Sharp GF-4949ZS, GF-4949ZG Service Manual

SHARP

SERVICE

MANUAL

S03C4G

F4949ZG

PHOTO: G

F-4949ZG

GENERAL

Power source

:

Speakers:

Output power:

Semiconductors:

Dimensions: Width;

Height;

Depth;

Weight:

GF-4949ZG

GF-4949ZS

In the interests of user-safety the set should be

restored to its original condition and only parts

identical to those specified be used.

For the mechanical adjustment, refer to the

620X

Service Manual

(ATSM281022TRC)

already

issued.

SPECIFICATIONS

(AC operation)

RMS; 6W (3W + 3W) (DC opera-

AC 1

IOV-127V

and

22OV-24OV,

tion, 10% distortion)

5

ICS

4 Transistors

50/60Hz

11

Diodes

2 LEDs

445mm (17-l/2”)

233.5mm (9-3/l

6”)

DC 9V

(UM/SUM-1

or

R20

type x 6)

98mm

(3-7/8”)

3.1 kg (6.8

tbs.)

without batteries

12cm

(4-3/4”)

woofer x 2

Ceramic type tweeter x 2

PMPO; 16W

(BW

+ 8W)

(AC operation)

MPO; 12W (6W + 6W)

TAPE RECORDER

Tape

:

Compact cassette tape

Frequency response:

50Hz - 10,OOOHz

Signal/noise ratio:

45dB

Input sensitivity and impedance:

External mic.;

600 ohms

Loaded impedance:

Headphones;

8 ohms - 25 ohms

RADIO

Frequency range:

FM; 87.6 MHz -

108

MHz

AM; 526.5 - 1605.5

kHz

SW1 ;

2.3 MHz - 7.3 MHz

SW2 ; 7.3 MHz - 22.0 MHz

Specifications for this model are subject to change without

prior notice.

FOR A COMPLETE DESCRIPTION OF THE OPERATION OF THIS UNIT,

PLEASE REFER TO THE OPERATION MANUAL.

