Page 1

Date: May. 12, 1994

DUPLICATOR: SD-3062

1. FIBER GLASS CRACKING PREVENTION DURING CABINET ASSEMBLY.

2. CHANGE IN THE PAPER GUIDE FULCRUM SHAFT OF THE CENTER TRAY UNIT TO

IMPROVE PRODUCTIVITY.

3. CHANGE IN THE HARNESS OF THE COPY LAMP UNIT IN ACCORDANCE WITH SAFETY

STANDARDS (200V SERIES, EXPORT MODELS ONLY).

No. : DTE-139

1. Fiber glass cracking prevention during cabinet assembly.

1.Model name: SD-2060 / 3062

2.General: When attaching the left side of the upper cabinet and the operating section of the

machine, the cabinet teeth sometimes scratch the metal frame plate and fiber glass

dust scraped off the plate falls into the optical unit through a hole in the frame plate.

To alleviate this problem, a sheet has been added to cover the hole in the metal frame

plate.

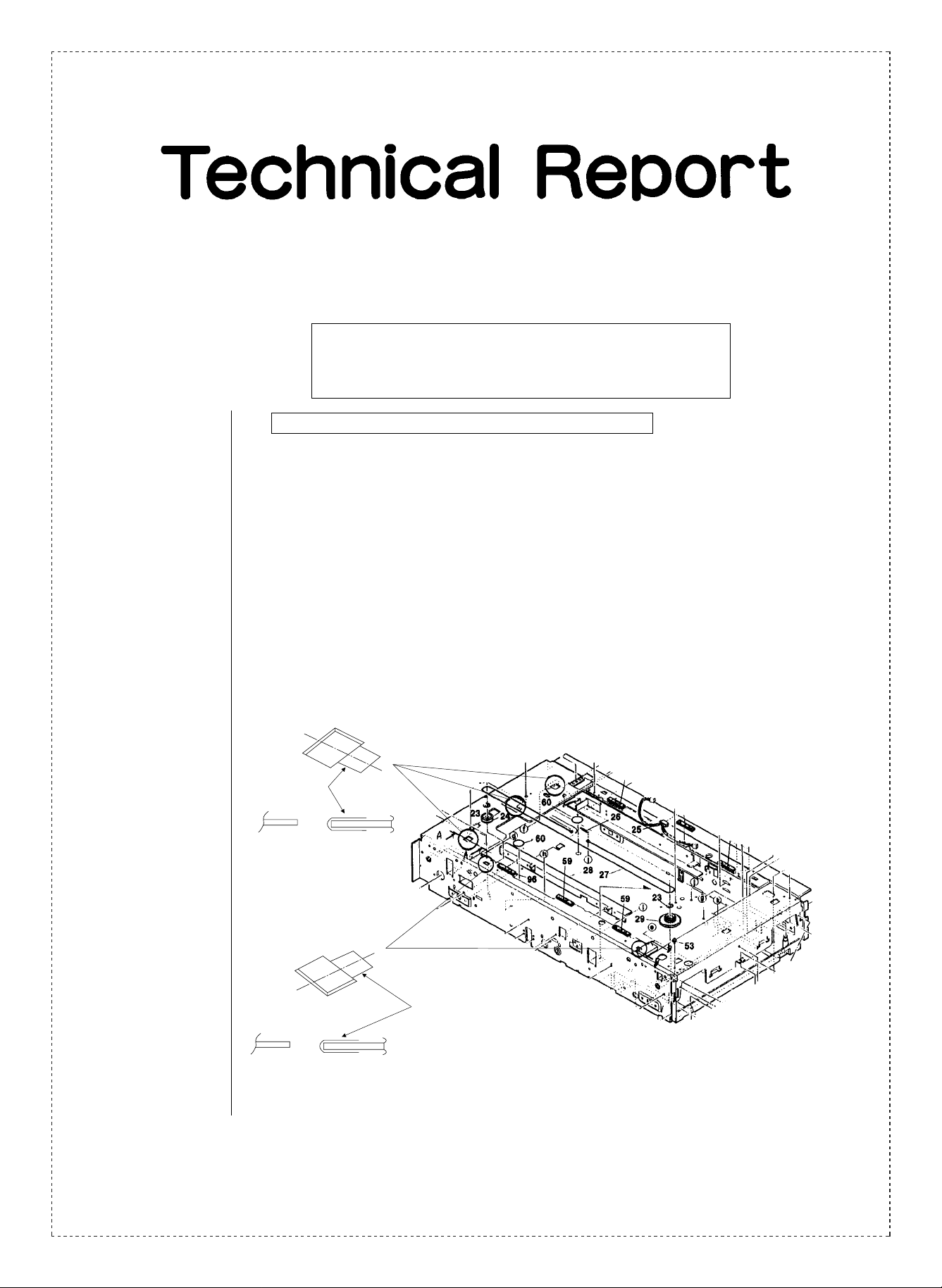

3.Description: As shown in the figure below, sheets A and B have been added to the hook section of

the metal frame plate.

Hook section sheet A (PSHEP3562FCZZ) Q’ty: 2

Hook section sheet B (PSHEP3563FCZZ) Q’ty: 3

Hole

Hook section

sheet B

Aligning the sheet with the

center of the hole, the

sheet is folded in half and

attached (3 locations).

Hole

Hook section sheet A.

Aligning the sheet with the center of

the hole, the sheet is folded in half

and attached (2 locations).

SHARP CORPORATION Reprography Division

1/4

Green

C

Page 2

4.Action: (Factory action)

SD-3062: From the first lot of mass production.

SD-2060: From 1993 October production.

2. Change in the paper guide fulcrum shaft of the center tray unit to improve

productivity.

1.Model name: SD-2060 / 3062

2.General: The paper guide fulcrum shaft of the center tray unit has been changed to improve

productivity.

