Page 1

TopPage

LC-40C37U

SERVICE MANUAL

No. S46S3LC40C37U

LCD COLOR TELEVISION

MODEL

In the interests of user-safety (Required by safety regulations in some countries) the set should

be restored to its original condition and only parts identical to those specified should be used.

LC-40C37U

OUTLINE

This model is based on the LC-37D40U and is changed some parts. This Service Manual covers the modifications

alone. For the other points, refer to the LC-37/45D40U Service Manual.

CONTENTS

LIST OF CHANGED PARTS

LC-40C37U .........................................................i

SAFETY PRECAUTION

IMPORTANT SERVICE SAFETY PRE-

CAUTION ........................................................... ii

PRECAUTIONS A PRENDRE LORS DE

LA REPARATION.............................................. iii

PRECAUTIONS FOR USING LEAD-FREE

SOLDER ........................................................... iv

CHAPTER 1. SPECIFICATIONS

[1] SPECIFICATIONS ......................................... 1-1

CHAPTER 2. OPERATION MANUAL

[1] OPERATION MANUAL .................................. 2-1

CHAPTER 3. DIMENSIONS

[1] DIMENSIONS ................................................ 3-1

Parts Guide

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with specified ones for maintaining the

safety and performance of the set.

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Page 2

LC-40C37U

LC-40C37U

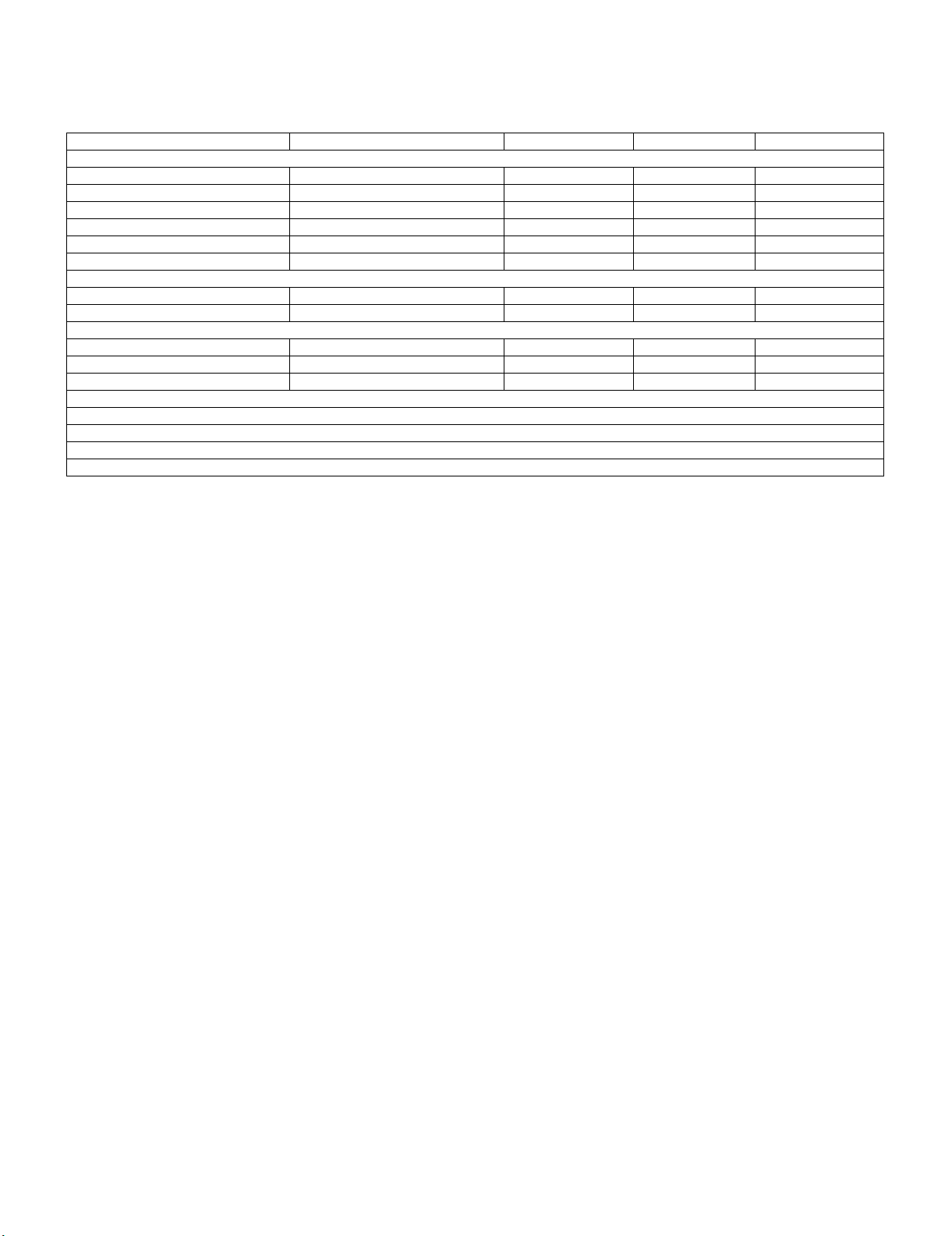

LIST OF CHANGED PARTS

Service Manual

LC-40C37U

Ref. No. Description LC-37D40U LC-40C37U Note

PWB ASSEMBLIES

MAIN Unit DUNTKD640FM06 DUNTKD640FM12 No parts changed

LED Unit DUNTKD641FM06 DUNTKD641FM12 No parts changed

IF Unit DUNTKD643FM06 DUNTKD643FM12 Some parts changed

KEY Unit DUNTKD716FM06 DUNTKD716FM12 No parts changed

POWER SUPPLY Unit RDENCA161WJQZ ← —

LCD PANEL

37" WIDE LCD Panel Module Unit R1LK370T3LZ5BY R1LK370T3LZ5BW —

IF Unit

FB2707 Balun, BLN-A192WJ — RBLN-A192WJZZY *Add

FB2708 Balun, BLN-A192WJ — RBLN-A192WJZZY *Add

CABINET AND MECHANICAL PARTS

Please refer to a Parts list.

