st-i~~~

SERVICE

MANUAL :i

OUTSTANDING RECEPTION THE WORLD OVER

ATSM882109RCS

This Service Manual omits the descriptions about the adjustment

and block diagram of the Radio

(High

Frequency) Circuit, and for

their details, refer to the GF-54542 Service Manual (ATSM182013-

RCS)

or GF-5454 Service Manual (ATSM382047RCT).

In the interests of user-safety the set should be

restored to its original condition and only parts

identical to those specified be used.

INDEX

TO CONTENTS

SPECIFICATIONS 2

POWER

SUPPLY/VOLT&

.iiLi&i&i

’ : : : : : : : : : : : : : : : : : : : : : : : : : : : : 2

DIAL CORD STRINGING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

NAMES OF CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

DISASSEMBLY

.*...............................,

4

AUDIO

BLOCK

DlAikil

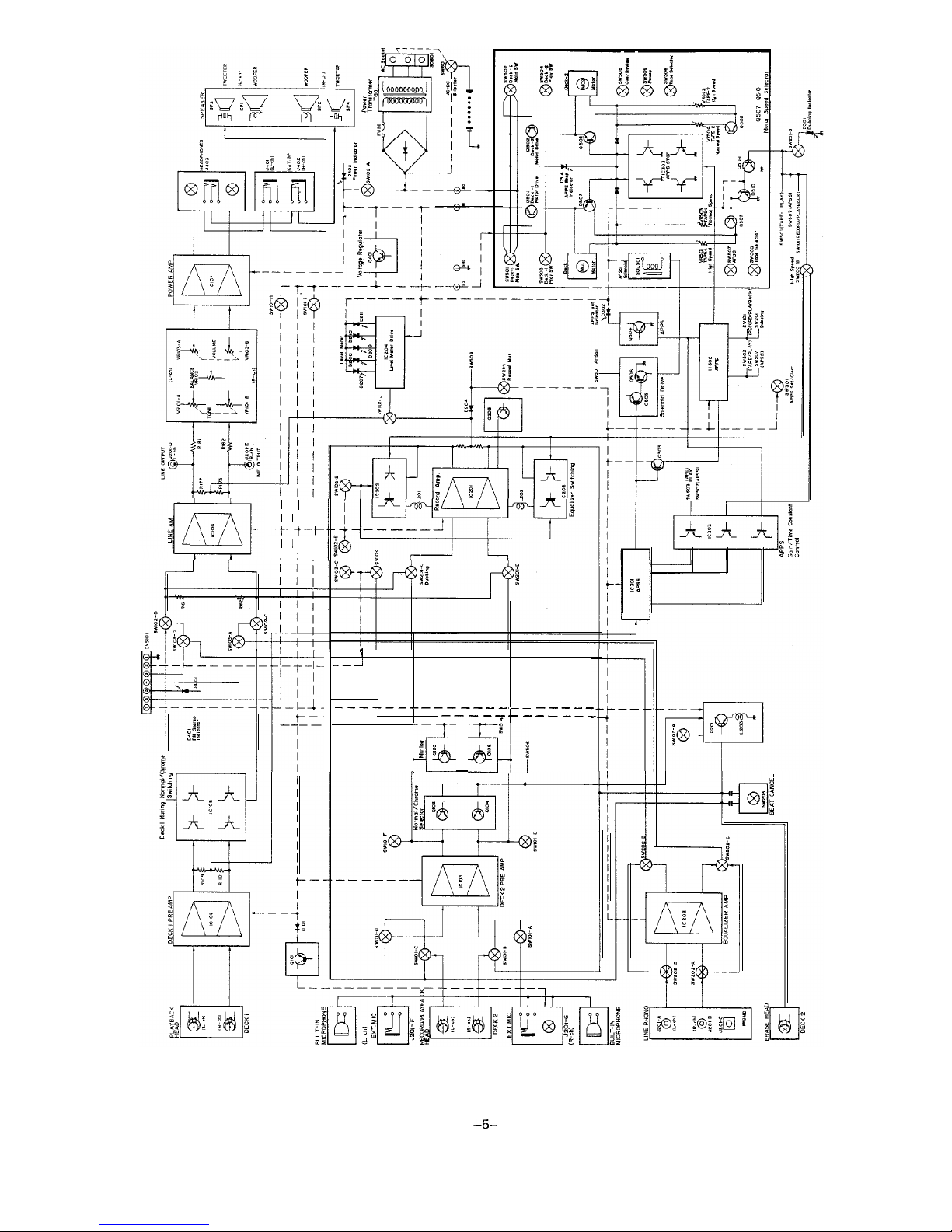

’ : : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

CIRCUIT CONSTRUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

APPS FLOW CHART

.7,8

MECHANICAL

ADJUSiM’Efi- ’ : : : : : : : : : : : : : : : : : : : : : : :‘: : : : : : : : : :

. 9

CHECKING OF

AUDIO

(LOW FREQUENCY) CIRCUIT . . . . . . . . . . . . . . . . . . .

.lO

SCHEMATIC DIAGRAM

(l/Z), (Z/Z)

. . . . . . . . . . . . . . . . . . . . . . . . . .

11,12,15

WIRING SIDE OF PRINTED WIRING BOARD

(l/Z), (Z/Z)

. . . . . . . . . . , . . . . .

