Page 1

Date: Nov. 19, 1993

DUPLICATOR : SD-2060

1.PREVENTION OF COPY IMAGE DISALIGNMENT DURING PRINTING.

2.PREVENTION OF LCD CORNER FADING BY CHANGING THE LIQUID

CRYSTAL ATTACHMENT PLATE.

3.PREVENTION OF WRINKLING DURING BACK SIDE COPYING.

No. : DTE-099

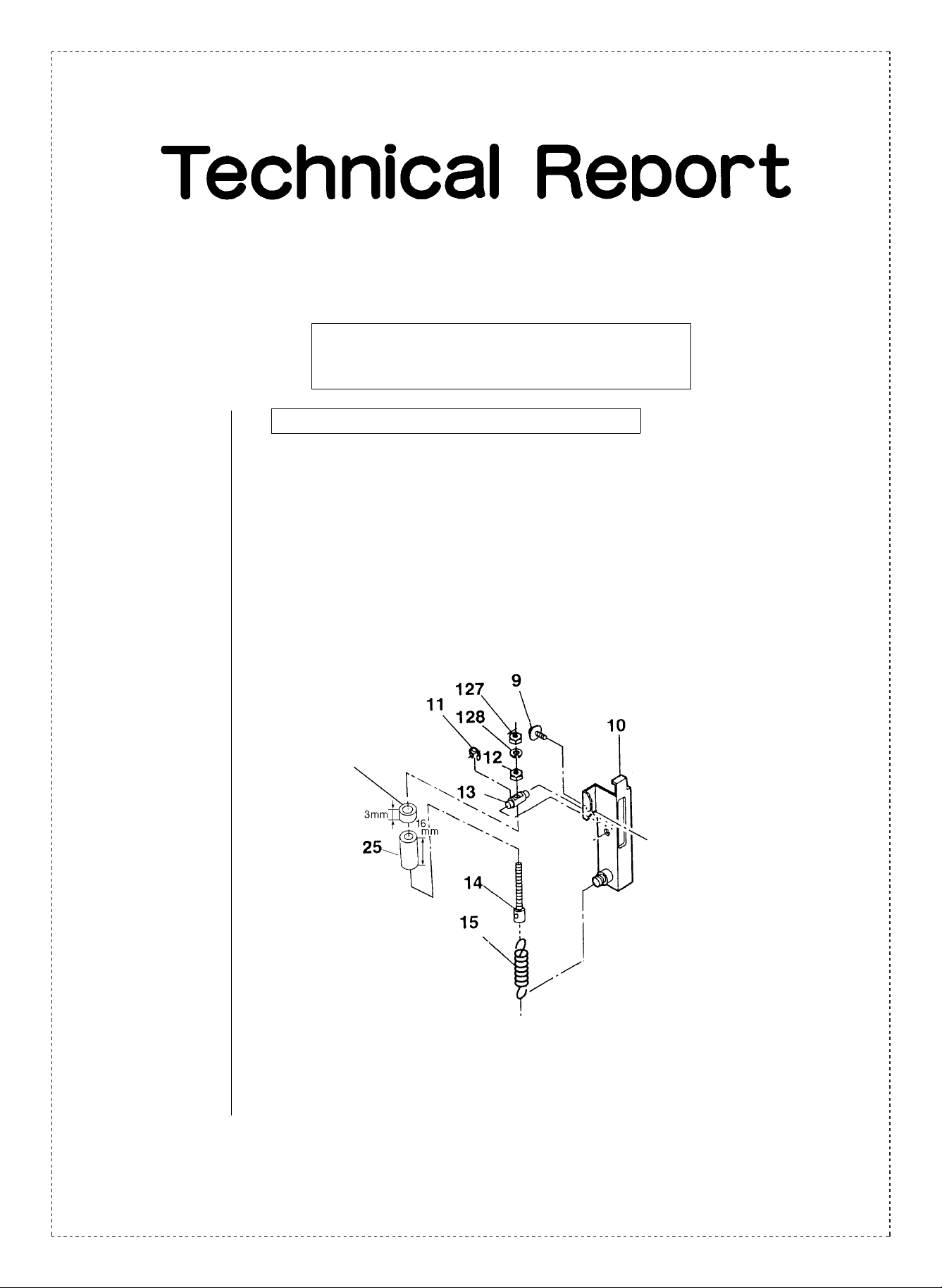

1. Prevention of copy image disalignment during printing.

1.General: Copy image disalignment sometimes occurs during the paper gripping process of the

heat rollers. To prevent this the pressure of the heat rollers has been reduced.