PACKING PARTS AND ACCESSORIES

Please refer to a Parts list.

i

Page 3

LC-40C37U

LC-40C37U

SAFETY PRECAUTION

Service Manual

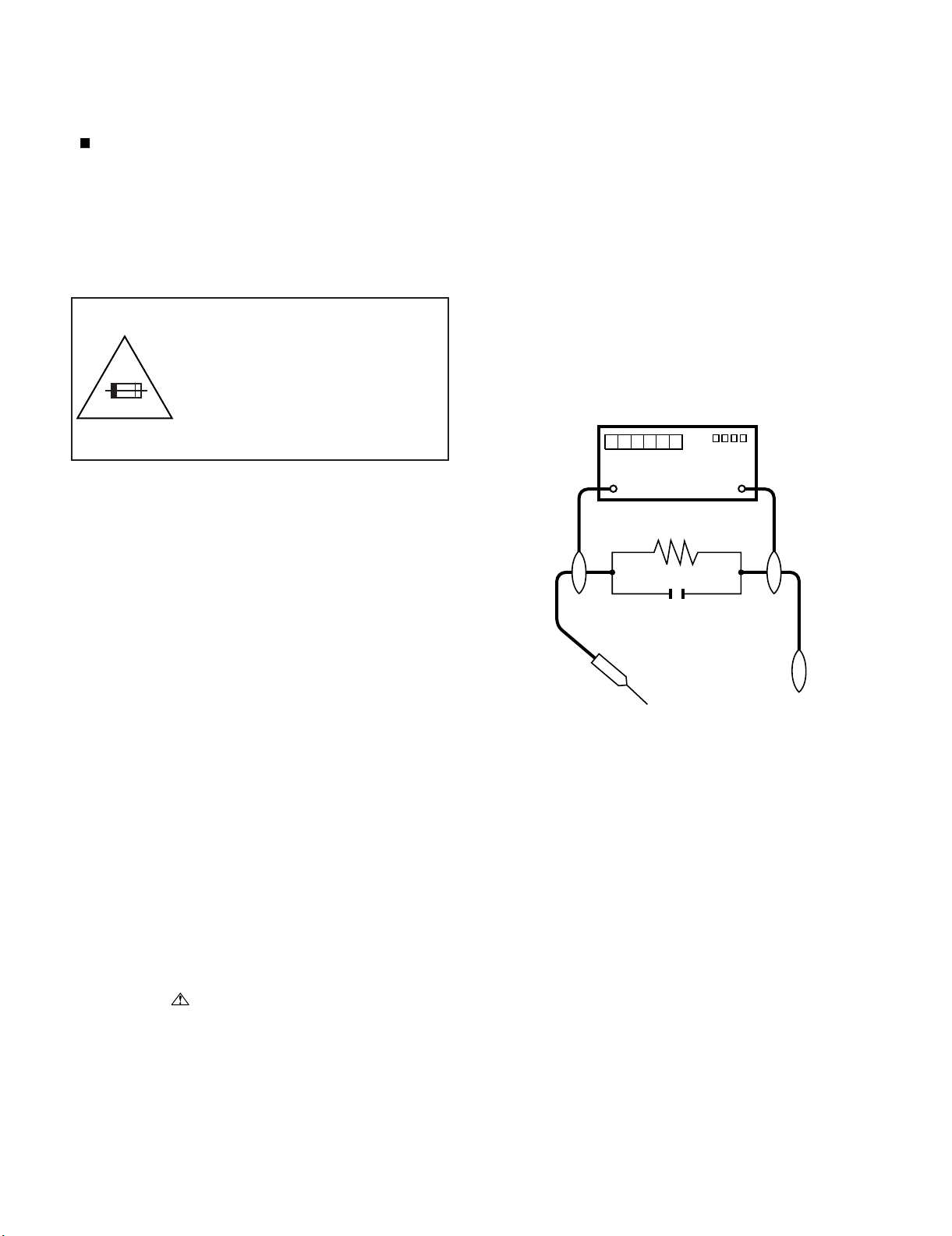

IMPORTANT SERVICE SAFETY PRECAUTION

Service work should be performed only by qualified service technicians who are thoroughly familiar with all safety checks and the

servicing guidelines which follow:

WARNING

1. For continued safety, no modification of any circuit should be

attempted.

2. Disconnect AC power before servicing.

CAUTION: FOR CONTINUED

PROTECTION AGAINST A RISK OF

FIRE REPLACE ONLY WITH SAME

TYPE FUSE.

AV

F701 (8A, 125V),

F4701, F5701 (3A~, 250V, 115

O

C)

• Use an AC voltmeter having with 5000 ohm per volt, or higher, sensitivity or measure the AC voltage drop across the resistor.

• Connect the resistor connection to all exposed metal parts having a

return to the chassis (antenna, metal cabinet, screw heads, knobs

and control shafts, escutcheon, etc.) and measure the AC voltage

drop across the resistor.

All checks must be repeated with the AC cord plug connection

reversed. (If necessary, a nonpolarized adaptor plug must be used

only for the purpose of completing these checks.)

Any reading of 0.75 Vrms (this corresponds to 0.5 mA rms AC.) or

more is excessive and indicates a potential shock hazard which

must be corrected before returning the monitor to the owner.

DVM

BEFORE RETURNING THE RECEIVER (Fire &

Shock Hazard)

Before returning the receiver to the user, perform the following

safety checks:

3. Inspect all lead dress to make certain that leads are not pinched,

and check that hardware is not lodged between the chassis and

other metal parts in the receiver.