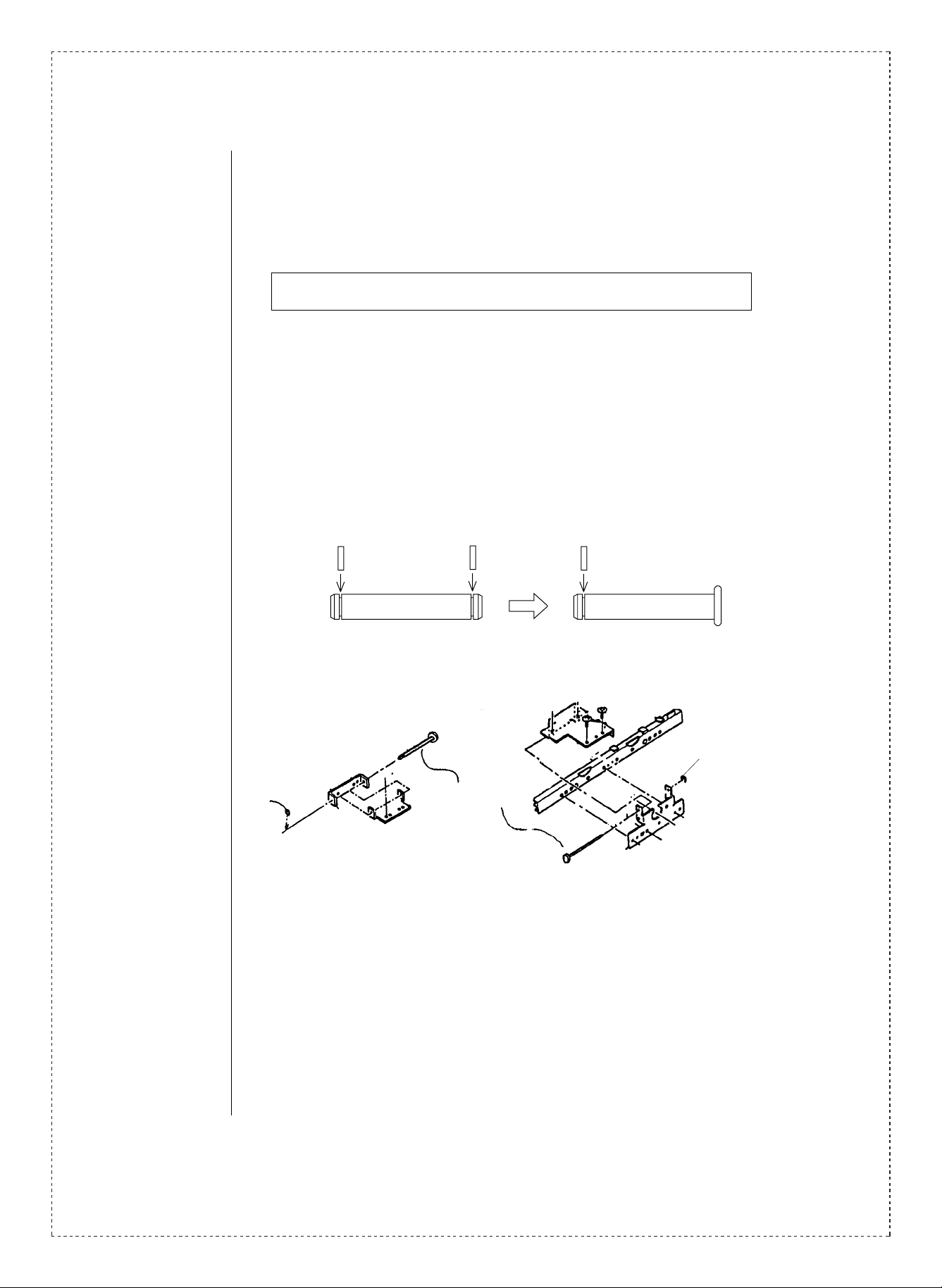

3.Description: The shape of the head of the paper guide fulcrum shaft of the center tray unit has been

changed so that an E-ring will be used in only one location (previously there were two

E-rings employed).

Old New

E3 E3 E3

NSFTZ1974FCZZ NSFTZ2072FCZZ

<Upper paper guide section.>

E3

4.Action: (Factory action)

From 1994 April production.

E3

Paper guide fulcrum

shaft

<Moving frame section>

2/4

Page 3

3. Change in the harness of the copy lamp unit in accordance with safety standards

(200V series, export models only).

1.Model name: SD-02060 / 3062

2.General: The changes described below have been carried out on the 200V series in accordance

with safety standards.

3.Description: Tubes have been added to the CL harness and the optical harness. In addition,

electrical shock warning labels have been added to the darkening cover s of the 240V

AB series.

Location of the added tubes.

Copy lamp unit.

Location of the added tubes.

Location of the added electrical shock warning label (for 240V AB series machines

only).

Electrical shock warning label

Upper darkening cover sheet

3/4

Page 4

Ref.

No.

1

2

Model

name

SD-3062

Version P/G No.

5

5

All

31 -14 NSFTZ1974FCZZ NSFTZ2072FCZZ AC

