Page 1

Date: Jan. 19, 1998

DUPLICATOR SD-2060/2260

Request for correction of Technical Report (DTE-309)

1. Model Name: SD-2060/2260/3062

2. General: Since there are some error in the description and illustration of "Subject: Countermeasure

against trouble in 2000/3000 tray unit" of Technical Report (DTJ-312/DTE-309) already issued,

No. : DTE-354

correct them as shown below.

Corrected versio

3. Changes of 2000/3000 tray unit

1. Model Name: SD-2060/2260/3062

2. General: To improve the noise from 3000 tray unit (SD-2260) and breakage of actuator at the lower limit,

the following countermeasures are taken. The vendor of the M sensor plate is also changed to

improve the productivity.

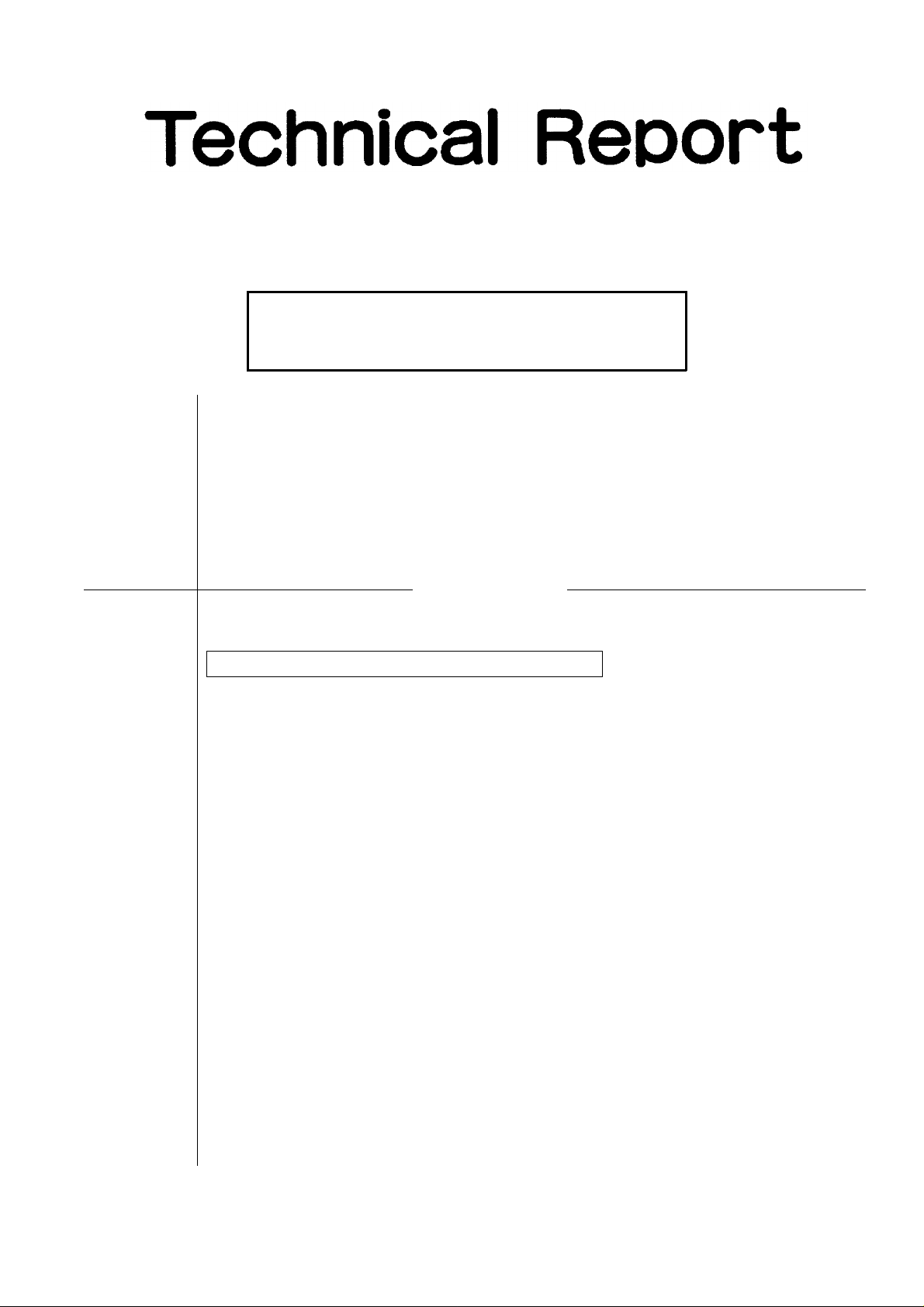

1. Countermeasure against abnormal noise during operation of 3000 tray

Since the noise results from the precision variation of the dimension of 30T gear, it is changed

to one whose dimensional precision is improved. It is added that grease is coated on the

bearing of the plate on which the lift motor is installed.

