Sharp GF-A2Z(S),GF-A2Z(G) Service Manual

mmM

SHARI=

SERVICE

MANUAL

,

S5452G F-A2ZSl

GF-A2Z(S)

GF-A2Z(G)

In the interests of usersafety the set should be restored to its

original condition and only parts identical to those specified be

used.

Photo: G

F-APZ(S)

/-INDEX

TO CONTENTS

--.

Page

SPECIFICATIONS

...............................................

1

NAMESOFPARTS

..............................................

2

VOLTAGE SELECTION

...........................................

2

STRINGING OF DIAL CORD

.......................................

2

DISASSEMBLY

.................................................

3

BLOCKDIAGRAM

..............................................

4

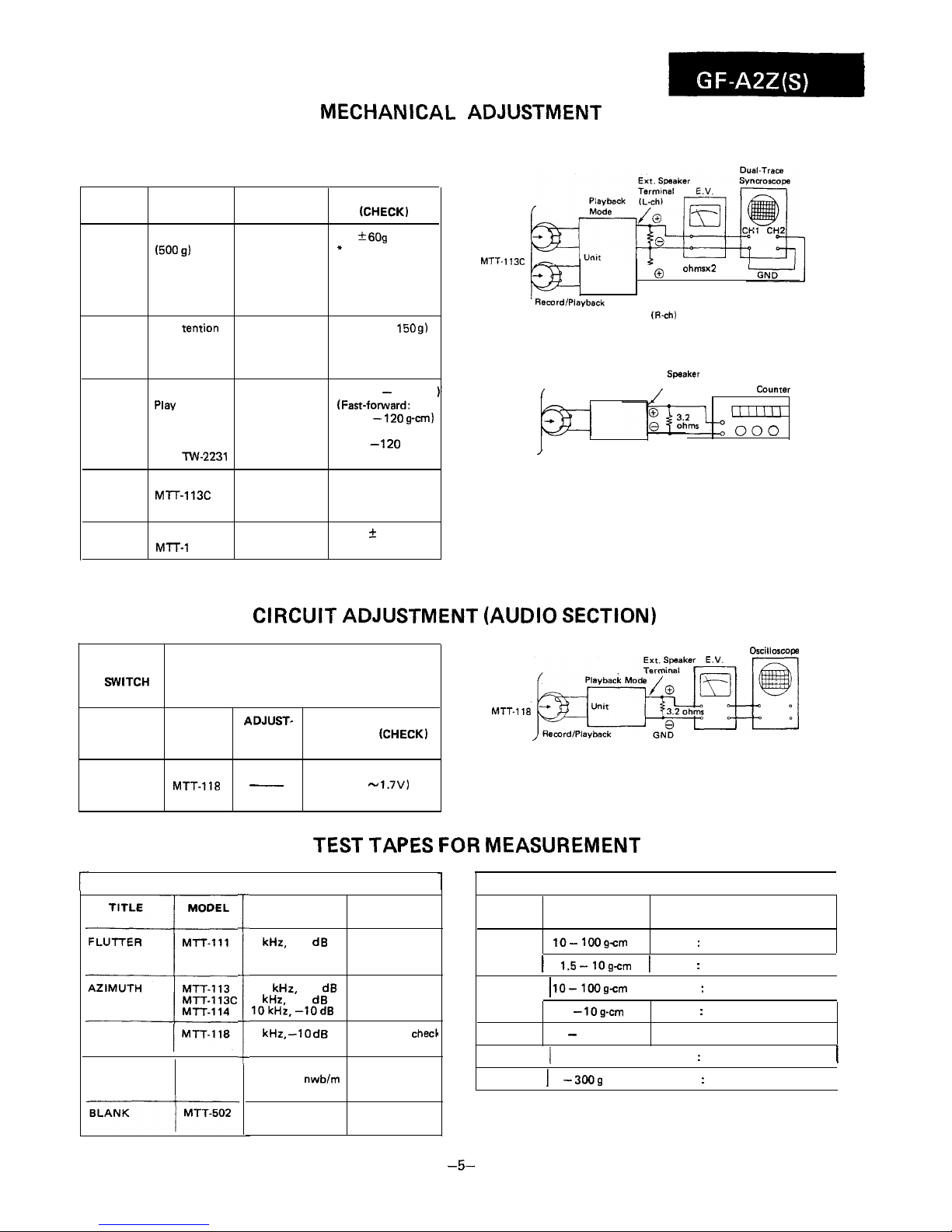

TEST TAPES FOR MEASUREMENT

..................................

