Page 1

查询PC354供应商

PREPARED BY:

DATE:

SPEC. No. ED-9466 1B

I

October 29. 1999

APPROVED BY: DATE:

DEVICE SPECIFICATION FOR

MODEL No.

I

SHA

ELECTRONIC COMPO

GROUP SHARP CORPORATION

SPECIFICATION

PHOTOCOUPLER

OF’TO-ELECT=

I

Business dealing name

I I

PC354

1. These speciilcation sheets include materials protected under copyright of Sharp Corporation (‘Sharp”).

Please do not reproduce or cause anyone to reproduce them without Sharp’s consent.

2. When using this product, please observe the absolute maximum ratings and the instructions for use outlined

in these specification sheets, as well as the precautions mentioned below. Sharp assumes no responsibility

for any damage resulting from use of the product which does not comply with the absolute maximum ratings

and the instructions included in these specification sheets, and the precautions mentioned below.

(Precautions)

(1) This product is designed for use in the following application areas :

l

l

OA equipment

. Telecommunication equipment (Terminal) * Measuring equipment

l

Tooling machines l Computers

1

If the use of the product in the above application areas is for equipment listed in paragraphs

(21 or (31, please be sure to observe the precautions given in those respective paragraphs.

(21 Appropriate measures, such as fail-safe design and redundant design considering

the safety design of the overall system and equipment, should be taken to ensure reliability

and safety when this product is used for equipment which demands high reliability and

safety in function and precision, such as ;

* Transportation control and safety equipment (aircraft, train, automobile etc.)

* Tram signals * Gas leakage sensor breakers * Rescue and security equipment

l

Other safety equipment

[

(31 Please do not use this product for equipment which require extremely high reliability

and safety in function and precision, such as :

* Space equipment * Telecommunication equipment (for trunk lines)

* Nuclear power control equipment * Medical equipment

[

(4) Please contact and consult with a Sharp sales representative if there are any questions

regarding interpretation of the above three paragraphs.

3. Please contact and consult with a Sharp sales representative for any questions about this product.

Audio visual equipment

* Home appliances

1

1

1

CUSTOMERS APPROVAL

DATE

BY

DATE

PRESENTED ;(i

BY

K. Hachimura.

Department General Manager of

Engineering Dept. ,I1

Opto-Electronic Devices Div.

ELECOM Group

SHARP CORPORATION

4

Page 2

SHARP CORPORATION

ED-94(

1. Application

This specification applies to the outline and characteristics of p

Model No. PC354.

2. Outline

Refer to the attached drawing No. CY6488KO2.

3. Ratings and characteristics

Refer to the attached sheet, page 4 to 6.

4. Reliability

Refer to the attached sheet, page 7.

5. Incoming inspection

Refer to the attached sheet, page 8.

6. Supplement

6.1 Isolation voltage shall be measured in the following method.

(1) Short between anode and cathode on the primary side and between

collector and emitter on the secondary side.

(2) The dielectric withstand tester with zero-cross circuit shall be used.

(3) The wave form of applied voltage shall be a sine wave.

