Sharp GU-X24SCR, GB-X24SCR, GU-X18SCR, GB-X18SCR, GU-X36SCR Installation And Operation Manual

...Page 1

DUCT TYPE ROOM AIR CONDITIONER

INSTALLATION AND OPERATION MANUAL

ENGLISH

ITALIANO

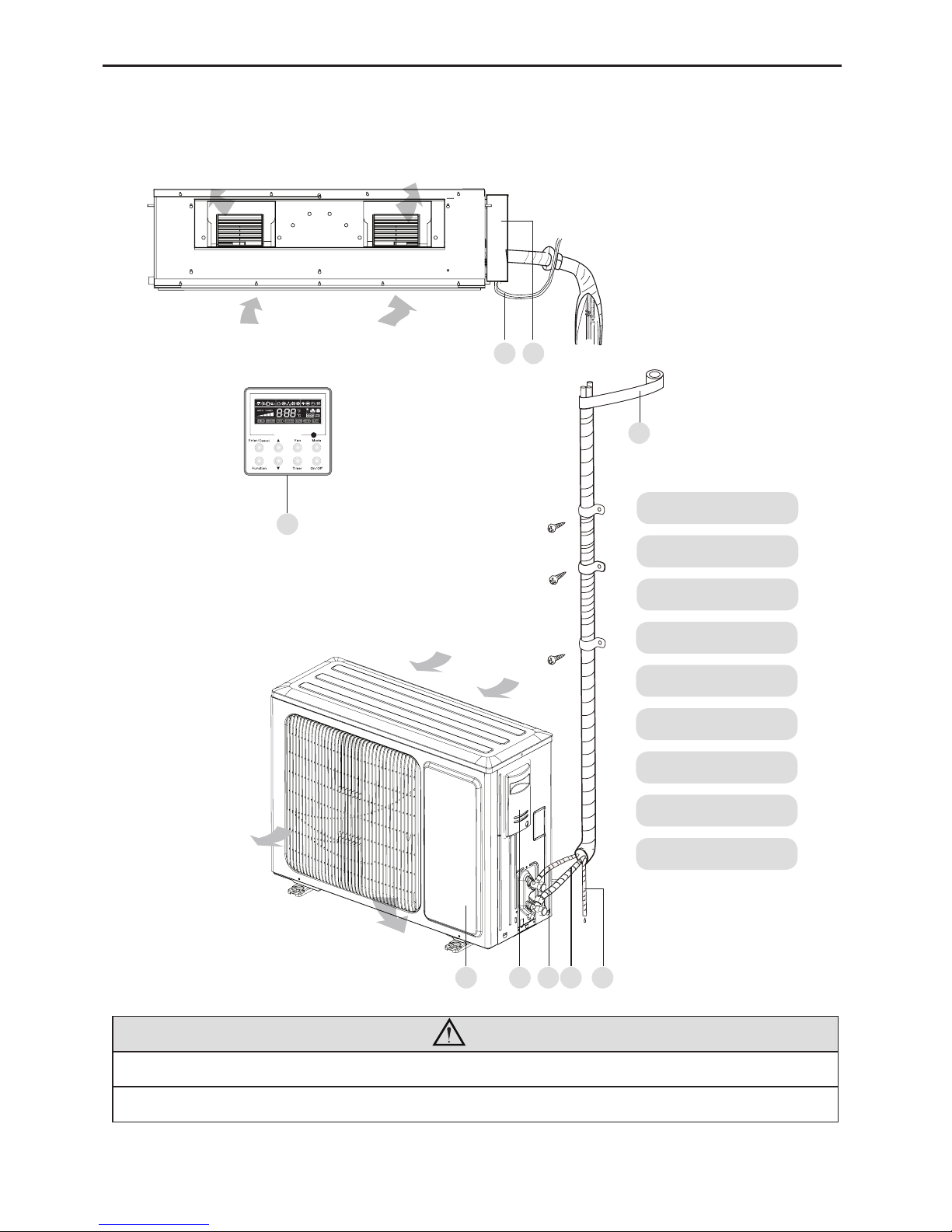

INDOOR UNIT OUTDOOR UNIT

GB-X18SCR GU-X18SCR

GB-X24SCR GU-X24SCR

GB-X36SCR GU-X36SCR

Page 2

Page 3

Information on the Disposal of this Equipment

IF YOU WISH TO DISPOSE OF THIS EQUIPMENT, DO NOT USE THE ORDINARY

WASTE BIN, AND DO NOT PUT THEM INTO A FIREPLACE!

Used electrical and electronic equipment should always be collected and treated

SEPARATELY in accordance with local law.

Separate collection promotes an environment-friendly treatment, recycling of materials,

and minimizing final disposal of waste. IMPROPER DISPOSAL can be harmful to

human health and the environment due to certain substances! Take USED EQUIPMENT

to a local, usually municipal, collection facility, where available.

If in doubt about disposal, contact your local authorities or dealer and ask for the

correct method of disposal.

Page 4

1 Safety Precautions .......................................................................................... 1

2 Outline of the Unit and Main Parts................................................................... 2

3 Preparative for Installation ............................................................................... 3

3.1 Standard Accessory Parts .......................................................................... 3

3.2 Selection of the Installation Location .......................................................... 4

3.3 Connection Pipe Requirement ................................................................... 5

3.4 Electrical Requirement ............................................................................... 6

4 Installation of the Unit ...................................................................................... 7

4.1 Installation of the Indoor Unit ...................................................................... 7

4.2 Installation of the Outdoor Unit ................................................................. 11

4.3 Installation of the Connection Pipe ........................................................... 12

4.4 Vacuum and Gas Leakage Inspection ...................................................... 16

4.5 Installation of the Drain Hose ................................................................... 17

4.6 Installation of the Duct .............................................................................. 20

4.7 Electrical Wiring ........................................................................................ 23

5 Installation of Controllers ............................................................................... 28

6 Test Running .................................................................................................. 28

6.1 Trial Operation and Testing ....................................................................... 28

6.2.Working Temperature Range .................................................................... 29

7 Unit Function ................................................................................................. 30

7.1 Setting of Double Indoor Room Sensors .................................................. 30

7.2 Checking of Outdoor Ambient Temperature ............................................. 30

7.3 Fresh Air Control ...................................................................................... 31

8 Troubleshooting and Maintenance ................................................................ 32

8.1 Troubleshooting ........................................................................................ 32

8.2 Routine Maintenance ............................................................................... 32

Contents

Page 5

DC Inverter Duct Type Unit

1

1 Safety Precautions

WARNING!

This mark indicates procedures which, if improperly performed, might lead to the

death or serious injury of the user.

CAUTION!

This mark indicates procedures which, if improperly performed, might possibly

result in personal harm to the user, or damage to property.

WARNING!

(1). For operating the air conditioner pleasantly, install it as outlined in this installation manual.

(2). Connect the indoor unit and outdoor unit with the room air conditioner piping and cord available

from our standard parts. This installation manual describes the correct connections using the

installation set available from our standard parts.

(3). Installation work must be performed in accordance with national wiring standards by authorized

personnel only.

(4). If refrigerant leaks while work is being carried out, ventilate the area. If the refrigerant comes in

contact with a ame, it produces toxic gas.

(5). Do not power on until all installation work is complete.

(6). During installation, make sure that the refrigerant pipe is attached firmly before you run the

compressor.

Do not operate the compressor under the condition of refrigerant piping not attached properly with

2-way or 3-way valve open.

This may cause abnormal pressure in the refrigeration cycle that leads to breakage and even

injury.

(7). During the pump-down operation, make sure that the compressor is turned off before you remove

the refrigerant piping.

Do not remove the connection pipe while the compressor is in operation with 2-way or 3-way

valve open.

This may cause abnormal pressure in the refrigerant cycle that leads to breakage and even injury.

(8). When installing and relocating the air conditioner, do not mix gases other than the specified

refrigerant (R410A) to enter the refrigerant cycle.

If air or other gas enters the refrigerant cycle, the pressure inside the cycle will rise to an

abnormally high value and cause breakage, injury, etc.

(9). This appliance can be use by children aged fron

8 years and above and persons with reduced

physical, sensory or mental capab

ilities or lack of experience and kowledge if they have been

given supervision or instruction

concerning use of the appliance in a safe way and understand

the hazards involved.

(10).

Children shall not play with the appliance. Cleaning and user maintenance shall not be made by

children without supervision.

