Page 1

SERVICE MANUAL

S95N7DT-100//

MULTIMEDIA PROJECTOR

DT-100

MODEL DT-100

In the interests of user-safety (Required by safety regulations in some countr ies) the set should be restored to its original condition and only parts identical to those specified should be used.

SHARP CORPORATION

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Page 2

DT-100

• SPECIFICATIONS ............................................3

• IMPORTANT SERVICE SAFETY

NOTES (for USA)..............................................4

• NOTE TO SERVICE PERSONNEL ..................6

• OPERATION MANUAL ...................................10

• DIMENSIONS ................................................. 16

• RESETTING THE TO TAL LAMP TIMER .........17

• REMOVING OF MAJOR PARTS.....................19

• THE OPTICAL UNIT OUTLINE ......................22

• ELECTRICAL ADJUSTMENT .........................24

• TROUBLE SHOOTING TABLE ....................... 30

• BLOCK DIAGRAM ..........................................40

CONTENTS

Page Page

• OVERALL WIRING DIAGRAM........................42

• DESCRIPTION OF SCHEMATIC DIAGRAM .. 44

• WAVEFORMS ................................................. 45

• SCHEMATIC DIAGRAM..................................46

• PRINTED WIRING BOARD ASSEMBLIES..... 74

• PARTS LIST

Ë

ELECTRICAL PARTS.................................94

Ë

CABINET AND MECHANICAL PARTS ....105

Ë

ACCESSORIES PARTS...........................109

Ë

PACKING PARTS.....................................109

• PACKING OF THE SET ................................110

2

Page 3

SPECIFICATIONS

DT-100

Product type

Model

Video system

Display method

DMD panel

Lens

Projection lamp

Component input signal

(INPUT1/2)

Horizontal resolution

Computer RGB input

(INPUT 1/2)/output

(OUTPUT) signal

S-video input signal

(INPUT 3)

Video input signal

(INPUT 4)

Ver tical frequency

Horizontal frequency

Pixel clock

RS-232C terminal

Audio input signal

Audio output signal

(AUDIO OUTPUT 1-4)

Speaker system

Rated voltage

Input current

Rated frequency

Power consumption

Power consumption (standby)

Heat dissipation

Operating temperature

Storage temperature

Cabinet

I/R carrier frequency

Dimensions (approx.)

Weight (approx.)

Replacement parts

Projector

DT-100

NTSC3.58/NTSC4.43/PAL/PAL-M/PAL-N/PAL-60/SECAM/DTV480I/DTV480P/

DTV540P/DTV576I/DTV576P/DTV720P/DTV1035I/DTV1080I/DTV1080I-50

Single Chip Digital Micromirror Device

Panel size:

No. of dots:

1–1.15 zoom lens, F2.4–2.6, f = 19.0–21.9 mm

×

"

, 1chipDMD

0.53

409,920 dots (854 [H] 480 [V])

TM

(DMDTM) by Texas Instruments

×

275 W DC lamp

15-pin mini D-sub connector

Y: 1.0 Vp-p, sync negative, 75 terminated

P

: 0.7 Vp-p, 75 terminated

B

P

: 0.7 Vp-p, 75 terminated

R

Ω

Ω

Ω

520 TV lines (DTV720P)

15-pin mini D-sub connector

RGB separate/sync on green type analog input: 0–0.7 Vp-p , positive, 75 terminated

Ω

HORIZONTAL SYNC. SIGNAL: TTL level (positive/negative)

VERTICAL SYNC. SIGNAL: Same as above

4-pin mini DIN connector

Y (luminance signal): 1.0 Vp-p, sync negative, 75 terminated

C (chrominance signal): Burst 0.286 Vp-p, 75 terminated

RCA connector: VIDEO, composite video, 1.0 Vp-p, sync negative, 75

Ω

Ω

Ω

terminated

45–85 Hz

15–70 kHz

12–108 MHz

9-pin mini DIN connector

ø3.5 mm minijack or RCA terminal: 0.5 Vrms, more than 22 k (stereo)

ø3.5 mm minijack: 0.5 Vrms, less than 2.2 k

4 cm 2.85 cm oval 1

××

Ω

Ω

AC 100–240 V

3.6 A

50/60 Hz

350 W (Lamp Setting “Bright”)/

305 W (Lamp Setting “Eco + Quiet”)

with AC 100 V

330 W (Lamp Setting “Bright”)/

285 W (Lamp Setting “Eco + Quiet”)

with AC 240 V

4 W (AC 100 V) – 5 W (AC 240 V)

1,315 BTU/hour (Lamp Setting “Bright”)/

1,145 BTU/hour (Lamp Setting “Eco + Quiet”) with AC 100 V

1,240 BTU/hour (Lamp Setting “Bright”)/

1,070 BTU/hour (Lamp Setting “Eco + Quiet”) with AC 240 V

41°F to 95°F (+5°C to +35°C)

–4°F to 140°F (–20°C to +60°C)

Plastic

38 kHz

13

12

12

×

/32" 4 19/64" 11 1/32" (315 (W) 109 (H) 280 (D) mm) (main body only)

13

/32" 4 47/64" 11 37/64" (315 (W) 120 (H) 294 (D) mm) (including adjust-

×

×

×

×

×

×

×

ment foot and projecting parts)

8.6 lbs. (3.9 kg)

Remote control, Power cord for U.S. and Canada,

3 RCA to 15-pin D-sub adaptor, Operation manual

As a part of policy of continuous improvement, SHARP reserves the right to make design and

specification changes for product improvement without prior notice. The performance specification figures indicated are nominal values of production units. There may be some deviations from

these values in individual units.

3

Page 4

DT-100

2

2

IMPORTANT SERVICE SAFETY NOTES (for USA)

Ë Service work should be performed only by qualified service technicians who are

thoroughly familiar with all safety checks and servicing guidelines as follows:

WARNING

1. For continued safety, no modification of any circuit

should be attempted.

2. Disconnect AC power before servicing.

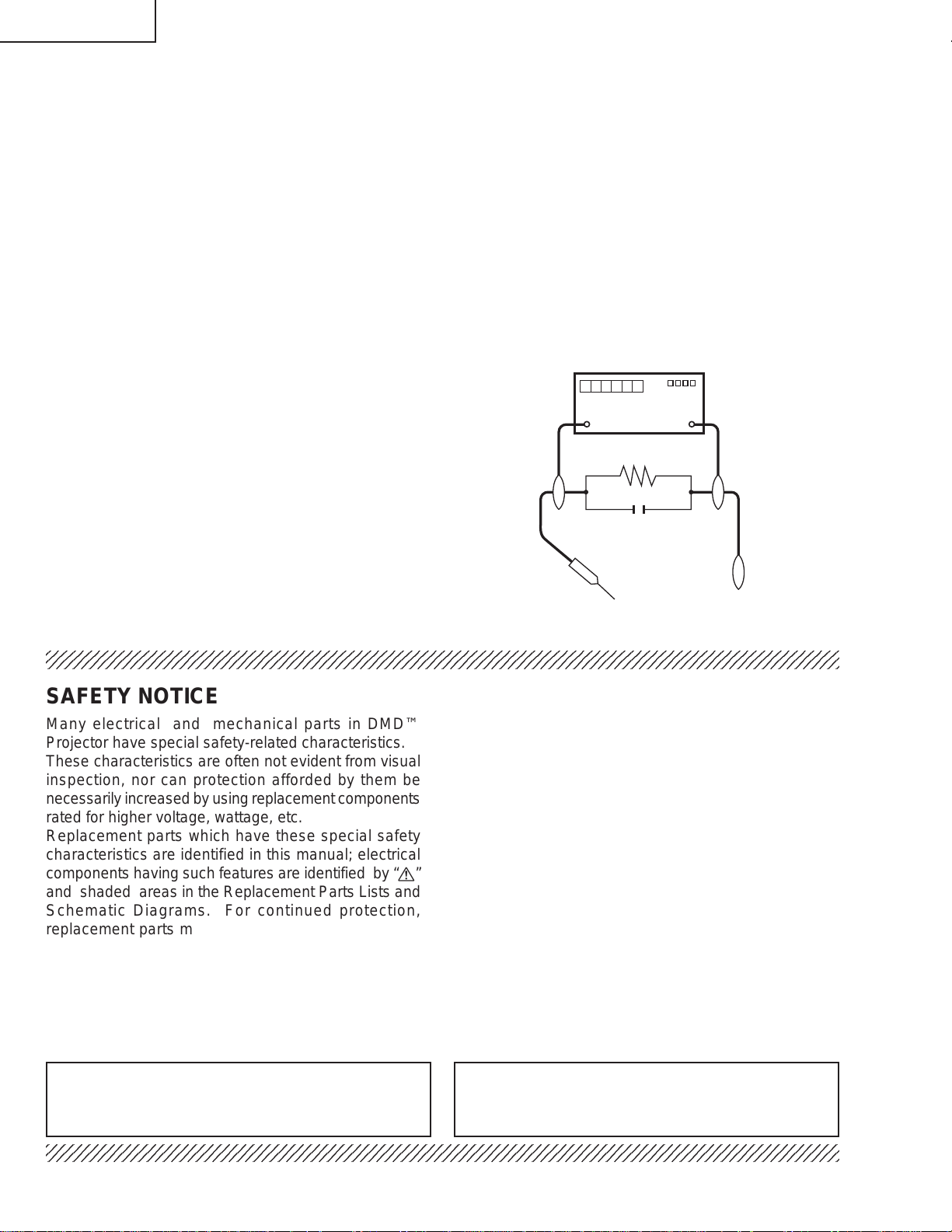

» Use an AC voltmeter with sensitivity of 5000 ohm per

volt., or higher, sensitivity to measure the AC voltage

drop across the resistor (See Diagram).

» All checks must be repeated with the AC plug

connection reversed. (If necessary, a non-polarized

adapter plug must be used only for the purpose of

BEFORE RETURNING THE PROJECTOR:

(Fire & Shock Hazard)

Before returning the projector to the user, perform

the following safety checks:

1. Inspect lead wires are not pinched between the chassis

completing these checks.)

Any reading of 0.3 volts RMS (this corresponds to 0.2

milliamp. AC.) or more is excessive and indicates a

potential shock hazard which must be corrected before

returning the unit to the owner.

and other metal parts of the projector.

2. Inspect all protective devices such as non-metallic

control knobs, insulating materials, cabinet backs,

DVM

AC SCALE

adjustment and compartment covers or shields,

isolation resistor-capacity networks, mechanical

insulators, etc.

1.5k ohm

10W

3. To be sure that no shock hazard exists, check for

current leakage in the following manner:

» Plug the AC cord directly into a 120-volt AC outlet, (Do

not use an isolation transformer for this test).

0.15 µF

TEST PROBE

» Using two clip leads, connect a 1.5k ohm, 10 watt

resistor paralleled by a 0.15µF capacitor in parallel

between all exposed metal cabinet parts and earth

ground.

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

TO EXPOSED

METAL PARTS

CONNECT TO

KNOWN EARTH

GROUND

SAFETY NOTICE

Many electrical and mechanical parts in DMD™

Projector have special safety-related characteristics.

These characteristics are often not evident from visual

inspection, nor can protection afforded by them be

necessarily increased by using replacement components

rated for higher voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this manual; electrical

components having such features are identified by “å”

and shaded areas in the Replacement Parts Lists and

Schematic Diagrams. For continued protection,

replacement parts must be identical to those used in

the original circuit. The use of a substitute replacement

parts which do not have the same safety characteristics

as the factory recommended replacement parts shown

in this service manual, may create shock, fire or other

hazards.

AVIS POUR LA SECURITE

De nombreuses pièces, électriques et mécaniques, dans

les projecteur à DMD™ présentent des caractéristiques

spéciales relatives à la sécurité, qui ne sont souvent pas

évidentes à vue.

Le degré de protection ne peut pas être nécessairement

augmentée en utilisant des pièces de remplacement

étalonnées pour haute tension, puissance, etc.

Les pièces de remplacement qui présentent ces

caractéristiques sont identifiées dans ce manuel;

les pièces électriques qui présentent ces particularités

sont identifiées par la marque “å” et hachurées dans la

liste des pièces de remplacement et les diagrammes

schématiques. Pour assurer la protection, ces pièces

doivent être identiques à celles utilisées dans le circuit

d’origine. L’utilisation de pièces qui n’ont pas les mêmes

caractéristiques que les pièces recommandées par l’usine,

indiquées dans ce manuel, peut provoquer des

électrocutions, incendies ou autres accidents.

WARNING: The bimetallic component has the primary

conductive side exposed. Be very careful in

handling this component when the power is on.

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

AVERTISSEMENT:La composante bimétallique dispose du

conducteur primaire dénudé. Faire attention

lors de la manipulation de cette

composante sous tension.

4

Page 5

DT-100

PRECAUTIONS A PRENDRE LORS DE LA REPARATION

Ë

Ne peut effectuer la réparation qu' un technicien spécialisé qui s'est parfaitement

accoutumé à toute vérification de sécurité et aux conseils suivants.

AVERTISSEMENT

1. N'entreprendre aucune modification de tout circuit.

C'est dangereux.

2. Débrancher le récepteur avant toute réparation.

VERIFICATIONS CONTRE L'INCEN-DIE ET

LE CHOC ELECTRIQUE

Avant de rendre le récepteur à l'utilisateur, effectuer

les vérifications suivantes.

1. Inspecter tous les faisceaux de câbles pour s'assurer

que les fils ne soient pas pincés ou qu'un outil ne soit

pas placé entre le châssis et les autres pièces

métalliques du récepteur.

2. Inspecter tous les dispositifs de protection comme les

boutons de commande non-métalliques, les isolants, le

dos du coffret, les couvercles ou blindages de réglage

et de compartiment, les réseaux de résistance-capacité,

les isolateurs mécaniques, etc.

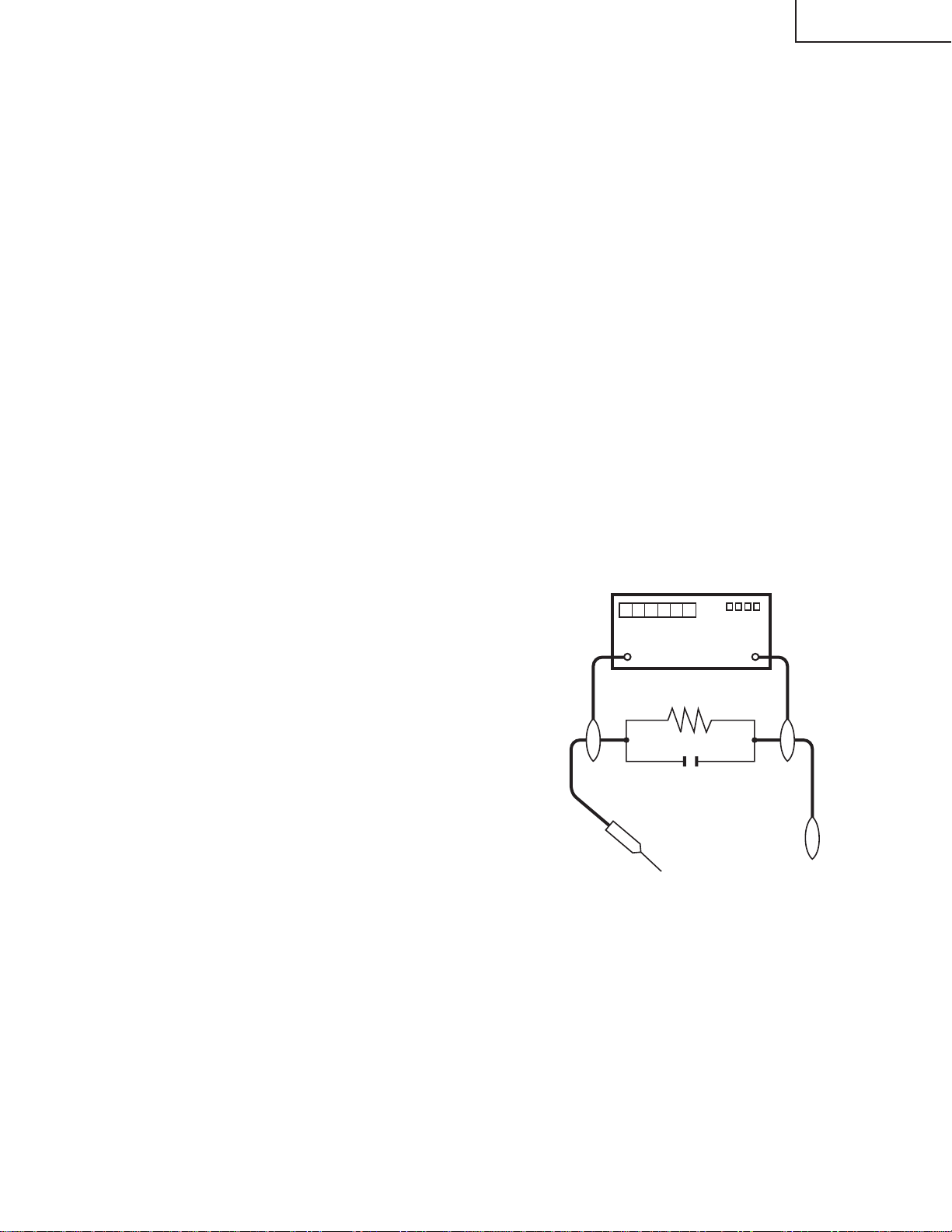

3. S'assurer qu'il n'y ait pas de danger d'électrocution en

vérifiant la fuite de courant, de la facon suivante:

• Brancher le cordon d'alimentation directem-ent à une

prise de courant de 110-240V. (Ne pas utiliser de

transformateur d'isolation pour cet essai).

• A l'aide de deux fils à pinces, brancher une résistance

de 1.5 kΩ 10 watts en parallèle avec un condensateur

de 0.15µF en série avec toutes les pièces métalliques

exposées du coffret et une terre connue comme une

conduite électrique ou une prise de terre branchée à la

terre.

• Utiliser un voltmètre CA d'une sensibilité d'au moins

5000Ω/V pour mesurer la chute de tension en travers

de la résistance.

• Toucher avec la sonde d'essai les pièces métalliques

exposées qui présentent une voie de retour au châssis

(antenne, coffret métallique, tête des vis, arbres de

commande et des boutons, écusson, etc.) et mesurer la

chute de tension CA en-travers de la résistance. T outes

les vérifications doivent être refaites après avoir inversé

la fiche du cordon d'alimentation. (Si nécessaire, une

prise d'adpatation non polarisée peut être utilisée dans

le but de terminer ces vérifications.)

Tous les courants mesurés ne doivent pas dépasser 0.5

mA.

Dans le cas contraire, il y a une possibilité de choc

électrique qui doit être supprimée avant de rendre le

récepteur au client.

DVM

ECHELLE CA

1.5k ohm

10W

5

AUX PIECES

METALLIQUES

EXPOSEES

0.15 µF

SONDE D'ESSAI

BRANCHER A UNE

TERRE CONNUE

Page 6

DT-100

NO TE TO SER VICE

PERSONNEL

UV-RADIATION PRECAUTION

The light source, UHP lamp, in the LCD projector

emits small amounts of UV-Radiation.

