Page 1

SERVICE MANUAL

Serial Dot Matrix

Printer

MODEL DP-750

CONTENTS

CHAPTER 1. Printer Handling and Maintenance.............................................1

CHAPTER 2. Specifications and Operation Principles.....................................2

CHAPTER 3. Disassembly and Assembly .....................................................10

CHAPTER 4. Troubleshooting........................................................................29

PARTS GUIDE (PRINTER ASSEMBLY : KI-OB2014RC01)

APPLICATION MODEL : UP-600 ("U" & "A" version)

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with specified

ones for maintaining the safety and performance of the set.

This document has been published to be used

SHARP CORPORATION

for after sales service only.

The contents are subject to change without notice.

Page 2

Symbol/PartsCod)

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

INTRODUCTION

This manual explains the operation principles and servicing procedures for the Citizen dot matrix printer DP750 series. It is written for personnel

servicing these printers in the field.

FEATURES

The DP750 series printer are a station printers providing 45 mm x 2 line print capability. Developed for POS/ECR applications, the printers offer the

following features.

• The High-performance 9-pin print head with a print speed of approx 3.0 lines per second ensures high-quality printouts.

• Clamshell design (opening and closing mechanism for the paper feed section) makes paper loading easy and facilitates easier maintenance.

• Pull-type paper transport reduces risk of paper jams.

• Versatile array of options:

Take-up device, paper feed device, validation sensor, receipt/journal near-end sensor.

CONTENTS

CHAPTER 1. Printer Handling and Maintenance ..........1

CHAPTER 2. Specificatio ns and Ope ratio n Princip les ....2

2-1 General Specifications .............................................2

2-2 Mechanism Outline ...................................................4

2-3 Mechanism and Operation Principles .....................4

2-3-1 Drive Force Transmission Assembly ...................4

2-3-2 Sensor Assembly .................................................4

2-3-3 Print Head Assembly ............ .............. .. .. .. ...........5

2-3-4 Paper Feed Assembly .........................................6

2-3-5 Ribbon Cassette Assembly .................. .. .. .. .. .. .....6

2-3-6 Paper Take-up Assembly ....................................7

2-4 Connectors ................................................................8

CHAPTER 3. Disassembly and Assembly ...................10

3-1 Required Tools .......................................................10

3-2 Disassembly Procedure .........................................10

3-3 Assembly Procedure ..............................................10

3-4 Adjustment ..............................................................23

3-4-1 Print Speed Adjustment .....................................23

3-4-2 Platen/Head Gap Adjustment ............................24

3-4-3 Bi-directional Printing Shift Adjustment .............24

3-4-4 RP/HP Waveform Check ...................................25

3-5 Head Assembly Replacement ...............................26

3-5-1 Disassembly Procedure ....................................26

3-5-2 Assembly Procedure .........................................27

2-4-1 Terminal Layout .................... .. .......................... ...8

2-4-2 Terminal Functions ......... .. .. .............. .. .............. .. .8

2-4-3 Terminal Circuit Diagram .....................................9

CHAPTER 4. Troubleshooting ........................................29

4-1 Repair Procedure ...................................................29

4-2 Repair Steps ...........................................................29

Page 3

CHAPTER 1. Printer Handling and Maintenance

(1) If printer paper other than the recommended

paper is used, print quality and service life

cannot be guaranteed.

Make sure that the paper width and quality

are within specifications.

(2) Protect the head surface from mechanical

shocks and from foreign objects.

(3) Remove any contamination from the print

head surface by lightly wiping with a cotton

swab moistened with ethanol or similar product.

(4) During transport and during extended

periods of non-use, remove the ribbon

cartridge.

(5) If the print head is powered while

condensation is present, the head may be

destroyed.

Make sure that any condensation has been

fully dried before starting to print.

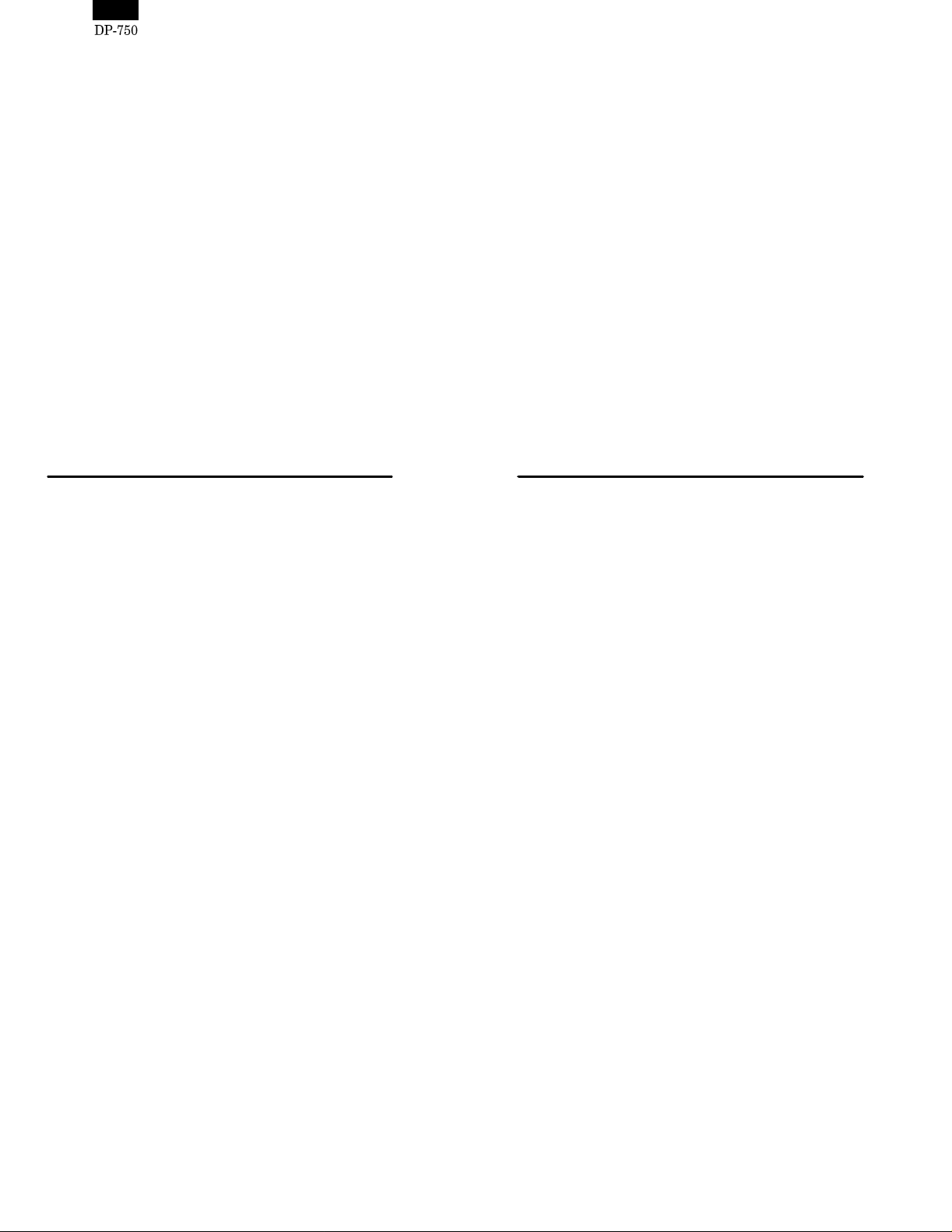

(6) Loading paper

Cut the tip of the paper in a straight line and

make sure that the paper is not frayed, folded,

or creased.

When the paper emerges from above the

print head, grasp it and pull it out slightly, to

verify that it is set straight.

(7) Removing paper

Remove the paper only after printer operation

has ceased.

Pull the paper straight out in the same direction

which it emerges from the printer.

o: correct

u : incorrect

1

Page 4

CHAPTER 2 . Specifications and Operation Principles

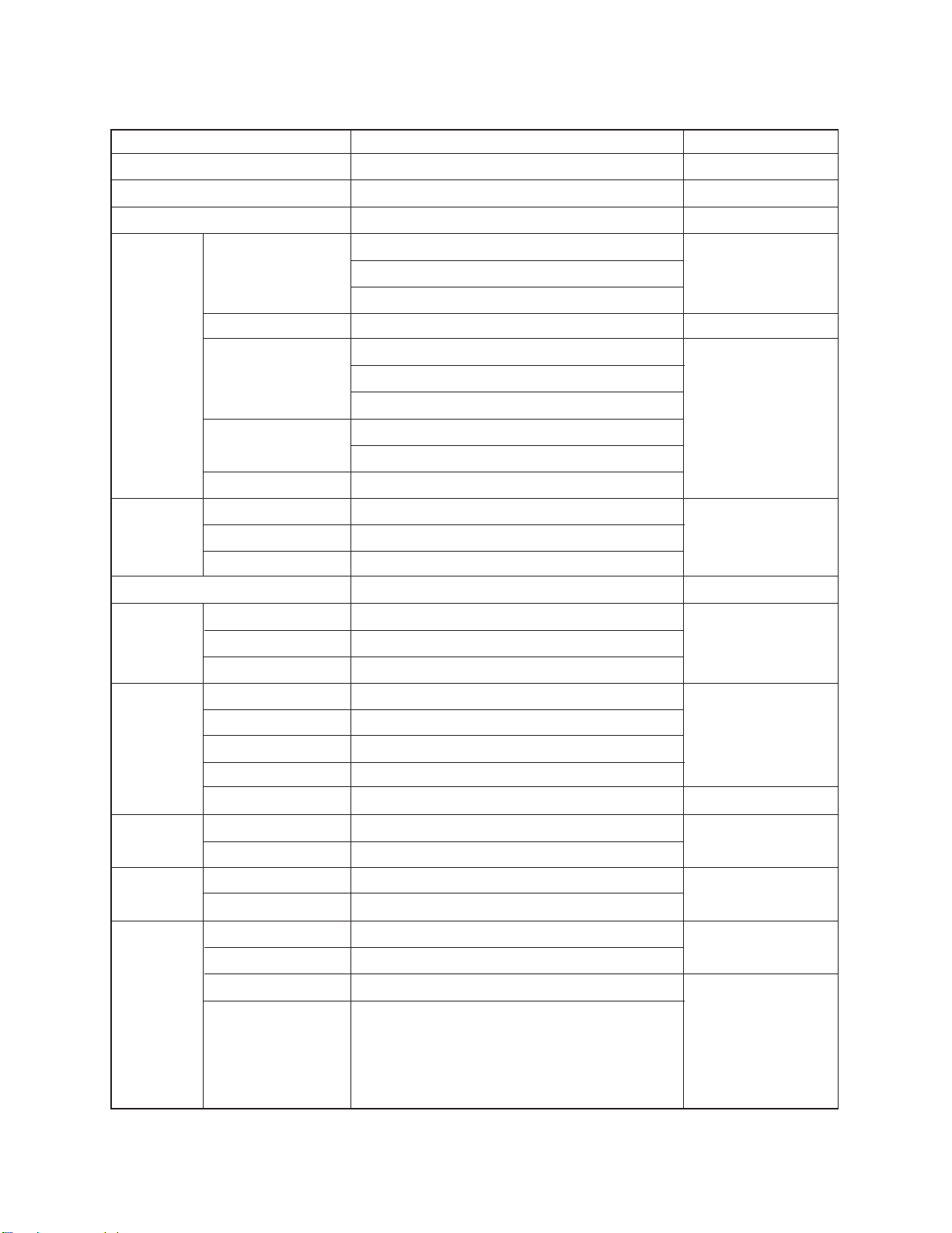

2-1 General Specifications

Printing method

Printing direction

Printing speed

Print format

Paper feed

Print head

Detection

functions

Paper feed

solenoid

Print solenoid

Total number of dots

Basic character configuration

Basic number of columns

Character dimensions

Column spacing

Paper feed principle

Paper feed pitch

Fast-forward speed

Inking

Number of wires

Wire diameter

Wire pitch

Dot pulse

Reset pulse

Home position

Validation

Near end

Drive voltage

Resistance

Drive voltage

Resistance

Rating

Serial impact dot matrix printer

Bi-directional printing

Approx. 3.0 lines/second m10%

Receipt side: 108 dots/216 positions

Journal side: 108 dots/216 positions

Validation: 248 dots/495 positions

7 x 7 or 7 x 9 (half-dot)

