Page 1

GP2A200LCS0F

Series

GP2A200LCS0F Series

Detecting Distance : 2 to 22mm

*

OPIC Output,

Refl ective Photointerrupter with

Connector

Description

■

GP2A200LCS0F Series

photointerrupters with emitter and detector facing the

same direction in a molding that provides non-contact

sensing. This family of devices uses light modulation to

reduce the affects of disturbing light, and the sensor is

optimized to work in the selected focal distance. A 3-pin

connector is included to allow remote-mount or off-board

designs.

Features

■

1. Refl ective with OPIC Light Modulated Output

2. Highlights :

• Includes additional screw fi xing holes

• Position pin to prevent mis-alignment

• Long focal distance

3. Key Parameters :

• Detecting distance : 2 to 22mm (White paper)

5 to 15mm (Black paper)

• Undetecting distance : over 90mm (White paper)

• Connector :

(PN : 292133-3)

(PN : 292133-3)

GP2A240LCS0F

(PN : 292133-3)

4. RoHS directive compliant

GP2A200LCS0F

GP2A200LCSCF

GP2A210LCSJF

(PN : 4-292133-3)

are OPIC output, reflective

; Tyco Electronics AMP K.K.

; Tyco Electronics AMP K.K.

; Tyco Electronics AMP K.K.

; Tyco Electronics AMP K.K

.

Agency approvals/Compliance

■

1. Compliant with RoHS directive

Applications

■

1. General purpose detection of paper presence or motion.

2. Example: PPC, FAX, Printer

* "OPIC"(Optical IC) is a trademark of the SHARP Corporation. An OPIC consists of a light-detecting element and a signal-

processing

Notice The content of data sheet is subject to change without prior notice.

In the absence of confi rmation by device specifi cation sheets, SHARP takes no responsibility for any defects that may occur in equipment using any SHARP

devices shown in catalogs, data books, etc. Contact SHARP in order to obtain the latest device specifi cation sheets before using any SHARP device.

