Page 1

Date: Jan. 24, 1994

DUPLICATOR: SD-2060

No. : DTE-126

TROUBLE SHOOTING ORIGINAL PAPER JAMS

IN THE OPTICAL AREA OF THE MACHINE.

1.Model name: SD-2060

2.General: When using the RADF, and especially when using thin original paper, the original paper

sometimes gets caught between the original stopper and the table glass. This problem

is generally caused by double feeding or by unevenness of the leading edge of the

original. The space between the table glass and the original stopper has been

narrowed, preventing this problem from occurring.

3.Cause: To prevent cams of the original paper in the optical area of the machine.

4.Description: The stopper bearing has been changed and a stopper adjustment plate has been

added. In carrying this out, the space between the copy table glass and the original

stopper has be decreased from the previous 0.3 ~ 0.5 mm to 0.08 ~ 0.1 mm, effectively

preventing the front edge of the original paper from becoming caught between the table

glass and the original stopper.

Note: Adjustment of the space between the table glass and the original spacer should

always be carried out (adjustment procedure is set forth under the section, “Field

action”, described below.)

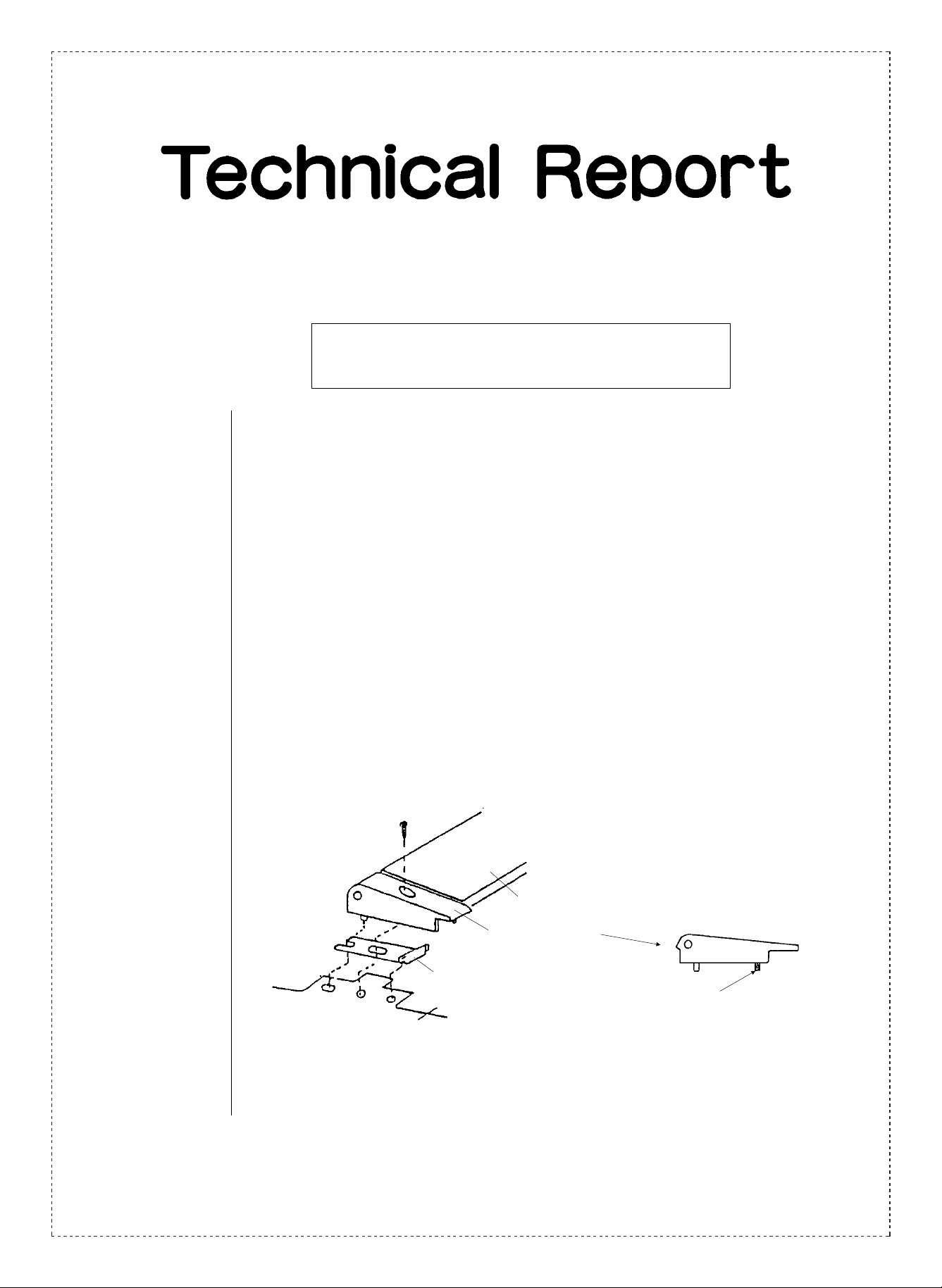

Original stopper.

Stopper bearing

(changed).

Stopper adjustment plate

(added).

This boss has been cut.

SHARP CORPORATION Reprography Division

1/4

Green

C

Page 2

5.Action: (Factory action)

From 1994 February production.

(Field action)

When the same problem as described above occurs in a machine that is already out

on the, the procedure described below should be followed, and the space between the

original stopper and the table class should be adjusted.

* When the original is on paper that is 50 g/m

should be used.

SD-2060

Trouble shooting procedure for original paper jams in the optical area of the machine.

➀ Remove the upper left cabinet (parts guide 1 - 23).

➁ Remove the copy table glass.

➂ Remove the original stopper and the stopper bearing (front and rear).

* The stopper bearing is no longer needed.

2

to 35 g/m2, the RADF thin paper mode

(Assembly order)

