Page 1

LC-37SH20U

S36S1LC37SH20

LCD COLOR TELEVISION

MODEL

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored

to its original condition and only parts identical to those specified should be used.

LC-37SH20U

OUTLINE

This model is based on the LC-37D40U and partially modified.

For the contents not covered in this Service Manual, accordingly, please refer to the LC-37D40U Service

Manual.

CONTENTS

» IMPORTANT SERVICE SAFETY PRECAUTION .........................................................................................3

» SPECIFICATIONS ........................................................................................................................................ 6

» OPERATION MANUAL .................................................................................................................................7

» DIMENSIONS ............................................................................................................................................. 11

» REMOVING OF MAJOR PARTS ................................................................................................................12

» DESCRIPTION OF SCHEMATIC DIAGRAM .............................................................................................. 17

» SCHEMATIC DIAGRAM ............................................................................................................................. 18

» REPLACEMENT PARTS LIST ....................................................................................................................24

» PACKING OF THE SET ..............................................................................................................................27

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Page 2

LC-37SH20U

LIST OF CHANGED PARTS

Ref. No. Description LC-37D40U LC-37SH20U Note

PRINTED WIRING BOARD ASSEMBLIES

MAIN Unit DUNTKD640FM06 DUNTKD640FM08 Some parts change

R/C,LED Unit DUNTKD641FM06 DUNTKD641FM08 Some parts change

IF Unit DUNTKD643FM06 DUNTKD643FM08 Some parts change

KEY Unit DUNTKD716FM06 DUNTKD716FM08 No parts change

POWER Unit RDENCA161WJQZ RDENCA161WJQZ

MAIN Unit

C1513 Capacitor RC-KZA510WJPZY — Delete

C1515 Capacitor VCKYCZ1CB103KY — Delete

C1517 Capacitor RC-KZA510WJPZY — Delete

C1519 Capacitor VCKYCZ1EF104ZY — Delete

D1503 Diode VHDDAN202K/-1Y — Delete

D1505 Diode VHD1SS355//-1Y — Delete

D1509 Diode VHD1SS226//-1Y — Delete

D1513 Diode VHD1SS226//-1Y — Delete

D1514 Diode VHD1SS355//-1Y — Delete

FB1510 Ferrite Bead RBLN-0210TAZZY — Delete

IC1501 IC VHi24LC2BiN-1Y — Delete

L1506 Coil RCiLFA116WJZZY — Delete

L1507 Coil RCiLFA116WJZZY — Delete

L1508 Coil RCiLFA116WJZZY — Delete

L1509 Coil RCiLFA116WJZZY — Delete

Q1503 Transistor VSUM6K1NTN+-1Y — Delete

Q1506 Transistor VSKRC404E++-1Y — Delete

Q1508 Transistor VSKRC404E++-1Y — Delete

Q1514 Transistor VSiMD2A////-1Y — Delete

R1501 Resistor VRS-CZ1JF102JY — Delete

R1532 Resistor VRS-CZ1JF473FY — Delete

R1535 Resistor VRS-CZ1JF473FY — Delete

R1536 Resistor VRS-CZ1JF100JY — Delete

R1539 Resistor VRS-CZ1JF473FY — Delete

R1540 Resistor VRS-CZ1JF100JY — Delete

R1545 Resistor VRS-CY1JF474JY — Delete

R1546 Resistor VRS-CY1JF474JY — Delete

R1555 Resistor VRS-CZ1JF103JY — Delete

R1559 Resistor VRS-CZ1JF103JY — Delete

R1633 Resistor — VRS-CZ1JF103JY Add

R8124 Resistor — VRS-CZ1JF103JY Add

R8188 Resistor VRS-CZ1JF103JY — Delete

SC1501 Socket QSOCZA072WJZZQ — Delete

R/C,LED Unit

C103 Capacitor VCKYCY1HF103ZY — Delete

C104 Capacitor VCEASX1CN106MY — Delete

IC101 IC VHiTPS850++-1Y — Delete

IF Unit

C511 Capacitor RC-KZA237WJZZY — Delete

C513 Capacitor RC-KZA237WJZZY — Delete

C517 Capacitor RC-KZA237WJZZY — Delete

C533 Capacitor — VCKYCY1EF104ZY Add

C534 Capacitor — VCKYCY1EF104ZY Add

C535 Capacitor — VCKYCY1EF104ZY Add

D515 Diode VHDDAN217U+-1Y — Delete

D516 Diode VHDDAN217U+-1Y — Delete

D517 Diode VHDDAN217U+-1Y — Delete

FB511 Ferrite Bead RBLN-A204WJZZY — Delete

FB514 Ferrite Bead RBLN-A204WJZZY — Delete

FB517 Ferrite Bead RBLN-A204WJZZY — Delete

J502 Jack QTANJA093WJZZ QTANJA101WJZZ

R519 Resistor VRS-TQ2BD750JY — Delete

R520 Resistor VRS-CY1JF102JY — Delete

R525 Resistor VRS-TQ2BD750JY — Delete

R530 Resistor VRS-TQ2BD750JY — Delete

R554 Resistor VRS-CY1JF220JY — Delete

R555 Resistor VRS-CY1JF220JY — Delete

R556 Resistor VRS-CY1JF220JY — Delete

R558 Resistor VRS-CY1JF101JY — Delete

R602 Resistor — VRS-CY1JF000JY Add

2

Page 3

LC-37SH20U

2

3

3

1.5k ohm

10W

0.15 µF

TEST PROBE

TO EXPOSED

METAL PARTS

CONNECT TO

KNOWN EARTH

GROUND

DVM

AC SCALE

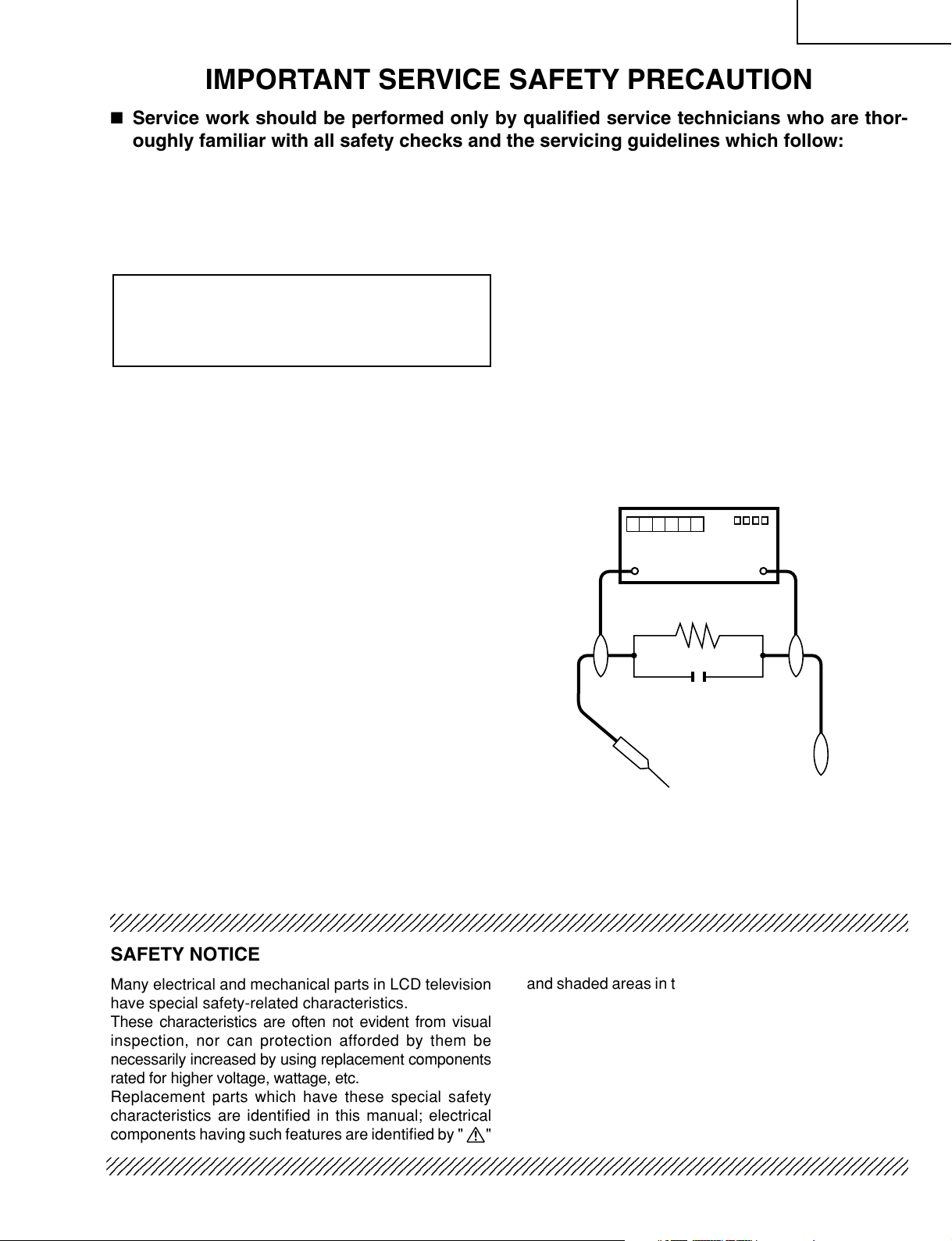

IMPORTANT SERVICE SAFETY PRECAUTION

Ë

Service work should be performed only by qualified service technicians who are thoroughly familiar with all safety checks and the servicing guidelines which follow:

WARNING

1. For continued safety, no modification of any circuit

should be attempted.

2. Disconnect AC power before servicing.

CAUTION: FOR CONTINUED PROTECTION

AGAINST A RISK OF FIRE REPLACE ONLY WITH

SAME TYPE F701 (8A, 125V) AND F4701, F5701

(3A~, 250V, 115°C) FUSE.

BEFORE RETURNING THE RECEIVER

(Fire & Shock Hazard)

Before returning the receiver to the user, perform

the following safety checks:

1. Inspect all lead dress to make certain that leads are

not pinched, and check that hardware is not lodged

between the chassis and other metal parts in the

receiver.

2. Inspect all protective devices such as non-metallic

control knobs, insulation materials, cabinet backs,

adjustment and compartment covers or shields, isolation

resistor-capacitor networks, mechanical insulators, etc.

3. To be sure that no shock hazard exists, check for

leakage current in the following manner.

• Plug the AC cord directly into a 120 volt AC outlet.

• Using two clip leads, connect a 1.5k ohm, 10 watt

resistor paralleled by a 0.15µF capacitor in series with

all exposed metal cabinet parts and a known earth

ground, such as electrical conduit or electrical ground

connected to an earth ground.