Sheet No.: D3-A05101FEN

1

Date Jun. 30. 2005

© SHARP Corporation

Page 2

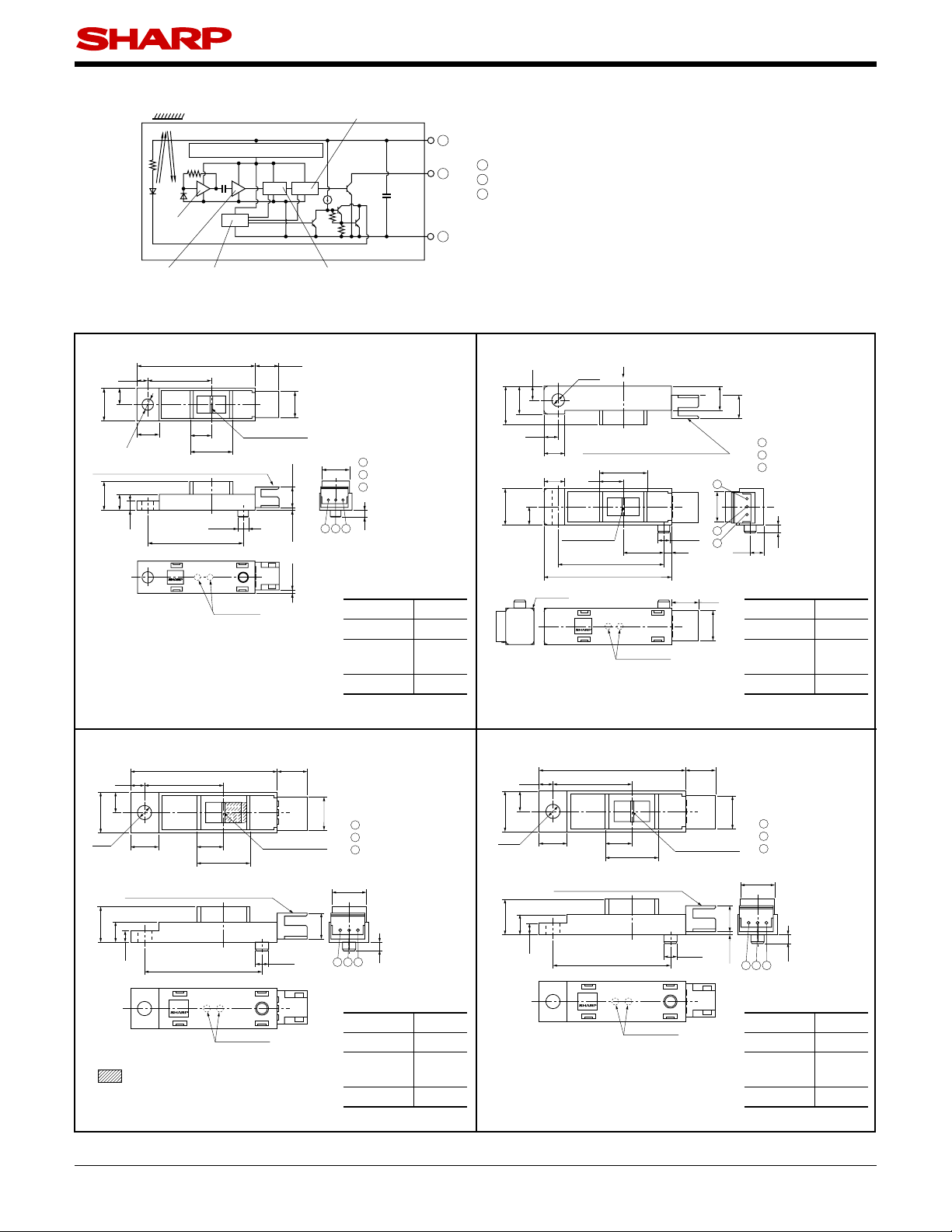

Internal Connection Diagram

■

GP2A200LCS0F Series

Reflective object

Voltage regulator

Amp.

Demodulator circuit

1

1

V

2

3

CC

V

OUT

GND

2

3

Comparator Oscillator circuit Sync. detecting circuit

Outline Dimensions

■

GP2A200LCS0F GP2A200LCSCF

3.1

4.5

9

6.2

φ3.2

Connector : 292133-3 (Tyco Electronics AMP. K. K)

8

4.5

2.5

17.7

33

26.5

6

12

φ3

0 7

+0

−0.2

Date code

Product mass : approx. 1.95g Product mass : approx. 2.3g

(6.8)

(7.8)

Optical center

(5.8)(0.65)(0.9)

1

V

7.8

1 2 3

2

3

2

CC

V

OUT

GND

• Unspecifi ed tolerance

shall be as follows ;

Dimensions

less than 6

6 or more

less than 14

14 or more

Tolerance

0.2

±

0.3

±

0.4

±

• *( ) : Reference dimensions

9.6

9

7

3.5

3.5

4.5

4-SR1

View A

φ3.2

Connector : 292133-3

5.2

(Tyco Electronics AMP K.K.)

6

View A

12

26.5

32

02

Date code

5.2

Optical center

10.2

(Unit : mm)

6.1

(5.8)

1

V

CC

2

V

OUT

3

GND

3

7.8

+0.0

2

φ3

−0.2

1

2

(6.8)

(7.8)

2

3.5

• Unspecifi ed tolerance

shall be as follows ;

Dimensions

less than 6

6 or more

less than 14

14 or more

Tolerance

0.2

±

0.3

±

0.4

±

• *( ) : Reference dimensions

GP2A210LCSJF

33

3.1

4.54.5

98

φ3.2

Connector : 4-292133-3 (Yellow)

(Tyco Electronics AMP K.K.)

