Page 1

TopPage

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

xxxxxxxxx

SERVICE MANUAL

No.S87O7LC42XL2E

LCD COLOUR TELEVISION

LC-42XL2E/S/RU

LC-46XL2E/S/RU

LC-46X20E/S/RU

LC-42/46/52XL2E/S/RU LC-46/52X20E/S/RU

MODELS

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored to its original condition and only parts identical to those specified should be used.

LC-52XL2E/S/RU

LC-52X20E/S/RU

CONTENTS

SAFETY PRECAUTION

IMPORTANT SERVICE SAFETY

PRECAUTION...............................................

Precautions for using lead-free solder ..........

CHAPTER 1. OPERATION MANUAL

[1] SPECIFICATIONS

(LC-42/46/52XL2E/S/RU)..............................

[2] SPECIFICATIONS

(LC-46/52X20E/S/RU)...................................

[3] OPERATION MANUAL

(LC-42/46/52XL2E/S/RU)..............................

[4] OPERATION MANUAL

(LC-46/52X20E/S/RU)...................................

[5] DIMENSIONS (LC-42/46/52XL2E/S/RU)......

[6] DIMENSIONS (LC-46/52X20E/S/RU)...........

CHAPTER 2. REMOVING OF MAJOR PARTS

[1] REMOVING OF MAJOR PARTS

(LC-42XL2E/S/RU)........................................

[2] REMOVING OF MAJOR PARTS

(LC-46XL2E/S/RU)........................................

[3] REMOVING OF MAJOR PARTS

(LC-46X20E/S/RU)........................................

[4] REMOVING OF MAJOR PARTS

(LC-52XL2E/S/RU)........................................

[5] REMOVING OF MAJOR PARTS

(LC-52X20E/S/RU)........................................

CHAPTER 3. ADJUSTMENT PROCEDURE

[1] ADJUSTMENT PROCEDURE......................

CHAPTER 4. TROUBLESHOOTING TABLE

[1] TROUBLESHOOTING TABLE......................

.............. i

............. ii

..........1-1

..........1-2

..........1-3

..........1-8

........1-13

........1-14

..........2-1

........2-14

........2-26

........2-38

........2-50

..........3-1

..........4-1

CHAPTER 5. MAJOR IC INFORMATIONS

[1] MAJOR IC INFORMATIONS.........................

CHAPTER 6. BLOCK DIAGRAM/WIRING DIAGRAM

[1] SYSTEM BLOCK DIAGRAM ........................

[2] TERMINAL BLOCK DIAGRAM.....................

[3] MAIN BLOCK DIAGRAM ..............................

[4] POWER BLOCK DIAGRAM..........................

[5] WIRING DIAGRAM (LC-42XL2E/S/RU) .......

[6] WIRING DIAGRAM (LC-46XL2E/S/RU) .......

[7] WIRING DIAGRAM (LC-46X20E/S/RU) .......

[8] WIRING DIAGRAM (LC-52XL2E/S/RU) .......

[9] WIRING DIAGRAM (LC-52X20E/S/RU) .......

CHAPTER 7. PRINTED WIRING BOARD

[1] MAIN UNIT PRINTED WIRING BOARD.......

[2] TERMINAL UNIT PRINTED WIRING BOARD

[3] R/C, LED UNIT PRINTED WIRING BOARD.

[4] KEY UNIT PRINTED WIRING BOARD.........

[5] MINI AV UNIT PRINTED WIRING

BOARD .........................................................

[6] ILLUMINATION UNIT PRINTED WIRING

BOARD .........................................................

[7] POWER UNIT PRINTED WIRING BOARD ..

[8] AC INLET UNIT PRINTED WIRING BOARD

CHAPTER 8. SCHEMATIC DIAGRAM

[1] DESCRIPTION OF SCHEMATIC DIAGRAM

[2] SCHEMATIC DIAGRAM ...............................

Parts Guide

..........5-1

..........6-1

..........6-2

..........6-3

..........6-4

..........6-5

..........6-6

..........6-7

..........6-8

..........6-9

..........7-1

..........7-5

..........7-7

..........7-7

..........7-8

........7-10

........7-11

........7-13

..........8-1

..........8-2

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with specified ones for maintaining the

safety and performance of the set.

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Page 2

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

LC42XL2E

SAFETY PRECAUTION

Service Manual

IMPORTANT SERVICE SAFETY PRECAUTION

Service work should be performed only by qualified service technicians who are thoroughly familiar with all safety checks and the

servicing guidelines which follow:

WARNING

1. For continued safety, no modification of any circuit should be

attempted.

2. Disconnect AC power before servicing.

CAUTION:

FOR CONTINUED PROTECTION AGAINST A

RISK OF FIRE REPLACE ONLY WITH SAME

TYPE FUSE.

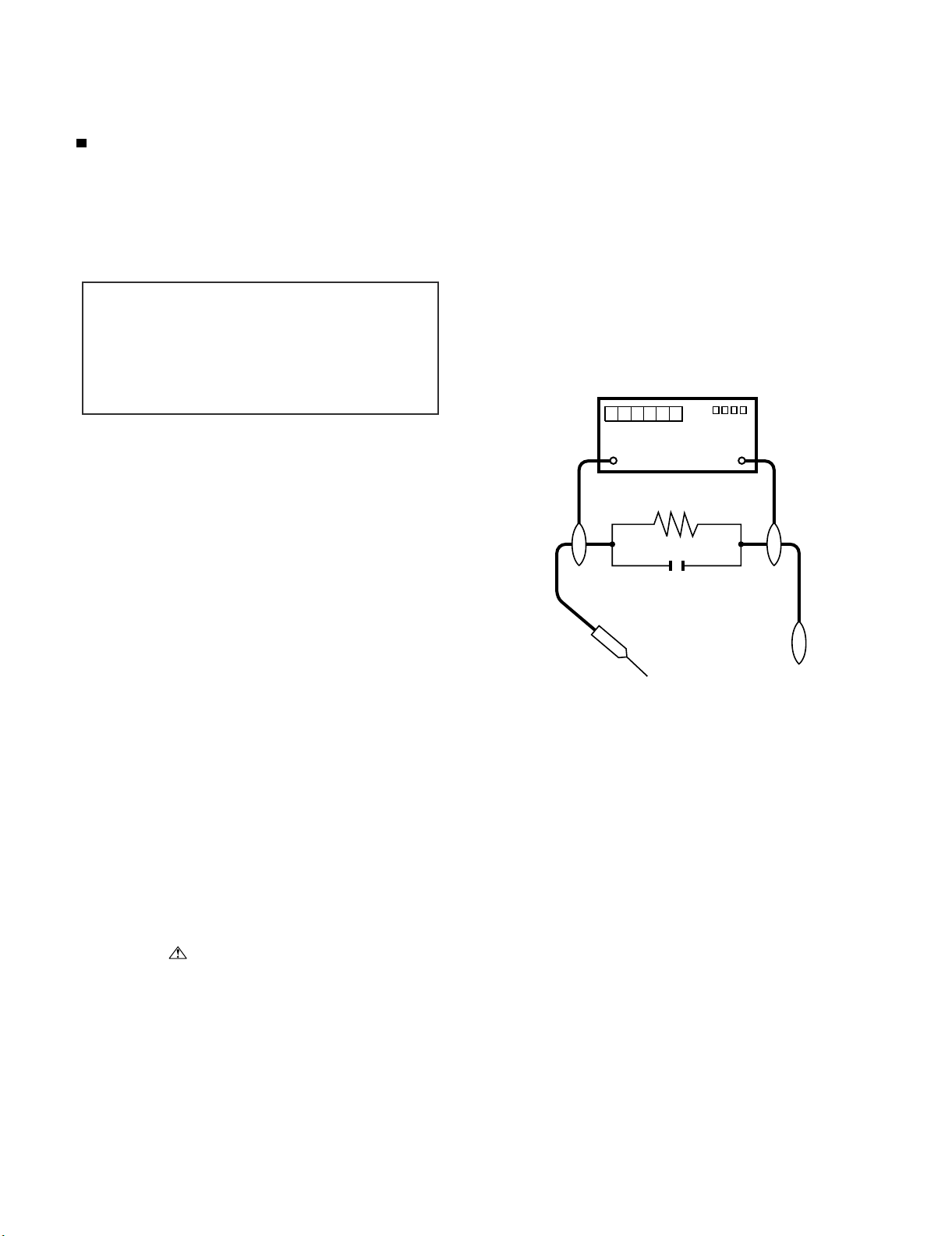

• Use an AC voltmeter having with 5000 ohm per volt, or higher, sensitivity or measure the AC voltage drop across the resistor.

• Connect the resistor connection to all exposed metal parts having a

return to the chassis (antenna, metal cabinet, screw heads, knobs

and control shafts, escutcheon, etc.) and measure the AC voltage

drop across the resistor.

All checks must be repeated with the AC cord plug connection

reversed. (If necessary, a nonpolarized adaptor plug must be used

only for the purpose of completing these checks.)

Any reading of 1.05 V peak (this corresponds to 0.7 mA peak AC.)

or more is excessive and indicates a potential shock hazard which

must be corrected before returning the monitor to the owner.

F7000 (6.3A/250V)

BEFORE RETURNING THE RECEIVER

(Fire & Shock Hazard)

Before returning the receiver to the user, perform the following

safety checks:

3. Inspect all lead dress to make certain that leads are not pinched,

and check that hardware is not lodged between the chassis and

other metal parts in the receiver.

4. Inspect all protective devices such as non-metallic control knobs,

insulation materials, cabinet backs, adjustment and compartment

covers or shields, isolation resistor-capacitor networks, mechanical

insulators, etc.

5. To be sure that no shock hazard exists, check for leakage current in

the following manner.

• Plug the AC cord directly into a 220~240 volt AC outlet.

• Using two clip leads, connect a 1.5k ohm, 10 watt resistor paralleled by a 0.15µF capacitor in series with all exposed metal cabinet

parts and a known earth ground, such as electrical conduit or electrical ground connected to an earth ground.

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

TO EXPOSED

METAL PARTS

SAFETY NOTICE

Many electrical and mechanical parts in LCD color television have

special safety-related characteristics.

These characteristics are often not evident from visual inspection, nor

can protection afforded by them be necessarily increased by using

replacement components rated for higher voltage, wattage, etc.

Replacement parts which have these special safety characteristics are

identified in this manual; electrical components having such features

are identified by “ ” and shaded areas in the Replacement Parts

List and Schematic Diagrams.

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

For continued protection, replacement parts must be identical to those

used in the original circuit.

The use of a substitute replacement parts which do not have the same

safety characteristics as the factory recommended replacement parts

shown in this service manual, may create shock, fire or other hazards.

DVM

AC SCALE

1.5k ohm

10W

0.15µF

TEST PROBE

CONNECT TO

KNOWN EARTH

GROUND

i

Page 3

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

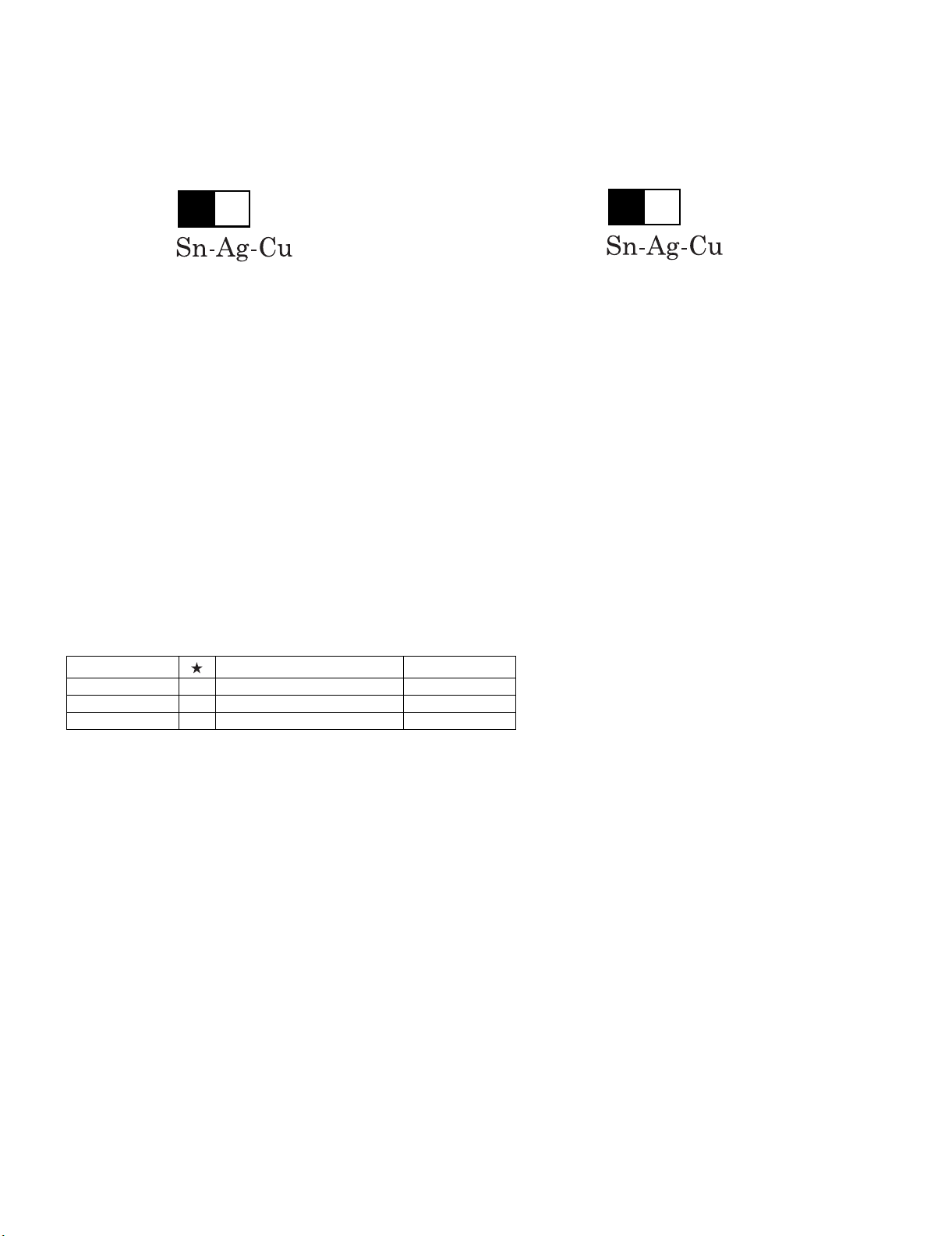

Precautions for using lead-free solder

Employing lead-free solder

• “PWBs” of this model employs lead-free solder. The LF symbol indicates lead-free solder, and is attached on the PWBs and service manuals. The

alphabetical character following LF shows the type of lead-free solder.

Example:

L Fa

Indicates lead-free solder of tin, silver and copper.

Indicates lead-free solder of tin, silver and copper.

L F a/a

Using lead-free wire solder

• When fixing the PWB soldered with the lead-free solder, apply lead-free wire solder. Repairing with conventional lead wire solder may cause damage or accident due to cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40 °C, we recommend you to use a dedicated soldering

bit, if you are not familiar with how to obtain lead-free wire solder or soldering bit, contact our service station or service branch in your area.

Soldering

• As the melting point of lead-free solder (Sn-Ag-Cu) is about 220 °C which is higher than the conventional lead solder by 40 °C, and as it has poor

solder wettability, you may be apt to keep the soldering bit in contact with the PWB for extended period of time. However, Since the land may be

peeled off or the maximum heat-resistance temperature of parts may be exceeded, remove the bit from the PWB as soon as you confirm the

steady soldering condition.

Lead-free solder contains more tin, and the end of the soldering bit may be easily corroded. Make sure to turn on and off the power of the bit as

required.

If a different type of solder stays on the tip of the soldering bit, it is alloyed with lead-free solder. Clean the bit after every use of it.

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sandpaper.

• Be careful when replacing parts with polarity indication on the PWB silk.

Lead-free wire solder for servicing

Part No. Description Code

ZHNDAi123250E J φ0.3mm 250g (1roll) BL

ZHNDAi126500E J φ0.6mm 500g (1roll) BK

ZHNDAi12801KE J φ1.0mm 1kg (1roll) BM

ii

Page 4

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

LC42XL2E

CHAPTER 1. OPERATION MANUAL

Service Manual

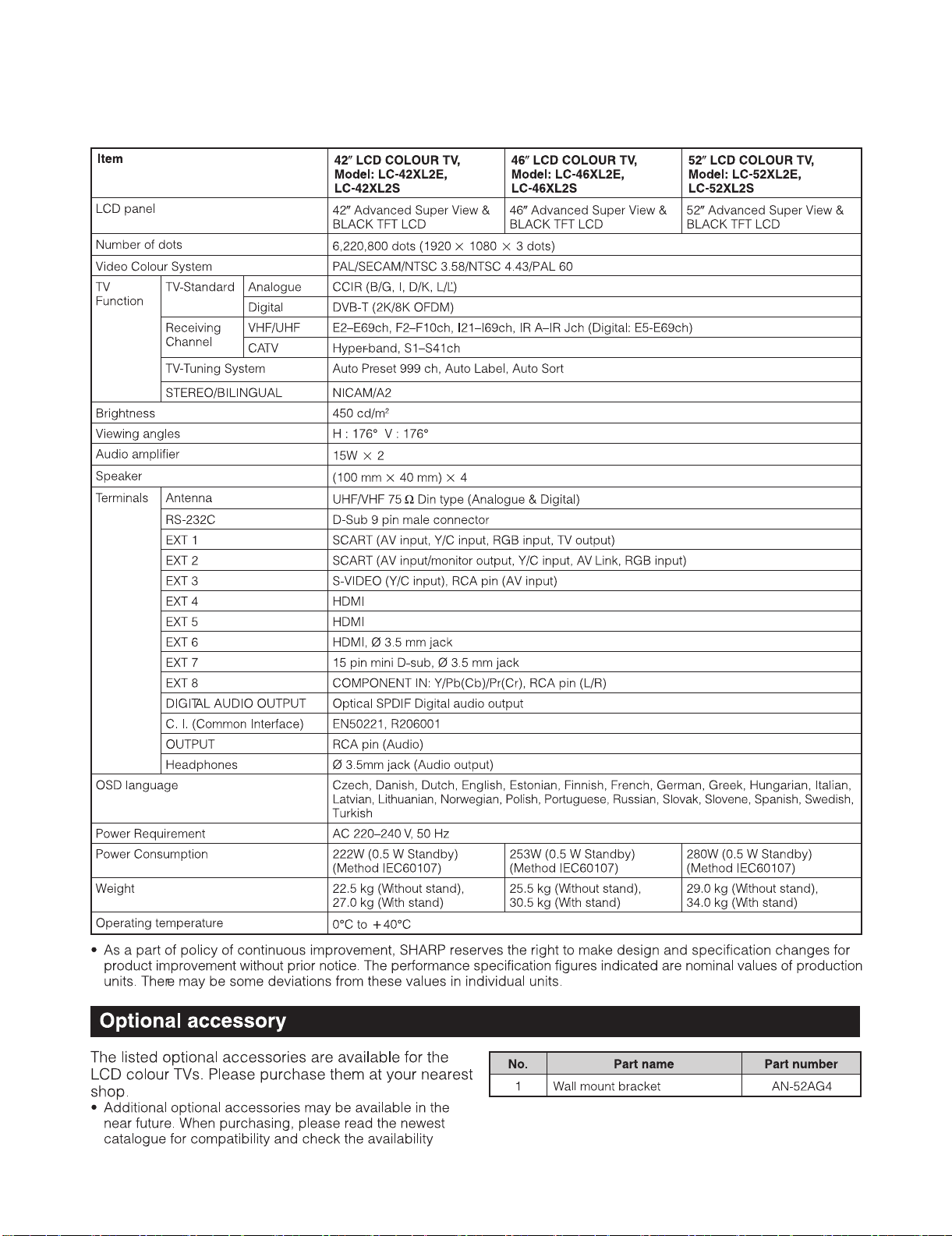

[1] SPECIFICATIONS (LC-42/46/52XL2E/S/RU)

1 – 1

Page 5

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

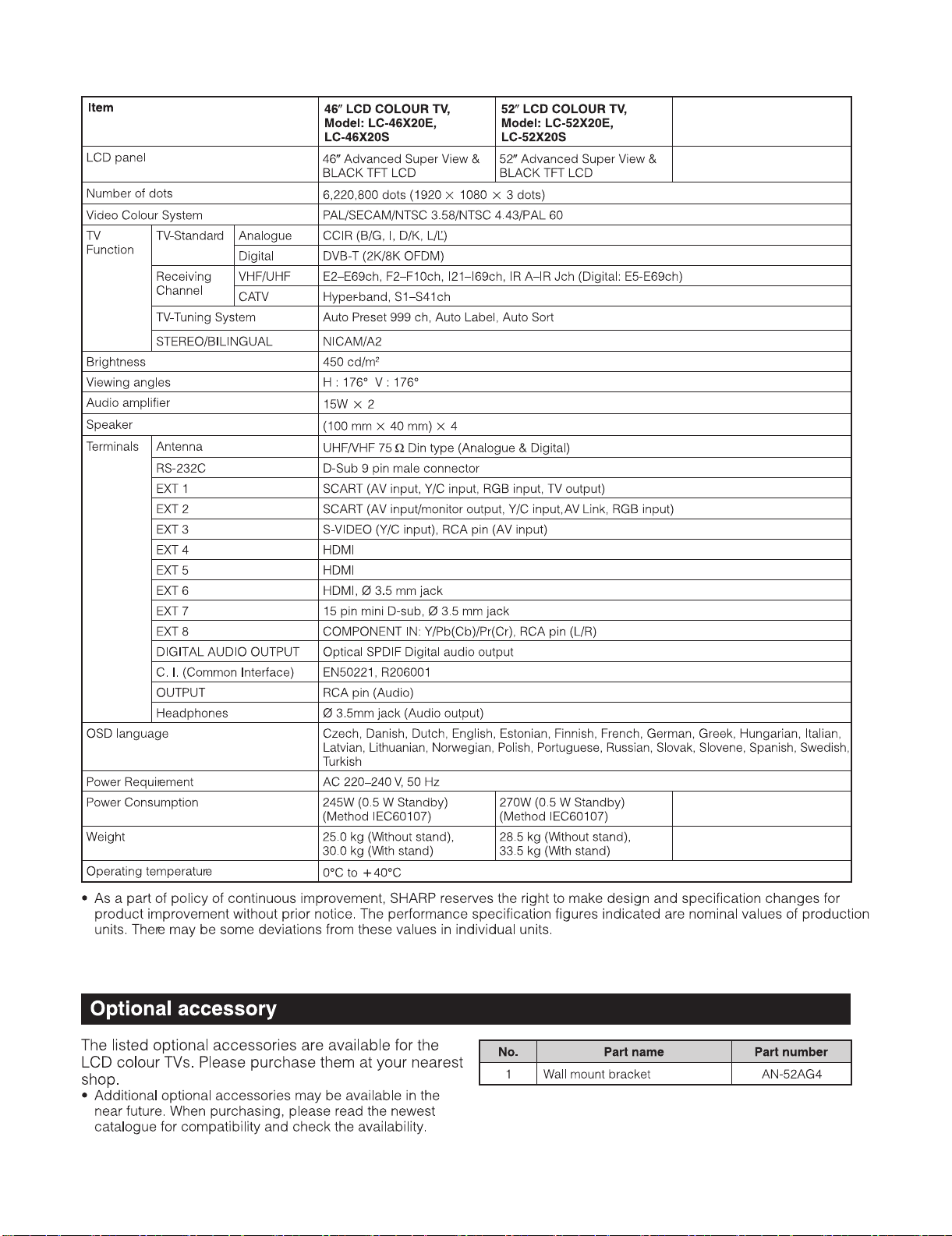

[2] SPECIFICATIONS (LC-46/52X20E/S/RU)

1 – 2

Page 6

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

[3] OPERATION MANUAL (LC-42/46/52XL2E/S/RU)