6.2 Packaging specifications

Page 3

SHARPCORPORATION

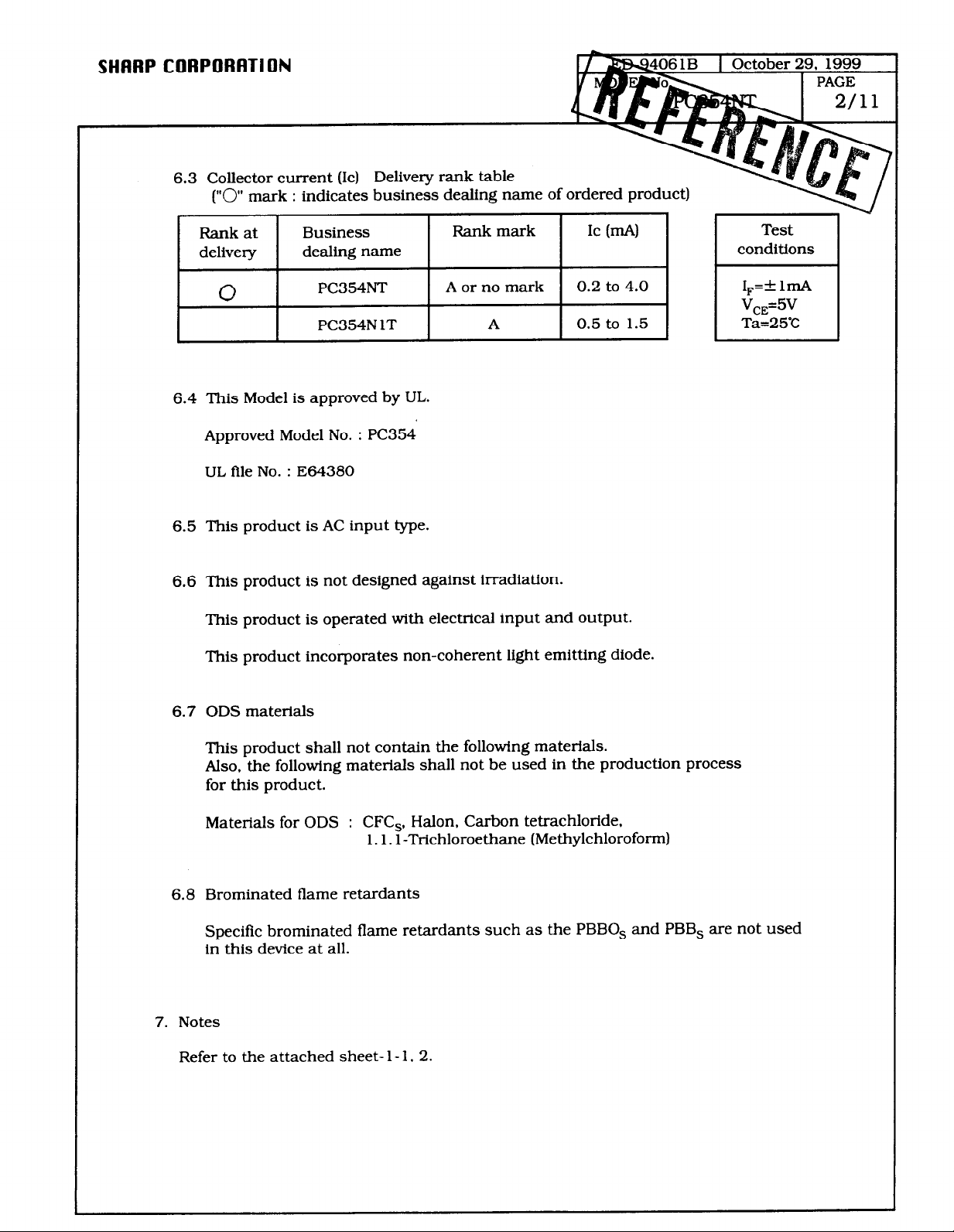

6.3 Collector current (Ic) Delivery rank table

(“0”

mark : indicates business dealing name of ordered product)

Rank at Business

delivery dealing name

8

6.4 This Model is approved by UL.

Approved Model No. : PC354

UL file No. : E64380

6.5 This product is AC input type.

6.6 This product is not designed against irradiation.

This product is operated with electrical input and output.

This product incorporates non-coherent light emitting diode.

PC354NT A or no mark 0.2 to 4.0

PC354N 1T A 0.5 to 1.5

Rank mark

Ic b-M

Test

conditions

I,=+ 1mA

V ca=5v

Ta=25C

6.7 ODS materials

This product shall not contain the following materials.

Also, the following materials shall not be used in the production process

for this product.

Materials for ODS : CFC,, Halon. Carbon tetrachloride.

1.1.1 -Trichloroethane (Methylchloroform)

6.8 Brominated flame retardants

Speciiic brominated flame retardants such as the PBBO, and PBB, are not used

in this device at all.

7. Notes

Refer to the attached sheet- 1- 1, 2.