(11). If the supply cord is damaged, it must be replaced by the manufacturer, its service agent or

similarly qualied persons in order to avoid a hazard.

Page 6

DC Inverter Duct Type Unit

2

2 Outline of the Unit and Main Parts

Indoor

Outdoor

1. Power Cord

2. Electric Box

3. Wired Controller

4. Binding tape

5. Drain Pipe

6. Gas Pipe

7. Liquid Pipe

8. Big Handle

9. Front Board

1 2

3

4

9

Air outlet

Air outlet

Air inlet

Air inlet

Fig.1

NOTE!

① .

The connection pipe and duct for this unit should be prepared by the user.

② .

The unit is standard equipped with rectangular duct.

8 7 6

5

Page 7

DC Inverter Duct Type Unit

3

3 Preparative for Installation

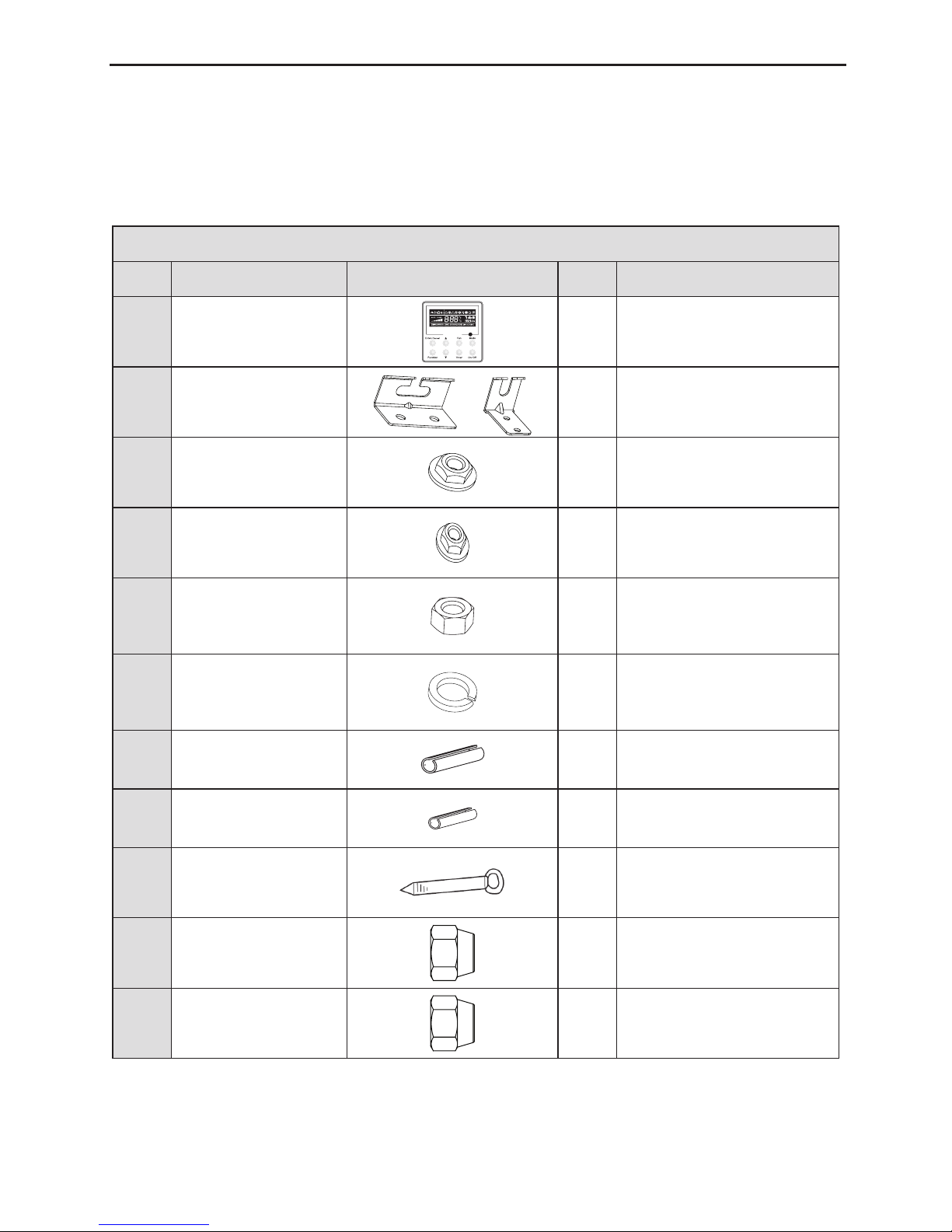

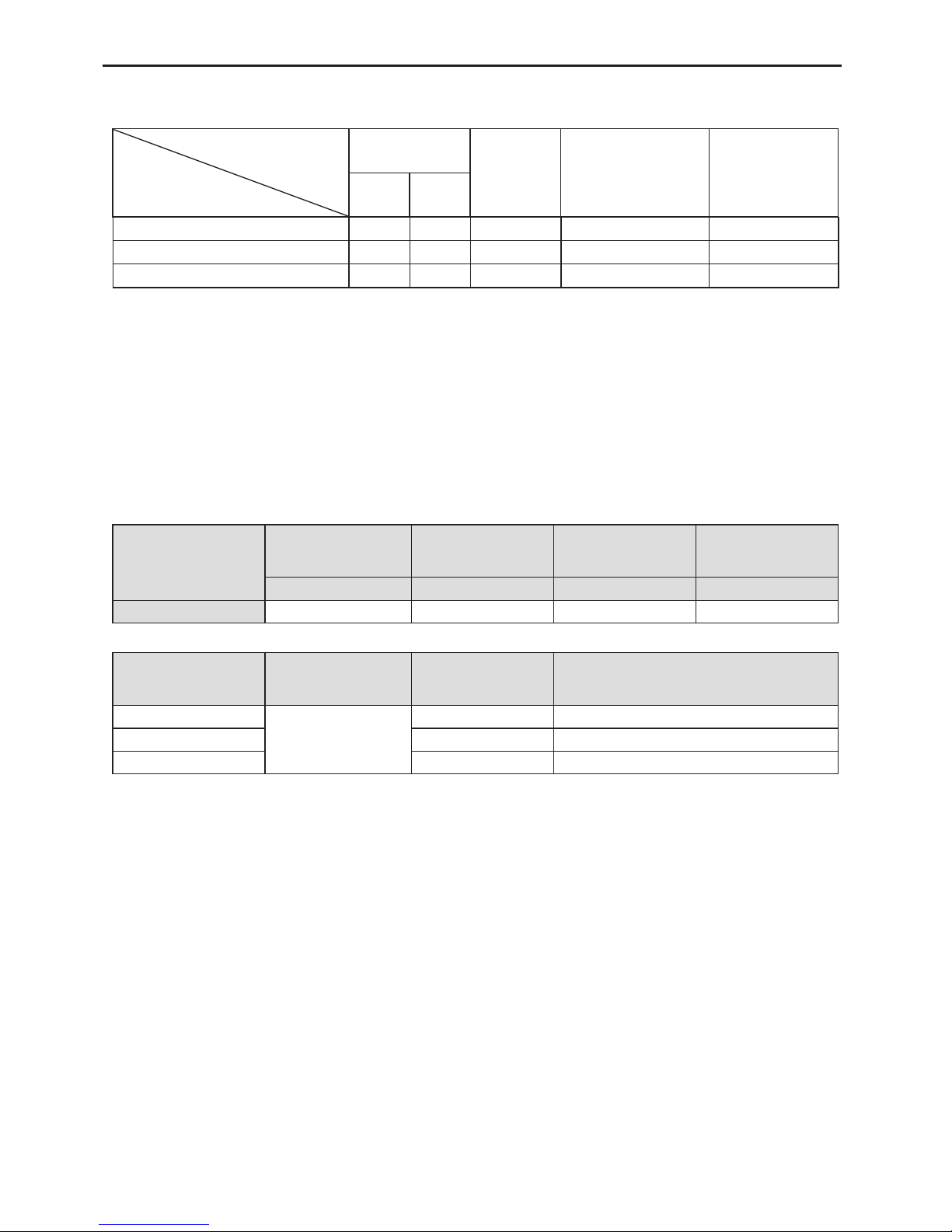

3.1 Standard Accessory Parts

The standard accessory parts listed below are furnished and should be used as required.