4. Inspect all protective devices such as non-metallic control knobs,

insulation materials, cabinet backs, adjustment and compartment

covers or shields, isolation resistor-capacitor networks, mechanical

insulators, etc.

5. To be sure that no shock hazard exists, check for leakage current in

the following manner.

• Plug the AC cord directly into a 120 volt AC outlet.

• Using two clip leads, connect a 1.5k ohm, 10 watt resistor paralleled by a 0.15µF capacitor in series with all exposed metal cabinet

parts and a known earth ground, such as electrical conduit or electrical ground connected to an earth ground.

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

TO EXPOSED

METAL PARTS

AC SCALE

1.5k ohm

10W

0.15µF

TEST PROBE

CONNECT TO

KNOWN EARTH

GROUND

SAFETY NOTICE

Many electrical and mechanical parts in LCD color television have

special safety-related characteristics.

These characteristics are often not evident from visual inspection, nor

can protection afforded by them be necessarily increased by using

replacement components rated for higher voltage, wattage, etc.

Replacement parts which have these special safety characteristics are

identified in this manual; electrical components having such features

are identified by " " and shaded areas in the Replacement Parts

List and Schematic Diagrams.

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

For continued protection, replacement parts must be identical to those

used in the original circuit.

The use of a substitute replacement parts which do not have the same

safety characteristics as the factory recommended replacement parts

shown in this service manual, may create shock, fire or other hazards.

ii

Page 4

LC-40C37U

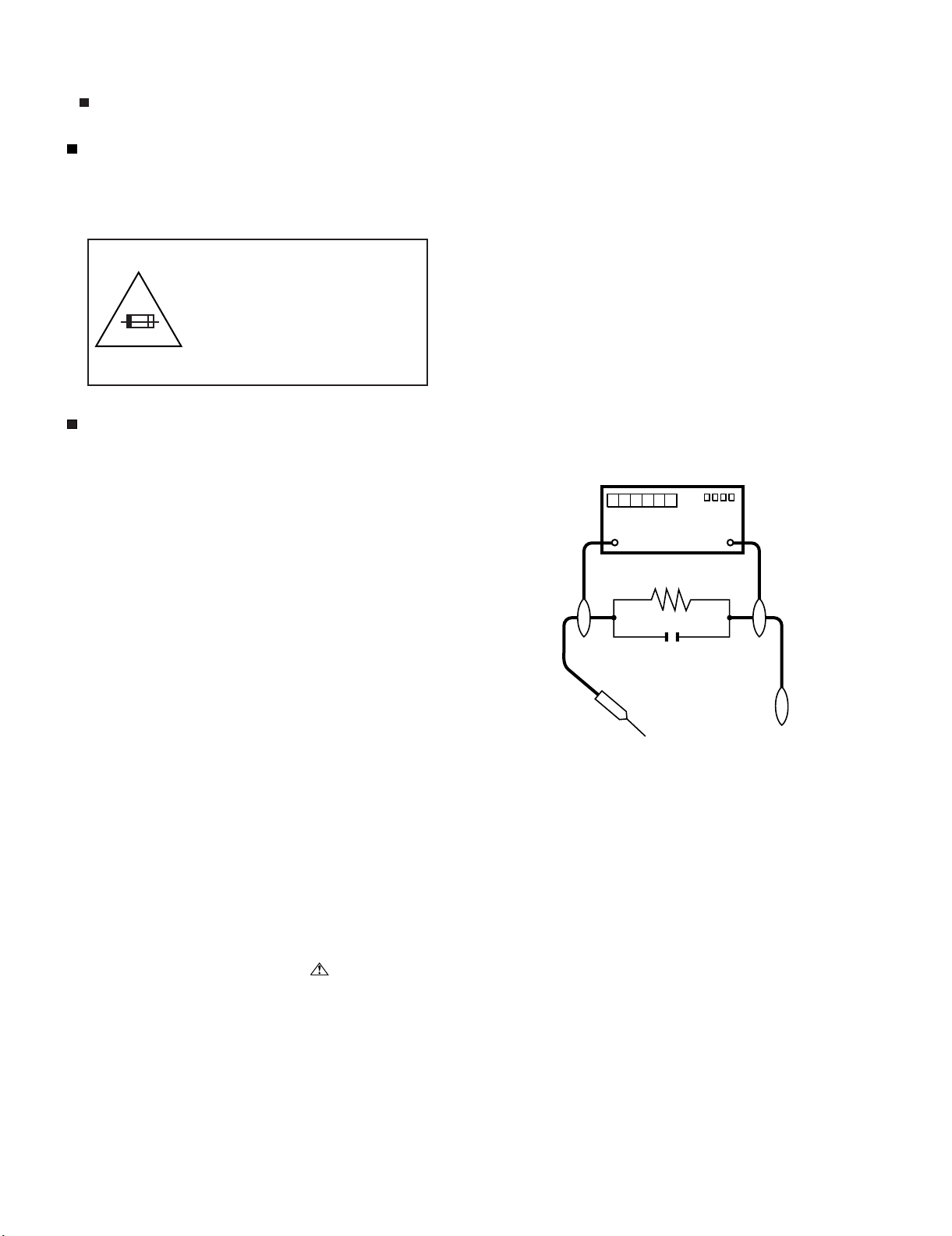

PRECAUTIONS A PRENDRE LORS DE LA REPARATION

Ne peut effectuer la réparation qu' un technicien spécialisé qui s'est parfaitement accoutumé à toute vérification de sécurité et aux

conseils suivants.

•

AVERTISSEMENT

1.

N'entreprendre aucune modification de tout circuit. C'est dangereux.

2.

Débrancher le récepteur avant toute réparation.

