Page 1

Date: Feb. 21, 1994

DUPLICATOR: SD-2060

TROUBLE SHOOTING DIAGONAL FEEDING AND DF

BELT DAMAGE BY CARRYING OUT CHANGES IN THE

PRESSURE RO LLER STAYS.

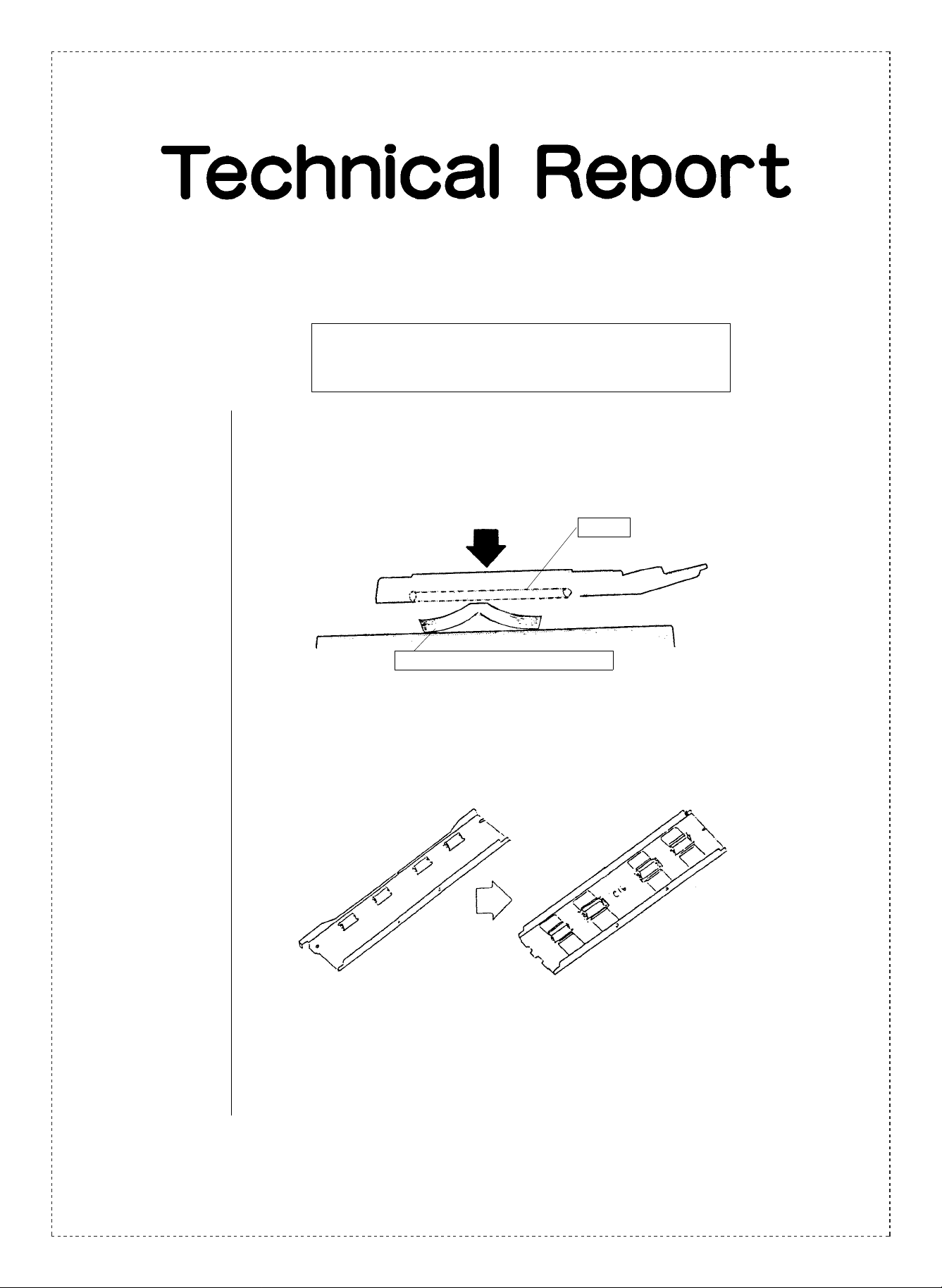

1.General: When making copies in the OC mode of thick original copies such as books, the

pressure roller stay of the conveyor area can become deformed and bent upwards

when too much pressure is placed on the conveyor area of the RADF. This can cause

diagonal feeding of original copies and in extreme cases the DF belt can be damaged.

