Page 1

Date: Nov. 24, 1993

DUPLICATOR : SD-2060

1.PREVENTION OF COPY LIGHTNESS AND COPY STREAKING — IMPROVEMENT IN DEVELOPER

FLOW DUE TO DO CTOR SHAPE ALTERAT IO N.

2.PREVENTION OF DOOR SWITCH MALFUNCTIONING DUE TO HARNESS ENTANGLEMENT.

3.PREVENTION OF DIAGONAL FEEDING FROM THE MIDDLE PAPER FEEDING TRAY.

4.PREVENTION OF 1000 AIR PAPER FEEDING UNIT FEEDING DUCT CRACKING.

5.TRIAC CHANGE FOR MODEL COMPATA BILITY.

No. : DTE-100

1. Prevention of copy lightness and copy streaking — improvement in developer flow

due to doctor shape alteration.

1.General: Prevention of copy lightness and copy streaking.

2.Cause: To improve developer flow. When developer gets clogged between the Doctor and the

MG roller, it is not evenly spread.

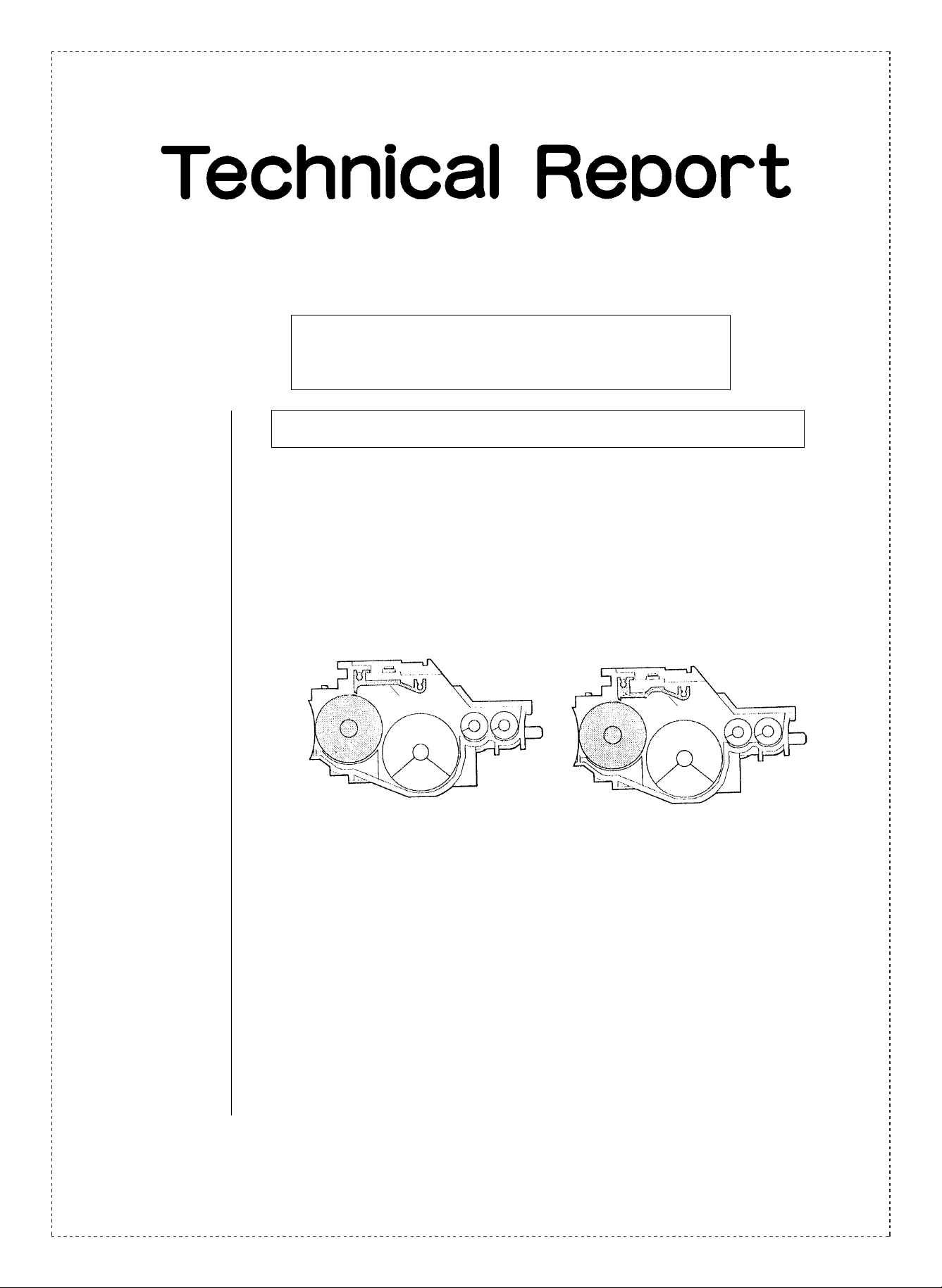

3.Description: As shown in the diagram below, the shape of the doctor has been changed, and the

flow of the developer has been stabilized.

