Sharp DT300, XV-Z200U, XV-Z201E Service Manual

XV-Z200U/E, XV-Z201E

DT-300

SERVICE MANUAL

SERVICE-ANLEITUNG

S14N4XV-Z200U

PROJECTOR

PROJEKTOR

XV-Z200U/E

XV-Z201E

MODELS

MODELLE

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored to its original condition and only parts identical to those specified should be used.

Im lnteresse der Benutzersicherheit (erforderliche Sicherheitsregeln in einigen Ländern) muß das Gerät in seinen

Originalzustand gebracht werden. Außerdem dürfen für die spezifizierten Bauteile nur identische Teile verwendet

werden.

DT-300

SHARP CORPORATION

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

XV-Z200U/E, XV-Z201E

DT-300

• SPECIFICATIONS............................................. 3

• IMPORTANT SERVICE SAFETY

NOTES .............................................................. 4

• NOTE TO SERVICE PERSONNEL ................... 5

• OPERATION MANUAL ..................................... 9

• DIMENSIONS ................................................. 13

• REMOVING OF MAJOR PARTS..................... 14

• THE OPTICAL UNIT OUTLINE ...................... 20

• RESETTING THE TOTAL LAMP TIMER ......... 21

• ELECTRICAL ADJUSTMENT ......................... 23

• TROUBLE SHOOTING TABLE ....................... 27

• CHASSIS LAYOUT.......................................... 68

CONTENTS

Page Page

• BLOCK DIAGRAM .......................................... 70

• OVERALL WIRING DIAGRAM........................ 72

• DESCRIPTION OF SCHEMATIC DIAGRAM .. 74

• WAVEFORMS ................................................. 75

• SCHEMATIC DIAGRAM.................................. 76

• PRINTED WIRING BOARD ASSEMBLIES... 112

• PARTS LIST

Ë

ELECTRICAL PARTS............................... 120

Ë

CABINET AND MECHANICAL PARTS ....134

Ë

ACCESSORIES PARTS ............................ 138

Ë

PACKING PARTS ......................................138

• PACKING OF THE SET ................................139

Seite Seite

• TECHNISCHE DATEN .................................... 37

• HINWEISE FÜR DAS

WARTUNGSPERSONAL ................................ 38

• BEDIENUNGSANLEITUNG ............................ 40

• ABMESSUNGEN ............................................ 44

• ENTFERNEN DER HAUPTTEILE .................. 45

• BESCHREIBUNG DER OPTIK-INHEIT .......... 51

• RÜCKSTELLEN DES

LAMPENBETRIEBSEIT-TIMERS ................... 52

• ELEKTRISCHE EINSTELLUNG ..................... 54

• FEHLERSUCHTABELLE ................................ 58

• CHASSIS-ANORDNUNG ............................... 68

• BLOCKSCHALTBILD ......................................70

INHALT

• GESAMTSCHALTPLAN.................................. 72

• BESCHREIBUNG DES SCHEMATISCHEN

• WELLENFORMEN .......................................... 75

• SCHEMATISCHER SCHALTPLAN .................76

• LEITERPLATTENEINHEITEN....................... 112

• ERSATZTEILLISTE

• VERPACKEN DES GERÄTS ........................139

SCHALTPLANS .............................................. 74

Ë

ELEKTRISCHE BAUTEILE ....................... 120

Ë

GEHÄUSE UND MECHANISCHE

BAUTEILE ................................................. 134

Ë

ZUBEHÖRTEILE....................................... 138

Ë

VERPACKUNGSTEILE ............................. 138

2

SPECIFICATIONS

This unit has some inactive pixels within acceptable

tolerances which may result in inactive dots on the picture

screen. This will not affect the picture quality or the life

expectancy of the unit. If you have any questions about this

matter, please call toll free 1-877-DTV-SHARP (1-877-388-

7427).

U.S.A. ONLY

Product type

Models

Video system

Display method

DLP panel

Lens

Projection lamp

Video input signal

S-video input signal

Component input signal

(INPUT 1)

Component input signal

(INPUT 2)

Horizontal resolution

RGB input signal

Pixel clock

Vertical frequency

Horizontal frequency

Computer control signal

Rated voltage

Input current

Rated frequency

Power consumption

Heat dissipation

Operating temperature

Storage temperature

Cabinet

I/R carrier frequency

Dimensions (approx.)

Weight (approx.)

Supplied accessories

Replacement parts

Projector

XV-Z200U/DT-300/XV-Z200E/XV-Z201E

PAL/PAL 60/PAL-M/PAL-N/SECAM/NTSC 3.58/NTSC 4.43

DTV 480I/480P/720P/1080I/576I/576P

DLP chip, RGB optical shutter method

Panel size: 0.6

Display method: Single Panel Digital Micromirror Device (DMD™) by Texas Instruments

Drive method: Digital Light Processing (DLP™)

No. of dots: 589,824 dots (1,024 [H] 576 [V])

1–1.2 zoom lens, F1.75–2.04 f=28.0–33.5 mm (XV-Z200U/E), F2.0–2.4 f=16.9–20.2 (XV-Z201E, DT–300)

210 W/168 W SHP lamp

RCA Connector: VIDEO (INPUT 4), composite video, 1.0 Vp-p, sync negative, 75 Ω

terminated

4-pin Mini DIN connector (INPUT 3)

Y (luminance signal): 1.0 Vp-p, sync negative, 75 Ω terminated

C (chrominance signal): Burst 0.286 Vp-p, 75 Ω terminated

RCA Connector

Y: 1.0 Vp-p, sync negative, 75 Ω terminated

P

B

: 0.7 Vp-p, 75 Ω terminated

P

R

: 0.7 Vp-p, 75 Ω terminated

29-pin connector

DVI input signal: Digital 250–1,000 mV 50 Ω

Analog 0.7 Vp-p 75 Ω

Y: 1.0 Vp-p, sync negative, 75 Ω terminated

P

B

: 0.7 Vp-p, 75 Ω terminated

P

R

: 0.7 Vp-p, 75 Ω terminated

520 TV lines (NTSC 3.58 input)

DVI-I terminal

<Digital>

Input impedance 50 Ω

Input level 250-1000 mV

<Analog>

Input impedance 75 Ω

Input level 0.7 Vp-p

<Synchronization signal>

• Separate sync/Composite sync

Input level TTL level

Input impedance 1 KΩ

• Green on sync

Input level (Synchronizing input) 0.286 Vp-p

Input impedance 75 Ω

12–80 MHz

43–75 Hz

15–70 kHz

9-pin D-sub connector (RS-232C Port)

AC 100–240 V

3.2 A

50/60 Hz

285 W

1,070 BTU/hour

41°F to 95°F ( 5°C to 35°C)

4°F to 140°F ( 20°C to 60°C)

Plastic

38 kHz

14

1

⁄2 (W) 69⁄16 (H) 127⁄8 (D) (368 153.8 327 mm) (including swivel stand)

14

1

⁄2 (W) 45⁄8 (H) 127⁄8 (D) (368 118 327 mm) (main body only)

10.1 lbs. (4.6 kg) (including swivel stand)

9.0 lbs. (4.1 kg) (main body only)

Remote control, Two AA size batteries, Power cord, Terminal cover, Lens cap (attached

on the body), Operation manual, Screws for terminal cover, 21-pin RCA conversion adaptor, Video cable

Lamp unit (Lamp/cage module) (BQC-XVZ200++1), Remote control

(RRMCGA218WJSA), AA size batteries, Power cord (QACCDA007WJPZ:SEC/SECL, QACCV4002CEZZ:

This SHARP projector uses a DMD chip. This very

sophisticated chip contains 589,824 pixels. As with any high

technology electronic equipment such as large screen TVs,

video systems and video cameras, there are certain

acceptable tolerances that the equipment must conform to.

Specifications are subject to change without notice.

×× ××

×× ××

SEEG/SEI, QACCBA012WJPZ:SUK/SRS/SRH/SEEM, QACCLA018WJPZ:SCA/SNZ), Terminal cover

(GCOVAA116WJKB), Lens cap (CCAPHA004WJ01), Operation manual (SEC/SECL:TiNS-B005WJZZ

(XV-Z200U/E)/TiNS-B006WJZZ (XV-Z201E, DT–300), SEEG/SUK:TiNS-B007WJZZ (XV-Z200U/E)/TiNSB009WJZZ (XV-Z201E, DT–300), SCA/SNZ/SRS/SRH/SEEM/SEI:TiNS-B008WJZZ (XV-Z200U/E)/TiNSB010WJZZ (XV-Z201E, DT–300)), Screws for terminal cover (XBBSN40P10000), 21-pin RCA converter

adaptor (QSOZ0361CEZZ:SEEG/SUK), Video cable (QCNWGA001WJZZ))

XV-Z200U/E, XV-Z201E

DT-300

3

XV-Z200U/E, XV-Z201E

AC

VOLTMETER

1.5k ohm (10W)

0.15µF

TEST PROBE

TO EXPOSED

METAL PARTS

CONNECT TO KNOWN

EARTH GROUND

DT-300

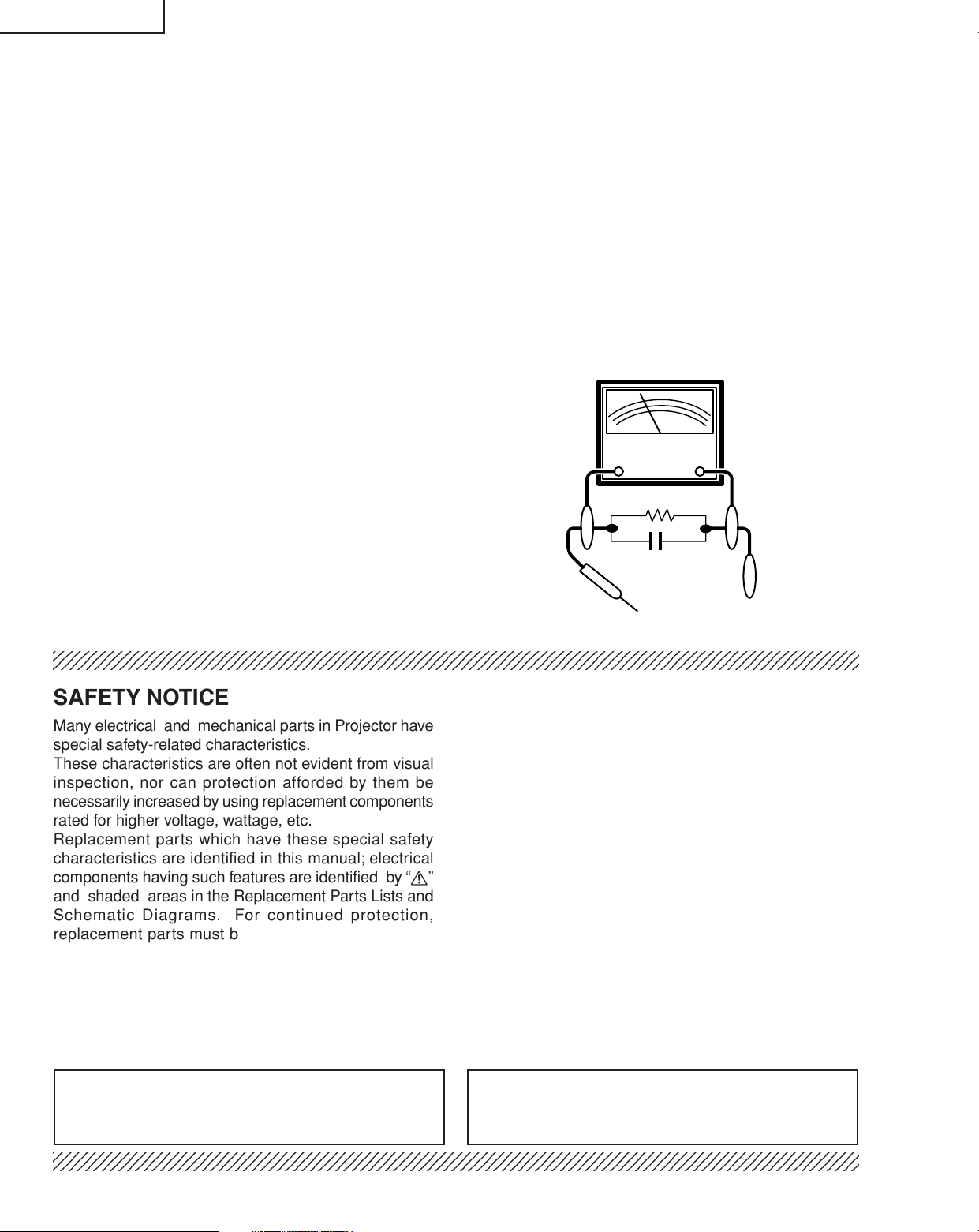

IMPORTANT SERVICE SAFETY NOTES

Ë Service work should be performed only by qualified service technicians who are

thoroughly familiar with all safety checks and servicing guidelines as follows:

WARNING

1. For continued safety, no modification of any circuit

should be attempted.

2. Disconnect AC power before servicing.

BEFORE RETURNING THE PROJECTOR:

(Fire & Shock Hazard)

Before returning the projector to the user, perform

the following safety checks:

1. Inspect lead wires are not pinched between the chassis

and other metal parts of the projector.

2. Inspect all protective devices such as non-metallic

control knobs, insulating materials, cabinet backs,

adjustment and compartment covers or shields,

isolation resistor-capacity networks, mechanical

insulators, etc.

3. To be sure that no shock hazard exists, check for

current leakage in the following manner:

» Plug the AC cord directly into a 120-volt AC outlet,

(Do not use an isolation transformer for this test).

» Using two clip leads, connect a 1.5k ohm, 10 watt

resistor paralleled by a 0.15µF capacitor in parallel

between all exposed metal cabinet parts and earth

ground.

» Use an AC voltmeter with sensitivity of 5000 ohm per

volt., or higher, sensitivity to measure the AC voltage

drop across the resistor (See Diagram).

» All checks must be repeated with the AC plug

connection reversed. (If necessary, a non-polarized

adapter plug must be used only for the purpose of

completing these checks.)

Any reading of 0.3 volts RMS (this corresponds to 0.2

milliamp. AC.) or more is excessive and indicates a

potential shock hazard which must be corrected before

returning the unit to the owner.

SAFETY NOTICE

Many electrical and mechanical parts in Projector have

special safety-related characteristics.

These characteristics are often not evident from visual

inspection, nor can protection afforded by them be

necessarily increased by using replacement components

rated for higher voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this manual; electrical

components having such features are identified by “å”

and shaded areas in the Replacement Parts Lists and

Schematic Diagrams. For continued protection,

replacement parts must be identical to those used in

the original circuit. The use of a substitute replacement

parts which do not have the same safety characteristics

as the factory recommended replacement parts shown

in this service manual, may create shock, fire or other

hazards.

WARNING: The bimetallic component has the primary

conductive side exposed. Be very careful in

handling this component when the power is on.

AVIS POUR LA SECURITE

De nombreuses pièces, électriques et mécaniques, dans

les projecteur à présentent des caractéristiques spéciales

relatives à la sécurité, qui ne sont souvent pas évidentes

à vue.

Le degré de protection ne peut pas être nécessairement

augmentée en utilisant des pièces de remplacement

étalonnées pour haute tension, puissance, etc.

Les pièces de remplacement qui présentent ces

caractéristiques sont identifiées dans ce manuel;

les pièces électriques qui présentent ces particularités

sont identifiées par la marque “å” et hachurées dans la

liste des pièces de remplacement et les diagrammes

schématiques. Pour assurer la protection, ces pièces

doivent être identiques à celles utilisées dans le circuit

d’origine. L’utilisation de pièces qui n’ont pas les mêmes

caractéristiques que les pièces recommandées par l’usine,

indiquées dans ce manuel, peut provoquer des

électrocutions, incendies ou autres accidents.

AVERTISSEMENT: La composante bimétallique dispose du

conducteur primaire dénudé. Faire attention

lors de la manipulation de cette

composante sous tension.

