Page 1

Date: Jun. 27, 1994

DUPLICATOR : SD-2060

1. PREVENTION OF SNAP BAND CONTACT INSIDE CENTER TRAY UNIT

2. DISCONTINUE TRAY SHEET F AND R INSIDE 1000 TRAY UNIT

(THIS IS AIMING TO IMPROVE PRODUCTIVITY)

3. IMPROVEMENT OF MODE SELECTION GATE FUNCTION (MARGINS) INSIDE FINISHER

4. CHANGE TO THE FORM OF GATE SHEET N. (THIS IS AIMING TO IMPROVE PRODUCTIBITY)

No. : DTE-165

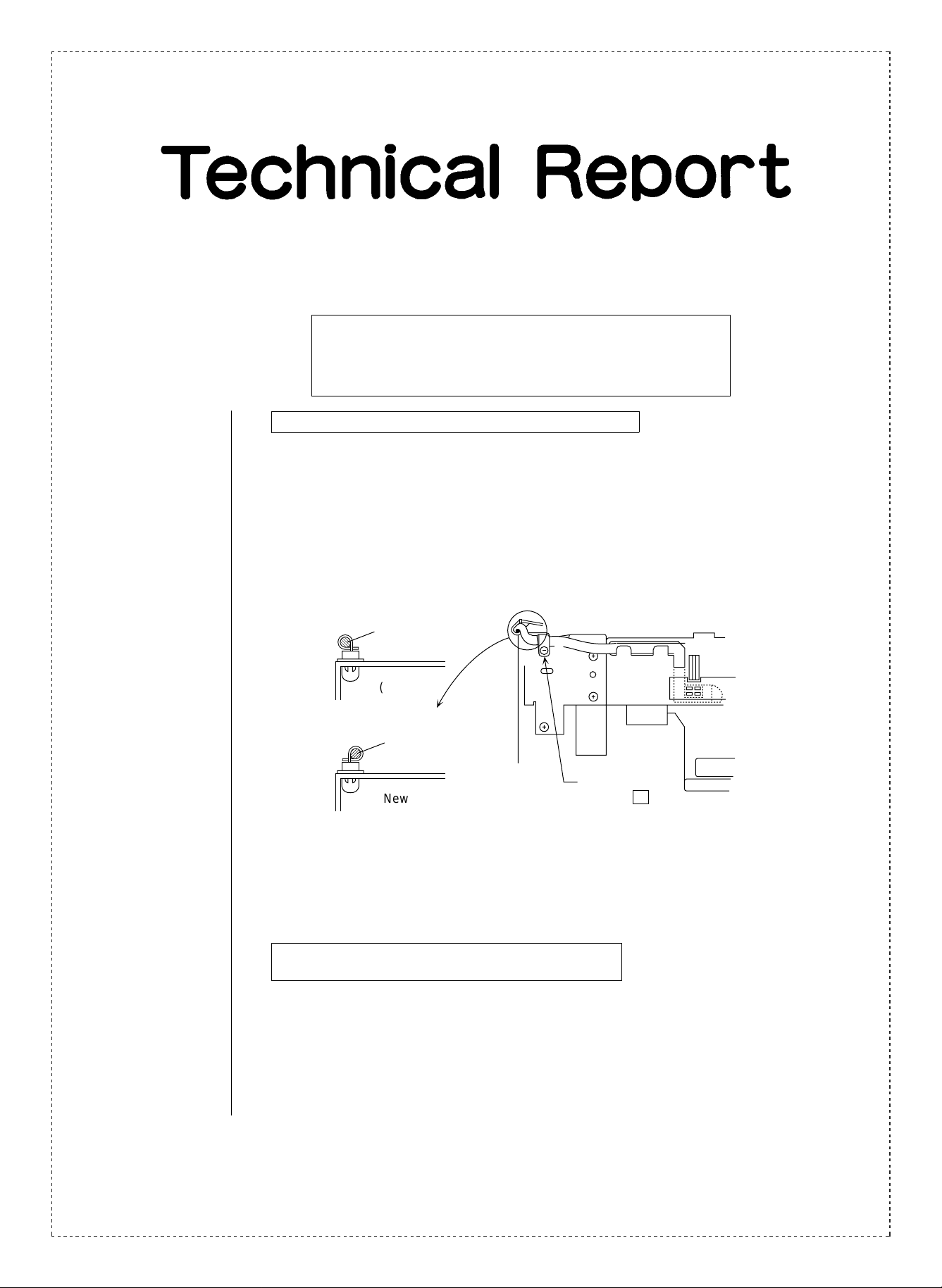

1. Prevention of snap band contact inside center tray unit

1.Model name: SD-2060, 3062

2.General: Harness inside moving paper guide unit of center tray unit was fixed with snap band.

