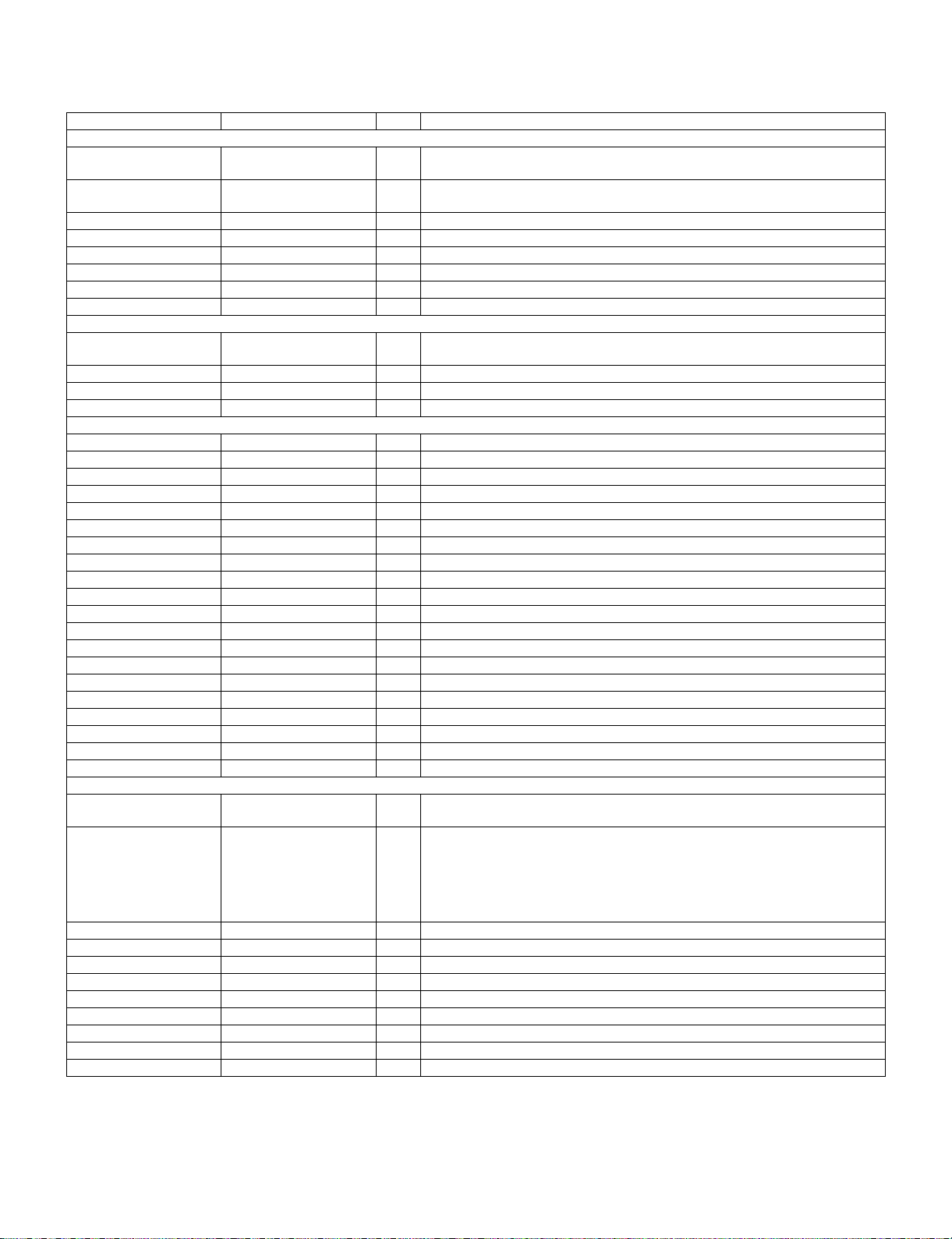

DIFFERENCES FROM BASE MODEL

LIST OF CHANGED PA RTS (LC-65RX1H)

Ref. No. Description LC-65RX1M LC-65RX1H Note

PRINTED WIRING BOARD ASSEMBLIES

N MINI-AV Unit DUNTKE632FM02 DUNTKE632VJ01 No internal parts changed

N R/C, LED Unit DUNTKE682FM02 DUNTKE682VJ01 No internal parts changed

N KEY Unit DUNTKD910FM12 DUNTKD910VJ01 No internal parts changed

N MAIN Unit DUNTKE630FM02 DUNTKE630VJ01 Some parts changed

N SUB Unit DUNTKE631FM02 DUNTKE631VJ01 No internal parts changed

N FRC Unit DUNTKE046FM03 DUNTKE046VJ03 Some parts changed

N POWER Unit-1 RDENCA283WJQZ ← -

N POWER Unit-2 RDENCA284WJQZ ← -

N AC-INLET Unit RUNTKA447WJQZ ← -

N INVERTER Unit A RDENC2509TPZZ ← -

N INVERTER Unit B RDENC2510TPZZ ← -

N INVERTER Unit C RDENC2511TPZZ ← -

N INVERTER Unit D RDENC2512TPZZ ← -

N INVERTER Unit E RDENC2513TPZZ ← -

N INVERTER Unit F RDENC2514TPZZ ← -

N C-PWB CPWBY3723TPZB ← -

LCD PANEL

N 65” Panel Ass’y R1LK645D3LZ3F R1LK645D3LZ30 Changes

MAIN Unit: DUNTKE630VJ01

Q2406 Transistor VSRDTA144EK-1Y VSDTA144EKA-1Y Changes

Q2411 Transistor VSRDTA144EK-1Y VSDTA144EKA-1Y Changes

Q2602 Transistor VSRDTA144EK-1Y VSDTA144EKA-1Y Changes

SC2401 Socket QSOCNA706WJZZ QSOCNA718WJZZ Changes

FRC Unit: DUNTKE046VJ03

C4810 Capacitor RC-KZA531WJQZY VCKYCZ1AB105KY Changes

C4811 Capacitor RC-KZA531WJQZY VCKYCZ1AB105KY Changes

C6001 Capacitor RC-KZA531WJQZY VCKYCZ1AB105KY Changes

C6008 Capacitor RC-KZA531WJQZY VCKYCZ1AB105KY Changes

C6012 Capacitor RC-KZA531WJQZY VCKYCZ1AB105KY Changes

C6013 Capacitor RC-KZA531WJQZY VCKYCZ1AB105KY Changes

65” Panel Ass’y: R1LK645D3LZ30

Please refer to a Parts Guide

LIST OF CHANGED PA RTS (LC-65RX1X)

Ref. No. Description LC-65RX1M LC-65RX1X Note

PRINTED WIRING BOARD ASSEMBLIES

N MINI-AV Unit DUNTKE632FM02 DUNTKE632FM03 No internal parts changed

N R/C, LED Unit DUNTKE682FM02 DUNTKE732FM01 No internal parts changed

N KEY Unit DUNTKD910FM12 ← -

N MAIN Unit DUNTKE630FM02 DUNTKE630FM03 No internal parts changed

N SUB Unit DUNTKE631FM02 DUNTKE730FM01 Changes

N FRC Unit DUNTKE046FM03 ← -

N POWER Unit-1 RDENCA283WJQZ ← -

N POWER Unit-2 RDENCA284WJQZ ← -

N AC-INLET Unit RUNTKA447WJQZ ← -

N INVERTER Unit A RDENC2509TPZZ ← -

N INVERTER Unit B RDENC2510TPZZ ← -

N INVERTER Unit C RDENC2511TPZZ ← -

N INVERTER Unit D RDENC2512TPZZ ← -

N INVERTER Unit E RDENC2513TPZZ ← -

N INVERTER Unit F RDENC2514TPZZ ← -

N C-PWB CPWBY3723TPZB ← -

LCD PANEL

N 65” Panel Ass’y R1LK645D3LZ3F ← -

SUB Unit: DUNTKE730FM01

Please refer to a Parts Guide

ii

Page 4

LC-65RX1H/X

LC65RX1H

SAFETY PRECAUTION

ServiceManual

IMPORTANT SAFETY PRECAUTION

Service work should be performed only by qualified service technicians who are thoroughly familiar with all safety checks and the

servicing guidelines which follow:

WARNING

1. For continued safety, no modification of any circuits should be

attempted.

2. Disconnect AC power before servicing.

BEFORE RETURNING THE RECEIVER

(Fire & Shock Hazard)

Before returning the receiver to the user, perform the following

safety checks:

3. Inspect all lead dress to make certain that leads are not pinched,

and check that hardware is not lodged between the chassis and

other metal parts in the receiver.

4. Inspect all protective devices such as non-metallic control knobs,

insulation materials, cabinet backs, adjustment and compartment

covers or shields, isolation resistor-capacitor networks, mechanical

insulators, etc.

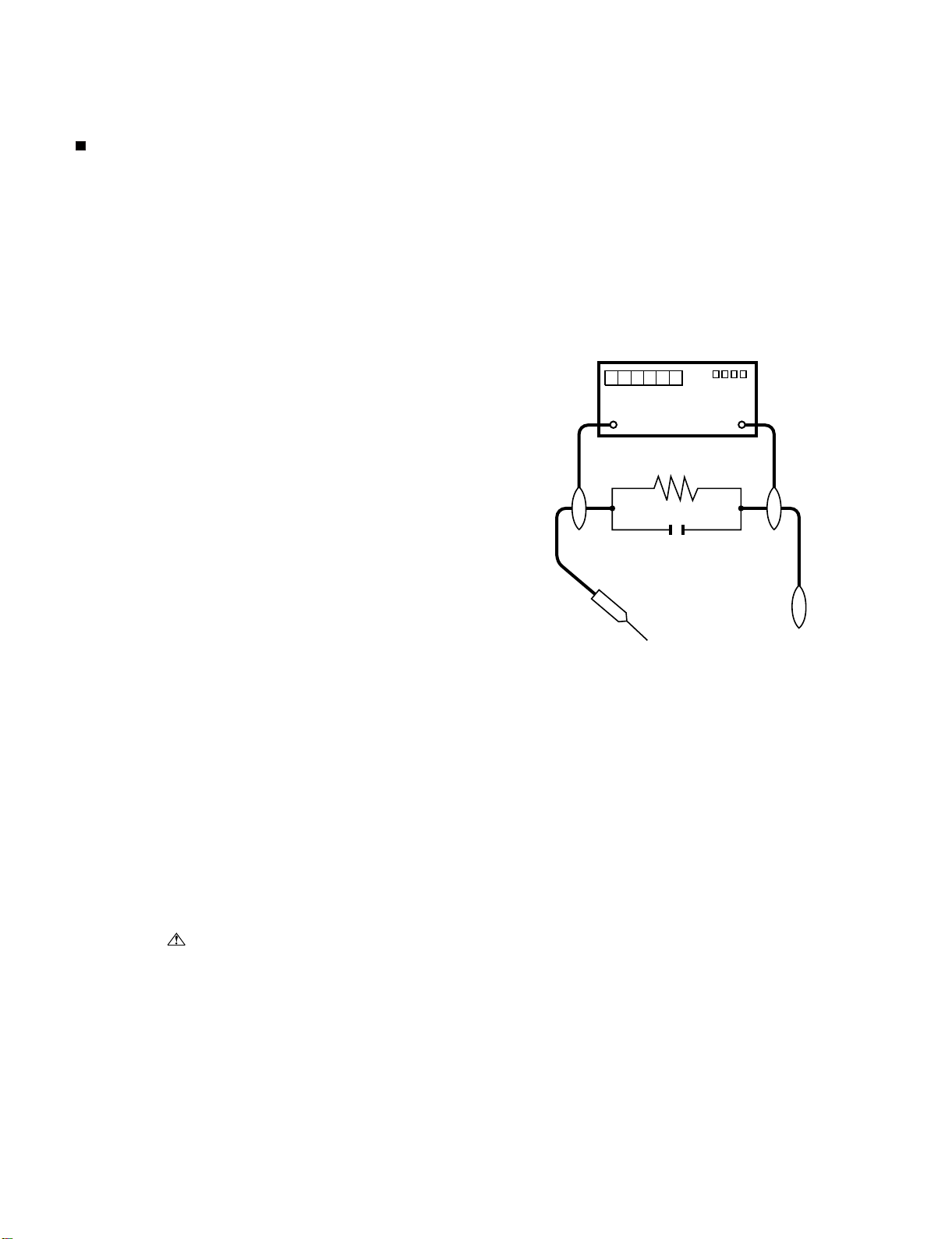

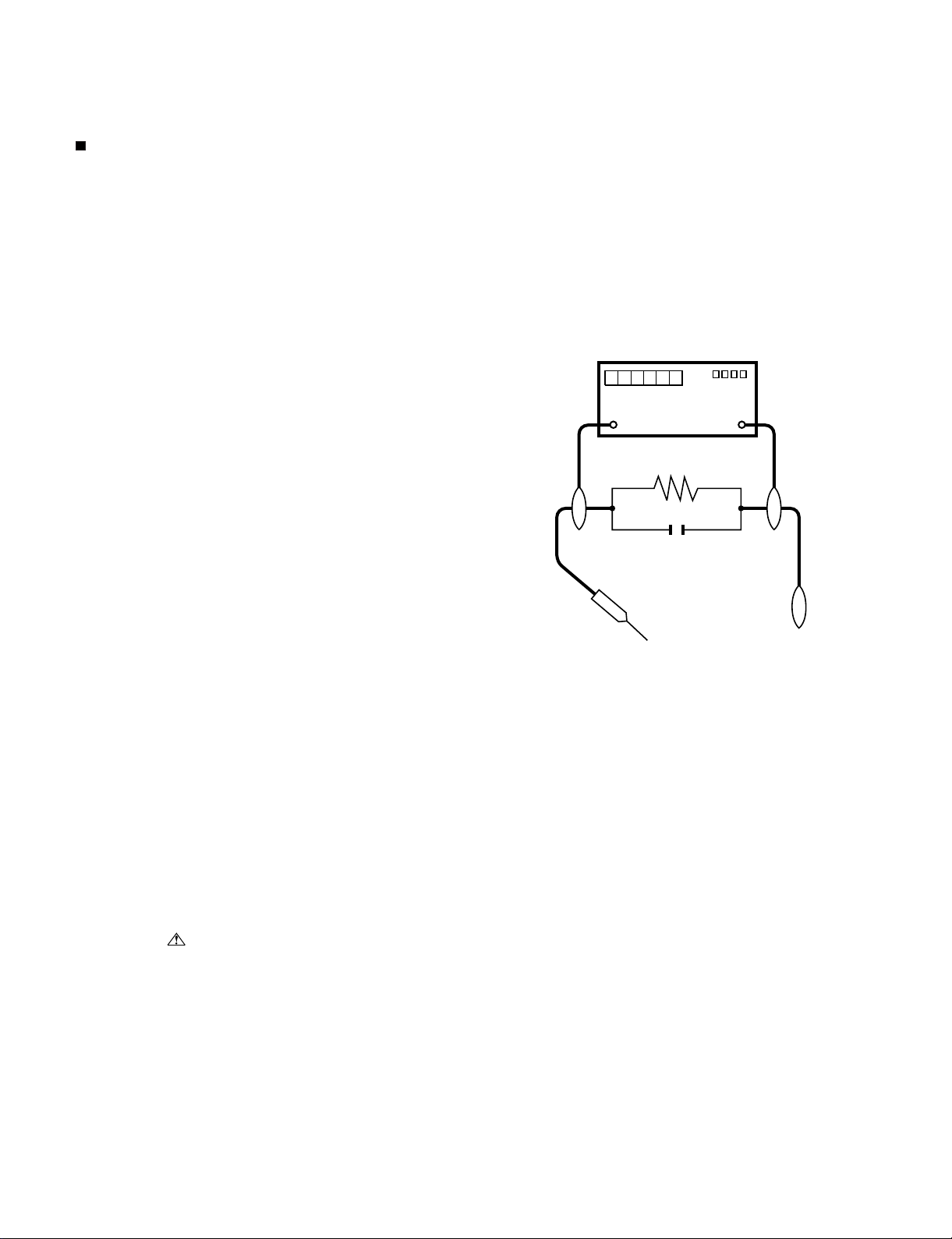

5. To be sure that no shock hazard exists, check for leakage current in

the following manner.

• Plug the AC cord directly into a 110 ~ 240 volt AC outlet.

• Using two clip leads, connect a 1.5k ohm, 10 watt resistor paralleled by a 0.15µF capacitor in series with all exposed metal cabinet

parts and a known earth ground, such as electrical conduit or electrical ground connected to an earth ground.

• Use an AC voltmeter having with 5000 ohm per volt, or higher, sensitivity or measure the AC voltage drop across the resistor.

• Connect the resistor connection to all exposed metal parts having a

return to the chassis (antenna, metal cabinet, screw heads, knobs

and control shafts, escutcheon, etc.) and measure the AC voltage

drop across the resistor.

All checks must be repeated with the AC cord plug connection

reversed. (If necessary, a non polarized adaptor plug must be used

only for the purpose of completing these checks.)

Any reading of 0.74 V rms (this corresponds to 0.5 milliamp. rms

AC.) or more is excessive and indicates a potential shock hazard

which must be corrected before returning the monitor to the owner.

DVM

AC SCALE

1.5k ohm

10W

0.15µF

TEST PROBE

TO EXPOSED

METAL PARTS

CONNECT TO

KNOWN EARTH

GROUND

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

SAFETY NOTICE

Many electrical and mechanical parts in LCD color television have

special safety-related characteristics.

These characteristics are often not evident from visual inspection, nor

can protection afforded by them be necessarily increased by using

replacement components rated for higher voltage, wattage, etc.

Replacement parts which have these special safety characteristics are

identified in this manual; electrical components having such features

are identified by " " and shaded areas in the Replacement Parts

Lists and Schematic Diagrams.

For continued protection, replacement parts must be identical to those

used in the original circuit.

The use of a substitute replacement parts which do not have the same

safety characteristics as the factory recommended replacement parts

shown in this service manual, may create shock, fire or other hazards.

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

iii

Page 5

LC-65RX1H/X

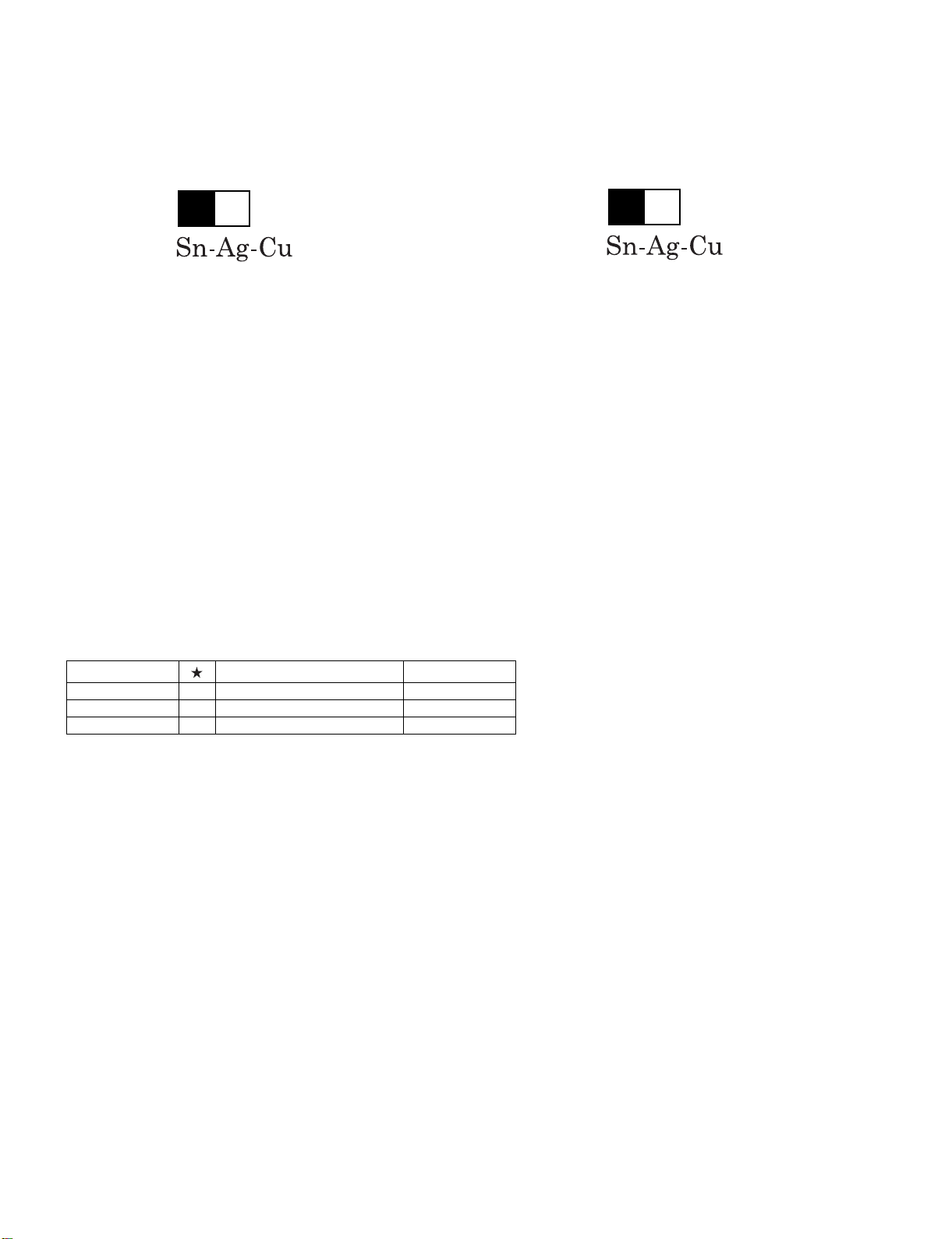

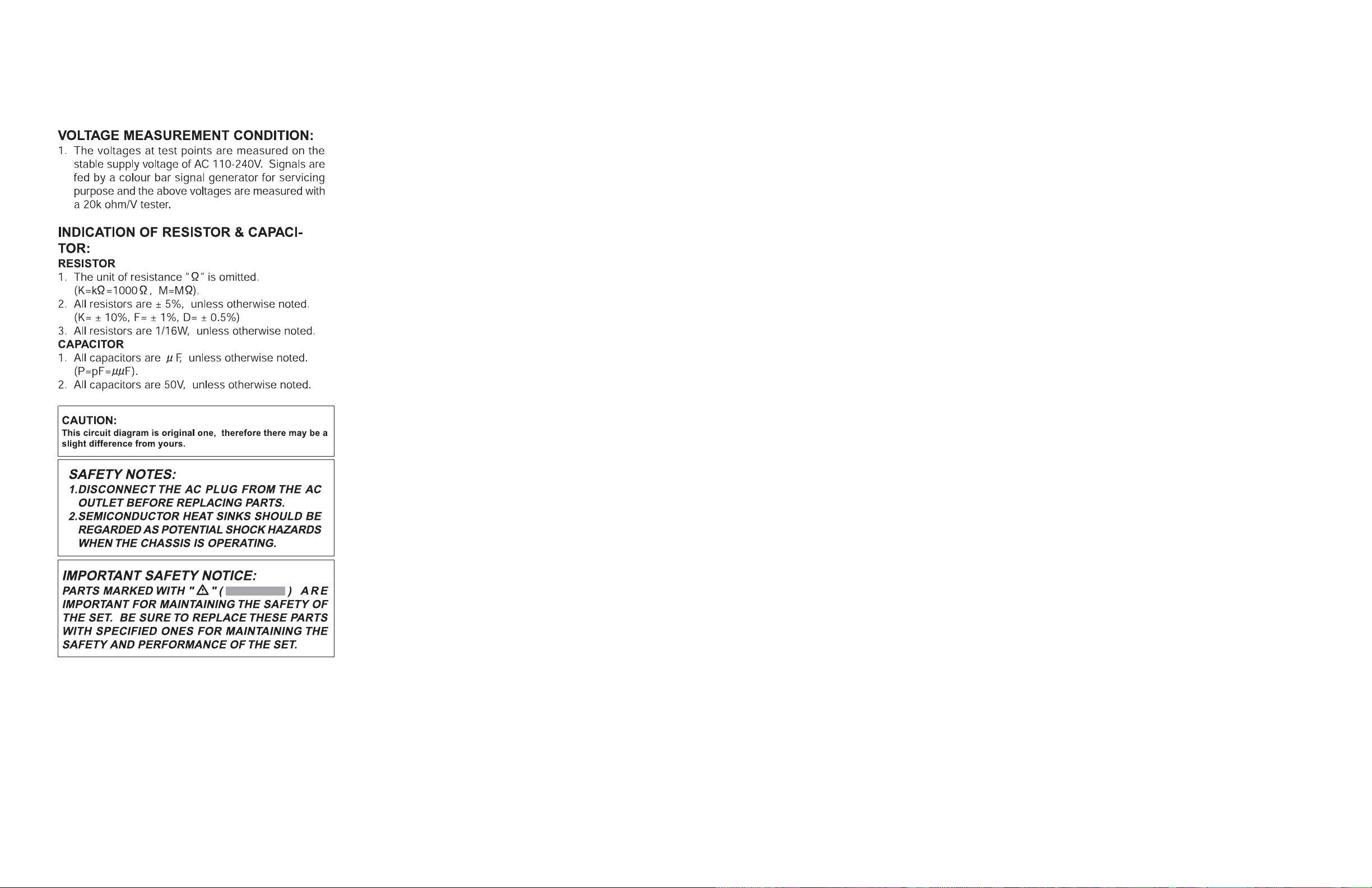

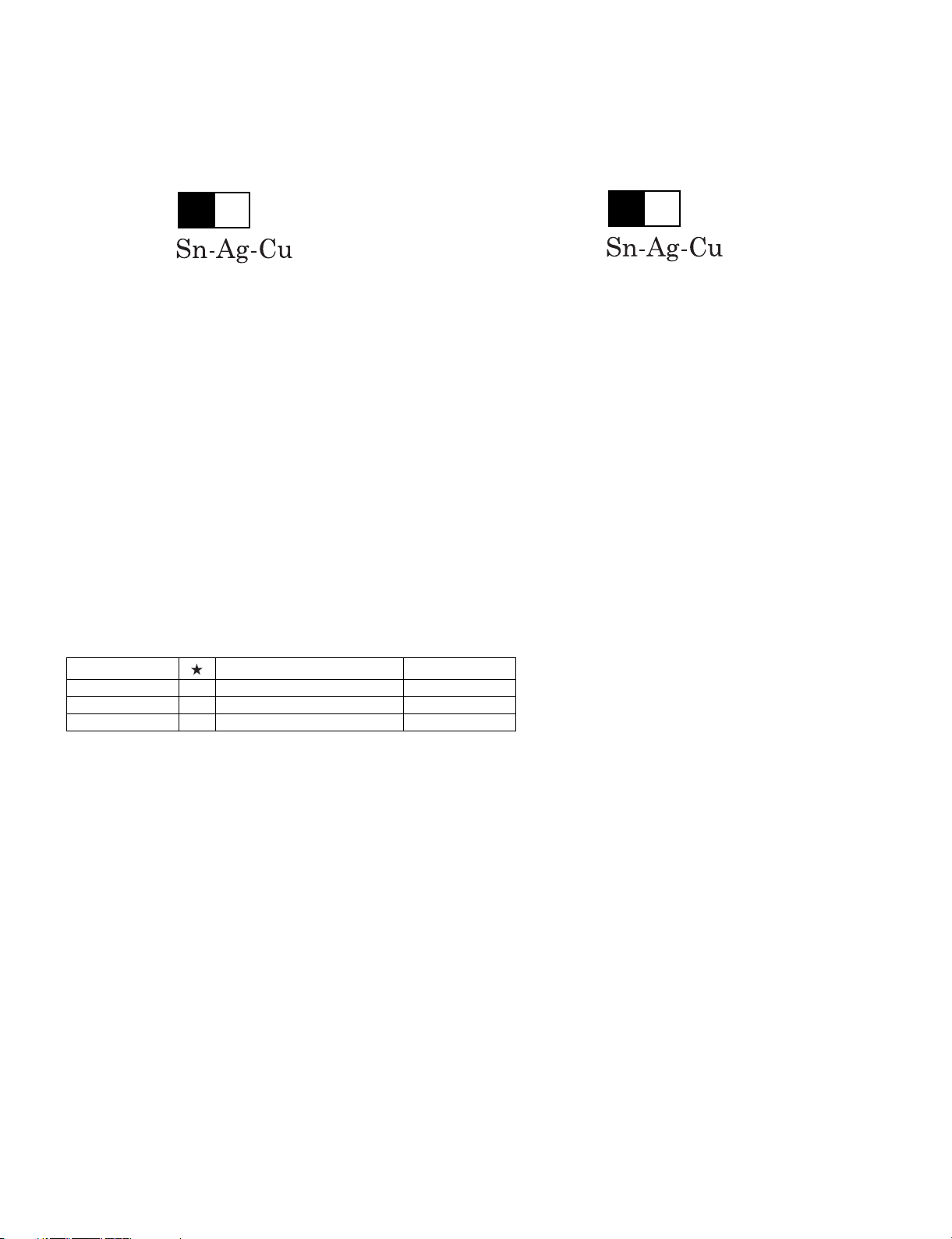

Precautions for using lead-free solder

Employing lead-free solder

• “All PWBs” of this model employs lead-free solder. The LF symbol indicates lead-free solder, and is attached on the PWBs and service manuals.

The alphabetical character following LF shows the type of lead-free solder.

Example:

L Fa

Indicates lead-free solder of tin, silver and copper.

Indicates lead-free solder of tin, silver and copper.

L F a/a

Using lead-free wire solder

• When fixing the PWB soldered with the lead-free solder, apply lead-free wire solder. Repairing with conventional lead wire solder may cause damage or accident due to cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40 °C, we recommend you to use a dedicated soldering

bit, if you are not familiar with how to obtain lead-free wire solder or soldering bit, contact our service station or service branch in your area.