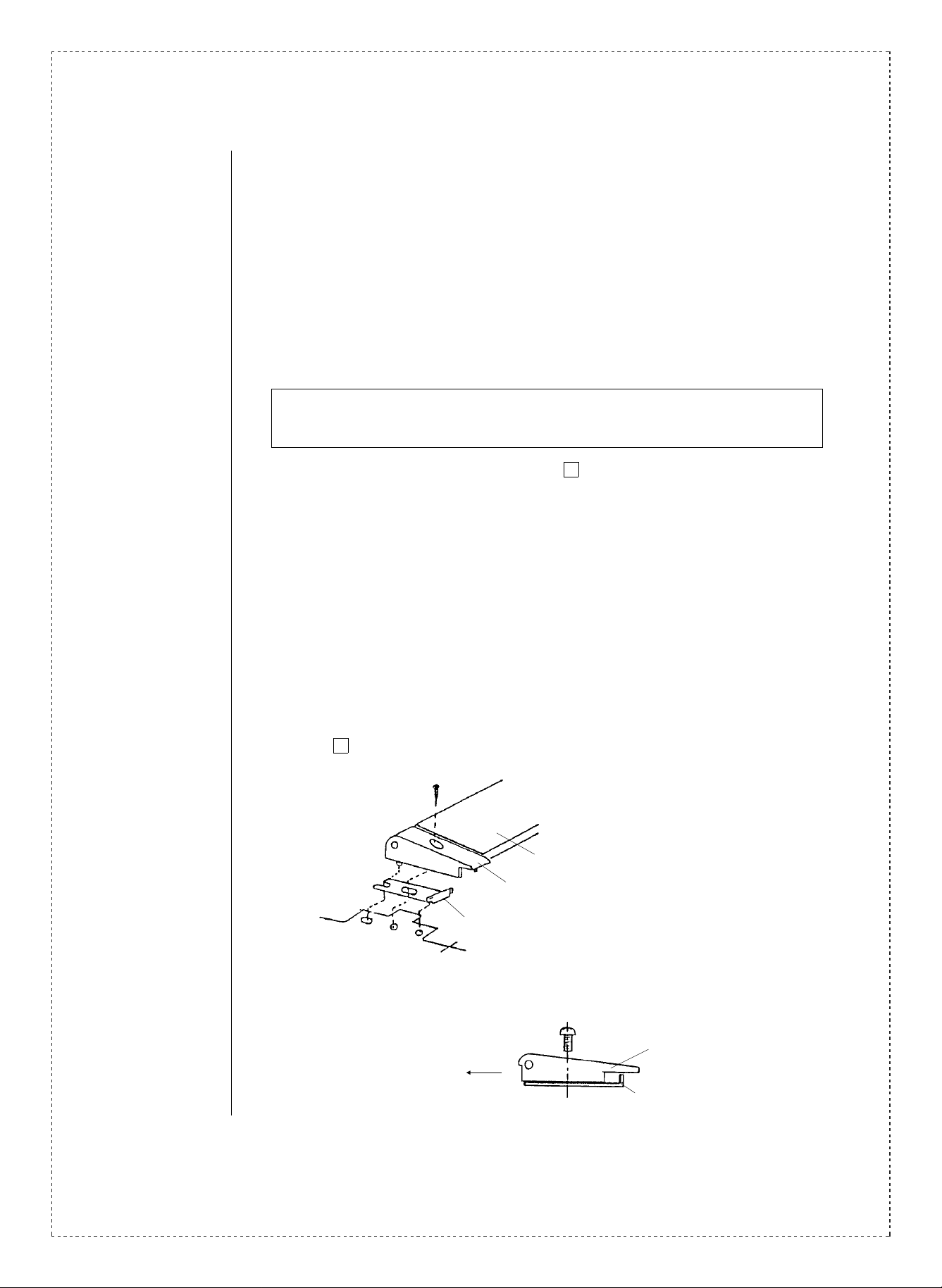

➃ Attach the changed stopper bearing and the stopper adjustment plate.

As shown in the illustration below, attach the stopper adjustment plate and the stopper

bearing on the front frame side. Next, the stopper adjustment plate and the stopper

bearing on the rear frame side should be attached while the original stopper is in the

attached position. Attach the rear frame stopper adjustment plate and the stopper

bearing to the attached front frame bearing, and after lifting the upper cabinet (parts

guide 1 - 19) it should be pushed into position.

Original stopper.

Stopper bearing.

Stopper adjustment plate.

➄ The stopper should be temporarily fixed. (fix the stopper as far as possible in the

direction shown below.

2/4

Stopper bearing.

Direction of copy paper output.

Stopper adjustment plate.

Page 3

➅ Exercising caution concerning the direction of the table glass, it should be fixed.

(The white painted edge of the table glass should be facing to the right front after

fixing.) At this time the stopper adjustment plate should be such that both F and R are

in line.

* Caution should be exercised. If hit too strongly the adjustment plate can become

deformed.

➆ Adjustment of the space between the table glass and the original stopper.

A4 size paper (thickness of 0.086 ~ 0.087) should be inserted between the original

stopper and the table glass. The stopper should then be pressed down and fixed.

After adjustment, check to see whether or not standard copy paper fits between the

original stopper and the table glass.

(Caution): If the temperature rises the space between the original stopper and the

table glass increases. As a result, when making adjustments the

temperature of the stopper should be checked. If it feels hot, the adjustment