Old New

Doctor.

Doctor.

As a temporary measure, ABS plate has been used to hold the screws in a manner

such as to create a shape similar to the new one, implemented from the 1st lot in

mid-June, 1993.

4.Effective time: (Factory action)

From mid-June, 1993.

SHARP CORPORATION Reprography Division

1/5

Green

C

Page 2

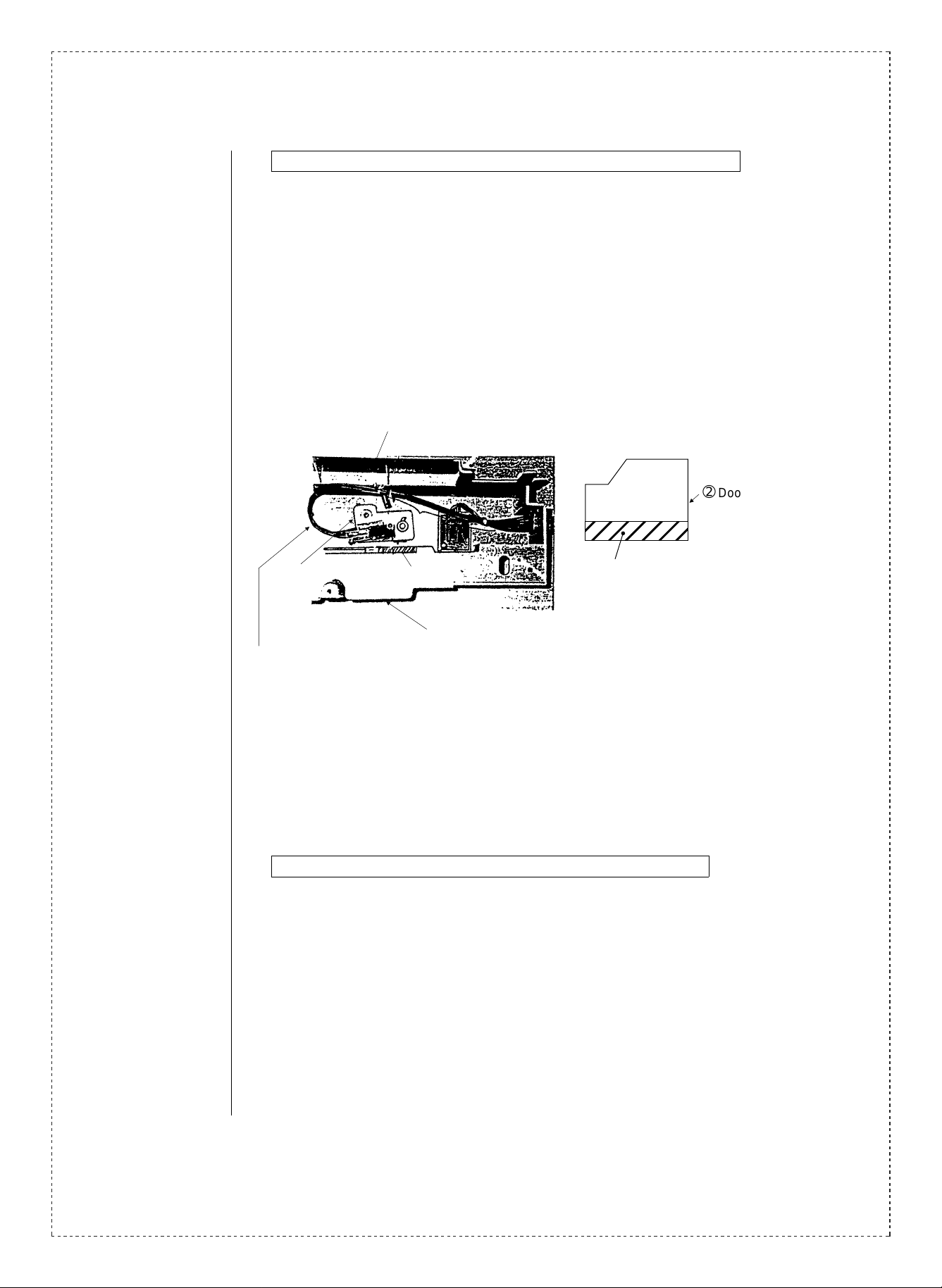

2. Prevention of door switch malfunctioning due to harness entanglement.

1.General: Because the harness clamp on the operation panel side sags and drops during the

door switch movement strokes, the micro-switch gets snagged in the harness, and the

indication “CH” sometimes fails to be given when the door is opened. To remedy this

problem, mylar has been added to prevent the snagging of the harness.