Table 1

Indoor Unit Accessories

No. Name Appearance Q'ty Usage

1 Wired Controller 1 To control the indoor unit

2 Hanger or 4 To x the indoor unit

3 Nut with Washer 8

To x the hook on the cabinet

of the unit.

4 Nut with Washer 4

To x the hook on the cabinet

of the unit.

5 Nut 4

To be used together with the

hanger bolt for installing the

unit.

6 Washer 4

To be used together with the

hanger bolt for installing the

unit.

7 Insulation 1 To insulate the gas pipe

8 Insulation 1 To insulate the liquid pipe

9 Fastener 8 To fasten the sponge

10 Nut 1 To connect liquid pipe

11 Nut 1 To connect gas pipe

Page 8

DC Inverter Duct Type Unit

4

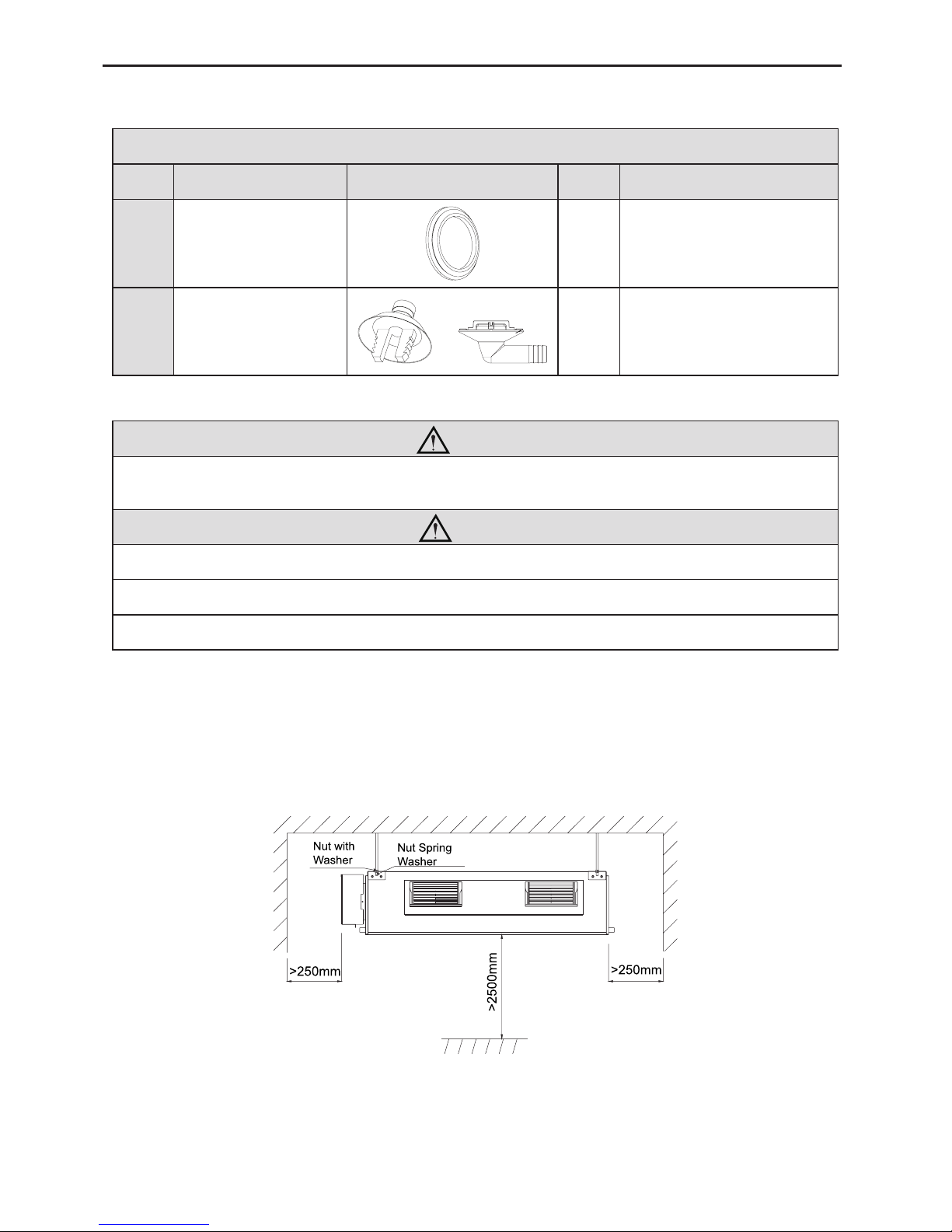

Table 2

Outdoor Unit Accessories

No. Name Appearance Q'ty Usage

1 Drain Plug 3 To plug the unused drain hole.

2 Drainage Connecter

or

1

To connect with the hard PVC

drain pipe

3.2 Selection of the Installation Location

WARNING!

The unit must be installed where strong enough to withstand the weight of the unit and xed securely,

otherwise the unit would topple or fall off.

CAUTION!

① .

Do not install where there is a danger of combustible gas leakage.

② .

Do not install the unit near heat source, steam, or ammable gas.

③ .

Children under 10 years old must be supervised not to operate the unit.

Decide the installation location with the customer as follows:

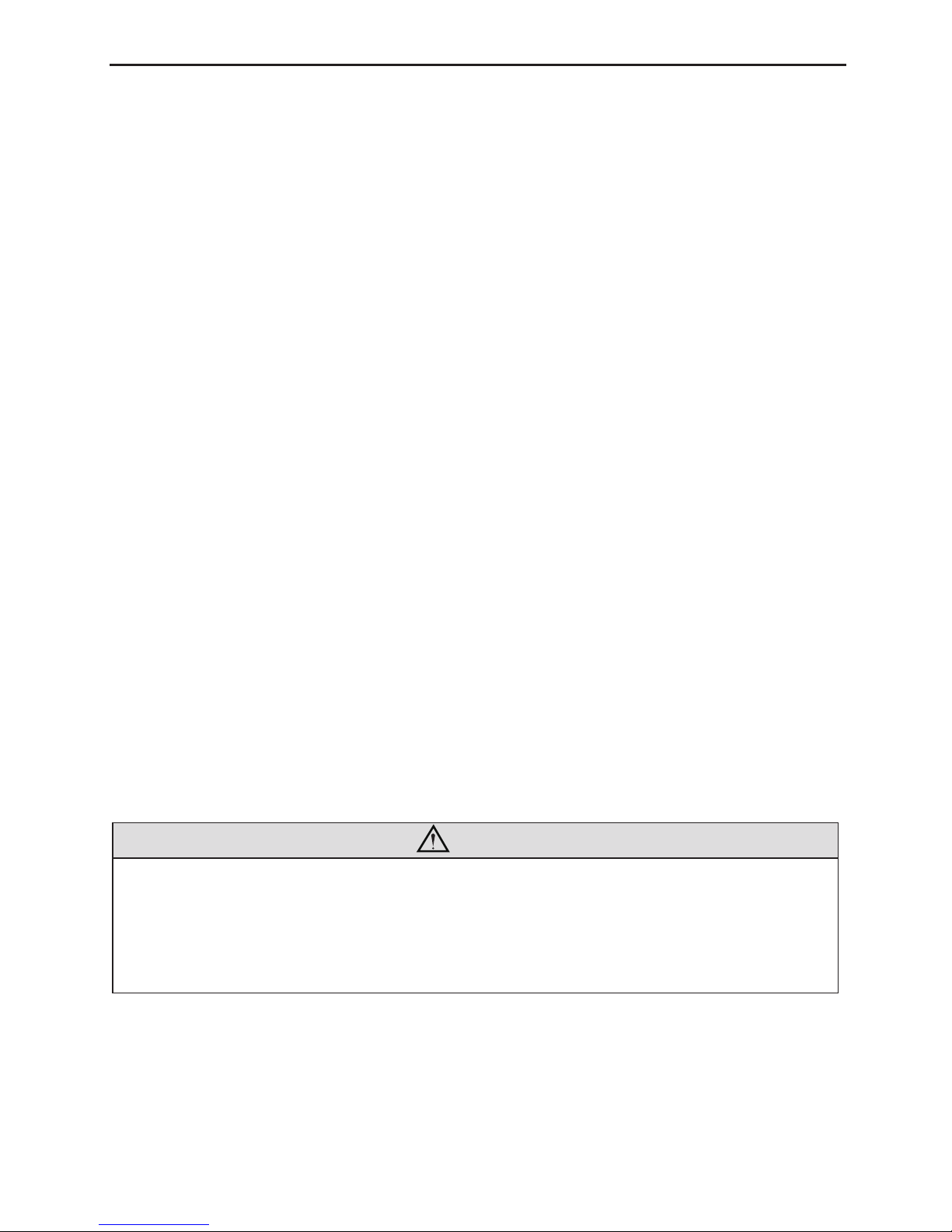

3.2.1 Indoor Unit

(1). Install the unit at a place where is strong enough to withstand the weight of the unit.

