Page 1

DUPLICATOR : SD-2260

Date

:

Jul. 7, 1997

1. MEASURE TO ALLEVIATE PROBLEMS OF THE CENTER TRAY PAPER GUIDE GETTING CAUGHT.

2. ESTABLISHMENT OF PART INTERCHANGEABILITY CARRIED OUT AS A MEASURE TO IMPROVE

PRODUCTIVITY.

3. MEASURE TO ALLEVIATE PROBLEMS OF ABNORMAL NOISE IN THE 2000 AND 3000 TRAY UNITS.

4. CHANGE IN PARTS CARRIED OUT AS A MEASURE TO IMPROVE PRODUCTIVITY.

No. : DTE-309

1. Measure to alleviate problems of the center tray paper guide getting caught.

1.Model Name: SD-2060/ 2260/ 3062

2.General: There have been problems of the center tray paper guide becoming caught, causing

operation misses. As a measure to alleviate this problem, the measures described below

have been carried out.

3.Description: <1> There have been problems of the paper flow ribs of the upper paper guide and the

center paper guide upper becoming caught on the edge section of the fixed upper

paper guide. As a measure to alleviate this problem, a change has been carried out in

the ribs, reducing the height of the ribs to prevent obstruction. (Please refer to figure 1.)

<2> The addition of a spacer has been carried out to the back side of the paper feeding

paper guide lower. This change has been carried out as a measure to prevent the fixed

upper paper guide from warping and bending upwards. (Please refer to figure 2.)

<3> In accordance with the extending of the length of the ribs of the upper paper guide,

the mylar (Qty: 4) sheets have been discontinued. (Please refer to figure 3.)

<4> A change in the fixing screws (Qty: 8) which secure the fulcrum plate on the moving

side and the opening and closing plate on the moving side of the upper paper guide

has been carried out. This change has been carried out as a measure to improve

productivity. (Please refer to figure 1.)

Note: When carrying out replacement operations of the upper paper guide described in

above, replacement operations should also be carried out simultaneously on the

screws described in above.