2.5

17.7

26.5

66.2

12

99

Date code

Optical center

φ3

• : Portion Built-in IR-90 fi lter

Product mass : approx. 1.95g

(6.8)

+0.0

−0.2

(7.8)

1

V

CC

2

V

OUT

3

GND

7.8

(5 .8)

2

1 2 3

• Unspecifi ed tolerance

shall be as follows ;

Dimensions

less than 6

6 or more

less than 14

14 or more

Tolerance

±

±

±

• *( ) : Reference dimensions

0.2

0.3

0.4

GP2A240LCS0F

33

17.7

66.2

12

Connector : 292133-3

(Tyco Electronics AMP K.K.)

26.5

51

Date code

98

φ3.2

3.1

4.54.5

2.5

Product mass : approx. 1.95g

Connector terminal plating material : Sn

2

(6.8)

Optical center

+0.0

φ3

−0.2

(7.8)

1

V

CC

2

V

OUT

3

GND

7.8

(5 .8)(0.65)

2

1 2 3

• Unspecifi ed tolerance

shall be as follows ;

Dimensions

less than 6

6 or more

less than 14

14 or more

Tolerance

0.2

±

0.3

±

0.4

±

• *( ) : Reference dimensions

Sheet No.: D3-A05101FEN

Page 3

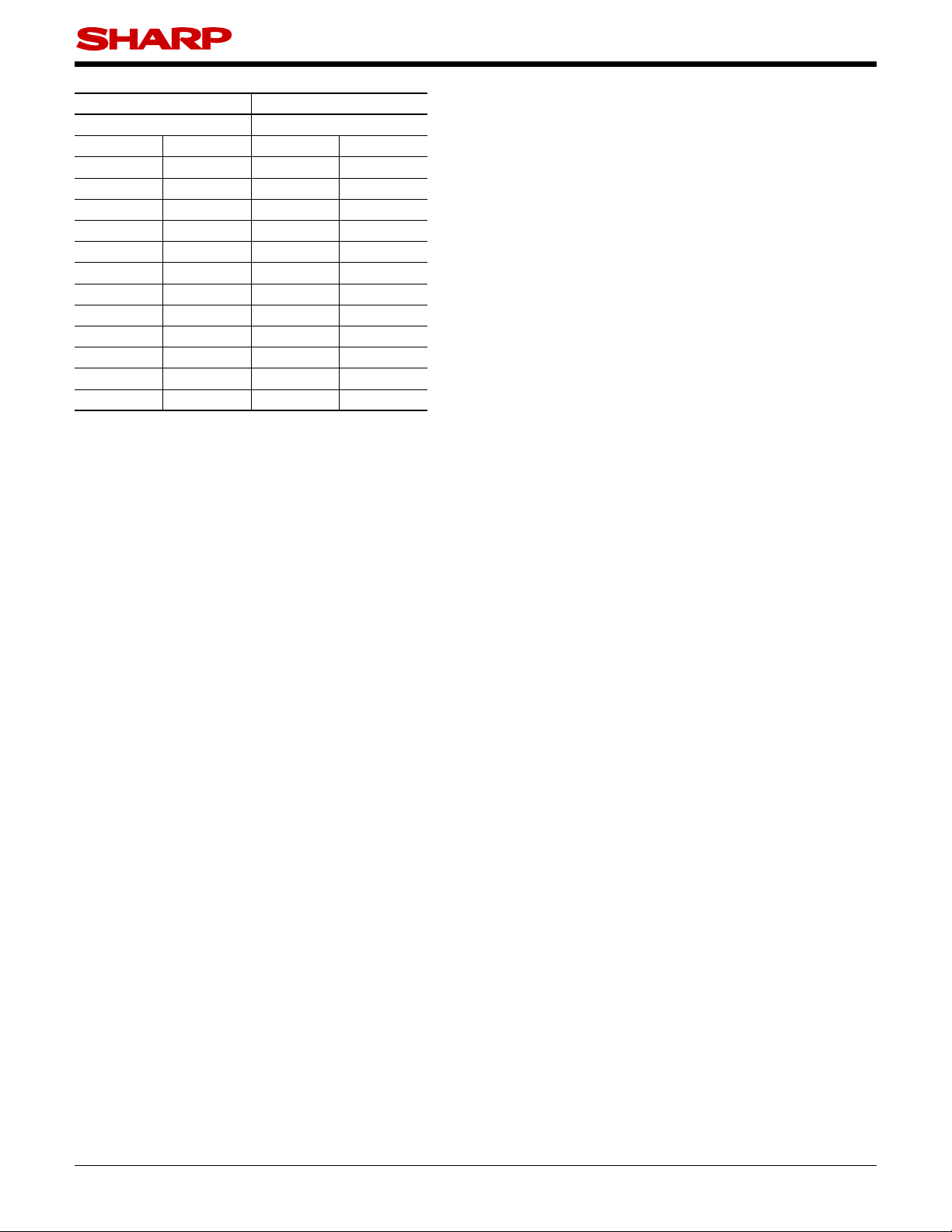

Date code (2 digit)

1st digit 2nd digit

Year of production Month of production

A.D. Mark Month Mark

2000 0 1 1

2001 1 2 2

2002 2 3 3

2003 3 4 4

2004 4 5 5

2005 5 6 6

2006 6 7 7

2007 7 8 8

2008 8 9 9

2009 9 10 X

2010 0 11 Y

: : 12 Z

repeats in a 10 year cycle

GP2A200LCS0F Series

Country of origin

Japan

3

Sheet No.: D3-A05101FEN

Page 4

Absolute Maximum Ratings

■

Parameter Symbol Rating Unit

Supply voltage V

Output voltage V

*1

Output current I

*2

Operating temperature T

*2

Storage temperature T

∗

1 Sink current refer to