5

MECHANICAL ADJUSTMENT

......................................

5

CIRCUITADJUSTMENT

........................................

5-7

ACPOWERSUPPLYCORD

.........................................

7

NOTES ON SCHEMATIC DIAGRAM

..................................

8

WlRlNGSlDEOFP.W.BOARD

...................................

.9,10

SCHEMATIC DIAGRAM

........................................

II,12

EXPLODEDVIEW..

..........................................

13,14

REPLACEMENT PARTS LIST

....................................

15-18

SPECIFICATIONS

GENERAL

Power source:

Output power:

Semiconductors:

Dimensions:

AC

110 -

127V and 220 - 240V

DC 9 V

(UM/SUM-1

or

R20

type x 6)

PMPO; 15

W

(7.5 w + 7.5

W)

(AC operation)

MPO; 8

W

(4w+4w)

(AC operation)

RMS; 4.6

W

(2.3 W + 2.3

W)

(DC operation

10 %

distortion)

8

ICs

3 Transistors

13 Diodes

6

LEDs

Width; 550 mm

(21-5/8”)

Height; 220 mm

(8-5/8”)

TAPE RECORDER

Tape:

Frequency range:

Signal/noise ratio:

Wow and flutter:

Input impedance:

Loaded impedance:

Headphones;

External speakers;

RADIO

Frequency range:

SPEAKER

Speakers:

Impedance:

Compact cassette tape

80 Hz - 10,000 Hz

36

dB

0.15 %

(WRMS)

External mic: 600 ohms

8 - 25 ohms

3.2 - 8 ohms

FM; 87.6 MHz -

108

MHz

AM; 526.5 kHz - 1606.5 kHz

SW1 ;

2.3 MHz - 7.3 MHz

SW,; 7.3 MHz - 22 MHz

12 cm

(4-3/4”)

woofer x 2

Horn type tweeter x 2

3.2 ohms

Weight:

Depth; 130 mm (5-I

/8”)

3.6 kg (7.9

Ibs.)

without batteries

Specifications for this model are subject to change without

prior notice.

SHARP CORPORATION

FOR A COMPLETE DESCRIPTION OF THE OPERATION OF THIS UNIT,

PLEASE REFER TO THE OPERATION MANUAL.