4

XV-Z200U/E, XV-Z201E

DT-300

NOTE TO SERVICE

PERSONNEL

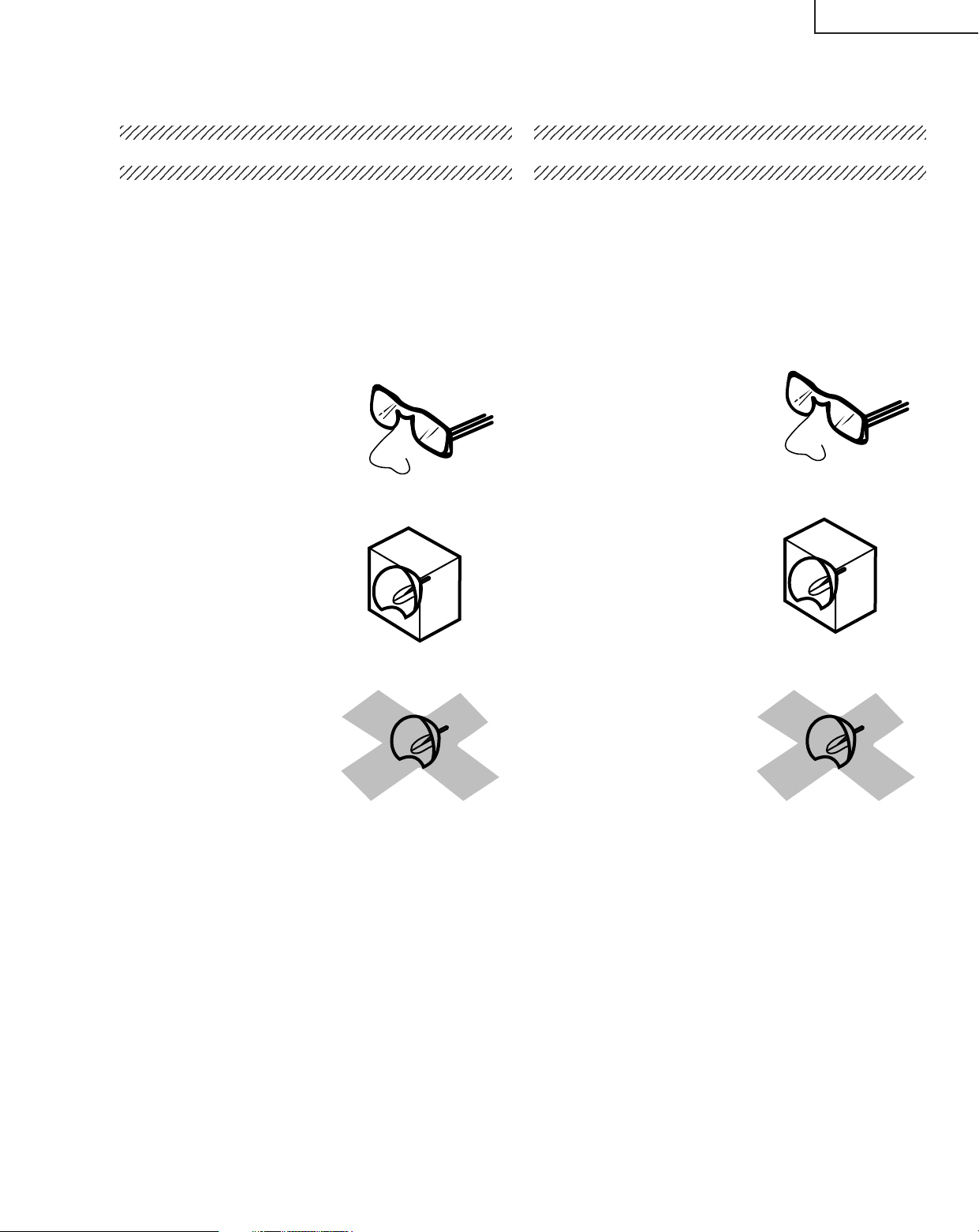

UV-RADIATION PRECAUTION

The light source, metal halide lamp, in the projector

emits small amounts of UV-Radiation.

AVOID DIRECT EYE AND SKIN EXPOSURE.

To ensure safety please adhere to the following:

1. Be sure to wear sun-glasses when servicing the

projector with the lamp

turned “on” and the top

enclosure removed.

2. Do not operate the lamp outside of the lamp housing.

NOTE POUR LE PERSONNEL

D’ENTRETIEN

PRECAUTION POUR LES RADIATIONS UV

La source de lumière, la lampe métal halide, dans

le projecteur émet de petites quantités de

radiation UV.

EVITEZ TOUTE EXPOSITION DIRECTE DES

YEUX ET DE LA PEAU.

Pour votre sécurité, nous vous prions de respecter

les points suivants:

1. Toujours porter des lunettes de soleil lors d’un entretien

du projecteur

avec la lampe allumée

et le haut du coffret retiré.

2. Ne pas faire fonctionner la lampe à l’extérieur du boîtier

de lampe.

3. Do not operate for more than 2 hours with the enclosure

removed.

UV-Radiation and Medium Pressure

Lamp Precautions

1. Be sure to disconnect the AC plug when replacing the

lamp.

2. Allow one hour for the unit to cool down before

servicing.

3. Replace only with same type lamp. Type BQCXVZ200++1 rated 370V/210W.

4. The lamp emits small amounts of UV-Radiation, avoid

direct-eye contact.

5. The medium pressure lamp involves a risk of explosion.

Be sure to follow installation instructions described

below and handle the lamp with care.

3. Ne pas faire fonctionner plus de 2 heures avec le coffret

retiré.

Précautions pour les radiations UV

et la lampe moyenne pression

1. Toujours débrancher la fiche AC lors du remplacement

de la lampe.

2. Laisser l’unité refroidir pendant une heure avant de

procéder à l’entretien.

3. Ne remplacer qu’avec une lampe du même type. Type

BQC-XVZ200++1 caractéristique 370V/210W.

4. La lampe émet de petites quantités de radiation UVéviter tout contact direct avec les yeux.

5. La lampe moyenne pression implique un risque

d’explosion. Toujours suivre les instructions

d’installation décrites ci-dessous et manipuler la lampe

avec soin.

5

XV-Z200U/E, XV-Z201E

1

2

1

2

DT-300

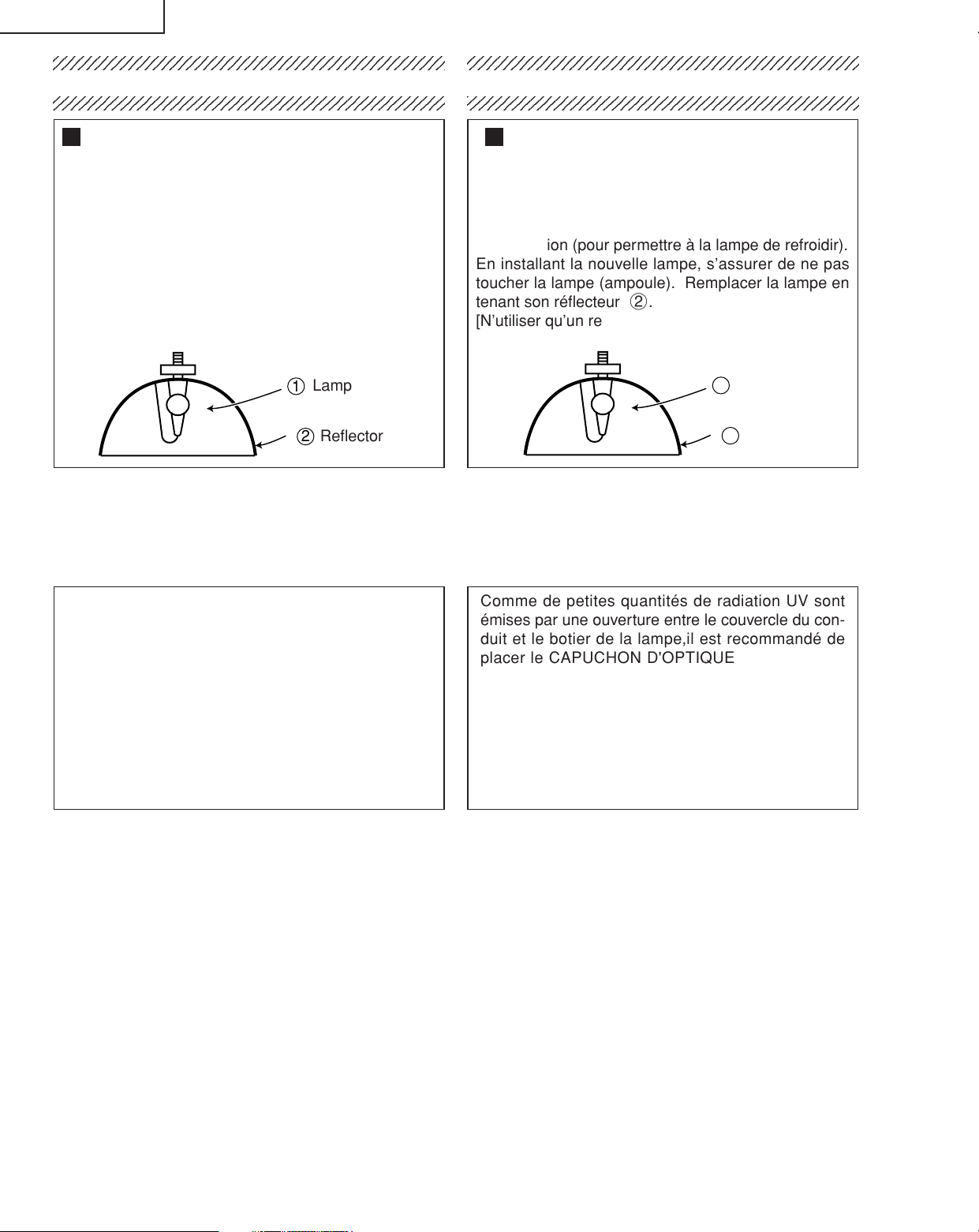

UV-RADIATION PRECAUTION (Continued)

Lamp Replacement

Note:

Since the lamp reaches a very high temperature during

units operation replacement of the lamp should be

done at least one hour after the power has been turned

off. (to allow the lamp to cool off.)

Installing the new lamp, make sure not to touch the

lamp (bulb) replace the lamp by holding its reflector

2.

[Use original replacement only.]

Lamp

Reflector

DANGER ! –– Never turn the power on without the

lamp to avoid electric-shock or damage of the devices

since the stabilizer generates high voltages at its start.

PRECAUTION POUR LES RADIATIONS UV (Suite)

Remplacement de la lampe

Remarque:

Comme la lampe devient très chaude pendant le

fonctionnement de l’unité, son remplacement ne doit

être effectué au moins une heure après avoir coupé

l’alimentation (pour permettre à la lampe de refroidir).

En installant la nouvelle lampe, s’assurer de ne pas

toucher la lampe (ampoule). Remplacer la lampe en

tenant son réflecteur 2.

[N’utiliser qu’un remplacement d’origine.]

Lampe

Reflecteur

DANGER ! –– Ne jamais mettre sous tension sans la

lampe pour éviter un choc électrique ou des

dommages des appareils car le stabilisateur génère

de hautes tensions à sa mise en route.

Since small amounts of UV-Radiation are emitted

from an opening between the duct cover and the

lamp housing, it is recommended to place the LENS

CAP on the opening during servicing to avoid eye

and skin exposure.

Note: Please obtain a lens cap before servicing a

models XV-Z200U/DT-300/XV-Z200E/XVZ201E that is received without one.

Comme de petites quantités de radiation UV sont

émises par une ouverture entre le couvercle du conduit et le botier de la lampe,il est recommandé de

placer le CAPUCHON D'OPTIQUE sur l'ouverture

pendant l'entretien pour éviter une exposition des yeux

et la peau.

Remarque: Priére de se procurer un capuchon

d'optique acant d'entretien un modéle XVZ200U/DT-300/XV-Z200E/XV-Z201E qui

est livré sans.

6

XV-Z200U/E, XV-Z201E

DT-300

WARNING: High brightness light source, do not stare into the beam of light, or view directly. Be especially

careful that children do not stare directly in to the beam of light.

WARNING: TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK, DO NOT EXPOSE THIS UNIT TO

MOISTURE OR WET LOCATIONS.

CAUTION

RISK OF ELECTRIC SHOCK.

DO NOT REMOVE SCREWS

EXCEPT SPECIFIED USER

SERVICE SCREW.

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK,

DO NOT REMOVE CABINET.

NO USER-SERVICEABLE PARTS EXCEPT LAMP UNIT.

REFER SERVICING TO QUALIFIED SERVICE

PERSONNEL.

The lighting flash with arrowhead within a

triangle is intended to tell the user that

parts inside the product are risk of electric

shock to persons.

The exclamation point within a triangle is

intended to tell the user that important

operating and servicing instructions are in

the manual with the projector.

CAUTION

(POWER Unit)

8.0A 250V

AVERTISSEMENT: Source lumineuse de grande intensité. Ne pas fixer le faisceau lumineux ou le regarder

For continued

protection against a

risk of fire, replace

only with same type

8.0A, AC250V fuse.

(F7001)

directement. Veiller particulièrement à éviter que les enfants ne fixent directement le

faisceau lumineux.

AVERTISSEMENT: AFIN D’EVITER TOUT RISQUE D’INCENDIE OU D’ELECTROCUTION, NE PAS PLACER

CET APPAREIL DANS UN ENDROIT HUMIDE OU MOUILLE.

ATTENTION

RISQUE

D’ÉLECTROCUTION. NE

PASR ETIRER LES VIS Á

L’EXCEPTION DE LA VIS DE

REPARATION UTILISATEUR

SPECIFIEES

ATTENTION: POUR EVITER TOUT RISQUE

D’ELECTROCUTION, NE PAS RETIRER LE CAPOT.

AUCUNE DES PIECES INTERIEURES N’EST REPARABLE

PAR L’UTILISATEUR, A L’EXCEPTION DE L’UNITE DE

LAMPE. POUR TOUTE REPARATION, S’ADRESSER A UN

TECHNICIEN D’ENTRETIEN QUALIFIE.

L’éclair terminé d’une flèche à l’intérieur

d’un triangle indique à l’utilisateur que les

pi‘eces se trouvant dans l’appareil sont

susceptibles de provoquer une décharge

électrique.

Le point d’exclamation à l’intérieur d’un

triangle indique à l’utilisateur que les

instructions de fonctionnement et

d’entretien sont détaillées dans les

documents fournis avec le projecteur.

PRECAUTION

(Unité de PUTSSANCE)

8.0A 250V

Pour une protection

continue contre un

risques d’incendie, ne

remplacer qu’avec un

fusible 8.0A,AC250V

du même type.

(F7001)

7

XV-Z200U/E, XV-Z201E

L Fa

DT-300

Precautions for using lead-free solder

1 Employing lead-free solder

"MAIN, THERMINAL1/2, LED, KEY, FRONT-R/C RECEIVER, REAR-R/C RECEIVER, POWER, BALLAST PWBs"

of this model employs lead-free solder. The LF symbol indicates lead-free solder, and is attached on the PWBs and

service manuals. The alphabetical character following LF shows the type of lead-free solder.

Example:

Indicates lead-free solder of tin, silver and copper.

2 Using lead-free wire solder

When fixing the PWB soldered with the lead-free solder, apply lead-free wire solder. Repairing with conventional

lead wire solder may cause damage or accident due to cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40°C, we recommend you

to use a dedicated soldering bit, if you are not familiar with how to obtain lead-free wire solder or soldening bit,

contact our service station or service ranch in your area.

3 Soldering

As the melting point of lead-free solder (Sn-Ag-Cu) is about 220°C which is higher than the conventional lead solder

by 40°C, and as it has poor solder wettabillty, you may be apt to keep the soldering bit in contact with the PWB for

extended period of time. However, Since the land may be peeled off or the maximum heat-resistance temperature

of parts may be excoeded, remove the bit from the PWB as soon as you conurm the steady soldering condition.

Lead-free solder contains more tin, and the end of the soldering bit may be easily corroded. Make sure to tum on

and off the power of the bit as required.

if a different type of solder stays on the tip of the soldering bit, it is alloyed with lead-free solder. Clean the bit after

every use of it.

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sandpaper.

Becareful when replacing parts with polarity indication on the PWB silk.

Lead-free wire solder for servicing

Part No. ★ Description Code

ZHNDAi123250E J φ0.3mm 250g(1roll) BL

ZHNDAi126500E J φ0.6mm 500g(1roll) BK

ZHNDAi12801KE J φ1.0mm 1kg(1roll) BM

8

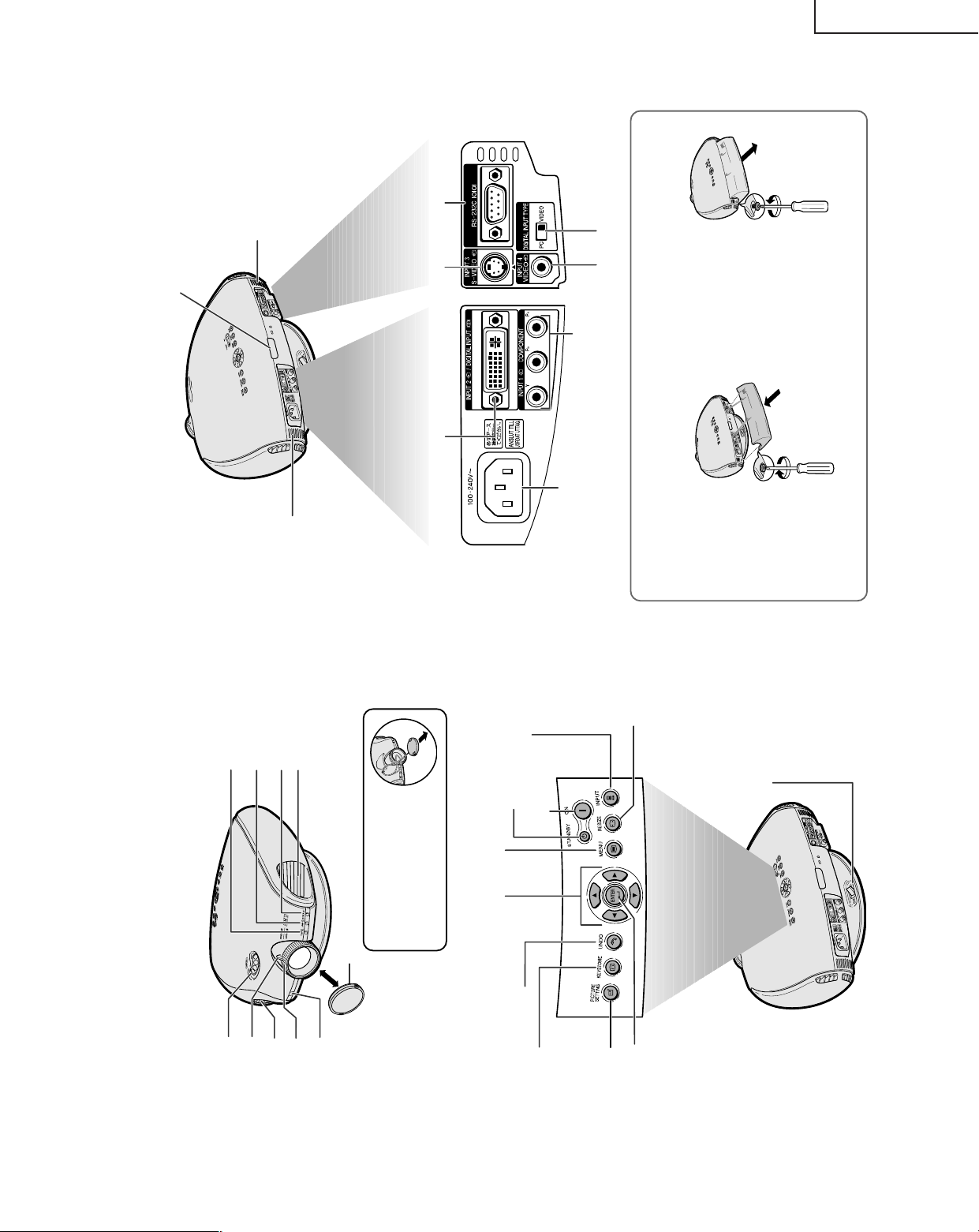

Projector (Front and Top View)

Part Names

POWER indicator

Exhaust ventilative hole

LAMP indicator

TEMPERATURE

WARNING indicator

ADJUSTMENT buttons

()

UNDO button

MENU button

RESIZE button

INPUT button

Swivel Stand

LOCK/UNLOCK lever

Remote control sensor

Lens cap

Zoom knob

Exhaust ventilative hole

Focus ring

Lens shift dial

ENTER button

KEYSTONE button

ON button

STANDBY

button

PICTURE SETTING button

Attaching the Lens Cap

The lens cap can be attached to the

projector using commercially

available straps

(for cellular phones

etc.), as shown in the figure.