AVOID DIRECT EYE AND SKIN EXPOSURE.

To ensure safety please adhere to the following:

1. Be sure to wear sun-glasses when servicing the

projector with the lamp

turned “on” and the top

enclosure removed.

2. Do not operate the lamp outside of the lamp housing.

NOTE POUR LE PERSONNEL

D’ENTRETIEN

PRECAUTION POUR LES RADIATIONS UV

La source de lumière, la lampe UHP, dans le projecteur

LCD émet de petites quantités de radiation UV.

EVITEZ TOUTE EXPOSITION DIRECTE DES

YEUX ET DE LA PEAU.

Pour votre sécurité, nous vous prions de respecter

les points suivants:

1. T oujours porter des lunettes de soleil lors d’un entretien

du projecteur

avec la lampe allumée

et le haut du coffret retiré.

2. Ne pas faire fonctionner la lampe à l’extérieur du boîtier

de lampe.

3. Do not operate for more than 2 hours with the enclosure

removed.

UV-Radiation and Medium Pressure

Lamp Precautions

1. Be sure to disconnect the AC plug when replacing the

lamp.

2. Allow one hour for the unit to cool down before

servicing.

3. Replace only with same type lamp. Type AN-100LP

rated 275W DC.

4. The lamp emits small amounts of UV -Radiation, av oid

direct-eye contact.

5. The medium pressure lamp involves a risk of explosion.

Be sure to follow installation instructions described

below and handle the lamp with care.

3. Ne pas faire fonctionner plus de 2 heures av ec le coffret

retiré.

Précautions pour les radiations UV

et la lampe moyenne pression

1. Toujours débrancher la fiche AC lors du remplacement

de la lampe.

2. Laisser l’unité refroidir pendant une heure avant de

procéder à l’entretien.

3. Ne remplacer qu’avec une lampe du même type. Type

AN-100LP, caractéristique 275 W-DC.

4. La lampe émet de petites quantités de radiation UVéviter tout contact direct avec les yeux.

5. La lampe moyenne pression implique un risque

d’explosion. Toujours suivre les instructions

d’installation décrites ci-dessous et manipuler la lampe

avec soin.

6

Page 7

DT-100

6

6

6

6

2345678901234567890123456789012123456789012345

UV-RADIATION PRECAUTION (Continued)

2345678901234567890123456789012123456789012345

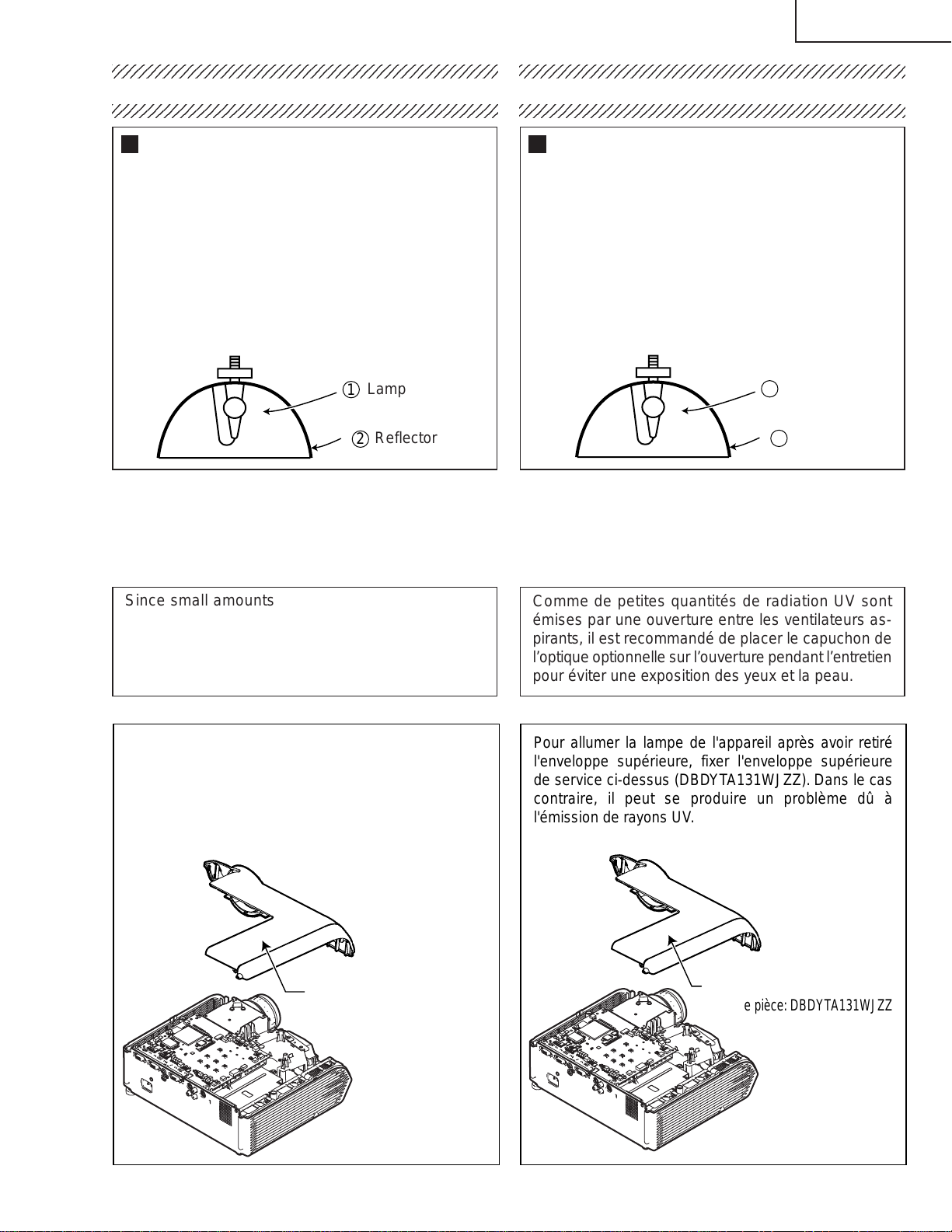

Lamp Replacement

Note:

Since the lamp reaches a very high temperature during

units operation replacement of the lamp should be

done at least one hour after the power has been turned

off. (to allow the lamp to cool off.)

Installing the new lamp, make sure not to touch the

lamp (bulb) replace the lamp by holding its reflector

2.

[Use original replacement only.]

Lamp

1

Reflector

2

DANGER ! –– Never turn the power on without the

lamp to avoid electric-shock or damage of the de vices

since the stabilizer generates high voltages at its start.

2345678901234567890123456789012123456789012345

PRECAUTION POUR LES RADIATIONS UV (Suite)

2345678901234567890123456789012123456789012345

Remplacement de la lampe

Remarque:

Comme la lampe devient très chaude pendant le

fonctionnement de l’unité, son remplacement ne doit

être effectué au moins une heure après avoir coupé

l’alimentation (pour permettre à la lampe de refroidir).

En installant la nouvelle lampe, s’assurer de ne pas

toucher la lampe (ampoule). Remplacer la lampe en

tenant son réflecteur 2.

[N’utiliser qu’un remplacement d’origine.]

1

Lampe

2

Reflecteur

DANGER ! –– Ne jamais mettre sous tension sans la

lampe pour éviter un choc électrique ou des

dommages des appareils car le stabilisateur génère

de hautes tensions à sa mise en route.

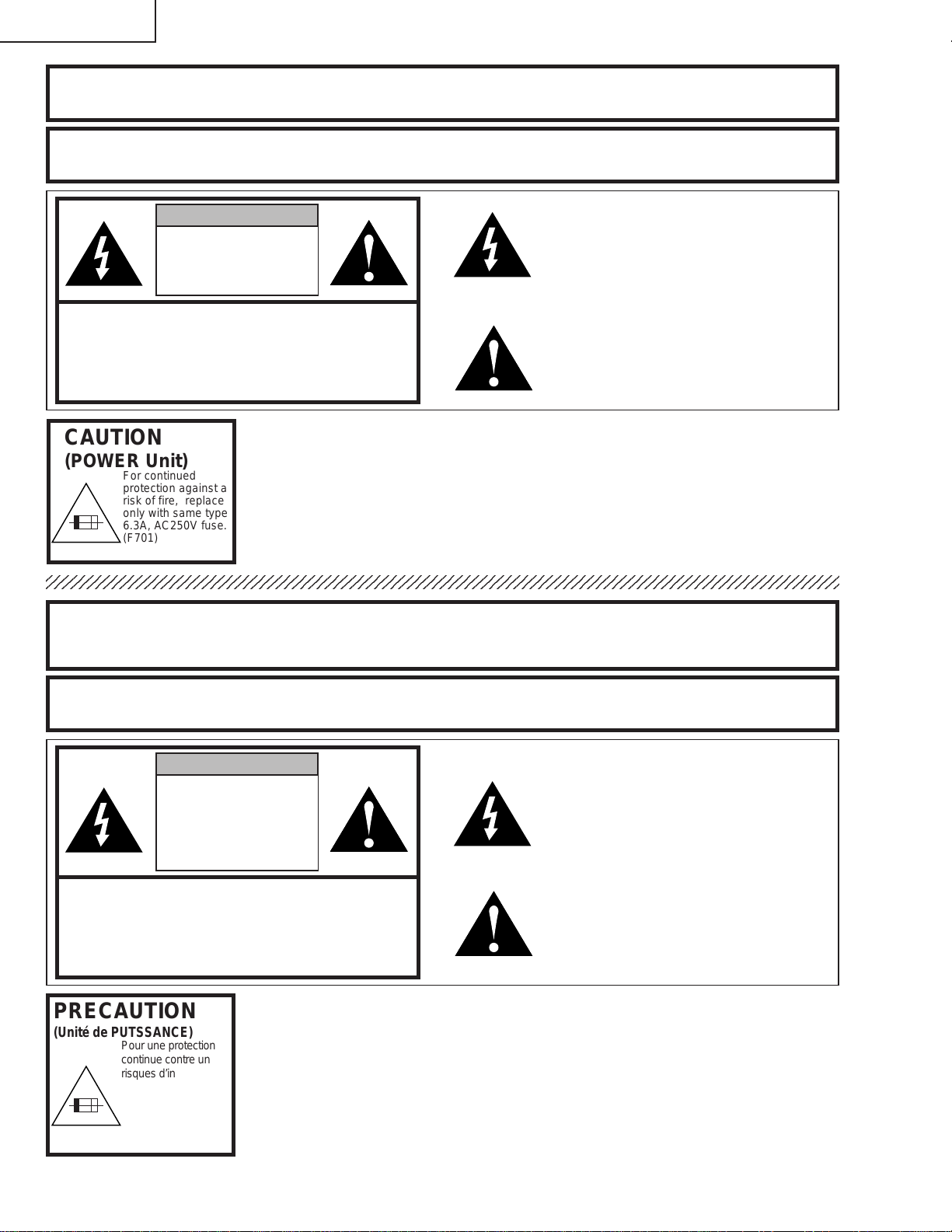

Since small amounts of UV-radiation are emitted

from an opening between the exhaust fans , it is recommended to place the cap of the optional lens on

the opening during servicing to avoid eye and skin

exposure.

To illuminate the lamp in the unit with Top Body

removed, attach the above Service Top Body

(DBDYTA131WJZZ). If not, problems may be caused

by UV light emitted from the lamp.

Top Body

Part code:DBDYTA131WJZZ

Comme de petites quantités de radiation UV sont

émises par une ouverture entre les ventilateurs aspirants, il est recommandé de placer le capuchon de

l’optique optionnelle sur l’ouverture pendant l’entretien

pour éviter une exposition des yeux et la peau.

Pour allumer la lampe de l'appareil après avoir retiré

l'enveloppe supérieure, fixer l'enveloppe supérieure

de service ci-dessus (DBDYTA131WJZZ). Dans le cas

contraire, il peut se produire un problème dû à

l'émission de rayons UV.

Enveloppe supérieur

Code de pièce:DBDYTA131WJZZ

7

Page 8

DT-100

WARNING: High brightness light source, do not stare into the beam of light, or view directly. Be especially

careful that children do not stare directly in to the beam of light.

WARNING: TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK, DO NOT EXPOSE THIS UNIT TO

MOISTURE OR WET LOCATIONS.

CAUTION

RISK OF ELECTRIC SHOCK.

DO NOT REMOVE SCREWS

EXCEPT SPECIFIED USER

SERVICE SCREW.

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK,

DO NOT REMO VE CABINET.

NO USER-SERVICEABLE PARTS EXCEPT LAMP UNIT.

REFER SERVICING T O Q U ALIFIED SER VICE

PERSONNEL.

The lighting flash with arrowhead within a

triangle is intended to tell the user that

parts inside the product are risk of electric

shock to persons.

The exclamation point within a triangle is

intended to tell the user that important

operating and servicing instructions are in

the manual with the projector.

CAUTION

(POWER Unit)

6.3A 250V

AVERTISSEMENT: Source lumineuse de grande intensité. Ne pas fix er le faisceau lumineux ou le regarder

For continued

protection against a

risk of fire, replace

only with same type

6.3A, AC250V fuse.

(F701)

directement. Veiller particulièrement à éviter que les enfants ne fixent directement le

faisceau lumineux.

AVER TISSEMENT : AFIN D’EVITER TOUT RISQUE D’INCENDIE OU D’ELECTROCUTION, NE P AS PLA CER

CET APPAREIL DANS UN ENDROIT HUMIDE OU MOUILLE.

ATTENTION

RISQUE

D’ÉLECTROCUTION. NE

PASR ETIRER LES VIS Á

L’EXCEPTION DE LA VIS DE

REPARATION UTILISATEUR

SPECIFIEES

L’éclair ter miné d’une flèche à l’intérieur

d’un triangle indique à l’utilisateur que les

pi‘eces se trouvant dans l’appareil sont

susceptibles de provoquer une décharge

électrique.

Le point d’exclamation à l’intérieur d’un

ATTENTION: POUR EVITER T OUT RISQ UE

D’ELECTR OCUTION, NE PAS RETIRER LE CAPOT .

AUCUNE DES PIECES INTERIEURES N’EST REPARABLE

PAR L’UTILISATEUR, A L’EXCEPTION DE L’UNITE DE

LAMPE. POUR T OUTE REPARATION, S’ADRESSER A UN

TECHNICIEN D’ENTRETIEN QU ALIFIE.

triangle indique à l’utilisateur que les

instructions de fonctionnement et

d’entretien sont détaillées dans les

documents fournis avec le projecteur.

PRECAUTION

(Unité de PUTSSANCE)

6.3A 250V

Pour une protection

continue contre un

risques d’incendie, ne

remplacer qu’avec un

fusible 6.3A,AC250V

du même type.

(F701)

8

Page 9

DT-100

Precautions for using lead-free solder

1 Employing lead-free solder

"PWBs" of this model employs lead-free solder. The LF symbol indicates lead-free solder, and is attached on the

PWBs and service manuals. The alphabetical character following LF shows the type of lead-free solder.

Example:

L Fa

Indicates lead-free solder of tin, silver and copper.

2 Using lead-free wire solder

When fixing the PWB soldered with the lead-free solder, apply lead-free wire solder. Repairing with conventional

lead wire solder may cause damage or accident due to cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40°C, we recommend y ou

to use a dedicated soldering bit, if you are not familiar with how to obtain lead-free wire solder or soldering bit,

contact our service station or service branch in your area.

3 Soldering

As the melting point of lead-free solder (Sn-Ag-Cu) is about 220°C which is higher than the conventional lead solder

by 40°C, and as it has poor solder wettability, you may be apt to keep the soldering bit in contact with the PWB for

extended period of time. Ho we v er, since the land may be peeled off or the maximum heat-resistance temperature of

parts may be exceeded, remove the bit from the PWB as soon as you confirm the steady soldering condition.

Lead-free solder contains more tin, and the end of the soldering bit may be easily corroded. Make sure to tur n on

and off the power of the bit as required.

If a different type of solder stays on the tip of the soldering bit, it is allo yed with lead-free solder. Clean the bit after

every use of it.

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sandpaper.

Be careful when replacing parts with polarity indication on the PWB silk.