Receipt: 24

Journal: 24

Validation: 55 (1line)

1.36 (W) x 2.4 (H) mm (7 x 7 dots)

1.36 (W) x 3.1 (H) mm (7 x 9 dots)

1.59 mm

Friction feed, separate for receipt and journal

4.23 mm m10% (1/6 inch)

Approx. 30.0 lines/second

Dedicated ribbon cartridge (monochrome: purple)

9

Ø 0.3 mm

H: 0.176 mm, V: 0.353 mm

Photo interruptor

Photo interruptor

Photo interruptor

Photo interruptor

Micro switch

24.0 V DC m10%

˚C

34 ohms m10% (at 25

)

24.0 V DC m10%

˚C

8.25 ohms m10% (at 25

)

RemarksItem

24.0 V DC, 25˚C, continuous printing

Character spacing: 2 positions

Option

Motor

Type

Drive voltage

Peak current

Average current

DC brush motor

24.0 V DC m10%

Approx. 1.6 A

Approx. 250 mA

2

At startup with 24.0 V DC, 25˚C

During continuous

printing with 24.0 V DC,

25˚C

Page 5

Rating

Printer paper Width: 44.5 0.5 mm, outer diameter: max. Ø 83 mm

Take-up device

Connection principle

Service life

Ambient

conditions

Dimensions

Roll paper

Validation paper

Mechanism

Head

Operation

environment

Storage

environment

135 - 210 mm (W) x min. 70 mm (H) Single-line validation

Built-in

Pin connector

MCBF 4 million lines, maximum 8 million lines

100 million characters (2 million dots/pin)

Temperature: 0 to 50˚C

Humidity: 10-90% RH, above 39˚C equivalent to 40˚C 85% RH

Temperature: -25 to +70˚C

Humidity: 40˚C 90% RH, 96 hours

150 (W) x 230.3 (D) x 150.7 (H) mm (Type A)

150 (W) x 234.6 (D) x 123.7 (H) mm (Type B)

RemarksItem

No condensation

To be stored with ribbon

cartridge removed

Including take-up

device

Weight

Approx. 1180 g

3

Page 6

)

2-2 Mechanism Outline

g

The mechanism of this printer can be divided

into 9 blocks.

• Drive force transmission assembly

• Sensor assembly

• Print head assembly

• Paper feed assembly

• Ribbon cassette assembly

• Paper take-up assembly

• Frame

• Motor assembly

For information on peripheral circuitry

connected to this printer, please refer to the

respective documentation.

2-3 Mechanism and Operation

Principles

This section explains the construction and

operation of 8 out of the 10 blocks listed above

(excluding the frame and motor assembly).

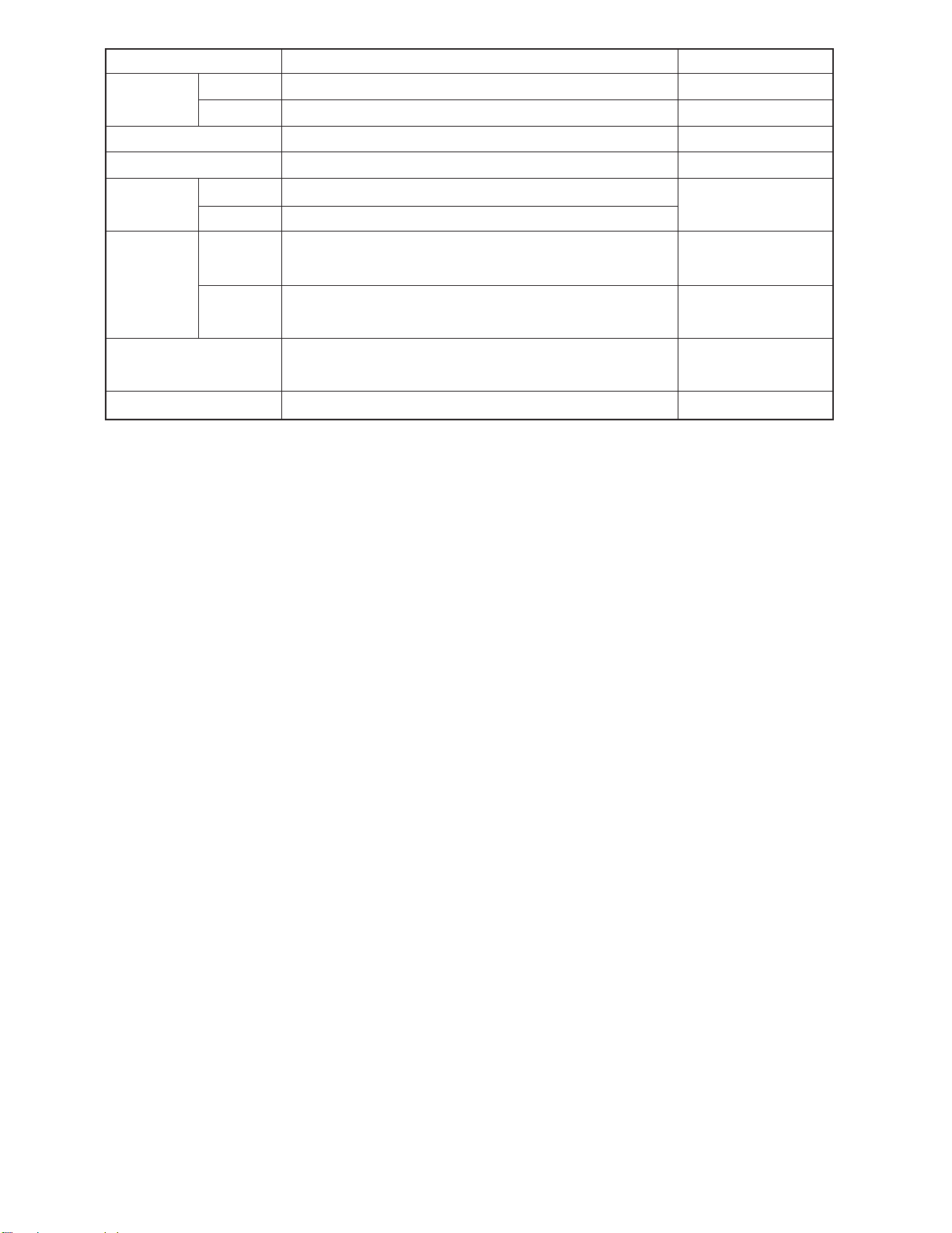

2-3-1 Drive Force Transmission Assembly

The drive force of the motor assembly is

transmitted to the various parts as follows. Print

head via bevel gear, Paper feed, via PF gear,

Ribbon cassette via worm wheel, Paper take-up

assembly via winder pulley.

2-3-2 Sensor Assembly

The sensor assembly is comprised of 3 sensors;

the dot pulse sensor (DP), home position sensor

(HP) and reset pulse sensor (RP).

(1) Dot pulse sensor/home position sensor

Main PCB assembly

Home position sensor (HP)

Dot pulse sensor (DP

Motor assembly

(2) Reset pulse sensor

Worm wheel

Motor assembly

Idling gear 2

Idling gear 1

Bevel gear 1

Bevel gear 2

Motor gear

Reduction gear 1

PF gear

Reduction

gear 2

Reduction

gear 4

Reduction

ear 3

Winder

pulley

Reset pulse sensor (RP)

Main PCB assembly

Head assembly

Carriage

4

Page 7

g

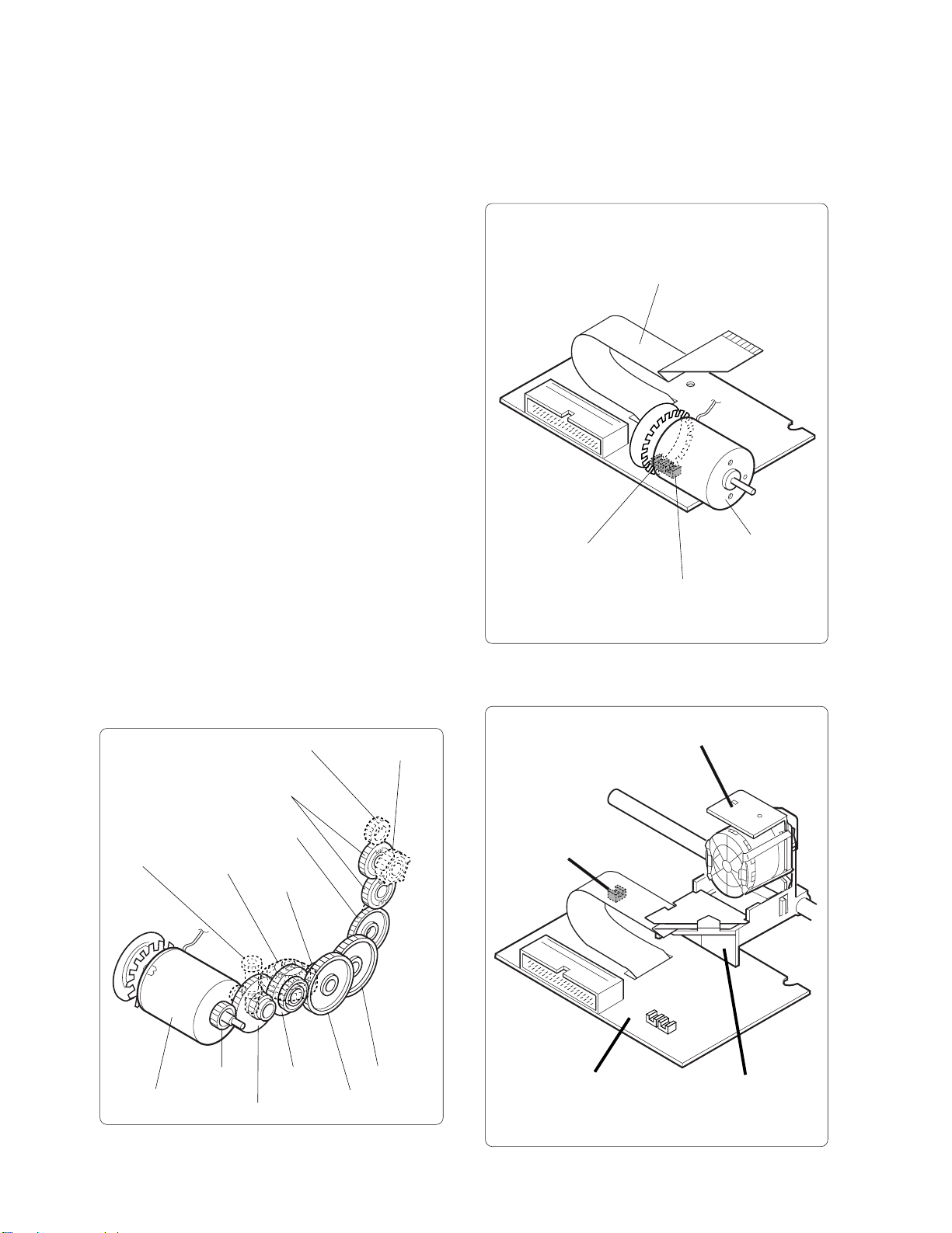

(2) Head drive assembly

Head assembly

Carriage drive pulley

Timing belt assembly

Carriage drive pulley

Carriage

2-3-3 Print Head Assembly

(1) Print control

Printing is carried out by the print head

comprising of 9 solenoids and moving from left

to right. The print timing is controlled by the

home position sensor (HP), dot pulse sensor

(DP), and reset pulse sensor (RP).

