Page 1

TopPage

XV-Z20000/XV-Z21000/DT-5000

SERVICE MANUAL

No. S96W3XVZ20000

DLP PROJECTOR

XV-Z20000

XV-Z21000

CONTENTS

SAFETY PRECAUTION

IMPORTANT SERVICE SAFETY NOTES.............i

Precautions for using lead-free solder ...............v

CHAPTER 1. OPERATION MANUAL

[1] Specifications ................................................. 1-1

[2] Parts Name and Basic Operation................... 1-2

[3] DIMENSIONS ................................................ 1-7

[4] Resetting the total lamp timer ........................ 1-8

CHAPTER 2. REMOVING OF MAJOR PARTS

[1] Removing the Top body ................................. 2-1

[2] Removing the Fans and PWB Unit Assem-

bly................................................................... 2-2

[3] Removing the Rear panel assembly, PC I/F

PWB and the Main PWB ................................ 2-3

[4] Precaution on Mounting the PC I/F PWB........ 2-4

[5] Removing the Power unit shield assembly

and Power/Ballast assembly .......................... 2-5

[6] Removing the Optical mechanism unit, R/C

Front PWB and IRIS Drive PWB .................... 2-6

[7] Removing the Lamp unit, CW fan, Outlet

Fan, Lamp duct, Lamp fan, Bimetal, Temp

sensor and Formatter unit. ............................. 2-7

MODELS

CHAPTER 5. TROUBLE SHOOTING TABLE

[1] TROUBLE SHOOTING TABLE ..................... 5-1

CHAPTER 6. BLOCK DIAGRAM/OVERALL WIRING

DIAGRAM

[1] BLOCK DIAGRAM.........................................6-1

[2] OVERALL WIRING DIAGRAM ......................6-3

CHAPTER 7. PRINTED WIRING BOARD

[1] MAIN Unit ......................................................7-1

[2] FORMATTER Unit .........................................7-9

[3] POWER/BALLAST Unit...............................7-17

[4] PC I/F Unit ...................................................7-23

[5] KEY Unit ......................................................7-31

[6] R/C Front Unit..............................................7-32

[7] R/C Rear Unit ..............................................7-33

[8] LED Unit ......................................................7-34

[9] IRIS DRIVE Unit .......................................... 7-35

[10] BALLAST CONTROL Unit...........................7-36

CHAPTER 8. WAVEFORMS

[1] WAVEFORMS ...............................................8-1

[2] WAVEFORM MEASUREMENT CONDI-

TION ..............................................................8-1

DT-5000

CHAPTER 3. THE OPTICAL UNIT OUTLINE

[1] THE OPTICAL UNIT OUTLINE...................... 3-1

CHAPTER 4. ELECTRICAL ADJUSTMENT

[1] ELECTRICAL ADJUSTMENT........................ 4-1

[2] Process menu ................................................ 4-4

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with specified ones for maintaining the

safety and performance of the set.

CHAPTER 9. SCHEMATIC DIAGRAM

[1] DESCRIPTION OF SCHEMATIC DIA-

GRAM............................................................ 9-1

[2] SCHEMATIC DIAGRAM ................................9-2

Parts Guide

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Page 2

XV-Z20000/XV-Z21000/DT-5000

XV-Z20000

SAFETY PRECAUTION

IMPORTANT SERVICE SAFETY NOTES

IMPORTANT SERVICE SAFETY NOTES (for USA)

Service work should be performed only by qualified service technicians who are

thoroughly familiar with all safety checks and servicing guidelines as follows:

WARNING

1. For continued safety, no modification of any circuit

should be attempted.

2. Disconnect AC power before servicing.

BEFORE RETURNING THE PROJECTOR:

(Fire & Shock Hazard)

Before returning the projector to the user, perform

the following safety checks:

1. Inspect lead wires are not pinched between the chassis

and other metal parts of the projector.

2. Inspect all protective devices such as non-metallic

control knobs, insulating materials, cabinet backs,

adjustment and compartment covers or shields,

isolation resistor-capacity networks, mechanical

insulators, etc.

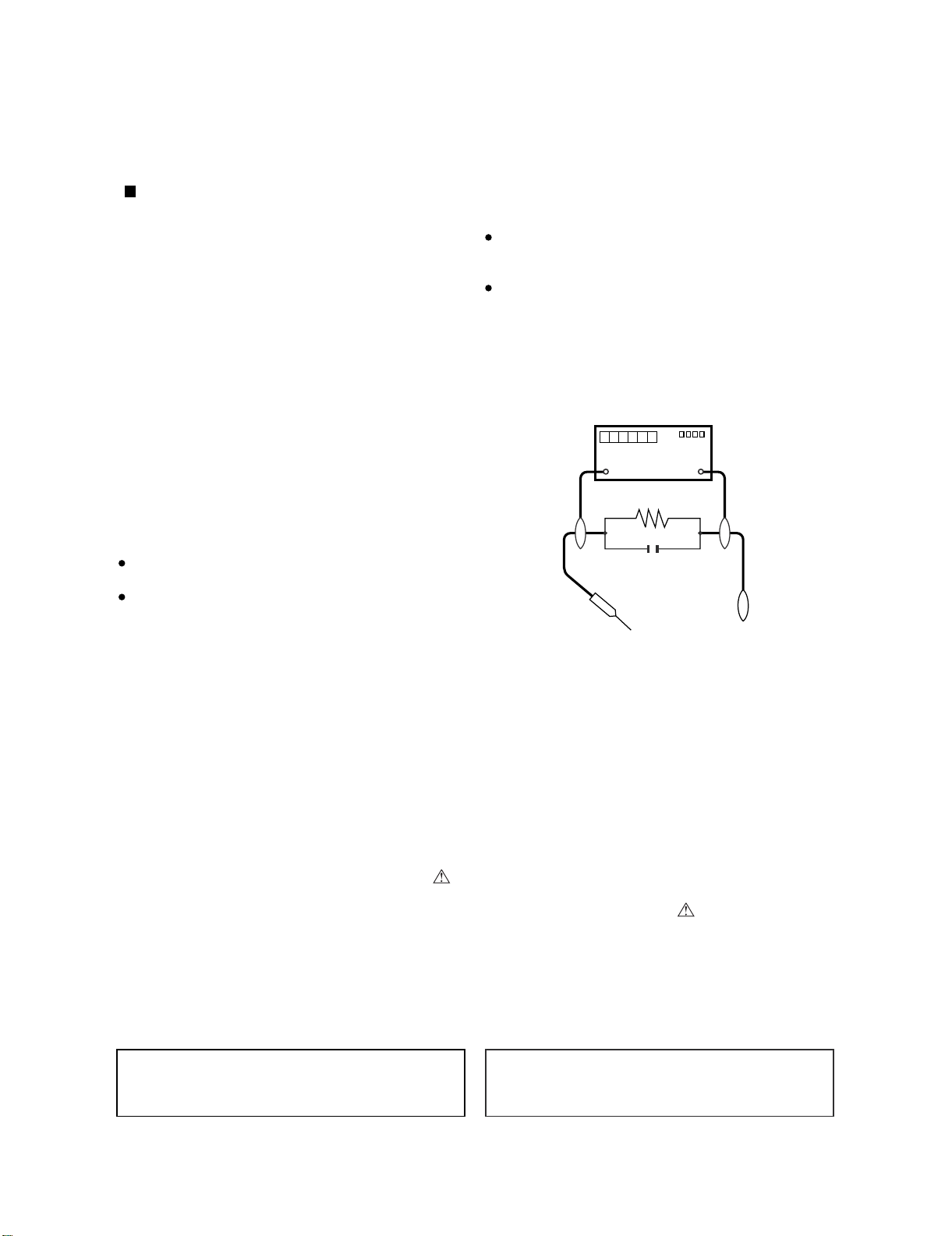

3. To be sure that no shock hazard exists, check for

current leakage in the following manner:

Plug the AC cord directly into a 120-volt AC outlet, (Do

not use an isolation transformer for this test).

Using two clip leads, connect a 1.5k ohm, 10 watt

resistor paralleled by a 0.15μF capacitor in parallel

between all exposed metal cabinet parts and earth

ground.

Service Manual

Use an AC voltmeter with sensitivity of 5000 ohm per

volt., or higher, sensitivity to measure the AC voltage

drop across the resistor.

All checks must be repeated with the AC plug

connection reversed. (If necessary, a non-polarized

adapter plug must be used only for the purpose of

completing these checks.)

Any reading of 0.3 volts RMS (this corresponds to 0.2

milliamp. AC.) or more is excessive and indicates a

potential shock hazard which must be corrected before

returning the unit to the owner.

DVM

AC SCALE

1.5k ohm

10W

0.15 μF

TEST PROBE

TO EXPOSED

METAL PARTS

CONNECT TO

KNOWN EARTH

GROUND

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

SAFETY NOTICE

Many electrical and mechanical parts in DMD™

Projector have special safety-related characteristics.

These characteristics are often not evident from visual

inspection, nor can protection afforded by them be

necessarily increased by using replacement components

rated for higher voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this manual; electrical

components having such features are identified by “ ”

and shaded areas in the Replacement Parts Lists and

Schematic Diagrams. For continued protection,

replacement parts must be identical to those used in

the original circuit. The use of a substitute replacement

parts which do not have the same safety characteristics

as the factory recommended replacement parts shown

in this service manual, may create shock, fire or other

hazards.

WARNING: The bimetallic component has the primary

conductive side exposed. Be very careful in

handling this component when the power is on.

AVIS POUR LA SECURITE

De nombreuses pièces, électriques et mécaniques, dans

les projecteur à DMD™ présentent des caractéristiques

spéciales relatives à la sécurité, qui ne sont souvent pas

évidentes à vue.

Le degré de protection ne peut pas être nécessairement

augmentée en utilisant des pièces de remplacement

étalonnées pour haute tension, puissance, etc.

Les pièces de remplacement qui présentent ces

caractéristiques sont identifiées dans ce manuel;

les pièces électriques qui présentent ces particularités

sont identifiées par la marque “ ” et hachurées dans la

liste des pièces de remplacement et les diagrammes

schématiques. Pour assurer la protection, ces pièces

doivent être identiques à celles utilisées dans le circuit

d’origine. L’utilisation de pièces qui n’ont pas les mêmes

caractéristiques que les pièces recommandées par l’usine,

indiquées dans ce manuel, peut provoquer des

électrocutions, incendies ou autres accidents.

AVERTISSEMENT: La composante bimétallique dispose du

conducteur primaire dénudé. Faire attention

lors de la manipulation de cette

composante sous tension.

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

i

Page 3

XV-Z20000/XV-Z21000/DT-5000

NOTE POUR LE PERSONNEL

D’ENTRETIEN

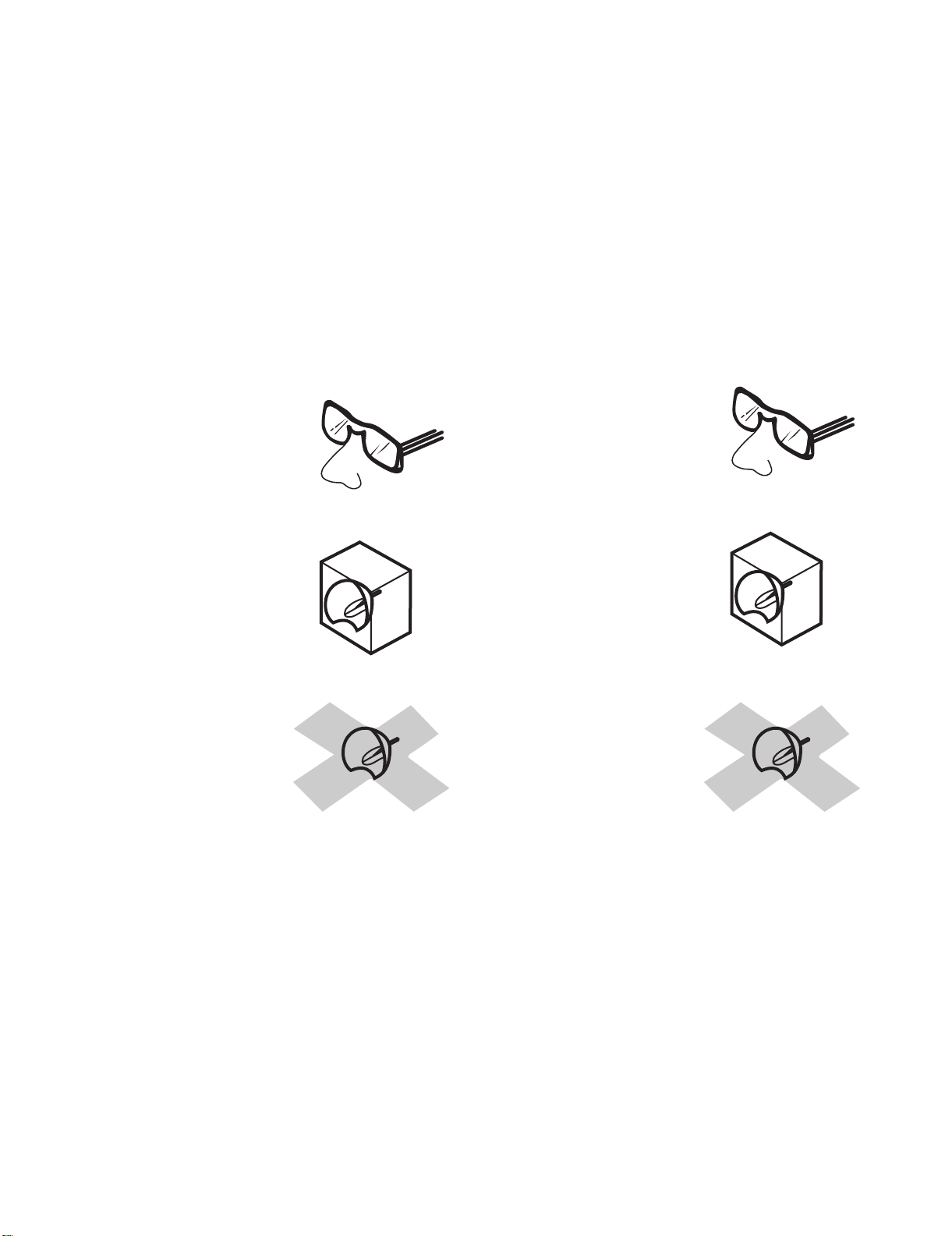

PRECAUTION POUR LES RADIATIONS UV

La source de lumière, la lampe UHP, dans le projecteur

LCD émet de petites quantités de radiation UV.

EVITEZ TOUTE EXPOSITION DIRECTE DES

YEUX ET DE LA PEAU.

Pour votre sécurité, nous vous prions de respecter

les points suivants:

Précautions pour les radiations UV

et la lampe moyenne pression

NOTE TO SERVICE

PERSONNEL

UV-RADIATION PRECAUTION

The light source, UHP lamp, in the LCD proje ctor

emits small amounts of UV-Radiation.

AVOID DIRECT EYE AND SKIN EXPOSURE.

To ensure safety please adhere to the following:

UV-Radiatio n and Medium Pressure

Lamp Precautions

//////////////////////////////////////////////////////////////

//////////////////////////////////////////////////////////////

1. Be sure to wear sun-glasses when servicing the

projector with the lamp

turned “on” and the top

enclosure removed.

2. Do not operate the lamp outside of the lamp housing.

//////////////////////////////////////////////////////////////

//////////////////////////////////////////////////////////////

1. Toujours porter des lunettes de soleil lors d’un entretien

du projecteur

avec la lampe allumée

et le haut du coffret retiré.

2. Ne pas faire fonctionner la lampe à l’extérieur du boîtier

de lampe.

3. Do not operate for more than 2 hours with the enclosure

removed.

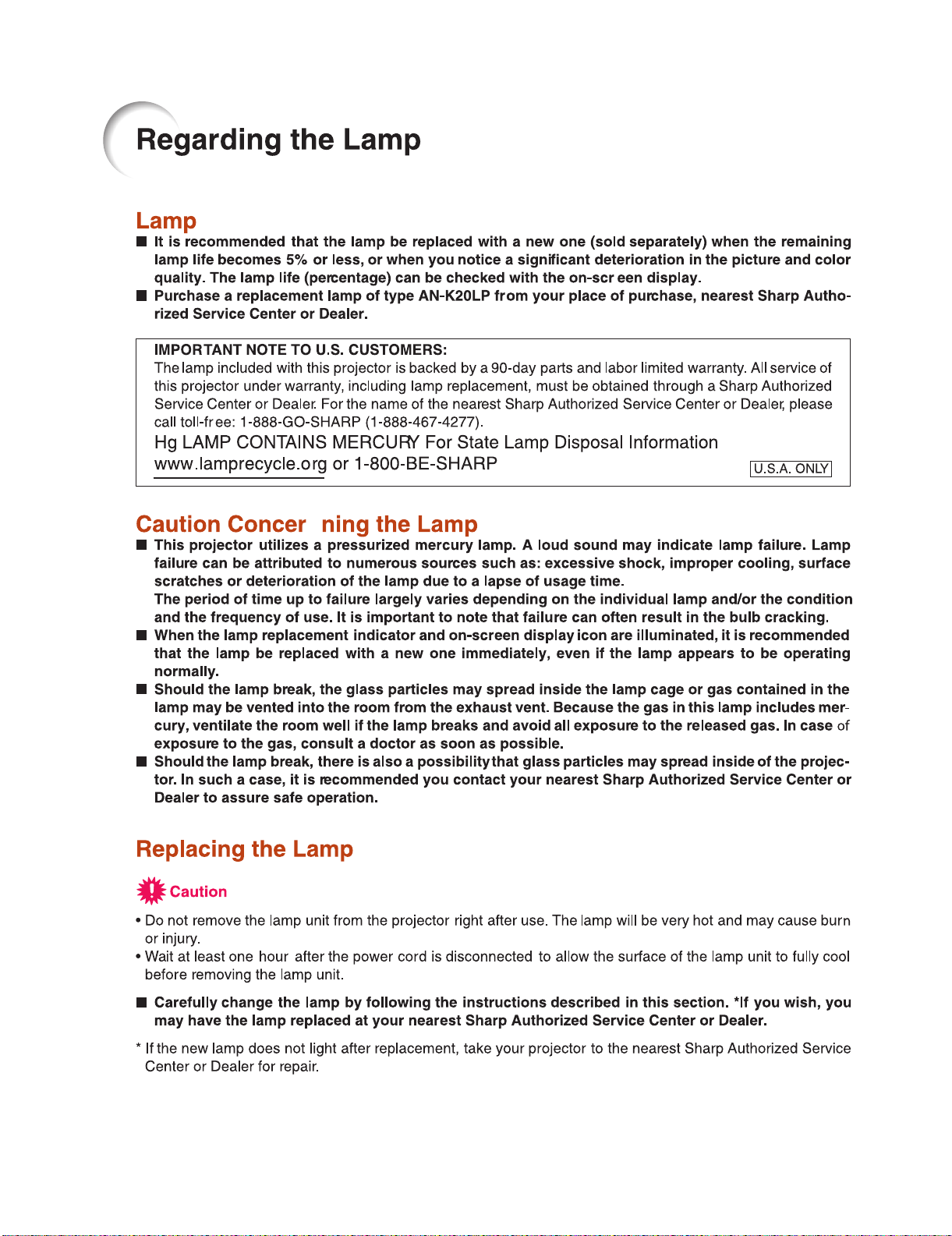

1. Be sure to disconnect the AC plug when replacing the

lamp.

2. Allow one hour for the unit to cool down before

servicing.

3. Replace only with same type lamp. Type AN-K20LP

rated 355V/220W.

4. The lamp emits small amounts of UV-Radiation, avoid

direct-eye contact.

5. The medium pressure lamp involves a risk of explosion.

Be sure to follow installation instructions described

below and handle the lamp with care.

3. Ne pas faire fonctionner plus de 2 heures avec le coffret

retiré.

1. Toujours débrancher la fiche AC lors du remplacement

de la lampe.

2. Laisser l’unité refroidir pendant une heure avant de

procéder à l’entretien.

3. Ne remplacer qu’avec une lampe du même type. Type

AK-K20LP, caractéristique 355/220W.

4. La lampe émet de petites quantités de radiation UVéviter tout contact direct avec les yeux.

5. La lampe moyenne pression implique un risque

d’explosion. Toujours suivre les instructions

d’installation décrites ci-dessous et manipuler la lampe

avec soin.

ii

Page 4

XV-Z20000/XV-Z21000/DT-5000

Remplacement de la lampe

Remarque:

DANGER !

UV-RADIATION PRECAUTION (Continued)

Lamp Replacement

Note:

DANGER !