• Use an AC voltmeter having with 5000 ohm per volt, or

higher, sensitivity or measure the AC voltage drop

across the resistor.

• Connect the resistor connection to all exposed metal

parts having a return to the chassis (antenna, metal

cabinet, screw heads, knobs and control shafts,

escutcheon, etc.) and measure the AC voltage drop

across the resistor.

All checks must be repeated with the AC cord plug

connection reversed. (If necessary, a nonpolarized

adaptor plug must be used only for the purpose of

completing these checks.)

Any reading of 0.75V rms (this corresponds to 0.5 mA

rms AC.) or more is excessive and indicates a potential

shock hazard which must be corrected before returning

the monitor to the owner.

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

SAFETY NOTICE

Many electrical and mechanical parts in LCD television

have special safety-related characteristics.

These characteristics are often not evident from visual

inspection, nor can protection afforded by them be

necessarily increased by using replacement components

rated for higher voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this manual; electrical

components having such features are identified by " å"

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212

and shaded areas in the

Schematic Diagrams

Replacement Parts Lists

.

For continued protection, replacement parts must be

identical to those used in the original circuit.

The use of a substitute replacement parts which do not

have the same safety characteristics as the factory

recommended replacement parts shown in this service

manual, may create shock, fire or other hazards.

3

and

Page 4

LC-37SH20U

1

1

1

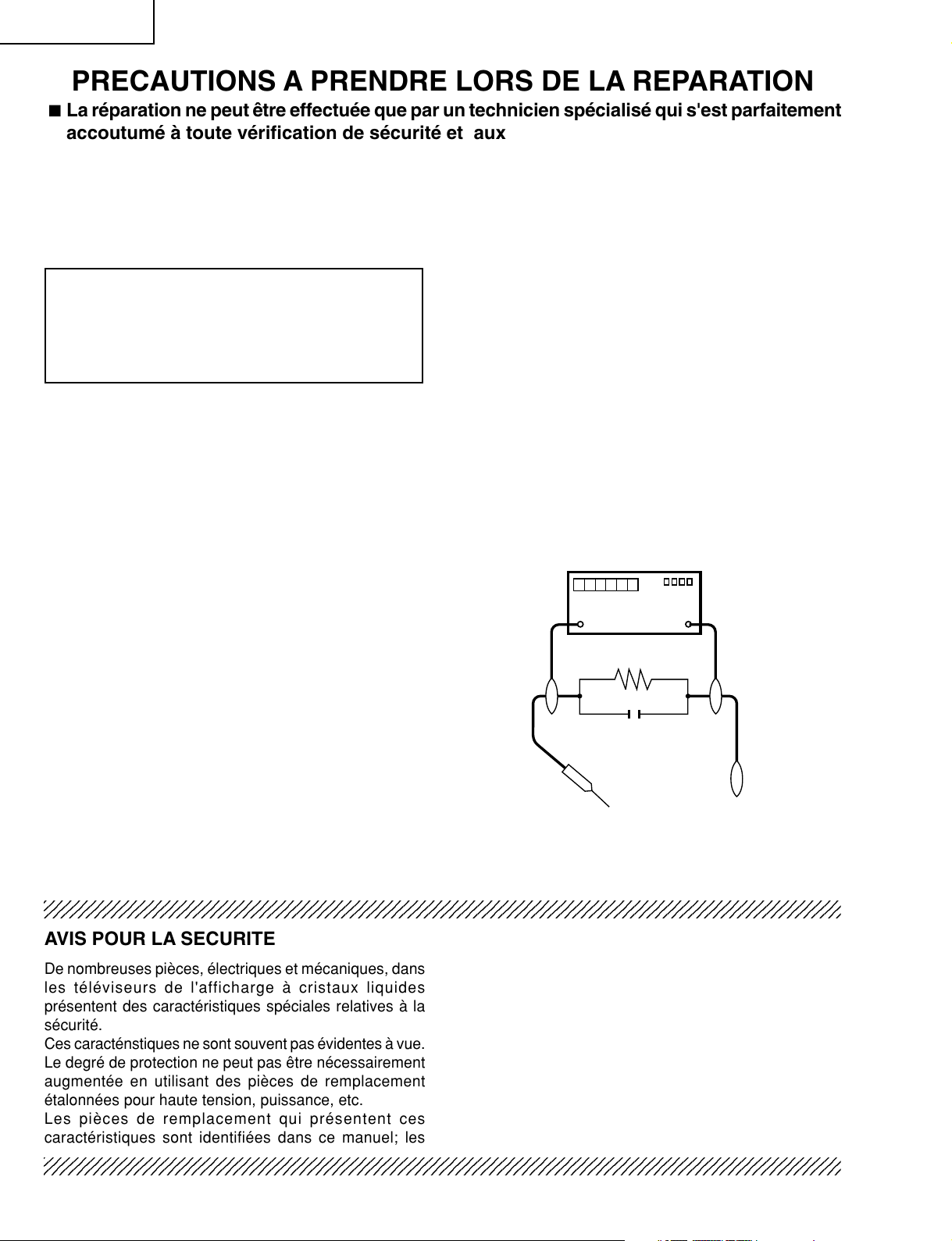

PRECAUTIONS A PRENDRE LORS DE LA REPARATION

Ë

La réparation ne peut être effectuée que par un technicien spécialisé qui s'est parfaitement

accoutumé à toute vérification de sécurité et aux conseils suivants.

AVERTISSEMENT

1. Pour la sécurité continue, n'entreprendre aucune

modification de tout circuit.

2. Débrancher l'alimentation CA avant la réparation.

PRECAUTION: POUR LA PROTECTION

CONTINUE CONTRE LES RISQUES

D'INCENDIE, REMPLACER LE FUSIBLE PAR UN

FUSIBLE DE MEME TYPE F701 (8A, 125V) UND

F4701, F5701 (3A~, 250V, 115°C) FUSE.

AVANT DE RENDRE LE RECEPTEUR A

L’UTILISATEUR (Incendie et choc électrique)

Avant de rendre le récepteur à l'utilisateur, effectuer

les vérifications suivantes.

1. Inspecter tous les faisceaux de câbles pour s'assurer

que les fils ne soient pas pincés ou qu'un outil ne soit

pas placé entre le châssis et les autres pièces

métalliques du récepteur.

2. Inspecter tous les dispositifs de protection comme les

boutons de commande non-métalliques, les isolants,

le dos du coffret, les couvercles ou blindages de réglage

et de compartiment, les réseaux de résistance-capacité,

les isolateurs mécaniques, etc.

3. S'assurer qu'il n'y ait pas de danger d'électrocution en

vérifiant la fuite de courant, de la facon suivante:

• Enficher le cordon d'alimentation directement dans une

prise de 120V CA.

• A l'aide de deux fils à pinces, brancher une résistance

de 1.5kΩ 10 watts en parallèle avec un condensateur

de 0.15µF en série avec toutes les pièces métalliques

exposées du coffret et une terre connue comme une

conduite électrique ou une prise de terre branchée à la

terre.

• Utiliser un voltmètre CA d'une sensibilité d'au moins

5000Ω/V pour mesurer la chute de tension CA en

travers de la résistance.

• Toucher avec la sonde d'essai les pièces métalliques

exposées qui présentent une voie de retour au châssis

(antenne, coffret métallique, tête des vis, arbres de

commande et des boutons, écusson, etc.) et mesurer

la chute de tension CA en travers de la résistance.

Toutes les vérifications doivent être refaites après avoir

inversé la fiche du cordon d'alimentation. (Si nécessaire,

une prise d'adpatation non polarisée doit être utilisée

dans le but de terminer ces vérifications.)

La tension de pointe mesurèe ne doit pas dépasser

0.75V RMS (correspondante au courant CA de pointe

de 0.5mA RMS). Dans le cas contraire, il y a une

possibilité de choc électrique qui doit être supprimée

avant de rendre le récepteur au client.

DVM

ECHELLE CA

1.5k ohm

10W

0.15 µF

SONDE D'ESSAI

AUX PIECES

METALLIQUES

EXPOSEES

BRANCHER A UNE

TERRE CONNUE

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

AVIS POUR LA SECURITE

De nombreuses pièces, électriques et mécaniques, dans

les tél éviseurs de l'afficharge à cristaux liquides

présentent des caractéristiques spéciales relatives à la

sécurité.

Ces caracténstiques ne sont souvent pas évidentes à vue.

Le degré de protection ne peut pas être nécessairement

augmentée en utilisant des pièces de remplacement

étalonnées pour haute tension, puissance, etc.

Les pièces de remplacement qui présentent ces

caractéristiques sont identifiées dans ce manuel; les

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

pièces électriques qui présentent ces particularités sont

identifiées par la marque " å " et hachurées dans la

des pièces de remplacement

schématiques

.

et les

diagrammes

Pour assurer la protection, ces pièces doivent être

identiques à celles utilisées dans le circuit d'origine.

L'utilisation de pièces qui n'ont pas les mêmes

caractéristiques que les pièces recommandées par

l'usine, indiquées dans ce manuel, peut provoquer des

électrocutions, incendies ou autres accidents.

4

liste

Page 5

LC-37SH20U

Precautions for using lead-free solder

1 Employing lead-free solder

"All PWBs" of this model employs lead-free solder. The LF symbol indicates lead-free solder, and is attached on

the PWBs and service manuals. The alphabetical character following LF shows the type of lead-free solder.

Example:

L Fa

Indicates lead-free solder of tin, silver and copper.

2 Using lead-free wire solder

When fixing the PWB soldered with the lead-free solder, apply lead-free wire solder. Repairing with conventional

lead wire solder may cause damage or accident due to cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40°C, we recommend

you to use a dedicated soldering bit, if you are not familiar with how to obtain lead-free wire solder or soldering bit,

contact our service station or service branch in your area.

3 Soldering

As the melting point of lead-free solder (Sn-Ag-Cu) is about 220°C which is higher than the conventional lead

solder by 40°C, and as it has poor solder wettability, you may be apt to keep the soldering bit in contact with the

PWB for extended period of time. However, Since the land may be peeled off or the maximum heat-resistance

temperature of parts may be exceeded, remove the bit from the PWB as soon as you confirm the steady soldering

condition.

Lead-free solder contains more tin, and the end of the soldering bit may be easily corroded. Make sure to turn on

and off the power of the bit as required.

If a different type of solder stays on the tip of the soldering bit, it is alloyed with lead-free solder. Clean the bit after

every use of it.

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sandpaper.

Be careful when replacing parts with polarity indication on the PWB silk.