No. : DTE-116

DF belt.

Thick original copies (such as books).

2.Description: Changes are carried out to prevent deformation of the pressure roller stay and to

improve efficiency when copying thick original copies.

Old. New.

Note: The parts comprising the pressure roller stay area have also been changed, and

shall all be reported.

SHARP CORPORATION Reprography Division

1/3

Green

C

Page 2

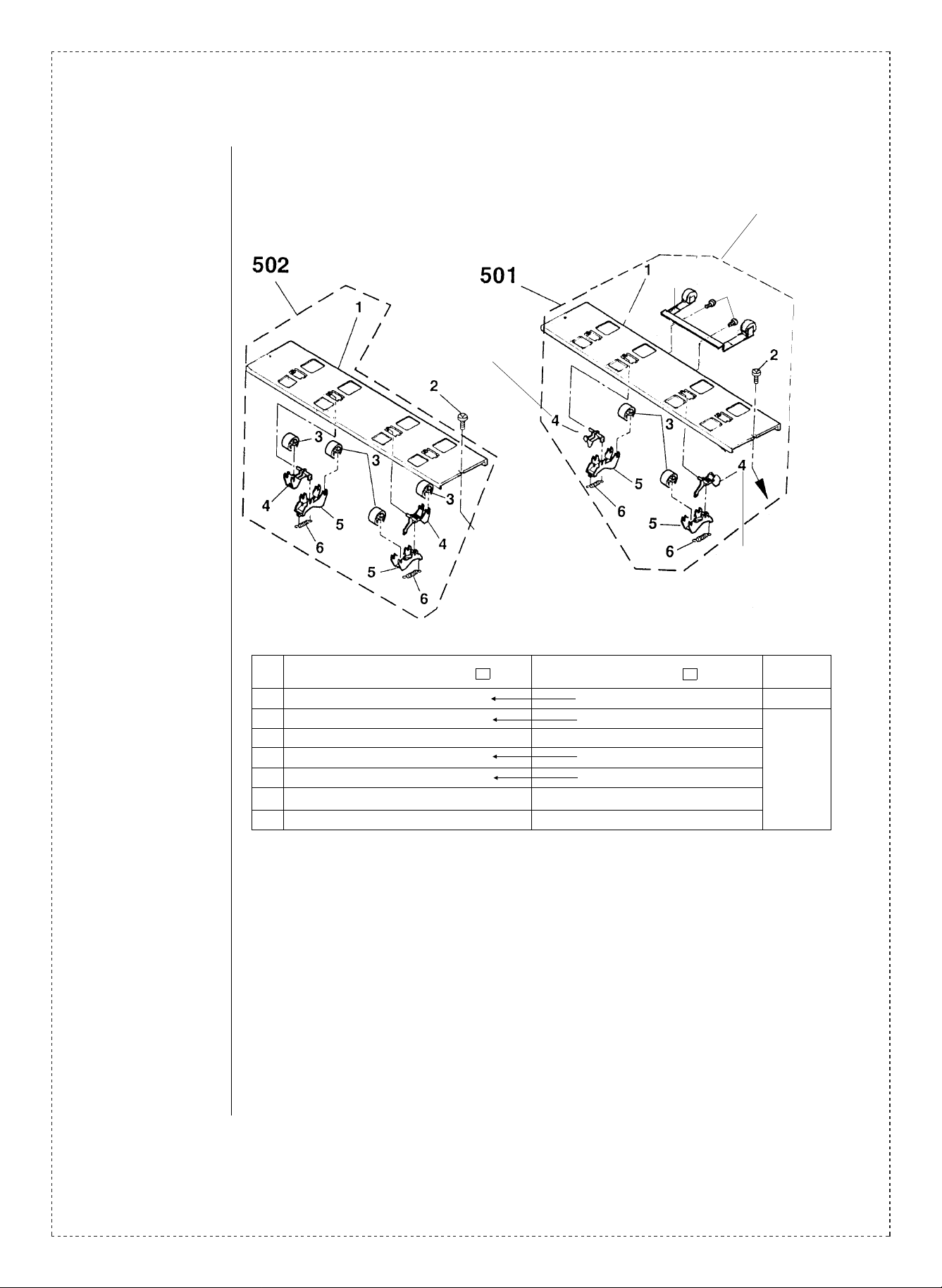

Designed to clip on to the edge of the stay, and added

as a temporary measure from the beginning of mass

production. From 1993 Mid-August the changes

shown in the figure below have been carried out.

Right pressure roller stay assembly. Left pressure roller stay assembly.

Pressure plate spring

plate assembly.

Pressure holder C.

Screws

(M3 x 6).

Pressure holder C.

P/G

Right pressure roller stay assembly ( 44 -502). Left pressure roller stay ( 44 - 501).

No.

1 Changed pressure roller stay. ’93/12

3 Changed pressure bearing (Q’ty: 4). (Q’ty: 2)

4 Pressure holder 1. Pressure holder C

5 Pressure holder 2.

6 Pressure bearing spring.

3.Action: (Factory action)

From 1994 December production.

(Market action)

Changes should be carried out when replacing the pressure roller stay.

Effective

time.

From the

start of

mass

production.

Pressure plate spring plate assembly.

Screws (M3 x 6).

2/3

Page 3

Ref.

Model

No.

SD-2060 All

<Interchange>

1. Interchangeable. 4. Not interchangeable.

2. C urr e nt t y pe c a n be u s ed i n p la ce of new ty pe .

