Page 1

Date: May 23, 1994

ELECTRONIC TYPEWRITER: PA-4000 etc.

[Parts changes]

1. CHAN GE OF T HE M AIN CON T ROL PW B PARTS

2. CHAN GE OF THE RI BB ON HO LD ER PARTS F OR THE CARR IA GE UNI T

3. CHAN GE AND ADDI TIO N OF T HE PARTS FOR IM PRO VI NG THE

PRODUCT QUALI T Y

4. CHAN GE OF T HE SO LEN OI D FIXIN G SC REW AND OF THE RATCHET

S SHAPE

1. CHANGE OF THE MAIN CONTROL PWB PARTS

1) Model name: PA-4000

2) General: The following main control PWB parts have been and will be changed.

No. : ETE-294

3) Description: The causes and descriptions are as follows.

No. Cause Description

(1)

(2)

(3)

Correction of P/G

error

(4)

(5)

(6)

Improvement of

(7)

printing looks

Improvement of the

(8)

productivity

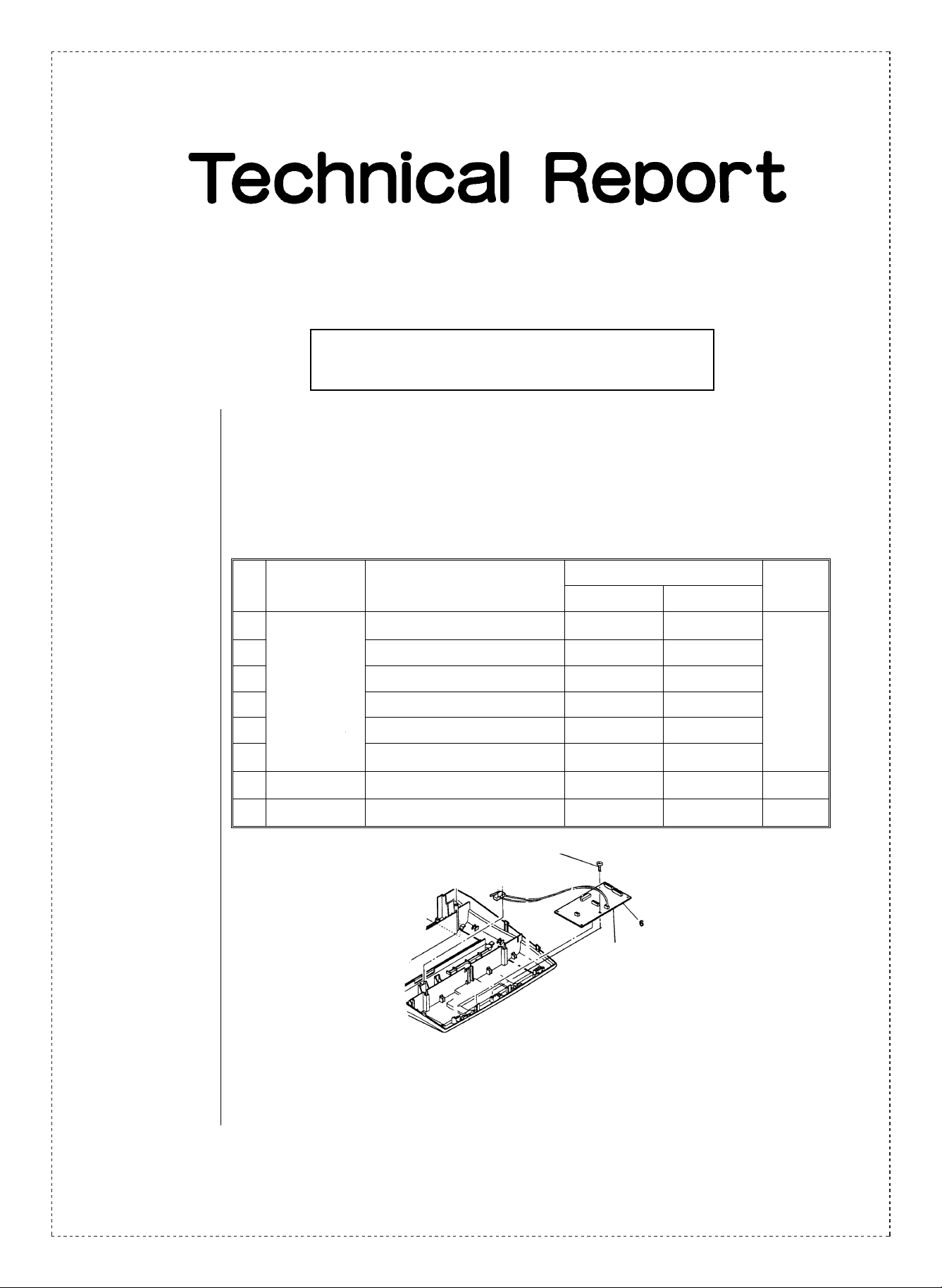

(6) Addition of the PWB fixing screw (XUPSD30P08000)