PRECAUTION POUR LES RADIA

////////////////////////////////////////////////////////////////

////////////////////////////////////////////////////////////////

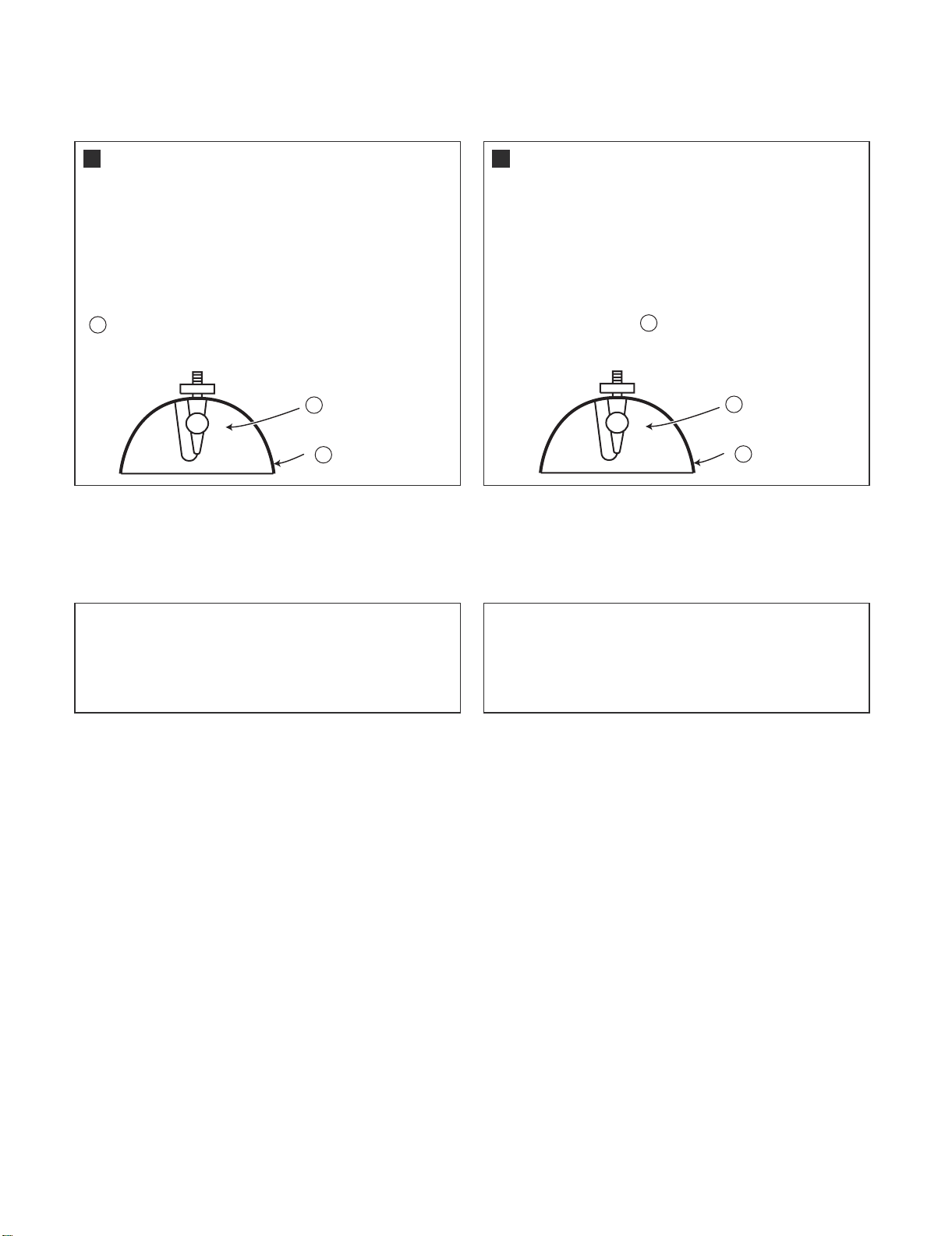

Since the lamp reaches a very high temperature during

units operation replacement of the lamp should be

done at least one hour after the power has been turned

off. (to allow the lamp to cool off.)

Installing the new lamp, make sure not to touch the

lamp (bulb) replace the lamp by holding its reflector

2

.

[Use original replacement only.]

Lamp

1

Reflector

2

–– Never turn the power on without the

lamp to avoid electric-shock or damage of the devices

since the stabilizer generates high voltages at its start.

////////////////////////////////////////////////////////////////

////////////////////////////////////////////////////////////////

Comme la lampe devient très chaude pendant le

fonctionnement de l’unité, son remplacement ne doit

être effectué au moins une heure après avoir coupé

l’alimentation (pour permettre à la lampe de refroidir).

En installant la nouvelle lampe, s’assurer de ne pas

toucher la lampe (ampoule). Remplacer la lampe en

tenant son réflecteur .

[N’utiliser qu’un remplacement d’origine.]

–– Ne jamais mettre sous tension sans la

lampe pour éviter un choc électrique ou des

dommages des appareils car le stabilisateur génère

de hautes tensions à sa mise en route.

2

TIONS UV (Suite)

1

Lampe

2

Reflecteur

Since small amounts of UV-radiation are emitted

from an opening between the exhaust fans, it is recommended to place the cap of the optional lens on

the opening during servicing to avoid eye and skin

exposure.

Comme de petites quantités de radiation UV sont

émises par une ouverture entre les ventilateurs aspirants, il est recommandé de placer le capuchon de

l’optique optionnelle sur l’ouverture pendant l’entretien

pour éviter une exposition des yeux et la peau.

iii

Page 5

XV-Z20000/XV-Z21000/DT-5000

WARNING: High brightness light source, do not stare into the beam of light, or view directly. Be especially

careful that

children do not stare directly in to the beam of light.

WARNING: TO REDUCE TH E RISK OF FIRE OR ELECTRIC SHOCK, DO NOT EXPOSE

THIS UNIT TO

MOISTURE OR WET LOCATIONS.

CAUTION

AVERTISSEMENT: Source lumineuse de grande intensité. Ne pas fixer le faisceau lumineux ou le regarder

directement. Ve

iller particulièrement à éviter que les enfants ne fixent directement le

faisceau lumineux.

AVERTISSEMENT: AFIN D’EV

ITER TOUT RISQUE D’INCENDIE OU D’ELECTROCUTION, NE PAS PLACER

CET APPAREIL DANS UN ENDROIT HUMIDE OU MOUILLE.

ATTENTION

CAUTION

(POWER Unit)

PRECAUTION

(Unité de PUTSSANCE)

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK,

NO USER-SERVICEABLE PARTS EXCEPT LAMP UNIT.

For continued

protection against a

risk of fire, replace

only with same type

6.3AH, AC250V fuse (F701)

1.6AL, AC250V fuse (F702)

REFER SERVICING TO QUALIFIED SERVICE

RISK OF ELECTRIC SHOCK.

DO NOT REMOVE SCREWS

EXCEPT SPECIFIED USER

SERVICE SCREW.

DO NOT REMOVE CABINET.

PERSONNEL.

The lighting flash with arrowhead within a

triangle is intended to tell the user that

parts inside the product are risk of electric

shock to persons.

The exclamation point within a triangle is

intended to tell the user that important

operating and servicing instructions are in

the manual with the projector.

//////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

RISQUE D’ÉLECTROCUTION.

NE PAS RETIRER LES VIS

RÉSERVÉE L’ENTRETIEN.

L’éclair terminé d’une flèche à l’intérieur

d’un triangle indique à l’utilisateur que les

pi‘eces se trouvant dans l’appareil sont

L’EXCEPTION DE LA VIS

susceptibles de provoquer une décharge

électrique.

Le point d’exclamation à l’intérieur d’un

D’ELECTROCUTION, NE PAS RETIRER LE CAPOT.

AUCUNE DES PIECES INTERIEURES N’EST REPARABLE

PAR L’UTILISATEUR, A L’EXCEPTION DE L’UNITE DE

LAMPE. POUR TOUTE REPARATION, S’ADRESSER A UN

Pour une protection

continue contre un

risques d’incendie, ne

remplacer qu’avec un

fusible 6.3AH, AC250V fuse (F701)

1.6AL, AC250V fuse (F702)

ATTENTION: POUR EVITER TOUT RISQUE

TECHNICIEN D’ENTRETIEN QUALIFIE.

triangle indique à l’utilisateur que les

instructions de fonctionnement et

d’entretien sont détaillées dans les

documents fournis avec le projecteur.

iv

Page 6

XV-Z20000/XV-Z21000/DT-5000

Precautions for using lead-free solder

Employing lead-free solder

• "PWBs" of this model employs lead-free solder. The LF symbol indicates lead-free solder, and is attached on the PWBs and service manuals. The

alphabetical character following LF shows the type of lead-free solder.

Example:

L Fa

Indicates lead-free solder of tin, silver and copper.

Using lead-free wire solder

• When fixing the PWB soldered with the lead-free solder, apply lead-free wire solder. Repairing with conventional lead wire solder may cause damage or accident due to cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40 °C, we recommend you to use a dedicated soldering

bit, if you are not familiar with how to obtain lead-free wire solder or soldering bit, contact our service station or service branch in your area.

Soldering

• As the melting point of lead-free solder (Sn-Ag-Cu) is about 220 °C which is higher than the conventional lead solder by 40 °C, and as it has poor

solder wettability, you may be apt to keep the soldering bit in contact with the PWB for extended period of time. However, Since the land may be

peeled off or the maximum heat-resistance temperature of parts may be exceeded, remove the bit from the PWB as soon as you confirm the

steady soldering condition.

Lead-free solder contains more tin, and the end of the soldering bit may be easily corroded. Make sure to turn on and off the power of the bit as

required.

If a different type of solder stays on the tip of the soldering bit, it is alloyed with lead-free solder. Clean the bit after every use of it.

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sandpaper.

• Be careful when replacing parts with polarity indication on the PWB silk.