Soldering

• As the melting point of lead-free solder (Sn-Ag-Cu) is about 220 °C which is higher than the conventional lead solder by 40 °C, and as it has poor

solder wettability, you may be apt to keep the soldering bit in contact with the PWB for extended period of time. However, Since the land may be

peeled off or the maximum heat-resistance temperature of parts may be exceeded, remove the bit from the PWB as soon as you confirm the

steady soldering condition.

Lead-free solder contains more tin, and the end of the soldering bit may be easily corroded. Make sure to turn on and off the power of the bit as

required.

If a different type of solder stays on the tip of the soldering bit, it is alloyed with lead-free solder. Clean the bit after every use of it.

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sandpaper.

• Be careful when replacing parts with polarity indication on the PWB silk.

Lead-free wire solder for servicing

Part No. Description Code

ZHNDAi123250E J φ0.3mm 250g (1roll) BL

ZHNDAi126500E J φ0.6mm 500g (1roll) BK

ZHNDAi12801KE J φ1.0mm 1kg (1roll) BM

iv

Page 6

LC-65RX1H/X

LC65RX1H

CHAPTER 1. SPECIFICATIONS

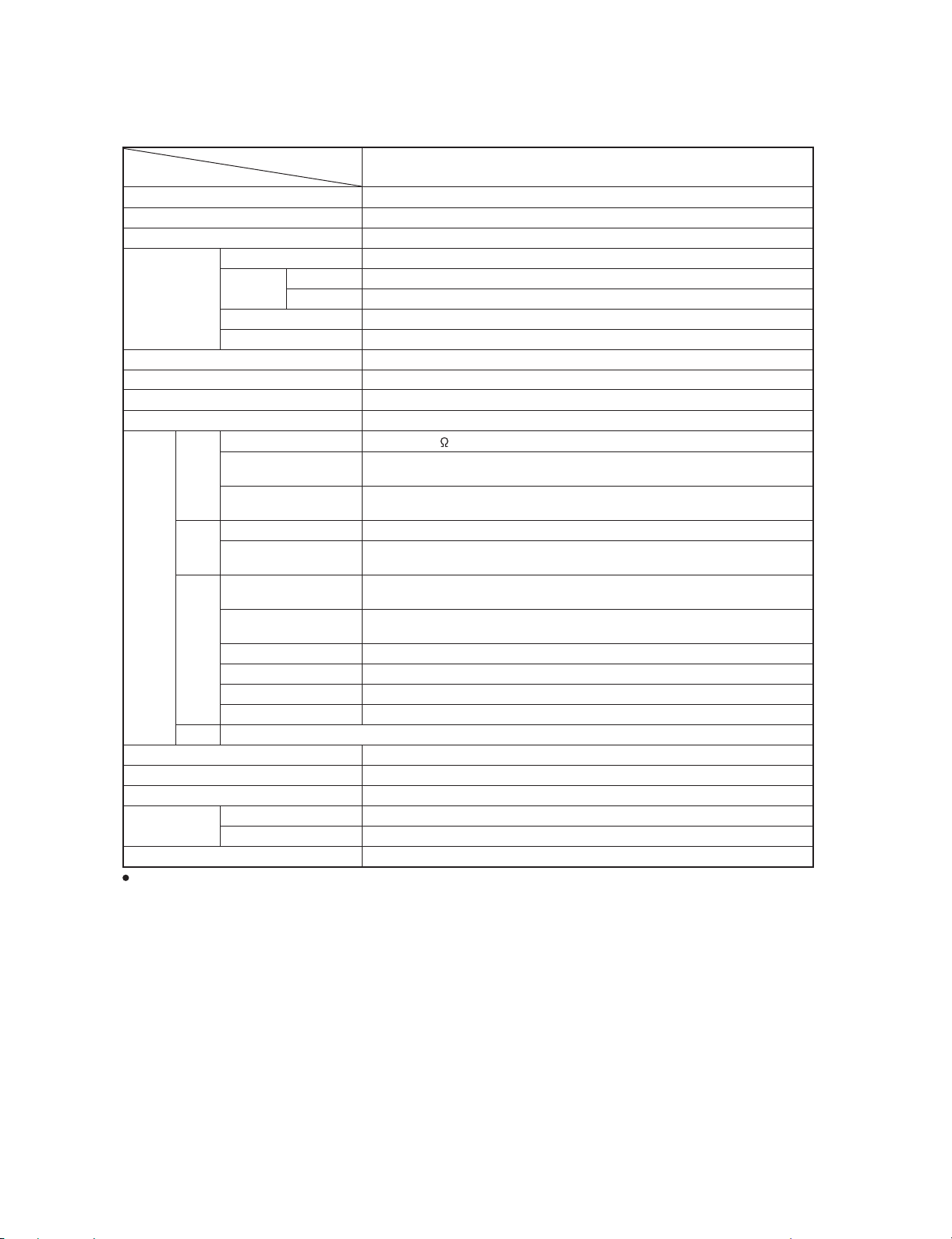

[1] LC-65RX1H

ServiceManual

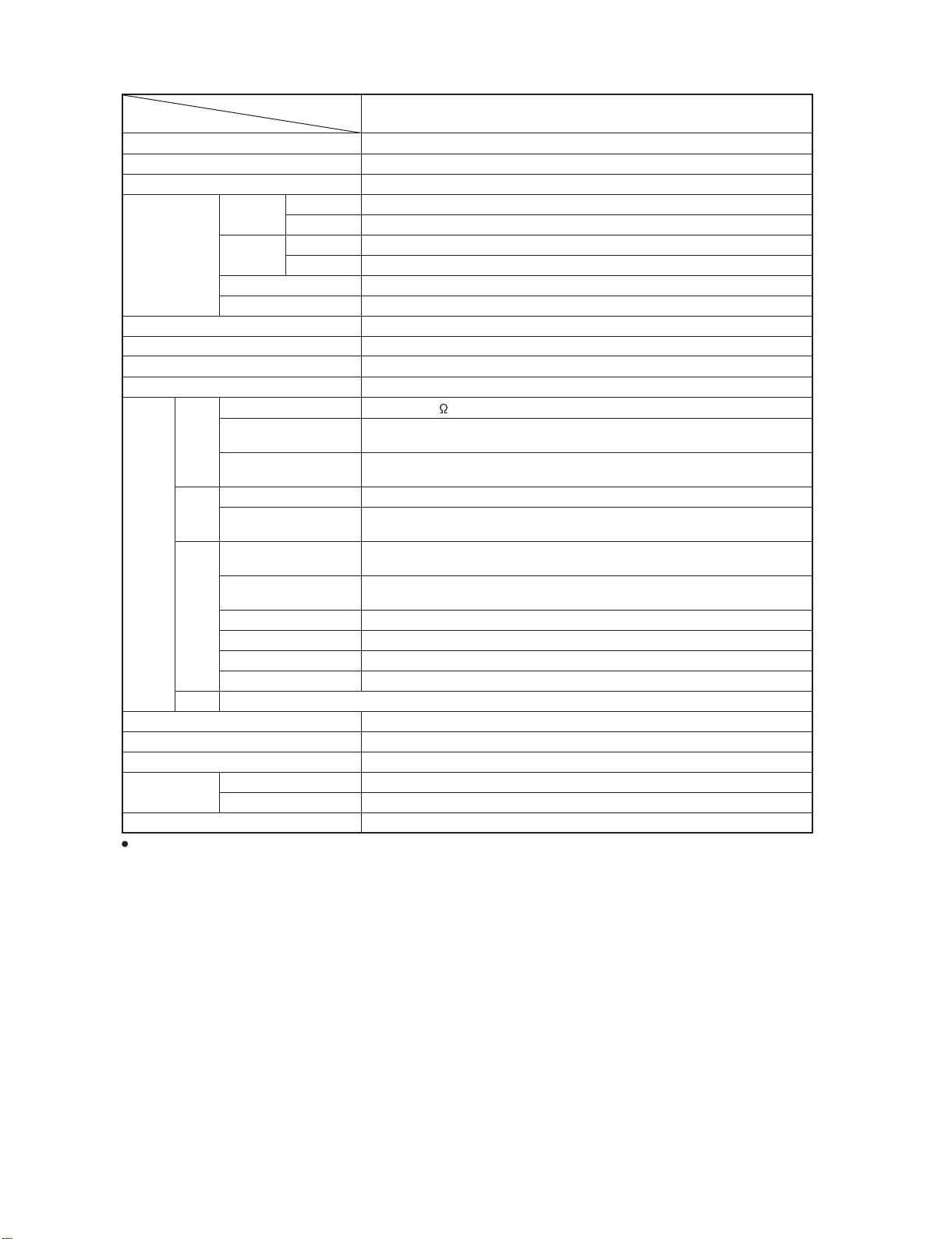

Model

Item

LCD panel

Resolution 2,073,600 pixels (1920×1080)

Video Colour System PAL/SECAM/NTSC 3.58/NTSC 4.43/PAL 60

TV Function TV-Standard PAL: B/G, D/K, I SECAM: B/G, D/K, K/K

Receiving

Channel

TV-Tuning System Auto Preset 99 ch

STEREO/BILINGUAL NICAM: B/G, I, D/K A2 stereo: B/G

Brightness 450 cd/m

Viewing angles H : 176º V : 176º

Audio amplifier

Speakers

Terminals

OSD language English/Simplified Chinese/Traditional Chinese/Arabic

Power Requirement AC 110-240 V, 50/60 Hz

Power Consumption 481 W (0.5 W Standby)

Weight without stand 62.0 kg

Operating Temperature 0°C - 40°C

Rear Antenna input

INPUT 1 VIDEO in, AUDIO in, COMPONENT in (480I, 576I, 480P, 576P, 720P/50Hz,

INPUT 2 VIDEO in, AUDIO in, COMPONENT in (480I, 576I, 480P, 576P, 720P/50Hz,

Side INPUT 3 S-VIDEO in, VIDEO in, AUDIO in

INPUT 4

Rear INPUT 5

INPUT 6

INPUT 7 (PC input) 15 pin mini D-sub, AUDIO in (Ø 3.5 mm jack)

MONITOR OUT VIDEO out, AUDIO out

RS-232C 9 pin D-sub male connector

DIGITAL AUDIO OUTPUT

Front Headphone

with stand 66.0 kg

As a part of policy of continuous improvement, SHARP reserves the right to make design and specification changes for

product improvement without prior notice. The performance specification figures indicated are nominal values of production

units. There may be some deviations from these values in individual units.

VHF/UHF 44.25 - 863.25 MHz

CATV S1 - S41ch (including Hyperband)

65" (1639 mm) Advanced Super View & BLACK TFT LCD

2

7.5W x 2 + 15W

10 x 4cm 2pcs, Ø2cm 2pcs, Ø5.5cm 1pc

UHF/VHF 75

720P/60Hz, 1080I/50Hz, 1080I/60Hz)

720P/60Hz, 1080I/50Hz, 1080I/60Hz)

HDMI (HDMI input) (480I, 576I, 480P, 576P, 720P/50Hz, 720P/60Hz, 1080I/50Hz,

1080I/60Hz, 1080P/50Hz, 1080P/60Hz, 1080P/24Hz)

HDMI (HDMI input) (480I, 576I, 480P, 576P, 720P/50Hz, 720P/60Hz, 1080I/50Hz,

1080I/60Hz, 1080P/50Hz, 1080P/60Hz, 1080P/24Hz)

HDMI (HDMI input) (480I, 576I, 480P, 576P, 720P/50Hz, 720P/60Hz, 1080I/50Hz,

1080I/60Hz, 1080P/50Hz, 1080P/60Hz, 1080P/24Hz), AUDIO in (Ø 3.5 mm jack)

Optical Digital Audio output

DIN type

LC-65RX1H

1

,NTSC:M

1 – 1

Page 7

[2] LC-65RX1X

LC-65RX1H/X

Model

Item

LCD panel

Resolution 2,073,600 pixels (1920×1080)

Video Colour System PAL/SECAM/NTSC 3.58/NTSC 4.43/PAL 60

TV Function TV-

Brightness 450 cd/m

Viewing angles H : 176º V : 176º

Audio amplifier

Speakers

Terminals

OSD language English/Simplified Chinese/Traditional Chinese/Arabic

Power Requirement AC 110-240 V, 50/60 Hz

Power Consumption 481 W (0.5 W Standby)*

Weight without stand 62.0 kg

Operating Temperature 0°C - 40°C

As a part of policy of continuous improvement, SHARP reserves the right to make design and specification changes for

product improvement without prior notice. The performance specification figures indicated are nominal values of production

units. There may be some deviations from these values in individual units.

* Standby power consumption is approx. 45W for 15-30 minutes after the TV is turned off by the remote control. This is

required for automatically capturing EPG data for all tuned digital channels.

Standard

Receiving

Channel

TV-Tuning System Auto Preset 99 ch

STEREO/BILINGUAL NICAM: B/G, I, D/K A2 stereo: B/G

Rear Antenna input

INPUT 1 VIDEO in, AUDIO in, COMPONENT in (480I, 576I, 480P, 576P, 720P/50Hz,

INPUT 2 VIDEO in, AUDIO in, COMPONENT in (480I, 576I, 480P, 576P, 720P/50Hz,

Side INPUT 3 S-VIDEO in, VIDEO in, AUDIO in

INPUT 4

Rear INPUT 5

INPUT 6

INPUT 7 (PC input) 15 pin mini D-sub, AUDIO in (Ø 3.5 mm jack)

MONITOR OUT VIDEO out, AUDIO out

RS-232C 9 pin D-sub male connector

DIGITAL AUDIO OUTPUT

Front Headphone

with stand 66.0 kg

Analogue PAL: B/G, D/K, I SECAM: B/G, D/K, K/K

Digital DVB-T

VHF/UHF 44.25 - 863.25 MHz

CATV S1 - S41ch (including Hyperband)

65" (1639 mm) Advanced Super View & BLACK TFT LCD

2

7.5W x 2 + 15W

10 x 4cm 2pcs, Ø2cm 2pcs, Ø5.5cm 1pc

UHF/VHF 75

720P/60Hz, 1080I/50Hz, 1080I/60Hz)

720P/60Hz, 1080I/50Hz, 1080I/60Hz)

HDMI (HDMI input) (480I, 576I, 480P, 576P, 720P/50Hz, 720P/60Hz, 1080I/50Hz,

1080

I/60Hz, 1080P/50Hz, 1080P/60Hz, 1080P/24Hz)

HDMI (HDMI input) (480I, 576I, 480P, 576P, 720P/50Hz, 720P/60Hz, 1080I/50Hz,

1080I/60Hz, 1080P/50Hz, 1080P/60Hz, 1080P/24Hz)

HDMI (HDMI input) (480I, 576I, 480P, 576P, 720P/50Hz, 720P/60Hz, 1080I/50Hz,

1080I/60Hz, 1080P/50Hz, 1080P/60Hz, 1080P/24Hz), AUDIO in (Ø 3.5 mm jack)

Optical Digital Audio output

DIN type

LC-65RX1X

1

1 – 2

Page 8

LC-65RX1H/X

LC65RX1H

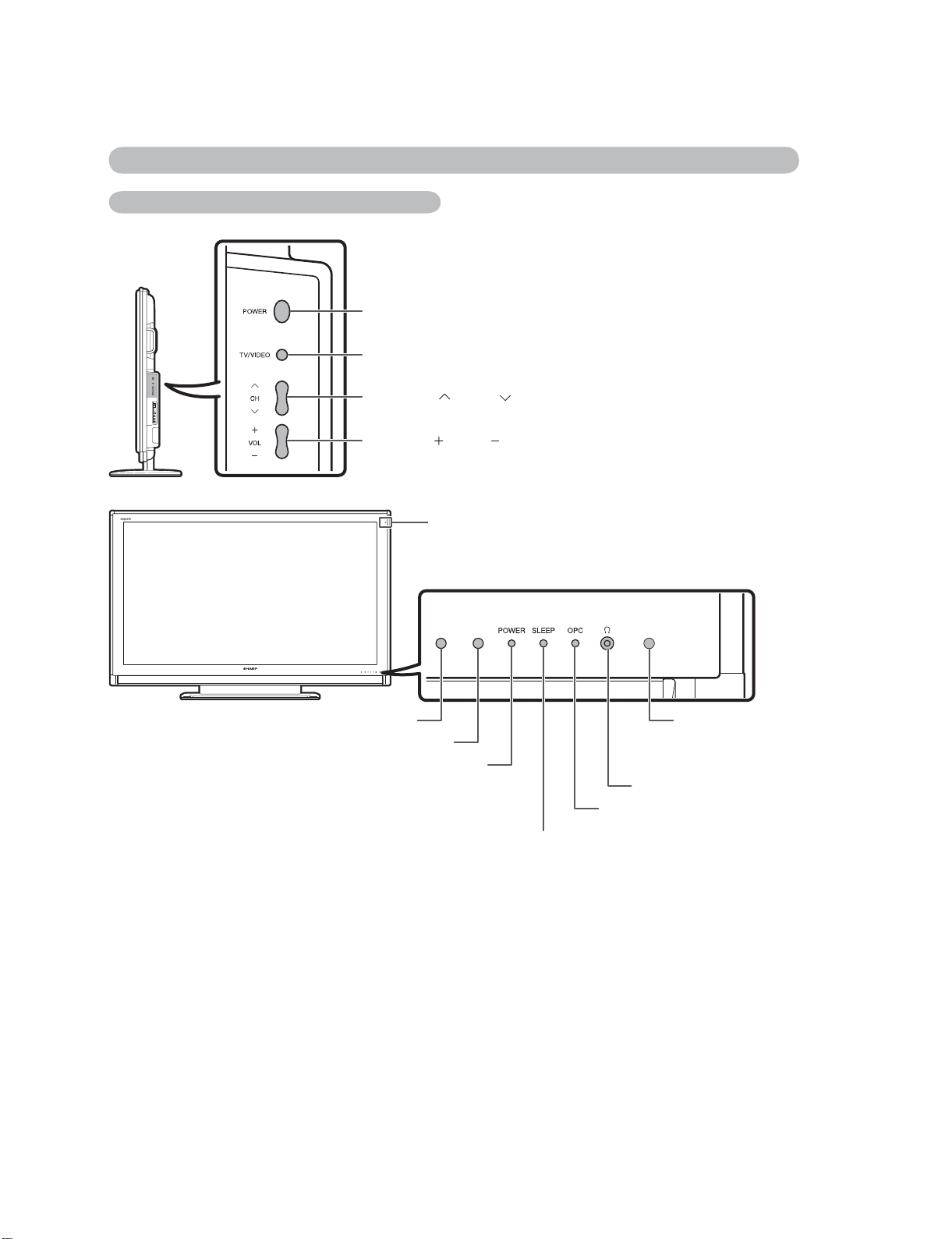

CHAPTER 2. OPERATION MANUAL

[1] OPERATION MANUAL

Part names

TV (Front/Side)

POWER (On/Off) button

TV/VIDEO button

Channel up ( )/down ( ) buttons

Volume up ( )/down ( ) buttons

ServiceManual

Remote control sensor

OPC sensor

POWER indicator

Such sensor is not applicable to Hong Kong model.

Such sensor is not applicable

to this model.

Headphone jack

OPC indicator*

SLEEP timer indicator

*OPC: Optical Picture Control

2 – 1

Page 9

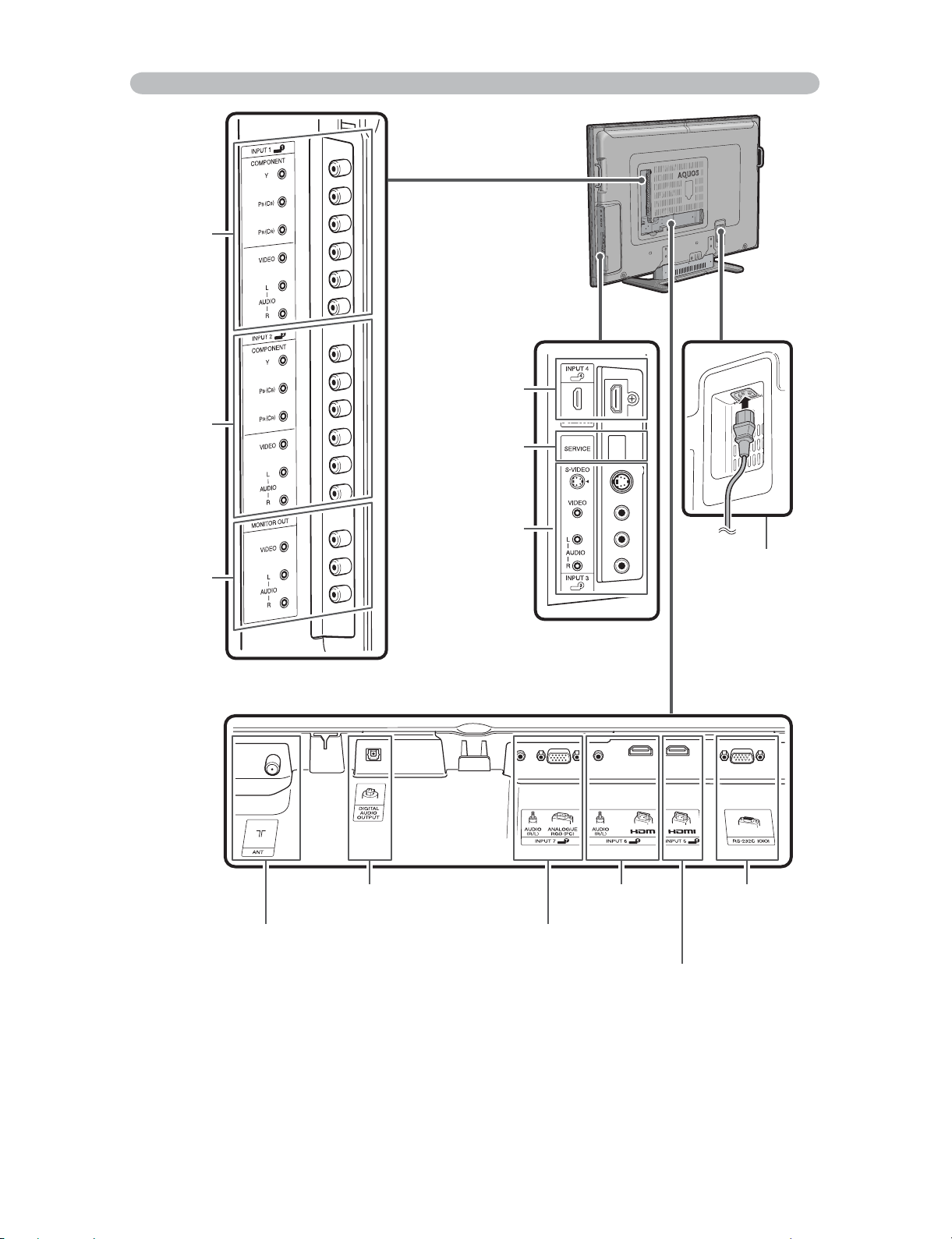

TV (Rear)

INPUT 1

terminals

INPUT 2

terminals

LC-65RX1H/X

INPUT 4 (HDMI)

terminal

SERVICE ONLY

terminal*

MONITOR

OUTPUT

terminals

DIGITAL AUDIO OUTPUT terminal

Antenna input terminal

*

Usuallydo not connect

anything to this terminal

as it is reserved only

for service personnel.

INPUT 3 terminals

INPUT 7 (PC) terminals

INPUT 6 (HDMI)