However, moving paper guides sometimes meet with rear frame because of ineffective

way of fixing. We change the position of fixed harness to the opposite side to prevent

contact with rear frame.

3.Description:

Harness

(Current)

Harness

(New)

4.Action: From mid-April 1994 production.

2. Discontinue tray sheet F and R inside 1000 tay unit

(This is aiming to improve productivity)

1.Model name: SD-2060, 3062

Rear

Frame

Code Band

(P/G No. 31 -75)

2.General: To prevent the feeding trouble of the last paper in tray at 1000 tray corners, we attached

tray sheet. With aiming to improve productivity, we place guides ribbing that has same

function with tray sheet F and R, and discontinue tray sheet F and R.

Green

C

SHARP CORPORATION Reprography Division

1/3

Page 2

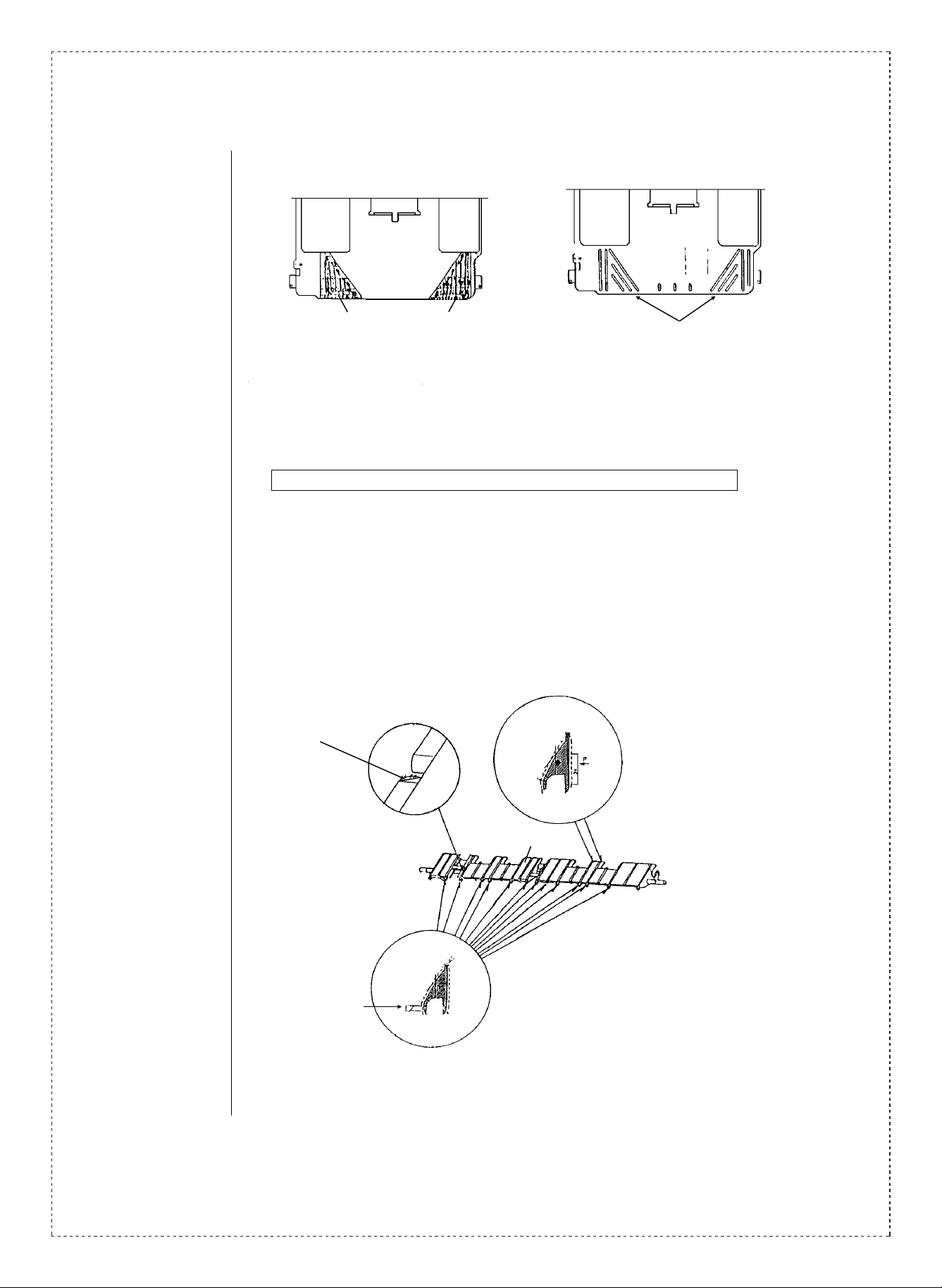

3.Description: (Current) (New)

Discontinuance

of tray sheet F

Discontinuance

of tray sheet R

Addition of guides ribbing

4.Action: From mid-May 1994 production.

3. Improvement of mode selection gate function (margins) inside finisher

1.Model name: SD-3062

2.General: To improve in function (margins) of mode selection gate inside finisher, changes in form

are made as follows.

3.Description: Fig 1 Improve margin to prevent contact with pusher

Fig 2 Improve margin to attach gate sheet N

Fig 3 Improve function when staple mode is on

2/3

4. Action:

Add Taper (Cut)

Fig 1

Change (Cut)

12 points

Fig 3

From mid-April 1994 production.

E-E cross section

(Cut Ribs with two points)

Fig 2

Mode selection gate

Page 3

4. Changes to the form of gate sheet N. (This is aiming to improve productivity)

1.Model name: SD-3062

2.General: We change the form of gate sheet N that attached to mode selection gate in finisher