Projector (Side and Rear View)

"/'/\/|

Projector (Rear View)

Using the Terminal Cover

When the projector is used on a desktop, high mounted or ceiling mounted, attach the terminal cover (supplied)

to hide the connecting cables.

Attaching the Terminal

Cover

1 Align with the tabs on

the projector and

then press the

terminal cover in the

direction of the arrow.

2 Tighten the two

screws on the bottom

of the projector.

Removing the Terminal

Cover

1 Loosen the two screws

on the bottom of the

projector.

2 Raise the terminal cover

and pull it out in the

direction of the arrow.

2 Tighten the screws

1 Loosen the screws

1

2

Intake ventilative hole

AC socket

Intake ventilative hole

INPUT 2/DIGITAL INPUT

terminal

INPUT 1 COMPONENT

terminals (RCA)

INPUT 4 VIDEO terminal (RCA) DIGITAL INPUT

TYPE switch

INPUT 3 S-VIDEO terminal

(4-pin Mini DIN)

RS-232C terminal

(9-pin D-sub)

Remote control sensor

OPERATION MANUAL

XV-Z200U/E, XV-Z201E

DT-300

9

XV-Z200U/E, XV-Z201E

Part Names

Remote Control (Front View)

Remote Control (To p View)

FREEZE button

STANDBY button

ENTER button

KEYSTONE button

UNDO button

INPUT 1 button

INPUT 2 button

INPUT 4 button

AUTO SYNC button

RESIZE button

PICTURE SETTING button

MENU button

ON button

ADJUSTMENT buttons

()

INPUT 3 button

DIGITAL INPUT button

RGB/COMP. button

Remote control signal transmitters

"/'/\/|

Operating the Remote Control

■ The remote

control can be

used to control the proj ector

within the

ranges shown in the illustratio

n.

Note

• The signal from the remote

control

can be reflected off a screen

for easy op

eration.

However, the effective distance

of the signal

may differ

due to the screen material.

When using the remote control:

• Be sure no

t to drop, or expose to moisture or high temperature.

• The remote control may malfunction under a fluorescent lamp.

Under that circumstance, move the projecto r away from the fluo -

rescent la

mp.

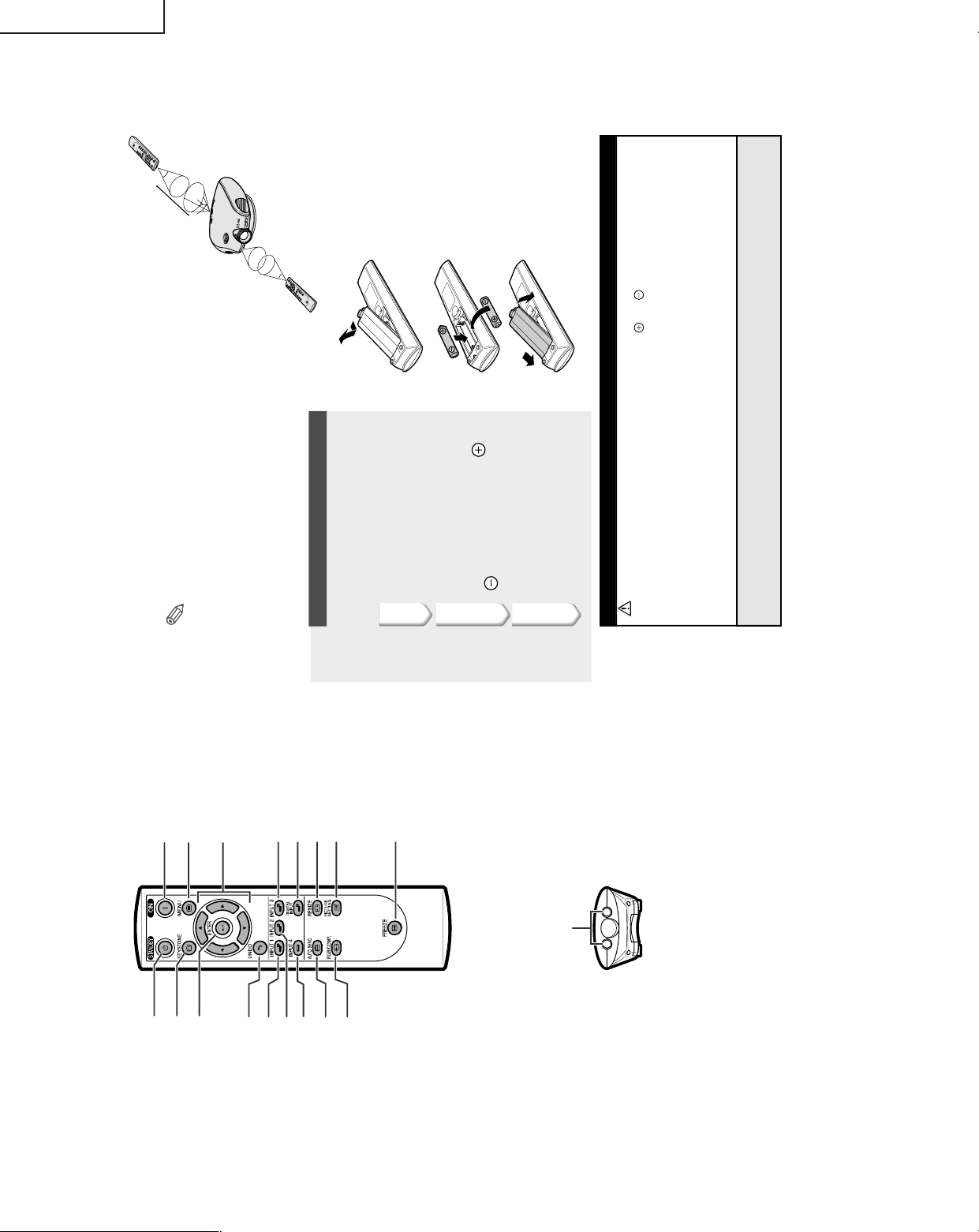

Incorrect use of the batteries may cause them to leak or explode. Please follow the precautions below.

Caution

• Insert the batteries making sure the polarities correctly match the

and

marks inside the battery compart-

ment.

• Batteries of different types have different properties, therefore do not mix batteries of different types.

• Do not mix new and old batteries.

This may shorten the life of new batteries or may cause old batteries to leak.

• Remove the batteries from the remote control once they have run out, as leaving them can cause them to leak.

Battery fluid from leaked batteries is harmful to your skin, therefore be sure to first wipe them and then remove

them using a cloth.

• The batteries included with this projector may exhaust over a short period, depending on how they are kept.

Be sure to replace them as soon as possible with new batteries when they have run out.

• Remove the batteries from the remote control if you will not be using the remote control for a long time.

Available Range of the Remote Control

45˚

23' (7 m)

30˚

30˚

45˚

30˚

Inserting the Batteries

The batter

ies (two

“AA” size) are

included in

the package.

1

Pull down the tab on the cover

and remove the cover toward

the direction of the arrow.

2

Insert the included batteries.

• Insert the batteries making sure the

polarities correctly match the

and

marks inside the battery compart-

ment.

3

Insert the lower tab of the

cover into the opening, and

lower the cover until it clicks

in place.

Remote control

Remote control

DT-300

10

XV-Z200U/E, XV-Z201E

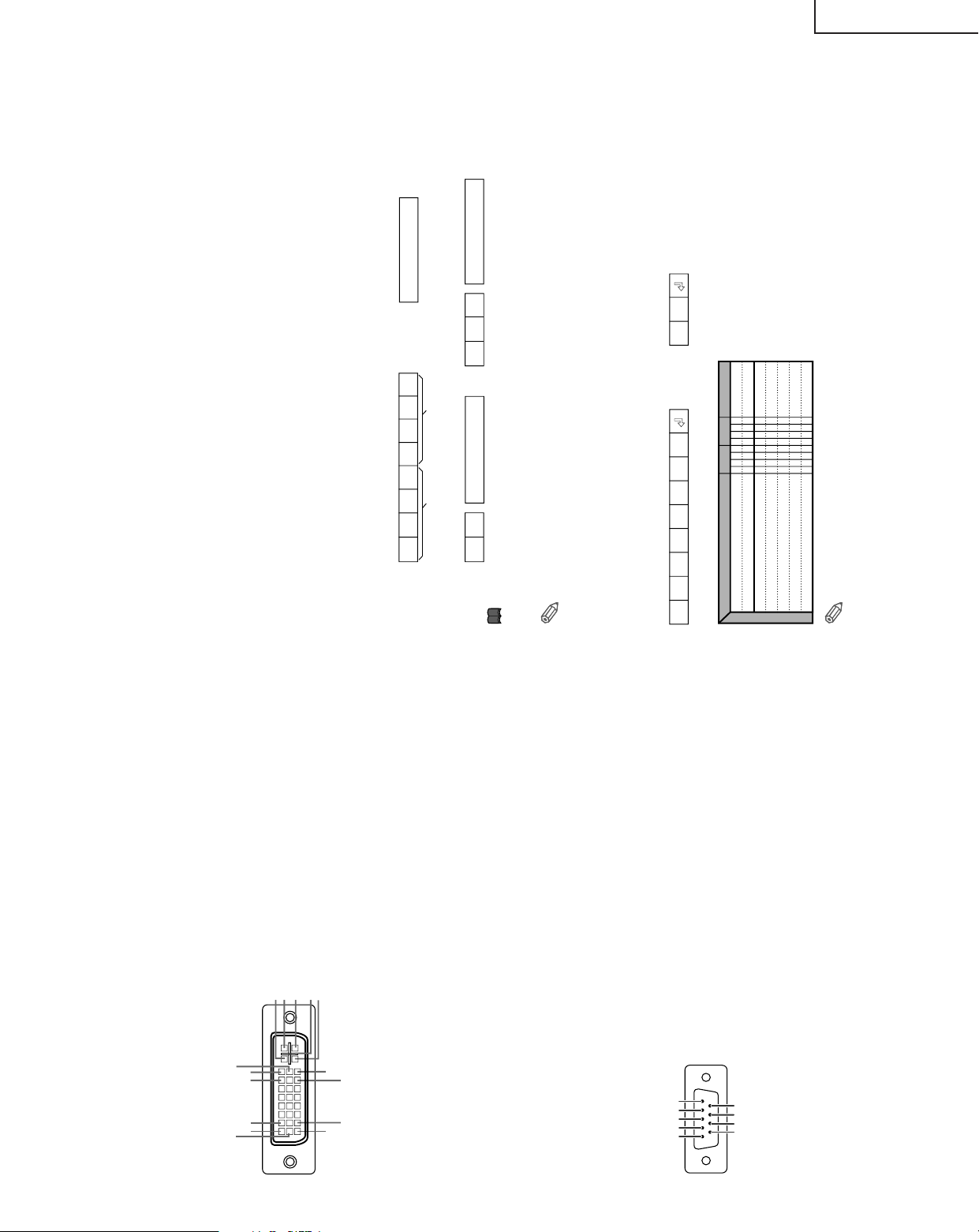

Connecting Pin Assignments

RS-232C Port: 9-pin D-sub male connector

Pin No. Signal Name I/O Reference

1 Not connected

2 RD Receive Data Input Connected to internal circuit

3 SD Send Data Output Connected to internal circuit

4 Reserved Connected to internal circuit

5 SG Signal Ground Connected to internal circuit

6 Reserved Connected to internal circuit

7 Reserved Connected to internal circuit

8 Reserved Connected to internal circuit

9 Not connected

DVI-I (INPUT 2 / DIGITAL INPUT) port :

29 pin connector

• DVI Digital INPUT

Pin No. Signal Pin No. Signal

1 T.M.D.S data 2– 16 Hot plug detection

2 T.M.D.S data 2+ 17 T.M.D.S data 0–

3 T.M.D.S data 2 shield 18 T.M.D.S data 0+

4 Not conn ected 19 T.M.D.S data 0 shield

5 Not conn ected 20 Not co nnected

6 DDC cloc k 21 Not connected

7 DDC data 22 T.M.D.S clock shield

8 Not conn ected 23 T.M.D.S clock+

9 T.M.D.S data 1– 24 T.M.D.S clock–

10 T.M.D.S data 1+ C1 Not connected

11 T.M.D.S data 1 shield C2 No t connected

12 Not connected C3 Not connected

13 Not connected C4 Not connected

14 +5V power C5 Ground

15 Ground

• DVI Analog RGB Input

Pin No. Signal Pin No. Sign al

1 Not connected 16 Hot plug detection

2 Not connected 17 Not connected

3 Not connected 18 Not connected

4 Not connected 19 Not connected

5 Not connected 20 Not connected

6 DDC clock 21 Not connected

7 DDC data 22 Not connected

8 Vertical sy nc 23 Not connected

9 Not connected 24 Not connected

10 Not connected C1 Analog input Red

11 Not connected C2 Analog input Green

12 Not connected C3 Analog input Blue

13 Not connected C4 Horizontal sync

14 +5V power C5 Grou nd

15 Ground

• DVI Analog Component Input

Pin No. Si gnal Pin No. Signal

1 Not conn ected 16 Not connected

2 Not conn ected 17 Not connected

3 Not conn ected 18 Not connected

4 Not conn ected 19 Not connected

5 Not conn ected 20 Not connected

6 Not conn ected 21 Not connected

7 Not conn ected 22 Not connected

8 Not conn ected 23 Not connected

9 Not conn ected 24 Not connected

10 Not connected C1 Analog input P r/Cr

11 Not connected C2 Analog input Y

12 Not connected C3 Analog input P b/Cb

13 Not connected C4 No t connected

14 Not connected C5 Grou nd

15 Ground

17

•••

••••••

~

•••

••••••

••••

~

••••

••••

~

••••

24

18 23

C3

21

9

16

C1

C2

C4

C5

87

6

7

8

9

1

2

3

4

5

PC control

A computer can be used to control the projector by con

necting an RS-232C cable (null mod

em, cross type,

commercially available) to the projec tor.

Communication conditions

Set the serial port settings of the computer to match

that of the ta ble.

Signal form

at: Conforms to RS-232C standard.

Baud rate: 9,600 bps

Data length: 8 bits

Parity bit: None

Stop bit: 1 bit

Flow control: None

Basic format

Commands from the computer are sent in the following order: command, parameter, and return code. After

the projector processes the command from the compute r, it sends a response code to the computer.

Info

• When more than one code is being sent, send each command only after the OK response code for the

previous command from the projector is verified.

Note

• When using the computer control function of the projector, the projector’s operating status cannot be read by

the co

mputer. Therefore, confirm the status by transmitting the display commands for each adjustment

menu and checking the status with the on-screen display.

Commands

Example:

• When power on.

Response code format

Normal response

Problem response (communication error or incorrect command)

Command format

(RS-232C) Specifications and Command Settings

→

←

POWR _ 1__

OK

ProjectorComputer

Return code (

0DH

)

C1 C2 C3 C4 P1 P2 P3 P4

Command 4-digit

Parameter 4-digit

O K

Return code (

0DH

)

E R R

Return code (

0DH

)

Note

• If an underbar (_) appears in the parameter column, enter a space.

