Page 1

SERVICE MANUAL

X

OPERATE

DV-SL80/DV-SL80X

SERVICE MANUAL

S45S9DV-SL80/

DVD VIDEO PLAYER

NTSC/PAL

DVD VIDEO PLAYER

---DV-SL80 ---DV-SL80

3 4

SPECIFICATIONS ............................................................................................................................. 1-1-1

LASER BEAM SAFETY PRECAUTIONS .......................................................................................... 1-2-1

IMPORTANT SAFEGUARDS AND PRECAUTIONS......................................................................... 1-3-1

STANDARD NOTES FOR SERVICING............................................................................................. 1-4-1

MODELS DV-SL80/DV-SL80X

OPERATING CONTROLS AND FUNCTIONS .................................................................................. 1-5-1

CABINET DISASSEMBLY INSTRUCTIONS ..................................................................................... 1-6-1

FIRMWARE RENEWAL MODE .........................................................................................................1-7-1

TROUBLESHOOTING .......................................................................................................................1-8-1

BLOCK DIAGRAMS........................................................................................................................... 1-9-1

SCHEMATIC DIAGRAMS/ CBA’S AND TEST POINTS ..................................................................1-10-1

WAVEFORMS.................................................................................................................................. 1-11-1

WIRING DIAGRAM ..........................................................................................................................1-12-1

SYSTEM CONTROL TIMING CHARTS .......................................................................................... 1-13-1

IC PIN FUNCTION DESCRIPTIONS ...............................................................................................1-14-1

LEAD IDENTIFICATIONS................................................................................................................ 1-15-1

EXPLODED VIEWS .........................................................................................................................1-16-1

MECHANICAL PARTS LIST ............................................................................................................1-17-1

ELECTRICAL PARTS LIST ............................................................................................................. 1-18-1

MODELS

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored to its

original condition and only parts identical to those specified

be used.

CONTENTS

DV-SL80

DV-SL80X

Page

SHARP CORPORATION

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

1

Page 2

SPECIFICATIONS

ITEM CONDITIONS UNIT NOMINAL LIMIT

1 Video Output 75 Ω Vpp 1.0 ±0.1

2-1 Coaxial Digital Out mVpp 500

2-2 Optical Digital Out dBm -18

(DV-SL80X only)

3 Audio (PCM)

3-1. Output Level 1 kHz 0 dB Vrm 2.0

3-2. S/N dB 120

3-3. Freq. Response

DVD fs=48 kHz 20 ~ 22 kHz dB ±0.5

CD fs=44.1 kHz 20 ~ 22 kHz dB ±0.5

3-4. THD +N

DVD 1k Hz 0 dB % 0.0025

CD 1k Hz 0 dB % 0.003

4 Power consumption 14 W (Standby: 2.0 W) --- [ DV-SL80 ]

12 W (Standby: 1.5 W) --- [ DV-SL80X ]

5 Weight 1.3kg

6 Dimension 435 mm X 51 mm X 211 mm

NOTES:

1. All Items are measured without pre-emphasis unless otherwise specified.

2. Power supply : AC110 - 240 V ~ 50/60Hz --- [ DV-SL80 ]

AC220 - 240 V ~ 50/60Hz --- [ DV-SL80X ]

3. Load imp. : 100 k ohm

4. Room ambient : 5 °C ~ 40 °C

1-1-1

E5943SP

Page 3

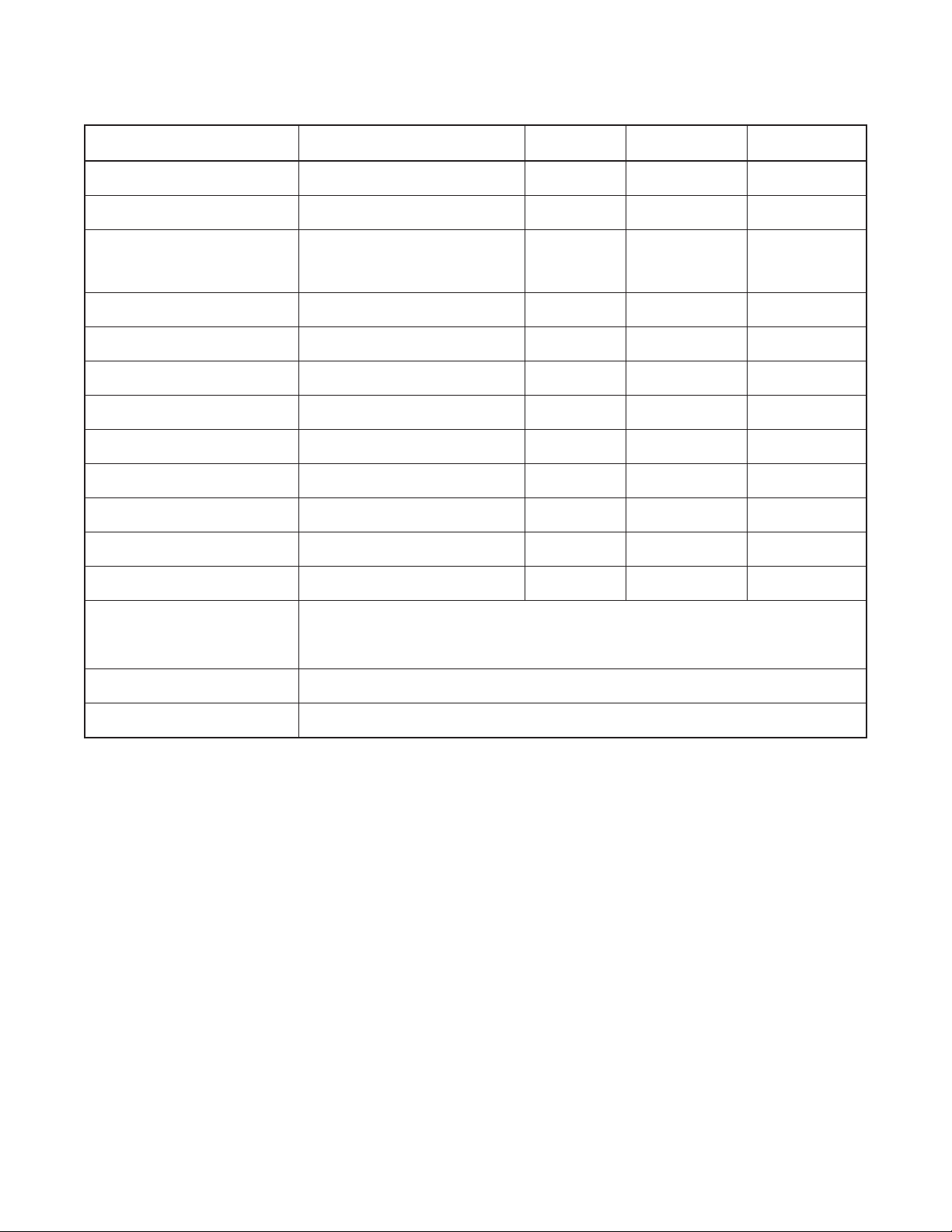

LASER BEAM SAFETY PRECAUTIONS

D

This DVD player uses a pickup that emits a laser beam.

Do not look directly at the laser beam coming

from the pickup or allow it to strike against

your skin.

The laser beam is emitted from the location shown in the figure. When checking the laser diode, be sure to keep your

eyes at least 30cm away from the pickup lens when the diode is turned on. Do not look directly at the laser beam.

Caution: Use of controls and adjustments, or doing procedures other than those specified herein, may result in

hazardous radiation exposure.

rive Mecha Assembly

Laser Beam Radiation

Laser Pickup

Turntable

1-2-1

DVD_LASER

Page 4

IMPORTANT SAFEGUARDS AND PRECAUTIONS

T

M

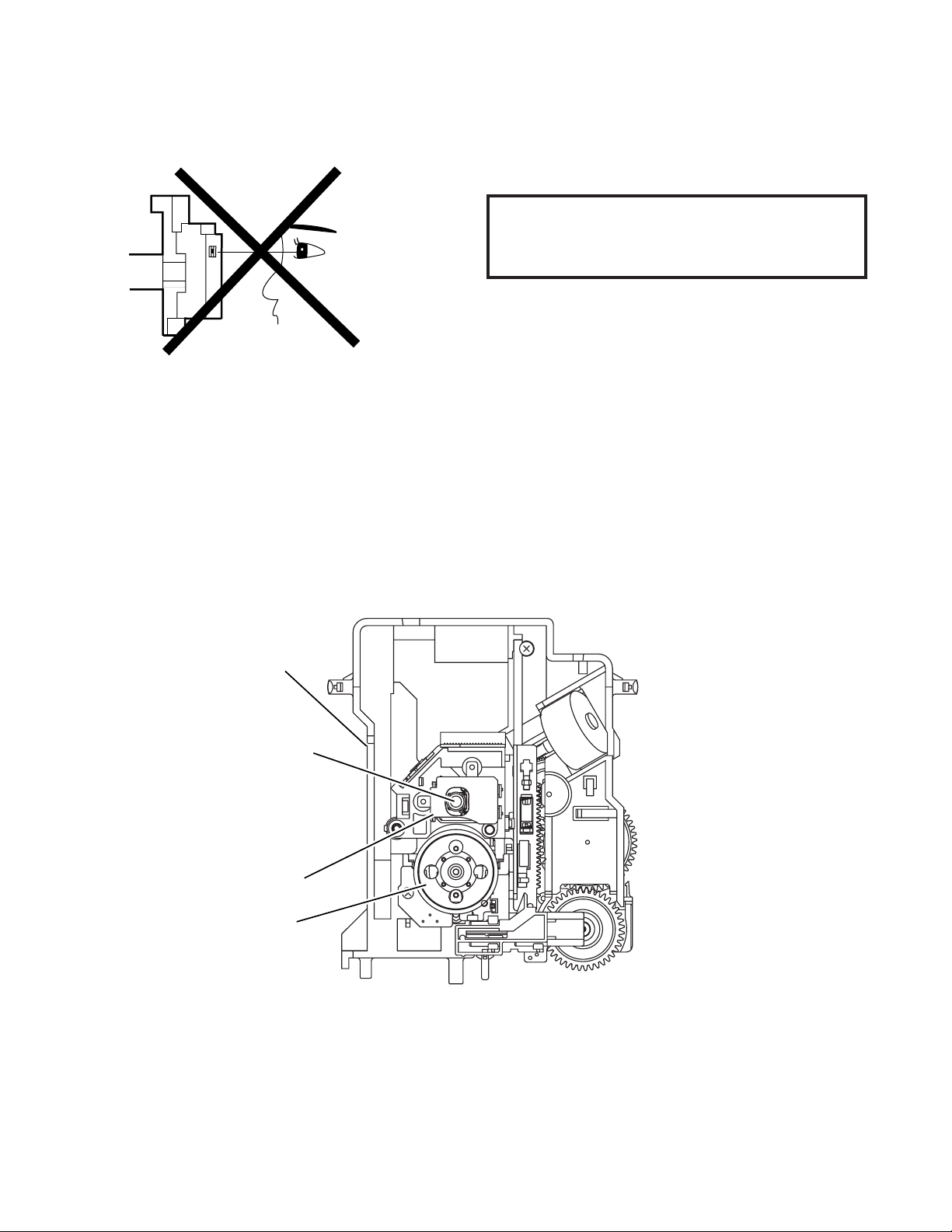

1. IMPORTANT SERVICE NOTES

BEFORE RETURNING THE DVD VIDEO PLAYER

Before returning the DVD video player to the user,

perform the following safety checks.

1. Inspect all lead dress to make certain that leads are

not pinched or that hardware is not lodged between

the chassis and other metal parts in the DVD video

player.

2. Inspect all protective devices such as non-metallic

control knobs, insulation materials, cabinet backs,

adjustment and compartment covers or shields, isolation resistor/capacitor networks, mechanical insulators etc.

3. To be sure that no shock hazard exists, check for

current in the following manner.

Plug the AC line cord directly into a 230 volt AC outlet

(Do not use an isolation transformer for this test).

Using two clip leads, connect a 1.5k ohm, 10 watt

resistor paralleled by a 0.15µF capacitor in series with

all exposed metal cabinet parts and a known earth

ground, such as a water pipe or conduit.

Use an DVM or VOM with 1000 ohm per volt, or higher,

sensitivity or measure the AC voltage drop across the

resistor (See Diagram).

Move the resistor connection to earth exposed metal

part having a return path to the chassis (metal cabinet,

screw heads, knobs and control shafts, etc.) and

measure the AC voltage drop across the resistor.

Reverse the AC plug on the set and repeat AC voltage

measurements for each exposed part. Any reading of

1.4V rms (this corresponds to 0.7mA rms AC.) or more

is excessive and indicates a potential shock hazard

which must be corrected before returning the DVD

video player to the owner.

SSVM

AC SCALE

1.5k ohms.

10W

F

0.15

TEST PROBE

O EXPOSED

ETAL PARTS

CONNECT TO

KNOWN EARTH

GROUNG

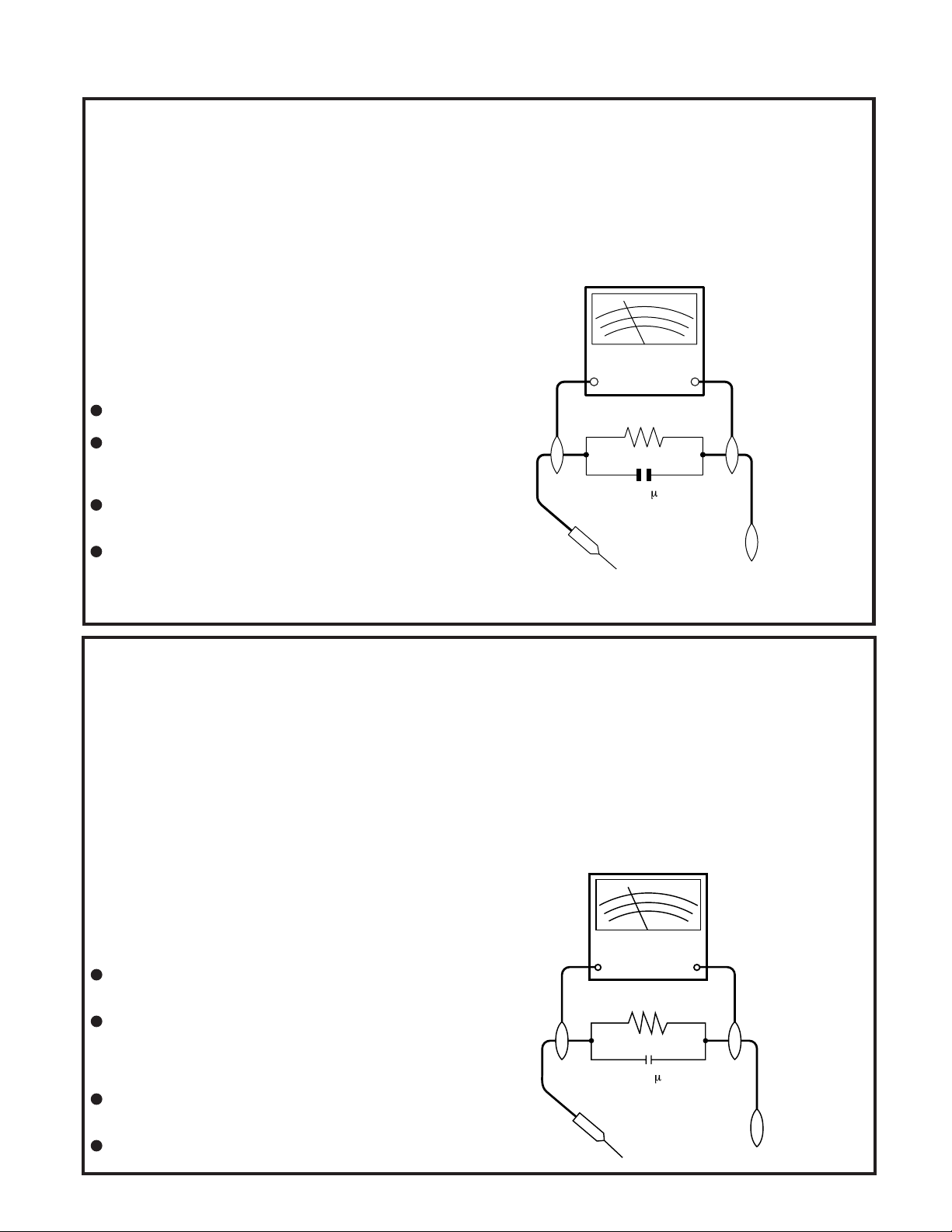

1. NOTES DE SERVICE IMPORTANTES

AVANT DE RENDRE LE REPRODUCTOR DE VíDEO

DVD

Avant de rendre le reproductor de vídeo DVD à l’utilisateur,

effectuer les vérifications de sécurité suivantes.

1. Vérifier toutes les gaines de fil pour être sûr que les fils

ne sont pas pincés ou que le matériel n’est pas coincé

entre le châssis et les autres pièces métalliques dans le

reproductor de vídeo DVD.