1 – 3

Page 7

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

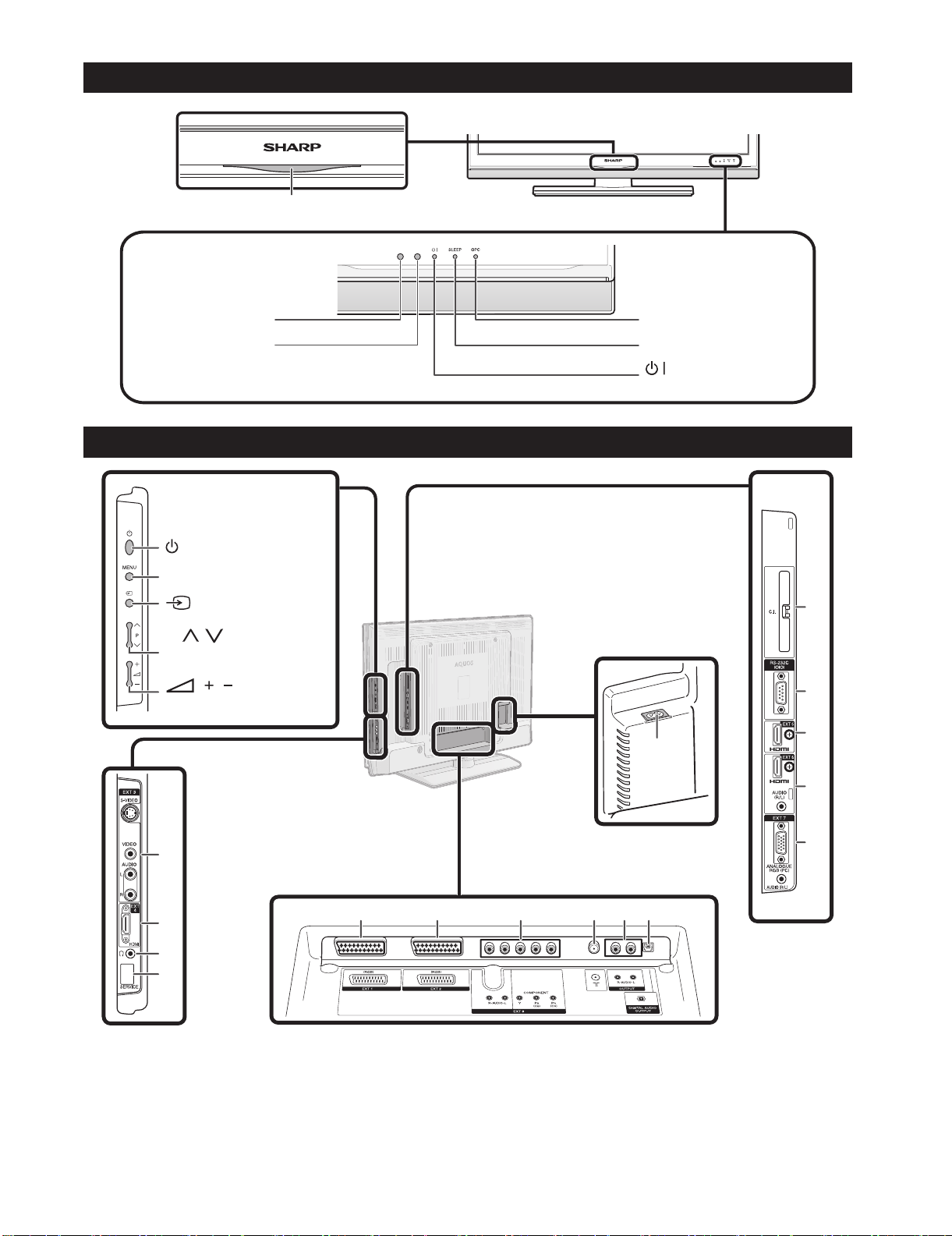

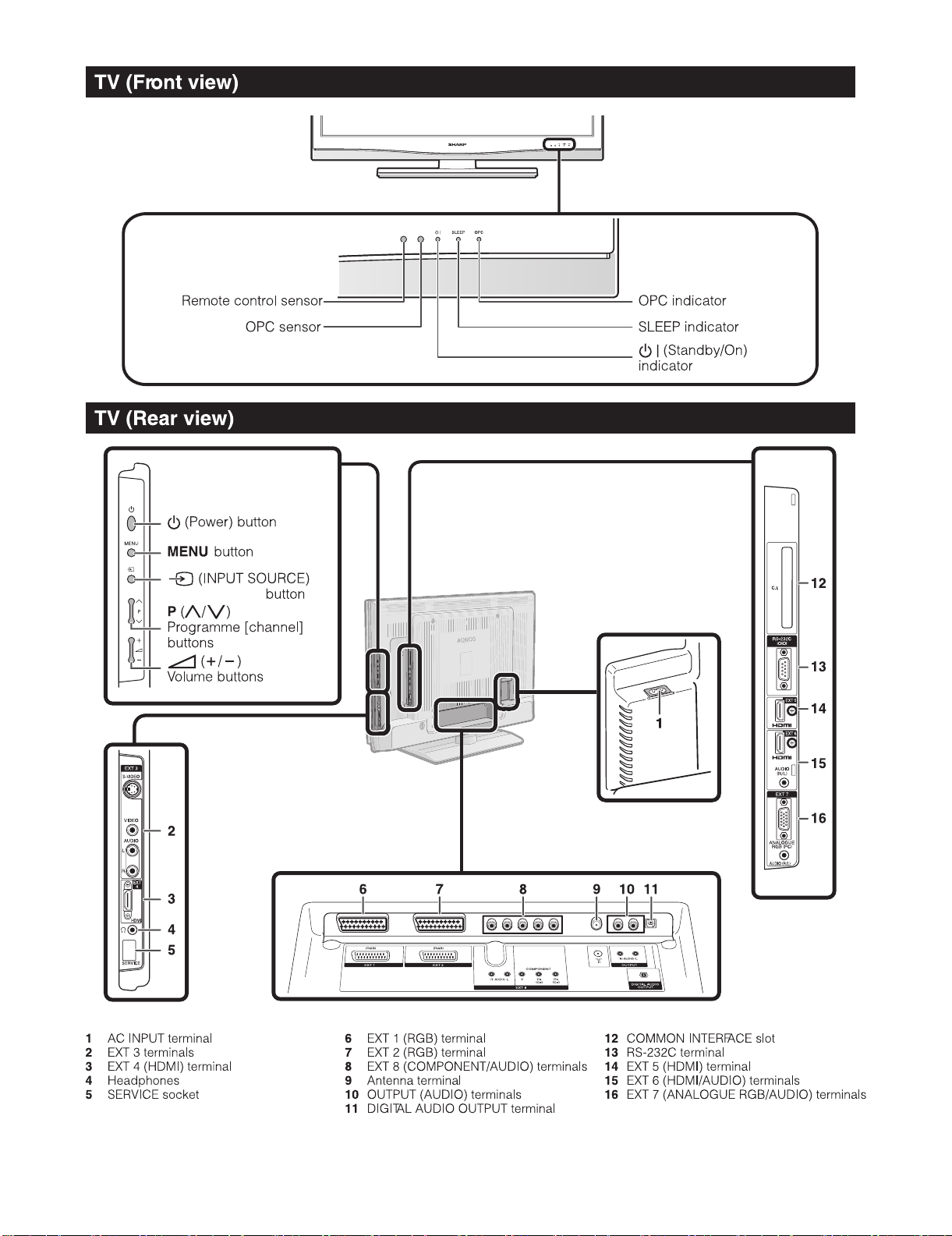

TV (Front view)

Blue illumination LED indicator

Remote control censor

OPC censor

TV (Rear view)

(Power) button

MENU button

(Input source) button

P (

/ )

Programme [channel]

buttons

( / )

Volume buttons

OPC indicator

SLEEP indicator

(Standby/On)

indicator

12

13

14

1

2

3

4

5

1 AC INPUT terminal

2 EXT 3 terminals

3 EXT 4 (HDMI) terminal

4 Headphones

5 SERVICE socket

6 7891011

6 EXT 1 (RGB) terminal

7 EXT 2 (RGB) terminal

8 EXT 8 (COMPONENT/AUDIO) terminals

9 Antenna terminal

10 OUTPUT (AUDIO) terminals

11 DIGITAL AUDIO OUTPUT terminal

12 COMMON INTERFACE slot

13 RS-232C terminal

14 EXT 5 (HDMI) terminal

15 EXT 6 (HDMI/AUDIO) terminals

16 EXT 7 (ANALOGUE RGB/AUDIO) terminals

1 – 4

15

16

* Remove the cover when inserting the CI

Module.

Page 8

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

1 – 5

Page 9

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

1 – 6

Page 10

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

1 – 7

Page 11

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

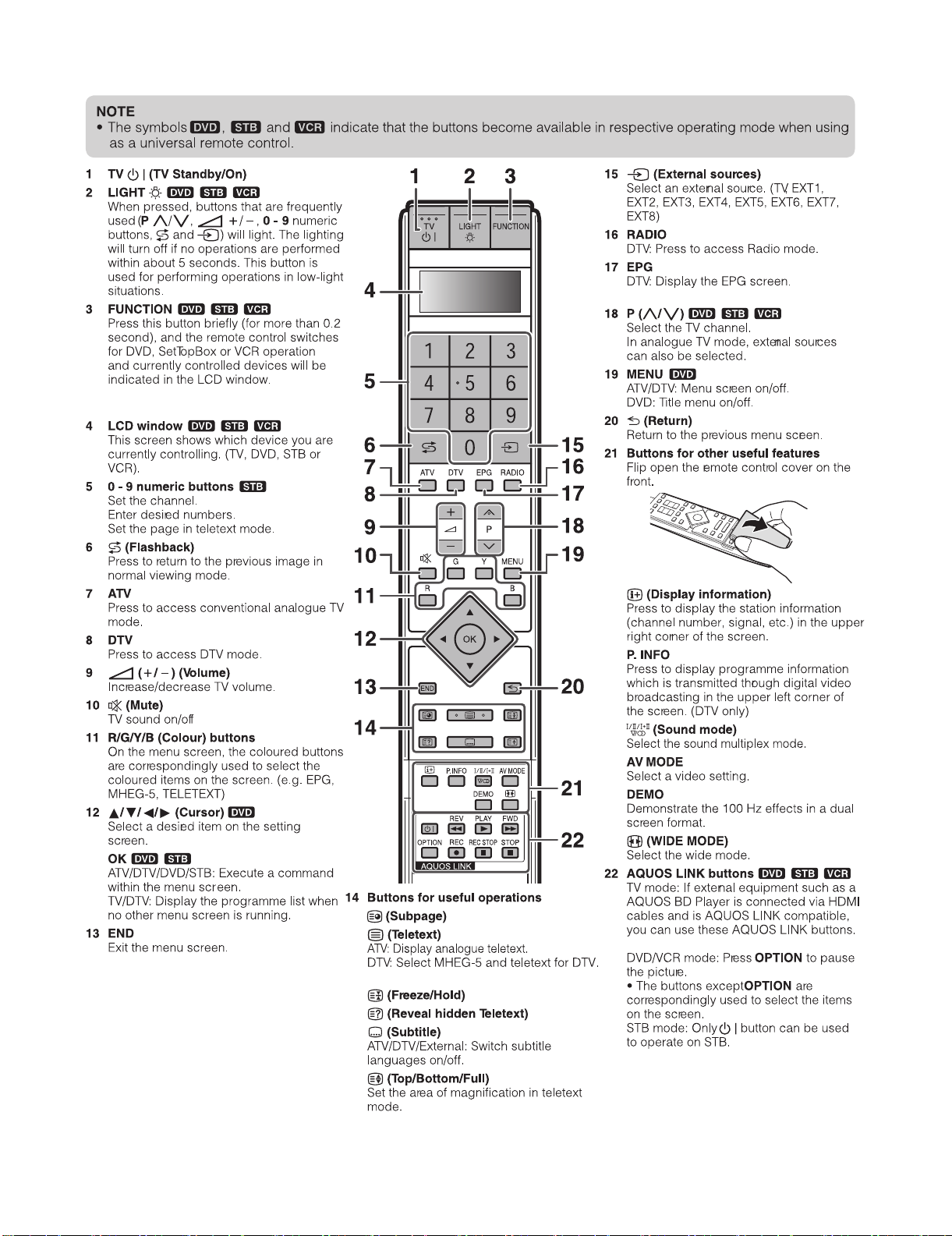

[4] OPERATION MANUAL (LC-46/52X20E/S/RU)

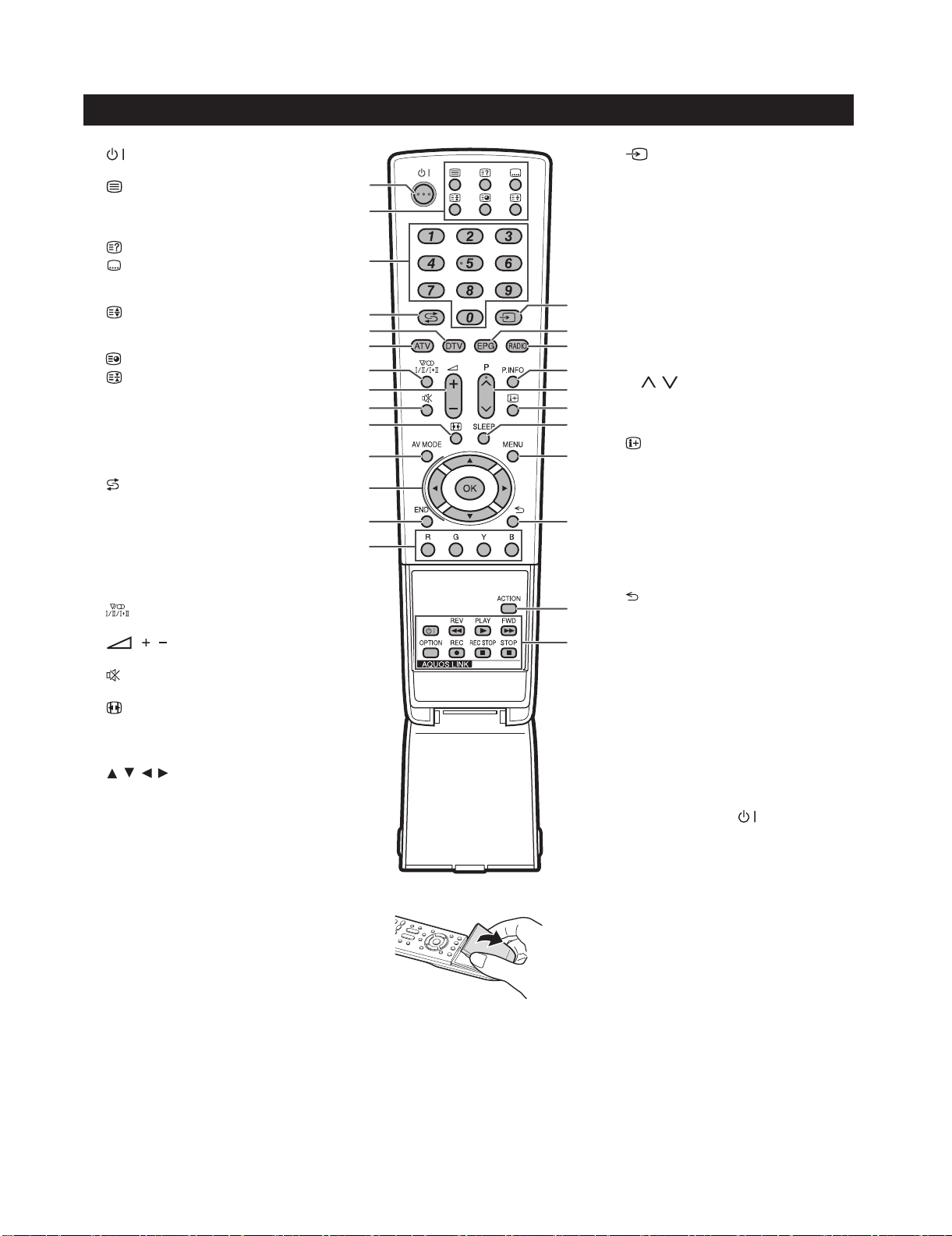

Remote control unit

1 (Standby/On)

2 Buttons for useful operations

(Teletext)

ATV: Display analogue teletext.

DTV: Select MHEG-5 and teletext for DTV.

(Reveal hidden Teletext)

(Subtitle)

ATV/DTV/External: Switch subtitle

languages on/off.

(Top/Bottom/Full)

Set the area of magnification in teletext

mode.

(Subpage)

(Freeze/Hold)

Press to freeze a moving image on the

screen.

3 0 - 9 numeric buttons

Set the channel.

Enter desired numbers.

Set the page in teletext mode.

4

(Flashback)

Press to return to the previous image in

normal viewing mode.

5DTV

Press to access DTV mode.

6ATV

Press to access conventional analogue TV

mode.

7

8 ( / ) (Volume)

9

10

11 AV MODE

12

13 END

14 R/G/Y/B (Colour) buttons

(Sound mode)

Select the sound multiplex mode.

Increase/decrease TV volume.

(Mute)

TV sound on/off

(WIDE MODE)

Select the wide mode.

Select a video setting.

/ / / (Cursor)

Select a desired item on the setting

screen.

OK

ATV/DTV/DVD/STB: Execute a command

within the menu screen.

ATV/DTV: Display the programme list

when no other menu screen is running.

Exit the menu screen.

On the menu screen, the coloured buttons

are correspondingly used to select the

coloured items on the screen. (e.g. EPG,

MHEG-5, TELETEXT)

10

11

12

13

14

15

1

2

3

4

5

6

7

8

9

15

16

17

18

19

20

16 EPG

17 RADIO

18 P. INFO

19 P (

21

20

22

21 SLEEP

23

22 MENU

23

24

24 ACTION (Action Mode)

25

25 AQUOS LINK buttons

(INPUT SOURCE)

Select an input source. (TV, EXT1, EXT2,

EXT3, EXT4, EXT5, EXT6, EXT7, EXT8)

DTV: Display the EPG screen.

DTV: Switch between Radio and Data

mode.

Press to display programme information

which is transmitted through digital video

broadcasting in the upper left corner of

the screen. (DTV only)

/ )

Select the TV channel.

In analogue TV mode, external sources

can also be selected.

(Display information)

Press to display the station information

(channel number, signal, etc.) in the upper

right corner of the screen.

Press to schedule a time for the TV to

automatically standby.

ATV/DTV: Menu screen on/off.

DVD: Title menu on/off.

(Return)

Return to the previous menu screen.

Action Mode on/off.

TV mode: If external equipment such as a

AQUOS BD Player is connected via HDMI

cables and is AQUOS LINK compatible,

you can use these AQUOS LINK buttons.

DVD/VCR mode: Press OPTION to pause

the picture.

• The buttons except OPTION are

correspondingly used to select the items

on the screen.

STB mode: Only the

used to operate on STB.

button can be

1 – 8

Page 12

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

1 – 9

Page 13

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

1 – 10

Page 14

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

1 – 11

Page 15

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

1 – 12

Page 16

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

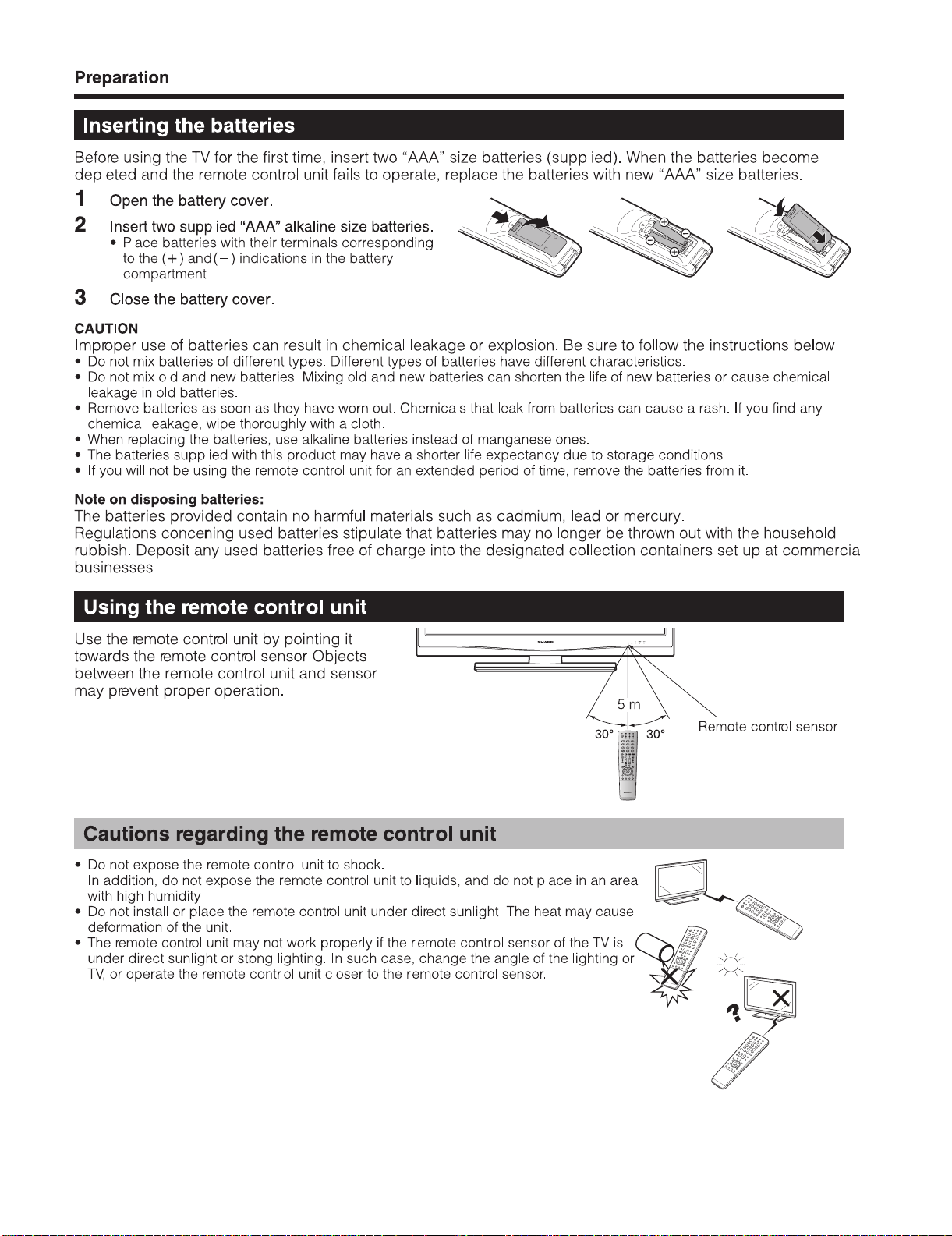

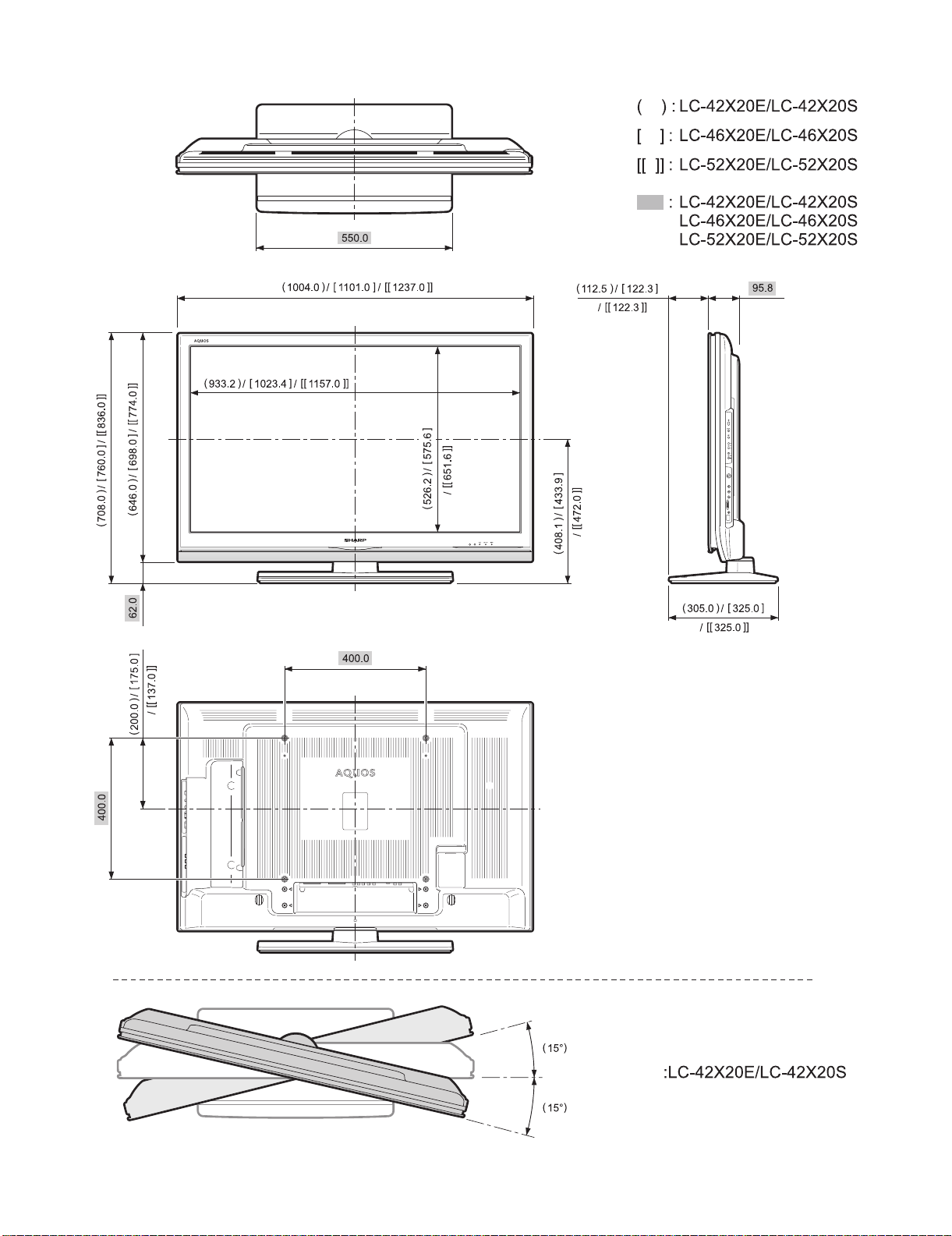

[5] DIMENSIONS (LC-42/46/52XL2E/S/RU)

Unit: mm

1 – 13

Page 17

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

[6] DIMENSIONS (LC-46/52X20E/S/RU)