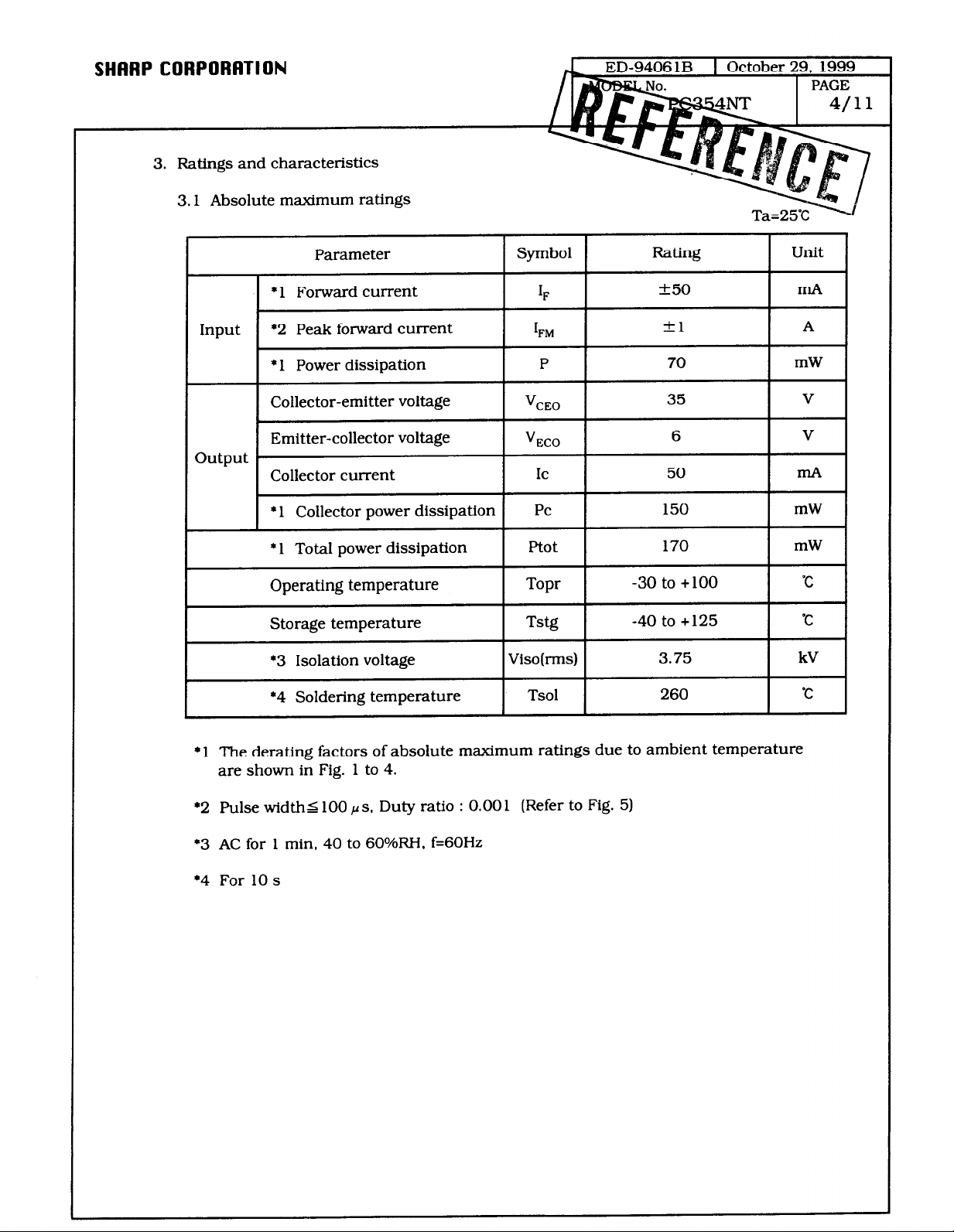

Page 4

SHARP CORPORATION

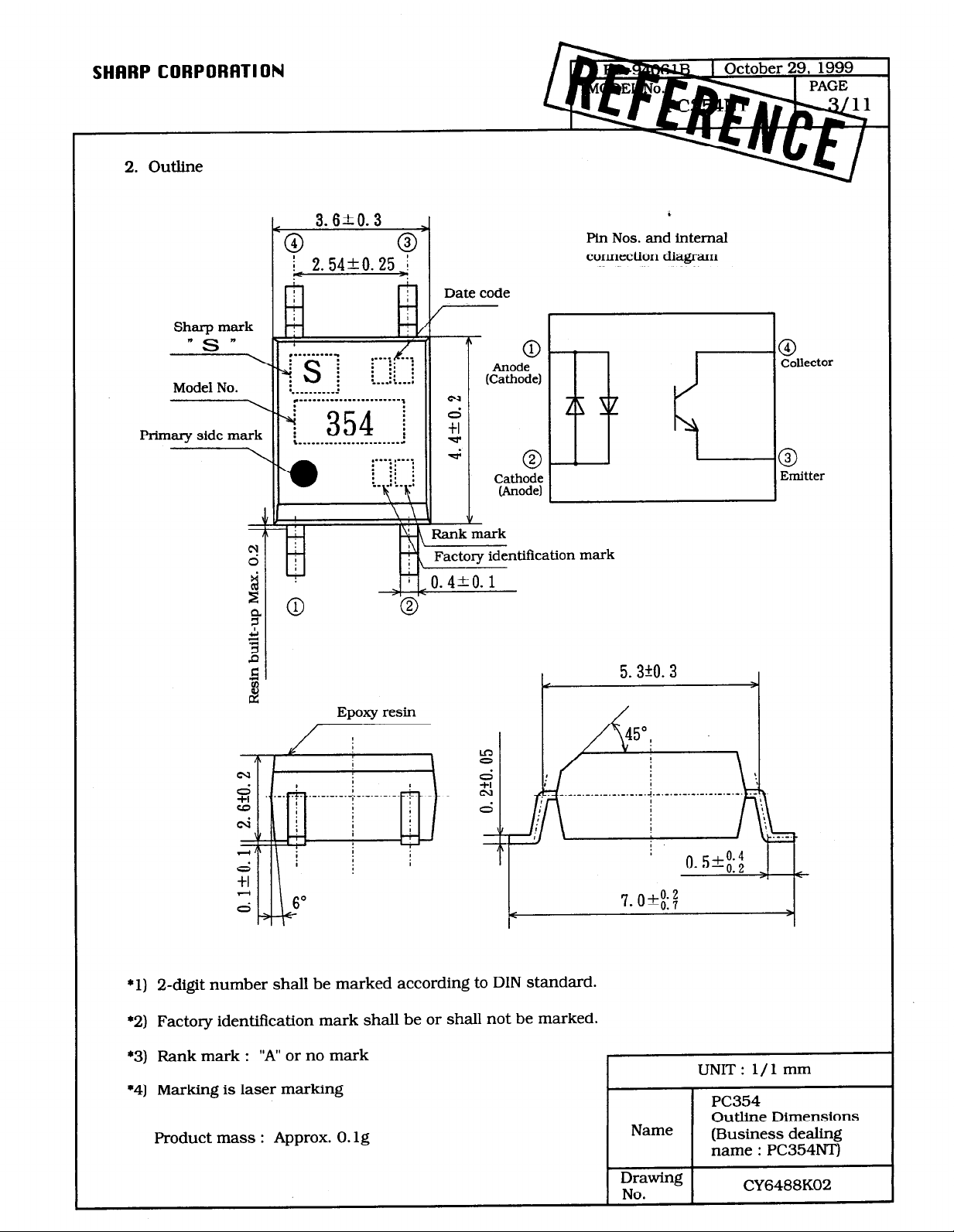

2. Outline

Sharp mark

“S”,

Model No.

\

Primary side mark

\

.

1

\,

. .

\*

c

3.6kO. 3

@

0

;

2.54kO.25

i

Date code

/

0

Anode

(Cathode)

d

&nk mark

0

Cathode

(Anode)

i

Pin Nos. and internal

connection diagram

Epoxy resin

+q=, g

4-L

6”

mark

3

Collector

3

Emitter

*l) 2-digit number shall be marked according to DIN standard.

*2) Factory identification mark shall be or shall not be marked.

*3) Rank mark : “A” or no mark

l

4) Marking is laser marking

Product mass : Approx. 0. lg

UNIT: l/l mm

Name

PC354

Outline Dimensions

(Business dealing

name : PC354NT)

Drawing

No.

CY6488KO2

L

Page 5

SHARP CORPORATION

3. Ratings and characteristics

3.1 Absolute maximum ratings

Input

output

Collector current

* 1 Total power dissipation

Operating temperature Topr

Storage temperature Tstg

*3 Isolation voltage Viso(rms) 3.75

*4 Soldering temperature Tsol 260 %

* 1 The derating factors of absolute maximum ratings due to ambient temperature

are shown in Fig. 1 to 4.