SHARP CORPORATION Reprography Division

1/3

Green

C

Page 2

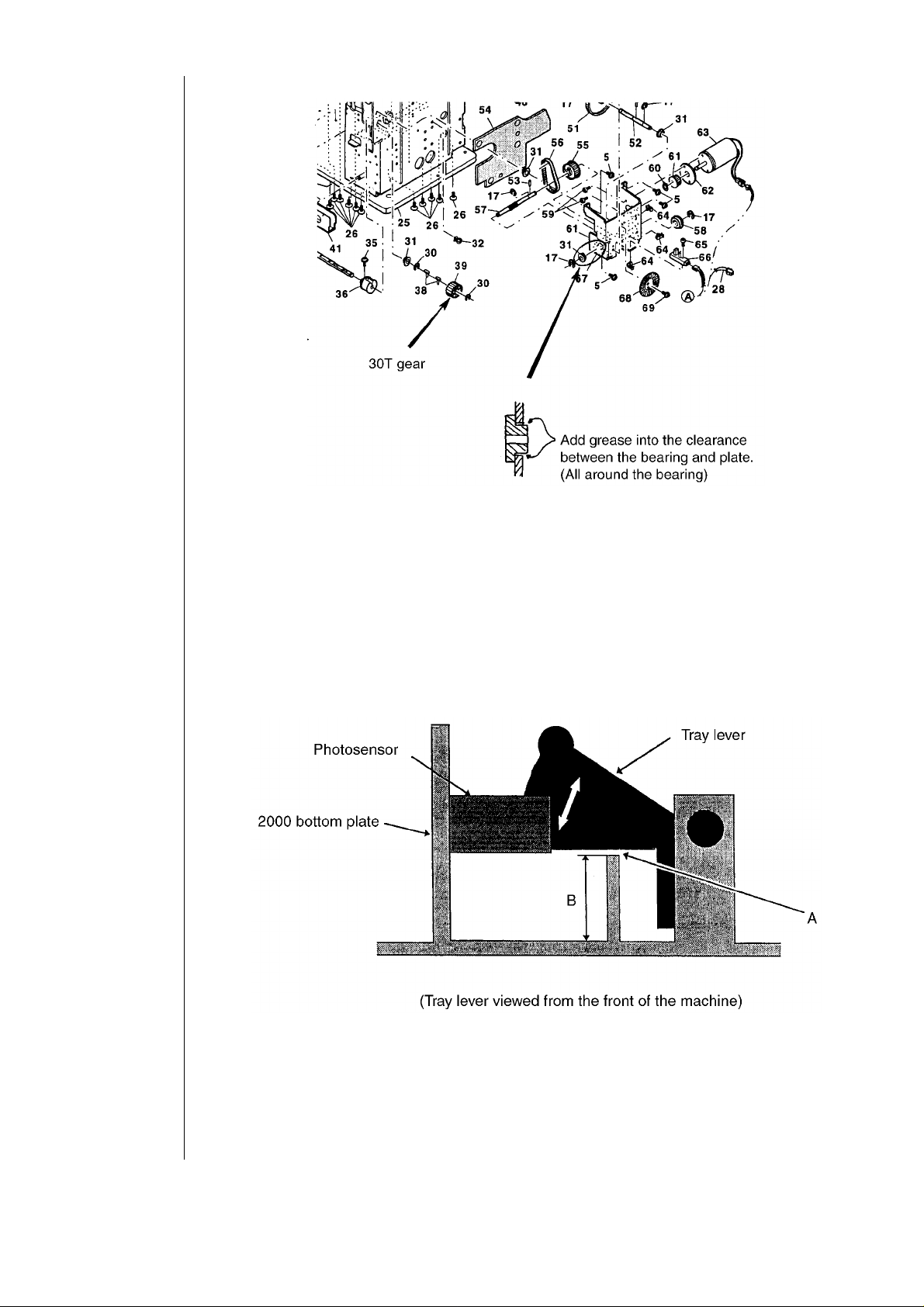

2. Countermeasure against lower limit actuator

When the 3000 tray lowers to the lower limit, the tray lever blocks the photo sensor as

shown below. If the 200 bottom plate and tray lever comes into contact at the area A as

shown below, the tray lever may be broken. Therefore, the dimension of the area B shown

below is made to be 1 mm shorter than that of the existing one.

3. Change of M sensor plate and part vendor

For better productivity, the part vendor of the M sensor plate is changed. Accordingly, the

part code is changed.2/3

Page 3

Along with the change of the above part, the 30T gear, 2000 bottom plate and M sensor plate

used on the 2000 tray unit (SD-2060/3062) are similarly changed for common use.

3. Action: 1st product in June, 1997

Ref.

Model

No.

name

1 SD-2260

SD-2060

2

SD- 3062

3 SD-2260

SD-2060

4

SD- 3062

5 SD-2260

SD-2060

6

SD- 3062

<Interchange>

1. Interchangeable. 4. Not interchangeable.

2. Current type can be used in place of new type.

New type cannot be used in place of current type.

3. Current type cannot be used in place of new type.

New type can be used in place of current type.

Parts marked with " " is important for maintaining the safety of the set. Be sure to replace these parts with specifie d ones

for maintaining the safety and performance of the set.

Version P/G No.

22 -39

21 -27

22 -25

ALL

21

22 -68

21 -51

Current parts New parts

Parts name

Parts code Parts code

NGERH0954FCZZ NGERH1215FCZZ AF 30T gear

LPLTM4329FCZ2 LPLTM4329FCZ3 AX

LPLTP2926FCZZ

PTNPT0019FCZZ

5. Interchangeable if replaced with same types of related

6. Others.

Price

rank

2000 bottom

plate

AD M sensor plate 1

parts in use.

Effec-

tive

time

1st lot

’97/6

Inter-

change-

ability

Note

3

1

3

1

3/3

Loading...

Loading...