13,14,16

SCHEMATIC DIAGRAM AND WIRING SIDE OF PRINTED WIRING BOARD AT

POWER SUPPLY SECTION OF GF-500 . . . . . . . . . . . . . . . . . . . . . . . . . . . _

.17

AC POWER SUPPLY CORD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.I7

NOTES ON SCHEMATIC DIAGRAM

18

DECK 1 MECHANISM EXPLODED

Vii : : : : : : : : : : : : : : : : : : : : : : : : : : : : :

19

DECK 2 MECHANISM EXPLODED VIEW . . . . . . . . . . . . . . . . . . . . . . . . . . .

.20

CABINET EXPLODED VIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21,22

REPLACEMENT PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23%

Back

SHARP CORPORATION

SHARP

ELECTRONICS

CORPORATION

1.

GENERAL

Power source:

(G

F-500)

(G

F-5002)

Speakers: Woofer;

Tweeter;

Output power:

(G

F-500)

(GF-5002)

Semiconductors:

(G

F-500)

(G

F-5002)

FOR A COMPLETE DESCRIPTION OF THE OPERATION OF THIS

UNIT, PLEASE REFER TO THE

OPERAT.lON

MANUAL.

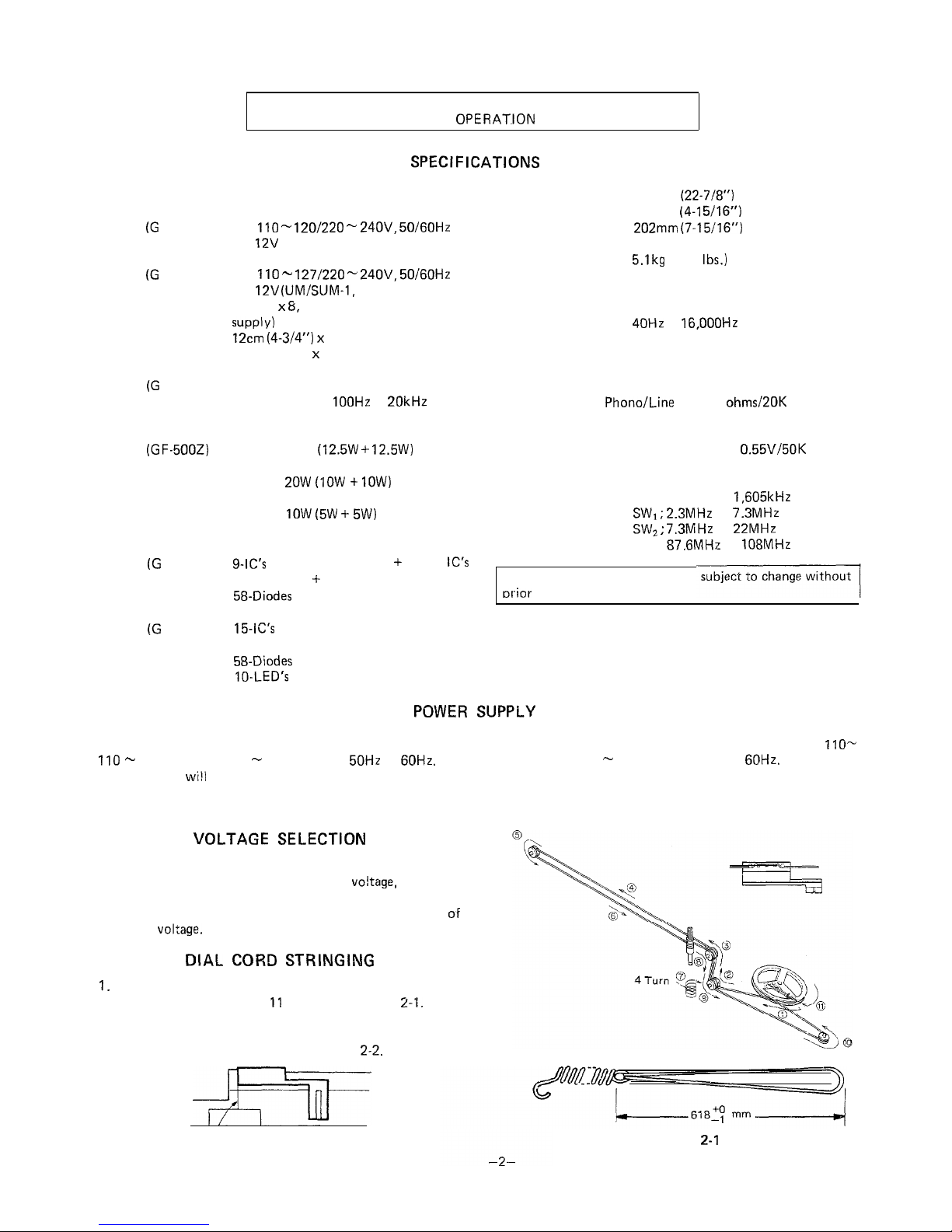

SPECIFICATIONS

AC 110 -

12Ol220 - 24OV, 50/60Hz

DC 12V (Ten “D” Size batteries or

external DC supply)

AC 110 -

127/220 - 24OV, 50/60Hz

DC

12V (UM/SUM-1,

R-20, HP-Z, or

battery x 8, “D” or external DC

supply)

12cm

(4-3/4”) x

2

Ceramic type x 2

2.3 Watts per channel, minimum RMS,

at 3 ohms, from

100Hz

to

20kHz

with

no more than 10% Total harmonic dis-

tortion.