Lead-free wire solder for servicing

Part No. ★ Description Code

ZHNDAi123250E J φ0.3mm 250g(1roll) BL

ZHNDAi126500E J φ0.6mm 500g(1roll) BK

ZHNDAi12801KE J φ1.0mm 1kg(1roll) BM

5

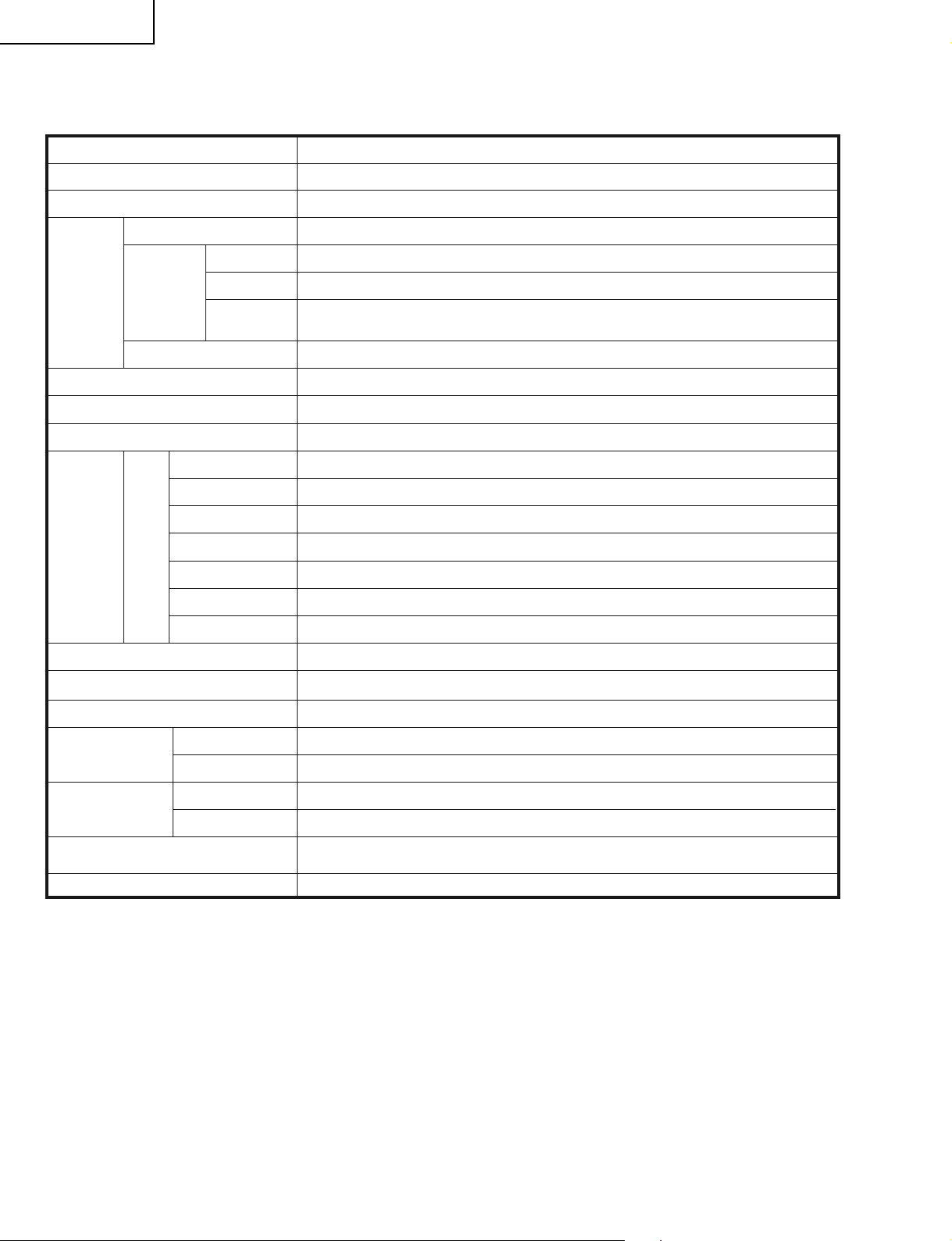

Page 6

LC-37SH20U

SPECIFICATIONS

Item

LCD panel

Number of dots

TV-standard (CCIR)

TV

Function

Brightness

Viewing angles

Audio out

Terminals

Receiving

Channel

Audio multiplex

Rear

Model: LC-37SH20U

37" Advanced Super View & BLACK TFT LCD

3,147,264 dots (1366 768 3 dots)

American TV Standard ATSC/NTSC System

VHF/UHF

CATV

Digital Terrestrial

Broadcast (8VSB)

INPUT 1

INPUT 2

INPUT 3

INPUT 4

ANTENNA

DIGITAL AUDIO OUTPUT

VHF 2-13ch, UHF 14-69ch

1-135ch* (non-scrambled channel only)

2-69ch

BTSC System

450cd/m

H : 170° V : 170°

10W 2

AV in, COMPONENT in

AV in

S-VIDEO in, AV in

Audio in, HDMI in with HDCP

75 Unbalance, F Type 1 for Analog (VHF/UHF/CATV) and Digital (AIR/CABLE)

Ω

Optical Digital audio output 1 (PCM/Dolby Digital)

××

2

×

×

×

OUTPUT

OSD language

Power Requirement

Power Consumption

Weight

Dimension

××

(W H D)

Accessories

Operating temperature

* Emergency alert messages via Cable are unreceivable.

As part of policy of continuous improvement, SHARP reserves the right to make design and specification changes for product

•

improvement without prior notice. The performance specification figures indicated are nominal values of production units.

There may be some deviations from these values in individual units.

w/o stand

with stand

w/o stand

with stand

Audio out

English/French/Spanish

AC 120 V, 60 Hz

186 W

46.3 lbs./21.5 kg

53.0 lbs./24.0 kg

25

36

36

Remote control unit (×1), AC cord (×1), “AA” size battery (×2), Cable clamp (×1),

Cable tie (×1), Stand unit (×1), Operation manual (×1)

×

/32 2561/64 445/64 inch

25

××

/32 285/16 129/32 inch

++ +

32°F to 104°F (0°C to 40°C)