Change of the resistor R39 & R40 from

4.7KΩ to 10KΩ

Disuse of the resistor R4 10KΩ VRD-RC2EY103J

Addition of the resistor R42 10KΩ

Addition of the resistor R43 4.7KΩ

Addition of the resistor R44 & R45 1KΩ

Addition of the control PWB fixing screw

(shown in the following figure)

Change of the mask CPU (IC4) VHIM38002-232 VHIM38002- 235

Change of the connector (18 pin) CN1 QCNCW5 1 1 1B C 1H QCNCW5132BC1H Jun. ’94

Parts code

Before changing Changed

VRD-RC2EY472J VRD-RC2EY103J

—

—

—

—

—

VRD-RC2EY103 J

VRD-RC2EY472 J

VRD-RC2EY102 J

XUPSD30P0800 0

Application

1st lot

Feb. ’94

4) Application: From the 1st lot - The a bove No. ( 1) ~ (6)

From the Feb. production in 1994 - The above No. (7)

From the June production in 1994 - The above No. (8)

SHARP CORPORATION

Printer and Scanner Division

Main control PWB

1/5

Orange

C

Page 2

2. CHANGE OF THE RIBBON HOLDER PARTS FOR THE CARRIAGE UNIT

1) Model name: PA-4000/3000III/3000X/3020III/3030III/3030X, QL-100/200/300, SM-8400

2) General: The following parts of the ribbon holder for the carriage unit have been changed for better

reliability.

3) Description: The following are the troubles and the relative changes.

