Page 1

Date: Aug. 22, 1994

ELECTRONIC TYPEWRITER: PA-4000

1.CHANGE OF THE PARTS FOR THE CARRIAGE UNIT AND

CORREC TIO N OF TH E PARTS CO DE OF T HE ROLLE R H OL DE R

2.CHANGE OF THE INNER STRUCTURE OF THE PLATEN

3. AD DI T ION O F TH E WH EE L CA SE

1. CHANGE OF THE PARTS FOR THE CARRIAGE UNIT AND CORRECTION OF THE

PARTS CODE OF THE ROLLER HOLDER

1) Model name: PA-4000 (for A, M, Q, EA)

Destination codes

No. : ETE-297

= Refer to the destination table in the parts guide for the above destinations.

2) General: Some parts of the carriage unit have been changed for better reliability and workability.

The parts code of the roller holder misprinted in the parts guide for Q and EA has been

corrected.

3) Description: [Change of the carriage unit]

(1) The material of the ratchet S has been changed for decreasing the contact noise at ribbon

feeding.

(Before changing) (Changed)

RATCHET S PTME-5018CHZA PTME-5018CHZB

(2) The mask CPU has been changed and the ratchet mechanism has been disused for better

reliability.

Description Before changing Changed

Mask CPU Change

RF drive gear Disuse NGERH5129CHZZ —

RF ratchet Disuse PTME-5019CHZZ —

RF gear spring Disuse MSPRD5206CHZZ —

RF gear Addition — NGERH5142CHZZ

Carriage unit Change CDAIH5037CH01 CDAIH5037CH04

VHIM38002-235

Version No. 235

VHIM38002-240

Version No. 240

SHARP CORPORATION

Printer and Scanner Division

1/4

Orange

C

Page 2

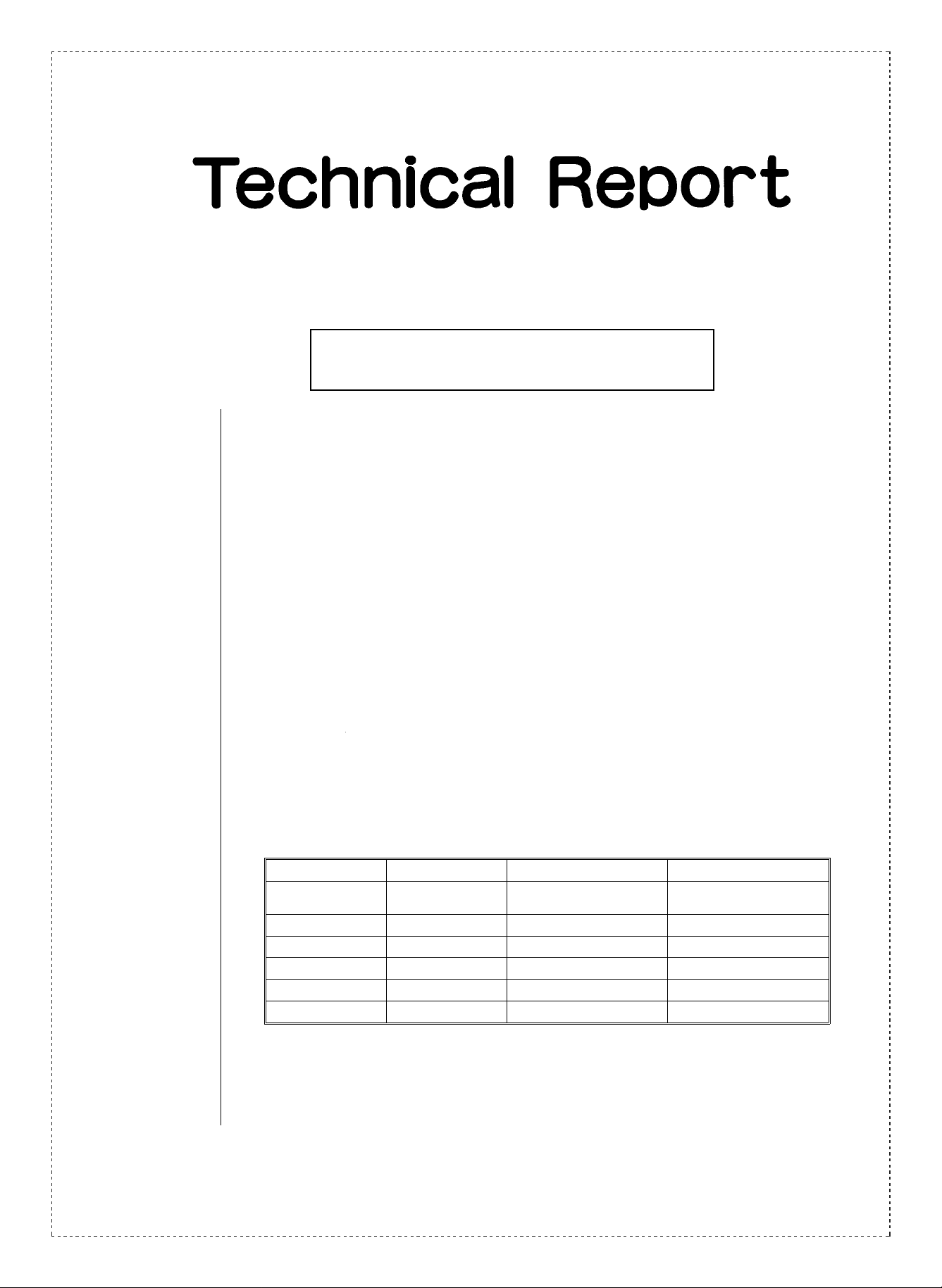

RF ratchet disused

Gear spring disused

RF gear added

Carriage unit changed

(Before changing)

Changed material of the ratchet S

RF drive gear disused

[Roller holder]

The parts code of the roller holder misprinted in the parts guide has been corrected as follows.

(Before changing) (Changed)

Roller holder LHLDR5089CHZZ LHLDR5083CHZZ

(Changed)