∗

2 The connector should be plugged in/out at normal temperature.

Electro-optical Characteristics

■

Fig.5.

CC

O

OL

opr

stg

Parameter Symbol Condhitions MIN. TYP. MAX. Unit

Supply voltage V

Current dissipation (I) I

*3

Current dissipation (II) I

Low level output voltage V

High level output voltage V

*4

Non detection distance

GP2A210LCSJF

*4

Detection distance

*5

Response time

*6

Acceptable illuminance

∗

3 Refer to Fig.1.

∗

4 Refer to Fig.2.

∗

5 Refer to Fig.3.

*

6 Refer to Fig.4.

CC

CC

CCP

OL

OH

L

LHL

L

HLS

L

HLL

t

PLH

t

PHL

Ev1

Ev2 1 500

(T

25˚C)

=

a

0.5 to +7V

−

30 V

50 mA

10 to +70 ˚C

−

20 to +80 ˚C

−

Smoothing value V

Pulse peak value V

V

5V, I

=

CC

5V, R

V

=

CC

=

OL

=1kΩ

L

KODAK Gray Cards, V

KODAK Gray Cards, V

Black paper, V

KODAK Gray Cards , V

Black paper, V

−

5V, R

CC

=

=∞−−

L

5V

=

CC

16mA, at detecting time

, at non detecting time 4.5

5V

=

CC

5V

=

CC

5V

=

CC

5V 22

=

CC

5V 15

=

CC

5V

V

=

CC

−

GP2A200LCS0F Series

4.75

−

−−

−−

−−

−−

−−

−−

−−

−−

−−

−−

−−

3 000

−−

−−

25˚C)

(T

=

a

5.25 V

30 mA

150 mA

0.4 V

V

90

70

2

5

mm

mm

mm

1ms

1ms

lx

lx

Refl ective object Black paper (black) : Standard refl ective object (provided by SHARP Corporation)

KODAK Gray Cards (use the white side refl ects about 90%)

: Standard refl ective object (provided by SHARP Corporation)

PPC paper : Standard refl ective object (provided by SHARP Corporation)