Print head

Powered

Powered

Powered

Powered

Powered

Powered

Powered

Powered

Powered

HP

DP

Print solenoid #1

Print solenoid #2

Print solenoid #3

Print solenoid #4

Print solenoid #5

Print solenoid #6

Print solenoid #7

Print solenoid #8

Print solenoid #9

Home position sensor

Dot pulse sensor

Carriage drive gear

ear 1

Bevel

(3) Print head drive assembly

Wire spring

Print wire

Armature

Solenoid assembly

Bevel gear 2

Armature stopper

Armature springNose assembly

RP

Reset pulse sensor

5

Page 8

2-3-4 Paper Feed Assembly

g

(1) Paper feed mechanism

2-3-5 Ribbon Cassette Assembly

(1) Ribbon cassette feed mechanism

Pressure rollers

Idling gear 2

PF gear

PF roller

assembly

PF latches

PF armature

PF solenoid

assembly

Ribbon cassette

Ribbon drive shaft

Ribbon drive gear

Worm wheel

Reduction

ear 1

6

Page 9

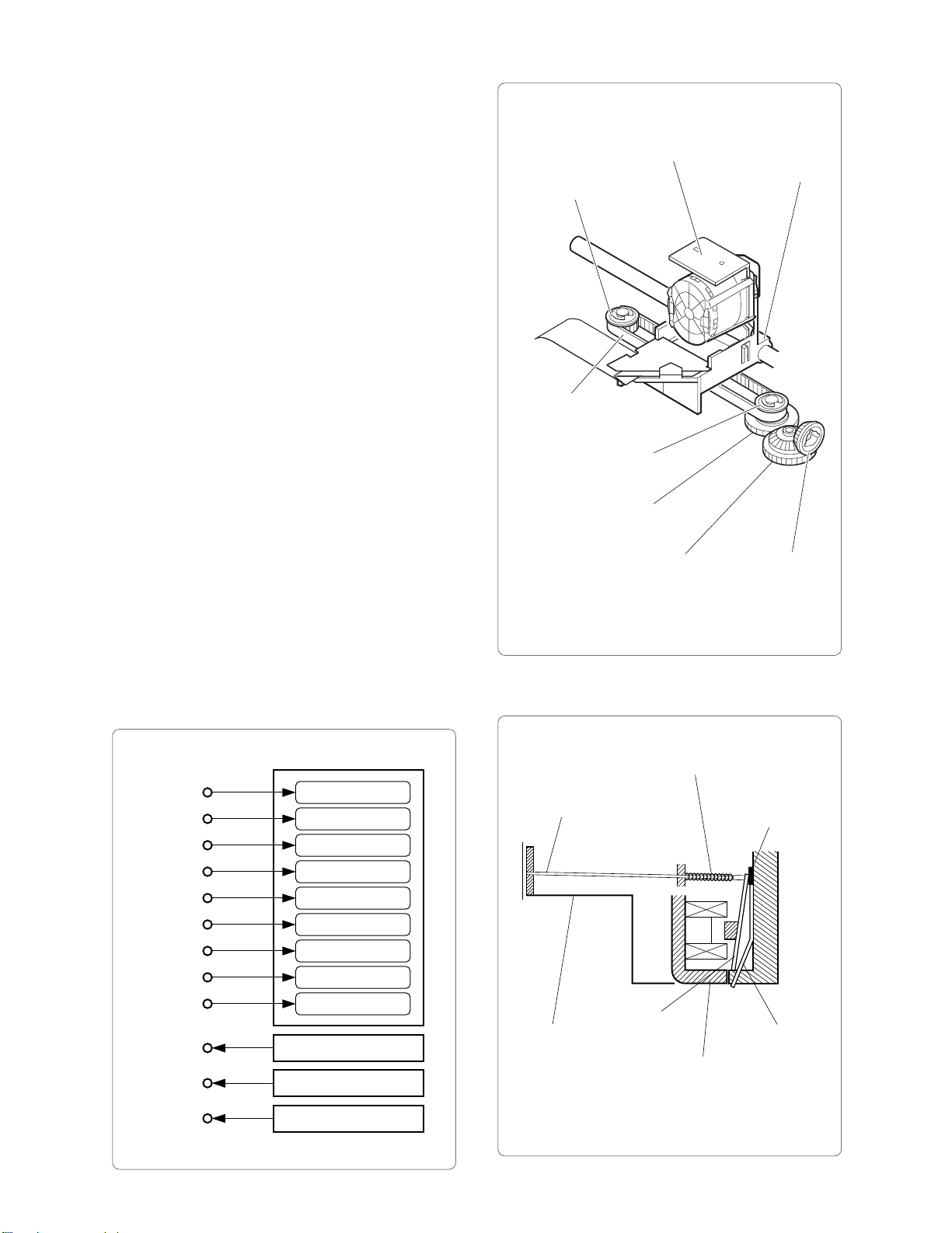

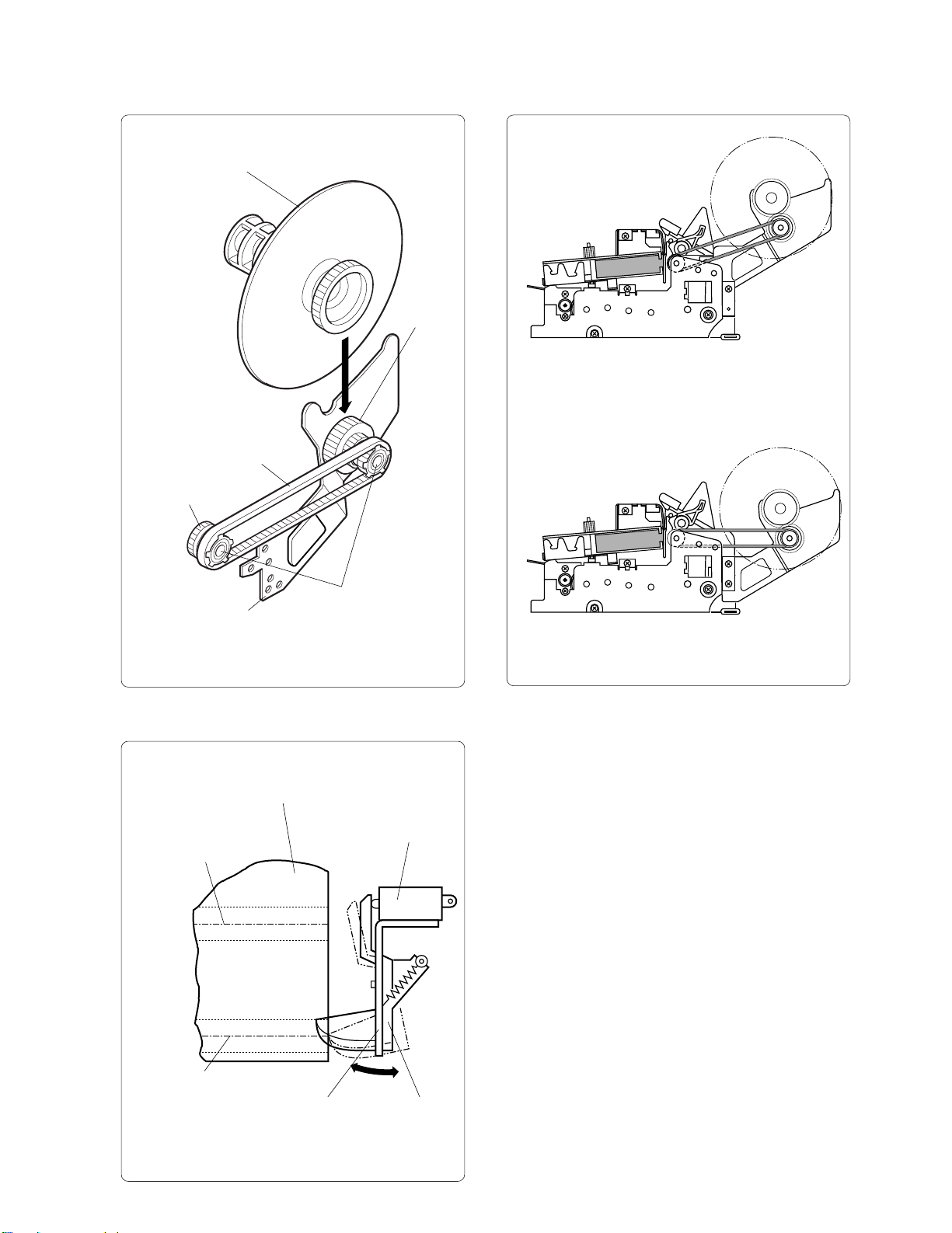

2-3-6 Paper Take-up Assembly

(1) Paper take-up mechanism

Spool

Winder timing belt

Idle gear 2

(3) Take-up mechanism types

Spool gear

Type which is the same height as the main unit

Spool holder assembly

(2) Near-end detection mechanism

Roll paper

Roll paper core

hole center

(when diameter is large)

Winder pulleys

Type which is lower than the height of the main unit

Microswitch

Roll paper core

hole center

(when diameter is small)