×

6

Page 7

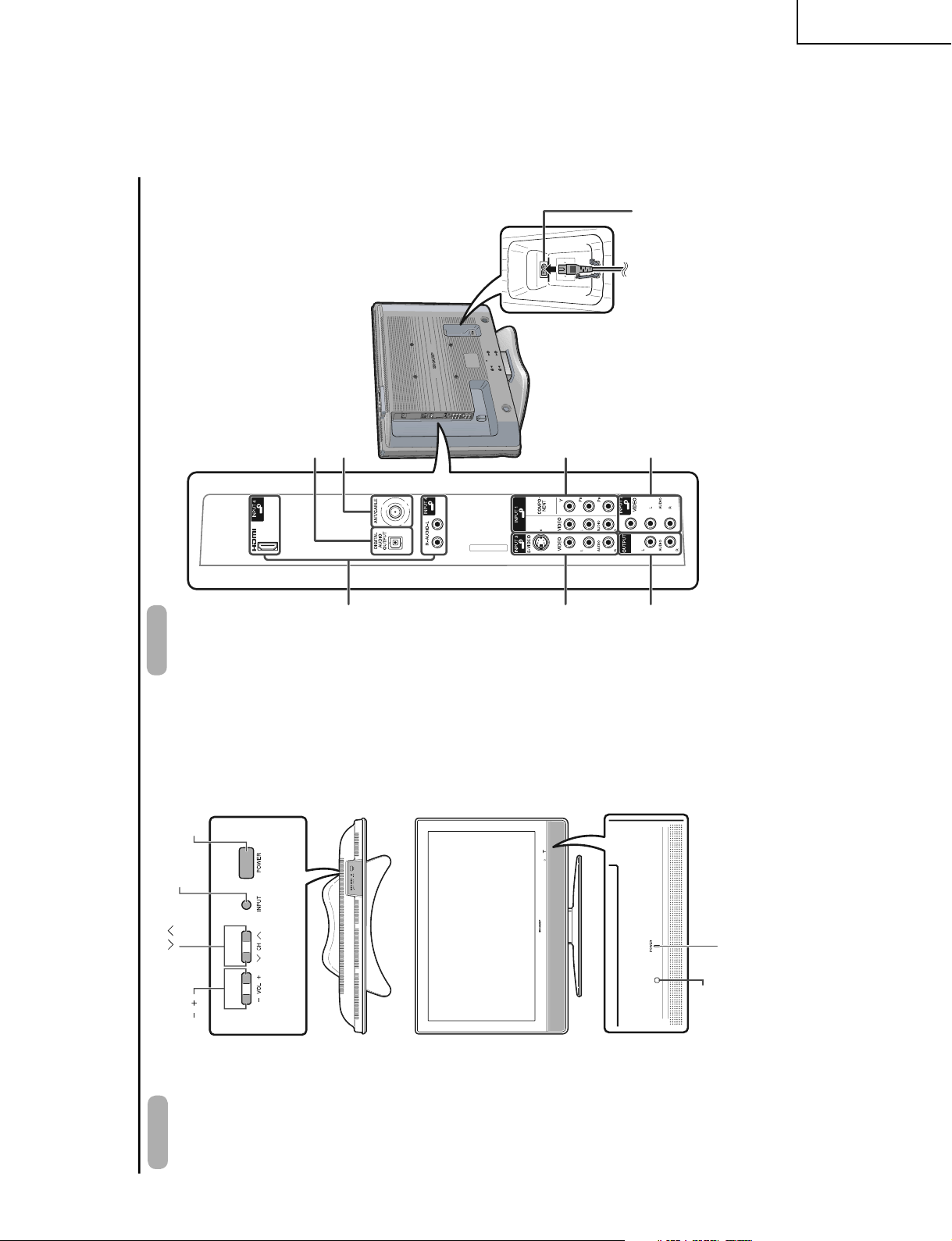

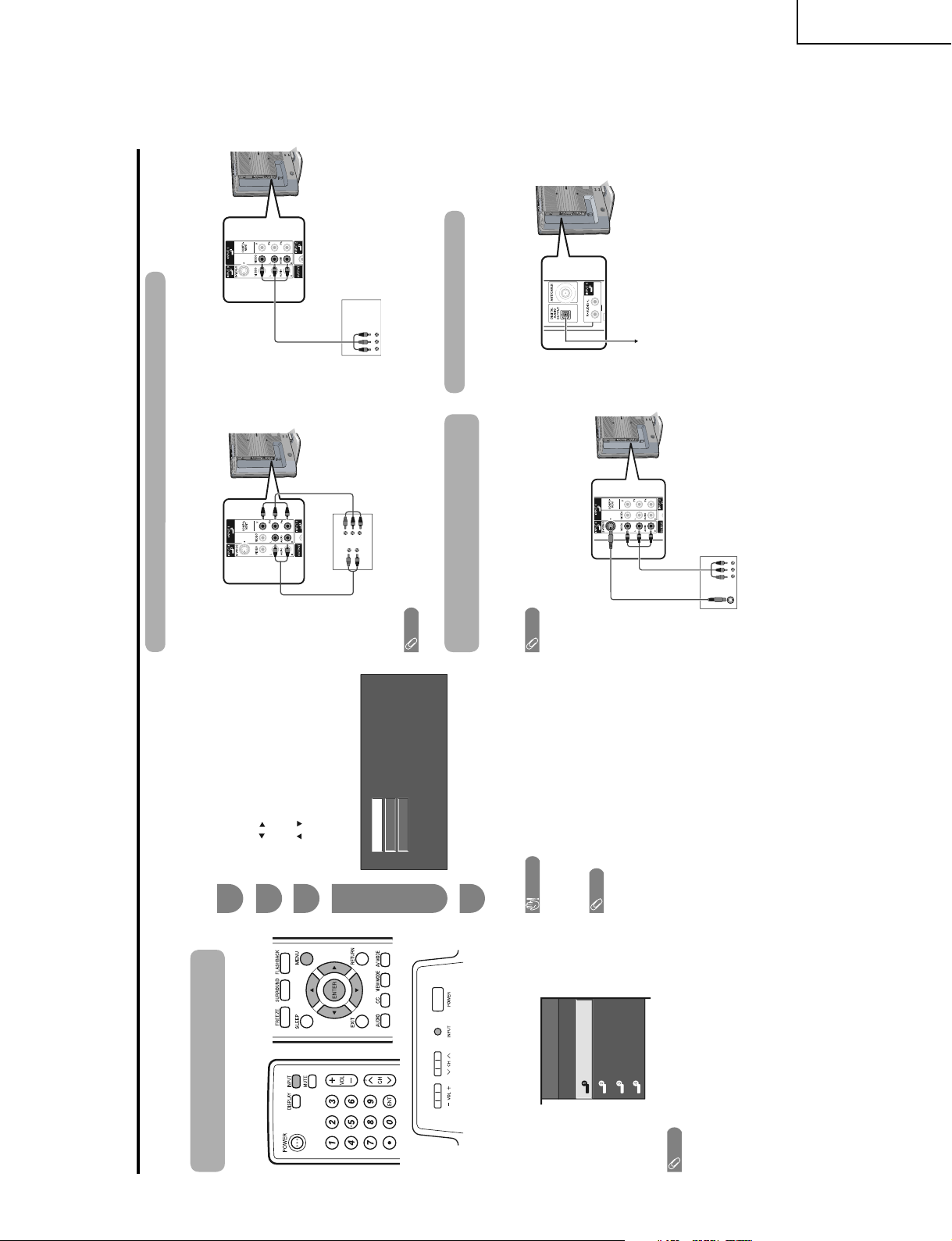

OPERATION MANUAL

Part names

POWER button

TV (Front)

Channel buttons

(CH /)

Volume buttons (VOL /)

INPUT button

POWER indicator*

Remote control sensor

INPUT 4

INPUT 3

AUDIO OUTPUT

DIGITAL AUDIO OUTPUT terminal

Antenna/Cable in

AC INPUT terminal

TV (Rear)

terminals

terminals

INPUT 1 terminals

INPUT 2 terminals

terminals

LC-37SH20U

7

Page 8

LC-37SH20U

1

3

5

4

11

2

16

12

13

14

15

18

17

19

22

20

21

9

10

7

8

6

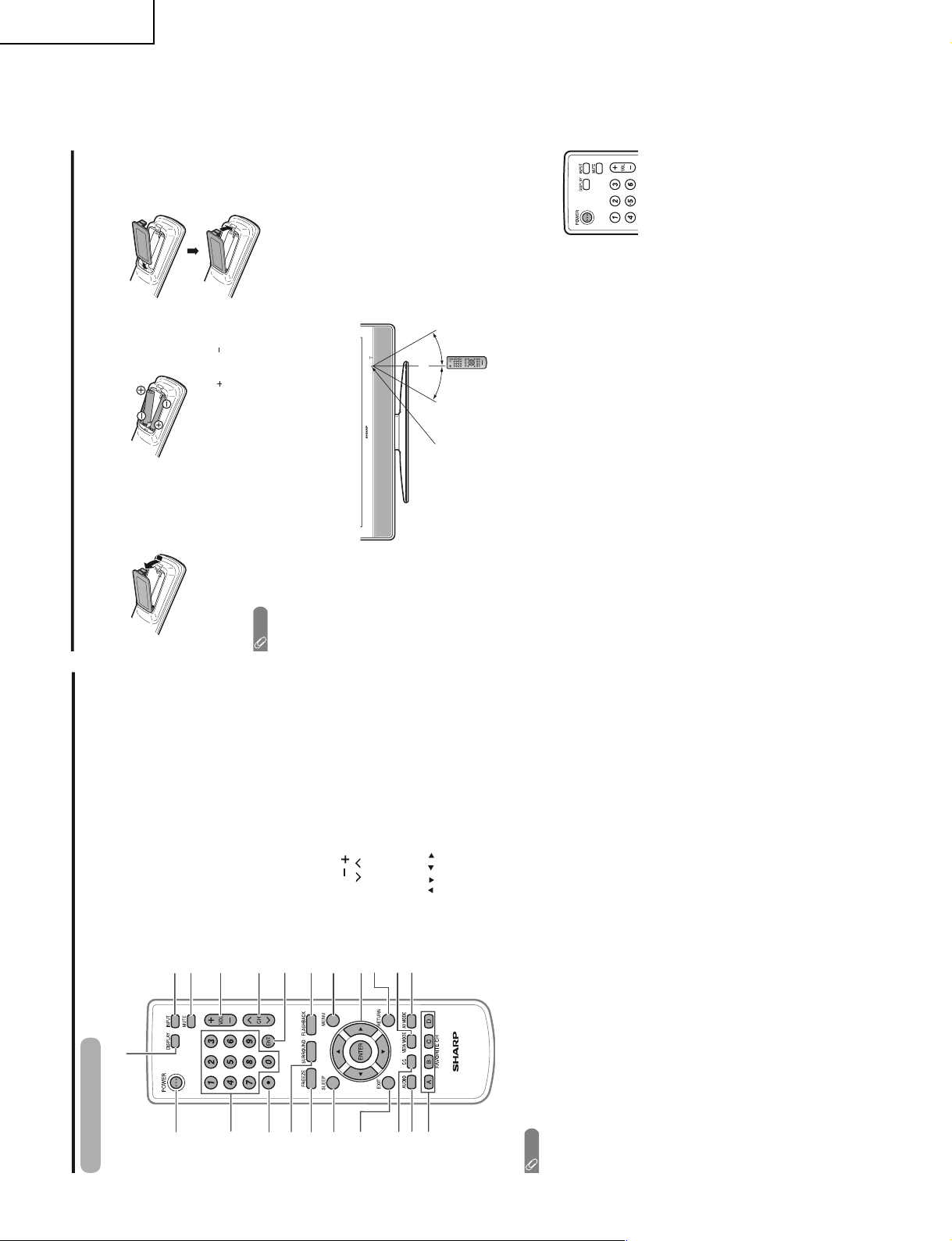

Part names

1 POWER: Switch the TV power on or enter standby

mode.

2 0 – 9: Set the channel.

3 • (DOT):

4 SURROUND: Select Surround settings.

5 FREEZE: Set the still image. Press again to return to

normal screen.

6 SLEEP: Set the sleep timer.

7 EXIT: Turn off the menu screen.

8 CC: Display captions from a closed-caption source.

9 AUDIO: Select the MTS/SAP or the audio mode during

multi-channel audio broadcasts.

10 FAVORITE CH

A, B, C, D: Select four preset favorite channels in four

different categories.

While watching, you can toggle the selected channels by

pressing A, B, C and D

11 DISPLAY: Display the channel information.

12 INPUT: Select a TV input source. (TV, INPUT 1, INPUT 2,

INPUT 3, INPUT 4)

13 MUTE: Mute the sound.

14 VOL /: Set the volume.

15 CH / : Select the channel.

16 ENT: Jump to a channel after selecting with the 0–9

buttons.

17 FLASHBACK: Return to the previous channel or input

external mode.

18 MENU: Display the menu screen.

19 /

///ENTER: Select a desired item on the

screen.

20 RETURN: Return to the previous menu screen.

21 VIEW MODE: Select the screen size.

22 AV MODE: Select an audio or video setting. (STANDARD,

MOVIE, GAME, USER, DYNAMIC (Fixed), DYNAMIC.)

Remote control unit

NOTE

• When using the remote control unit, point it at the TV.

30°30°

QUICK REFERENCE

If the remote control fails to operate TV functions, replace the batteries in the remote control unit.

1 Open the battery cover.

• Place the batteries with their terminals

corresponding to the ( ) and ( )

indications in the battery compartment.

NOTE

Improper use of batteries can result in chemical leakage or explosion. Be sure to follow the instructions below.

• Do not mix batteries of different types. Different types of batteries have different characteristics.

• Do not mix old and new batteries. Mixing old and new batteries can shorten the life of new batteries or cause chemical

leakage in old batteries.

• Remove batteries as soon as they are worn out. Chemicals that leak from batteries that come in contact with skin can cause

a rash. If you find any chemical leakage, wipe thoroughly with a cloth.

• The batteries supplied with this product may have a shorter life expectancy due to storage conditions.

• If you will not be using the remote control unit for an extended period of time, remove batteries from it.

Remote control

sensor

2 Insert two "AA" size batteries

(supplied with the product).

3 Close the battery cover.

IMPORTANT:

The POWER indicator on the television should light GREEN indicating you have power to the television.

If the POWER indicator on the television still does not light up, press POWER on the

remote control to turn the power on.

IMPORTANT:

IF THE UNIT DOES NOT POWER ON - UNPLUG THE TELEVISION FROM THE OUTLET AND REPEAT THE

INSTALLATION STEPS.

IF YOU STILL ENCOUNTER NO POWER, PLEASE CONTACT US AT 1-800-BE-SHARP.

Please refer to the BASIC ADJUSTMENT SETTINGS SECTION for EZ Setup and basic channel setup functions

and USING EXTERNAL EQUIPMENT SECTION for other device connections (DVD, VCR, AUDIO, etc) in your

operation manual.

16'4" (5 m)

8

Page 9

INPUT SOURCE

TV

INPUT1

INPUT2

INPUT3

INPUT4

Displaying an external equipment

image

This explanation is for the setting when connecting a

DVD player to the INPUT1 terminal.