(2). The air inlet and outlet of the unit should never be clogged so that the airow can reach

every corner of the room.

(3). Leave service space around the unit as required in Fig.2.

Fig.2

(4). Install the unit where the drain pipe can be easily installed.

(5). The space from the unit to the ceiling should be kept as much as possible so as for more

convenient service.

Page 9

DC Inverter Duct Type Unit

5

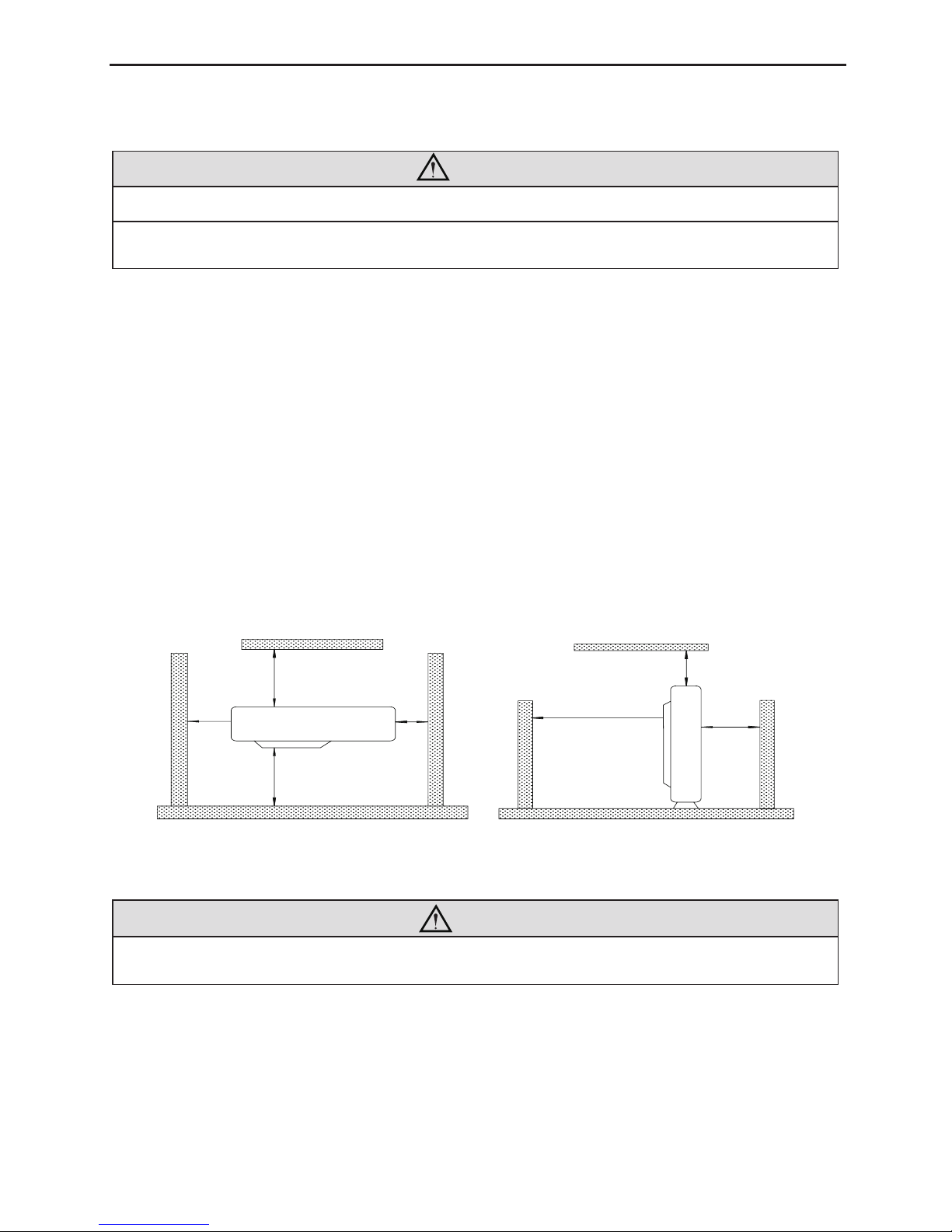

3.2.2 Outdoor Unit

WARNING!

① .

Install the unit where it will not be tilted by more than 5°.

② .

During installation, if the outdoor unit has to be exposed to strong wind, it must be fixed

securely.

(1). If possible, do not install the unit where it will be exposed to direct sunlight. (If necessary,

install a blind that does not interfere with the air ow.)

(2). Install the outdoor unit in a place where it will be free from getting dirty or getting wet by

rain as much as possible.

(3). Install the outdoor unit where it is convenient to connect the indoor unit.

(4). Install the outdoor unit where the condensate water can be drained out freely during

heating operation. Do not place animals and plants in the path of the warm air.

(5). Take the air conditioner weight into account and select a place where noise and vibration

are small.

(6). Install the outdoor unit where is capable of withstanding the weight of the unit and

generates as less noise and vibration as possible.

(7). Provide the space shown in Fig.3, so that the air flow is not blocked. Also for efficient

operation, leave three of four directions of peripheral constructions open.

Units: mm

>500

>500 >500

>500

>2000

>2000

>1000

Fig.3

3.3 Connection Pipe Requirement

CAUTION

!

The maximum length of the connection pipe is listed in the table below. Do not place the units between

which the distance exceeds the maximum length of the connection pipe.

Page 10

DC Inverter Duct Type Unit

6

Table 3

Size of Fitting

Pipe(Inch)

Max.

Pipe

Length

(m)

Max. Height

Difference between

Indoor Unit and

Outdoor Unit (m)

Drainage

pipe(Outer

Diameter × wall

thickness) (mm)

Liquid Gas

GB-X18SCR GU-X18SCR 1/4 1/2 20 15 Φ30X1.5

GB-X24SCR GU-X24SCR 3/8 5/8 30 15 Φ20X1.2

GB-X36SCR GU-X36SCR 3/8 5/8 30 15 Φ20X1.2

① .

The connection pipe should be insulated with proper water-proof insulating material.

② .

The pipe wall thickness shall be 0.5-1.0mm and the pipe wall shall be able to withstand the

pressure of 6.0 MPa.The longer the connecting pipe, the lower the cooling and heating effect

performs.

3.4 Electrical Requirement

Electric Wire Size and Fuse Capacity.

Table 4

Indoor Units

Power Supply

Fuse Capacity Breaker Capacity

Min. Power Supply

Cord

V/Ph/Hz A A mm

2

18K~36K 220-240V~ 50Hz 5 6 1.0

Table 5

Model

Power

Supply

Capability of Air

Switch(A)

Minimum Sectional Area of Power Cable

and Earth line (mm2)

220-240V

~

50Hz

GU-X18SCR 16 1.5

GU-X24SCR 20 2.5

GU-X36SCR 25 2.5

Item

Model

Page 11

DC Inverter Duct Type Unit

7

Note:

① .

The fuse is located on the main board.

② .

Install the disconnect device with a contact gap of at least 3mm in all poles nearby the units

(Both indoor unit and outdoor unit).The appliance must be positioned so that the plug is

accessible.

③ .

The specications of the breaker and power cable listed in the table above are determined

based on the maximum power (maximum amps) of the unit.

④ .

The specifications of the power cable listed in the table above are applied to the conduit-

guarded multi-wire copper cable (like, YJV copper cable, consisting of PE insulated wires and

a PVC cable jacket) used at 40°С and resistible to 90°С(see IEC 60364-5-52). If the working

condition changes, they should be modied according to the related national standard.

⑤ .

The specifications of the breaker listed in the table above are applied to the breaker with

the working temperature at 40°С. If the working condition changes, they should be modied

according to the related national standard.

⑥ .