Lead-free wire solder for servicing

Part No. ★ Description Code

ZHNDAi123250E J φ0.3mm 250g(1roll) BL

ZHNDAi126500E J φ0.6mm 500g(1roll) BK

ZHNDAi12801KE J φ1.0mm 1kg(1roll) BM

9

Page 10

DT-100

Operation Manual

10

Page 11

DT-100

11

Page 12

DT-100

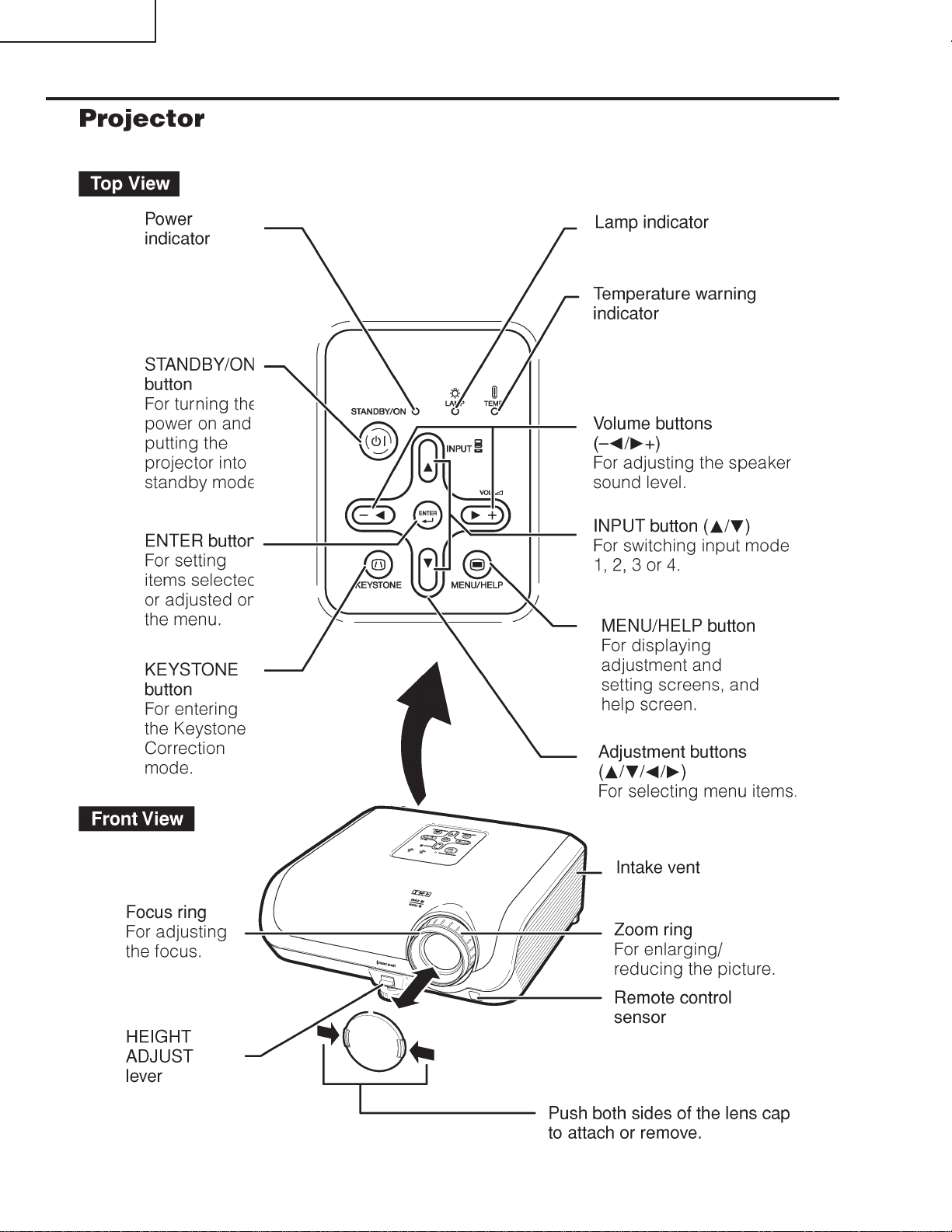

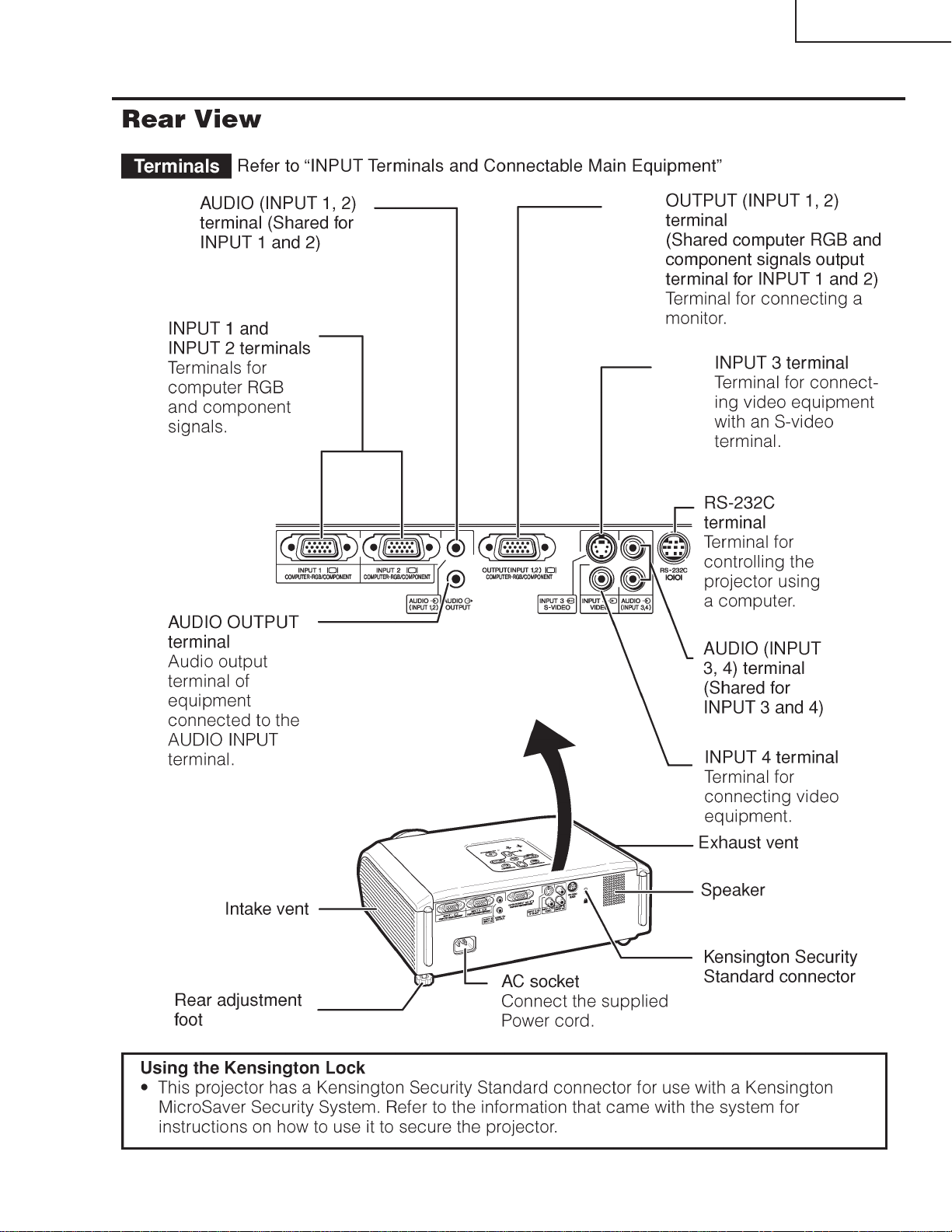

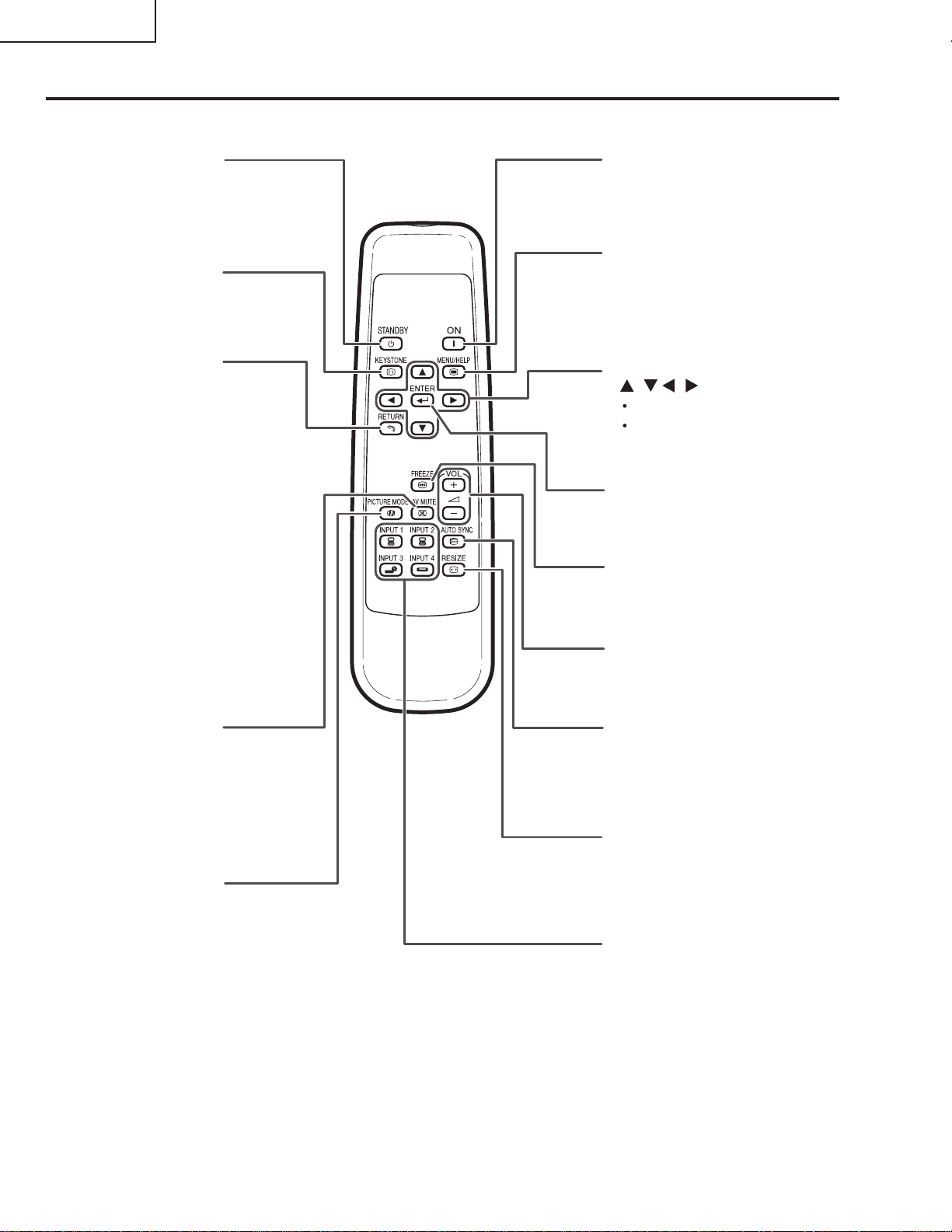

STANDBY button

For putting the

projector into the

standby mode.

KEYSTONE button

For entering the

Keystone Correction

mode.

RETURN button

For returning to the

previous menu screen

during menu operations.

ON button

For turning the power on.

MENU/HELP button

For displaying adjustment

and setting screens, and

help screen.

Adjustment buttons

(///)

For selecting menu items.

For adjusting the Keystone

Correction when in the

Keystone Correction mode.

ENTER button

For setting items selected

or adjusted on the menu.

FREEZE button

For freezing images.

AV MUTE button

For temporarily

displaying the black

screen and turning

off the sound.

PICTURE MODE

button

For selecting the

appropriate picture.

Volume buttons

For adjusting the

speaker sound level.

AUTO SYNC button

For automatically adjusting

images when connected

to a computer.

RESIZE button

For switching the screen

size (STRETCH, SIDE

BAR, CINEMA ZOOM).

INPUT 1, 2, 3 and 4

buttons

For switching to the

respective input modes.

12

Page 13

DT-100

13

Page 14

DT-100

14

Page 15

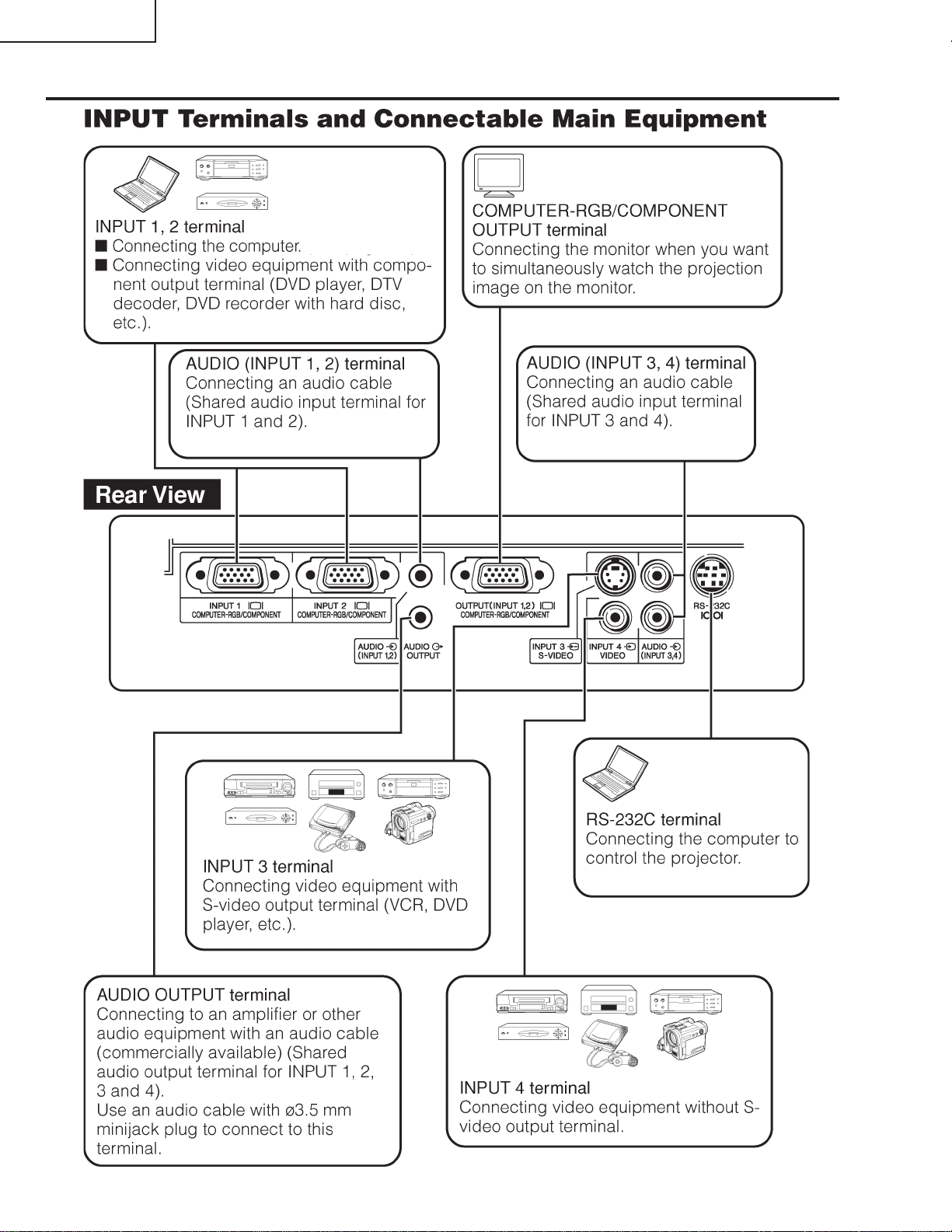

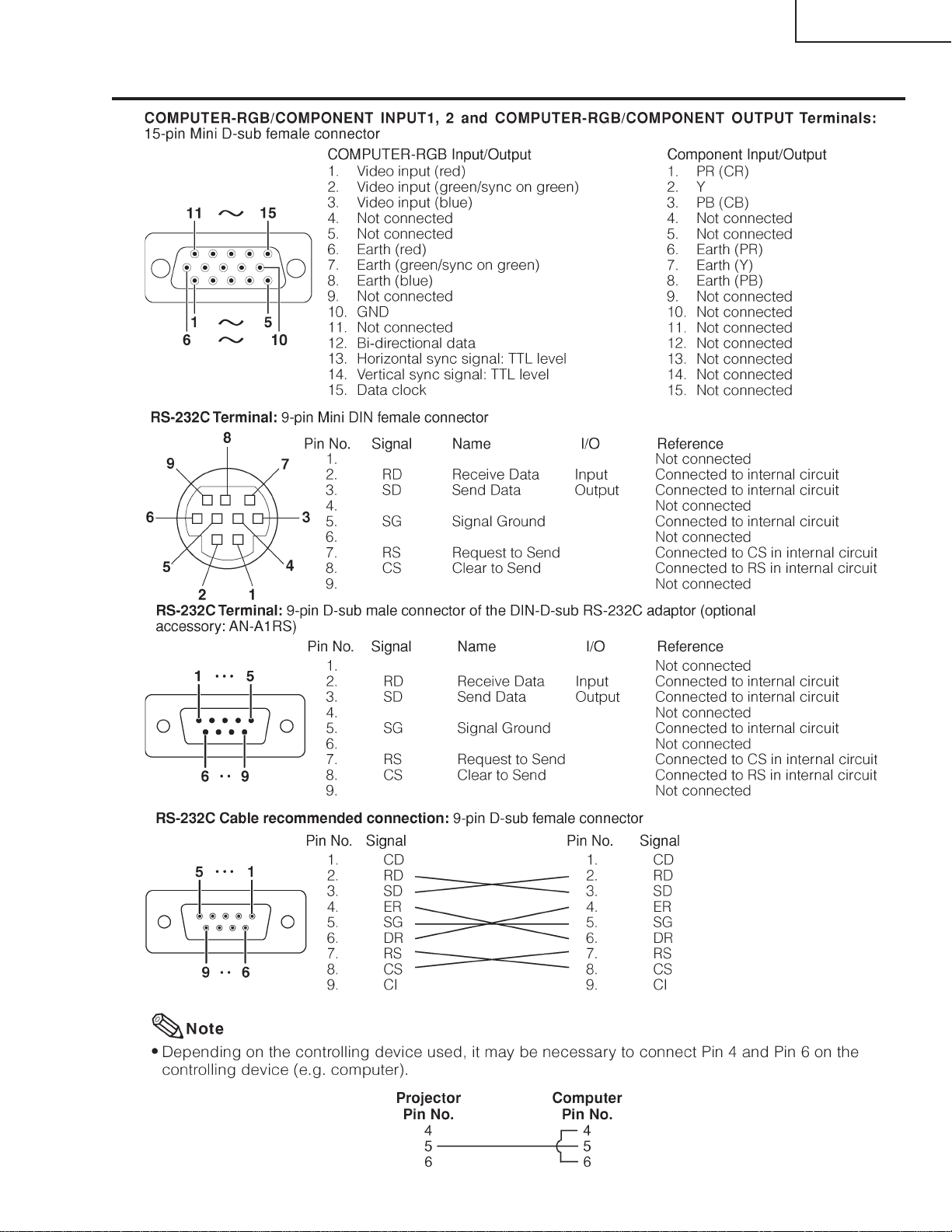

Connection Pin Assignments

DT-100

15

Page 16

DT-100

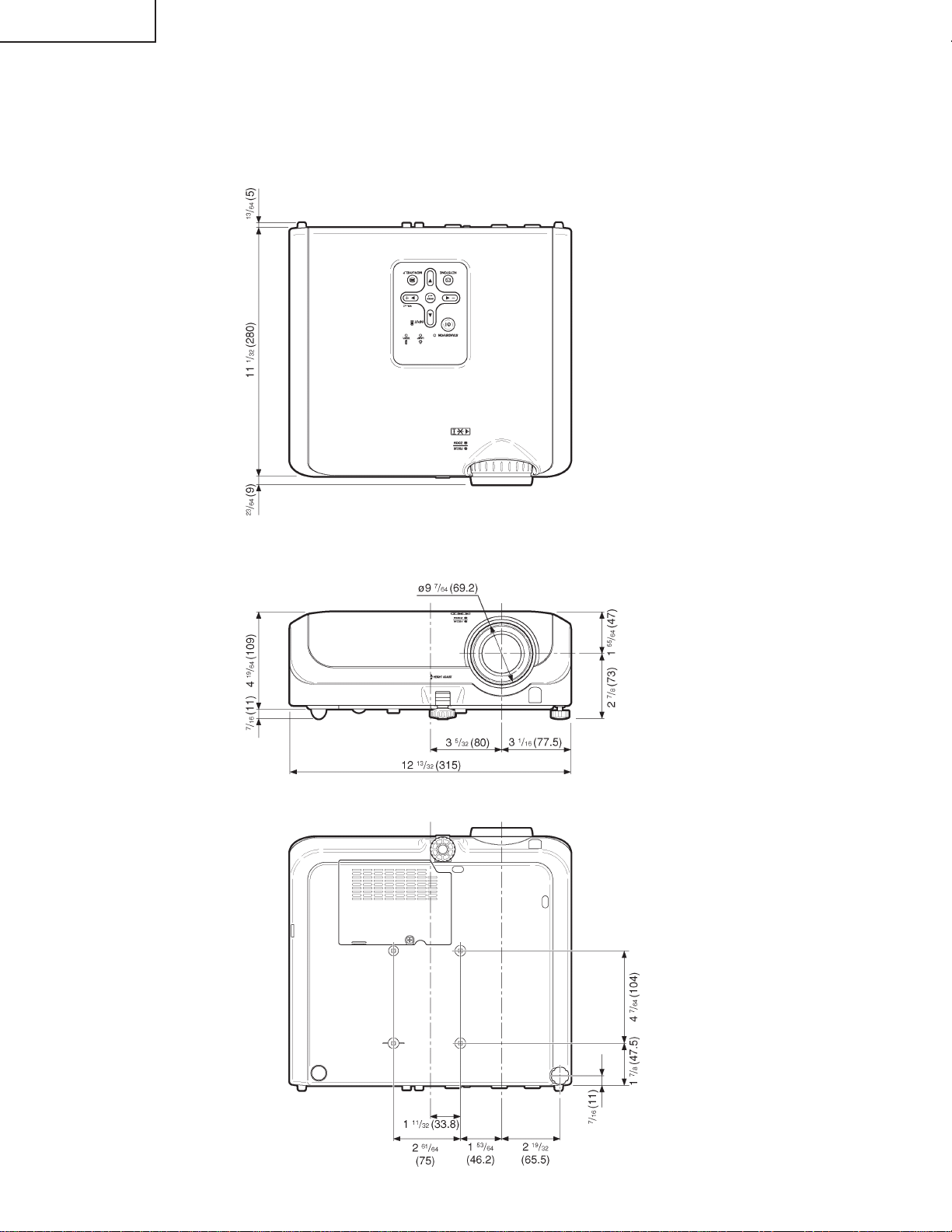

DIMENSIONS

Units: inches(mm)