The setting is stored and can be selected on the "INPUT

SOURCE" menu.

CAUTION

• To protect equipment, always turn off the TV before

connecting a DVD player, VCR, Digital TV tuner, HDMI

equipment, game console, camcorder or other external

equipment.

NOTE

• Please read the relevant operation manual (DVD player,

etc.) carefully before making connections.

• Each time INPUT is pressed, the input source toggles.

• Refer to your external equipment operation manual for the

signal type.

Using external equipment

NOTE

• If the image does not come in clearly, you may need to

change the input signal type setting on the "Input Select"

menu.

Selecting the INPUT signal

Press MENU and the MENU screen displays.

Press / to select "Option".

Press / to select "Input Select", and then

press ENTER.

Select the desired signal type.

For INPUT1 signal

1

2

4

3

Auto

COMPONENT

VIDEO

(Example)

Press MENU to exit.

5

You can connect many types of external equipment to your TV like a DVD player, VCR, Digital TV tuner, HDMI

equipment, game console or camcorder. To view external source images, select the input source from

INPUT on

the remote control unit or on the TV.

To watch a DVD image, select "INPUT1" from "INPUT

SOURCE" menu using

INPUT on the remote control

unit or on the TV.

Connecting a DVD player or a Digital TV STB (Air or Cable)

You can use the INPUT 1, INPUT 2 or INPUT 3 terminals when connecting to a DVD player, a Digital TV STB (Air or

Cable) and other audiovisual equipment.

DVD player/

Digital TV STB

NOTE

• See page for connecting a DVD player or a Digital TV STB to the HDMI terminal.

Connecting a VCR, game console or

camcorder

A VCR, game console, camcorder and other

audiovisual equipment can be conveniently connected

using the INPUT 1 to 3 terminals.

NOTE

• The S-video terminal takes priority over the video terminals.

(INPUT 3 only)

VCR/Game console/

Camcorder

Using Digital Audio Output

It is possible to output audio through the DIGITAL

AUDIO OUTPUT terminal.

PCM audio outputs from the terminal.

When using component cable. (INPUT 1) When using composite cable. (INPUT 1, 2 or 3)

Component video

cable (commercially

available)

AV cable

(commercially available)

Audio cable

(commercially

available)

S-video cable

(commercially

available)

AV cable (commercially

available)

To optical digital input of

external audio devices

DVD player/

Digital TV STB

Optical fiber cable

LC-37SH20U

9

Page 10

LC-37SH20U

INPUT SOURCE

TV

INPUT1

INPUT2

INPUT3

INPUT4

Connecting HDMI equipment

You can use the INPUT 4 terminal when connecting HDMI equipment.

HDMI cable (Commercially

available)

Press / / / to select the desired

setting and press ENTER.

NOTE

• Refer to your external equipment operation manual for the

signal type.

Using external equipment

When using an HDMI-DVI

conversion cable, input the

audio signal to AUDIO terminal

of INPUT 4.

HDMI equipment

Displaying an image from HDMI

equipment

To watch an HDMI equipment image, select

"INPUT4" from "INPUT SOURCE" menu

using INPUT on the remote control unit or on

the TV.

Press MENU and the MENU screen displays.

Press / to select "Option".

Press / to select “HDMI Setup”, and then

press ENTER.

Press / to select the desired item and

press ENTER.

1

2

3

4

5

6

HDMI

Setup

items

Selectable

items

Description

Signal

Type

Auto View

Audio

Select

RGB/YCbCr 4:4:4/

YCbCr 4:2:2

Digital/Analog

Select the video signal type from

the HDMI terminal.

Set whether or not to use

View Mode based on signal

recognition, including an HDMI

signal.

Select "Digital"” for an audio

signal via the HDMI terminal.

Select "Analog" for an audio

signal via the R-AUDIO -L

terminal.

MENU

[

Option

...

HDMI Setup

]

Option

Digital Noise Reduction

Output Select

Audio Only

Quick Shoot

[Fixed]

HDMI Setup

[Low]

Press MENU to exit.

7

[Off]

Enable/Disable

Picture

Setup

Audio

Option

Power Control

Digital Setup

ENTER

: Select : Enter

MENU

: Exit

RETURN

: Back

Menu items

List of menu items to help you with operations

Basic adjustment settings

Backlight

Contrast

Brightness

Color

Tint

Sharpness

Advanced

Color Temp.

Black

3D-Y/C

Monochrome

Film Mode

EZ Setup

CH Setup

Antenna Setup-DIGITAL

Input Skip

Input Label

Parental CTRL

Position

Picture Flip

Standby Mode

Language

Reset

Treble

Bass

Balance

Surround

Audio Only

Digital Noise Reduction

Input Select

HDMI Setup

Output Select

Quick Shoot

Color System

Caption Setup

Program Title Display

Favorite CH

No Signal Off

No Operation Off

Audio Setup

Menu operation buttons

Use the following buttons on the remote control to

operate the menu.

MENU: Press to open or close the menu screen.

///: Press to select a desired item on the

screen or adjust a selected item.

ENTER: Press to go to the next step or complete

the setting.

RETURN: Press to return to the previous step.

The bar above is an operational guide for

the remote control. The bar will change in

accordance with each menu setting screen.

10

Page 11

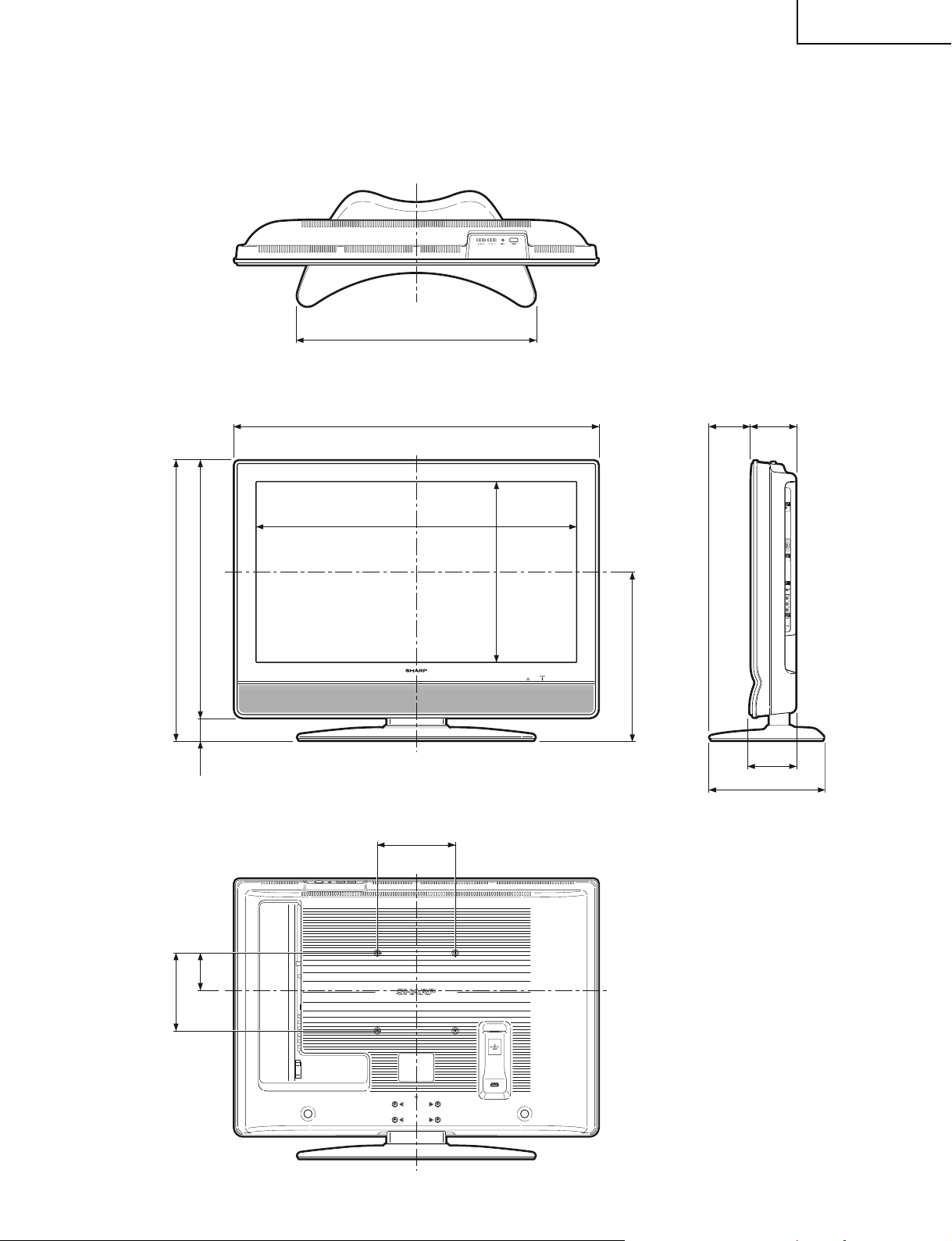

Unit: inch/(mm)

77/8 (200)

32

25

/64 (822.6)

36

25

/32 (934) 457/64 (124)417/32 (115)

12

9

/32 (312)

4

45

/64 (119)

24

13

/16 (630)

7

7

/

8

(200)

3

25

/

32

(96)

18

17

/

64

(463.8)

17

1

/

16

(433)

28

5

/

16

(719)

25

61

/

64

(659)2

3

/

8

(60)