Lead-free wire solder for servicing

Part No. Description Code

ZHNDAi123250E J φ0.3mm 250g(1roll) BL

ZHNDAi126500E J φ0.6mm 500g(1roll) BK

ZHNDAi12801KE J φ1.0mm 1kg(1roll) BM

v

Page 7

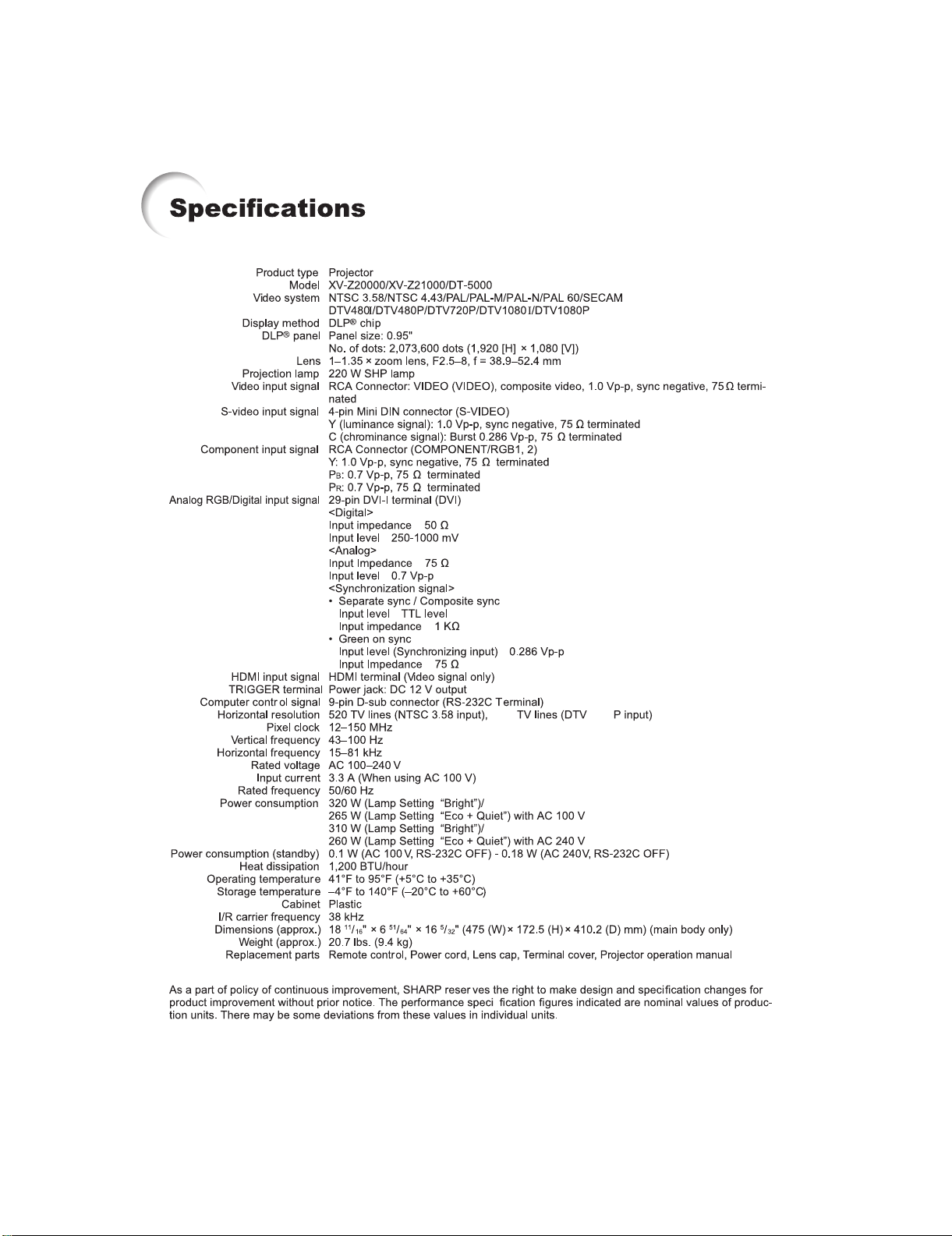

XV-Z20000

CHAPTER 1. OPERATION MANUAL

[1] Specifications

XV-Z20000/XV-Z21000/DT-5000

Service Manual

1080

1080

1 – 1

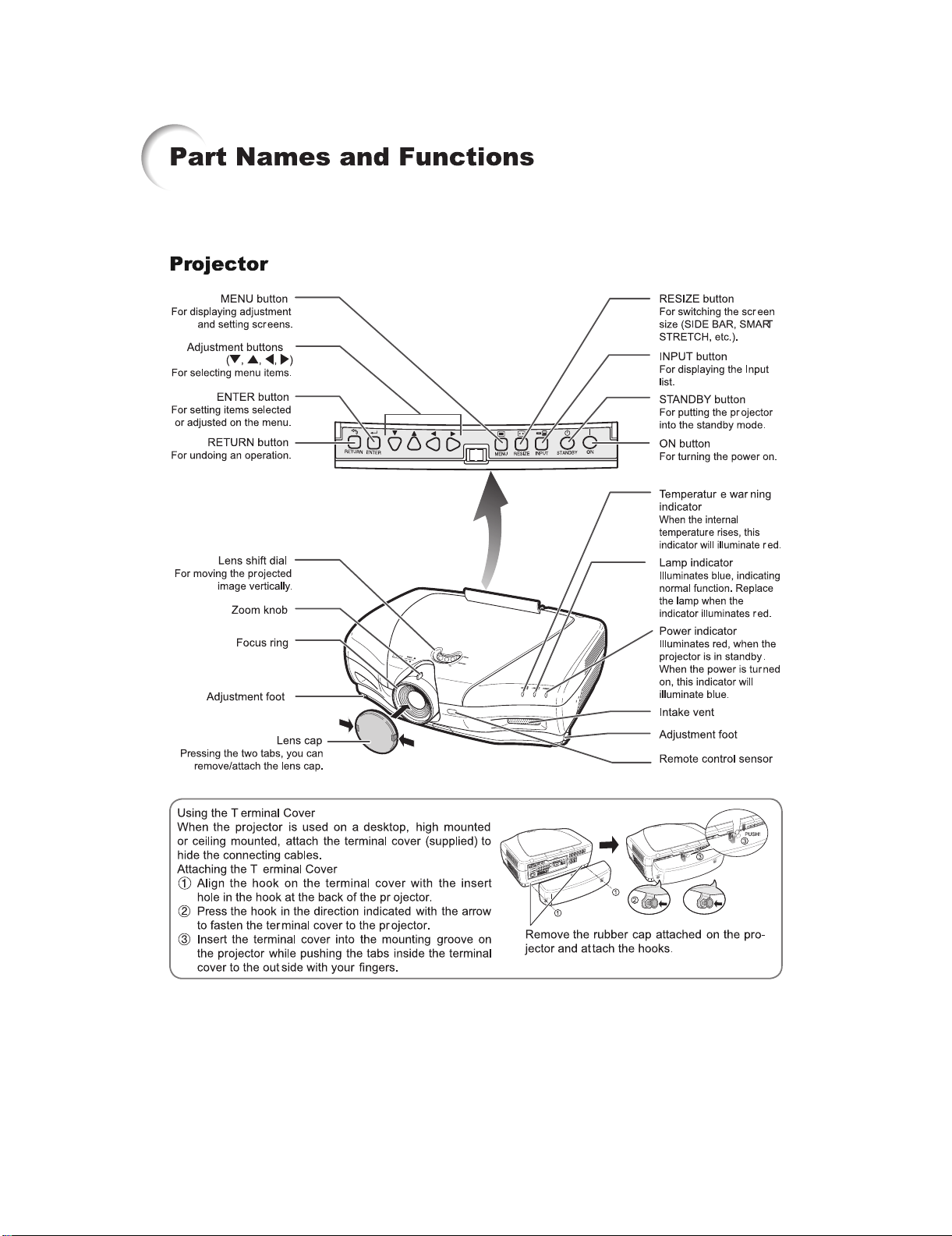

Page 8

XV-Z20000/XV-Z21000/DT-5000

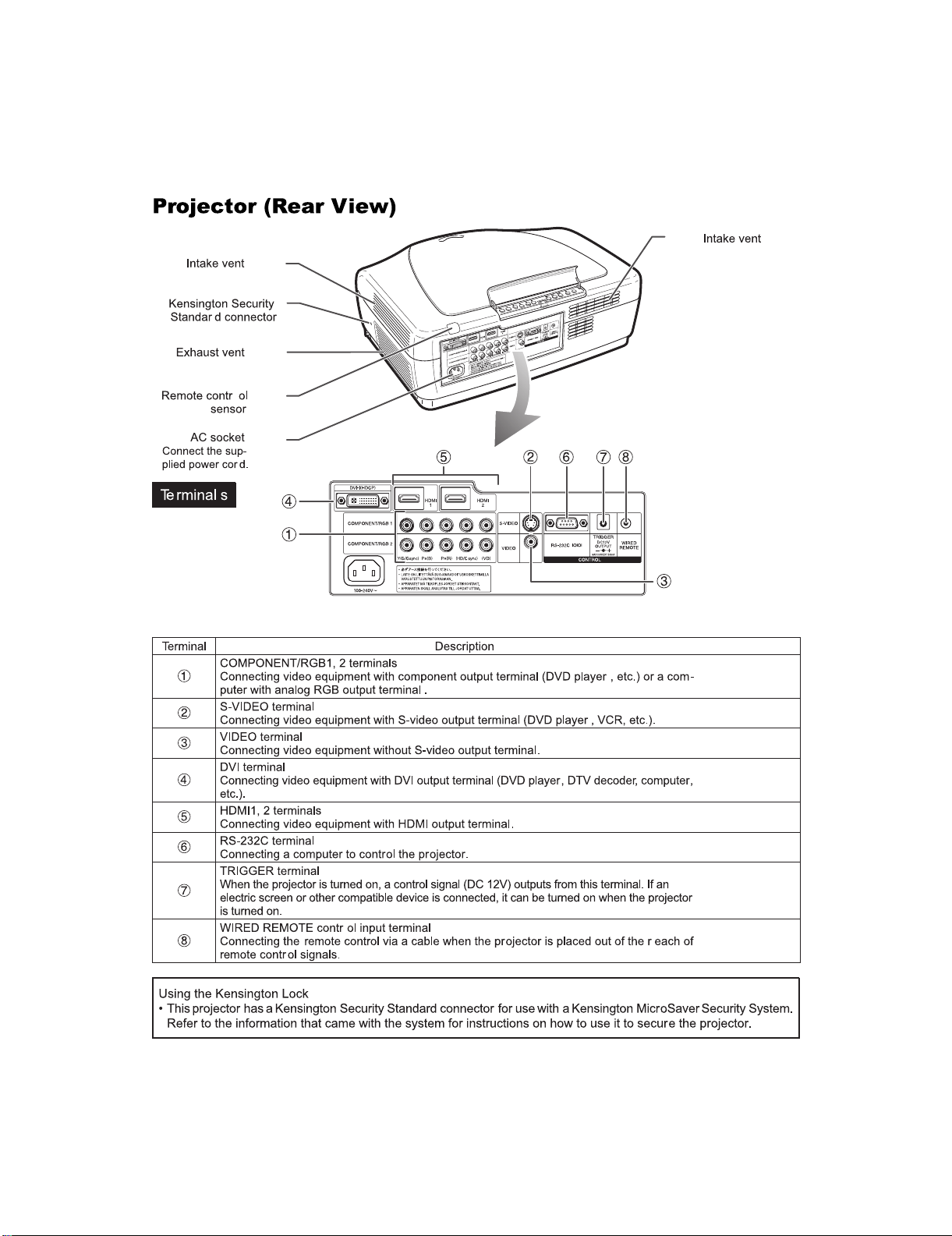

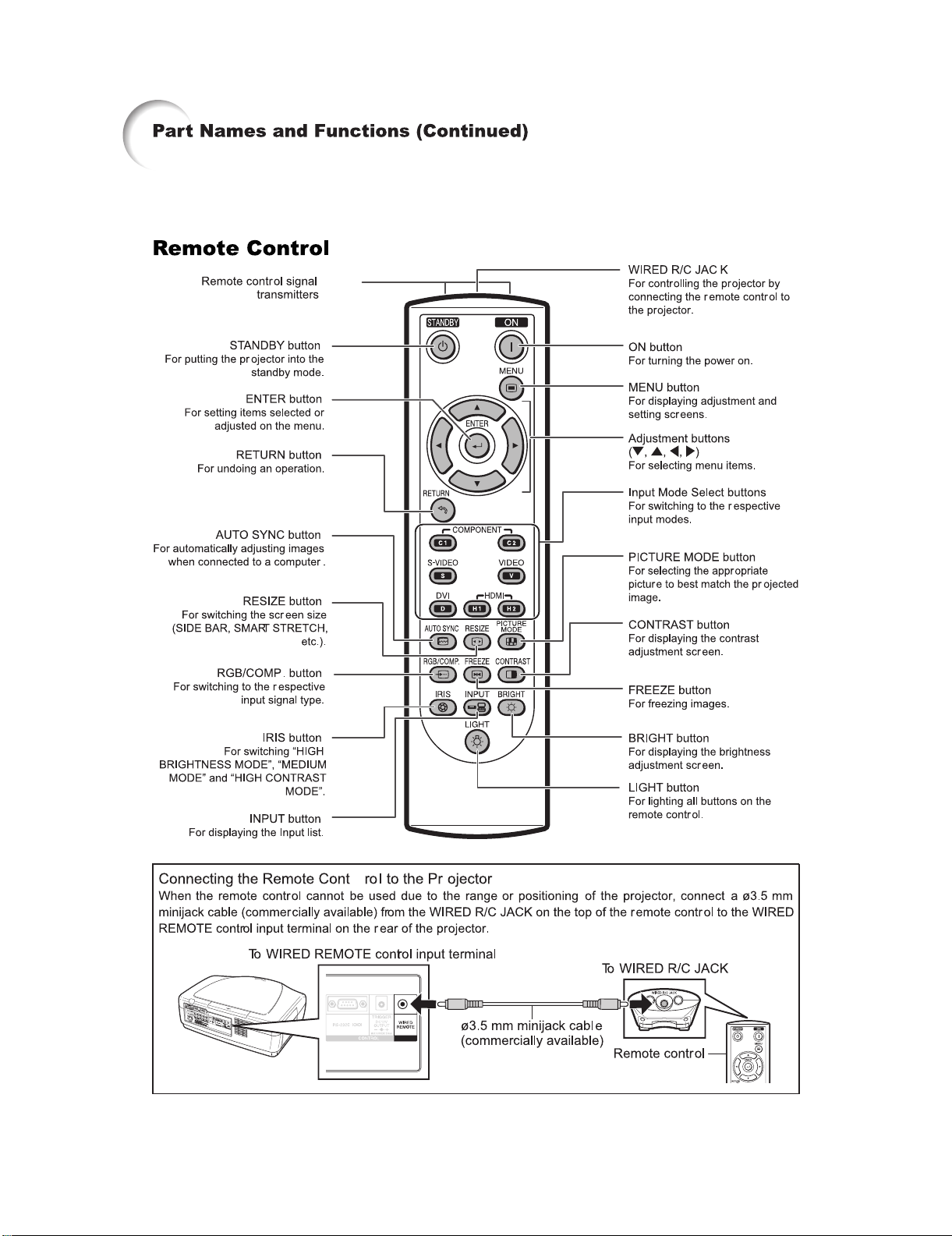

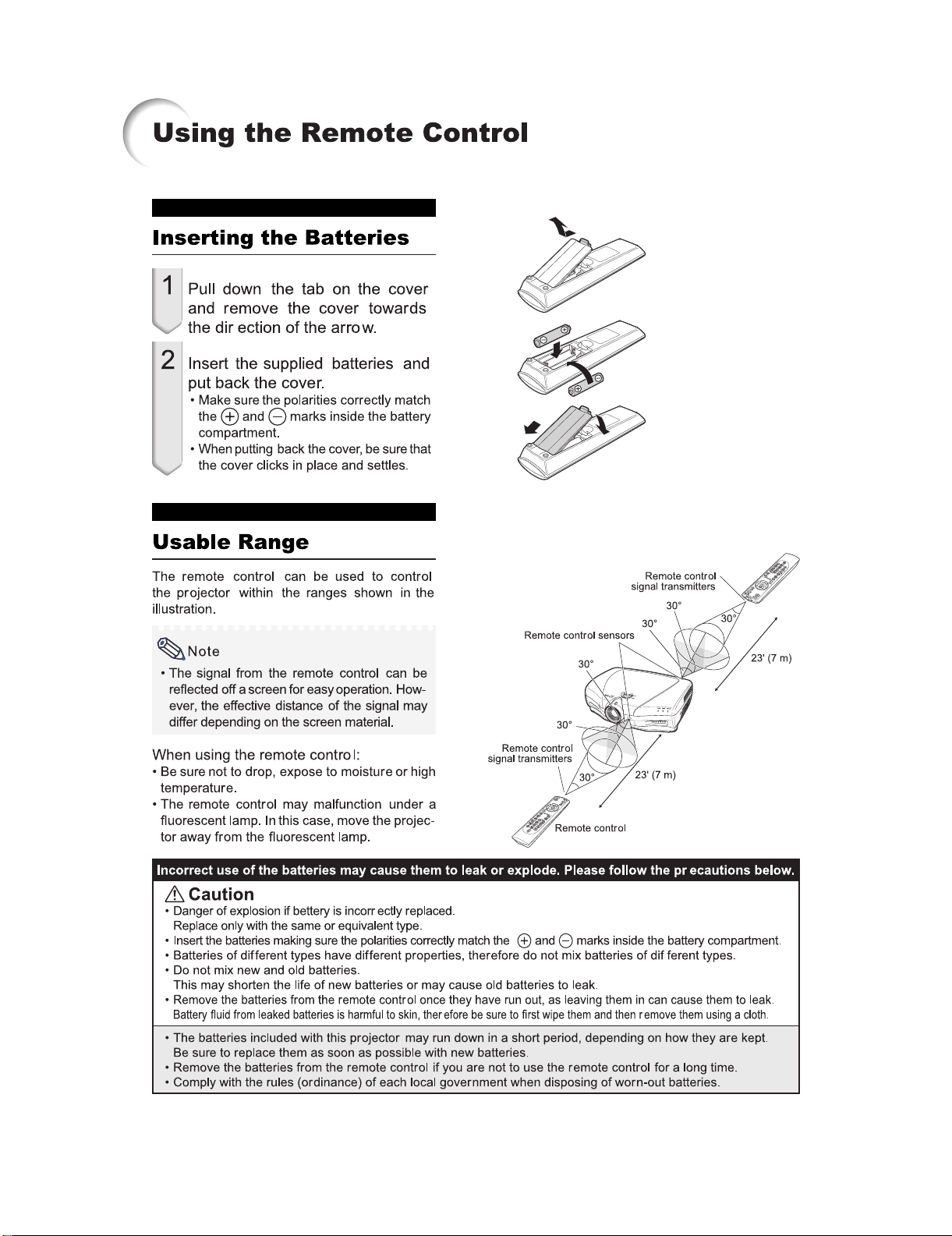

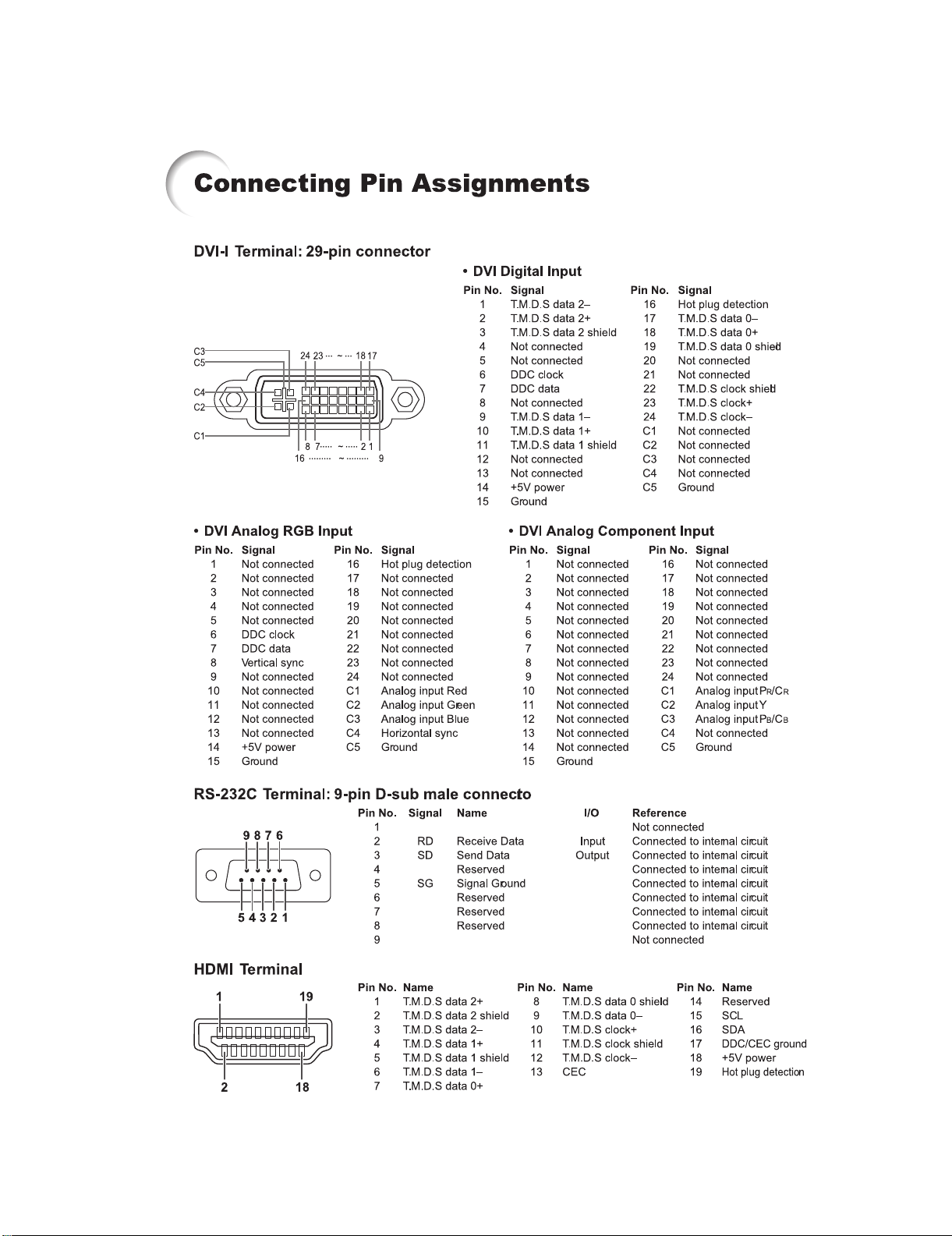

[2] Parts Name and Basic Operation

1 – 2

Page 9

XV-Z20000/XV-Z21000/DT-5000

1 – 3

Page 10

XV-Z20000/XV-Z21000/DT-5000

1 – 4

Page 11

XV-Z20000/XV-Z21000/DT-5000

1 – 5

Page 12

XV-Z20000/XV-Z21000/DT-5000

1 – 6

Page 13

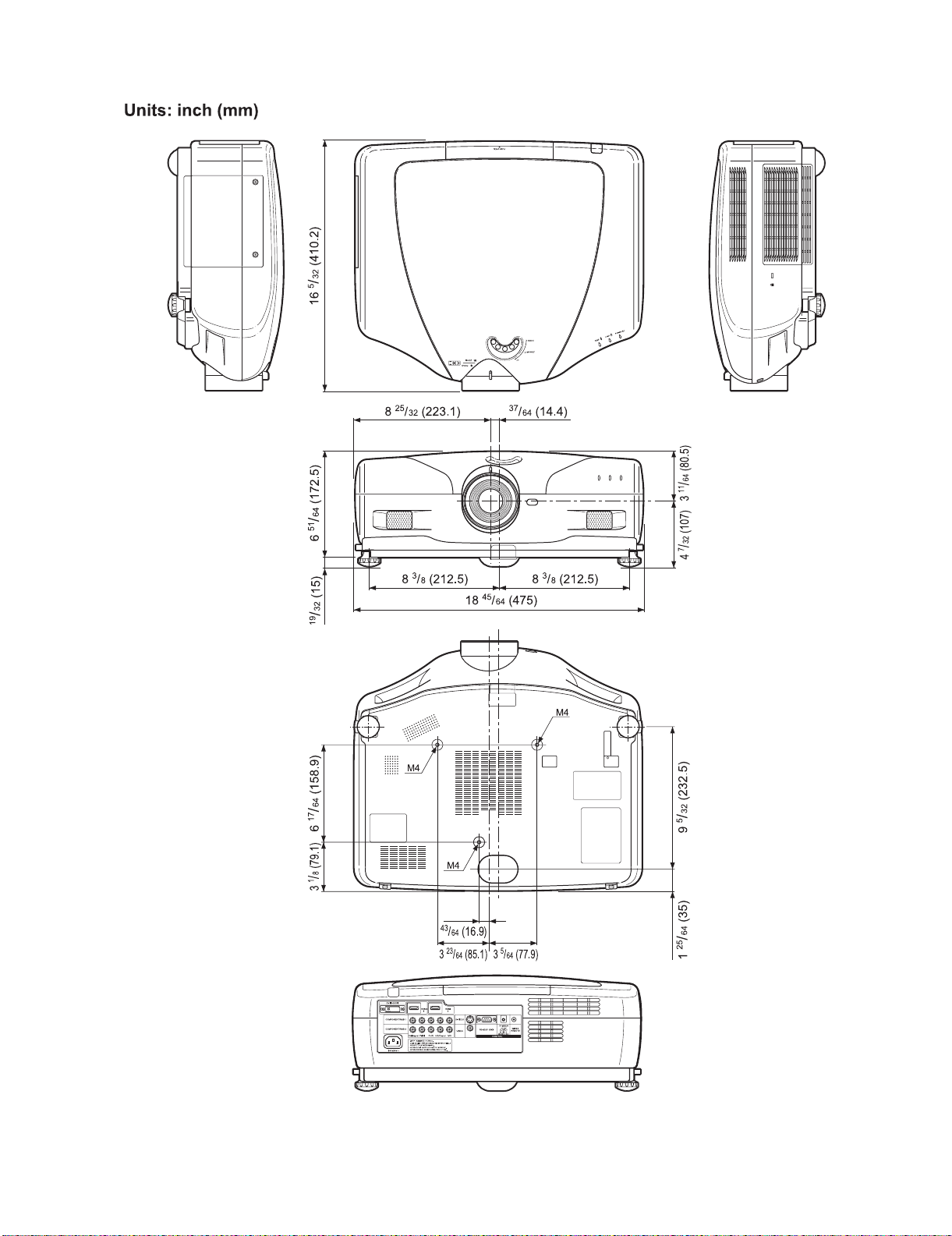

[3] DIMENSIONS

XV-Z20000/XV-Z21000/DT-5000

1 – 7

Page 14

XV-Z20000/XV-Z21000/DT-5000

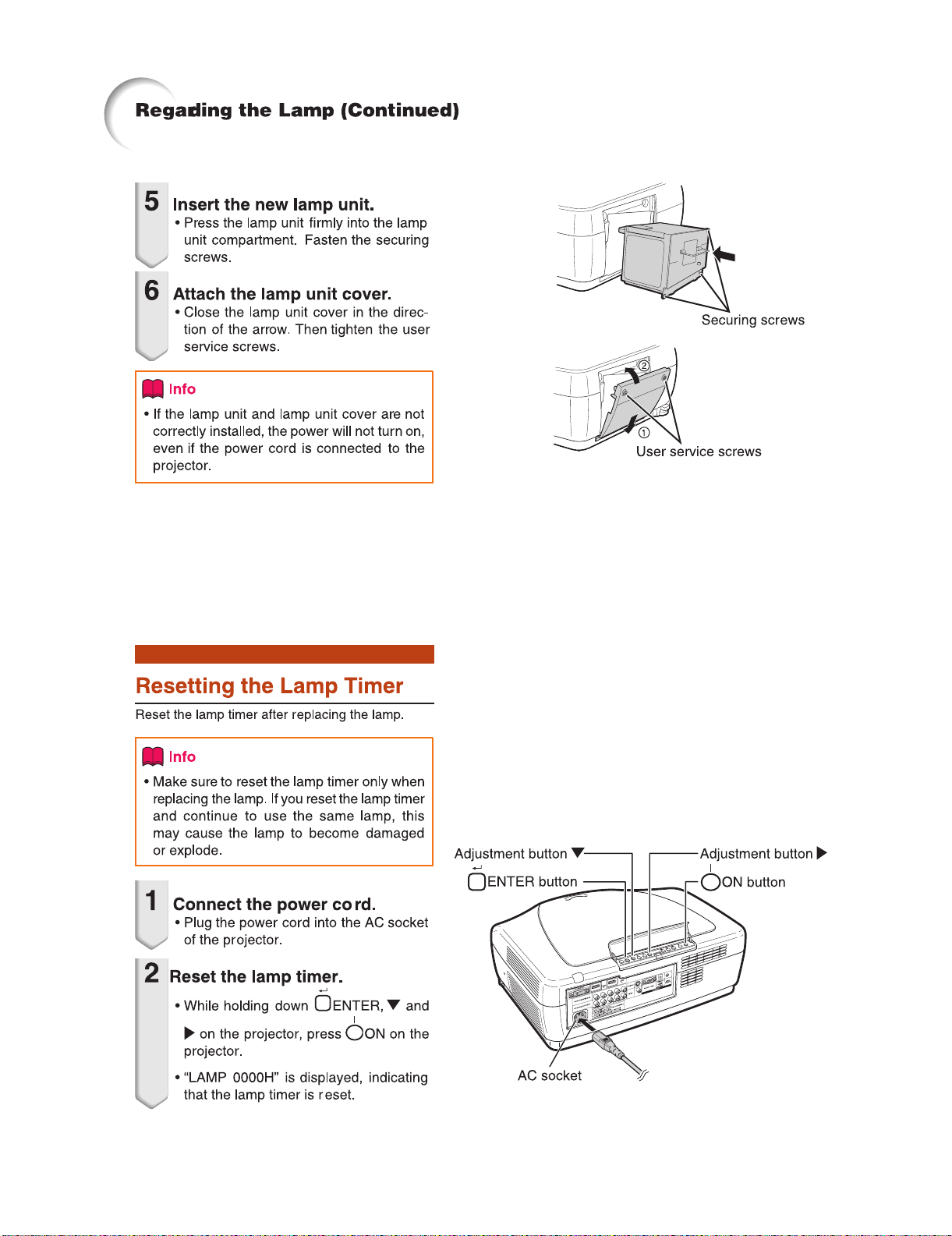

[4] Resetting the total lamp timer

1 – 8

Page 15

XV-Z20000/XV-Z21000/DT-5000

1 – 9

Page 16

XV-Z20000/XV-Z21000/DT-5000

1 – 10

Page 17

XV-Z20000

CHAPTER 2. REMOVING OF MAJOR PARTS

Service Manual

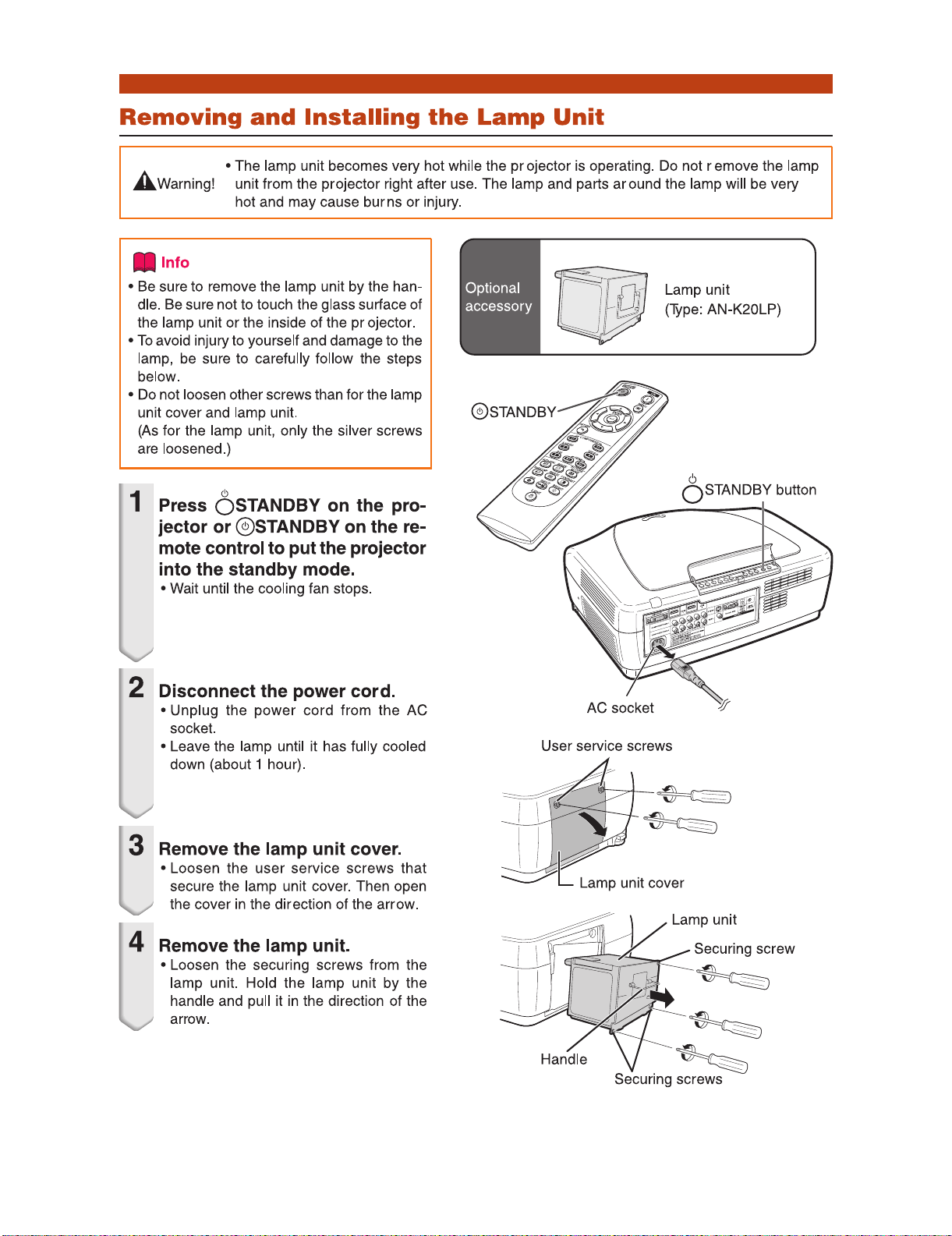

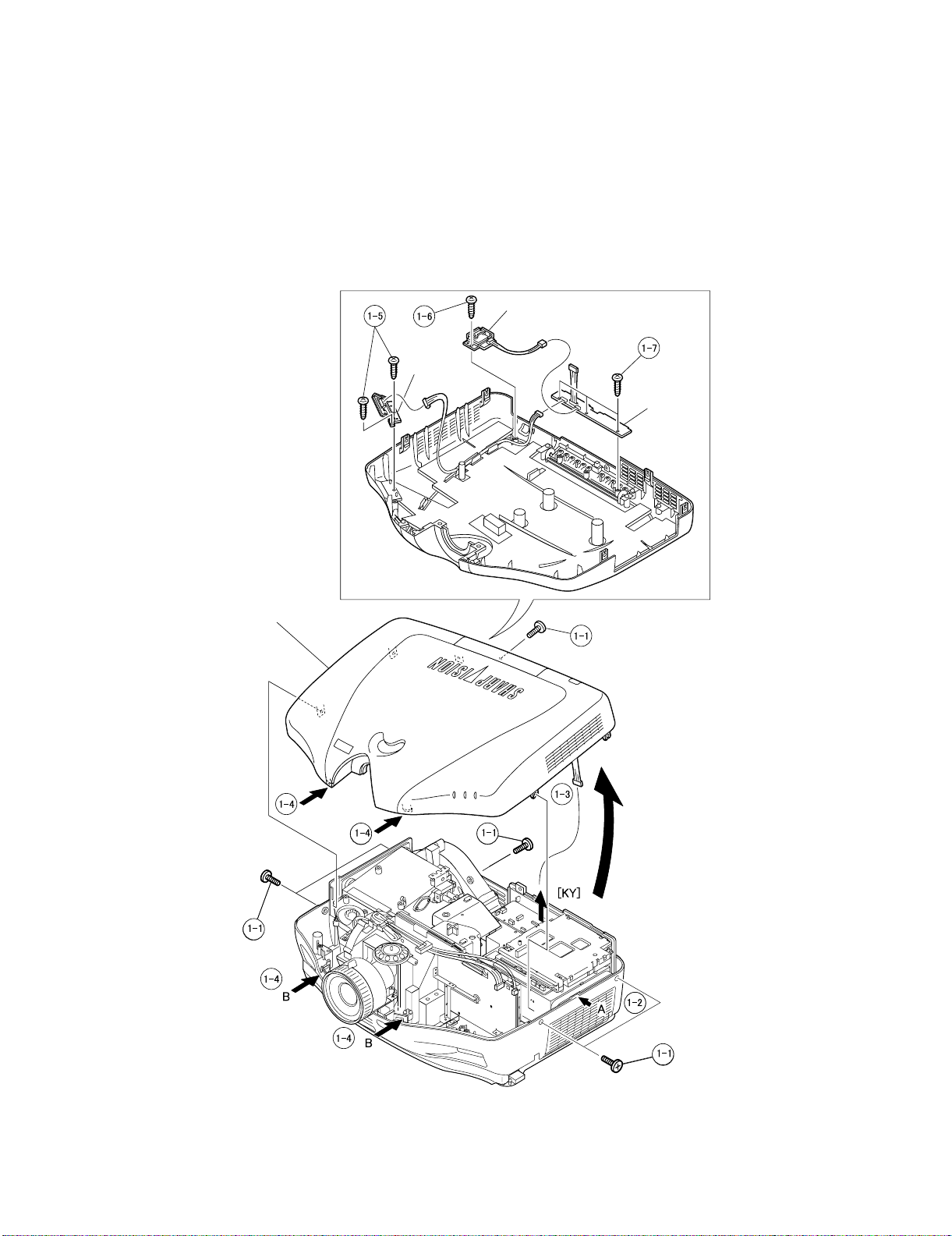

[1] Removing the Top body

1. Remove the six lock screws.

2. Press on side Arrow A of the Bottom body and lift the Rear of the Top body.

3. Dissconnect the connector.

4. Press on front Arrow B of the Bottom body and unhook the claws, and detach the Top body.

5. Remove the 2 screws and detach the LED PWB.

6. Remove the one screw and detach the R/C Rear PWB.

7. remove the three screws and detach the Operation PWB.

R/C Rear PWB

LED PWB

XV-Z20000/XV-Z21000/DT-5000

Operation

PWB

Top body

2 – 1

Page 18

XV-Z20000/XV-Z21000/DT-5000

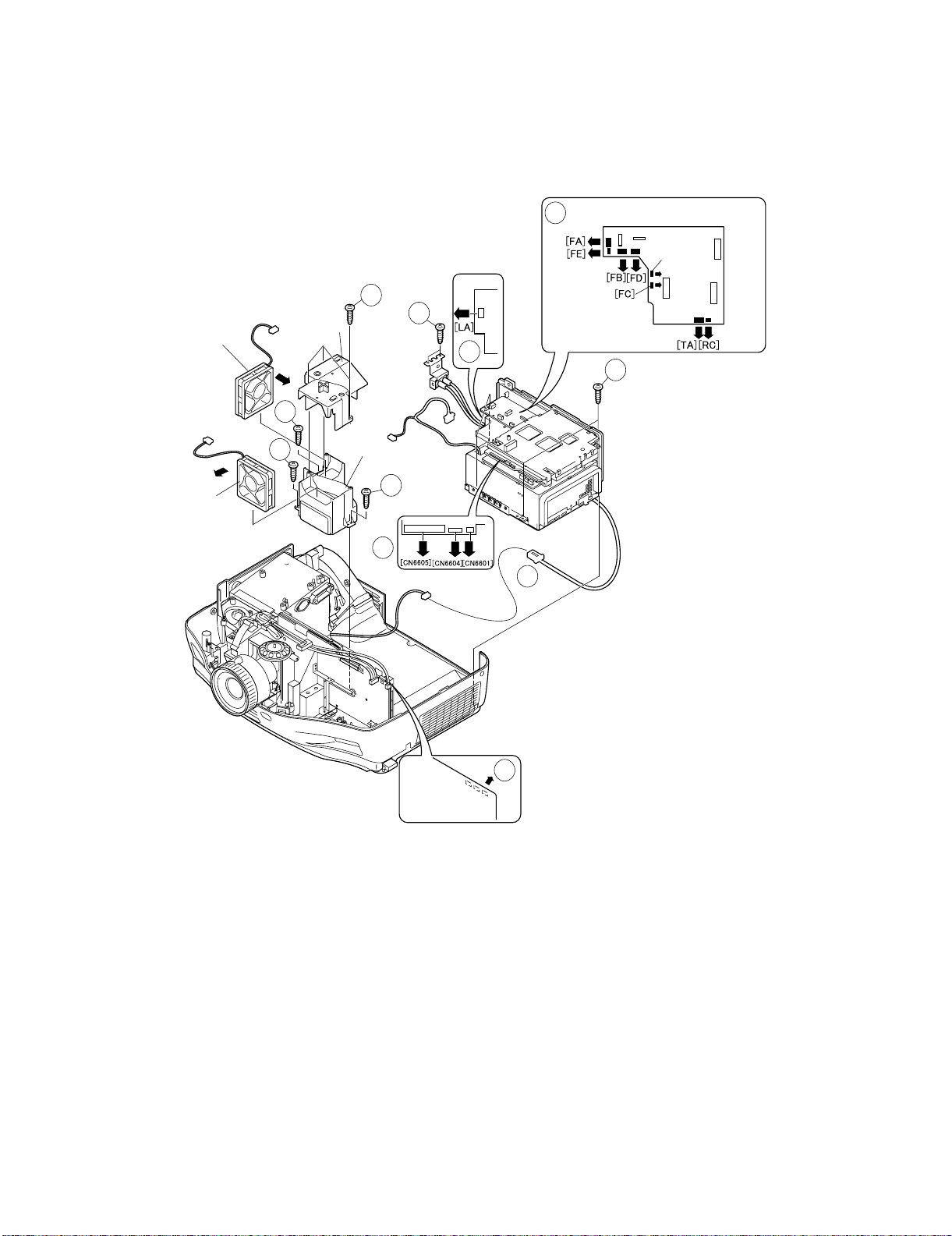

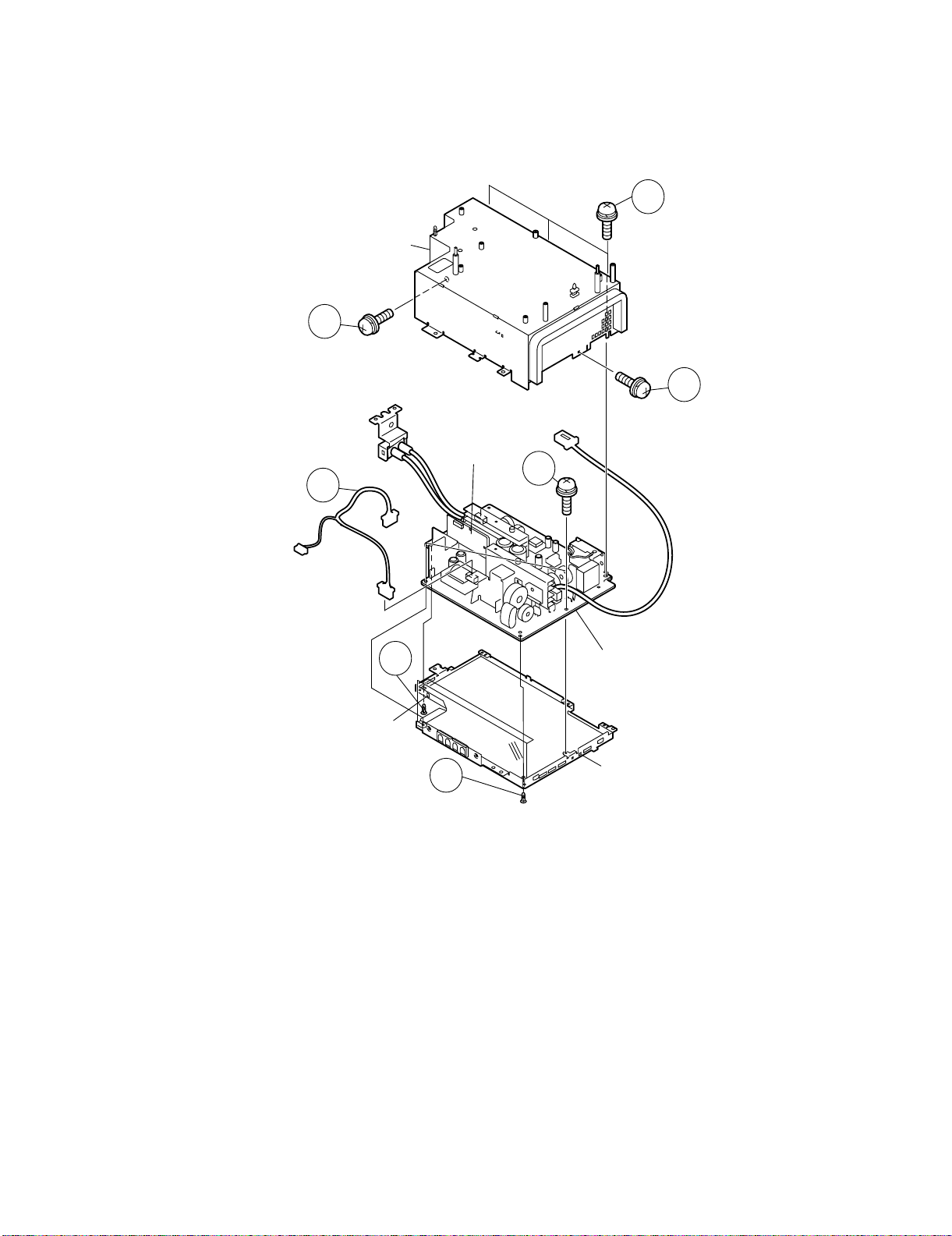

[2] Removing the Fans and PWB Unit Assembly

1. Dissconnect the fourteen connectors.

2. Remove the two screws and detach the Lamp socket.

3. Remove the three screws and detach the Intake duct (upper). Detach the two Fans.

4. Remove the four screws and detach the PWB Unit Assembly.

5. Remove the three screws and detach the Intake duct (lower).