Unit: mm

1 – 14

Page 18

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

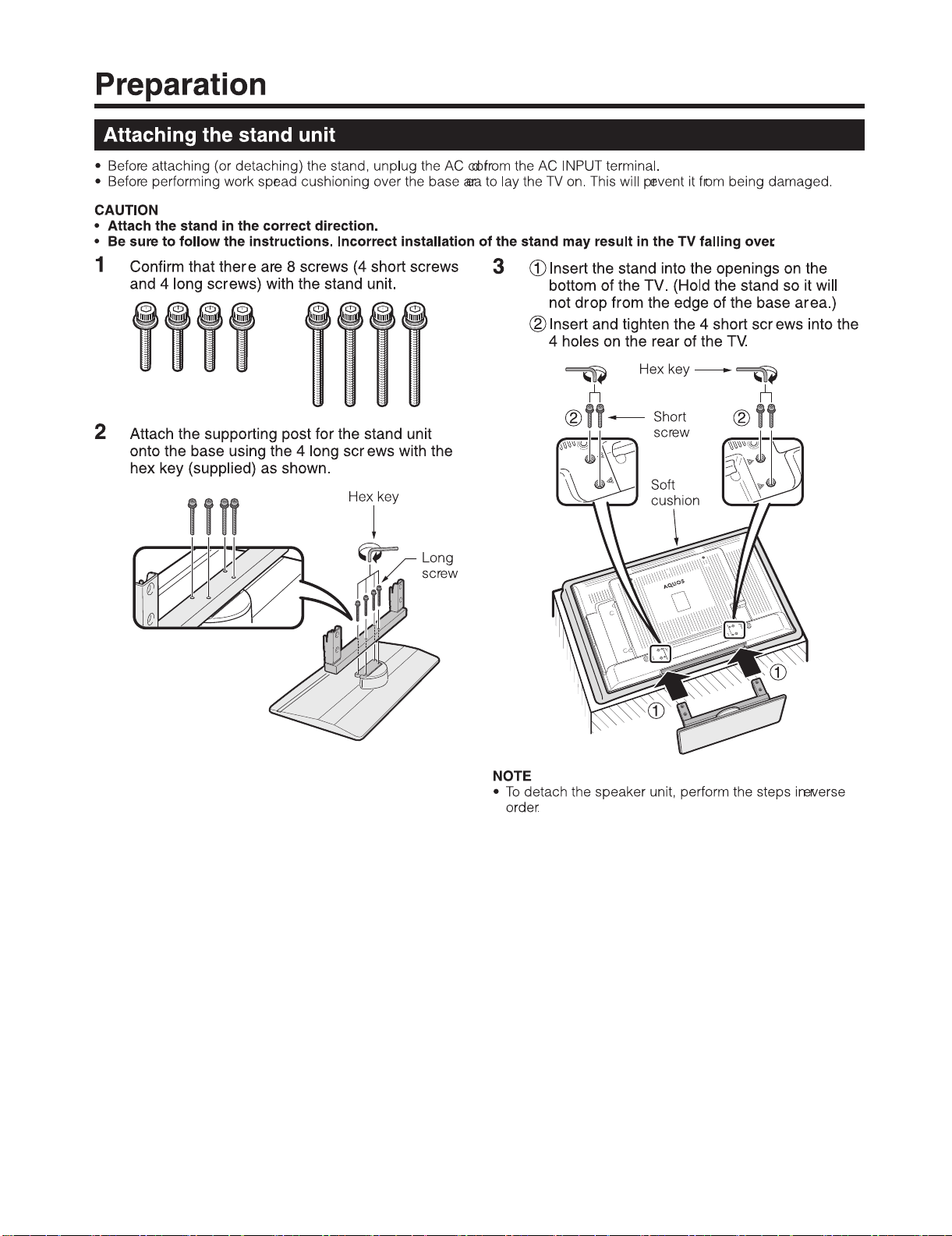

LC42XL2E

CHAPTER 2. REMOVING OF MAJOR PARTS

Service Manual

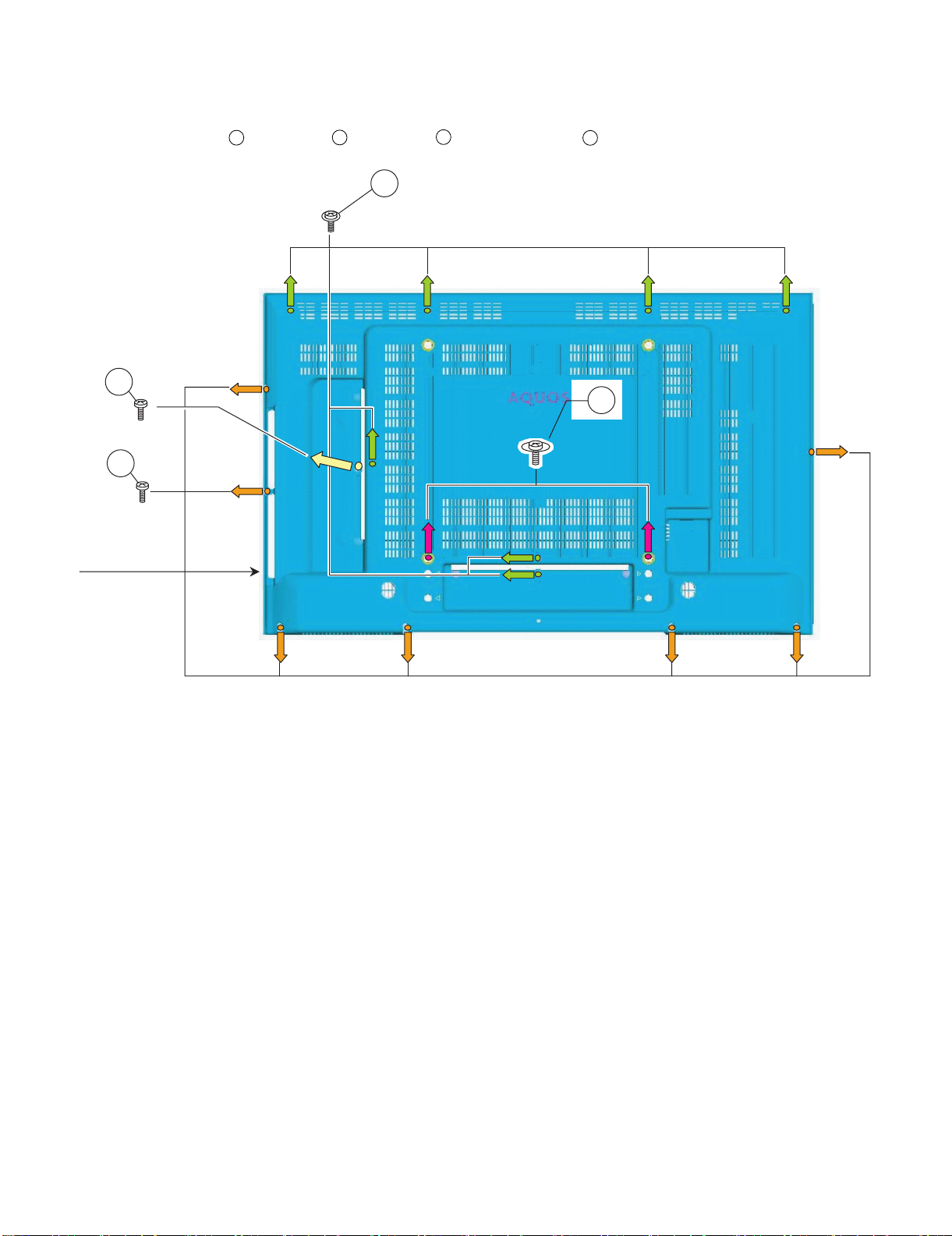

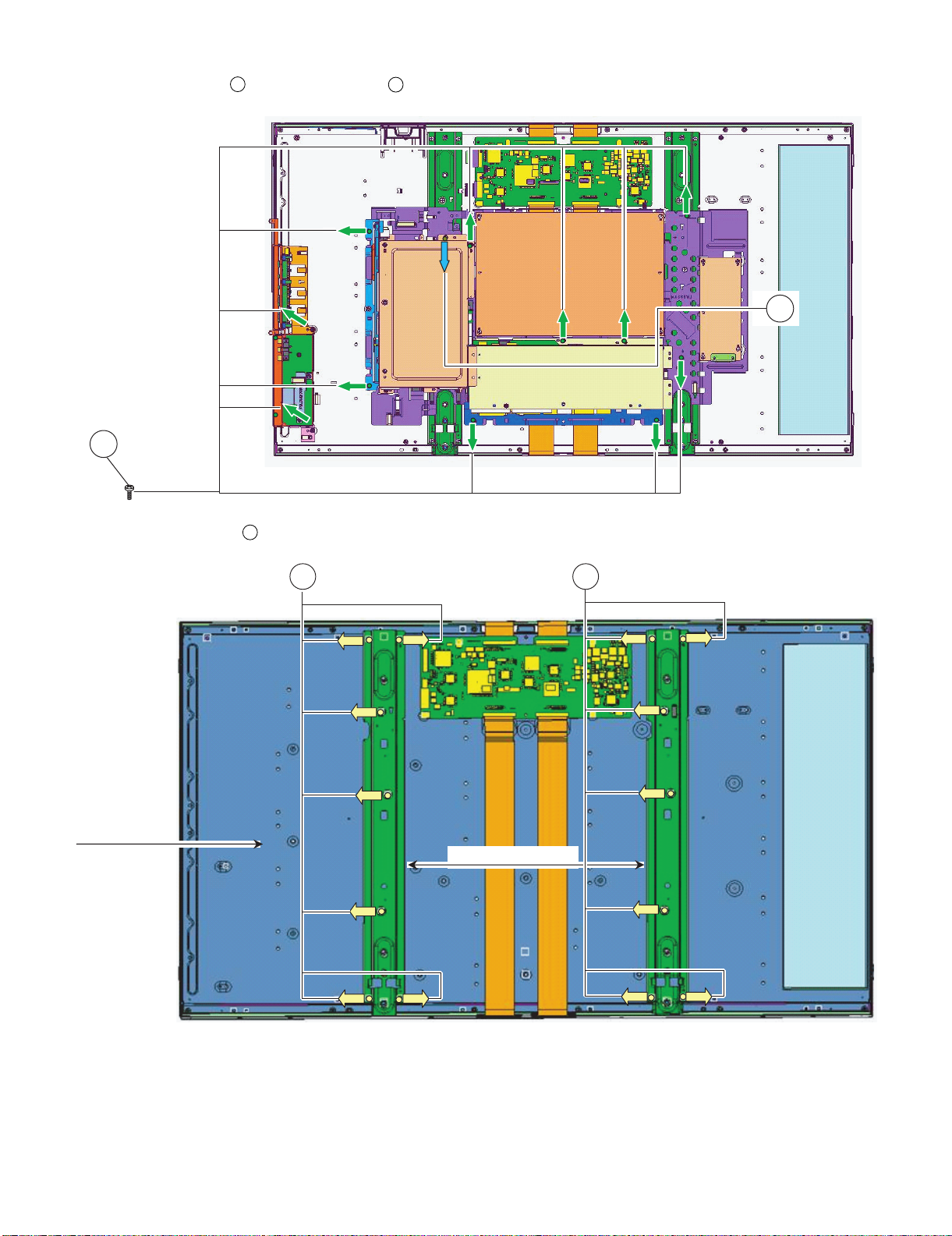

[1] REMOVING OF MAJOR PARTS (LC-42XL2E/S/RU)