2. Vérifier tous les dispositifs de protection tels que les

boutons de commande non métalliques, les matériaux

d’isolement, le dos du coffret, les couvercles de

compartiment et ajustement ou les boucliers, les

réseaux de résistance / condensateur d’isolement, Ies

isolateurs mécaniques, etc.

3. Pour être sûr qu’il n’y a aucun risque de choc électrique,

vérifier le courant de fuite de la maniére suivante.

Brancher le cordon d’alimentation secteur directement

dans une prise de courant de 230 volts. (Ne pas utiliser

de transformateur d’isolement pour cet essai).

Utiliser deux fils à pinces et connecter une résistance

de 10 watts 1,5 kohm en parallèle avec un condensateur

de 0,15 µF en série avec des pièces du coffret métallique

exposées et une masse de terre connue telle qu’un

tuyau ou un conduit d’eau.

Utiliser un DVM ou VOM avec une sensibilité de 1000

ohms par volt ou plus ou mesurer la chute de tension

CA entre la résistance (voir diagramme).

Déposer la connexion de la résistance à toutes les

pièces métalliques exposées ayant un parcours de

retour au châssis (coffret métallique, tétes de vis, boutons et arbres de commande, etc.) et mesurer la chute

de tension CA entre la résistance. Inverser la fiche CA

(une fiche intermédiaire non polarisée doit être utilisée

à seule fin de faire ces vérifications.) sur l’appareil et

répéter les mesures de tension CA pour chaque piéce

métallique exposée. Toute lecture de 1,4 V rms (ceci

correspond à 0,7 mA rms CA) ou plus est excessive et

signale un danger de choc qui doit être corrigé avant de

rendre le reproductor de vídeo DVD à son utilisateur.

VTVM

AC SCALE

1.5k ohms

10W

0.15 F

TEST PROBE

TO EXPOSED

METAL PARTS

CONNECT TO

KNOWN EARTH

GROUND

1-3-1

E5943IMP

Page 5

STANDARD NOTES FOR SERVICING

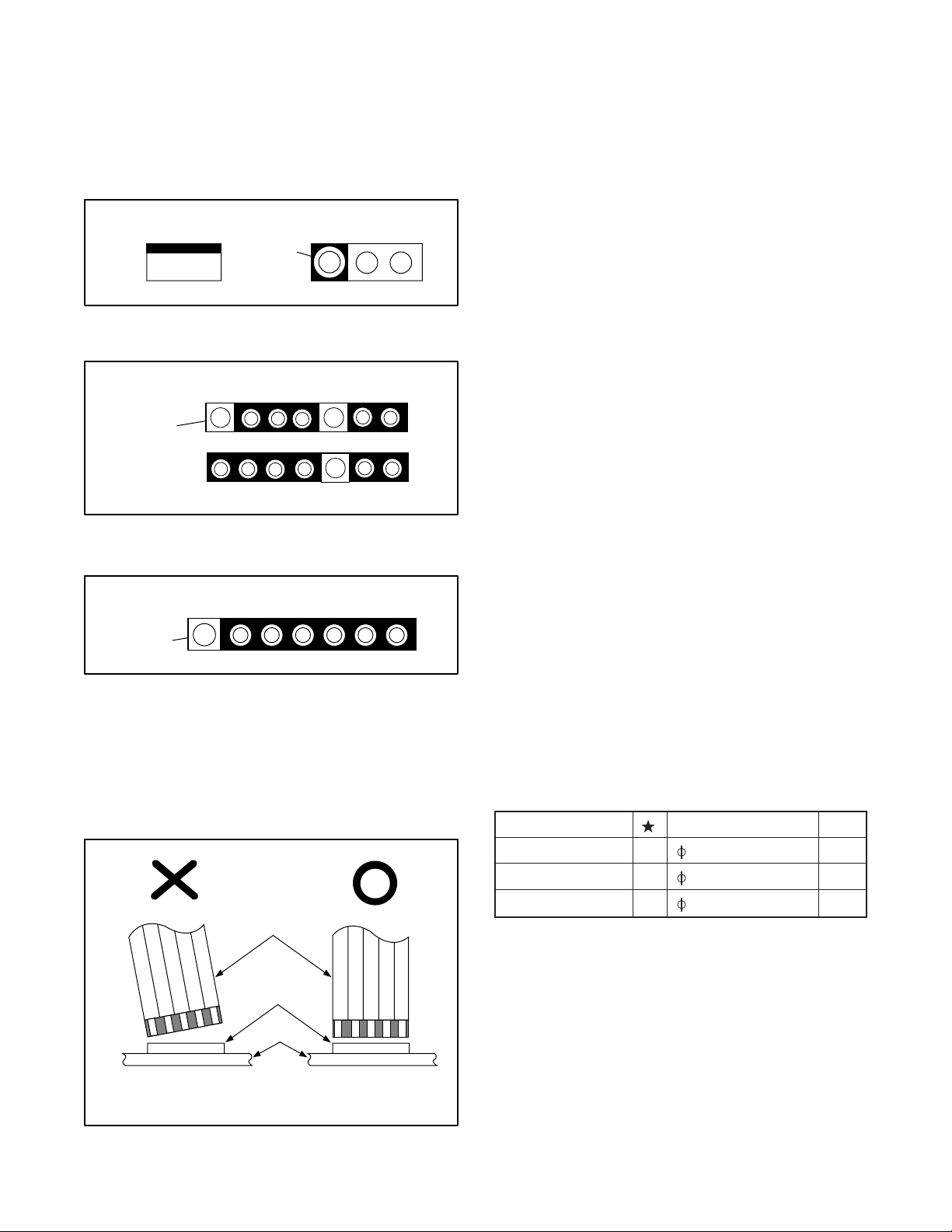

Circuit Board Indications

a. The output pin of the 3 pin Regulator ICs is indicated

as shown.

Top View

Out

b. For other ICs, pin 1 and every fifth pin are indicated

as shown.

< Bottom View >

Input

In

Bottom View

5

Pin 1

10

c. The 1st pin of every male connector is indicated as

shown.

< Bottom View >

Pin 1

Instructions for Connectors

1. When you connect or disconnect the FFC (Flexible

Foil Connector) cable, be sure to first disconnect the

AC cord.

2. FFC (Flexible Foil Connector) cable should be inserted parallel into the connector, not at an angle.

FFC Cable

Using lead-free wire solder

When fixing the PWB soldered with the lead-free solder,

apply lead-free wire solder. Repairing with conventional

lead wire solder may cause damage or accident due to

cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is

higher than the lead wire solder by 40°C, we recommend

you to use a dedicated soldering bit, if you are not

familiar with how to obtain lead-free wire solder or

soldening bit, contact our service station or service

ranch in your area.

Soldering

As the melting point of lead-free solder (Sn-Ag-Cu) is

about 220°C which is higher than the conventional lead

solder by 40°C, and as it has poor solder wettabillty, you

may be apt to keep the soldering bit in contact with the

PWB for extended period of time. However, Since the

land may be peeled off or the maximum heat-resistance

temperature of parts may be excoeded, remove the bit

from the PWB as soon as you conurm the steady

soldering condition.

Lead-free solder contains more tin, and the end of the

soldering bit may be easily corroded. Make sure to tum

on and off the power of the bit as required. if a different

type of solder stays on the tip of the soldering bit, it is

alloyed with lead-free solder. Clean the bit after every

use of it.

When the tip of the soldering bit is blackened during

use, file it with steel wool or fine sandpaper.

Becareful when replacing parts with polarity indication

on the PWB silk.

Lead-free wire solder for servicing

Part No. Description Code

ZHNDAi123250E J 0.3mm 250g(1roll) BL

ZHNDAi126500E J 0.6mm 500g(1roll) BK

ZHNDAi12801KE J 1.0mm 1kg(1roll) BM

Connector

CBA

* Be careful to avoid a short circuit.

1-4-1

DVD_NOTE2

Page 6

How to Remove / Install Flat Pack-IC

Flat Pack-IC

Desoldering Braid

Soldering Iron

Fig. S-1-3

Fine Tip

Soldering Iron

Sharp

Pin

Fig. S-1-4

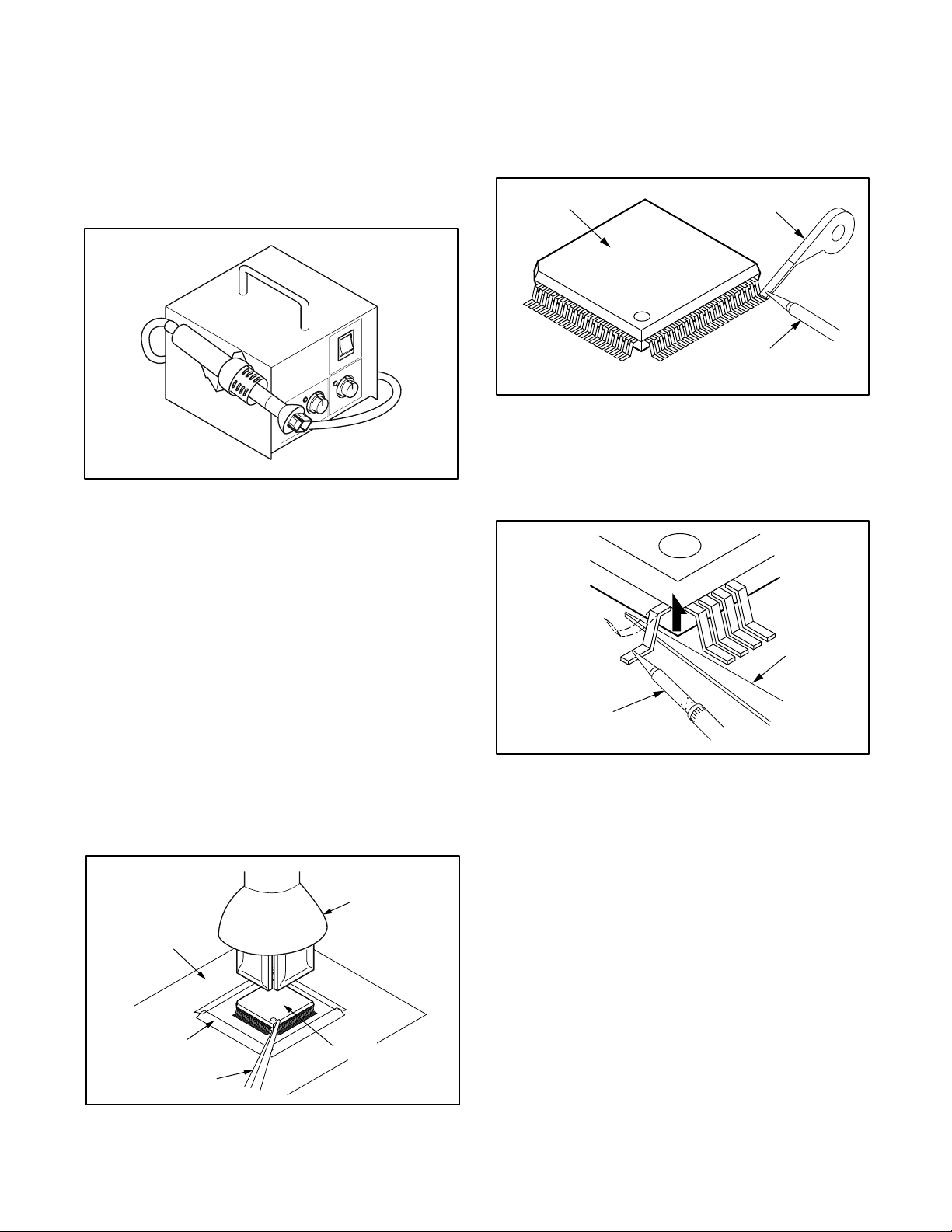

With Soldering Iron:

1. Removal

With Hot-Air Flat Pack-IC Desoldering Machine:

(1) Prepare the hot-air flat pack-IC desoldering ma-

(2)Remove the flat pack-IC with tweezers while apply-

(3)Bottom of the flat pack-IC is fixed with glue to the

(4)Release the flat pack-IC from the CBA using twee-

Caution:

1. Do not supply hot air to the chip parts around the flat

2. The flat pack-IC on the CBA is affixed with glue, so

chine, then apply hot air to the Flat Pack-IC (about 5

to 6 seconds). (Fig. S-1-1)

Fig. S-1-1

ing the hot air.

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

zers. (Fig. S-1-6)

pack-IC for over 6 seconds because damage to the

chip parts may occur. Put masking tape around the

flat pack-IC to protect other parts from damage.

(Fig. S-1-2)

be careful not to break or damage the foil of each pin

or the solder lands under the IC when removing it.

Hot-air

Flat Pack-IC

Desoldering

CBA

Masking

Tape

Tweezers

Machine

Flat Pack-IC

Fig. S-1-2

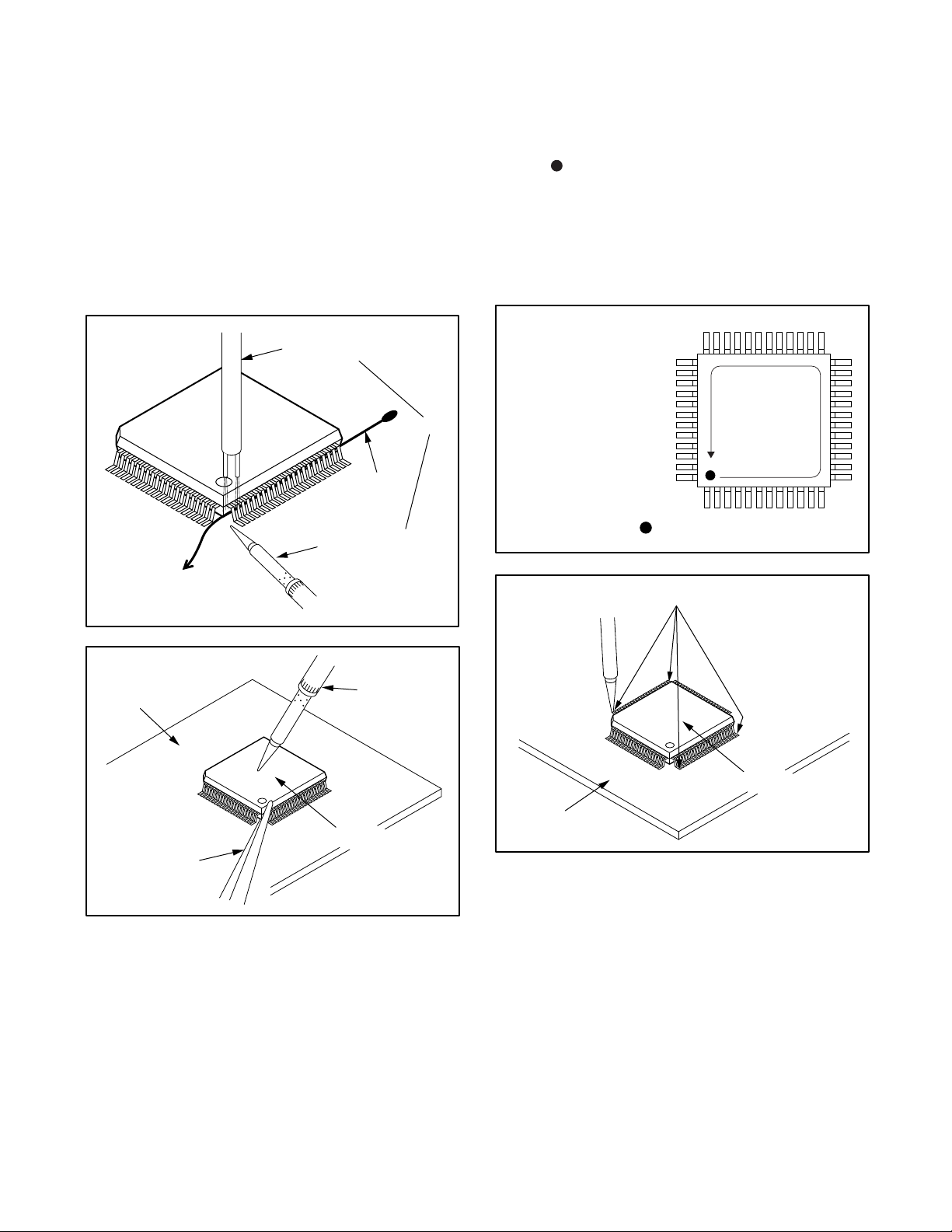

(1)Using desoldering braid, remove the solder from all

pins of the flat pack-IC. When you use solder flux

which is applied to all pins of the flat pack-IC, you can

remove it easily. (Fig. S-1-3)

(2)Lift each lead of the flat pack-IC upward one by one,

using a sharp pin or wire to which solder will not

adhere (iron wire). When heating the pins, use a fine

tip soldering iron or a hot air desoldering machine.

(Fig. S-1-4)

(3)Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

(4)Release the flat pack-IC from the CBA using twee-

zers. (Fig. S-1-6)

With Iron Wire:

(1)Using desoldering braid, remove the solder from all

pins of the flat pack-IC. When you use solder flux

which is applied to all pins of the flat pack-IC, you can

remove it easily. (Fig. S-1-3)

(2) Affix the wire to a workbench or solid mounting point,

as shown in Fig. S-1-5.