4) Application Roller h older -------- -- From the Marc h prod uctio n in 1 994

Ratche t S ----- ---- ----- From the May prod uctio n in 1994

Ratchet mechanism - From the July production in 1994

2. CHANGE OF THE INNER STRUCTURE OF THE PLATEN

1) Model name: PA-4000, QL-310

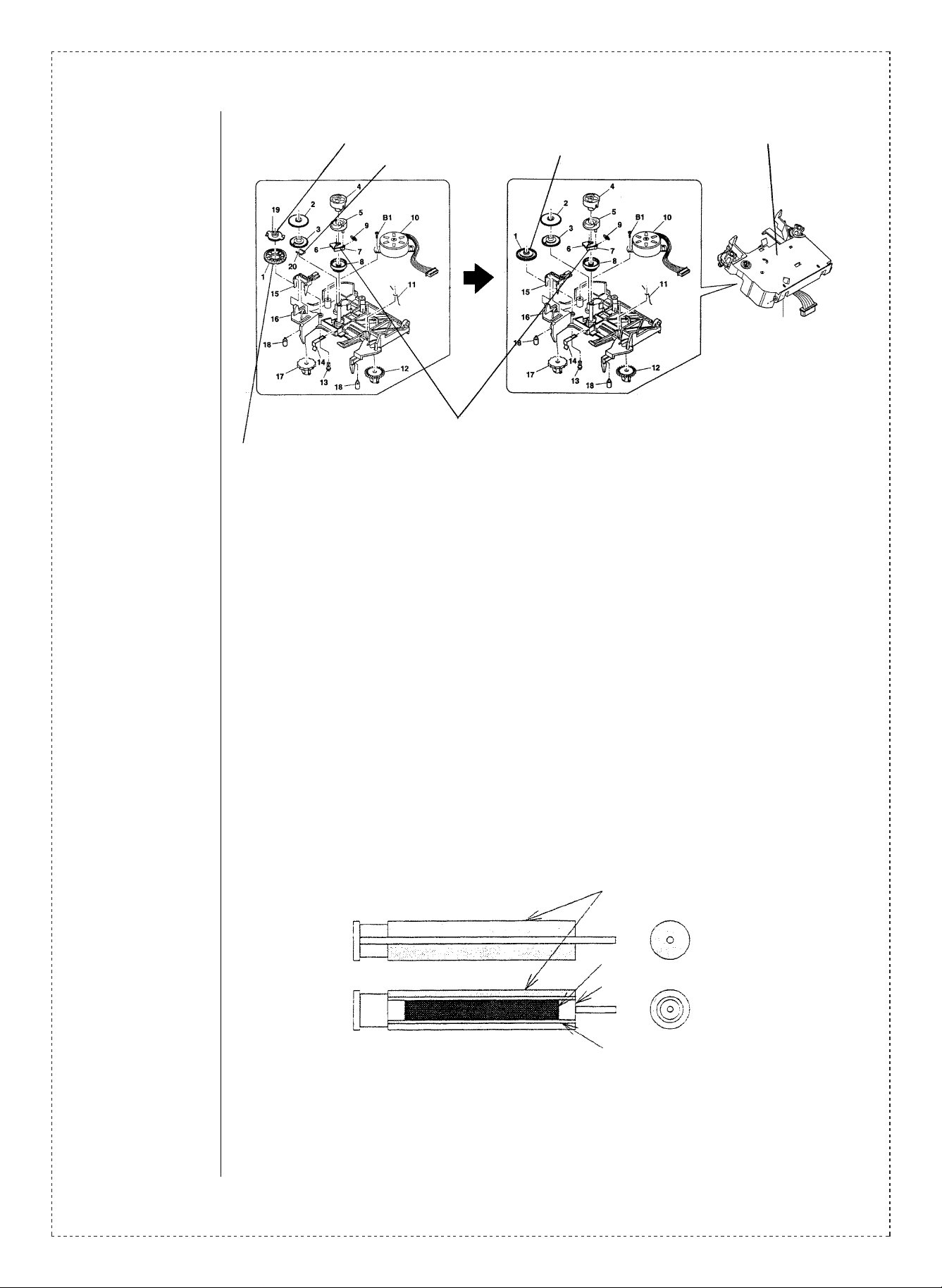

2) General The inner structure of the platen has been changed to have regenerated rubber filled in the

iron pipe and new rubber rolled on it as shown below for better productivity.

New rubber

(Old platen)

(Improved platen)

The parts code remains unchanged as the old platen and the new one have interchangeability.

Regenerated rubber

Formed bush

Iron pipe

2/4

3) Application From the June production in 1994

Page 3

3. ADDITION OF THE WHEEL CASE

1) Model name: PA-4000 (for A, M, Q, EA)

2) General: The packing of the wheel has been changed from assembled set packing to disassembled one

for s af er tra n spo rt at io n.

3) Description: In accordance with the above packing improved, the wheel case has been added and the

instruction book has been changed.

Wheel case added (GCASP5027CHZZ)

Wheel

4) Application: Wheel ca se for A - ---- -------- F rom th e May pro ductio n in 1994

Wheel case for M, Q, EA --- From the June production in 1994

Instruction book -------- ------- From the J uly produ ction in 1994

Instruction book changed

3/4

Page 4

Parts change

Ref

No.

Model

name

Version P/G No.

3 - 7