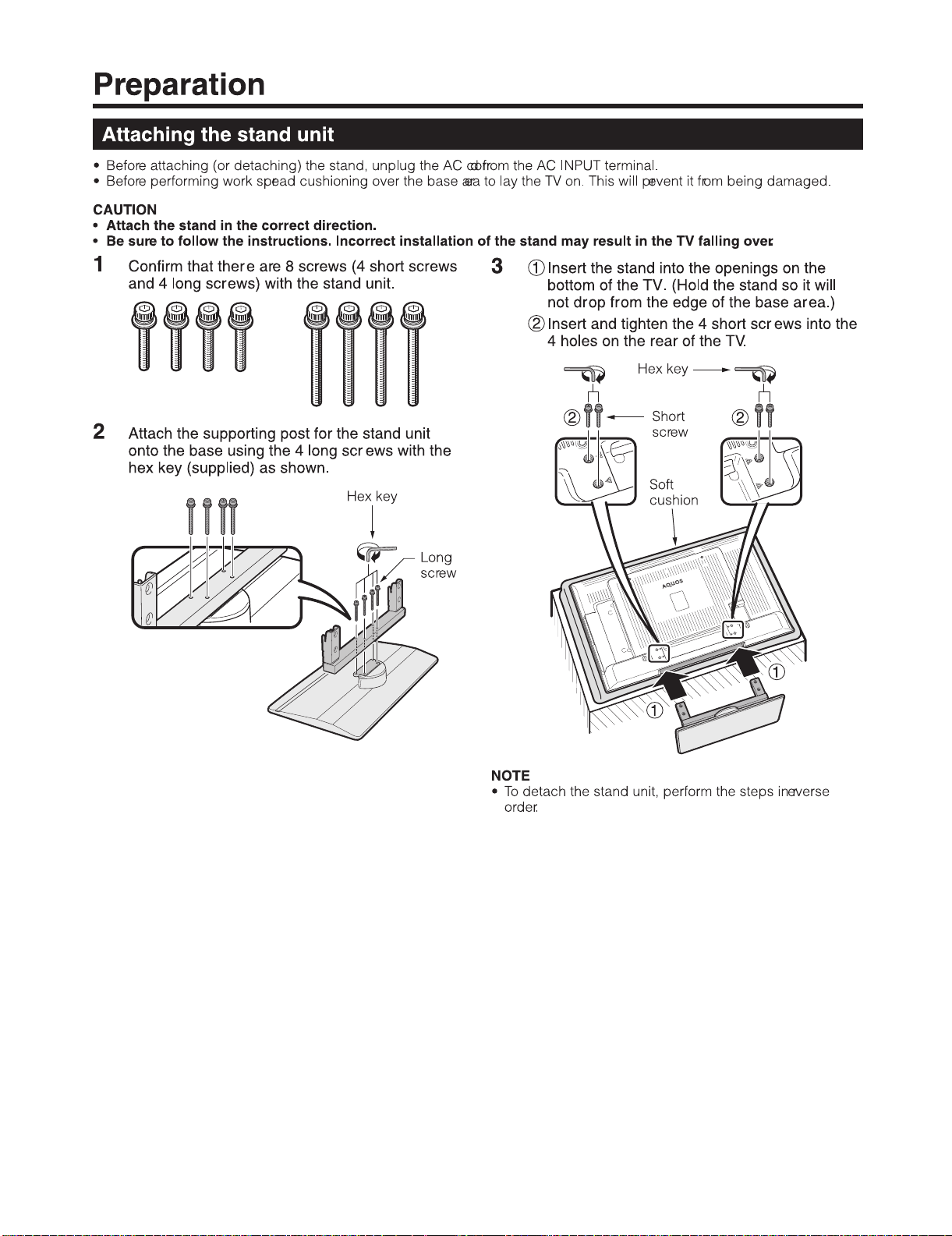

1. Remove the 1 lock screw , 2 lock screws , 7 lock screws and the 7 lock screws . Detach the Rear Cabinet.

1

2

3

4

4

1

2

3

REAR CABINET

2 – 1

Page 19

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

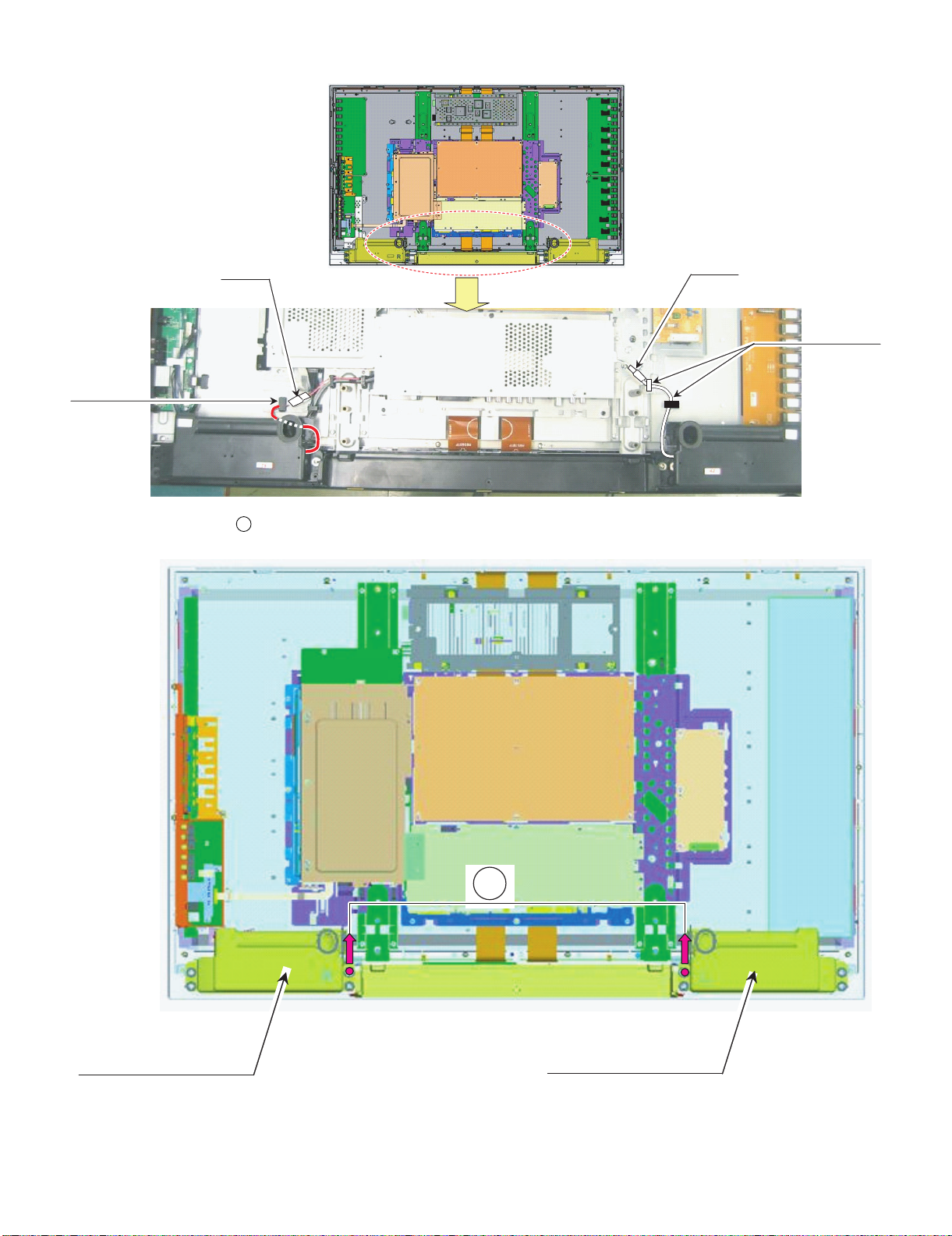

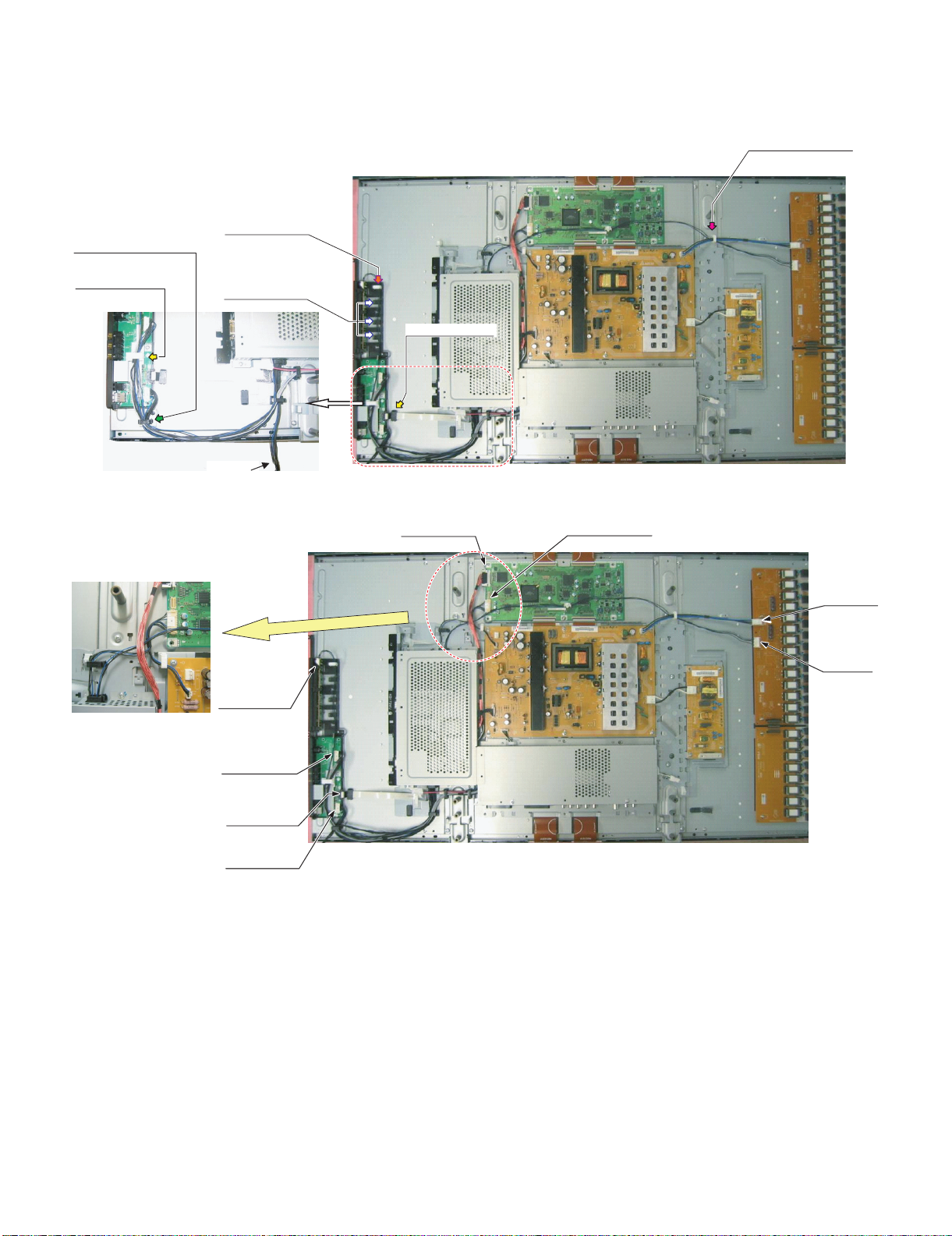

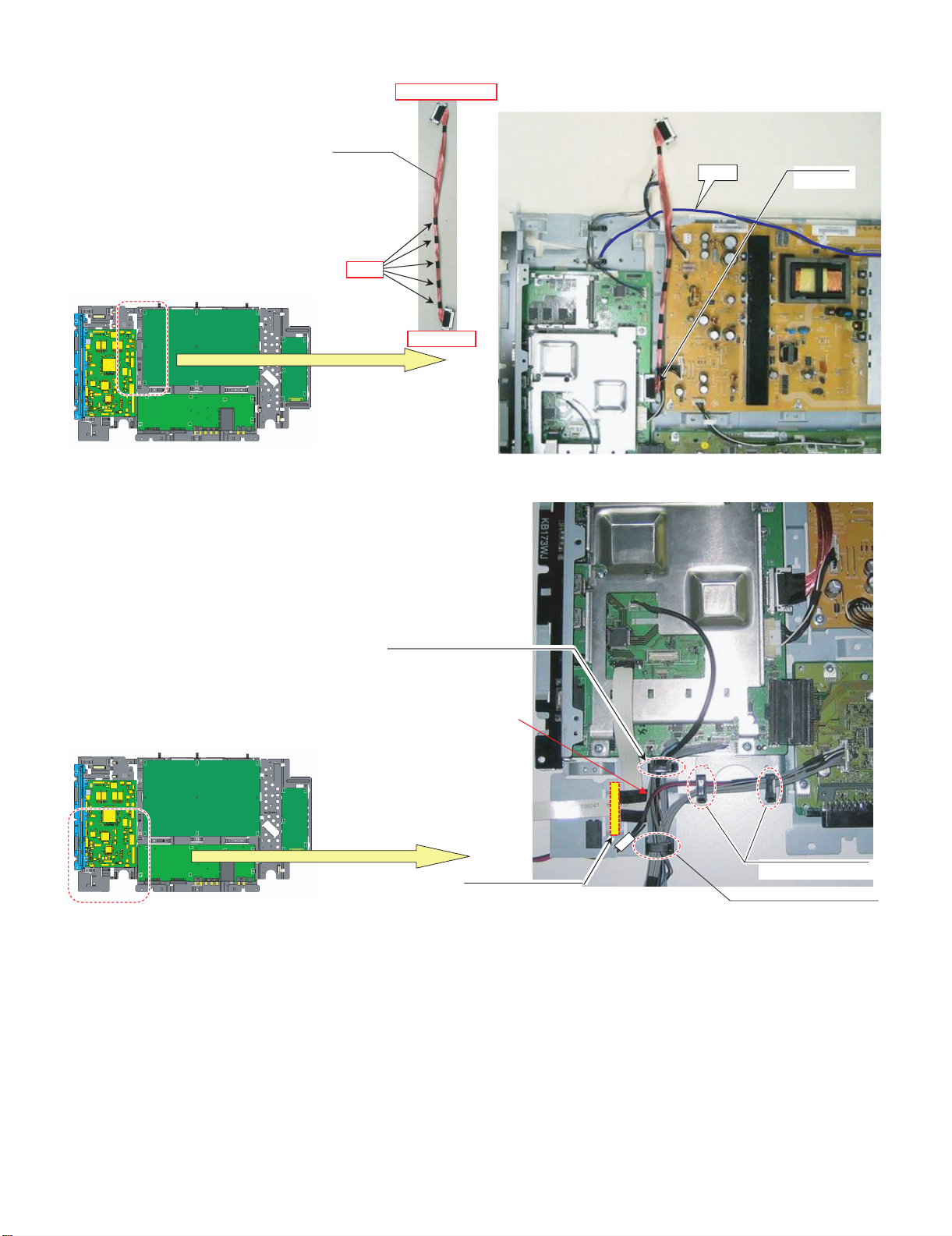

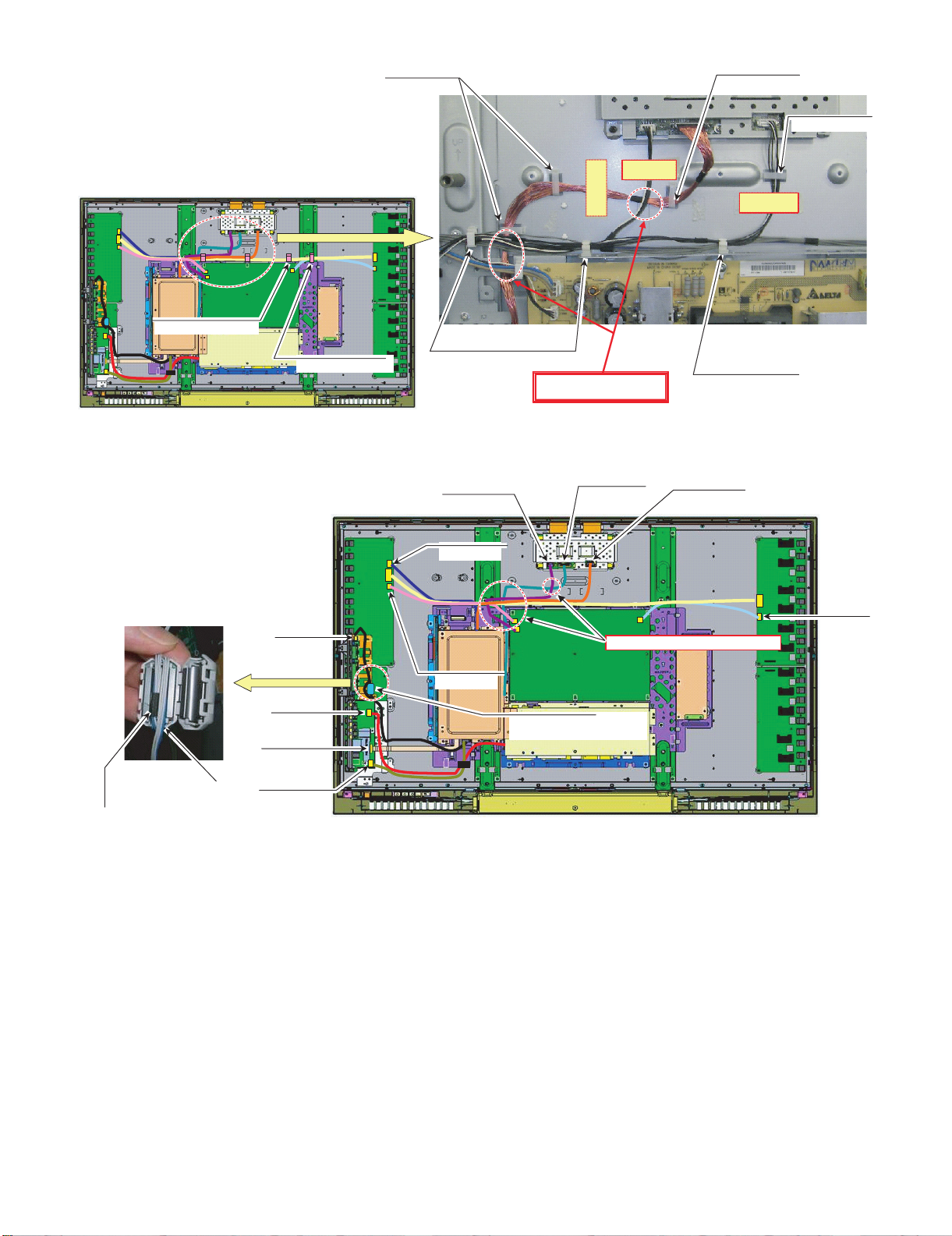

2. Remove all the connectors from PWBs.

Wire "SP"

Wire "SP" to WH

3. Remove the 2 lock screws . and detach the Speaker L/R.

5

Wire "SP"

Wire "SP" to WH

5

Speaker R Speaker L

2 – 2

Page 20

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

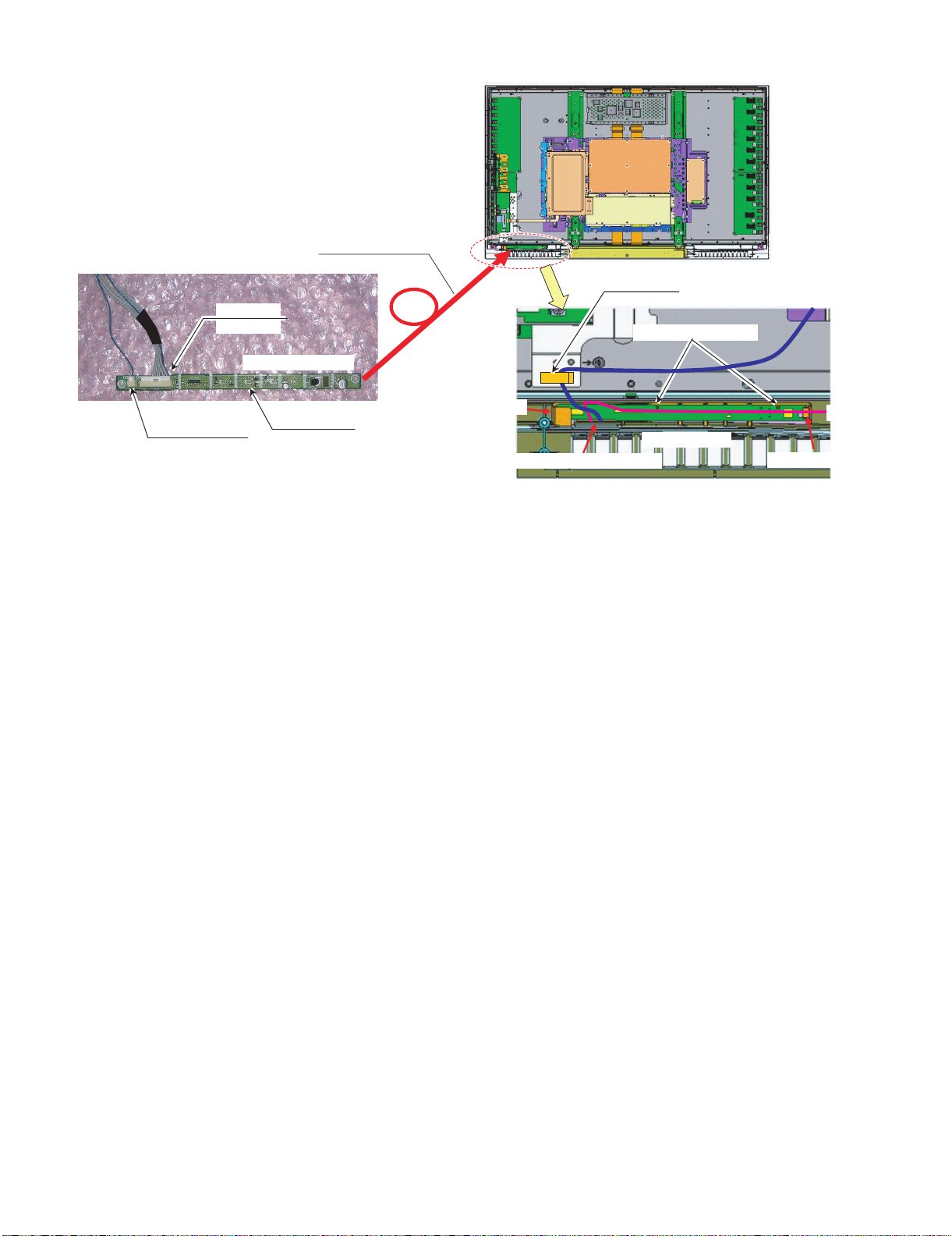

Wire "RA"

from OBON

Wire "RA"

LED PWB Front side

LED PWB Back side

Pull out Wire "IL","RA" from bottom

1st, Set LED PWB Under LIB

#Set PWB to gide lib surely

Next,Push PWB hooked

Wire "IL"

4. Remove all the connectors from PWBs.

LED PWB

(with wire)

Wire "RA" to WH

Wire "IL"

from Illumination

5. Remove the R/C, LED Unit.

LED PWB

2 – 3

Page 21

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

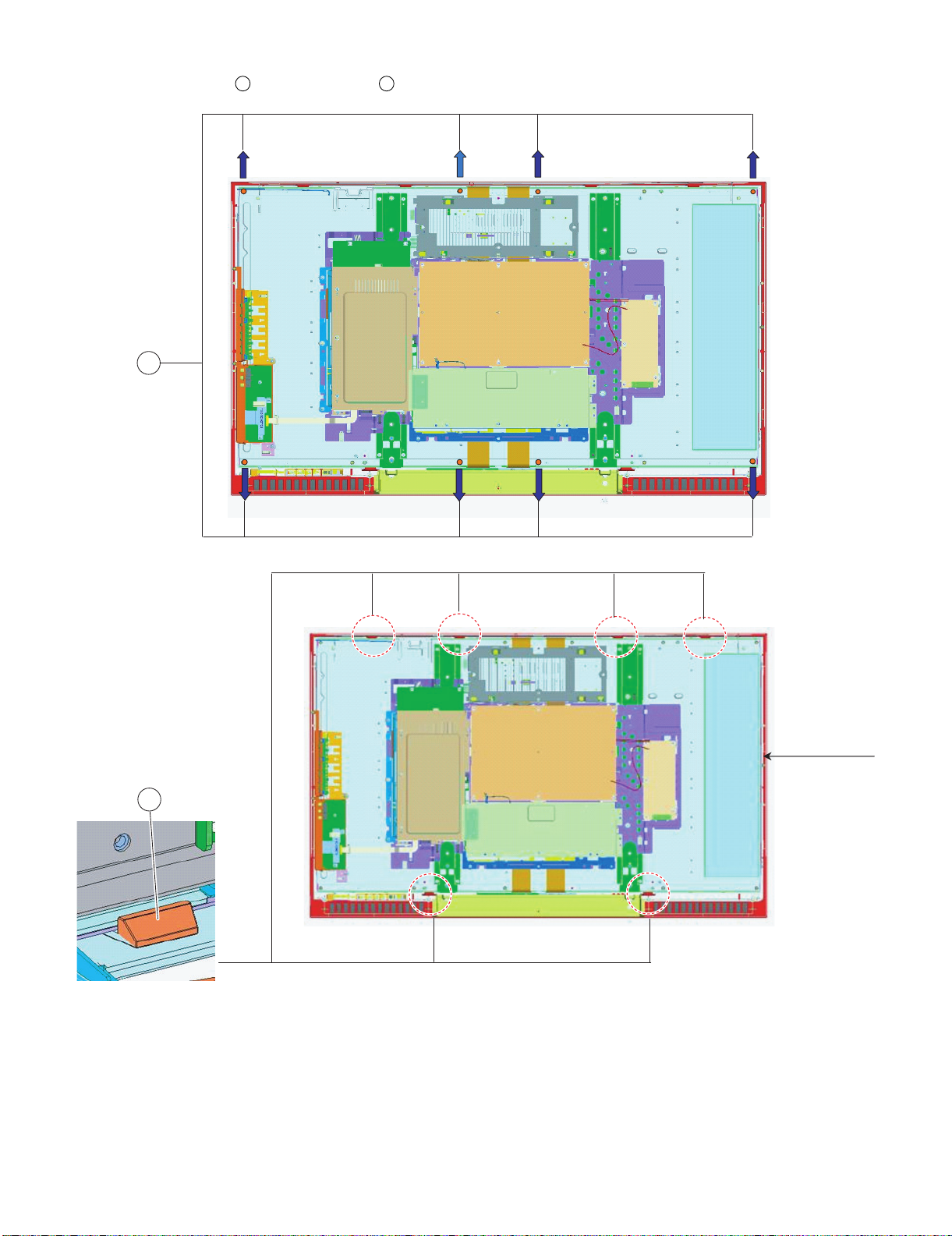

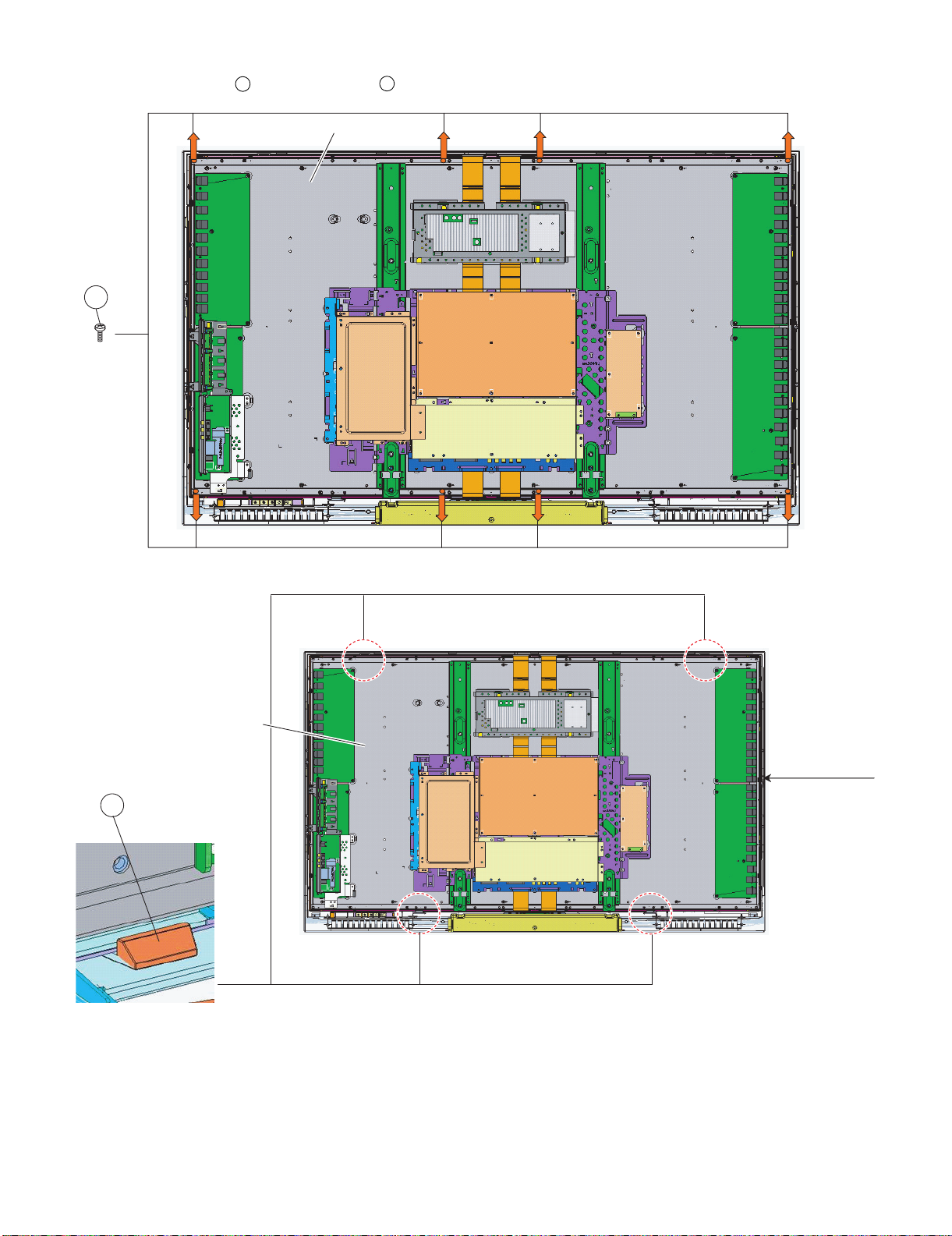

6. Remove the 8 lock screws , and the 6 lock hooks . Detach the LCD Panel Module.

6 7

6

FRONT CABINET

7

2 – 4

Page 22

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

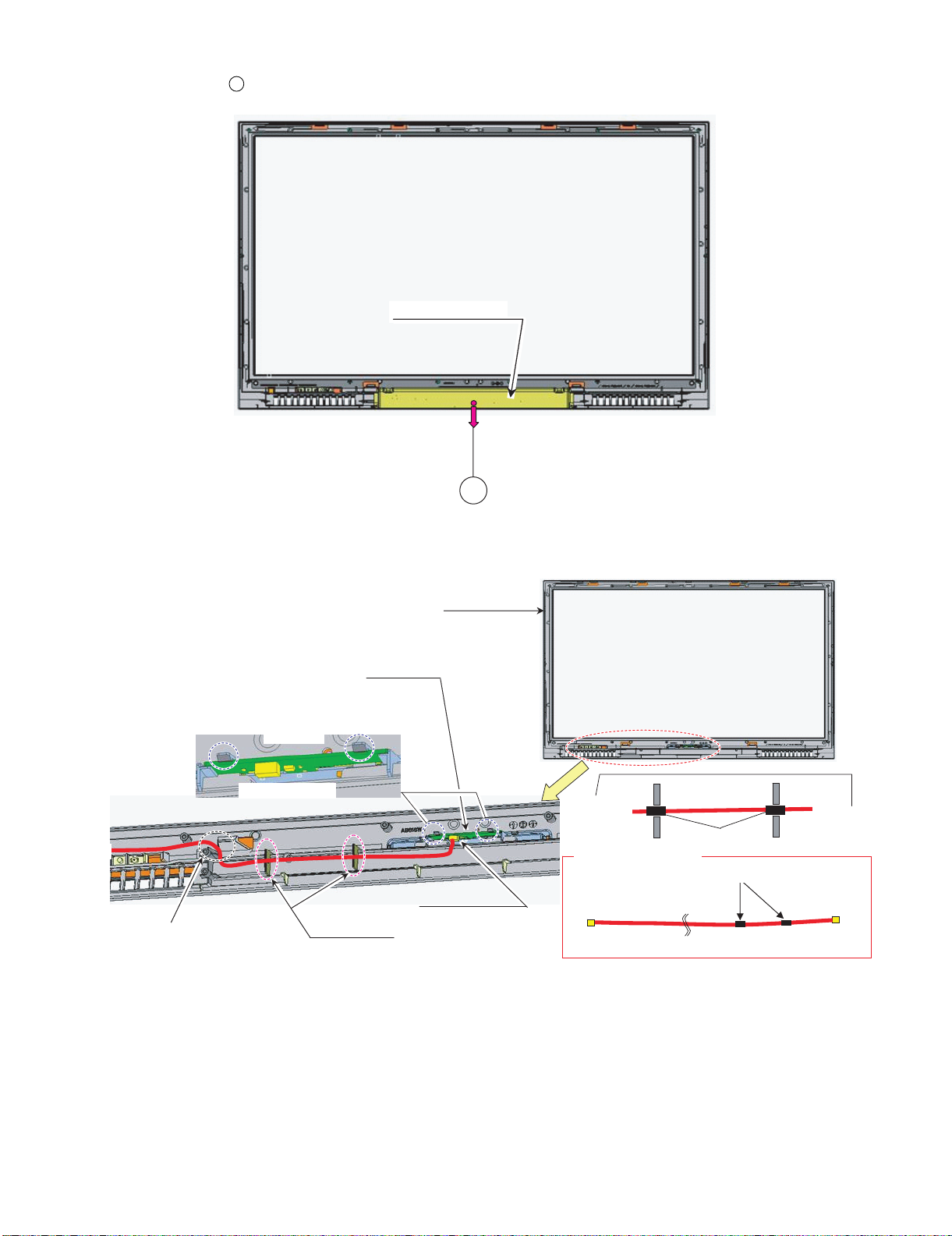

BOTTOM COVER

Wire "IL"

#Hook Surely

#Connector side Down

#Wire "IL" pass between SP Boss

and Panel hooker

Illumination Unit

To LED PWB

TAPING

Wire "IL" Connection Direction

Wire "IL"

Tape

Lib

Lib

7. Remove the 1 lock screw . and detach the Bottom Cover.

8

8. Remove all the connectors from PWBs.

9. Remove the Illumination Unit.

8

Wire "IL" to rib

FRONT CABINET

Illumination Unit

Wire "IL"