terminals

AC INPUT terminal

RS-232C terminal

2 – 2

INPUT 5 (HDMI) terminal

Page 10

LC-65RX1H/X

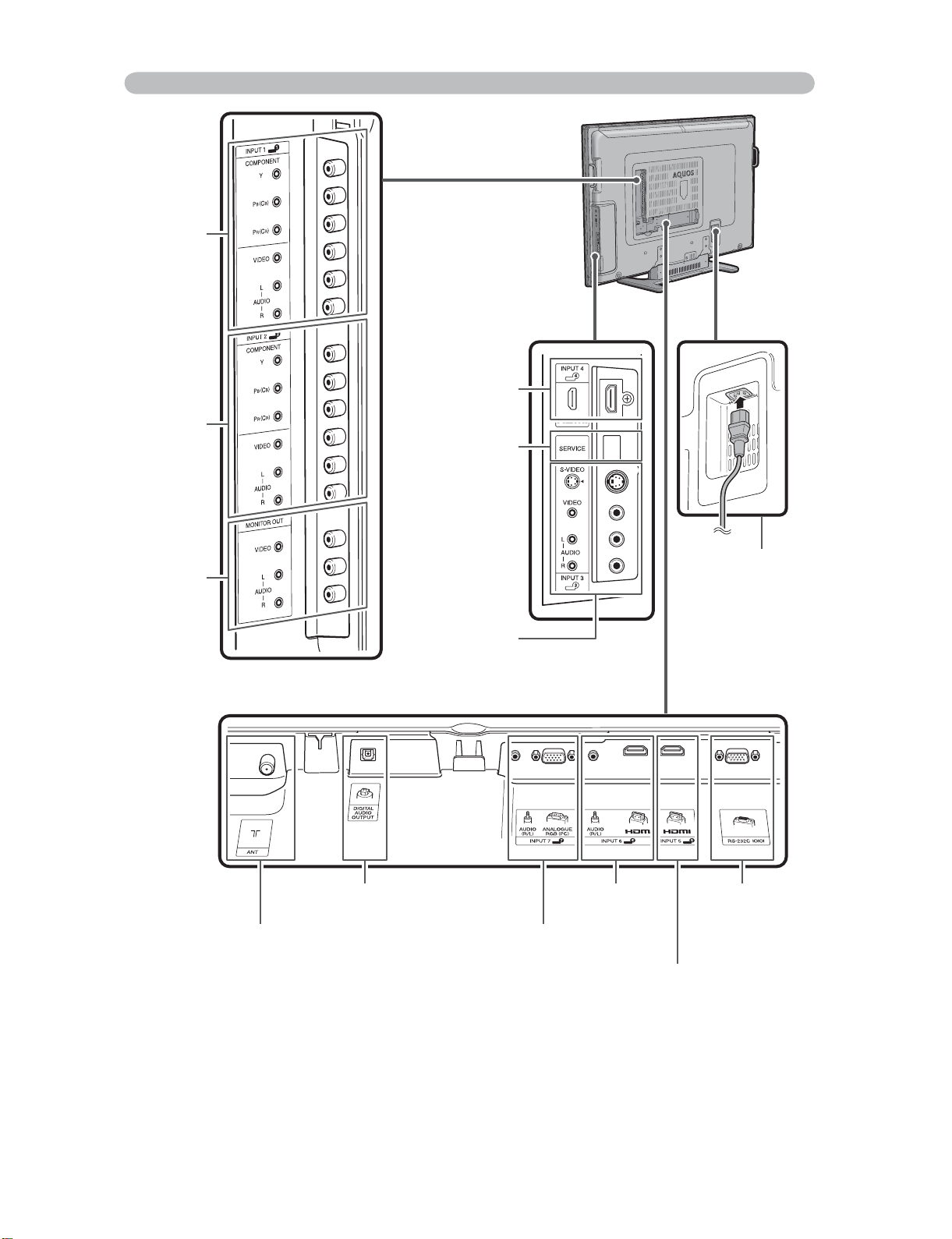

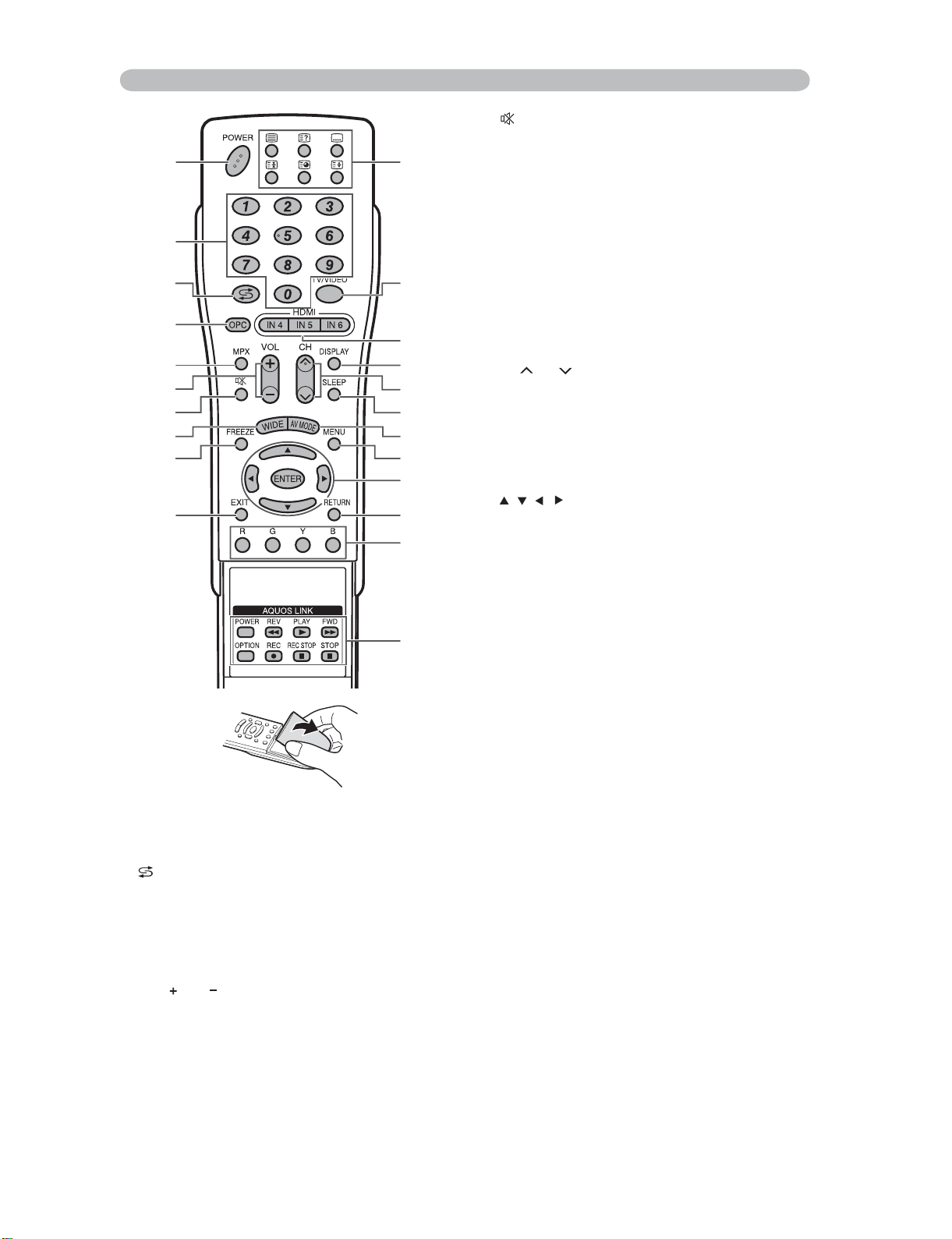

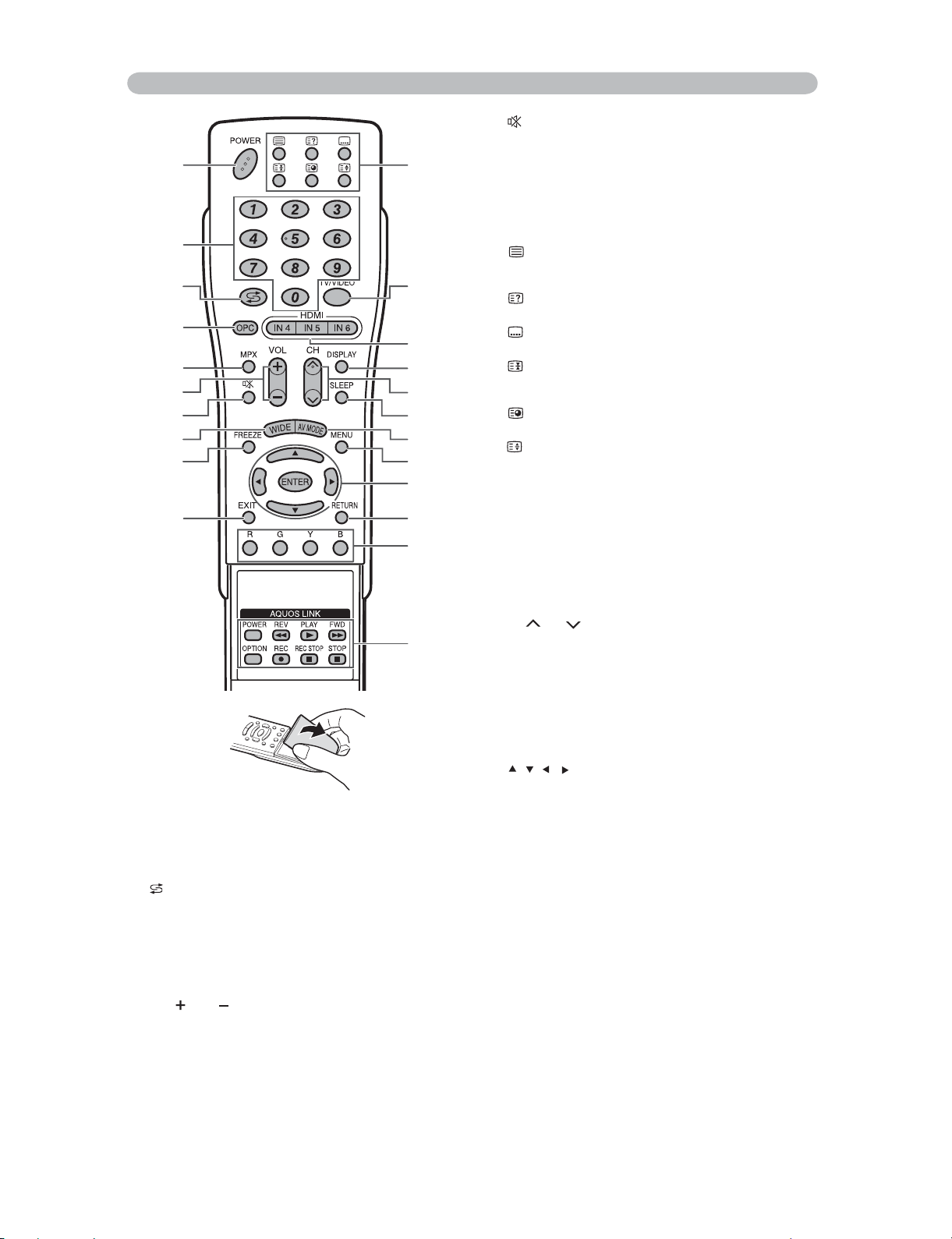

Remote control unit (LC-65RX1H)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

7 (Mute)

Mute the sound.

8 WIDE

Change the wide image mode.

9 FREEZE

Freeze a motion picture on the screen.

10 EXIT

Turn off the On-Screen Display.

11 Such buttons are not applicable to Hong Kong model.

12 TV/VIDEO (INPUT SOURCE)

Select an input source. (TV, INPUT 1, INPUT 2, INPUT 3,

INPUT 4, INPUT 5, INPUT6, INPUT7 (PC))

13 HDMI

Select an HDMI. (INPUT4, INPUT5, INPUT6)

14 DISPLAY

Displays the channel or input information.

15 CH /CH

TV input mode: Select the channel.

16 SLEEP

Set the Sleep timer.

17 AV MODE

Select a video setting.

18 MENU

Display the menu screen.

19 / / / (Cursor)

Select a desired item on the setting screen.

ENTER

Execute a command.

20 RETURN

MENU mode: Return to the previous menu screen.

21 Such buttons are not applicable to Hong Kong model.

22 AQUOS LINK buttons

If external equipment such as a AQUOS BD Player is

connected via HDMI-certified cables and is AQUOS LINK

compatible, you can use these AQUOS LINK buttons.

1 POWER (STANDBY/ON)

To switch the power on and off.

20-9

Set the channel.

3 (Flashback)

Press to return to the previous selected channel or

external input mode.

4OPC

To switch the Optical Picture Control on and off.

5 MPX

Select the sound multiplex mode.

6 VOL /VOL

Set the volume.

2 – 3

Page 11

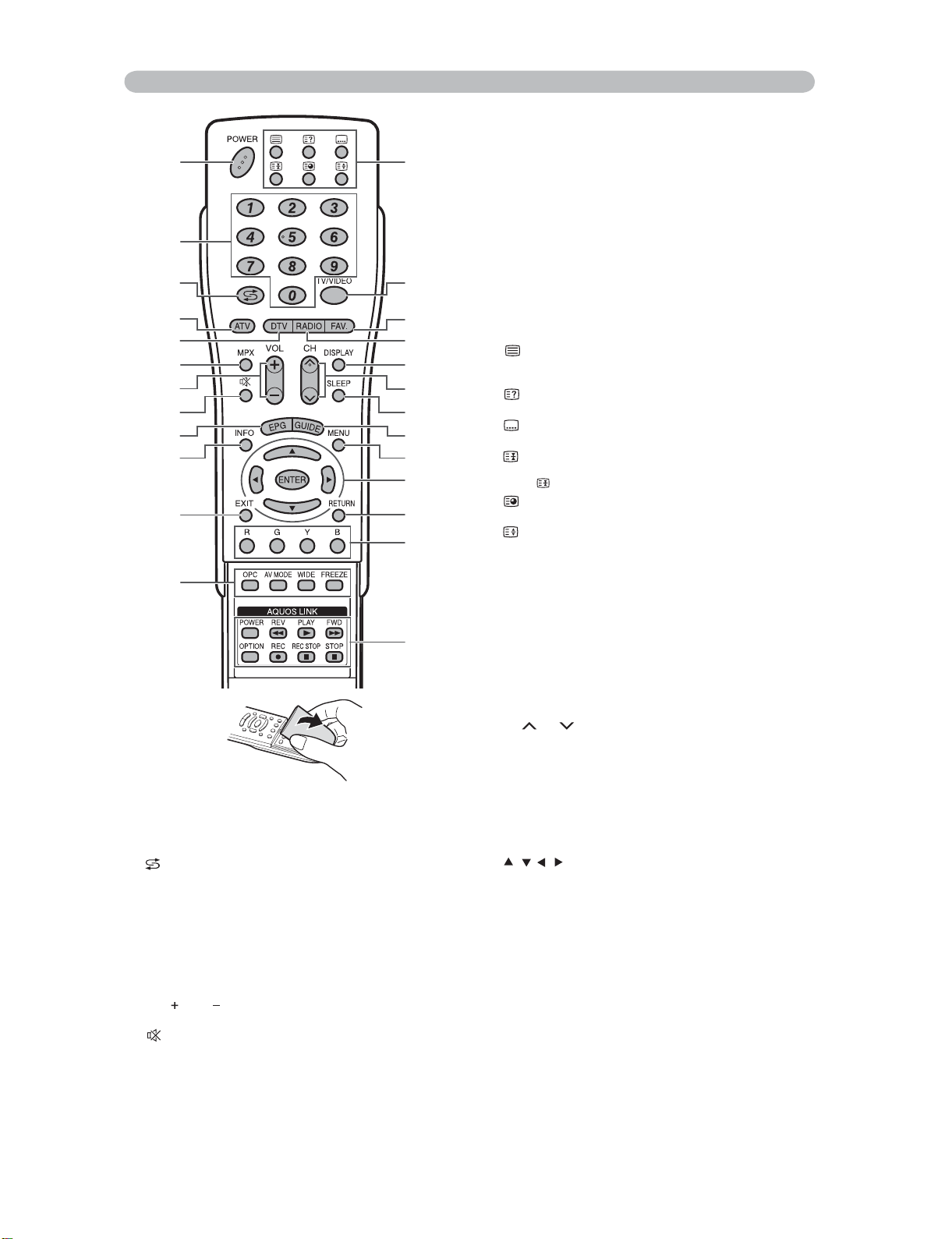

Remote control unit (LC-65RX1X)

1

2

3

4

5

6

7

8

9

10

11

12

1 POWER (STANDBY/ON)

To switch the power on and off.

20-9

Set the channel.

TELETEXT mode: Set the page.

3 (Flashback)

Press to return to the previous selected channel or external

input mode.

4ATV

Press to access ANALOGUE mode.

5DTV

Press to access DTV mode.

6MPX

Select the sound multiplex mode.

7VOL/VOL

Set the volume.

8 (Mute)

Mute the sound.

13

14

15

16

17

18

19

20

21

22

23

24

25

9EPG

DTV only: To display EPG (Electronic Programme Guide)

screen.

10 INFO

DTV only: Display the programme information.

11 EXIT

Turn off the On-Screen Display.

12 OPC

To switch the Optical Picture Control on and off.

AV MODE

Select a video setting.

WIDE

Change the wide image mode.

FREEZE

Freeze a motion picture on the screen.

13 (TELETEXT)

Select the TELETEXT mode. (all TV image, all TEXT image,

TV/TEXT image)

(Reveal hidden for TELETEXT)

TELETEXT mode: Display hidden characters.

(SUBTITLE for TELETEXT)

To turn the subtitles on and off.

(Hold)

TELETEXT mode: Stop updating Teletext pages automatically.

Press again to release the hold mode.

(Subpage)

Display the Teletext subpage directly.

(Top/Bottom/Full)

TELETEXT mode: Set the area of magnification.

14 TV/VIDEO (INPUT SOURCE)

Select an input source. (TV, INPUT 1, INPUT 2, INPUT 3, INPUT 4,

INPUT 5, INPUT6, INPUT7 (PC))

15 FAV.

DTV only: Display the favourite channel setting.

16 RADIO

DTV only: Press to access RADIO mode.

17 DISPLAY

Displays the channel or input information.

Displays the time information included in the Teletext

broadcast.

18 CH /CH

TV input mode: Select the channel.

TELETEXT mode: Select the page.

19 SLEEP

Set the Sleep timer.

20 GUIDE

DTV only: Display the programme list.

21 MENU

Display the menu screen.

22 / / / (Cursor)

Select a desired item on the setting screen.

ENTER

Execute a command.

23 RETURN

MENU mode: Return to the previous menu screen.

24 Colour (Red/Green/Yellow/Blue)

Select four preset favourite channels in four different

categories.

While watching, you can toggle the selected channels by

pressing R, G, Y and B.

TELETEXT mode: Select the page.

25 AQUOS LINK buttons

If external equipment such as a AQUOS BD Player is connected

via HDMI-certified cables and is AQUOS LINK compatible, you can

use these AQUOS LINK buttons.

LC-65RX1H/X

2 – 4

Page 12

LC-65RX1H/X

LC65RX1H

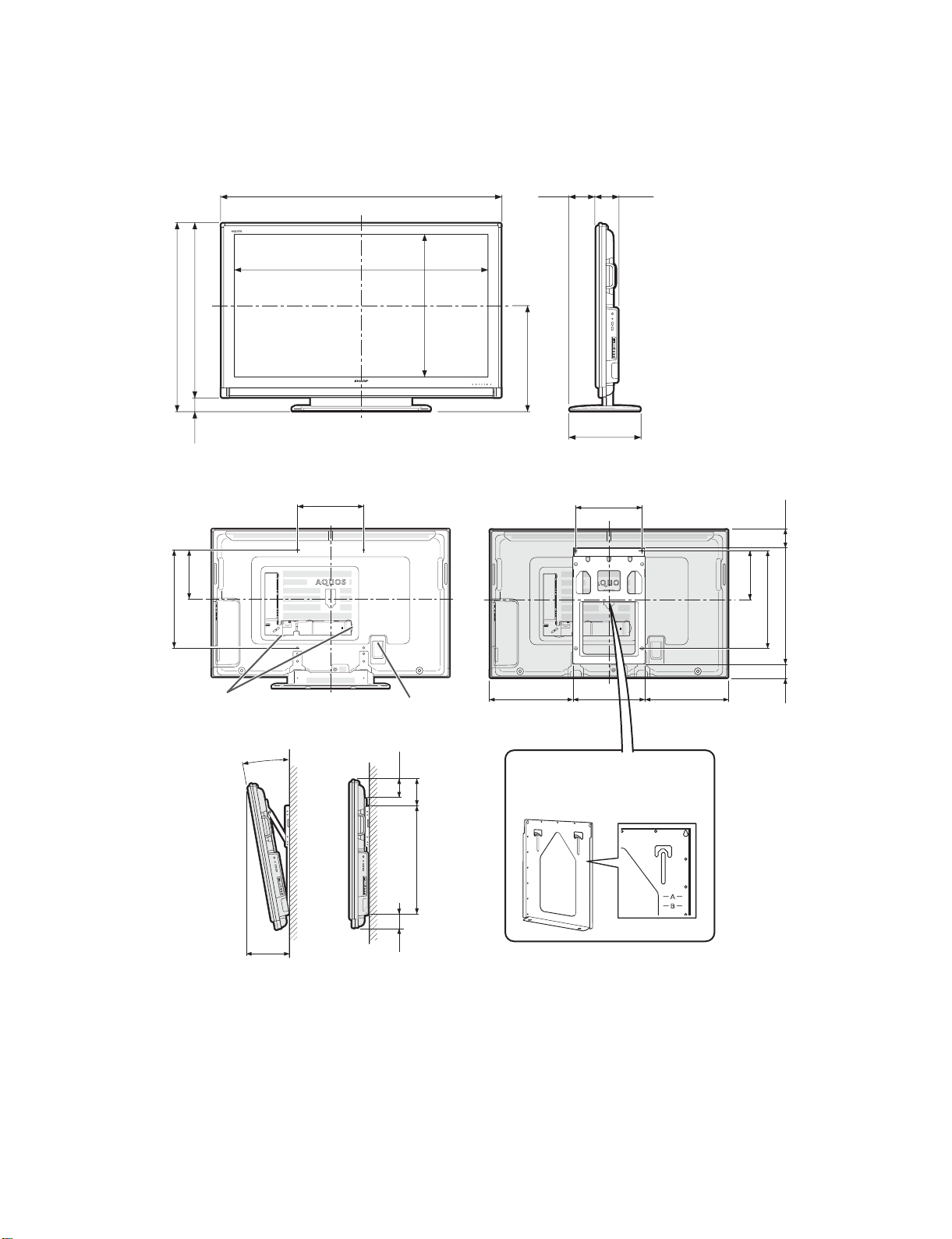

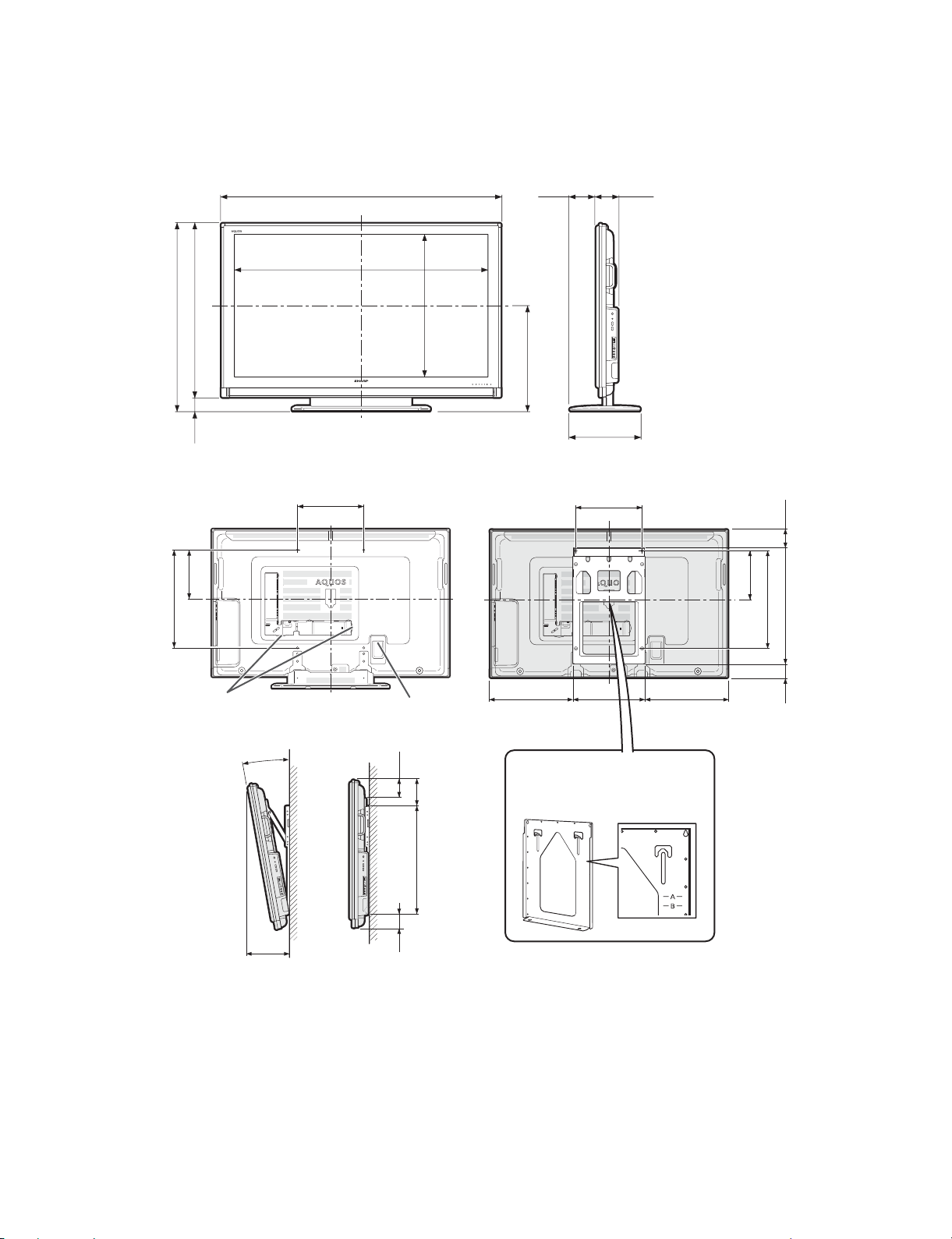

CHAPTER 3. DIMENSIONS

[1] DIMENSIONS

ServiceManual

Unit: mm

1579

1431.5

982

1062

806.5

80

When using wall mount bracket AN-65AG1

440

325

650

597

149

124

398

440

125

325

650

Cable opening

0°/5°/10°

278

Power code

connection terminal

192

18

21

On the wall bracket of AN-65AG1,

there is a letter 'A' indicating the

centre point of the TV monitor.