End switch leverSwitch holder

7

Page 10

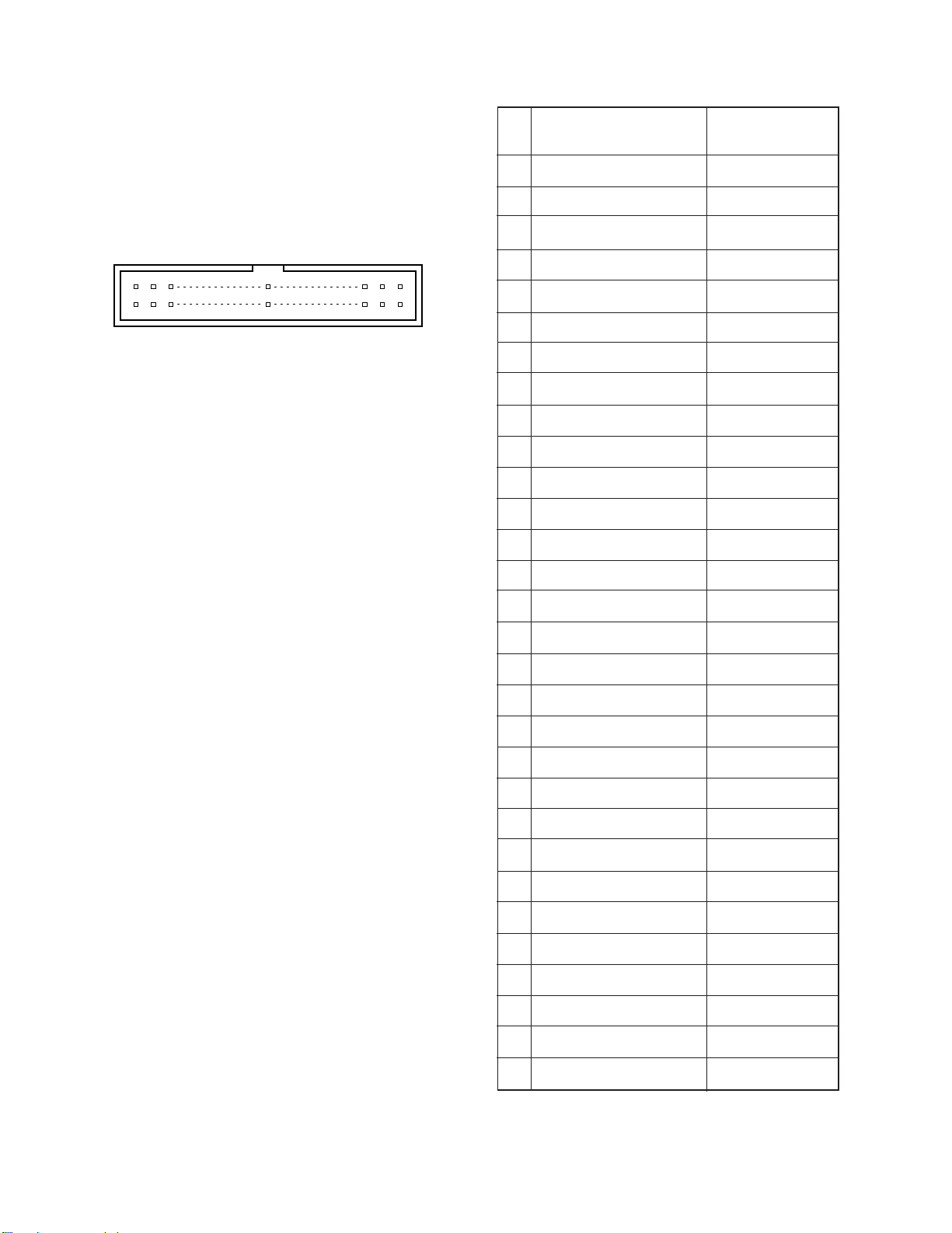

2-4 Connectors

2-4-2 Terminal Functions

2-4-1 Terminal Layout

Connector type

Printer side: Molex 5342-30T2

Host side: Molex 5320-30AT2

Pin arrangement diagram

29

30

Pin

no.

1

2

3

1

4

5

2

6

7

8

9

10

11

12

13

14

Terminal name Function

Print solenoid #3

Motor (-) VM COM.

VM COM.

Print solenoid #7

Motor on/off signal

Print solenoid COM.

Home position sensor output

Print solenoid COM.

VS

VS

Dot pulse sensor output

Print solenoid #5

Motor (+)

+VM (+24 V)

Print solenoid #2

—

Print solenoid #1

—

Multi-line validation

SOL. (option)

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

Print solenoid #9

—

Print solenoid COM.

—

Print solenoid #8

Paper feed solenoid (J)

Print solenoid #4

Paper feed solenoid (R)

Print solenoid COM.

GND

Print solenoid #6

Reset pulse sensor output

—

—

+5 V

VS

VS

30

—

8

Page 11

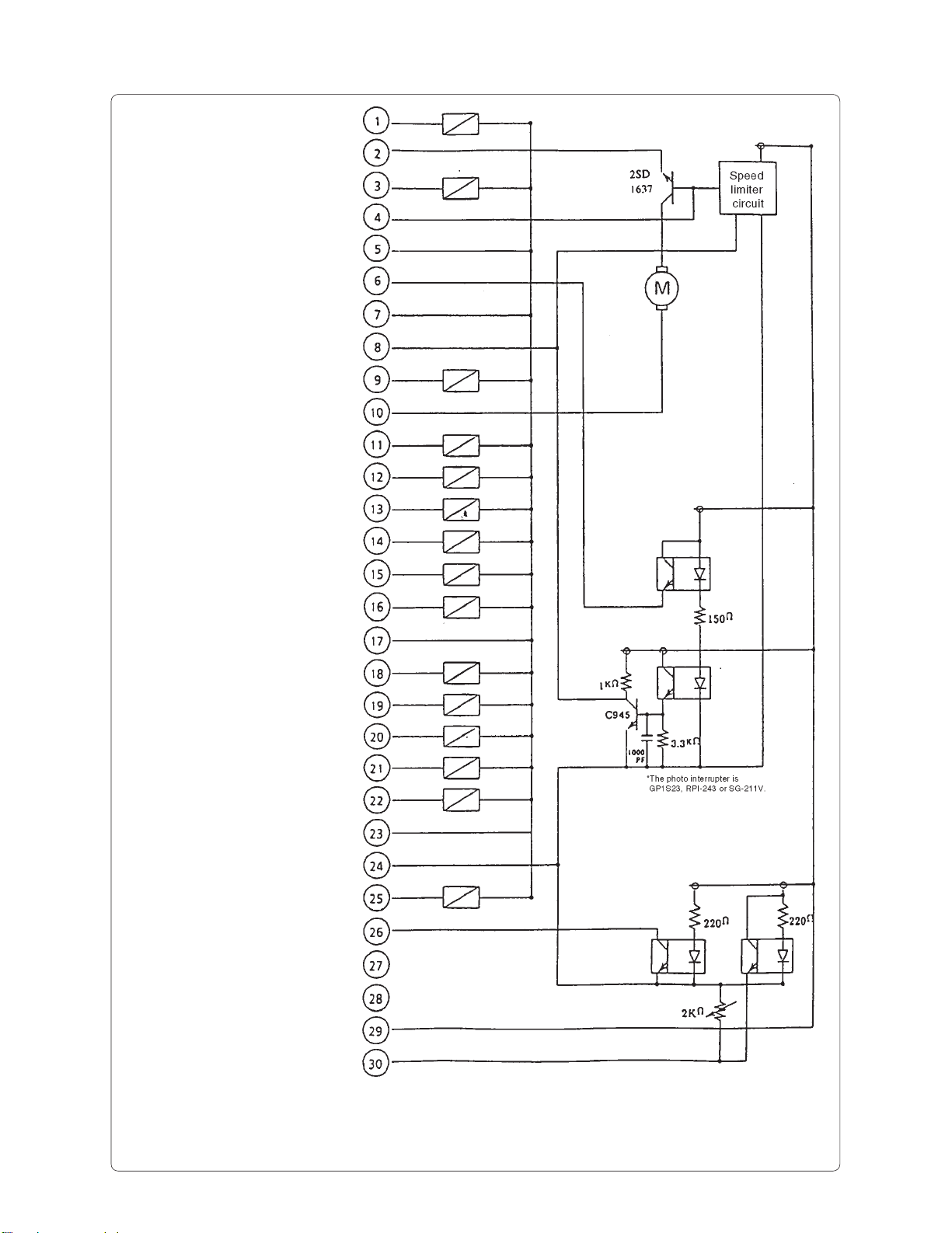

2-4-3 Terminal Circuit Diagram

Print solenoid #3

Motor (-) 24 V GND

Print solenoid #7

Motor ON/OFF signal

Print solenoid COM. (VS)

H.P. (home position pulse)

Print solenoid COM. (VS)

D.P. (dot pulse)

Print solenoid #5

Motor (+) (+24 V)

Print solenoid #2

(reserved)

Print solenoid #1

(reserved)

Print solenoid #9

(reserved)

Print solenoid COM. (VS)

Blank

Print solenoid #8

Paper feed solenoid (J)

Print solenoid #4

Paper feed solenoid (R)

Print solenoid COM. (VS)

GND

Print solenoid #6

RP (reset pulse)

Blank

Blank (RP)

+5 V

Blank

9

Page 12

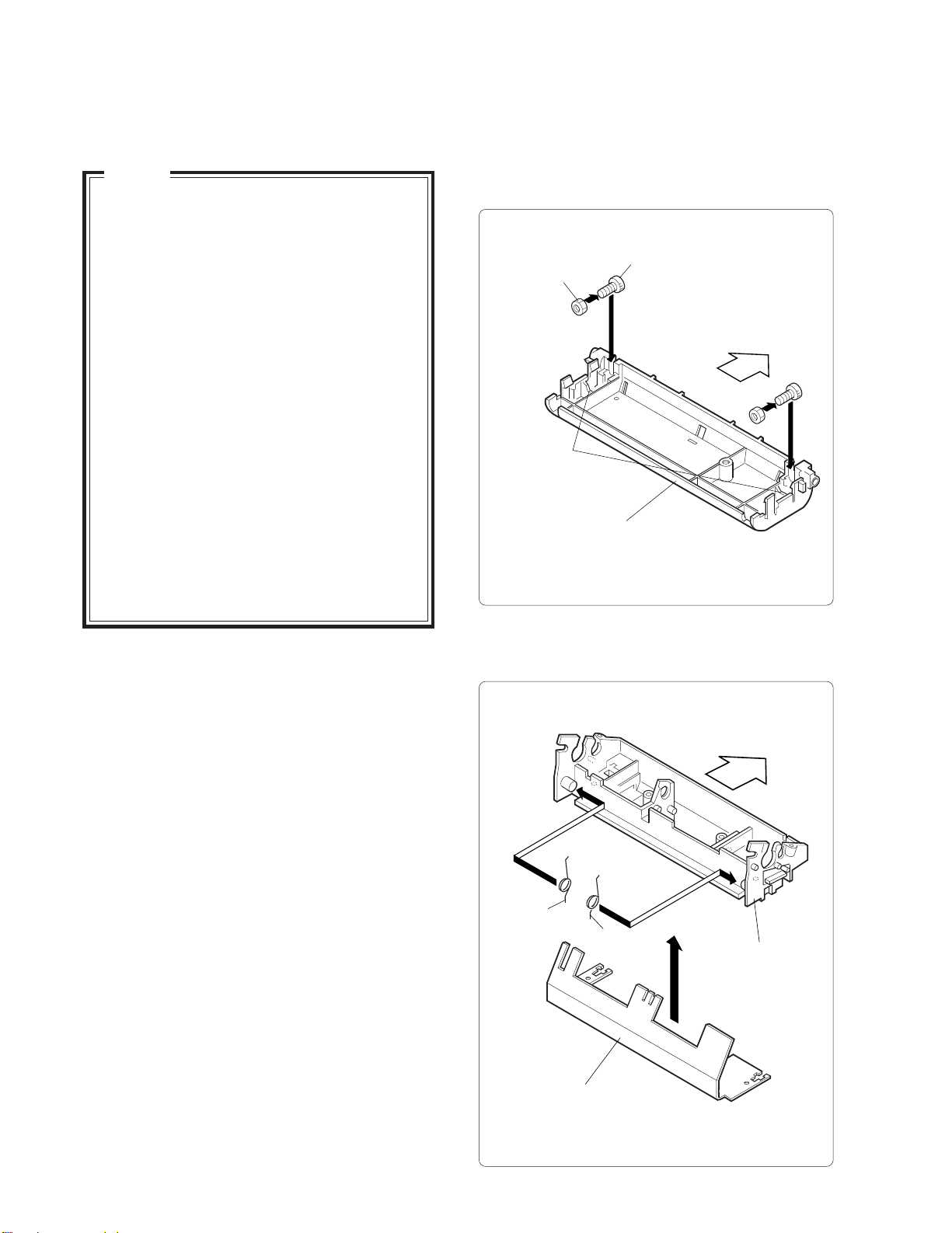

CHAPTER 3. Disassembly and Assembly

Please observe the following precautions when

performing maintenance.