2.Cause: The above problem is caused by the impact during the paper gripping process of the

heat rollers.

3.Description: To reduce the pressure of the heat rollers and thus make the paper gripping process

run more smoothly, a collar has been added. (The collar has been added to both front

and rear sides of the fixer unit.)

Added collar

(PCLR-0391FCZZ).

4.Effective time: (Factory action)

From mid-July, 1993.

SHARP CORPORATION Reprography Division

This diagram is of the front side

of the fixer unit.

1/4

Green

C

Page 2

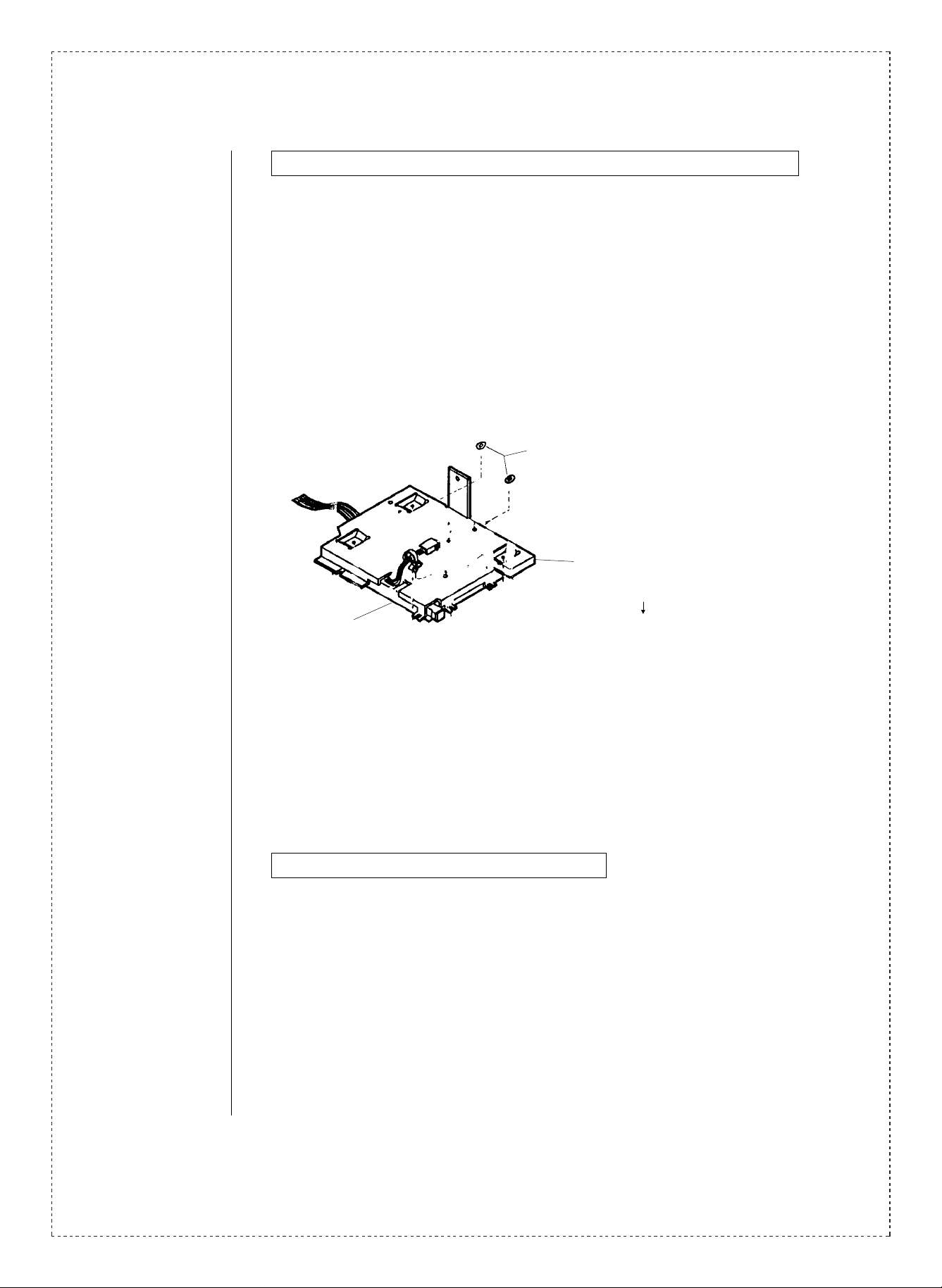

2. Prevention of LCD corner fading by changing the liquid crystal attachment plate.

1.General: A plastic washer with a thickness of 0.5 mm had been inserted between the LCD and

the liquid crystal attachment plate. To prevent fading of the liquid crystal display

corners, the shape of the liquid crystal attachment plate has been changed, and the use

of the washer has been discontinued.