LC-37SH20U

DIMENSIONS

11

Page 12

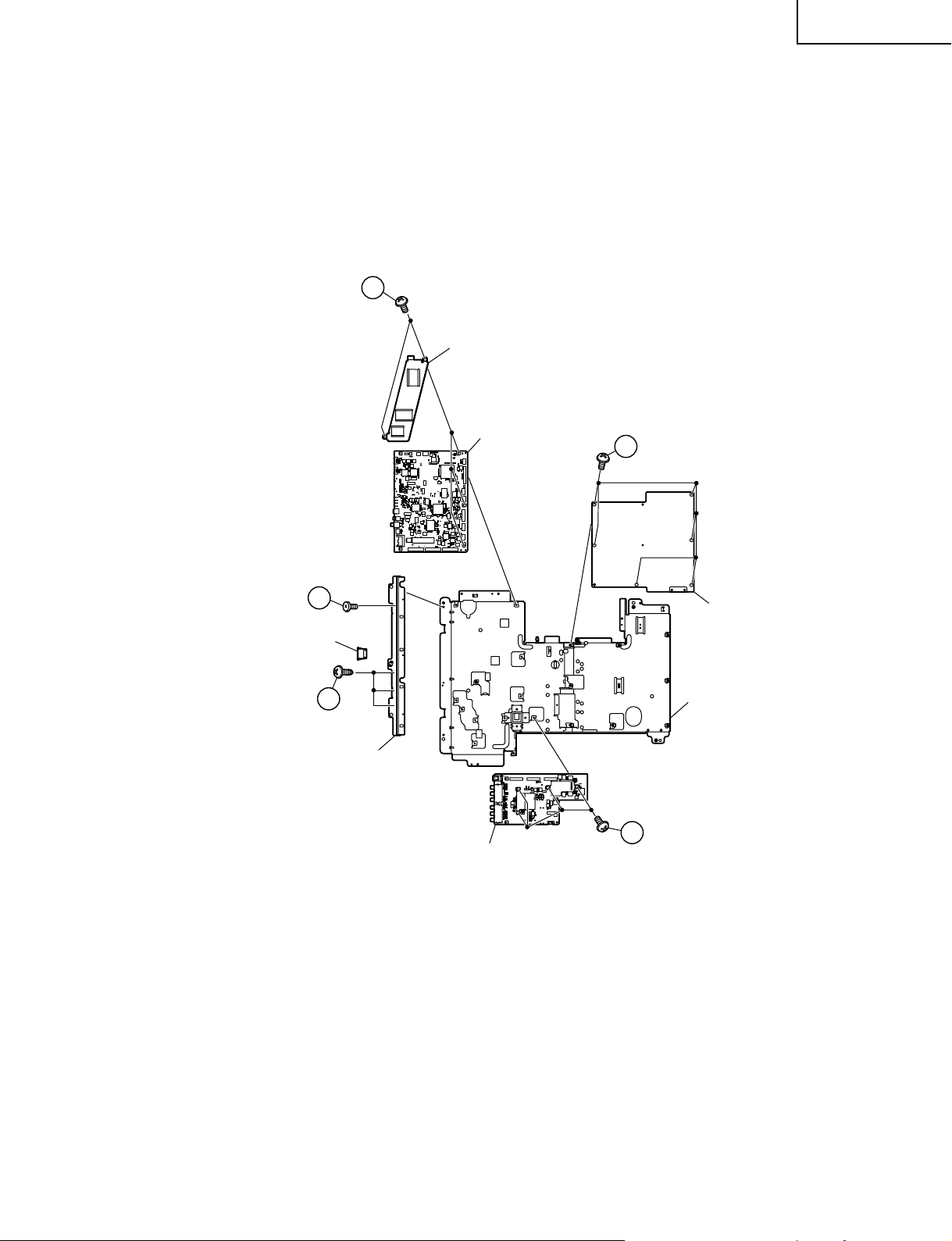

LC-37SH20U

REMOVING OF MAJOR PARTS

1. Remove the stand fixing screws (4 pcs.).

2. Remove the terminal screws (6 pcs.).

3. Remove the cabinet B fixing screws (9 pcs.).

4. Remove the cabinet B after opening from the direction of an arrow.

Cabinet B

3

Cabinet A

2

1

4

Stand

12

Page 13

5. Remove the 6 lock screws from the right and left center angles and take out both center angles.

6. Remove the stand cover fixing screws (3 pcs.).

7. Remove the stand assist angle fixing screws (2 pcs.).

8. Remove the stand fixing angle fixing screws (4 pcs.).

9. Remove the main PWB shield fixing screws (5 pcs.).

5

10. Disconnect all the connectors from all the PWBs.

Center Angle (R)

9

LC-37SH20U

5

Center Angle (L)

Main PWB Shield

5

5

Main PWB

IF PWB

Key PWB

10

R/C, LED PWB

10

10

10

Power PWB

10

13

Stand Fixing Angle

Stand Assist Angle

Stand Cover

8

7

6

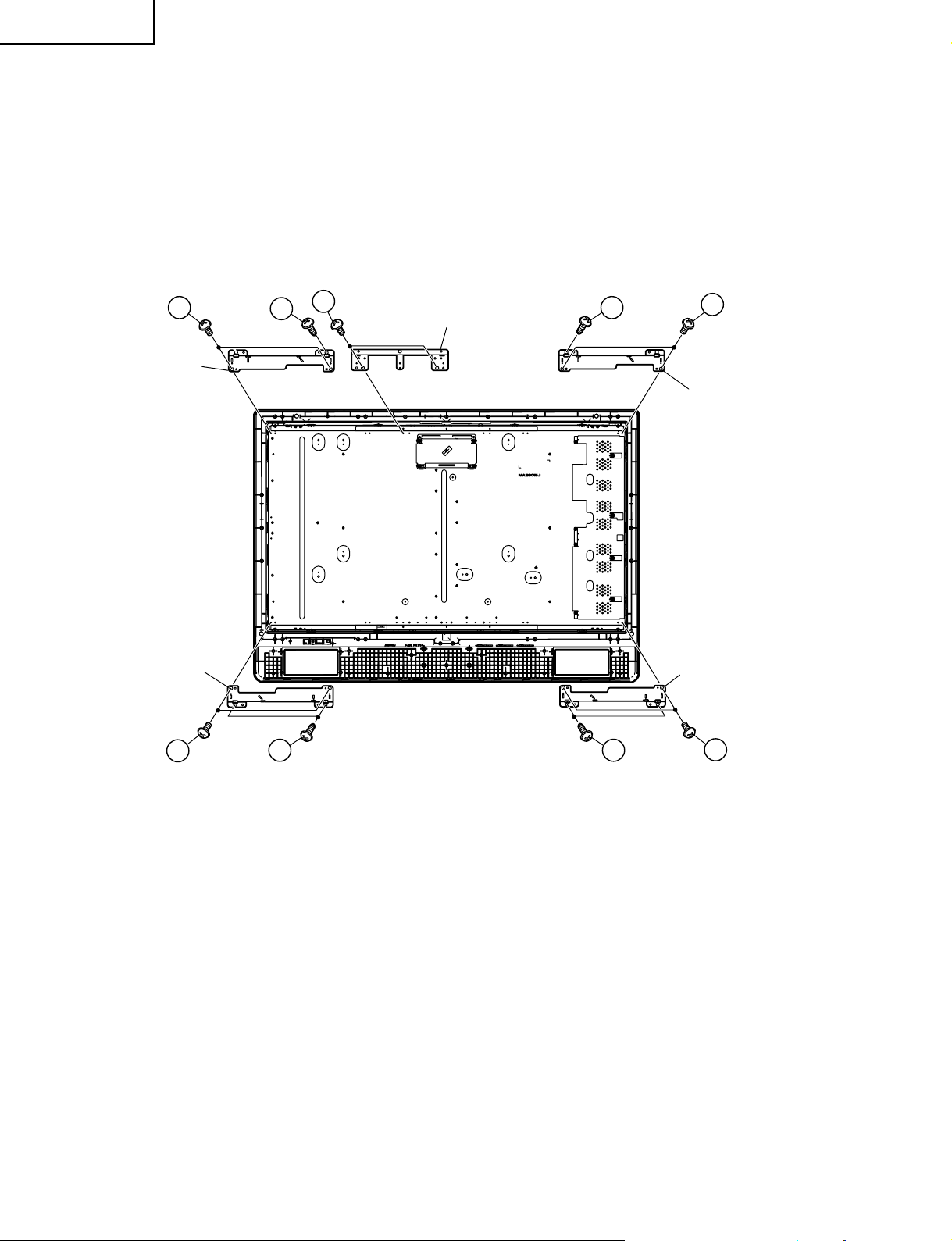

Page 14

LC-37SH20U

11. Remove the PWB unit ass’y fixing screws (4 pcs.).

12. Remove the top cover ass’y.

13. Remove the key PWB fixing screws (3 pcs.).

14. Remove the 8 lock screws from the right and left speakers and take out both speakers.

15. Remove the R/C,LED PWB fixing screws (2 pcs.).

Top Cover Ass'y

Key PWB

11

PWB Unit Ass'y

15

R/C, LED PWB

14

12

Speaker (R)

13

Speaker (L)

14

14

Page 15

16. Remove the SD card cover and terminal angle fixing screws (4 pcs.).

17. Remove the power PWB fixing screws (6 pcs.).

18. Remove the IF PWB fixing screws (4 pcs.).

19. Remove the heat sink and main PWB fixing screws (4 pcs.).

19

Heat Sink

Main PWB

LC-37SH20U

17

16

SD Card Cover

16

Terminal Angle

Power PWB

Chassis frame

18

IF PWB

15

Page 16

LC-37SH20U

20. Remove the center assist angle fixing screws (2 pcs.).

21. Remove the 6 lock screws from the right and left corner angles(top) and take out both center angles(top).

22. Remove the 8 lock screws from the right and left corner angles(bottom) and take out both corner angles(bottom).

21

Top Corner Angle (R)

Bottom Corner Angle (R)

22

21

20

Center Assist Angle

21

2222

21

Top Corner Angle (L)

Bottom Corner Angle (L)

22

16

Page 17

DESCRIPTION OF SCHEMATIC DIAGRAM

VOLTAGE MEASUREMENT CONDITION:

1. The voltages at test points are measured on the

stable supply voltage of AC 120V. Signals are fed

by a color bar signal generator for servicing purpose

and the above voltages are measured with a 20k

ohm/V tester.

INDICATION OF RESISTOR & CAPACITOR:

RESISTOR

1. The unit of resistance “Ω” is omitted.

(K=kΩ=1000 Ω, M=MΩ).

2. All resistors are ± 5%, unless otherwise noted.

(K= ± 10%, F= ± 1%, D= ± 0.5%)

3. All resistors are 1/16W, unless otherwise noted.

CAPACITOR

1. All capacitors are µF, unless otherwise noted.

(P=pF=µµF).

2. All capacitors are 50V, unless otherwise noted.

LC-37SH20U

CAUTION:

This circuit diagram is original one, therefore there may be a

slight difference from yours.

SAFETY NOTES:

1.DISCONNECT THE AC PLUG FROM THE AC

OUTLET BEFORE REPLACING PARTS.

2.SEMICONDUCTOR HEAT SINKS SHOULD BE

REGARDED AS POTENTIAL SHOCK HAZARDS

WHEN THE CHASSIS IS OPERATING.

IMPORTANT SAFETY NOTICE:

PARTS MARKED WITH “å” ( ) ARE

IMPORTANT FOR MAINTAINING THE SAFETY OF

THE SET. BE SURE TO REPLACE THESE PARTS

WITH SPECIFIED ONES FOR MAINTAINING THE

SAFETY AND PERFORMANCE OF THE SET.