Note

(1) If the unit is working properly, do not

disassemble, reassemble, or adjust it

unnecessarily. The adjustment screws in

particular should not be loosened needlessly.

(2) After servicing, double-check that the unit

has been assembled correctly before turning

the power on.

(3) Never attempt to print when printer paper is

not loaded.

(4) Verify that the printer paper is loaded

correctly.

(5) When servicing the unit, take care not to

leave any screws or other loose parts in the

unit.

(6) When disassembling and reassembling the

unit, take care not to place strain on any

connecting wires, and check that the wires

are not damaged or routed incorrectly.

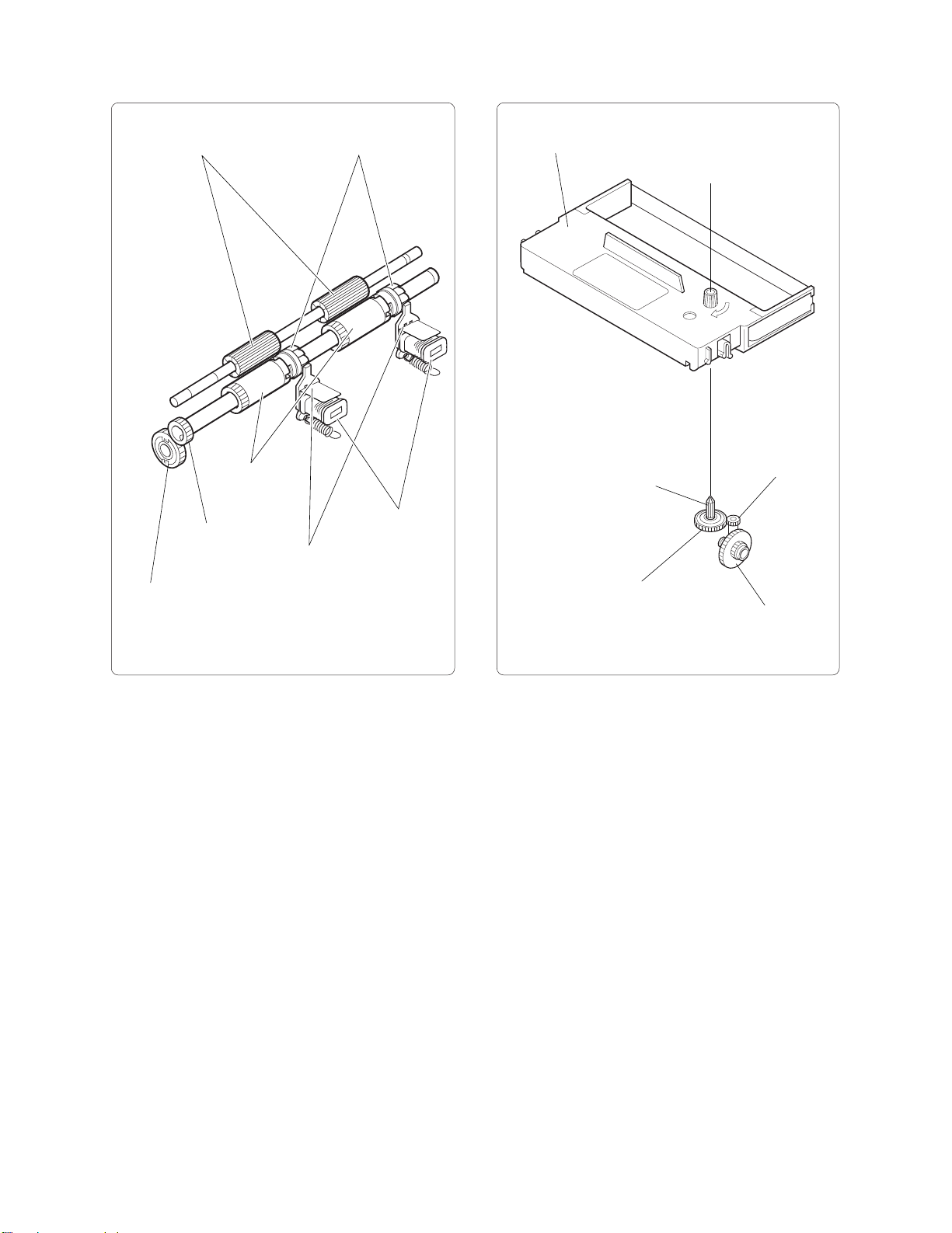

(1) Screw nuts on fastening screws (M3x10 hex socket

screws) and insert screws into paper guide (U). Make

sure that nuts fit snugly into V-shaped cutouts on

paper guide (U).

Fastening screw

Nut

Rear

V-shaped cutout

Paper guides (U)

3-1 Required Tools

1. Phillips screwdriver 8. Tester

2. Flatblade screwdriver 9. Oscilloscope

3. Pincette 10. Thickness gauge

4. Mini radio pliers (0.5 mm)

5. Oil brush 11. Dial tension gauge

6. Mini nipper (30 - 50 gf)

7. Hex wrench

(nominal 2.5)

3-2 Disassembly Procedure

Remove the parts from the frame in the opposite

order from the steps described in "3-3 Assembly

Procedure".

3-3 Assembly Procedure

The description of the assembly procedure

assumes that the individual assemblies are

complete. For information on the procedures for

individual assemblies, please refer to "Section 5

Parts List". The part names used in the

explanatory text are those indicated in Section 5

“Parts Lists”. These part names are used

commonly throughout this service manual.

(2) Fit pressure roller springs (L) and (R) onto both sides

of PF housing and set platen assembly in place.

Rear

Pressure roller

spring (L)

Platen assembly

Pressure roller

spring (R)

PF housing

10

Page 13

(3) Fit PF housing with mounted platen assembly into

paper guide (U) and fasten it with fastening screws

(A) (M3x6) and other fastening screw (M3x8).

Note: 1. When performing assembly procedures,

push the PF housing down until it is secured

by the four hooks on the paper guide (U).

2. Tighten the mounting screws (A) only after

adjusting the head gap.

Fastening screw (A)

PF housing

Hooks

Paper guide (U)

Rear

Hooks

(4) Apply Moly LG-S No. 1 to entire clutch spring area

on receipt side of PF shaft.

Note: 1. The PF shaft should have the slit on the

journal side and should not be on the

receipt side.

2. Apply the Moly LG-S No. 1 at about 30

mm from the tip of the receipt side.

(5) Apply Moly LG-S No. 1 to the inside of PF clutch

spring 2 and mount it on the clutch spring section

on the receipt side of the PF shaft.

Note: To facilitate mounting the spring, rotate it

in the direction where the spring

compresses while pushing it in.

(6) Mount PF roller assembly and journal PF latch onto

PF shaft from journal side.

Note: Pay attention to the mounting orientation

of the PF roller assembly and the PF latch.

Receipt side

PF clutch spring 2

Approx. 30 mm

Apply Moly LG-S No. 1

PF shaft

Receipt PF roller assembly

(7) Apply Moly LG-S No. 1 to the entire clutch spring

mounting section on the journal side of the PF shaft.

Note: Apply the Moly LG-S No. 1 at about 60

mm from the tip of the journal side.

(8) Fit the PF clutch spring onto clutch spring section

on journal side of PF shaft.

Note: To facilitate mounting the spring, rotate it

in the direction where the spring

compresses while pushing it in.

(9) Apply Mobile 1 to the PF shaft on the right and left

of the PF clutch springs.

Note: 1. Apply Mobile 1 for a width of about 5 mm,

starting about 10 mm from the right edge

of the PF clutch spring. This is the

mounting position for the PF roller

assembly.

2. The PF latch and PF clutch spring are

different on the receipt side and journal

side.

Receipt side: PF latch 2 (milk white)

PF clutch spring 2 (0.5 mm

dia.)

Journal side: PF latch 2 (black)

PF clutch spring (0.6 mm

dia.)

Journal side

Slit

Journal PF latch

11

Page 14

g

(10) Mount the PF latch 2 onto PF shaft from the receipt

side, and the PF roller assembly from the journal side.

Receipt side

PF latch 2

Journal side

5mm

Apply Mobile 1

PF latch

10mm

PF clutch spring 2

(Apply Moly LG-S No. 1

to outer circumference)

(Apply Moly LG-S No. 1

to outer circumference)

5mm

PF clutch spring

(11) Engage the PF roller assembly, PF latch and PF latch

2 with PF clutch spring and PF clutch spring 2,

respectively.

Note: There are protrusions at both ends of the

PF clutch springs. Match these to the slits

on the PF roller assembly and the PF latch.

5mm

Apply Mobile 1

10mm

5mm

PF roller assembly

(12) Insert the PF shaft assembly into the PF housing

and apply ORELUBE G-1/3 to the left and right

fixing lever (L)and (R).

Note: When mounting the PF shaft assembly,

match the PF roller assembly and PF latch

position to the platen width of the PF

housing.

Apply ORELUBE G-1/3

PF shaft assembly

Platen

Rear

Apply ORELUBE G-1/3

PF housin

PF latch

(PF latch 2)

PF clutch spring

(PF clutch spring 2)

Protrusion

Slit

Protrusion

PF roller assembly

Slit

12

Page 15

(13) Mount fixing levers (L) and (R) and PF gear on to

y

the PF shaft assembly, and fasten with E-rings (E4).

(14) Attach the fixing lever spring to fixing levers (L)

and (R).

(15) Insert the paper guide spring into pressure roller

shaft assembly.

Note: Pressure roller shaft assembly refers to

the pressure roller shaft with mounted

pressure rollers.

(16) While pushing the pressure roller springs (L) and

(R) towards the front side, mount the pressure

roller shaft assembly in the PF housing.

Note: After mounting, verify that the pressure

roller springs (L) and (R) are firmly

engaged in the grooves of the pressure

roller shaft assembly.

(17) Apply FLOIL G-337 to the PF armature tip. Then

mount the PF solenoid assembly to the PF housing

and fasten it with fixing screws (M3x8).

Fixing screws

Apply

FLOIL G-337

PF solenoid

assembly

Rear

PF housing

E-ring

Pressure

roller spring (L)

Fixing

lever spring

PF shaft

assembly

Groove

(Apply ORELUBE G 1/3)

Pressure roller

shaft assembly

(Apply ORELUBE G 1/3)

Fixing

lever (L)

Groove

Fixing lever (R)

Rear

PF housing

Pressure

roller spring (R)

Paper

guide spring

PF gear

E-ring

Fixing

lever spring

(18) Install the pull paper guide to the pressure

roller shaft assembly.

Note: When installing, engage one end of the

paper guide spring in the top right cutout

of the pull paper guide and the other end

in the slit of the PF shaft assembly.

