Page 1

CODE: 00ZDMDE2//A1E

Digital copier

: Paper feed unit

DM-DE1

MODEL DM-DE2

250-sheet paper

feed unit

500-sheet paper

feed unit

DM-DE2

CONTENTS

[1] PRODUCT OUTLINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

[2] SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

[3] UNPACKING AND INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . 1

[4] EXTERNAL VIEW AND INTERNAL STRUCTURE . . . . . . . . . . . . . 6

[5] OPERATIONAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

[6] DISASSEMBLY AND ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . 7

[7] MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

[8] ELECTRICAL SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Parts marked with "!" are important for maintaining the safety of the set. Be sure to replace these parts with specified

ones for maintaining the safety and performance of the set.

This document has been published to be used

SHARP CORPORATION

for after sales service only.

The contents are subject to change without notice.

Page 2

DM-DE2

[1] PRODUCT OUTLINE

The 250-sheet paper feed unit and the 500-sheet paper feed unit are

the optional paper feed cassettes for the digital copier, and they are

the same structure as the 250-sheet cassette of the copier.

The combination of the copier and the paper feed cassette is as

shown below:

Copier

(2-Tray Model)

Standard cassette

Standard cassette

250-sheet paper feed unit

250-sheet cassette

250-sheet cassette

500-sheet paper

feed unit

[2] SPECIFICA TIONS

1. Paper feed unit

DM-DE1 DM-DE2

Paper feed step(s) 1-step 2-step

Paper feed capacity 250 sheets × 1 step 250 sheets × 2 steps

Size detection None (The paper size is set by the user

Paper feed detection Available

Paper feed size 11 × 17, 8.5 × 14, 8.5 × 13, 8.5 × 11

Paper weight 56 ∼ 80g/m2, 15 ∼ 21lbs

Shipping size Inch series: 11" × 17"

Size selection User operation (Size setting by the user

Cassette

detachment

Heater Not available

Power source Supplied from the machine.

External dimension 590 (W) × 471 (D) ×

Weight About 5 Kg About 10 Kg

program.)

8.5 × 11R

program)