2-1

[TB]

Fan

Fan

2-5

2-5

Intak

duct

(upper)

2-3

2-2

2-1

2-4

Intake duct

2-5

2-1

2-1

P9702

2 – 2

2-1

Page 19

XV-Z20000/XV-Z21000/DT-5000

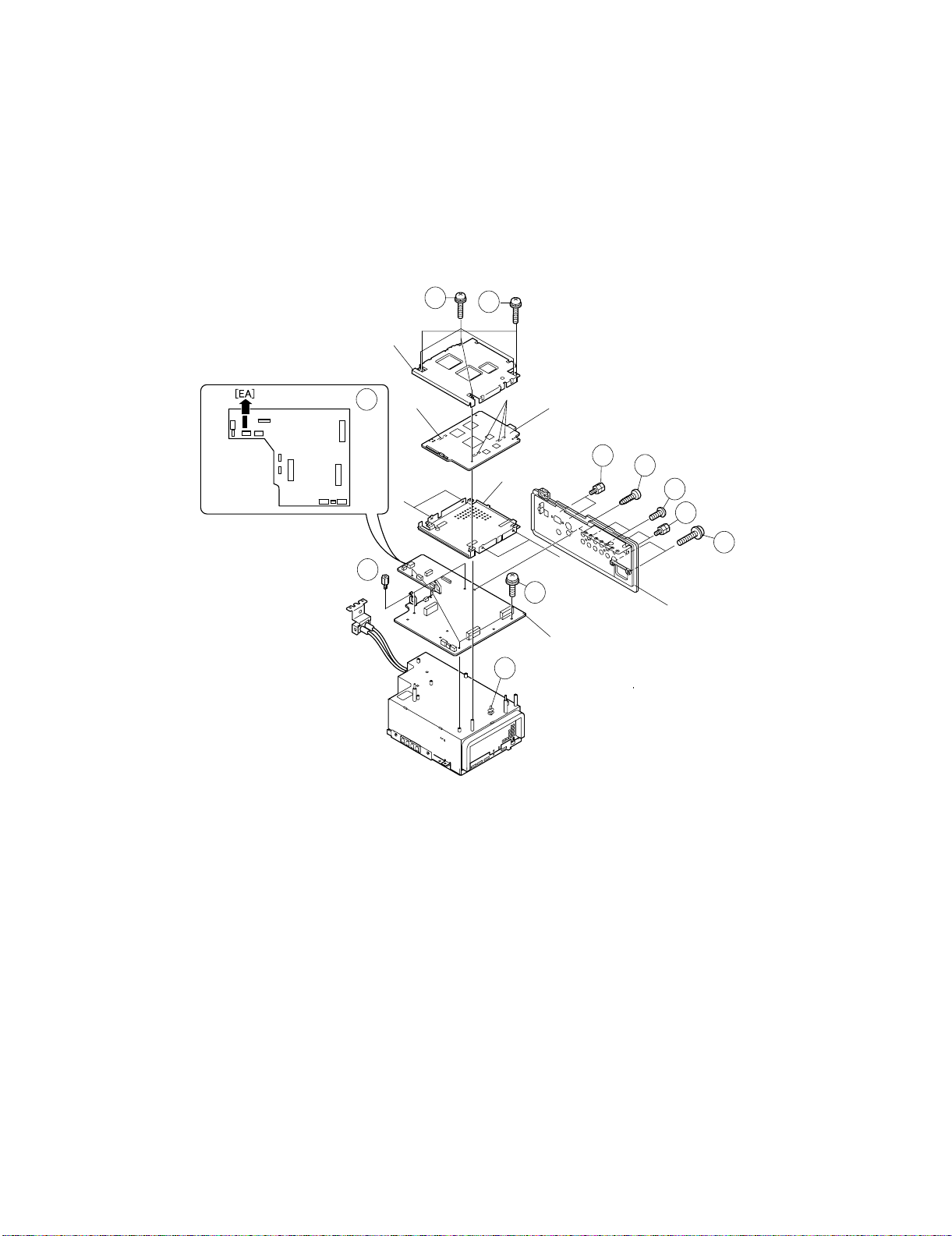

[3] Removing the Rear panel assembly, PC I/F PWB and the Main PWB

1. Remove the three screw.

2. Remove the two screws.

3. Remove the two screws.

4. Remove the four hexagonal supports and detach the Rear panel assembly.

5. Remove the four screws and detach the PC I/F assembly.

6. Remove the two screws and remove the four socket, and detach the shields.

7. Remove the one connector.

8. Remove the three screws and remove the two hexagonal supports.

9. Remove the one hook and detach the Main PWB.

Upper shield

3-7

Socket

hook

3-8

3-5

3-6

Socket

lower shield

3-9

PC I/F PWB

hook

3-8

Main PWB

3-4

3-1

Rear panel assembly

3-2

3-4

3-3

2 – 3

Page 20

XV-Z20000/XV-Z21000/DT-5000

[4] Precaution on Mounting the PC I/F PWB

1. Insert the lower shield into the power supply unit.

2. Align the PC I/F PWB with the socket on the main PWB, and securely connect them by pressing the 3 socket sections from above.

3. Fit the upper shield to the lower shield.

NOTE: (1) You must pay attention to the fitting direction of the upper and lower shields (both sides). (Figures 1 and 2)

(2) The upper shield on the terminal side must not be placed on the PWB. (Figure 3)

4. Install the 2 screws (3-6).

5. Install the 4 screws (3-5).

The upper shield must be located the outer side.

Upper shield

Hook

Lower shield

The lower shield must be located

the outer side.

Hook

Lower shield

Hook

PC I/F PWB

Upper shield

Upper Shield

Figure 1

The upper shield must be located the outer side.

Hook

The lower shield must be located the outer side.

Figure 2

The upper shield must not be

placed on the PWB.

Figure 3

2 – 4

Page 21

XV-Z20000/XV-Z21000/DT-5000

B

[5] Removing the Power unit shield assembly and Power/Ballast assembly

1. Remove the five screws and remove the two hooks, and detach the Power unit shield assembly.

2. Remove the one connector.

3. Remove the two screws and remove the two hooks, and detach the Power/Ballast assembly.

NOTE: Order the Power/Ballast assembly when replacing the ballast unit.

4-1

Power unit shield.