AVIS DE SECURITE IMPORTANT:

LES PIECES MARQUEES “å” ( )SONT

IMPORTANTES POUR MAINTENIR LA SECURITE

DE L'APPAREIL.

NE REMPLACER CES PIEDES QUE PAR DES

PIECES DONT LE NUMERO EST SPECIFIE POUR

MAINTENIR LA SECURITE ET PROTEGER LE BON

FONCTIONNEMENT DE L'APPAREIL.

17

Page 18

LC-37SH20U

121110987654321

A

B

C

D

E

F

G

H

Ë

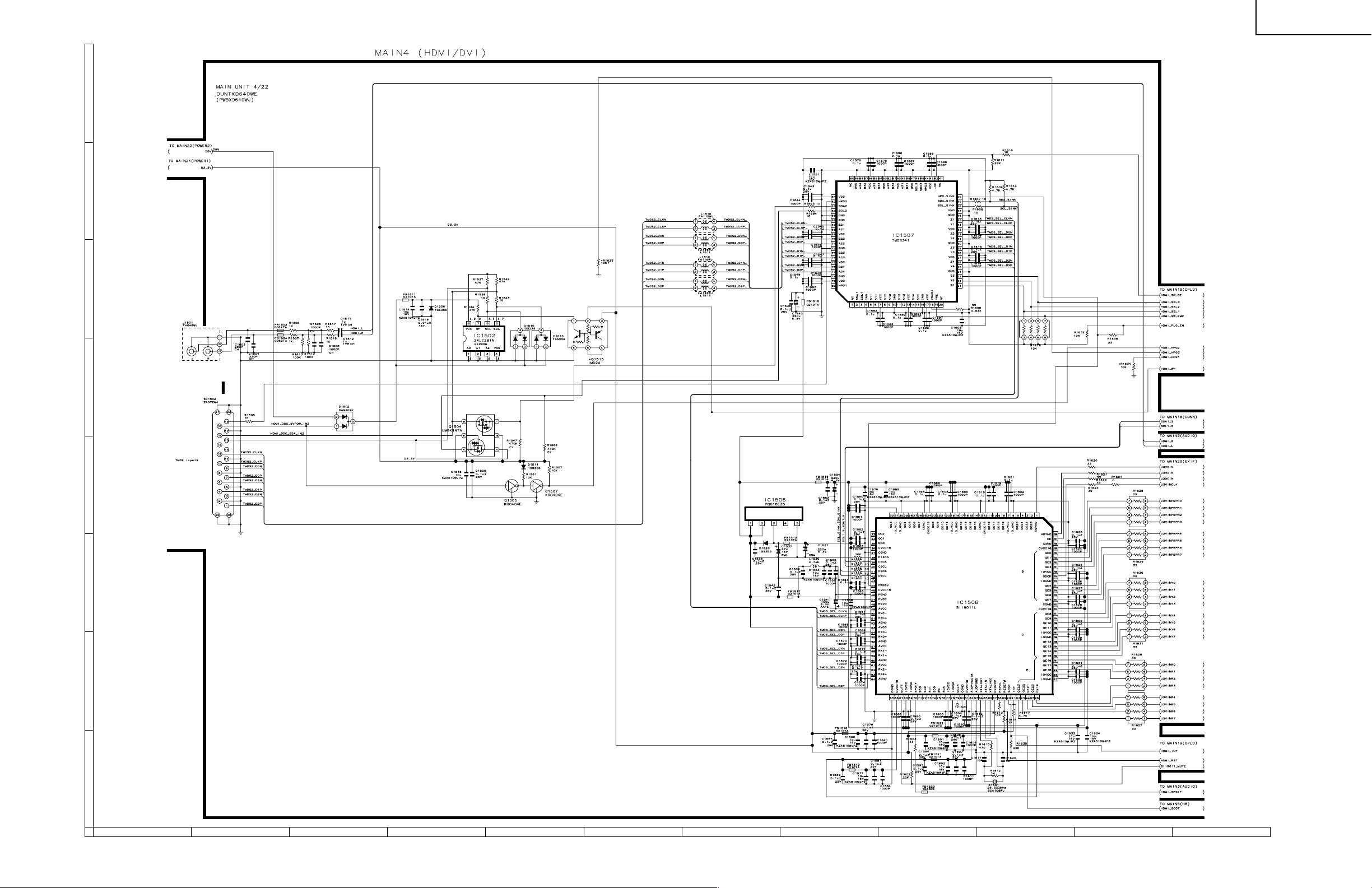

MAIN Unit-4/22

18

19

Page 19

LC-37SH20U

121110987654321

A

B

C

D

E

F

G

H

Ë

MAIN Unit-9/22

20

21

Page 20

LC-37SH20U

121110987654321

A

B

C

D

E

F

G

H

Ë

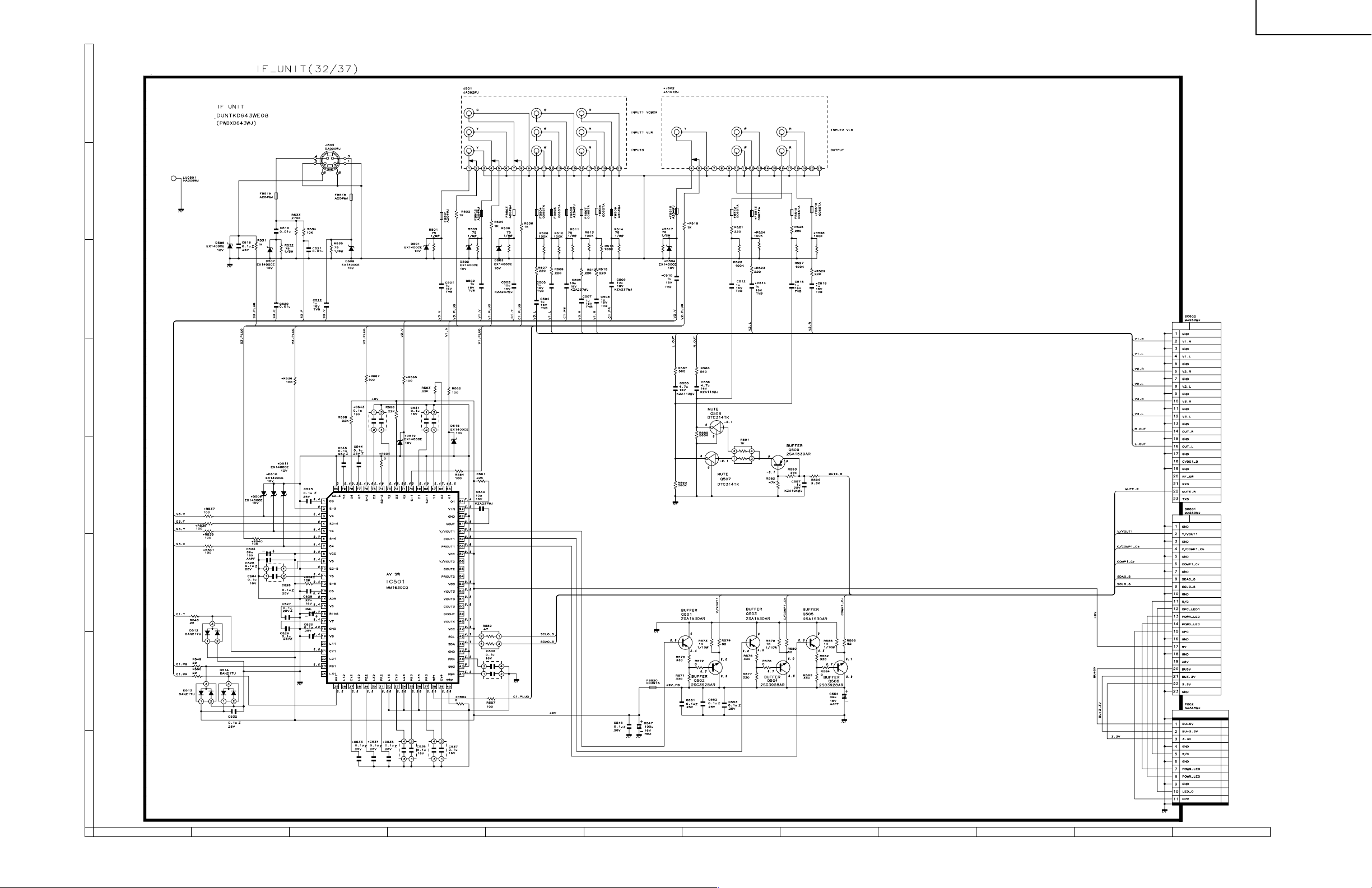

IF-Unit

22

23

Page 21

LC-37SH20U

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

PARTS LIST

LISTE DES PIECES

PARTS REPLACEMENT

Replacement parts which have these special safety characteristics identified in this manual ; electrical components having such features are

identified by å and shaded areas in the Replacement Parts Lists and

Schematic Diagrams. The use of a substitute replacement part which

does no have the same safety characteristic as the factory recommended

replacement parts shown in this service manual may create shock, fire

or other hazards.

"HOW TO ORDER REPLACEMENT PARTS"

To have your order filled promptly and correctly, please furnish the following informations.

1. MODEL NUMBER 2. REF. NO.

3. PART NO. 4. DESCRIPTION

in USA: Contact your nearest SHARP Parts Distributor to order. For

location of SHARP Parts Distributor, Please call Toll-Free;

1-800-BE-SHARP

★ MARK: SPARE PARTS-DELIVERY SECTION

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

Les pi`eces de rechange qui pr élelesentent ces caract éleristiques sp

éleciales de s élecurit éle, sont identifi élees dans ce manuel : les pi`eces

élelectriques qui pr élesentent ces particularit éles, sont rep éler élee

par la marque å et sont hachur élees dans les listes de pi`eces et dans

les diagrammes sch élematiques.

La substitution d'une pi`ece de rechange par une autre qui ne pr éLesente

pas les m éoemes caract éLeristiques de s élecurit éle que la pi`ece

recommand élee parl'usine et dans ce manuel de service, peut provoquer

une éLelectrocution, un incendie ou toutautre sinistre.

"COMMENT COMMANDER LES PIECES DE RECHANGE"

Pour que votre commande soit rapidement et correctement remplie,

veuillez fournir les renseignements suivants.