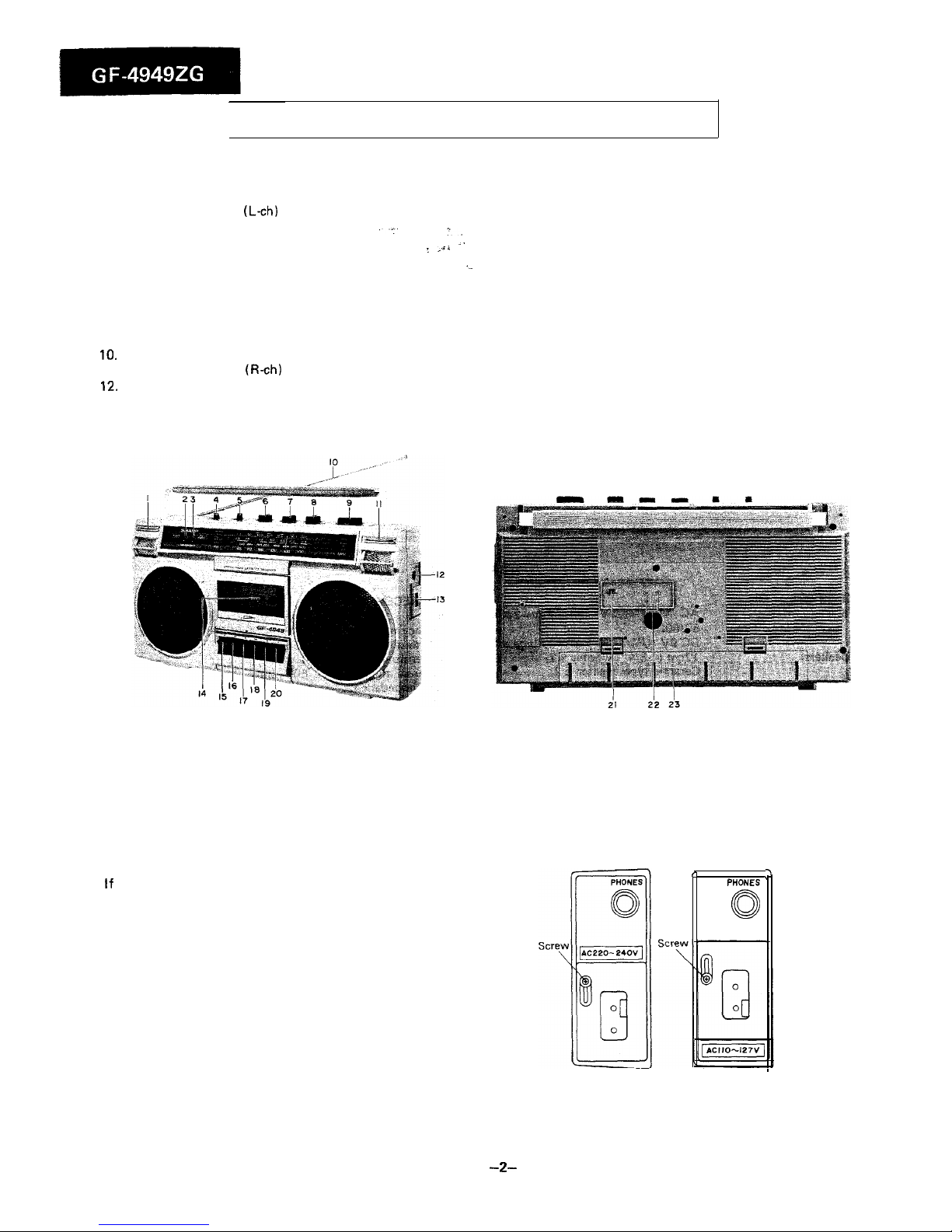

NAMES OF PARTS

1. Built-in Microphone (L-ch)

2. Power Indicator

3. FM Stereo indicator

4. Band Selector

5. Function Selector

6. Volume Control

7. Tone Control

8. Fine Tuning

9. Tuning Control

10. FM/SW Telescopic Rod Antenna

11. Built-in Microphone (R-ch)

12. Headphones Jack

13. AC Power Supply Socket

‘1

1.

14. Cassette Holder

: ,‘i -’

15. Record Button

16. Rewind Button

‘-

17. Playback Button

18. Fast-forward Button

19. Stop Button

20. Eject Button

21. Beat Cancel Switch

22. External Microphone Jacks

23. Battery Compartment Lid

Figure 2-l

Figure 2-2

VOLTAGE SELECTION

Before operating the unit on mains, check the preset voltage.

If

the voltage is different from your local voltage, adjust the

voltage as follows: Slide the AC power supply socket cover

by a little loosing one screw to the visible indication of the side

of your local voltage. See Figure 2-3.

c

7

PHONES ’