CONTROL CONTENTS

POWER ON

STANDBY

INPUT 1 (COMPONENT 1)

INPUT 2 (COMPONENT 2)

INPUT 3 (S-VIDEO)

INPUT 4 (VIDEO)

DIGITAL INPUT MODE

OK OR ERR

OK OR ERR

OK OR ERR

OK OR ERR

OK OR ERR

OK OR ERR

OK OR ERR

P

P

I

I

I

I

I

O

O

V

V

V

V

V

W

W

E

E

E

E

E

R

R

D

D

D

D

D

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

1

0

1

2

3

4

5

BUTTONS & REMOTE CONTROL BUTTONS

COMMAND

PARAMETER

RETURN

DT-300

11

XV-Z200U/E, XV-Z201E

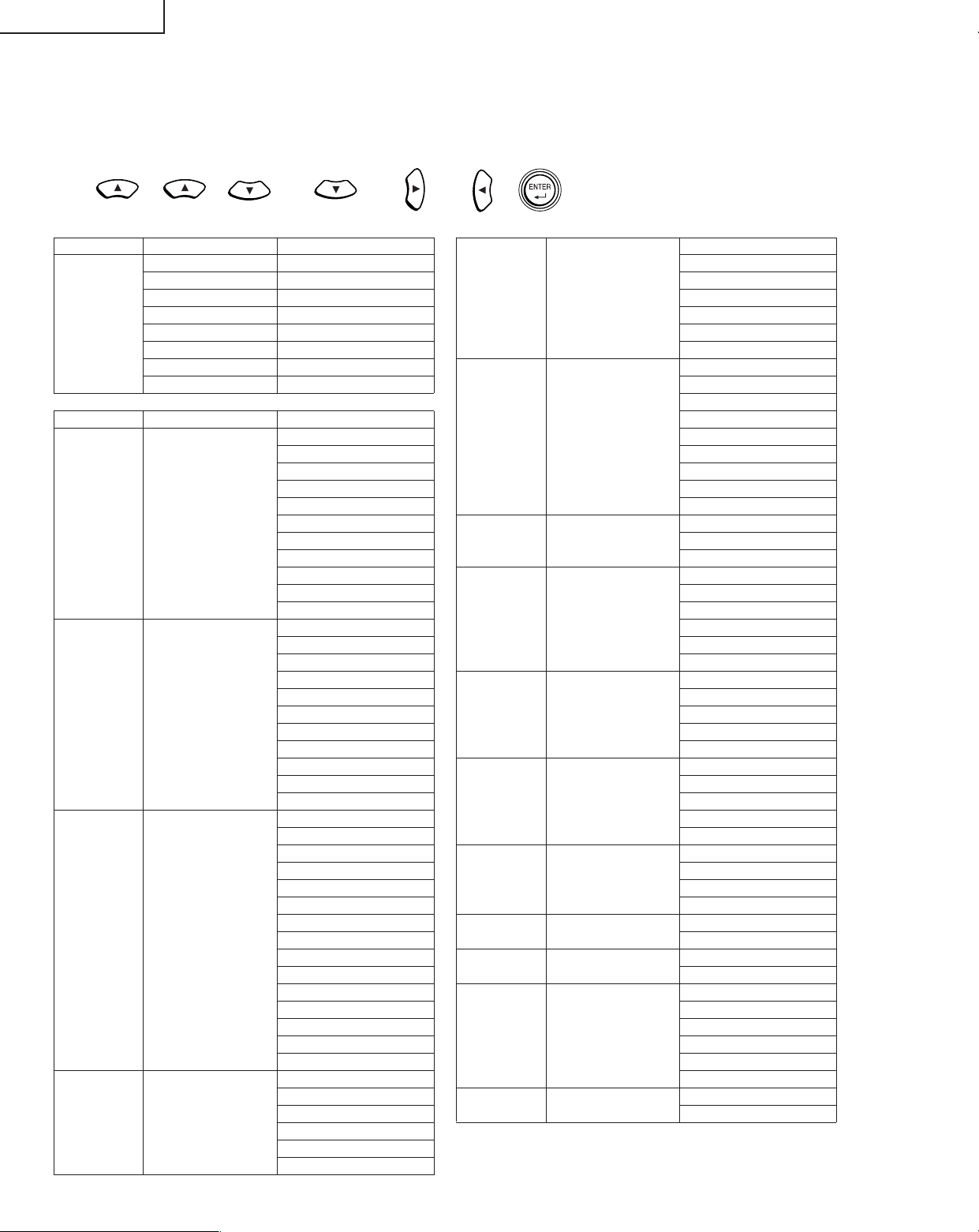

Menu Bar Items

Language ( ) English

Deutsch

Español

Nederlands

Français

Italiano

Svenska

Português

Front

Ceiling Front

Rear

Ceiling Rear

Picture ( )

Tint 3030

Color 3030

Sharp 3030

Contrast 3030

Bright 3030

Red 3030

Blue 3030

Reset

5500K

6500K

8500K

9300K

10500K

Standard

Cinema 1

Cinema 2

Memory 2

Memory 3

Memory 4

Memory 5

Memory OFF

Cinema 3

7500K

CLR Temp

Gamma

White Emphasis [ON/OFF]

Picture Setting

Memory 1

Fine Sync ( )

Auto Sync [ON/OFF]

Clock 3030

3030

3030

Phase 1515

H-Pos

V-Pos

Reset

Special Modes

Signal Info

Resolution

Hor Freq

Vert Freq

640 480

37.5 kHz

72 Hz

640 480

720 480

480P

RGB

Background [None/Blue]

Options ( )

Component

Auto Power Off

[ON/OFF]

Menu Position

Menu Color [Opaque/Translucent]

Center

Lamp Timer (Life)

OSD Display [ON/OFF]

Signal Type

Upper Right

Lower Right

Upper Left

Lower Left

Eco Mode [Eco/Standard]

PRJ Mode ( )

100

100

100

100

100

100

■ INPUT 1 / 2 / DIGITAL INPUT Mode

Main menu

Sub menu

Main menu

Note

• The resolution, vertical frequency and horizontal

frequency figures displayed above are for

example purposes only.

•“Color”, “Tint”, and “Sharp” do not appear when

“RGB” is selected in INPUT 2 mode.

•“Signal Type” is not displayed when using

INPUT 1.

•“Color”, “Tint”, “Sharp”, “Clock”, “Phase”, “H-

Pos”, “V-Pos”, “Special Modes” and “Auto Sync”

cannot be used in the DIGITAL INPUT mode.

•“Clock”, “Phase” and “Auto Sync” cannot be

used in the Component mode.

Lamp Timer (Life)

Picture ( )

Tint

Color

Sharp

Contrast

+30-30

+30-30

+30-30

+30-30

+30-30

+30-30

+30-30

Bright

Red

Blue

Reset

5500K

3D Progressive

6500K

3D Progressive

3D Progressive

8500K

3D Progressive

9300K

3D Progressive

10500K

3D ProgressiveStandard

3D ProgressiveCinema 1

3D Progressive

Cinema 2

3D ProgressiveMemory 2

3D ProgressiveMemory 3

3D ProgressiveMemory 4

3D ProgressiveMemory 5

Auto

3D ProgrOFFessiveMemory OFF

3D Progressive

Cinema 3

Background [None/Blue]

Options ( )

PAL

NTSC3.58

NTSC4.43

PAL–M

PAL–60

SECAM

Language ( )

English

Deutsch

Español

Nederlands

Français

Italiano

Svenska

Português

Auto Power Off

[ON/OFF]

Menu Position

Menu Color [Opaque/Translucent]

Center

PRJ Mode ( )

Front

Ceiling Front

Rear

Ceiling Rear

7500K

CLR Temp

Gamma

White Emphasis [ON/OFF]

Picture Setting

3D Progressive

Memory 1

OSD Display [ON/OFF]

Video System

PAL–N

Upper Right

Lower Right

Upper Left

Lower Left

Eco Mode

[Eco/Standard]

100

100

100

100

100

100

Note

•“Tint” cannot be used with PAL, SECAM, PAL-M,

PAL-N or PAL-60.

INPUT 3 / 4 Mode

Main menu

Sub menu

Main menu

■

DT-300

12

12

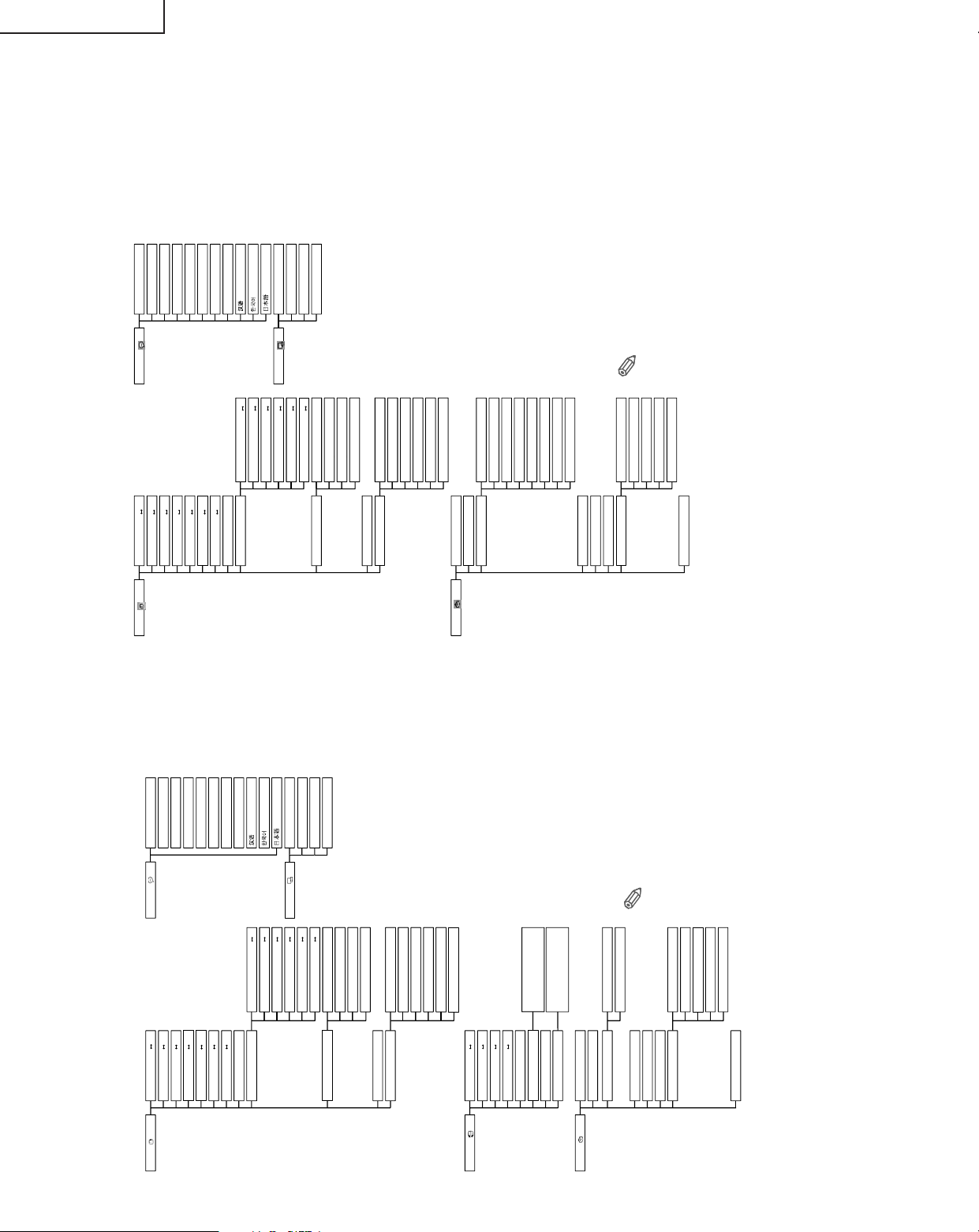

7

/

8

(327)

6

9

/

16

(153.8)

4

5

/

8

(118)

141/2 (368)

Front View

Bottom View

Side View

Top View

Side View

Rear View

Units: inches (mm)

XV-Z200U/E, XV-Z201E

DT-300

DIMENSIONS

13

XV-Z200U/E, XV-Z201E

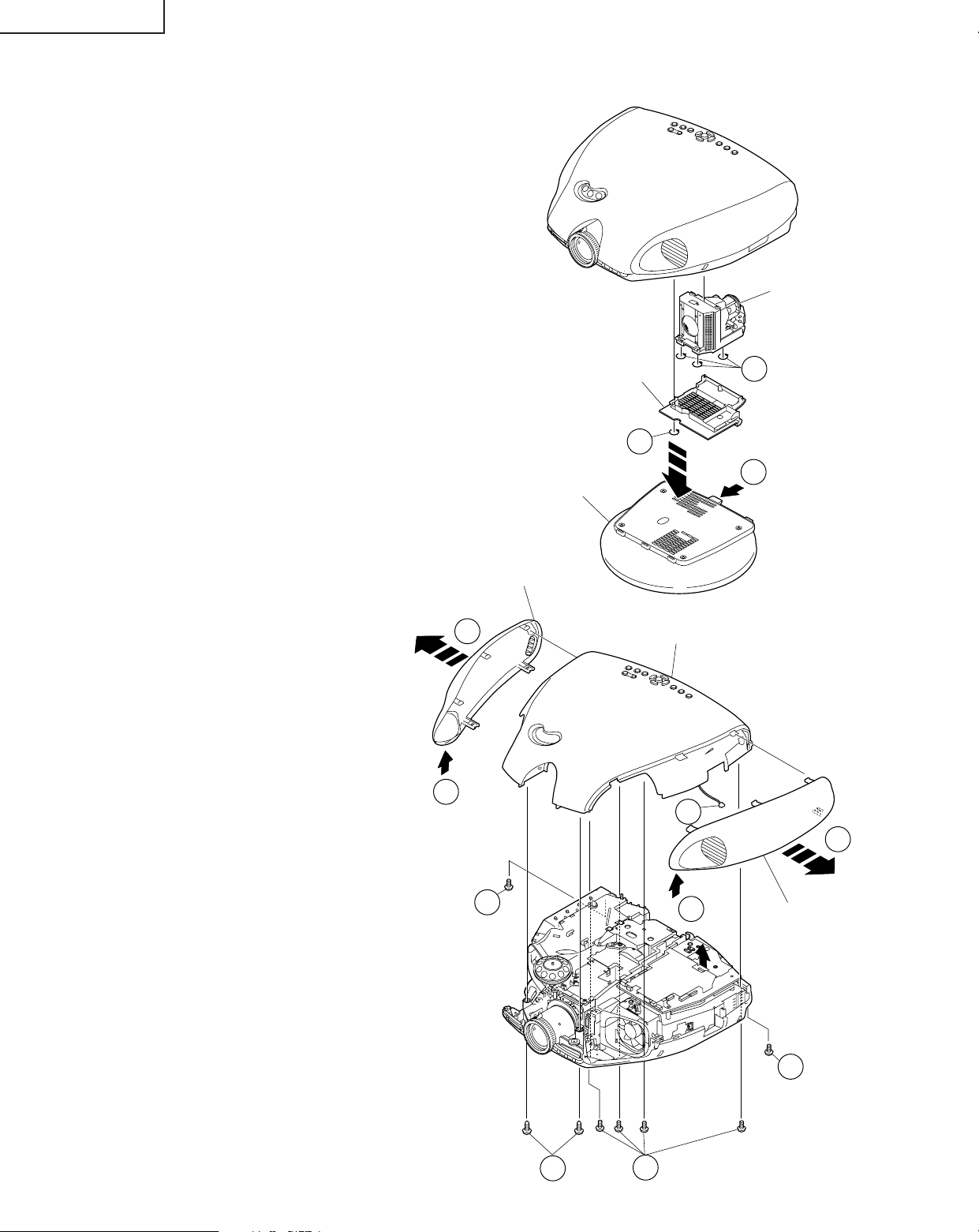

1-1

1-3

1-2

Lamp Box

Lamp door

Swivel Stand

2-1

2-1

2-3

2-1

2-3

2-2

2-3

2-3

2-2

Side Cover (L)

Side Cover (R)

Top Body

(KY)

(KY)

DT-300

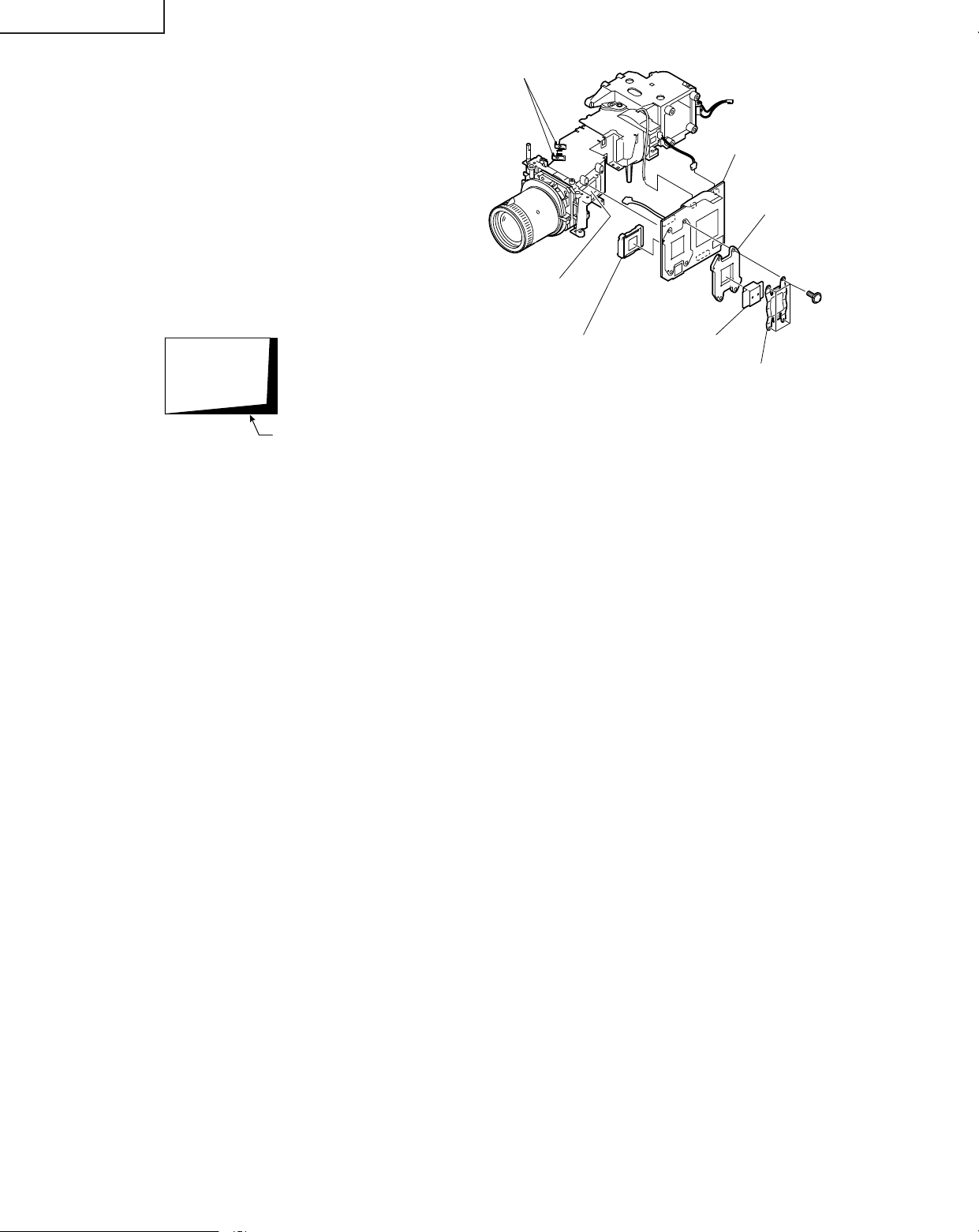

REMOVING OF MAJOR PARTS

1. Removing the swivel stand and the lamp box.

1-1. Remove lock lever, and remove the swivel stand.