3 – 1

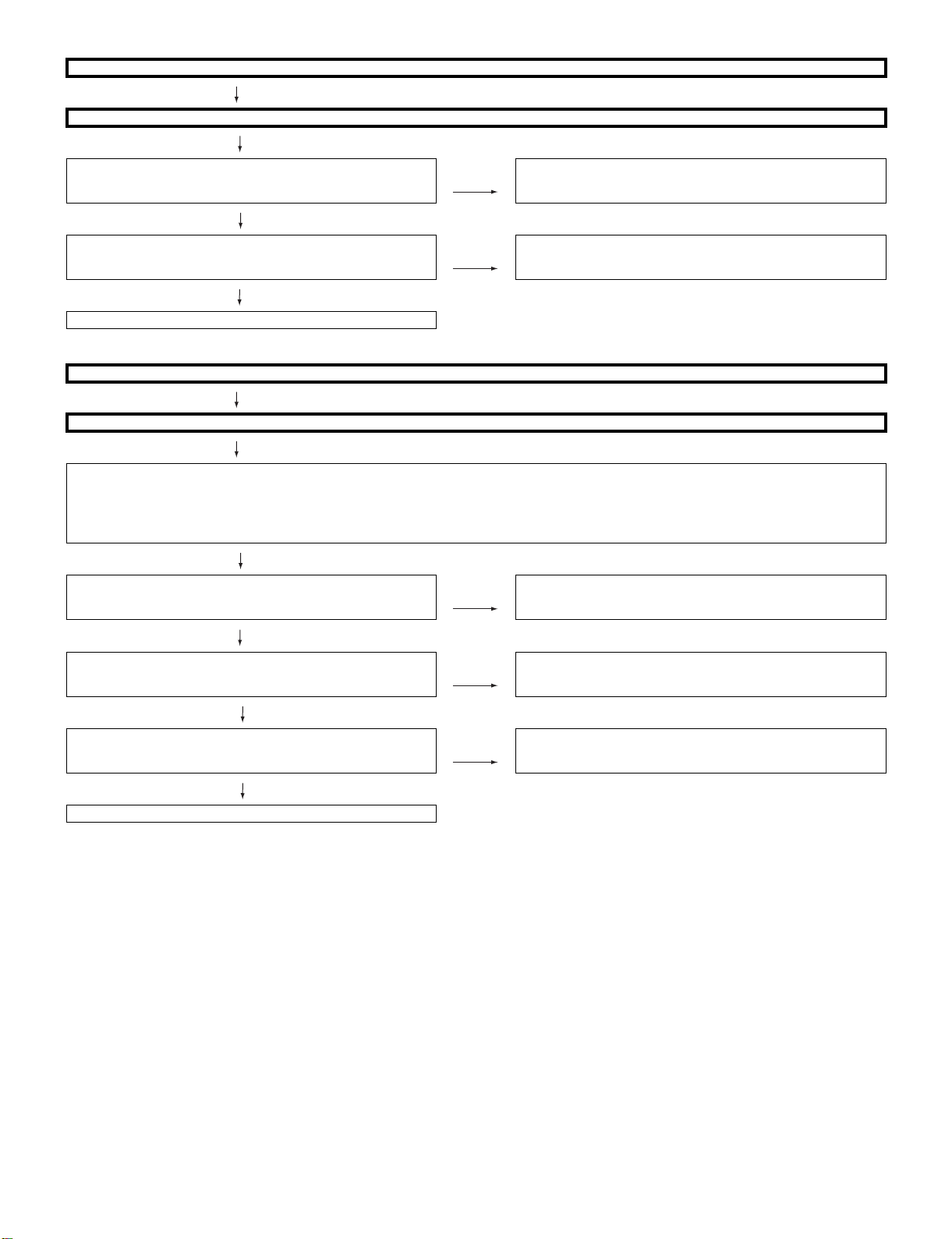

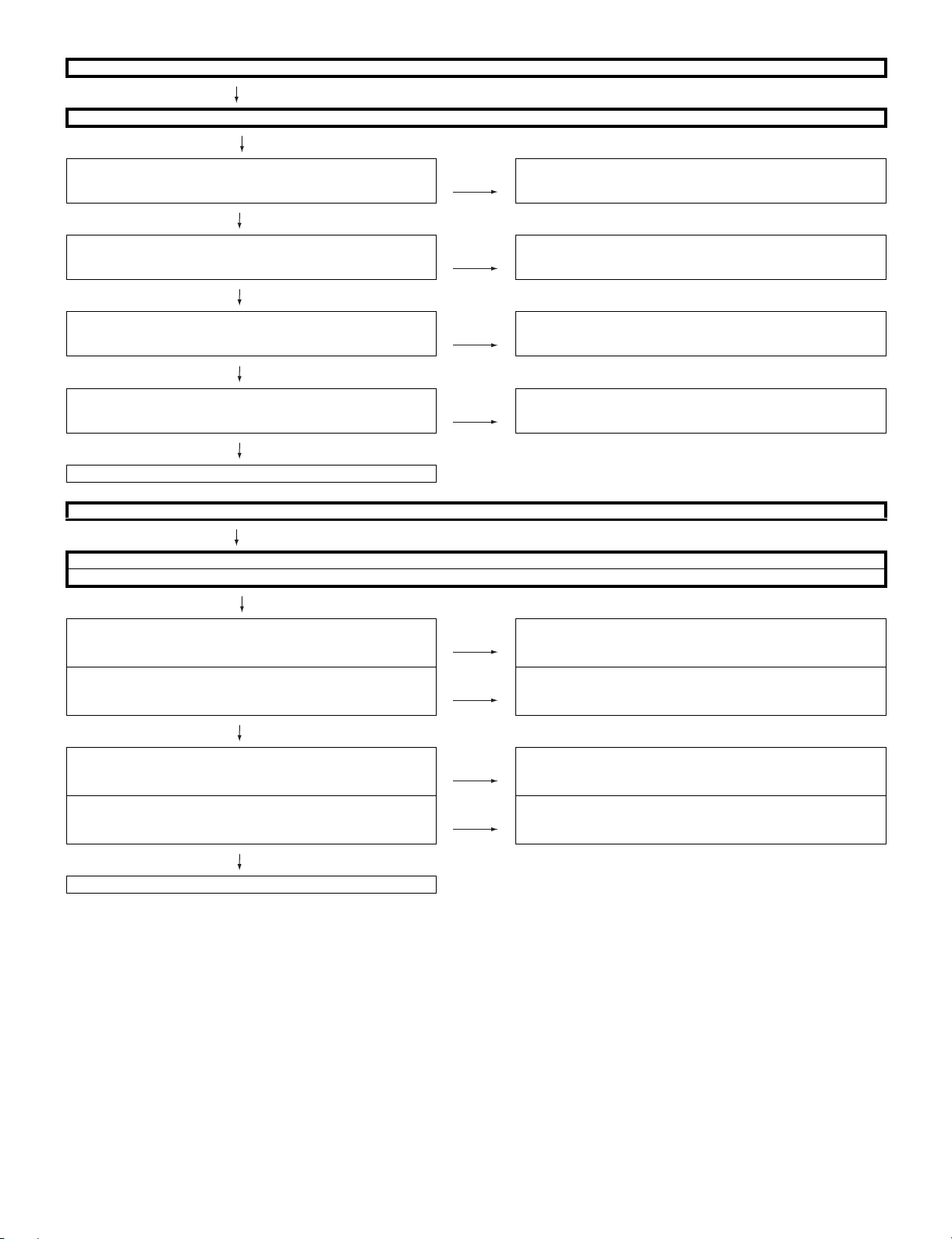

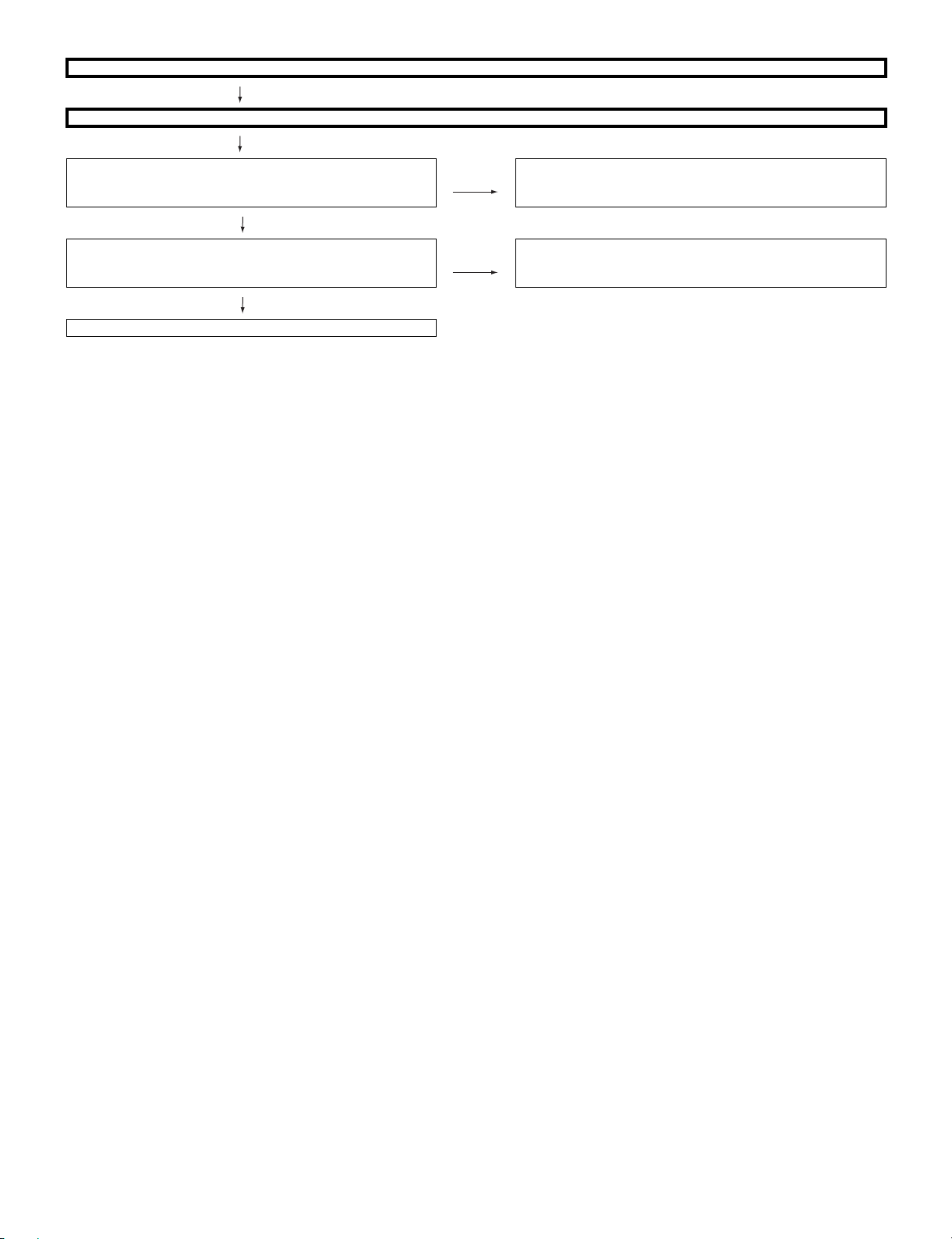

Page 13

LC65RX1H

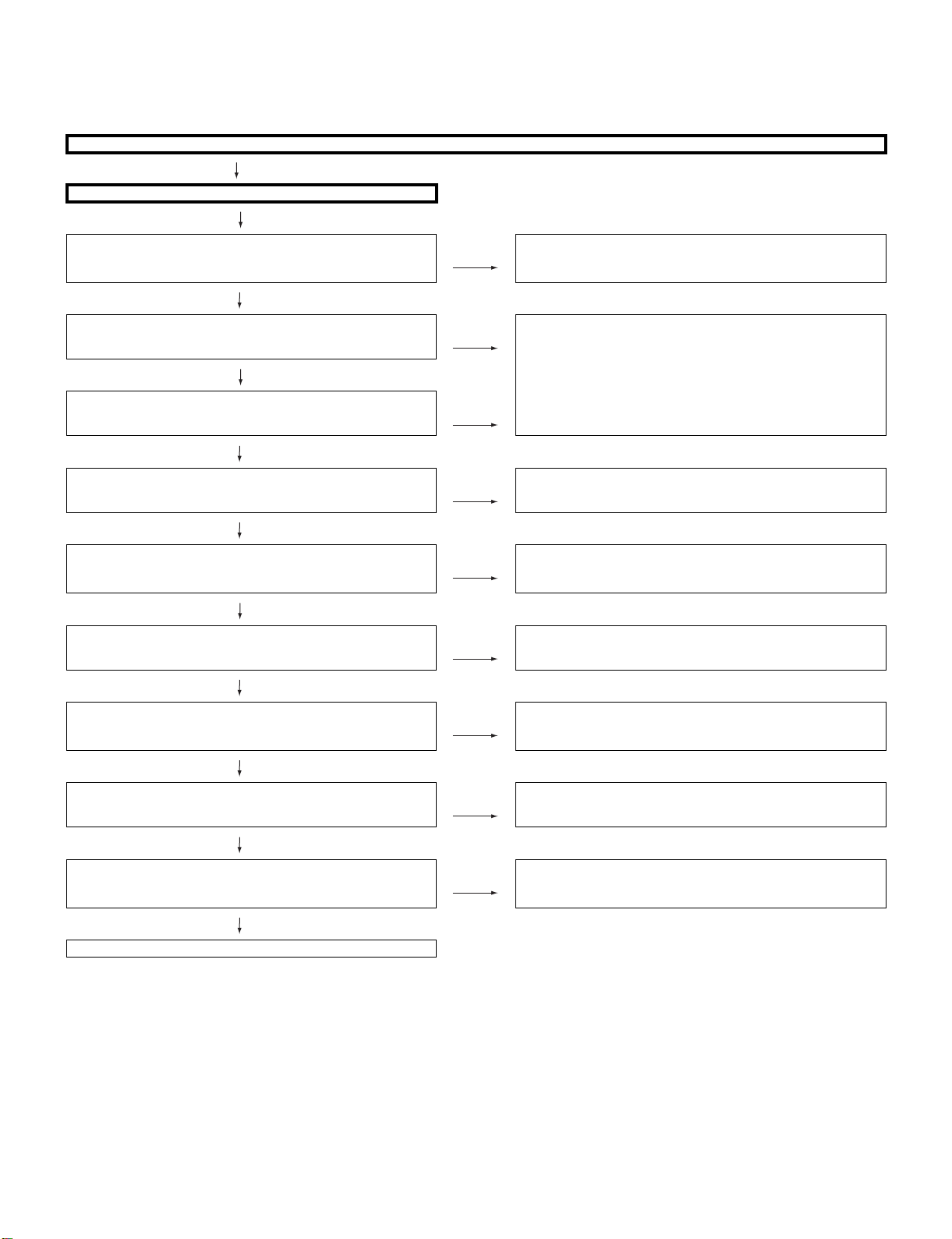

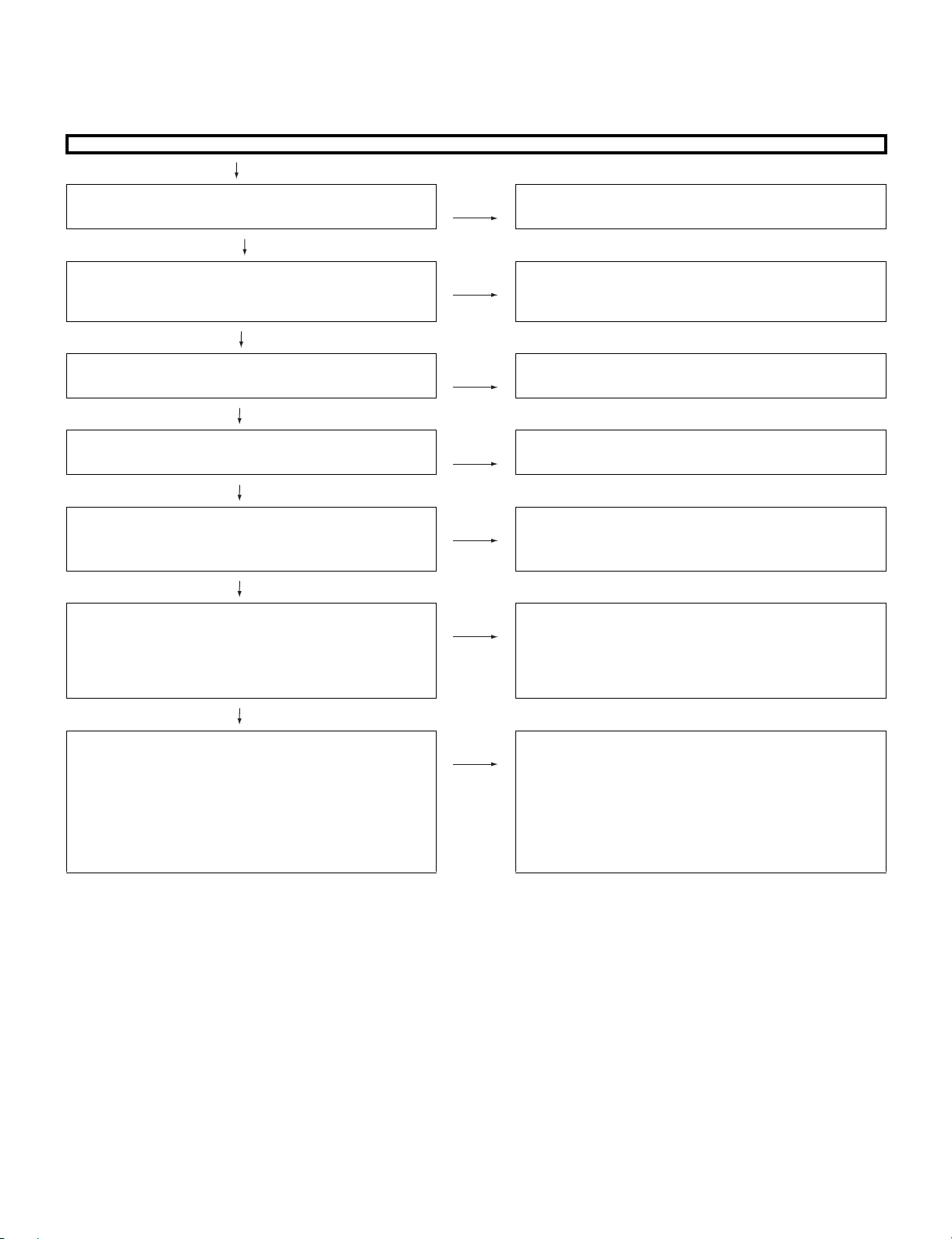

CHAPTER 4. TROUBLESHOOTING TABLE

ServiceManual

[1] TROUBLESHOOTING TABLE (for LC-65RX1X)

No picture on the display (3)

Does not the picture come out when DTV is received?

TERMINAL UNIT:

Is the voltage of regulation for a TUNER circuit and the power

supply terminal of IC7507 (COFDM) supplied?

(Refer to the circuit diagram)

YES

Is IF signal output from pin (20), (21) of TUNER (TU7501) to pin

(30), (30) of IC7507 (COFDM)?

TERMINAL UNIT: YES

Similarly, is communication control carried out between pin

(14),(15) of TU7501, and pin (4), (5) of IC7507?

YES

Does X7502 (20.48MHz) oscillate? NO Check X7502 and its peripheral circuits.

NO Each power supply circuit is checked.

NO Check the tuner, IC7507 and their peripheral circuits.

Replace as required.

NO

LC-65RX1H/X

YES

Is MPEG data (FECLK, FED_D, FESTR_PSYNC, FEVAL_DEN)

from IC7507 are output to pin (48)/FECLK, (46)/FED_D, (51)/

FESTR_PSYNC, (50)/FEVAL_DEN of a connector (SC501)?

MAIN UNIT: YES

Is the digital signal input into pin (48)/FECLK, (46)/FED_D, (51)/

FESTR_PSYNC, (50)/FEVAL_DEN of a connector (SC1101)?

YES

Is the digital signal input into pin (AF3)/FECLK, (AF2)/ FED_D,

(AF4)/FESTR_PSYNC, (AH3)/FEVAL_DEN of IC8101 (CPU/

DECODER)?

YES

Do X8101 (24.00MHz)/ X8102 (32.768kMHz) oscillate? NO Check the X8101/ X8102 and their peripheral circuits.

YES

Are video signal VDB_R [0:9], VDB_G [0:9], VDB_B [0:9], and

VBD_CLK/DE/HD/VD are output from IC8101 to IC3301 (VIDEO

PROCESSOR)?

YES

Refer to “The picture doesn't appear in all modes.”

NO Is the control signal named IC7507 and IC9101 (CPLD) normal?

(FE_RST_LINE, FEERR_LINE, FEPG0_COMP_LINE,

FEPG1_LOCK_LINE, etc.)

NO Connector SC501/SC1101 are checked.

NO Check the line between SC1101 and IC8101.

NO Check IC8101, IC3301 and their peripheral circuits.

(IC8301-IC8304 (DDR2_SDRAM), etc.)

4 – 1

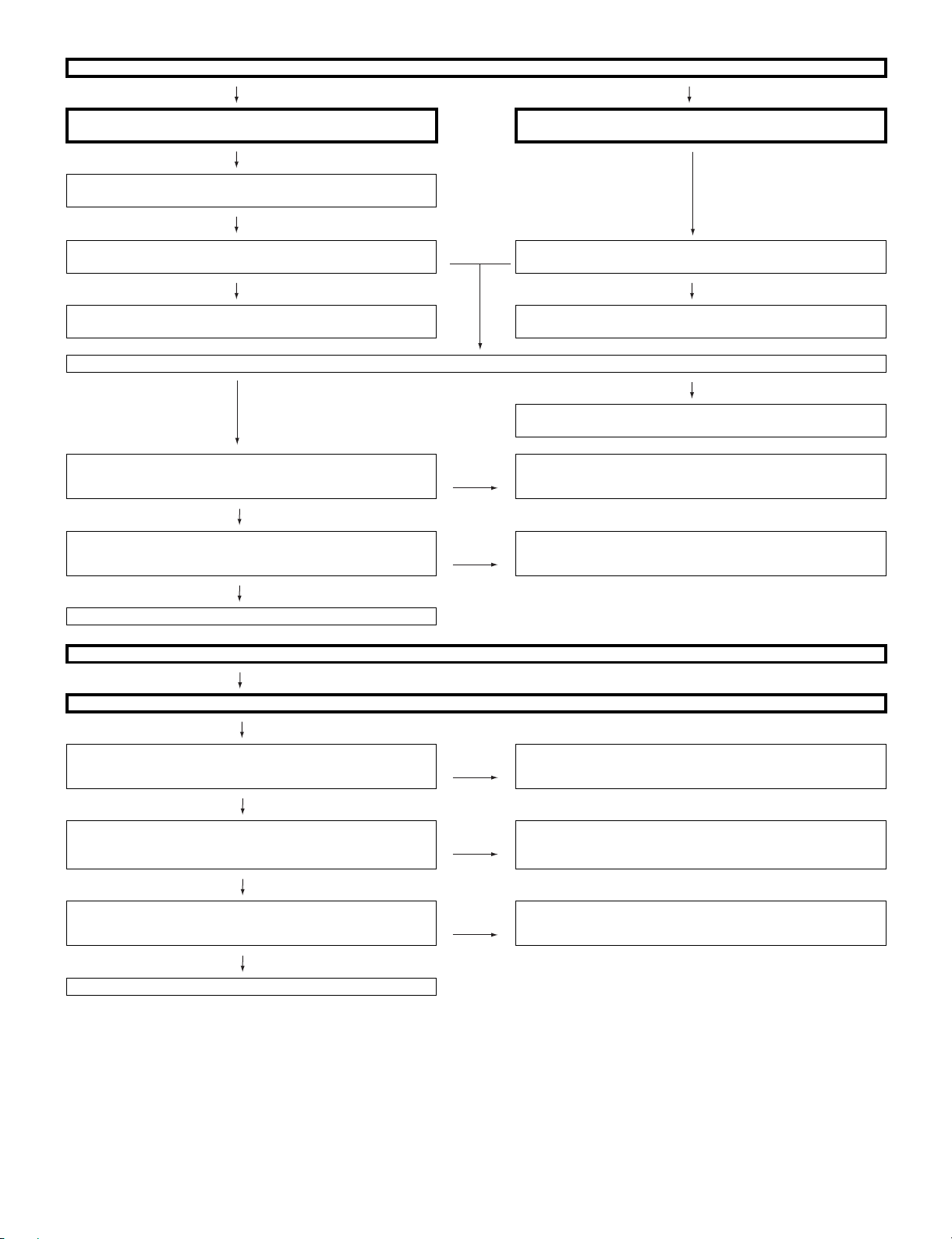

Page 14

LC-65RX1H/X

No sound (during the reception of TV (DIGITAL) broadcasting)

Does not the sound go out though the picture has come out when DTV is received?

MAIN UNIT:

Is DTV_SPDIF audio signal output from pin (T2) of IC8101 (CPU/

DECODER) to pin (42) of connector SC1101?

TERMINAL UNIT: YES

Is DTV_SPDIF audio signal input from pin(42) of connector

SC501 to pin(4) of IC1404(CODEC)?

YES

Refer to “No sound output in all modes”.

<During external connection> No picture on the monitor (2)

No picture appears on MONITOR OUT1 - connected monitor during the tuner (DTV) reception.

Checklist:

1) Is ANT-CABLE disconnected or connected improperly? ⋅ ⋅ ⋅ Connect it correctly as per the operation manual.

2) The picture is sent to the monitor in a CVBS signal if the source during display is TV, CVBS or Y/C of INPUT1-3.

When sent by component, etc., that signal is not sent to the monitor.

3) When the monitor picture is not sent and is not displayed on the monitor, refer to “No picture” for each terminal.

NO Check the line between IC8101 and SC1101, and their peripheral

circuits.

NO Check the line between SC501 and IC1404.

(SC1101/SC501, etc.)

TERMINAL UNIT:

Is CVBS signal outputted from pin (51) of IC506 to pin (6) of

J1701?

MAIN UNIT: NO

Is DTV_CVBS signal output from pin (18) of connector (SC1101)

to pin (15) of IC506?

NO

Is DTM_CVBS signal output to pin (AD4) of IC8101? YES Check the line between IC8101 and SC1101.

NO

Check the IC8101 and its peripheral circuits.

YES Check the setting of an external input device that connects of

J1701.

YES Check the line between SC1101 (MAIN_UNIT)/ SC501 (TERMI-

NAL UNIT) and IC506.