PRECAUTION:POURLA

PROTECTION CONTINUE

CONTRE LES RISQUES

D'INCENDIE, REMPLACER LE

FUSIBLE

AV

F701 (8A, 125V),

F4701, F5701 (3A~, 250V, 115

O

C)

VERIFICATIONS CONTRE L'INCEN-DIE ET LE

CHOC ELECTRIQUE

Avant de rendre le récepteur à l'utilisateur, effectuer les vérifications suivantes.

Inspecter tous les faisceaux de câbles pour s'assurer que les fils

3.

ne soient pas pincés ou qu'un outil ne soit pas placé entre le châssis et les autres pièces métalliques du récepteur.

4.

Inspecter tous les dispositifs de protection comme les boutons de

commande non-métalliques, les isolants, le dos du coffret, les couvercles ou blindages de réglage et de compartiment, les réseaux

de résistancecapacité, les isolateurs mécaniques, etc.

5.

S'assurer qu'il n'y ait pas de danger d'électrocution en vérifiant la

fuite de courant, de la facon suivante:

•

Brancher le cordon d'alimentation directem-ent à une prise de courant de 120V. (Ne pas utiliser de transformateur d'isolation pour

cet essai).

A l'aide de deux fils à pinces, brancher une résistance de 1.5 kΩ

10 watts en parallèle avec un condensateur de 0.15µF en série

avec toutes les pièces métalliques exposées du coffret et une terre

connue comme une conduite électrique ou une prise de terre

branchée à la terre.

•

Utiliser un voltmètre CA d'une sensibilité d'au moins 5000Ω/V pour

mesurer la chute de tension en travers de la résistance.

•

Toucher avec la sonde d'essai les pièces métalliques exposées qui

présentent une voie de retour au châssis (antenne, coffret métallique, tête des vis, arbres de commande et des boutons, écusson,

etc.) et mesurer la chute de tension CA en-travers de la résistance.

Toutes les vérifications doivent être refaites après avoir inversé la

fiche du cordon d'alimentation. (Si nécessaire, une prise

d'adpatation non polarisée peut être utilisée dans le but de terminer ces vérifications.)

La tension de pointe mesurèe ne doit pas dépasser 0.75V (correspondante au courant CA de pointe de 0.5mA).

Dans le cas contraire, il y a une possibilité de choc électrique qui

doit être supprimée avant de rendre le récepteur au client.

DVM

ECHELLE CA

1.5k ohm

10W

µ

F

0.15

SONDE D'ESSAI

AUX PIECES

METALLIQUES

EXPOSEES

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

BRANCHER A UNE

TERRE CONNUE

AVIS POUR LA SECURITE

De nombreuses pièces, électriques et mécaniques, dans les téléviseur ACL présentent des caractéristiques spéciales relatives à la sécurité, qui ne sont souvent pas évidentes à vue. Le degré de protection ne peut pas être nécessairement augmentée en utilisant des

pièces de remplacement étalonnées pour haute tension, puissance,

etc.

Les pièces de remplacement qui présentent ces caractéristiques sont

identifiées dans ce manuel; les pièces électriques qui présentent ces

particularités sont identifiées par la marque " " et hachurées dans la

liste des pièces de remplacement et les diagrammes schématiques.

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

Pour assurer la protection, ces pièces doivent être identiques à celles

utilisées dans le circuit d'origine. L'utilisation de pièces qui n'ont pas

les mêmes caractéristiques que les pièces recommandées par l'usine,

indiquées dans ce manuel, peut provoquer des électrocutions, incendies, radiations X ou autres accidents.

iii

Page 5

LC-40C37U

PRECAUTIONS FOR USING LEAD-FREE SOLDER

Employing lead-free solder

• "PWBs" of this model employs lead-free solder. The LF symbol indicates lead-free solder, and is attached on the PWBs and service manuals. The

alphabetical character following LF shows the type of lead-free solder.

Example:

Indicates lead-free solder of tin, silver and copper. Indicates lead-free solder of tin, silver and copper.

Using lead-free wire solder

• When fixing the PWB soldered with the lead-free solder, apply lead-free wire solder. Repairing with conventional lead wire solder may cause damage or accident due to cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40 °C, we recommend you to use a dedicated soldering

bit, if you are not familiar with how to obtain lead-free wire solder or soldering bit, contact our service station or service branch in your area.

Soldering

• As the melting point of lead-free solder (Sn-Ag-Cu) is about 220 °C which is higher than the conventional lead solder by 40 °C, and as it has poor

solder wettability, you may be apt to keep the soldering bit in contact with the PWB for extended period of time. However, Since the land may be

peeled off or the maximum heat-resistance temperature of parts may be exceeded, remove the bit from the PWB as soon as you confirm the

steady soldering condition.

Lead-free solder contains more tin, and the end of the soldering bit may be easily corroded. Make sure to turn on and off the power of the bit as

required.

If a different type of solder stays on the tip of the soldering bit, it is alloyed with lead-free solder. Clean the bit after every use of it.

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sandpaper.

• Be careful when replacing parts with polarity indication on the PWB silk.