1-2. Loosen 1 scrwew, and remove the lamp door.

1-3. Loosen 3 screws, and take out a lamp box.

2. Removing the side covers and the top body.

2-1. Remove 4 screws from the side cover. Push

up the side cover front bottom to unlock the

side cover.

2-2. Pull the side cover in the direction of the ar-

row, and remove it.

2-3. Remove 4 screws from the top body. Unlock

the top body from the lens, slightly push up

the top body, and disconnect the KY lead. Now

lift away the top body.

14

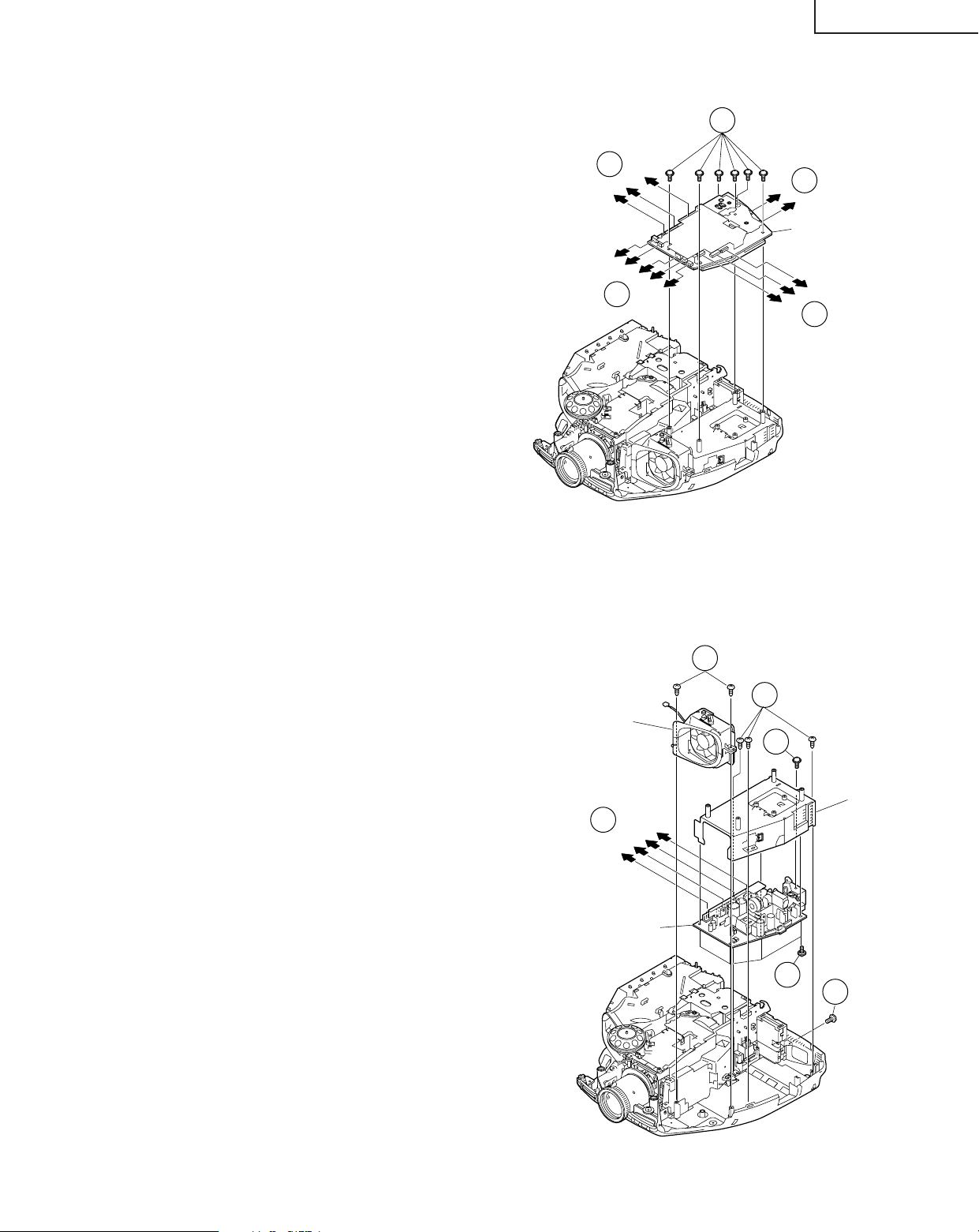

3. Removing the main PWB.

3-2

3-2

3-1

3-2

3-2

Main PWB

(TF)

(DA)

(TD)

(BA)

(FD)

(FB)

(PG)

(FA)

(FC)

(ED)

(TC)

(TH)

(RB)

4-1

4-2

4-3

4-4

4-4

4-3

Power PWB

Power Unit Fan

Power Shield

(EC)

(EA)

(EA1)

(EB)

3-1. Remove 6 screws.

3-2. Remove each connector on the main PWB.

XV-Z200U/E, XV-Z201E

DT-300

4. Removing the power unit.

4-1. Remove each connector on the power PWB.

4-2. Remove 2 screws, and remove the power unit fan.

4-3. Remove 3 screws, and take out the power unit as-

sembly.

4-4. Remove 5 screws, and remove power shield.

15

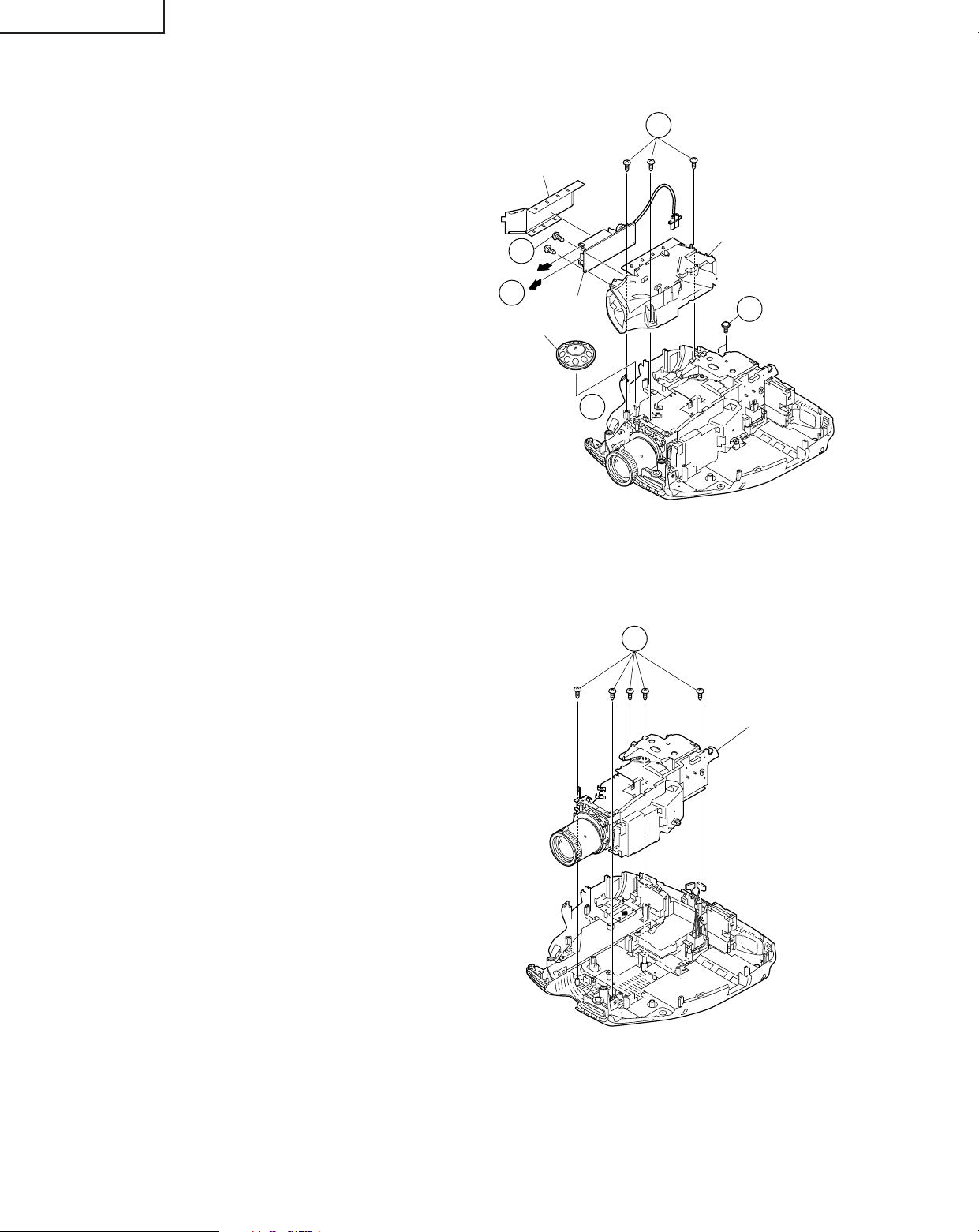

XV-Z200U/E, XV-Z201E

5-4

5-2

5-3

5-1

5-5

Shielding Plate

Ballast PWB

Lens Shift Knob

Exhaust Duct Unit

(EC)

(BA)

6-1

Optic Mechanism Unit

DT-300

5. Removing the Ballast unit.

5-1. Remove lens shift knob.

5-2. Remove 2 screws, and remove the ballast socket.

5-3. Remove 3 screws, and remove the ballast unit.

5-4. Remove shielding plate, and remove 2 connectors

on the ballast PWB.

5-5. Remove 2 screws, and remove ballast PWB.

6. Removing the optic mechanism unit.

6-1. Remove 5 screws, and remove the optic mechanism

unit.

16

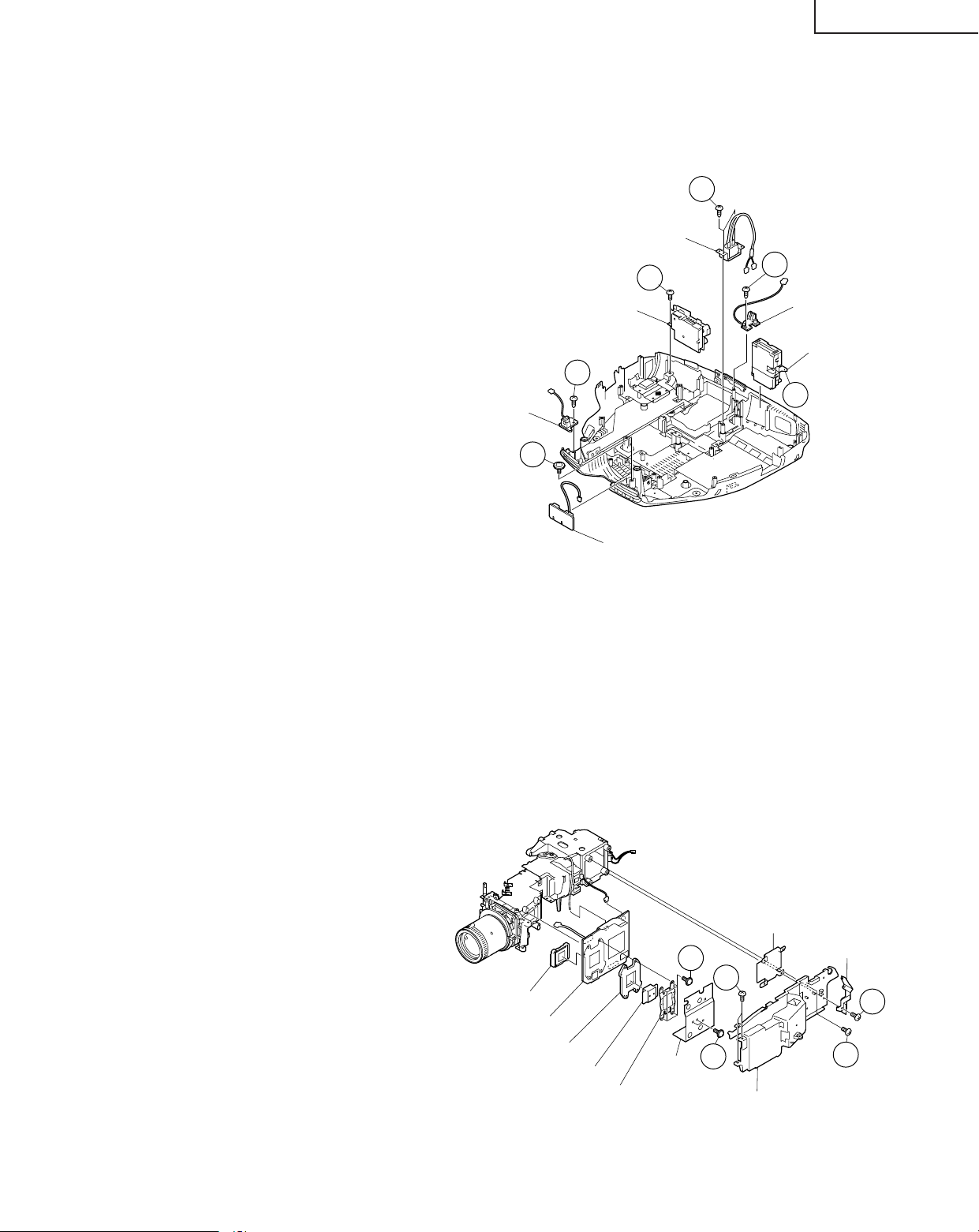

7. Removing the each other PWBs.

7-2

7-1

7-3

7-4

7-5

7-6

Lamp door switch

Terminal-2 PWB

Front R/C Receiver PWB

Rear R/C Receiver PWB

LED PWB

Terminal-1 PWB

8-1

8-2

8-2

8-4

8-3

Angle

Lamp Shield

Blower Fan Unit

Heat Sink

Stud Spring M

Stud M

Backer Plate M

Formatter PWB

DMD

7-1. Remove 1 screw, and remove front R/C receiver PWB

unit .

7-2. Remove 1 screw, and remove LED PWB unit.

7-3. Remove 1 screw, and remove a terminal-2 PWB unit.

7-4. Remove 2 screws, and remove an Lamp door switch.

7-5. Remove 1 screw, and remove rear R/C receiver PWB

unit.

7-6. Remove 1 screw, and remove terminal-1 PWB unit.

XV-Z200U/E, XV-Z201E

DT-300

8. Removing the formatter PWB.

8-1. Remove 1 screws, and remove the angle.

8-2. Remove 3 screws, and remove the blower fan unit.

8-3. Remove 2 screws, and remove the heat sink.

8-4. Remove 4 screws. Remove the backer plate M, stud

plate M, stud spring M, and 2 connectors from the

formatter PWB. After that, remove the formatter PWB.

17

XV-Z200U/E, XV-Z201E

Fig.1

Shade

Stud Spring M

Stud M

Backer Plate M

DMD

(Digital Micromirror

Device) chip

+Outer Frame M

+C-Spring

(CLGA)

Mirror Adjusting Plate

Formatter PWB

Prism Surface

DT-300

Precautions in replacing the DMD chip

Note: Be careful not to allow dust and fingerprint

on the cover glass of DMD chip and prism

surface of optical engine.