*2 Pulse widths 100 /1 s. Duty ratio : 0.00 1 (Refer to Fig. 51

*3 AC for 1 min. 40 to 6O%RH, f=GOHz

*4 For 10s

-30 to +lOO ‘C

-40 to +125 “C

kV

Page 6

SHARP CORPORATION

3.2 Electra-optical characteristics

Input

output

Parameter Symbol Conditions MIN. m. MAX. uni;

Forward voltage

VF

1,=+2omA 1.2 1.4 v

Terminal capacitance Ct

v=o, f=lkHz

30 250 pF

Dark current

I,

EO

vc,=2ov, IF0 100 nA

Collector-emitter

BvCEO

Ic=O. 1 mA 35 - - V

breakdown voltage I,=0

Emitter-collector

BVECO

I,= 10 rA, I,=0 6 - - V

breakdown voltage

Collector current

IC

1,=+1mA, vc,=5v 0.2 - 4.0 mA

Collector-emitter

‘CE(sat)

1,=+2omA 0.1 0.2 v

saturation voltage

Ic=lmA

Transfer Isolation resistance Riso DCSOOV

5XlO’O 10” - Q

charac- 40 to 6O%RH

teristics

Floating capacitance Cf

V=O, f= 1 MHz 0.6 1.0 pF

Response time Rise tr VcE=2V

4 18 ps

’ Ic=2mA

Response time Fall tf Iq=lOOQ

3 18 ps

Page 7

SHARP CORPORATION

(Fig. 1) Forward current vs.

ambient temperature

-30 0 25 55 75 100 125

80

c

3 70

g 60

z

;ij

b

40

3

g 20

3

.2

n O

-30 0 25

100 125

Ambient temperature Ta (“C)

(Fig. 3) Collector power dissipation

vs. ambient temperature

-30 0 25 50 75 100 125

Ambient temperature Ta ("C)

(Fig. 5) Peak forward current

3

vs. duty ratio

Ambient temperature Ta (“C)

(Fig. 4) Total power dissipation

g 170

s 150

.9

2

100

;ij

F

Pulse widths 100 p s

Ta=25”C

-30 0 25 50 75 100 125

Ambient temperature Ta ("C)

vs. ambient temperature

a”

Duty ratio

Page 8

SHARP CORPOMTION

4. Reliability

The reliability of products shall satisfl

items listed below.

Test Items

Solderability *2

Soldering heat *3

Terminal strength

(Bending) *4

Mechanical shock

Variable frequency

vibration

Temperature

cycling

High temp. and high

humidity storage *5

23O’C. 5 s

26O’C. 10s

Weight : 1N

1 time/each terminal

150OOm/s*, 0.5ms

3 times/+X, +Y. +Z direction

100 to 2000 to lOOHz/4min

200m/s*

4 times/ X, Y. 2 direction

1 cycle -40°C to + 125’C

20 cycles test

+85-C. 85%RH. 500h

Test Conditions Failure Judgement

(30min) (30min)

Confidence level : 90%

LTPD : 100/o/20%

*1 Criteria

v,>ux 1.2

kEO>UX2

Ic<LX0.7

V

CE(sat)>ux 1.2

U : Upper

specification

limit

n=ll. C=O

n=ll, C=O

n=ll. C=O

n=ll. C=O

n=ll. C=O

n=22.C=0

n=22.C=0

‘I

High temp. storage +125-C. lOOOh

Low temp. storage -4O’C. lOOOh

Operation life

* 1 Test method, conforms to EIAJ ED 470 1.

*2 Solder shall adhere at the area of 95% or more of immersed portion of

lead, and pin hole or other holes shall not be concentrated on one portion.

l 3 The lead pin depth dipped into solder shall be 0.2mm away from the

root of lead pins.

*4 Terminal bending direction is shown below.

‘5 It in ~vall~at~rl after washing hv specified solvent in attach sheet- l- 1. 2.