0

Figure 2-3

-2-

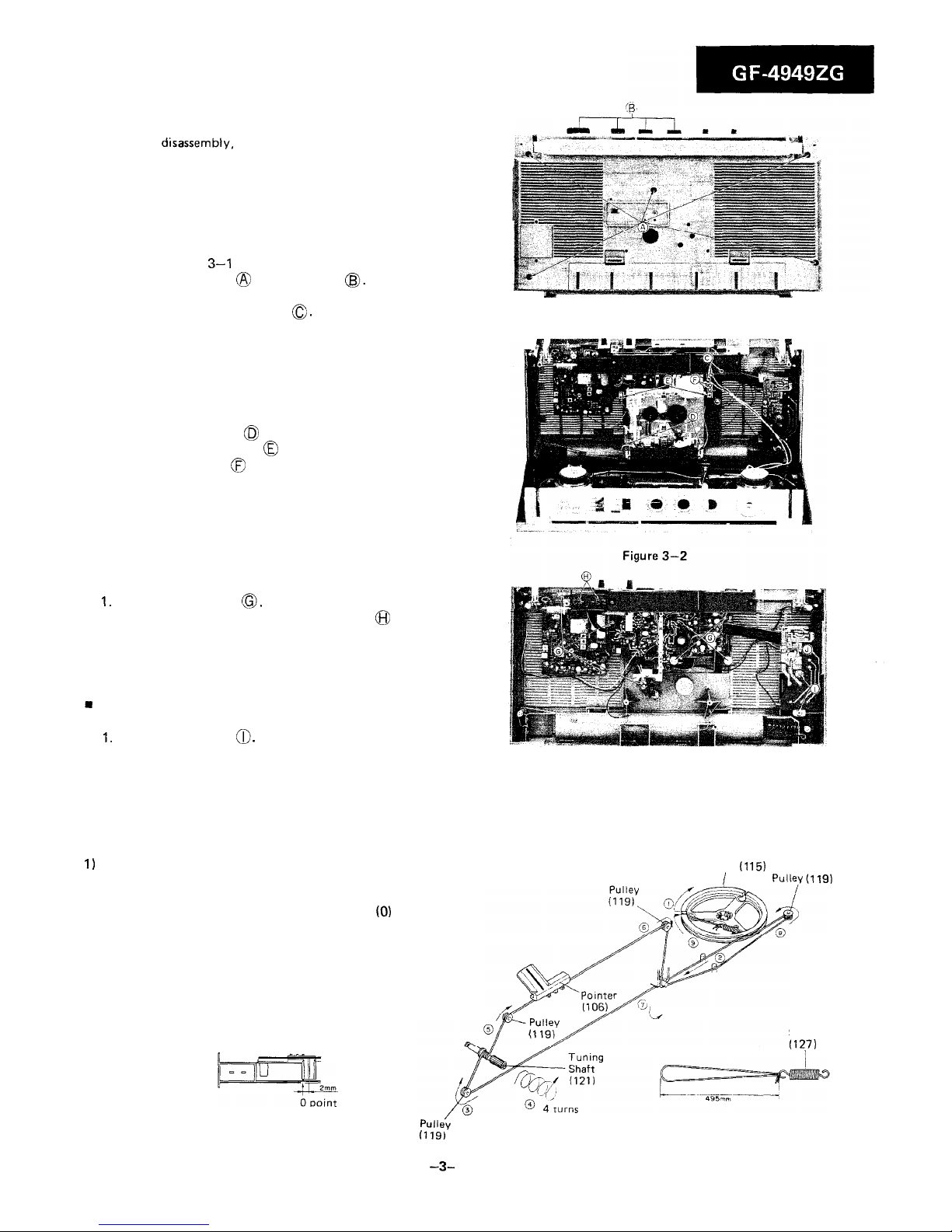

DISASSEMBLY

Caution:

Prior to the

disassembly,

be sure to remove the AC power

supply cord, cassette tape and batteries from the unit.

n

FRONT CABINET REMOVAL

(Refer to Figures

3-1

and 3-2.)

1. Remove five screws @ and four knobs

@j).

2. Pull the front cabinet frontward by holding its upper

part and disconnect three tips

0.

n

MECHANISM BLOCK REMOVAL

(Refer to Figure 3-2.)

1. Remove two screws @ .

2. Disconnect two sockets 0 .

3. Unsolder two tips @ and then the mechanism block

can be removed.

Figure 3-l

q

MAIN P.W.B. REMOVAL

(Refer to Figure 3-3.)

1.

Remove eight screws

0.

2. Remove the LED P.W.B. from two stoppers @ .

Then the main P.W.B. can be removed from the back

cabinet.

= POWER P.W.B. REMOVAL

(Refer to Figure 3-3.)

1,

Remove two screws

0.

2. Disconnect one socket@.

Figure 3-3

DIAL CORD STRINGING

1)

Turn the drum fully clockwise and stretch its cord over

the parts in the numerical order as shown in Figure 3-4.

2) Turn the tuning control shaft fully counterclockwise, and

fix it with the pointer aligned with the zero (0) point on

the frame. See Figure 3-5.

Drum (I 15)

i

Pulley(ll9)

Spring

(127)