Lead-free wire solder for servicing

Part No, Description Code

ZHNDAi123250E J φ0.3mm 250g(1roll) BL

ZHNDAi126500E J φ0.6mm 500g(1roll) BK

ZHNDAi12801KE J φ1.0mm 1kg(1roll) BM

iv

Page 6

LC-40C37U

LC-40C37U

CHAPTER 1. SPECIFICATIONS

[1] SPECIFICATIONS

Service Manual

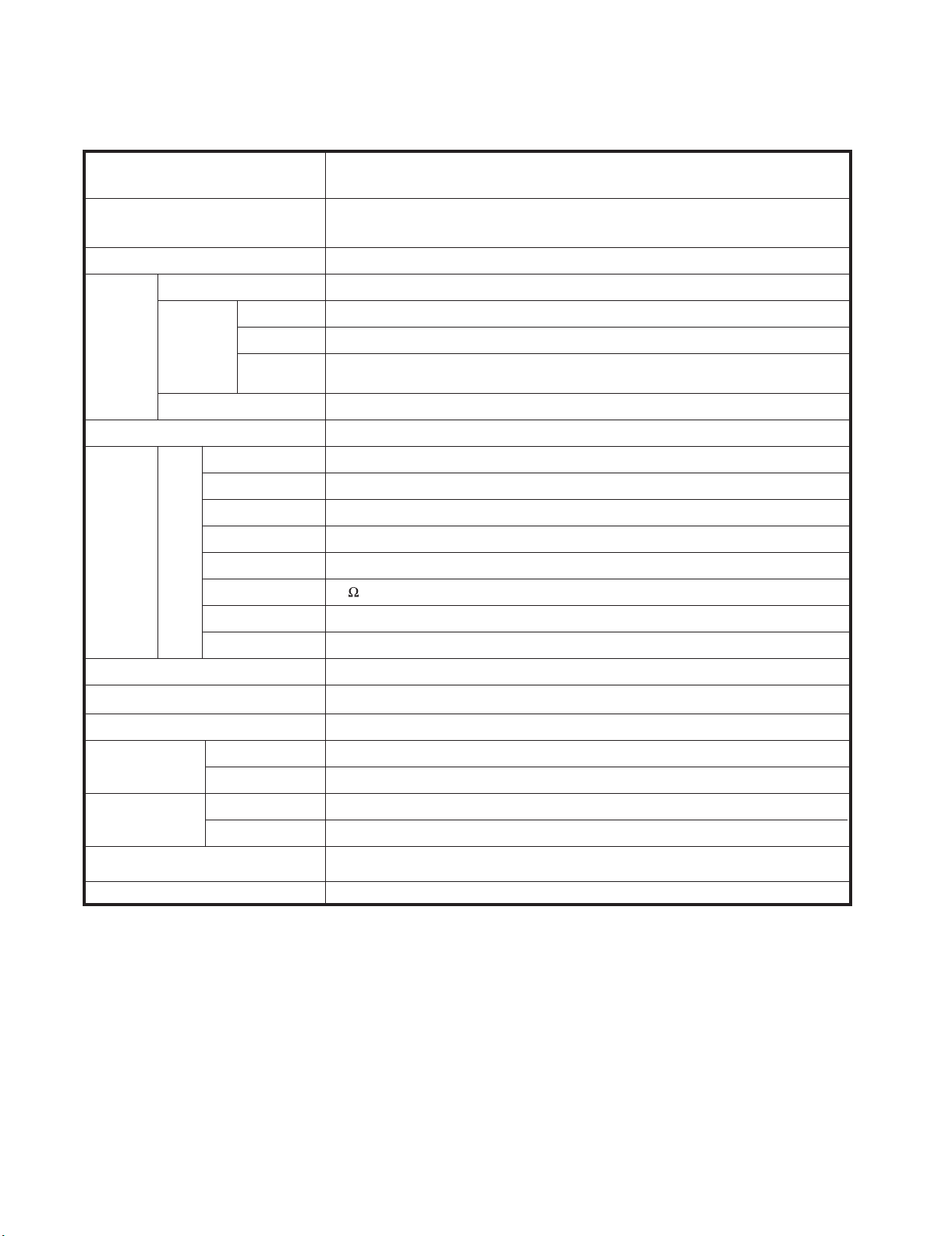

Item

LCD panel

Number of dots

TV-standard (CCIR)

TV

Function

Receiving

Channel

Audio multiplex

Audio out

Terminals

Rear

VHF/UHF

CATV

Digital Terrestrial

Broadcast (8VSB)

INPUT 1

INPUT 2

INPUT 3

INPUT 4

INPUT 5

ANTENNA

DIGITAL AUDIO OUTPUT

Model: LC-40C37U

37" Advanced Super View & BLACK TFT LCD

x

3,147,264 dots (1366 768 3 dots)

x

American TV Standard ATSC/NTSC System

VHF 2-13ch, UHF 14-69ch

1-135ch* (non-scrambled channel only)

2-69ch

BTSC System

x

10W 2

AV in, COMPONENT in

AV in, COMPONENT in

S-VIDEO in, AV in

Audio in, HDMI in with HDCP

HDMI in with HDCP

75 Unbalance, F Type 1 for Analog (VHF/UHF/CATV) and Digital (AIR/CABLE)

Optical Digital audio output 1 (PCM/Dolby Digital)

x

x

OUTPUT

OSD language

Power Requirement

Power Consumption

w/o stand

Weight

with stand

Dimension

(W H D)

xx

w/o stand

with stand

Accessories

Operating temperature

Emergency alert messages via Cable are unreceivable.

•

As part of policy of continuous improvement, SHARP reserves the right to make design and specification changes for product

•

Audio out

English/French/Spanish

AC 120 V, 60 Hz

186 W

48.5 lbs./22.0 kg

53.8 lbs./24.4 kg

1

37

/42615/

xx

1

xx

/42835/

37

Remote control unit ( 1), AC cord ( 1), “AAA” size battery ( 2), Cable clamp ( 1),

Cable tie ( 1), Stand unit ( 1), Operation manual ( 1)

32°F to 104°F (0°C to 40°C)

++ +

45/8inch

64

121/64inch

64

x

xxx

xx

x

improvement without prior notice. The performance specification figures indicated are nominal values of production units.

There may be some deviations from these values in individual units.