Model Trouble & countermeasure Change Before changing Changed Remarks

PA-4000

PA-4000

PA-3030III

PA-3020III

PA-3000X

PA-3030X

QL-100

QL-200

QL-300

SM-8400

PA-4000

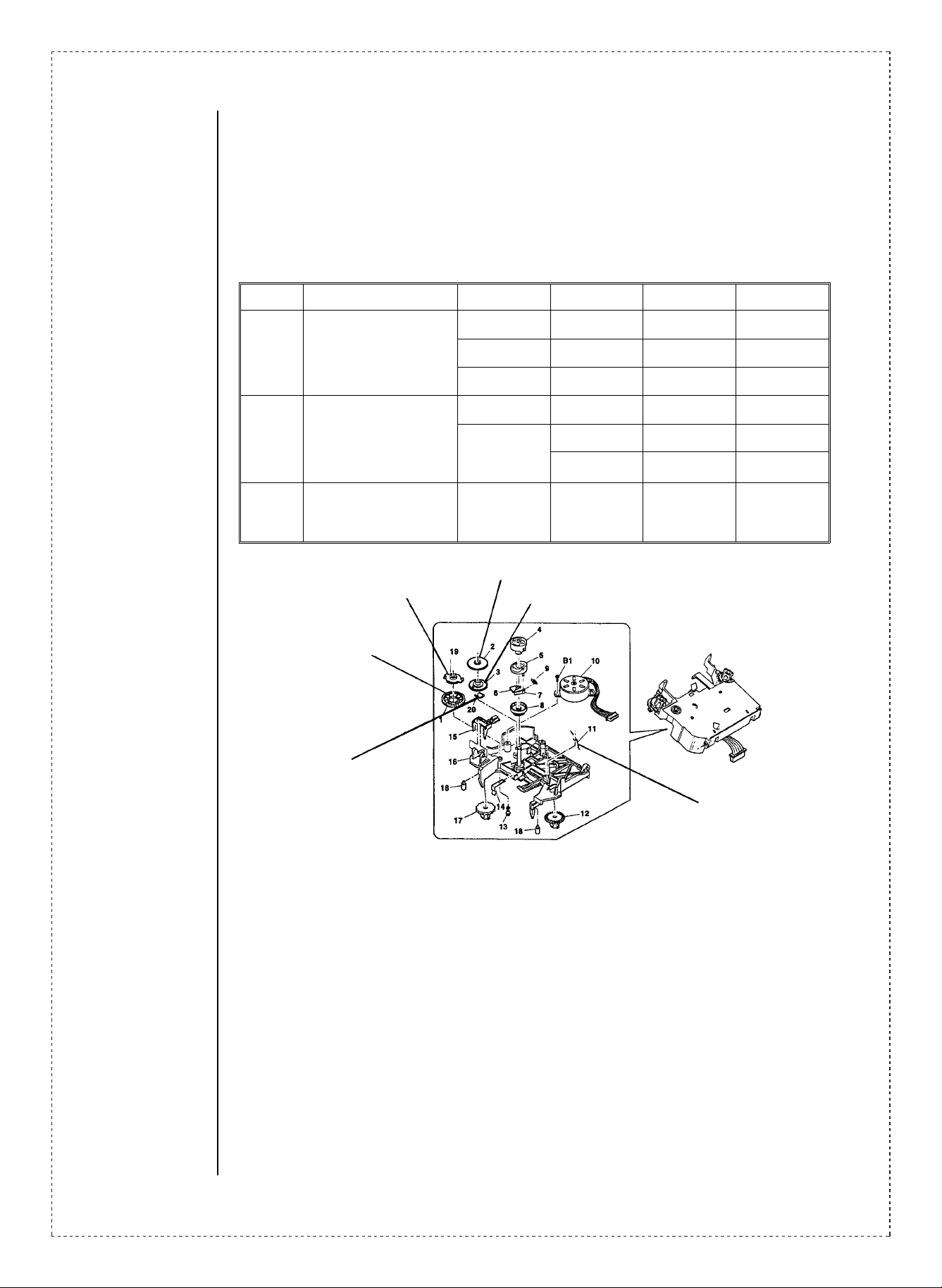

The ratchet mechanism has

been added to prevent the ribbon

from looseness.

The ratchet gear shape and the

R idle gear shape have been

changed to improve defective

overstrike which brings about

poor printing looks by imperfect

ribbon winding.

The back tension spring shape

has been changed to prevent the

back tension spring and the

correction gear from touching

each other.

Change of the RF

gear

Addition of the RF

ratchet

Addition of the

gear spring

Shape change of

the ratchet gear

Shape change of

the R idle gear

Shape change of

the back tension

spring

NGERH5142CHZZ NGERH5129CHZZ

—

— MSPRD5206CHZZ

NGERH5130CHZZ NGERH5130CHZA

NGERH5131CHZZ NGERH5131CHZA

NGERH5131HHZZ NGERH5131HHZA

MSPRD5201CHZB MSPRD5201CHZC

PTME-5019CHZZ

Refer to (A) in the

following fig.

Refer to (B) in the

following fig.

Refer to (C) in the

following fig.

Refer to (D) in the

following fig.

Refer to (E) in the

following fig.

Refer to (E) in the

following fig.

Refer to (F) in the

following fig.

(B) Addition of the RF ratchet

(A) Change of the RF gear

(C) Addition of the gear spring

4) Application: From the 1s t lo t - PA -4 000

From the Jan. production in 1994 - PA-3020III/3030III

From the April production in 1994 - QL-100/200/300, PA-3000X/3030X, SM-8400

(E) Change of the R idle gear

(D) Change of the ratchet gear

(F) Change of the back tension spring

2/5

Page 3

3. CHANGE AND ADDITION OF THE PARTS FOR IMPROVING THE PRODUCT QUALITY

1) Model name: PA-4000

2) General: The following parts have been changed and added for improving the product quality.

3) Description: 1) A piece of vinyl sheet ((A) in the following fig.) and a piece of ribbon add. ((B) in the following

fig.) have been added against vibration and falling possible in transportation.

(B) Addition of a piece of ribbon add. against falling

SPAKX6015CHZZ

(A) Addition of a piece of vinyl

sheet against vibra tio n

SPAKA6014CHZZ

2) The release spring has been changed for improving the product quality.

<Before changing> <Changed>

MSPRT5156BCZZ → MSPRT5228CHZZ

3) A starting point adjusting screw of the wheel motor ((C) in the following fig.) has been added.