Cutout

Pull paper guide

Rear

Paper guide spring

Pressure roller

shaft assembl

13

Page 16

(

)

(19) Install four paper side guide plates on the bottom

g

of paper guide (U).

(23) Apply ORELUBE G-1/3 to the pivot of the main

frame assembly. Mount the carriage drive gear and

carriage drive pulley and fasten with E-ring (E2.5).

Rear

Paper guide (U)

Paper side

uide plates

(20) Insert the washer and spool spring into the spool

gear assembly and apply Moly LG-S No. 1.

Note: 1. The spool gear assembly refers to the spool

gear with inserted spool spring bush.

2. When installing, the hook of the spool

spring should face forward, and the spring

should be turned counterclockwise.

(21) Apply Moly LG-S No. 1 to the outer circumference

of the spool spring and install the winder pulley.

(22) Apply Moly LG-S No. 1 to the pivot of the spool holder

assembly. Fit the spool gear assembly with the mounted

winder pulley in and fasten it with E-ring (E3).

Carriage drive gear

Main frame

assembly

E-ring

Carriage drive pulley

Apply ORELUBE G-1/3

Pivot

Rear

Pivot

E-ring

Winder pulley

Spool gear

assembly

Spool holder assembly

(Apply Moly LG-S No. 1 )

Apply Moly LG-S No. 1

Washer

Spool spring

14

Page 17

(24) Apply ORELUBE G-1/3 to the pivot of the pulley

drive assembly. Mount the carriage drive pulley and

fasten with E-ring (E2.5).

(25) Align the positions of the mounted carriage drive

pulley cutout and the cutout of the other carriage drive

pulley andmount timing belt assembly.

(26) Provisionally fasten the pulley drive assembly with

M3 washer and fastening screw (M3x5).

(27) Move the carriage drive pin to the center of the pulley

drive assembly, perform the tension adjustment to

determine the position of pulley drive plate assembly,

and fasten the assembly. Use a dial tension gauge

for the tension adjustment. When pushed with a force

of 30 gf, the timing belt displacement must be 2 mm.

(28) Apply ORELUBE G-1/3 to the fastening boss of the

stamp lever plate in the paper guide (L) assembly and

to the three slits contacting the plate.

Note: Paper guide (L) assembly refers to the

paper guide (L) with pressure rollers,

paper pressure sheet, 1-line validation

PCB assembly and validation guide plate

installed.

Rear

Paper guide (L)

assembly

Fastening screw

Washer

Main frame

assembly

Apply

ORELUBE G-1/3

Pulley drive plate assembly

Pulley drive

plate assembly

Position

adjustment

E-ring

Carriage drive pulley

2mm 30gf

Timing belt

assembly

Rear

Carriage drive

assembly

Carriage drive

pin center position

(Apply ORELUBE G-1/3)

Boss

(29) Install the paper guide (L) assembly in the main frame

assembly and fasten with fastening screws (M3x6).

Fastening screw

Stamp lever plate

Paper guide (L)

assembly

Rear

15

Main frame assembly

Fastening

screw

Page 18

y

(30) Mount the motor assembly and motor spacer on to

the right side of the main frame assembly and

fasten with fastening screws (M3x5).

Note: Mount the motor so that the lead wires are

on the bottom side.

Motor assembly

Rear

Motor spacer

Rear

Main frame

assembly

(31) Apply ORELUBE G-1/3 to the three pivots on the

right side of the main frame assembly.

Fastening

screws

Rear

E-ring

Main frame

assembly

Motor gear

Bevel gear 1

Bevel gear 1

pivot

E-ring

(34) Install the idle gear 1 and idle gear 2 and the winder

pulley assembly.

Note: 1. Winder pulley assembly refers to the

winder pulley with the idle gear 2 installed.

2. Mount the winder gear 2 and the winder pulley

assembly while disengaging the securing

hook.

Rear

Winder pulley

assembly

Pivot

Main frame

assembly

(Apply ORELUBE G-1/3)

(32) Mount the motor gear on the shaft of the motor assembly.

(33) Install the bevel gear 1 and fasten with E-ring (E2) over

the bevel gear 1 pivot.

16

Main frame

assembl

Idle gear 2

Securing hook

Idle gear 1

Page 19

(35) Apply ORELUBE G-1/3 to the four pivots on the

y

frame (R) support plate assembly and on the ribbon

drive shaft mount hole.

Bevel gear 2

assembly

Reduction gear 2

Reduction gear 4

Rear cushion

Apply ORELUBE G-1/3

Apply ORELUBE G-1/3

Frame (R) support

plate assembl

(36) Apply ORELUBE G-1/3 to the ratchet on inside of

ribbon gear and mount on ribbon drive shaft. Then

install the frame (R) support plate assembly and

fasten with E-ring (E4).

E-ring

Ribbon gear

Ribbon drive shaft

E-ring

Washer

Reduction gear 1

Frame (R) support

plate assembly

(41) Rotate the motor gear so that timing disc home

position slit is at the topmost position. Then rotate

bevel gear 1 so that the carriage drive pin is at the

horizontal left most position.

Carriage drive pin

horizontal left most position

Rear

Frame (R) support

plate assembly

Apply ORELUBE

G-1/3 to ratchet

(37) Combine reduction gear 4 and the bevel gear 2

assembly, and install.

Note: Bevel gear 2 assembly refers to reduction

gear 3 with installed bevel gear 2.

(38) Mount the reduction gear 2.

(39) Install the reduction gear 1 and slide washer, and

fasten with E-ring (E2).

(40) Install the rear cushion.

Note: Install the rear cushion from the side

opposite the slit.

Home position slit

top most position

Timing disc

Bevel gear 1

Motor gear

17

Page 20

(42) Pull the winder timing belt onto the winder pulley

y

assembly.

(43) Install the frame (R) support plate assembly on to the

main frame assembly and fasten with fastening screws

(M3x8).

Rear

Winder pulley

assembly

Rear cushion

Rear

Winder

timing belt

Main frame

assembly

Frame (R) support

plate assembl

Fastening

screws

(44) Apply EPINOC AP-1 to the gears of the worm

wheel assembly.

(45) Set the worm wheel assembly in the worm wheel

assembly mounting position on the frame (R)

support plate assembly.

(46) Mount E-ring (E2) on to the worm wheel pivot.

(47) Apply EPINOC AP-1 to the worm wheel pivot.

(48) Insert the worm wheel pivot from the hole in the

bottom of the main frame assembly and install

in the worm wheel assembly.

(49) Push the worm wheel pivot into the hole of the ribbon

pivot bushing and fit the bushing into the frame (R)

support plateassembly mount hole. Then fasten

with E-ring (E1.5).

(50) Mount the rear cushion on the main frame assembly.

Note: Install the rear cushion from the side

opposite the slit.

Main frame

assembly

Frame (R) support

plate assembly

Ribbon pivot bushing

Gear

(Apply EPINOC AP-1)

Worm wheel

assembly

Worm wheel pivot

(Apply EPINOC AP-1)

E-ring

Mount

hole

E-ring

(51) Apply EPINOC AP-1 to the moving part of the carriage

on the main frame assembly, and apply ORELUBE G-1/3

to the carriage drive pin of the timing belt assembly.

Carriage drive pin

(Apply ORELUBE G 1/3)

Carriage moving part

(Apply EPINOC AP-1)

Rear

Main frame

assembly

18

Page 21

(52)

Mount the felt on the carriage and install in the

main frame assembly with the carriage shaft

inserted from the left side.

Note:1.Moisten the felt with Mobile 1.

2. When installing, start from a position

where the carriage drive pin is parallel to

the receipt side wall of the main frame

assembly (see illustration).

3. Insert the carriage shaft from the nonchamfered end.

(53) Fasten the carriage shaft to the main frame assembly

with the washer and fastening screw (M3x3).

Fastening

screw

Main frame

assembly

PF housing

assembly

Rear

Boss

(There is a boss in the

opposite side as well)

Fastening

screw

Fastening screw

washer

Carriage

shaft

Fastening

screw

Carriage drive pin

Main frame assembly

Chamfered section

Carriage

Carriage shaft

Screw mount

hole

Felt

(54) Apply ORELUBE G-1/3 to two the PF housing

assembly mount holes (2 locations) on the main frame

assembly. Then install the PF housing assembly and

fasten with the fastening screws (M3x6).

Note: 1. The PF housing assembly has been built

in steps (1) - (27).

2. When installing the PF housing assembly,

fit the left and right boss into the mount

hole on each side in sequence.

Mount holes

(Apply ORELUBE G-1/3)

(55) Install the main PCB assembly from the bottom of

the main frame assembly.

Note: 1. Install after moving the carriage to the

center.

2. When installing, pass the lead wires of the

motor assembly through the rectangular

cutout in the PCB to the bottom side.

3. Take care that the ceramic condenser and

transistor on the PCB around dot pulse

sensor do not come into contact with the

motor assembly timing disc.

(56) Mount the FFC fixer plate on the main PCB assembly

and fasten with fastening screw (M3x6).

19

Page 22

(57) Place the insulating sheet and transistor on the main

PCB assembly, and fasten with the fastening screw

(M3x10).

Note: When installing, bend the transistor legs

at a right angle, in alignment with the

soldering holes on PCB.

(58) Screw the nut (M3) on to the fastening screw (M3x10)

and fasten the FFC fixer plate.

Fastening screw

Transistor

Insulating sheet

Carriage

Rear

Main frame assembly

Soldering holes

FFC fixer plate

Nut

Main PCB assembly

Ceramic condenser

Transistor

Rectangular cutout

Dot pulse sensor

Fastening screw

20

Page 23

(61)

Loosen the fastening screw of the frame (R) support

plate assembly and engage the winder timing belt

on the winder pulley of the winder assembly. Then

engage the winder assembly boss in the main frame

assembly hole, and fasten with fastening screws

(M3x6). Finally tighten the loosened screw again.

Note: The winder pulley has been assembled

with steps (20) - (22).

Head cable

Cable

fixing sheet

Head assembly

Rear

Main frame assembly

Frame (R) support

plate assembly

Rear

Winder timing belt

Loosen

Winder assembly

Boss

Fastening

screws

Winder

pulley

(62) Insert the head cable from the main PCB assembly

into the head assembly.

(68) Mount the head assembly in the carriage.

Note: 1. When installing, insert cable fixing sheet

into slit of carriage and mount carriage on

head assembly with cable grasped

between sheet and carriage.

2. Take care not to scratch the head cable.

Head cable Slit Carriage

(64) Install the ribbon plate assembly in the main frame

assembly and fasten with the fastening screws (M3x5).

Note: 1. Ribbon plate assembly refers to the ribbon

plate with blind label and ribbon cassette

cushion.

2. When installing, engage the protrusion on

the ribbon plate assembly in the mount

hole on the main frame assembly, and

then slide the assembly to the right.

Mount holes

Rear

Ribbon plate assembly

21

Fastening screw

Protrusions

Main frame

assembly

Page 24

(65) Insert the ribbon plate spring in the ribbon plate

assembly and the main frame assembly front center.

(66) Mount the head cover on the main frame assembly

and fasten with fastening screws (M3x5).

Note: While installing, the PF housing assembly

should be open.

Fastening screw

Rear

(68)

Install the grounding spring in the PF housing

assembly.

Note: 1. Insert the grounding spring between the

right side of the PF housing assembly and

the right side plate of the main frame

assembly.

2. Fit the bent sections of the grounding

spring into the positioning slits on the PF

housing assembly.