1. Tighten 4 screws gradually from opposite sides

to fix the backer plate M, stud spring M, and stud

M. To perform this step, press the shadow part

of the stud spring M to the formatter PWB with

your finger.

2. If something shade appears on the projection

screen like Fig1, release 2 screws on mirror

adjusting plate and move that plate to adjust

illumination area of DMD chip.

18

XV-Z200U/E, XV-Z201E

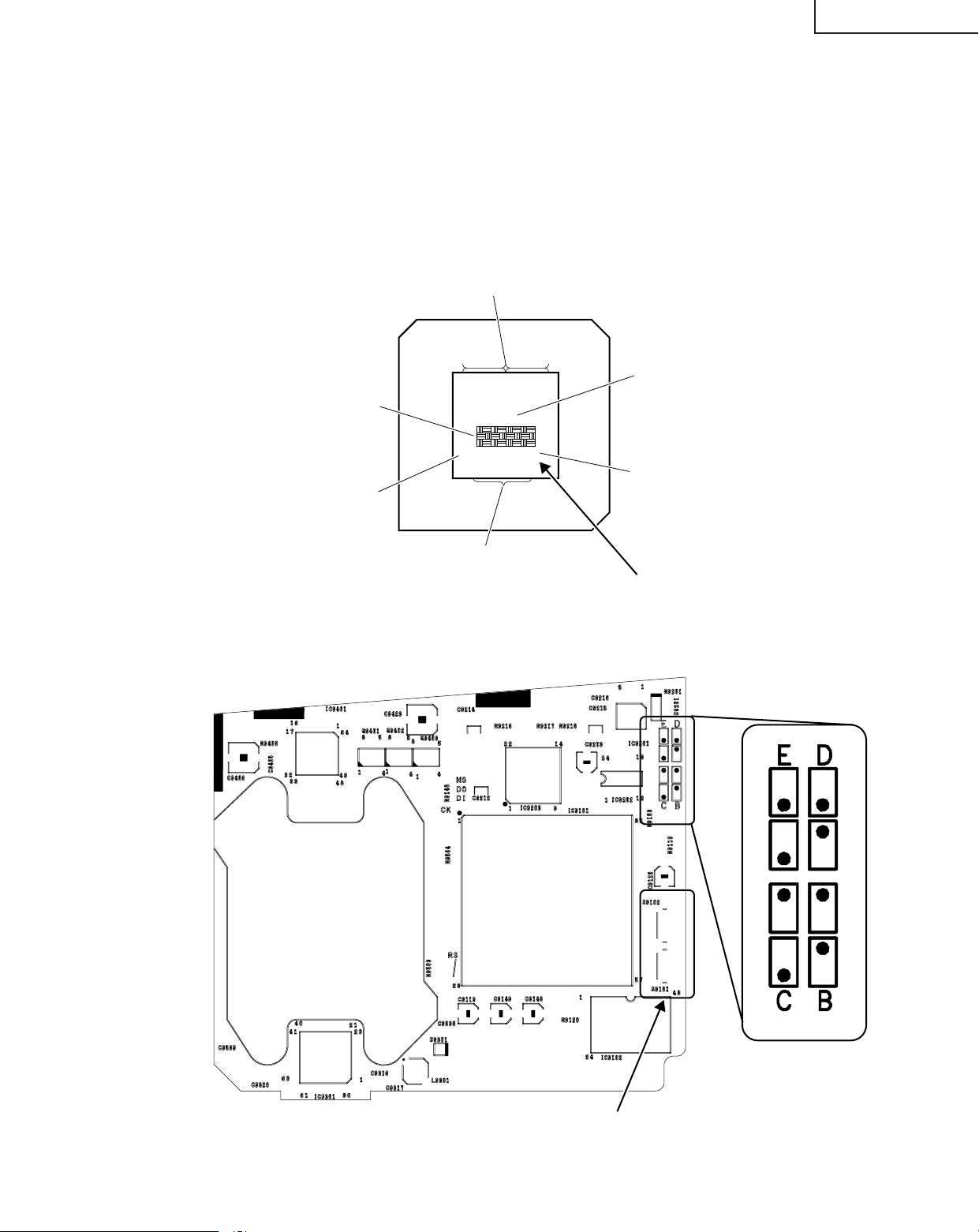

*1057-6bbc

CHXXXX

LLLLL

YYYYYYY

L LLL LM

TI Intemal Numbering

TI Intemal Numbering

2-Dimensional Matrix Code

(DMD Part Number and

Serial Number)

Part 1 of Serial Number

(7 characters)

Part 2 of Serial Number

(6 or7 characters)

DMD Part Number

1 The last alphabet letter indicates the

Bin voltage setting (B~E).

2 Set these two switches.

3

DT-300

* Precautions in setting up the DMD (Digital Micromirror Device) unit

Before connecting the formatter PWB to the optical engine, take the following steps. Look at the voltage rank marking

that is on the DMD itself. Referring to this marking, set the DIP switches on the formatter PWB. And connect this PWB

to the optical engine. Wrong settings will adversely affect the system performance.

DMD Setting: Check the last alphabet character shown in 1, and set the two switches shown in 2 according to the

configurations shown in 3.

Set the formatter PWB switches according to the Bin voltage shown on the back face of the DMD.

19

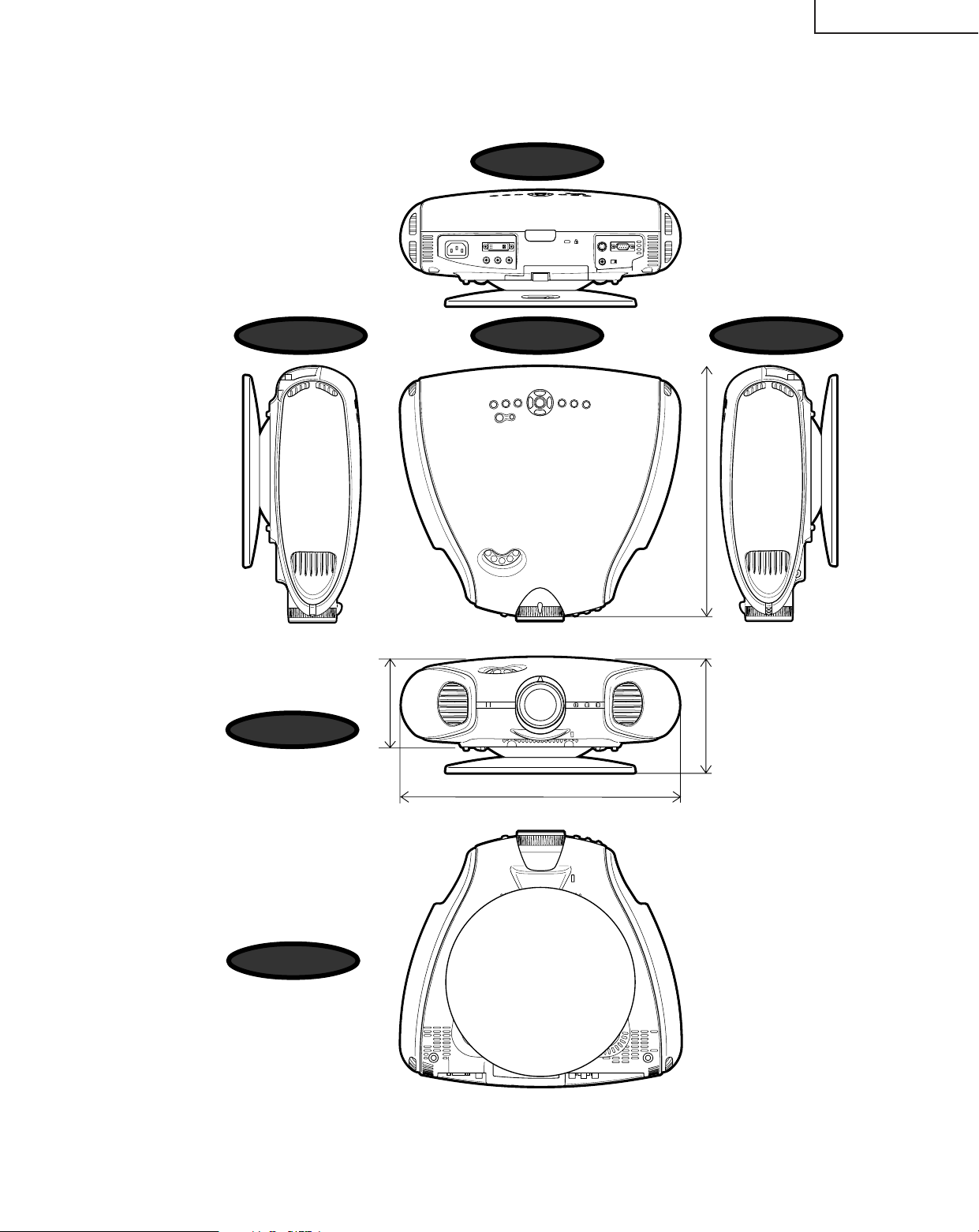

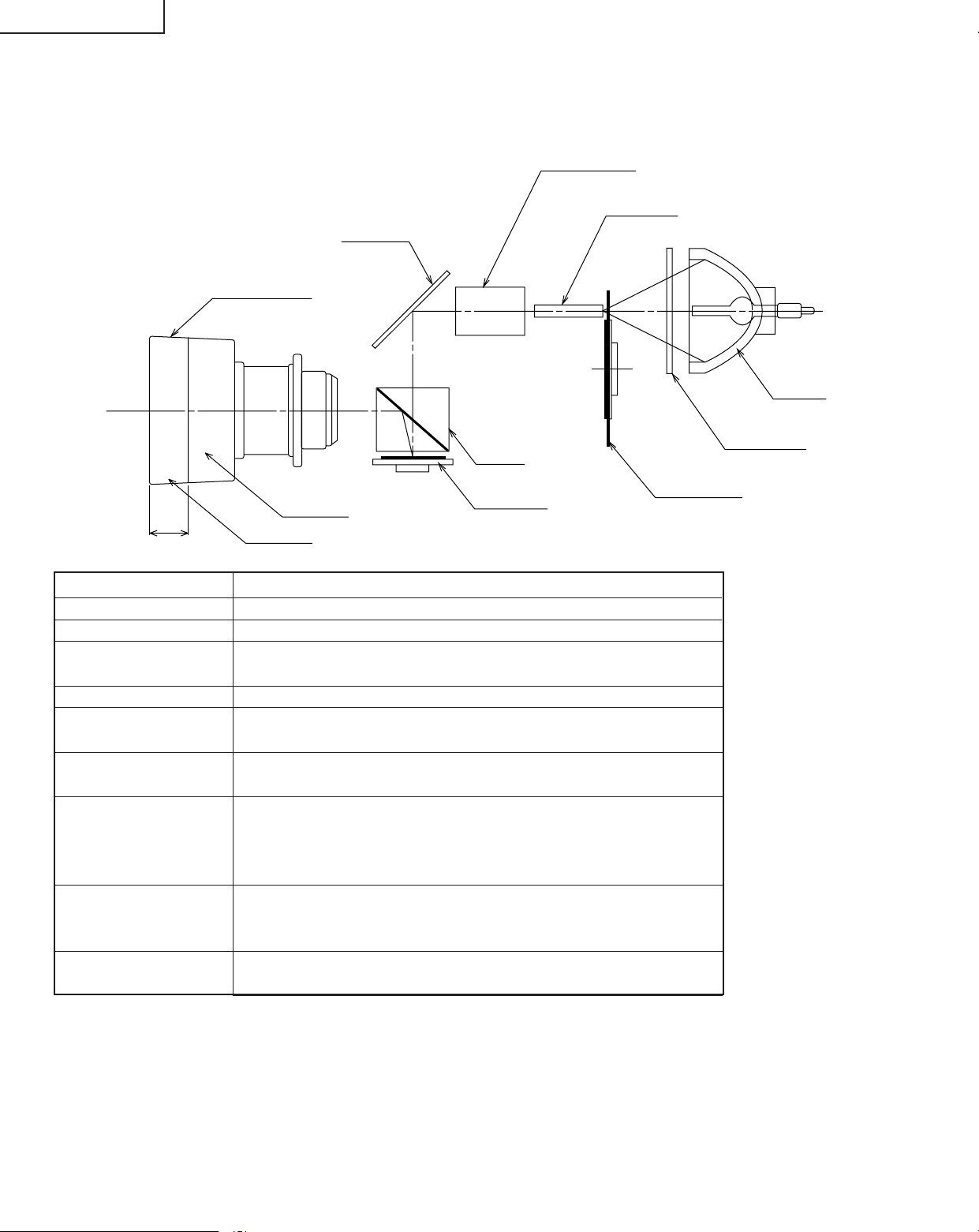

XV-Z200U/E, XV-Z201E

DMD chip

Prism

Projection lens

Reflector

Relay lenses

Rod lens

Lamp

UV/IR filter

Color wheel

<Layout>

Width

Zoom ring

Focus ring

DT-300

THE OPTICAL UNIT OUTLINE

Item

Lamp

UV/IR filter

Color wheel

Rod lens

Relay lenses

Reflector

Prism

DMD chip

Projection lens

Distinction between long and short focal length lens

Caution when repairing without top cabinet

To repair this set without top cabinet, attach the left side body beforehand. (Since the exhaust heat gets in around the

set and the temperature sensor detects it giving the TEMP error and the lamp goes off.)

Function

Light source. DC-driven high-pressure mercury vapor lamp.

Used to absorb ultraviolet and infrared rays.

Used to let the source light through the color filter and to

separate it into R, G and B colors.

Used to make for uniform light beams.

Used to collect the light from the rod lens into the DMD

chip.

Used to reflect the light from the relay lenses against the

DMD chip.

Used to introduce the light from the reflector over the effective surface of the DMD chip. When the micromirror gets

tilted (ON) as specified, the reflected light is guided to the

projection lens.

Used to turn on and off the micromirror in response to the

ratio of color components at each dot and thus to reflect the

incoming light accordingly.

Used to enlarge the light from the DMD chip and to get the

light projected on the screen.

• Long focal length lens: focus ring width: about 18 mm | XV-Z200U, XV-Z200E

• Short focal length lens: focus ring width: about 27 mm | DT-300, XV-Z201E

20

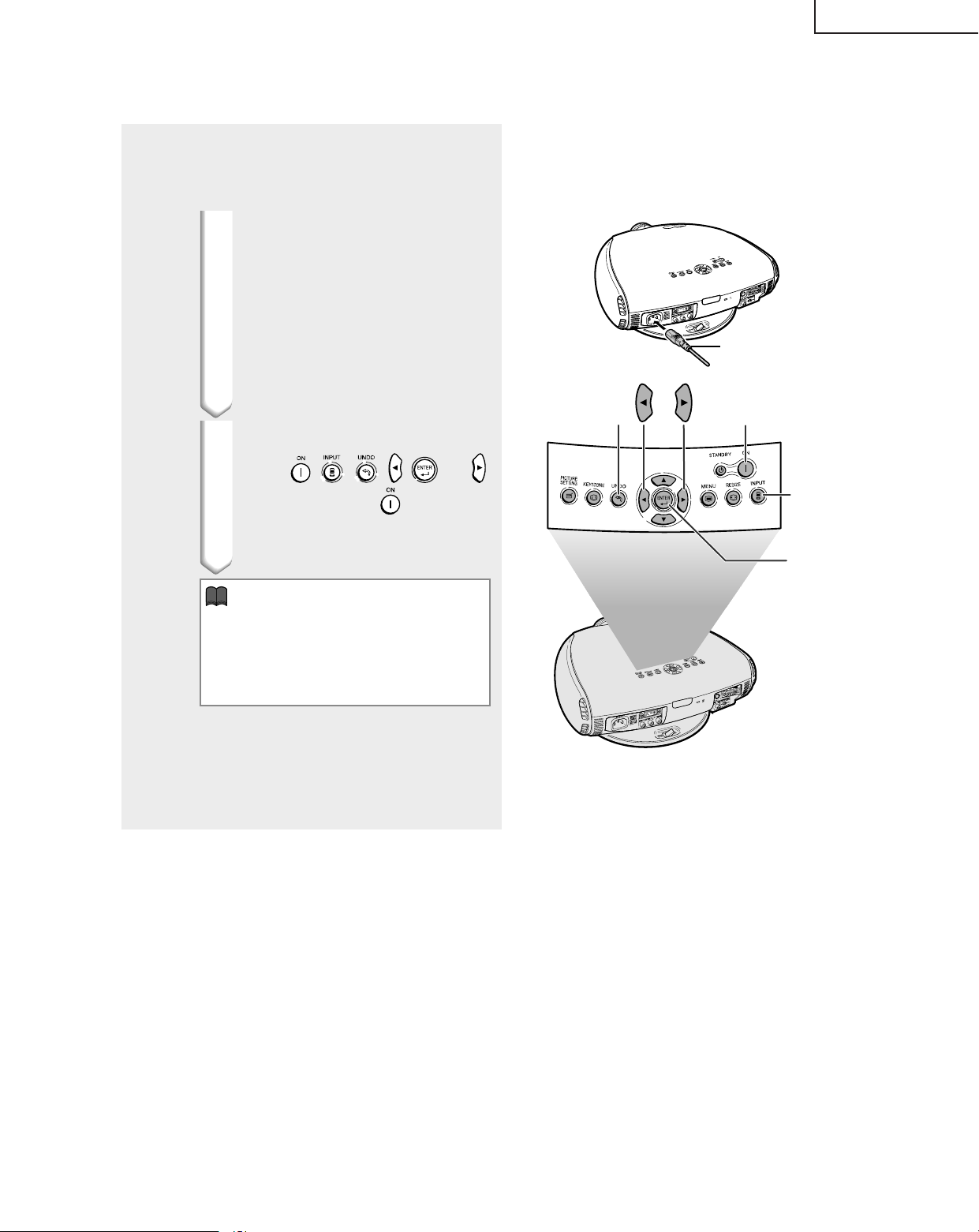

RESETTING THE TOTAL LAMP TIMER

Resetting the Lamp

Timer

Reset the lamp timer after replacing the lamp.