4-1

4-1

Ballast CTR

PWB

4-3

4-2

hook

4-3

4-3

Power PW

hook

2 – 5

Page 22

XV-Z20000/XV-Z21000/DT-5000

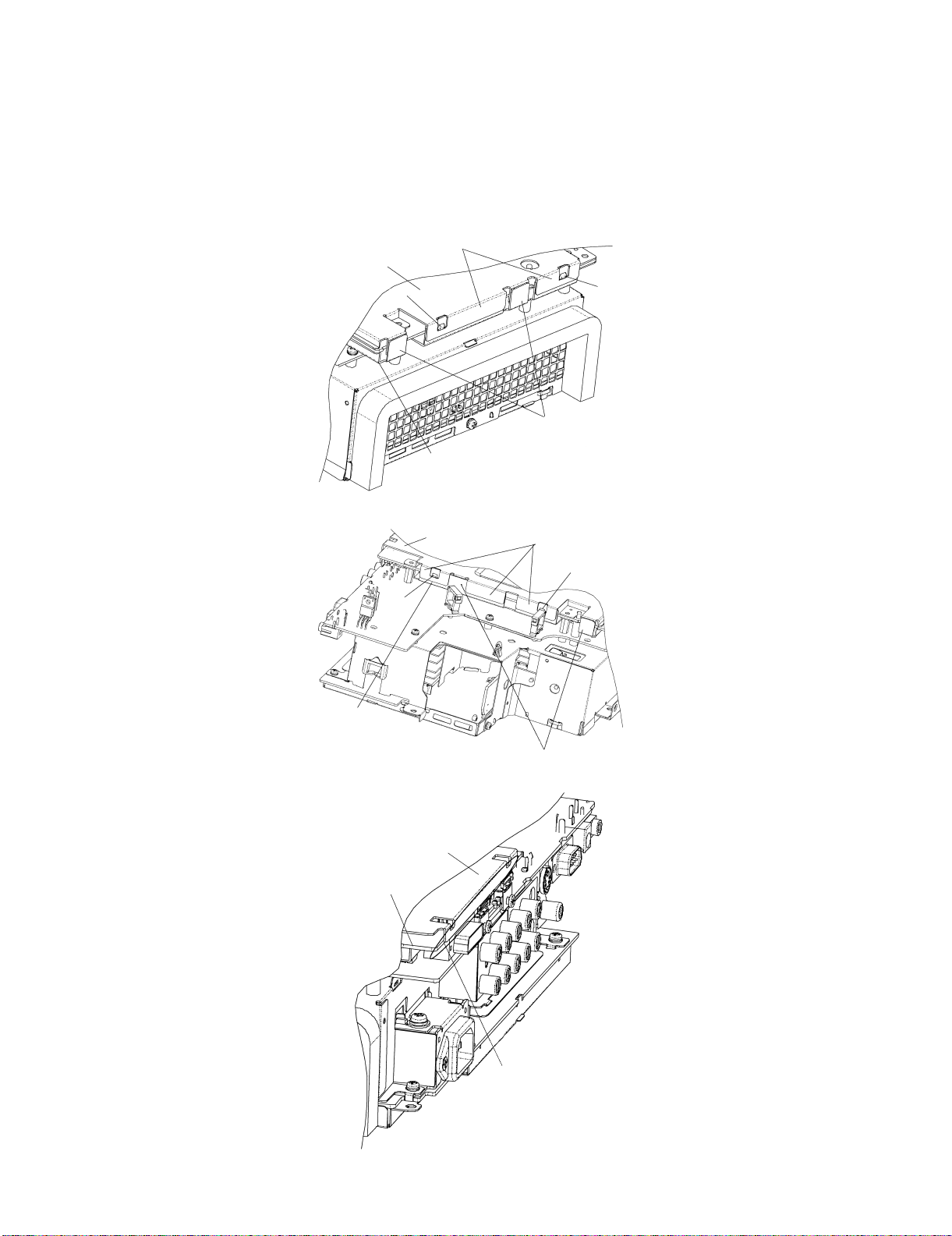

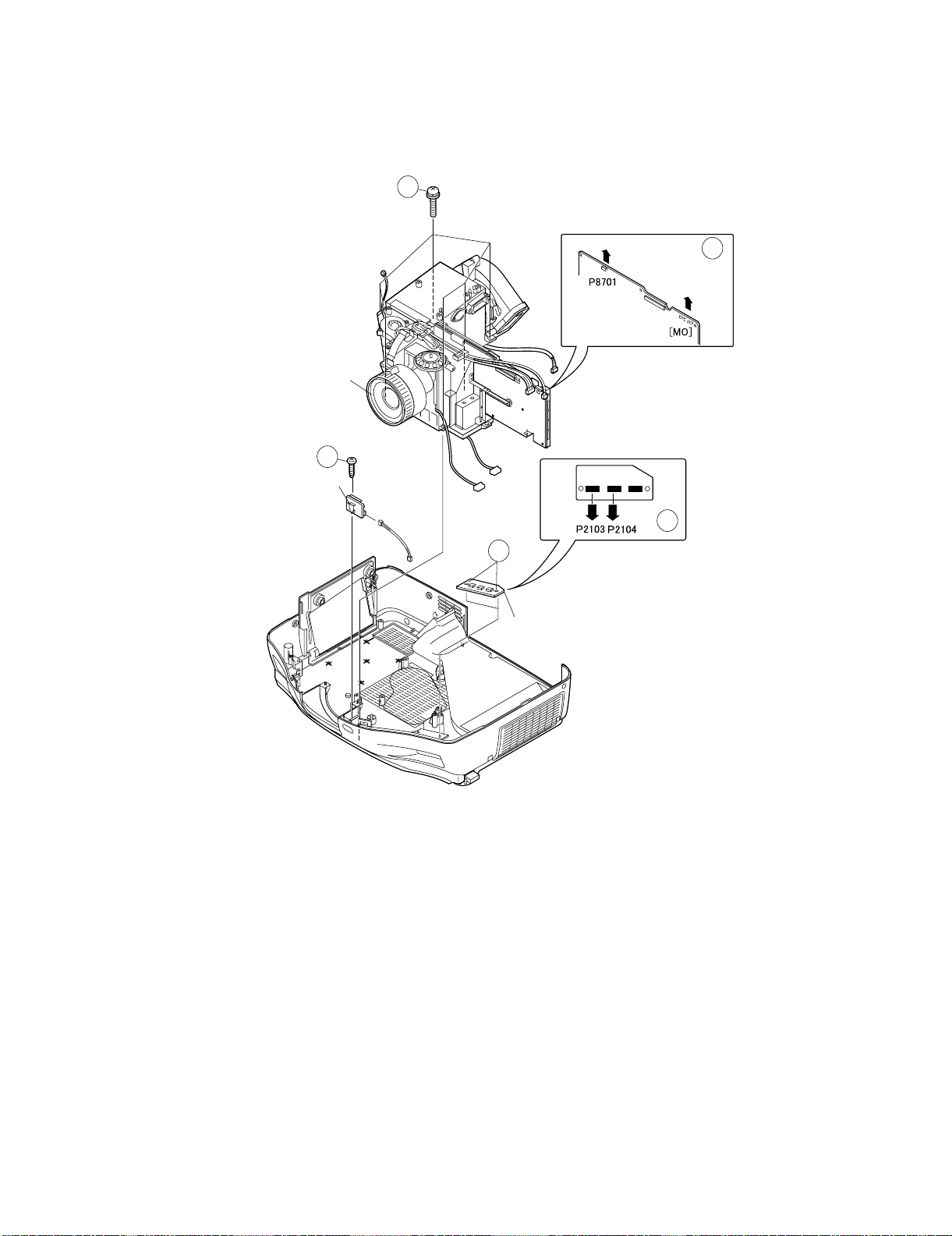

[6] Removing the Optical mechanism unit, R/C Front PWB and IRIS Drive PWB

1. Remove the four connectors.

2. Remove the six screws and detach the Optical mechanism unit.

3. Remove the one screw and the one connector. Detach the R/C Front PWB.

4. Remove the two hooks and detach the IRIS Drtive PWB.

5-2

5-1

Optical mechanism unit

5-3

R/C Front PWB

5-1

5-4

IRIS Drive PWB

2 – 6

Page 23

XV-Z20000/XV-Z21000/DT-5000

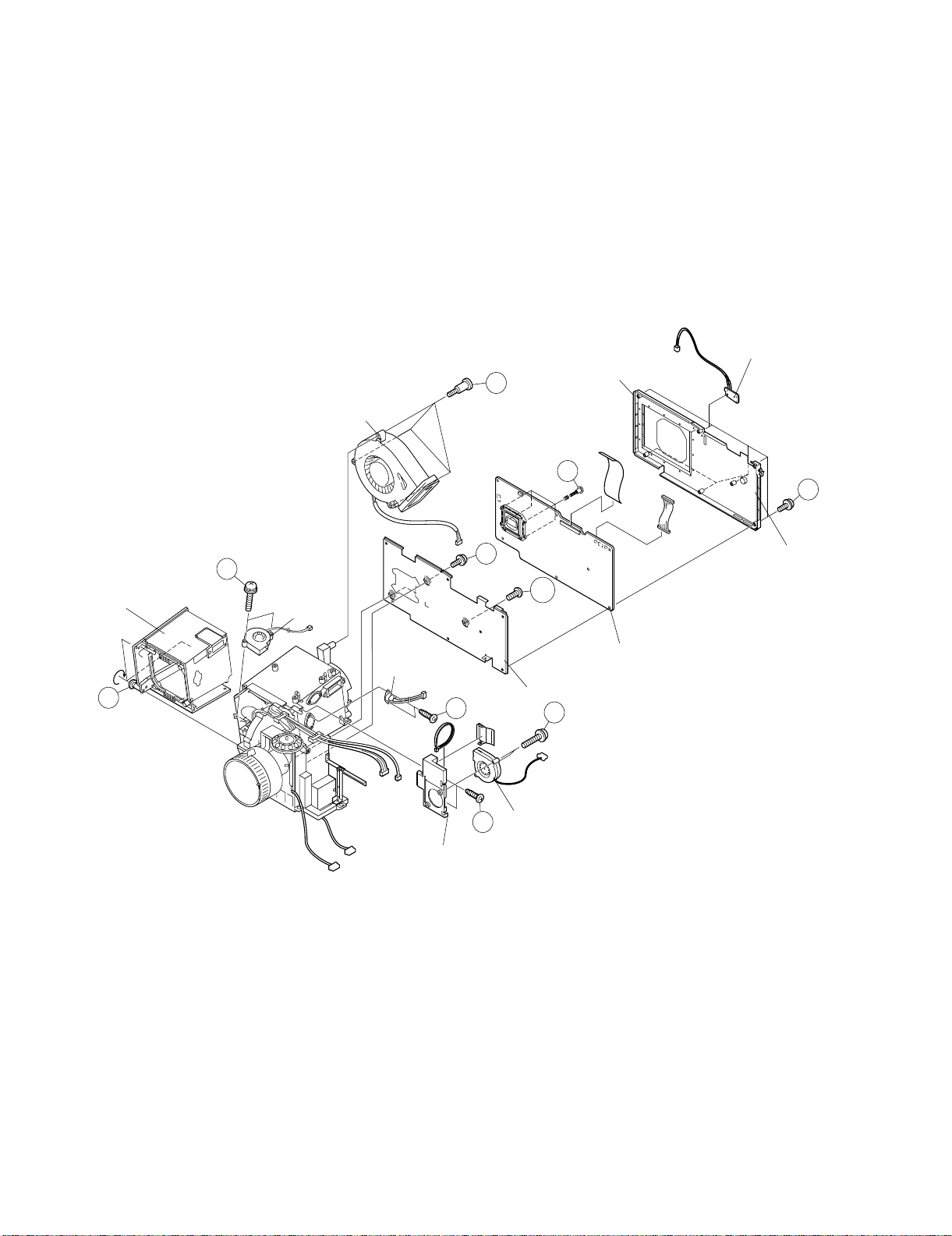

[7] Removing the Lamp unit, CW fan, Outlet Fan, Lamp duct, Lamp fan, Bimetal, Temp sensor and Formatter unit.

1. Remove the three screws and detach the Lamp unit.

2. Remove the two screws and detach the CW fan.

3. Remove the three screws and detach the Outlet fan.

4. Remove the two screws and detach the Lamp duct.

5. Remove the two screws and detach the Lamp fan.

6. Remove the two screws and detach the Bimetal.

7. Remove the seven screws and detach the Temp sensor and Formatter shield (Back).

8. Remove the four screws and detach the Formatter PWB.

9. Remove the two screws.

10.Remove the one screw and detach the Formatter shield (Front)

Lamp unit

6-1

6-2

Outlet fan

CW fan

Bimetal

6-6

6-9

6-4

6-3

Formatter shield (Front)

6-8

6-10

Formatter shield (Front)

6-5

Lamp fan

Temp sensor

6-7

Formatter

shield (Back)

Formatter PWB

Lamp duct

2 – 7

Page 24

XV-Z20000/XV-Z21000/DT-5000

XV-Z20000

CHAPTER 3. THE OPTICAL UNIT OUTLINE

Service Manual

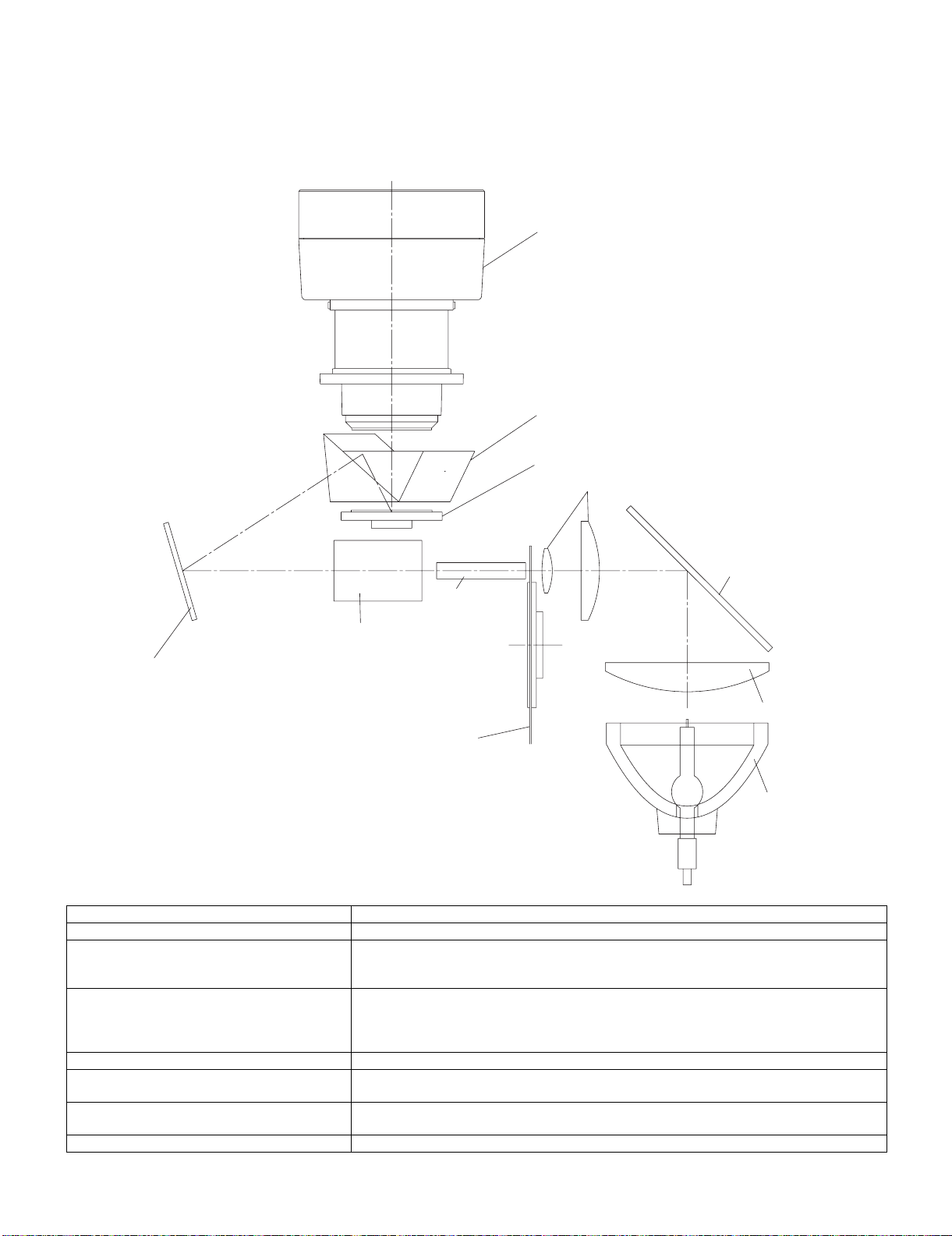

[1] THE OPTICAL UNIT OUTLINE

1. Layout for proper setup of the optical components and parts (top view)

Projection lens

Prism

DMD Chips

Condensor lens

IR-cut mirror

Light tunnel

Relay lens

Fold mirror

Condensor lens

Color filter

Lamp

Item Descriptions

1. Lamp The DC Light source lamp with parabola reflector.

2. Condensor lens, IR-cut mirror and light- tunnel The condensor lens leads the light generated from the lamp to the end surface of the light-tunnel through the IR-cut mirror.

The IR-cut mirror is set in this unit to eliminate the excessive heat by the lamp energy.

3. Color filter This color filter separates the white light into the 3 colors R,G and B.

A photo-sensor should be set in this unit to detect the transition timing properly between color

filters.

The maximum rotating speed is 9000rpm.

4. Relay lens and fold mirror This unit leads the illumination spot to effective area on DMD.

5. Prism This prism also leads the illumination spot to effective area on DMD and at the same time leads

the reflection lights on the DMD to the projection lens.

6. DMD chip This chip turns on and off in projection to each color component per dot depending on the input

source.

7. Projection lens This lens enlarges and projects the incidend light coming from the DMD.

3 – 1

Page 25

XV-Z20000/XV-Z21000/DT-5000

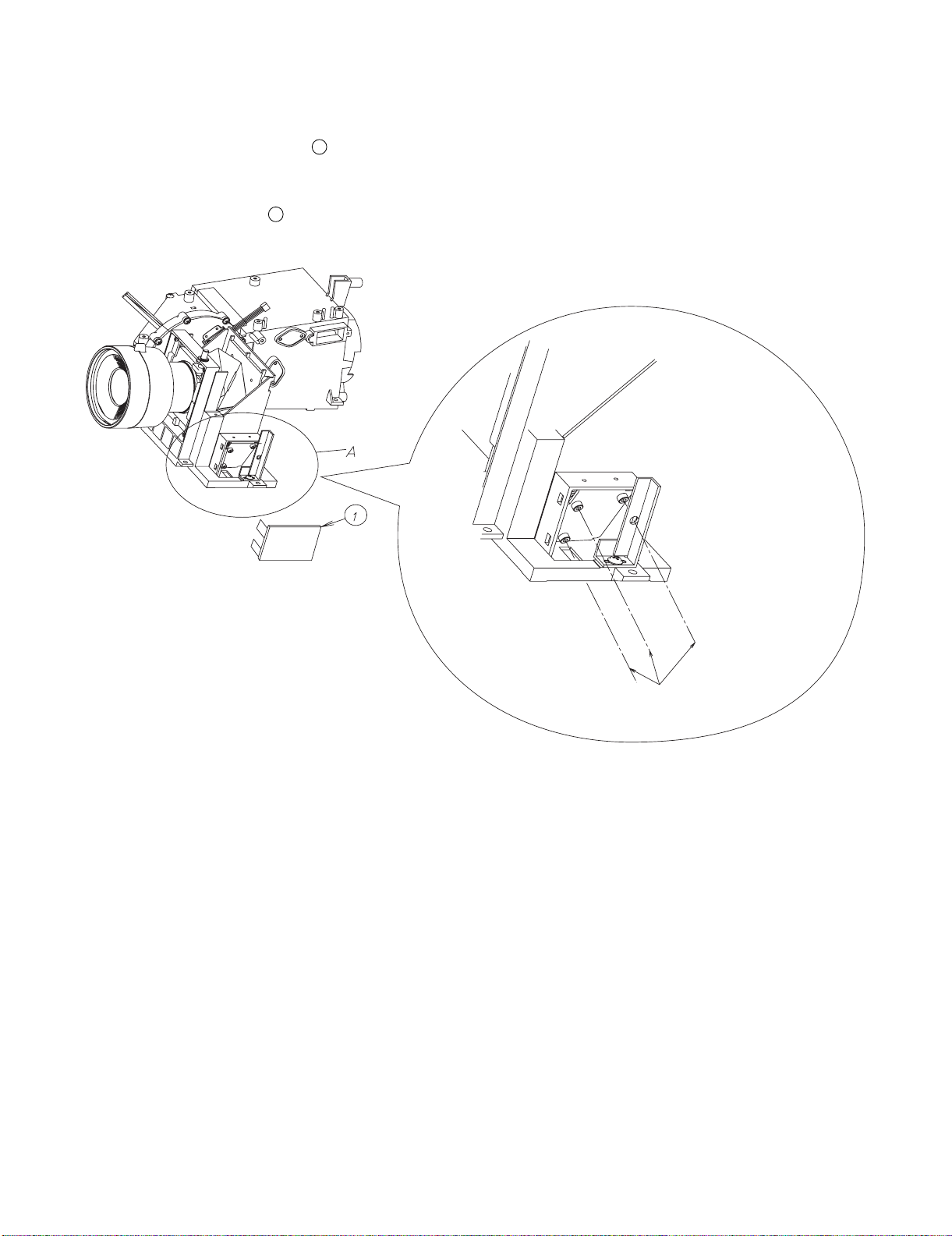

2. Adjusting the mirrors

Make adjustment by the indication territory on the screen to prevent the circumference of the screen from getting dark because a lighting range deviated.

1. Remove the top body so that the optical unit may be seen. Display white only screen on the screen.

2. Detach the mirror adjustment part cover on the bottom right of the projection lens.

3. Turn three screws with special hexagon wrench (9HPH10XL120) and adjust so that a part of the screen may not get dark because a lighting range

deviated

4. Mount the adjustment part cover .

5. Mount the top panel.

1

1

Insert hexagon wrench

in this direction.

Expansion figure of part A

3. Adjusting the back focal distance after replacing the projection lens

NOTE: A piece of temporary tape is attached on the focus ring that comes with the replacement projection lens. Keep this tape in place until the finish

of the adjustment.

1. Provide a distance of 2.4 m between the set and the screen and adjust the zoom knob to “wide end”.

2. Adjust the lens shift until the projection lens comes to the same level as the center of the screen.

3. Detach the optical unit top cover A from behind the projection lens.

4. Loosen the four hex screws B in the back of the projection lens.

5. Insert the adjustment screwdriver C (9EVDRIVERZ9000) in the hole D at the back of the lens. Put the center of the screen in the best focus. (Preferably feed the signal for 1-dot white crosshatch pattern or 1-dot white dot pattern on black background.)