(3)While heating the pins using a fine tip soldering iron

or hot air blower, pull up the wire as the solder melts

so as to lift the IC leads from the CBA contact pads

as shown in Fig. S-1-5.

1-4-2

DVD_NOTE2

Page 7

(4)Bottom of the flat pack-IC is fixed with glue to the

Example :

Pin 1 of the Flat Pack-IC

is indicated by a " " mark.

Fig. S-1-7

Presolder

CBA

Flat Pack-IC

Fig. S-1-8

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

(5)Release the flat pack-IC from the CBA using twee-

zers. (Fig. S-1-6)

Note:

When using a soldering iron, care must be taken to

ensure that the flat pack-IC is not being held by glue.

When the flat pack-IC is removed from the CBA,

handle it gently because it may be damaged if force

is applied.

Hot Air Blower

or

Iron Wire

2. Installation

(1)Using desoldering braid, remove the solder from the

foil of each pin of the flat pack-IC on the CBA so you

can install a replacement flat pack-IC more easily.

(2) The “

(3)Solder all pins of the flat pack-IC. Be sure that none

” mark on the flat pack-IC indicates pin 1. (See

Fig. S-1-7.) Be sure this mark matches the 1 on the

PCB when positioning for installation. Then presolder the four corners of the flat pack-IC. (See Fig. S1-8.)

of the pins have solder bridges.

To Solid

Mounting Point

CBA

Tweezers

Soldering Iron

Fig. S-1-5

Fine Tip

Soldeing Iron

Flat Pack-IC

Fig. S-1-6

1-4-3

DVD_NOTE2

Page 8

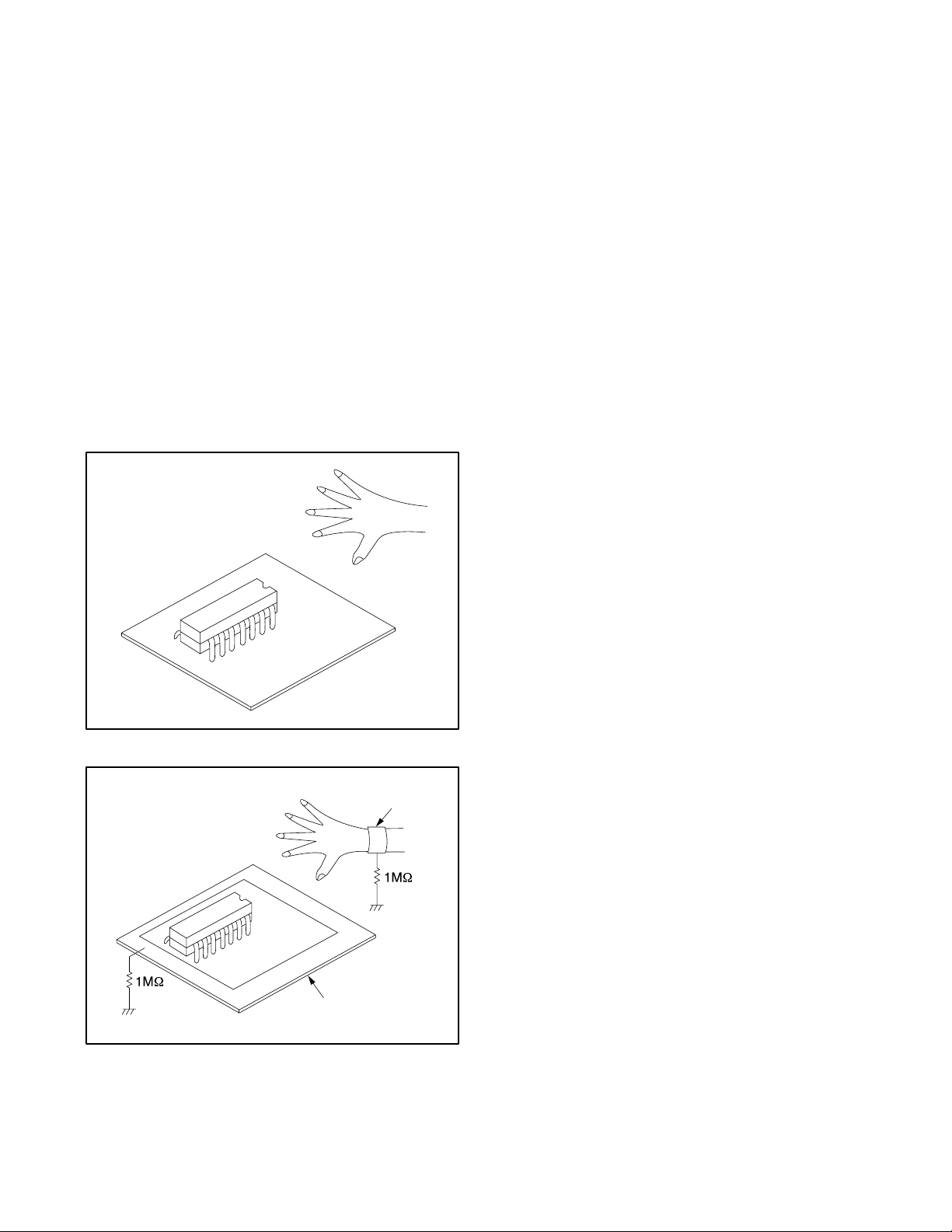

Instructions for Handling

Semi-conductors

Electrostatic breakdown of the semi-conductors may

occur due to a potential difference caused by electrostatic

charge during unpacking or repair work.

1. Ground for Human Body

Be sure to wear a grounding band (1MΩ) that is properly

grounded to remove any static electricity that may be

charged on the body.

2. Ground for Workbench

Be sure to place a conductive sheet or copper plate with

proper grounding (1MΩ) on the workbench or other

surface, where the semi-conductors are to be placed.

Because the static electricity charge on clothing will not

escape through the body grounding band, be careful to

avoid contacting semi-conductors with your clothing.

< Incorrect >

< Correct >

CBA

Grounding Band

CBA

Conductive Sheet or

Copper Plate

1-4-4

DVD_NOTE2

Page 9

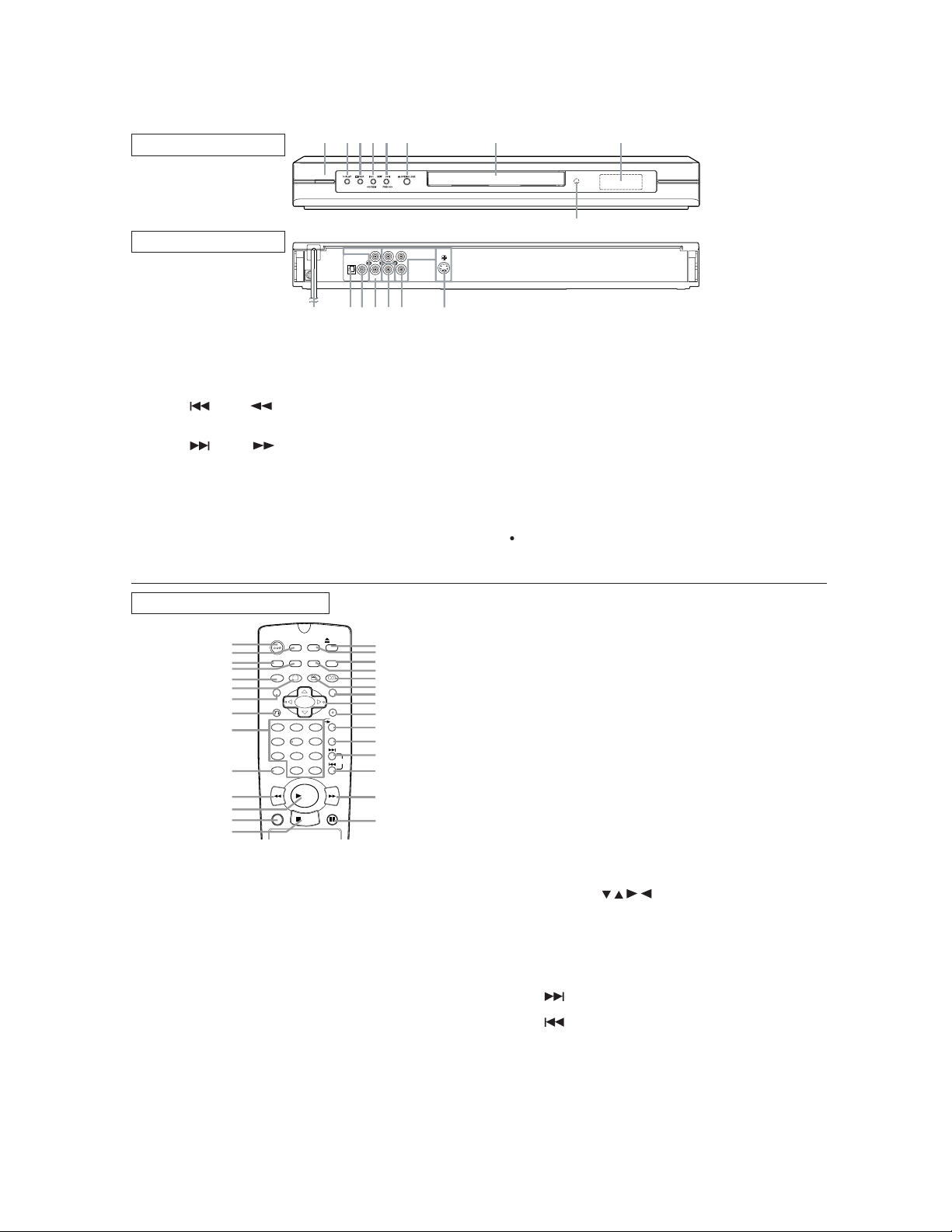

OPERATING CONTROLS AND FUNCTIONS

1

r

FRONT PANEL

REAR VIEW

24351

OPERATE

AUDIO OUT

DIGITAL AUDIO OUT

4

10

COAXIALOPTICAL

11 13 14 161512

LY

B

/ P

R

VIDEO

C

OUT

6

C

R

/ P

R

COMPONENT

VIDEO OUT

B

1. OPERATE

to switch the player to ON or OFF

2. PLAY

to start or resume disc playback

3. STOP

to stop playback

4. SKIP

/ REV

goes to previous chapter or track during playback; press

and hold for 1.5 seconds for a reverse search

5. SKIP

/ FWD

goes to next chapter or track during playback; press and

hold for 1.5 seconds for a forward search

6. OPEN/CLOSE

to open/close the disc tray

7. Disc tray

8. Remote sensor window

9. Display

0. MAINS (AC Power Cord)

connect to a standard AC outlet

7

S-VIDEO

OUT

9

8

11. OPTICAL (Digital audio out)

connect to digital (optical) audio equipment

(DV-SL80X only)

12. COAXIAL (Digital audio out)

connect to AUDIO inputs of a digital (coaxial) audio

equipment

13. AUDIO OUT (Left/Right)

connect to AUDIO inputs of an amplifier, receiver or

stereo system

14. VIDEO OUT

connect to the Video Input of a TV

15. COMPONENT VIDEO OUT

connect to a TV with Component video in jacks

16. S-VIDEO OUT

connect to a TV with S-Video inputs

CAUTION:

Do not touch the inner pins of the jacks on the rea

panel. Electrostatic discharge may cause permanent damage to the player.

PLA YButton

REMOTE CONTROL

OPEN/

ON

OPERATE

1

2

3

4

5

6

7

8

9

10

DIMMER

ZOOM

TITLE

RETURN

1 2 3

7

CLEAR

C

REV

11

12

13

14

1.

OPERATE Button

Press to turn the power on and off.

2.

ON SCREEN Button

Displays the current status on the TV screen for checking

purposes.

3.

DIMMER Button

Press to change the Panel Display settings.

4.

GAMMA Button

Press to adjust the black parts of the picture brighter.

5.

ZOOM Button

Enlarges part of a DVD-reproduced image.

6.

SUBTITLE Button

Press to select a desired subtitle language.

7.

TITLE Button

Displays the title menu.

8.

RETURN Button

Returns to the previous operation.

9.

Numerical Buttons

10.

CLEAR Button

Resets a setting.

11.

REV Button

SCREEN

GAMMA

SUBTITLE

54

8 9

0

PLAY

STOP

SETUP

MODE

ANGLE AUDIO

6

+

10

CLOSE

MARKER

MENU

ENTER

A-B REPEAT

FWD

STILL/PAUSEDIRECT SKIP

REPEAT

15

16

17

18

19

20

21

22

23

24

25

26

SKIP

27

28

29

12.

Starts playback of the disc contents.

13.

DIRECT SKIP Button

Press to locate a desired point.

STOP Button

14.

Stops operation of the disc.

OPEN/CLOSE Button

15.

Press to insert discs into or remove them from the tray.

SETUP Button

16.

Press to enter the setup mode or to change setup items.

MARKER Button

17.

Press to call back the Marker display.

MODE Button

18.

Activates programme playback or random playback mode.

(CD/MP3/JPEG)

Activates the 3D sound or Rapid Play. (DVD)

AUDIO Button

19.

Press to select a desired audio language or sound mode.

20.

ANGLE Button

Press to change the camera angle to see the sequence

being played back from a different angle.

21.

MENU Button

Displays the DVD menus and MP3 file lists.

22.

Arrow Buttons (

)

(left/right/up/down) Select an item in the menu.

23.

ENTER Button

Press to accept a setting.

REPEAT Button

24.

Repeats playback of the current disc, title, chapter or track.

25.

A-B REPEAT Button

Repeats playback of a selected section.

26.

SKIP

Button

Plays back from the beginning of the next chapter or track.

27.

SKIP

Button

Plays back from the beginning of the current chapter or

track.

28.

FWD Button

Fast forwards playback to a desired point.

29.

STILL/PAUSE Button

Pause playback temporarily/frame-by-frame playback.

Fast reverse playback to a desired point.

