Page 1

Date: Oct. 14, 1993

COPIER : SF-3076

[Service information]

1. IMPROVEMENT OF SPONGE ROLLER IN THE FINISHING AREA

2. EFFECTIVE REPLACEMENT PERIOD OF ELEVATOR MOTOR IN THE

FINISHING AREA

3. CHANGES TO IC DRIVERS TO IMPROVE PRODUCTION

1. Improvement of sponge roller in the finishing area

1.Model name: SD-F201/F200

No. : DTE-091

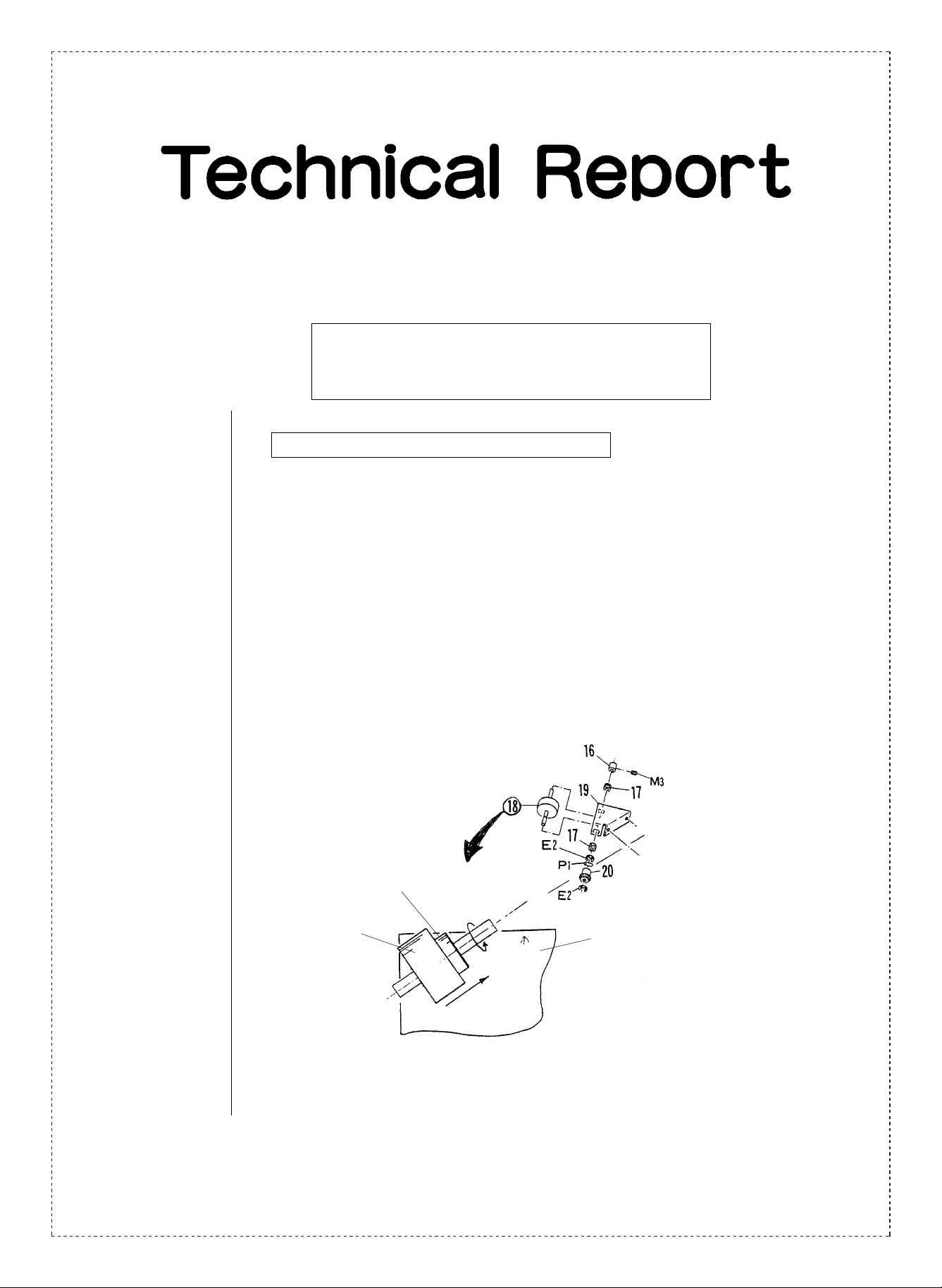

2.General: When loading paper, the sponge roller applies force in the direction shown in the

illustration. As a result, the sponge roller tends to peel off from the shaft. T o prevent

peeling, a rubber bush was added to the flank of the sponge roller.

3.Reason: Improvement of the sponge roller

4.Description: To prevent peeling, a rubber bush was added to the flank of the sponge roller (one side

only).

Rubber bush addition

Sponge roller

Paper

Direction of

applied force

SHARP CORPORATION Reprography Division

1/3

Green

C

Page 2

Due to the rubber bush addition, the parts code for the sponge roller was changed.

Old New

0BL94X-12110/ 0BL94X-12050/

* The rubber bush will be available as service parts in order to added them to existing

sponge rollers on the market.

Rubber bush 0BL94X-12070/ Price rank

5.Action: For production: From October 1993.

2. Replacement period of elevator motor in finishing area

1.Model name: SD-F201 / F200

2.General: The following changes were made regarding the replacement period of the elevator

motor in the finishing area.

3.Description: Replace elevator motor every one millionth sheet (1000K). Replacement interval may

vary depending on actual printer usage.

P/G No. Parts code Parts name

47 -12 0BL051-100121 Elevator motor

* F1-01 or F1-05 appears as motor drive trouble. The brush wears down due to the

repeated movements of the CW/CCW during motor start-up/shutdown. When the brush

wears down, the motor doesn’t move and the trouble timer is set into action. This

causes F1-04 or F1-05 to appear in the mode.

3. Changes to IC drivers to improve productivity

1.Model name: SD-3076 / 2075

2.General: Changes were made to the IC driver for the following reasons.

3.Reason: Improvement of productivity

2/3

Page 3

4.Description: The IC drivers in the master and slave PWBs will be changed. New and old types have

compatability.

VHIUPA2004C-1 VHIULN2004AN1

Please note that the total number of IC drivers will vary depending on the PWB.

Master PWB: Q’ty 1

Slave PWB : Q’ty 13

5.Action: For production : From August 1993.

Ref.

Model

No.

<Interchange>

1. Interchangeable. 4. Not interchangeable.

2. C urr e nt t y pe c a n be u s ed i n p la ce of new ty pe .

New ty pe cann ot be us ed i n place of curr ent type .

3. C urre nt ty pe cann ot be used i n place of new ty pe.

New t y pe c a n be u sed in p la ce of curr en t ty p e.

Parts m ar ke d wi t h “ ” is i mpor t an t fo r m a in ta i ning t he s a fe ty of the s e t. B e su r e to re pl ac e t he se pa r ts wi t h

specified ones for maintaining the safety and performance of the set.

name

Version P/G No.

Current parts New parts

Parts code Parts code

5. Interchangeable if replaced with same types of

relate d parts in use .

6. Others.

Price

rank

Parts name

Effec-

tive

time

Inter-

change-

ability

Note

3/3

Page 4

Page 5

2/2

Page 6

Loading...

Loading...