1. NUMERO DU MODELE 2. NO. DE REF

3. NO. DE PIECE 4. DESCRIPTION

in CANADA: Contact SHARP Electronics of Canada Limited

★ MARQUE: SECTION LIVRAISON DES PIECES DERECHANGE

CHANGE DES PIECES

Phone (416) 890-2100

PRINTED WIRING BOARD ASSEMBLYS

(NOT REPLACEMENT ITEM)

DUNTKD640FM08 R MAIN Unit —

DUNTKD641FM08 X R/C,LED Unit —

DUNTKD643FM08 X IF Unit —

DUNTKD716FM08 X KEY Unit —

RDENCA161WJQZ X POWER Unit BQ

CABINET AND MECHANICAL PARTS

1 CCABAB318WJ01 X Cabinet A Ass’y BQ

1-1

1-2

1-3 HBDGBA065WJSB X Badge, "SHARP" AF

1-4

1-5

1-6 TLABZA742WJZZ X "POP" Label AD

Not Available

Not Available

Not Available

Not Available

– Cabinet A —

– R/C,LED Cover —

– Mask Spacer-S, x2 —

– Mask Spacer-L, x2 —

LCD PANEL

NOTE: THE PARTS HERES SHOWN ARE SUPPLIED AS AN

ASSEMBLY BUT NOT INDEPENDENTLY.

R1LK370T3LZ5BY X 37" LCD Panel Module FD

Unit Ass'y

DUNTKD640FM08

MAIN Unit

RESISTORS

R1633 VRS-CZ1JF103JY R 10k 1/16W Metal Oxide AA

R8124 VRS-CZ1JF103JY R 10k 1/16W Metal Oxide AA

DUNTKD643FM08

IF Unit

CAPACITORS

C533 VCKYCY1EF104ZY X 0.1 25V Ceramic AA

C534 VCKYCY1EF104ZY X 0.1 25V Ceramic AA

C535 VCKYCY1EF104ZY X 0.1 25V Ceramic AA

RESISTORS

R602 VRS-CY1JF000JY X 0 1/16W Metal Oxide AA

MISCELLANEOUS PARTS

J502 QTANJA101WJZZ X Terminal AG

2 CCABBA767WJ01 X Cabinet B Ass’y BS

2-1

2-2 LHLDWA055WJKZ X Wire Holder, x1 AC

2-3 LHLDWA131WJKZ X Wire Holder, x1 AF

2-4

3 CCOVAB497WJ02 X Top Cover Ass’y AZ

3-1

3-2

4 CDAI-A269WJ01 X Stand Base Ass’y

4-1

4-2 CANGKA635WJ01 X Stand Base Angle Ass’y BA

4-2-1

4-2-2

4-2-3

4-3

4-4 XEBSN40P08000 X Screw, x14 AB

5 CDAI-A270WJ01 X Stand Support Ass’y AZ

5-1

5-2

5-3

6 R1LK370T3LZ5BY X

7 GCOVAA678WJKA X SD Card Cover AG

8 GCOVAB507WJKA X Stand Cover AU

9 HINDPB671WJSA X Model Label AH

10 HINDPB672WJSA X Terminal Indication Label AH

11 HINDPB715WJSA X Terminal Label AF

12 LANGKA644WJFW X Terminal Angle AL

13 LANGKA649WJFW X Stand Fixing Angle AR

14 LANGKA655WJFW X Centre Assist Angle AH

15 LANGKA663WJFW X Corner Angle, x4 AK

16 LANGTA266WJFW X Stand Assist Angle AR

17 LANGTA291WJFW X Centre Angle(R) AR

18 LANGTA292WJFW X Centre Angle(L) AR

Not Available

Not Available

Not Available

Not Available

Not Available

Not Available

Not Available

Not Available

Not Available

Not Available

Not Available

Not Available

– Cabinet B —

– Cushion Spacer, x1 —

– Top Cover —

– Operation Button —

– Stand Base —

– Stand Base Angle —

– Leg Cushion-A, x4 —

– Leg Cushion-B, x4 —

– Label —

– Stand Support —

– Support Cover —

– Screw Guide, x4 —

37" LCD Panel Module Unit Ass’y

FD

24

Page 22

CABINET AND MECHANICAL PARTS

LC-37SH20U

H

6

g

G

3-1

3

3-2

49

1-1

A

1-4

1-5

E

F

C

1-5

F

59

1-4

39

a

57

52

C

45

b

57

D

52

H

h

e

E

1-6

1-3

1

42

h

D

C

55

50

23

24

20

H

B

D

1-2

d

B

e

f

44

40

36

g

37

55

21

22

22

41

34

a

29

46

24

43

34

55

30

33

25

59

47

32

22

55

19

34

31

33

55

27

b

28

d

48

38

22

12

10

55

33

53

18

53

I

55

55

60

35

7

11

56

15

21

G

f

I

A

2

2-1

17

55

13

16

57

55

E

14

55

15

21

53

53

55

58

8

4

55

57

51

55

2-2

B

5

4-2-3

55

57

9

54

5-2

4-2-2

4-2-3

61

4-2-2

54

2-3

5-1

4-3

4-2-3

26

26

5-3

5-3

4-1

4-2-3

4-2-2

G

F

15

57

15

58

54

4-2

4-2-1

4-2-2

4-4

A

654321

25

Page 23

LC-37SH20U

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

CABINET AND MECHANICAL PARTS

(Continued)

19 LBSHZA005WJZZ X Bush, x2 AB

20 LCHSMA286WJFW X Chassis Frame AX

21 LHLDW1173CEZZ X Wire Holder, x3 AE

22 LHLDWA043WJKZ X Wire Holder, x4 AC

23 LHLDWA048WJKZ X Wire Holder, x1 AB

24 LHLDWA092WJZZ X Wire Holder, x2 AB

25 LHLDWA096WJKZ X Wire Holder, x1 AD

26 LX-BZA147WJF8 X Screw, x4 AP

27 LX-NZ3047GEZZ X Nut AB

28 PRDARA192WJFW X Heat Sink AE

29 PRDARA204WJFW X Heat Sink AE

30 PRDARA312WJFW X Heat Sink AE

31 PRDARA330WJFW X Heat Sink AM

32 PSLDMA910WJFW X MAIN PWB Shield AV

33 PSPAZA635WJKZ X Spacer, x3 AC

34 PSPAZA700WJKZ X Spacer, x3 AD

35 QCNCWA496WJZZ X Connecting Cord AK

36

37

38 QCNW-E265WJQZ X Connecting Cord(RA) AK

39

40 QCNW-E267WJQZ X Connecting Cord(LB) AG

41

42 QCNW-E439WJQZ X Connecting Cord(LA) AH

43

44 QCNW-E537WJPZ X Connecting Cord(LV) BA

45 QCNW-E619WJQZ X Connecting Cord(SP) AK

46 DUNTKD640FM08 R MAIN Unit —

47 DUNTKD641FM08 X R/C,LED Unit —

48 DUNTKD643FM08 X IF Unit —

49 DUNTKD716FM08 X KEY Unit —

50 RDENCA161WJQZ X POWER Unit BQ

51

52 VSP1206PA034A X Speaker, x2 AP

53 XBBS740P06000 X Screw, x6 AA

54 XBBS930P06000 X Screw, x7 AA

55 XBPS730P06WS0 X Screw, x39 AB

56 XEBS930P08000 X Screw, x3 AA

57 XEBS940P10000 X Screw, x14 AB

58 XEBS940P16000 X Screw, x12 AA

59 XEBSN30P10000 X Screw, x5 AA

60 XBPS930P08000 X Screw, x1 AA

61 LX-BZA146WJF7 X Screw, x4

Not Available

Not Available

Not Available

Not Available

Not Available

Not Available

– Connecting Cord(PE) —

– Connecting Cord(PD) —

– Connecting Cord(KM) —

– Connecting Cord(SH) —

– Connecting Cord —

– Serial No. Label —

SUPPLIED ACCESSORIES

X1 LHLDW0110CESD X Cable Clamp, x1 AF

X2 LHLDWA083WJ00 X Cable Tie, x1 AD

å X3 QACCDA039WJPZ X AC Cord AR

X4 RRMCGA470WJSA X Remote Control Unit AP

X5 TCAUZA228WJZZ X Caution Card

X6 TGAN-A216WJN1 X Guarantee Card AC

X7 TINS-C311WJZZ X Operation Manual AY

X8 CDAI-A269WJ01 X Stand Base Ass'y

X9 CDAI-A270WJ01 X Stand Support Ass'y AZ

X10 LX-BZA154WJ01 X Screw AN

X11

Not Available

– "AA" size Battery, x2 —

PACKING PARTS

(NOT REPLACEMENT ITEM)

S1 SPAKCC520WJZZ – Packing Case —

S2 SPAKFB012WJZZ – Packing Case(Stand) —

S3 SPAKPA338WJZZ – Wrapping Paper —

S4 SPAKPA602WJZZ – Wrapping Paper —

S5 SPAKPA679WJZZ – Wrapping Paper(Stand) —

S6 SPAKXB032WJZZ – Buffer Material —

S7 SPAKXB089WJZZ – Buffer Material(Stand) —

S8 SSAKA0101GJZZ – Polyethylene Bag —

S9 TLABKA009WJZZ – No. Label —

SERVICE JIGS

(USE FOR SERVICING)

QCNW-C799WJPZ J RCA cable L=1500mm, AG

QCNW-D483WJQZ J 12pins L=1000mm, AX

QCNW-E068WJQZ J 6pins L=1000mm, AS

QCNW-E670WJQZ J 4-8pins L=1000mm, AP

QCNW-E671WJQZ J 10-14pins L=1000mm, AW

QCNW-E673WJQZ J 30pins L=1000mm, BE

QCNW-E674WJQZ J 7pins L=1000mm, AS

Tuner Extension

Main to Power Unit PE (PA)

Main to Power Unit PD (MI)

Main to Inverter Unit (LA)

Power to Inverter Unit (LA)

Main to Controller Unit (LV)

Main to Controller Unit (SH)

Supplied Accessories

Remote control unit (x1)

X4 X3X11

Cable clamp (x1)

X1 X7

"AA" size battery (x2)

X8

Stand Unit (x1)Cable tie (x1)

X9

X10X2

26

AC cord (x1)

Operation manual (x1)

Page 24

PACKING OF THE SET

X1

X2

X6

X4

S8

X7

X11

LC-37SH20U

S6

S6

S3

X3

S6

X5

X8

X9

X10

S4

S5

S7

S2

S1

S6

S8

27

Page 25

LC-37SH20U

COPYRIGHT © 2006 BY SHARP CORPORATION

ALL RIGHTS RESERVED.

No part of this publication may be reproduced,

stored in a retrieval system, or transmitted in

any form or by any means, electronic, mechanical,

photocopying, recording, or otherwise, without

prior written permission of the publisher.

Apr. 2006 Printed in Japan

TQ1995-S

Design and Production Information

Design : Japan

Production : SEMEX

SY. KG

SHARP CORPORATION

AV Systems Group

CS Promotion Center

Yaita, Tochigi 329-2193, Japan

Loading...

Loading...