16

Page 17

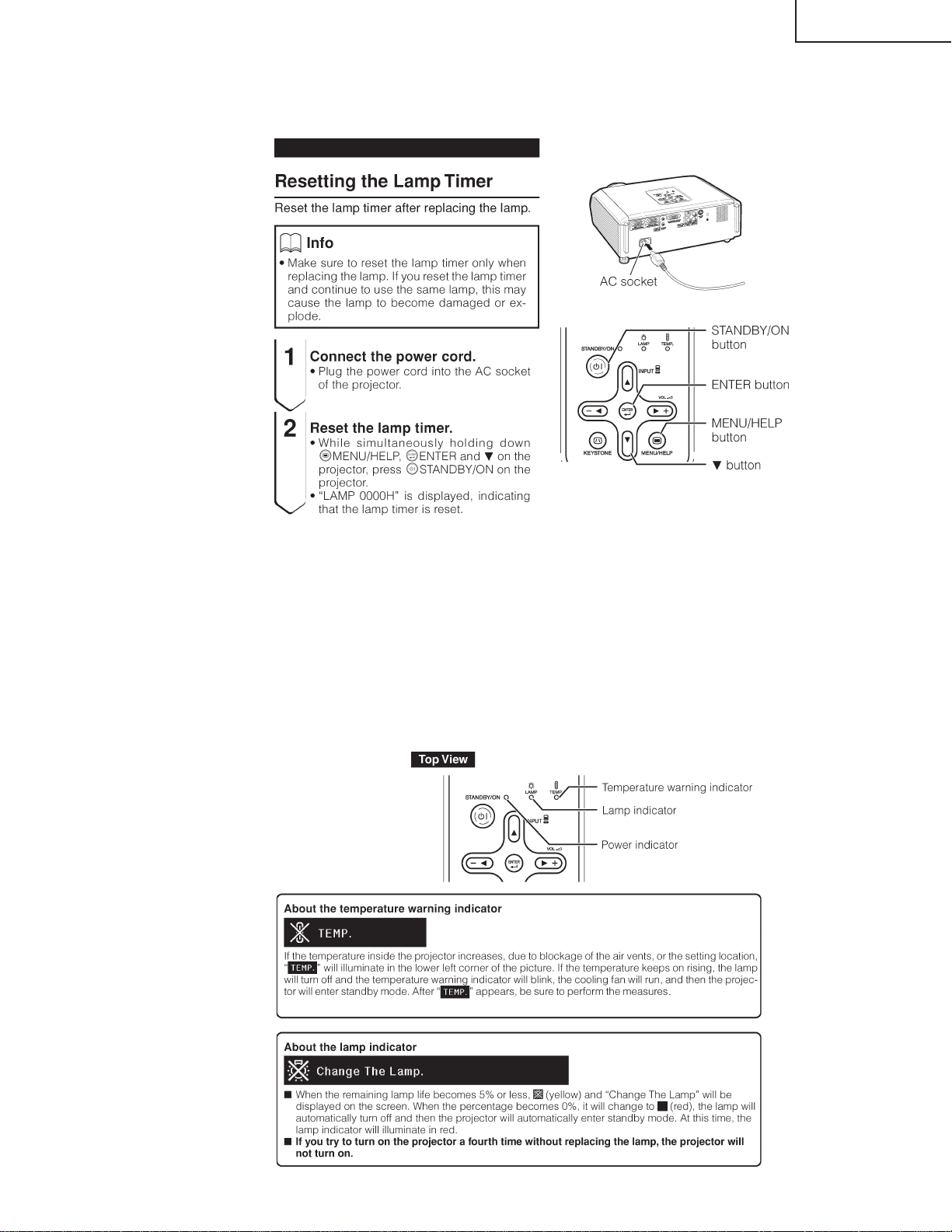

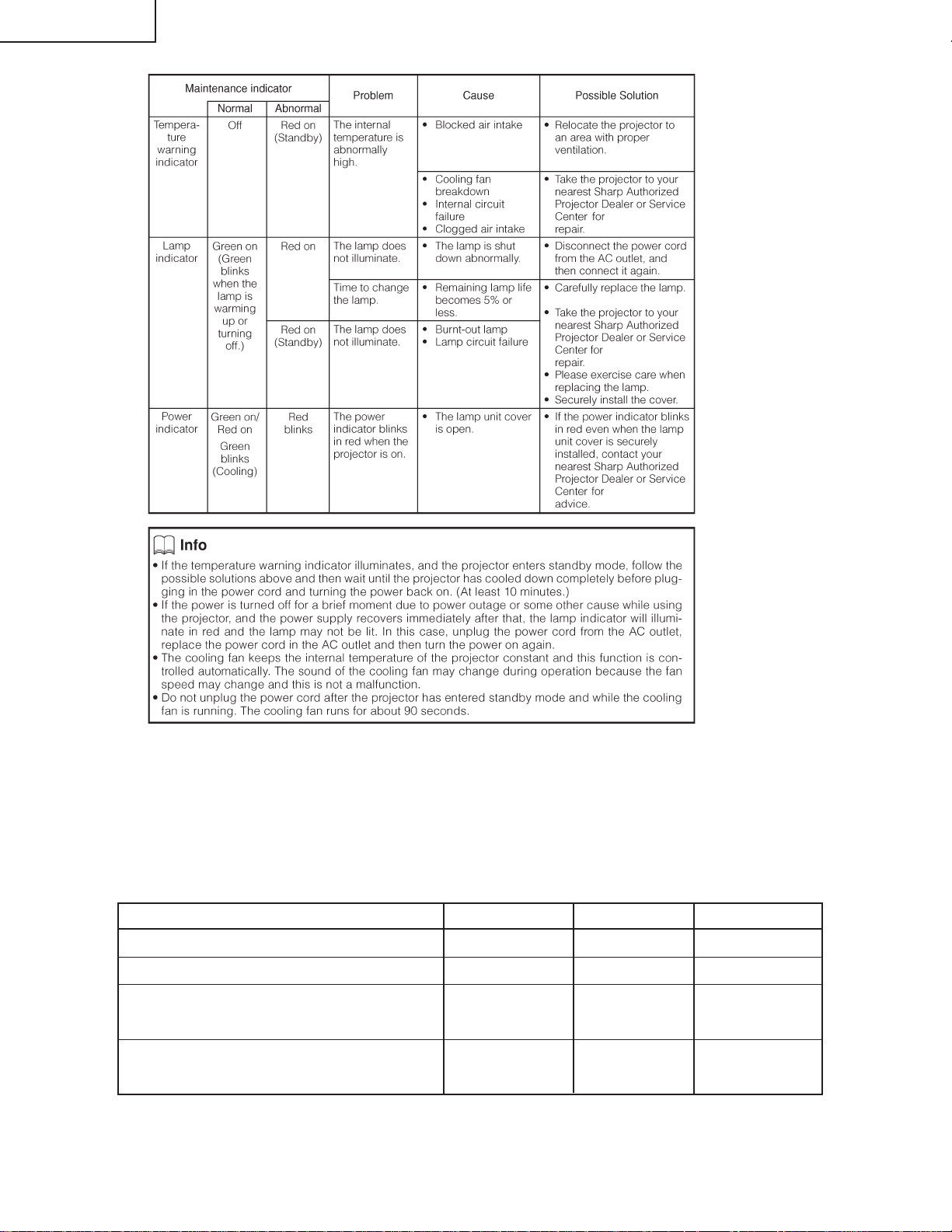

RESETTING THE T OT AL LAMP TIMER

● Resetting the total lamp timer

When replacing the lamp, reset the total lamp timer in the procedure below.

DT-100

Lamp

■ It is recommended that the lamp (sold separately) be replaced when the remaining lamp life becomes 5% or less,

or when you notice a significant deterioration in the picture and color quality. The lamp life (percentage) can be

checked with the on-screen display.

■ Purchase a replacement lamp of type AN-100LP from y our place of purchase, nearest Sharp A uthorized Projector

Dealer or Service Center.

■ The warning lights (power indicator, lamp indicator and temperature warning indicator) on the projector indicate

problems inside the projector.

■ If a problem occurs, either the temperature warning indicator or the lamp indicator will illuminate red, and the

projector will enter standby mode. After the projector has entered standby mode, follow the procedures given

below.

17

Page 18

DT-100

■Keystone correction range expansion and vertical compression adjustment function

The variable range of the keystone can be expanded to over the user adjustable range by using

the following RS-232C commands. In addition, the vertical compression can be adjusted.

Command description

Control Command Parameter Return

Disabling function BKLM _0 OKorERR

Enabling function BKLM _1 OKorERR

Keystone correction range expansion BKST **** OKorERR

(-200 - +200)

Vertical compression adjustment BKVO **** OKorERR

(-300 - +300)

18

Page 19

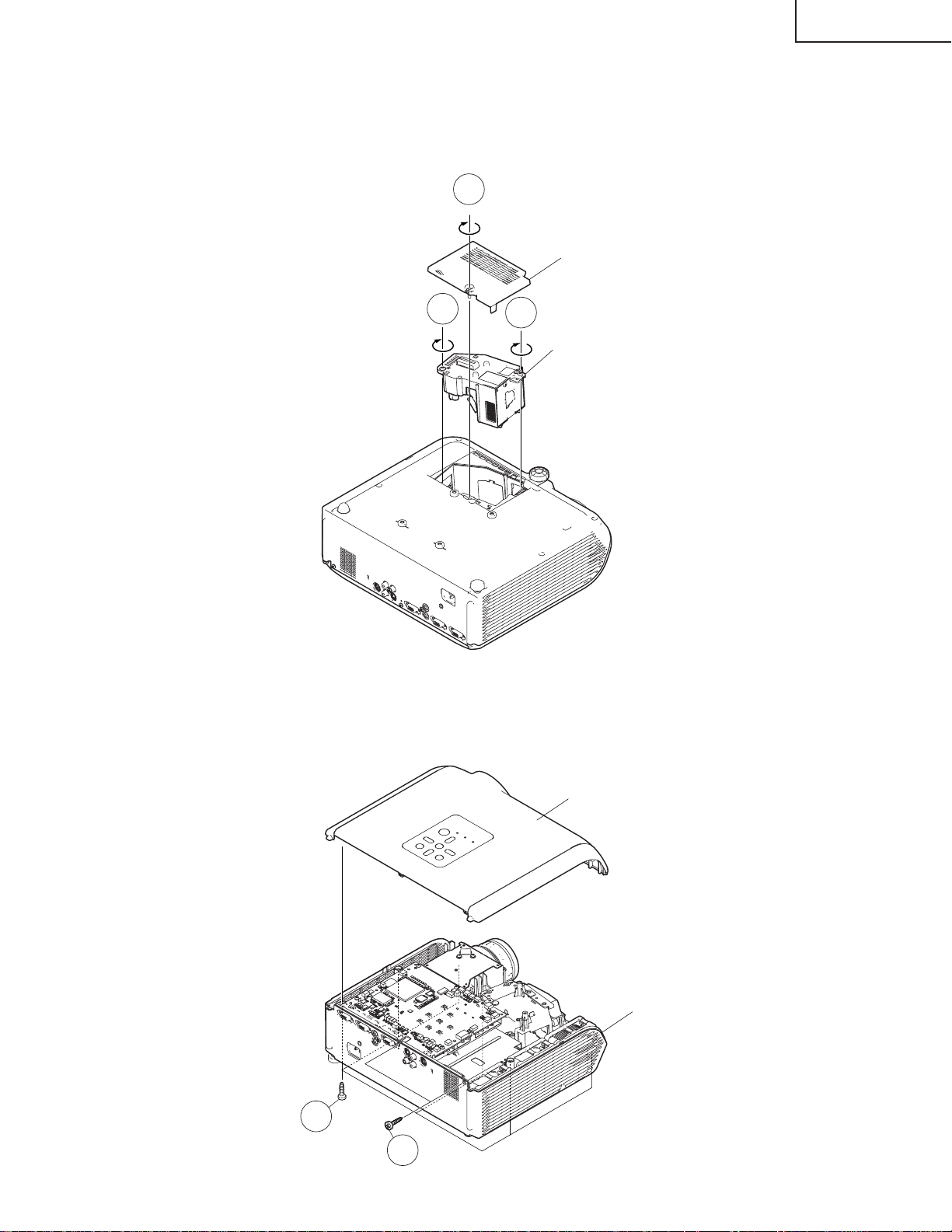

REMOVING OF MAJOR PARTS

1.Removing the lamp door and the lamp unit

1-1. Loosen the lamp door fixing screw. Lift off the lamp door.

1-2. Remove 2 lamp unit fixing screws to detach the lamp unit.

1-1

DT-100

Lamp Door

1-2

2.Removing the top body

2-1. Remove 8 top body fixing screws to detach the Top body.

1-2

Lamp Unit

2-1

Top Body

Bottom Body

2-1

19

Page 20

DT-100

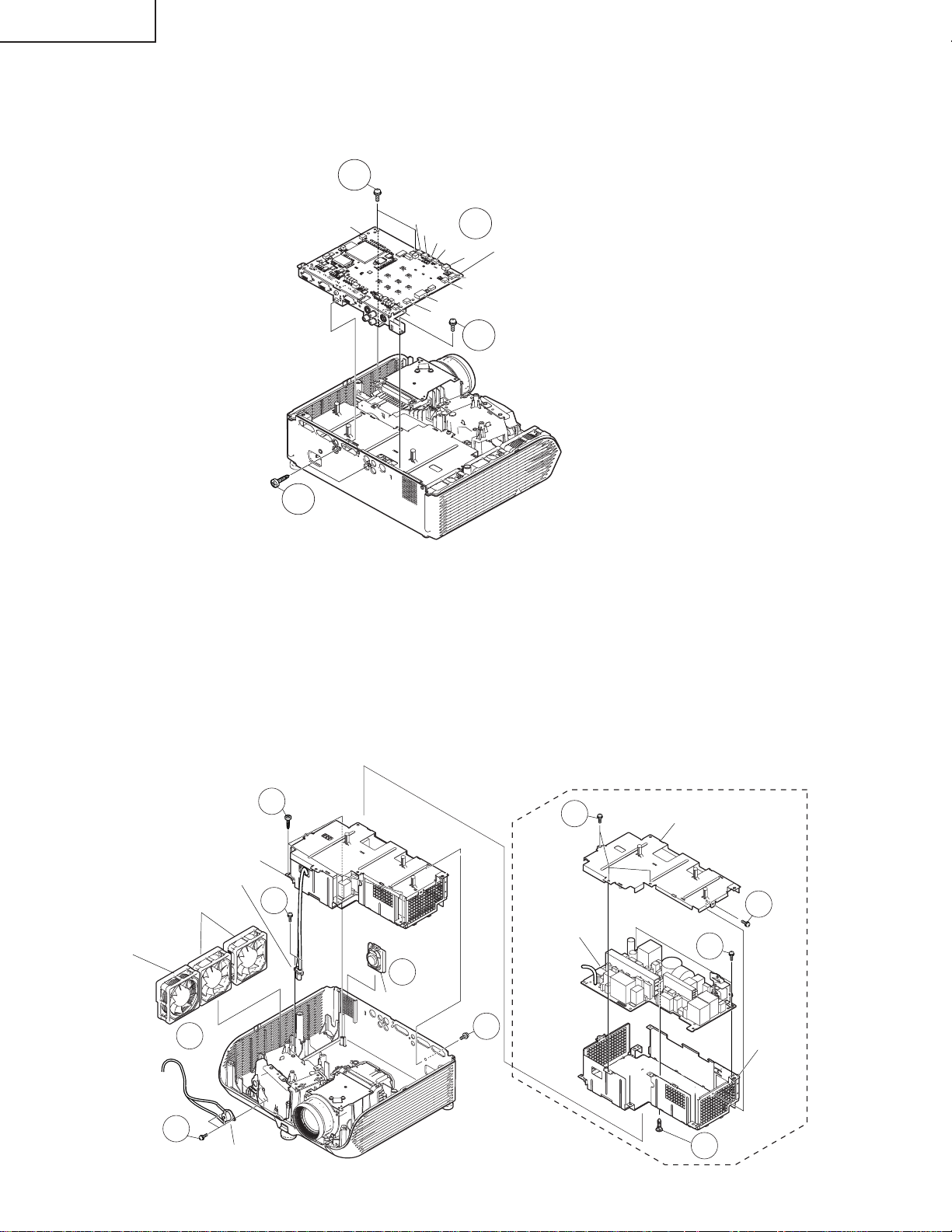

3.Removing the main PWB unit

3-1. Remove all connectors from the main PWB unit.

3-2. Remove 2 terminal fixing screws.

3-3. Remove 3 main PWB fixing screws to detach the main PWB unit.

3-3

[RC]

[CW]

[SO]

[FA]

[MO]

[FB]

[EA]

[LF]

3-1

[BB]

MAIN PWB Unit

[FD]

[FC]

3-3

3-2

4.Removing the speaker, fan, and power supply ballast unit

4-1. Remove the speaker.

4-2. Remove 2 fans for the power supply ballast unit and 1 fan for the optical mechanism unit.

4-3. Remove 2 bimetal fixing screws to detach the bimetal.

4-4. Remove 2 lamp socket fixing screws to detach the lamp socket.

4-5. Remove 1 inlet fixing screw.

4-6. Remove 4 ballast unit fixing screws to detach the power supply ballast unit.

4-7. Remove 4 ballast shield (upper) fixing screws to detach the ballast shield (upper).

4-8. Remove 2 ballast PWB fixing screws and 1 clip to detach the power supply PWB unit from the ballast shield

(lower).