Figure 3-5

Figure 3-4

0 SH

SH

f

I

i

r

-

-

-

-

-

r

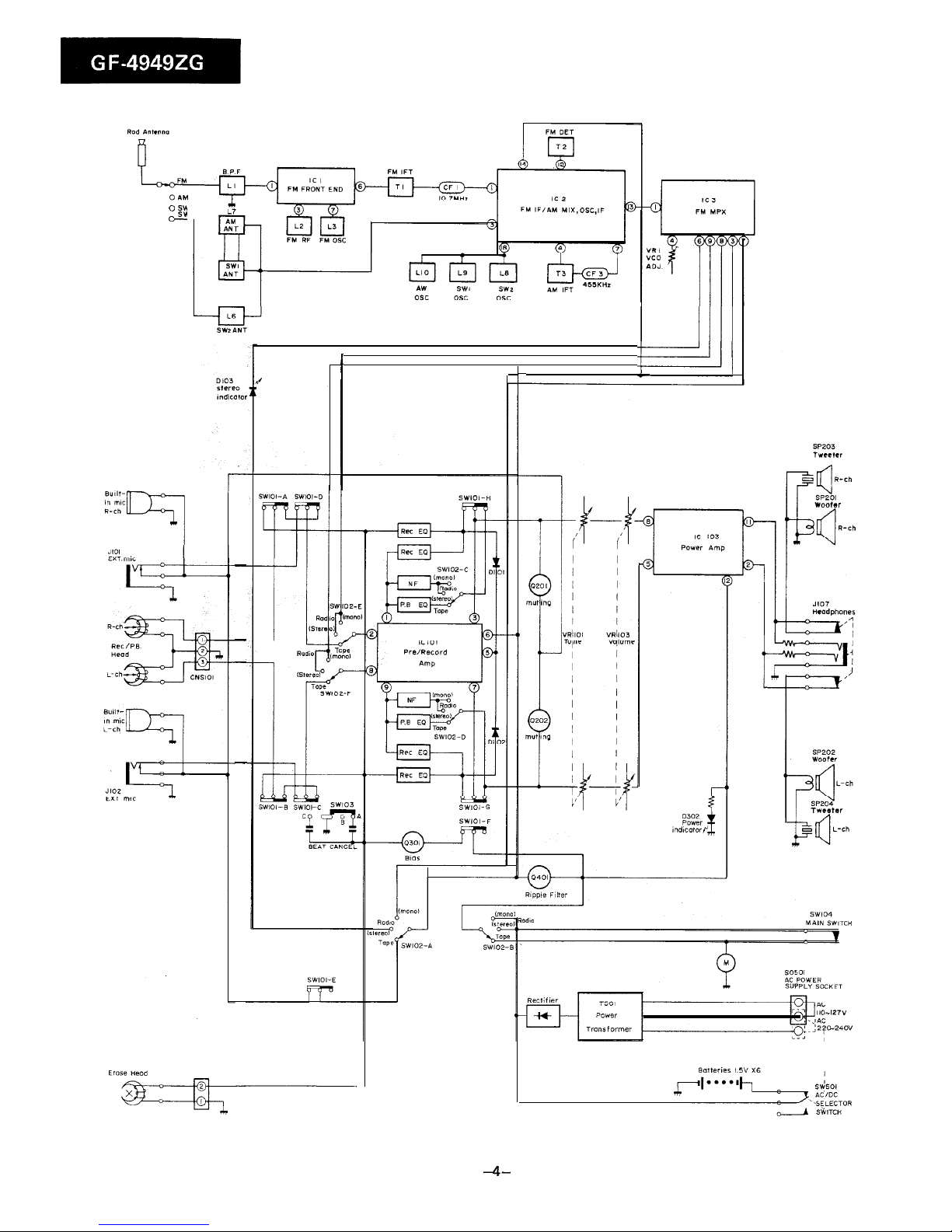

Figure 4 BLOCK DIAGRAM

-4-

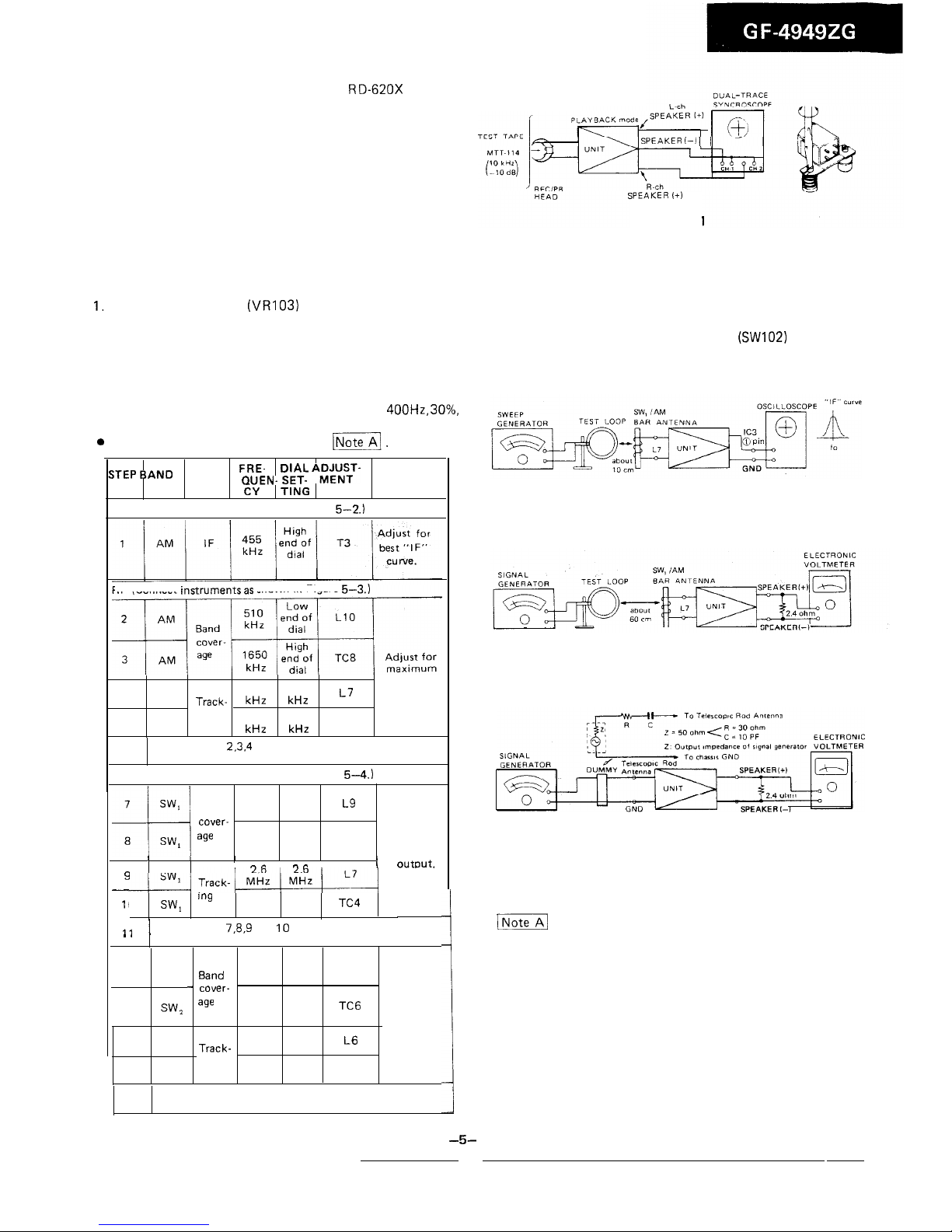

MECHANICAL ADJUSTMENT

Except for the following item, refer to the

RD620X

Service

Manual already issued.

n

RECORD/PLAYBACK HEAD AZIMUTH ADJUSTMENT

As shown in Figure 5-1, connect instruments, and adjust

the head azimuth adjusting screw so that the output signals

from both channels will have maximum waveform with the

same phase in right and left.

SPEAKER f-1

SPEAKER

(+I

Figure 5-l

GENERAL ALIGNMENT INSTRUCTION

Should it become necessary at any time to check the alignment of this receiver, proceed as follows;

1.

Set the volume control

(VR103)

to maximum.

2. Attenuate the signals from the generator enough to swing

the most sensitive range of the output meter.

3. Use a non-metallic alignment tool.

4. Repeat adjustments to insure good results.

5. Set the Function Selector Switch (SW102) to “radio”

position.

AM IF/RF ALIGNMENT

l

Set the signal generator to produce a signal of

400Hz, 30%,

AM modulated.

0 For adjustments in steps 4 and 9, see

-1.

E

TEST

FRE-

‘TEP

BAND

STAGE

QUEN-

SET-

D’AL A;;\y-

REMARKS

CY

TING

IF

(Connect instruments as shown in Figure

5-2.)

RF (Connect

