Page 1

Date: Jan. 17, 1994

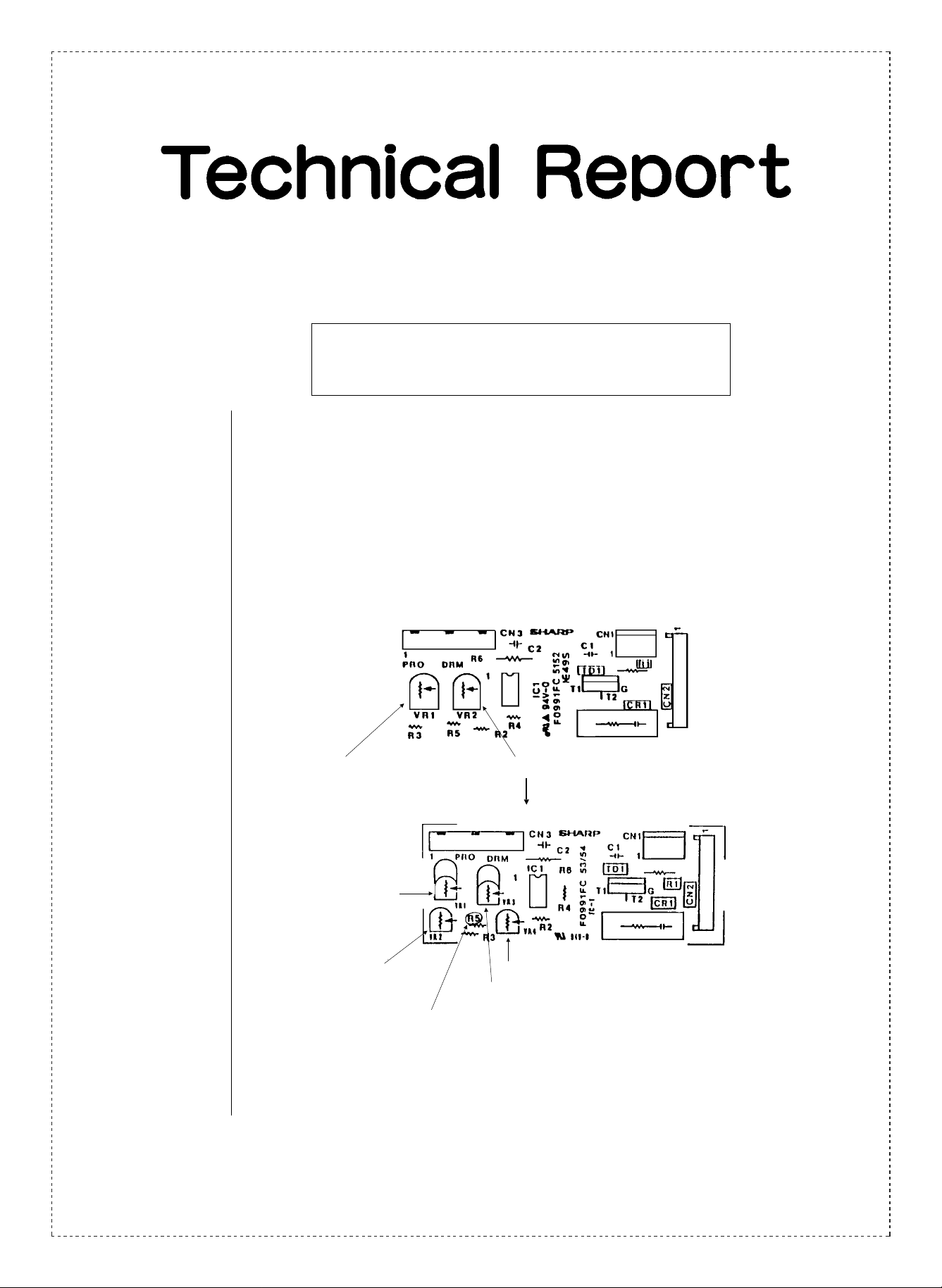

DUPLICATOR : SD - 2060

No. : DTE - 110

CHANGE IN PROCESS CONTROL PWB TO IMPROVE

SERVICABILITY .