1

Plug the power cord.

• Confirm that the POWER indicator

illuminates red.

2

Reset the lamp timer.

• Press , , , , and

in order. Then press .

• LAMP 0000H is displayed on the

screen.

Info

• Make sure to reset the lamp timer only

when replacing the lamp. If you reset the

lamp timer and continue to use the same

lamp, the lamp may become damaged or

explode.

Power cord

ON buttonUNDO button

INPUT button

ENTER button

XV-Z200U/E, XV-Z201E

DT-300

21

XV-Z200U/E, XV-Z201E

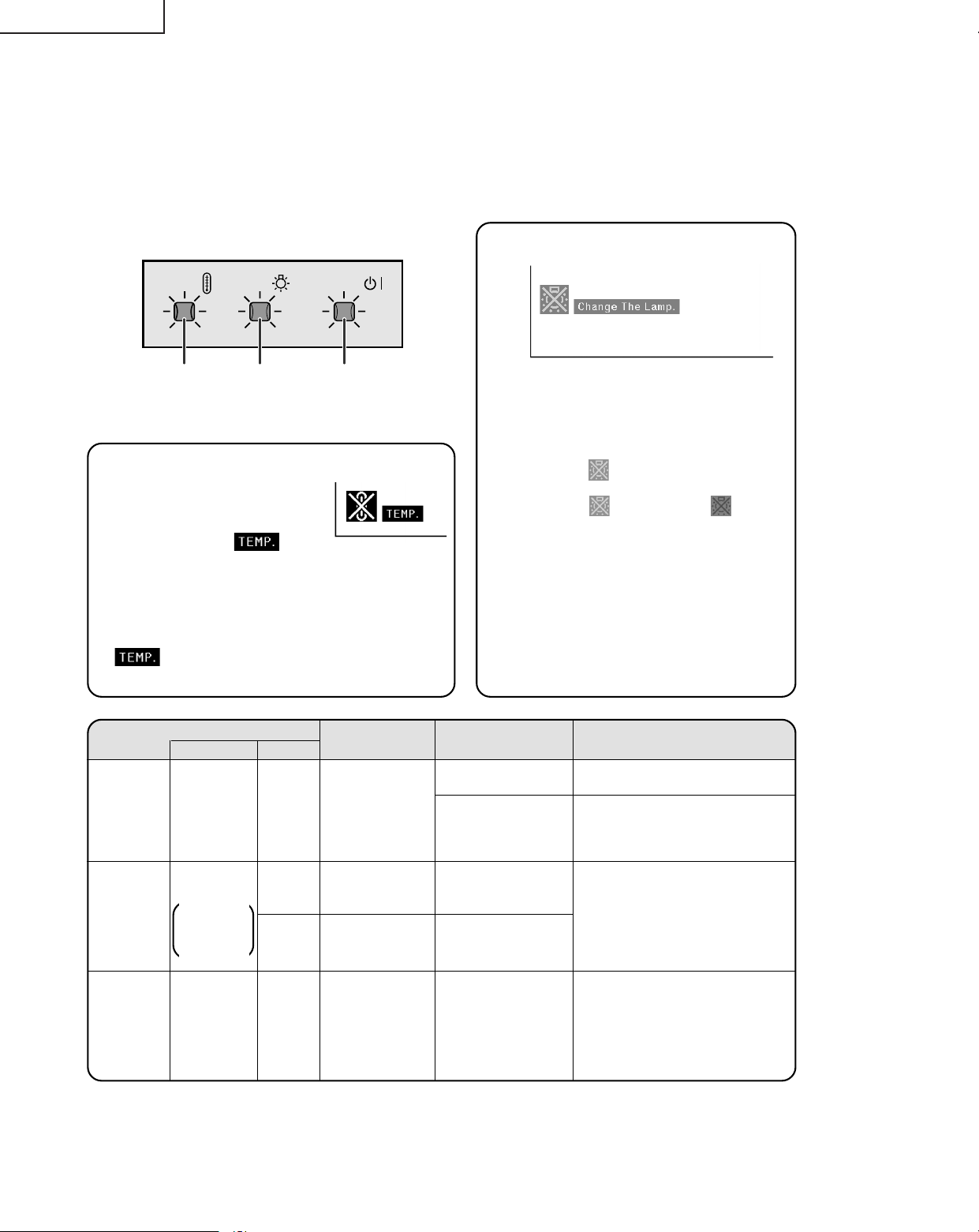

Maintenance Indicators

Ë The warning lights on the projector indicate problems inside the projector.

Ë If a problem occurs, either the temperature warning indicator or the lamp indicator will illuminate

red, and the projector will enter the standby mode. After the projector has entered the standby

mode, follow the procedures given below.

TEMPERATURE

WARNING

indicator

POWER

indicator

LAMP

indicator

TEMP. LAMP POWER

About the temperature warning indicator

If the temperature inside the

projector increases, due to

blockage of the air vents, or the

setting location, “

” will

illuminate in the lower left corner of the picture. If

the temperature keeps on rising, the lamp will turn off

and the temperature warning indicator will blink, the

cooling fan will run for a further 90 seconds, and then

the projector will enter the standby mode. After

“

” appears, be sure to perform the following

measures.

About the lamp indicator

ËThe lamp life becomes 0%, when used

for approximately 4,000 hours with “Eco

mode” or when used for approximately

3,000 hours with “Standard mode”

.

ËWhen the remaining lamp life becomes

5% or less, “

” (yellow) will be displayed

on the screen. When the percentage becomes 0%, “

” will change to “ ” (red),

the lamp will automatically turn off and

then the projector will automatically enter the standby mode. At this time, the

lamp indicator will illuminate in red.

ËIf you try to turn on the projector a fourth

time without replacing the lamp, the projector will not turn on.

Maintenance indicator

Condition

Problem Possible Solution

Temperature

warning

indicator

Normal

Abnormal

Off

Red on/

Standby

The internal

temperature is

abnormally high.

Abnormal

•

Blocked air intake

•

Relocate the projector to an area

with proper ventilation.

•

Cooling fan breakdown

•

•

Internal circuit failure

Clogged air intake

•

Take the projector to your nearest

Authorized SharpVision Service

Center or Dealer for repair.

Lamp

indicator

Red on/

Standby

The lamp does

not illuminate.

•

Burnt-out lamp

•

Lamp circuit failure

•

Carefully replace the lamp.

•

Take the projector to your nearest

Authorized SharpVision Service

Center or Dealer for repair.

•

Please exercise care when

replacing the lamp.

Red on

Time to change

the lamp.

•

Remaining lamp life

becomes 5% or less.

Power

indicator

The power is

not turned on.

•

The lamp unit cover

is open.

•

Securely install the cover.

•

If the power is not turned on even

when the lamp unit cover is

securely installed, contact your

nearest Authorized SharpVision

Service Center or Dealer for

advice.

Green on/

Red on

Off

Green on

Green blinks

when the

lamp is

warming up.

DT-300

22

ELECTRICAL ADJUSTMENT

R

G

B

No. Adjusting point Adjusting conditions Adjusting procedure

XV-Z200U/E, XV-Z201E

DT-300

1 Initialization of

EEPROM

2 Adjustment of

CW index

3-1 R-Bright / R-

Contrast

(Manual or auto

adjustment)

1. Turn on the power (the

lamp lights up) and warm

up the system for 15 minutes.

1. Input the gradation pattern of RGB.

(SVGA60Hz or XGA)

2. Select the following

group and subject.

Group: DLP

Subject: Select INDEX

DELAY.

1. Group: AD

Subject: R-BRIGHT

(Black level)

R-CONTRAST

(White level)

2. Feed the window pattern

signal containing 91%

(0.64Vp-p) R signal and

0% level.

(Process/Gamma interaction)

(SVGA or XGA)

Input 2 RGB input

1. Carry out the following setting.

Using the remote controller or press S2002 to

enter the process mode, and execute SS2 on SS

menu.

1. Select subject and make adjustment so that the

lamp gradation patterns of R, G and B should be

smooth without noise.

1. Observe the 0% window pattern.

2. On the screen with missing bits (red bright spot

appearing at the center of the screen), adjust

the R-Bright setting until the all-black screen

becomes bit-less for the first time.

3. Observe the 91% window pattern.

4. On the screen with missing bits, adjust the RContrast setting until the all-black screen becomes

bit-less for the first time.

3-2 G-Bright / G-

Contrast

(Manual or auto

adjustment)

1. Group: AD

Subject: G-BRIGHT

(Black level)

G-CONTRAST

(White level)

2. Feed the window pattern

signal containing 91%

(0.64Vp-p) G signal and

0% level.

(Process/Gamma interaction)

(SVGA or XGA)

Input 2 RGB input

1. Observe the 0% window pattern.

2. On the screen with missing bits, adjust the GBright setting until the all-black screen becomes

bit-less for the first time.

3. Observe the 91% window pattern.

4. On the screen with missing bits, adjust the GContrast setting until the all-black screen becomes

bit-less for the first time.

23

XV-Z200U/E, XV-Z201E

DT-300

No. Adjusting point Adjusting conditions Adjusting procedure

3-3 B-Bright / B-

Contrast

(Manual or auto

adjustment)

4-1 DTV Bright/

Contrast Adjustment

4-2 DTV R-Bright/

Contrast Adjustment

1. Group: AD

Subject: B-BRIGHT

(Black level)

B-CONTRAST

(White level)

2. Feed the window pattern

signal containing 91%

(0.64Vp-p) B signal and

0% level.

(Process/Gamma interaction)

(SVGA or XGA)

Input 2 RGB input

1. Group: DTV

Subject:BRIGHT

(Black level)

CONTRAST

(White level)

1. Group: DTV

Subject:R-BRIGHT

(Black level)

R-CONTRAST

(White level)

1. Observe the 0% window pattern.

2. On the screen with missing bits, adjust the BBright setting until the all-black screen becomes

bit-less for the first time.

3. Observe the 91% window pattern.

4. On the screen with missing bits, adjust the BContrast setting until the all-black screen becomes

bit-less for the first time.

1. Check the fixed value.

Contrast: 5

Bright: 55

1. Observe the 0% window pattern.

2. On the screen with missing bits, adjust the RBright setting until the all-black screen becomes

bit-less for the first time.

3. Observe the 100% white window pattern.

4. On the screen with missing bits, adjust the Contrast setting until the all-black screen becomes

bit-less for the first time.

4-3 DTV G-Bright/

Contrast Adjustment

4-4 DTV B-Bright/

Contrast Adjustment

1. Group: DTV

Subject:G-BRIGHT

(Black level)

G-CONTRAST

(White level)

1. Group: DTV

Subject:B-BRIGHT

(Black level)

B-CONTRAST

(White level)

1. Observe the 0% window pattern.

2. On the screen with missing bits, adjust the GBright setting until the all-black screen becomes

bit-less for the first time.

3. Observe the 100% white window pattern.

4. On the screen with missing bits, adjust the Contrast setting until the all-black screen becomes

bit-less for the first time.

1. Observe the 0% window pattern.

2. On the screen with missing bits, adjust the BBright setting until the all-black screen becomes

bit-less for the first time.

3. Observe the 100% white window pattern.

4. On the screen with missing bits, adjust the Contrast setting until the all-black screen becomes

bit-less for the first time.

24

No. Adjusting point Adjusting conditions Adjusting procedure

XV-Z200U/E, XV-Z201E

DT-300

5 DTV Tint 1. Group: DTV

Subject: Tint

6 DTV Color

Saturation

1. Group: DTV

Subject: Color

1. Check the fixed value.

Tint: 8

1. Check the fixed value.

Color: 6

Level

7 DVD Bright/

Contrast Adjustment

1. Group: DVD

Subject:BRIGHT

(Black level)

1. Check the fixed value.

Contrast: 5

Bright: 55

CONTRAST

(White level)

8 DVD Tint 1. Check the fixed value.

9 DTV Color

Saturation Level

10 Video Bright/

Contrast

Adjustment

1. Group: DVD

Subject: Tint

1. Group: DVD

Subject: Color

1. Group: VIDEO

Subject:BRIGHT

(Black level)

Tint: 4

1. Check the fixed value.

Color: 8

1. Check the fixed value.

Contrast: 5

Bright: 55

CONTRAST

(White level)

11 VIDEO Tint 1. Group: VIDEO

Subject:N-Tint

P-Tint

S-Tint

12 VIDEO Color

Saturation Level

1. Group: VIDEO

Subject:N-Color

P-Color

S-Color

13 DVD White

balance

(Auto

adjustment)

1. Feed the XGA 75% gray

scale signal.

2. Group: PIXEL

Subject:R-GAIN (R)

B-GAIN (B)

Input 2

14 Factory settings

1. Check the fixed values.

N-Tint: 8

P-Tint: 4

S-Tint: 4

1. Check the fixed values.

N-Color: 7

P-Color: 4

S-Color: 7

1. Adjust the white balance by controlling R-GAIN and

B-GAIN.

(Adjust x=296 and y=325.)

1. Make the following settings

Destination Process adjustment

Europe SS3 Factory setting 3

North America SS4 Factory setting 4

Remote controller setting

25

XV-Z200U/E, XV-Z201E

DT-300

» Entering the adjustment process mode

There are following two methods.

» Press the S2002 on the MAIN PWB.

» Press the following keys in this order.