3. The bent tip of the grounding spring must

contact the PF shaft.

Head cover

Ribbon plate spring

PF housing assembly

Fastening

screw

(67) Mount the manual cutter on the 2-station housing cover.

2-station housing cover

Manual cutter

Protrusion

(Apply EPINOC AP-1)

Right

side plate

Positioning slit

PF housing assembly

Bent tip

(Apply EPINOC AP-1)

Grounding spring

PF shaft

Rear

Rear

22

Page 25

(69) Install the 2-station housing cover on the PF housing

assembly and fasten with fastening screws (M3x8).

Fastening screw

PF housing

assembly

2-station

housing cover

Rear

Fastening

screw

3-4 Adjustment

There are six adjustment items for this printer, as

listed below. Perform the adjustments in the listed

order.

(1) Print speed adjustment

(2) Platen/head gap adjustment

(3) Bidirectional printing shift adjustment

(4) Reset pulse (RP)/home position (HP)

waveform check

3-4-1 Print Speed Adjustment

(1) Procedure

Perform the bi-directional printing and use an

oscilloscope to measure cycle A of the reset pulse

(RP).

(70) Install the ribbon cassette.

Ribbon cassette

Rear

RP

A

(2) Check points

RP waveform: Connector pin 26

GND: Connector pin 24

Note Perform the adjustment under the

following conditions.

•Ribbon cassette: Loaded

•Printer paper: Loaded

•Motor drive voltage: 24V

•Ambient temperature: Normal room

temperature

•Printing mode: Continuous

printing

23

Page 26

(3) Adjustment

Adjust the print speed adjustment VR on the

solder side of the main PCB assembly until cycle

A falls within the range shown below.

Value of A Adjustment procedure

3-4-3 Bi-directional Printing Shift Adjustment

(1) Procedure

Perform bidirectional printing. Judge the results

and rotate the motor shaft while holding the

timing disc stationary, until there is no printing

shift.

601m-733ms

Print speed

adjustment VR

When A is out of range: Perform

adjustment by turning the VR.

Validation sensor

adjustment VR

Main PCB assembly

3-4-2 Platen/Head Gap Adjustment

(1) Procedure

1. Remove the 2-station housing cover.

2. Loosen the two fastening screws of the PF

housing platen assembly.

(2) Adjustment

Use a thickness gauge to measure the gap between

the head assembly and the platen assembly.

Adjust the two adjustment screws (M3x10 hex

socket screws) on the rear until the gap is within

the range shown below.

(2) Adjustment

Hold the timing disc stationary with a flat object

(such as the grip of a pincette). Grasp the motor

shaft with a pair of radio pliers and rotate the shaft

in the direction as indicated in the table below.

Print condition Adjustment procedure

Rotate shaft in clockwise

direction until shift is

within 1 dot.

Rotate shaft in

counterclockwise

direction until shift is

within 1 dot.

Gap Adjustment procedure

When gap is out of range:

0.5 - 0.55 mm

Adjust the gap by turning two

adjustment screws on rear.

Note 1. Adjust the gap in three locations (right,

left, center).

2. Retighten the loosened screws.

24

Page 27

3-4-4 RP/HP Waveform Check

(1) Procedure

Perform bi-directional printing and use an

oscilloscope to measure the phase shift A between

the reset pulse (RP) waveform and home position

pulse (HP) waveform.

OFF OFFON

RP

A

HP

DP

OFF

(2) Check points

RP waveform: Connector pin 26

HP waveform: Connector pin 6

GND: Connector pin 24

(3) Adjustment

Verify that the value of A is between 3 and 8 ms.

ON

25

Page 28

3-5 Head Assembly Replacement

Head cover

3-5-1 Disassembly Procedure

(1) Remove printer from the POS/ECR.

(2) Remove the ribbon cassette.

(3) Push the right and left fixing lever and open the PF

housing assembly.

Ribbon cassette

Rear

PF housing

assembly

Fixing

lever

Rear

Fastening

screw

Fastening

screw

(5) Move the ribbon plate as follows.

[1] Remove the ribbon plate fastening screw (M3x5).

[2] Raise the ribbon plate (rear side) and slide to left.

[3] Raise the ribbon plate (front) and disengage

from the main frame assembly protrusion.

[4] Raise the ribbon plate and rotate counterclockwise

around the ribbon drive shaft, until the head

cable is visible.

Note: Because the ribbon plate is tensioned by

the ribbon plate spring, care must be

taken not to damage the ribbon drive shaft

when turning the plate.

(4) Remove fastening screws (M3x5) and remove the head

cover.

26

Page 29

Ribbon plate

Fastening

screw

1

Ribbon plate

spring

Ribbon plate

2

Protrusion

4

Ribbon drive

shaft

3

Rear

(6) Grasp the left side of the cable fixing sheet and raise

to the left to remove.

Note: The cable fixing sheet is thin and small.

Take care not to drop it into the printer or

otherwise lose it.

(7) Grasp the protrusion on the head assembly and lift up.

(8) When the head assembly is removed from the carriage,

pull out the head cable and disconnect.

3-5-2 Assembly Procedure

(1) Plug the head cable into the head assembly connector.

Note: Make sure that the head cable is pushed

fully into the connector.

(2) Insert the head assembly into the carriage guide. Just

before the assembly is fully seated, push the bent

section of the head cable into the carriage slit.

Note: Take care not to damage the head cable.

(3) Push the head assembly further in until it locks into

place.

(4) Check orientation of the cable fixing sheet and

insert the sheet into the carriage slit.

Head assembly

Head cable

Cable fixing

sheet

Rear

Guide

Head assembly

Head cable

Cable fixing

sheet

Head cable Slit Carriage

Protrusion

Head cable Slit Carriage

Rear

27

Page 30

(5) Reinstall the ribbon plate by reversing the disassembly

procedure.

Note: Make sure that ribbon plate fastening

screw section is on the inside of the main

frame assembly.

Rear

Fastening

section

Fastening

screw

Ribbon plate

spring

Ribbon plate

4

3

1

Fastening screw

Head cover

Protrusion

Main frame

assembly

Rear

Fastening

screw

Protrusion

Ribbon plate

2

Ribbon drive

shaft

(6) Install the head cover.

Note: When installing, make sure that the head

cover left/right positioning part and the main

frame assembly left/right protrusion are

fully matched.

(7) Fasten the head cover with 2 screws.

(8) Open the PF housing assembly.

(9) Insert the ribbon cassette.

(10) Mount the printer in the POS/ECR system.

Ribbon cassette

Rear

PF housing

assembly

28

Page 31

If not rotating, replace motor.

Check points Countermeasure

Apply rated voltage (24 V DC) to motor lead solder

If not supplied, repair printer control

section.

points on main PCB assembly (+: red, -: black) and

check whether motor turns.

Measure voltage between pins 10 (+) and 2 (-) of

connector on main PCB assembly and verify that 24 V

If there is no conductivity, replace

main PCB assembly.

Remove any jammed paper or foreign

objects.

Replace print head assembly and

ribbon cassette.

DC is supplied.

Check conductivity between pin 10 of connector on

main PCB assembly and red motor lead, and pin 2 and

black motor lead.

Open PF housing and check for jammed paper or foreign

objects.

Check whether head wire is tangled in ink ribbon or

paper.

If not moving, remove any foreign

objects or replaced damaged gear.

Rotate motor gear by hand and check whether gear train

moves.

faults.

Symptom............. Begin searching with this column. If there are several symptoms, take all applicable items into consideration. This will allow you to discover a potential

When a problem has occurred, check the symptoms carefully and use the instruction in the section "4-2 Repair Steps" to isolate the problem. When the cause is found, repair

it as specified.

4-1 Repair Procedure

CHAPTER 4. Troubleshooting

problem.

Condition ............ Information given here is a precondition for determining the cause in the next column. Use the item together with the previous column to pinpoint the

Cause................... Lists conceivable causes. Select a possible cause from the list, and verify as described in the next column.

Check points ....... Perform these checks to confirm that the problem is really caused by the respective condition.

Countermeasure .. Repair the problem as described here.

By following the above procedure, effective troubleshooting is possible.

Motor is defective

Motor does not

operate.

Symptom Condition Cause

Carriage does not

move.

4-2 Repair Steps

29

Problem with voltage

applied to motor

Head movement problem

Main PCB assembly

is defective

Paper jam

Paper is jammed with ink

ribbon or print head wire.

Foreign object in gear

wheel train, or gear is

damaged.

Page 32

If there is a phase shift, reseat the time

belt assembly.

Lubricate if not sufficiently

lubricated.

If not supplied, repair the printer control

section.

Check points Countermeasure

Remove carriage and check engaging condition of

carriage drive pin and pulley.

Check whether carriage rails (front and back) are

lubricated.

Measure voltage between pins 29 (+) and 24 (-) of

connector on main PCB assembly and verify that 5 V DC

If signal is not normal, replace the main

PCB assembly.

If there is a problem, repair the printer

control section or replace the connecting

cable.

Reinsert FFC if disconnected.

is supplied.

Observe waveform of signal at pin 6 (HP), pin 8 (DP),

and pin 26 (RP) and check whether signal is normal.

Check circuit hardware of printer control section and

connection cable to printer.

Check FFC connection condition.

If operation is normal, replace the print

head assembly.

Check whether replacing print head assembly solves the

problem.

If not correct, reinsert.

If not supplied, repair the printer control

section.

If signal is not normal, replace the main

PCB assembly.

Note that if the printer control section is defective, the

head can be destroyed.

Verify that ribbon cassette is loaded correctly.

Measure voltage between pins 29 (+) and 24 (-) of

connector on main PCB assembly and verify that 5 V DC

is supplied.

Observe waveform of signal at pin 6 (HP), pin 8 (DP),

and pin 26 (RP) and check whether signal is normal.

Timing belt assembly and

pulley phase shift

Carriage actuator problem

DP/HP/RP signal problem

Motor does not

move.

Symptom Condition Cause

Carriage does not

move.

Head movement problem Print problem

Motor normal

Carriage does not

stop.

Control section problem

Head FFC disconnected

Print head assembly

is defective

Carriage operation

normal

Unit does not print

(all dots/specific

dots).

30

Ribbon cassette not

inserted properly

DP/HP/RP signal problem

Page 33

If there is a problem, repair printer

control section or replace connecting

cable.

Remove.

Check points Countermeasure

Check circuit hardware of printer control section and

the connection cable to printer.

Remove the print head assembly and check the print

section for presence of foreign objects. Check whether

Insert correctly.

the ribbon cassette is inserted correctly.

Replace ribbon cassette if there is a

problem.

Turn ribbon cassette take-up knob in arrow direction and

check knob rotation and take-up action of the ribbon.

If not rotating, remove foreign object

or replace gear if damaged.

Turn motor gear clockwise by hand and check whether

gear train moves.

Readjust the gap if necessary.

Repair the printer control section if

required.

If shift problem is cleared, perform

readjustment.

If not correct, prepare the paper tip

correctly and reinsert.

If out of range, replace with paper that

meets specified requirements.

Remove any paper scraps or foreign

object.

If out of range, replace the PF solenoid.

Check gap between print head and platen.

Check voltage and continuity of print solenoid voltage

supplied by printer control section.

Check whether shift disappears when rotating timing

disk while holding motor shaft.

Check whether paper tip is folded or not properly cut.