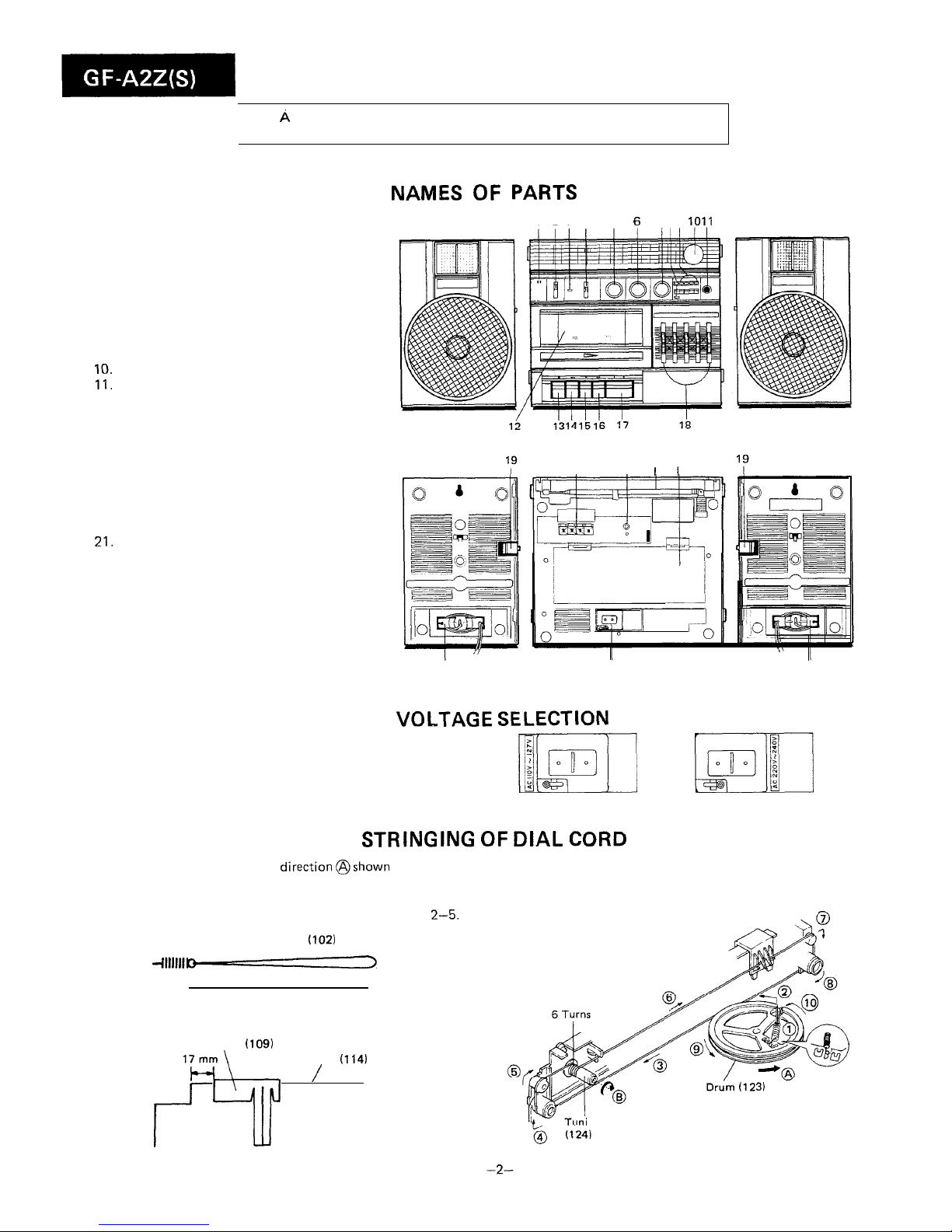

1.

Built-in Microphone

2. Band Selector Switch

3.

FM

Stereo Indicator

4. Function Selector Switch

5.

Volume Control

6.

Balance Control

7. Fine Tuning Control

8.

Power Indicator

9. Sound Level Meter

10.

Tuning Control

11.

Headphones Jack

12.

Cassette Compartment

13.

Record Button

14.

Rewind Button

15.

Play Button

16.

Fast-Forward Button

17.

Stop/Eject Button

18. Graphic Equalizer Controls

19. Speaker Release Knob

20. External Speaker Terminals

21.

External Microphone Jack

22. FM/SW Telescopic Rod Antenna

23.

Battery Compartment

24. Speaker Cord Holder

25. AC Power Supply Socket

NAMES OF PARTS

1234 5 6

789 1011

Figure 2-l

20

21

22 23

I

I I I

24

25

Figure 2-2

24

VOLTAGE

SELECTION

Before operating the unit on mains,

check

the preset voltage.

If the voltage is different from your local voltage,

adjust the

voltage as follows: Slide the AC power supply socket cover by

slightly loosing the screw to the visible indication of the side

mi

m’:1II

of your local voltage.

Figure 2-3

STRINGING OF DIAL

CORD

1. Turn the drum fully in the

direction@shown

in Fig. 2-4

and stretch its cord over the parts in the numerical order.

2. Then turn the tuning control shaft fully in the direction@

shown in Fig. 2-4 and fix its pointer as shown in Fig.

2-5.

Spring

with Dial Cord

(102)

451 mm

Pointer

(109)

17 mm

Frame

(114)

