Page 1

Date: Nov. 19, 1993

DUPLICATOR : SD-2060

1.REVENTION OF TC/AC CASE SOILING CAUSED BY IMPROPER GROUNDING.

2.ADDITION OF AIR SEALS TO PREVENT OF STAT IC NOISE EMITTED FROM THE

NOISE INSULLATION DUCT .

3.CHANGE OF D TERMINAL GATE SOLENOID SCREWS TO PREVENT INTERNAL

SHORT CIRCUITING OF THE SOLENOID.

4.HARNESS CLAMPS CHANGE TO IMPROVE OPERATING EFFICIENCY .

No. : DTE-098

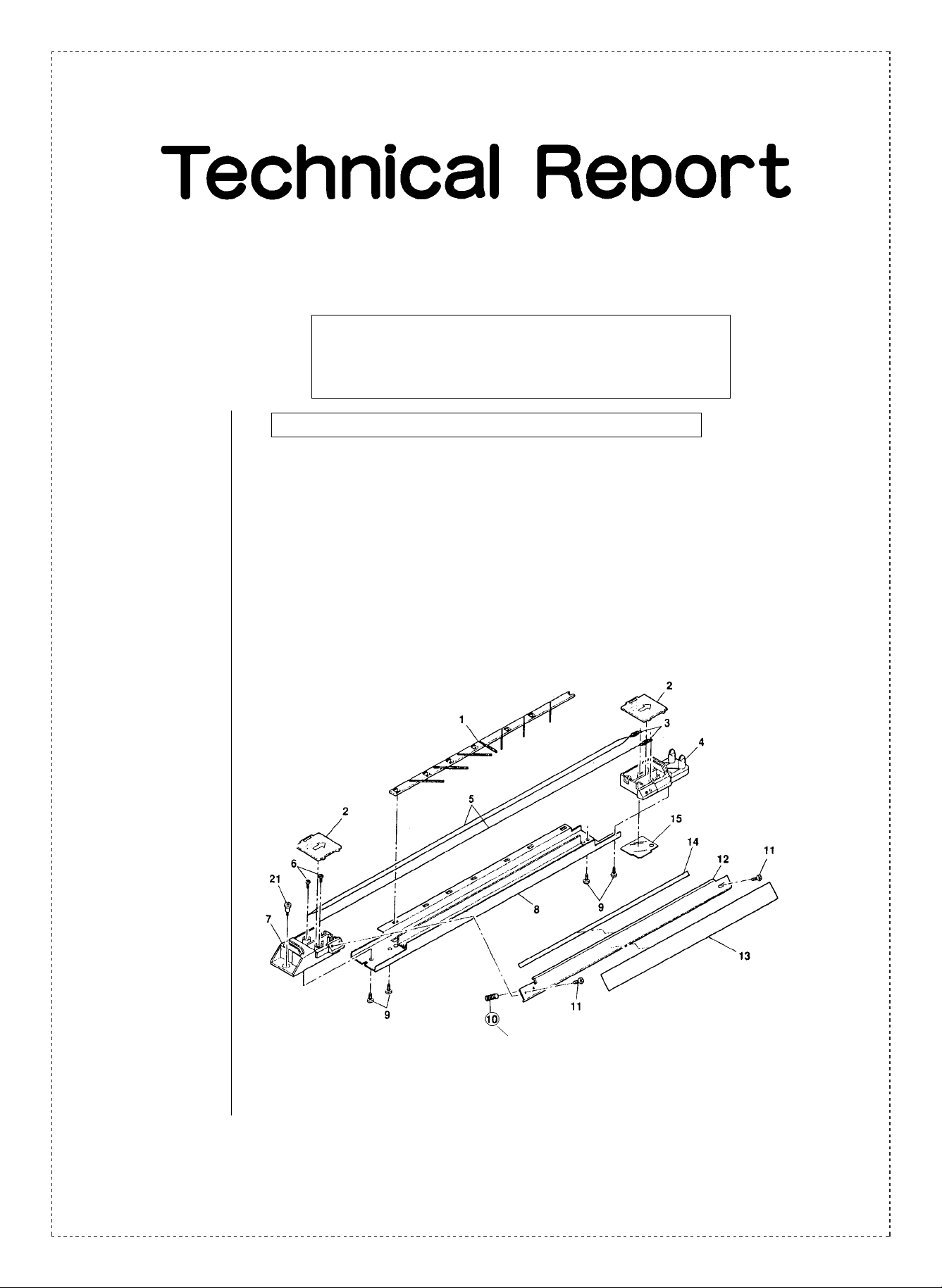

1. Revention of TC/AC case soiling caused by improper grounding.

1.General: When the grounding spring malfunctions and no longer grounds the charged static