Addition of the screw (C) (LX-BZ5125CHZZ)

4) Application: From the Feb. production in 1994

3/5

Page 4

4. CHANGE OF THE SOLENOID FIXING SCREW AND OF THE RATCHET S SHAPE

1) Model name: PA-4000/3000II/3000III/3000X/3000H/3020II/3020III/3030II/3030III/3030H/3030X/3030S/3100III

PA-3100X/3140II/3140S/W1400/1410/1200, QL-100/200/300/20/30, SM-8400

2) General: The solenoid fixing screw and the ratchet S shape have been changed by the following reasons.

3) Description: 1) The length of the solenoid fixing screw has been shortened to prevent it from touching the

solenoid bobbin.

<Before changing> <Changed> <Model applicable>

LX-BZ5119CHZZ → LX-BZ5131CHZZ PA-4000 only

(4.6mm long) (4.3mm long)

2) The shape of the ratchet S has been changed for decreasing the rotation load.

<Before changing> <Changed> <Models applicable>

PTME-5018CHZZ → PTME-5018CHZA The above current models

(Color: black) (Color: natural)

4) Application: The Jan. production in 1994 - PA-4000

Running change for the other models

4/5

Page 5

Parts change:

Ref

No.

Model

name

1

PA-4000 U.S.A.

Version

P/G No.

5 - 78

5 - 79

5 - 45 VRD-RC2EY103J — —

5 -

1 -

5 - 40

Current parts

Parts code Parts code

VRD-RC2EY472J VRD-RC2EY103J AA

—

—

—

—

VHIM38002-232 VHIM38002-235 AW

New parts

VRD-RC2EY103J AA

VRD-RC2EY472J AA

VRD-RC2EY102J

XUPSD30P08000

Price

rank

Resistor

(1/4W 10KΩ ±5%)

Resistor

(1/4W 4.7KΩ ±5%)

Resistor

AA

(1/4W 1KΩ ±5%)

Screw (3 × 8)

AA

Mask CPU

Parts name

Inter-

Effective

change-

time

ability

1st lot 6

Feb. ’94 3 IC4

Note

R39

R40

R4

disused

R42

added

R43

added

R44 &

R45

added

—

2

PA-4000

PA-3030III

PA-3030X

QL-100 etc.

PA-4000 U.S.A.

PA-3020III

PA-3030III

QL-100/200/300

PA-3000X/3030X

SM-8400

PA-4000

3

5 - 12

QCNCW5111BC1H QCNCW5132BC1H AC

3 - 1 NGERH5142CHZZ NGERH5129CHZZ AD RF gear

— PTME-5019CHZZ AD RF ratchet

3 -

— MSPRD5206CHZZ AB Gear spring —

3 - 11 MSPRD5201CHZB MSPRD5201CHZC AB Back tension spring

U.S.A.

3 - 3 NGERH5130CHZZ NGERH5130CHZA AB Ratchet gear ∗ 1

All Apr. ’94

All

except

Europe

Europe NGERH5131HHZZ NGERH5131HHZA AA —

U.S.A.

NGERH5131CHZZ NGERH513 1C HZA AC

3 - 2

— SPAKA6014CHZZ AD Vinyl sheet

4 -

— SPAKX6015CHZZ AE Ribbon add —

2 - 7

MSPRT5156BCZZ MSPRT5228CHZZ

Connector

(18 pin)

R idle gear

AA Release spring 3 —

Jun. ’94 1 CN1

3—

6

Jan. ’94

3

Jan. ’94

6

Feb. ’94

—

—

—

—

—

3 - B4

3 - B2

3 - B3

PA-4000

4

PA-3000II/3000III

PA-3000X etc.

<Interchange>

1. Interchangeable. 4. Not interchangeable.

2. Current type can be used in place of new type.

New type cannot be used in place of current type.

3. Current type cannot be used in place of new type.

New type can be used in place of current type.

Parts marked with " ! " is important for maintaining the safety of the set.

Be sure to replace these parts with specified ones for maintaining the safety and performance of the set.

* 1 Changed period: mentioned before

* 2 Destination & produced period: mentioned before

U.S.A.

3 - 7 PTME-5018CHZZ PTME-5018CHZA AD Ratchet S’

All 1

— LX-BZ5125CHZZ

LX-BZ5119CHZZ LX-BZ5131CHZZ

5. Interchangeable if replaced with same types of

6. Others.

AB

Screw

AB 3 —

related parts in use.

Jan. ’94

Jan. ’94

Running

change

Q’ty:

6

1→2

3

∗ 2

5/5

Loading...

Loading...