f9

/

Figure 2-5

ing Control Shaft

Figure 2-4

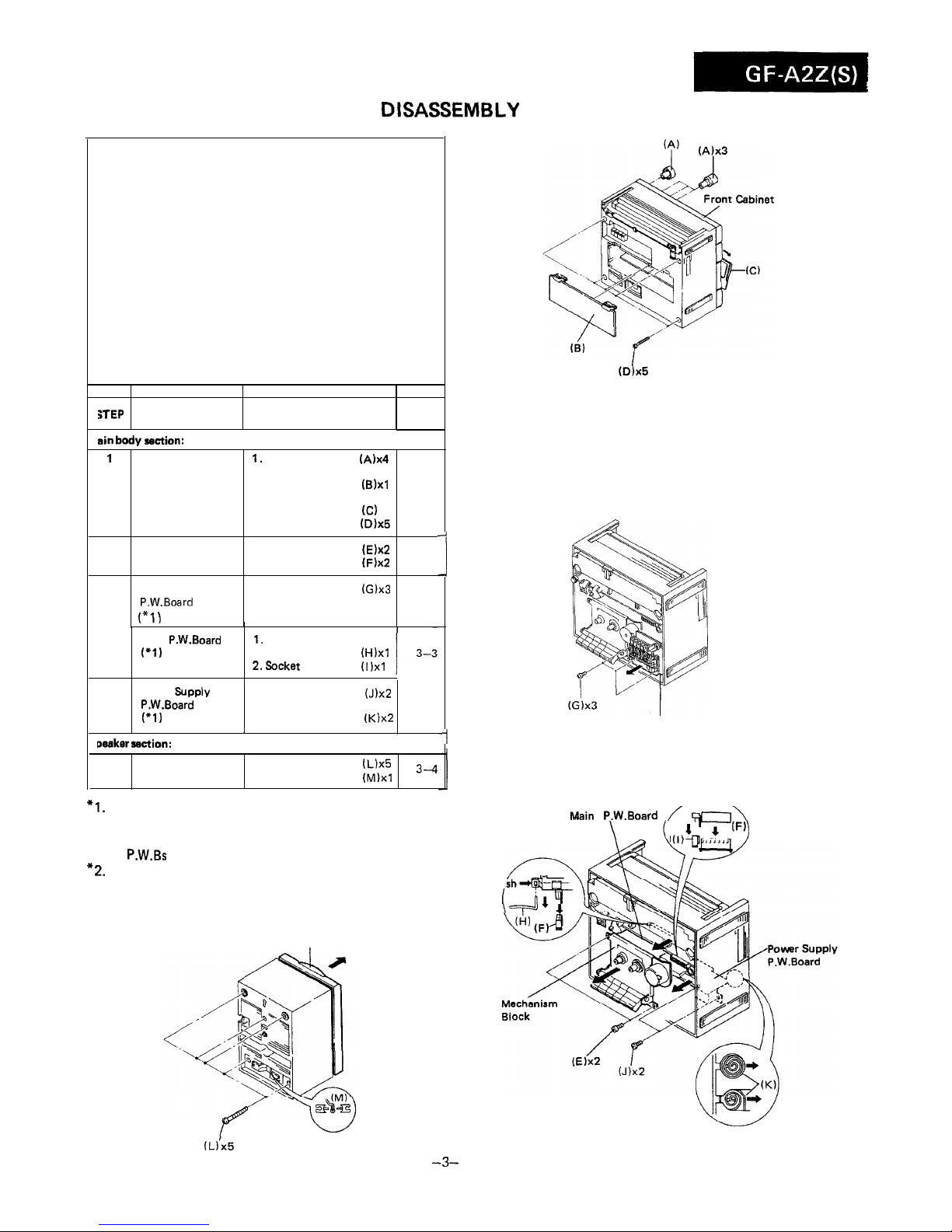

DISASSEMBLY

Caution on Disassembly

Follow the below-mentioned notes when disassembling the

unit and reassembling it, to keep its safety and excellent

performance:

1. Take cassette tape out of the unit.

2. Be sure to remove the power supply plug from the wall

outlet before starting to disassemble the unit and remove

the batteries from the unit.

3. Take off nylon bands or wire holders where they need be

removed when disassembling the unit. After servicing

the unit, be sure to rearrange the leads where they were

before disassembling.

4. Take sufficient care on static electricity of integrated

circuits and other circuits when servicing.

iTEP

REMOVAL

PROCEDURE

FIGURE

1

sin body section:

1

Front cabinet

1.

Knob . . . . . . .

(A)x4

2. Battery compartment

lid

. . . . . . . , .

03)x1

3. Open the cassette

holder . . . . . . . (C)

4. Screw . . . . . . .

(D)x5

3-l

2 Mechanism block 1. Screw . . . . . . .

(E)x2

2. Socket . . . . . .

(F)x2

3-3

Graphic Equalizer 1. Screw (G)x3

P.W.Board

3-2

(“1)

I

3

Main P.W.Board

1.

Record interlocking

(‘1)

lever. . . . . . .

(H)xl

(‘2)

2.Socket

. . . . . .

(1)x1

4

Power Bupply

1. Screw . . . . . . . (J)x~

P.W.Board 2. Battery terminal

(‘1)

spring . . . . . . .

(K)x2

I

,

paaker section:

Front Cabinet

1. Screw , . . . . . .

(L)x5

2. Speaker Cord . .

(~)xl

3--4

-I

*I.

Each P.W.B. should be removed until the parts to be

exchanged can be removed when servicing. If the parts to

be exchanged are in the exchangeable condition, the rest

of

P.W.Bs

need not to be removed.