POWER SUPPLY BALLAST Unit

Lamp Socket

Fans for power supply

ballast unit

Fan for

optical

mechanism

unit

4-2

4-3

Bimetal

4-6

4-4

4-1

Speaker

20

POWER SUPPLY

BALLAST PWB

Unit

4-5

4-7

Ballast shield (upper)

4-7

4-8

Ballast

shield

(lower)

4-8

Page 21

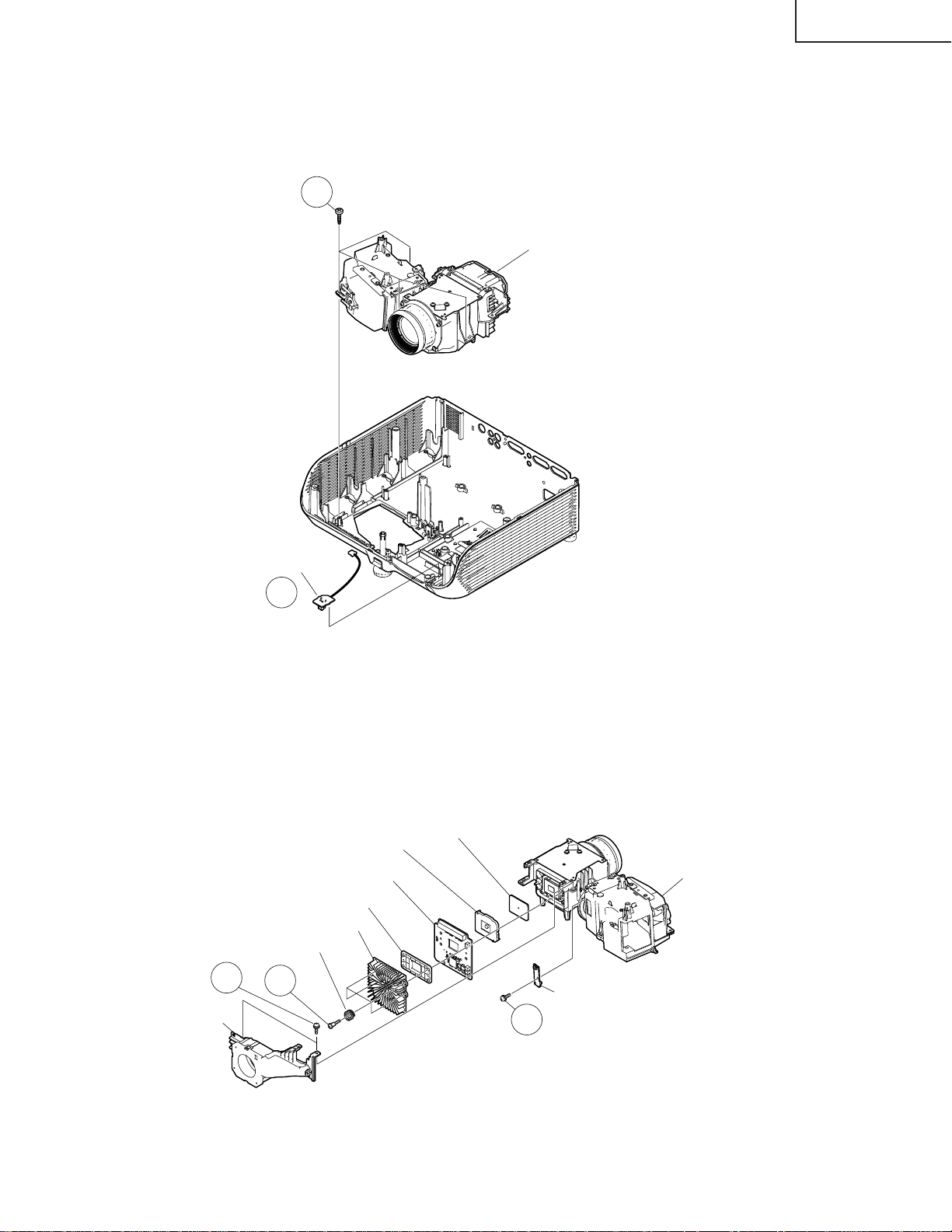

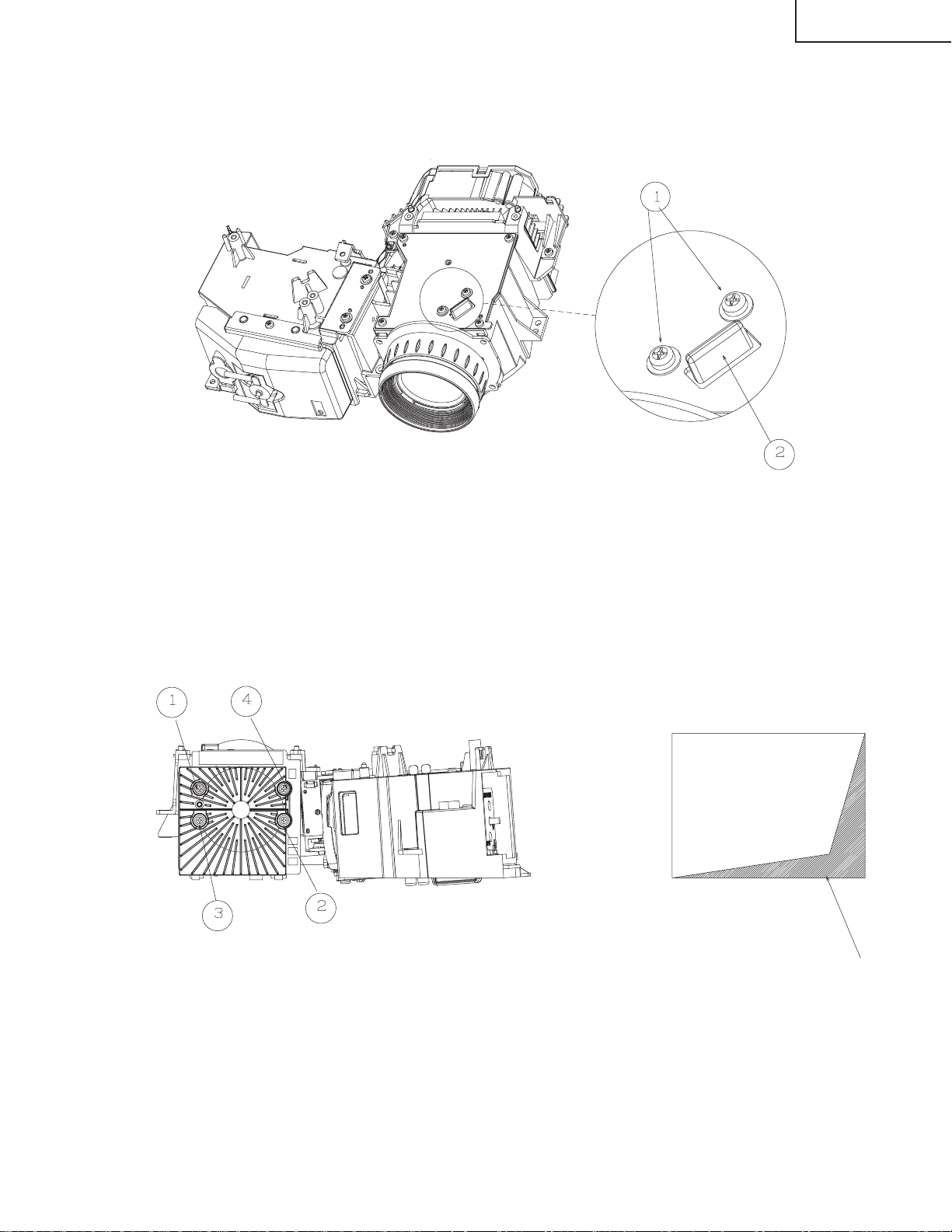

5.Removing the optical mechanism unit and RC light receiver PWB

5-1. Remove 4 optical mechanism unit fixing screws to detach the optical mechanism unit.

5-2. Remove the RC light receiver PWB unit.

5-1

Optical Mechanism Unit

DT-100

RC Light Receiver PWB

5-2

6.Removing the photosensor PWB unit, blower fan, DMD PWB, and DMD

6-1. Remove 1 photosensor PWB fixing screw to detach the photosensor PWB.

6-2. Remove 2 blower fan fixing screws to detach the blower fan.

6-3. Remove 4 DMD heatsink fixing screws to detach the DMD PWB unit and the DMD.

DMD

Optical Mechanism Unit

Photosensor PWB Unit

6-1

Blower fan

DMD spring

6-2

DMD socket

DMD PWB Unit

Backer plate

DMD heatsink

6-3

21

Page 22

DT-100

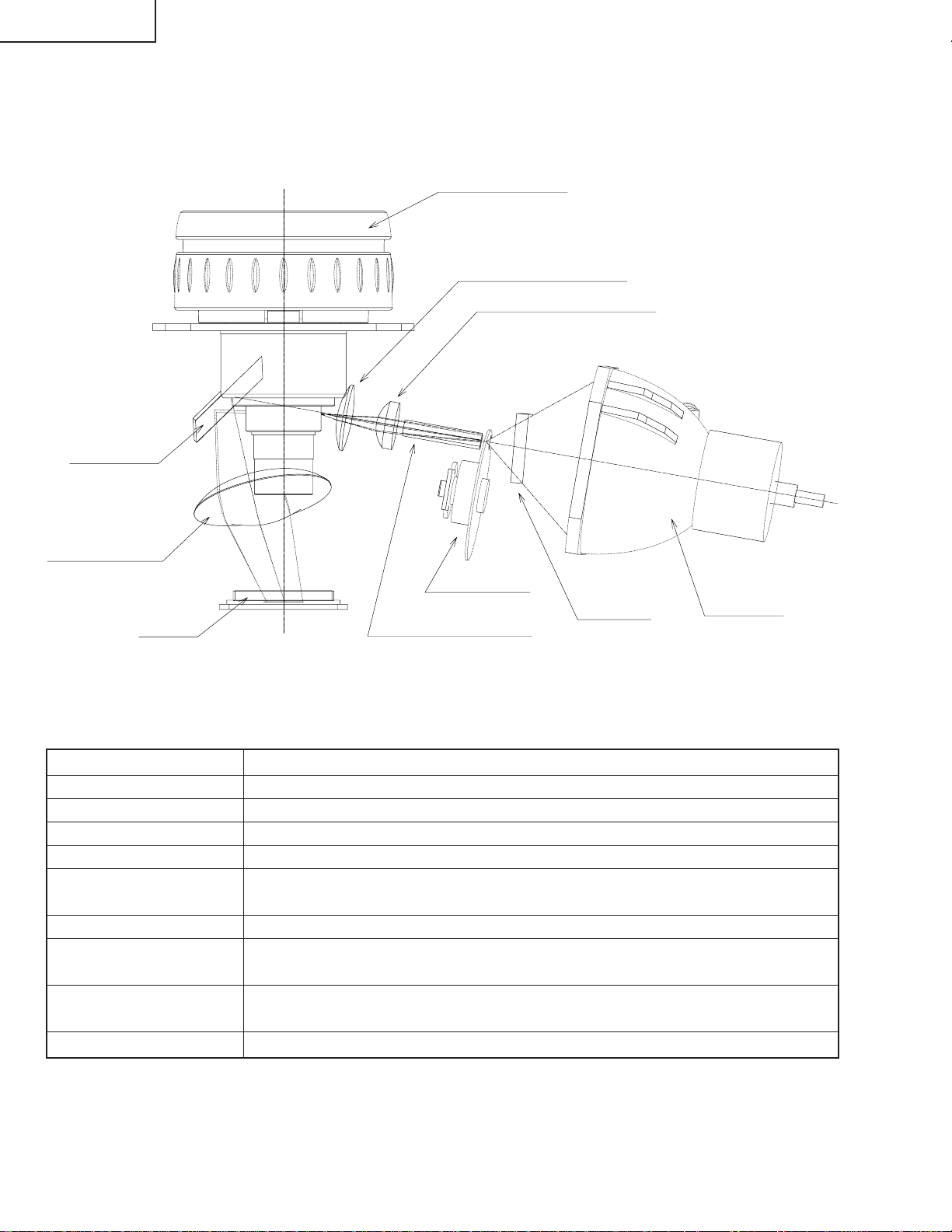

THE OPTICAL UNIT OUTLINE

Layout for proper setup of the optical components and parts (top view)

(Schematic diagram)

Projection lens

Illumination lens 2

Illumination lens 1

Reflection

mirror

Plastic Lens

Color wheel

DMD

Item Function

Lamp Light source. DC high-pressure mercury lamp.

UV/IR cut filter (UV GLASS)

Color wheel Splits light from the light source into R, G, B and W through a color filter.

Rod (ROD INTEGRATOR) Assures uniform light ray.

Illumination lens Focus light from the rod on DMD.

(ILLUMINATION LENS 1, 2)

Reflection mirror Reflects light from the illumination lenses toward DMD.

Condencer Lens Condenses the light from the reflection mirror to the DMD and the pupil of the

(PLASTIC LENS)

DMD Turns the internal micromirror ON/OFF at the rate of color component of each dot

Projection lens Enlarges light from DMD and projects it on a screen.

Filters out harmful UV and IR rays from the lamp.

projection lens.

of the input source to reflect light.

Rod Integrator

UV Glass

Lamp

22

Page 23

DT-100

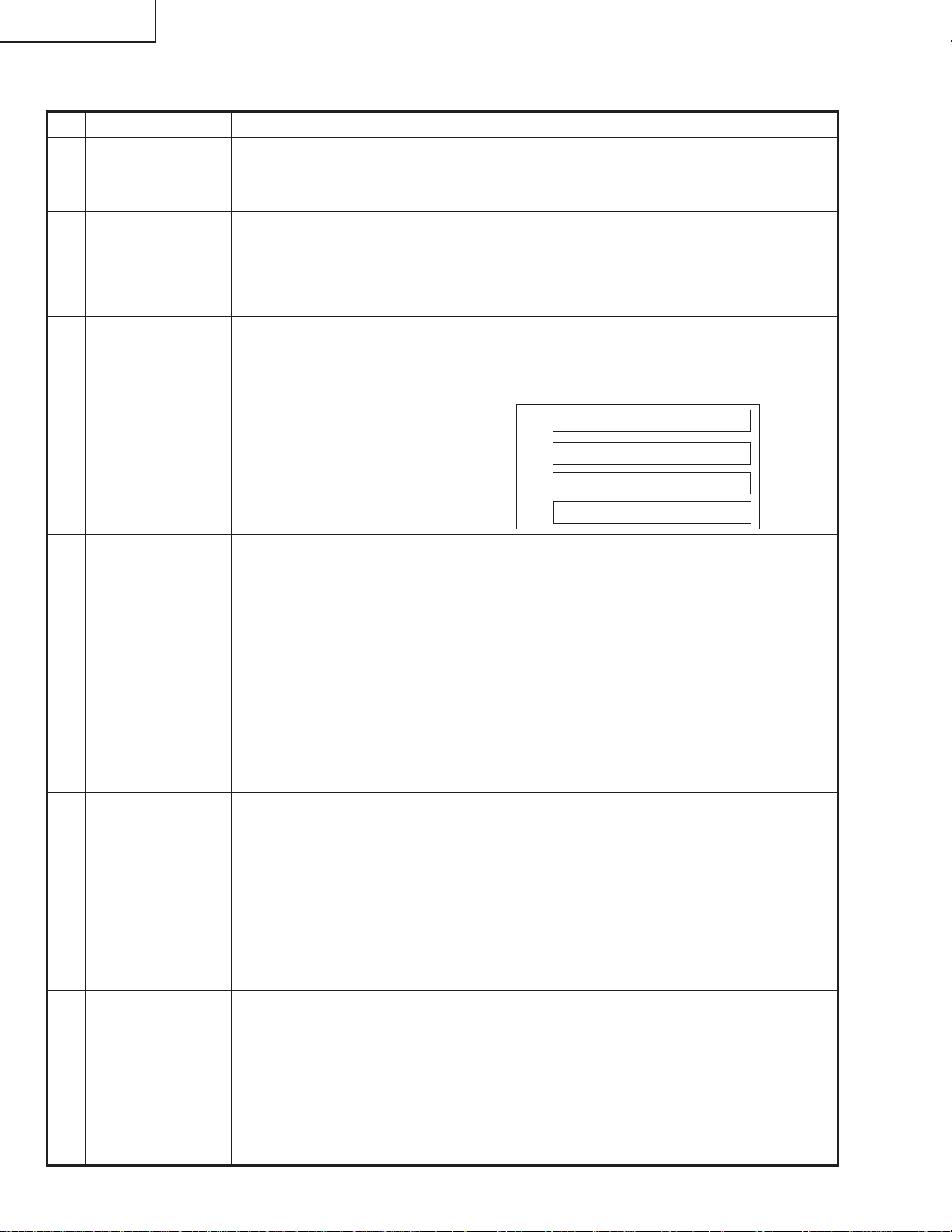

If shading shown in Figure 1 appears on the screen after replacing DMD, turn the adjustment screw of the optical

engine to adjust the lighting area of DMD.

1. Loosen the adjustment lever fixing screw 1. After adjusting the lighting area with the adjustment lever 2, tighten

the adjustment lever fixing screw 1.

Tightening order: 1→2→3→4

Screw torque: 0.44 ± 0.05 N·m

When mounting DMD, tighten the 4 screws evenly.

Fig. 1

Shading

23

Page 24

DT-100

ELECTRICAL ADJUSTMENT

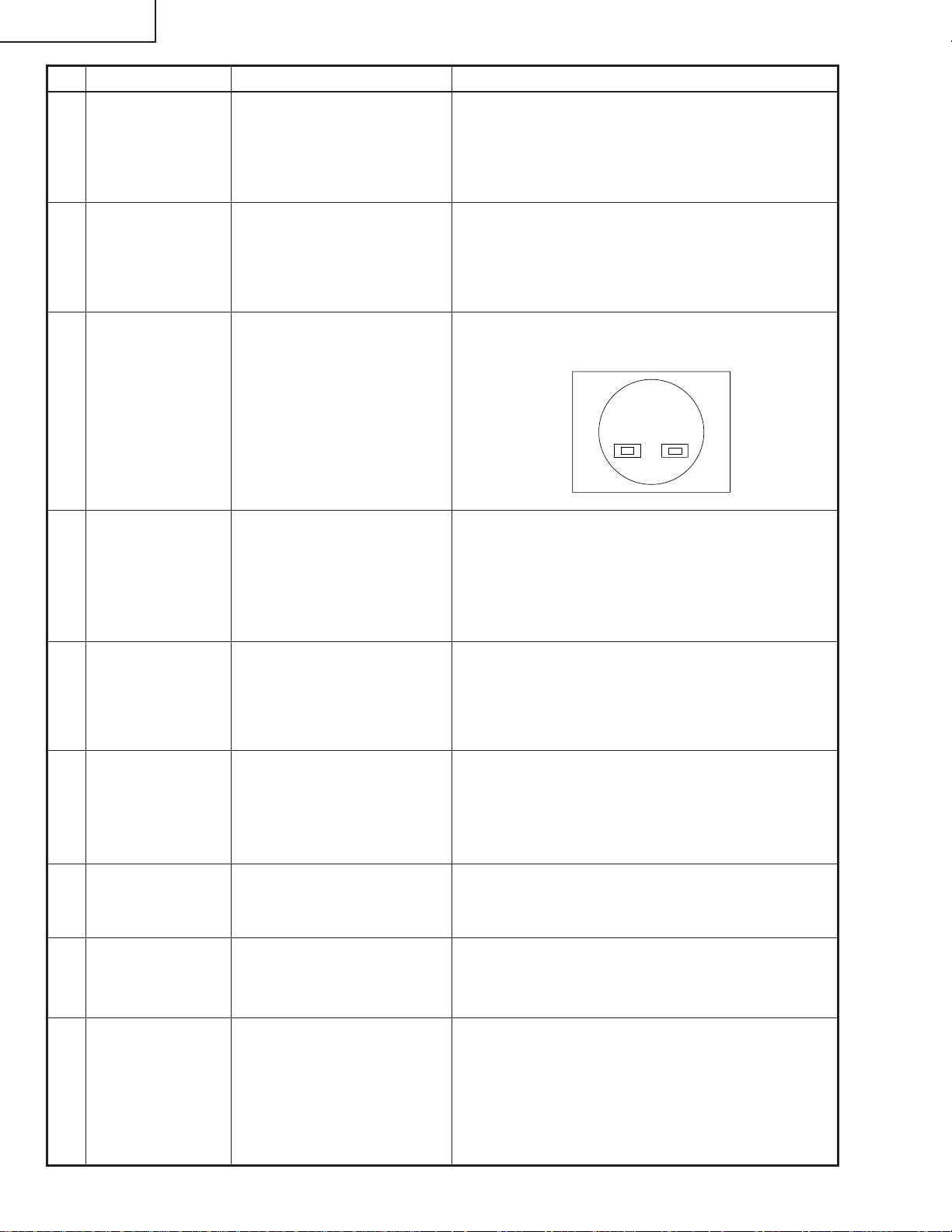

No. Adjusting point Adjusting conditions Adjusting procedure

1 EEPROM

initialization

2 Model setting (Process menu)

3 Adjustment of

CW index

4 R/G/B contrast

adjustment

(manual or

automatic)

1. T urn on the power (with the

lamp on) and warm up the

set for 15 minutes.