6. Tighten the four hex screws B to the torque of 0.3 Nm (3.06 kgfcm), and apply screw loctite to them.

7. Peel the temporary tape off the focus ring of the projection lens.

8. Attach the optical unit top cover A back into position. Finally fix the two screws E and apply screw loctite to them.

3 – 2

Page 26

XV-Z20000/XV-Z21000/DT-5000

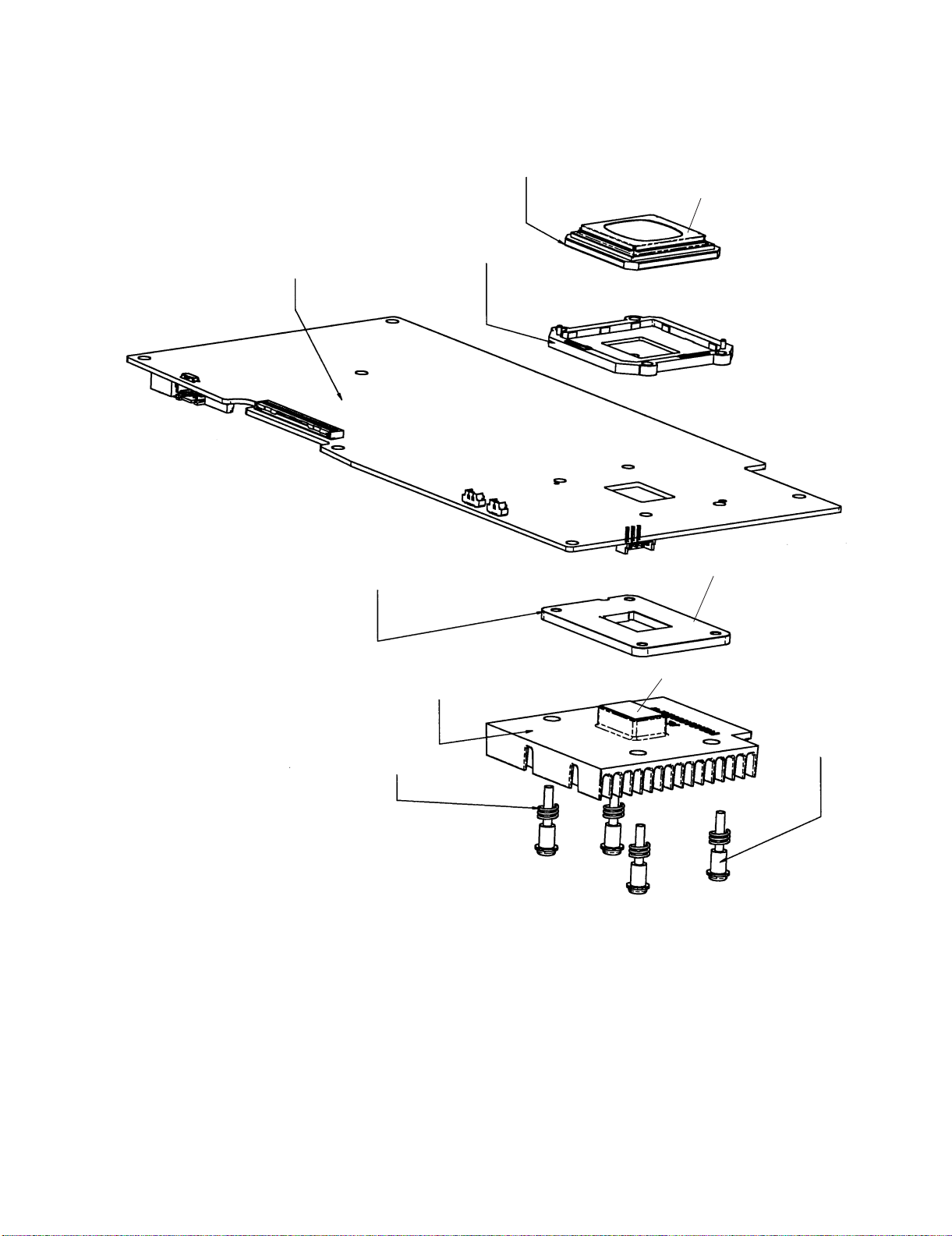

4. Joint of DMD and the unit

Wipe to clean the contamination of the PWB contacting part (gold plating part) with ethanol.

Set the position of the interposer with DMD attached to the optical unit, and then put the unit PWB on the interposer.

Sandwich the unit PWB and the back plate with the heatsink from the reverse side of the unit PWB and tighten with screws and springs.

The tightening toruqus is 0.45±0.05 Nm (4.5Kgfcm)

DMD

DMD Shield

Formatter unit

Backer plate

Interposer

Backer Plate Sheet

Carbon Sheet

Heat sink

Spring (4pcs)

Screw (4pcs)

3 – 3

Page 27

XV-Z20000/XV-Z21000/DT-5000

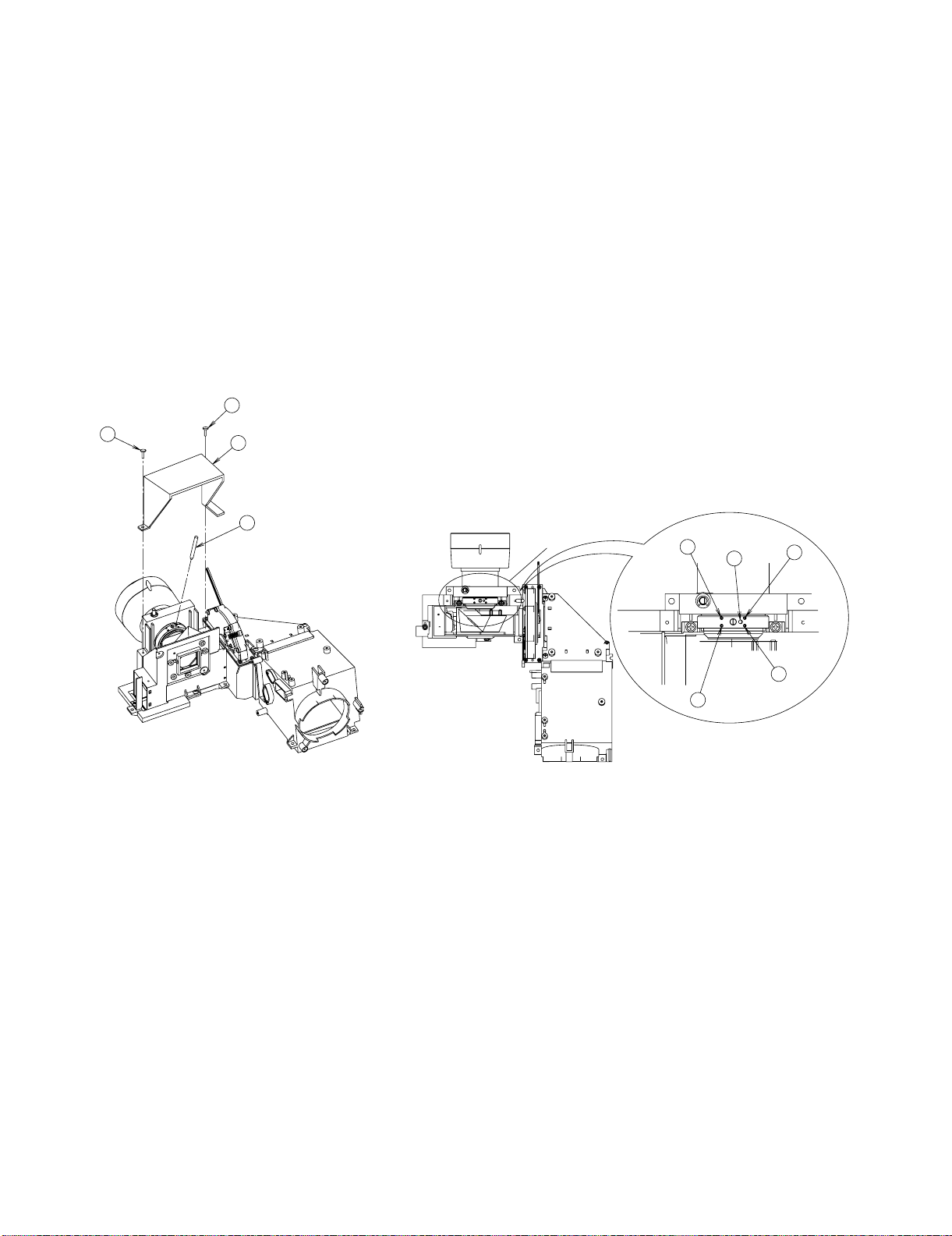

5. When the DMD unit has been replaced

NOTE: DMD chip and Formatter PWB are supplied at the same time, and an exchange only with DMD isn't done.Refer to "REMOVING OF MAJOR

PARTS" when exchanging Formatter PWB.

There is no need to readjust the back focal distance of the projection lens. If focusing is noticeably poor, however, make this readjustment.

1. Provide a distance of 2.4 m between the set and the screen.

2. Adjust the lens shift until the projection lens comes to the same level as the center of the screen.

3. Detach the optical unit top cover A from behind the projection lens.

4. Loosen the four hex screws B in the back of the projection lens.

5. Adjust the zoom knob at the front of the projection lens to "tele end" and ensure good focusing.

6. Then adjust the zoom knob at the front of the projection lens to "wide end".

7. Insert the adjustment screwdriver C (9EVDRIVERZ9000) in the hole D at the back of the lens. Put the center of the screen in the best focus. (Preferably feed the signal for 1-dot white crosshatch pattern or 1-dot white dot pattern on black background.)

8. Move the zoom knob from "wide end" back to "tele end" and see if focusing is ensured. If not, repeat the above steps (5), (6) and (7) until the best

focus is achieved.

9. Tighten the four hex screws B to the torque of 0.3 Nm (3.06 kgfcm), and apply screw loctite to them.

10.Attach the optical unit top cover A back into position. Finally fix the two screws E and apply screw loctite to them.

E

E

A

C

X

B

D

B

B

B

Expansion figure

of part X

3 – 4

Page 28

XV-Z20000/XV-Z21000/DT-5000

R

W

G

B

XV-Z20000

CHAPTER 4. ELECTRICAL ADJUSTMENT

Service Manual

[1] ELECTRICAL ADJUSTMENT

The unit has been adjusted optimally at the time of factory shipment. However, if the screen position is deviated or when exchanging parts, make an

adjustment as shown below.

• Turn on the power (lamp on state) and wait for 15 minutes for aging.

• Enter the adjustment process mode with SW2002 (tact switch) on the main unit.

• Select the group to adjust with the DOWN ( ) key or the UP ( ) key on the remote control, and enter the adjustment item with the ENTER

( ) key on the remote control.

• Select the adjustment item with the DOWN ( ) key or the UP ( ) key on the remote control.

• Use the LEFT ( ) key or the RIGHT ( ) key for adjustment.

• To return from the adjustment item to the adjustment group, use the UNDO ( ) key.

• To exit the adjustment process mode, execute the factory setting at the end of the adjustment.

If the factory setting is not executed, the adjusted contents are not reflected.

<Cautions for adjustment>

1. Initialization and factory setting

If the initialization S1 or the factory setting S5 of EEPROM is carried out, time for writing the data is necessary.

When executing EEPROM initialization S1 or S5, the OSD of adjustment process mode disappears, and the OSD of SET1 or SET5 appears. After

completing setting, the input is switched automatically (SET1: DVI A-RGB input, SET5: C1). Never turn off the power until the input is switched (a

little less than 1 minute).

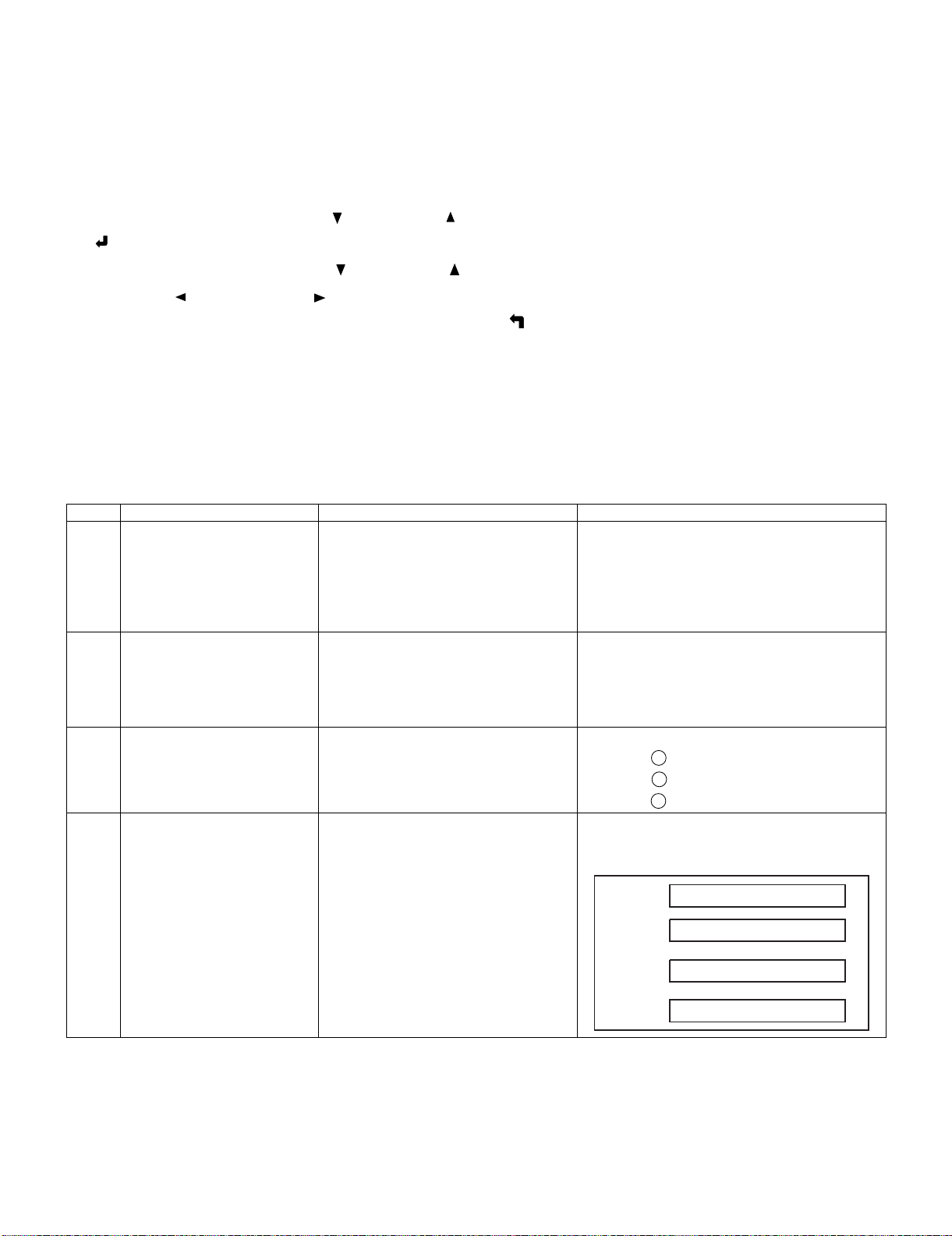

No. Adjusting point Adjusting conditions Adjusting procedure

1 EEPROM initialization 1. Turn on the power (with the lamp on) and

warm up the set for 15 minutes.

2 MODEL setting and model name

check

3 Color wheel sequence setting Check the number marked at CW.

4 Color wheel index adjustment 1. Adjustment device: DDP3021

Process menu: LINE

Select MODEL.

Adjustment group: DLP

Adjustment item: SEQUENCE

Initial value: 2

2. Adjustment group: DLP

3. Adjustment item: CWINDEX

Initial value: 40

The built-in pattern for INDEX adjustment is

displayed.

1. Make the following settings.

Press SW2002 to enter the process mode, and execute S1 to initialize EEPROM.

After executing S1, the input switches to DVIAnalogRGB.

S1: Main and Sub EEPROM initialization

S2: Sub EEPROM initialization

MODEL 0 DT5000

1 XVZ20000

2 XVZ21000

After setting, check that the model name displayed in

the first line of process menu is the same as the setting.

Color wheel number: SEQUENCE number

1

2

3

1. Adjust the setting so that the R, G and B Ramp tone

pattern should be smooth without noises.

1

2

3

4 – 1

Page 29

XV-Z20000/XV-Z21000/DT-5000

No. Adjusting point Adjusting conditions Adjusting procedure

5-1 R-bright/contrast adjustment 1. Device: AD998417

5-2 G-bright/contrast adjustment 1. Device: AD998417

5-3 B-bright/contrast adjustment 1. Device: AD998417

6-1 Component R-offset 1. Adjustment device: AD998417

6-2 Component B-offset

(Auto adjustment)

6-3 Component G-bright 1. Adjustment device: AD998417

2. Adjustment group: AD (RGB)

(Process gamma linkage)

3. Adjustment item: R-Bright

Initial value: 40

Adjustment item: R-D

Initial value: 60

4. Input terminal: DVI A-RGB (Input switching linkage)

5. Input signal: XGA

Wind pattern having 100% (0.7 Vpp) R signal and 0%

2. Adjustment group: AD (RGB)

(Process gamma linkage)

3. Adjustment item: G-Bright

Initial value: 40

Adjustment item: G-D

Initial value: 60

4. Input terminal: DVI A-RGB (Input switching linkage)

5. Input signal: XGA

Wind pattern having 100% (0.7 Vpp) G signal and 0%

2. Adjustment group: AD (RGB)

(Process gamma linkage)

3. Adjustment item: B-Bright

Initial value: 40

Adjustment item: B-D

Initial value: 60

4. Input terminal: DVI A-RGB (Input switching linkage)

5. Input signal: XGA

Wind pattern having 100% (0.7 Vpp) B signal and 0%

2. Adjustment group: AD (COMP)

(Process gamma linkage)

3. Adjustment item: CR-OFFSET

Initial value: 50

4. Input terminal: DVI A-Component

(Input switching linkage)

5. Input signal: Component 100% Ramp signal

1. Adjustment device: AD998417

2. Adjustment group: AD (COMP)

(Process gamma linkage)

3. Adjustment item: CB-OFFSET

Initial value: 50

4. Input terminal: DVI A-Component

(Input switching linkage)

5. Input signal: Component 100% Ramp signal

2. Adjustment group: AD (COMP)

(Process gamma linkage)

3. Adjustment item: G-BRIGHT

Initial value: 70

4. Input terminal: DVI A-Component

(Input switching linkage)

5. Component wind pattern having 100%

(0.7 Vpp) G signal and 0%

6. Perform adjustment after adjusting CROFFSET and CB-OFFSET.

1. Observe the 0% portion.

2. Vary R-Bright (increment direction), and adjust to

the point reduced by 1 point from the point where red

bit dropout appears.

3. Observe the 100% portion.

4. Vary R-D (increment direction), and adjust to the

point raised by 2 points from the point where red bit

dropout appears.

1. Observe the 0% portion.

2. Vary G-Bright (increment direction), and adjust to

the point reduced by 1 point from the point where

green bit dropout appears.

3. Observe the 100% portion.

4. Vary G-D (increment direction), and adjust to the

point raised by 2 points from the point where green bit

dropout appears.

1. Observe the 0% portion.

2. Vary B-Bright (increment direction), and adjust to

the point reduced by 1 point from the point where blue

bit dropout appears.

3. Observe the 100% portion.

4. Vary B-D (increment direction), and adjust to the

point raised by 2 points from the point where blue bit

dropout appears.

1. Vary CR-OFFSET, and place the red line appearing

near the center over the green line.

2. The line color turns yellow.

1. Vary CB-OFFSET, and place the blue line over the

line turning yellow by CR-OFFSET adjustment.

2. The line color turns white.

1. Observe the 0% portion.

2. Vary G-BRIGHT (decrement direction), and the

screen starts to whiten.

3. Adjust to the point where no bit dropout is found

and the screen becomes completely white.

4 – 2

Page 30

XV-Z20000/XV-Z21000/DT-5000

No. Adjusting point Adjusting conditions Adjusting procedure

6-4 Component RGB-gain adjust-

ment

(Auto adjustment)

7 White balance adjustment 1. Adjustment device: DDP3021

8 Factory setting 1. Group: SSS 1. Perform the following settings.

Do not change the process adjustment values other than the above since they are set so that optimal images are obtained.

1. Adjustment device: AD998417

2. Adjustment group: AD (COMP) (Process

gamma linkage)

3. Adjustment item: G-D

Initial value: 70

4. Input terminal: DVI A-Component

(Input switching linkage)

5. Component wind pattern having 100%

(0.7 Vpp) G signal and 0%

6. Perform adjustment after adjusting CROFFSET, CB-OFFSET and G-BRIGHT.

2. Adjustment group: DLP

3. Adjustment item: R-GAIN

Initial value: 95

B-GAIN

Initial value: 95

4. Input terminal: DVI A-Component

(Input switching linkage)

5. Input signal: Component 75% gray signal

1. Observe the 100% portion.

2. Vary G-GAIN (decrement direction), and the illuminance and chromaticity start to change.

3. Adjust to the point raised by 2 points from the point

where bit dropout appears on the screen.

1. Observe the chromaticity of 75% portion using

CL200.

2. Adjust the y value to adjustment chromaticity ±

0.005 with B-GAIN.

3. Adjust the x value to adjustment chromaticity ±

0.005 with R-GAIN.