PMPO; 25W (12.5W + 12.5W)

(AC Operation)

MPO;

2ow (low

+

low)

(AC Operation)

RMS;

IOW

(5W

+ 5W)

(DC Operation, 10% Distortion)

9-IC’s

(Integrated Circuits) + 6 Aux. IC’s

2 Transistors + 21 Aux. Transistors

58-Diodes

1 O-LED’s

15-IC’S

23 Transistors

58-Diodes

IO-LED’s

Dimensions: Width; 582mm

(22-7/g”)

Depth; 125mm

(4-I 5/16”)

Height;

202mm (7-15/16”)

Weight (without batteries):

5.lkg

(11.3

Ibs.)

TAPE RECORDER/PLAYER

Tape: Philips-type compact cassette tape

Frequency response:

40Hz

to

16,OOOHz

(Metal tape)

S/N ratio: Deck 2

50dB (Normal tape recording)

Deck 1 55dB (Playback)

Wow and flutter: 0.06% (WRMS)

Input impedance: External Mic; 600 ohms

Phone/Line

in; 50K

ohms/20K

ohms

Output impedance:

Headphones;

8 ohms to 32 ohms

External speaker; 3 ohms to 8 ohms

Line out;

0.55Vl50K

ohms

RADIO

Frequency range:

AM; 525kHz to

1,605kHz

SW1 ; 2.3MHz

to

7.3MHz

SW2 ; 7.3MHz

to

22MHz

FM;

87.6MHz

to

108MHz

Specifications for this model are

orior

notice.

POWER

SUPPLY

The GF-500Z Unit will operate on an AC power supply of The GF-500 Unit will operate on an AC power supply of 11

O-

110 -

127 Volts, or 220

-

240 Volts of

50Hz

or

60Hz.

For 120 Volts, or 220

-

240 Volts of 50Hz or

60Hz.

For portable

portable use it

will

operate on its internal batteries, or from an

use it will operate on its internal batteries, or from an external

external 15 Volts DC supply (with an adaptor).

15 Volts DC supply (with an adaptor).

VOLTAGE SELECTION

Before operating the unit on mains, check the preset voltage.

If the voltage is different from your local

vo!tage,

adjust the

voltage as follows: Slide the AC power supply socket cover by

a little loosing screw to the visible indication of the side

OF

your local

voltage.

1.

2.

DIAL

CORD

STRINGING

Turn the drum fully clockwise, and set the cord in the

numerical order from 1 to 11 as shown in Figure

2-I.

Turn the tuning control knob driving shaft fully clockwise,

and adjust the dial pointer to come into “Marking-off Line”

position of the dial scale plate. See Figure

2-2.