2 – 5

Page 23

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

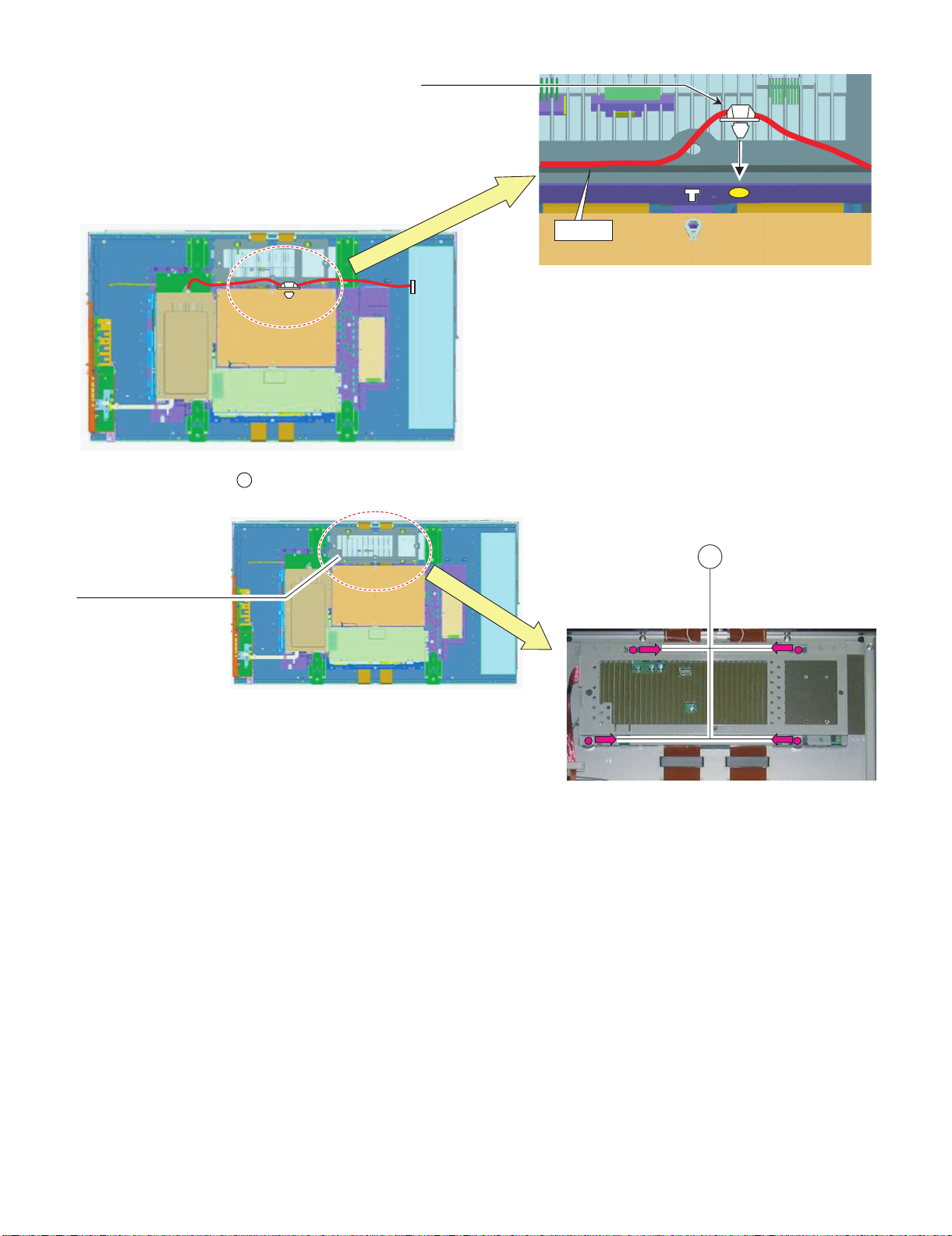

㪮㫀㫉㪼㩷㪣㪙

Wire "LB" to Hole

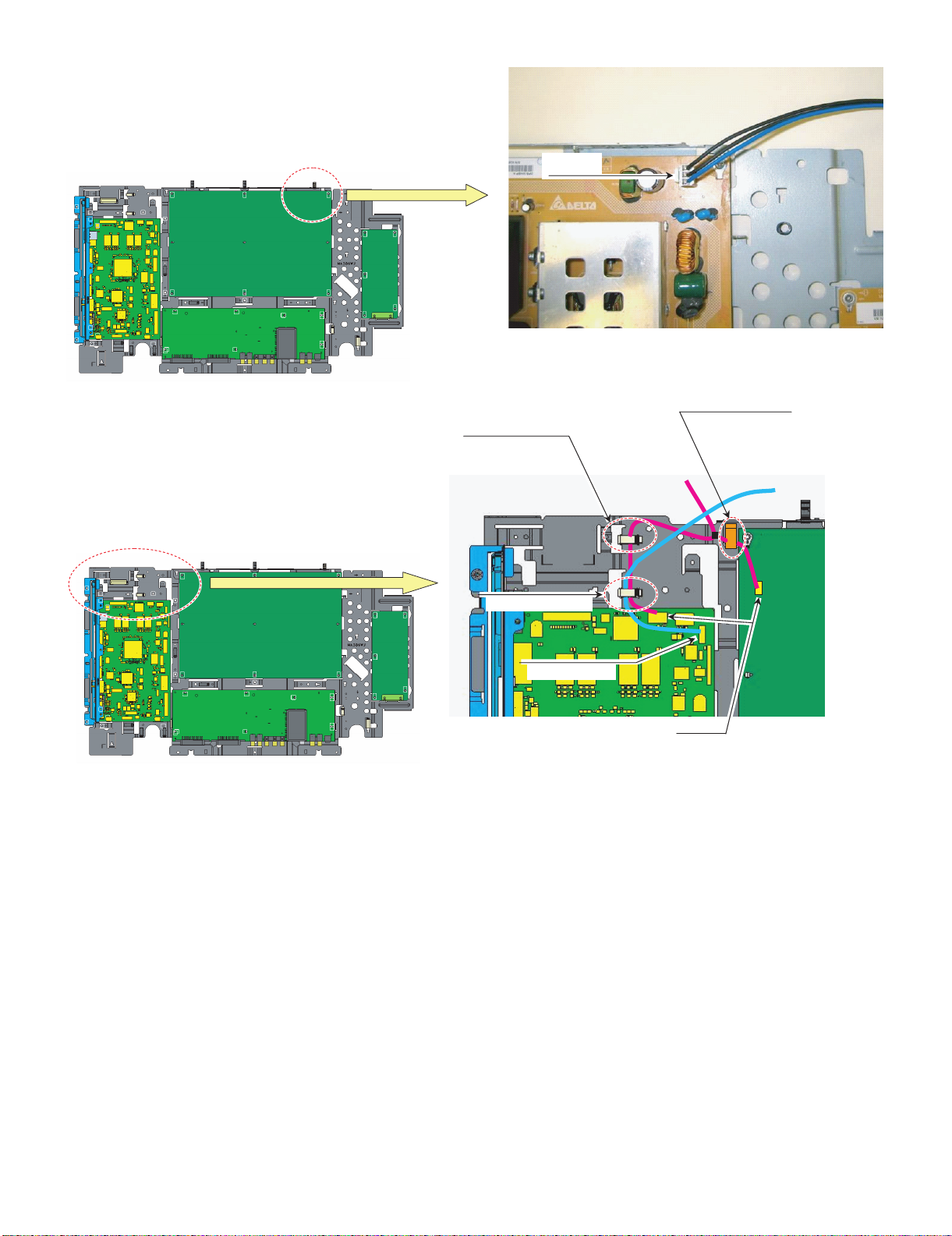

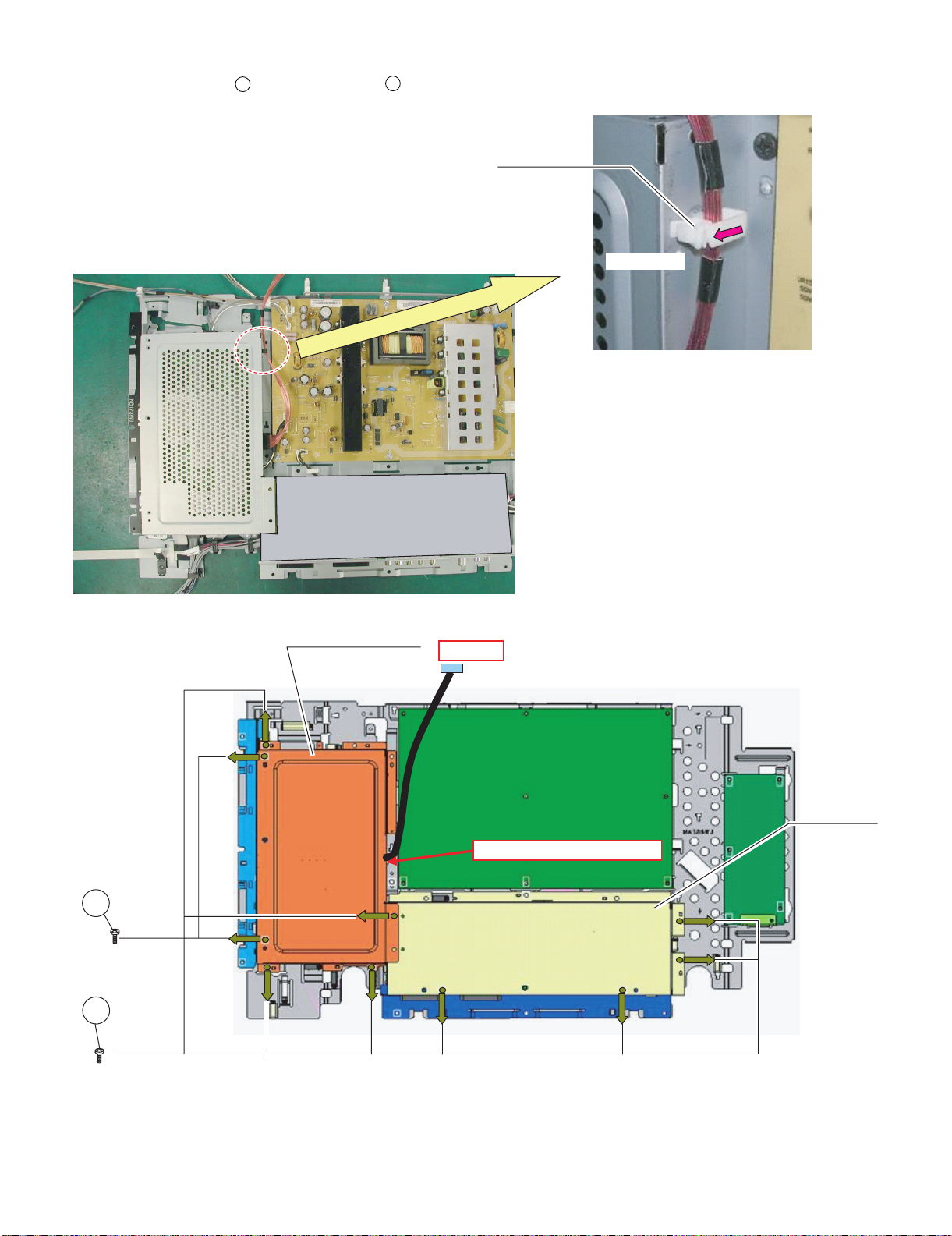

10.Remove the 4 lock screws . and detach the CTL SHIELD with RADIATOR.

CTL-SHIELD with RADIATOR

9

9

2 – 6

Page 24

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

FFC "HM" to WH

Wire "RA"

11.Remove all the connectors from PWBs.

Wire "LB", "LA1" to WH

Wire "KM" to WH

Wire "KM", "VD", "US" to WH

Wire "KM", "VD"to WH

Wire "KM" to Hook

Wire "KM"

Wire "LW"

Wire "FR"

Wire "LA1"

Wire "LB"

Wire "VD"

FFC "HM"

Wire "US"

2 – 7

Page 25

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

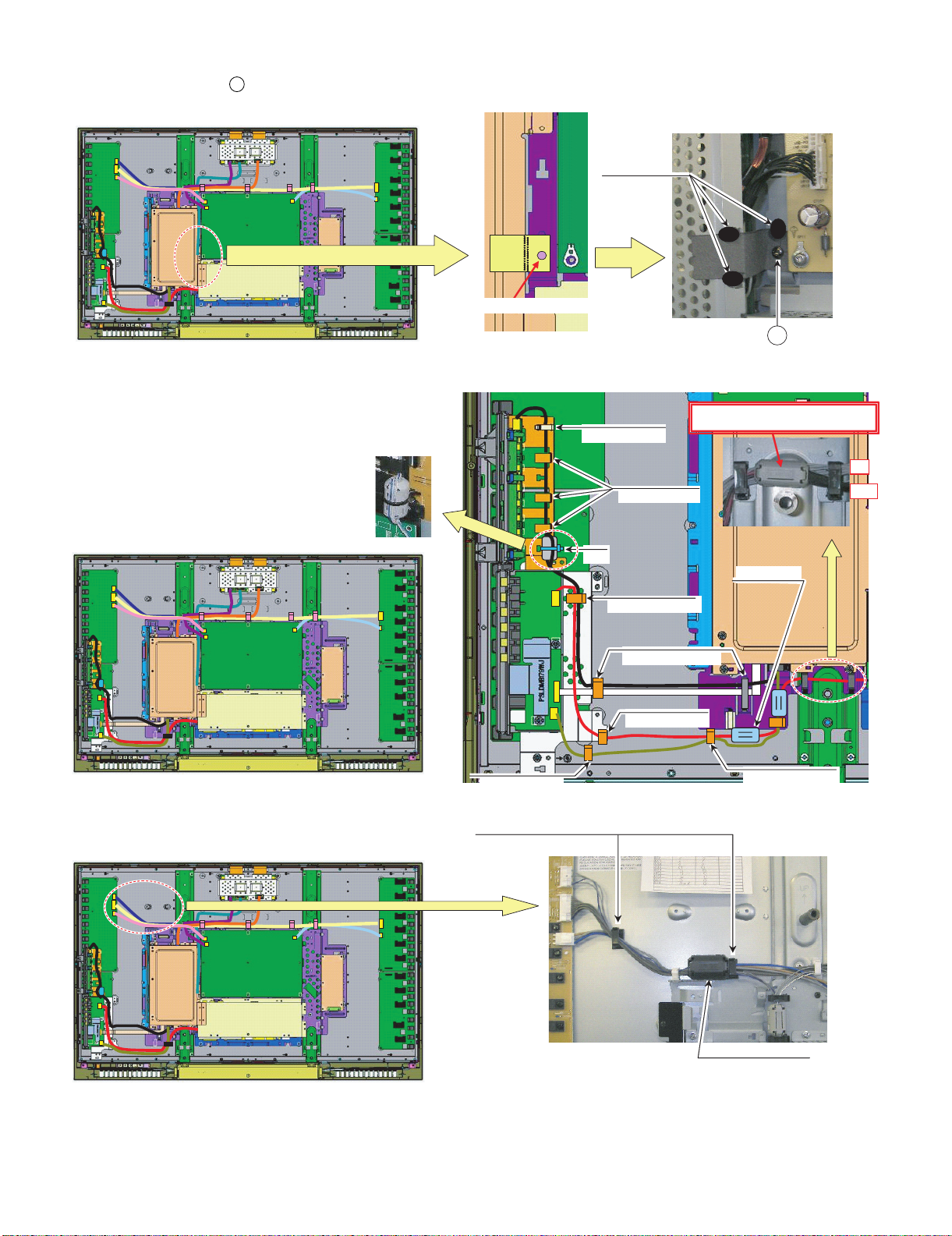

PNL SUPPORT ANG

12.Remove the 1 lock screw , and the 11 lock screws . Detach the Chassis Tray and MINI AV Sub Ass’y.

10

11

11

13.Remove the 14 lock screws . and detach the Panel Support Angle.

12

10

LCD MODULE

1212

2 – 8

Page 26

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

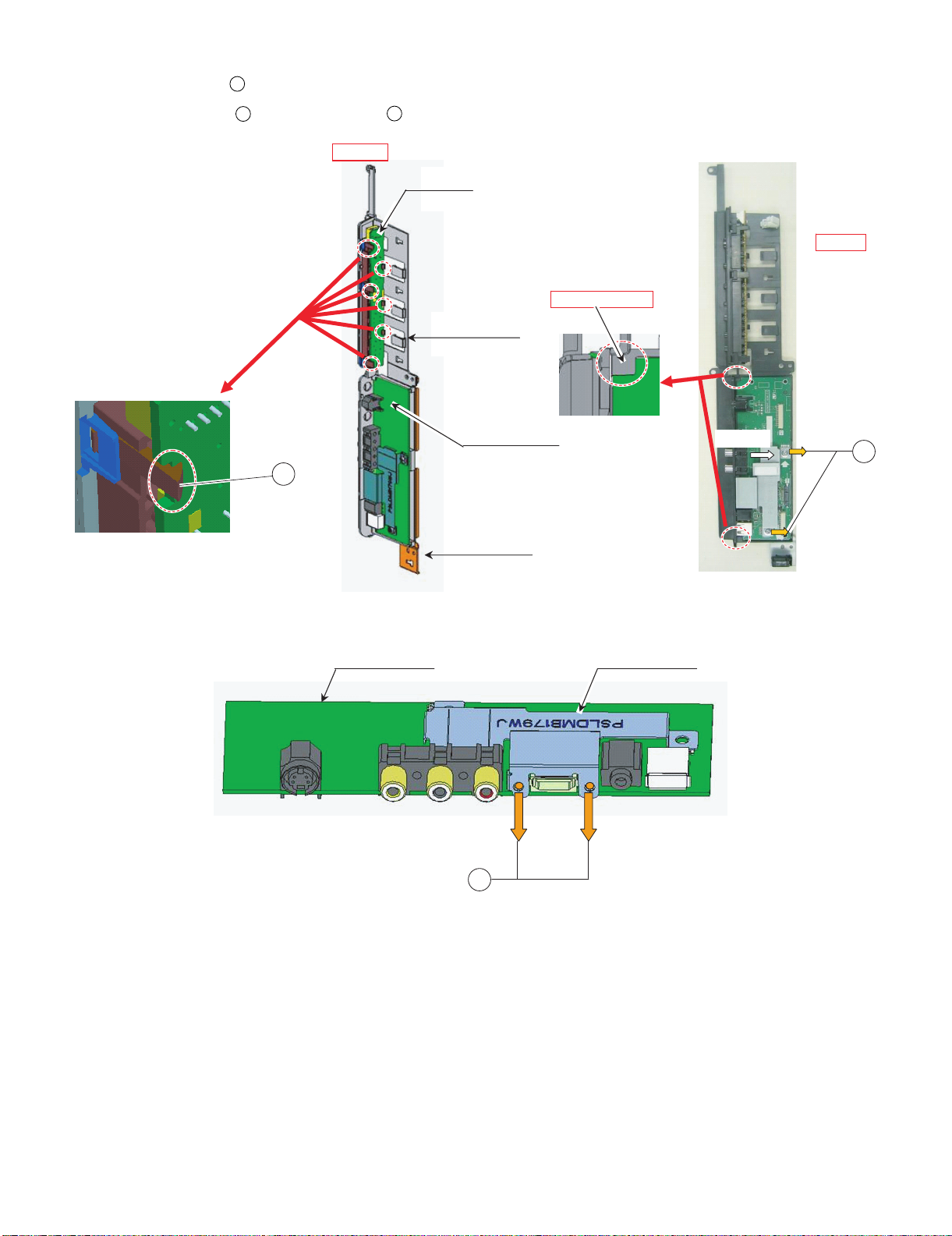

M-AV KEY COV

KEY PWB

Slant View

Top View

#Set PWB under LIB

Open side

14.Remove the 6 lock hooks . and detach the KEY Unit.

15.Remove the 2 lock screws , and the 2 lock screws . Detach the MINI AV Unit.

13

14

15

MINI AV PWB

13

14

MINI AV PWB

MINI AV ANG

MINI-AV SHIELD

15

2 – 9

Page 27

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

Open Side

Pull out Wire "LW" form Opening

Wire "LW"

16.Remove all the connectors from PWBs.

17.Remove the 10 lock screws . and detach the Main Shield and AV Shield.

16

Wire "LW" to WH

16

MAIN SHIELD

AV SHIELD

2 – 10

Page 28

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

B to B connection

Pull same time

#SCART Angle Stepping on terminal

18.Remove all the connectors from PWBs.

19.Remove the 2 lock screws , and the 1 lock screw . Detach the Terminal Angle Bottom.

17

18

18 17

TML ANG BTM

SCART ANGLE

2 – 11

Page 29

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

Wire "LW"

wire LB

To Main PWB

To LCD Control PWB

Taping

Wire "VD","SP_R" to WH

Wire "HM" to WH

20.Remove all the connectors from PWBs.

Wire "LW"

Wire "RA","US","KM" to WH

Upper side wire SP_R

Wire "RA","US","KM","VD" to WH

2 – 12

Page 30

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

Wire "LA1"

Wire "LB","PL" to WH

Wire "LB"

Wire "PL" to WH

Wire "PL" to WH

Wire "LB" to this WH

Wire ”PL”

2 – 13

Page 31

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

[2] REMOVING OF MAJOR PARTS (LC-46XL2E/S/RU)

1. Remove the 2 lock screws , 6 lock screws and the 8 lock screws . Detach the Rear Cabinet.

1

2

3

3

REAR CABNET

2 1

2 – 14

Page 32

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

2. Remove all the connectors from PWBs.

Wire "SP"

Wire "SP" to WH

Wire "SP" to PIN

3. Remove the 2 lock screws . and detach the Speaker L/R.

4

Wire "SP"

Wire "SP" to WH

4

Speaker R Speaker L

2 – 15

Page 33

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

Wire "RA"

from OBON

Wire "IL"

Wire

R/C, LED PWB Front side

LED PWB Back side

(3-3)Pull out Wire "IL","RA" from bottom

(3-1) Set R/C, LED PWB Under LIB

(3-2) Push PWB hooked

#Set PWB to gide lib surely

4. Remove all the connectors from PWBs.

R/C, LED PWB

(with wire)

Wire "RA" to WH

Wire "IL"

from Illumination

5. Remove the R/C, LED Unit.

R/C, LED PWB

2 – 16

Page 34

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

6. Remove the 8 lock screws , and the 6 lock hooks . Detach the LCD Panel Module.

LCD PANEL MODULE

5

6

5

LCD PANEL MODULE

6

FRONT CABINET

2 – 17

Page 35

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

BOTTOM COVER

FRONT CABINET

Wire "IL"

#Hook Surely

#Connector side Down

#Wire "IL" pass between SP Boss

and Panel hooker

Wire "IL" Connection Direction

7. Remove the 2 lock screws . and detach the Bottom Cover.

7

8. Remove all the connectors from PWBs.

7

Illumination Unit

Wire "IL" to rib

FRONT CABINET

Wire "IL"

To Illumination UnitTo R/C, LED PWB

2 – 18

Page 36

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

FFC "HM" to WH

Wire "KM" to Hook

Wire "LC", "LA1" to WH

9. Remove the Illumination Unit.

10.Remove the 4 lock screws . and detach the CTL SHIELD with RADIATOR.

CTL-SHIELD with RADIATOR

8

11.Remove all the connectors from PWBs.

Wire "LC", "LA2", "LB" to WH

Wire "LW", "PL" to WH

8

Wire "LC" to WH

Wire "KM" to WH

Wire "LB"

Wire "LA2"

Wire "KM"

Wire "KM", "VD", "US" to WH

Wire "LW"

Wire "LP"

Wire "LA1"

Wire "VD"

FFC "HM"

Wire "US"

2 – 19

Page 37

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

Wire "LC "

PNL SUPPORT ANG

Wire "LC"

12.Remove the 1 lock screw , and the 12 lock screws . Detach the Chassis Tray and MINI AV Sub Ass’y.

MINI AV SUB ASSY

9

CHASSIS TRAY

10

9

10

13.Remove the 14 lock screws . and detach the Panel Support Angle.

LCD MODULE

11

11

2 – 20

Page 38

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

M-AV KEY COV

Slant View

Top View

#Set PWB under LIB

14.Remove the 6 lock hooks . and detach the KEY Unit.

15.Remove the 2 lock screws , and the 2 lock screws . Detach the MINI AV Unit.

12

13 14

KEY PWB

MINI AV PWB

12

MINI AV ANG

13

MINI AV PWB

MINI-AV SHIELD

14

2 – 21

Page 39

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

Open Side

Wire "LW"

Pull out Wire "LW" form Opening

16.Remove all the connectors from PWBs.

17.Remove the 10 lock screws . and detach the Main Shield and AV Shield.

15

Wire "LW" to WH

15

MAIN SHIELD

AV SHIELD

2 – 22

Page 40

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

B to B connection

Pull same time

#SCART Angle Stepping on terminal

18.Remove all the connectors from PWBs.

19.Remove the 2 lock screws , and the 1 lock screw . Detach the Terminal Angle Bottom.

TML ANG BTM

16 17

1716

SCART ANGLE

2 – 23

Page 41

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

Wire "VD" to WH

Wire "KM"

#Shape Wire "US"

like this

Wire "RA","US","KM" to WH

Wire "VD"

Wire "RA"

#Don't make mistake Wire "VD" and "RA"

Wire "LW"

Wire "HM"

Wire

Wire "US"

Wire

Wire "VD"

Wire

Wire "RA"

Wire "LW"

To Main PWB

To LED PWB

To Main PWB

To LCD Control PWB

Wire "LA1"

Wire "LA1"

#No shape Wire "LA1" to WH

20.Remove all the connectors from PWBs.

Wire "US"

Wire "LW"

Wire "HM"

Wire "HM" to WH

Wire "RA","US","KM","VD" to WH

2 – 24

Page 42

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

Wire "LB"

Wire "LB","PL" to WH

Wire "PL"

Wire "LA2"

Wire "LB"

Wire "PL"

Wire "LA2","PL" to WH

Wire "LA2","LB" to WH

Wire "LA2"

2 – 25

Page 43

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

[3] REMOVING OF MAJOR PARTS (LC-46X20E/S/RU)

1. Remove the 1 lock screw , 2 lock screws , 6 lock screws and the 7 lock screws . Detach the Rear Cabinet.

1

2

3

4

4 1

REAR CABINET

23

2 – 26

Page 44

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

Wire "SP" to WH

Wire "SP"

2. Remove all the connectors from PWBs.

Wire "SP" to WH

Wire "SP" to PIN

Wire "SP"

3. Remove the 2 lock screws . and detach the Speaker L/R.

5

5

Speaker R Speaker L

2 – 27

Page 45

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

#Fit CONDUCTIVE Tape hole to SCREW hole

#For EMC

Set Wire "VD" under Wire "SP-R" (with core)

VD

SP-R

for Wire "VD"

Wire "HM","KM" to WH

Wire "US","VD" to WH

Wire "US" to WH

Wire "VD" to WH

Wire "VD","KM to WH

Wire "KM to WH

Wire "KM" to Hook

WH

4. Remove the 1 lock screw .

6

5. Remove all the connectors from PWBs.

SILICON BOND

6

Wire "LA2","LB","LC" to WH

for Wire "LA2","LB","LC"

2 – 28

Page 46

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

Wire "LC", "LA1" to WH

Wire "LC" to WH

#For EMC

Set Wire "LW" under other wires

Wire "FR" to WH

Wire "LB"

Wire "LA2"

for Wire "KM"

#Wind Wire "KM" one time to core

Set taping to core inside.

To Main PWB

To Key PWB

Wind wire "KM" one

time to core.

#For EMC,Set Wire "LW" under other wires.