Adjustment chromaticity

x = 0.299 ±0.005

y = 0.316 ±0.005

Destination Process adjustment Remote control

setting

Europe: S3 Factory setting 3

North America: S4 Factory setting 4

Japan: S5 Factory setting 5

China: S6 Factory setting 6

South America: S7 Factory setting 7

4 – 3

Page 31

[2] Process menu

Group Subject

AD(RGB)

AD(COMP)

DLP

VIDEO1

VIDEO2

OUTPUT

LINE

XV-Z20000/XV-Z21000/DT-5000

R-BRIGHT Adjustment Value Subject

G-BRIGHT Adjustment Value Subject

B-BRIGHT Adjustment Value Subject

R-D Adjustment Value Subject

G-D Adjustment Value Subject

B-D Adjustment Value Subject

AD-AUTO — No Use

G-BRIGHT Adjustment Value Subject

CR-OFFSET Adjustment Value Subject

CB-OFFSET Adjustment Value Subject

G-D Adjustment Value Subject

COMP-AUTO 0 Fixed Value

CW-INDEX Adjustment Value Subject

DLP-GAMMA 1 Fixed Value

R-BRIGHT 100 Fixed Value

G-BRIGHT 100 Fixed Value

B-BRIGHT 100 Fixed Value

R-GAIN Adjustment Value Subject

G-GAIN 95 Fixed Value

B-GAIN Adjustment Value Subject

CCA 0 Fixed Value

SEQUENCE Adjustment Value Subject

PICTURESUB 128 Fixed Value

PICTURE 136 Fixed Value

BRIGHT 128 Fixed Value

TINT 128 Fixed Value

N-COLOR 128 Fixed Value

P-COLOR 120 Fixed Value

SV-COLOF 5 Fixed Value

YGC-CNT 0 Fixed Value

SETUP 1 Fixed Value

CTI 7 Fixed Value

N358DLY 7 Fixed Value

PALDLY 7 Fixed Value

H-CENTER 128 Fixed Value

VIDEO-AUTO 0 Fixed Value

YTRAP FILNP 0 Fixed Value

CTRAP FILNP 0 Fixed Value

YTRAP FILS 1 Fixed Value

CTRAP FILS 2 Fixed Value

YCTRAP FIL 1 Fixed Value

YCTRAP GAIN 0 Fixed Value

FCTRAP SYS 1 Fixed Value

PEAK GAIN 128 Fixed Value

PEAK FIL 2 Fixed Value

PEAK CORING 0 Fixed Value

CR LPF 1 Fixed Value

CB LPF 1 Fixed Value

R1-GAIN 128 Fixed Value

G1-GAIN 128 Fixed Value

B1-GAIN 128 Fixed Value

V-R1-GAIN 128 Fixed Value

V-G1-GAIN 128 Fixed Value

V-B1-GAIN 128 Fixed Value

C-R1-GAIN 128 Fixed Value

C-G1-GAIN 128 Fixed Value

C-B1-GAIN 128 Fixed Value

MODEL Setting Value Setting Item

TIME — Fixed Value

LAMP 0 Fixed Value

OFF 0 Fixed Value

TEMP OFF 4 Fixed Value

SENSOR CHECK — Fixed Value

4 – 4

Page 32

XV-Z20000/XV-Z21000/DT-5000

Group Subject

S1 (Main+Sub EEPROM Initialized) —

S2 (Sub EEPROM Initialized) —

S3 (EU) —

SSS

PATT ERN

CVIC

SPECIAL

S4 (US) —

S5 (JPN) —

S6 (CHINA) —

S7 (South America) —

RGB 100% White Signal

RGB50 50% Gray Scale Signal

CROSS Crosshatch Signal

STEP Gray Step Signal

COLOR Colour Bar Signal

RAMP Lamp Signal

INDEX PATTERN Index Adjustment Signal

ENHANCED SD — Fixed Value

ENHANCED HD — Fixed Value

DNR — Fixed Value

MNR SD — Fixed Value

MNR HD — Fixed Value

UNVEIL — Fixed Value

ACC — Fixed Value

OSD DIMMER — Fixed Value

CMS HUE — Fixed Value

CMS SAT — Fixed Value

CM S VAL — F ixed Va l ue

GAMMA POS — Fixed Value

IPL

E2PROM —

ADR RD/WR —

PRG VER.

SUB VER —

FMT VER. —

—

—

—

—

4 – 5

Page 33

XV-Z20000

CHAPTER 5. TROUBLE SHOOTING TABLE

Service Manual

[1] TROUBLE SHOOTING TABLE

Checking the basic performance

XV-Z20000/XV-Z21000/DT-5000

Is the POWER LED on or flickering in red or

blue?

YES

Is the set turned on by the set's or remote

controller's power key?

YES

Is the cooling fan running? Is the lamp on? NO Go to "Checking the lamp light-up".

YES

Is the user menu displayed? NO Check the formatter circuit's peripheral circuits

YES

Is the video input (VIDEO, S-VIDEO) as

specified?

YES

Is the component input (C1, C2) as specified?

NO Go to "Checking the power unit"

NO Go to "Checking the microcomputer peripher-

als"

and go to “checking the PC PWB”

NO Are there output signals at TL3053, TL3504,

TL3517?

YES

go to “checking the PC PWB”

NO Are there output signals at TL3506, TL3508,

TL3512?

NO Check the Q2501,

Q2502, Q2504 and their

peripheral circuits.

NO Check the IC2501,

IC2502 and their peripheral circuits.

YES

Check the PC board circuit's peripheral circuits.

YES

Is the RGB input (DVI) as specified? NO Check the PC board circuit's peripheral circuits.

YES

Does the RS-232C interface function? NO Are there output signals at every other pin from

pins (10) to (40) of P3580?

YES

Check the IC5003 on the PC PWB

YES

Recommended

communication software: "TERA TERM"

Make the following settings: baud rate at

9600 bps, bit length at 8 bits, stop bit at 1 bit

and no parity. Press the RETURN key on the

keyboard. Does "ERR" show up again?

YES

END

NO Check the IC5003 on the PC PWB

NO Check the IC2001 circuit

and its peripheral circuits.

5 – 1

Page 34

XV-Z20000/XV-Z21000/DT-5000

Checking the power unit

Are all the connectors inside the

power unit tightly connected?

YES

Is the lamp cover closed completely? NO Tighten up the lamp door closed with the

YES

Is the bimetal switch off? NO Replace the bimetal switch or press the

YES

Is AC voltage applied across the

RY701 relay?

YES

Is AC voltage applied across L706? NO Replace F702.

YES

Is there DC voltage of about 6 V

across C723?

NO Insert the connectors P702, P704, CN90

and P703 tightly.

screws.

red button to reset.

NO Replace F701.

NO Check the T701, L705, R706, R718.

Replace any of them as required.

YES

Is a voltage of DC370V applied to

C737 and C740?

YES

Is there the specified voltage at the

output terminal of P704?

YES

Check the output PWB

NO Check the circuits leading to the primary

side of T704 for damage.

Replace any of them as required.

NO Check the circuits leading to the second-

ary side of T704 for damage.

Replace any of them as required.

5 – 2

Page 35

Check of the microprocessor's

peripheral circuits

XV-Z20000/XV-Z21000/DT-5000

The power indicator does not light

up?

NO

When connecting to an AC outlet, the

power indicator lights red for a

moment and flashes red at 1-second

intervals?

NO

The power indicator flashes red at 4-

second intervals?

YES

Check the voltage of TL6503 on the

PC board unit.

Is it 3V or more?

YES

Is clock output to TL5015 on the PC

board unit?

YES Check the power supply BU6V system

and output voltage of IC2810 and IC2002.

Check peripheral circuits of IC2005.

YES Check the lamp door and lamp switch. Try

to press the red button of bimetal SW.

Check each output of power supply.

NO Go to “Check of lamp lighting”.

NO Check the output voltage of DCDC regula-

tor IC on the main unit and PC board unit.

NO Are X5001 (16.59 MHz) and X5002

(32.768 MHz) oscillated?

Or check peripheral circuits of IC5003.

YES

Is pulse output to TL5009 when connecting to an AC outlet?

YES

Check peripheral circuits of IC5003,

IC5101 and IC5104.

Check of lamp lighting

The lamp indicator lights blue and goes out in

about 15 seconds. The power indicator flashes

red at 1-second intervals.

NO

The lamp flashes blue, but it lights solid red after

about one minute.

NO

The lamp lights up. After about 100 seconds, the

TEMP warning indicator appears on the screen,

and the unit enters the stand-by. (The power indicator and temperature monitor indicator flash red.)

NO Check peripheral circuits of IC2005.

YES Check the 13 V power supply and the

cooling fan drive circuit.

YES The lamp or the ballast unit is defective.

YES If TEMP error occurs even at low ambient

temperatures, check the TEMP1 and

TEMP3 signal lines. Check the fan.

NO

Go to "The lamp is flashing blue continuously".

5 – 3

Page 36

XV-Z20000/XV-Z21000/DT-5000

The lamp is flashing blue continuously.

Is a voltage of 2.5 V or more present

at pins TL6610 in the PC PWB unit?

YES

Is a voltage of 3 V or more present at

TL6611 in the PC PWB unit?

NO

Are a 1 Vp-p clock signals present at

R8731, R8732 in the formatter unit?

YES

Is power output of IC9701 and

IC9702 normal? (1.8V/1.2V/2.5V/

3.3V)

YES

Is a pulse present at each address

pin of IC8602 and IC9602 in the formatter unit, immediately after turning

the power on?

YES

Is a pulse being output to each data

pin of IC8602 and IC9602 in the for-

matter unit, immediately after turning

the power on?

NO Check IC2005 (sub-microcomputer) and

peripheral parts.

YES Check IC2005 (sub-microcomputer) and

peripheral parts.

NO Check X8701, Check the peripheral cir-

cuits of IC8711 and IC8712.

NO Check peripheral circuits of IC9701 and

IC9702.

NO IC9101 is defective.

NO IC8602 or IC9602 is defective.

YES

Are IC8602 and IC9702 warm when

touching them?

YES

Is a motor drive pulse present at pins

(2), (3), and (4) of P9701 in the formatter unit?

YES

Is a pulse present at pin (4) of P8901

in the formatter unit?

YES

IC8301 or IC9301 is defective.

NO Check IC8301 and IC9301 and peripheral

circuits of IC8601 and IC9601.

NO Check IC9701 and its peripheral circuits.

NO The color wheel unit is defective.

5 – 4

Page 37

Check the PC PWB unit.

XV-Z20000/XV-Z21000/DT-5000

Can the menu display be

brought up?

NO

Check OSD. Check the input at the compo-

YES Check the RGB input. Check the basic flow of the signals.

nents.

Check the VIDEO input. Since the VIDEO input enters CVIC through a different

Check the 480iRGB (or component) input.

Since the component and VIDEO signals follow the

same path to the output as the formatter unit uses,

after CVIC (IC6001), the check that would otherwise

be performed after the CVIC does not need to be performed. (480i and 576i are excluded.)

The signal passes through the same circuit as the

RGB input. Mainly, check the SOG (Sync On Green)

circuit and the color adjustment circuit. (480i and 576i

are excluded.)

route than the RGB input, check the VIDEO IC.

(480i and 576i are excluded.)

The video signal and the color signal pass through the

same circuits as the RGB input. However, since the

synchronization signal uses the VIDEO IC,

check the synchronization signal path.

Check the DVI analog input.

Check the DVI digital/HDMI

input.

END

The signal is reproduced in an IC specially designed

for use with the TMDS, and it enters the CVIC.

5 – 5

Page 38

XV-Z20000/XV-Z21000/DT-5000

Check OSD.

Press the key on the main unit or the

[MENU] key on the remote control.

Is the menu display brought up?

NO

Is there a clock signal at TL6618? NO Is aclock signal (74.25MHz) present at

YES

Is a synchronization signal present at

TL6617, TL6620-21?

YES

Check TL6622, TL6619 using an

oscilloscope. Is the signal seen correct?

YES

END

TL6007?

YES

Is there a clock signal at TL6006 NO X6002 is defective.

YES

Check peripoheral citcuits of IC6001

NO Check the bus signal between IC5003

and IC6001.

NO The connector CN6604 or FPC and for-

matter unit are defective.

NO Check peripoheral citcuits of

IC6001

NO

IC6001 (CVIC) is defective.

5 – 6

Page 39

Check the RGB input.

Input the sync separation RGB signal

to C1 or C2 (except 480i and 576i).

Select C1 or C2 using the operation

key or the remote control.

Is a projection image displayed? NO Go to "Check the video input”.

YES

Is the picture distorted? YES Go to "Check the synchronization signal".

NO

Are all three colors (R, G, and B)

being output?

NO Go to "IC5652 peripheral check".

XV-Z20000/XV-Z21000/DT-5000

YES

Is the image frame normal? NO Go to "IC5652 peripheral check".

YES

End

Check the video input.

Is the signal generator (input source)

set correctly?

YES

Is the video signal present at pin (8)

of IC5209?

YES

Is the video signal present at

TL5659?

NO Set the signal generator (input source)

correctly.

NO Check the installation of the main unit.

The main unit is defective.

NO Check the peripheral circuit of IC5209.

YES

Go to "Check the synchronization signal".

Go to "IC5652 peripheral check".

5 – 7

Page 40

XV-Z20000/XV-Z21000/DT-5000

Check the synchronization signal.

Is the signal generator (input source)

set correctly?

YES

Is a vertical synchronization signal

present at TL5505?

YES

Is a horizontal synchronization signal

present at TL5504?

YES

Is a vertical synchronization signal

present at TL5515?

YES

Is a horizontal synchronization signal

present at TL5509?

YES

Synchronization signals are normal.

NO Set the signal generator (input source)

correctly.

NO Peripheral circuits of IC5502 and 5503 are

defective.

Or the main unit is defective.

NO Peripheral circuits of IC5502 and 5503

are defective.

Or the main unit is defective.

NO The IC5504, IC5510 or IC5511 peripheral

parts are defective.

NO The IC5504, IC5510 or IC5511 peripheral

parts are defective.

IC5652 peripheral check

Set the signal generator to output a

RAMP signal.

Is a synchronization signal present at

R5610 and TL5515?

YES

Is a clock signal present at R5679? NO The IC5652 clock oscillation circuit or

YES

Are video signals sent to TL5655 ?

TL5661?

YES

Is a pulse present at pins (28) - (63)

of IC5652?

NO The IC5511 peripheral parts or IC6001

(CVIC) are defective.

IC5652 is defective.

NO The IC5209 peripheral circuit or the main

unit is defective.

NO IC5652 is defective.

YES

IC6001 (CVIC) is defective.

5 – 8

Page 41

Check the input at the components

(480i and 576i are excluded).

Supply a component signal to C1 or

C2. (Separate HV sync signal is not

connected.)

Select C1 or C2 using the key on the

main unit or the remote control.

Is a projection image displayed? NO Go to "Check the SOG circuit.".

YES

Is the color normal? NO Perform the process adjustment.

Does the color become normal?

YES

Is the image frame normal? NO Go to "IC5652 peripheral check".

XV-Z20000/XV-Z21000/DT-5000

NO Go to “IC5652 peripheral check”.

YES

End.

Check the SOG circuit.

Is the signal generator (input source)

set correctly?

YES

Is a composite synchronization signal

present at TL5513?

NO

Is a composite synchronization signal

with the correct timing being output to

TL5511?

NO

Is a video signal present at R5551? YES The SOG circuits (IC5512, IC5513 and

NO Set the signal generator (input source)

correctly.

YES The SOG circuit is normal.

YES The IC5514 peripheral circuit is defective.

Q5570 - 09) are defective.

NO

The IC5209 peripheral circuit is

defective or the main unit is defective.

5 – 9

Page 42

XV-Z20000/XV-Z21000/DT-5000

Check the 525i (625i) RGB (or component) input.

Supply a 525i (625i) RGB (or component) signal to C1 or C2.

Select C1 or C2 using the key on the

main unit or the remote control.

Is a projection image displayed? NO Go to "Check the SOG circuit."

YES

Is the picture distorted? NO Go to "Check the VIDEO synchronization

signal."

YES

Is the color normal? NO Perform the process adjustment.

YES

Is the image frame normal? NO Go to "IC5652 peripheral check".

YES

END.

5 – 10

Page 43

Check the composite VIDEO

(CVBS) input.

Supply an NTSC3.58 VIDEO signal

to VIDEO.

Select VIDEO using the key on the

main unit or the remote control.

XV-Z20000/XV-Z21000/DT-5000

Is a projection image displayed?

Is the picture distorted?

YES

Is the color normal?

Is the image frame normal?

YES

END.

Check the S-VIDEO input.

Supply an NTSC3.58 S-VIDEO signal

to S-VIDEO.

Select S-VIDEO using the key on the

main unit or the remote control.

NO Go to "Check the VIDEO synchronization

signal."

NO Go to "IC5706 peripheral check".

Is a projection image displayed?

Is the picture distorted?

YES

Is the color normal?

Is the image frame normal?

YES

END.

NO Go to "Check the VIDEO synchronization

signal."

NO Go to "IC5706 peripheral check".

5 – 11

Page 44

XV-Z20000/XV-Z21000/DT-5000

Check the

VIDEO synchronization

signal.

Is a vertical synchronization signal present at

TL5710?

YES

Is a horizontal

synchronization

signal present at

TL5711?

YES YES

The VIDEO synchronization signal is normal.

NO

NO

Is a clock signal

(24.57 MHz)

present at

X5701?

Is a video signal

present at

TL5712?

NO

Is the input signal

525iRGB (or component)?

NO

Check the voltage

NO

YES IC5706 is defec-

YES Is a video signal

output of IC5702

and

IC5703.X5701 or

IC5706 is defective.

tive.

present at

TL5703?

NO

Check peripheral

circuits of Q5701

and Q5707.

The main unit is

defective.

YES IC5706 is defec-

tive.

Is the input signal

composite VIDEO

(CVBS)?

NO

Is the input signal

S-VIDEO?

YES Is a video signal

present at

TL5707?

NO

Check peripheral

circuits of Q5706

and Q5712.

The main unit is

defective.

YES Are video signals

sent to TL5705

and TL5706?

NO

Check peripheral

circuits of Q5704,

Q5705, Q5710

and Q5711.

The main unit is

defective.

YES Is S-VIDEO pro-

jected normally?

YES

Check peripheral

circuits of IC5707.

YES IC5706 is defec-

tive.

NO IC5706 is defec-

tive.

5 – 12

Page 45

IC5706 peripheral check

XV-Z20000/XV-Z21000/DT-5000

Is a clock signal (24.57 MHz) present

at X5701?

YES

Is a clock signal present at TL5712? NO IC5706 is defective.

YES

Supply a RAMP signal to VIDEO, and

observe pins (86 - 100) of

IC5706using an oscilloscope.

Is a pulse present at pins (86 - 100) of

IC5706?

YES

.Supply a color bar signal to VIDEO,

and observe pins (112 - 122) of

IC5706.

NO Check X5701, or IC5706 is defective.

NO IC5706 is defective.

Is a pulse present at pins (112 - 122)

of IC5706?

YES

IC6001 or after is defective.

NO IC5706 is defective.

5 – 13

Page 46

XV-Z20000/XV-Z21000/DT-5000

Check the DVI analog input.

Supply a PC-RGB analog signal to

DVI.

Select DVI using the key on the main

unit or the remote control.

Check the input signal type. When checking the optional input signal

Is a projection image displayed? YES END.

NO

Is an RGB signal present at pins (2),

(8), and (14) of IC5652?

YES

Is a vertical synchronization signal

present at TL5505?

YES

Is a horizontal synchronization signal

present at TL5504?

YES

Is a synchronization signal present at

TL5509 and TL5515?

NO Check in the vicinity of the DVI connector.

NO IC5502 or peripheral parts are defective.

NO IC5503 or peripheral parts are defective.

NO

on the menu display, set it to "A. RGB".

IC5511 is defective.

YES

IC5652 or after is defective.

5 – 14

Page 47

Check the DVI digital/HDMI

Supply a PC-RGB digital signal to

DVI.

Select DVI using the key on the main

unit or the remote control.

XV-Z20000/XV-Z21000/DT-5000

Check the input signal type. When checking the optional input signal

Is a projection image displayed? YES

NO

Is a clock signal present at TL5368? NO Are images projected when the HDMI sig-

YES NO

Is a pulse present at pins (92 - 124)

and (2 - 35) of IC5357?

YES

Is a synchronization signal present

atTL5364, TL5366 and TL5370?

NO Check peripheral circuits of IC5356 and

NO IC5357 is defective.

on the menu display, set it to "D. PC

RGB"..

END.

nal is input into H1 or H2 and INPUT is

selected?

IC5357.

YES Check peripheral circuits of DVI

connector.

Check peripheral circuits of

IC5356.

YES

Is a synchronization signal present at

TL5509 and TL5515?

YES

Check IC6001 or after.

NO IC5511 is defective.