1 – 1

Page 7

LC-40C37U

CHAPTER 2. OPERATION MANUAL

[1] OPERATION MANUAL

LC-40C37U

Service Manual

AC INPUT terminal

Part names

INPUT button

POWER button

INPUT 5 terminal

DIGITAL AUDIO OUTPUT terminal

Antenna/Cable in

INPUT 4

terminals

INPUT 1 terminals

terminals

INPUT 3

INPUT 2 terminals

terminals

AUDIO OUTPUT

OPC indicator*

Channel buttons

(CH /)

TV (Front) TV (Rear)

Part names

+

/)

-

VOL

Volume buttons (

2 – 1

Remote control sensor

OPC sensor*

POWER

indicator**

Page 8

LC-40C37U

hex key

Detach the stand from the TV.

(Hold the stand so it will not drop from the edge of the

base area.)

About setting the TV angle

AngleofTV

0° or 5°LC-40C37U

Angular mounting

CAUTION

Appendix

Before detaching (or attaching) stand, unplug the AC cord from the AC INPUT terminal.

mode.

1 TV POWER: Switch the TV power on or enters standby

2 DISPLAY: Display the channel information.

• Do not remove the stand from the TV unless using an optional wall mount bracket to mount it.

equipment on and off.

3 SOURCE POWER: Turns the power of the external

Before attaching/detaching stand

• Before performing work make sure to turn off the TV.

4 External equipment operational buttons: Operate the

place.

NOTE

• To attach the stand, perform the above steps in reverse order.

damaged.

12

• Before performing work spread cushioning over the base area to lay the TV on. This will prevent it from being

Unfasten the four screws used to secure the stand in

Setting the TV on the wall

CAUTION

should not attempt to do the work themselves. SHARP bears no responsibility for improper mounting or

• Installing the TV requires special skill that should only be performed by quali-ed service personnel. Customers

mounting that results in accident or injury.

Using an optional bracket to mount the TV

• You can ask a quali-ed service professional about using an optional AN-37AG2 bracket to mount the TV to the

wall.

• Carefully read the instructions that come with the bracket before beginning work.

Hangingonthewall

+

multi-channelaudio broadcasts.

SAT, VCR, DVD and AUDIO operation. Indicator lights up

for the current mode.

* To enter the code registration mode, you need to press

14 FUNCTION: Switches the remote control for TV, CBL/

17

18

FUNCTION and DISPLAY at the same time.

control unit will light. The lighting will turn off if no

15 LIGHT : When pressed all buttons on the remote

19720

operations are performed within about 5 seconds. This

button is used for performingoperations in low-light

situations.

16 VIEW MODE: Select the screen size.

17 ENT: Jumps to a channel after selecting with the 0–9

21

buttons.

18 FLASHBACK: Return to the previouschannel or input

22

external mode.

19 CH / : Select the channel.

20 MUTE: Mute the sound.

21 MENU: Display the menu screen.

24

22 ////ENTER: Select a desired item on the

screen.

23 RETURN: Returnto the previous menu screen.

25

A, B, C, D: Select four preset favorite channels in four

24 FAVORITE CH

26

external equipment.

5 0–9:Set the channel.

6 • (DOT):

8VOL/:Set the volume.

9 SURROUND: Select Surround settings.

10 FREEZE: Set the still image. Press again to return to

normal screen.

16

11 EXIT: Turn off the menu screen.

12 SLEEP: Set the sleep timer.

13 AUDIO: Selectsthe MTS/SAP or the audio mode during

INPUT3, INPUT 4, INPUT5)

7 INPUT: Select a TV inp ut source. (TV, INPUT 1, INPUT 2,

15

AN-37AG2 wall mount bracket. (See the bracket instructions for details.)

different categories.

While watching, you can toggle the selected channels by

pressing A, B, C and D

25 FAVORITE: Register favorite channel.

26 CC: Display captions from a closed-caption source.

Vertical mounting

NOTE

• Detach the cable clamp on the rear of the TV when using the optional mount bracket.

MOVIE,GAME, USER, DYNAMIC(Fixed), DYNAMIC.)

27 AV M ODE: Selec t an audio o r video set ting . (STANDARD,

Remote control unit Removing the stand

Part names

114

3

2

4

5

6

8

9

10

11 23

12

13 27

2 – 2

Page 9

LC-40C37U

Digital Setup

Menu items

Basic adjustment settings

Option

Picture

List of menu items to help you with operations

Audio Only

Digital Noise Reduction

Input Select

OPC

Backlight

Contrast

HDMI Setup

Output Select

Quick Shoot

Color System

Brightness

Color

Tint

Sharpness

Caption Setup

Program Title Display

Favorite CH

Color Temp.

Black

3D-Y/C

Advanced

Audio Setup

Monochrome

Film Mode

Range of OPC

Audio

Treble

Bass

Balance

Surround

2 – 3

No Signal Off

No Operation Off

Setup

EZ Setup

CH Setup

Antenna Setup-DIGITAL

Input Skip

Input Label

Parental CTRL

Position

Picture Flip

Standby Mode

Language

Reset

Power Contr ol

Page 10

LC-40C37U

LC-40C37U

CHAPTER 3. DIMENSIONS

[1] DIMENSIONS

Service Manual

Unit: inch/(mm)

243/32(612)

(725)

64

/

35

28

(666)

64

/

15

26

(59)

64

/

21

2

25

32

/64(822.6)

1

37

/4(946)

77/8(200)

(463.8)

64

/

17

18

(434)

32

/

3

17

45

/64(119)

4

12

1

45/8(117)

/64(305)

(200)

8

/

7

7

(96)

32

/

25

3

3 – 1

Page 11

PartsGuide

LC-40C37U

PARTS GUIDE

No. S46S3LC40C37U

★ MARK: SPARE PARTS-DELIVERY SECTION

CONTENTS

[1] PRINTED WIRING BOARD

ASSEMBLIES (NOT

REPLACEMENT ITEM)

[2] LCD PANEL (NOTE: THE PARTS

HERE SHOWN ARE SUPPLIED AS

AN ASSEMBLY BUT NOT

INDEPENDENTLY.)