1,=+5OmA. Ptot= 170mW

Ta=25’C, lOOOh

L : Lower n=22,C=O

specification

limit n=22.C=0

0.2mm or

n=22,C=O

H

more

+

Weight : 1N

Soldering a~

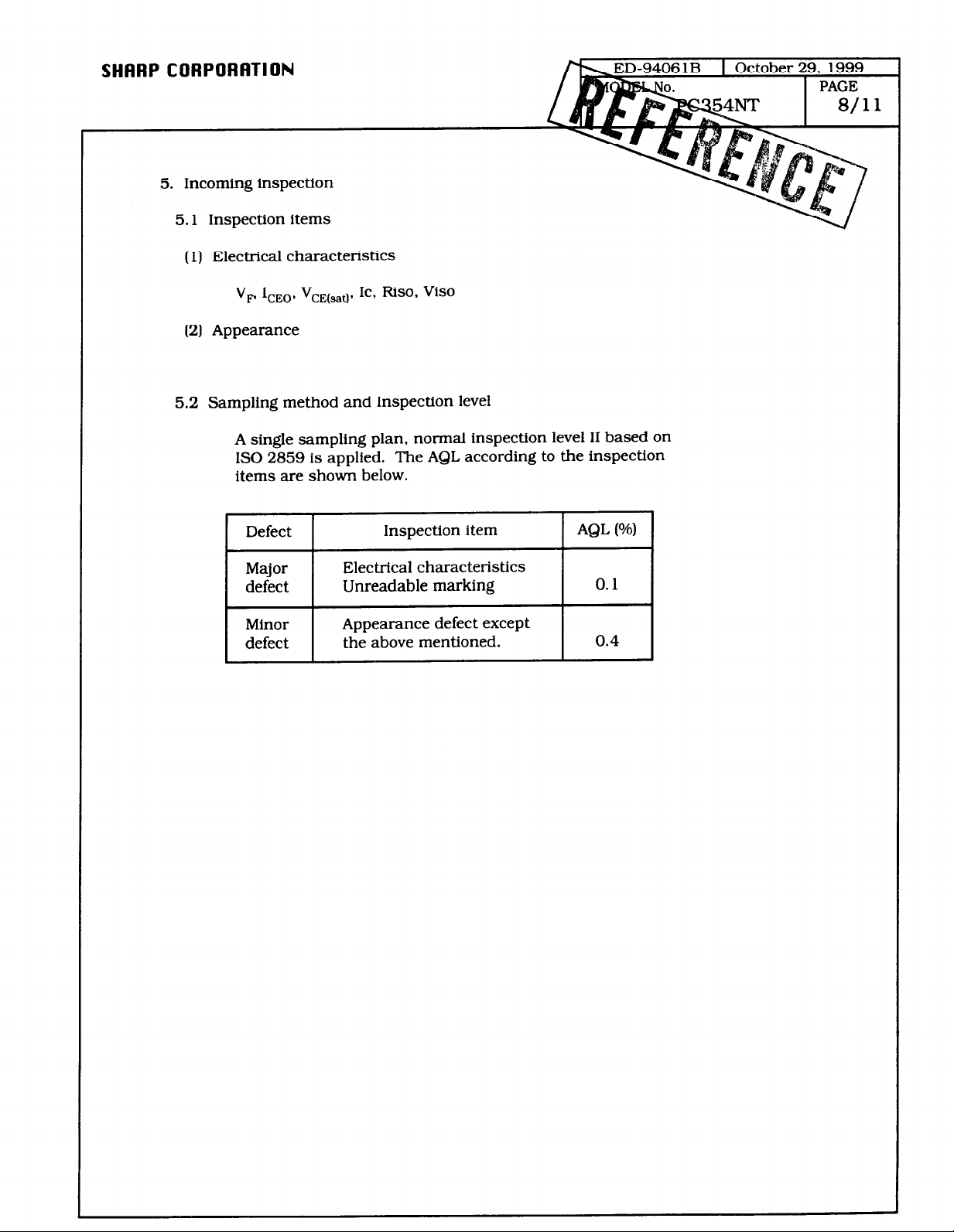

Page 9

SHARP CORPORATION

5. Incoming inspection

5.1 Inspection items

(1) Electrical characteristics

V,, I,,,, V,,(,,). Ic, Rise. Viso

(2) Appearance

5.2 Sampling method and Inspection level

A single sampling plan, normal inspection level II based on

IS0 2859 is applied. The AQL according to the inspection

items are shown below.

Defect

Major

defect

Minor

defect

Inspection item

Electrical characteristics

Unreadable marking

Appearance defect except

the above mentioned.