Wire "LW" to WH

Wire "LC","PL","FR" to WH

Wire "PL"

Wire "LW"

Wire "LW" to WH

Wire "LC","FR" to WH

Wire "FR"

Wire "KM"

Wire "VD"

FFC "HM"

Wire "US"

Wire "LA1"

2 – 29

Page 47

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

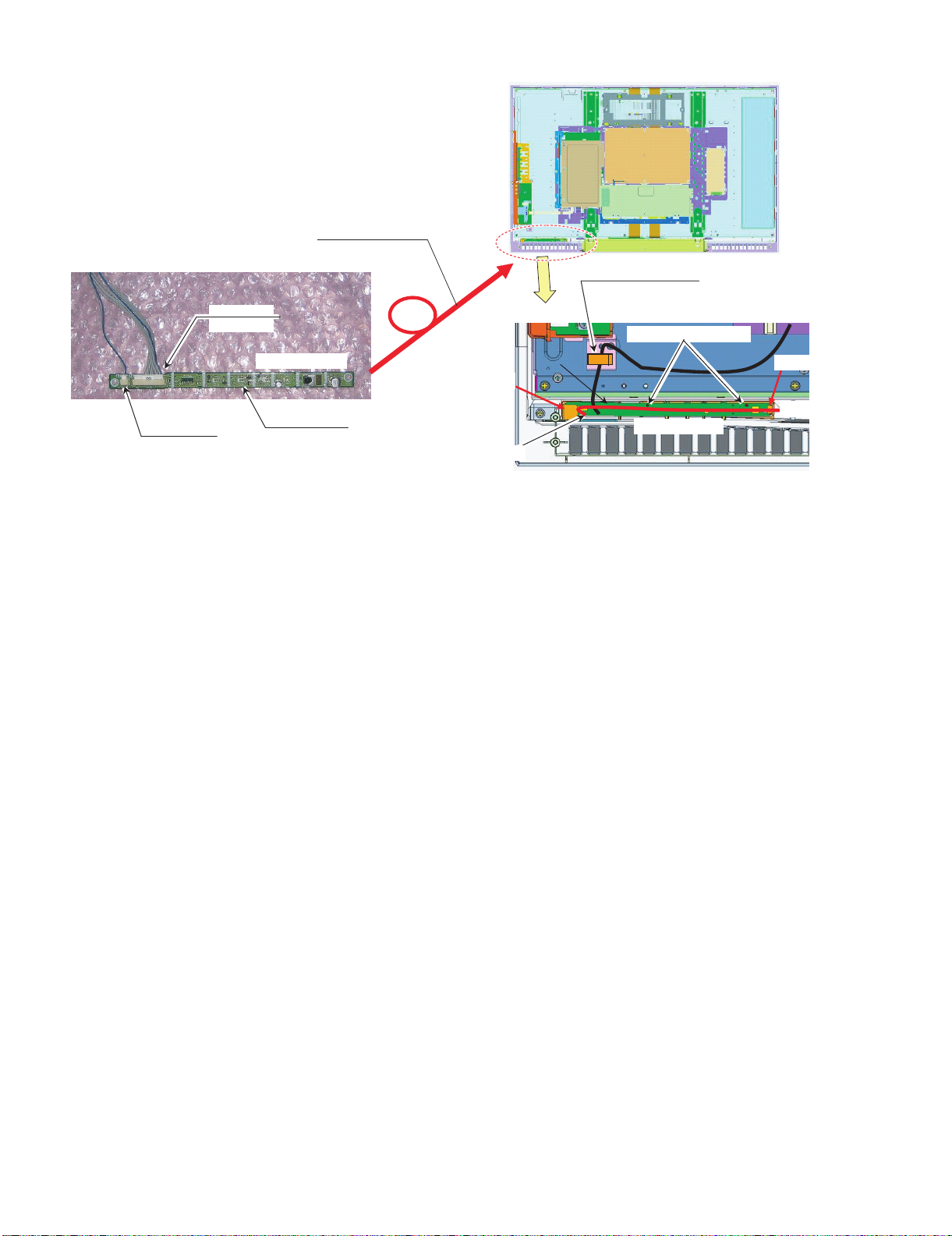

Wire "RA"

R/C, LED PWBFront side

LED PWB Back side

Pull out Wire "RA" from bottom

1st,Set R/C, LED PWB Under LIB

Next,Push PWB hooked

#Set PWB to gide lib surely

Set Wire "RA" to

panel hollow.

Wire "RA"

from OBON

6. Remove the R/C, LED Unit.

R/C, LED PWB

(with wire)

R/C, LED PWB

Wire "RA" to WH

7. Remove the 4 lock screws . and detach the CTL SHIELD.

7

7

2 – 30

Page 48

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

Wire "LC"

PNL SUPPORT ANG

Wire "LC"

8. Remove the 1 lock screw , and the 11 lock screws . Detach the Chassis Tray and MINI AV Sub Ass’y.

MINI AV SUB ASSY

8

CHASSIS TRAY

9

8

9

9. Remove the 14 lock screws . and detach the Panel Support Angle.

10

10

2 – 31

Page 49

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

Wire "LC"

10.Remove the 8 lock screws , and the 6 lock hooks . Detach the LCD Panel Module.

11

12

11

LCD MODULE

12

2 – 32

Page 50

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

FRONT CABINET

BOTTOM COVER

Top View

#Set PWB under LIB

11.Remove the 1 lock screw . and detach the Bottom Cover.

13

13

12.Remove the 6 lock hooks . and detach the KEY Unit.

13.Remove the 2 lock screws , and the 2 lock screws . Detach the MINI AV Unit.

14

15

16

KEY PWB

KEY Button with PWB

M-AV KEY COV

MINI AV PWB

14

MINI AV ANG

MINI AV PWB

15

MINI-AV SHIELD

16

2 – 33

Page 51

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

Wire "LW"

Pull out Wire "LW" form Opening

Wire "LW"

14.Remove all the connectors from PWBs.

15.Remove the 10 lock screws . and detach the Main Shield and AV Shield.

17

Wire "LW" to WH

17

MAIN SHIELD

AV SHIELD

2 – 34

Page 52

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

B to B connection

Pull same time

#SCART Angle Stepping on terminal

16.Remove all the connectors from PWBs.

17.Remove the 2 lock screws , and the 1 lock screw . Detach the Terminal Angle Bottom.

18

19

18 19

TML ANG BTM

SCART ANGLE

2 – 35

Page 53

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

Wire"VD"toWH

Wire "KM"

Wire "KM,"HM" to WH

Wire "RA","US","KM" to WH

Wire "RA"

#Don't make mistake Wire "VD" and "RA"

Wire "LW"

Wire "HM"

Wire

Wire "US"

Wire

Wire "VD"

Wire

for Wire "FR","LB"

Wire "SP-R"

#Set at SRC

Core for "SP-R"

#Set at SRC

VD

SP-R

Wire "RA"

Wire "LW"

To Main PWB

To LED PWB

To Main PWB

To LCD Control PWB

Wire "LA1"

#No Shape/Lock Wire "LA1" to WH

18.Remove all the connectors from PWBs.

Wire "HM"

Wire "RA","US","VD" to WH

Wire "US"

Wire "LW"

Wire "VD"

Wire "LA1"

2 – 36

Page 54

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

Wire "LA2"

Wire "PL"

Wire "LB"

Wire "LA2"

Wire "PL"

Wire "FR"

Wire "LB","FR" to WH

Wire "PL","LA2" to WH

for Wire "FR","LB"

Wire "FR"

Wire "LB"

2 – 37

Page 55

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

[4] REMOVING OF MAJOR PARTS (LC-52XL2E/S/RU)

1. Remove the 2 lock screws , 7 lock screws and the 8 lock screws . Detach the Rear Cabinet.

1

2

3

3

Rear Cabinet

2

1

2 – 38

Page 56

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

Wire "SP"

Wire "SP" to WH

Wire "SP" to PIN

2. Remove all the connectors from PWBs.

Wire "SP"

Wire "SP" to WH

3. Remove the 2 lock screws . and detach the Speaker L/R.

4

4

Speaker R

Speaker L

2 – 39

Page 57

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

Wire "RA"

from OBON

R/C, LED PWB Front side

Wire "RA"

R/C, LED PWB Back side

Pull out Wire "RA" from bottom

Set R/C, LED PWB Under LIB

Next,Push PWB hooked

#Set PWB to gide lib surely

Wire "IL"

#Please let the IL wire go

through over R/C, LED PWB.

#Hook Surely

#Connector side Down

#Wire "IL" pass between SP Boss

and Panel hooker

R/C, LED PWB side

Illumination Unit side

Wire "IL"

Wire "IL"

Lib

Lib

4. Remove all the connectors from PWBs.

R/C, LED PWB

(with wire)

Wire "RA" to WH

Wire "IL"

Wire "IL"

from Illumination

R/C, LED PWB

Wire "IL" to rib

FRONT CABINET

Illumination Unit

Wire "IL"

5. Remove the R/C, LED Unit and Illumination Unit.

2 – 40

Page 58

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

6. Remove the 8 lock screws , and the 6 lock hooks . Detach the LCD Panel Module.

5

LCD PANEL MODULE

6

5

LCD PANEL MODULE

6

FRONT CABINET

2 – 41

Page 59

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

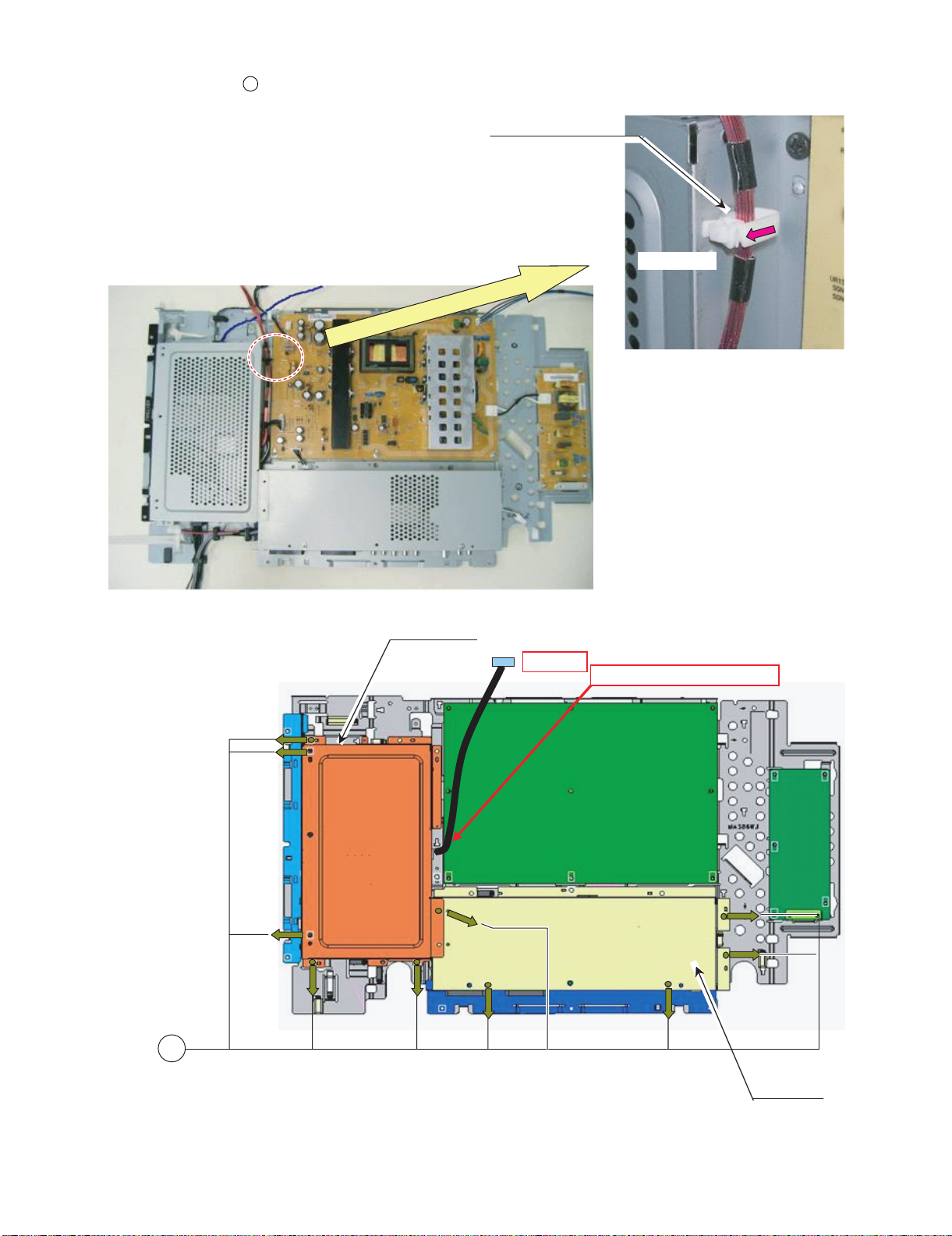

CTL Shield Sub Ass'y

7. Remove the 2 lock screws . and detach the Bottom Cover.

FRONT CABINET

7

Bottom Cover

8. Remove the 4 lock screws . and detach the CTL SHIELD with RADIATOR.

8

7

8

2 – 42

Page 60

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

Wire "LC", "LA2", "LB" to WH

Wire "LC" to WH

Wire "LC", "LA1" to WH

FFC "HM" to WH

Wire "KM", "VD", "US" to WH

Wire "RA", "KM", "VD", "US" to

Wire "FR"

Wire "LW"

9. Remove all the connectors from PWBs.

Wire "KM" to Hook

Wire "KM" to WH

Wire "SP" to WH

Wire "LB"

Wire "LA2"

Wire "KM"

Wire "VD"

FFC "HM"

Wire "US"

Wire "LA1"

2 – 43

Page 61

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

10.Remove the 1 lock screw , and the 12 lock screws . Detach the Chassis Tray and MINI AV Sub Ass’y.

MINI-AV SUB ASSY

9

10

10

CHASSIS TRAY

9

11.Remove the 14 lock screws . and detach the Panel Support Angle.

LCD PANEL MODULE

11

11

PNL SUPPORT ANG

2 – 44

Page 62

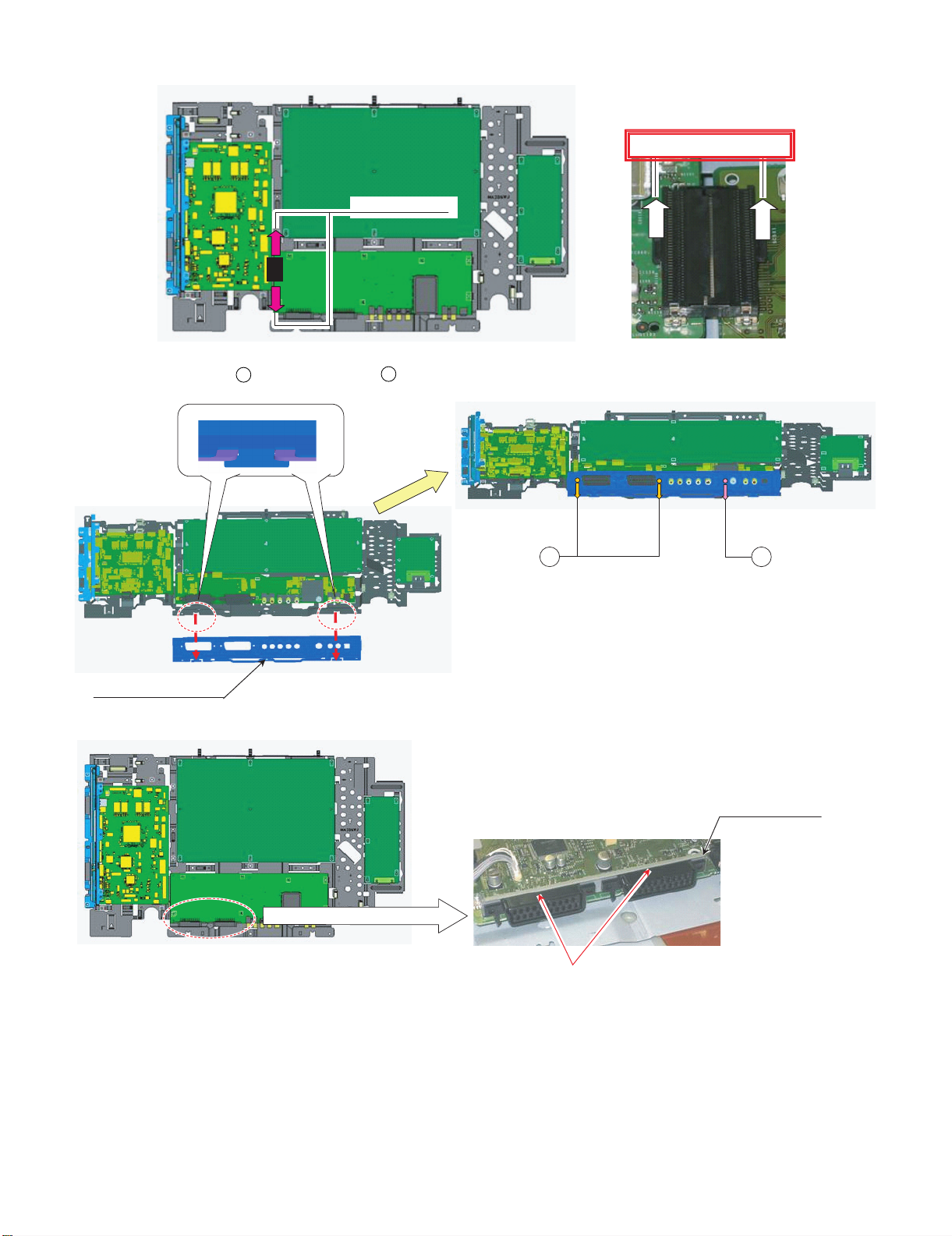

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

M-AV KEY COV

Slant View

Top View

#Set PWB under LIB

12.Remove the 6 lock hooks . and detach the KEY Unit.

13.Remove the 2 lock screws , and the 2 lock screws . Detach the MINI AV Unit.

12

13 14

KEY PWB

MINI AV PWB

MINI AV ANG

13

12

MINI AV PWB

MINI-AV SHIELD

14

2 – 45

Page 63

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

Open Side

Wire "LW"

Pull out Wire "LW" form Opening

14.Remove all the connectors from PWBs.

15.Remove the 8 lock screws , and the 2 lock screws . Detach the Main Shield and AV Shield.

15

16

Wire "LV" to WH

16

15

MAIN SHIELD

AV SHIELD

2 – 46

Page 64

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

B to B connection

Pull same time

#SCART Angle Stepping on terminal

16.Remove all the connectors from PWBs.

17.Remove the 2 lock screws , and the 1 lock screw . Detach the Terminal Angle Bottom.

17

18

17 18

TML ANG BTM

SCART ANGLE

2 – 47

Page 65

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

Wire "VD","SP" to WH

Wire "RA","US","KM" to WH

Wire "RA","US","KM","VD" to WH

Wire "HM" to WH

Main

PWB side

LCD Controler

side

#Shape Wire "US"

like this

Wire "VD"

Wire "RA"

Main

PWB side

LED

PWB side

Wire "RA"

#Don't make mistake Wire "VD" and "RA"

Wire "RA"

Wire "VD"

18.Remove all the connectors from PWBs.

Wire "LW"

Wire "US"

Wire "HM"

Wire "KM"

2 – 48

Page 66

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

Wire "LA1"

Wire "FR"

Wire "LB"

Wire "LB","FR" to WH

Wire "LA2","LB" to WH

Wire "LA2","FR" to WH

Wire "LB","FR" to WH

Wire "LA2"

2 – 49

Page 67

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

[5] REMOVING OF MAJOR PARTS (LC-52X20E/S/RU)

1. Remove the 1 lock screw , 2 lock screws , 7 lock screws and the 7 lock screws . Detach the Rear Cabinet.

1

2

3

4

3 4

Rear Cabinet

2

1

2 – 50

Page 68

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

Wire "SP"

Wire "SP" to WH

Wire "SP"

Wire "SP" to WH

Wire "SP" to PIN

2. Remove all the connectors from PWBs.

3. Remove the 2 lock screws . and detach the Speaker L/R.

5

5

Speaker R

Speaker L

2 – 51

Page 69

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

Wire "RA"

from OBON

Wire "RA"

R/C, LED PWB Front side

R/C, LED PWB Back side

Pull out Wire "RA" from bottom

Set R/C, LED PWB Under LIB

R/C, LED PWB

(with wire)

Next,Push PWB hooked

#Set PWB to gide lib surely

4. Remove all the connectors from PWBs.

R/C, LED PWB

Wire "RA" to WH

5. Remove the R/C, LED Unit.

2 – 52

Page 70

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

6. Remove the 8 lock screws , and the 6 lock hooks . Detach the LCD Panel Module.

6

LCD PANEL MODULE

7

6

LCD PANEL MODULE

7

FRONT CABINET

2 – 53

Page 71

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

CTL Shield

7. Remove the 1 lock screw . and detach the Bottom Cover.

FRONT CABINET

8

Bottom Cover

8. Remove the 4 lock screws . and detach the CTL SHIELD.

9

8

9

2 – 54

Page 72

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

Wire "LA1"

Wire "LC"

Wire "LA1"

Wire "SP-L"

Wire "SP" to WH

Wire "LA1","LC" to WH

Wire "LC" to WH

Wire "LA2","LB","LC" to WH

Wire "LA2","LB","LC" to WH

Wire "LC"

Wire "FR"

Wire "PL"

Wire "LA2"

Wire "LB"

Wire "LA2"

for Wire "LB","LA2","LC"

9. Remove all the connectors from PWBs.

2 – 55

Page 73

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

Wire "LW" to WH

Wire "PL", "LC" to WH

Wire "PL" to WH

Wire "LC"

Wire "FR"

Wire "LW"

Wire "PL"

#Please arrange wire"LW"

below than wire"PL",w ire"LC"

and wire"FR".

#Please arrange wire"LW" below than

wire"PL".

Wire "KM"

#Please pull it to the

direction of the arrow .

#Please put it through

the hole.

#Please lock it to become

it beside a core.

Wire "KM" to WH

Wire "KM" to Hook

Wire "KM" to WH

Wire "KM"

Wire "RA"

Wire "VD","KM" to WH

Wire "HM","KM" to WH

Wire " VD" to WH

Wire "HM"

Wire "FR", "PL", "LC" to WH

Wire "FR", "PL", "LC" to WH

Wire "KM"

Wire "FR"

Wire "LW"

Wire "PL"

Wire "VD"

Wire "US"

VD

HM

US

Wire " US" to WH

Wire " VD","US" to W H

forWire "VD"

2 – 56

Page 74

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

Silicone Bond

10.Remove all the connectors from PWBs.

11.Remove the 1 lock screw .

12.Remove the 1 lock screw , and the 12 lock screws . Detach the Chassis Tray and MINI AV Sub Ass’y.

10

11

12

10

MINI-AV SUB ASSY

12

CHASSIS TRAY

11

2 – 57

Page 75

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

13.Remove the 14 lock screws . and detach the Panel Support Angle.

LCD PANEL MODULE

13

13

PNL SUPPORT ANG

2 – 58

Page 76

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

Slant View

Top View

#Set PWB under LIB

14.Remove the 6 lock hooks . and detach the KEY Unit.

15.Remove the 2 lock screws , and the 2 lock screws . Detach the MINI AV Unit.

14

15

16

KEY PWB

MINI AV PWB

15

14

MINI AV ANG

MINI AV PWB

MINI-AV SHIELD

16

2 – 59

Page 77

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

Wire "LW"

Wire "LW"

Pull out Wire "LW" form Opening

16.Remove the 8 lock screws , and the 2 lock screws . Detach the Main Shield and AV Shield.

17 18

Wire "LW" to WH

18

17

MAIN SHIELD

AV SHIELD

2 – 60

Page 78

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

B to B connection

Pull same time

#SCART Angle Stepping on terminal

17.Remove all the connectors from PWBs.

18.Remove the 2 lock screws , and the 1 lock screw . Detach the Terminal Angle Bottom.

19

20

19 20

TML ANG BTM

SCART ANGLE

2 – 61

Page 79

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

Wire "PL"

Wire "LB"

Wire "LB","FR" to WH

Wire "FR"

Wire "LW"

Lock it in this range.

Wire "US" to WH

Main

PWB side

LCD Controler

side

Wire "VD","SP" to WH

Wire "HM","KM" to WH

Wire "RA","US","KM" to WH

Wire "KM","HM" to WH

19.Remove all the connectors from PWBs.

Wire "LA2","LB" to WH

Wire "LB","FR" to WH

for Wire "FR","LB"

Wire "LA2","PL" to WH

Wire "LA2"

Wire "RA","US","VD" to WH

Wire "LW"

2 – 62

Page 80

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

for Wire "US","RA"

Wire "VD"

Wire "RA"

Main

PWB side

LED

PWB side

Wire "RA"

#Don't make mistake Wire "VD" and "RA"

Wire "VD"

Wire "RA"

Wire "US"

Wire "HM"

Wire "KM"

Wire "LA1"

2 – 63

Page 81

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

LC42XL2E

CHAPTER 3. ADJUSTMENT PROCEDURE

Service Manual

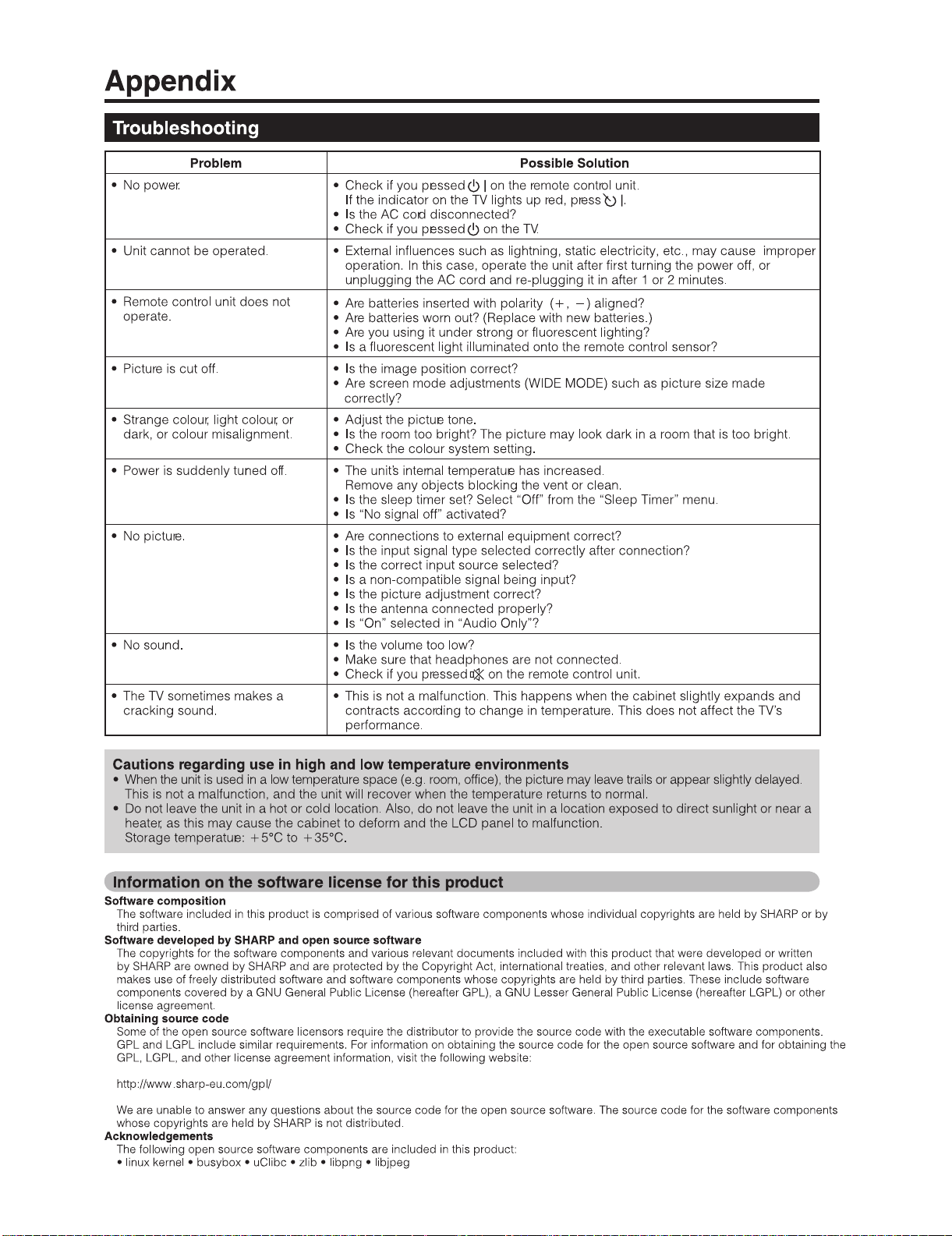

[1] ADJUSTMENT PROCEDURE

1. Adjustment method after PWB and/or IC replacement due to repair

The unit is set to the optimum at the time of shipment from the factory. If any value should become improper or any adjustment is necessary due to

the part replacement, make an adjustment according to the following procedure.