1.Model name: SD-2060

2.General: The rough adjustment volume has been added to the fine adjustment volume in the

process control PWB in order to facilitate the adjustment of the drum marking sensor

and process control sensor.

3. Description: A change in volume resistance (VR 1, VR 2), an addition of volume resistance (VR 3,

VR 4) and a change in R5 have been carried out (Refer to Page 2).

Current.

Process control sensor

adjustment volume.

Process control sensor fine

adjustment volume (VR 1).

Process control sensor rough

adjustment volume (VR 2).

Drum marking sensor adjustment volume.

New.

Drum marking sensor rough adjustment volume (VR 4).

Drum marking sensor fine adjustment volume (VR 3).

4.Action: (Factory action)

From 1994 Mid-January production.

SHARP CORPORATION Reprography Division

R5 changed (1.3 KΩ → 680Ω ).

1/2

Green

C

Page 2

Process Control PWB Adjustment

1. Drum marking sensor adjustment procedure.

➀ Turn VR 3, VR 4 as far to the left (counter clock-wise) as possible.

➁ Input Sim 44 - 02.

➂ Adjust fine adjustment volume VR 3 to 170 ±10.

➃ If after performing step ➂ above the VR 3 adjustment range does not rise even after

turning it as far to the right as possible, return VR 3 as far to the left as possible, and

adjust the rough adjustment volume VR 4 to between 105 and 160.

➄ Adjust VR 3 to 170 ±10.

2. Process control sensor adjustment procedure.

➀ Turn VR 1, VR 2 as far to the left as possible.

➁ Input Sim 44 - 03.

➂ Adjust the fine adjustment volume VR 1 to 815 ±15.

➃ If after performing step ➂ above the VR 1 adjustment range does not rise even after

turning it as far to the right as possible, return VR 1 as far to the left as possible, and

adjust the rough adjustment volume VR 2 to between 673 and 800.

➄ Adjust VR 1 to 815 ±15.

Ref.

Model

No.

SD-2060

(L)

<Interchange>

1. Interchangeable. 4. Not interchangeable.

2. C urr e nt t y pe c a n be u s ed i n p la ce of new ty pe .

New ty pe cann ot be us ed i n place of curr ent type .

3. C urre nt ty pe cann ot be used i n place of new ty pe.

New t y pe c a n be u sed in p la ce of curr en t ty p e.

Parts m ar ke d wi t h “ ” is i mpor t an t fo r ma in ta i ning t he s a fe ty of t he se t. Be su r e to re pl ac e t he se pa r ts wi t h

specified ones for maintaining the safety and performance of the set.

name

Version P/G No.