gate frame unit to improve working efficiency of attaching.

3.Description:

(Current) (New)

PSHEP3658FCZZ PSHEP3658FCZ1

Note:There are old (PGIDM1469FCZ1) and new (PGIDM1469FCZ2) types of mode

selection gate where fate sheet N is attached. Old types of gate only correspond to

old type sheet, but new types of gate correspond to both new and old types of sheets.

4.Action: From the first unit of May 1994 production.

Attachment Standard

Attach without

warps or windings

Gate Sheet N

Mode Selection Gate

Base line

Base line

(Attach not to slip out of Gate)

Ref.

Model

No.

SD-2060

2

SD-3062

3

SD-3062

4

<Interchange>

1. Intercha ng ea bl e. 4. N ot i nt er ch an ge ab l e.

2. Current type can be used in place of new type.

New type cannot be used in place of current type.

3. Current type cannot be used in place of new type.

New type can be used in place of current type.

Parts marked with “ ” is important for maintaining the safety of the set. Be sure to replace these parts with

s p ec ifi e d on es fo r m aintaini ng t he s a fe ty and per fo rmance o f th e s et .

name

Version P/G No.

20 -10 LSOU-0111FCZZ LSOU-0111FCZ1 BC 1000 tray

20 -68 PSHEZ3537FCZZ

All

20 -69 PSHEZ3538FCZZ

53 -6 PGIDM1469FCZ1 PGIDM1469FCZ2 AT

53 PSHEP3658FCZZ PSHEP3658FCZ1 AB Gate sheet N

!

Current parts New parts

Parts code Parts code

Discontinued

(Q’ty: 2)

Discontinued

(Q’ty: 2)

5. Interchangeable if replaced with same types of

6. Others.

rank

AH

AH

Parts name

1000 tray sheet

F

1000 tray sheet

R

Mode change

gate

Price

relate d parts in use .

Effec-

tive

time

Mid-

’94/5

Mid-

’94/4

1st lot

’94/5

Inter-

change-

ability

3 Q’ty: 2

—

—

3

2

Note

3/3

Loading...

Loading...