1-5-1

E5943IB

Page 10

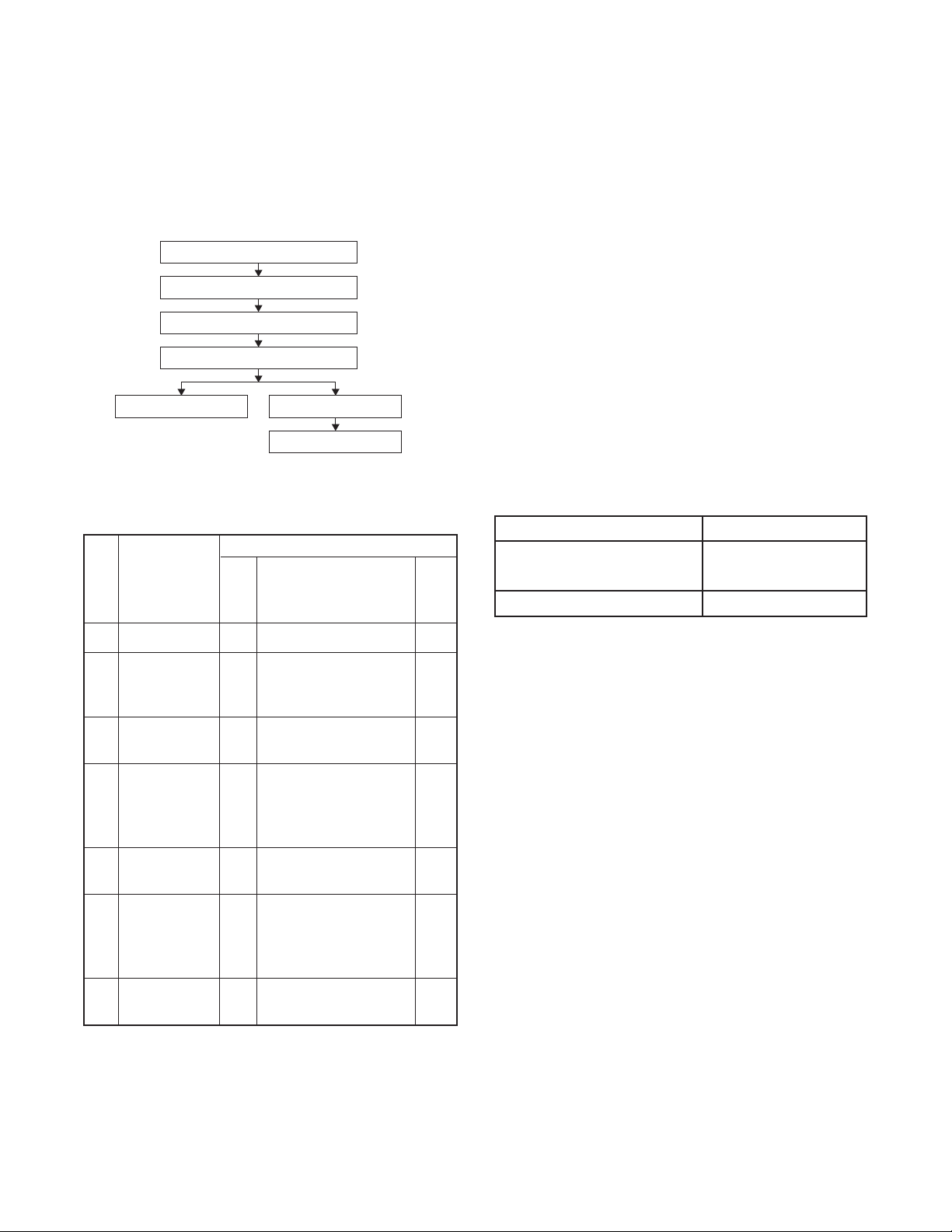

CABINET DISASSEMBLY INSTRUCTIONS

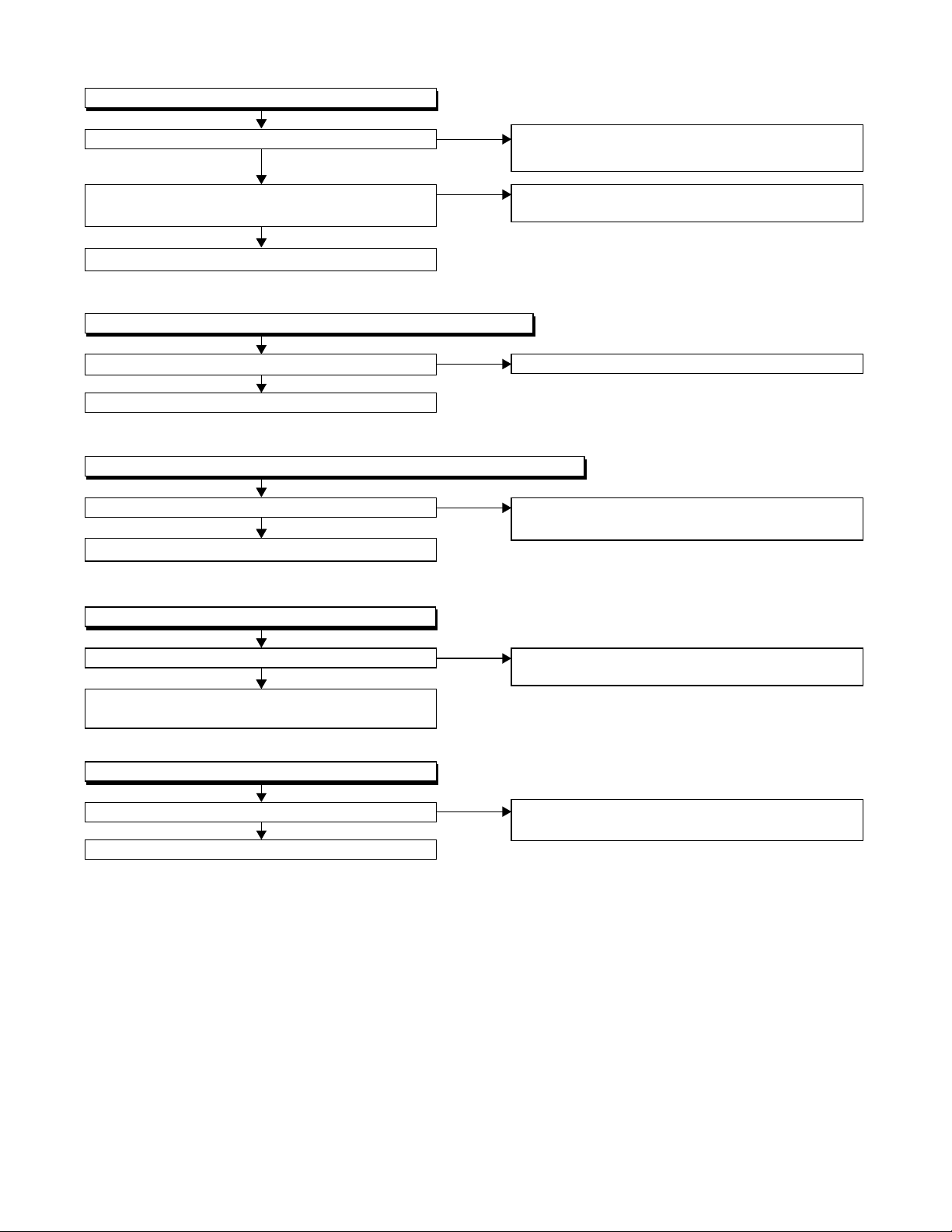

1. Disassembly Flowchart

This flowchart indicates the disassembly steps to gain

access to item(s) to be serviced. When reassembling,

follow the steps in reverse order. Bend, route, and dress

the cables as they were originally.

[1] T op Case

[2] Front Assembly

[3] Reinforce Plate

[4] DVD Main CBA Unit

[5] DVD Mecha

[6] AV CBA

1 : Identification (location) No. of parts in the figures

2 : Name of the part

3 : Figure Number for reference

4 : Identification of parts to be removed, unhooked,

unlocked, released, unplugged, unclamped, or desoldered.

P=Spring, L=Locking Tab, S=Screw,

CN=Connector,

*=Unhook, Unlock, Release, Unplug, or Desolder

e.g.5(S-1) = five Screws (S-1),

2(L-2) = two Locking Tabs (L-2)

5 : Refer to "Reference Notes."

[7] Function CBA

2. Disassembly Method

ID/

LOC.

No.

[1] Top Case 1 3(S-1) [2] Front 2 *4(L-1), *3(L-2), 1

[3]

[4]

[5] DVD 5 4(S-4) -

[6] AV CBA 6 (S-5), -

[7]

↑↑↑ ↑ ↑

123 4 5

PART

Assembly *3(L-3), 1-1

Reinforce

Plate

DVD

Main 4 (S-3A), (S-3B), 2

CBA Unit *CN201, *CN301, 2-1

Mecha

Function

CBA

Fig.

No.

3 3(S-2) -

6 *CN2001 -

REMOVAL

REMOVE/

*UNHOOK/UNLOCK/

RELEASE/UNPLUG/

DESOLDER

*CN401, *CN601 2-2

4(S-6)---[DV-SL80]

5(S-6)---[DV-SL80X],

*2(L-5)

Note

1-2

3

About tightening screws

When tightening screws, tighten them with the following

torque.

Screws Torque

(S-1), (S-2), (S-3A), (S-4), 0.45 ± 0.05 N•m

(S-5), (S-6)

(S-3B) 0.38 ± 0.04 N•m

Reference Notes

CAUTION 1: Locking Tabs (L-1), (L-2) and (L-3) are

fragile. Be careful not to break them.

1-1. Release four Locking Tabs (L-1). Then, release

three Locking Tabs (L-2) .

1-2. Release three Locking Tabs (L-3). Then remove

the Front Assembly.

CAUTION 2: Electrostatic breakdown of the laser diode

in the optical system block may occur as a potential

difference caused by electrostatic charge accumulated

on cloth, human body etc., during unpacking or repair

work.

To avoid damage of pickup follow next procedures.

2-1. Short the three short lands (either of two places) of

FPC cable with solder before removing the FFC

cable (CN201) from it as shown in “View for A” in

Fig. 4. If you disconnect the FFC cable (CN201),

the laser diode of pickup will be destroyed. (Fig. 4)

2-2. Disconnect Connectors (CN301), (CN401) and

(CN601). Remove two Screws (S-3A) and (S-3B)

and lift the DVD Main CBA Unit. (Fig. 4)

CAUTION 3: When reassembling, confirm the FFC

cable (CN201) is connected completely. Then remove

the solder from the three short lands of FPC cable.

(Fig. 4)

1-6-1

E5943DC

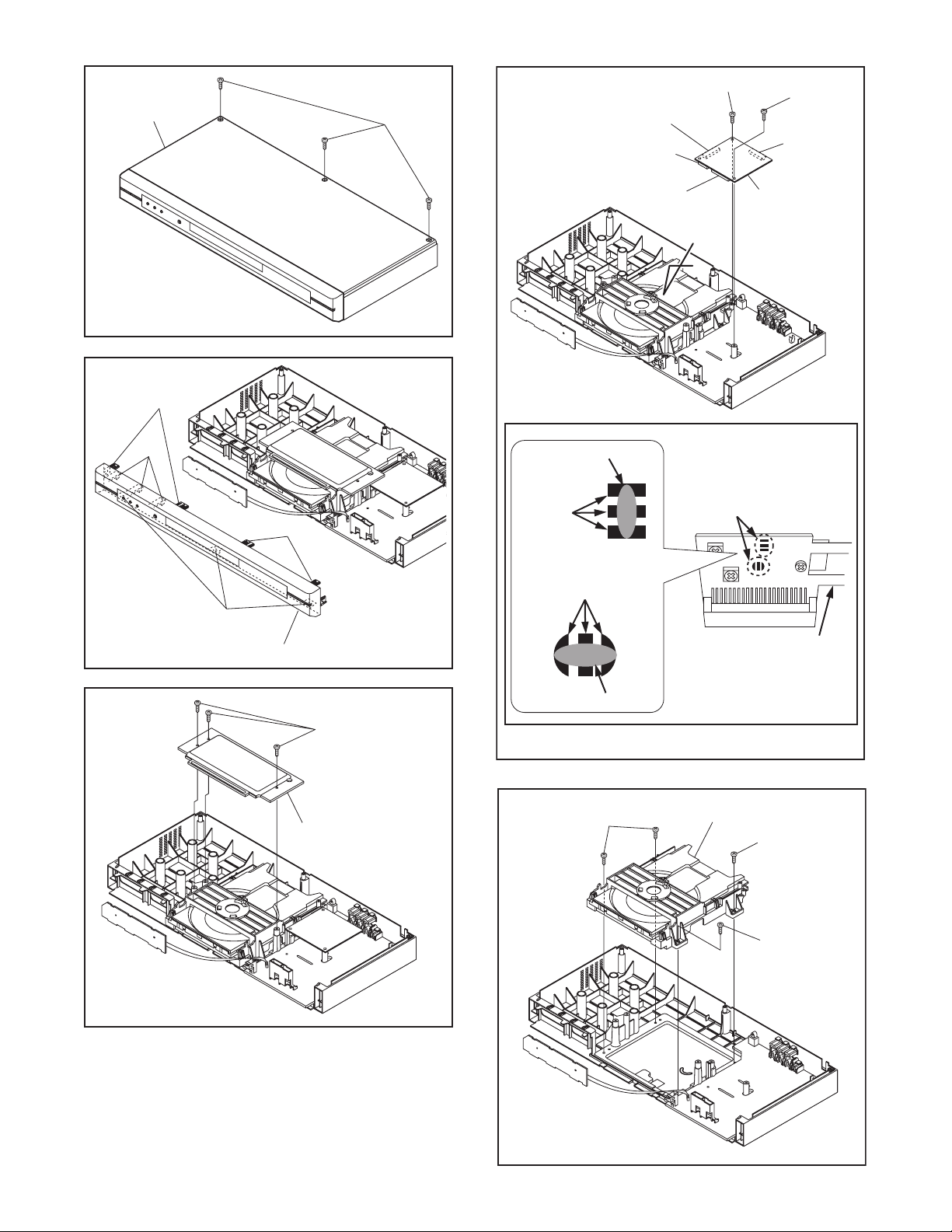

Page 11

[1] T op Case

(S-4)

(S-4)

(S-4)

[5] DVD Mecha

Fig. 5

(S-1)

CN201

CN301

(S-3B)

(S-3A)

CN601

(L-1)

(L-3)

(L-1)

(L-2)

[2] Front Assembly

Fig. 1

Fig. 2

Short

lands

Short lands

Solder

OR

CN401

[4] DVD Main

CBA Unit

A

Short the three short lands

by soldering.

(Either of two places.)

FPC Cable

[3] Reinforce Plate

(S-2)

Fig. 3

Solder

View for A

Fig. 4

1-6-2

E5943DC

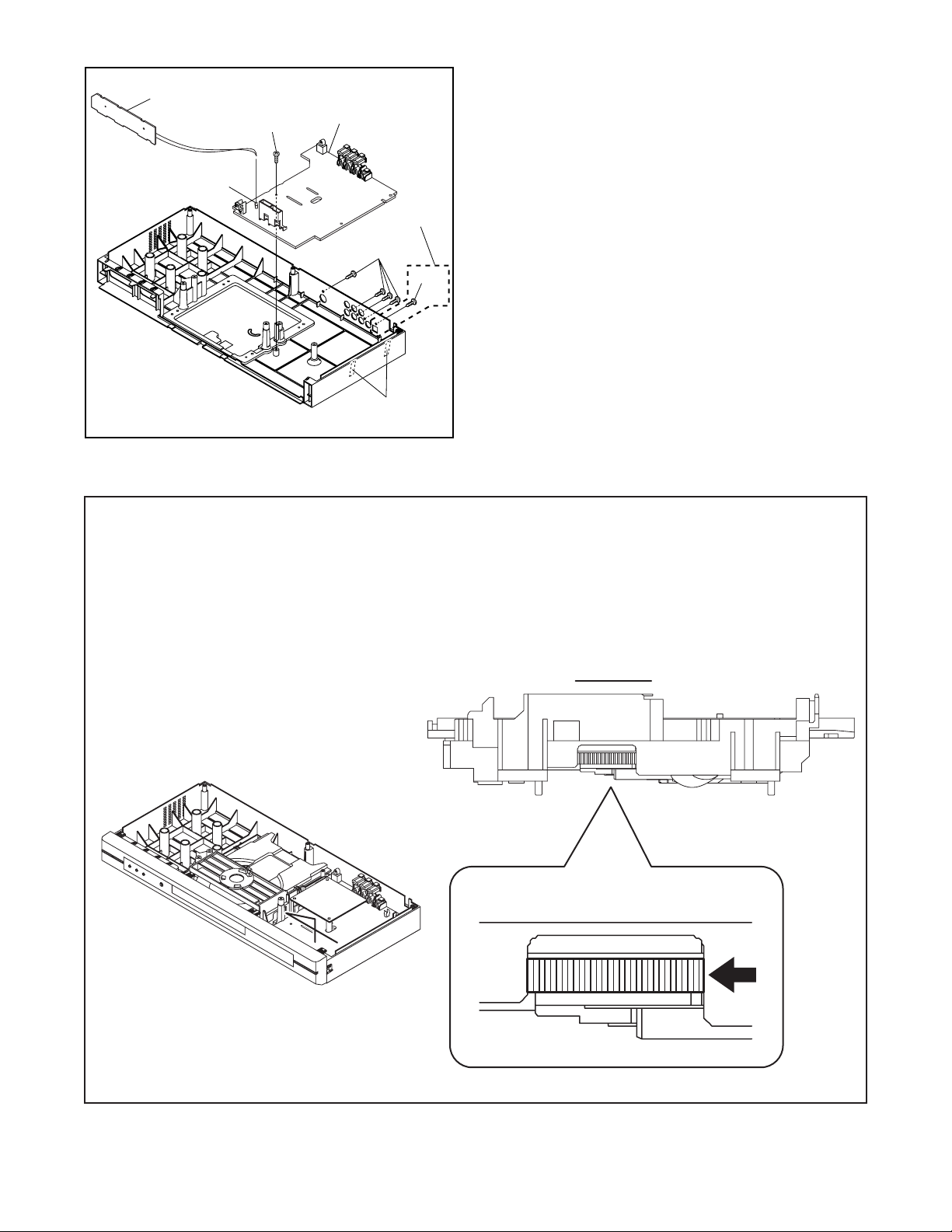

Page 12

[7] Function CBA

(S-5)

CN2001

[6] AV CBA

DV-DL80X

only

(S-6)

(L-5)

(S-6)

Fig. 6

HOW TO EJECT MANUALLY (Method 1)

1 Remove the Top Case.

2 Remove the Reinforce Plate.

3 Rotate the roulette in the direction of the arrow as shown below.

Rotate this roulette in

the direction of the arrow

A

View for A

1-6-3

E5943DC

Page 13

HOW TO EJECT MANUALLY (Method 2)

1 Turn the unit over.

2 Insert the shaft less than a diameter of 3 mm (e.g. screwdriver) straightly into the opening

as shown.

3 Turn the shaft along with the opening clockwise.

4 Repeat steps 2 and 3 until the tray will open.

5 Pull the tray slowly with a hand.

View for B

Rear

Turn the shaft along with

the opening clockwise.

Shaft

(e.g. screwdriver)

Opening

B

Front

1-6-4

E5943DC

Page 14

s.

F

e

s.