4 – 2

Page 15

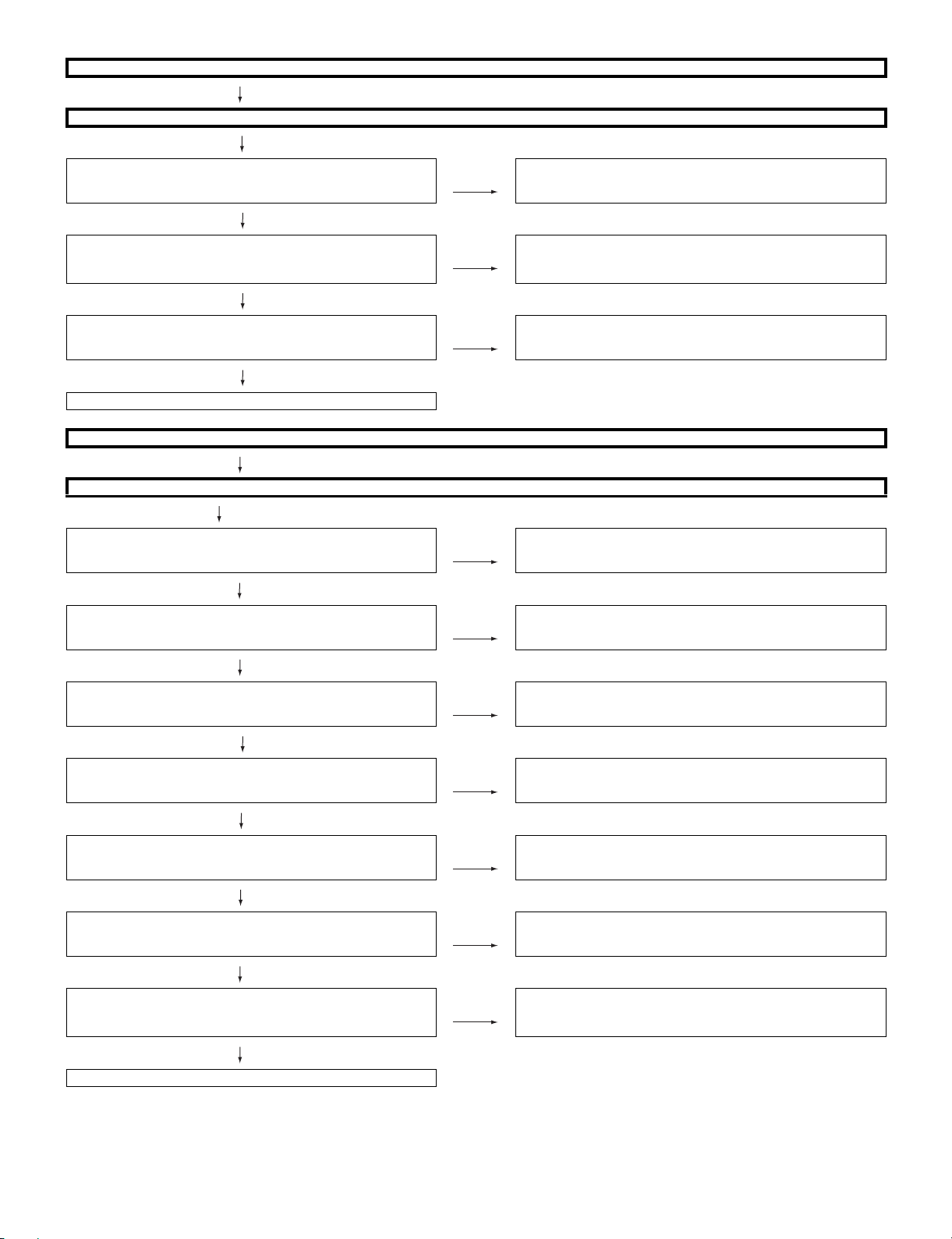

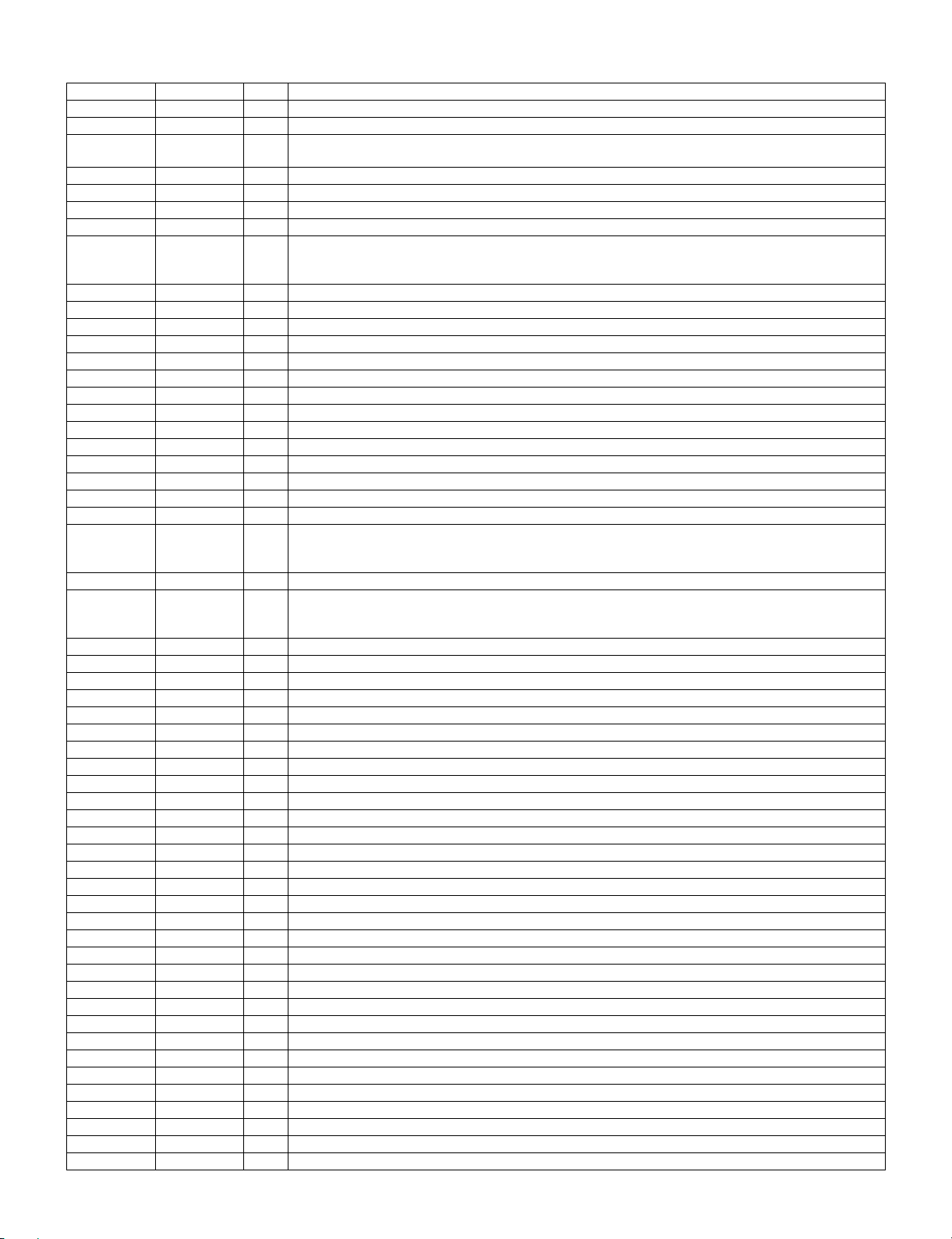

LC65RX1H

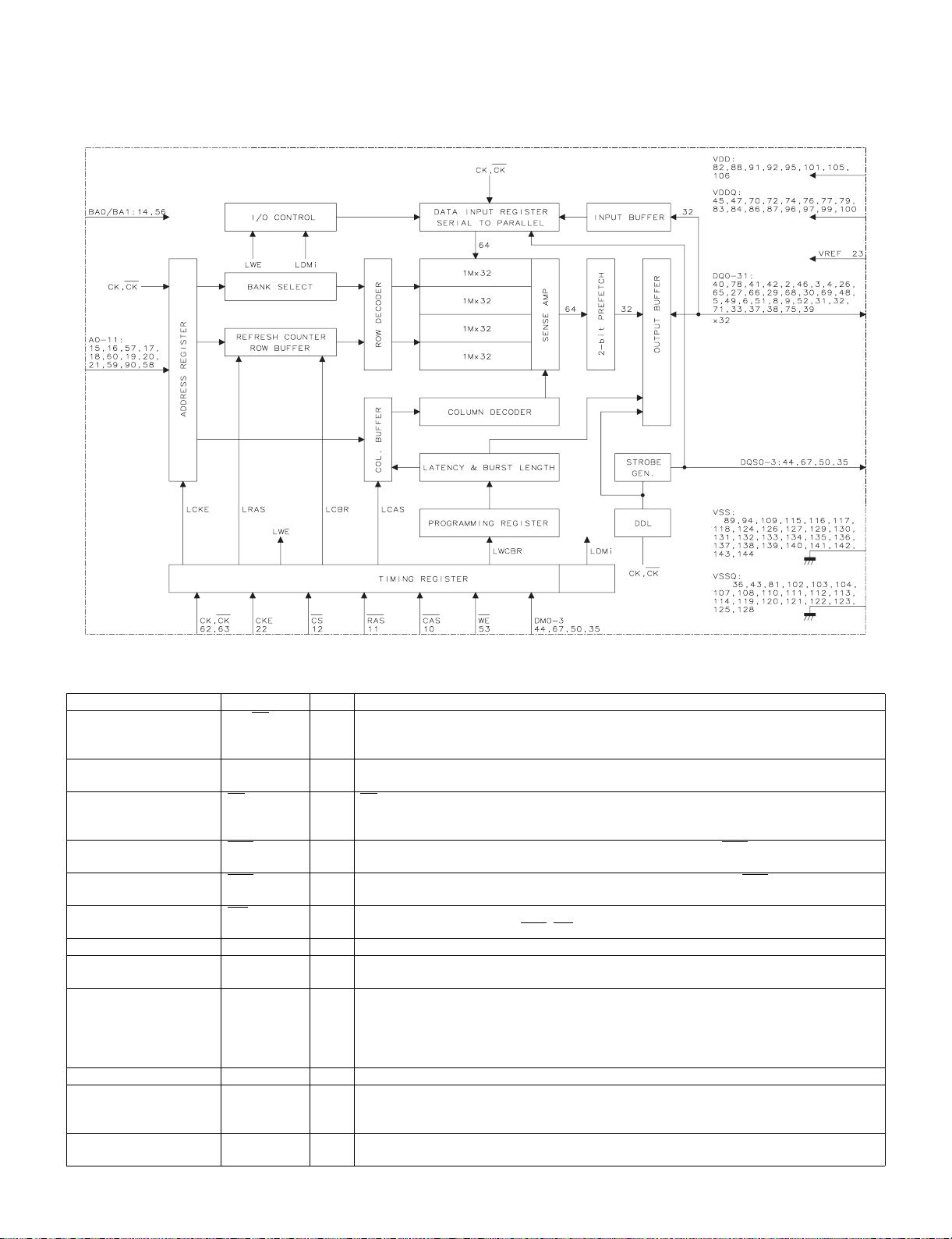

CHAPTER 5. OVERALL WIRING DIAGRAM/BLOCK DIAGLAM

[1] OVERALL WIRING DIAGRAM

LC-65RX1H/X

ServiceManual

5 – 1

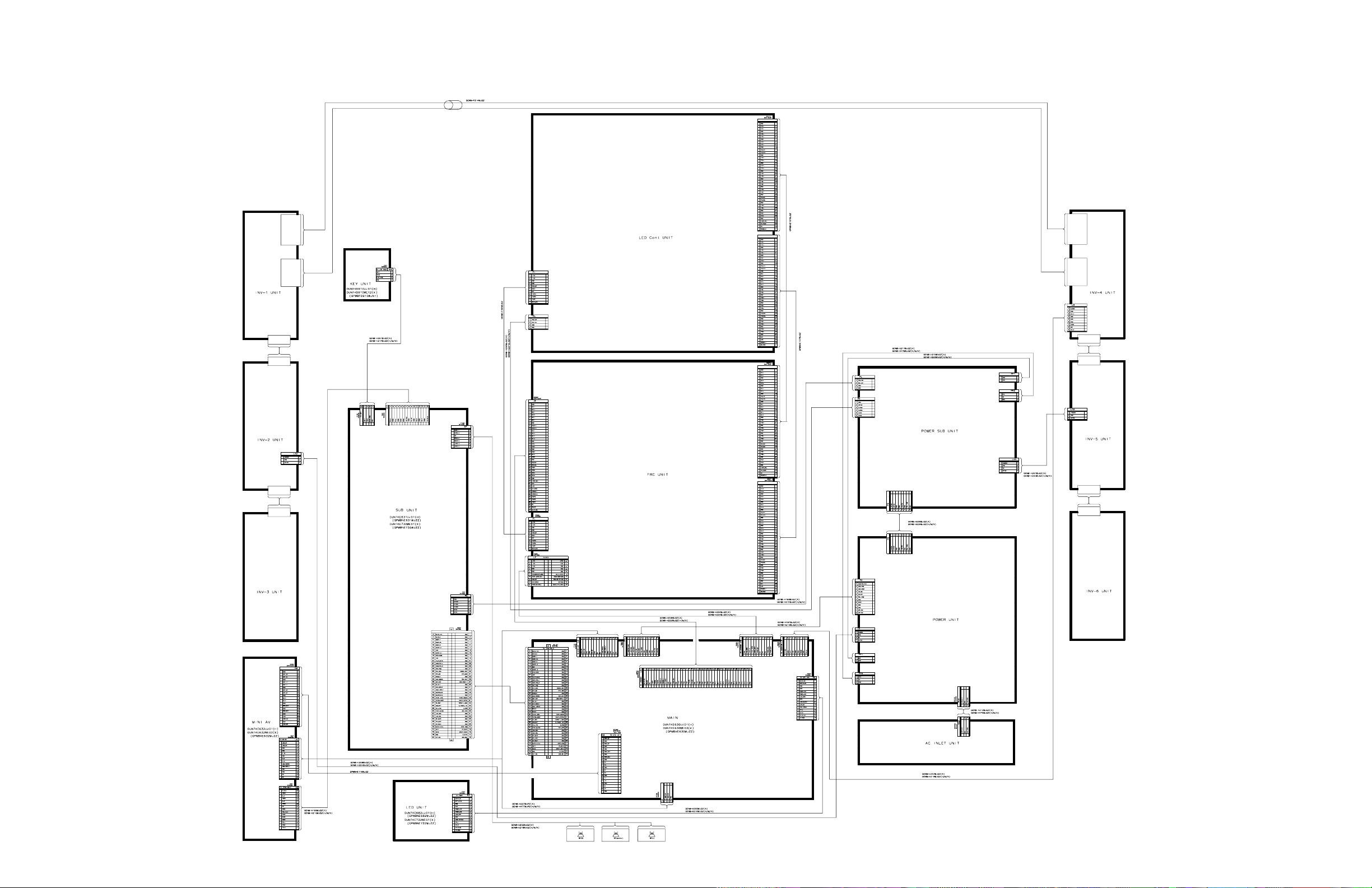

Page 16

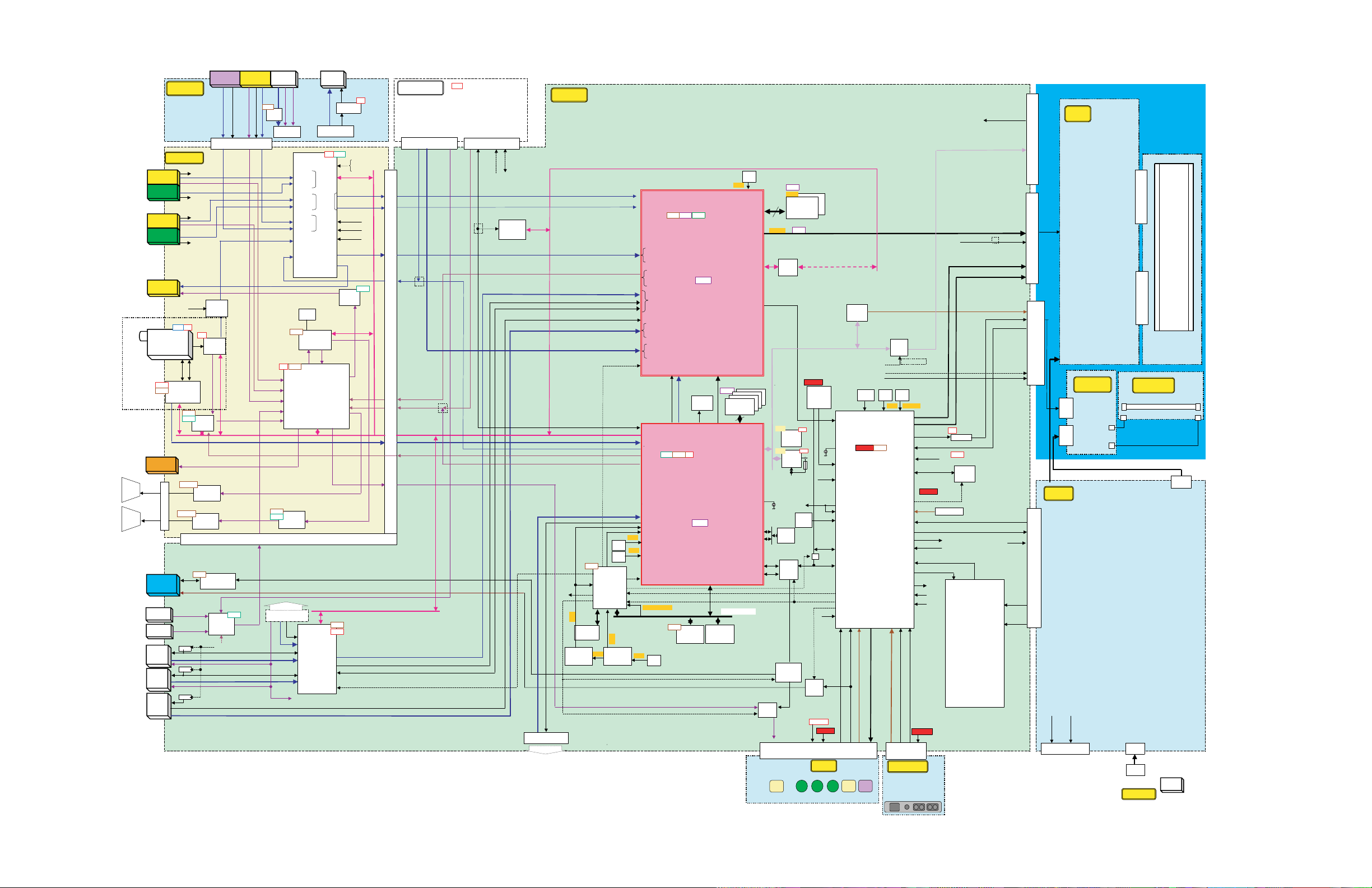

LC-65RX1H/X

[2] SYSTEM BLOCK DIAGRAM (LC-65RX1X)

58KFGQ

%8$5.4

*&/+

+0276

+0276

/10+614

4(+0

䇼㪪㪧䇽

㪇㪅㪈㪺㪿

+0276

+0276

+0276

+0276

+0276

176

/+0+#8

5;%

+0276+( 22+0

6'4/+0#.

8A2.7)

%8$5.4

;2D2T

%8$5.4

;2D2T

/10+614

176

67

#.25##9,3<

8

8

126+%#.

176

45%

*&+/#WFKQ

/KPK2NWI

2%#WFKQ

/KPK2NWI

*&/+

*&/+

&57$

RKP

%8$5

.4

;2D2T

%1/2A2.7)

8A2.7)

%8$5

.4

;2D2T

%1/2A2.7)

%8$5

.4

+%

㪫㪬㪶㪧㪶㪞㪘㪠㪥

8%#

$##(

8

8

6WPGT

6&3)

%1(&/&GOQF

+PVGN%'

#)%#(6

+%

&A+(

8

8

+%

8

+(

+%

5+(&'%

4#

%8$5

+%

+(&'/1&

6&#

5+(

65A176

㪛㪫㪭㪶㪠㪉㪪

126A176

#/28

+%

#WFKQ#/2

;<

#/28 +%

㪧㪈㪊㪇㪉

+%

㪣㪚㪟

#WFKQ#/2

;<

8

+%

45%6Z4Z

+5.

4%

*&/+A.4

+%

#WFKQ59

2%A.4

0,/

92

''241/

4:AZ

''241/

(TQO%2.&

92

4:AZ

92

''241/

#0#.1)4)$

%8$5

8.4

8A2.7)

5A2.7)

+0276

8

+0A.4

+0A.4

+0A.4

2%*&/+&6/A.4

#0#.1).4

5GTKCN㧕

㪣㪃㪩㪚㪟

+(VQ/#+0+(2+09#9,

.4

8A#

5%

%'%

%'%

*8

4:AZ

%'%

+%

+%

6/&5

*&/+((%

61/#+0

8

+5&52 5&176

8

8

+0

+0

+0

+0

+0

8

8A#

&#%

#-'6

6Z&4Z&

㪝㪝㪚䈪㫄㫀㫅㫀㩷㪘㪭

4:AZ

+%

8KFGQ59+6%*

//:3

8KFGQ

8

;2D2T

8KFGQ

8

;2D2T

8KFGQ

8

;%

6WPGT

8

&KIKVCN

8

+%

''241/

+%

&52

6#5

+5A#

+%

%1&'%

#-'3

6:

126176

.4%-$%-1765&176

+%

*&/+59

8GT

5++#

+P

+P

+P

5'.

6Q/QPKVQT/KEQP

75$

75$A7275$A&0

75$

61/#+0

8A#

8

.

㩰

.

68

/CKP

1WV

176

2.7)

&'6

68

/CKP

1WV

176

/10+614

1768

.4%-$%-1765&176

/10A176

*&/+A52&+(

&68A52&+(

52A176

*2A176

8

8

8$75

+%

40$

888

%1/2

;2D2T

+%

0,/

+5A$

6/&5

4:AZ

/CKP;8

/CKP%

5

#/2

8

+PFWEKPI

FKUVKPEVKQP

UGVVKPI

&6/A%8$5

8A#

&+)+6#.70+6

*&/$6

&6/+( 22+0

&6/A%8$5

+(VQ /#+0 +( 2+0 9# 9,

*&/+A52&+(

&68A52&+(

65

5GTKCN

&68A+5

%-*&8&&'

8

/#+0

&'6A20.8

&6/+( 22+0

5%.5&#

&6/A45

&6/A6:&4:&

%2.&

)2+1A

/CKP;8

/CKP%

+%

5%+5

7#46+%

-*\

;2D2T

*&/+A52&+(

6/&54Z

%-*&8&'0

5%.5&#

*&8&

2%A4)$

;2D2T

6Q%2.&

&68A%8$5

&68A+5

&68A52&+(

%8$5;

%8

5%#46A)8㧕

5%#46A$9

5%#46A4;

($;

;9

2D;

2T9

52&+(9

955&5%-#7&+1%.78;9

2%A4)$*&88&7

2%A47

2%A);

2%A$9

4GUGV(

4Z&6Z&

7#46A#8

+%A

655

*&/+

;;㧕

2D;

2T8

67'4

8

8

8

+%

+:%9,

8KFGQ2TQEGUUGT

5829:

㪩㪼㫍㪅㪚

&+0

2

',6#) ↪

㩄㩒㩂㩊

&A176

$㩘㩩㨺㩎

88

8

&6/A.4

;2D2T

&6/A52&+(

+%

*K&682TQ.:

+:%9,

&KIKVCN#8FGEQFG/CKP%27

)2

75$A7275$A&0

75$A221075$A1%

22+0

75$

㪫㫆㩷㫄㫀㫅㫀㩷㪘㪭

20.A219A/#+0

/*\

2

%QPPGEVQTHQT

%2.&YTKVKPI

+%

+08'46'4

8*%6

8

/*\

+%

%2.&

+:%9,

+:%9,3<

:VCN

-*\

:VCN

/*\

/*\

+%

%.1%-

-*\

/*\

75$

4'5'6

:6.+

:6.1

2%+%.-/*\㧕

/*\

%-

%-'

)2+1

:VCN

/*\

8

%.10'A4%

+%

(.#5*

/DKV

㪩㪼㫍㪅㪚

(.#5*$75

%QPPGEVQTHQT

5QHVYCTGYTKVKPI

$75

$75

5%

/*\

*5/

85/

&2$A%.-4

8

+%

&&4

/DKVZ

5+%A5%.

5+%A5%.

(.#5*2%+$75

/*\

:VCN

:6.+

:6.1

/*\

.8&5176

5%.*

5&#*

DKV

+%A

':'A.'&

)2+1

4Z&6Z&

7#46

4Z&6Z&

7#46

45A$7(A%06

45A6:&4:&

3

ޣ4#ޤ2R0#9,

DKV

-*\

75'4

&6%2

&GDWI

%QPPGEVQT

+%

㪟㪧

8

/*\

'/#$+

2

%JKR

&GDWII GT

%QPPGVQT

+%

''241/

MDKV

+%

''241/

MDKV

92

+%':6

(TQO*&/+

%QPPGE VQTH QT

FKUVKP EVKQP

2

+%

5VCVG

6%9

45A6:&4:&

*2A.4

+%

&&4

/DKV

8

8

8

2

㪦㪧㪚㪪㪣㪜

$78

20.A2192/A4'3

2CKT

2

5RHVYCTGYTKVVKPI

'OWNCVQT

%QPPGEVQT

85;0%

+06

':'A.'&

9#-'A72

%'%A1

%'%A+

25+<A.

25+<A*

#4'#

#4'#

20.6;2'

59

4Z&6Z&

0A54'5'6

+4A2#55

#)%#(6

*2A2.7)

+%

+4A59

5'6

1268

$78

.'&

㪧㪮

㪜㪧

+%

8$46

&#%

/(2

(TQO%2.&

(TQO%2.&

+%

4GUGV

+%

%27

/%

$78 8

+1

+06+

1

+06+

+1

+06+

7#46(QTTGYTKVKPI

7#46

+1

+1

+1

#&

#&

+1

+06

4%

12%

.'&Z

.'&A;1;#-7.'&A12%.'&A4.'&A)

12%

4%

㪦㪧㪚 㪩㪚

/*\

:VCN

+1Z

+%

$7559

97

-*\

:VCN

/*\

#&Z

219A59

-';-';

2R

0#9,

5%.5&#

20.A+%A'0

-*\

+1

+1

+1

+1

+1

+%

+1

#&

+06

+1

+1

+1

+1

+1

+1

+1

+06

+1

+06

56$;A219

$78

ޣ-/ޤ

-';

㪧㫆㫎㪼㫉

㪠㫅㫇㫌㫋㩷 㪪㪼㫃㪼㪺 㫋

㪚㪿㪸㫅㫅㪼 㫃㩷㪪㪼㫃 㪼㪺㫋

㪭㫆㫃㫌㫄㪼

%2.&߆ࠄ

6'/2=?15A5'641/5'.(4#/'

8%1/A92

8

+08A81056$

8$7(

+08A'44'44A20.

8

&'6A2#0.8

+%

''241/

+%A5%.

$4.(

+%A5&#

$78

9A2416A/

356'/2

6JGTOKUVGT

#%A&'6

25A10

#06A219

.0$5*146

&'6A20.8&'6A8&'6A8

&'6A&8&'6A8

&A21945A10.+0-A219'7A2195/219

/76'A#A#..

$CEM7R(CEVKQP

5;0%A&'6

˴$78

$78

&8+#A&'6

/CKP(CEVKQP

˴#8(TQO57$㧕

˴&8

&8A75$

˴&8

˴&8

˴&8

˴&8

&8

˴&6/A8

219'429$

2'

20.8A10

(TQO%2.&

20.A219A/#+0

5%.5&#

4.7&

$78

748

R

ޣ.2ޤ2

ޣ.9ޤ2

R%QCZKCN

8QP

2

ޣ.$ޤ

ޣ2&ޤ21 9'4˴% 106˴22+0

%106

RKP

ޣ.$ޤ

RKP

ޣ.#ޤ

RKP

20.8

219'4

#/28

748

ޣ2#ޤ6Q 6GTO KPCN

R

.%&

+08'46'4

㪠㪥㪭㪜㪩 㪫㪜㪩㩷㪧 㪮㪙

((%

ޣ#%ޤ

R

ޣ#%ޤ

R

#%+0.'6

((%

㧮㧸

QT9CXGNGPIVJ

㪣㪚㪛

㪧㪘㪥㪜㪣

㪈㪐㪉㪇㬍

㪈㪇㪏㪇

ޣ2)ޤ

#%

+0

R

㧦

㧦

8

5 – 2

Page 17

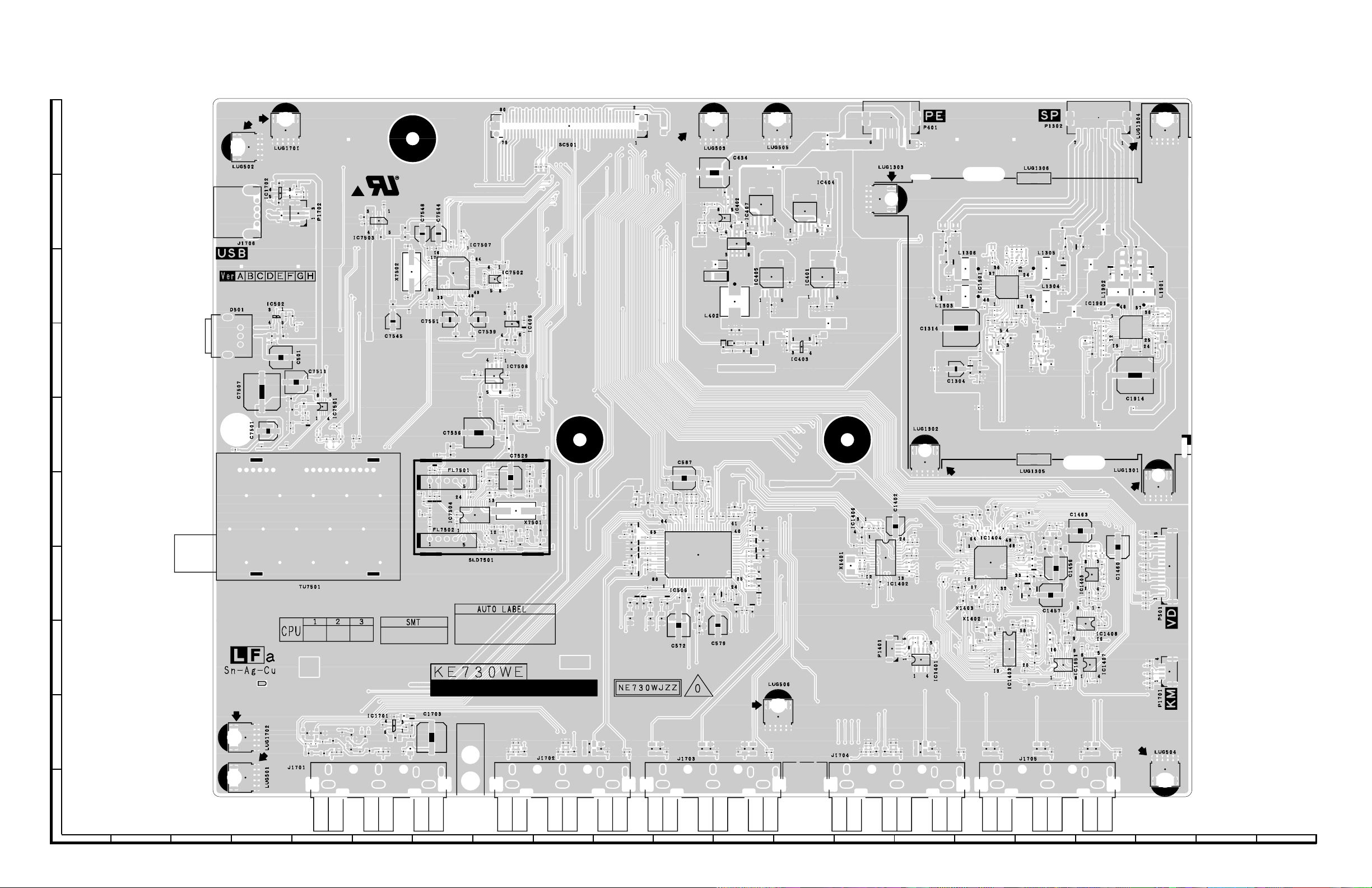

LC65RX1H

CHAPTER 6. PRINTED WIRING BOARD

[1] SUB UNIT (LC-65RX1X)