Take 2 pieces of power cord of 0.75mm2 as the communication lines between indoor and

outdoor unit, with their longest lengths of 50m. Please select the appropriate line length as per

the actual installation conditions. The communication lines can not be twisted together. For

the unit (≤30K), it’s recommended to use 8m long communication line.

⑦ .

Take 2 pieces of power cord of 0.75mm2 as the communication lines between the wired

controller and the indoor unit, with their longest lengths of 30m. Please select the appropriate

line length as per the actual installation conditions. The communication lines can not be twisted

together. It’s recommended to use 8m long communication line.

⑧ .

The wire size of the communication line should be no less than 0.75mm2. It’s recommended to

take 0.75mm2 power cords as the communication line.

4 Installation of the Unit

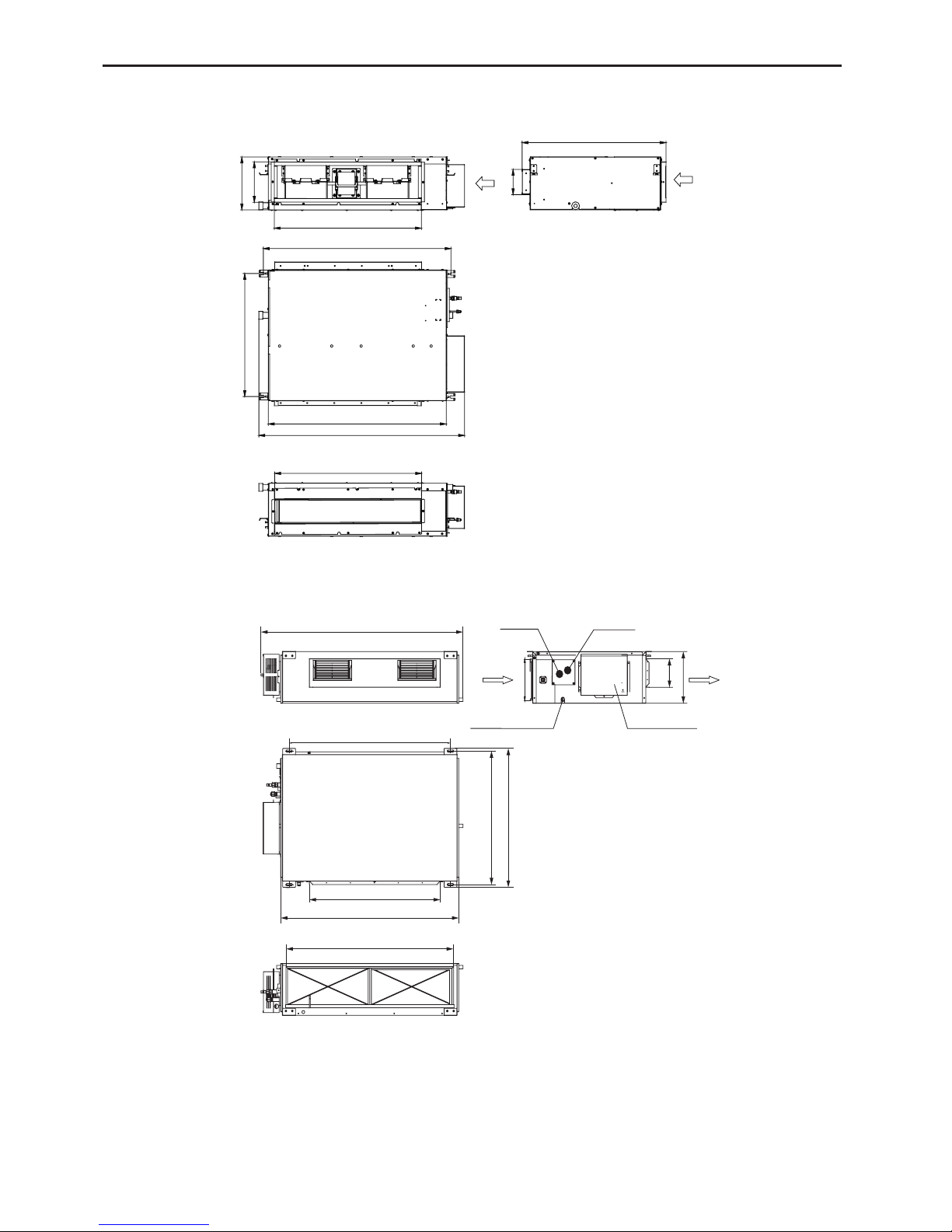

4.1 Installation of the Indoor Unit

4.1.1 Indoor unit dimension

WARNING!

① .

Install the indoor unit in a location which can withstand a load of at least ve times the weight

of the main unit and which will not amplify sound or vibration.

② .

If the installation location is not strong enough, the indoor unit may fall and cause injuries.

③ .

If the job is done with the panel frame only, there is a risk that the unit will come loose. Please

take care.

Page 12

DC Inverter Duct Type Unit

8

For the units: 18K

J

B

H

I

G

F

Max

Air intake

E

D

C

Max

A

For the units: 24~36K

J

I

H

G

B

F

A

E

C

D

Gas Pipe

Liquid Pipe

Drainage Pipe

Electric Box

Air Intake

Max

Max

Page 13

DC Inverter Duct Type Unit

9

Table 6

Item

Model

A B C D E F G H I J

945 618 738 892 1037 721 738 125 203 266 GB-X18SCR

GB-X24SCR

1101 517 820 1159 1279 558 1002 160 235 268

1011 748 820 1115 1226 775 979 160 231 290

GB-X36SCR

Page 14

DC Inverter Duct Type Unit

10

4.1.2 Drilling Holes for Bolts and Installing the Bolts

Using the installation template, drill holes for bolts (four holes). (Fig. 5)

4.1.3 Installing the Suspension Bolts

(1). Install the bolts to the ceiling at a place strong enough to hang the unit. Mark the bolt

positions from the installation template. With a concrete drill, drill for 12.7mm (1/2”)

diameter holes. (Fig. 6)

(2). Insert the anchor bolts into the drilled holes, and drive the pins completely into the anchor

bolts with a hammer. (Fig. 7)

(3). Install the hanger to the unit. (Fig.8)

(4). Pass the unit hangers over the bolts installed to the ceiling and install the unit with the

special nut.(Fig.9)

60 to 70 mm

Fig.6Fig. 5 Fig.7

Φ12.7mm

Fig.8

Hanger

I

I

2:1

Hook

Screw

Nut

Nu

t

Fig.9

Page 15

DC Inverter Duct Type Unit

11

4.1.4 Leveling

The water level test must be done after installing the indoor unit to make the unit is horizontal,

as shown below.

Horizontal tester

4.2 Installation of the Outdoor Unit

WARNING

① .

Install the unit where it will not be tilted by more than 5°.

② .

During installation, if the outdoor unit has to be exposed to strong wind, it must be fixed

securely.

4.2.1 Outdoor unit dimension

D

A

B

C

E

Fig.11

Fig.10

Page 16

DC Inverter Duct Type Unit

12

GU-X24SCR 980 427 790 610 395

GU-X36SCR

1107 440 1100 631 400

4.2.2 Condensate Drainage of the Outdoor Unit(Only for the heat pump unit) (Fig.12)

(1). It is required to install a drain pipe for the outdoor unit to drain out the condensate water

during heating operation. (only for the heat pump unit)

(2). When installing the drain pipe, apart from the drain pipe mounting hole, all other holes

should be plugged so as to avoid water leakage.(only for the heat pump unit)

(3). Installation Method: Insert the pipe joint into the hole φ25 located at the base plate of the

unit and then connect the drain pipe to the pipe joint.

Bottom

Drain cap

Drain pipe mounting hole

Fig.12

4.3 Installation of the Connection Pipe

4.3.1 Flare Processing

(1). Cut the connection pipe with the pipe cutter and remove the burrs.

(2). Hold the pipe downward to prevent cuttings from entering the pipe.

(3). Remove the are nuts at the stop valve of the outdoor unit and inside the accessory bag of

the indoor unit, then insert them to the connection pipe, after that, are the connection pipe

with a aring tool.

(4). Check if the are part is spread evenly and there are no cracks (see Fig.13).

Fig.13

Table 6 Unit: mm

Item

Model

A B C D E

GU-X18SCR 955 396 700 560 360

Page 17

DC Inverter Duct Type Unit

13

4.3.2 Bending Pipes

(1). The pipes are shaped by your hands. Be careful not to collapse them.