New ty pe cann ot be us ed i n place of curr ent type .

3. C urre nt ty pe cann ot be used i n place of new ty pe.

New t y pe c a n be u sed in p la ce of curr en t ty p e.

Parts m ar ke d wi t h “ ” is i mpor t an t fo r m a in ta i ning t he s a fe ty of the s e t. B e su r e to re pl ace t he s e pa r ts wi t h

specified ones for maintaining the safety and performance of the set.

name

Version P/G No.

44 -501 0CW2176K072A/ 0CW2176K094A/ AZ

44 -502 0CW2176K045A/ 0CW2176K072E/ AX

44 -1 0CW2176P111A/ 0CW2176P111E/ AQ

44 -5 0CW2158P033B/ 0CW2158P033C/ AD

44 -6 0CW2176P329A/ 0CW2176P374B/ AD

44 -4 0CW2158P032C/ 0CW2158P032D/ AD

44 — 0CW2176P028A AH

44 — 0CW2176K095A AS

44 — 0CW030060FZTP AA

!

Current parts New parts

Parts code Parts code

5. Interchangeable if replaced with same types of

relate d parts in use .

6. Others.

Price

Parts name

rank

Left pressure

roller stay

assembly.

Right pressure

roller stay

assembly.

Pressure roller

stay.

Pressure holder

2.

Pressure

bearing spring.

Pressure holder1.Mid-

Pressure holder

C.

Pressure plate

spring plate

assembly.

Screws (M3 x 6

tapping).

Effec-

tive

time

’93/12 3

’93/12 3

’93/12 3 Q’ty: 2

1st lot. Q’ty: 4

1st lot. Q’ty: 4

’93/8

1st lot. *2

1st lot. —

1st lot. — Q’ty: 2

Inter-

change-

ability

Note

*1

Added

to the

left side.

*1 Change in Q’ty: 4 to 2 (Discontinued from the left side).

*2 Quantity: 2 (Added to the left side).

3/3

Loading...

Loading...