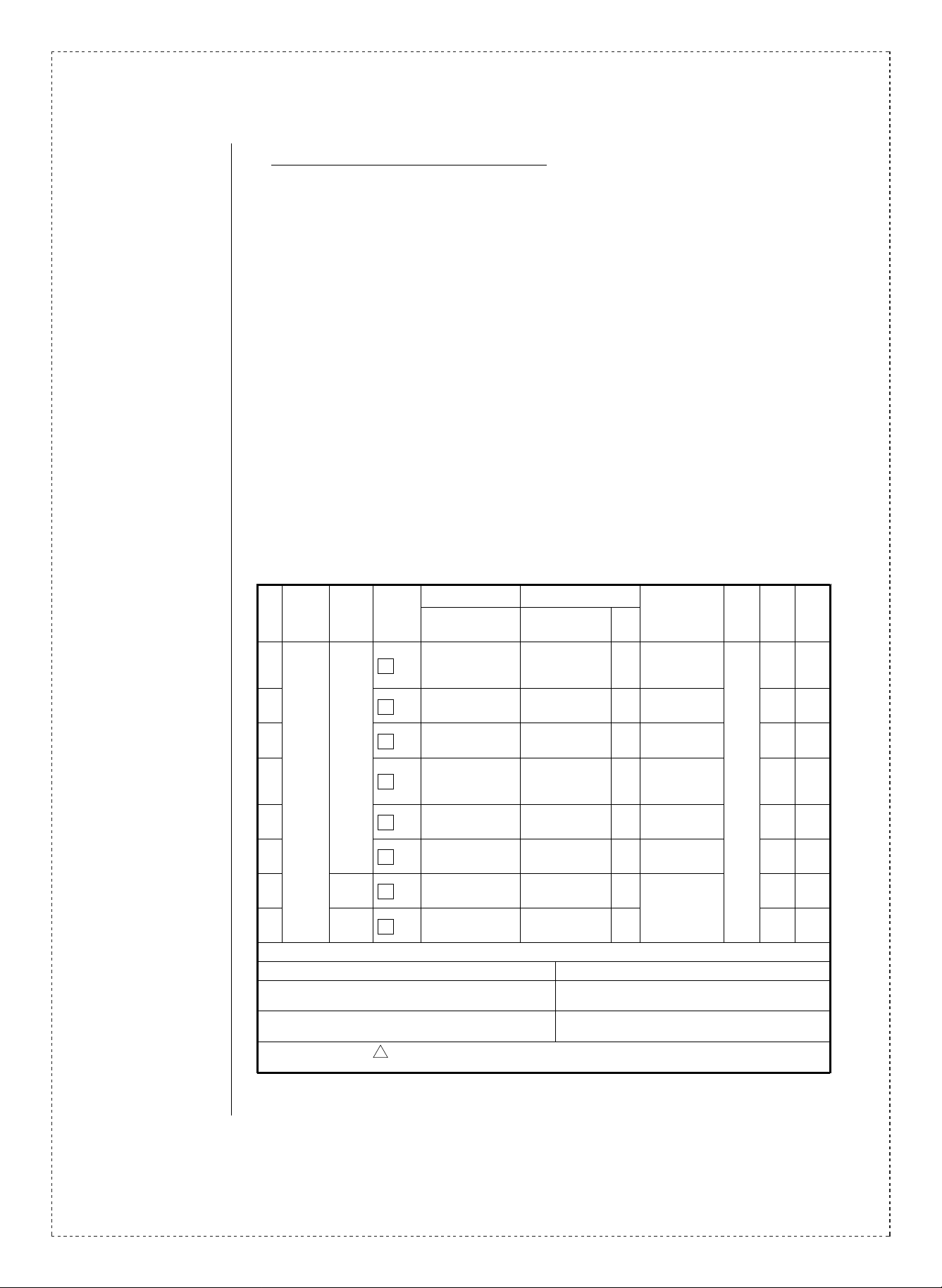

50 -5 RVR-M1500QCZZ Eliminated —

50 -11 VRD-RC2EY132J Eliminated —

50 -12 VRD-RC2EY681J

ALL

50 — RVR-M1100QCZZ AD

50 — RVR-M1514QCZZ AE

50 — RVR-MD400QCZZ AE

100V

50 -901 CPWBF0991FC51 CPWBF0991FC53 AY

series

200V

50 -901 CPWBF0991FC52 CPWBF0991FC54 AY 3

series

!

Current parts New parts

Parts code Parts code

Change in

quantity:(1→2)

5. Interchangeable if replaced with same types of

relate d parts in use .

6. Others.

Price

rank

Volume

resistance

Resistance

(1.3 KΩ 1/4 W)

Resistance

—

(680Ω 1/4 W)

Volume

resistance(10KΩ)

Volume resistance

(100KΩ)

Volume resistance

(47KΩ)

Process control

circuit board

Parts name

Effec-

tive

time

MidJan.

1994.

Inter-

change-

ability

3

Note

Q’ty: 2

(VR 1,

VR 2)

Q’ty: 1

(R5)

R3,R5

Q’ty: 2

(VR1,

VR3)

Q’ty: 1

(VR2)

Q’ty: 1

(VR4)

2/2

Loading...

Loading...