Marking-off Line

Figure 2-2

Figure

2-I

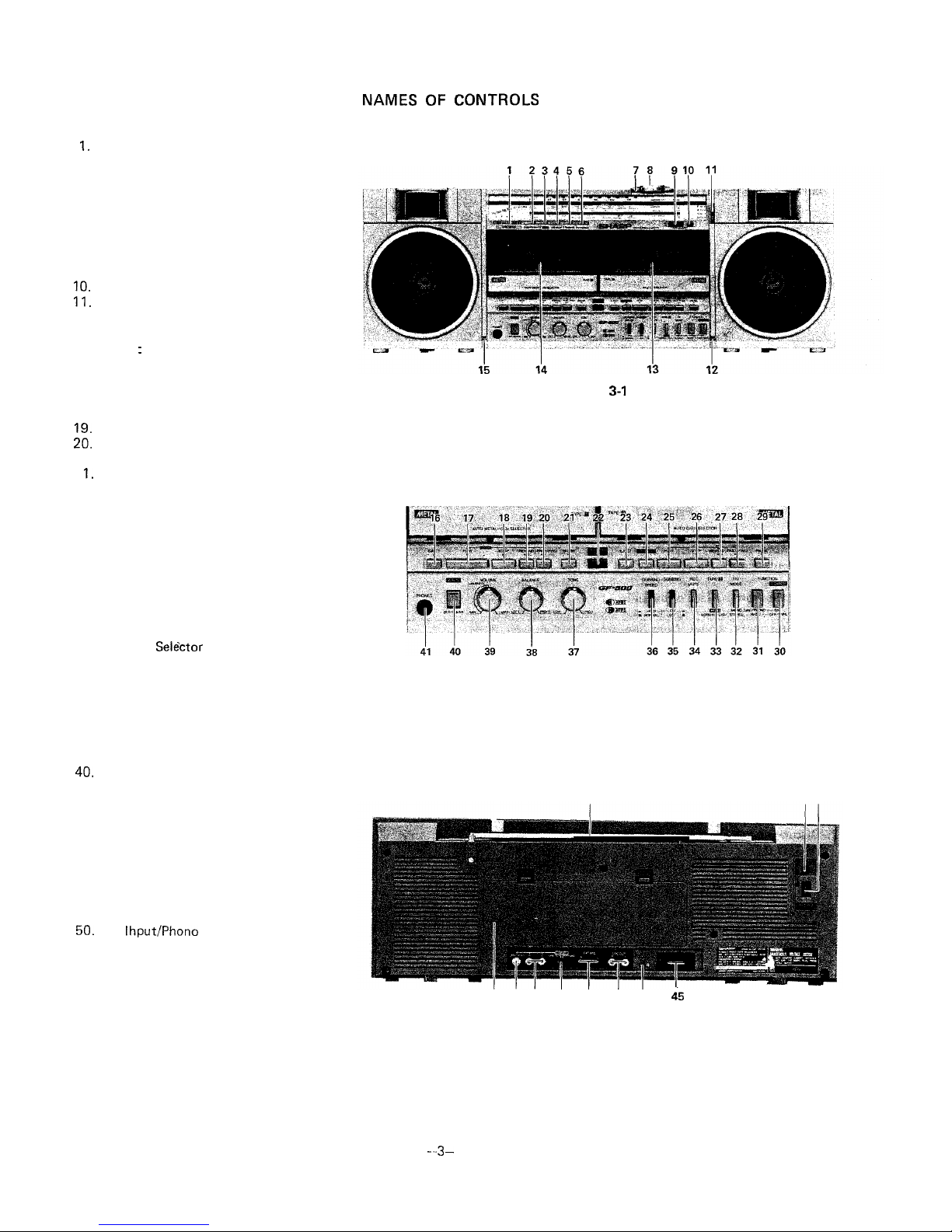

1.

Level Meter

2. Power On/Battery Indicator

3. APPS Indicator

4. APPS End-Pause indicator

5. Dubbing Indicator

6. FM Stereo Indicator

7. Tuning Control

8. Fine Tuning Control

9. Deck 2: Digital Tape Counter

IO.

Tape Counter Reset Button

11. Band Selector

12. Built-in Microphone (Right Channel)

13. Deck 2: Cassette Compartment

14. Deck 1 : Cassette Compartment

15. Built-in Microphone (Left Channel)

16. Deck 1: Eject Button

17. Deck 1: Play Button

18. Deck 1: Stop Button

19. Deck 1: Rewind/Reverse APSS Button

29.

Deck 1: Fast Forward/Forward APSS

Button

2 1.Deck 1: Pause Button

22. Dubbing Start Button

23. Deck 2: Eject Button

24. Deck 2: Record Button

25. Deck 2: Play Button

26. Deck 2: Stop Button

27. Deck 2: Rewind/Review Button

28. Deck 2: Fast Forward/Cue Button

29. Deck 2: Pause Button

30. Power Switch

31. Function Selector Switch

32.

FM Mode

Selactor

33. Deck 2: Tape Selector Switch

34. Deck 2: Record Muting Switch

35. Dubbing Switch

36. Dubbing Speed Selector Switch

37. Tone Control

38. Balance Control

39. Volume Control

49.

APPS Set/Clear Switch

41. Headphones Socket

42. FM/SW Telescopic Rod Antenna

43. External DC Power Supply Socket

44.

AC Power Supply Socket

45. External Speaker Sockets

46. Beat Cancel Switch

47. Line Output Sockets

48. External Microphone Sockets

49. Input Selector Switch

50.