SHARP CORPORATION Reprography Division

1/7

Green

C

Page 2

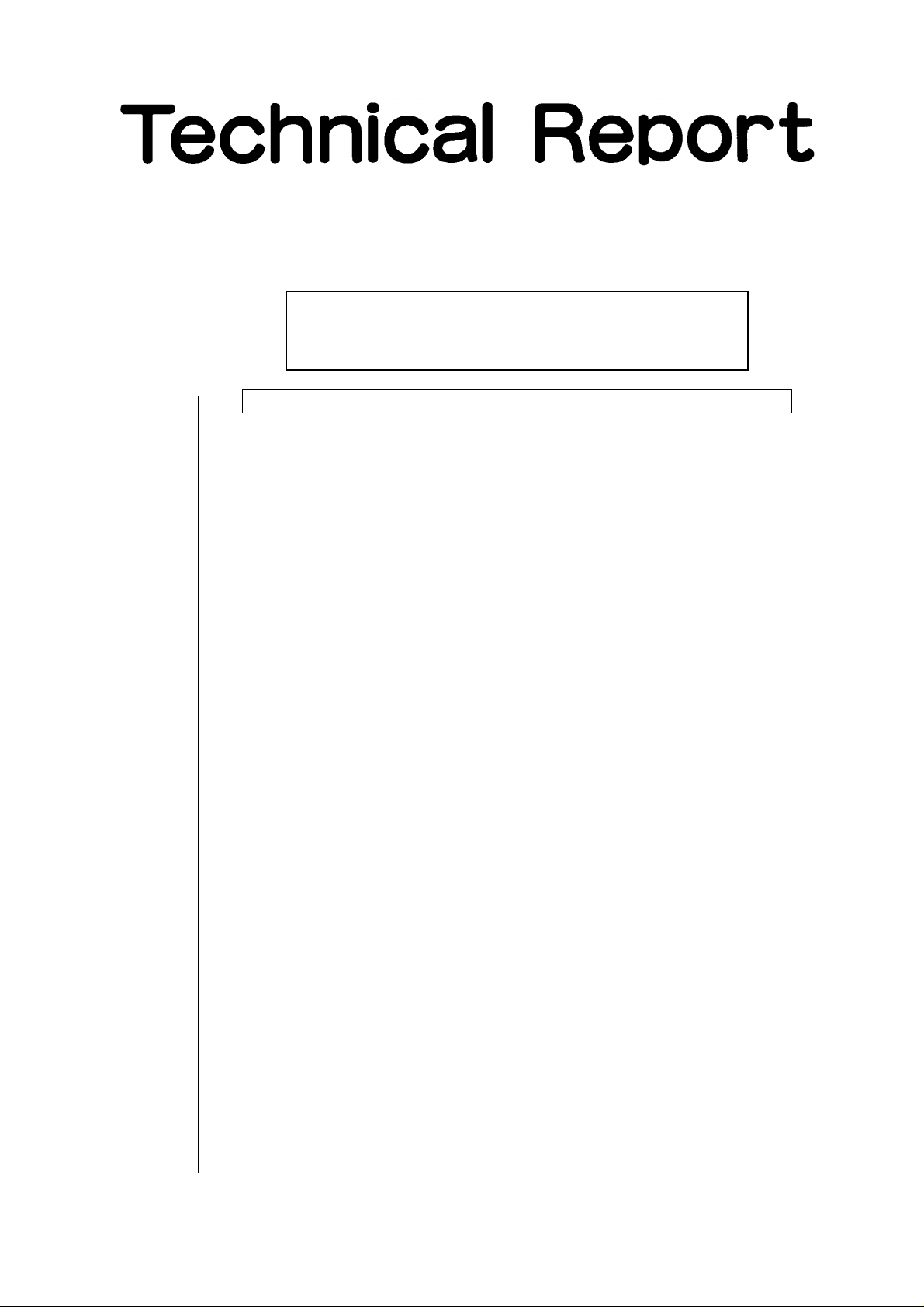

Figure 1

Change carried out in the screws

Upper paper guide

Fixed paper guide

The shaded sections of the figures shown below have been cut.

Fixed upper PG

Figure 2

The fixed upper PG warps and bends upward

due to the roller section pressing upward.

Paper feeding PG lower

Center paper guide upper

Center PG upper

Paper feeding PG lower

Fixed upper PG

The addition of a spacer

has been carried out.

The addition of a spacer has been

carried out in the paper feeding PG lower

as a measure to correct the upward

bending of the fixed upper PG.

Fixed upper PG

Moving roller

Upper PG

Belt rib

2/7

Fixed upper PG

Page 3

Paper feeding PG lower

(PGIDH1405FCZ1)