11 × 17, 8.5 × 14, 8.5 × 11, 8.5 × 11R

Possible by the user

590 (W) × 471 (D) ×

88 (H) mm

173.5 (H) mm

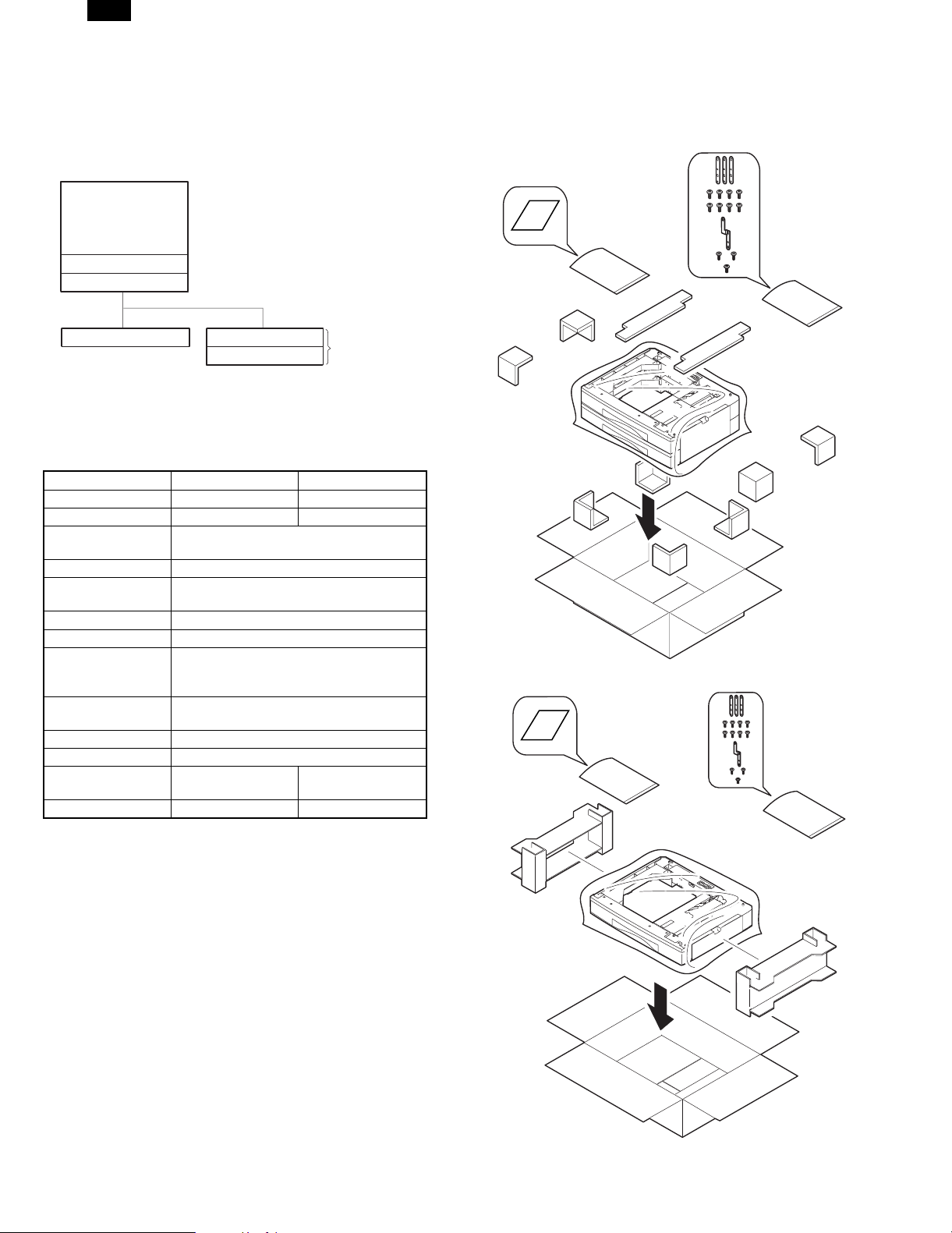

[3] UNPACKING AND INSTALLATION

1. Unpacking

(DM-DE2)

(DM-DE1)