Line

Ihput/Phono

Input Sockets

51. Earth Terminal

52. Battery Compartment

NAMES OF

CONTROLS

Figure

3-1

Figure 3-2

42

4344

52 51 50 49 48

47 46

45

Figure 3-3

-..3-

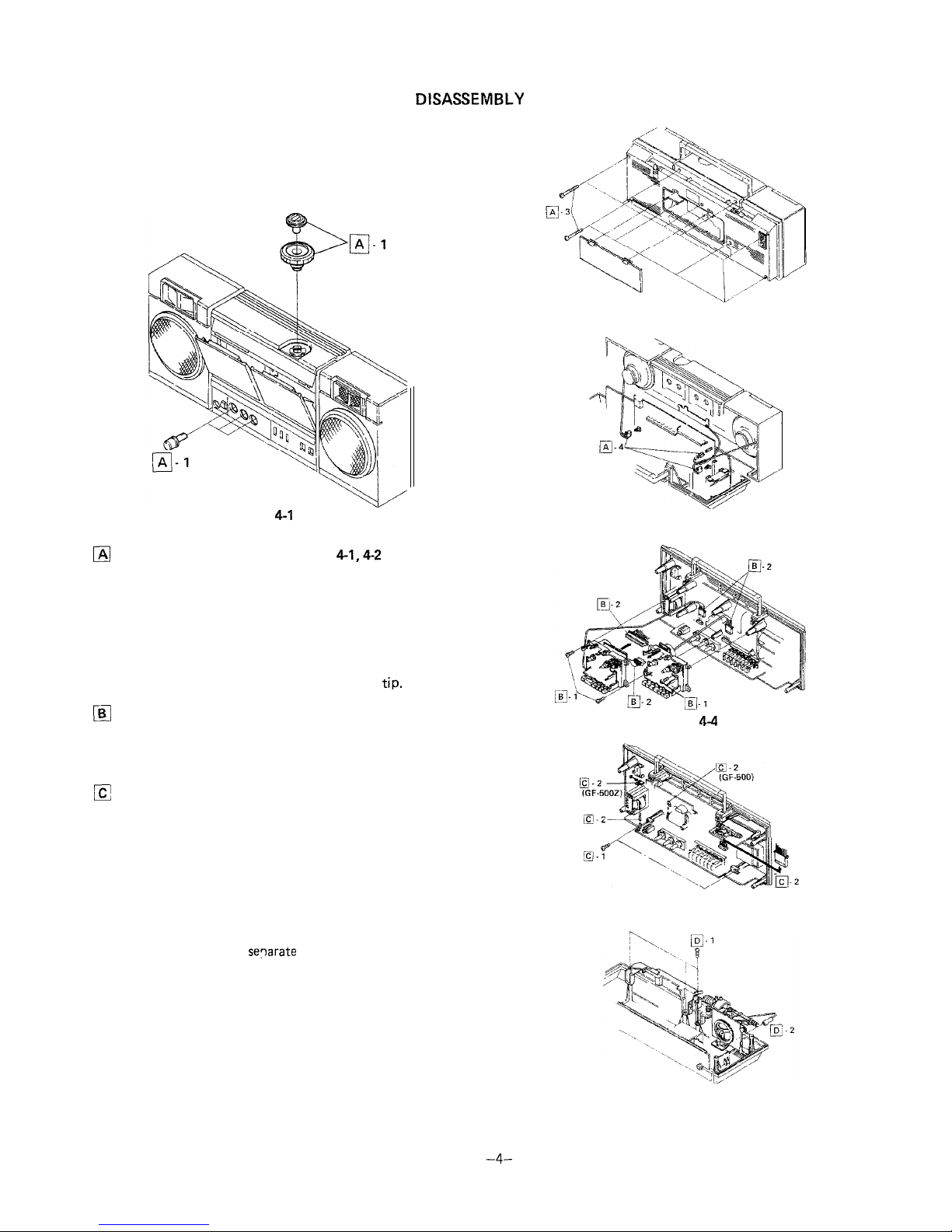

DISASSEMBLY

Caution:

Prior to the disassembly, be sure to draw the AC power supply

lead plug from the AC power supply socket of the unit and to

unload the cassette compartment with a cassette tape and the

battery compartment with batteries.

Figure 4-1

m

Removal of Front Cabinet (See Figs.

4-1,4-2

and 4-3)

1. Pull out one tuning control knob one fine tuning control

knob and three control knobs (volume, balance and tone),

all at the front surface of the unit.

2. Push the eject button to open the cassette compartment.

3. Remove nine screws from the front cabinet and back

cabinet: one screw of the nine is found in the battery

compartment.

4. Disconnect two speaker sockets and one earth

tip.

a

Removal of Mechanism Block (See Fig. 4-4)

1. Remove three screws from the mechanism block and the

drive belt from the tape counter.

2. Disconnect four sockets and detach the mechanism block.

a

Removal of Main P.W.B. (See Fig. 4-5)

1. Remove two screws from the main P.W.B. and pull the

P.W.B. forwards.

2. Disconnect two sockets and pull one tip out, then detach

the P.W.B.

3. If necessary, it is recommended to detach the indicator

P.W.B. from the tuner frame.

q

Removal of Tuner Frame (See Fig. 4-6)

1. Remove three screws from the tuner frame.

2. Pull out one tip and

separate

the tuner from the back

cabinet.

Figure 4-2

Figure 4-3

Figure

44

Figure 4-5

Figure 4-6

-4-

zl-

II I

a

5

"