F

e)

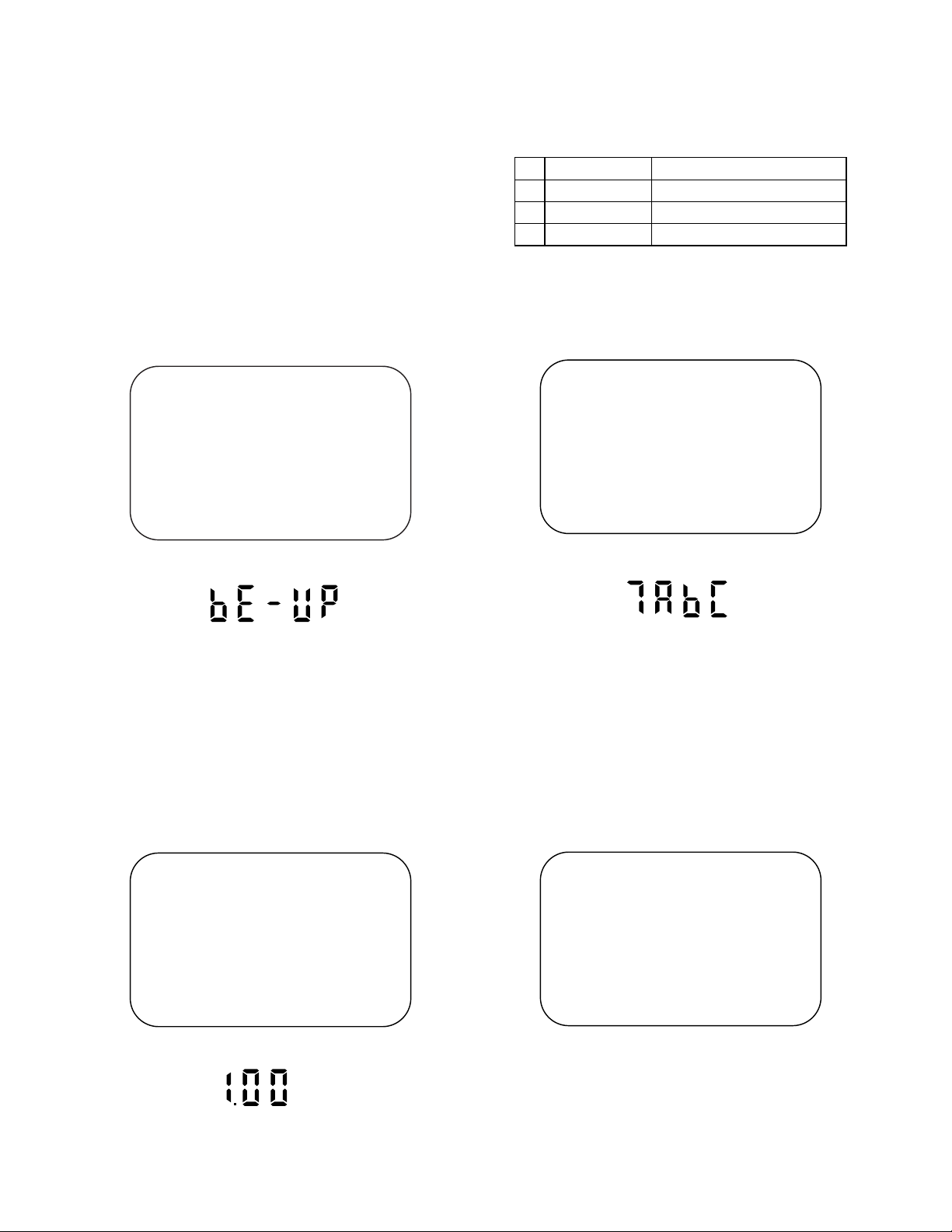

FIRMWARE RENEWAL MODE

s.

F

e)

s.

FIRMWARE is built-in program to operate DVD player.

To get rid of error when playing new software (disc) in

the market, FIRMWARE version is updated. Perform

the following to update the FIRMWARE version.

1. Turn the power on and remove the disc on the tray.

2. To put the DVD player into version up mode, press

[9], [8], [7], [6], and [DIRECT SKIP] buttons on the

remote control unit in that order. The tray will open

automatically.

Fig. a appears on the screen and Fig. b appears on

the VFD.

"

" differ depending on the model

*******

F/W Version Up Mode Model No : *******

Please insert a DISC

for F/W Version Up.

Fig. a Version Up Mode Screen

VERSION : *.**

EXIT: POWER

The appearance shown in (*2) of Fig. c is described

as follows:

AppearanceNo. State

1

Reading... Sending files into the memory

2

Erasing... Erasing previous version data

Programming...

3 Writing new version data

5. After programming is finished, the tray opens automatically. Fig. e appears on the screen and the

checksum in (*3) of Fig. e appears on the VFD.

(Fig. f)

"

" differ depending on the model

*******

F/W Version Up Mode

VERSION : E5****_****.ab5

Completed

SUM : 7ABC (*3)

Fig. e Completed Program Mode Screen

Model No : *******

VERSION : *.**

ig. b VFD in Version Up Mod

The DVD player can also enter the version up mode

with the tray open. In this case, Fig. a will be shown

on the screen while the tray is open.

3. Load the disc for version up.

4. The DVD player enters the F/W version up mode

automatically. Fig. c appears on the screen and Fig.

d appears on the VFD. If you enter the F/W for

different models, "Disc Error" will appear on the

screen, then the tray will open automatically.

"

" differ depending on the model

*******

F/W Version Up Mode Model No : *******

VERSION : E5****_****.ab5

Reading...(*2)

Fig. c Programming Mode Screen

ig. d VFD in Programming Mode (Exampl

VERSION : *.**

ig. f VFD upon Finishing the Programming Mode (Exampl

At this time, no buttons are available.

6. Remove the disc on the tray.

7. Unplug the AC cord from the AC outlet. Then plug it

again.

8. Turn the power on by pressing the [OPERATE]

button and the tray will close.

9. Press [1], [2], [3], [4], and [ON SCREEN] buttons on

the remote control unit in that order.

Fig. g appears on the screen.

"

" differ depending on the model

*******

MODEL : *******

Version

Region

: *.**

: *

EXIT: POWEREEPROM CLEAR : CLEAR

Fig. g

10.Press [CLEAR] button on the remote control unit.

Fig. h appears on the screen.

1-7-1

E5945TEST

Page 15

"

s.

" differ depending on the model

*******

MODEL : *******

Version

Region

: *.**

: *

EXIT: POWEREEPROM CLEAR : CLEAR

EEPROM CLEAR : OK

Fig. h

When "OK" appears on the screen, the factory

default will be set. Then the firmware renewal mode

is complete.

11.To exit this mode, press [OPERATE] button.

1-7-2

E5945TEST

Page 16

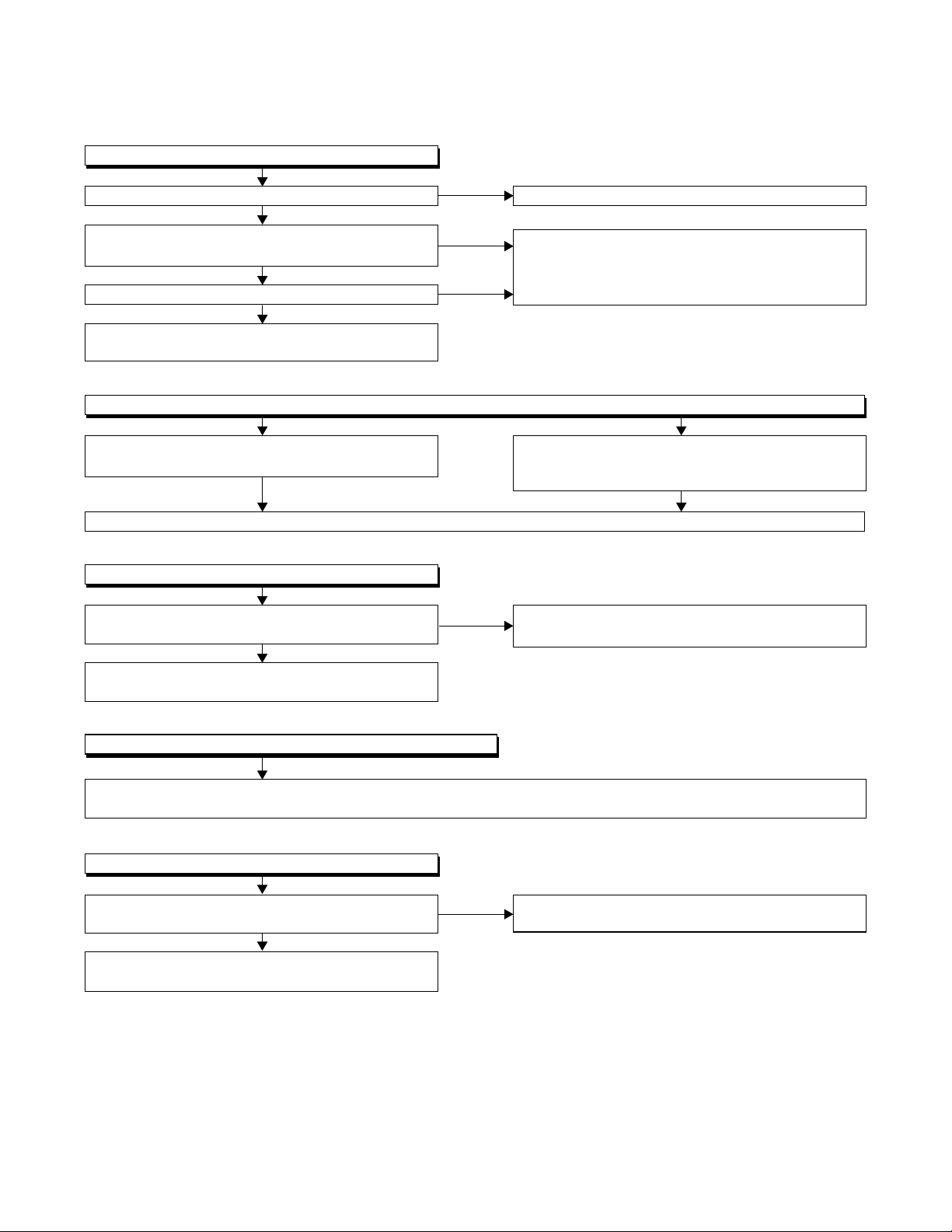

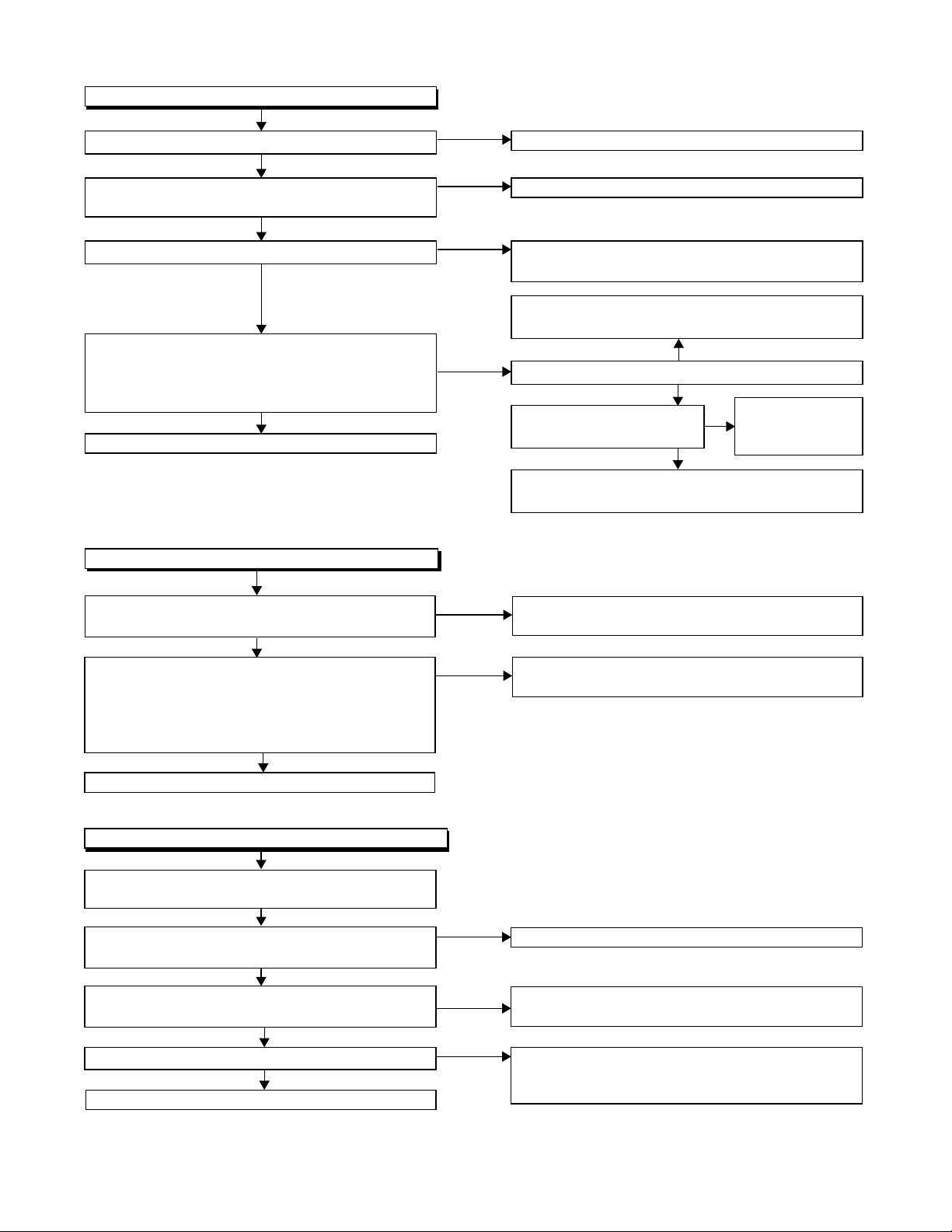

FLOW CHART NO.1

.

The power cannot be turned on.

TROUBLESHOOTING

Is the fuse normal?

Yes

Is normal state restored when once unplugged

power cord is plugged again after several seconds?

Yes

Is the EV +3.3V line voltage normal?

Yes

Check each rectifying circuit of the secondary circuit

and service it if defective.

FLOW CHART NO.2

The fuse blows out.

Check the presence that the primary component

is leaking or shorted and service it if defective.

After servicing, replace the fuse.

FLOW CHART NO.3

When the output voltage fluctuates.

Does the photo coupler circuit on the secondary

side operate normally?

Yes

Check IC1001, D1012, D1024 and their periphery,

and service it if defective.

No

No

No

No

See FLOW CHART No.2 <The fuse blows out.>

Check if there is any leak or short-circuiting on the

primary circuit component, and service it if defective

(Q1001, Q1003, Q1008, T1001, D1001, D1002,

D1004, D1005, D1011, C1003, C1005)

Check the presence that the rectifying diode or

circuit is shorted in each rectifying circuit of

secondary side, and service it if defective.

Check IC1001, IC1006, D1048 and their

periphery, and service it if defective.

FLOW CHART NO.4

When buzz sound can be heard in the vicinity of power circuit.

Check if there is any short-circuit on the rectifying diode and the circuit in each rectifying circuit of the secondary

side

, and service it if defective.

FLOW CHART NO.5

-FL is not outputted.

Is approximately -23V voltage supplied to the

anode of D1003?

Check if there is any leak or short-circuit

on the loaded circuit, and service it if defective.

(D1003, D1006, D1008, D1016, D1030, IC1002, Q1002, Q1004, Q1005, Q1011)

No

Yes

Check D1003 and periphery circuit, and service it

if defective.

1-8-1

E5943TS

Page 17

.

FLOW CHART NO.6

P-ON+10V (EV+11V) is not outputted.

Is 11V voltage supplied to the emitter of Q1002?

Yes

Is the voltage of base on Q1002 lower than the

voltage of emitter on Q1002 when turning the power on?

Yes

Replace Q1002.

FLOW CHART NO.7

P-ON+5V is not outputted. (EV+11V is outputted normally.)

Is the "H" signal inputted into the base of Q1004?

Yes

Replace Q1004.

FLOW CHART NO.8

P-ON+3.3V is not outputted. (P-ON+10V is outputted normally.)

Is 3.3V voltage supplied to the collector of Q1011?

Yes

Replace Q1011 or R1067.

No

No

No

No

Check D1030, D1048, C1035, C1048, L1009 and

the periphery circuit, and service it if defective.

Check Q1016 and PWRCON line and service it if

defective.

Check R1068 and D1046, and service it if defective

Check D1008, C1007, C1038, L1007 and the

periphery circuit, and service it if defective.

FLOW CHART NO.9

EV+5V is not outputted.

Is EV+11V outputted normally?

Yes

Check D1047 and the periphery circuit,

and service it if defective.

FLOW CHART NO.10

EV+1.2V is not outputted.

Is 2.5V voltage supplied to Pin(1) of IC1002?

Yes

Replace IC1002.

No

No

Refer to "FLOW CHART NO.6"

<P-ON+10V (EV+11V) is not outputted.>

Check D1006, C1014, L1008 and the periphery

circuit, and service it if defective.

1-8-2

E5943TS

Page 18

.

FLOW CHART NO.11

.

The fluorescent display tube does not light up.

Is 3.3V voltage supplied to Pins(6,24) of IC2001?

Yes

Is the voltage of approximately -20V supplied to

Pin(15) of IC2001?

Yes

Is there 500kHz oscillation at Pin(26) of IC2001?