Wiring

Side-A

J

I

H

LC-65RX1H/X

ServiceManual

G

F

E

D

C

B

A

123456789

10 11 12 13 14 15 16 17 18 19 20 21

6 – 1

Page 18

LC-65RX1H/X

Chip Parts

Side-A

J

I

H

G

F

E

D

C

C1403

C1401

C1405

C1407

R1415

C1411C1408

IC1406

R1416R1413

C1412

C1413R1403

R1408

C1410

C1409

LUG1303

R1402

R1409

IC1402

P401

R1329

LUG1306

R1332

R1333

P1401

C1402

R1405

C1450

R1412

R1406

R1959

R1414

C1406

R1417

R1404

R1407

C1451

C1469

R1411

R1438

IC1401

D1305

R1330 C1304

LUG1302

R1419

R1401

R1410

C1326

C1323

D1306

C1320

C1319

C1424

C1314

C1414

R1423

R1420

R1422

C1417

C1425

C1427

C1423

C1421

C1422

R1426

R1421

L1303L1306

R1954

D1302R1309

C1428

C1429

R1436

R1434

R1429

R1310

R1315

C1431

C1420

R1430

Q1303R1308R1313

C1430

X1403

C1317

X1402

C1432

C1419

C1329

C1306

R1338

C1436

R1431

IC1404

R1439

R1440

R1427

R1428

R1446

R1450

R1319

R1317

C1313

C1308

C1311

C1301

R1321

R1305

R1302

R1442

C1438

C1302

R1445

C1437

C1418

R1437

IC1301

C1315

Q1301

R1339

R1320R1325

C1312

R1336C1331

C1309

C1305

R1454

IC1403

C1416

C1307C1332

C1440

C1442

C1444

C1454

R1326R1327

R1455

R1456

C1446

R1312

C1443

C1453

FB1403

C1415

R1337C1328

R1955

C1455

C1426

R1328

R1334R1311

R1314

C1439

C1441

R1453

D1401

D1402

R1435

Q1403

C1447

C1445

D1404

R1433

C1433

C1330

C1316

R1335

R1303

R1304R1307

LUG1305

C1448

C1449

D1403

FB1404

C1434

C1435

R1443

C1327

Q1302

R1322

D1301

FB1401

R1464

C1452

R1907

R1906

R1301

Q1401

L1305

L1304

C1457

C1952

C1951

R1951

C1956

R1418

C1303

R1952

C1456Q1402

R1953

R1331

R1306

D1405

R1462

R1483

C1953

R1958

R1746

R7546

R1745

Q7505

Q7506

R7541

R7573C7581

R1744

SC501

KAME2

R565

L502

R650 R661

C617

Q516

C1745

D550

R612

C600

R610

R616

D546

R537

D545

R644

D543

C589

R599

C593

R536

R595

R643

D541

R535

D531

D532

R575C580

C587

R671

Q520

Q518

R670

R660

R649

R618

C575

D530

R569C571

R574C574

C572

LUG1701

LUG502

C1749

R1740

R1739

R1743

IC1702

C1748

C1747

P1702

VA1702

J1706

D501

C7510

L1701

VA1701

KU3

Q521

R534

IC502

D521

C525

R503

L501

C518

C502

C501

C7511

R7505

C7503

FB7501

Q7501

C7508

R7509

C7502

R7502

R7504

TU7501

D7501

KAME1

R7568

R7501

IC7501

C7505

R7527

C7506

R7564

C7507

C7501

C7504

C7509

KU2

KAME5

C7514

C7522

R7547

C7521

IC7503

C7580

C7526

C7545L7506

L7509

L7510

C7560

C7561

C7553

X7502

R7517

R7512

C7548

C7565

C7554

C7516

C7563

C7564

C7557

R7519

D7503

C7519R7530R7506

C7566

C7552

C7515

D7505

D7504

C7544

C7567

R7518

D7506

C7556

FL7501

FL7502

C7518

C7520

C7551

L7502

C7517

IC7507

R7516

L7511

C7523R7521

R7567

R7566

R7508

C7568

C7524

R7520

C7540

L7504

C7539

C7573

C7536

SLD7501

IC7504

C7577

R7534C7575

C7525

R7522

C7528

C7533

R7570R7572

R7524

R7528

R7523

C7532

C7538

C7530

R7538

R7569

IC7502

R7549

IC7508

R7526C7535

C7542

C7574

R7510

R7548

C7541

R7533

C7550

C7547

R7571

C7513

R438

IC7506

R7525

C433

C7572

L7503

R7539

C431

C7576

R7552

R7550

R7529

IC406

C7529

R7536

FB7502

C426

Q407

X7501

Q7504

Q7507

R7551

R7540

C428

D408

Q7502

C7537

L7505

C7543

R7537

C7527

R7535

R7544R7545

LUG503

C434

C414

C411

C406

C405

R415

IC402

C407

R420

C408

R408R409R410

R402C402

R566

R623C608

R622C611

R673C632

C602

C601

R619R625

IC506

C578

C577

C506

L503

C503

R501

C505

FB402

R423

Q402

D405

D402

L402

C417

C420

D410

R432 D411 C404

D409

R433

D412

C588

R621

C615

FB519

R628

R540

R614

R615C610

C603

C604

R582

R652

D529

R646

R580

R571

R572

D533

C579

LUG505

R445

IC407

R442

C436

C435

R443

IC405

C429

C430

R401

R403

C403

R538

R539

R613

R609

D548

R606

R608

D544

R600

R604

D542

R596

R598

D534

R592

R591

R589

R587

R656

R657

R586D537D536

R570

D535

FB405

FB406

FB404

IC404

C422

R431R430

C423

C424

R502

R405FB403

C409

IC401

C432

R407

R406

C410

C412

R404

FB401

C401

IC403

C1404

X1401

R1324

C1322

C1324

C1473

R1478

D1303

C1318C1321

C1954

C1955

IC1951

R1957

R1424

R1956

R439

R1479

C1463

R1323

D1304

R1473

C1462

C1470

R1476

C1901

R1472

R1468

C1459

IC1408

R441

C1461

R1469

R1482

R1475

R1901

R1908

R1927

Q1902

R1903

IC1407

C1907

IC1405

R1477

P1302

C1916

C1904

R1466

R1463

R1467

R1905

C1472

R1481

C1471

R1474

R440

C1911

C1909

C1913

C1910

C1902

R1911

R1910

R1925

R1470

R1465

R1461

C1458

R1460

R1480

D1903

L1902

C1921

C1460

C1915

R1923

C1924

C1923

IC1901

R1902

C1914

R1924

C1922

L1901

C1918

FB524

C629

FB523

C628

FB522

C627

FB521

C626

FB520

C625

FB509

C623

FB518

C624

C1917

C1743

FB1704

FB1703

C1744

FB1702

C1746

D1904

R1914

R1917

C1919

R1929

C1920

R1921

R1922

R1916

R1928

LUG1301

R1918

R1920

LUG1304

R1919

Q1901

P501

P1701

FB1701

C1711

C1717

D1701

R1705

R1736

D1702

C1719

J1701

R1718

C1708

R1708

IC1701

C1718

R1702

R1710

R1701

C1703

R1729

B

LUG1702

LUG501

Q1703

R1728

C1726

R1738

R1737

Q1704

R1727

C1720

C1725

R1717

C1714

R1709

Q1701

Q1702

A

123456789

C1709

R1712R1726

R1735C1730

C1732

C1704

J1702

R1711C1724

R1734R1722

C1731

R1742

C1733

R1703

LUG506

C1702

C1716

R1713

C1734

R1730

C1727

C1735

J1703

R1723

C1721

C1712

R1719

C1736

C1706

R1707

C1710

R1716R1725

R1733C1729

C1738

C1737

R1732R1721

J1704

R1714C1723

C1705

R1741

C1739

R1704

C1701

C1715

R1715

C1740

R1731

C1728

C1741

J1705

R1724

C1722

C1713

R1720

C1742

R1706

C1707

LUG504

10 11 12 13 14 15 16 17 18 19 20 21

6 – 2

Page 19

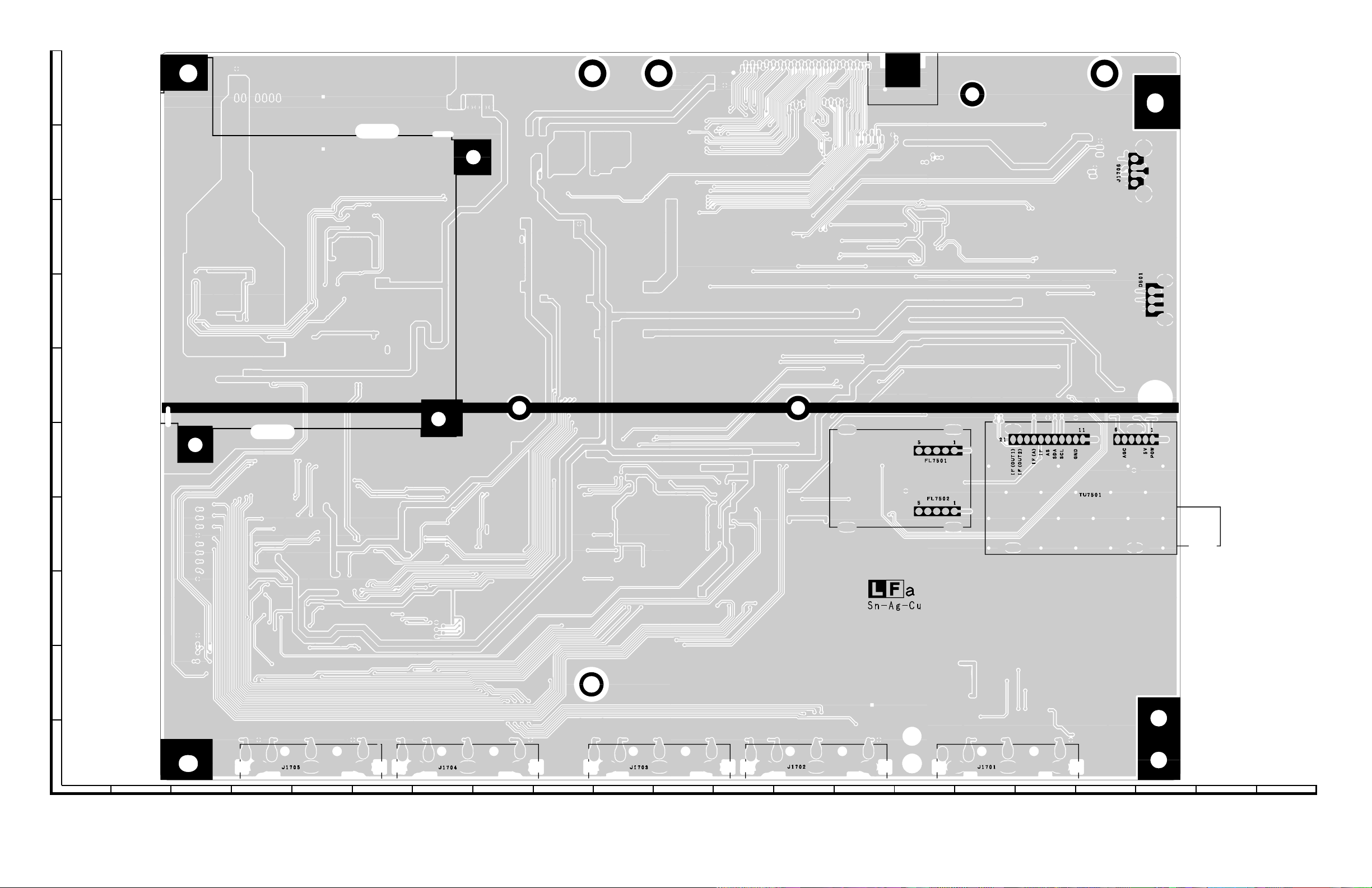

J

I

H

G

LC-65RX1H/X

Wiring

Side-B

F

E

D

C

B

A

123456789

10 11 12 13 14 15 16 17 18 19 20 21

6 – 3

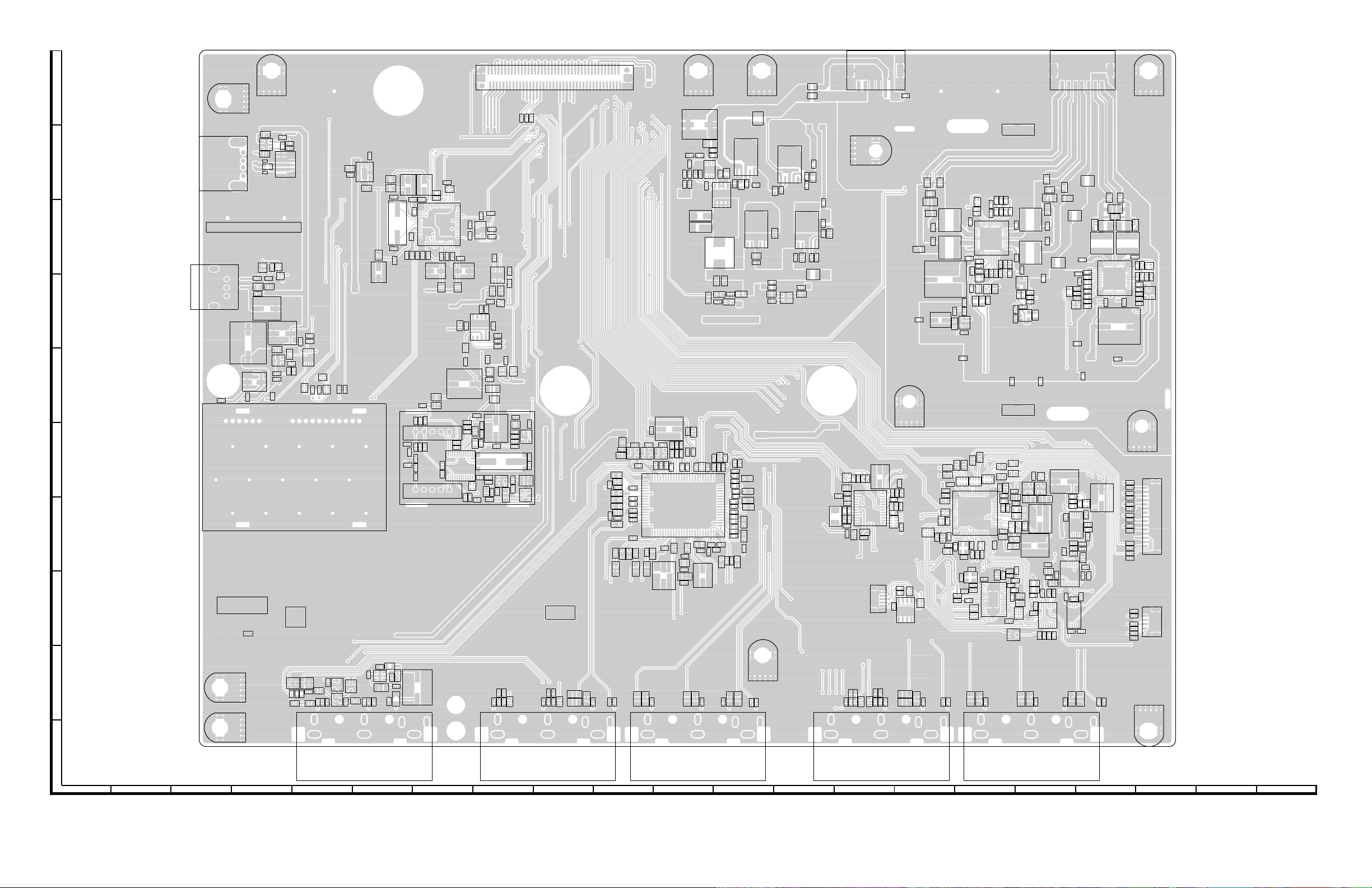

Page 20

LC-65RX1H/X

LC65RX1H

CHAPTER 7. SCHEMATIC DIAGRAM

[1] SCHEMATIC DIAGRAM (LC-65RX1X)

1. DESCRIPTION OF SCEMATIC DIAGRAM

ServiceManual

7 – 1

Page 21

2. SUB UNIT-1

J

I

H

G

LC-65RX1H/X

F

E

D

C

B

A

123456789

10 11 12 13 14 15 16 17 18 19 20 21

7 – 2

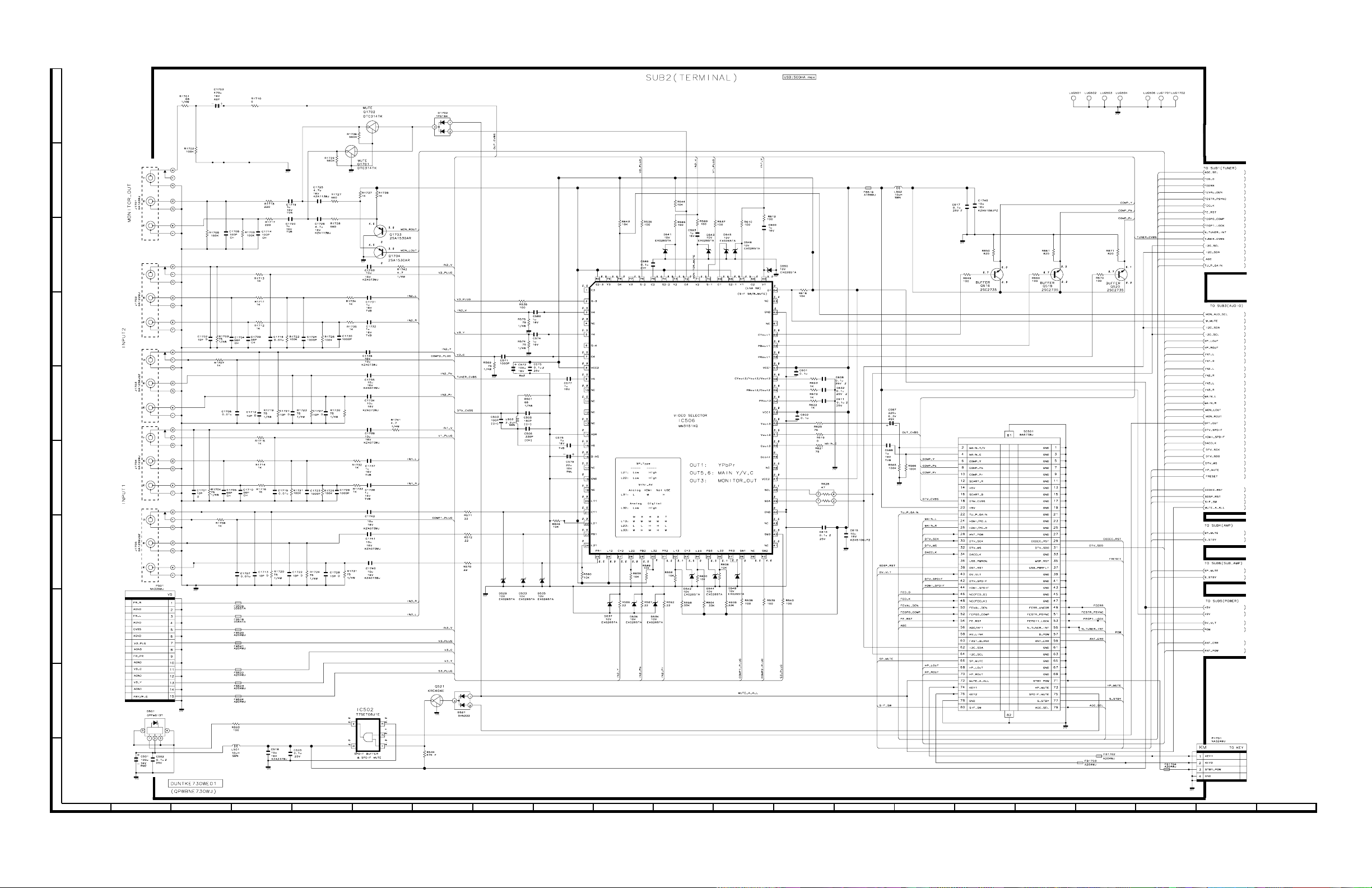

Page 22

LC-65RX1H/X

3. SUB UNIT-2

J

I

H

G

F

E

D

C

B

A

123456789

10 11 12 13 14 15 16 17 18 19 20 21

7 – 3

Page 23

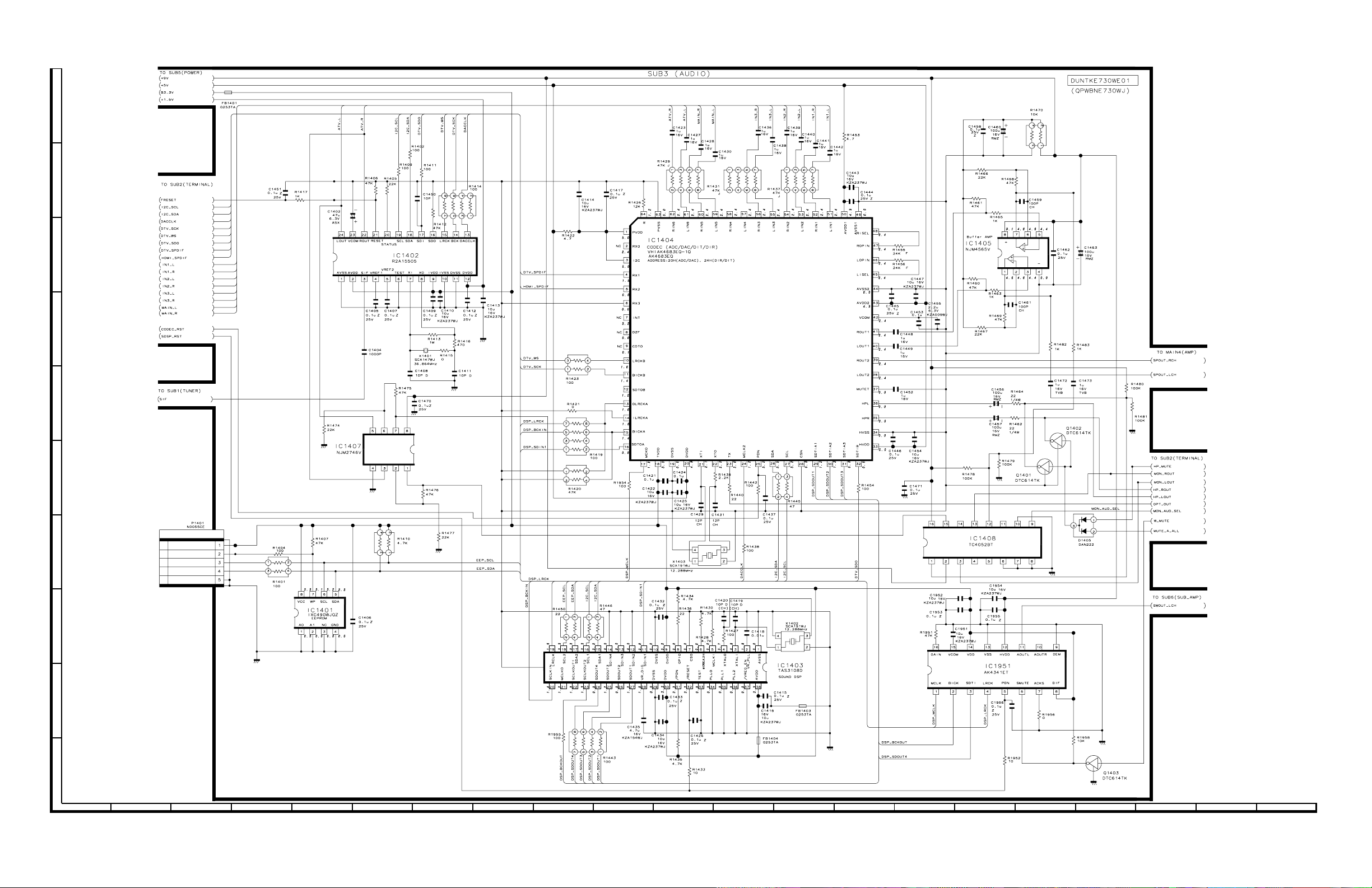

4. SUB UNIT-3

J

I

H

G

LC-65RX1H/X

F

E

D

C

B

A

123456789

10 11 12 13 14 15 16 17 18 19 20 21

7 – 4

Page 24

LC-65RX1H/X

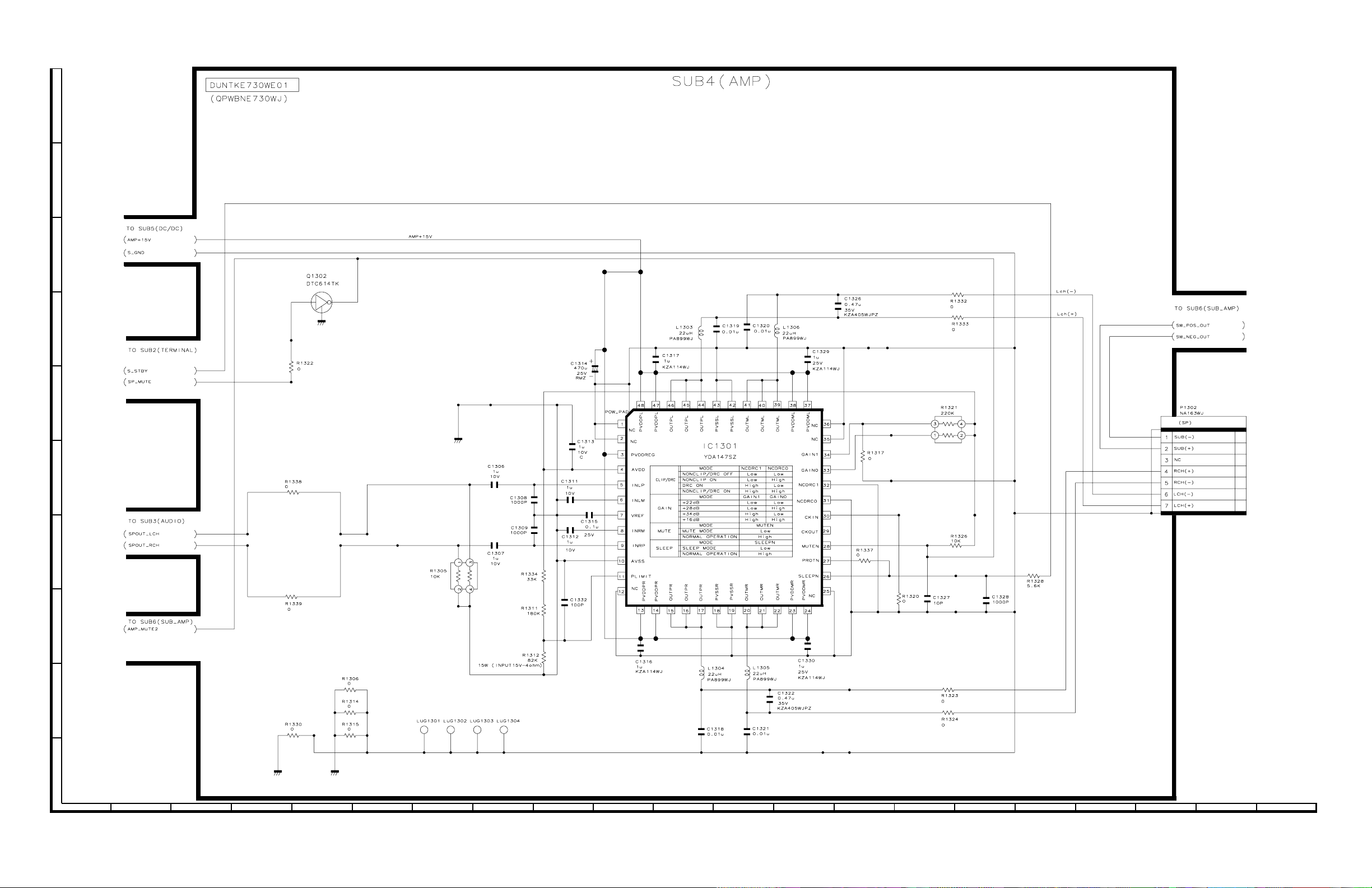

5. SUB UNIT-4

J

I

H

G

F

E

D

C

B

A

123456789

10 11 12 13 14 15 16 17 18 19 20 21

7 – 5

Page 25

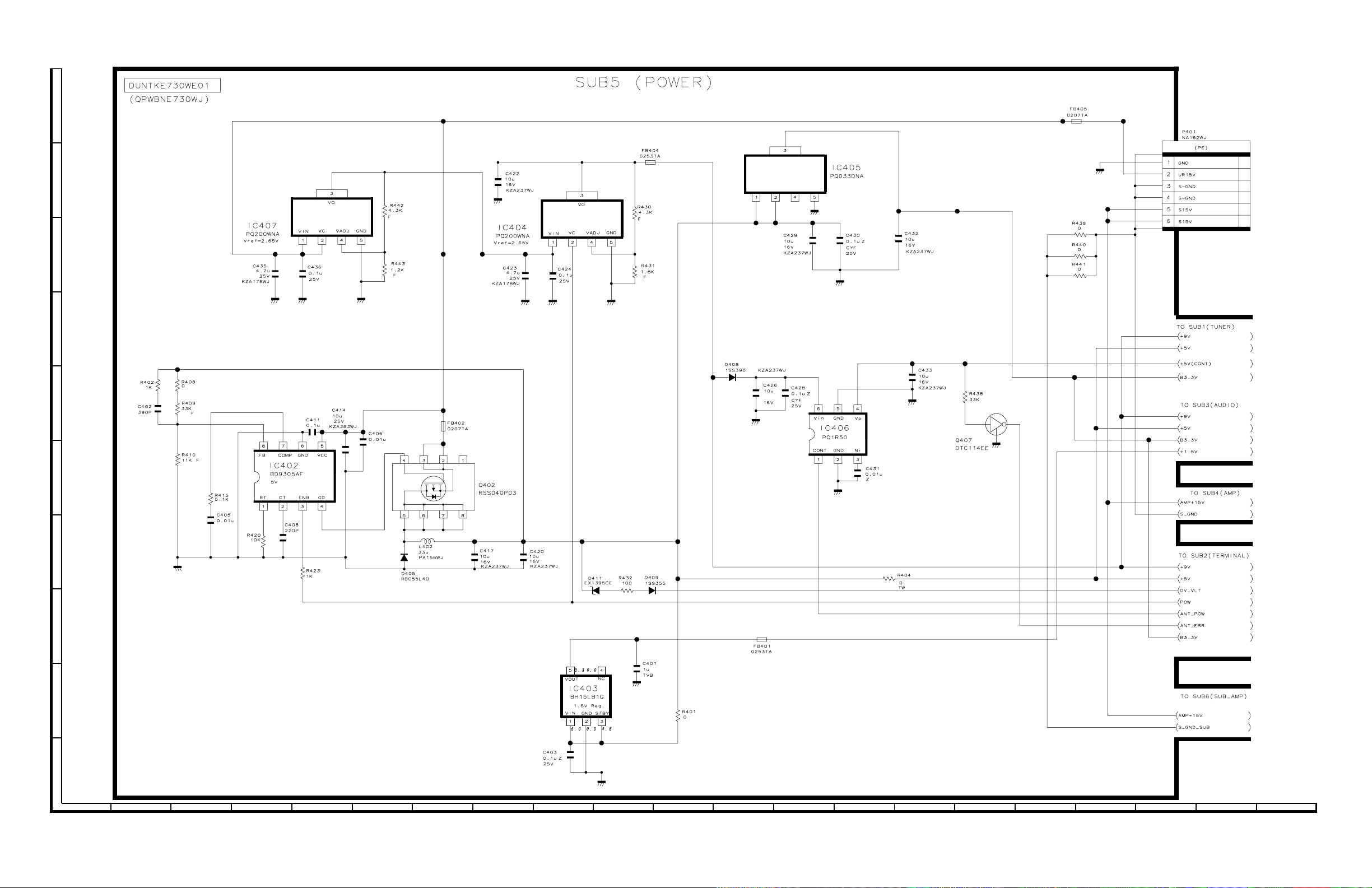

6. SUB UNIT-5

J

I

H

G

LC-65RX1H/X

F

E

D

C

B

A

123456789

10 11 12 13 14 15 16 17 18 19 20 21

7 – 6

Page 26

LC-65RX1H/X

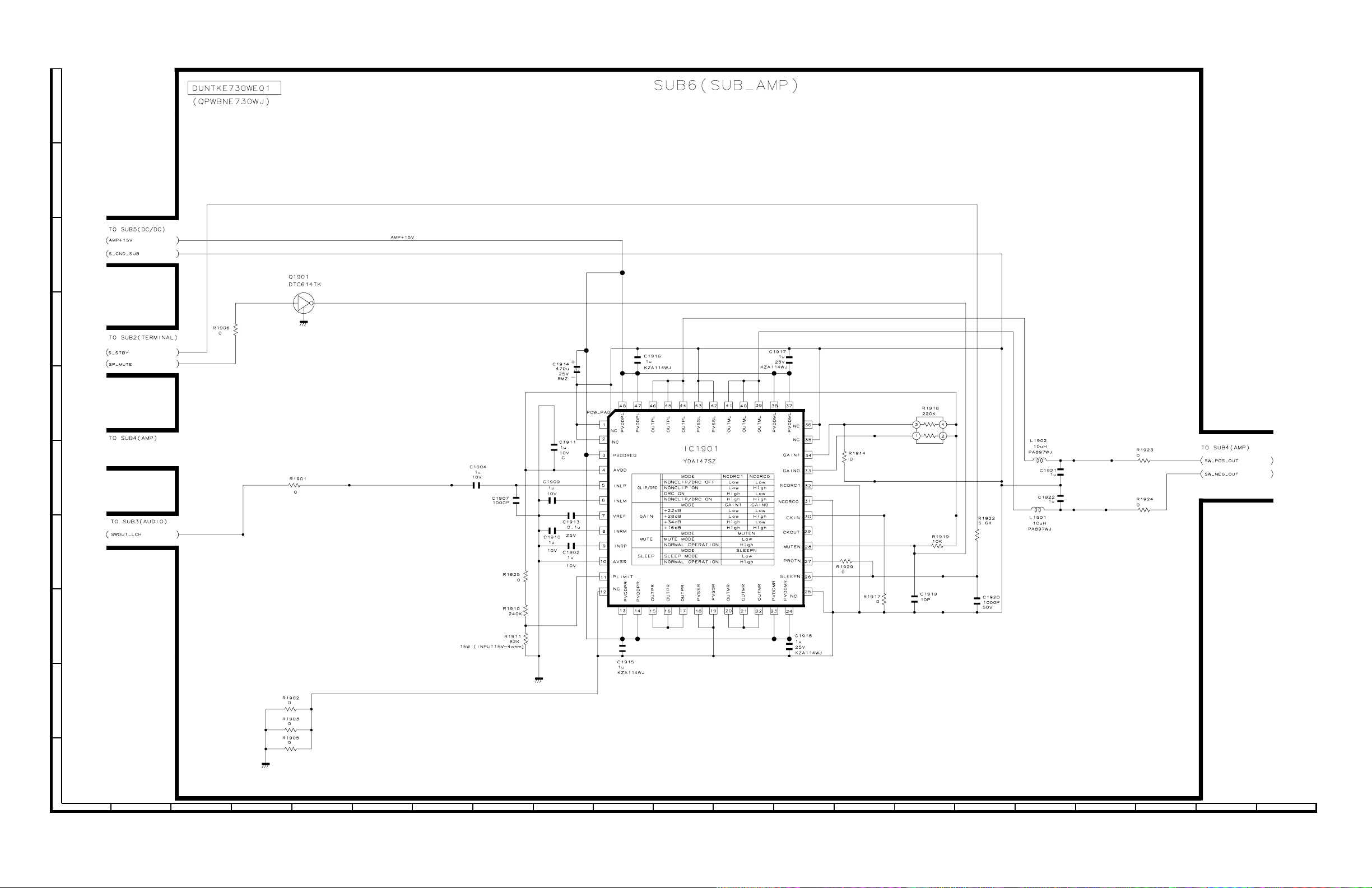

7. SUB UNIT-6

J

I

H

G

F

E

D

C

B

A

123456789

10 11 12 13 14 15 16 17 18 19 20 21

7 – 7

Page 27

TopPage

LC-65RX1M

SERVICE MANUAL

No. S58K6LC65RX1M

LCD COLOR TELEVISION

MODEL

In the interests of user safety (required by safety regulations in some countries) the set should be restor ed to its

original condition and only parts identical to those specified should be used.

LC-65RX1M

CONTENTS

SAFETY PRECAUTION

IMPORTANT SAFETY PRECAUTION................i

Precautions for using lead-free solder ...............ii

CHAPTER 1. SPECIFICATIONS

[1] SPECIFICATIONS ......................................... 1-1

CHAPTER 2. OPERATION MANUAL

[1] OPERATION MANUAL..................................2-1

CHAPTER 3. DIMENSIONS

[1] DIMENSIONS ................................................ 3-1

CHAPTER 4. REMOVING OF MAJOR PARTS

[1] REMOVING OF STAND AND CABINET........4-1

[2] REMOVING OF MAJOR PARTS FROM

PANEL UNIT .................... ... .... ... ... ... .... .......... 4-2

[3] REMOVING OF MAJOR PARTS FROM

CHASSIS TRAY.............................................4-6

CHAPTER 5. ADJUSTMENT PROCEDURE

[1] ADJUSTMENT PROCEDURE.......................5-1

CHAPTER 6. TROUBLESHOOTING TABLE

[1] TROUBLESHOOTING TABLE ......................6-1

CHAPTER 7. MAJOR IC INFORMATIONS

[1] MAJOR IC INFORMATIONS.........................7-1

CHAPTER 8. BLOCK DIAGRAM/OVERALL WIRING

DIAGRAM

[1] SYSTEM BLOCK DIAGRAM..... .... ... ... ... .... ...8-1

[2] OVERALL WIRING DIAGRAM......................8-2

CHAPTER 9. PRINTED WIRING BOARD

[1] MAIN UNIT ....................................................9-1

[2] SUB UNIT......................................................9-5

[3] FRC UNIT......................................................9-8

[4] MINI-AV UNIT..............................................9-12

[5] R/C, LED/KEY UNIT....................................9-13

CHAPTER 10. SCHEMATIC DIAGRAM

[1] SCHEMATIC DIAGRAM..............................10-1

Parts Guide

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with specified ones for maintaining the

safety and performance of the set.

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Page 28

LC-65RX1M

LC65RX1M

SAFETY PRECAUTION

ServiceManual

IMPORTANT SAFETY PRECAUTION

Service work should be performed only by qualified service technicians who are thoroughly familiar with all safety checks and the

servicing guidelines which follow:

WARNING

1. For continued safety, no modification of any circuits should be

attempted.

2. Disconnect AC power before servicing.

BEFORE RETURNING THE RECEIVER

(Fire & Shock Hazard)

Before returning the receiver to the user, perform the following

safety checks:

3. Inspect all lead dress to make certain that leads are not pinched,

and check that hardware is not lodged between the chassis and

other metal parts in the receiver.

4. Inspect all protective devices such as non-metallic control knobs,

insulation materials, cabinet backs, adjustment and compartment

covers or shields, isolation resistor-capacitor networks, mechanical

insulators, etc.

5. To be sure that no shock hazard exists, check for leakage current in

the following manner.

• Plug the AC cord directly into a 110 ~ 240 volt AC outlet.

• Using two clip leads, connect a 1.5k ohm, 10 watt resistor paralleled by a 0.15µF capacitor in series with all exposed metal cabinet

parts and a known earth ground, such as electrical conduit or electrical ground connected to an earth ground.

• Use an AC voltmeter having with 5000 ohm per volt, or higher, sensitivity or measure the AC voltage drop across the resistor.

• Connect the resistor connection to all exposed metal parts having a

return to the chassis (antenna, metal cabinet, screw heads, knobs

and control shafts, escutcheon, etc.) and measure the AC voltage

drop across the resistor.

All checks must be repeated with the AC cord plug connection

reversed. (If necessary, a non polarized adaptor plug must be used

only for the purpose of completing these checks.)