Check whether paper thickness, width, and roll diameter

are within specifications.

Open paper feed unit and check for jammed paper or

foreign object.

Measure whether resistance of PF solenoid is within

specifications (approx. 34 ohms).

Control section problem

Carriage operation

normal

Symptom Condition Cause

Unit does not print

(all dots/specific

Foreign object in print

dots).

section

Ribbon cassette not

inserted correctly

Ribbon cassette defective

Ribbon is not

transported.

Print is washed

out.

Print problem Paper feed problem

Foreign object in ribbon

drive mechanism or gear is

damaged.

Print head and platen gap

not correct

Control section problem

Ribbon feed is

normal.

Timing disc position

problem

Paper tip folded or not cut

correctly

Paper is not within

standard rating

Shift is greater

than 0.3 mm.

Bidirectional

printing shift

Cannot insert

paper.

31

Paper scraps or foreign

object

PF solenoid wire break

PF armature does

not operate.

Paper is not

transported at all

or erratically.

Page 34

If there is a problem, repair the printer

control section or replace connecting

cable.

If there is a paper jam, repair the paper

feed path.

If setting is incorrect, set the paper

properly.

If locked, remove foreign objects or

replace the gear if damaged.

If force is insufficient, replace the PF

slip mechanism.

If worn, replace any worn parts.

Check points Countermeasure

Check the circuit hardware of the printer control

section and the connection cable to the printer.

Check for a jam in the external paper path.

Check for a problem in the external paper setting mechanism.

Check for locking due to foreign object or damaged gear.

Check whether the PF slip mechanism has enough force

for paper feed.

Check the PF latch for wear.

If not set properly, reinsert correctly.

Check whether ribbon cassette is inserted correctly.

Replace the ribbon cassette as necessary.

If not rotating, remove any foreign

objects. If the gear is damaged, replace

the gear.

Turn ribbon cassette take-up knob in arrow direction and

check knob rotation and take-up action of the ribbon.

Turn motor gear clockwise by hand and check whether

the gear train moves.

Control section problem

PF armature does

not operate.

Symptom Condition Cause

Paper is not

transported at all

Paper jam outside printer

PF armature

or erratically.

Paper feed problem

operates.

Paper feed mechanism

is defective

Clutch mechanism is

defective

Ribbon cassette not

Paper feed amount

is too large.

Paper feed pitch is

wrong.

Ribbon is not

Ribbon feed problem

inserted correctly

Ribbon cassette is defective

Foreign object in ribbon

drive mechanism or gear

is damaged.

transported.

32

Page 35

DP-750

Parts guide

1 Mechanism etc No.1

NO. PARTS CODE

0CZC3401-637/

1

0CZE11130-05/

2

0CZE11130-06D

3

0CZE11230-08/

5

0CZE60330-00/

8

0CZE60340-00/

9

0CZM4317-02//

10

0CZNE09710-0/

20

0CZNE10201-0/

21

0CZNE10202-1/

22

0CZNE10203-0/

23

0CZNE10204-1/

24

0CZNE10206-0/

26

0CZNE10207-1/

27

0CZNE10208-1/

28

0CZNE12003-1/

29

0CZNE14104-0/

31

0CZNE14201-2/

32

0CZC4600-065/

33

0CZNE16701-0/

34

0CZNE19101-0/

35

0CZNE19102-0/

36

0CZNE20201-0/

37

0CZNE20202-1/

38

0CZNE20203-0/

39

0CZNE20205-1/

41

0CZNE23606-1/

52

0CZNE24208-0/

66

0CZNE26901-0/

71

0CZNE30701-0/

72

0CZNE30202-0/

73

0CZNE32001-0/

74

0CZNE32201-0/

75

0CZNE34102-1/

76

0CZNE43601-0/

79

0CZNE44108-1/

81

0CZNE66701-1/

84

0CZC7802-029/

87

0CZE00730-05/

88

0CZNE22005-0/

89

0CZE60320-00/

90

0CZNE64101-0/

100

0CZE40230-00/

101

0CZE11130-10/

102

0CZNE30702-0/

103

0CZT6209-01//

104

0CZNE34702-0/

105

0CZNE44707-0/

106

0CZNE11902-0/

107

0CZE50130-00/

108

0CZE00130-03/

109

0CZE60325-00/

110

0CZNE16702-0/

111

0CZNE44704-4/

112

0CZNE44702-6/

113

0CZNE10209-0/

114

0CZNE44711-1/

115

0CZNE29704-2/

116

0CZNE24702-4/

117

0CZNE24705-0/

118

0CZNE15701-3/

119

0CZNE31201-0/

128

0CZE60315-00/

129

0CZE50230-00/

220

0CZNE67906-1/

841

0CZNE66901-2/

842

PRICE

RANK

NEW

PART

MARK

AN B Transistor (2SD1637)

AD C Screw (PTH(ST),M3×5)

AD C Screw (PHT(ST),M3×6)

AD C Screw (PHT(PT),M3×8)

AD C E-ring (E3)

AD C E-ring (E4)

AH C Rear cushion

BS B SA, Head

AH C Gear, Motor

AH C Pulley, Drive, Carriage

AH C Gear, Drive, Carriage

AH C Gear 1, Bevel

AH C Gear 2, Reduction

AH C Gear 2, Bevel

AK C Gear 3, Reduction

AP C Shaft, Carriage

AH C Spacer, Motor

AU D Carriage

AP B Poly switch

AX C SA, Belt, Timing

AE C Felt

AH C Sheet, Fixer, Cable

AK C Gear 4, Reduction

AK C Gear 1, Idle

AH C Gear 2, Idle

AH C Pulley, Winder

AK C Spring, Spool

AS C Spool

AN C Belt, Timing, Winder

AV C SA, wheel, worm

AH C Gear, Drive, Ribbon

AL C Pivot, Wheel, Worm

AH C Shaft, Drive, Ribbon

AN C Plate, Ribbon

AG C Spring, Plate, Ribbon

AP D Cover, Head

BH E SA, PWB, Main

AH C Insulating sheet (S-16)

AD C Screw (PH(SW),M3×5)

AK C Pivot, Gear 1, Bebel

AD C E-ring (E2)

AH C Plate,fixer,FPC

AD C Nut(#3) (M3)

AD C Screw (PHT(ST),M3×10)

AX C Kit,wheel,worm

AB C Washer B

AP N C SA, Ribbon plate 2

AQ N D SA, Head cover

AD N C Washer,slide gear 1

AD N C Washer,plain,3

AD N C Screw (PH,M3.0×3)

AD N C E-ring (E2.5)

AN N C SA,Pplate,pulley,drive

BF N D SA,Frame,main

BC N C Frame R,side

AS N C Gear 1,reduction

AT N D SA,plate,support,frame R

AZ N C SA,Winder

AS N C SA,Holder,spool

AR N C SA,Gear,spool

BD N B SA,Motor,DC

AD N C Bushing,pivot,ribbon

AD N C E-ring (E1.5)

AD N C Washer,plain,(#2) (3)

AP C Cable, head

AR E PWB, MAIN

RANK

DESCRIPTION

– 1 –

Page 36

1 Mechanism etc No.1

DP-750

20

36

35

105

76

33

119

2

106

32

81

23

22

10

89

2

112

90

24

90

107

113

21

114

26

39

27

38

129

128

115

118

41

37

104

52

28

B

41

8

71

9

10

A

2

108

111

110

34

110

22

220

109

79

2

A

31

102

1

87

841

84

B

88

842

100

90

3

101

29

66

116

117

3

5

RCP00390

– 2 –

73

75

90

72

74

5

103

Page 37

DP-750

2 Mechanism etc No.2

NO. PARTS CODE

0CZE11130-06D

3

0CZE11230-06U

4

0CZE11230-08/

5

0CZE20130-10/

6

0CZE40130-00/

7

0CZE60330-00/

8

0CZE60340-00/

9

0CZNE20204-0/

40

0CZNE22001-0/

43

0CZNE22201-1/

45

0CZNE22203-1/

46

0CZNE22701-1/

47

0CZNE23601-1/

48

0CZNE23602-1/

49

0CZNE23603-1/

50

0CZNE23605-1/

51

0CZNE23609-0/

53

0CZNE24101-1/

55

0CZNE24103-1/

56

0CZNE24112-0/

58

0CZNE24113-0/

59

0CZNE24202-1/

61

0CZNE24205-1/

64

0CZNE24206-1/

65

0CZNE24701-1/

68

0CZNE25701-1/

70

0CZNE43101-0/

78

0CZNE44201-1/

82

0CZT6115-01//

86

0CZNE24117-0/

96

0CZNE43102-0/

97

0CZNE24201-3/

120

0CZNE22002-2/

121

0CZNE22206-0/

122

0CZNE23614-0/

123

0CZNE24203-2/

124

0CZNE24204-2/

125

0CZNE24209-1/

126

0CZNE22702-0/

127

0CZNE23612-0/

130

0CZNE66903-0/

701

0CZNE25702-0/

702

PRICE

RANK

NEW

PART

MARK

AD C Screw (PHT(ST),M3×6)

AD N C Screw (PHT(PT),M3×6)

AD C Screw (PHT(PT),M3×8)

AD C Screw (HSC,M3×10)

AD C Nut (M3)

AD C E-ring (E3)

AD C E-ring (E4)

AG C Gear, PF

AP C Shaft, Roller, Pressure

AK C Roller, Pressure

AH C Latch, PF

AP C SA, Roller, PF

AE C Spring R, Roller, Pressure

AE C Spring, Guide, Paper

AK C Spring, Clutch, PF

AD C Spring, Lever, Fixer

AE C Spring L, Roller, Pressure

AK C Sheet, Pressure, Paper

AH C Armature, PF

AH C Cutter, Manual

AS C Plate, Guide, Validation

AS C Guide, Paper, Pull

AW C Guide U, paper

AH C Plate, Guide, Paper Side

AS C SA, Platen

AX B SA, Solenoid, PF

AG C Spring, Earth

BA C Guide L, Paper

AD C Roll, Pressure

AG C Residual, solenoid

AG C Spring, earth, manual cut

BA N D Housing,PF

AP N C Shaft,PFf

AH N C Latch,PF 2

AK N C Spring,clutch,PF 2

AH N C Lever R,fixer

AH N C Lever L,fixer

AY N D Cover,housing,2 stations

BC N C SA,Shaft,PF

AD N C Spring,armature,PF

AH E PWB,solenoid,PF/CU

AR C Coil,solenoid

RANK

DESCRIPTION

– 3 –

Page 38

2 Mechanism etc No.2

DP-750

125

702

96

56

56

5

701

5

70

5

126

5

58

3

9

51

51

8

45

8

43

97

53

96

130

48

120

68

5

122

3

123

78

47

51

121

127

124

46

50

61

8

45

8

49

7

6

64

6

7

47

40

9

59

55

RCP003901

82

86

65

65

65

4

4

– 4 –

Page 39

COPYRIGHT 2001 BY SHARP CORPORATION

All rights reserved.

Printed in Ja pan.

No part of this public ation may be reproduced,

stored in a retrieval system, or transmitted.

In any form or by any means ,

electronic, mechanical, photocop ying, recording, or oth erwise,

without prior written permission of the publisher.

SHARP CORPORATION

Digital Document Systems Group

Quality & Reliability Control Center

Yamatokoriyama, Nara 639-1186, Japan

2001 May Printed in Japan

Loading...

Loading...