×

√

Fig.14

(2). Do not bend the pipes in an angle more than 90°.

(3). When pipes are repeatedly bent or stretched, the material will harden, making it difcult to

bend or stretch them any more. Do not bend or stretch the pipes more than three times.

(4). When bending the pipe, do not bend it as is. The pipe will

be collapsed. In this case, cut the heat insulating pipe

with a sharp cutter as shown in Fig.15, and bend it after

exposing the pipe. After bending the pipe as you want, be

sure to put the heat insulating pipe back on the pipe, and

secure it with tape.

Fig.15

Pipe

Cutter

Cutt line

Heat insulating

pipe

CAUTION!

① .

To prevent breaking of the pipe, avoid sharp bends. Bend the pipe with a radius of curvature

of 150 mm or over.

② .

If the pipe is bent repeatedly at the same place, it will break.

4.3.3 Connecting the Pipe at the Indoor Unit Side

Detach the caps and plugs from the pipes.

CAUTION!

① .

Be sure to apply the pipe against the port on the indoor unit correctly. If the centering is

improper, the flare nut cannot be tightened smoothly. If the flare nut is forced to turn, the

threads will be damaged.

② .

Do not remove the are nut until the connection pipe is to be connected so as to prevent dust

and impurities from coming into the pipe system.

Centering the pipe against port on the indoor unit, turn the are nut with your hand.

CAUTION!

Hold the torque wrench at its grip, keeping it in the right angle with the pipe as shown in Fig. 15,

in order to tighten the are nut correctly.

Page 18

DC Inverter Duct Type Unit

14

When the are nut is tightened properly by your hand, use a torque wrench to nally tighten it.

Fig.16

Fig.17

Table 7 Flare nut tightening torque

Pipe Diameter Tightening Torque

1/4˝(Inch) 15-30 (N·m)

3/8˝(Inch) 35-40 (N·m)

5/8˝(Inch) 60-65 (N·m)

1/2˝(Inch) 45-50 (N·m)

CAUTION!

Be sure to connect the gas pipe after connecting the liquid pipe completely.

4.3.4 Connecting the Pipe at the Outdoor Side Unit

Tighten the flare nut of the connection pipe at the outdoor unit

valve connector. The tightening method is the same as that as at

the indoor side.

4.3.5 Checking the Pipe Connections for Gas Leaking

For both indoor and outdoor unit side, check the joints for gas

leaking by the use of a gas leakage detector without fail when

the pipes are connected.

4.3.6 Heat Insulation on the Pipe Joints (Indoor Side Only)

Stick coupler heat insulation (large and small) to the place where connecting pipes.

Fig.18

Page 19

DC Inverter Duct Type Unit

15

Fig.19

4.3.7 Liquid Pipe and Drain Pipe

Sealed

Drain

pipe

Saddle

Fig.20

Fig.21

Trap

If the outdoor unit is installed lower than

the indoor unit (See Fig.20)

(1). A drain pipe should be above ground

and the end of the pipe does not

dip into water. All pipes must be

restrained to the wall by saddles.

(2). Taping pipes must be done from

bottom to top.

(3). All pipes are bound together by tape

and restrained to wall by saddles.

If the outdoor unit is installed higher than

the indoor unit (See Fig.21)

(1). Taping should be done from lower to

the upper part.

(2). All pipes are bound and taped

together and also should be trapped

to prevent water from returning to the

room (See Fig.49)

(3). Restraint all pipes to the wall with

saddles.

Page 20

DC Inverter Duct Type Unit

16

4.4 Vacuum and Gas Leakage Inspection

CAUTION!

Do not purge the air with refrigerants but use a vacuum pump to vacuum the installation! There is

no extra refrigerant in the outdoor unit for air purging!

4.4.1 Vacuum

(1). Remove the caps of the liquid valve, gas valve and also the service port.

(2). Connect the hose at the low pressure side of the manifold valve assembly to the service

port of the unit’s gas valve, and meanwhile the gas and liquid valves should be kept closed

in case of refrigerant leak.

(3). Connect the hose used for evacuation to the vacuum pump.

(4). Open the switch at the lower pressure side of the manifold valve assembly and start the

vacuum pump. Meanwhile, the switch at the high pressure side of the manifold valve

assembly should be kept closed, otherwise evacuation would fail.

(5). The evacuation duration depends on the unit’s capacity, generally,

20 minutes for the 18K units, 30 minutes for the 36K units,

And verify if the pressure gauge at the low pressure side

of the manifold valve assembly reads -1.0Mp (-75cmHg), if not, it indicates there is leak

somewhere. Then, close the switch fully and then stop the vacuum pump.

(6). Wait for some time to see if the system pressure can remain unchanged,

5 minutes for the 18K~24K units, 10 minutes for the unit 36k

During this time, the reading of the pressure gauge at the low pressure side can not

be larger than 0.005Mp (0.38cmHg).

(7). Slightly open the liquid valve and let some refrigerant go to the connection pipe to balance

the pressure inside and outside of the connection pipe, so that air will not come into the

connection pipe when removing the hose. Note that the gas and liquid valve can be opened

fully only after the manifold valve assembly is removed.

(8). Place back the caps of the liquid valve, gas valve and also the service port.

Hose with the valve pin

gauge manifold

pipe

pipe

VAC valve

Vacuum pump

Service port

Low pressure gauge

High pressure gauge

Gauge manifold kit

Fig.22

Note: For the large-sized unit, it has the service port for both the gas valve and the liquid valve.

Page 21

DC Inverter Duct Type Unit

17

During evacuation, it is available to connect two hoses of the manifold valve assembly to two

service ports to quicken the evacuating speed.

4.4.2 Additional Charge

Refrigerant suitable for a piping length of 5m is charged in the 18~36K outdoor unit at the

factory.

When the piping of 18~36k unit is longer than 7.5m,

additional charging is necessary .

For the additional amount, see Table 8.

Table 8

Model

Item

Standard Pipe Length

Unnecessary Charge

Pipe Length

Additional Refrigerant Amount

for Extra Pipe

18K 5m ≤ 7.5m 30 g/m

24~36K 5m ≤ 7.5m 60 g/m

When the height difference between the indoor unit and outdoor unit is larger than 10 meters,

an oil bend should be employed for every 6 meters.

Oil bend

Oil bend

Indoor

Outdoor

6m

4.5 Installation of the Drain Hose

4.5.1 Installation of Drain Piping

CAUTION!

Install the drain hose in accordance with the instructions in this installation manual and keep the

area warm enough to prevent condensation. Problems with the piping may lead to water leaks.

(1). Install the drain hose with downward gradient (1/50 to 1/100) and no risers or traps are

used for the hose.(Fig.23)

(2). Be sure there is no crack or leak on the drain hose to avoid the formation of air pocket.

(Fig.23)

(3). When the hose is long, install supporters.(Fig.24)

(4). Always use the drain hose which has been insulated properly.

Page 22

DC Inverter Duct Type Unit

18

×

√

Fig.23

Fig.24 Fig.25

As the inside of the unit

is in the negative pressure

status, it is required to set

up a backwater elbow. The

requirements is:

A=B≥P/10+20(mm)

P is the absolute pressure

inside the unit. The unit of the

pressure is Pa.

Condensate Drainpipe

B

A

Condensate Drainpipe

Enlarged View

B

A

Fig.26

Page 23

DC Inverter Duct Type Unit

19

(5). Use a suitable drain hose, and see Table 3 for its size.

(6). There is a drain port on both the left and right sides. Select

the drain port to match the local conditions.(Fig.25)

(7). When the unit is shipped from the factory, the drain port is

defaulted to be the one on the left side (electric box side),

the port on right side has been plugged.

(8). When using the drain port on the right side of the unit,

reinstall the drain cap to the left side drain port.(Fig.27)

Fig.27

CAUTION!

Always check that the drain cap is installed to the unused drain port and is fastened with the nylon

fastener. If the drain cap is not installed, or is not sufciently fastened by the nylon fastener, water may

drip during the cooling operation.

(9). Be sure to insulate where the drain port and the drain hose is connected.(Fig.28 )

(10). The unused drain port also should be insulated properly.(Fig.29)

Fig.28 Fig.29

(11). There is adhesive on one side of the insulation so that after removing the protective paper

over it the insulation can be directly attached to the drain hose.