I I

I

--+-t--lI I

I

I I I

I

--

i

------.---_------

_____

----T

.-------

j&

211

Figure 5 BLOCK DIAGRAM

-5-

-.--...-

---.---..--.-

CIHCU17

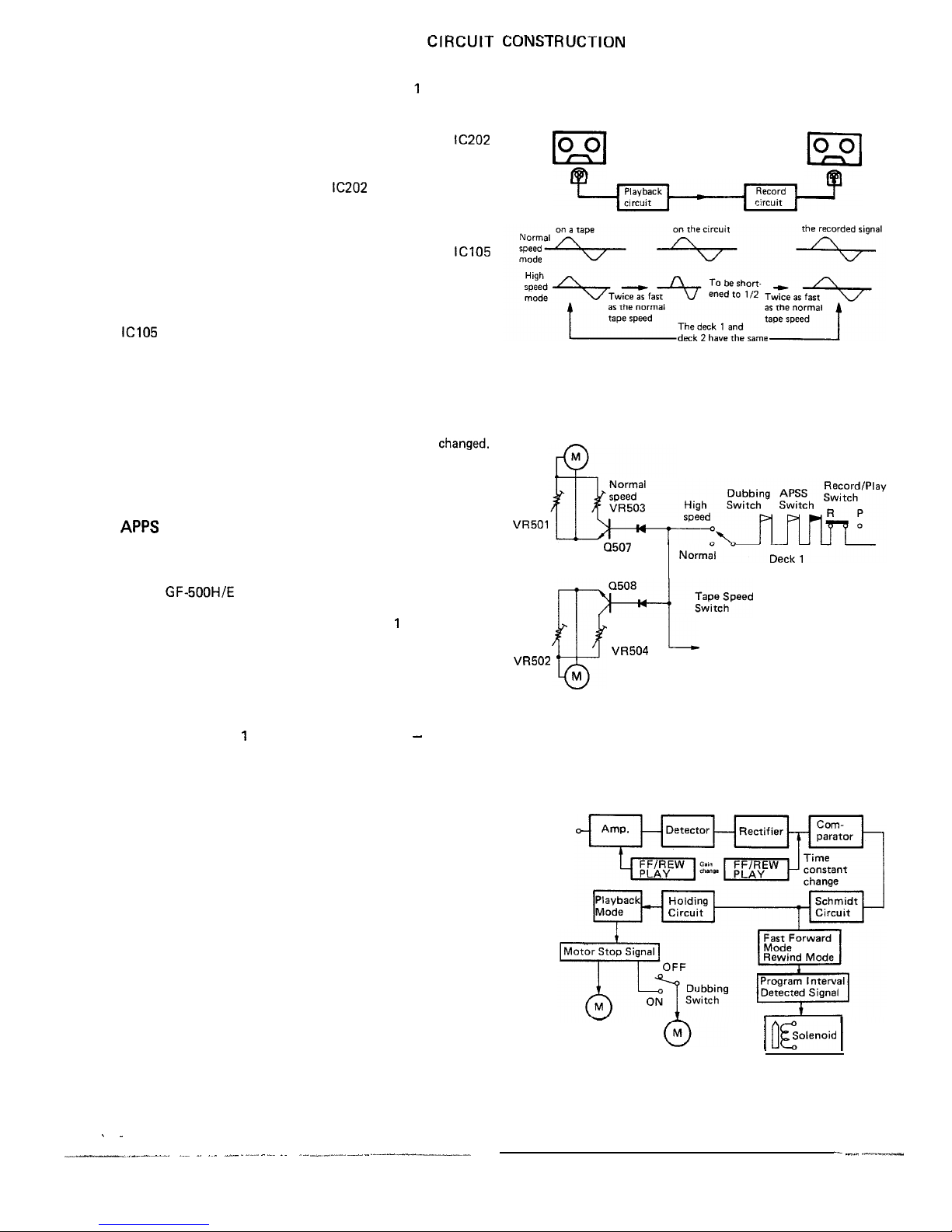

It is possible to select either normal tape speed or high tape

speed when you perform dubbing from the deck 1 to the deck

2 and the high speed is twice as fast as the normal speed.

l

Normal speed/high speed record selector circuit

Being provided at the deck 2, the integrated circuit

IC202

works to select the normal speed mode or the high speed

mode: the frequency at the high speed is two times higher

than that at the normal speed. The

IC202

also works to detect

whether a normal tape or a metal tape has been loaded in the

unit.

l

Normal speed/high speed playback selector circuit

Being provided at the deck 1, the integrated circuit

ICI05

works to select the normal speed mode or the high speed

mode: the frequency at the high speed is two times higher

than that at the normal speed. Here is also given proper

equalization for the signals of both speed modes. Further the

IC105

changes its constant according to whether a normal tape

or a metal tape has been loaded in the unit.

l

Normal speed/high speed selector circuit

Change of the motor’s rotational speed results in a changeover

between the tape normal speed and high speed modes. The

electronic switch is used to act on the motor control circuits

of the deck 1 and deck 2 at a time as their speeds are

changed.

Fig. 6-2 shows how the circuit works to get the unit in the

high speed mode, whose expression is made with use of the

mechanical switch instead of the electronic switch.

APPS

(Automatic Program Pause System)

The existing APSS, as you know, is to automatically detect an

end of the program when the unit is in fast forward or rewind

mode and then to return it to play mode. The APPS employed

for the GF-SOOH/E is something new which is based on the

same ideas as with such APSS, and it is activated not only

when the unit is in play mode (at the deck 1 only) but also

when it is in dubbing mode (from the deck 1 to the deck 2).

In the dubbing mode (either at normal speed or at high speed),

as soon as an end of the program is detected by the APSS in

the deck 1, the APPS works to stop the motor circuits of both

decks 1 and 2 simultaneously -that is, motions of the deck 1

and deck 2 are stopped just at a time.

Therefore, the deck 1 has two automatic controls - APSS and

APPS, that is, it is controlled by the APSS when it is in play

mode (with the deck 2 in stop mode) and by the APPS when it

is in dubbing mode.

The two controls APSS and APPS are differentiated by the

following:

l

Difference in gain and frequency characteristic between

APSS and APPS.

l

Difference in program detect time between APSS and

APPS.

These differences are due to that the tape speed is different

according to whether the unit is in play mode or dubbing

mode, and according to these, the electronic switch selects the

APSS or APPS to get it in action.

CUNS~I KUCTION

Deck 1

Dubbing

Deck 2

Wave length

Wave length

Wave length of

signal wave length.

Figure 6-l

Deck 1 Motor

High

Speed

VR501

Q507

Motor Selector

Transistor

Deck 2

Speed

Play Switch

‘k”

Normal

High

Speed

Speed

L

Deck 1 Playback Equalizer Selector

VR504

VR502

Deck 2 Record Equalizer Selector

M

Deck 2 Motor

Figure 6-2

Input

signal

Deck 1 Motor

Deck 2 Motor

Figure 6-3

-6-

/ fleolenoid 1

/ .

__-L-__Illl.

___ ---.-.

.._ _ .~_

,_.- . .._- . -..~. .I __., --~ .--- -- .--1----_--

- ._.._

_I--

APPS Flow Chart

I

/-- - - - - - -APPSallclear

APPS not settable

Deck 1 is in play mode?

The motor stops and the yellow indicator

-

(D314)

lights up. The red indicator is still

-

lit at the time.

(SW201)

is turned on?

Syncronous operation

of

Deck 1 and Deck 2 is

(EL:

With Deck 2 in stop or play mode, or

with the dubbing switch turned off)

I

The motor of Deck 1 gets

in a stop: Deck 2 alone can

be operated.

+

I

stopped.

I

No.

buttons (for play mode)

0 The motor of Deck 1 starts again.

0

APSS set/clear switch is at “set”

position. (The indicators D302

and D314 are both put off).

I

L-e--

----

------------

Deck 1 is in APSS mode or in stop mode.