electricity on the TC guide sheet AS (CSHEP3485FC01) plate of the TC/AC case unit,

toner clings to the TC side charger wire and other parts. To remedy this problem, the

grounding spring has been changed to a material with better conductivity.

2.Cause: To prevent soiling of the printing charger caused by poor grounding.

3.Description: The grounding spring has been changed to a material with better conductivity. In order

to distinguish between the old grounding springs and the new ones, the color of the

springs has been changed from black to silver.

4.Effective time: (Factory action)

From June, 1993.

SHARP CORPORATION Reprography Division

Changed spring.

1/4

Green

C

Page 2

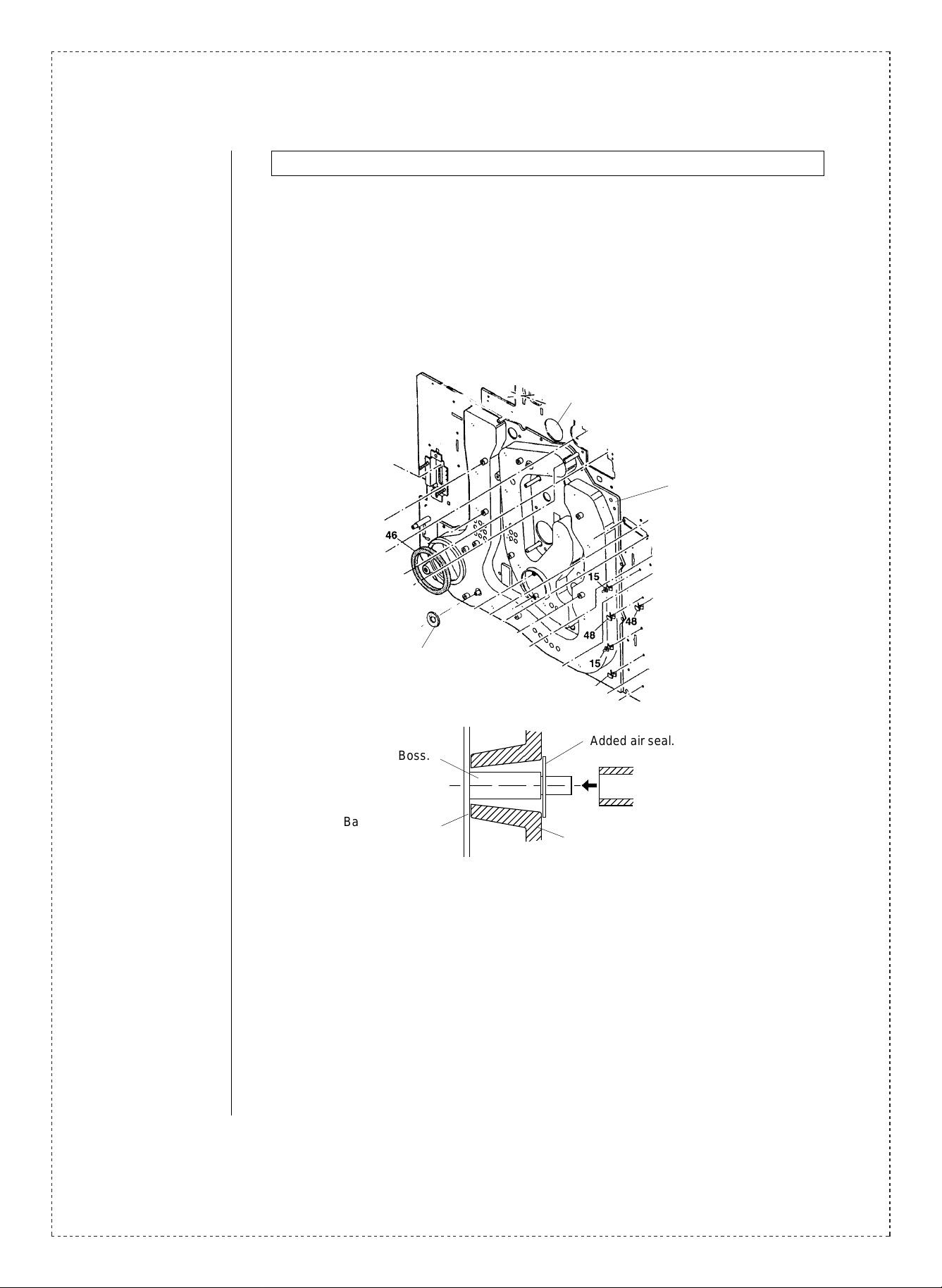

2. Addition of air seals to prevent of static noise emitted from the noise insullation duct.

1.General: To prevent static noise caused by air leaking from the noise insulation duct, an air seal

has been added.

2.Cause: To prevent static noise emitted from the noise insulation duct.

3.Description: An air seal has been added to the boss on the back side frame extending from the

noise insulation duct opening.

Back side frame.

Duct.

Back side frame.

4.Effective time: (Factory action)

From August, 1993.

Added air seal.

(PSEL-0581FCZZ)

Added air seal.

Boss.

Noise insulation duct A.

Duct.

2/4

Page 3

3. Change of D terminal gate solenoid screws to prevent internal short circuiting of the

solenoid.

1.General: There is no leeway between the ends of the screws fastening the D terminal gate

solenoid and the solenoid coils. This poses the danger of the ends of the screws

coming into contact with the solenoid. T o prevent this the length of the screws has been

changed.

2.Description: The present screws being issued, M3 x 5 have been changed to M3 x 4.

D terminal gate solenoid.

Changed screws.

XBPSD30P05K00 (M3x5)