1. Select the following group

and subject.

Group: CONFIRM

Subject: MODEL

1. Signal input: Send 256

STEP color bar.

XGA series (XGA60HZ),

SVGA series (SVGA60HZ)

2. Select the following group

and subject.

Group: ADJUST

CW/Auto KS

Subject: CW-INDEX.

1. Select the following group

and subjects.

Group : ADJUST

AD/DLP

Subject : R-CONT

G-CONT

B-CONT

(Process GAMMA interlock)

2. Feed white signal with the

amplitude level of 96%

(0.67Vpp). XGA series

(XGA60HZ), SVGA series

(SVGA60HZ)

» Make the following settings.

Press S2551 to call the process mode and execute

"SS2" on SS menu.

1. Set as below.

: 1 (default)

1. Feed the signal to input 1.

2. Select the adjustment item and adjust the lamp

gradation patterns of RGBW so that smooth

patterns without noise appear.

W

R

G

B

1. Measure chromaticity of the 96% white wind pattern

using CA100.

2. On the screen where bit dropouts occur, raise the

values of R/G/B-Contrast. Adjust the values so that

bright red, green, and blue bit dropouts appear on a

black background; and amounts of change in x value

of R and y values of G/B become 100/1000 or more.

3. If adjustment is performed manually watching the

screen, make adjustment so that bright red, green,

and blue bit dropouts appear on more than half of

the screen.

5 RGB white

balance adjustment

6 sRGB white

balance adjustment

1. Feed the 50% gray signal.

XGA series (XGA60HZ),

SVGA series (SVGA60HZ)

2. Select the following group

and subjects.

Group : ADJUST

AD/DLP

Subject : R-GAIN

G-GAIN

B-GAIN

1. Feed the 50% gray signal.

XGA series (XGA60HZ),

SVGA series (SVGA60HZ)

2. Select the following group

and subjects.

Group : CONFIRM/DLP

Subject : S-G-OS

S-B-OS

1. Raise the values of two of R/G/B-GAIN (default:

100) so that the following chromaticity values are

obtained using CL200.

x value: 300 ± 5

y value: 320 ± 5

1. Adjust S-G-OS and S-B-OS so that the following

chromaticity values are obtained using CL200.

x value: 313 ± 5

y value: 329 ± 5

24

Page 25

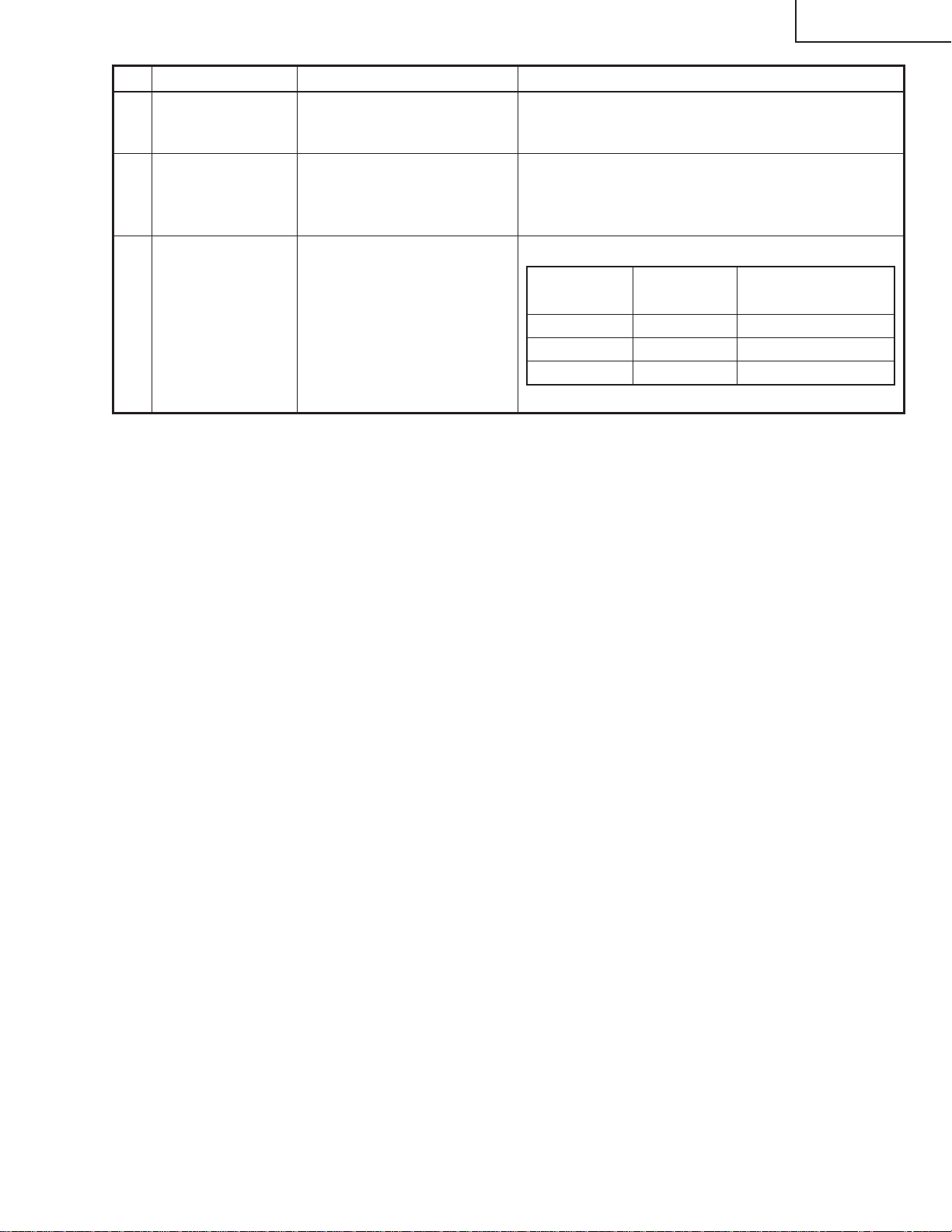

Check items

No. Adjusting point Adjusting conditions Adjusting procedure

DT-100

1 Adjustment of

RGB brightness

2 Adjustment of

Component

offset

3 Adjustment of

DLP Brightness

1. Select the following group

and subjects.

Group : CONFIRM/AD

Subject : R-BRIGHT

G-BRIGHT

B-BRIGHT

(Process GAMMA interlock)

1. Feed 10-step signal with

480P component 100%

amplitude.

2. Select the following group

and subjects.

Group : CONFIRM/AD

Subject :C-R-OS

C-B-OS

(Process GAMMA interlock)

1. Select the following group

and subject.

Group : CONFIRM/DLP

Subject :R-BLK

G-BLK

B-BLK

(Process GAMMA interlock)

1. Check the fixed value.

Fixed value : 127

1. Check the fixed value.

C-R-OS : 260

C-B-OS : 260

1. Check the fixed value.

Fixed value : 256

4 Video Contrast

adjustment

5 Adjustment of

Video Brightness

1. Feed NTSC 100% wind

pattern signal. (Signal with

burst)

2. Select the following group

and subjects.

Group : CONIRM/

VIDEO

Subject : V-CONT

1. Feed NTSC 100% wind pattern signal. (Signal with

burst)

2. Select the following group

and subject.

Group : CONFIRM/VIDEO

Subject : V-BRIGHT

1. Check the fixed value.

Fixed value : 124

1. Check the fixed value.

Fixed value : 68

25

Page 26

DT-100

No. Adjusting point Adjusting conditions Adjusting procedure

6 Adjustment of

Video Tint

7 Adjustment of

Video color

saturation

8 RGB tone

reproduction

adjustment

9 VIDEO white

balance adjustment

1. Feed split color bar.

2. Select the following group

and subject.

Group : CONFIRM/VIDEO

Subject : V-HUE

1. Select the following group

and subject.

Group : CONFIRM/VIDEO

Subject : V-COLOR

1. Feed the SMPTE pattern

signal.

1. Feed the 50% gray signal.

2. Select the following group

and subjects.

Group :CONFIRM/VIDEO

Subject : V-R-OS

V-B-OS

1. Check the fixed value.

Fixed value : 128

1. Check the fixed value.

Fixed value : 154

1. Make sure the 100% and 95% white as well as the

0% and 5% black gradations are visible.

1. V-R-OS is 132.

V-B-OS is 132.

10 White balance

checking and

readjustment

11 Off-timer per-

formance

performance

checking

13 Auto sync

performance

checking

14 Monitor out

check

1. RGB Inputt

sRGB Input

VIDEO Input

DTV Input

DVD Input

1. Select the following group

and subjects.

Group :CONFIRM/CHECK

Subject : TEMP-OFF

1. Heat the thermistor with a

hair dryer.

1. Feed the phase check pattern signal.

1. Send signals to INPUT 1

and INPUT 2.

2. Connect another monitor to

the monitor out.

3. Connect the audio OUT.

Check that there is no deviation of white balance with

the monitor.

1. Select OFF from the process mode.

Make sure the off-timer starts with 5 minutes

onscreen and count one minute in one second.

And then indication is 0 minute, the power supply

of the set is cut off.

1. Make sure that the temperature is indicated.12 Thermistor

1. In the VGA, SVGA, XGA and SXGA modes, make

sure the Clock, Phase, H-Pos and V-Pos settings

can be automatically adjusted.

1. Check that the same images as seen on the screen

appear on the connected monitor and that the sound

from the sound source connected to the audio OUT

is heard.

26

Page 27

No. Adjusting point Adjusting conditions Adjusting procedure

DT-100

15 RS232C opera-

tion check

16 Model name and

version check

17 Delivery set-

tings

* Writing a software program (before main PWB is mounted)

Use the DLP Composer Lite Ver. 4.2 or higher to download the firmware.

After writing the specified version of firmware to the PWB using the RS232C cable, check the version of the written

firmware.

If no software program is written, all three LEDs light up in the chassis inspection process.

1. Connect the unit and a PC

with the RS232C cable.

1. Select the following group.

Group : INFO/VERSION.

1. Send a command from the PC, and check it functions correctly.

1. The model name appears in the MODEL field, and

the firmware version in the VERSION field. Check

that they are correct.

1. Make the following settings.

Destination Process Remote control

adjustment adjustment

USA SS4 Factory setting at 4

China SS6 Factory setting at 6

Others SS3 Factory setting at 3

1. Calling and quitting the process mode with the control keys on this model.

∗ Although it is possible for the process OUT to exit using the process menu, the IN/OUT toggle command is also

available considering the existing specification.

1-1. Calling and quitting

With the menu not displayed, press the "ENTER", "ENTER", "VOL+", "VOL-", "ENTER", "ENTER" and "MENU"

keys on the remote control (one for C50/45 or P25/20 system is also usable) or on the main unit.

1-2. Others

Press the S2551 process key (toggle) on the main PWB to call and quit the process menu.

Note: When adjusting in the process mode, set a signal with a vertical frequency of 60 Hz or no signal. (May not be

properly adjusted with other signals.)

2. Resetting the lamp timer for this model

2-1. Resetting procedure

In Stand-by, run this command to clear the operating time of the lamp to 0 and turn on the power.

Press and hold """, "ENTER", and "MENU", and then press the "STANDBY/ON" key of the set.

3. Forced disabling of the System-Lock of this model

3-1. Disabling procedure

With System-Lock input window onscreen, press the "MENU", "ENTER", "ENTER", "MENU", "ENTER", "ENTER"

and "MENU" keys, in this order, on the remote controller.

27

Page 28

DT-100

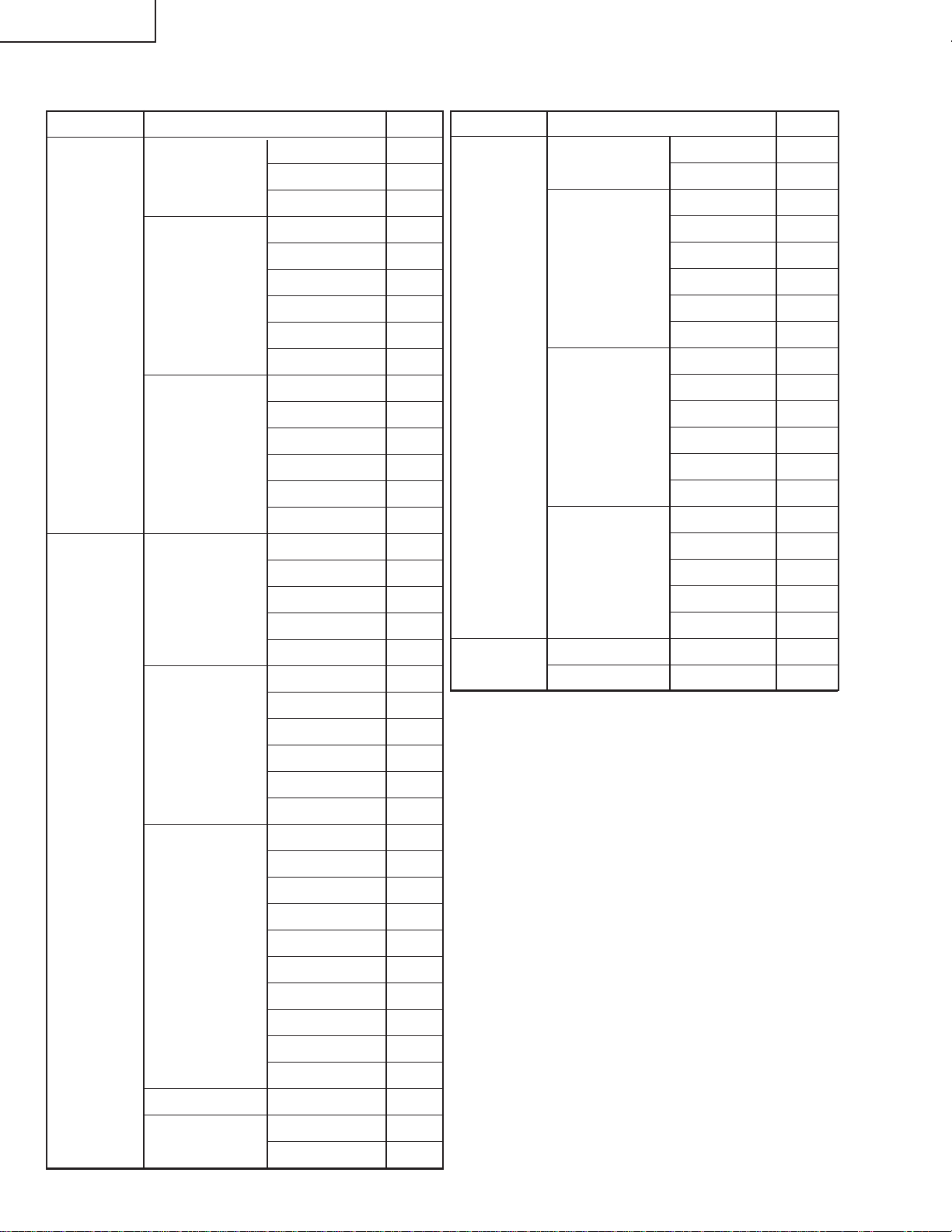

» Adjustment mode process menu

1st Layer 2nd Layer Default

ADJUST CW/Auto KS CW-INDEX 20

CAL

K-SENS (0)

AD/DLP R-CONT 110

G-CONT 110

B-CONT 110

R-GAIN 100

G-GAIN 100

B-GAIN 100

SS SS1 −

SS2 −

SS3 −

SS4 −

SS5 −

SS6 −

CONFIRM AD R-BRIGHT 127

G-BRIGHT 127

B-BRIGHT 127

C-R-OS 260

C-B-OS 260

DLP R-BLK 256

G-BLK 256

1st Layer 2nd Layer Default

INFO VERSION MODEL −

VER. −

PATTERN RGB 1

RGB50 1

CORSS 1

STEP 1

COLOR 1

CHR 1

LAMP CURRENT 0

HISTORY1 0

HISTORY2 0

HISTORY3 0

HISTORY4 0

TOTAL 0

TEMP/FAN TEMP1 −

TEMP2 −

FAN0 3

FAN1 3

FAN2 3

OTHER 232C

EXIT

232C-MODE

0

B-BLK 256

S-R-OS 128

S-G-OS 128

S-B-OS 128

VIDEO V-CONT 124

V-BRIGHT 68

V-COLOR 154

V-HUE 128

V-R-OS 132

V-G-OS 128

V-B-OS 132

OFFSET-MODE

OFFSET-CONT

OFFSET-BRI

MODEL

CHECK LED-CHK 0

MODEL-SELECT

TEMP-OFF −

0

0

0

1

28

Page 29

RefNo.