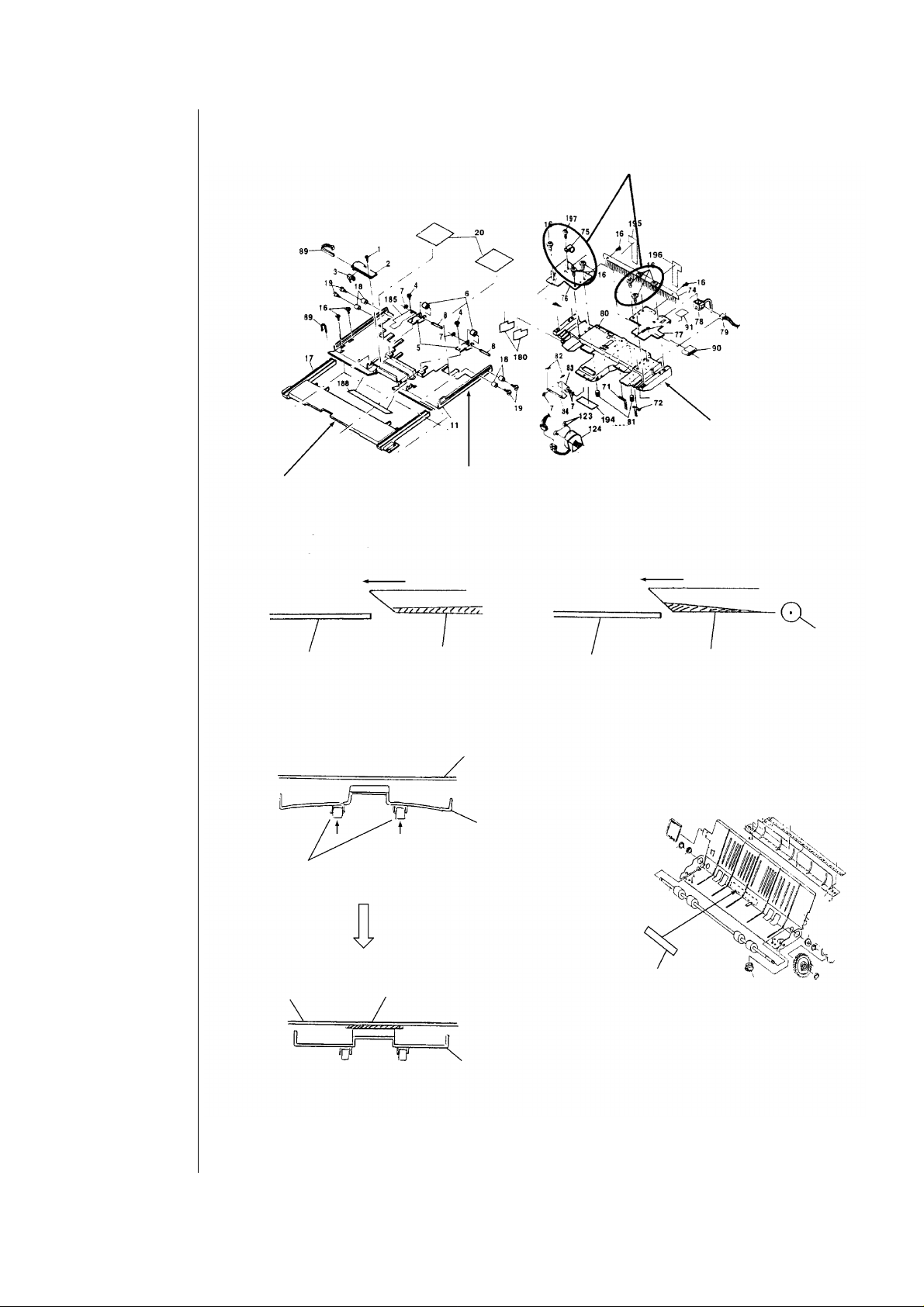

Figure 3

Belt rib

(PSHEZ3507FCZZ)

Upper paper guide sheet F

(PSHEP3549FCZZ)

(Used in two locations)

Standard

Detail of section ’a’

Mylar sheets (two mylar sheets in the front and two mylar sheets in the rear)

have been discontinued in accordance with a change in the shape of the

upper paper guide (the length of the ribs have been extended).

4.Action: From the start of 1997 June production.

Upper paper guide

Upper paper guide sheet R

(PSHEP3550FCZZ)

(Used in two locations)

Standard

Detail of section ’b’

3/7

Page 4

2. Establishment of part interchangeability carried out as a measure to improve

productivity.

1.Model Name: SD-2260

2.General: Some changes in shape have been carried out on the parts described below. These

changes have been carried out as a measure to enable the parts, which are being used

in model SD-2260 listed above, to be used in other models as well.

Note: When using the parts for model SD-2260, both the old parts and the new parts

can be used without adverse effect.

Duct (P/G [10]-17) PDUC-0124FCZZ → PDUC-0124FCZ1

3000 frame F (P/G [22]-24) CFRM-0925FC02 → CFRM-0925FC03

3000 frame R (P/G [22]-23) CFRM-0926FC02 → CFRM-0926FC03

3.Action: From 1997 mid-June production.

3. Measure to alleviate problems of abnormal noise in the 2000 and 3000 tray units.

1.Model Name: SD-2060/2260/3062

2.General: The measures described below have been carried out in order to alleviate problems of

abnormal noise in the 2000 and the 3000 tray units, and also to alleviate problems of

cracking of the lower limit actuator in the 2000 and 3000 units.

3.Description: <1> A change has been carried out in the 30 T gear. A part of higher precision is now

being used. This change has been carried out as a measure to alleviate problems of

abnormal noise.