(12). Considerations for the unit with the condensate pump:

i). For the unit with the condensate pump, only one drain port at the side close to the electric

box is prepared and only through it the drain hose can be connected.

ii). See table 3 for the size of the drain port of the unit with the condensate pump, which is

different from that of the unit without the condensate pump.

iii). For the unit with the condensate pump, two drain ports at the bottom are defaulted to be

factory plugged with drain caps. After the installation of the drain hose, these two drain

ports also need to be insulated properly with the same way aforementioned.

iv). The drain hose for the unit with the condensate pump should be arranged as shown in the

gure below.

Fig.30

a. The vertical height of the drain hose should be 75mm or less so that it is unnecessary for

1000mm

Page 24

DC Inverter Duct Type Unit

20

the drain port to withstand additional force.

Fig.31

b. When multiple drain hoses are used, their installation should be performed as shown in the

gure below.

0~1000mm

Fig.32

4.5.2 Testing of Drain Piping

After piping work is finished, check if drainage

ows smoothly.

As shown in the figure, add approximately

1liter of water slowly into the drain pan and check

drainage ow during COOL running.

4.6 Installation of the Duct

4.6.1 Dimensions of the Supply Air Outlet/Return Air Inlet

Fig.33

B

21

A

Fig.34 Supply Air Outlet

Page 25

DC Inverter Duct Type Unit

21

Fig.35 Return Air Inlet

Table 9

Item

Model

Supply Air Outlet Return Air Inlet

A B C D

GB-X18SCR 123 736 710 166

GB-X24SCR 158 818 994 195

GB-X36SCR 158 818 1000 206

4.6.2 Installation of the Supply Air Duct

(1). Installation of the Rectangular Duct.

No. Name No. Name

1 Hanger 5 Filter

2 Air Intake Pipe 6

Main Air

Supply Pipe

3

Canvas Air

Pipe

7

Air Supply

Outlet

4 Air Intake

Fig.36

CAUTION!

① .

The maximum length of the duct means the maximum length of the supply air duct plus the

maximum length of the return air duct.

② .

The duct is rectangular and connected with the air inlet/outlet of the indoor unit. Among all

supply air outlets, at least one should be kept open.

Bottom Return Air Installation only for Units 09/12/18K

Page 26

DC Inverter Duct Type Unit

22

(2). The default installation location of the rectangular ange is at the back, as shown in Fig.37.

Return Air Cover Plate

Bottom Return Air

Rear Return Air

Rectangular Flange

Fig.37

(3). If the bottom return air is desired, just change the place of the rectangular ange and the

return air cover plate.

(4). Connect one end of the return air duct to the return air outlet of the unit by rivets and the

other to the return air louver. For the sake of the convenience to freely adjust the height, a

cutting of canvas duct will be helpful, which can be reinforced and folded by 8# iron wire.

(5). More noise is likely to be produced in the bottom return air mode than the backward return

air mode, so it is suggested to install a silencer and a static pressure box to minimize the

noise.

(6). The installation method can be chosen with considering the conditions of the building and

maintenance etc., as shown in Fig.38.

1

Return air Return air

Install the Return Air Duct (a)

Supply air Supply air

Install the Return Air Duct (b)

1

2

4

5

3

64

5

Supply air

Supply air

Return air

Return air

Install the return air duct (b)Install the return air duct (a)

Fig.38 Install the return air duct

Table 10 Installation of the return air duct

No. Name No. Name

1 Return Air Inlet (with lter) 4 Indoor unit

2 Canvas Duct 5 Supply Air Duct

3 Return Air Duct 6 Grille

Page 27

DC Inverter Duct Type Unit

23

4.7 Electrical Wiring

4.7.1 Wiring Precautions

WARNING !

① .

Before obtaining access to terminals, all supply circuits must be disconnected.

② .

The rated voltage of the unit is as shown as table 4 and Table 5

③ .

Before turning on, verify that the voltage is within the 198~264V range(for single phrase unit)

④ .

Always use a special branch circuit and install a special receptacle to supply power to the air

conditioner.

⑤ .

Use a special branch circuit breaker and receptacle matched to the capacity of the air

conditioner.

⑥ .

The special branch circuit breaker is installed in the permanent wiring. Always use a circuit

that can trip all the poles of the wiring and has an isolation distance of at least 3mm between

the contacts of each pole.

⑦ .

Perform wiring work in accordance with standards so that the air conditioner can be operated

safely and positively.

⑧ .

Install a leakage special branch circuit breaker in accordance with the related laws and

regulations and electric company standards.

CAUTION !

① .

The power source capacity must be the sum of the air conditioner current and the current of

other electrical appliances. When the current contracted capacity is insufcient, change the

contracted capacity.

② .

When the voltage is low and the air conditioner is difcult to start, contact the power company

to raise the voltage.

4.7.2 Electrical Wiring

(1). For solid core wiring (Fig.39)

i). Cut the wire end with a wire cutter or wire-cutting pliers, then strip the insulation about 25

mm (15/16") .

ii). Using a screwdriver, remove the terminal screw(s) on the terminal board.

iii). Using pliers, bend the solid wire to form a loop suitable for the terminal screw.

iv). Shape the loop wire properly, place it on the terminal board and tighten securely with the

terminal screw using a screwdriver.

(2). For strand wiring (Fig.39)

i). Cut the wire end with a wire cutter or wire-cutting pliers, then strip the insulation about 10

mm (3/8") .

Page 28

DC Inverter Duct Type Unit

24

ii). Using a screwdriver, remove the terminal screw (s) on the terminal board.

iii). Using a round terminal fastener or pliers, securely clamp a round terminal to each stripped

wire end.

iv). Position the round terminal wire, and replace and tighten the terminal screw with a

screwdriver.(Fig.40)

Fig.39

Fig.40 Fig.41

(3). How to x connection cord and power cord by cord clamp

After passing the connection cord and power cord through the insulation tube, fasten it with the

cord clamp.(Fig.41)

WARNING!

① .

Before starting work, check that power is not being supplied to the indoor unit and outdoor

unit.

② .

Match the terminal block numbers and connection cord colors with those of the indoor unit

side.

③ .

Erroneous wiring may cause burning of the electric parts.

④ .

Connect the connection cords rmly to the terminal block. Imperfect installation may cause a

re.

⑤ .

Always fasten the outside covering of the connection cord with cord clamps. (If the insulator is

not clamped, electric leakage may occur.)

⑥ .

Always connect the ground wire.

Page 29

DC Inverter Duct Type Unit

25

(4). Electric wiring between the indoor and outdoor units

Single-phase units (18K~24K)

GU-X18SCR+GB-X18SCR

① .

Power cord 3×1.5mm

2

(H07RN-F)

② .

Power cord 3×1.0mm

2

(H05RN-F)

③ .

Communication Cords 2×0.75mm

2

(H05RN-F)

GU-X24SCR+GB-X24SCR

① .

Power cord 3×2.5mm

2

(H07RN-F)

② .

Power cord 3×1.0mm

2

(H05RN-F)

③ .

Communication Cords 2×0.75mm

2

(H05RN-F)

Single-phase units (36K)

GU-X36SCR+GB-X36SCR

① .

Power cord 3×2.5mm

2

(H07RN-F)

② .

Power cord 3×1.0mm

2

(H05RN-F)

③ .

Communication Cords 2×0.75mm

2

(H05RN-F)

Fig.42

Page 30

DC Inverter Duct Type Unit

26

(5). Electric wiring of indoor unit side

Remove the electric box cover from the electric box sub-assy and then connect the wire.

Fig.43

The F, C, O connect to the COMMOM, CLOSE and OPEN terminal of the fresh air valve

respectively.

CAUTION!

① .

The power cord and the wire of the fresh air valve are high-voltage, while the communication

cord and connection wire of the wired controller are low-voltage. They should run separately

against electromagnetic interference.

② .

The high-voltage and low-voltage lines should pass through the rubber rings at different

electric box covers.

③ .

Do not bundle the connection wire of the wired controller and the communication cord

together, or arrange them in parallel, otherwise improper operation would occur.

④ .

The high-voltage and low-voltage lines should be xed separately and securely, with internal

big clamps for the former and small clamps for the latter.

⑤ .

Tighten the indoor/outdoor connection cord and power cord respectively on the terminal

boards with screws. Faulty connection may cause a re.

⑥ .