Yes

Are the filament voltage supplied between

Pins(1, 2) and Pins(29, 30) of the fluorescent

display tube? And the negative voltage applied

between these pins and GND?

Yes

Replace the fluorescent display tube.

FLOW CHART NO.12

The key operation is not functioning.

No

No

No

No

Check the EV+3.3V line and service it if defective.

Check the -FL (-20V) line and service it if defective

Check R2002, IC2001 and their periphery, and

service it if defective.

Check D1016, D1017, T1001, and their periphery,

and service it if defective.

No

Is -15V voltage supplied to collector of Q1005?

Yes

Is the "H" signal inputted

to base of Q1016?

Check Q1015, Q1016, D1055, and

their periphery, and service it if defective.

No

Yes

Check PWRCON

line, and service

it if defective.

Are the contact point and the installation state of the

key switches (SW2101, SW2104-2108) normal?

Yes

When pressing each switches (SW

2108

), do the voltage of each pin of IC2001

(shown below) increase?

SW2104, 2106, 2107: IC2001 3PIN

SW2101, 2105, 2108: IC2001 4PIN

Yes

Replace IC2001.

FLOW CHART NO.13

No operation is possible from the remote control unit.

Operation is possible from the DVD, but no

operation is possible from the remote control unit.

Is 5V voltage supplied to Pin(3) terminal of

the infrared remote control receiver (RM2001)?

Yes

Is the "L" pulse sent out Pin(1) terminal of receiver

(RM2001) when the infrared remote control is activated?

Yes

Is the "L" pulse supplied to the Pin(22) of CN1001?

Yes

Replace DVD Main CBA.

2101, SW2104-

No

No

No

No

No

Re-install the switches (

correctly or replace the poor switch.

Check the switches (

their periphery, and service it if detective.

Check EV+5V line and service it if defective.

Replace the infrared remote control receiver (RM2001)

Or replace the remote control unit.

Check the line between Pin(1) terminal of receiver

(RM2001) and Pin(22) of CN1001, and service it if

defective.

SW2101, SW2104-2108

SW2101, SW2104-2108

)

) and

1-8-3

E5943TS

Page 19

FLOW CHART NO.14

The disc tray cannot be opened and closed. (It can be done using the remote control unit.)

Is the normal control voltage inputted to Pin(4) of

IC2001?

operation is not functioning.>

Refer to "FLOW CHART NO.15" <The disc tray

cannot be opened and closed.>

FLOW CHART NO.15

The disc tray cannot be opened and closed.

Replace the DVD Main CBA.

No improvement can be found.

Replace the DVD Mecha.

FLOW CHART NO.16

[No Disc] indicated. (When the focus error occurs.)

Replace the DVD Main CBA.

No improvement can be found.

Replace the DVD Mecha.

Refer to "FLOW CHART NO.12" <The key

Yes

Yes

Yes

No

No

No

Replace the "OPEN/CLOSE" button (SW2108).

Original DVD Main CBA is poor.

Original DVD Main CBA is poor.

FLOW CHART NO.17

[No Disc] indicated. (When the focus servo is not functioning.)

Replace the DVD Main CBA.

No improvement can be found.

Yes

Replace the DVD Mecha.

FLOW CHART NO.18

[No Disc] indicated. (When the laser beam does not light up.)

Replace the DVD Main CBA.

No improvement can be found.

Yes

Replace the DVD Mecha.

No

No

Original DVD Main CBA is poor.

Original DVD Main CBA is poor.

1-8-4

E5943TS

Page 20

FLOW CHART NO.19

Both functions of picture and sound do not operate normally.

Replace the DVD Main CBA.

No improvement can be found.

Yes

Replace the DVD Mecha.

FLOW CHART NO.20

Picture does not appear normally.

Set the disc on the disc tray, and playback.

Are the video signals outputted to each pin of

CN1601 on the AV CBA?

CN1601 4PIN Cr/Pr

CN1601 6PIN Cb/Pb

CN1601 8PIN S-Y

CN1601 10PIN S-C

Yes

Are the video signals shown above inputted into

each pin of IC1402?

IC1402 1PIN S-C

IC1402 3PIN S-Y

IC1402 6PIN Cb/Pb

IC1402 8PIN Cr/Pr

Yes

Are the video signals outputted to each pin

of IC1402?

No

No

No

Original DVD Main CBA is poor.

Replace the DVD Main CBA or DVD Mecha.

Check the line between each pin of CN1601 and

each pin of IC1402 on the AV CBA, and service

it if detective.

CN1601 10PIN → IC1402 1PIN S-C

CN1601 8PIN → IC1402 3PIN S-Y

CN1601 6PIN → IC1402 6PIN Cb/Pb

CN1601 4PIN → IC1402 8PIN Cr/Pr

IC1402 13PIN S-Y

IC1402 11PIN Cb/Pb

IC1402 10PIN Cr/Pr

IC1402 14PIN CVBS

IC1402 15PIN S-C

Yes

Are the video signals outputted to the specific

output terminal?

Are the luminance signals outputted to the

S-OUT terminal (JK1401)?

Are the chroma signals outputted to the

S-OUT terminal (JK1401)?

Are the component video signals outputted to the

VIDEO OUT terminal (JK1404)?

Are the composite video signals outputted to

the VIDEO OUT terminal (JK1404)?

No

No

No

No

No

Is 5V voltage applied to the pin(4, 12) of IC1402?

Yes No

Replace IC1402.

Check the periphery of JK1401 from

Pin (13) of IC1402 and service it if detective.

Check the periphery of JK1401 from

Pin (15) of IC1402 and service it if detective.

Check the periphery of JK1404 from Pins (10, 11,

13) of IC1402 and service it if detective.

Check

the periphery of

IC1402

and service it if detective.

Check P-ON+5V line and

service it if detective.

JK1404 from Pin(14) of

1-8-5

E5943TS

Page 21

FLOW CHART NO.21

Audio is not outputted normally.

Set the disc on the disc tray, and playback.

Are the analog audio signals outputted to each pin

of CN1601 on AV CBA?

CN1601 14PIN AUDIO-L

CN1601 16PIN AUDIO-R

Yes

Are the analog audio signals inputted to each pin

of IC1201.

IC1201 2PIN AUDIO-L

IC1201 6PIN AUDIO-R

Yes

Is the "H" level mute signal outputted to CN1601

on AV CBA ?

CN1601 13PIN A-MUTE

CN1601 15PIN A-R-MUTE

Yes

Are the analog audio signals outputted to each pin

of IC1201?

IC1201 1PIN AUDIO-L

IC1201 7PIN AUDIO-R

Yes

Are the audio signals outputted to the specific

output terminal?

Are the audio signals outputted to the audio

terminal (JK1404)?

No

No

No

No

No

Replace the DVD Main CBA or DVD Mecha.

Check each line between each pin of CN1601

and each pin of IC1201 on AV CBA, and service it

if detective.

CN1601 14PIN → IC1201 2PIN AUDIO-L

CN1601 16PIN → IC1201 6PIN AUDIO-R

Replace the DVD Main CBA or DVD Mecha.

Replace IC1201.

Check the periphery between Pins(1,7) of IC1201

and JK1404, and service it if detective.

1-8-6

E5943TS

Page 22

BLOCK DIAGRAMS

System Control / Servo Block Diagram

FL2001

GRID FIP

~

23

17

~

7G

1G

789

a/KEY-1

b/KEY-2

SEGMENT

10

c/KEY-3

d/KEY-4

KEY

MATRIX

FUNCTION CBA

KEY-1 5

KEY-3 4

K2 1

KEY-2 3

KEY-4 6

5

CN2001 CN2101

12

11

131416

i

f

g

h

e

K1 2

4

1

3

6

2

3

4

K1

K2

IC101

(MICRO CONTROLLER)

ADAC-MD

A-MUTE

PCM-SCLK

57

88

163

56 ADAC-MC

86 ADAC-ML

IC462

+3.3V

IC461

+3.3V

RESET73

RESET

1 3

RESET

2 1

VREF

(SERVO DRIVE)

IC301

FOCUS DRIVE

FD-OFST

148

146

26

25

27

-

+

-

+

FOCUS

ACTUATOR

DRIVE

15

16

24

IC2001

(FRONT PANEL CONTROL)

TD-OFST

139

+

TRACKING

TRACKING

147

-

+

ACTUATOR

14

DRIVE

-

DRIVE

13

312

SPDL

76

-

+

-

+

SPINDLE

MOTOR

DRIVE

12

11

645

FP-STB

FP-DIN

2

28

CN1001

FP-STB 20

FP-DIN 19

2019211822

CN401

82

60

FP-DIN

FP-STB

SLD75

23

-

+

SLED

MOTOR

DRIVE

17

18

FP-DOUT

FP-CLK

1

27

FP-DOUT 21

FP-CLK 18

REMOTE 22

61

67

59

FP-CLK

REMOTE

FP-DOUT

IC202

(OP AMP)

SENSOR

REMOTE

RM2001

SP-ROT

143

1

2

3

SL-AMP

81

7

14

6

5

+3.3V

13

12

TRAY-IN

66

DVD MAIN CBA UNIT AV CBA

A-MUTE

ADAC-MD

PCM-SCLK

TO

VIDEO/ AUDIO

ADAC-MC

BLOCK DIAGRAM

ADAC-ML

FS(+)

FS(-)

TO DIGITAL SIGNAL

TS(+)

TS(-)

PROCESS BLOCK

DIAGRAM

1-9-1

3SP(+)

4SP(-)

5TRAY-IN

6GND

7SL(-)

CN301

8SL(+)

DRIVE CBA

TRAY-IN

SPINDLE

MOTOR

M

SLED

MOTOR

M

E5943BLS

Page 23

Digital Signal Process Block Diagram

TO

VIDEO

/AUDIO

BLOCK

DIAGRAM

TO

VIDEO

/AUDIO

BLOCK

DIAGRAM

FLASH

ROM

Note:

IC103 is not supplied separatery.

Be sure to replace with the DVD Main CBA unit when servicing IC103.

*

DATA(AUDIO) SIGNAL

DATA

RAM

DSP

INST.

ROM

DECODER

STREAM

I/F

DATA

RAM

I/O

INST.

ROM

PROCESSOR

SPDIF

177

PCM-BCK

PCM-DATA

PCM-LRCLK

170

171

AUDI O

I/F

UMAC

169

SERIAL

GENERAL

I/O

INTERRUPT

CPU

I/F

READ

MEMORY

VIDEO-Y

Y

CONTROLLER

149

D/A

TIMER

VIDEO-C

158

C

D/A

NTSC/PAL

VIDEO

WATCH DOG

TIMER

VIDEO-Cr/Pr

152

Cr/Pr

D/A

ENCODER

I/F

REMOTE

CONTROL

VIDEO-Cb/Pb

151

Cb/Pb

D/A

32BIT CPU

BCU

DATA

INST

DEBUG

RAM

RAM

IC103 (FLASH ROM)

~

*

1

23~51

9

~

162548

FADR (0-19)

~

293638

FDQ (0-15)

~

45

DATA(VIDEO/AUDIO) SIGNAL VIDEO SIGNAL

~~

222629

IC503 (SDRAM) IC101 (MICRO CONTROLLER)

DECODER

I/F

ECC

EXTERNAL

MEMORY

I/F

SDRAM ADDRESS(0-11)

~

217

SDRAM ADDRESS(0-11)

238

35

SDRAM

~~

1

~~

2

18

134253

SDRAM DATA(0-15)

252

SDRAM DATA(0-15)

256

114

115

DMA

116

DVD/CD

RF

SIGNAL

117

132

CN201

C16

FORMATTER

PROCESS

CIRCUIT

131

134

A17

D18

192~212

CPU

I/F

BCU

WATCH DOG

5

9

GND(LD)

GND(CD-PD)

INTERRUPT

TIMER

TIMER

CONTROLLER

CD/DVD

83

TO SYSTEM

CONTROL/SERVO

BLOCK DIAGRAM

6

IC201

(SW)

4

1 3

CD DVD

FS

TS

FS(+)

CN201

FS(+) 2

FS(-)

FS(-) 3

TS(+)

TS(+) 1

TS(-)

DVD MAIN CBA UNIT

TS(-) 4

PICK-UP

UNIT

32BIT

CPU

INST.

ROM

DATA

RAM

126

124

125

AMP

Q253,Q254

AMP

CN201

CD-LD 10

DVD-LD 8

123

Q251,Q252

6

PD-MONI 7

GND(DVD-PD)

133

129

130

F12

B15

E14

CD/DVD 19

DETECTOR

1-9-2

E5943BLD

Page 24

Video / Audio Block Diagram

JK1401

S-VIDEO OUT

AUDIO SIGNALDATA(AUDIO) SIGNAL

2

1

3 4

YC

VIDEO SIGNAL

15

JK1404

WF3

COMPOSITE

VIDEO OUT

14

VIDEO-Y

OUT

13

VIDEO-Cb/Pb

OUT

VIDEO-Cr/Pr

11

10

OUT

IC1204

DV-SL80X

DIGITAL

OPTICAL

AUDIO

OUT

JK1202

AMP

Q1351

COAXIAL

(AMP)

IC1201

WF6

JK1404

WF4

1

3

AUDIO-L

OUT

2

AUDIO-R

675

WF5

OUT

+5V

Q1202

Q1204

Q1201

+3.3V

2dB

AMP

LPF DRIVER

4dB

AMP

IC1402 (VIDEO DRIVER)

1

WF2

88VIDEO-Y

10 10VIDEO-C

CN601 CN1601

DRIVER

2dB

AMP

2dB

4dB

WF1

66VIDEO-Cb/Pb

44VIDEO-Cr/Pr

AMP

LPF DRIVER

AMP

3

2dB

AMP

LPF DRIVER

4dB

AMP

6

2dB

AMP

LPF DRIVER

4dB

AMP

8

7

L-CH

LPF+AMP

DAC

ENHANCED

MULTI-LEVEL

DELTA-SIGMA

4X/8X

/FUNCTION

DIGITAL FILTER

OVERSAMPLING

CN601 CN1601

8

R-CH

LPF+AMP

DAC

MODULATOR

CONTROLLER

19

SPDIF

19

16

AUDIO-R

14 14AUDIO-L

16

15 15A-R-MUTE

13 13A-MUTE

11

ZERO DETECT

16

SYSTEM CLOCK

DVD MAIN CBA UNIT AV CBA

VIDEO-Y

VIDEO-C

TO DIGITAL

SIGNAL PROCESS

VIDEO-Cb/Pb

VIDEO-Cr/Pr

BLOCK DIAGRAM

1-9-3

PORT

SERIAL

IC601 (AUDIO DAC)

123

PCM-BCK

SPDIF

PCM-DATA

PCM-LRCLK

TO

DIGITAL

SIGNAL

PROCESS

BLOCK

DIAGRAM

SERIAL

131415

ADAC-MD

ADAC-MC

ADAC-ML

CONTROL

PCM-SCLK

A-MUTE

TO

SYSTEM

CONTROL

/SERVO

BLOCK

DIAGRAM

E5943BLV

Page 25

Power Supply Block Diagram

EV+1.2V

TO CN401

1,2

CN1001

EV+3.3V

3,4,5

EV+11V7P-ON+5V6P-ON+3.3V17PWRCON

8,9

-FL

The voltage for parts in hot circuit is measured using

hot GND as a common terminal.

NOTE :

D1003

RECTIFIER

11

CAUTION

FOR CONTINUED PROTECTION AGAINST FIRE HAZARD,

REPLACE ONLY WITH THE SAME TYPE FUSE.

F1

P-ON+10V

F2

+1.2V

IC1002

SCHOTTKY

D1006

12

EV+5V

EV+3.3V

REG.

BARRIER

D1008

P-ON+5V

SCHOTTKY

P-ON+3.3V

Q1002

BARRIER

D1030

131514

RECTIFIER

Q1011

Q1004

Q1016

Q1015

Q1005

REG

2

IC1006

(SHUNT REGULATOR)

D1016

RECTIFIER

16

17

18

1

T1001

2

BRIDGE

RECTIFIER

D1001, D1002

D1004, D1005

LINE

FILTER

L1001

CAUTION !

Fixed voltage ( or Auto voltage selectable ) power supply circuit is used in this unit.

If Main Fuse (F1001) is blown, check to see that all components in the power supply

circuit are not defective before you connect the AC plug to the AC power supply.

Otherwise it may cause some components in the power supply circuit to fail.

HOT CIRCUIT. BE CAREFUL.

F1001

T1.6A L 250V

AC1001

AC CORD

Q1001

Q1003

4

SWITCHING

CONTROL

SWITCHING

4

IC1001

ERROR

7

6

VOLTAGE DET

3

AV CBA

HOT

DV-SL80

Q1008

LATCH

1-9-4

E5943BLP

Page 26

e

SCHEMATIC DIAGRAMS / CBA’S AND TEST POINTS

(

Standard Notes

WARNING

Many electrical and mechanical parts in this chassis

have special characteristics. These characteristics often

pass unnoticed and the protection afforded by them

cannot necessarily be obtained by using replacement

components rated for higher voltage, wattage, etc.