*2.

When taking the main P.W.B. out the unit, the P.W.B.

cannot be removed unless the every external speaker

terminal knobs located at the rear side are let down.

Front Cabinet

I

(D)x5

Figure 3-l

Graphic Equalizer P.W. Board

Figure 3-2

Vain

P.W.Board /

F‘c7\

. . .

\

Pu

!

(L)‘x5

Figure 3-4

-3-

Figure 3-3

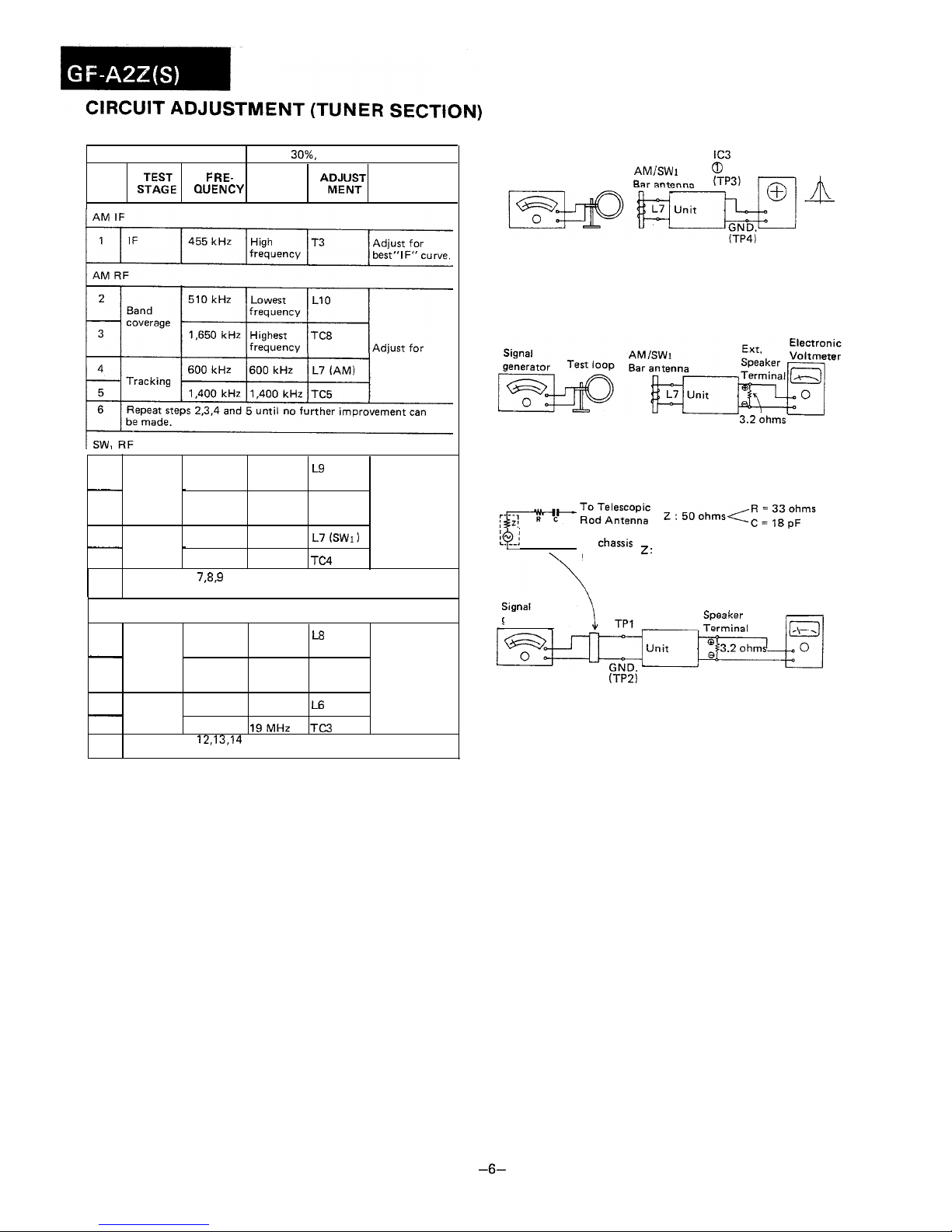

AM IF/RF ADJUSTMENT

SIGNAL GENERATOR

400 Hz, 30%, AM modulated

STEP

S;;gE

FRE-

DIAL

POINTER

A;pNy

QUENCY

SETTING

REMARKS

maximal output

7

2.25 MHz

Lowest

LS

Band

frequency

-

coverage

I

8

7.4 MHz

Highest

TC7

frequency

Adjust for

maximal9output

2.6 MHz

2.6 MHz L7

(SWl)

-

Tracking

-

10

6.0 MHz

6.0 MHz

TC4

11

Repeat steps

78,s

and 10 until no further improvement can

be made.