– 1 –

Page 3

DM-DE2

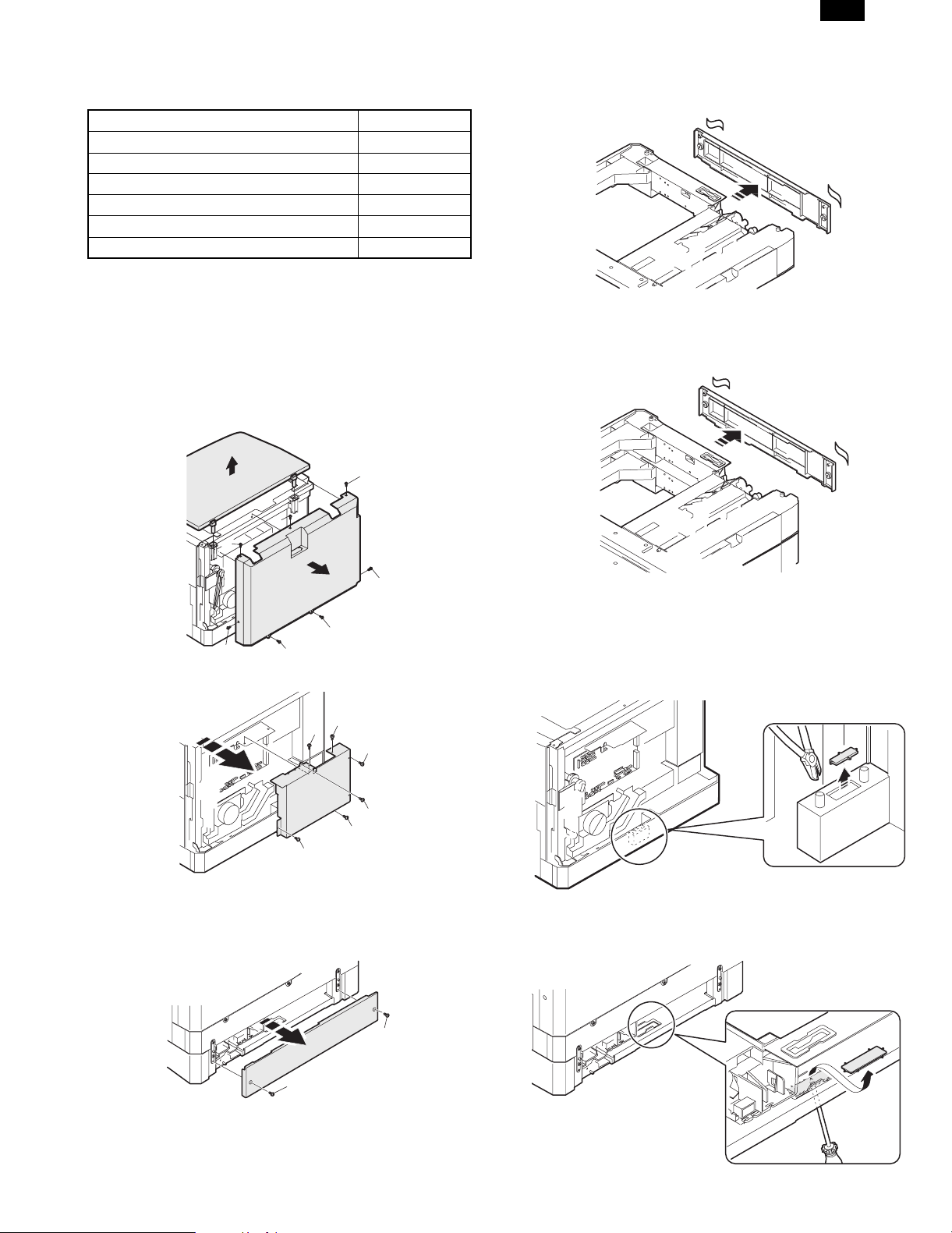

2. Installation

Included parts

Part name Quantity

Screw (for plastic M4) 8

Screw (for steel M4) 2

Screw (flat-head M3) 1

Fixing plate 3

Fixing plate 1

Paper size label 1

1) Remove the platen cover, rear cabinet, shielding plate

and rear cover.

DM-DE1 (Copier with 2 cassettes + Second cassette)

DM-DE2 (Copier with 2 cassettes + Multi-step cassette)

Remove the platen cover.

Remove the seven screws and then remove the rear cabinet.

A: M3 × 6 for steel

B: M3 × 8 for steel

C: M4 × 10 for plastic

A

2) Remove the rear cover.

DM-DE1 (Remove the rear cover which is attached to the second

cassette by tape.)

When installing, fix it using the two screws (for steel M4).

DM-DE2 (Remove the rear cover (upper stage) from the multi

stage cassette attached by tape.)

A

A

C

C

C

B

C

Remove the six screws.

A

A

A

A

A

A

DM-DE1 (Copier with 2 cassettes + Second cassette)

DM-DE2 (Copier with 2 cassettes + Multi-step cassette)

Remove the two screws.

D: M4 × 10 for steel

When installing, fix it using the two screws (for steel M4).

3) Remove the cut out plate in the copier base.

DM-DE1 (Copier with one cassette + Second cassette)

DM-DE2 (Copier with one cassette + Multi-step cassette)

Use nippers to cut and remove the plate.

DM-DE1 (Copier with 2 cassettes + Second cassette)

DM-DE2 (Copier with 2 cassettes + Multi-step cassette)

Use a screwdriver to assist in removing the plate.