Any reading of 0.74 V rms (this corresponds to 0.5 milliamp. rms

AC.) or more is excessive and indicates a potential shock hazard

which must be corrected before returning the monitor to the owner.

DVM

AC SCALE

1.5k ohm

10W

0.15µF

TEST PROBE

TO EXPOSED

METAL PARTS

CONNECT TO

KNOWN EARTH

GROUND

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

SAFETY NOTICE

Many electrical and mechanical parts in LCD color television have

special safety-related characteristics.

These characteristics are often not evident from visual inspection, nor

can protection afforded by them be necessarily increased by using

replacement components rated for higher voltage, wattage, etc.

Replacement parts which have these special safety characteristics are

identified in this manual; electrical components having such features

are identified by " " and shaded areas in the Replacement Parts

Lists and Schematic Diagrams.

For continued protection, replacement parts must be identical to those

used in the original circuit.

The use of a substitute replacement parts which do not have the same

safety characteristics as the factory recommended replacement parts

shown in this service manual, may create shock, fire or other hazards.

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

i

Page 29

LC-65RX1M

Precautions for using lead-free solder

Employing lead-free solder

• “All PWBs” of this model employs lead-free solder. The LF symbol indicates lead-free solder, and is attached on the PWBs and service manuals.

The alphabetical character following LF shows the type of lead-free solder.

Example:

L Fa

Indicates lead-free solder of tin, silver and copper.

Indicates lead-free solder of tin, silver and copper.

L F a/a

Using lead-free wire solder

• When fixing the PWB soldered with the lead-free solder, apply lead-free wire solder. Repairing with conventional lead wire solder may cause damage or accident due to cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40 °C, we recommend you to use a dedicated soldering

bit, if you are not familiar with how to obtain lead-free wire solder or soldering bit, contact our service station or service branch in your area.

Soldering

• As the melting point of lead-free solder (Sn-Ag-Cu) is about 220 °C which is higher than the conventional lead solder by 40 °C, and as it has poor

solder wettability, you may be apt to keep the soldering bit in contact with the PWB for extended period of time. However, Since the land may be

peeled off or the maximum heat-resistance temperature of parts may be exceeded, remove the bit from the PWB as soon as you confirm the

steady soldering condition.

Lead-free solder contains more tin, and the end of the soldering bit may be easily corroded. Make sure to turn on and off the power of the bit as

required.

If a different type of solder stays on the tip of the soldering bit, it is alloyed with lead-free solder. Clean the bit after every use of it.

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sandpaper.

• Be careful when replacing parts with polarity indication on the PWB silk.

Lead-free wire solder for servicing

Part No. Description Code

ZHNDAi123250E J φ0.3mm 250g (1roll) BL

ZHNDAi126500E J φ0.6mm 500g (1roll) BK

ZHNDAi12801KE J φ1.0mm 1kg (1roll) BM

ii

Page 30

LC-65RX1M

LC65RX1M

CHAPTER 1. SPECIFICATIONS

[1] SPECIFICATIONS

ServiceManual

Model

Item

LCD panel

Resolution 2,073,600 pixels (1920×1080)

Video Colour System PAL/SECAM/NTSC 3.58/NTSC 4.43/PAL 60

TV Function TV-Standard PAL: B/G, D/K, I SECAM: B/G, D/K, K/K

Receiving

Channel

TV-Tuning System Auto Preset 99 ch

STEREO/BILINGUAL NICAM: B/G, I, D/K A2 stereo: B/G

Brightness 450 cd/m

Viewing angles H : 176º V : 176º

Audio amplifier

Speakers

Terminals

OSD language English/Simplified Chinese/Traditional Chinese/Arabic

Power Requirement AC 110-240 V 50/60 Hz

Power Consumption 481 W (0.5 W Standby)

Weight without stand 62.0 kg

Operating Temperature 0°C - 40°C

Rear Antenna input

INPUT 1 VIDEO in, AUDIO in, COMPONENT in (480I, 576I, 480P, 576P, 720P/50Hz,

INPUT 2 VIDEO in, AUDIO in, COMPONENT in (480I, 576I, 480P, 576P, 720P/50Hz,

Side INPUT 3 S-VIDEO in, VIDEO in, AUDIO in

INPUT 4

Rear INPUT 5

INPUT 6

INPUT 7 (PC input) 15 pin mini D-sub, AUDIO in (Ø 3.5 mm jack)

MONITOR OUT VIDEO out, AUDIO out

RS-232C 9 pin D-sub male connector

DIGITAL AUDIO OUTPUT

Front Headphone

with stand 66.0 kg

As a part of policy of continuous improvement, SHARP reserves the right to make design and specification changes for

product improvement without prior notice. The performance specification figures indicated are nominal values of production

units. There may be some deviations from these values in individual units.

VHF/UHF 44.25 - 863.25 MHz

CATV S1 - S41ch (including Hyperband)

65" (1639 mm) Advanced Super View & BLACK TFT LCD

2

7.5W X 2 + 15W

10 X 4cm 2pcs, Ø2cm 2pcs, Ø5.5cm 1pc

UHF/VHF 75

720P/60Hz, 1080I/50Hz, 1080I/60Hz)

720P/60Hz, 1080I/50Hz, 1080I/60Hz)

HDMI (HDMI input) (480I, 576I, 480P, 576P, 720P/50Hz, 720P/60Hz, 1080I/50Hz,

1080I/60Hz, 1080P/50Hz, 1080P/60Hz, 1080P/24Hz)

HDMI (HDMI input) (480I, 576I, 480P, 576P, 720P/50Hz, 720P/60Hz, 1080I/50Hz,

1080I/60Hz, 1080P/50Hz, 1080P/60Hz, 1080P/24Hz)

HDMI (HDMI input) (480I, 576I, 480P, 576P, 720P/50Hz, 720P/60Hz, 1080I/50Hz,

1080

I/60Hz, 1080P/50Hz, 1080P/60Hz, 1080P/24Hz), AUDIO in (Ø 3.5 mm jack)

Optical Digital Audio output

DIN type

LC-65RX1M

1,NTSC:M

1 – 1

Page 31

LC65RX1M

CHAPTER 2. OPERATION MANUAL

[1] OPERATION MANUAL

Part names

TV (Front/Side)

POWER (On/Off) button

TV/VIDEO button

Channel up ( )/down ( ) buttons

Volume up ( )/down ( ) buttons

LC-65RX1M

ServiceManual

Remote control sensor

OPC sensor

POWER indicator

Such sensor is not

applicable to this model

Headphone jack

OPC indicator*

SLEEP timer indicator

*OPC: Optical Picture Control

2 – 1

Page 32

LC-65RX1M

TV (Rear)

INPUT 1

terminals

INPUT 2

terminals

INPUT 4 (HDMI)

terminal

SERVICE ONLY

terminal*

MONITOR

OUTPUT

terminals

INPUT 3 terminals

* Usually do not connect anything to this terminal

as it is reserved only for service personnel.

DIGITAL AUDIO OUTPUT terminal

Antenna input terminal

INPUT 6 (HDMI)

terminals

INPUT 7 (PC) terminals

AC INPUT terminal

RS-232C terminal

INPUT 5 (HDMI) terminal

2 – 2

Page 33

Remote control unit

1

2

3

4

5

6

7

8

9

10

1 POWER (STANDBY/ON)

To switch the power on and off.

20-9

Set the channel.

TELETEXT mode: Set the page.

3 (Flashback)

Press to return to the previous selected channel or

external input mode.

4OPC

To switch the Optical Picture Control on and off.

5MPX

Select the sound multiplex mode.

6 VOL /VOL

Set the volume.

11

12

13

14

15

16

17

18

19

20

21

22

7 (Mute)

Mute the sound.

8WIDE

Change the wide image mode.

9 FREEZE

Freeze a motion picture on the screen.

10 EXIT

Turn off the On-Screen Display.

11 (TELETEXT)

Select the TELETEXT mode. (all TV image, all TEXT

image, TV/TEXT image)

(Reveal hidden for TELETEXT)

TELETEXT mode: Display hidden characters.

(SUBTITLE for TELETEXT)

To turn the subtitles on and off.

(Hold)

TELETEXT mode: Stop updating Teletext pages

automatically. Press3again to release the hold mode.

(Subpage)

Display the Teletext subpage directly.

(Top/Bottom/Full)

TELETEXT mode: Set the area of magnification.

12 TV/VIDEO (INPUT SOURCE)

Select an input source. (TV, INPUT 1, INPUT 2, INPUT 3,

INPUT 4, INPUT 5, INPUT6, INPUT7 (PC))

13 HDMI

Select an HDMI. (INPUT4, INPUT5, INPUT6)

14 DISPLAY

Displays the channel or input information.

Displays the time information included in the Teletext

broadcast.

15 CH /CH

TV input mode: Select the channel.

TELETEXT mode: Select the page.

16 SLEEP

Set the Sleep timer.

17 AV MODE

Select a video setting.

18 MENU

Display the menu screen.

19 / / / (Cursor)

Select a desired item on the setting screen.

ENTER

Execute a command.

20 RETURN

MENU mode: Return to the previous menu screen.

21 Colour (Red/Green/Yellow/Blue)

TELETEXT mode: Select the page.

22 AQUOS LINK buttons

If external equipment such as a AQUOS BD Player is

connected via HDMI-certified cables and is AQUOS LINK

compatible, you can use these AQUOS LINK buttons.

See pages 40 to 44 for details.

LC-65RX1M

2 – 3

Page 34

LC-65RX1M

LC65RX1M

CHAPTER 3. DIMENSIONS

[1] DIMENSIONS

ServiceManual

Unit: mm

1579

1431.5

982

1062

806.5

80

When using wall mount bracket AN-65AG1

440

325

650

597

149

124

398

440

125

325

650

Cable opening

0°/5°/10°

278

Power code

connection terminal

192

18

21

On the wall bracket of AN-65AG1,

there is a letter 'A' indicating the

centre point of the TV monitor.

3 – 1

Page 35

LC-65RX1M

LC65RX1M

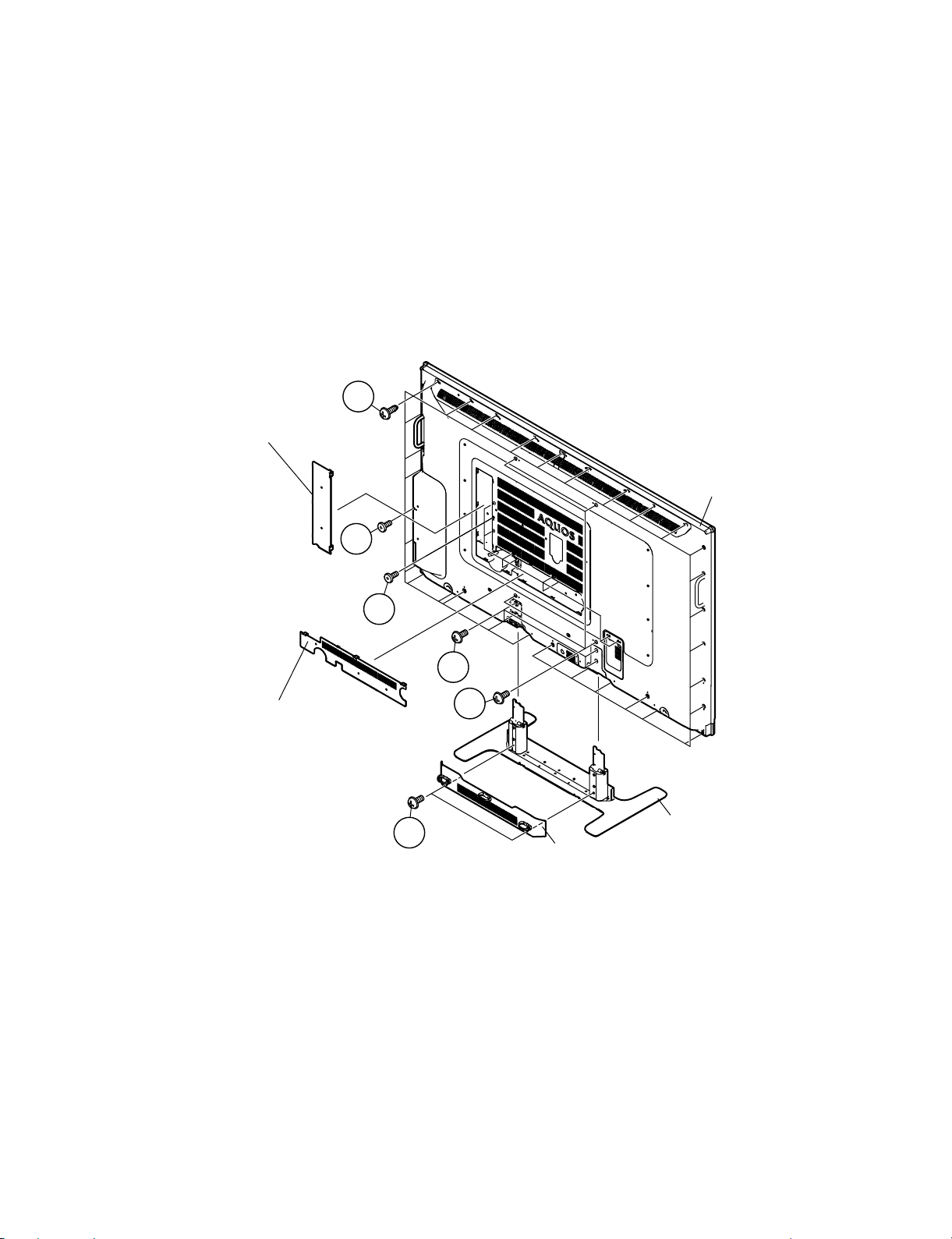

CHAPTER 4. REMOVING OF MAJOR PARTS

ServiceManual

[1] REMOVING OF STAND AND CABINET

1. REMOVING OF STAND

1. Remove the Stand fixing 4 screws.

2. Detach the Stand from Cabinet.

3. When the Rear Cabinet is removed with the stand applied, remove the stand rear cover fixing 2 screws, and the stand rear cover is removed.

2. REMOVING OF CABINET

1. Detach the Terminal Cover Top/Bottom.

2. Remove the Rear Cabinet fixing 31 screws.

3. Remove the Rear Cabinet fixing 14 screws.

4. Detach the Rear Cabinet.

2-2

Terminal Cover Top

Rear Cabinet

2-3

2-3

Terminal Cover Bottom

1-3

1-1

2-3

Stand

Stand Rear Cover

4 – 1

Page 36

LC-65RX1M

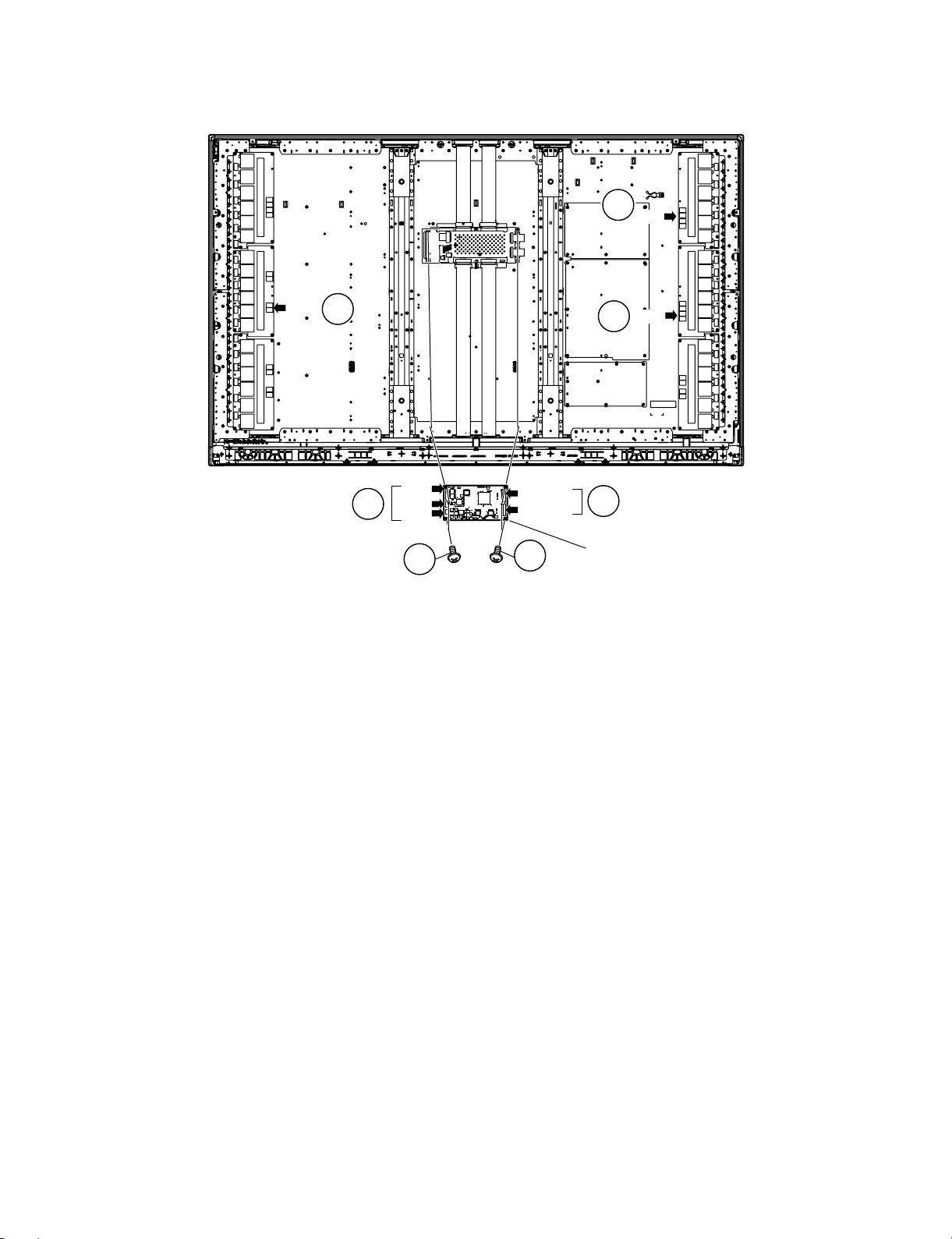

[2] REMOVING OF MAJOR PARTS FROM PANEL UNIT

1. REMOVING OF SPEAKER SUPPORT ANGLES

1. Remove the Speaker Support Sub Angle fixing 6 screws.

2. Remove the 14 screws and detach the Speaker Support Angles.

㪪㫇㪼㪸㫂㪼㫉㩷㪪㫌㫇㫇㫆㫉㫋

㪪㫌㪹㩷㪘㫅㪾㫃㪼

1-1

1-2

㪪㫇㪼㪸㫂㪼㫉㩷

㪪㫌㫇㫇㫆㫉㫋

㪘㫅㪾㫃㪼

1-2

㪪㫇㪼㪸㫂㪼㫉㩷㪪㫌㫇㫇㫆㫉㫋

㪪㫌㪹㩷㪘㫅㪾㫃㪼

1-1

㪪㫇㪼㪸㫂㪼㫉㩷㪪㫌㫇㫇㫆㫉㫋

1-1

㪪㫌㪹㩷㪘㫅㪾㫃㪼

1-2

㪪㫇㪼㪸㫂㪼㫉㩷㪪㫌㫇㫇㫆㫉㫋㩷㪘㫅㪾㫃㪼

4 – 2

Page 37

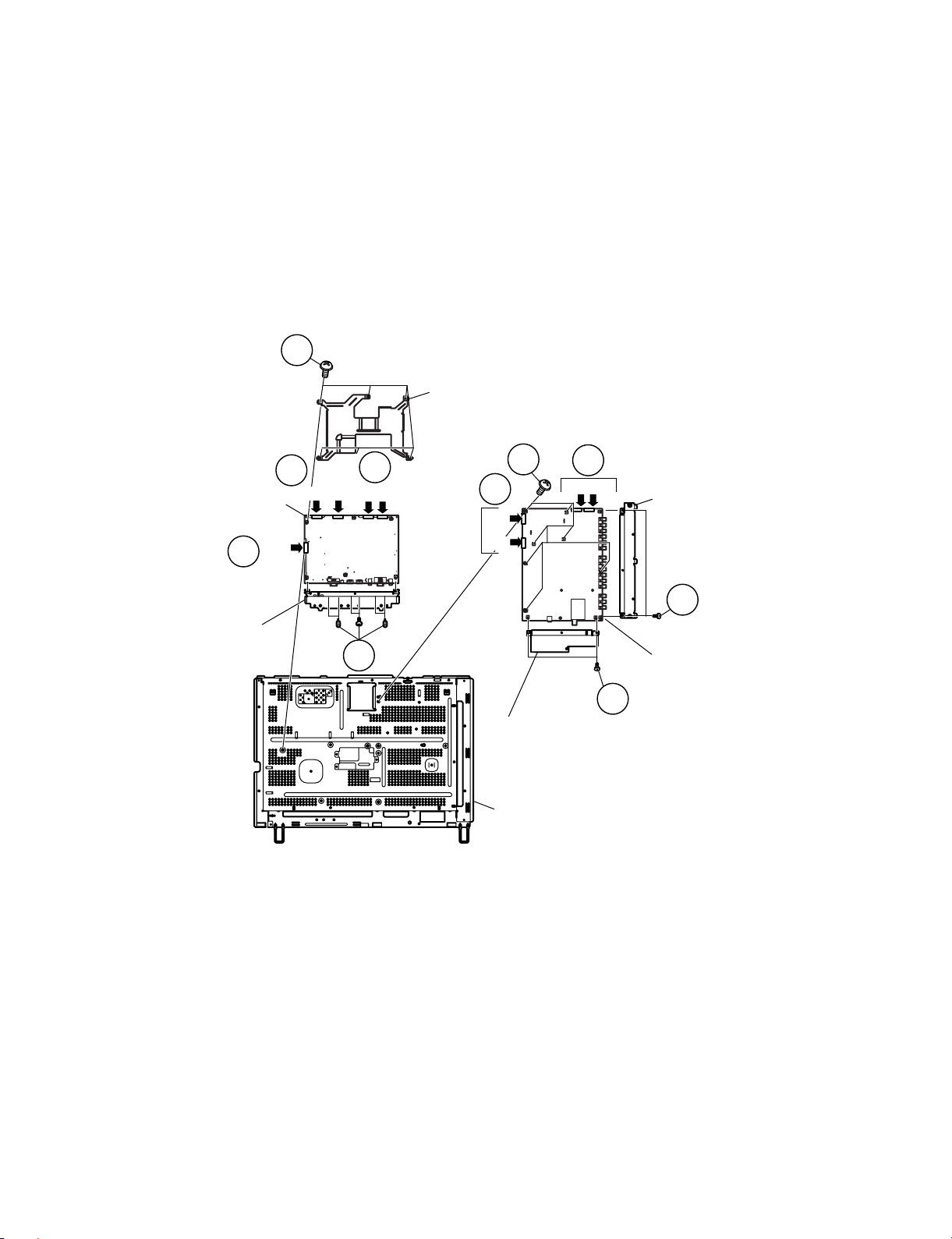

2. REMOVING OF CHASSIS TRAY

1. Remove the 5 screws and detach the Chassis Tray.

3. REMOVING OF MINI-AV PWB

1. Disconnect the connecting cord.

2. Remove the 2 screws and detach the MINI-AV PWB Cover.

3. Detach the MINI-AV PWB.

4. Detach the MINI-AV PWB Holder.

5. Remove the 4 screws and detach the Side Chassis.

4. REMOVING OF KEY PWB

1. Remove the 3 screws and detach the Top Cover.

2. Remove the 2 screws and detach the Insulation Plate.

3. Disconnect the connecting cord.

4. Detach the KEY PWB.

5. Detach the Operate Button.

5. REMOVING OF SPEAKERS

1. Disconnect the connecting cord.

2. Detach the Speaker L/R and Sub woofer.

LC-65RX1M

㪦㫇㪼㫉㪸㫋㪼

㪙㫌㫋㫋㫆㫅

㪢㪜㪰㩷㪧㪮㪙

㪫㫆㫇㩷㪚㫆㫍㪼㫉

㪠㫅㫊㫌㫃㪸㫋㫀㫆㫅㩷㪧㫃㪸㫋㪼

4-1

䎾䎮䎰䏀

4-3

㪤㪠㪥㪠㪄㪘㪭㩷㪧㪮㪙㩷㪟㫆㫃㪻㪼㫉

2-1

㪚㪿㪸㫊㫊㫀㫊㩷㪫㫉㪸㫐

4-2

3-5

3-2

䎾䎫䎰䏀

3-1

䎾䎸䎶䏀

䎾䎹䎧䏀

3-2

㪤㪠㪥㪠㪄㪘㪭㩷㪧㪮㪙

㪤㪠㪥㪠㪄㪘㪭㩷㪧㪮㪙㩷㪚㫆㫍㪼㫉

㪪㫀㪻㪼

㪚㪿㪸㫊㫊㫀㫊

㪪㫇㪼㪸㫂㪼㫉

䎾䎶䎳䏀

4 – 3

5-1

䎾䎶䎳䏀

5-1

䎾䎶䎳䏀

5-1

㪪㫇㪼㪸㫂㪼㫉㪪㫌㪹㩷㪮㫆㫆㪽㪼㫉

Page 38

LC-65RX1M

6. REMOVING OF POWER PWB 1, POWER PWB 2 AND AC INLET PWB

1. Disconnect the connecting cord.

2. Remove the 6 screws and detach the POWER PWB 2.

3. Disconnect the connecting cord.

4. Remove the 6 screws and detach the POWER PWB 1.

5. Disconnect the connecting cord.

6. Remove the 6 screws and detach the AC INLET PWB.

7. REMOVING OF R/C, LED PWB

1. Remove the 1 screw and detach the CORNER F ANGLE (R BOTTOM).

2. Disconnect the connecting cord.

3. Remove the 2 screws and detach the R/C, LED PWB.

4. Detach the Irss Cover.

5. Detach the LED Cover.

6-2

㪠㫉㫊㫊㩷㪚㫆㫍㪼㫉

㪣㪜㪛㩷㪚㫆㫍㪼㫉

7-5

6-1

䎾䎳䎯䏀

䎾䎳䎨䏀

6-4

䎾䎳䎧䏀

䎾䎯䎤䎯䏀

6-3

䎾䎳䎳䎔䏀

䎾䎳䎳䎕䏀

6-6

㪘㪚㩷㪠㪥㪣㪜㪫㩷㪧㪮㪙

䎾䎳䎳䎔䏀

䎾䎳䎳䎕䏀

䎾䎯䎤䎵䏀

6-1

㪧㪦㪮㪜㪩㩷㪧㪮㪙㩷㪉

㪧㪦㪮㪜㪩

㪧㪮㪙㩷㪈

6-3

䎾䎤䎦䏀

䎾䎤䎦䏀

6-5

7-1

7-4

䎾䎵䎤䏀

7-2

7-3

㪩㪆㪚㪃㩷㪣㪜㪛㩷㪧㪮㪙

㪚㪦㪩㪥㪜㪩㩷㪝㩷㪘㪥㪞㪣㪜㩷㩿㪩㩷㪙㪦㪫㪫㪦㪤㪀

4 – 4

Page 39

8. REMOVING OF FRC PWB

1. Disconnect the connecting cord.

2. Remove the 4 screws and detach the FRC PWB.

䎾䎯䎤䎕䏀

8-1

8-1

8-1

LC-65RX1M

䎾䎯䎥䏀

䎾䎯䎤䎘䏀

8-1

䎾䎯䎺䏀

䎾䎩䎯䏀

䎾䎯䎩䏀

8-2

䎾䎶䎦䎙䎕䎔䎔䏀

䎾䎶䎦䎙䎕䎔䎕䏀

8-2

8-1

㪝㪩㪚㩷㪧㪮㪙

4 – 5

Page 40

LC-65RX1M

[3] REMOVING OF MAJOR PARTS FROM CHASSIS TRAY

1. REMOVING OF MAIN PWB

1. Remove the 6 screw and detach the MAIN PWB Shield.

2. Disconnect the connecting cord.

3. Detach the MAIN PWB.

4. Remove the 6 screws and detach the MAIN PWB Cover.

2. REMOVING OF SUB PWB

1. Disconnect the connecting cord.

2. Remove the 2 screws and detach the Terminal Cover Side.

3. Remove the 2 screws and detach the Tuner Cover.

4. Remove the 7 screws and detach the SUB PWB.

1-1

㪤㪘㪠㪥㩷㪪㪿㫀㪼㫃㪻

㪤㪘㪠㪥㩷㪧㪮㪙

1-2

㪤㪘㪠㪥㩷㪧㪮㪙

㪚㫆㫍㪼㫉

䎾䎵䎤䏀

1-2

䎾䎩䎵䏀

䎾䎯䎥䏀

䎾䎳䎧䏀

1-4

1-2

䎾䎸䎶䏀

2-4

2-1

䎾䎶䎳䏀

䎾䎳䎨䏀

㪫㫌㫅㪼㫉㩷㪚㫆㫍㪼㫉

㪚㪿㪸㫊㫊㫀㫊㩷㪫㫉㪸㫐

2-1

䎾䎹䎧䏀

䎾䎮䎰䏀

2-3

㪫㪼㫉㫄㫀㫅㪸㫃㩷

㪚㫆㫍㪼㫉㩷㪪㫀㪻㪼

2-2

㪪㪬㪙㩷㪧㪮㪙

4 – 6

Page 41

LC-65RX1M

LC65RX1M

CHAPTER 5. ADJUSTMENT PROCEDURE

ServiceManual

[1] ADJUSTMENT PROCEDURE

1. Adjustment method after PWB and/or IC replacement due to repair

The unit is set to the optimum at the time of shipment from the factory. If any value should become improper or any adjustment is necessary due to

the part replacement, make an adjustment according to the following procedure.

1. Procure the following units in order to replace the main unit, IC3301, IC8101, IC3501, IC3502, IC8301, IC8302, IC8303, or IC8304.