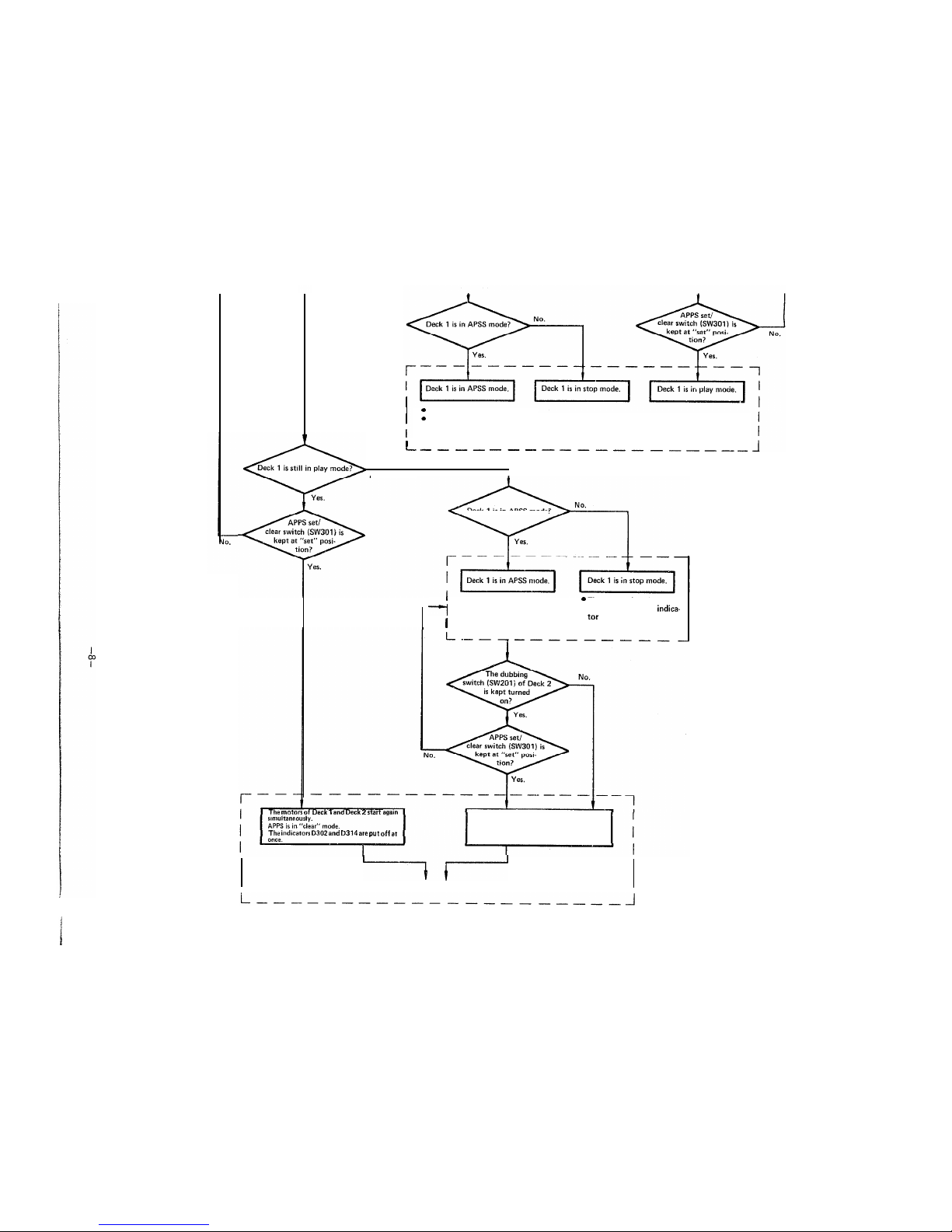

No.

I

Deck1is in APSS mode?

l

APPS set/clear switch is at

@

The motor of Deck 2 is kept

--I

“set” position.

in stop. (The yellow indica-

1

l

The motor of Deck 1 starts again.

tar

D314 keeps on lighting.)

(The red indicator D302 is put off.)

The

motors of

Deck 1 and Deck 2

start

again

The motor of Deck 1 starts again.

The indicators

D302

and

D314

are

put

off at

The yellow indicator D314 is put off.

bl--

APPS all clear.