instrumentsas

shown in Figure

5-3.)

4

output.

AM

600

600

kHz

kHz

L7

Track-

5

AM

ing

1400 1400

kHz kHz

TC5

6

Repeat steps

2.3.4

and 5 until no further Improvement

can be made.

RF (Connect instruments as shown in Figure

5-4.)

2.25

LOW

Band

MHz

end of

L9

dial

coverage

7.4

High

end of

TC7

MHz

Adjust for

dial

maximum

/

I

“A

n,.

I OUtDUt.

c

-

11

0

SW,

w

6.0 6.0

MHz

MHZ

TC4

11

1

Repeat steps

7.8.9

and 10 until no further improvement

, .

can be made.

7.2

Low

12 SW,

MHz

end of

La

Band

dial

-

cover-

22.5

High

13 SW,

age

end of

TC6

Adjust for

MHz

dial

maximum

a.5

a.5

output.

14 SW,

MHz

MHz

L6

Track-

15 SW,

ing

19

19

MHz

MHz

TC3

16

Repeat steps 12, 13, 14 and 15 until no further impro-

vement can be made.

1

1

-5-

Figure 5-2

Figure 5-3

Figure 5-4

1-1

Check the alignment of the receiver antenna coil by

bringing a piece of ferrite (such as a coil slug) near the antenna

loop stick, then a piece of brass. If ferrite increases output,

loop requires more inductance. If brass increases output, loop

requires less inductance. Change loop inductance by sliding the

bobbin toward the center of the ferrite core to increase induct-

ance, or away to decrease inductance.

Loading...

Loading...