SW, RF

12

7.2 MHz Lowest

i-8

Band

frequency

-

coverage

13

22.5 MHz Highest

TC6

frequency

Adjust for

14

-maximal output

8.5 MHz

8.5 MHz L6

-

Tracking

15 19 MHz

19MHz TC3

16

Repeat steps

12,13,14

and 15 until no further improvement can

be made.

Sweep

generator

Test loop

AM/SW 1

0

pin Oscilloscope

Figure 6-l AM IF

Figure 6-2 AM RF

8$-j

To

chassis

ground

2 :

Output impedance of signal generator

generator

Ext.

Electronic

Voltmeter

(TP2)

Figure 6-3 SW RF

-6-

MECHANICAL ADJUSTMENT

l

For the details of the test tapes used for the measurement,

refer to the Table “TEST TAPES FOR MEASUREMENT”.

E.V.: Electronic Voltmeter

ITEM

JIG

ADJUSTMENT

POINTS

REMARKS

(CHECK)

Pinch

roller

pressure

Tension gauge

Pinch roller 370 *

6Og

(500 9)

pressure spring* If the reading

is outside the

range, replace the

pressure spring of

the pinch roller.

Driving

power

Tape tention

measuring

cassette

TW-2412

(More than

150 g1

Torque Torque meter

Play

TW-2111

Fast-forward

TW-2231

Rewind

l-W-2231

(Play:35 - 60 g-cm

(Fast-fo~lard:

70 -

120 g-cm)

(Rewind:

70 -

120

g-cm)

Azimuth

Tape

speed

Test tape

M-f-r-1 13C

Test tape

Ml-T-1

11

Azimuth Sine waveform

adjusting attains the

screw

maximum.

Variable resistor

3,000 f 90 Hz

on motor

r

Test Tape

MTT- 113C

o

3.2 ohmsx2

, Record/Playback

Head

Ext. Speaker

Terminal

1%ch)

Test Tape

MTT-111

Figure 5-l AZIMUTH

Ext.

Speaker

I

Playback Terminal

Mode

Frequency Counrer

Unit

GND

/

Figure 5-2 TAPE SPEED

CIRCUIT ADJUSTMENT (AUDIO SECTION)

COMPACT CASSETTE TYPE

DISTORTION

DOLBY LEVEL MTT-150

CALIBRATION

i

FREQUENCY/

APPLICATION

MODEL MEASUREMENT

APPLICATION

LEVEL

RANGE

3 kHz, -10 dB

Tape speed,

Wow and flutter

check

TW-2111

lo-

1OOgcm

Normal : Playback torque

1 1.5-1Ogcm

1

Normal : Back tension

I

6.3

kHz,

-10

dB

Head azimuth

8 kHz, -10 dB adjustment

lOkHz,-1OdB

TW-2121 1

lo-1OOgcm

Reverse : Playback torque

I

1

kHz, -10

dB

Distortion

chech

level adjustment

TW-2231

1.5 -

log-cm

30 - 200 g-cm

Reverse : Back tension

Fast-forward, Rewind torque

Dolby B-Type

Dolby NR

Tone 200 nwblm

B-type level

adjustment

TW-2412 j 0-300g

Normal : Driving power

I

TW-2422 1 0 -

3009

Reverse : Driving power

I

Record fre-

quency check

SETTING

POSITION

OF

WITCH

AND KNOB

ITEM

l

Volume control: Maximum

l

Balance control: Center

*Graphic equalizer control: Center

l

Function selector switch: Tape

ADJUST-

INPUT

MENT

REMARKS

(CHECK)

POINT

Dscilloscop

Test Tape

MTT-118

Head

PLAY BACK Test tape

AMPLIFIER

MTT-118

-

(0.85 -

1.7V)

Figure 5-3 PLAYBACK AMPLIFIER SENSITIVITY

SENSITIVITY

TEST

TAPES FOR

MEASUREMENT

TORQUE METER FOR COMPACT CASSETTE

I

-5-

Loading...

Loading...