Replacement parts that have these special safety

characteristics are identified in this manual and its

supplements; electrical components having such

features are identified by the mark " ! " in the schematic

diagram and the parts list. Before replacing any of these

components, read the parts list in this manual carefully.

The use of substitute replacement parts that do not

have the same safety characteristics as specified in the

parts list may create shock, fire, or other hazards.

Capacitor Temperature Markings

Mark

(B)

(F)

(SR)

(Z)

Capacity

change rate

±10%

+30 - 80%

±15%

+30 - 80%

Standard

temperature

20°C

20°C

20°C

20°C

Temperatur

range

-25~+85°C

-25~+85°C

-25~+85°C

-10~+70°C

Notes:

1. Do not use the part number shown on these drawings for ordering. The correct part number is shown

in the parts list, and may be slightly different or

amended since these drawings were prepared.

2. All resistance values are indicated in ohms (K=103,

M=106).

3. Resistor wattages are 1/4W or 1/6W unless otherwise specified.

4. All capacitance values are indicated in µF

(P=10-6 µF).

5. All voltages are DC voltages unless otherwise specified.

6. Electrical parts such as capacitors, connectors, diodes, IC's, transistors, resistors, switches, and fuses

are identified by four digits. The first two digits are

not shown for each component. In each block of the

diagram, there is a note such as shown below to

indicate these abbreviated two digits.

Capacitors and transistors are represented by the

following symbols.

CBA Symbols

(Top View) (Bottom View)

+

Electrolytic Capacitor

Bottom View)

Transistor or Digital Transistor

E C B

(Top View)

E C B

(Top View)

E C B

NPN Transistor

NPN Digital Transistor

(Top View)

E C B

(Top View)

E C B

PNP Transistor

PNP Digital

Transistor

Schematic Diagram Symbols

Digital Transistor

1-10-1

SC-FN2

Page 27

LIST OF CAUTION, NOTES, AND SYMBOLS USED IN THE SCHEMATIC DIAGRAMS ON THE FOLLOWING

T

both PLAY & STOP modes

e

e

1

".

".

3

2

1

PAGES:

1. CAUTION:

FOR CONTINUED PROTECTION AGAINST FIRE HAZARD, REPLACE ONLY WITH THE SAME TYPE FUSE.

2. CAUTION:

Fixed Voltage (or Auto voltage selectable) power supply circuit is used in this unit.

If Main Fuse (F1001) is blown, first check to see that all components in the power supply circuit are not defective

before you connect the AC plug to the AC power supply. Otherwise it may cause some components in the power

supply circuit to fail.

3. Note:

(1)Do not use the part number shown on the drawings for ordering. The correct part number is shown in the parts

list, and may be slightly different or amended since the drawings were prepared.

(2)To maintain original function and reliability of repaired units, use only original replacement parts which are listed

with their part numbers in the parts list section of the service manual.

4. Voltage indications for PLAY and STOP mode on the schematics are as shown below:

2

(Unit: Volt)

he same voltage for

1

5.0

3

5.0

(2.5)

Indicates that the voltage

is not consistent here.

PLAY mod

STOP mod

5. How to read converged lines

-D3

Distinction Area

Line Number

(1 to 3 digits)

Examples:

1. "1-D3" means that line number "1" goes to area "D3

2. "1-B1" means that line number "1" goes to area "B1

6. Test Point Information

: Indicates a test point with a jumper wire across a hole in the PCB.

: Used to indicate a test point with a component lead on foil side.

: Used to indicate a test point with no test pin.

: Used to indicate a test point with a test pin.

AREA D3

AREA B1

1-D3

ABCD

1-B1

1-10-2

SC-FN2

Page 28

DVD Main 1/3 Schematic Diagram

1-10-3

1-10-4

E5943SCD1

Page 29

DVD Main 2/3 Schematic Diagram

1-10-5

1-10-6

E5943SCD2

Page 30

IC101 VOLTAGE CHART

PIN.NO PLAY STOP PIN. NO PLAY STOP PI N. NO PLAY STOP PIN.NO PLAY ST OP

129 2.3 2.3 161 3.4 3.4 193 ~ ~ 225 3.4 3.4

130 2.3 2.3 162 0 0 194 ~ ~ 226 ~ ~

131 2.3 2.3 163 1.8 1.8 195 ~ ~ 227 ~ ~

132 2.4 2.3 164 0 0 196 3.4 3.4 228 ~ ~

133 2.4 2.4 165 1.7 1.8 197 ~ ~ 229 0 0

134 2.4 2.4 166 1.7 1.7 198 ~ ~ 230 ~ ~

135 2.3 2.3 167 3.4 3.4 199 ~ ~ 231 3.4 3.4

136 2.3 2.3 168 0 0 200 ~ ~ 232 1.3 1.6

137 2.3 2.3 169 1.8 1.8 201 0 0 233 ~ ~

138 2.3 2.3 170 1.7 1.7 202 3.4 3.4 234 1.9 2.3

139 1.7 1.7 171 1.3 0.1 203 ~ ~ 235 0 0

140 ----- ----- 172 1.3 1.3 204 ~ ~ 236 1.3 1.3

141 3.4 3.4 173 0 0 205 0 0 237 ~ ~

142 1.3 1.3 174 ----- ----- 206 ~ ~ 238 ~ ~

143 2.1 1.7 175 ----- ----- 207 ~ ~ 239 3.4 3.4

144 2.2 2.2 176 ----- ----- 208 ~ ~ 240 3.4 3.3

145 0 0 177 1.8 1.7 209 3.4 3.4 241 1.9 1.9

146 1.7 1.7 178 3.4 3.5 210 ~ ~ 242 0 0

147 1.8 1.7 179 0 0 211 ~ ~ 243 1.9 1.9

148 1.7 1.7 180 ----- ----- 212 ~ ~ 244 3.4 3.3

149 0.6 0.5 181 ----- ----- 213 0 0 245 3.4 3.4

150 3.4 3.4 182 ----- ----- 214 ----- ----- 246 3.4 3.4

151 0.5 0.6 183 ----- ----- 215 ----- ----- 247 0 0

152 0.5 0.4 184 ----- ----- 216 3.4 3.4 248 3.3 3.4

153 1.4 1.3 185 ----- ----- 217 ~ ~ 249 3.2 3

154 1.4 1.3 186 ----- ----- 218 0 0 250 0 0

155 2.4 2.4 187 ----- ----- 219 1.3 1.3 251 3.2 3.0

156 ----- ----- 188 ----- ----- 220 ~ ~ 252 ~ ~

157 0 0 189 ----- ----- 221 ~ ~ 253 0 0

158 0.9 0.9 190 3.4 3.5 222 0 0 254 ~ ~

159 3.4 3.4 191 0 0 223 ~ ~ 255 3.4 3.4

160 0 0 192 ~ ~ 224 ~ ~ 256 ~ ~

PIN.NO PLAY STOP PIN. NO PLAY STOP PI N. NO PLAY STOP PIN.NO PLAY STOP

1 ~ ~ 33 ~ ~ 65 0 0 97 ----- -----

2 ~ ~ 343.43.4663.43.5983.43.4

3 0 0 35 0 0 673.23.2990.90.8

4 ~ ~36~ ~68 0 01000 0

5 ~ ~ 37 ~ ~ 69 ----- ----- 101 2.4 2.4

6 3.4 3.4 38 0.4 0.3 70 3.4 3.4 102 2.2 2.2

7 ~ ~ 39 ~ ~ 71 ----- ----- 103 1.9 1.9

8 ~ ~ 40 ~ ~ 72 ----- ----- 104 0.4 0.3

90041~~733.43.410500

10 ~ ~ 42 ~ ~ 74 0 0 106 1.7 1.7

11 ~ ~ 43 ~ ~ 75 1.7 1.8 107 3.4 3.4

12 3.4 3. 4 44 1.3 1.3 76 2.3 1.8 108 ----- -----

13 ~ ~ 45 ~ ~ 77 ----- ----- 109 ----- -----

14 ~ ~ 46 ~ ~ 78 ----- ----- 110 1.9 1.9

15 ~ ~ 47 ~ ~ 79 ----- ----- 111 1.9 1.9

16 0 0 48 3.4 3.4 80 3.4 0.1 112 1.7 1.7

17 ~ ~ 49 0 0 81 0.1 0.1 113 1.7 1.7

18 ~ ~ 50 ~ ~ 82 2.8 2.8 114 1.7 1.7

19 3.4 3.4 51 ~ ~ 83 0.1 0.1 115 1.7 1.7

20 0 0 52 0.8 0.8 84 3.4 3.4 116 1.7 1.7

21 ----- ----- 53 0 0 85 0.1 0.1 117 1.7 1.7

22 3.5 3. 5 54 ----- ----- 86 3.6 3. 4 118 3.4 3.4

23 ~ ~ 55 ----- ----- 87 0 0 119 2.0 2.0

24 ~ ~ 56 3.4 3.4 88 3.5 0.1 120 1.7 1.7

25 ~ ~ 57 3.5 3.5 89 1.3 1.3 121 1.5 1.5

26 1.3 1. 3 58 ----- ----- 90 ----- ----- 122 0 0

27 ~ ~ 59 3. 4 3.4 91 ----- ----- 123 0.3 0.1

28 3.4 3. 4 60 3.4 3.4 92 ----- ----- 124 1.2 0.1

29 0 0 61 3.5 3.5 93 0 0 125 0.3 0.1

30 ~ ~ 62 3. 4 3.4 94 ----- ----- 126 0.1 0.1

31 ~ ~ 63 0 0 95 ----- ----- 127 2.3 2.3

32 ~ ~ 64 0 0 96 ----- ----- 128 1.7 1.7

1-10-7

1-10-8

Page 31

DVD Main 3/3 Schematic Diagram

Note:

*

IC103 is not supplied separately.

Be sure to replace with the DVD Main CBA unit when servicing IC103.

1-10-9

1-10-10

E5943SCD3

Page 32

AV 1/3 Schematic Diagram

CAUTION !

Fixed voltage ( or Auto voltage selectable ) power supply circuit is used in this unit.

If Main Fuse (F1001) is blown, check to see that all components in the power supply

circuit are not defective before you connect the AC plug to the AC power supply.

Otherwise it may cause some components in the power supply circuit to fail.

CAUTION

FOR CONTINUED PROTECTION AGAINST FIRE HAZARD,

REPLACE ONLY WITH THE SAME TYPE FUSE.

NOTE :

THE VOLTAGE FOR PARTS IN HOT CIRCUIT IS MEASURED USING

HOT GND AS A COMMON TERMINAL.

1-10-11

1-10-12

E5943SCAV1

Page 33

AV 2/3 Schematic Diagram

1-10-14

E5943SCAV21-10-13

Page 34

7G 6G 5G 4G 3G 2G 1G

a

b

c

d

e

f

g

c

d

e

ff

g

c

d

e

f

g

c

d

e

f

g

c

d

e

f

g

c

d

e

f

g

h

ii

a

b

a

b

a

b

a

b

a

b

FL2001 MATRIX CHART

REPEAT

TITLE

GROUP

VCR

CHP

REC

SACD

TRK

ALL

B

PSCAN

DVD

P

M

HD

V

CD

A

A

AV 3/3 & Function Schematic Diagram

7G

REPEAT

B

A

ALL

f

6G

TITLE

i

i

5G 4G 3G 2G 1G

CHP

REC

TRK

a

c

d

g

VCR

GROUP

SACD

PSCAN

DVD

b

PM

ef

HDVCD

A

1-10-15

1-10-16

E5943SCAV3

Page 35

DVD MAIN CBA Top View

1-10-17

1-10-18

BE5900G04012

Page 36

DVD MAIN CBA Bottom View

1-10-201-10-19

BE5900G04012

Page 37

AV CBA Top View

CAUTION !

Fixed voltage ( or Auto voltage selectable ) power supply circuit is used in this unit.

If Main Fuse (F1001) is blown, check to see that all components in the power supply

circuit are not defective before you connect the AC plug to the AC power supply.

Otherwise it may cause some components in the power supply circuit to fail.

CAUTION

FOR CONTINUED PROTECTION AGAINST FIRE HAZARD,

REPLACE ONLY WITH THE SAME TYPE FUSE.

NOTE :

The voltage for parts in hot circuit is measured

using hot GND as a common terminal.

BE5942F01011A1-10-221-10-21

Page 38

AV CBA Bottom View

CAUTION !

Fixed voltage ( or Auto voltage selectable ) power supply circuit is used in this unit.

If Main Fuse (F1001) is blown, check to see that all components in the power supply

circuit are not defective before you connect the AC plug to the AC power supply.

Otherwise it may cause some components in the power supply circuit to fail.

CAUTION

FOR CONTINUED PROTECTION AGAINST FIRE HAZARD,

REPLACE ONLY WITH THE SAME TYPE FUSE.

NOTE :

The voltage for parts in hot circuit is measured

using hot GND as a common terminal.

WF3

C1402

PLUS LEAD

WF2

PIN 10 OF

CN1601

WF1

PIN 8 OF

CN1601

WF4

PIN 14 OF

CN1601

WF5

PIN 16 OF

CN1601

WF6

PIN 19 OF

CN1601

1-10-241-10-23 BE5942F01011A

Page 39

FUNCTION CBA Top View

FUNCTION CBA Bottom View

1-10-261-10-25

BE5942F01011B

Page 40

SPDIF

1V

0.1

WF1

AUDIO-L

1V

0.5ms

AUDIO-R

1V

0.5ms

VIDEO-Y

0.2V

VIDEO-C

0.2V

VIDEO-CVBS

0.5V

Pin 8 of CN1601

WAVEFORMS

WF5

Pin 16 of CN1601

VIDEO-Y

WF2

Pin 10 of CN1601

VIDEO-C

WF3

C1402 PLUS LEAD

0.2V

0.2V

2020µ

2020µ

s

s

AUDIO-R

WF6

Pin 19 of CN1601

SPDIF

1V

1V

0.5ms

0.1

µ

s

VIDEO-CVBS

WF4

Pin 14 of CN1601

AUDIO-L

0.5V

1V

2020µ

0.5ms

NOTE:

Input

CD: 1kHz PLAY

(WF4~WF6)

s

1-11-1

DVD: POWER ON (STOP) MODE

(WF1~WF3)

E5PWF

Page 41

DV-SL80

DV-SL80X

(9HS1VSA10081B)

(9HS1VSA10069B)

FUNCTION CBA

WIRING DIAGRAM

CN2101 is soldered

directly to the PCB.

AC CORD

OPTICAL COAXIAL

DIGITAL AUDIO OUT

DV-SL80X

VIDEO-Cr/Pr

OUT

VIDEO-Cb/Pb

OUT

VIDEO-Y

OUT

S-VIDEO

OUT

AUDIO-R

OUT

K2 11K1 22KEY-2 33KEY-3 44KEY-1 55KEY-4 6

CN2001 CN2101

AV CBA

6

CN1601

DV-SL80

DV-SL80X

(9HS1VSA10081A)

(9HS1VSA10069A)

CN1001

(CN1001 is soldered directly to the PCB.) (CN1601 is soldered directly to the PCB.)

SPDIF 1919

AUDIO+5V 1818

AUDIO+5V 1717

AUDIO-R 1616

A-R-MUTE 1515

AUDIO-L 1414

A-MUTE 1313

AUDIO-GND 1212

AUDIO-GND 1111

VIDEO-C 1010

GND 99

VIDEO-Y 88

GND 77

VIDEO-Cb/Pb 66

GND 55

VIDEO-Cr/Pr 44

2222

REMOTE

FP-DOUT 2121

FP-STB 2020

FP-DIN 1919

FP-CLK 1818

PWRCON 1717

GND 1616

GND 1515

GND 1414

GND 1313

GND 1212

GND 1111

GND 1010

EV+11V 99

EV+11V 88

P-ON+5V 77

P-ON+3.3V 66

EV+3.3V 55

EV+3.3V 44

EV+3.3V 33

EV+1.2V 22

EV+1.2V 11

CN601

DVD MAIN CBA UNIT

CN401

CN201CN301

DV-SL80

DV-SL80X

(9HSN79S2HHP)

(9HSN79S4HAP)

20

P-ON+5V

19

CD/DVD

18

D

17

A

16

C

15

B

14

E

13

VREF

12

F

11

GND

CD-LD

10

9

GND(LD)

8

DVD-LD

7

PD-MONI

6

GND(DVD-PD)

5

GND(CD-PD)

4

TS(-)

3

FS(-)

2

FS(+)

1

TS(+)

8 SL(+)

SL(-)

7

GND

6

TRAY-IN

5

SP(-)

4

SP(+)

3

FS

M

SLED

MOTORMSPINDLE

4

DETECTOR

7 9 11 2 3 6 5

PICK UP UNIT

TS

DVD MECHA

MOTOR

DRIVE CBA

TRAY-IN

AUDIO-L

OUT

VIDEO

OUT

1-12-1

E5943WI

Page 42

SYSTEM CONTROL TIMING CHARTS

F

(

T

(

Tray Close ~ Play / Play ~ Tray Open

3.3V

Tray IN

(TL221)

Sled Drive

(TP303)

Disc Drive

(TP301)

ocus Drive

TP304)

0V

1.65V

0V

1.65V

0V

1.65V

0V

Tray

Close

Disc

Rotation

Play

Disc

Stop

Tray

Open

racking Drive

TP302)

1.65V

0V

1-13-1

E5945TI

Page 43

IC PIN FUNCTION DESCRIPTIONS

IC2001 ( PT6313-S -TP )

Pin

In/Out

No.