5 – 15

Page 48

XV-Z20000/XV-Z21000/DT-5000

㪽

㪮

㪩

XV-Z20000

CHAPTER 6. BLOCK DIAGRAM/OVERALL WIRING DIAGRAM

Service Manual

[1] BLOCK DIAGRAM

عBLOCK DIAGRAM

,

+

*

)

(

㪭㫀㪻㪼㫆

㪪㪄㪭㫀㪻㪼㫆

㪚㪦㪤㪧㩷㪈

㪮㫀㫉㪼㪻㩷㪩㪆㪚

㪊㪅㪌㱢㫁㪸㪺㫂

㪪㪄㪰

㪪㪄㪚

㪩㪆㪚

㩿㪩㪜㪘㪩㪀

㪛㪬㪥㪫㪢㪛

㪏㪌㪌㪮㪜

㪪㪜㪣㪜㪚㪫㪦㪩

㪚㪭㪙㪪㩷

㫍㫀㪻㪼㫆

㪩㪞㪙㩷㪘㫄㫇

㪠㪚㪉㪌㪇㪈

㪜㪣㪏㪊㪇㪉㪈

㪨㪉㪇㪇㪈

㪠㪚㪉㪇㪇㪊

㪩㪆㪚

㩿㪝㪩㪦㪥㪫㪀

㪛㪬㪥㪫㪢㪛

㪏㪌㪋㪮㪜

㪫㪟㪜㪩㪤㪠㪪㪫㪜㪩㪊

㪫㪟㪜㪩㪤㪠㪪㪫㪜㪩㪉

㪫㪟㪜㪩㪤㪠㪪㪫㪦㪩㪈

㪩㪪㪉㪊㪉㪚

㪉㪊㪉㪺

㪛㪩㪠㪭㪜㪩

㪠㪚㪉㪇㪇㪈

㪙㪬㪝㪝㪜㪩

㪠㪚㪉㪇㪇㪐

㪠㪚㪉㪇㪈㪇

㩿㪦㪧㪫㪠㪦㪥㪀

㪣㪜㪛㩷㪬㪥㪠㪫

㪛㪬㪥㪫㪢㪛

㪏㪌㪍㪮㪜

㪢㪜㪰㩷㪬㪥㪠㪫

㪛㪬㪥㪫㪢㪛

㪏㪌㪊㪮㪜

㪜㪜㪧㪩㪦㪤

㪠㪚㪉㪇㪇㪎

㪛㪚㩷㪈㪉㪭㫆㫌㫋

㪛㪚㩷㪦㪬㪫㩷

㪚㪦㪥㪫㪩㪦㪣

㪠㪚㪉㪏㪇㪏

㪫㪯㪄㪪㪟

㪩㪟㪄㪪㪟

㪚㪣㪢㪄㪪㪟

㪪㪟㪄㪩㪜㪨

㪣㪘㪤㪧

㪜㫏㪿㪸㫌㫊㫋㩷㪽㪸㫅

㪠㪚㪉㪏㪈㪍

㪝㪧㪮㪤㪈

㪽㫆㫉㩷

㪧㪦㪮㪜㪩㩷

㪽㪸㫅

㪠㪚㪉㪏㪈㪌

㪝㪧㪮㪤㪉

㪪㪬㪙㪄㪚㪧㪬

㪠㪚㪉㪇㪇㪌

㪣㪘㪤㪧㩷

㪙㫃㫆㫎㪼㫉㩷

㪽㪸㫅

㪩㪼㪾

㪠㪚㪉㪏㪇㪈

㪧㪚㪦㪥㪈

㪽㫆㫉

㪝㫆㫉㫄㪸㫋㫋㪼㫉

㪽㪸㫅

㪩㪼㪾

㪠㪚㪉㪏㪇㪉

㪛㪚㪛㪚㪊㪅㪊㫍

㪠㪚㪉㪎㪇㪉

㪛㪚㪛㪚㪉㪅㪌㫍

㪠㪚㪉㪎㪇㪋

㪚

㪠㪚

㪠㪉㪚㩷㪹㫌㫊

㪛㪛㪩㪘㪤

㪠㪚㪍㪈㪇㪈

㪠㪚㪍㪈㪇㪊

㪛㪚㪛㪚㪈㪅㪉㫍

㪣㪧㪝

㪠㪉㪚㩷㪹㫌㫊

㪜㪜㪧

㪩㪦㪤

㪠㪚㪌㪇㪇㪉

㪭㫀㪻㪼㫆

㪻㪼㪺㫆㪻㪼㫉

㪠㪚㪌㪎㪇㪍

㪝㫃㪸㫊㪿

㪠㪚㪌㪈㪇㪈

㪠㪚㪌㪍㪌㪉

㪘㪆㪛

㪛㪩㪘㪤

㪠㪚㪌㪈㪇㪋

㪤㪘㪠㪥㪄㪚㪧㪬

㪠㪚㪌㪇㪇㪊

㪪㪚㪘㪣㪜㪩

㪠㪚㪍㪇㪇㪈

㪚㪭㪄㪠㪚

㪩㪞㪙 㪘㫄㫇

㪠㪚㪉㪌㪇㪉

㪜㪣㪏㪊㪇㪉㪈

'

&

%

$

㪚㪦㪤㪧㩷㪉

㪛㪭㪠㪄㪠

㪟㪛㪤㪠㩷㪈

㪟㪛㪤㪠㩷㪉

㪩㪞㪙㩷㪘㫄㫇

㪠㪚㪌㪉㪇㪉

㪜㪣㪏㪊㪇㪉㪈

㪫㪤㪛㪪㩷

㪪㪜㪣㪜㪚㪫㪦㪩

㪠㪚㪌㪊㪌㪍

㪠㪦

㪠㪚㪌㪈㪇㪊

㪠㪚㪌㪉㪇㪐

㪛㪭㪠㪆㪟㪛㪤㪠

㪩㪜㪚㪜㪠㪭㪜㪩

㪠㪚㪌㪊㪌㪎

㪧㪚㩷㪠㪆㪝㩷㪬㪥㪠㪫㩷

㪛㪬㪥㪫㪢㪛㪏㪍㪈㪝㪤

㪝㪦㪩㩷㪣㪜㪥㪪㩷

#

㪠㪩㪠㪪

㪝㪦㪩㩷㪦㪧㪫㪠㪚㪘㪣㩷

㪠㪩㪠㪪

㪤㪦㪫㪦㪩

㪛㪩㪠㪭㪜㪩㩷

㪠㪚㪉㪈㪇㪌

㪠㪦㩷㪜㪯㪧㪘㪥㪛㪜㪩

㪠㪚㪉㪈㪇㪋

㪠㪩㪠㪪㩷㪛㪩㪠㪭㪜㩷㪬㪥㪠㪫

㪛㪬㪥㪫㪢㪛㪏㪌㪎㪮㪜

6 – 1

Page 49

XV-Z20000/XV-Z21000/DT-5000

㫊

㫉

㩷

㪜㪩㩷

㪈㪌

㪤㪉

㪧㪬

㪌

㪣㪘㪤㪧㩷

㪙㫃㫆㫎㪼㫉㩷

㪽㪸㫅

㪩㪼㪾

㪠㪚㪉㪏㪇㪈

㪧㪚㪦㪥㪈

㪛㪚㪛㪚㪈㪅㪉㫍

㪽㫆㫉

㪝㫆㫉㫄㪸㫋㫋㪼㫉

㪽㪸㫅

㪩㪼㪾

㪠㪚㪉㪏㪇㪉

㪛㪚㪛㪚㪊㪅㪊㫍

㪠㪚㪉㪎㪇㪉

㪛㪚㪛㪚㪉㪅㪌㫍

㪠㪚㪉㪎㪇㪋

㪽㫆㫉

㪚㪮㩷㪽㪸㫅

㪩㪼㪾

㪠㪚㪉㪏㪈㪏

㪝㪘㪥㩷㪣㪦㪚㪢

䌍㪘㪠㪥㩷㪬㪥㪠㪫

㪛㪬㪥㪫㪢㪛㪏㪌㪉㪮㪜

㪧㪚㪦㪥㪇

㪜㪚㪦

㪥㪄㪣㪠㪞㪟㪫

㪣㪘㪤㪧㪧㪦㪮

㪧㪦㪮㪜㪩㪆㪙㪘㪣㪣㪘㪪㪫㩷㪬㪥㪠㪫

㪛㪪㪜㪫㪬㪛㪏㪌㪐㪝㪤

㪍㪭

㪈㪊㪭

㪈㪉㪭

㪘㪚㩷㪠㪥㪣㪜㪫

㪣㪘㪤㪧㩷㪛㪦㪦㪩

㪪㪮㪠㪫㪚㪟

㪙㪠㪄㪤㪜㪫㪘㪣

㪣㪘㪤㪧

㪛㪚㪛㪚

㪠㪚㪐㪎㪇㪉

㪚㪦㪣㪦㪩㩷㪮㪟㪜㪜㪣㩷㪪㪜㪥㪪㪦㪩

㪚㪦㪣㪦㪩㩷㪮㪟㪜㪜㪣㩷㪤㪦㪫㪦㪩

㪛㪠㪞㪠㪫㪘㪣

㪤㪠㪚㪩㪦㪤㪠㪩㪩㪦㪩

㪛㪭㪠㪚㪜

㪠㪚㪐㪐㪇㪈

㪜㪩

㪜㩷㪬㪥㪠㪫

㪏㪌㪎㪮㪜

㪙㪬㪝㪝㪜㪩

㪠㪚㪏㪇㪇㪈

㪠㪚㪏㪇㪇㪉

㪠㪚㪏㪇㪇㪊

㪠㪚㪏㪇㪇㪋

㪠㪚㪏㪇㪇㪌

㪝㪦㪩㪤㪘㪫㪫㪜㪩㩷㪬㪥㪠㪫

㪛㪬㪥㪫㪢㪛㪏㪌㪏㪝㪤

㪝㫃㪸㫊㪿

㪠㪚㪏㪍㪇㪉

㪛㪣㪧㩷㪛㪘㪫㪘㩷㪧㪩㪦㪚㪜㪪㪪㪦㪩

㪛㪣㪧㩷㪛㪘㪫㪘㩷㪧㪩㪦㪚㪜㪪㪪㪦㪩

㪝㫃㪸㫊㪿

㪠㪚㪐㪍㪇㪉

㪩㪣㪛㪩㪘㪤

㪠㪚㪏㪍㪇㪈

㪛㪛㪧㪊㪇㪉㪈㪆㫄㪸㫊㫋㪼㫉

㪠㪚㪏㪊㪇㪈

㪛㪛㪧㪊㪇㪉㪈㪆㫊㫃㪸㫍㪼

㪠㪚㪐㪊㪇㪈

㪩㪣㪛㪩㪘㪤

㪠㪚㪐㪍㪇㪈

㪤㪦㪫㪦㪩㩷㪛㪩㪠㪭㪜㪩

㩽㪛㪚㪛㪚

㪠㪚㪐㪎㪇㪈

㪭㪩㪪㪫㪃㪭㪙㪠㪘㪪㩷

㪭㪩㪪㪫㪃㪭㪙㪠㪘㪪㩷

㪞㪜㪥

㪠㪚㪏㪐㪇㪈

㪞㪜㪥

㪠㪚㪏㪐㪇㪊

㪚㪮 㪠㪥㪛㪜㪯

6 – 2

Page 50

XV-Z20000/XV-Z21000/DT-5000

,

#

$

%

&

'

(

)

*

+

عOVERALL WIRING DIAGRAM

[2] OVERALL WIRING DIAGRAM

6 – 3

Page 51

XV-Z20000/XV-Z21000/DT-5000

6 – 4

Page 52

XV-Z20000/XV-Z21000/DT-5000

,

#

$

%

&

'

(

)

*

+

MAIN Unit (SIDE-A)

XV-Z20000

CHAPTER 7. PRINTED WIRING BOARD

[1] MAIN Unit

Service Manual

7 – 1

Page 53

XV-Z20000/XV-Z21000/DT-5000

7 – 2

Page 54

XV-Z20000/XV-Z21000/DT-5000

,

#

$

%

&

'

(

)

*

+

MAIN Unit (Chip SIDE-A)

7 – 3

Page 55

XV-Z20000/XV-Z21000/DT-5000

7 – 4

Page 56

XV-Z20000/XV-Z21000/DT-5000

MAIN Unit (SIDE-B)

,

+

*

)

(

'

&

%

$

#

7 – 5

Page 57

XV-Z20000/XV-Z21000/DT-5000

7 – 6

Page 58

XV-Z20000/XV-Z21000/DT-5000

,

#

$

%

&

'

(

)

*

+

MAIN Unit (Chip SIDE-B)

7 – 7

Page 59

XV-Z20000/XV-Z21000/DT-5000

7 – 8

Page 60

XV-Z20000/XV-Z21000/DT-5000

,

#

$

%

&

'

(

)

*

+

FORMATTER Unit (SIDE-A)

[2] FORMATTER Unit

7 – 9

Page 61

XV-Z20000/XV-Z21000/DT-5000

7 – 10

Page 62

XV-Z20000/XV-Z21000/DT-5000

FORMATTER Unit (Chip SIDE-A)

,

+

*

)

(

'

&

%

$

#

7 – 11

Page 63

XV-Z20000/XV-Z21000/DT-5000

7 – 12

Page 64

XV-Z20000/XV-Z21000/DT-5000

FORMATTER Unit (SIDE-B)

,

+

*

)

(

'

&

%

$

#

7 – 13

Page 65

XV-Z20000/XV-Z21000/DT-5000

7 – 14

Page 66

XV-Z20000/XV-Z21000/DT-5000

,

#

$

%

&

'

(

)

*

+

FORMATTER Unit (Chip SIDE-B)

7 – 15

Page 67

XV-Z20000/XV-Z21000/DT-5000

7 – 16

Page 68

XV-Z20000/XV-Z21000/DT-5000

,

#

$

%

&

'

(

)

*

+

POWER/BALLAST Unit (SIDE-A)

[3] POWER/BALLAST Unit

7 – 17

Page 69

XV-Z20000/XV-Z21000/DT-5000

7 – 18

Page 70

XV-Z20000/XV-Z21000/DT-5000

,

#

$

%

&

'

(

)

*

+

POWER/BALLAST Unit (SIDE-B)

7 – 19

Page 71

XV-Z20000/XV-Z21000/DT-5000

7 – 20

Page 72

XV-Z20000/XV-Z21000/DT-5000

POWER/BALLAST Unit (Chip SIDE-B)

,

+

*

)

(

'

&

%

$

#

7 – 21

Page 73

XV-Z20000/XV-Z21000/DT-5000

7 – 22

Page 74

XV-Z20000/XV-Z21000/DT-5000

,

#

$

%

&

'

(

)

*

+

PC I/F Unit (SIDE-A)

[4] PC I/F Unit

7 – 23

Page 75

XV-Z20000/XV-Z21000/DT-5000

7 – 24

Page 76

XV-Z20000/XV-Z21000/DT-5000

,

#

$

%

&

'

(

)

*

+

PC I/F Unit (Chip SIDE-A)˴

7 – 25

Page 77

XV-Z20000/XV-Z21000/DT-5000

7 – 26

Page 78

XV-Z20000/XV-Z21000/DT-5000

PC I/F Unit (SIDE-B)

,

+

*

)

(

'

&

%

$

#

7 – 27

Page 79

XV-Z20000/XV-Z21000/DT-5000

7 – 28

Page 80

XV-Z20000/XV-Z21000/DT-5000

PC I/F Unit (Chip SIDE-B)

,

+

*

)

(

'

&

%

$

#

7 – 29

Page 81

XV-Z20000/XV-Z21000/DT-5000

7 – 30

Page 82

XV-Z20000/XV-Z21000/DT-5000

[5] KEY Unit

,

+

*

)

(

'

&

%

$

#

KEY Unit (SIDE-A)

(Chip SIDE-A)

KEY Unit

KEY Unit (SIDE-B) KEY Unit

(Chip SIDE-B)

7 – 31

Page 83

[6] R/C Front Unit

,

+

*

)

XV-Z20000/XV-Z21000/DT-5000

R/C FRONT Unit (SIDE-A)

(

'

&

%

$

R/C FRONT Unit (SIDE-B)

#

R/C FRONT (Chip SIDE-B)

7 – 32

Page 84

XV-Z20000/XV-Z21000/DT-5000

[7] R/C Rear Unit

,

+

*

)

R/C REAR Unit (SIDE-A)

(

'

&

%

$

R/C REAR Unit (SIDE-B)

R/C REAR Unit (Chip SIDE-A)

R/C REAR Unit (Chip SIDE-B)

#

7 – 33

Page 85

[8] LED Unit

,

+

XV-Z20000/XV-Z21000/DT-5000

*

)

(

LED Unit (SIDE-A)

LED Unit (Chip SIDE-A)

'

&

LED Unit (SIDE-B)

%

$

#

LED Unit (Chip SIDE-B)

7 – 34

Page 86

XV-Z20000/XV-Z21000/DT-5000

[9] IRIS DRIVE Unit

,

+

*

)

(

IRIS DRIVE Unit (SIDE-A)

IRIS DRIVE Unit (Chip SIDE-A)

'

&

IRIS DRIVE Unit (SIDE-B)

%

$

#

IRIS DRIVE Unit (Chip SIDE-B)

7 – 35

Page 87

[10] BALLAST CONTROL Unit

,

+

XV-Z20000/XV-Z21000/DT-5000

*

)

BALLAST CONTROL Unit (SIDE-A)

C7745

X7701

C7727

P7701

IC7707

C7734

C7733

C7736

R7761

R7787

C7739

C7746

R7772

C7741

C7737

R7775

C7742

C7728

R7793

R7769

R7770

D7712

R7762

D7715

D7714

D7713

D7711

Q7707

C7753 C7754

R7756

R7768

R7799

C7755

R7798

C7710

C7715

D7703

R7720

R7723

R7776

D7716

R7804

IC7710

Q7712

R7803

R7719

C7712

C7731

R7755

C7756

R7728

C7701

R7704

R7708

R7797

R7724R7725

C7709

C7752

C7713

R7726

C7718

R7721

C7719

R7731

IC7709

C7717

IC7701

C7707

R7712

R7717

C7744

(

BALLAST CONTROL Unit (Chip SIDE-A)

'

&

BALLAST CONTROL Unit (SIDE-B)

%

R7709

R7702 R7703

C7702

R7705

R7710

C7705

C7703

R7707

C7704

R7711

R7753

$

R7752

R7730

R7706

R7713

R7718

C7711

R7734

R7732

R7727

C7716

R7766

C7735

Q7701C7706 Q7702

D7701

R7701

R7733

Q7704

Q7703

R7729

R7722

R7739

C7708

R7714

D7702

R7805

R7716

R7735

Q7706

Q7705

R7800

R7802

R7782

R7715

D7705

R7788

R7801

C7738

R7767

R7736

#

C7722

C7720

C7721

D7704

R7763

R7764

R7765

Q7711

R7771

R7806

Q7708

C7740

R7792

R7790

R7791

R7773

R7777

R7774

R7778

C7743

Q7709

IC7704

C7724

R7794

R7795

R7796

R7789

R7760

R7758

R7743

D7706

C7730

R7748

R7759

R7781

R7780

IC7705

R7737

R7786

R7785

R7744

R7745

C7723

R7779

C7725

R7741

C7726

R7742

R7740

R7747

R7751

R7757

R7754

R7738

R7749

R7746

R7750

C7751

C7750

C7749

R7783R7784

BALLAST CONTROL Unit (Chip SIDE-B)

7 – 36

Page 88

XV-Z20000/XV-Z21000/DT-5000

XV-Z20000

CHAPTER 8. WAVEFORMS

[1] WAVEFORMS

20 20

Service Manual

56 58 60

[2] WAVEFORM MEASUREMENT CONDITION

1. WAVEFORM MEASUREMENT CONDITION:

1. Waveforms at test points are observed at the supply voltage of AC 220V. Signals are fed by a color bar signal generator for servicing purpose.

8 – 1

Page 89

XV-Z20000

CHAPTER 9. SCHEMATIC DIAGRAM

[1] DESCRIPTION OF SCHEMATIC DIAGRAM

1. VOLTAGE MEASUREMENT CONDITION:

1. Voltages at test points are measured at the supply voltage of AC

100V/CROSS 10V-240. Signals are fed by a color bar signal generator for servicing purpose and the above voltages are measured

with a 20k ohm/V tester.

2. INDICATION OF RESISTOR & CAPACITOR:

RESISTOR

1. he unit of resistance “Ω” is omitted.

(K=kΩ=1000 Ω, M=MΩ).

2. All resistors are ± 5%, unless otherwise noted.

(J=± 5%, F= ± 1%, D= ± 0.5%)

3. All resistors are 1/10W, unless otherwise noted.

4. All resistors are Carbon type, unless otherwise noted.

XV-Z20000/XV-Z21000/DT-5000

Service Manual

: Solid : Cement

C

S

: Oxide Film : Special

N

: Metal Coating

CAPACITOR

1. All capacitors are μF, unless otherwise noted.

(P=pF=μμF).

2. All capacitors are 50V, unless otherwise noted.

3. All capacitors are Ceramic type, unless otherwise noted.

(ML): Mylar (TA): Tantalum

(PF): Polypro Film (ST): Styrol

CAUTION:

This circuit diagram is original one, therefore there may be a

slight difference from yours.

W

T

SAFETY NOTES:

1. DISCONNECT THE AC PLUG FROM THE AC

OUTLET BEFORE REPLACING PARTS.

2. SEMICONDUCTOR HEAT SINKS SHOULD BE

REGARDED AS POTENTIAL SHOCK HAZARDS

WHEN THE CHASSIS IS OPERATING.

IMPORTANT SAFETY NOTICE:

PARTS MARKED WITH “ ” ( ) ARE

IMPORTANT FOR MAINTAINING THE SAFETY OF THE

SET. BE SURE TO REPLACE THESE PARTS WITH

SPECIFIED ONES FOR MAINTAINING THE SAFETY AND

PERFORMANCE OF THE SET.

9 – 1

Page 90

XV-Z20000/XV-Z21000/DT-5000

[2] SCHEMATIC DIAGRAM

عMAIN Unit-1

,

+

*

)

(

'

&

%

$

#

9 – 2

Page 91

XV-Z20000/XV-Z21000/DT-5000

9 – 3

Page 92

XV-Z20000/XV-Z21000/DT-5000

,

#

$

%

&

'

(

)

*

+

عMAIN Unit-2

9 – 4

Page 93

XV-Z20000/XV-Z21000/DT-5000

9 – 5

Page 94

XV-Z20000/XV-Z21000/DT-5000

عMAIN Unit-3

,

+

*

)

(

'

&

%

$

#

9 – 6

Page 95

XV-Z20000/XV-Z21000/DT-5000

9 – 7

Page 96

XV-Z20000/XV-Z21000/DT-5000

عMAIN Unit-4

,

+

*

)

(

'

&

%

$

#

9 – 8

Page 97

XV-Z20000/XV-Z21000/DT-5000

9 – 9

Page 98

XV-Z20000/XV-Z21000/DT-5000

,

#

$

%

&

'

(

)

*

+

عMAIN Unit-5

9 – 10

Page 99

XV-Z20000/XV-Z21000/DT-5000

9 – 11

Page 100

XV-Z20000/XV-Z21000/DT-5000

,

#

$

%

&

'

(

)

*

+

عFORMATTER Unit-1

9 – 12

Loading...

Loading...