<2> Grease has been applied to the bushing of the lift motor attachment plate.

This change has been carried out as a measure to alleviate problems of abnormal

noise. (This change has been carried out only on the 3000 tray unit.) (Please refer to

figure 1.)

<3> A change in the shape of the 2000 bottom plate has been carried out. This change

has been carried out as a measure to alleviate problems of cracking in the lower limit

actuator. (Please refer to figure 2.)

<4> A change has been carried out in the maker of the M sensor plate. This change has

been carried out as a measure to improve productivity.

4/7

Page 5

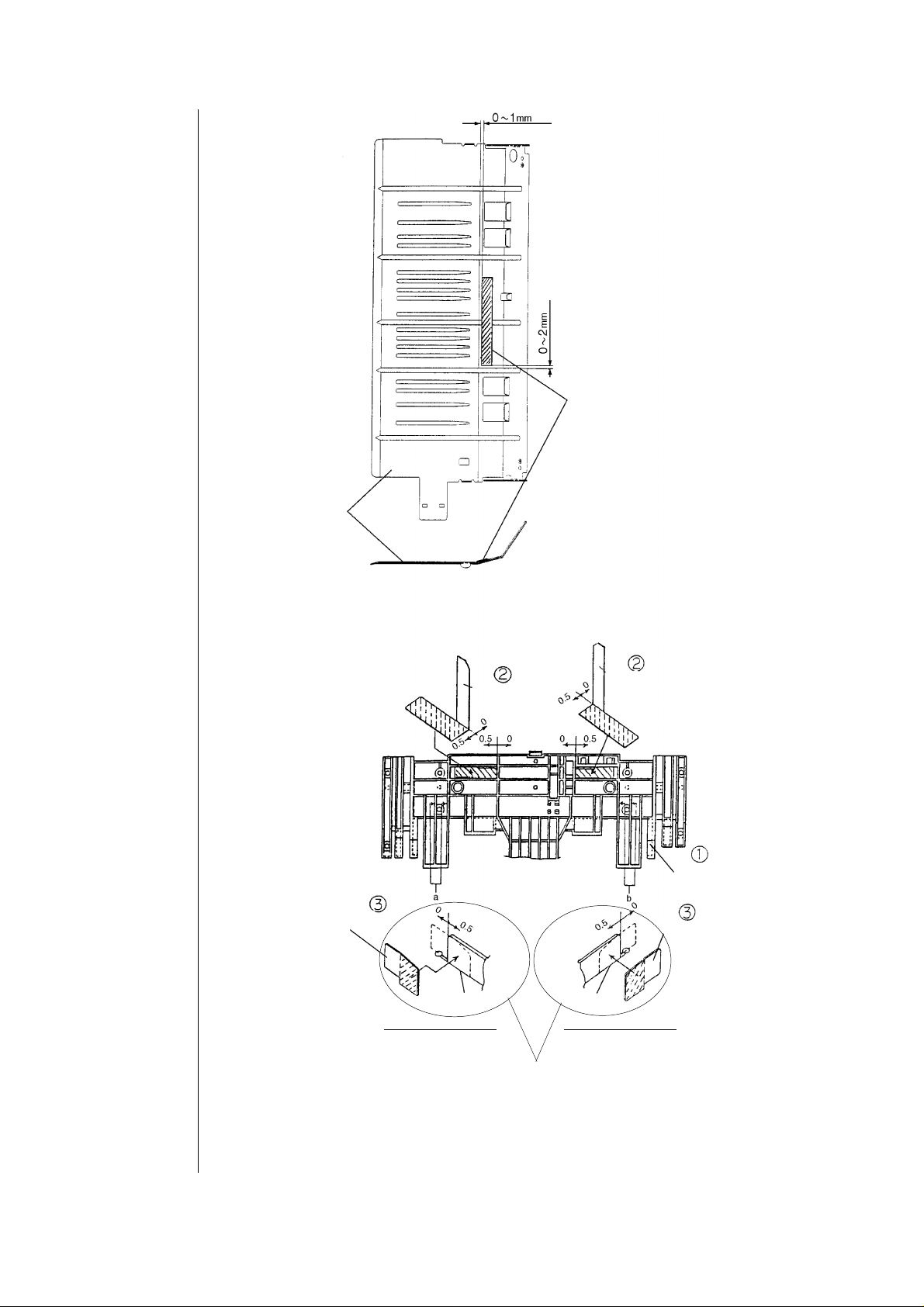

Figure 1

Figure 2

Added grease between the bearing

and metal plate.