Adj up→Adj up→Adj down→Adj down→Adj right→Adj left→Enter

» Adjustment mode process menu

Group Subject

1st layer DTV VERSION

DVD SS

VIDEO TEMP

AD OPTION

DLP PATTERN

VIDEO1 LAMP

PIXEL LINE

REDESTA EXIT

Group Subject

2nd layer DTV Contrast

Tint

Color

Sharpness

Bright

R-Bright

G-Bright

B-Bright

R-Contrast

G-Contrast

B-Contrast

DVD Contrast

Tint

Color

Sharpness

CTI-Level

LTI-Level

CB-Offset

CR-Offset

Bright

B-DRIVE

R-DRIVE

VIDEO Contrast

N-Tint

P-Tint

S-Tint

N-Color

P-Color

S-Color

Sharpness

CTI-Level

LTI-Level

CB-Offset

CR-Offset

Bright

B-DRIVE

R-DRIVE

AD R-Bright

G-Bright

B-Bright

R-Contrast

B-Contrast

B-Contrast

DLP Index Delay

R-Bright

G-Bright

B-Bright

R-Contrast

G-Contrast

B-Contrast

VIDEO1 N-Contrast

P-Contrast

S-Contrast

Color

NT3.58 Delay

NT4.43 Delay

PAL Delay

SECAM Delay

Sharpness2

PIXEL R-GAIN

G-GAIN

B-GAIN

Pedestal R-Bright

G-Bright

B-Bright

R-Contrast

G-Contrast

B-Contrast

VERSION Build

Boot Code

Config

Rom Code

GUI

SS SS2

SS3 EU

SS4 US

SS5 JPN

SS6 CHIN

TEMP Temp1

Temp2

Temp3

Temp4

OPTION PW365 Gamma

DLP Gamma

PATTERN Cross Hatch

Color Bar

LAMP Current Time

History1

History2

History3

History4

TOTAL TIME

LINE OFF

LED CHECK

26

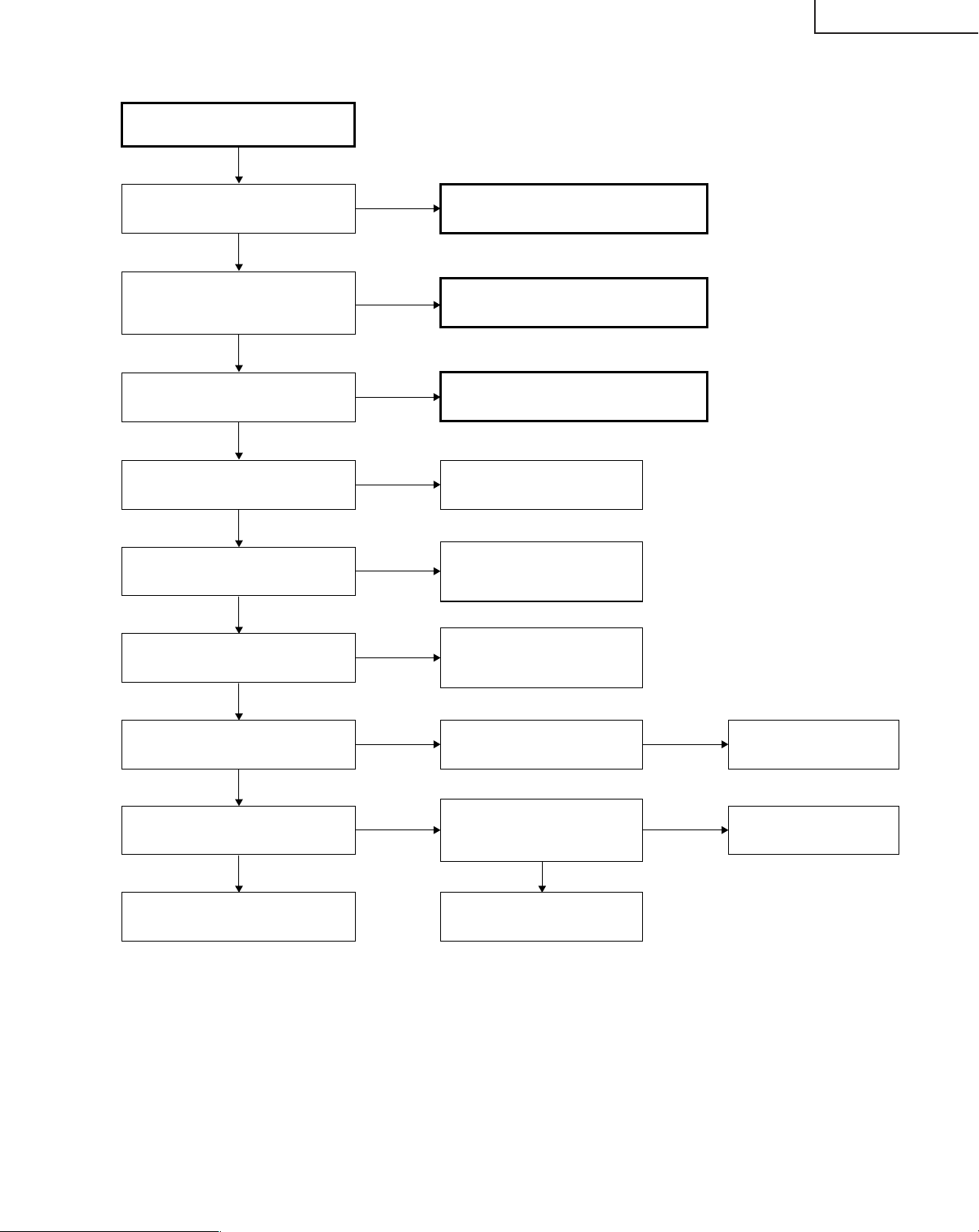

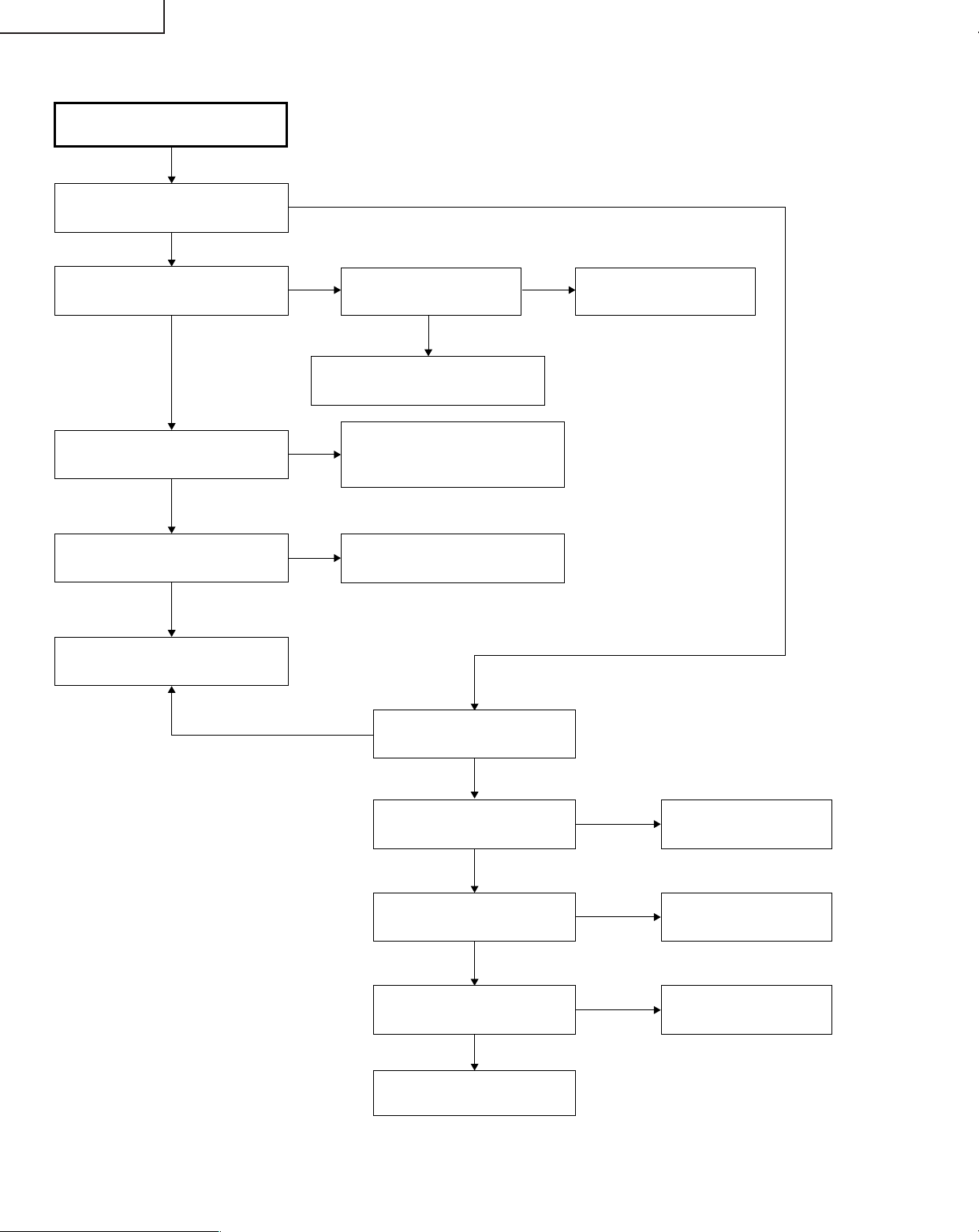

Yes

No

Checking of Basic Operation

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

Yes

Yes

No

Does the digital DVI input

operate normally?

Does the video input operate

normally?

Is the component input acting

normally?

Is the analog RGB input acting

normally?

Is the user menu displayed?

Does the cooling fan rotate and

does the lamp light up?

Go to "Checking of Power Unit".

Go to the "Check of IC2002 and

around I/O".

Go to "Checking of Lamp Lighting-up"

Check the formatter circuit and

its periphery.

Check of IC6004 (AD) or

IC3104 and check of analog

RGB input

Is there input signal at pins

(16), (18) and (20) of IC3104?

Check of IC502 of the DVITAN1 PWB and peripheral

circuits.

Go to "Checking of Video

Input". Is the input signal of

IC3105 coming?

Check IC3102 and its

peripheral circuit.

No

Check IC3104 and its

peripheral circuit.

No

Check IC3105 and its

peripheral circuit.

Does the POWER LED light up or

flicker in red or green?

End

Does the set operate by the set's

key or the remote controller's

power key?

XV-Z200U/E, XV-Z201E

DT-300

TROUBLESHOOTING TABLE

27

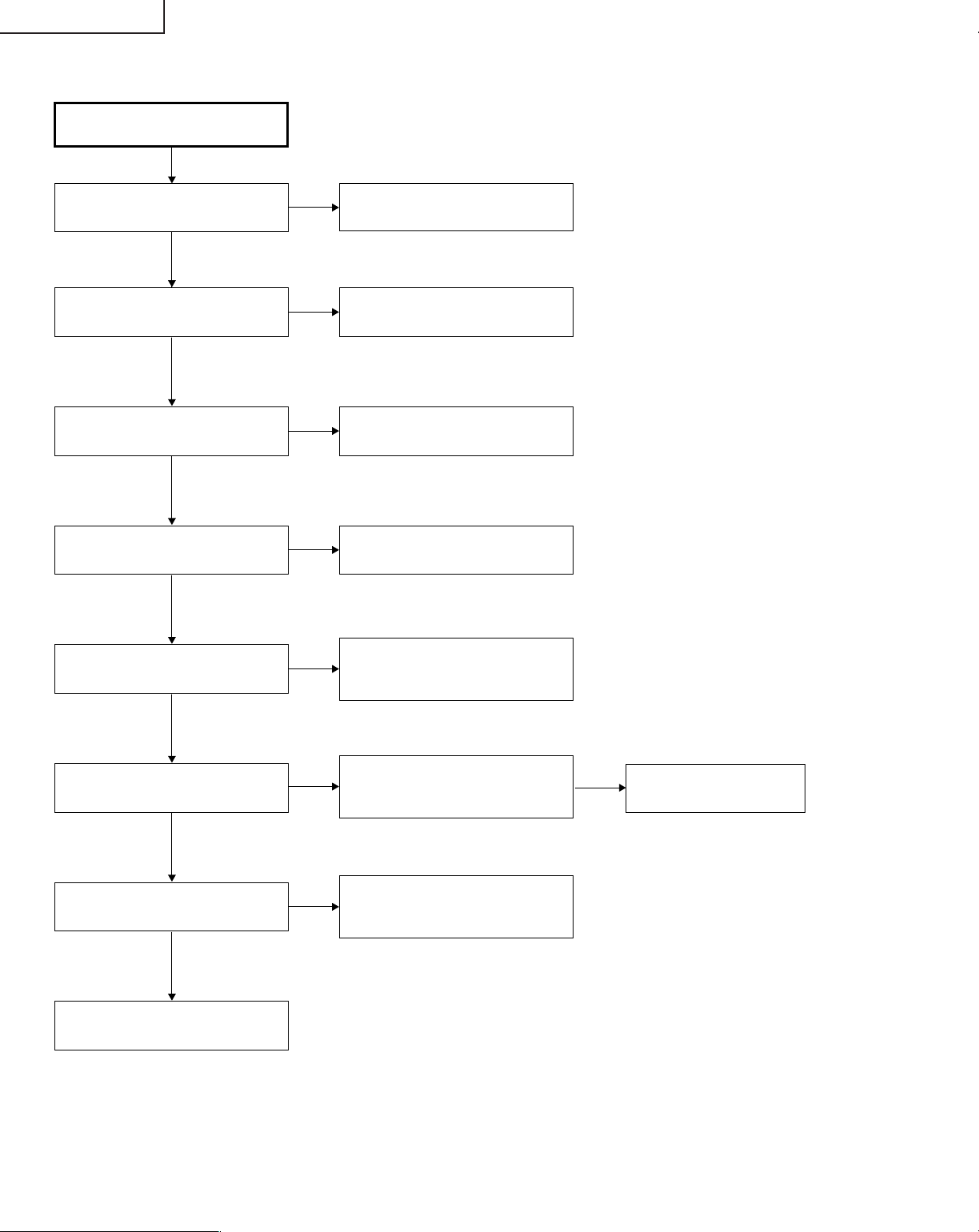

XV-Z200U/E, XV-Z201E

Yes

No

Checking of Power Unit

Are connectors in the power unit

completely inserted?

Yes

No

Is the lamp door closed

completely?

Close the lamp door completely by

screws.

Yes

No

Is the bimetal switch not cut?

Replace the bimetal switch or

press the red button to recover.

Yes

No

Is AC voltage applied to AC input

both ends of D7001?

Replace F7001.

Replace if any other damages, etc.

Yes

No

Is DC voltage about 6V on C7105

both ends?

Check around IC7003 of the

primary side and D7103.

Replace if any damages, etc.

Yes

No

Is voltage about 370 V DC on the

cathode of D7004?

Replace the ballast power

source side.

Yes

No

Is there rated voltage at the output

terminals of CN7101 and CN7102?

Check the secondly side circuit of

T7001, etc. Replace if any

damages, etc.

No

Check the primary side circuit of

IC7001, etc. Replace if any

damages, etc.

Check the PWB circuits of relevant

output sides.

Securely insert each connector.

DT-300

28

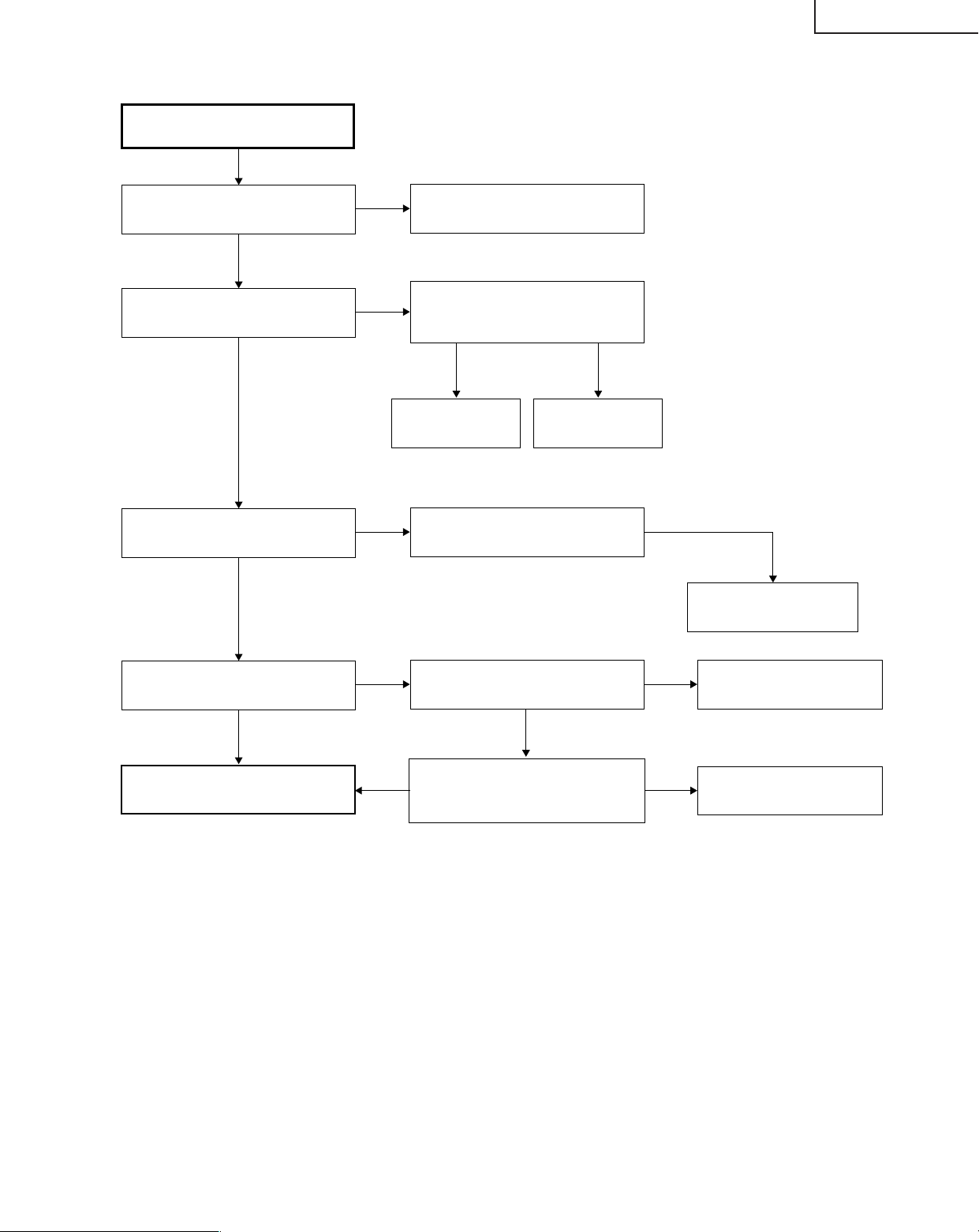

Lamp does not light up.

Yes

Yes

Is the cooling fan rotating?

Check the socket

Is the pin (22) of P1701 "L" level?

No

Check the power circuit or the fan

circuit of the main circuit.

Yes

Is the color wheel rotating sound

heard?

No

Check around IC9401 motor

driver IC circuit Q9401, Q9402

and Q9403.

No

Normal Abnormal

Is the lamp discharging sound

heard?

Yes

Yes

Is DC 370V voltage applied across

the ballast power?

Lamp failure to light up. Go to

"Formatter Unit Troubleshooting".

No

Check the control line P-SAVE.

Is the level converted at IC8001,

B5 output, RN4904?

No

Yes

Check the power circuit.

Yes

Check IC8001 and the

peripheral circuit.

No

Replace the color

wheel.

Check the

formatter PWB.

No

Replace the lamp.

XV-Z200U/E, XV-Z201E

DT-300

29

XV-Z200U/E, XV-Z201E

No

Yes

Does POWER LED flicker in red ?

Yes

Turn on the power again.

Yes

Is pin (9) of P1701 (P CON0) H?

Is the FAN voltage supplied?

No

Is it in the stand-by due to

an error?

No

This is the failure of

IC2002.

Yes

FAN_ERROR is being detected.

Check around Q1701 and around

pin (2) of IC2002.

Yes

No

No

No

Is 13 V outputted to pins (17), (18)

and (19) P1701?

Go to "Checking of Power Unit"

Check IC1708, IC1709 and

around these ICs.

Yes

No

Is BU 5 V outputted from

IC1701?

Yes

Is Bu+6.5V outputted to pins

(12), (13) and (14) of P1701?

Check IC1701 and its

periphery.

Yes

No

Is BU 3.3 V outputted from

IC1702?

Check IC1702 and its

periphery.

Check IC1703 and its

periphery.

Yes

No

Is BU 2.5 V outputted from

IC1703?

Check IC8001 and the circuit

around the IC.

Check of IC2002 and around I/O

DT-300

30

Loading...

Loading...