4

Sheet No.: D3-A05101FEN

Page 5

GP2A200LCS0F Series

Fig.1 Test Condition for Peak Pulse Value I

R=1Ω

1

V

2

3

R

V

CC

=1kΩ

L

V

O

GND

=5V

CCP

t

W

t

P

I

CCP=Vr

(TYP.)=8μs (GP2A240LCS0F : 2.5 to 9.3μs)

t

W

(TYP.)=130μs (GP2A240LCS0F : 40 to 150μs)

t

P

Photointerrupter

Fig.2 Test Condition for Detecting Distance Characteristics

Reflective object

Detection surface

V

O

Output V

OH

V

OL

Detecting distance L

L

HLS

L

LHS

L

HLL

L

LHL

/1Ω

r

V

Fig.3 Test Circuit for Response Time

Reflective object

Detection surface

L

=1kΩ

R

L

1

2

3

Photointerrupter

V

CC

V

O

GND

=5V

t

PHL

V

OUT

waveform

With reflective object

t

PLH

V

OH

1.5V

V

OL

Without reflective object

Fig.4 Test Condition for External Disturbing Light Illuminance

EV1 : At non-detecting EV2 : At detecting

Emission/detection

surface

Light source A

Photointerrupter

Illuminance shall be that on the emission/detection surface.

Output shall not go from "H" to "L".

Light source A

PPC paper

Emission/detection surface

Photointerrupter

Illuminance shall be that on the reflective

object.

Output shall not go from "L" to "H".

15mm

5

Sheet No.: D3-A05101FEN

Page 6

GP2A200LCS0F Series

Fig.5 Output Current vs.

Ambient Temperature

50

40

(mA)

OL

30

20

Output Current I

10

0

−100 25507570 100

Ambient temperature T

a

(C)

Fig.7 Low Level Output Voltage vs.

Low Level Output Current

VCC=5V

At detecting

(V)

OL

0.1

Fig.6 Low Level Output Voltage vs.

Ambient Temperature

0.3

(V)

OL

0.2

0.1

Low level output voltage V

0

−100 10203040506070

Fig.8

Dissipation Current(Smoothing Value)

IOL=30mA

Ambient temperature Ta (C)

VCC=5V

At detecting

16mA

5mA

vs. Ambient Temperature

(mA)

CC

7

6

5

4

Ta=−10˚C

25˚C

70˚C

3

2

Low level output voltage V

0.01

1 10 100

Low level output current I

OL

(mA)

Dissipation current I

1

0

4.75 4.85 4.95 5.05 5.15 5.25

Supply voltage V

(V)

CC

Remarks : Please be aware that all data in the graph are just for reference and not for guarantee.

6

Sheet No.: D3-A05101FEN

Page 7

Design Considerations

■

●

Design guide

1) VO terminal : Open collector output

This product operates the light emitter by pulse drive. Please supply the stable supply voltage in order to

prevent error operation by pulse current.

Please use this device after connecting a capacitor between V

2) Prevention of detection error

Please be careful that you need to keep the direct inverter light away from the photo detecting surface

since the device will not operate correctly in such case.

In addition, we recommend to make sure the operation test in the actual application.

3) Plugging in/out

The connector should be plugged in/out at normal temperature.

This product is not designed against irradiation and incorporates non-coherent IRED.

●

Parts

This product is assembled using the below parts.

GP2A200LCS0F Series

and GND for prevention of line noise.

O

• Photodetector (Q'ty : 1)

Category

Phototransistor 900 700 to 1 200 400

Maximum Sensitivity

wavelength (nm)

[Using a silicon photodiode as light detecting portion, and a bipolar IC as signal processing circuit]

Sensitivity

wavelength (nm)

• Photo emitter (Q'ty : 1)

Category Material

Infrared emitting diode

(non-coherent)

Gallium arsenide (GaAs) 950 0.3

Maximum light emitting

wavelength (nm)

• Material

Case Lens Bottom cover

GP2A200LCS0F

GP2A200LCSCF

GP2A210LCSJF

GP2A240LCS0F

∗

Black polyphernylene

Sulfi de resin (UL94 V-0)

Polycarbonate resin

(UL94 V-2)

Response time (μs)

I/O Frequency (MHz)

Polycarbonate resin (Gray)

(UL94 V-2)

Polycarbonate resin (Navy Blue)

(UL94 V-2)

The IR-90 fi lter (Fuji Photo Film Co., Ltd.) is inserted between case and detector side lens.

∗

• Others

Laser generator is not used.