2.Cause: The above change has been implemented as a permanent measure to prevent fading

of the LCD corners.

3.Description: Instead of using the plastic washer, the liquid crystal attachment plate has been tapered

0.5 mm. The parts codes affected by this have been changed accordingly.

A plastic washer with a thickness of 0.5

mm had been inserted between the LCD

and the liquid crystal attachment plate, but

the liquid crystal attachment plate has

been tapered 0.5 mm, and the use of the

plastic washer has been discontinued.

26

Liquid crystal attachment plate.

LPLTM4212FCZZ

24 (LCD)

LPLTM4212FCZ1

4.Effective time: (Factory action)

Addition of the 0.5 mm plastic washer:

From June, 1993.

Shape change of the liquid crystal attachment plate:

From October, 1993.

3. Prevention of wrinkling during back side copying.

1.General: Wrinkles sometimes occur during double side copying, caused by the formation of

moisture on the paper guides in the paper discharge unit. To remedy this problem,

ventilation holes have been added to the upper 2 paper guides and the lower paper

guides of the paper discharge unit, and the fixed supplementary paper guides have

been altered.

2.Cause: Moisture which forms on the paper guides is absorbed by the copy paper when being

discharged. When this damp paper is double side copied, it has a tendency to wrinkle.

In particular, when copying on damp paper, the moisture is vaporized and then forms on

the paper guides, causing wrinkles.

2/4

Page 3

3.Description: Ventilation holes have been added to the upper 2 paper guides and the lower paper

guides of the paper discharge unit to prevent the formation of moisture.

Moreover, the shape of the fixed supplementary paper guides has been altered. These

measures are designed to prevent the wrinkling of the copy paper when both sides are

copied.

Changed lower paper guides of the paper discharge unit.

Added ventilation holes.

Changed upper 2 paper guides

of the paper discharge unit.

Added ventilation holes.

Before change.

Paper guide A.

Fixed supplementary paper guides.

Method of distinguishing between old and new fixed supplementary paper guides.

Before change. After change.

After change.

(The new fixed supplementary paper guides

are slightly more curved than the old ones.)

3/4

Page 4

With this change the attachment position of the paper guide FA fixer unit has changed.

1) The F/R paper guide positioning plate is aligned with the top indicators of the Fu

frame F/R, and secured with screws. (originally center)

2) The paper guide FA is attached to the lower portion of the paper guide positioning

plate without clearance.

Fu frame F.

Paper guide

positioning plate F.

4.Effective time: (Factory action)

From September, 1993.

Ref.

Model

No.

1

2

SD-2060 All

3

<Interchange>

1. Interchangeable. 4. Not interchangeable.

2. C urr e nt t y pe c a n be u s ed i n p la ce of new ty pe .

New ty pe cann ot be us ed i n place of curr ent type .

3. C urre nt ty pe cann ot be used i n place of new ty pe.

New t y pe c a n be u sed in p la ce of curr en t ty p e.

Parts m ar ke d wi t h “ ” is i mpor t an t fo r m a in ta i ning t he s a fe ty of the s e t. B e su r e to re pl ace these pa rts wi t h

specified ones for maintaining the safety and performance of the set.

name

Version P/G No.

Aligned with the top indicators

of the P/G positioning plate.

Paper guide FA.

Current parts New parts

Parts code Parts code

11 — PCLR-0391FCZZ AA

2 -26

15 -38 PGIDH1461FCZZ PGIDH1461FCZ1 AN

15 -22 PGIDH1437FCZZ PGIDH1437FCZ1 AT

11 -107 PGIDH1476FCZZ PGIDH1476FCZ1 AS

!

LPLTM4212FCZZ LPLTM4212FCZ1 AP

Price

rank

5. Interchangeable if replaced with same types of

relate d parts in use .

6. Others.

Parts name

Holder fixing

collar.

Liquid crystal

attachment plate.

Upper 2 paper

guides of the paper

discharge unit .

Lower paper

guides of the paper

discharge unit.

Fixed supplement

paper guide.

Fu frame R.

Paper guide

positioning plate R.

Effec-

Inter-

tive

change-

time

Mid-

Jul.

1993

’93/10 3

’93/9

Note

ability

—

3

3

3

4/4

Loading...

Loading...