If the indoor unit connection cord (to the outdoor unit) and power supply are wired incorrectly,

the air conditioner may be damaged.

⑦ .

Connect the indoor unit connection cord properly based on the corresponding marks as

shown in Fig.42.

⑧ .

Ground both the indoor and outdoor units by attaching a ground wire.

⑨ .

Unit shall be grounded in compliance with the applicable local and national codes.

(6). Electric wiring of outdoor unit side

Note: When connecting the power supply cord, make sure that the phase of the power

supply matches with the exact terminal board. If not, the compressor will rotate reversely and

run improperly.

Remove the big handle of the outdoor unit and insert the end of the communication cord and

the power cable into the terminal board.

Page 31

DC Inverter Duct Type Unit

27

Single phase:

18K~24K

36K

Fig.44

Power lines should go along the right side plate and

be fixed to the fixation hook with binding wires to keep

no contact with pipelines. Communication lines between

indoor and outdoor units also should go along the right side

plate and keep away from power lines.

Routing of

External

Power Lines

Fig.46

Fig.45

Page 32

DC Inverter Duct Type Unit

28

5 Installation of Controllers

Refer to the Installation Manual of the controller for more details.

6 Test Running

6.1 Trial Operation and Testing

(1). The meaning of error codes as shown below:

Table 11

Number Error code Error Remarks

1 E1 Compressor high pressure protection

2 E2 Indoor anti-freeze protection

3 E3

Compressor low pressure protection, refrigerant lack

protection and refrigerant colleting mode

4 E4 Compressor high discharge temperature protection

5 E6 Communication error

6 E8 Indoor fan motor error

7 E9 Full water protection

8 F0 Indoor ambient temperature sensor error

9 F1 Evaporator temperature sensor error

10 F2 Condenser temperature sensor error

11 F3 Outdoor ambient temperature sensor error

12 F4 Discharge temperature sensor error

13 F5 Temperature sensor error of wired controller

15 C5 Capacity code error

16 EE Outdoor memory chip error

17 PF Electric box sensor error

18 H3 Compressor overload protection

19 H4 Overloading

20 H5 IPM protection

21 H6 DC fan motor error

22 H7 Drive desynchronizing protection

23 Hc Pfc protection

25 Lc Activation failure

26 Ld Compressor phase sequence protection

27 LE Compressor stalling protection

28 LF Power protection

29 Lp Indoor and outdoor mismatch

30 U7 4-way valve direction changing protection

31 P0 Drive reset protection

32 P5 Over-current protection

33 P6 Communication error between main control and drive

34 P7 Drive module sensor error

35 P8 Drive module over temperature protection

36 P9 Zero passage protection

37 PA AC current protection

Page 33

DC Inverter Duct Type Unit

29

38 Pc Drive current error

39 Pd Sensor connecting protection

40 PE Temperature drift protection

41 PL Bus low voltage protection

42 PH Bus high voltage protection

43 PU Charge loop error

44 PP Input voltage abnormality

45 ee Drive memory chip error

Note: When the unit is connected with the wired controller, the error code will be simultaneously

shown on it.

(2). Instructions to the Error Indicating Lamps on the Panel of the Duct Type Unit.

Power/Running

Indicating lamp

Cooling indicating lamp

Heating indicating lamp

Dehumidification

indicating lamp

“88” display

Receiver

“Cool” button

“Heat” button

Fig.47

6.2.Working Temperature Range

Table 12

Test Condition

Indoor Side Outdoor Side

DB(°C) WB(°C) DB(°C) WB(°C)

Nominal Cooling 27 19 35 24

Nominal Heating 20

−

7 6

Rated Cooling 32 23 48

−

Low Temp. Cooling 21 15 -15

−

Rated Heating 27

−

24 18

Low Temp. Heating 20

−

-10 -11

Note:

① .

② .

The air volume is measured at the relevant standard external static pressure.

③

Cooling (heating) capacity stated above is measured under nominal working conditions

corresponding to standard external static pressure. The parameters are subject to change

with the improvement of products, in which case the values on nameplate shall prevail.

.

In this table, there are two outside DB values under the low temp cooling conditions, and the

one in the brackets is for the unit which can operate at extreme low temperature.

Page 34

DC Inverter Duct Type Unit

30

7 Unit Function

7.1 Setting of Double Indoor Room Sensors

This series of ducted air-conditioning unit has two indoor room sensors. One is located at the

air intake of the indoor unit and the other one is located inside the wire controller.

User can select one from the two indoor room sensors on the basis of the engineering

requirement.

(Refer to the section of wire controller instructions for detailed operation.)

Indoor room sensor A

Indoor room sensor B

Fig.48

7.2 Checking of Outdoor Ambient Temperature

The outdoor ambient temperature can be checked on the wire controller for the convenience of

users before going out. (Refer to the section of wire controller instructions for detailed operation.)

Outdoor unit

Indoor unit

Outdoor room sensor

Fig.49

Page 35

DC Inverter Duct Type Unit

31

7.3 Fresh Air Control

11-levels control can be realized for the amount of fresh air taken in. The function not only

facilitates the health of users, but also controls the electricity consumption loss because of taking in

fresh air. This kind of control can be carried out through the wire controller. The function can set at

any time, goes into effect at any time, and features very simple operation. (Refer to the section of

wire controller instructions for detailed operation.)

Outdoor

fresh air

Fresh air

Air intake pipe

Air supply pipe

Indoor side

Air valve

Before starting up

the unit,please remove

all the sealing lm on the

healthy lter block

Fig.50

Page 36

DC Inverter Duct Type Unit

32

8 Troubleshooting and Maintenance

8.1 Troubleshooting

If your air-conditioning unit suffers from abnormal operation or failure, please rst check the

following points before repair:

Failure Possible Reasons

The unit cannot be started.

① .

The power supply is not connected.

② .

Electrical leakage of air-conditioning unit causes tripping of the leakage

switch.

③ .

The operating keys are locked.

④ .

The control loop has failure.

The unit operates for a

while and then stops.

① .

There is obstacle in front of the condenser.

② .

The control loop is abnormal.

③ .

Cooling operation is selected when the outdoor ambient temperature is

above 48°C.

Poor cooling effect.

① .

The air lter is dirty or blocked.

② .

There is heat source or too many people inside the room.

③ .

The door or window is open.

④ .

There is obstacle at the air intake or outlet.

⑤ .

The set temperature is too high.

⑥ .

There is refrigerant leakage.

⑦ .

The performance of room temperature sensor becomes worse

Poor heating effect

① .

The air lter is dirty or blocked.

② .

The door or window is not rmly closed.

③ .

The set room temperature is too low .

④ .

There is refrigerant leakage.

⑤ .

The outdoor ambient temperature is lower than -5°C.

⑥ .

Control loop is abnormal.

After carrying out the check of the above items and taking relevant measures to solve the

problems found but the air-conditioning unit still does not function well, please stop the operation

of the unit immediately and contact the local service agency designated by SHARP. Only

ask professional serviceman to check and repair the unit.

8.2 Routine Maintenance

Only a qualied service person is allowed to perform maintenance.

Before accessing to terminal devices, all power supply circuits must be disconnected.

Do not use water or air of 50°C or higher for cleaning air lters and outside panels.

Note:

① .

Do not operate the air conditioner with the lter uninstalled, otherwise dust would come into

the unit.

② .

Do not remove the air lter except for cleaning. Unnecessary handling may damage the lter.

③ .

Do not clean the unit with gasolene, benzene, thinner, polishing powder or liquid insecticide,

Page 37

DC Inverter Duct Type Unit

33

otherwise it would cause discoloration and deformation of the unit.

④ .

Do not wet the indoor unit in case of electric shock or re hazard.

Increase the frequency of cleaning if the unit is installed in a room where the air is extremely

contaminated.(As a yardstick for yourself, consider cleaning the lter once a half year.)

If dirt becomes impossible to clean, change the air lter. (Air lter for exchange is optional.)

i). Removing the air lter from the duct.

ii). Cleaning the air lter

Remove dust from the air lter using a vacuum cleaner and gently rinse them in cool water. Do

not use detergent or hot water to avoid lter shrinking or deformation. After cleaning dry them

in the shade.

Press the return air inlet lter

downward against the guide groove

sponge and take it off along the arrow

direction.There are two return air inlet

lters.

iii). Replacing the air lter

Reinstall the lter as before.

Page 38

Page 39

Loading...

Loading...