1. Procure the following units in order to replace the main unit, IC3301, IC8101, IC3501, IC3502, IC8301, IC8302, IC8303, or IC8304.

MAIN UNIT: DUNTKE186FM01 (LC-42/46/52XL2E)

DUNTKE186FM02 (LC-46/52XL20E)

NOTE: [Caution when replacing ICs in the main unit (IC1501/IC1502/IC1503/IC2002) or the mini av unit (IC802)]

The above ICs are EEPROMs storing the EDID data of HDMI and the monitor microcomputer. Before replacing the relevant part, procure the

following parts in which the data have been rewritten.

IC2002 RH-IXB986WJN8Q Monitor microcomputer

IC802 RH-IXC284WJQZS HDMI_EXT4

IC1501 RH-IXC285WJQZS HDMI_EXT5

IC1502 RH-IXC286WJQZS HDMI_EXT6

IC1503 RH-IXC287WJQZS RGB (PC)_EXT7

2. After replacing the LCD panel or LCD control PWB, check PANEL_SIZE in the following procedure.

1) Enter the process adjustment mode.

2) Use the cursor keys / and P / of R/C to select the item [PANEL_SIZE] on the page 33/33.

3) Verify that the panel size is displayed.

4) If the size doesn't match, select the values of the panel size with the Vol / keys.

5) After selection in Step 4), press the OK key, and it is completed with OK displayed.

3. After replacing the LCD panel or LCD control PWB, adjust the VCOM in the following procedure.

1) Enter the process adjustment mode.

2) Use the cursor keys / and P / of R/C to select the item [VCOM ADJ] on the page 10/33.

3) Press the OK key to verify that the adjustment pattern is displayed.

4) Use the +/- keys of VOL of L/C to adjust the flicker in the center of the screen to minimum.

5) When the optimal state is achieved in Step 4, press the OK key to turn the pattern to OFF.

4. After replacing LCD panel or LCD control PWB, perform the up/down brightness difference adjustment in the following procedure. (Note: It is applicable to LC-42/46/52XL2E only.)

1) Enter the process adjustment mode.

2) Use the cursor keys / and P / of R/C to select the item [LCD_LUMA_ADJ] on the page 10/33.

3) Press the OK key to verify that the adjustment pattern (all gray) is displayed.

4) Use the VOL +/- keys of R/C to adjust the upper/lower brightness difference in the center of the screen to minimum.

5) When the optimal state is achieved in Step 4, press the OK key to turn the pattern to OFF.

NOTE: LCD LUMA UD ** ←The value at the ** part is changed.

LCD LUMA DOWN 0 (Note that the value is changed if the P / keys are pressed in Step 4 above.)

3 – 1

Page 82

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

2. Entering and exiting the adjustment process mode

1. Press the “POWER” key on the set of running TV set to force off the power.

2. While holding down the “VOL (-)” and “INPUT” keys on the set at once, plug in the AC power cord to turn on the power.

The letter “K” appears on the screen.

3. Next, hold down the “VOL (-)” and “P (V)” keys on the set at once.

Multiple lines of character string appearing on the screen indicate that the set is now in the adjustment Process mode. If you fail to enter the

adjustment process mode (the display is the same as normal startup), retry the procedure. (Another procedure)

4. Press the “MENU” key on the main unit to display OSD.

5. Move the cursor to SERVICE (OSD) using the cursor keys on the remote control.

Then press the “MENU” key on the remote control to enter the service mode (adjustment process mode).

6. To exit the adjustment process mode after the adjustment is done, unplug the AC power cord to force off the power. (When the power is turned off

with the remote controller, once unplug the AC power cord and plug it in again. In this case, wait 10 seconds or so before plugging.)

CAUTION: Use due care in handling the information described here lest the users should know how to enter the adjustment process mode. If the

settings are tampered with in this mode, unrecoverable system damage may result.

3. Remote controller key operation and description of display in adjustment process mode.

1. key operation

Remote controller key Main unit key Function

P ( / )

P ( / )

Moving an item (line) by one (UP/DOWN)

VOL (+/-) VOL (+/-) Changing a selected item setting (+1/-1)

Cursor (UP/DOWN) — Turning a page (PREVIOUS / NEXT)

Cursor (</>) — Changing a selected line setting (+10/-10)

INPUT SOURCE on

— Input source switching (toggle switching) (TV→EXT1~8)

remote controller

RETURN — Returning to a present page

OK — Executing a function

Input mode is switched automatically when relevant adjustment is started so far as the necessary input signal is available.

4. Description of display

(1) Page/ of present number of total pages (5) Inducing display

(2) Page present title (4) Present colour system (6) Model name

1/33 [INFO] INPUT1 AUTO ??? 46E_XL2

(3) Input that has been selected now

MAIN Version

BOOT Version

Monitor Version

FRC Version

CPLD Version

EQ DATA CHECKSUM

LAMP ERROR

MONITOR ERR CAUSE

NORMAL STANDBY CAUSE

ERROR STANDBY CAUSE

(7) Item name (8) Parameter

1.00 (E 2007/07/10 D)

1.0

a6

ROM

0

11 11 11 11

0

1) 0 2) 0 3) 0

0H 0M 0H 0M 0H 0M

4) 0 5) 0

0H 0M 0H 0M

No. Description Display specification

(1) Page/ of present number of total pages 2char/2char Decimal Number mark.

(2) Page present title It bundles it by Max. 15 char “[“ ”]”.

(3) Input that has been selected now TV/INPUT1/INPUT2/INPUT3/INPUT5/INPUT6/INPUT7/INPUT8

(4) Present colour system NTSC/PAL/SECAM/COMP15K/COMP33K/COMP45K/COMP28K/COMP31K

(5) Inducing display EUROPE/RUSSIA/SWEDEN

(6) Model name MODEL NAME

(7) Item name Max. 30 char

(8) Parameter Max. 60 char

3 – 2

Page 83

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

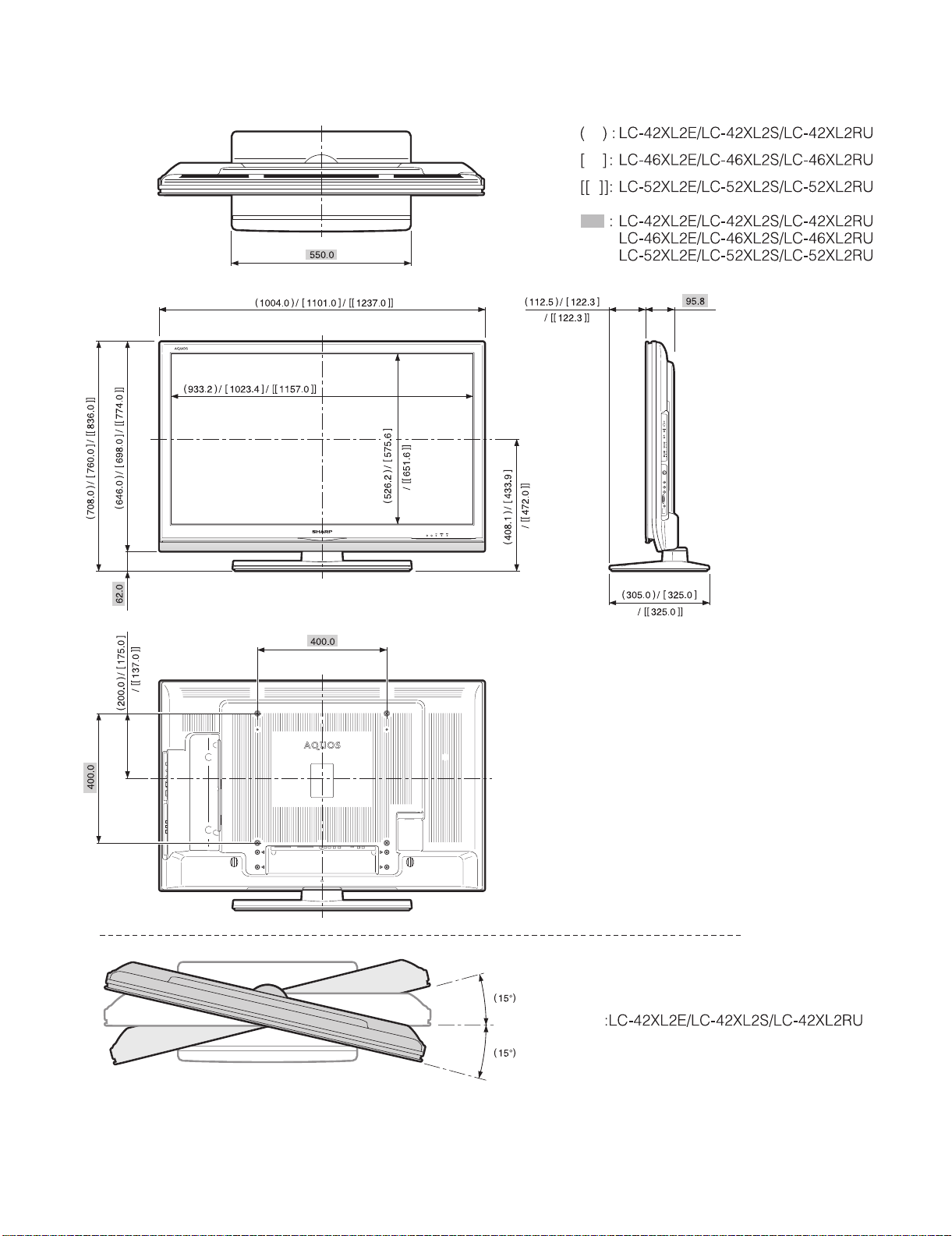

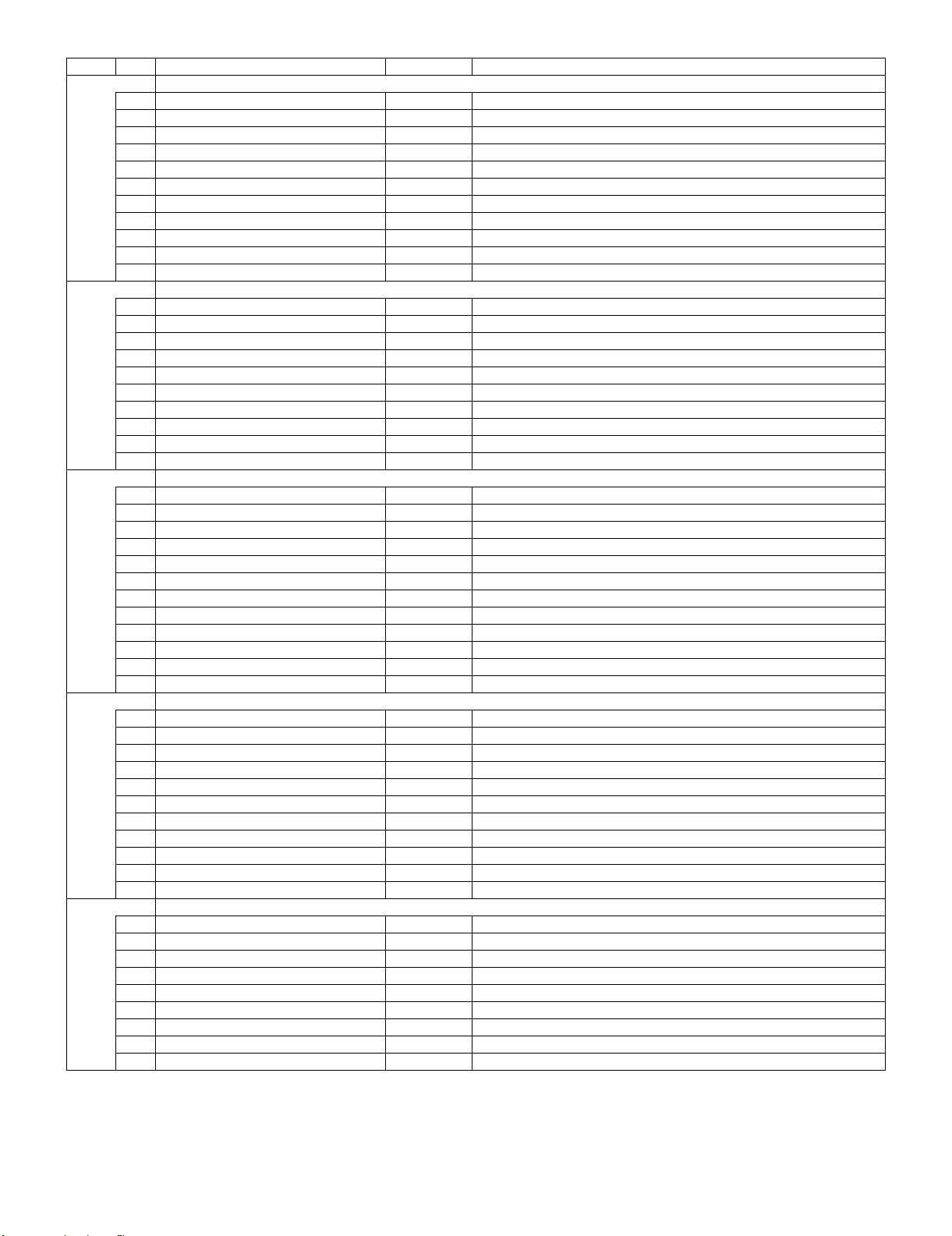

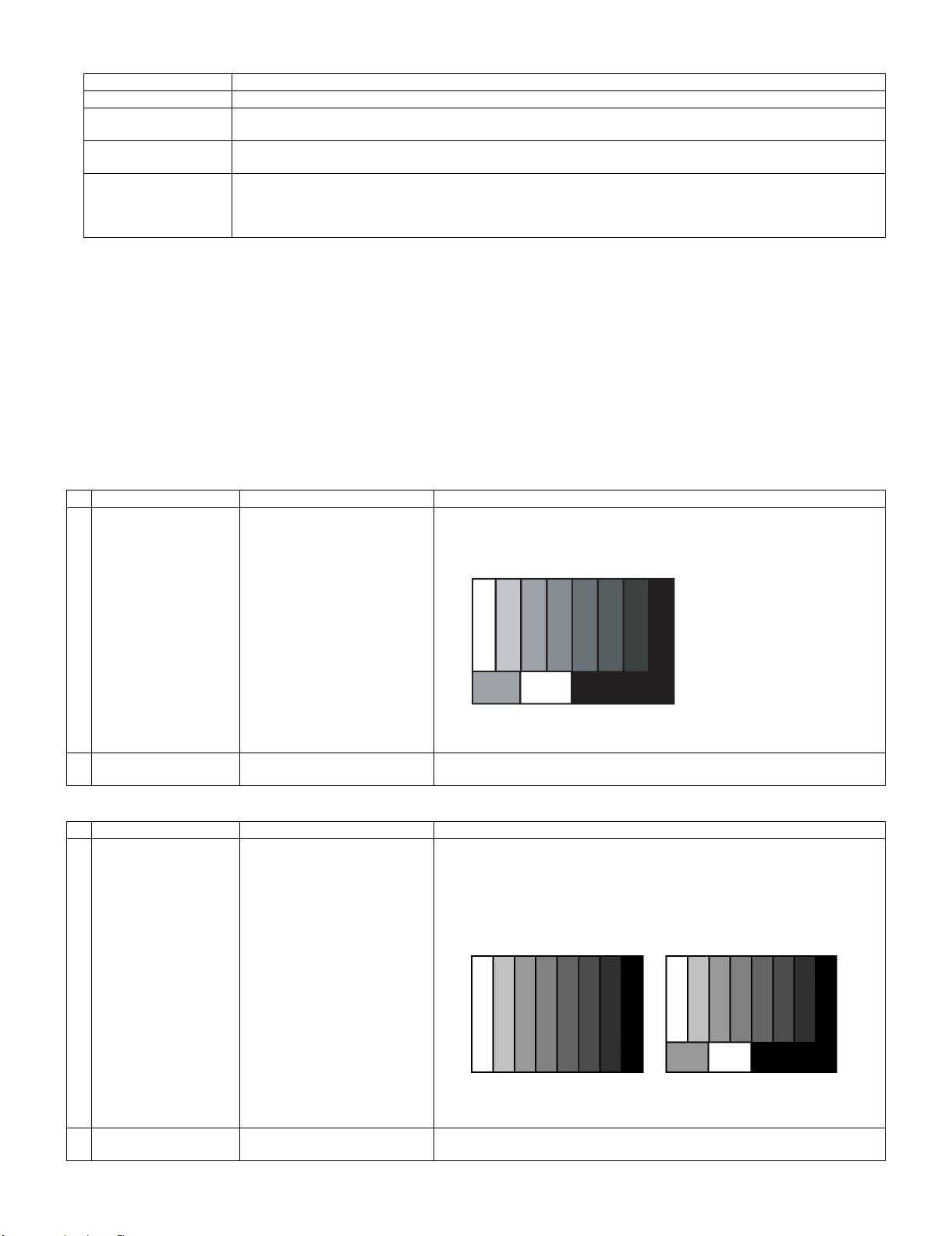

5. Adjustment process mode menu

The character string in brackets [ ] will appear as a page title in the adjustment process menu header.

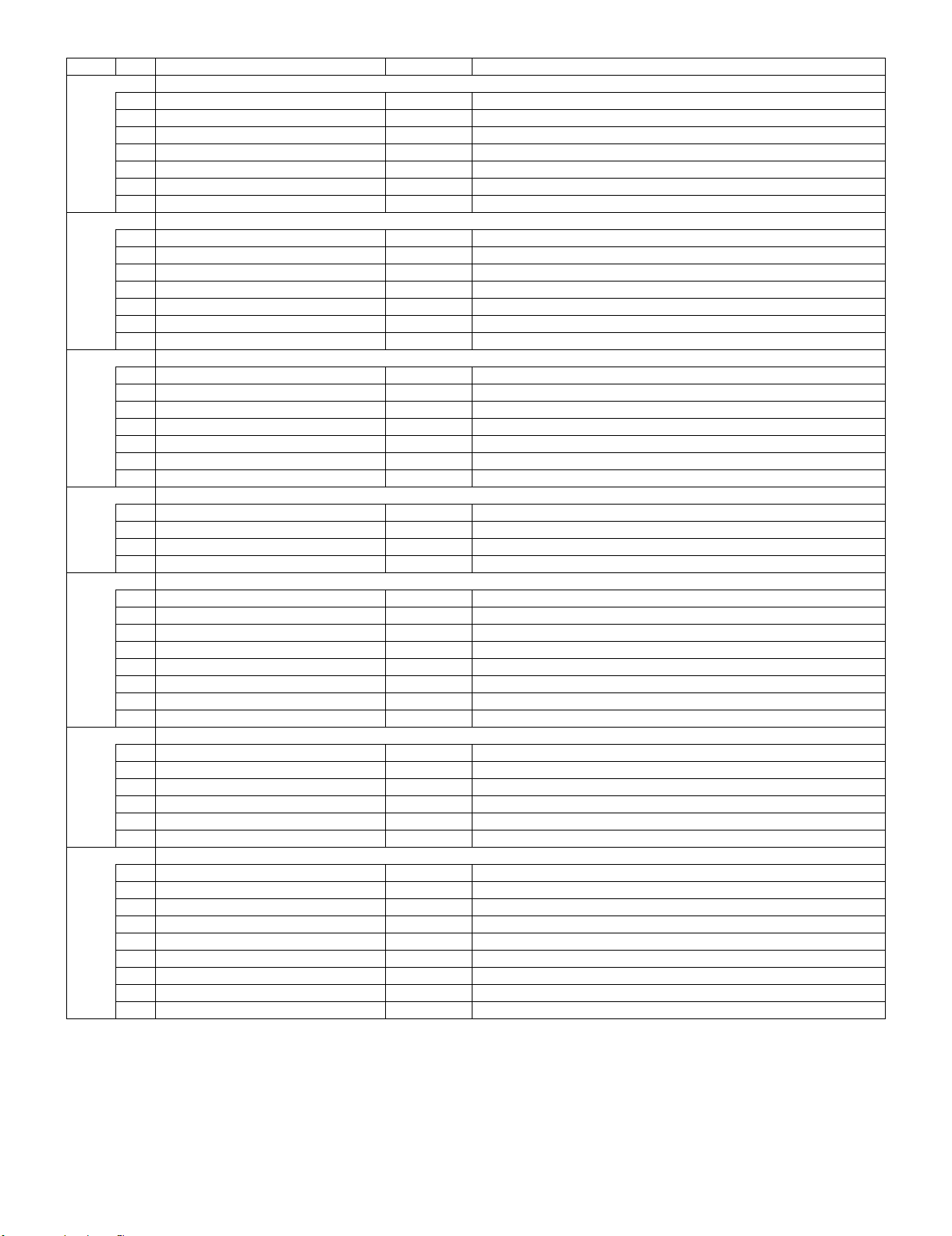

Page Line Item Description Remarks (adjustment detail, etc.)

1/33 [INFO]

1 MAIN Version Main software version

2 BOOT Version BOOT Version.

3 Monitor Version Monitor software version

4 FRC Version FRC Version

5 CPLD Version CPLD Version.

6 EQ DATA CHECKSUM Audio data checksum.

7 LAMP ERROR Number of termination due to lamp error.

8 MONITOR ERR CAUSE Last error standby cause.

9 NORMALSTANDBY CAUSE Situation that became standby at the end.

(Excluding the error)

10 ERROR STANDBY CAUSE [1] 00H 00M Error standby cause Total operating time before error.

[2] 00H 00M

[3] 00H 00M

[4] 00H 00M

[5] 00H 00M

2/33 [INIT]

1 INDUSTRY INIT Enter Initialization to factory settings execution.

2 INDUSTRY INIT(-Hotel) OFF Initialization to factory settings execution.

3 HOTEL MODE OFF Hotel mode setting execution.

4 Center Acutime 5H 0M Main operating hours.

5 RESET OFF Main operating hours reset.

6 Backlight Acutime 19H 35M Backlight operating hours.

7 RESET OFF Backlight operating hours reset.

8 LAMP ERROR RESET OFF Lamp error reset.

9 ADJ PARAM SET Enter ADJ PARAM SET

10 VIC XPOS 0 X-coordinate setting for VIC READ

11 VIC YPOS 0 Y-coordinate setting for VIC READ

12 VIC SIGNAL TYPE MAIN Signal type setting for VIC READ

13 VIC READ OFF Picture level acquisition function

3/33 [TUNER ADJ]

1 RF AGC ADJ Enter RF-AGC auto adjustment execution

2 TUNER ADJ Enter TUNER auto adjustment execution

3 PAL+TUNER ADJ Enter PAL TUNER auto adjustment execution

4 RF AGC ADJ(CA-8CH) Enter RF-AGC auto adjustment execution (CA-8CH)

5 TUNER ADJ(CA-8CH) Enter TUNER auto adjustment execution (CA-8CH)

6 PAL+TUNER ADJ(CA-8CH) Enter PAL TUNER auto adjustment execution (CA-8CH)

7 RF AGC 16 RF AGC adjustment

8 TUNER DAC 150 TUNER signal level adjustment

9RF AGC READ OFF

4/33 [PAL MAIN]

1 PAL ADJ Enter PAL adjustment

2 SECAM ADJ Enter SECAM adjustment

3 N358 ADJ Enter N358 adjustment

4 PAL CONTRAST 130 PAL contrast adjustment

5 SECAM CONTRAST 137 SECAM CONTRAST adjustment

6 N358 CONTRAST 120 N358 CONTRAST adjustment

5/33 [CEC TEST]

1 HDMI CEC TEST Enter CEC test

2 INSPECT USB TERM Enter

3 MONIDATA READ[TEMP/OPC] OFF MONITOR Temperature/ OPC Acquisition tool.

4 CAUSE RESET Enter

6/33 [COMP15KMAIN]

1 COMP15K ALL ADJ Enter Component 15K picture level adjustment

2 COMP15K MAIN Y GAIN 194 Y GAIN adjustment value

3 COMP15K MAIN CB GAIN 215 Cb GAIN adjustment value

4 COMP15K MAIN CR GAIN 212 Cr GAIN adjustment value

5 COMP15K Y OFFSET 66 Y OFFSET adjustment value

6 COMP15K CB OFFSET 512 Cb OFFSET adjustment value

7 COMP15K CR OFFSET 513 Cr OFFSET adjustment value

(Hotel mode is excluded)

(Level appears in green on the upper right)

3 – 3

Page 84

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

Page Line Item Description Remarks (adjustment detail, etc.)