2.Cause: Prevention of door switch malfunctioning caused by snagging of the harness.

3.Description: Mylar has been introduced between the harness and the micro-switch.

Harness clamp.

➁ Door SW Mylar.

(PSHEP3575FCZZ)

Door switch.

This is the harness which has been

snagging with the door switch.

➀

Operation base plate.

Double-sided tape.

The double-sided tape portion of the door

switch mylar ➁ is aligned with the section

of the operation base plate marked by the

shaded area ➀, and attached.

4.Effective time: (Factory action)

From mad August, 1993.

3. Prevention of diagonal feeding from the middle paper feeding tray.

1.General: The copy paper sometimes catches the ribs of the middle feeding tray, and is diagonally

fed during double-sided copy operations.

To remedy this problem, spacers have been introduced between the ribs of the paper

feeding tray. (Problems have been particularly common with WLT paper.)

2.Cause: To prevent diagonal feeding during double-side copying.

2/5

Page 3

3.Description: As shown in the diagram below, spacers have been added to both sides of the paper

feeding tray.

Paper feeding tray spacer A.

Paper feeding tray spacer C.

Paper feeding tray spacer B.

Paper feeding tray

spacer C.

Paper feeding

tray spacer B.

Paper feeding tray spacer A.

4.Effective time: (Factory action)

From June, 1993.

4. Prevention of 1000 air paper feeding unit feeding duct cracking.

1.General: During assembly of the 1000 air paper feeding unit in the production process, the screw

anchors of the vacuum duct which secure the vacuum out ducts and the vacuum in

ducts sometimes break.To prevent this problem the screws have been changed.

2.Cause: To prevent vacuum duct cracking.

3.Description: The screws previously used were M4 x 20 P-Tight type screws. They have been

changed to M4 x 16 P-Tight screws, so that they do not protrude from the screw

anchors of the vacuum ducts. This measure will prevent the vacuum duct cracking.

3/5

Page 4

Changed.

Changed.

16

M4 x 20 P-Tight (Bind) screws.

(XEBSD40P20000)

20

M4 x 16 P-Tight (Bind) screws.

(XEBSD40P16000)

4.Effective time: (Factory action)

From mid-July, 1993.

5. Triac change for model compatability . (only for 100 V series.)

1.General: In order to establish compatibility with other models, the TRIAC has been changed.

2.Cause: To establish parts compatibility with other models.

3.Description: The TRIAC on the AC circuit board (TD 302) has been changed.

VHSTM1641P/-1 VHITM1641P-L/

Current New

4.Effective time: (Factory action)

From October, 1993.

4/5

Page 5

Ref.

Model

No.

name

1

2

SD-2060 All

3

4

Version P/G No.

13 -38 LPLTZ4310FCZZ LPLTZ4310FCZ1 AX Doctor.

2

30 — PSPAZ0633FCZZ AB

30 — PSPAZ0634FCZZ AB

30 — PSPAZ0635FCZZ AD

17 -40 XEBSD40P20000 XEBSD40P16000 AA Screw (M4x16)

Current parts New parts

Parts code Parts code

— PSHEP3575FCZZ AC

Price

rank

Parts name

Door switch

mylar.

Copy paper tray

spacer A.

Copy paper tray

spacer B.

Copy paper tray

spacer C.

Effec-

Inter-

tive

change-

time

MidJun.

1993

MidAug.

1993

’93/6 — Q’ty: 2

’93/6 — Q’ty: 2

’93/6 — Q’ty: 2

MidJul.

1993

Note

ability

3

—

3 Q’ty: 4

5

<Interchange>

1. Interchangeable. 4. Not interchangeable.

2. C urr e nt t y pe c a n be u s ed i n p la ce of new t ype .

New ty pe cann ot be us ed i n place of curr ent type .

3. C urre nt ty pe cann ot be used i n place of new ty pe.

New t y pe c a n be u sed in p la c e of c u rr en t ty p e.

Parts m ar ke d wi t h “ ” is i mp ort an t fo r m a inta i ni ng t he sa fe ty of t he s e t. B e su r e to re pl ace these pa rts wi t h

specified ones for maintaining the safety and performance of the set.

52 -31

!

VHSTM1641P1-1 VHITM1641P-L/ AM Triac. ’93/10 1 TD302

5. Interchangeable if replaced with same types of

relate d parts in use .

6. Others .

5/5

Loading...

Loading...