XBPSD30P04K00 (M3x4)

3.Effective time: (Factory action)

From August, 1993.

4. Harness clamps change to improve operating efficiency.

1.General: The harness clamps have been changed for the reasons listed below.

2.Cause: To increase productivity in the production process.

3.Description: The harness clamps presently issued are too small, and there is a danger of wire

crimping when fastening the clamps with screws. To remedy this problem, the changes

shown in the diagrams below have been implemented.

Changed harness clamp.

3/4

Page 4

Location of wire

crimping danger.

4.Effective time: (Factory action)

From midway through August, 1993.

Before change. After change.

LBNDJ0010FCZZ LBNDJ0002FCZZ

Ref.

Model

No.

1

2

SD-2060 All

3

4

<Interchange>

1. Interchangeable. 4. Not interchangeable.

2. C urr e nt t y pe c a n be u s ed i n p la ce of new t ype .

New ty pe cann ot be us ed i n place of curr ent type .

3. C urre nt ty pe cann ot be used i n place of new ty pe.

New t y pe c a n be u sed in p la ce of cu r ren t ty p e.

Parts m ar ke d wi t h “ ” is i mp ort an t fo r m a inta i ning the sa fe ty of the se t. B e su r e to re pl ace these pa rts wi t h

specified ones for maintaining the safety and performance of the set.

name

Version P/G No.

41 -10 MSPRT1121FCZZ MSPRC2170FCZZ AB

8

31 -1 XBPSD30P05K00 XBPSD30P04K00 AA Screws (M3X4) ’93/8 3 Q’ty: 2

31 -75 LBNDJ0010FCZZ Quantity change. AB Harness clamp.

31 — LBNDJ0002FCZZ AA Harness clamp. — Q’ty: 1

!

Current parts New parts

Parts code Parts code

— PSEL-0581FCZZ AB Air seal. ’93/8 — Q’ty: 1

Price

5. Interchangeable if replaced with same types of

relate d parts in use .

6. Others .

Parts name

rank

TC Grounding

spring.

Effec-

tive

time

’93/6 3 Q’ty: 1

’93/8

Production in

progress.

Inter-

change-

ability

—

Note

Q’ty:

2 to 1

4/4

Loading...

Loading...