should be set so that one sheet of standard paper can barely be squeezed

in between the original stopper and the table glass.

Under normal temperatures, adjustment should be carried out so that the

standard copy paper can’t quite be inserted, 40g/m paper just fits.

(Caution): When adjusting the original stopper, the stopper should not be adjusted

while in the lowered position (the space between the original stopper and

the table glass becomes too narrow).

(Caution): From F to R in the the original copy stopper and the copy table glass

should not be touching. Raise and lower the stopper manually to check.

(Caution): Check the height of the stopper. (It is is not correct, carry out the necessary

readjustments.)

1.0mm

Table glass.

Sim 2 - 3 - 8. Solenoid is

in the ON position.

Original stopper.

2.0mm

Table glass.

Free condition.

➇ Attach the upper left cabinet section.

3/4

Page 4

Ref.

Model

No.

1 SD-2060 All

<Interchange>

1. Interc ha ng ea bl e. 4. N ot i nt er ch an ge ab l e.

2. Current type can be used in place of new type.

New type cannot be used in place of current type.

3. Current type cannot be used in place of new type.

New type can be used in place of current type.

Parts marked with “ ” is important for maintaining the safety of the set. Be sure to replace these parts with

speci fied ones fo r m ai n ta in ing the safe ty an d pe r fo rmance of the set.

name

Version P/G No.

5 -13

5

!

Current parts New parts

Parts code Parts code

NBRGP0474FCZZ NBRGP0474FCZ1 AD Stopper bearing.

— LPLTM4540FCZZ AD

Price

5. Interchangeable if replaced with same types of

relate d parts in use .

6. Others.

Parts name

rank

Stopper

adjustment plate.

Effec-

tive

time

’94/2 5

Inter-

change-

ability

Note

Q’ty: 2

Q’ty: 2

4/4

Loading...

Loading...