MAIN UNIT: DUNTKE630FM02

NOTE: [Caution when replacing ICs in the main unit (IC1501/IC1502/IC1503/IC2002) or the mini av unit (IC801)]

The above ICs are EEPROMs storing the EDID data of HDMI and the monitor microcomputer. Before replacing the relevant part, procure the

following parts in which the data have been rewritten.

IC2002 RH-IXB986WJNDQ Monitor microcomputer

IC801 RH-IXC284WJQZS INPUT4

IC1501 RH-IXC285WJQZS INPUT5

IC1502 RH-IXC286WJQZS INPUT6

IC1503 RH-IXC287WJQZS INPUT7

2. After replacing the LCD panel or LCD control PWB, check PANEL_SIZE in the following procedure.

1) Enter the process adjustment mode.

2) Use the cursor keys / and CH / of R/C to select the item [PANEL_SIZE] on the page 32/32.

3) Verify that the panel size is displayed.

4) If the size doesn't match, select the values of the panel size with the Vol +/- keys.

5) After selection in Step 4), press the ENTER key, and it is completed with OK displayed.

3. After replacing the LCD panel or LCD control PWB, adjust the VCOM in the following procedure.

1) Enter the process adjustment mode.

2) Use the cursor keys / and CH / of R/C to select the item [VCOM ADJ] on the page 9/32.

3) Press the ENTER key to verify that the adjustment pattern is displayed.

4) Use the +/- keys of VOL of L/C to adjust the flicker in the center of the screen to minimum.

5) When the optimal state is achieved in Step 4, press the ENTER key to turn the pattern to OFF.

5 – 1

Page 42

LC-65RX1M

(7)

(8)

2. Entering and exiting the adjustment process mode

1. Press the “POWER” key on the set of running TV set to force off the power.

2. While holding down the “VOL (-)” and “TV/VIDEO” keys on the set at once, press the “POWER” key on the set to turn on the power.

The letter “K” appears on the screen.

3. Next, hold down the “VOL (-)” and “CH ( )” keys on the set at once.

Multiple lines of character string appearing on the screen indicate that the set is now in the adjustment Process mode. If you fail to enter the

adjustment process mode (the display is the same as normal startup), retry the procedure. (Another procedure)

4. Press the “MENU” key on the main unit to display OSD.

5. Move the cursor to SERVICE (OSD) using the cursor keys on the remote control.

Then press the “MENU” key on the remote control to enter the service mode (adjustment process mode).

6. To exit the adjustment process mode after the adjustment is done, unplug the AC power cord to force off the power. (When the power is turned off

with the remote controller, once unplug the AC power cord and plug it in again. In this case, wait 10 seconds or so before plugging.)

CAUTION:Use due care in handling the information described here lest the users should know how to enter the adjustment process mode. If the

settings are tampered with in this mode, unrecoverable system damage may result.

3. Remote controller key operation and description of display in adjustment process mode.

1. key operation

Remote controller key Main unit key Function

CH (/)

CH ( / )

VOL (+/-) VOL (+/-) Changing a selected item setting (+1/-1)

Cursor ( / )

— Turning a page (PREVIOUS / NEXT)

Moving an item (line) by one (UP/DOWN)

Cursor ( / )

TV/VIDEO on remote

controller

— Changing a selected line setting (+10/-10)

— Input source switching (toggle switching) (TV→EXT1~8)

RETURN — Returning to a present page

ENTER — Executing a function

Input mode is switched automatically when relevant adjustment is started so far as the necessary input signal is available.

4. Description of display

(1) Page/ of present number of total pages (5) Inducing display

(2) Page present title (4) Present colour system (6) Model name

1/32 [INFO] INPUT1 AUTO ??? 42E_D83

MAIN Version

BOOT Version

Monitor Version

FRC Version

CPLD Version

EQ DATA CHECKSUM

LAMP ERROR

MONITOR ERR CAUSE

NORMAL STANDBY CAUSE

ERROR STANDBY CAUSE

(3) Input that has been selected now

1.00 (E 2007/07/10 D)

1.0

a6

ROM

0

11 11 11 11

0

1) 0 2) 0 3) 0

0H 0M 0H 0M 0H 0M

4) 0 5) 0

0H 0M 0H 0M

Item name

Parameter

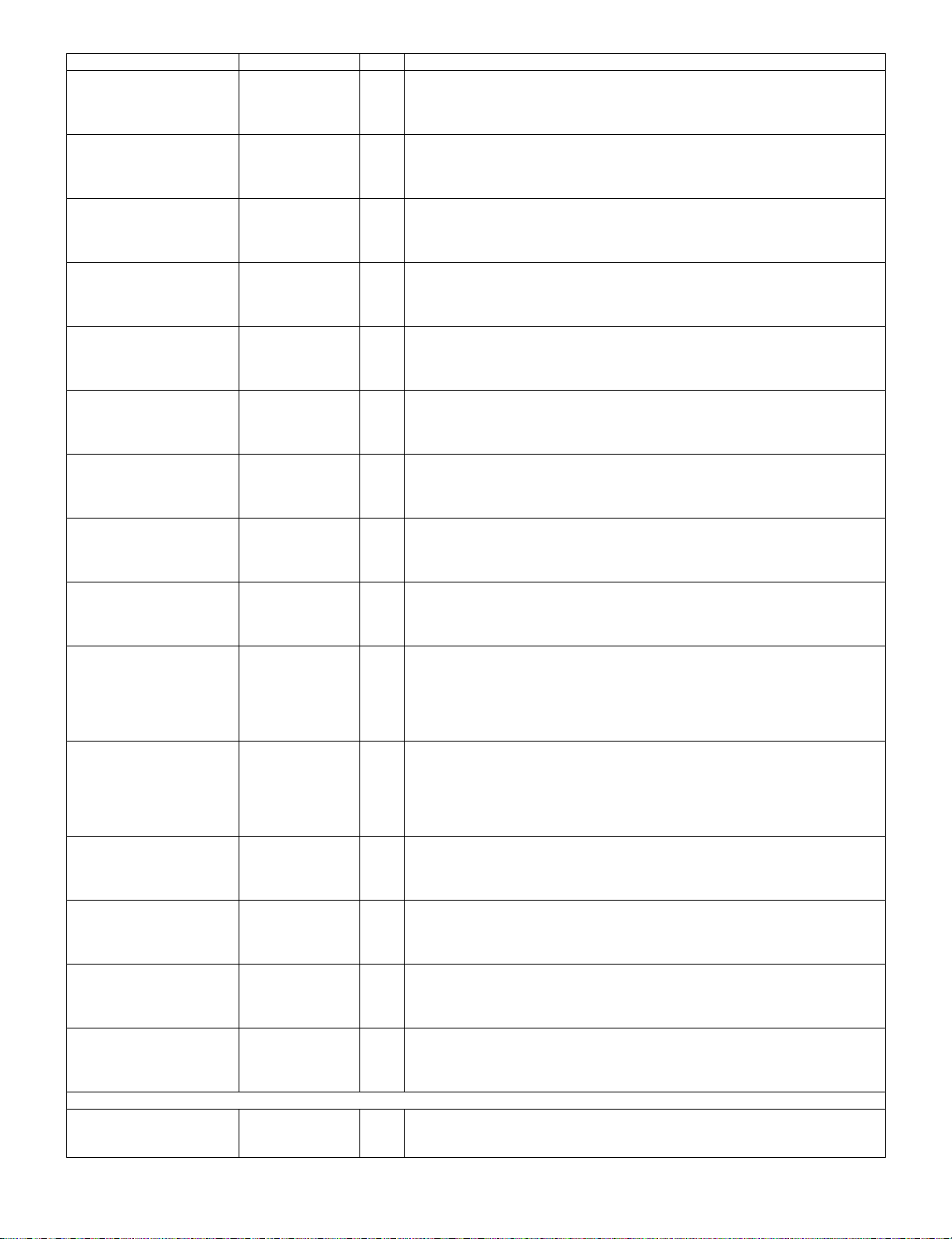

No. Description Display specification

(1) Page/ of present number of total pages 2char/2char Decimal Number mark.

(2) Page present title It bundles it by Max. 15 char “[“ ”]”.

(3) Input that has been selected now TV/INPUT1/INPUT2/INPUT3/INPUT5/INPUT6/INPUT7/INPUT8

(4) Present colour system NTSC/PAL/SECAM/COMP15K/COMP33K/COMP45K/COMP28K/COMP31K

(5) Inducing display EUROPE/RUSSIA/SWEDEN

(6) Model name MODEL NAME

(7) Item name Max. 30 char

(8) Parameter Max. 60 char

5 – 2

Page 43

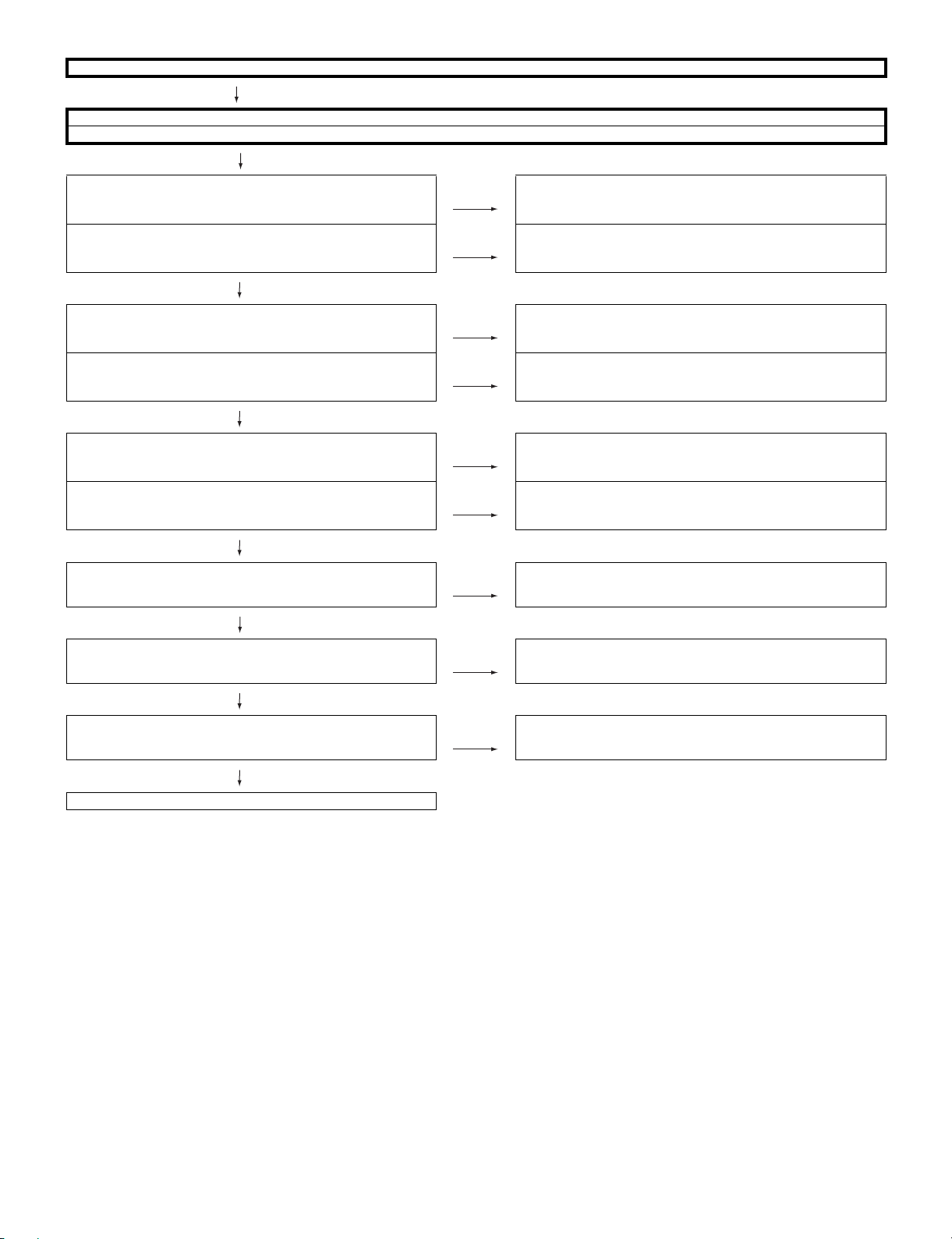

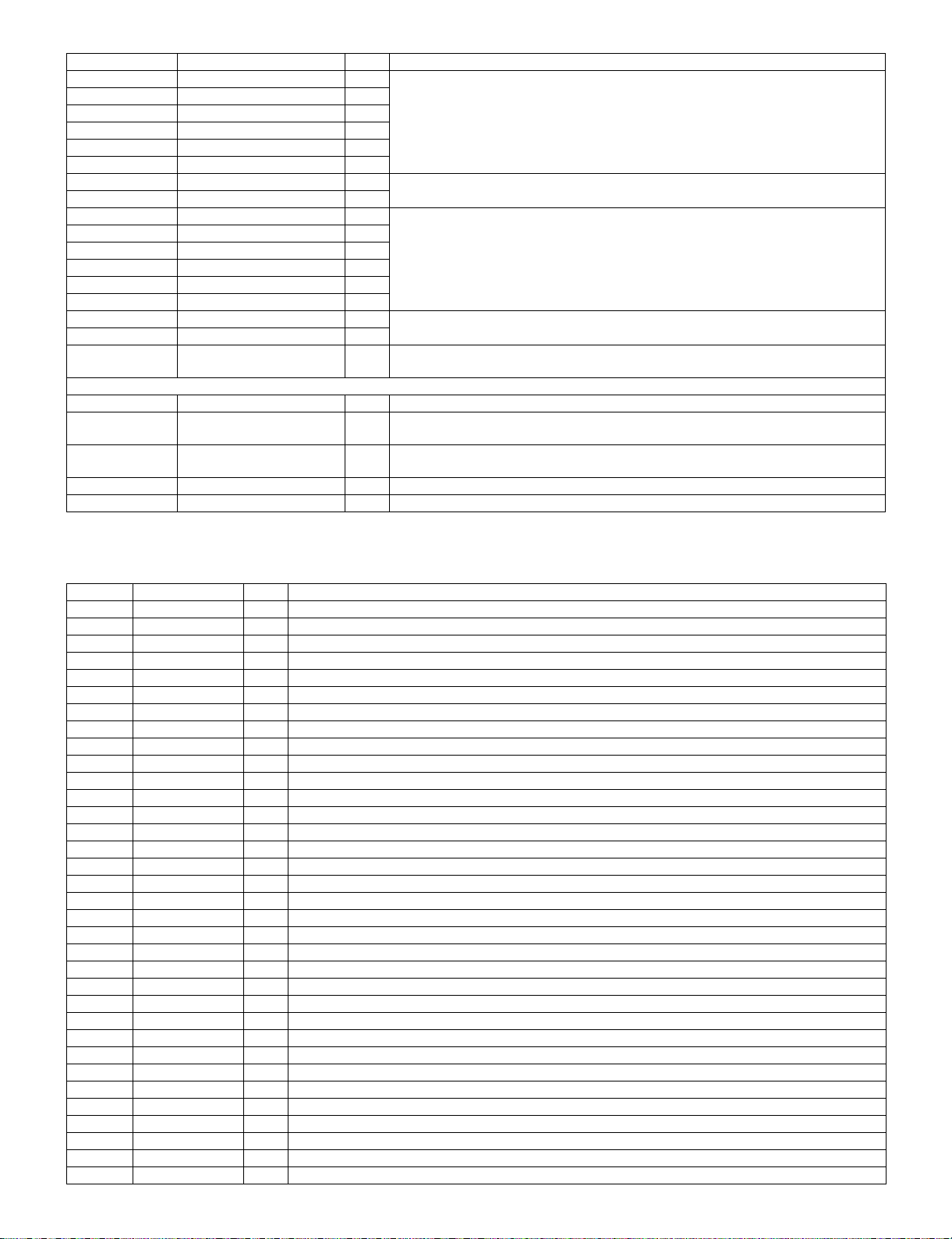

5. Adjustment process mode menu

The character string in brackets [ ] will appear as a page title in the adjustment process menu header.

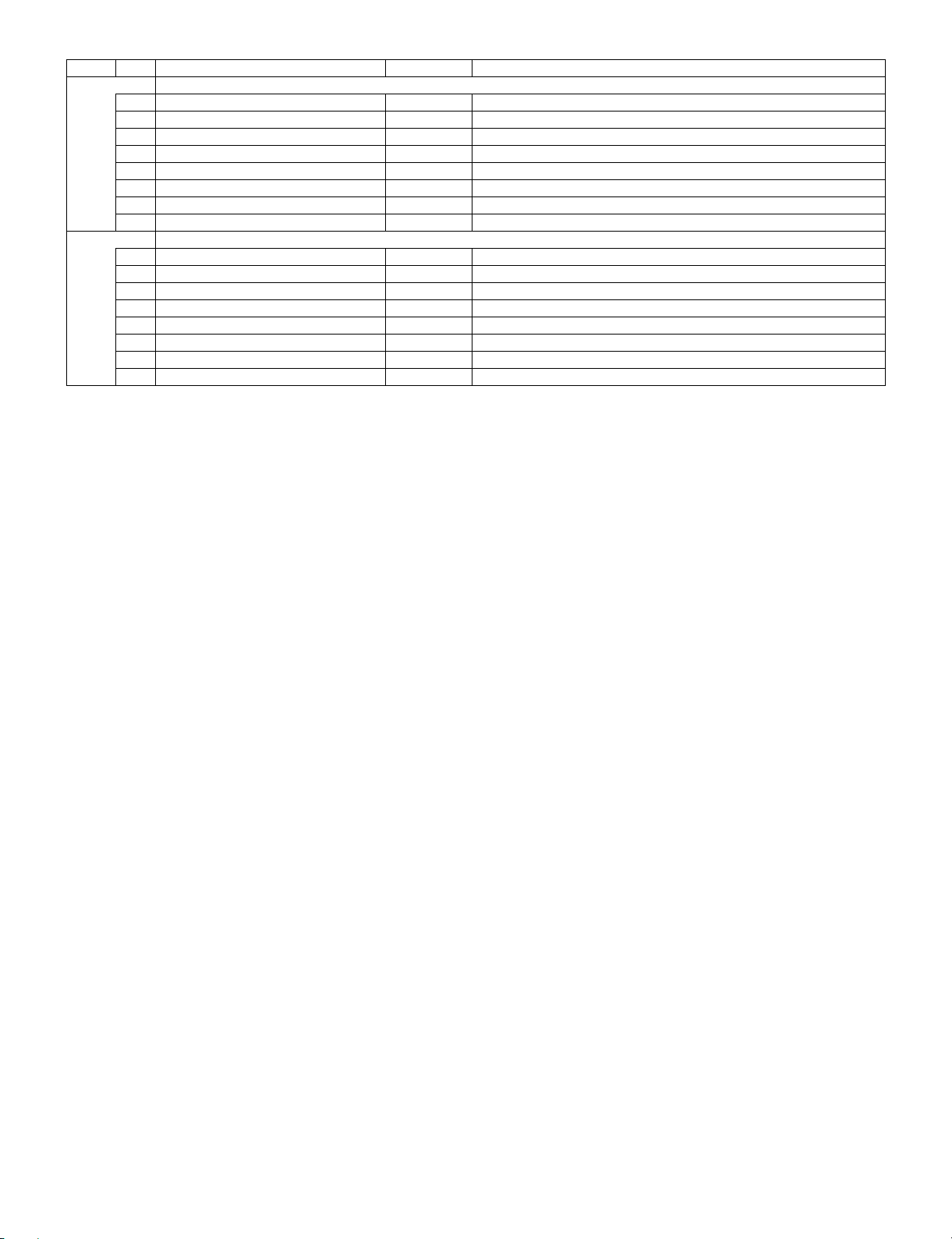

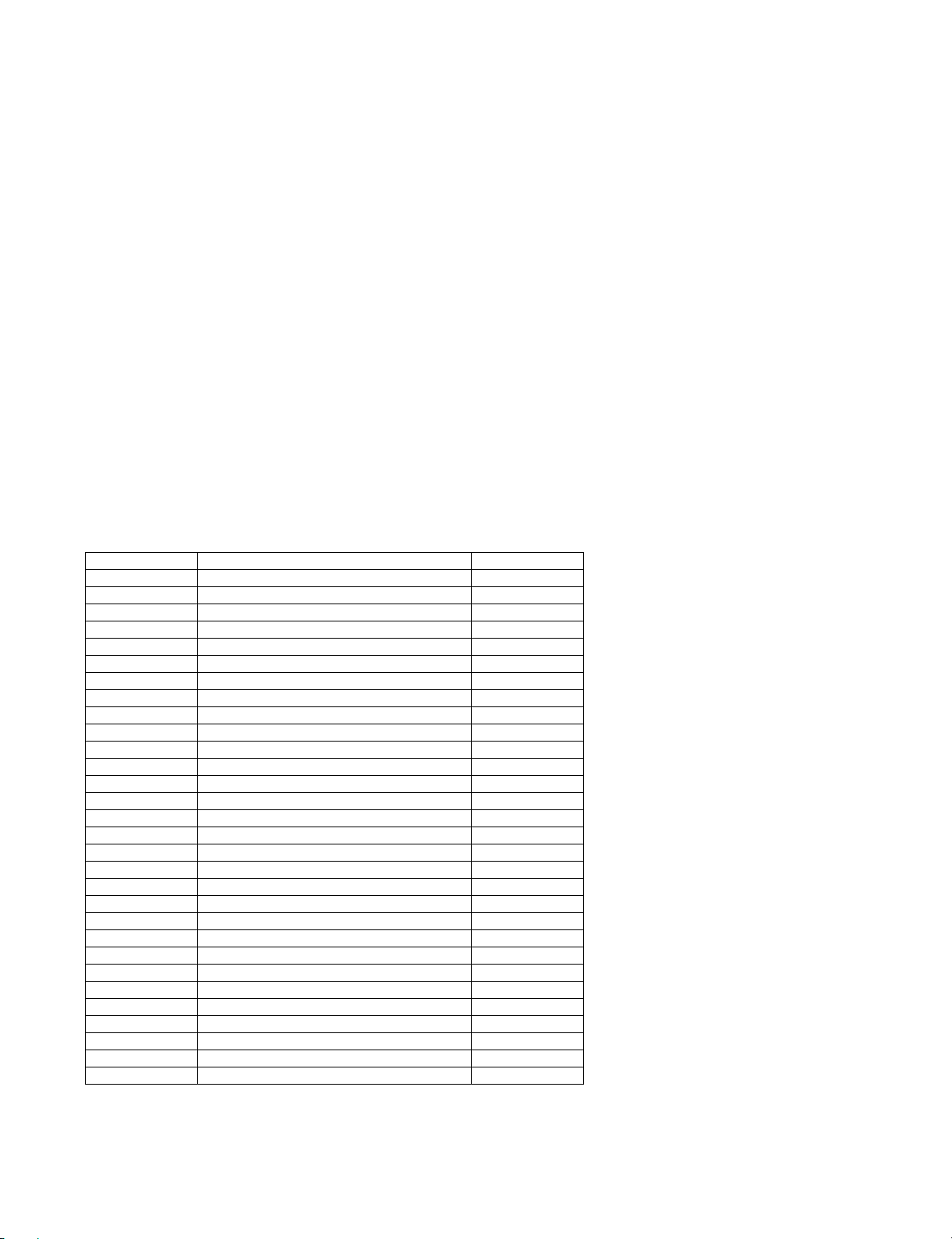

Page Line Item Description Remarks (adjustment detail, etc.)

1/35 [INFO]

1 MAIN Version Main software version

2 BOOT Version BOOT Version.

3 Monitor Version Monitor software version

4 FRC Version FRC Version

5 CPLD Version CPLD Version.

6 EQ DATA CHECKSUM Audio data checksum.

7 LAMP ERROR Number of termination due to lamp error.

8 MONITOR ERR CAUSE Last error standby cause.

9 NORMALSTANDBY CAUSE Situation that became standby at the end.

(Excluding the error)

10 ERROR STANDBY CAUSE [1] 00H 00M Error standby cause Total operating time before error.

[2] 00H 00M

[3] 00H 00M

[4] 00H 00M

[5] 00H 00M

2/35 [INIT]

1 INDUSTRY INIT Enter Initialization to factory settings execution.

2 INDUSTRY INIT(-Hotel) OFF Initialization to factory settings execution.

(Hotel mode is excluded)

3 HOTEL MODE OFF Hotel mode setting execution.

4 Center Acutime 5H 0M Main operating hours.

5 RESET OFF Main operating hours reset.

6 Backlight Acutime 19H 35M Backlight operating hours.

7 RESET OFF Backlight operating hours reset.

8 LAMP ERROR RESET OFF Lamp error reset.

9 ADJ PARAM SET Enter ADJ PARAM SET

10 VIC XPOS 0 X-coordinate setting for VIC READ

11 VIC YPOS 0 Y-coordinate setting for VIC READ

12 VIC SIGNAL TYPE MAIN Signal type setting for VIC READ

13 VIC READ OFF Picture level acquisition function

(Level appears in green on the upper right)

3/35 [TUNER ADJ]

1 RF AGC ADJ Enter RF-AGC auto adjustment execution

2 TUNER ADJ Enter TUNER auto adjustment execution

3 PAL+TUNER ADJ Enter PAL TUNER auto adjustment execution

4 RF AGC ADJ(CA-8CH) Enter RF-AGC auto adjustment execution (CA-8CH)

5 TUNER ADJ(CA-8CH) Enter TUNER auto adjustment execution (CA-8CH)

6 PAL+TUNER ADJ(CA-8CH) Enter PAL TUNER auto adjustment execution (CA-8CH)

7 RF AGC 25 RF AGC adjustment

8 TUNER DAC 164 TUNER signal level adjustment

9RF AGC READ OFF

4/35 [PAL MAIN]

1 PAL ADJ Enter PAL adjustment

2 SECAM ADJ Enter SECAM adjustment

3 N358 ADJ Enter N358 adjustment

4 PAL CONTRAST 124 PAL contrast adjustment

5 SECAM CONTRAST 130 SECAM CONTRAST adjustment

6 N358 CONTRAST 121 N358 CONTRAST adjustment

5/35 [CEC TEST]

1 HDMI CEC TEST Enter CEC test

2 INSPECT USB TERM Enter

3 MONIDATA READ[TEMP/OPC] OFF MONITOR Temperature/ OPC Acquisition tool.

4 CAUSE RESET Enter

6/35 [COMP15KMAIN]

1 COMP15K ALL ADJ Enter Component 15K picture level adjustment

2 COMP15K MAIN Y GAIN 200 Y GAIN adjustment value

3 COMP15K MAIN CB GAIN 210 Cb GAIN adjustment value

4 COMP15K MAIN CR GAIN 209 Cr GAIN adjustment value

5 COMP15K Y OFFSET 65 Y OFFSET adjustment value

6 COMP15K CB OFFSET 512 Cb OFFSET adjustment value

7 COMP15K CR OFFSET 513 Cr OFFSET adjustment value

LC-65RX1M

5 – 3

Page 44

LC-65RX1M

Page Line Item Description Remarks (adjustment detail, etc.)

7/35 [HDTV]

1 HDTV ADJ Enter HDTV video level adjustment

2 HDTV Y GAIN 197 HDTV Y GAIN adjustment value

3 HDTV CB GAIN 211 HDTV Cb adjustment value

4 HDTV CR GAIN 208 HDTV Cr adjustment value

5 HDTV Y OFFSET 65 HDTV Y OFFSET adjustment value

6 HDTV CB OFFSET 513 HDTV Cb OFFSET adjustment value

7 HDTV CR OFFSET 513 HDTV Cr OFFSET adjustment value

8/35 [ANALOG PC]

1 ANALOG PC ADJ Enter DVI ANALOG video level adjustment

2 R OFFSET 64 R CUTOFF adjustment value

3 G OFFSET 63 G CUTOFF adjustment value

4 B OFFSET 64 B CUTOFF adjustment value

5 R GAIN 195 R DRIVE adjustment value

6 G GAIN 188 G DRIVE adjustment value

7 B GAIN 198 B DRIVE adjustment value

9/35 [LUMAADJ]

1VCOM ADJ 62

2 LCD LUMA ADJ Enter

3 LCD LUMA UP 0

4 LCD LUMA DOWN 0

10/35 [FR DDRTEST]

1 DDRA TEST1 Enter

2 DDRA TEST2 Enter

3 DDRB TEST1 Enter

4 DDRB TEST2 Enter

5 DDRB TEST3 Enter

6 FRC ON/OFF Enter

7 SOUSAM DDR BIST Enter

8 SOUSAS DDR BIST Enter

11/35 [LEV]

1 LEV1 176

2 LEV2 352

3 LEV3 528

4 LEV4 656

5 LEV5 800

6 LEV6 928

12/35 [MGXX1]

1 MG1R 185 W/B adjustment, gradation 1R adjustment value

2 MG1G 162 W/B adjustment, gradation 1G adjustment value

3 MG1B 141 W/B adjustment, gradation 1B adjustment value

4 MG2R 366 W/B adjustment, gradation 2R adjustment value

5 MG2G 324 W/B adjustment, gradation 2G adjustment value

6 MG2B 286 W/B adjustment, gradation 2B adjustment value

7 MG3R 544 W/B adjustment, gradation 3R adjustment value

8 MG3G 486 W/B adjustment, gradation 3G adjustment value

9 MG3B 443 W/B adjustment, gradation 3B adjustment value

13/35 [MGXX2]

1 MG4R 674 W/B adjustment, gradation 4R adjustment value

2 MG4G 604 W/B adjustment, gradation 4G adjustment value

3 MG4B 561 W/B adjustment, gradation 4B adjustment value

4 MG5R 812 W/B adjustment, gradation 5R adjustment value

5 MG5G 737 W/B adjustment, gradation 5G adjustment value

6 MG5B 700 W/B adjustment, gradation 5B adjustment value

7 MG6R 928 W/B adjustment, gradation 6R adjustment value

8 MG6G 855 W/B adjustment, gradation 6G adjustment value

9 MG6B 843 W/B adjustment, gradation 6B adjustment value

5 – 4

Page 45