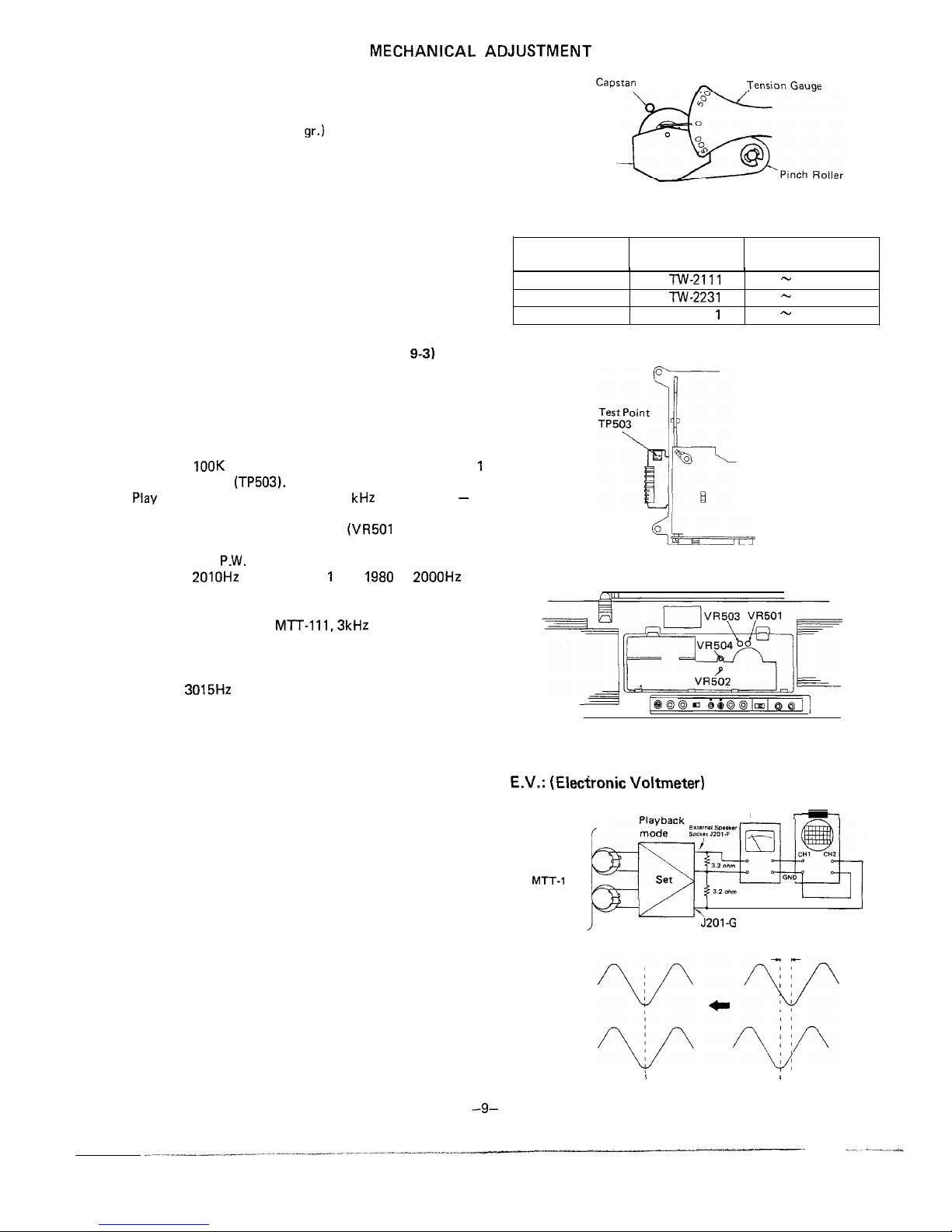

MECHANICAL ADJUSTMENT

PINCH ROLLER PRESSURE CHECK

1. Place the unit in PLAY mode.

2. Push the pinch roller, at the point shown in Fig. 9-1, by

using a tension gauge (500

gr.)

so that it will come off the

capstan. Then, release the tension slowly until the pinch

roller hits the capstan again (i.e., the pinch roller is about to

rotate again). Then check the tension gauge is reading

350 gr. to 420 gr.

3. If the reading is outside the range of 350 gr. to 420 gr.

replace the pressure spring of the pinch roller.

TORQUE CHECK AT PLAY, FAST FORWARD AND

REWIND MODES

Put a torque meter cassette in the cassette compartment of the

set, and see that the measured torque in each mode is normal

as follows:

TAPE SPEED ADJUSTMENT (See Figs. 9-2 and

9-3)

Note:

The high speed operation has priority over the normal speed

operation, and so try to do the adjustment for the former first

and then for the latter.

For High Speed Operation

1. Connect a wow/flutter meter to the Line Output socket

across a

100K

ohm resistor, and shortcircuit the deck

1

control terminal

(TP503).

2.

Play

a test tape (TEAC, MTT-118, 1

kHz

prerecorded) - at

its middle part but not at its start or end point.

3. Adjust the semi-variable resistors

(VR501

for the deck 1

and VR502 for the deak 2) located on the deck 1 and deck

2 mechanism

P.W.

Boards, so that the output frequency is

1990 to

2010Hz

for the deck 1 and

1980

to

2000Hz

for

the deck 2.

For Normal Speed Operation:

1. Play a test tape (TEAC,

Ml-T-1 11,3kHz

prerecorded).

2. Adjust the semi-variable resistors (VR503 for the deck 1

and VR504 for the deck 2) located on the deck 1 and deck

2 mechanism P.W. Boards, so that the output frequency is

2985 to

3015Hz

on the wow/flutter meter for both decks 1

and 2.

RECORD/PLAYBACK HEAD AZIMUTH ADJUSTMENT

1. Make Connection of instruments as shown in Fig. 9-4.

2. Set the Dubbing switch SW201 to the off position and Tape

Selector switch SW105 to Normal position.

3. Adjust the head azimuth adjusting screw so that sine

waveform attains the maximum and the same phase in right

and left.

4. Even without using the oscilloscope, also adjust the head

azimuth adjusting screw so that outputs of both the right

and left channels attain the maximum and the same phase

in right and left.

Note:

For some heads, there may be a phase difference between

right and left channels when the output is made maximum.

In this case, adjust the head azimuth so that such phase

difference will be as small as possible while keeping the

output still maximum.

Pinch Roller

Pressure Spring

Figure 9-l

Mode

Torque meter

cassette

Measured torque

Playback TW-2111

Fast-forward TW-2231

Rewind TW-223

1

35-60 gram-cm

90-135 gram-cm

90-135 gram-cm

<--

Figure 9-2

Figure 9-3

E.V.:

(Elecfronic Voltmeter)

Test Tape

MT-r-1

14

Oscilloscope

E.V.

h’

J201 -G

as small as possible

/

I

Figure 9-4

-9-

Loading...

Loading...