31 -7 XRESP30-04000 Q’ty change — E rings (E - 3) —

Current parts New parts

Parts code Parts code

— PSHEP3562FCZZ AB

— PSHEP3563FCZZ AB

Price

rank

Parts name

Hook section

sheet A

Hook section

sheet B

Paper guide

fulcrum shaft

Effec-

tive

time

SD-3062:

1st lot.

SD-2060:

’93/10

’94/4

2060

3-6

DHAI-2223FCZZ DHAI-2223FC11 AS

200V

series

3-5

DHAI-2224FCZZ DHAI-2224FC11 AD

3

240V

AB

3 -15

5

DHAI-2225FCZZ DHAI-2225FC11 AX CL Harness 3

— TCAUH0947FCZZ AB

series

Optical harness

A

Optical harness

B

Electrical shock

warning label

SD-3062:

1st lot.

SD-2060:

’93/10

<Interchange>

1. Interc ha ng ea bl e. 4. N ot i nt er ch an ge ab l e.

2. Current type can be used in place of new type.

New type cannot be used in place of current type.

3. Current type cannot be used in place of new type.

New type can be used in place of current type.

Parts marked with “ ” is important for maintaining the safety of the set. Be sure to replace these parts with

spec i fi e d on es fo r m ai n ta in i ng t he s a fe ty and performance o f th e s et .

!

5. Interchangeable if replaced with same types of

relate d parts in use .

6. Others .

Inter-

change-

ability

— Q’ty: 2

— Q’ty: 3

1 Q’ty: 2

3

3

—

Note

Q’ty:

19 to 17

4/4

Loading...

Loading...