Current parts New parts

Parts code Parts code

PTME-5018CHZA PTME-5018CHZB AB

Price

rank

Parts name

Ratchet S

Effec-

Inter-

tive

change-

time

ability

May ’94 3

Note

3

3 - 1 NGERH5129CHZZ — — RF drive gear

∗

A

M

3 - 19 PTME-5019CHZZ — — RF ratchet

1

PA-4000

3

<Interchange>

1. Interchangeable. 4. Not interchangeable.

2. Current type can be used in place of new type.

New type cannot be used in place of current type.

3. Current type cannot be used in place of new type.

New type can be used in place of current type.

Parts marked with " ! " is important for maintaining the safety of the set.

Be sure to replace these parts with specified ones for maintaining the safety and performance of the set.

Q

EA

3 - 20 MSPRD5206CHZZ — — Gear spring

5 - 40 VHIM38002-235 VHIM38002-240 AW Mask CPU IC4

2 - 501

3 - 901

∗

Q, EA

M, Q, EA

Q, EA

∗ For codes shown in the above list, refer to the code chart of the destination table of Parts Guide.

2 - 4

∗

4

A

∗

4

∗

A

∗

4 - 7

M

∗

— NGERH5142CHZZ AD RF gear

CDAIH5037CH01

LHLDR5089CHZZ

—

— GCASP5027CHZZ AG Jun. ’94

TINSE5666CHZZ TINSE5666CHZA AM

TINSK5675CHZZ TINSK5675CHZA AS

TINSE5674CHZZ TINSE5674CHZA AK

CDAIH5037CH04 BQ Carriage unit

LHLDR5083CHZZ AN Roller holder 1st lot

GCASP5027CHZZ AG

Wheel case

Instruction book

5. Interchangeable if replaced with same types of

related parts in use.

6. Others.

Jul. ’94 5

May ’94

Jul. ’94 3

—

6

—

4/4

Loading...

Loading...