1 In

2 In

3 In K1

4 In K2

5 - VSS

6 - VDD

7 Out a / KEY-1

8 Out b /

9 Out c /

10 Out d /

11 Out

12 f

Out

13 g

Out

14 h

Out

Signal

Name

FP-CLK

FP-STB

KEY-2

KEY-3

KEY-4

e

Name Function

Clock Input

Serial Interface Strobe

Key Data 1 Input

Key Data 2 Input

GND

Power Supply

Segment Output / Key

Souce-1

Segment Output / Key

Souce-2

Segment Output / Key

Souce-3

Segment Output/ Key

Souce-4

Segment Output

15 - VEE

16 O

17

18 6G

19 5G

20 4G

21 3G

22 2G

23 1G

24 - VDD

25 - VSS

26 In OSC

27 Out FP-DOUT

28 In FP-DIN

ut

Out

i

7G

Pull Down Level

Segment Output

Grid Output

Power Supply

GND

Oscillator Input

Serial Data Output

Serial Data Input

1-14-1

E5945PIN

Page 44

LEAD IDENTIFICATIONS

KTC3203(Y)

KTA1266 (Y)

E C B E C B

PQ070XZ5MZP

123345

1: Vin

2: Vc

3: Vo

4: V adj

5: GND

KIA4558P

8

1

KRA110M

KTA1267(Y)

KTC3199(GR,Y)

PT6313-S-TP

5

4

28

1

15

14

0C-0805T*002

123

KIA431-AT

MM1637XVBE

16

1

9

8

2SK3566

G D S

K A R

LTV-817B-F

A

K

C

E

Note:

A: Anode

K: Cathode

E: Emitter

C: Collector

B: Base

R: Reference

S: Source

G: Gate

D: Drain

1-15-1

E5943LE

Page 45

Cabinet

EXPLODED VIEWS

See Electrical Parts List

for parts with this mark.

Some Ref. Numbers are

not in sequence.

2L081

2B5

2L021

2L021

2L021

2L081

2L021

1B1

2L011

2L105

A16

DVD Main

CBA Unit

2L105

2L011

Comparison Chart of

Models and Marks

Model

DV-SL80

DV-SL80X

2L011

Mark

A

B

Function CBA

A1X

A13

2L031

JK1401

2B1

JK1404

JK1202

2B11

2L042

A21

IC1204

[ A ]

[ B ]

F1001

AV CBA

AC1001

2L041

2L041

[ B ]

1-16-1

A15

A13

E5943EX

Page 46

Packing

X2

X4

S4

X5

X10

X1

S2

A22

Unit

S2

S1

1-16-2

E5943EX

Page 47

MECHANICAL PARTS LIST

PRODUCT SAFETY NOTE: Products marked with a ! have special characteristics important to safety. Before

replacing any of these components, read carefully the product safety notice in this service manual. Don't degrade

the safety of the product through improper servicing.

COMPARISON OF MODELS

Model Mark

DV-SL80

DV-SL80X

Ref. No. Mark Description Part No. Code

A1X FRONT ASSEMBLY E5946AD 9HS1VM220070 AX

A13 FOOT(REAR) E5710UD 9HS0VM415007 AC

A15 A CHASSIS(V0) E5942HD 9HS0VM204660 AQ

A15 B CHASSIS(V0) E5946AD 9HS0VM204661 AQ

A16 CASE, TOP E5 PLASTIC 9HS0VM306830 AS

A21! A LABEL,MODEL NO. E5943PD ---------- -A21! B LABEL,MODEL NO. E5946AD ---------- -A22 A LABEL, BAR CODE E5943PD ---------- -A22 B LABEL, BAR CODE E5946AD ---------- -1B1 DVD MECHA(FG LESS) 0838 VCZL0500 9HSN79F0HVM BS

2B5 REINFORCE PLATE E5 PLASTIC 9HS0VM306575 AF

2L011 SCREW, P-TIGHT 3X10 BIND HEAD+ 9HSGBEP3100 AA

2L021 SCREW, P-TIGHT 3X11 BIND HEAD+ 9HSGBMP3110 AA

2L031 P-TIGHT SCREW 3X8 BIND + 9HSGBMP3080 AA

2L041 SCREW, B-TIGHT M3X8 BIND HEAD + 9HSGBKB3080 AA

2L081 SCREW, P-TIGHT M3X8 WASHER+ 9HSGCMP3080 AA

2L105 P-TIGHT SCREW 3X8 BIND + 9HSGBMP3080 AA

S1 A GIFT BOX CARTON E5943PD 9HS0VM306958 AV

S1 B GIFT BOX CARTON E5946AD 9HS0VM306957 AV

S2 A SIDE PAD E5940CD 9HS0VM101366 AG

S2 B SIDE PAD(UK) E5914BD 9HS0VM101379 AG

S4 UNIT, BAG E5500UD 9HS0VM411683 AC

X1 REMOTE CONTROL UNIT DVD 0364 VCZF05EE 9HSNA533ED AY

X2 DRY BATTERY R6P/2S 9HSB0M451T0001 AE

X4 ACCESSORY BAG E5700UD 9HS0VM415576 AC

X5 AV CORD 9HSX1E56B5-001 AL

X10! A OWNER'S MANUAL E5942HD 9HS0VMN04100 AH

X10! B OWNER'S MANUAL E5946AD 9HS0VMN04099 AH

A

B

1-17-1

E5943CA

Page 48

ELECTRICAL PARTS LIST

PRODUCT SAFETY NOTE: Products marked with a ! have special characteristics important to safety. Before

replacing any of these components, read carefully the product safety notice in this service manual. Don't degrade

the safety of the product through improper servicing.

NOTES:

1. Parts that not assigned part numbers (---------) are not available.

2. IC103 is not supplied separately. Be sure to replace with the DVD Main CBA unit when servicing IC103.

3. Tolerance of Capacitors and Resistors are noted with the following symbols.

C.....±0.25% D.....±0.5% F.....±1% G.....±2% J......±5% K.....±10%

M.....±20% N.....±30% Z.....+80/-20%

COMPARISON OF MODELS

Model Mark

DV-SL80

DV-SL80X

A

B

DVD MAIN CBA UNIT

Ref. No. Mark Description Part No. Code

A DVD MAIN CBA UNIT 9HSN79S2HHP BU

B DVD MAIN CBA UNIT 9HSN79S4HAP BU

CAPACITORS

C101 CHIP CERAMIC CAP.(1005) F Z 0.1µF/16V 9HSHB1CZ30F104 AA

C102 CHIP CERAMIC CAP.(1005) F Z 0.1µF/16V 9HSHB1CZ30F104 AA

C103 CHIP CERAMIC CAP.(1005) F Z 0.1µF/16V 9HSHB1CZ30F104 AA

C104 CHIP CERAMIC CAP.(1005) F Z 0.1µF/16V 9HSHB1CZ30F104 AA

C105 CHIP CERAMIC CAP.(1005) F Z 0.1µF/16V 9HSHB1CZ30F104 AA

C106 CHIP CERAMIC CAP.(1005) F Z 0.1µF/16V 9HSHB1CZ30F104 AA

C107 CHIP CERAMIC CAP.(1005) F Z 0.1µF/16V 9HSHB1CZ30F104 AA

C108 CHIP CERAMIC CAP.(1005) F Z 0.1µF/16V 9HSHB1CZ30F104 AA

C109 CHIP CERAMIC CAP.(1005) F Z 0.1µF/16V 9HSHB1CZ30F104 AA

C110 CHIP CERAMIC CAP.(1005) F Z 0.1µF/16V 9HSHB1CZ30F104 AA

C111 CHIP CERAMIC CAP.(1005) F Z 0.1µF/16V 9HSHB1CZ30F104 AA

C112 CHIP CERAMIC CAP.(1005) F Z 0.1µF/16V 9HSHB1CZ30F104 AA

C113 CHIP CERAMIC CAP.(1005) F Z 0.1µF/16V 9HSHB1CZ30F104 AA

C114 CHIP CERAMIC CAP.(1005) F Z 0.1µF/16V 9HSHB1CZ30F104 AA

C116 CHIP CERAMIC CAP.(1005) F Z 0.1µF/16V 9HSHB1CZ30F104 AA

C117 CHIP CERAMIC CAP.(1005) F Z 0.1µF/16V 9HSHB1CZ30F104 AA

C118 CHIP CERAMIC CAP.(1005) F Z 0.1µF/16V 9HSHB1CZ30F104 AA

C119 CHIP CERAMIC CAP.(1005) F Z 0.1µF/16V 9HSHB1CZ30F104 AA

C120 CHIP CERAMIC CAP.(1608) B K 1µF/10V 9HSHD1AK30B105 AC

C121 CHIP CERAMIC CAP.(1005) F Z 0.1µF/16V 9HSHB1CZ30F104 AA

C122 CHIP CERAMIC CAP.(1005) B K 0.1µF/10V 9HSHB1AK30B104 AA

C123 CHIP ELECTROLYTIC CAP. 330µF/6.3V M(UD) 9HSA0K331NC182 AC

C124 CHIP CERAMIC CAP.(1005) F Z 0.1µF/16V 9HSHB1CZ30F104 AA

C125 CHIP CERAMIC CAP.(1005) F Z 0.1µF/16V 9HSHB1CZ30F104 AA

C126 CHIP CERAMIC CAP.(1005) F Z 0.1µF/16V 9HSHB1CZ30F104 AA

C127 CHIP CERAMIC CAP.(1005) F Z 0.1µF/16V 9HSHB1CZ30F104 AA

C128 CHIP CERAMIC CAP.(1005) F Z 0.1µF/16V 9HSHB1CZ30F104 AA

C129 CHIP CERAMIC CAP.(1005) F Z 0.1µF/16V 9HSHB1CZ30F104 AA

C130 CHIP CERAMIC CAP.(1005) F Z 0.1µF/16V 9HSHB1CZ30F104 AA

C131 CHIP CERAMIC CAP.(1005) F Z 0.1µF/16V 9HSHB1CZ30F104 AA

C134 CHIP CERAMIC CAP.(1005) F Z 0.1µF/16V 9HSHB1CZ30F104 AA

C135 CHIP CERAMIC CAP. F Z 4.7µF/16V(2012) 9HSHE1CZ30F475 AC

C136 CHIP ELECTROLYTIC CAP. 1000µF/6.3V M(UR) 9HSA0K102NC183 AD

C152 CHIP CERAMIC CAP.(1005) F Z 0.1µF/16V 9HSHB1CZ30F104 AA

Consists of the following

1-18-1

E5943EL

Page 49

Ref. No. Mark Description Part No. Code

C191 CHIP CERAMIC CAP.(1005) CH J 15pF/50V 9HSHB1JJ3CH150 AA

C192 CHIP CERAMIC CAP.(1005) CH J 22pF/50V 9HSHB1JJ3CH220 AA

C195 CHIP CERAMIC CAP.(1005) F Z 0.1µF/16V 9HSHB1CZ30F104 AA

C196 CHIP CERAMIC CAP.(1005) F Z 0.1µF/16V 9HSHB1CZ30F104 AA

C201 CHIP CERAMIC CAP.(1005) F Z 0.1µF/16V 9HSHB1CZ30F104 AA

C202 CHIP CERAMIC CAP.(1005) F Z 0.1µF/16V 9HSHB1CZ30F104 AA

C203 CHIP CERAMIC CAP.(1005) F Z 0.1µF/16V 9HSHB1CZ30F104 AA

C207 CHIP CERAMIC CAP.(1005) B K 0.1µF/10V 9HSHB1AK30B104 AA

C208 CHIP CERAMIC CAP.(1005) B K 0.1µF/10V 9HSHB1AK30B104 AA

C210 CHIP CERAMIC CAP.(1005) F Z 0.1µF/16V 9HSHB1CZ30F104 AA

C211 CHIP CERAMIC CAP.(1005) B K 0.1µF/10V 9HSHB1AK30B104 AA

C212 CHIP CERAMIC CAP.(1005) F Z 0.1µF/16V 9HSHB1CZ30F104 AA

C215 CHIP CERAMIC CAP.(1005) F Z 0.1µF/16V 9HSHB1CZ30F104 AA

C217 CHIP CERAMIC CAP.(1608) B K 1µF/10V 9HSHD1AK30B105 AC

C218 CHIP CERAMIC CAP.(1608) B K 1µF/10V 9HSHD1AK30B105 AC

C219 CHIP CERAMIC CAP.(1608) B K 1µF/10V 9HSHD1AK30B105 AC

C220 CHIP CERAMIC CAP.(1608) B K 1µF/10V 9HSHD1AK30B105 AC

C221 CHIP CERAMIC CAP.(1005) CH J 47pF/50V 9HSHB1JJ3CH470 AA

C222 CHIP CERAMIC CAP.(1005) B K 0.1µF/10V 9HSHB1AK30B104 AA

C223 CHIP CERAMIC CAP.(1005) B K 0.033µF/16V 9HSHB1CK30B333 AA

C224 CHIP CERAMIC CAP.(1005) CH J 47pF/50V 9HSHB1JJ3CH470 AA

C225 CHIP CERAMIC CAP.(1005) B K 0.1µF/10V 9HSHB1AK30B104 AA

C226 CHIP CERAMIC CAP.(1005) B K 0.1µF/10V 9HSHB1AK30B104 AA

C227 CHIP CERAMIC CAP.(1005) B K 0.1µF/10V 9HSHB1AK30B104 AA

C228 CHIP CERAMIC CAP.(1005) CH J 47pF/50V 9HSHB1JJ3CH470 AA

C229 CHIP CERAMIC CAP.(1005) CH J 47pF/50V 9HSHB1JJ3CH470 AA

C230 CHIP CERAMIC CAP.(1005) B K 0.018µF/25V 9HSHB1EK30B183 AA

C231 CHIP CERAMIC CAP.(1005) B K 5600pF/25V 9HSHB1EK30B562 AA

C232 CHIP CERAMIC CAP.(1005) B K 0.01µF/25V 9HSHB1EK30B103 AA

C233 CHIP CERAMIC CAP.(1005) B K 0.01µF/25V 9HSHB1EK30B103 AA

C234 CHIP CERAMIC CAP.(1005) B K 560pF/50V 9HSHB1JK30B561 AA

C237 CHIP CERAMIC CAP.(1005) B K 0.1µF/10V 9HSHB1AK30B104 AA

C238 CHIP CERAMIC CAP.(1005) B K 0.1µF/10V 9HSHB1AK30B104 AA

C239 CHIP CERAMIC CAP.(1005) B K 0.1µF/10V 9HSHB1AK30B104 AA

C250 CHIP CERAMIC CAP.(1005) F Z 0.1µF/16V 9HSHB1CZ30F104 AA

C253 CHIP ELECTROLYTIC CAP. 47µF/6.3V M(WR) 9HSA0K470NC180 AC

C255 CHIP ELECTROLYTIC CAP. 4.7µF/25V M(WX) 9HSA1E4R7NC181 AB

C257 CHIP CERAMIC CAP.(1608) B K 1µF/10V 9HSHD1AK30B105 AC

C259 CHIP CERAMIC CAP.(1608) B K 1µF/10V 9HSHD1AK30B105 AC

C263 CHIP ELECTROLYTIC CAP. 47µF/6.3V M(WR) 9HSA0K470NC180 AC

C280 CHIP CERAMIC CAP.(1005) B K 0.1µF/10V 9HSHB1AK30B104 AA

C281 CHIP CERAMIC CAP.(1005) F Z 0.1µF/16V 9HSHB1CZ30F104 AA

C284 CHIP CERAMIC CAP.(1005) B K 6800pF/25V 9HSHB1EK30B682 AA

C288 CHIP CERAMIC CAP.(1005) B K 0.047µF/16V 9HSHB1CK30B473 AA

C289 CHIP CERAMIC CAP.(1005) B K 0.047µF/16V 9HSHB1CK30B473 AA

C301 CHIP CERAMIC CAP.(1005) B K 0.1µF/10V 9HSHB1AK30B104 AA

C302 CHIP CERAMIC CAP.(1005) B K 820pF/50V 9HSHB1JK30B821 AA

C303 CHIP CERAMIC CAP.(1005) CH J 68pF/50V 9HSHB1JJ3CH680 AA

C305 CHIP CERAMIC CAP.(1005) B K 6800pF/25V 9HSHB1EK30B682 AA

C308 CHIP CERAMIC CAP.(1005) B K 0.039µF/16V 9HSHB1CK30B393 AA

C310 CHIP CERAMIC CAP.(1005) F Z 0.1µF/16V 9HSHB1CZ30F104 AA

C311 CHIP CERAMIC CAP.(1005) F Z 0.1µF/16V 9HSHB1CZ30F104 AA