[3] DUNTKD643FM12 (IF Unit)

MODEL

[4] CABINET AND MECHANICAL

PARTS

[5] SUPPLIED ACCESSORIES

[6] PACKING PARTS (NOT

REPLACEMENT ITEM)

[7] SERVICE JIGS

LC-40C37U

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these

parts with specified ones for maintaining the safety and performance of the set.

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

Page 12

LC-40C37U

NO. PARTS CODE

PRICE

RANK

NEW

MARK

★

DESCRIPTION

[1] PRINTED WIRING BOARD ASSEMBLIES (NOT REPLACEMENT ITEM)

N DUNTKD640FM12 - R MAIN Unit

N DUNTKD641FM12 - X LED Unit

N DUNTKD643FM12 - X IF Unit

N DUNTKD716FM12 - X KEY Unit

N RDENCA161WJQZ BQ X POWER SUPPLY Unit

[2] LCD PANEL (NOTE: THE PARTS HERE SHOWN ARE SUPPLIED AS AN ASSEMBLY BUT NOT INDEPEN-

DENTLY.)

N R1LK370T3LZ5BW EX X 37" WIDE LCD Panel Module Unit

[3] DUNTKD643FM12 (IF Unit)

FB2707 RBLN-A192WJZZY AA X Balun, BLN-A192WJ

FB2708 RBLN-A192WJZZY AA X Balun, BLN-A192WJ

2

Page 13

[4] CABINET AND MECHANICAL PARTS

3-1

10

59

64

1-1

4-1

4-2

4-3

5-1

5-2

1

50

51

30

55

55

11

4

5

38

43

63

62

36

18

15

61

44

56

54

35

58

26

32

29

29

21

1-3

1-2

1-6

1-6

1-6

1-6

6

53

23

53

16

12

24

21

27

55

20

55

57

57

55

2-1

2-4

2-2

2

27

65

49

21

32

55

30

13

8

59

45

3-2

3-4

3-3

31

27

57

3

47

46

48

34

1-4

1-4

1-5

1-5

2-3

5-3

5-4

5-3

5-4

5-4

5-3

17

52

41

55

14

22

19

55

58

55

25

37

7

43

42

55

66

33

42

9

39

55

37

1-7

5-3

5-5

40

5-5

5-6

LC-40C37U

3

Page 14

LC-40C37U

NO. PARTS CODE

PRICE

RANK

NEW

MARK

★

[4] CABINET AND MECHANICAL PARTS

1 CCABAB259WJ02 BK X Front Cabinet Ass'y

1-1 Not Available - - Front Cabinet

1-2 Not Available - - Front Cover

1-3 HBDGBA065WJSA AD X Badge, SHARP

1-4 PSPAHA416WJZZ AC X Mask Spacer, x2

1-5 Not Available - - Mask Spacer, x2

1-6 Not Available - - Spacer, x6

1-7 Not Available - - POP Label

2 CCABBA726WJ01 BQ X Rear Cabinet Ass'y

2-1 Not Available - - Rear Cabinet

2-2 LHLDWA055WJKZ AC X Wire Holder (for AC-code)

2-3 LHLDWA131WJKZ AF X Wire Holder

2-4 Not Available - - Spacer

3 CCOVAB497WJ01 BD X Top Cover Ass'y

3-1 Not Available - - Top Cover

3-2 JBTN-A429WJKA AD X Power Button

3-3 JBTN-A535WJKA X Operation Button

3-4 MSPRCA049WJFW AD X Power Button Spring

4 CDAi-A247WJ01 BC X Stand Support Ass'y

4-1 Not Available - - Support Cover

4-2 Not Available - - Stand Support

4-3 Not Available - - Screw Guide, x4

5 CDAi-A246WJ03 BA X Stand Base Ass'y

5-1 Not Available - - Stand Base Cover

5-2 Not Available - - Base Angle

5-3 Not Available - - LEG Cushion-A, x4

5-4 Not Available - - LEG Cushion-B, x4

5-5 XEBS740P10000 AB X Screw, x10

5-6 Not Available - - Stand Label

6 R1LK370T3LZ5BW EX X 37" WIDE LCD Panel Module Unit

7 DUNTKD640FM12 - R MAIN Unit

8 DUNTKD641FM12 - X LED Unit

9 DUNTKD643FM12 - X IF Unit

10 DUNTKD716FM12 - X

11 RDENCA161WJQZ BQ X POWER SUPPLY Unit

12 GCOVAA678WJKA AG X SD Card Cover

13 GCOVAB501WJSA AF X LED Cover

14 GCOVAB507WJKA AU X Stand Cover

15 HiNDPB603WJSA AK X Jack Indicator

16 HiNDPB715WJSA AF X Terminal Label

17 HiNDPB701WJSA AH X MODEL Label

18 LANGKA644WJFW AL X Jack Angle Long

19 LANGKA649WJFW AR X Stand Fix Angle

20 LANGKA655WJFW AH X Center Asist Angle

21 LANGKA663WJFW AK X Rug Angle, x4

22 LANGTA266WJFW AR X Stand Asist Angle

23 LANGTA291WJFW AR X Center Angle-R

24 LANGTA292WJFW AR X Center Angle-L

25 LBSHZA005WJZZ AB X Clip, x2

26 LCHSMA286WJFW AX X Chassis

27 LHLDW1173CEZZ AE X Wire Holder, x3

29 LHLDWA043WJKZ AC X Wire Holder (for Shield), x2

30 LHLDWA043WJKZ AC X Wire Holder (for Chassis), x2

31 LHLDWA048WJKZ AB X Wire Holder (for POWER Unit)

32 LHLDWA092WJZZ AB X Wire Holder (for Chassis), x2

33 LHLDWA096WJKZ AD X Wire Holder (for IF Unit)

34 Not Available - - Screw (for Stand Ass'y), x4

35 Not Available - - Screw (for Stand), x4

36 LX-NZ3047GEZZ AB X Hexiagonal Nut

37 PRDARA192WJFW AE X Hest Sink (for AV Switch)

38 PRDARA204WJFW AE X Hest Sink (for AMP-Bottom)

39 PRDARA312WJFW AE X Hest Sink (for AMP-Top)

40 PRDARA330WJFW AM X Hest Sink (for MAIN Unit)

41 PSLDMA910WJFW AV X MAIN Shield

42 PSPAZA635WJKZ AC X Spacer (Cool Sheet), x3

43 PSPAZA700WJKZ AD X Spacer (Cool Sheet), x3

44 QCNCWA496WJZZ AK X Connector (F-RCA)

QCNW-E265WJQZ AK X Connecting Cord (RA)