AQL (O/o)

0.1

0.4

Page 10

SHARP CORPORATION

6.2 Package specifications

6.2.1 Taping conditions

(1) Tape structure and Dimensions (Refer to the attached sheet, Page 10)

The tape shall have a structure in which a cover tape is sealed heat-pressed on

the carrier tape of protect against static electricity.

(2) Reel structure and Dimensions (Refer to the attached sheet, Page 11)

The taping reel shall be of plastic with its dimensions

as shown in the attached drawing.

(3) Direction of product insertion (Refer to the attached sheet, Page 11)

Product direction in carrier tape shall direct to the anode mark at the

hole side on the tape.

(4) Joint of tape

The cover tape and carrier tape in one reel shall be jointless.

(5) The way to repair taped failure devices

The way to repair taped failure devices cut a bottom of carrier tape with a cutter, and

after replacing to good devices, the cut portion shall be sealed with adhesive tape.

6.2.2 Adhesiveness of cover tape

. The exfoliation force between carrier tape and cover tape shall be

0.2N to 0.7N for the angle from 160’ to 180’ .

6.2.3 Rolling method and quantity

l

Wind the tape back on the reel so that the cover tape will be outside the tape.

Attach more than 20cm of blank tape to the trailer and the leader of the tape

and fur the both ends with adhesive tape. One reel shall contain 750~~s.

6.2.4 Marking

. The outer packaging case shall be marked with following information.

l

Model No.

* Number of pieces delivered l Production date

6.2.5 Storage condition

l

Taped products shall be stored at the temperature between

5 and 30°C and the humidities lower than 7O%RH.

6.2.6 Safety protection during shipping

l

There shall be no deformation of component or degradation of electrical

characteristics due to shipping.

Page 11

SHARP CORPORATION

Carrier tape structure and Dimensions

F I.-E I_

t

I- -I- i

D

5”

max

unit

\

Unit

\

Symbol

mm

Symbol

mm

A

12.0

F

4.0

f0.3

kO.1

B C

~

f0.05

5.5

G

+o. 1

-0.0

$J3 1.5

1.75

H

7.4

+o. 1

kO.1

D

kO.1

8.0

E

kO.05

2.0

-1

I J

-Lo.05 -to.1

0.3 3.1

-I-

K

kO.1

4.0

Page 12

SHARP CORPORATION

Reel structure and Dimensions

I

e

.

3

C

f

a

’ b

Check word

a b

C

d

I

e

I

f

I

g

I

mm 1 180 113.5S.51 8Okl.O 1 13f0.5 1 21fl.O 1 2.OkO.5 12.0f0.5 1

Direction of product insertion

Pull-out direction

Page 13

SHARP CORPORATION

Precautions for Photocouplers

1 For cleaning

(1) Solvent cleaning :

Solvent temperature 45C or less

Immersion for 3 min or less

(2) Ultrasonic cleaning : The effect to device by ultrasonic cleaning differs

by cleaning bath size, ultrasonic power

output, cleaning time, PCB size or device mounting

condition etc. Please test it in actual using condition

and confirm that doesn’t occur any defect before starting

the ultrasonic cleaning.

(3) Applicable solvent :

Ethyl alcohol, Methyl alcohol, Isopropyl alcohol

In case when the other solvent is used, there are cases that

the packaging resin is eroded. Please use the other solvent

aiter thorough confirmation is performed in actual using condition.

2. The LED used in the Photocoupler generally decreases the light emission power

by operation.

In case of long operation time, please design the circuit with considering

the degradation of the light emission power of the LED. (50%/5years)

3. There are cases that the deviation of the CTR and the degradation of the light emission power

of the LED become big at IF is less than l.OmA.

Please design the circuit with considering this point.

Page 14

SHARP CORPORATION

4. Precautions for Soldering Photocouplers

(1) If solder reflow :

It is recommended that only one soldering be done at the temperature

and the time within the temperature profile as shown in the figure below.

h-9406 11

25°C

amin

<

+I+

30 s

lmin

1.5 min

lmin

<

>

Since, influence to the device is different according to reflow equipment

and its condition, please use the device after confirming no damage

in the actual using condition.

(2) Other precautions

An infrared lamp used to heat up for soldering may cause a localized

temperature rise in the resin. So keep the package temperature within

that specified in Item (1). Also avoid immersing the resin part in the solder.

Loading...

Loading...