(over the entire curved surface).

Location of the change

in shape.

(Both front and rear).

3000 frame F

2000 base plate

Standard

4.Action: From the start of 1997 June production.

4. Change in parts carried out as a measure to improve productivity.

1.Model Name: SD-2060/2260/3062

2.General: Changes have been carried out in the 30 T gear and the M sensor plate of the 1000 tray

unit. These changes were carried out in accordance with the same changes that were

carried out as described in Item 3 above. These changes have been carried out as a

measure to improve productivity.

3.Action: From the start of 1997 June production.

5/7

Page 6

Ref.

Model

name

Version P/G No.

No.

SD-2060

SD-3062

SD-2260 30 -80

1

(1)

SD-2060

SD-3062

SD-2260

31 -80

31 -17

30 -17

Current parts New parts

Parts code Parts code

PGIDM1413FCZZ PGIDM1413FCZ1 AX Upper paper guide

PGIDM1415FCZZ PGIDM1415FCZ1 AY Center paper guide upper

Price

rank

Parts name

Effec-

tive

time

Inter-

change-

ability

3

Note

SD-2060

SD-3062

1

(2)

SD-2260 30

SD-2060

SD-3062

SD-2260 30 -181

1

(3)

SD-2060

SD-3062

SD-2260

SD-2060

SD-3062

1

(4)

SD-2260

2 SD-2260

All

31

31 -181

31 -180

30 -180

31 -16

30 -16

30 -197 XBPSD40P08000 LX-BZ0700FCZZ

10 -17 PDUC-0124FCZZ PDUC-0124FCZ1 BE Duct

22 -24 CFRM-0925FC02 CFRM-0925FC03 AY 3000 frame F

22 -23 CFRM-0926FC02 CFRM-0926FC03 AX 3000 frame R

---- PSHEZ3507FCZZ AK Belt sheet

(Q’ty: 2)

PSHEP3549FCZZ

Discontinued ----

(Q’ty: 2)

PSHEP3550FCZZ

(Q’ty: 8)

LX-BZ0465FCZZ

(Q’ty: 7)

LX-BZ0465FCZZ

(Q’ty: 8)

LX-BZ0700FCZZ

(Q’ty: 7)

LX-BZ0700FCZZ

Upper PG sheet F

Upper PG sheet R ----

AA Screw (4×12) 6

1st lot

’97/6

Mid-

’97/6

6

1

6/7

Page 7

Ref.

Model

name

Version P/G No.

No.

SD-2060

SD-3062

3

(1)

SD-2260 22 -39

SD-2060

SD-3062

3

(3)

SD-2260

21 -27

21

22 -25

Current parts New parts

Parts code Parts code

NGERH0954FCZZ NGERH1215FCZZ AF 30T gear

LPLTM4329FCZ2 LPLTM4329FCZ3 AX 2000 bottom plate

Price

rank

Parts name

Effec-

tive

time

Inter-

change-

ability

3

Note

SD-2060

SD-3062

3

(4)

SD-2260 22 -68

SD-2060

SD-3062

SD-2260 21 -93

4

SD-2060

SD-3062

SD-2260

<Interchange>

1. Interchangeable. 4. Not interchangeable.

2. Current type can be used in place of new type.

New type cannot be used in place of current type.

3. Current type cannot be used in place of new type.

New type can be used in place of current type.

Parts marked with ‘‘ ’’ is important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

21

All

20 -93

20 -60

21 -60

LPLTP2926FCZZ PTNPT0019FCZZ AD M sensor plate

NGERH0954FCZZ NGERH1215FCZZ AF 30T gear

LPLTP2926FCZZ PTNPT0019FCZZ AD M sensor plate

5. Interchangeable if replaced with same types of

related parts in use.

6. Others.

1st lot

’97/6

1

7/7

Loading...

Loading...