7

Sheet No.: D3-A05101FEN

Page 8

Manufacturing Guidelines

■

●

Cleaning instructions

Polycarbonate resin is used as the material of the lens surface. So this product shall not be cleaned by

cleaning solvent absolutely. Dust and stain shall clean by air blow, or shall clean by soft cloth.

●

Presence of ODC

This product shall not contain the following materials.

And they are not used in the production process for this product.

Regulation substances : CFCs, Halon, Carbon tetrachloride, 1.1.1-Trichloroethane (Methylchloroform)

Specifi c brominated fl ame retardants such as the PBBOs and PBBs are not used in this product at all.

This product shall not contain the following materials banned in the RoHS Directive (2002/95/EC).

•Lead, Mercury, Cadmium, Hexavalent chromium, Polybrominated biphenyls (PBB), Polybrominated

diphenyl ethers (PBDE).

GP2A200LCS0F Series

8

Sheet No.: D3-A05101FEN

Page 9

Package specifi cation

■

●

Case package

Package materials

Anti-static plastic bag : Polyethtylene

Moltopren : Urethane

Packing case : Corrugated fi berboard

Package method

100 pcs of products shall be packaged in a plastic bag, Ends shall be sealed by stapler. The bottom ot the

packing case is covered with moltopren, and 2 plastic bags shall be put int the packing case.

Moltopren should be located after all product are settled (1 packing conteains 200 pcs).

Packing composition

GP2A200LCS0F Series

Moltopren

plastic bag

Packing case

9

Sheet No.: D3-A05101FEN

Page 10

Important Notices

■

· The circuit application examples in this publication

are provided to explain representative applications of

SHARP devices and are not intended to guarantee any

circuit design or license any intellectual property rights.

SHARP takes no responsibility for any problems related

to any intellectual property right of a third party resulting

from the use of SHARP's devices.

· Contact SHARP in order to obtain the latest device

specification sheets before using any SHARP device.

SHARP reserves the right to make changes in the

specifi cations, characteristics, data, materials, structure,

and other contents described herein at any time

without notice in order to improve design or reliability.

Manufacturing locations are also subject to change

without notice.

· Observe the following points when using any devices

in this publication. SHARP takes no responsibility for

damage caused by improper use of the devices which

does not meet the conditions and absolute maximum

ratings to be used specifi ed in the relevant specifi cation

sheet nor meet the following conditions:

(i) The devices in this publication are designed for use

in general electronic equipment designs such as:

--- Personal computers

--- Offi ce automation equipment

--- Telecommunication equipment [terminal]

--- Test and measurement equipment

--- Industrial control

--- Audio visual equipment

--- Consumer electronics

(ii) Measures such as fail-safe function and redundant

design should be taken to ensure reliability and safety

when SHARP devices are used for or in connection

GP2A200LCS0F Series

with equipment that requires higher reliability such as:

--- Transportation control and safety equipment (i.e.,

aircraft, trains, automobiles, etc.)

--- Traffi c signals

--- Gas leakage sensor breakers

--- Alarm equipment

--- Various safety devices, etc.

(iii) SHARP devices shall not be used for or in

connection with equipment that requires an extremely

high level of reliability and safety such as:

--- Space applications

--- Telecommunication equipment [trunk lines]

--- Nuclear power control equipment

--- Medical and other life support equipment (e.g.,

scuba).

· If the SHARP devices listed in this publication fall

within the scope of strategic products described in the

Foreign Exchange and Foreign Trade Law of Japan, it

is necessary to obtain approval to export such SHARP

devices.

· This publication is the proprietary product of SHARP

and is copyrighted, with all rights reserved. Under

the copyright laws, no part of this publication may be

reproduced or transmitted in any form or by any means,

electronic or mechanical, for any purpose, in whole or in

part, without the express written permission of SHARP.

Express written permission is also required before any

use of this publication may be made by a third party.

· Contact and consult with a SHARP representative

if there are any questions about the contents of this

publication.

[H176]

10

Sheet No.: D3-A05101FEN

Loading...

Loading...