1

R905

2

--

3

IC7707

4

IC7704

5

IC7701

1

2

Adjustmentjig(resistanceload25Ω)

Partname

Partname

Partcode

Partcode

PWMcontroller

RR-FZA002WJZZ

DUNTKD148WEF0

RH-iXB458WJZZ

Manufacturer

RUNTZA018WJZZ

AsahiCommunication

SMK

VHITA78L05F-1Y

VHIM51995AF-1Y

Cementresistor

ControlPWB

Ballastmicroprocessor

5Vregulator

BallastUnit

LampCable

(QCNW-D573WJQZ)

AdjustmentJig

(RUNTZA018WJZZ)

ConnectingCord

(Q C NW -E007WJZZ)

Projector

TP1

TP2

−

+

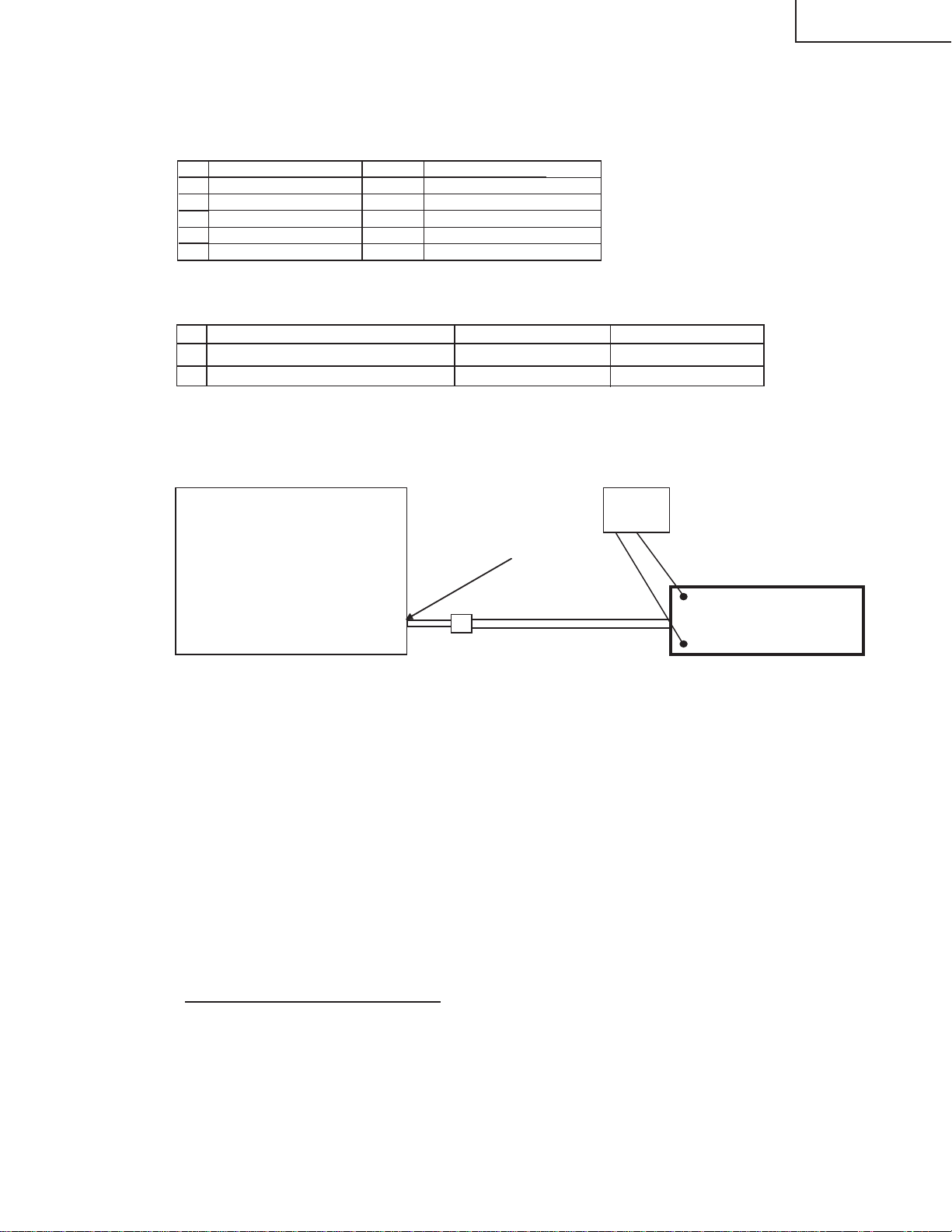

[Adjustmentofballastunitoutputpower(lamppower)]

1.Listofpartsrequiringadjustment

Whenreplacingthefollowingparts,adjusttheballastunitoutputpower(lamppower).

2.Adjustmentjigs

Thefollowingjigsarerequiredforadjustingtheballastunitoutputpower(lamppower).

3.Ballastunitoutputpower(lamppower)adjustmentmethod

Adjusttheballastunitoutputpower(lamppower)inthefollowingmethod.

[Adjustmentmethod]

(1)Unplugtheballastunitlampcable(QCNW-D573WJQZ)oftheprojectorfrom

thelampandconnectthecabletotheconnectingcord(QCNW-E007WJZZ).

(2)Connecttheconnectingcord(QCNW-E007WJZZ)totheadjustmentjig

(RUNTZA018WJZZ).

(3)ConnectTP1oftheadjustmentjig(RUNTZA018WJZZ)tothenegativeterminalofthe

testerandTP2tothepositiveterminal.

(4)Turnontheprojector.

(5)Agetheprojectorfor60secondsormore.

(6)Adjustthevolumeresistor(R7728)oftheballastcontrolPWB(DUNTKD148WEF0)so

thatthevoltageofthetesterreaches83±0.5V.

Adjustmentvalue:83±0.5V

[Cautions]

(1)Cautionforelectricshock:DonottouchthetestpointsTP1andTP2oftheadjustment

jigwhensupplyingpowersinceahighvoltageandlargecurrentisappliedtothem.

(2)Cautionforheat:Becarefulthattheresistanceloadoftheadjustmentjigproducesahigh

temperaturewhensupplyingpower.

(3)Connectionofthelampcable:Checkthatthelampcableandconnectingcord(QCNW-E

007WJZZ)areconnectedsecurely.

Poorconnectionmaycausesmokingorignitionduetoarcdischarge.

[Settingmethod]

Tester

(Voltage)

DT-100

29

Page 30

DT-100

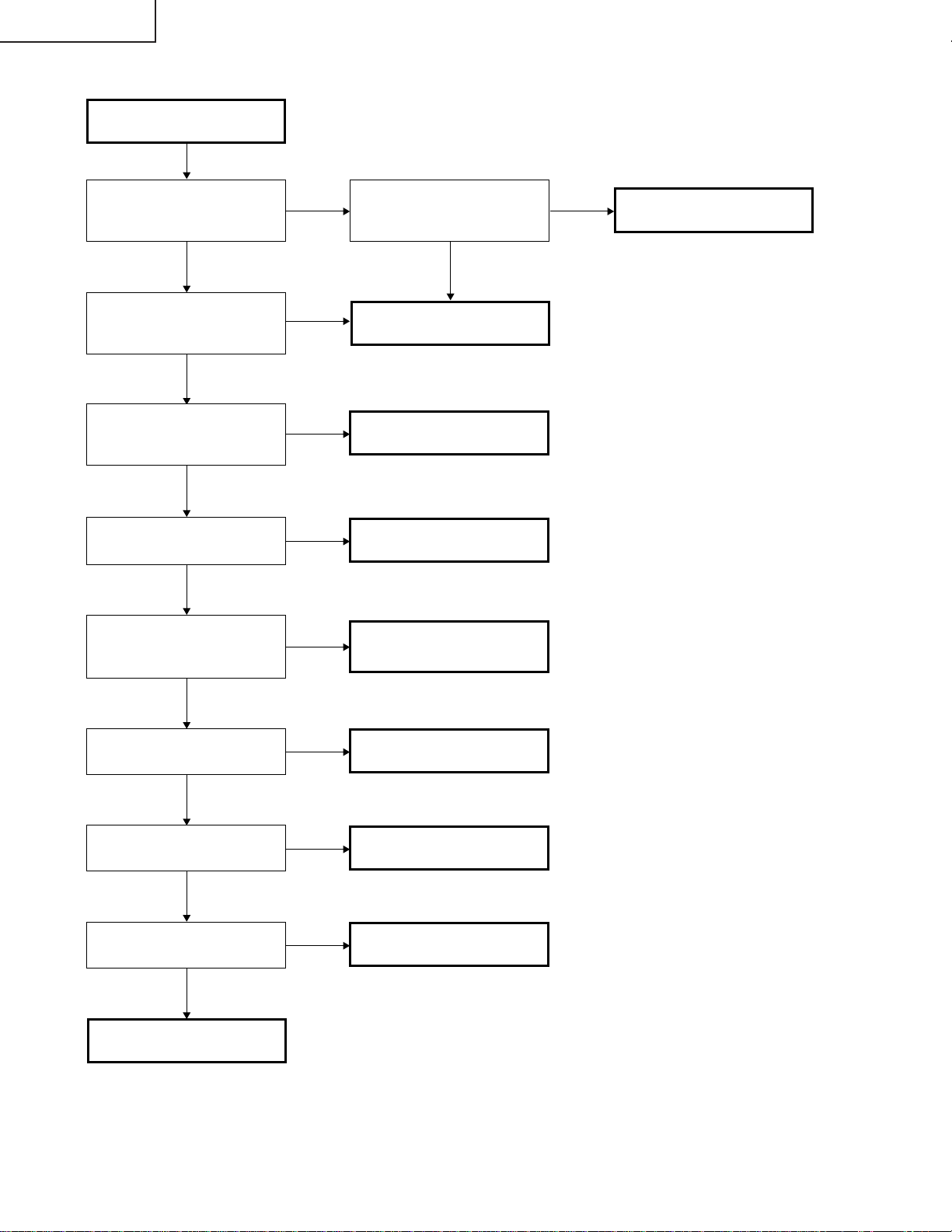

TROUBLE SHOOTING TABLE

Checking the basic

operation

Does the power LED light

up or flash in red or green?

YES

Does the set function with

its keys or the remote

controller?

YES

Lamp does not turn on or it

turns off in a short time.

NO

Nothing is displayed or

white vertical line noise

NO

Colors are not displayed

normally. Color deviation

and color fluctuation occur.

NO

NO

NO

YES

YES

YES

Has P1701 come off or is it

loose?

NO

Go to "Main PWB check".

Go to "Checking the lamp

light-up".

Go to "DMD system

check".

Check PHOTO SENSOR

circuit.

YES

Fully insert the connector.

Are RGB and component

input displayed normally?

YES

Is VIDEO input displayed

normally?

YES

Is S-VIDEO input

displayed normally?

YES

END

NO

NO

NO

Go to "RGB and

component signal check".

Go to "VIDEO input

check".

Go to "S-VIDEO input

check".

30

Page 31

YES

NO

Is 6 V applied to TL1702

and 13 V to TL1703?

Is approx. 6 V applied to

TL1742?

YES

Is 1.5 V applied to

TL1741?

Go to "Power supply

ballast PWB check".

NO

Check IC1742 and

peripheral circuits.

NO

Check IC1741 and

peripheral circuits.

YES

Is 3.3 V applied to

TL1762?

NO

Check IC1763 and

peripheral circuits.

Is 2.5 V applied to

TL1763?

NO

Check IC1762 and

peripheral circuits.

YES

Is 5 V applied to TL1791?

NO

Check IC1791 and

peripheral circuits.

YES

Is 3.3 V applied to

TL1792?

NO

Check IC1792 and

peripheral circuits.

YES

Is 12 V applied to

TL1761?

NO

Check IC1761 and

peripheral circuits.

YES

Main PWB check

YES

Is 3.3 V applied to pin(1)

of IC1743?

NO

Check IC1743 and

peripheral circuits.

YES

Is 3.18 V applied to pin(1)

of IC2001?

NO

Check IC2001 and

peripheral circuits.

YES

Is 3.3 V applied to pin(3)

of S2001?

NO

Check that it is set to the N

side. Or remove S2001.

YES

Is rectangular wave of 50

MHz sent to X2251 pin(3)?

NO

YES

Check IC2002, IC2262,

IC2263 and peripheral

circuits.

Check X2251 and

peripheral circuits.

DT-100

31

Page 32

DT-100

DMD system check

Check P2501 for breakage

and solder crack and

peripheral resistance for

solder crack.

Check SC9101 for

breakage and solder crack.

Is there any vertical stripe

(block noise) on the

NO

Is the screen all black?

YES

Is 3.27 V applied to IC2231

pin(1) and 1.8 V to TL2231?

YES

Is 400 MHz on IC2241 pin

(20)?

YES

Is approx. 7 V applied to

TL9303?

YES

NO

YES

NO

NO

NO

Check IC2231, IC2201,

and their peripheral

circuits.

Check IC2241 and

peripheral circuits.

The main PWB and DMD

PWB are in poor contact.

Check the contact surface

for dirt and smear.

Check the DMD connector

for breakage.

Reassemble the DMD,

optical mechanism, and

DMD PWB.

Is approx. 26 V applied to

TL9301?

YES

Is approx. -26 V applied to

TL9302?

YES

NO

NO

Check IC9301 and

peripheral circuits.

32

Page 33

Power supply PWB

check

DT-100

Is 6 V applied to pins (7)

and (8) of the connector

P704?

YES

Is 13 V applied to pins (3)

and (4) of the connector

P704?

YES

Does the lamp turn on?

YES

Check the main PWB.

Are connectors P704 and

CN901 fully inserted?

NO

NO

NO

NO

1

Check peripheral circuits of

IC703.

Securely insert the

connectors.

YES

Is DC voltage of 380 V

applied to both ends of

C704?

YES

Is R766 in the OPEN

status?

YES

Check circuits R766 and

after or replace R766.

NO

NO

Is pin (11) of the connector

P704 at "H"?

YES

Check peripheral circuits

of IC902.

Is LAMP-EN/SYNC signal

properly sent to pin (14) of

the connector P704?

(Refer to the waveform

chart 1.)

YES

Are GATE waveforms of

Q901 and Q903

appropriate?

(See waveform diagram

8.)

NO

NO

NO

Check the main PWB.

Check the main PWB.

Check the ballast PWB.

33

Page 34

DT-100

1

Are connectorsP701 and

P702 fully inserted?

YES

Is AC voltage between 100

− 240 V applied to both

ends of C707?

YES

Is the bimetal broken?

(Connection between 1 and

2 of P702)

YES

Is R717 open?

YES

Check that P704 connector

pin (11) is at "H". Replace

R717.

NO

NO

NO

NO

Securely insert the connectors.

Replace F701.

Press the red button on the

bimetal.

Is R705 open?

YES

Replace F705.

Check that the power

supply FAN FB and FC

are not stopped.

NO

Check peripheral circuits of

IC703.

34

Page 35

NO

Go to "Check when the

lamp turns off soon after

turning on".

YES

Securely insert the

connectors.

YES

Securely insert the

connectors.

YES

Check IC3581 and

peripheral circuits. (Refer

to the waveform chart 2.)

NO

Check IC1701 and

peripheral circuits. (Refer

to the waveform chart 1.)

NO

Fully insert the connectors

or replace the harnesses.

YES

Replace the lamp.

YES

Go to "Power supply PWB

check".

NO

Replace both D911 and

D912.

YES

Replace D914 or D910,

whichever is short-circuited.

YES

Replace the color wheel.

YES

Checking the lamp

light-up

Does the lamp turn on

when the power is turned

Is the lamp tight in the

socket?

NO

Has the FPC cable to

SC3581 come off or is it

loose?

Is rotating sound of the

color wheel heard?

NO

Is approx. 0.7 V applied to

TL1706?

YES

NO

Has the harness connected

to P702 on the power

supply unit come off, or is it

loose? Otherwise, is it

broken?

NO

Dose the lamp turn on after

the replacement?

YES

Is 340 VDC applied to both

ends of C914?

NO

Is D911 or D912 shortcircuited?

Is D914or D910 shortcircuited?

YES

DT-100

35

Page 36

DT-100

Check when the lamp turns

off soon after turning on

Have connectors P1703,

P1721, P1722, P1723 and

P1724 come off or are they

loose?

NO

Is each cooling fan

rotating?

YES

Is approx. 3 V applied to

TL1721?

YES

Is 12 V applied to TL1761?

YES

Is 2.5 V applied to

TL1763?

YES

YES

NO

NO

NO

NO

Securely insert the

connectors.

Check the cooling fan.

Check peripheral circuits of

Q1721.

Check IC1761, IC3581 and

peripheral circuits.

Is 3.3 V applied to TL1762?

NO

YES

Go to "DMD system check".

Check IC1762 and

peripheral circuits.

Is 5 V applied to TL1791?

YES

Is 5 V applied to TL1712?

YES

Is the signal of 180 Hz

sent to TL1716?(When

vertical frequency of the

input signal is 60 Hz)

YES

Is the signal of 180 Hz

sent to TL1706? (When

vertical frequency of the

input signal is 60 Hz)

YES

NO

NO

NO

NO

Check IC1763 and

peripheral circuits.

Check IC1791 and

peripheral circuits.

Is 5 V applied to TL1712

with P1703 removed?

YES

Check PHOTO SENSOR

PWB.

Check IC1701 and

peripheral circuits.

NO

Check connection of

FB1710.

Check the power supply

ballast PWB.

36

Page 37

YES

End

YES

Check IC3002 and the

peripheral circuits (check

IC3052 for INPUT 2).

NO

Check IC1792 and

peripheral circuits.

NO

Check IC1763 and

peripheral circuits.

NO

RGB and component

signal check

Send component signal or

RGB signal of 1080i (or

720P) from INPUT 1 or

INPUT 2. Select INPUT 1

or INPUT 2 using keys on

the main unit or the remote

control.

Is image displayed

normally?

Are picture signals sent to

TL3201, TL3204, and

TL3205?

NO

YES

Is 3.3V applied to TL1792?

Is 3.3V applied to TL1762?

YES

Check IC3201 and

peripheral circuits.

YES

DT-100

37

Page 38

DT-100

S-VIDEO (INPUT 3)

check

Send S-Video signal (color

signal) from INPUT 3.

Select INPUT 3 using keys

on the main unit or the

remote control.

Is image displayed

normally?

NO

Is image displayed in black

and white?

NO

Is S-VIDEO signal (Y) sent

to R3306?

YES

YES

YES

NO

VIDEO (INPUT 4) check

Send VIDEO signal from

INPUT 4. Use buttons on

the main unit or the remote

control to select INPUT 4.

End

Check S-VIDEO terminal

and peripheral circuits of

Q3311.

Check S-VIDEO terminal

and peripheral circuits of

Q3301.

Is 1.8 V applied to

TL3358?

YES

Is 3.3 V applied to

TL1792?

YES

Is 1.5 V applied to

TL1762?

YES

NO

NO

NO

End

Check VIDEO terminal and

peripheral circuits of

Q3321.

Check IC3352 and

peripheral circuits.

Check IC1792 and

peripheral circuits.

Check IC1763 and

peripheral circuits.

YES

Is image displayed

normally?

NO

Is VIDEO signal sent to

C3326?

NO

YES

Check IC3351 and

peripheral circuits.

38

Page 39

- M E M O -

DT-100

39

Page 40

DT-100

BLOCK DIAGRAM

H

G

F

E

D

C

B

A

87109654321

40

Page 41

DT-100

41

1716 1918151413121110

Page 42

DT-100

U

O VERALL WIRING DIAGRAM

H

G

F

D

E

D

C

B

RH-HXA015WJPZ

P3502

B+3.3VA

TEMP1-AD

A

POWER

87109654321

42

Page 43

DUNTKD139FMF7

DT-100

43

PHOTO

1716 1918151413121110

Page 44

DT-100

DESCRIPTION OF SCHEMATIC DIAGRAM

VOLTAGE MEASUREMENT CONDITION:

1. Voltages at test points are measured at the

supply voltage of AC 220V. Signals are f ed by a color

bar signal generator for servicing purpose and the

above voltages are measured with a 20k ohm/V tester.