7/33 [HDTV]

1 HDTV ADJ Enter HDTV video level adjustment

2 HDTV Y GAIN 195 HDTV Y GAIN adjustment value

3 HDTV CB GAIN 205 HDTV Cb adjustment value

4 HDTV CR GAIN 203 HDTV Cr adjustment value

5 HDTV Y OFFSET 65 HDTV Y OFFSET adjustment value

6 HDTV CB OFFSET 512 HDTV Cb OFFSET adjustment value

7 HDTV CR OFFSET 512 HDTV Cr OFFSET adjustment value

8/33 [ANALOG PC]

1 ANALOG PC ADJ Enter DVI ANALOG video level adjustment

2 R OFFSET 64 R CUTOFF adjustment value

3 G OFFSET 64 G CUTOFF adjustment value

4 B OFFSET 66 B CUTOFF adjustment value

5 R GAIN 193 R DRIVE adjustment value

6 G GAIN 189 G DRIVE adjustment value

7 B GAIN 194 B DRIVE adjustment value

9/33 [SCART]

1 SCART RGB ADJ Enter SCART RGB level adjustment

2 SCART R CUTOFF 65 SCART R CUTOFF adjustment value

3 SCART G CUTOFF 60 SCART G CUTOFF adjustment value

4 SCART B CUTOFF 64 SCART B CUTOFF adjustment value

5 SCART R GAIN 200 SCART R GAIN adjustment value

6 SCART G GAIN 195 SCART G GAIN adjustment value

7 SCART B GAIN 201 SCART B GAIN adjustment value

10/33 [LUMAADJ]

1VCOM ADJ 69

2 LCD LUMA ADJ Enter

3 LCD LUMA UP 26

4 LCD LUMA DOWN 13

11/33 [FR DDRTEST]

1 DDRA TEST1 Enter

2 DDRA TEST2 Enter

3 DDRB TEST1 Enter

4 DDRB TEST2 Enter

5 DDRB TEST3 Enter

6 FRC ON/OFF Enter

7 SOUSAM DDR BIST Enter

8 SOUSAS DDR BIST Enter

12/33 [LEV]

1 LEV1 176

2 LEV2 352

3 LEV3 528

4 LEV4 656

5 LEV5 800

6 LEV6 928

13/33 [MGXX1]

1 MG1R 178 W/B adjustment, gradation 1R adjustment value

2 MG1G 184 W/B adjustment, gradation 1G adjustment value

3 MG1B 138 W/B adjustment, gradation 1B adjustment value

4 MG2R 227 W/B adjustment, gradation 2R adjustment value

5 MG2G 232 W/B adjustment, gradation 2G adjustment value

6 MG2B 177 W/B adjustment, gradation 2B adjustment value

7 MG3R 316 W/B adjustment, gradation 3R adjustment value

8 MG3G 322 W/B adjustment, gradation 3G adjustment value

9 MG3B 249 W/B adjustment, gradation 3B adjustment value

3 – 4

Page 85

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

Page Line Item Description Remarks (adjustment detail, etc.)

14/33 [MGXX2]

1 MG4R 474 W/B adjustment, gradation 4R adjustment value

2 MG4G 485 W/B adjustment, gradation 4G adjustment value

3 MG4B 384 W/B adjustment, gradation 4B adjustment value

4 MG5R 791 W/B adjustment, gradation 5R adjustment value

5 MG5G 815 W/B adjustment, gradation 5G adjustment value

6 MG5B 673 W/B adjustment, gradation 5B adjustment value

7 MG6R 905 W/B adjustment, gradation 6R adjustment value

8 MG6G 948 W/B adjustment, gradation 6G adjustment value

9 MG6B 800 W/B adjustment, gradation 6B adjustment value

15/33 [ACTIVEBL1]

1 ABL TEST MODE Enter

2 PRINT DEBUG OFF

16/33 [SOUND1]

1 AUDIO_PARAMETER_SWITCH ROM

2AU_FLAT

3 INPUT_MIXER_GAIN

4 OUTPUT_MIXER_GAIN

5 PEQ1_F0

6 PEQ1_Q

7 PEQ1_GAIN

8 PEQ2_F0

9 PEQ2_Q

10 PEQ2_GAIN

11 PEQ3_F0

12 PEQ3_Q

13 PEQ3_GAIN

17/33 [SOUND 2]

1 PEQ4_F0

2 PEQ4_Q

3 PEQ4_GAIN

4 PEQ5_F0

5 PEQ5_Q

6 PEQ5_GAIN

7 GAIN_ADJUSTER1

8 GAIN_ADJUSTER2

9 GAIN_ADJUSTER3

10 GAIN_ADJUSTER4

11 GAIN_ADJUSTER5

12 GAIN_ADJUSTER6_SP

13 GAIN_ADJUSTER6_HP

18/33 [SOUND 3]

1 LOUT1_VOLUME_CONTROL

2 ROUT1_VOLUME_CONTROL

19/33 [M PWM]

1PWM

2PWM FREQ

3 PWM DUTY

4OSC FREQ

5 OSC DUTY

20/33 [M OPC1]

1 OPC LDUTY0

2 OPC LDUTY1

3 OPC LDUTY2

4 OPC LDUTY3

5 OPC LDUTY4

6 OPC LDUTY5

7 OPC LDUTY6

8 OPC LDUTY7

9 OPC LDUTY8

10 OPC LDUTY9

11 OPC LDUTY10

12 OPC LDUTY11

3 – 5

Page 86

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

Page Line Item Description Remarks (adjustment detail, etc.)

21/33 [M OPC2]

1 OPC LDUTY12

2 OPC LDUTY13

3 OPC LDUTY14

4 OPC LDUTY15

5 OPC LDUTY16

6 OPC LDUTY17

7 OPC LDUTY18

8 OPC LDUTY19

9 OPC LDUTY20

10 OPC LDUTY21

11 OPC LDUTY22

22/33 [M OPC3]

1 OPC LDUTY23

2 OPC LDUTY24

3 OPC LDUTY25

4 OPC LDUTY26

5 OPC LDUTY27

6 OPC LDUTY28

7 OPC LDUTY29

8 OPC LDUTY30

9 OPC LDUTY31

10 OPC LDUTY32

23/33 [M ADL1]

1 OPC33 ADLEVEL 0

2 OPC33 ADLEVEL 1

3 OPC33 ADLEVEL 2

4 OPC33 ADLEVEL 3

5 OPC33 ADLEVEL 4

6 OPC33 ADLEVEL 5

7 OPC33 ADLEVEL 6

8 OPC33 ADLEVEL 7

9 OPC33 ADLEVEL 8

10 OPC33 ADLEVEL 9

11 OPC33 ADLEVEL 10

12 OPC33 ADLEVEL 11

24/33 [M ADL2]

1 OPC33 ADLEVEL 12

2 OPC33 ADLEVEL 13

3 OPC33 ADLEVEL 14

4 OPC33 ADLEVEL 15

5 OPC33 ADLEVEL 16

6 OPC33 ADLEVEL 17

7 OPC33 ADLEVEL 18

8 OPC33 ADLEVEL 19

9 OPC33 ADLEVEL 20

10 OPC33 ADLEVEL 21

11 OPC33 ADLEVEL 22

25/33 [M ADL3]

1 OPC33 ADLEVEL 23

2 OPC33 ADLEVEL 24

3 OPC33 ADLEVEL 25

4 OPC33 ADLEVEL 26

5 OPC33 ADLEVEL 27

6 OPC33 ADLEVEL 28

7 OPC33 ADLEVEL 29

8 OPC33 ADLEVEL 30

9 OPC33 ADLEVEL 31

3 – 6

Page 87

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

Page Line Item Description Remarks (adjustment detail, etc.)

26/33 [M V6THE]

1V6 OS THERMO 1 64

2V6 OS THERMO 2 77

3V6 OS THERMO 3 87

4V6 OS THERMO 4 97

5 V6 OS THERMO 5 108

6 V6 OS THERMO 6 119

7 V6 OS THERMO 7 131

27/33 [M V5THE]

1V5 OS THERMO 1 64

2V5 OS THERMO 2 77

3V5 OS THERMO 3 87

4V5 OS THERMO 4 97

5 V5 OS THERMO 5 108

6 V5 OS THERMO 6 119

7 V5 OS THERMO 7 131

28/33 [M BLCTL TEMP]

1BL TEMP1

2BL TEMP2

3BL TDUTY

29/33 [M EEP SET]

1 MONITOR TIME OUT ON Monitor and the main communication time-out setting

2 MONITOR MAX TEMP 43 MONITOR MAX temperature setting

3 MONITOR EEP READ / WRITE WRITE MONITOR EEPROM READ/WRITE Setting/execution

4 MONITOR EEP ADR 0x 0 MONITOR EEPROM arbitrary addressing

5 MONITOR EEP DATA 0x 0 MONITOR EEPROM arbitrary data specification

30/33 [M TEST PATTERN]

1 LCD TEST PATTERN OFF Pattern with built-in LCD controller display

31/33 [MEM CLEAR]

1 KEY LOCK(1217) Enter

2 KOUTEI AREA ALL CLEAR Adjustment value clearness in all areas in process

3 A MODE AREA CLEAR Adjustment value clearness of process A mode

4 BACKUP AREA CLEAR Adjustment value clearness in process backup area

5 B MODE AREA CLEAR Adjustment value clearness of process B mode

6 EXECUTION Clear execution

32/33 [FR REGI]

1 READ/WRITE READ

2 SLAVE ADDRESS SLAVE0

3 REGISTOR ADDRESS 0x 0

0x 0

4 WRITE DATA 0x 0

0x 0

5 READ DATA 0x 0

0x 0

33/33 [ETC]

1 EEP SAVE OFF Writing setting values to EEPROM.

2 EEP RECOVER OFF Reading setting values from EEPROM.

3 MONITOR ERROR CAUSE RESET OFF

4 STANDBY CAUSE RESET OFF Reset stand by cause.

5 MODEL NAME XL2 Model name setting

6 PANEL SIZE 52 Panel size setting.

7 PRODUCT EEP ADR 0x 0

8 PRODUCT EEP DATA 0x 0

3 – 7

Page 88

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

6. Special features

1. NORMAL STANDBY CAUSE (Page 1/33)

Display of a cause (code) of the last standby.

The cause of the last standby is recorded in EEPROM whenever possible.

Checking this code will be useful in finding a problem when you repair the troubled set.

2. EEP SAVE (Page 33/33)

Storage of EEP adjustment value

3. EEP RECOVER (Page 33/33)

Retrieval of EEP adjustment value from storage area.

7. Lamp error detection

1. Function

This LCD color TV set incorporates a lamp error detection feature that automatically turns off the power for safety under abnormal lamp or lamp

circuit conditions. If by any chance anything is wrong with the lamp or lamp circuit or if the lamp error detection feature is activated for some reason, the following will result.

1) The power is interrupted in about 6 seconds after it is turned on.

(The power LED on the front of the TV set turns red from green and keeps blinking in red: ON for 250 ms and OFF for 1 sec.).

2) If the above phenomenon 1) occurs 5 times consecutively, it becomes impossible to turn on the power. (The power LED remained red).

2. Measures

1) Checking with lamp error detection OFF

Enter the adjustment process mode, referring to 1. Entering and exiting the adjustment process mode.

If there is a problem with the lamp or lamp circuit, the lamp will go out. (The power LED is green.)

Then, you can check the operation to see if the lamp and lamp circuit are in trouble.

2) Resetting the lamp error count

After the lamp and lamp circuit are found out of trouble, reset the lamp error count. If a lamp error is detected five consecutive times, the power

cannot be turned on. Using the cursor (UP/DOWN) key, move to the cursor to [LAMP ERROR RESET], Line 8 on adjustment process mode

service page 2/33. With the cursor (LEFT/RIGHT) keys, select the [LAMP ERROR RESET] value. Finally press the cursor (OK) eys to reset the

value to “0”.

Table of contents of adjustment process mode Page 2/33

[INIT]

INDUSTRY INIT Enter

INDUSTRY INIT(-Hotel) OFF

HOTEL MODE OFF

Center Acutime

RESET

OFF

Backlight Acutime

RESET

LAMP ERROR RESET

OFF

OFF

ADJ PARAM SET Enter

VIC XPOS 0

VIC YPOS 0

VIC SIGNAL TYPE MAIN

VIC READ OFF

Resetting to "0"

3 – 8

Page 89

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

8. Public Mode (Hotel Mode)

1. Starting the Public Mode

• There are two following ways to display the PUBLIC Mode setting screen.

1) On the process adjustment mode screen (2/33), set the “HOTEL MODE” Flag to ON.

Turn off the power, and turn it on again, pressing the and keys of the main unit at the same time.

CHANNEL UP

Volume UP

2) Enter the Pass Word, and start the unit.

a) Turn on the power, pressing the and keys of the main unit at the same time.

INPUT

Volume UP

b) Display the Pass Word input screen.

Operation procedure

• The initial input position is the digit at the left end.

9

• For the numeric keys to of R/C, key input is accepted. Input of the other keys is prohibited.

0

• Change “-” to “*” by inputting the numeric key at the input position, and shift the input position rightward one digit.

• When three digits are completely input, the Pass Word is judged.

c) Check the Pass Word by inputting three digits.

2 7

If the Pass Word is , it shifts to the PUBLIC Mode setting screen.

0

In another case, the screen is erased, and it operates in the ordinary mode.

2. Exiting the Public Mode screen

• There are two following ways to exit the Public Mode setting screen.

1) Turn off the power.

2) Select “Execution” in the PUBLIC_Mode to execute it.

Activate the restart under the set content. Here, the START input SOURCE setting is excluded since this item is referred to only when the

power is turned on.

3. Set value of the Public Mode

• Each set value in the PUBLIC Mode is initialized when the factory setting is applied.

(The setting of the PUBLIC MODE Flag in the process adjustment mode screen is not changed.)

3 – 9

Page 90

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

4. Basic operation in the Public Mode

Volume / or Cursor ←/→

Channel / or Cursor ↑/↓

Decision (ok) Execution (Used by the items “Execution” and “RESET”.)

PUBLIC Mode R/C Ordinary operation mode: It enters the PUBLIC Mode.

PUBLIC Mode: It exits the PUBLIC Mode.

Public Mode

POWER ON FIXED [VARIABLE]

SHUT DOWN MODE [NORMAL]

MAXIMUM VOLUME [60]

VOLUME FIXED [VARIABLE]

VOLUME FIXED LEVEL [20]

RC BUTTON [RESPOND]

PANEL BUTTON [RESPOND]

Change or execution of the set value.

Movement to the selected item.

PUBLIC MODE Flag is set to “ON”.

PUBLIC MODE Flag does not change.

Any set item in PUBLIC Mode is not initialized.

MENU BUTTON [RESPOND]

AV POSITION FIXED [VARIABLE]

ON SCREEN DISPLAY [YES]

INPUT MODE START [NORMAL]

INPUT MODE FIXED [VARIABLE]

LOUD SPEAKER [ON]

RC PATH THROUGH [OFF]

232C POWON [DISABLE]

HOTELMODE [ON]

RESET

EXECUTE

5. Operation after “RESET”

Select “RESET” in the PUBLIC Mode, and it operates as follows when it is executed (refer to the basic operation).

• The set contents in the PUBLIC mode are initialized.

• It does not exit the PUBLIC mode.

• PUBLIC MODE Flag does not change. (It is not set to OFF.)

3 – 10

Page 91

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

6. Setting items (* Item names and selective items are expressed in English.)

1) Power ON Fixed (POWER ON FIXED)

Selection “VARIABLE” or “FIXED” is selectable. (Loop is provided.)

Default “VARIABLE”

Function • When "FIXED" is set, “Power ON/Standby Key” of the main unit and R/C is disabled.

Keys disabled when not

set to Default

Remarks The function does not work for any other standby factors (see below).

If the power button is pressed in the ordinary mode when set to “FIXED”, the caution is displayed for 5 seconds.

When power button on the main unit is pressed When power button on R/C is pressed

No Power off by power button. No Power off by remote control.

* The OSD display is an example.

If another ODS is previously displayed, the status is reset (MENU or similar).

2) Volume Maximum Level [MAXIMUM VOLUME]

• OFF_TIMER (SLEEP)

• No operation OFF

• No signal OFF (including the power management)

Selection 0~60 (Loop is not provided.)

Default 60

Function • Even if VOL is adjusted to a value higher than the adjusted one, it is not set to that value. (Only the speakers of

the main unit)

Exception

Remarks • When it is set to 59 or less, the number is displayed and the volume bar is not displayed during operation in the

3) Volume Fixed [VOLUME FIXED]

Selection “VARIABLE” or “FIXED” is selectable. (Loop is provided.)

Default “VARIABLE”

Function It is selectable whether or not the volume is fixed to the value adjusted in the volume fixed level mode. (Only the

Exception • In the adjustment process, the volume can be set as desired regardless of this setting.

Keys disabled when not

set to Default

Remarks • Volume Fixed is prior to Volume Maximum Level.

4) Volume Fixed Level [VOLUME FIXED LEVEL]

Selection 0~60 (Loop is not provided.)

Default Currently set volume

Function The volume is fixed to the adjusted value. (Only the speakers of the main unit)

Exception • In the adjustment process, the volume can be set as desired regardless of this setting.

Keys disabled when not

set to Default

Remarks • When Volume Fixed is set to “VARIABLE”, the setting is inhibited to change.

ordinary mode.

• VOLUME can be abbreviated to VOL.

speakers of the main unit)

• Volume high/low (VOL+/-) (Both R/C and main unit)

• Mute (MUTE)

• Even if the above disabled keys are operated, the volume is not displayed.

• VOLUME can be abbreviated to VOL.

• VOLUME can be abbreviated to VOL.

3 – 11

Page 92

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

5) R/C Operation [RC BUTTON]

Selection “RESP0ND” or “NO RESPOND” is selectable. (Loop is provided.)

Default RESP0ND

Function R/C key operation is set.

When set to “NO RESPOND”, the R/C keys are disabled in the ordinary mode.

The power key (Power ON/Standby Key) is also disabled.

Exception • Regardless of the setting contents, the process mode, inspection mode and PUBLIC_Mode Key are enabled.

• Regardless of the setting contents, all keys can be used while entering the process mode, inspection mode or

PUBLIC_Mode.

Remarks The CARD function stops all functions including the input switching and direct key when set to “NO RESPOND”.

6) Main Unit Operation [PANEL BUTTON]

Selection “RESP0ND” or “NO RESPOND” is selectable. (Loop is provided.)

Default RESP0ND

Function NO RESPOND: Excluding power supply (Video/Standby key), the main unit keys are disabled.

Exception • Regardless of the setting contents, the start operation of the process mode, inspection mode and PUBLIC_Mode

is enabled.

• Regardless of the setting contents, all keys can be used while entering the process mode, inspection mode and

PUBLIC_Mode.

7) MENU Operation [MENU BUTTON]

Selection “RESP0ND” or “NO RESPOND” is selectable. (Loop is provided.)

Default RESP0ND

Function The MENU keys on the main unit and R/C MENU are disabled.

Exception • Regardless of the setting contents, the start operation of the process mode, inspection mode and PUBLIC_Mode

is enabled.

• Regardless of the setting contents, all keys can be used whileentering the process mode, inspection mode or

PUBLIC_Mode.

Key that becomes

invalid excluding Default

besides MENU Key

because of setting

Remarks When set to “NO RESPOND”,

ON_TIMER, Auto Preset, Manual_Memory, and clock setting

All Direct Shift keys to the MENU display

• ON_TIMER is set to “OFF”.

8) ODS Display [ON SCREEN DISPLAY]

Selection “YES” or “NO” is selectable. (Loop is provided.)

Default YES

Function When set to “ON”, the following OSD is not displayed.

Register, Setting, Adjustment MENU, Channel_Call, Volume Bar

In the case of Wide Model, if the following operation is performed, it is immediately switched (since MENU can not be

displayed).

Input switching

Keys which can be

enabled (Exquisite

example)

Keys disabled when not

set to Default (Example)

Remarks • When set to “ON”,

9) Start Mode [INPUT MODE START]

Selection “NORMAL”, “TV(*Channel)”, “INPUT1”, “INPUT2” (Loop is provided.)

Default NORMAL

Function When the power is ON, the input source or channel to start is set.

Remarks • When set to a mode other than “NORMAL”,

Brightness sensor, light control

Still screen, screen display, MENU, OFF_TIMER, A V Position, Wide Mode switch, Auto Instolation

a) The OFF_TIMER (SLEEP TIMER) setting time is cleared.

In the NORMAL mode, it follows the contents of Last_Memory.

a) It is inhibited to display the Channel Setting MENU and to set the Channel.

b) On start with “ON_TIMER”, the set Channel of ON_TIMER is prior.

• When set to “NORMAL”, “Mode Fixed (START MODE FIXED)” is set to “VARIABLE” to inhibit the selection.

3 – 12

Page 93

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

10)Mode Fixed [INPUT MODE FIXED]

Selection “VARIABLE” or “FIXED” is selectable. (Loop is provided.)

Default VARIABLE

Function When set to “FIXED”, it is disable to switch to other channel or input after start in the set value of “Start Mode (INPUT

MODE START)”.

Keys disabled when not

set to Default (Example)

Remarks • When “START MODE” is set to “NORMAL”, this item is disable to set. (Automatically set to “VARIABLE”.)

9. Video signal adjustment procedure

* The adjustment process mode menu is listed in Section 4.

Signal generator level adjustment check (Adjustment to the specified level)

• Composite signal PAL : 0.7Vp-p ± 0.02Vp-p (Pedestal to white level)

• RGB signal : 0.7Vp-p ± 0.02Vp-p

• 15K component signal (50 Hz) : Y level : 0.7Vp-p ± 0.02Vp-p (Pedestal to white level)

1. Entering the adjustment process mode

Enter the adjustment process mode according to Section 3.

2. RF AGC adjustment

Adjustment point Adjustment Conditions Adjustment procedure

1 Setting [Signal]

Channel UP/Down, Direct, Channel Button, FLASHBACK, INPUT, STILL, Digit Select and Direct input switching

• When set to “FIXED”,

The Channel setting MENU (Menu-setup-Auto Installation, Programme setup and Child Lock item hatching) and

Input Selection MENU in MENU are not displayed.

: PB, PR level : 0.7Vp-p ± 0.02Vp-p

• Feed the PAL Split Field colour bar signal (E-12ch) to TUNER.

PAL

Split Field Colour Bar RF signal

U/V

Signal level: 55 dB µV ± 1dB (75Ω LOAD)

[E-12CH]

[Terminal]

TUNER

2 Auto adjustment

performance

3. PAL signal & tuner adjustment

Adjustment point Adjustment Conditions Adjustment procedure

1 Setting [Signal]

Page 3/33 Bring the cursor on [RF AGC ADJ] and press [OK] [RF AGC ADJ OK] appears

PAL

Full Field Color Bar Composite

or RF signal

[Terminal]

EXT1 SCART IN TUNER

㸡100% white

when finished.

• Feed the PAL full field colour bar signal (75% colour saturation) to EXT1

SCART IN.

• Feed the RF signal (PAL colour bar) to TUNER.

• Make sure the PAL colour bar pattern has the sync level of 7:3 with the pic-

ture level.

㪲VIDEO IN SIGNAL]

[RF Signal]

2 Auto adjustment

performance

㸡100% white

Page 3/33 Bring the cursor on [PAL+TUNER ADJ] and press [OK] [PAL+TUNER ADJ OK]

appears when finished.

㸡100% white

3 – 13

Page 94

LC-42XL2E/S/RU, LC-46XL2E/S/RU, LC-46X20E/S/RU, LC-52XL2E/S/RU, LC-52X20E/S/RU

4. SECAM adjustment

Adjustment point Adjustment Conditions Adjustment procedure

1 Setting [Signal]

SECAM

Full Field Colour Bar signal

[Terminal]

EXT1 SCART IN

• Feed the SECAM full field colour bar signal (75% colour saturation) to EXT1

SCART IN.

100% white

Black

2 Auto adjustment

performance

5. ADC adjustment (Component 15K)

Adjustment point Adjustment Conditions Adjustment procedure

1 Setting [Signal]

2 Auto adjustment

performance

6. ADC adjustment (Component 33K)

Adjustment point Adjustment Conditions Adjustment procedure

1 Setting [Signal]

Page 4/33 Bring the cursor on [SECAM ADJ] and press [OK] [SECAM ADJ OK] appears

COMP15K, 50Hz

100% Full Field Colour Bar signal

[Terminal]

EXT8 COMPONENT IN