45

46 QCNW-E267WJQZ AG X Connecting Cord (LB)

47 QCNW-E286WJQZ AH X Connecting Cord (SP)

48 QCNW-E439WJQZ AH X Connecting Cord (LA)

49 QCNW-E537WJPZ BA X Connecting Cord (LV)

50 RSP-ZA166WJZZ AU X Speaker L

51 RSP-ZA167WJZZ AU X Speaker R

52 Not Available - - No. Label

53 XBBS740P06000 AA X Screw (for Angle), x6

54 XBBS930P06000 AA X Screw (for Cab-B), x5

55 XBPS730P06WS0 AB X Screw (for Angle, PWB), x39

56 XBPS930P08000 AA X Screw (for HDMI), x2

57 XEBS940P10000 AB X Screw (for Panel), x4

58 XEBS940P16000 AA X Screw (for Cab-B), x12

59 XEBSN30P10000 AA X Screw (for PWB), x5

61 XEBS930P08000 AA X Screw (for Jack), x3

62 QCNW-E257WJQZ AH R Connecting Cord (PE)

63 QCNW-E258WJQZ AG R Connecting Cord (PD)

KEY Unit

DESCRIPTION

4

Page 15

LC-40C37U

NO. PARTS CODE

PRICE

RANK

[4] CABINET AND MECHANICAL PARTS

64 QCNW-E266WJQZ AF R Connecting Cord (KM)

65 QCNW-E278WJQZ AH R Connecting Cord (SH)

66 QCNW-E442WJPZ AH R Connecting Cord (COAXIAL)

[5] SUPPLIED ACCESSORIES

X1

X7 X5

NO. PARTS CODE

[5] SUPPLIED ACCESSORIES

!

Cable Clamp

Operation manual

X2

PRICE

RANK

X1 LHLDW0110CESD AF X Cable Clamp

X2 LHLDWA083WJ00 AD X Cable Band

X3 QACCDA039WJPZ AR X AC Cord

X4 RRMCGA416WJSA BA X Remote Control Unit

X5 CDAi-A246WJ25 BL X Stand Ass'y

X6 TCADEA126WJZZ AC X Enquete Card

X7 TiNS-C413WJZZ AQ X Operation Manual

X8 TCAUZA228WJZZ X Caution Card

X9 TCAUHA184WJZZ AD X Set up Guide

X10 Not Available - - "AAA" Size Battery

NEW

MARK

Cable Band

Stand Ass'y

NEW

MARK

★

X3

AC Cord

X6

X8

X9

X10

★

DESCRIPTION

X4

DESCRIPTION

Remote Control Unit

5

Page 16

LC-40C37U

[6] PACKING PARTS (NOT REPLACEMENT ITEM)

S6

S6

S3

S4

S5

S7

S2

S6

NO. PARTS CODE

PRICE

RANK

NEW

MARK

S6

S1

★

[6] PACKING PARTS (NOT REPLACEMENT ITEM)

S1 SPAKCC521WJZZ - - Packing Case

S2 SPAKFA916WJZZ - - Stand Case

S3 SPAKPA338WJZZ - - Wrapping Paper (Monitor)

S4 SPAKPA601WJZZ - - Wrapping Paper (Mirror Mat A)

S5 SPAKPA602WJZZ - - Wrapping Paper (Mirror Mat B)

S6 SPAKXA957WJZZ - - Packing Add.

S7 SPAKXB198WJZZ - - Stand Pad

S8 TLABKA009WJZZ - - No. Label

S8

DESCRIPTION

6

Page 17

LC-40C37U

NO. PARTS CODE

PRICE

RANK

NEW

MARK

★

[7] SERVICE JIGS

N QCNW-C799WJPZ AG J RCA Cable L=1500mm, Tuner to Terminal

N QCNW-D483WJQZ AX J 12pins L=1000mm, Main to Power Unit (PE)

N QCNW-E068WJQZ AS J 6pins L=1000mm, Main to Power Unit (PD)

N QCNW-E670WJQZ AP J 4-8pins L=1000mm, Main to Inverter Unit (LB)

N QCNW-E671WJQZ AW J 10-14pins L=1000mm, Power to Inverter Unit (LA)

N QCNW-E673WJQZ BE J 32pins L=1000mm, Main to Controller Unit (LV)

N QCNW-E674WJQZ AS J 7pins L=1000mm, Main to Controller Unit (SH)

DESCRIPTION

7

Page 18

LC-40C37U

COPYRIGHT 2006 BY SHARP CORPORATION

ALL RIGHTS RESERVED.

No part of this publication may be reproduced,

stored in a retrieval system, or transmitted in

any form or by any means, electronic, mechanical,

photocopying, recording, or otherwise, without

prior written permission of the publisher.

TQ2016-S

Apr. 2006 Printed in Japan

Design and Production Information

Design: Japan

Production: SEMEX

SY. KD

SHARP CORPORATION

AV Systems Group

CS Promotion Center

Yaita, Tochigi 329-2193, Japan

Loading...

Loading...