WAVEFORM MEASUREMENT CONDITION:

1. Waveforms at test points are observed at the supply

voltage of AC 220V. Signals are fed by a color bar

signal generator for servicing purpose.

INDICATION OF RESISTOR & CAPACITOR:

RESISTOR

1. The unit of resistance “Ω” is omitted.

(K=kΩ=1000 Ω, M=MΩ).

2. All resistors are ± 5%, unless otherwise noted.

(J= ± 5%, F= ± 1%, D= ± 0.5%)

3. All resistors are 1/10W, unless otherwise noted.

4. All resistors are Carbon type, unless otherwise noted.

C : Solid

S : Oxide Film T : Special

N : Metal Coating

CAPACITOR

1. All capacitors are µF, unless otherwise noted.

(P=pF=µµF).

2. All capacitors are 50V, unless otherwise noted.

3. All capacitors are Ceramic type, unless otherwise

noted.

(ML): Mylar (TA): Tantalum

(PF): Polypro Film (ST): Styrol

W

: Cement

CAUTION:

This circuit diagram is original one, therefore there may be a

slight difference from yours.

SAFETY NOTES:

1.DISCONNECT THE AC PLUG FROM THE AC

OUTLET BEFORE REPLACING PARTS.

2.SEMICONDUCTOR HEAT SINKS SHOULD BE

REGARDED AS POTENTIAL SHOCK HAZARDS

WHEN THE CHASSIS IS OPERATING.

IMPORTANT SAFETY NOTICE:

PARTS MARKED WITH “å” ( ) ARE

IMPORTANT FOR MAINTAINING THE SAFETY OF

THE SET. BE SURE TO REPLACE THESE PARTS

WITH SPECIFIED ONES FOR MAINTAINING THE

SAFETY AND PERFORMANCE OF THE SET.

44

Page 45

WAVEFORMS

DT-100

45

1716 1918151413121110

Page 46

DT-100

SCHEMATIC DIA GRAM

Ë

H

G

F

MAIN UNIT-1/8

iXB589WJ

E

D

iXB589WJ

C

B

A

87109654321

46

Page 47

DT-100

47

1716 1918151413121110

Page 48

DT-100

Ë

H

G

F

MAIN UNIT-2/8

E

D

C

B

A

87109654321

48

Page 49

DT-100

49

1716 1918151413121110

Page 50

DT-100

Ë

H

G

F

MAIN UNIT-3/8

E

D

C

B

A

87109654321

50

Page 51

DT-100

51

1716 1918151413121110

Page 52

DT-100

Ë

H

G

F

MAIN UNIT-4/8

E

D

C

B

A

87109654321

52

Page 53

DT-100

53

1716 1918151413121110

Page 54

DT-100

Ë

H

G

F

MAIN UNIT-5/8

E

D

C

B

A

87109654321

54

Page 55

DT-100

55

1716 1918151413121110

Page 56

DT-100

Ë

H

G

F

MAIN UNIT-6/8

E

D

C

B

A

87109654321

56

Page 57

DT-100

57

1716 1918151413121110

Page 58

DT-100

Ë

H

G

F

MAIN UNIT-7/8

E

D

C

B

A

87109654321

58

Page 59

DT-100

59

1716 1918151413121110

Page 60

DT-100

Ë

H

G

F

MAIN UNIT-8/8

E

D

C

B

A

87109654321

60

Page 61

DT-100

61

1716 1918151413121110

Page 62

DT-100

Ë

H

G

F

DMD UNIT-1/3

E

D

C

B

A

87109654321

62

Page 63

DT-100

63

1716 1918151413121110

Page 64

DT-100

Ë

H

G

F

DMD UNIT-2/3

E

D

C

B

A

87109654321

64

Page 65

DT-100

65

1716 1918151413121110

Page 66

DT-100

Ë

H

G

F

DMD UNIT-3/3

E

D

C

B

A

87109654321

66

Page 67

DT-100

67

1716 1918151413121110

Page 68

DT-100

Ë

H

G

F

BALLAST POWER UNIT

E

D

C

B

A

87109654321

68

Page 69

DT-100

69

1716 1918151413121110

Page 70

DT-100

Ë

H

G

F

BALLAST CONTROL UNIT

E

D

C

B

A

87109654321

70

Page 71

DT-100

458

1716 1918151413121110

71

Page 72

DT-100

Ë

H

G

F

PHOTOSENSOR UNIT

E

D

C

B

A

654321

72

Page 73

DT-100

Ë

R/C UNIT

H

G

F

E

D

C

B

A

654321

73

Page 74

DT-100

PRINTED WIRING BOARD ASSEMBLIES

H

G

F

E

D

C

B

A

MAIN Unit (Side-A)

87109654321

74

Page 75

DT-100

75

1716 1918151413121110

Page 76

DT-100

R3224

R3225

FB3521FB3522

D3051

R3051

D3056

R3052

D3057

R3053

R3054

R3055

R3056

R3057

R3058

R3059

IC3051

IC3052

FB3351

FB3352

FB3353

FB3354

FB3355

D3065

C1726

D3066

D3067

R1704

R3069

R1706

R3070 R3071

R3072

R3073

R3074

FB2201

P2532

P2533

R2503 R2504

R2505

R2506

R2507

R2508

R2509

Q2531

P3301

R2510

R2511

R2512

R2513

R2514

R2515

R2516

R2517

R2518

R2521

R2522

R2523

C3103

R2524

R2525

R1779

R2527

R2528

R2529

FB2241

D2531

D2532

R2532

R2533

R2534

R2535

FB3001

FB3002

FB3003

C3511

FB3201

C3512

FB3202

R3102

C3513

FB3203

R3103

C3514

FB3204

IC3102

R2553R2554

C3521

C3522

C3523

C3524

R3511

C3151

R3512

C3152

C3153

C3154

S2551

C3354

C3355

R3521R3522

FB3051

C3362

FB3052

C3363

FB3053

C3364

FB3054

C3365

FB3055

FB3056

FB3057

C3369

R3151 R3152

C3370

C3371

R3155

C3372

R3156

R3157

R3158

IC3152

FB1708

R3355

FB1709

R3356

R3359

FB1710

FB1711

FL3102

FL3103

R3360

C2001

C2002

C2003

R3365

R3366

C2203

C2204

C2205 C2206

C2207 C2208

C2209

C2210

C2211

C2212

C2213

C2214

C2215

C2216

C2217

C2218

C2219

C2028

R2001

R2002

C2220

R2004

C2221

R2005

C2222

C2223

C2031

IC2001

IC2002

R2202R2203

R2204

R2205

R2206

R2207 R2208 R2209

IC2201

R2019

R2210 R2211 R2212

R2213

R2214

C2241

S2001

C2242

C2245

C2246

C2248

C2250

C2251

C2252C2253

C3001

C3201

C2262

C3202

C3203

C3204

FB2531

FB2532

C3206

C3207

C3208

R2241

C3209

R2244

C3210

IC2241

C3211

C3212

C3215

C3216

C3217

C3218

C3219

D3001

SC2531

R3001

D3006

FB3102

R3002

D3007

FB3103

R3003

C3220

R3004

C3221

R3005

C3222

R3006

C3223

R3007

R3009

IC3001

IC3002

C3227

R3201

R3202

R3203

R3010

R3204

R3205

D3015

R3206

D3016

D3017

R3209

IC3201

IC2263

R3211

R3212

R3213

P1703

R3020

R3214

P1704

R3021

R3215

R3022

R3216

R3023

R3217

R3024

R3218

R3025

R3219

C3051

FB3511 FB3512

R3220

C3055

R3221

R3222

C3056

C3057

R3223

H

G

F

E

D

C

B

A

MAIN Unit (Chip Parts Side-A)

76

87109654321

Page 77

DT-100

3

5

C3514

5

3

3

1

1

1

1

1

1

1

1

1

2

2

2

P3562

FB3566

C3572

FB3565

L1723

L1727

FB1729

C1724

FB1728

D1725

Q1724

R1727

R1728

FB1732

C1725

Q1725

FB1731

D1726

FB1730

D2571D2572D2573

FB1727

D1731

D1732 D1733

R1701

C1701

D1701

P1723P1724

P1722

P3561

R1702

C1703

Q1701

R3589

R3592

R3593

P1702

R1708

S2555

S2556

S2554

FB1707

R1707

R1705

P1705

C1705

S2557

S2558S2559

P1703

FB1710

FB1711

R1704

R1706

C1726

P2533

2528

2529

2

1

0

9

8

7

6

5

4

3

2

1

365

353

352

66

3355

372

D1730

S2553

P1721

FB1723

S2552

FB1722

FB1721

FB3582

C3591

FB3583

R3591

SC3581

FB3584 FB3585

R3588

C3586 C3588

R3304

Q3301

R3302

C3323

R3325

L3321L3322

C3322

C3301

R3303

FB3301

D3301

R3301

R3324

FB3321

R3321

FB3311

D3321

R3322

R3311

R3323

C3321

C3502

FB3501

R3502

C3504

C3506

R3501

C3501

C3503

D3552

D3553

FB3502

D2561 D2562

R2564

FB2562

FB3552

FB3551

FB2561

D2563

D2564

P3551

R2563

R3326

C3326

C3324

C3325 Q3321

C3304

C3305

C3306

L3302

C3302

C3303

R3306

C3104

R3305

L3301

R3101

D3104D3105

FB3101

FL3101

D3102

D3101

FB3105

D3103

FB3104

IC3101

C3103

12

12

512

R3103

FB3103

FL3103

R3102

FB3102

FL3102

1716 1918151413121110

77

Page 78

DT-100

H

G

F

E

D

C

B

A

MAIN Unit (Side-B)

87109654321

78

Page 79

DT-100

79

1716 1918151413121110

Page 80

DT-100

2

0

IC1764

Q3512

R3515

3

3

H

G

F

E

D

C

B

FB1726

FB1725

C1723

D1724

L1726

FB1724

R1730

Q1723

L1722

L1728

R1710

FB1703

FB1704

FB1705

FB1706

FB1701

FB1702

FB2563

R2566

R2565

R2567

R1731

C1727

C2561

C2563

C2562

C1721

R1711

R1703

R1712

IC2561

R3578

TH3561

C1728

C3567

R3572

R3573

C3568

IC3551

R3556

R2568

C2564

L1724

C3565

C3554

C2565

C3571

R3577

R3558

R3560

R1732

FB3563

C3570

R3506

Q3501

D3501

R3504

IC1701

C3557

R3552

R3503

S3561

R3559

R3551

R1726

R1764

R1765

C3566

FB3564

R3557

C3555

R3554

R3555

C3553

D3502

R3507

Q3502

R3505

R1761

R1769

C1764

C3564

R3571

R3576

C3569

C1702

R1709

R1713

D3551

IC3552

R1725

D1722

D1721

C1762

R2571

C3556

C3552

C1763

Q2571

R2575

R2576

Q1721

R1723

R1724

C1760

R3570

C3563

R3553

R3541

L3311

R3312

C3311

R1722

R1721

D1761

IC1761

R3544

C3312

R3315

Q2572

R2577

R2578

R3579

R3580

C3313

Q3311

C1761

IC3562

C3541

C3540

R3543

R3567

R3606

L3312

D3311

C3595

Q3537

R3542

C3314

R3314

R3313

Q3535

C3535

Q2573

R2579

R2580

R2020

C3315

R3597

R3596

R3595

R3594

C3562

FB3562

R3538

R3535

C3596

Q2574 Q2575

R2582

R2581

C3561

FB3561

R3566

R1792

C1794

IC1791

R3539

R3533

Q3534

C3537

C3533

R3536

C3532

R3564

C3538

IC3533

D1702

C3593

C3530

R1791

C1792

R3598

R3540

C1704

R2584

R2583

IC3561

R3563

D1791

R3599

Q3536

C3590

R2572

R3562

C3536

C3594

C3592

C3589

C3534

R3545

R3531

R3546

R3532

R3537

D3581 D3582 D3583

R3590

C3587

FB3581

C1781

R1777

R3561

C1793

C1791

C3526

C3528

R3534

R3601

C3544

C3545

C3539

C3531

IC3531

IC3581

C1778

C1779

R1748

FB1761

R1749

R3526

R3530

R3529

R3602

C3601

C3585

R1776

IC1743

C1753

C3527

C3529

C3584

R1775

R1774

C1774

Q3524

R3518

Q3601

R3603

R3109

D3584

R1750

R3527

C3583

C1776

C1755

C1754

FB1741

R3568

R3565

R3574

C3525

C3582

C1775

IC1763

Q3522

R3548

R3547

R3549

R3550

Q3523

R3525

R3520

R3604 R3605

R1772

C1756

C1748

C1771

C1773

C1772

D1764

L1761

IC1742

C1749

R3575

Q3521

R3528

C3602

IC3601

C3101

C1722

C1777

C1770

R1771

R1768

R1770

R1747

R1773

R1780

R1781

C1780

C1752

R1745

C1746

R1795

D1723

C1747

D1762

C1765

C1767

C1769

C1751

R1717

R1794

R1746

IC1741

C1766

C1745

R1744

D1742

R3372

R1714

IC1792

C1797

R1793

C1798

L1721

IC1762

D1765

C1744

C3102

L1741

Q1703

Q1722

D1763

R1743

R1741

R1742

C1750

R1716

C1796

R1729

C1768

D1741

C1741

C1742

C1743

R3371

R2232

R2231

C1729

Q1702

C1795

C2231

C2232

C2233

R2234

R2235

IC1721

C3367

R1718

R3369

Q3331

C1711 C171

R1715

C3515

C3505

C

D3331

IC3

R3370

D17

R

D3512

A

MAIN Unit (Chip Parts Side-B)

87109654321

80

Page 81

Q1722

D1763

R1743

R1741

R1742

C1750

R1716

C1796

R1729

C1768

D1741

C1741

C1742

C1743

R3371

R2232

R2231

C1729

Q1702

C1795

IC1721

C1711

R1718

C3515

C2231

C3367

Q3331

R1715

C2232

C2233

R2234

R2235

C3505

R3369

D3331

R3370

C1712

D1703

D3512

C3368

IC3352

IC1764

Q3512

R3515

R2233

IC2231

R3513

D2231

R3352

R3516R3517

Q3511

R3514

C1710

D3511

R2242

R2243

C3366

C3357

X3351

C3356

D3521

R3523

C2247

R2245

R2246

D3522

R2248

R2247

R3362 R3363

C3359 C3360 C3361

IC3351

C3351

C3352

R3524

R2017

C2015

R2013

C3353

C2004

R2252

D3054

C2255

R2531

FB2002

R3361

C3358

D3053

P2501

FB2251

C2254

X2251

R3354

R3351

C3213

R3107

R3110

D3052

R3353

R2520

C2256

IC2251

L2005

R2519

C2035

R2015

R2008

R2012

L2004

R3587

R3358

R3357

C3008

R2009

R2014

R3582

C2033 C2034

R2010

R2007

C2027

C2023

C2022

C2017

R2201

C2201

C2202

C2012

C2008

R3367

R3368

R3153

Q3101

R3108

R3034

D3055

R3033

R2018

C3226

FB3207

R3154

C3007

C2029

C3225

R3026R3027

C2016

C2018

FB3206

R3029

R3036

R3065

R3028

R3030

C3224

D3060

R3064

C3054

R3035

R3037

C2030

R2016

C2026

C2013

C2010

C2005

FB2001

R3210

R3068

Q3102

Q3103

C2025

C2014

R2003

C2007

D3059

R3063

R3062

C3053

R3031 R3032

C3009

R3038 R3039

R3067

IC3003

C2032

C2020

C2019

R2526

R3569

C2009

R3041 R3042

D3058

R3060

R3061

C3052

D3002

D3003

D3004

D3005

R3581

R3586

C2557

C3010

R3066

C2006

C2021

C2011

C3581

R2006

C2553

C2555

R2551 R2552

IC3004

R3044

R3040

D3010

R3015

R3016

C3004

FB3005

FB3007

FB3004

R3008

FB3006

C2551

C3205

C3214

R3043

R3019

R3584

R3585

C2558

C2556

R3208

R3207

R3014

R2561

R3583

C2554

D3009

R3013

C3003

C2552

C1785

R3018

R2501R2502

R2562

R1778

C1784

C1783

C3006

C3005

R3012

R2261

C1782

D3008

R3011

C3002

C2501

IC2261

R2263

R3017

IC2262

C2261

DT-100

C2264

C2263

FB2261

81

1716 1918151413121110

Page 82

DT-100

H

G

F

E

DMD Unit (Side-A)

TH9102

R9102

C9102

C9101

R9103

D

C9318

C9315

R9305

C9314

C

B

C9316

C9311

C9309

C9301 C9302

C9306

D9302

D9301

R9301

C9307

IC9301

C9304

R9302

L9301

L9302

FB9301

R9303

C9313

FB9302

C9303

C9312

C9310

R9304

D9303

C9317

C9507

C9505

C9511

C9508

FB9303

C9503

C9510

C9502

C9504

C9509

C9506

C9513

C9512

SC9101

C9308

C9305

A

C9514

DMD Unit (Chip Parts Side-A)

C9501

654321

82

Page 83

DT-100

H

G

F

E

D

C

B

DMD Unit (Side-B)

A

654321

83

Page 84

DT-100

H

G

F

E

D

C

B

A

BALLAST POWER Unit (Side-A)

87109654321

84

Page 85

DT-100

85

1716 1918151413121110

Page 86

DT-100

H

G

F

E

D

C

B

A

BALLAST POWER Unit (Side-B)

87109654321

86

Page 87

DT-100

87

1716 1918151413121110

Page 88

DT-100

FB705

FB706

R702

R703 R704 R705

R706

R707

R708

R710

R711

R712

R715

R718

R721

R917

R725

R728

R730 R731

R732

C702

C703

C705

C706

C708

C903

C713

C716

C717

R762

R763 R764

C92

C923

D702

D704

D705

D706 D707

D719 D720

D722

IC902

H

G

F

E

D

C

B

A

BALLAST POWER Unit (Chip Parts Side-B)

87109654321

88

Page 89

R708

R707

R706

D710

D708

C701

R735

C723

C724

R736

C722

R733

C718

Q705

C739

R738

R737

D713

R743

Q706

C719

C729

R742

R740

R749

R748

R752

R753

FB701

FB702

R754

C736

DT-100

FB704

FB704

R760

R759

R757R758

R756

R755

R751

IC704

R750

C921

R918

903

R917

C923

C922

D915

R913

FB904

D906

R945

R946

R914

Q904

R907

R909

R944

R943

C904

C924

R901

FB903

R911

C905

R912

R902 R903

R921

R924

C909

R923

R920

C910

R908

D909

C912

R904

R935

C913

R932

R931

R930

C925

R934

C918

R933

R929

R925

R939

R928

R927

R926

Q906

R936

R940

C919

R947

Q907

R942

R941

R938

C902