D

D

– 2 –

Page 4

DM-DE2

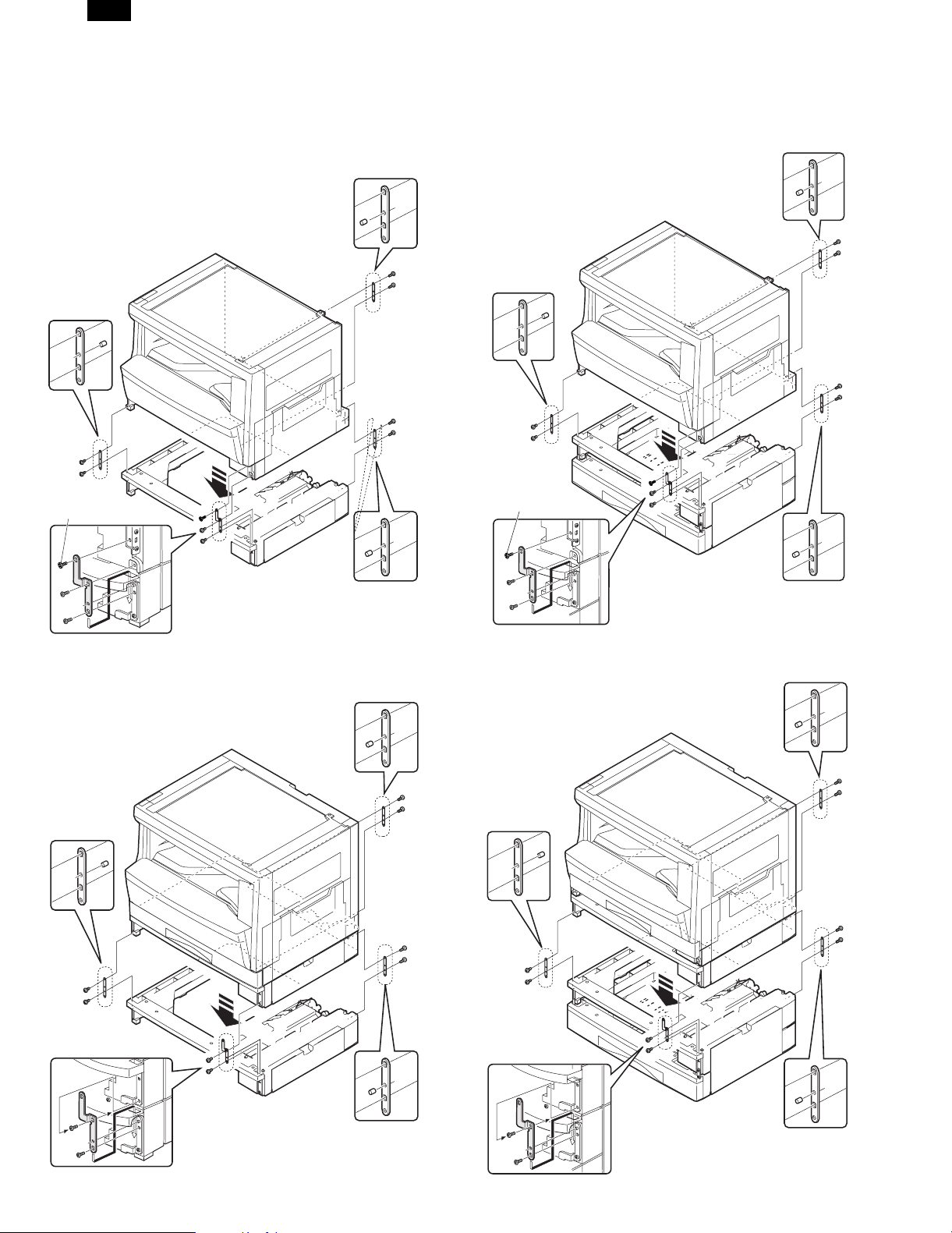

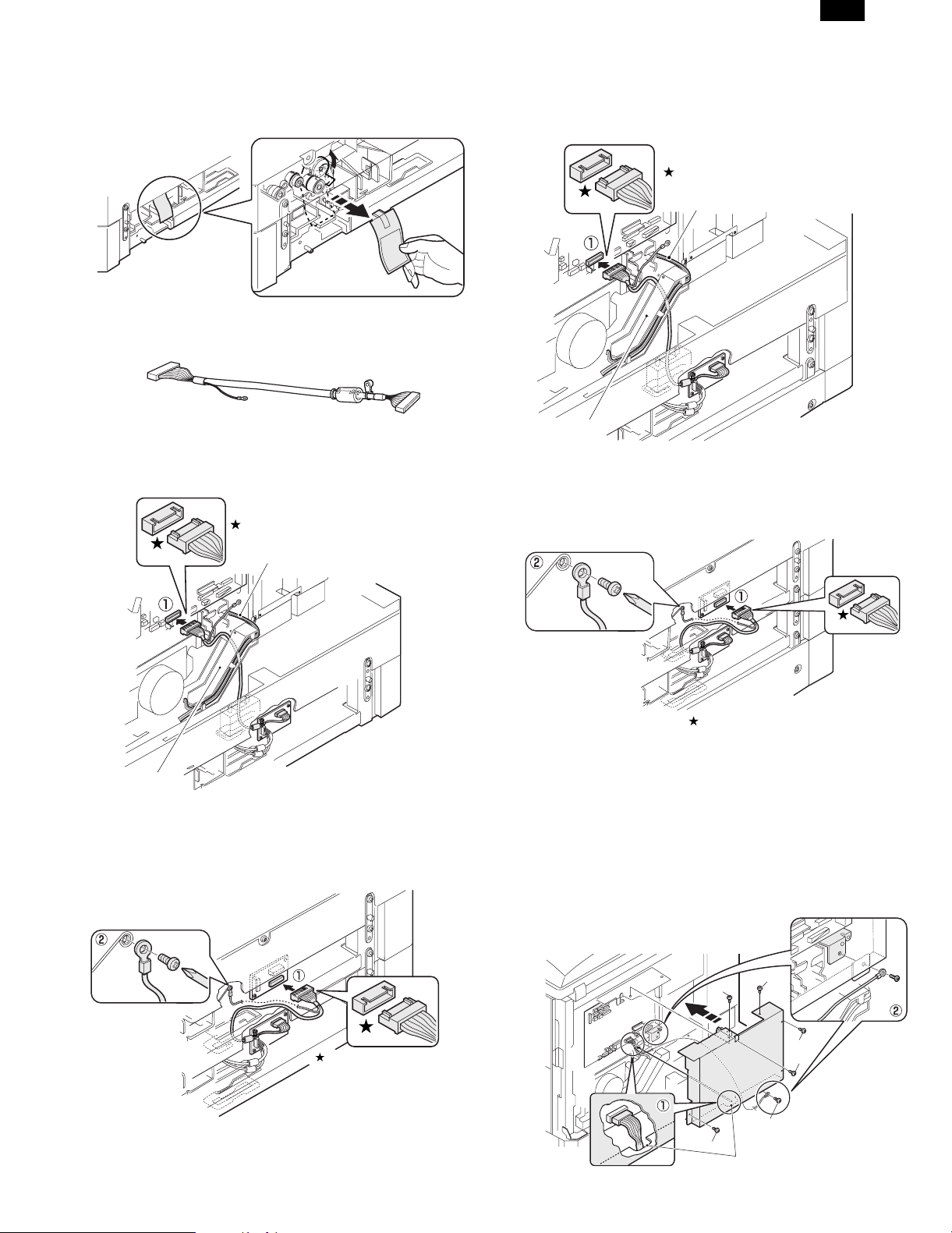

4) Install the copier.

DM-DE1 (Copier with one cassette + Second cassette)

Put the copier on the second cassette, and fix with the four fixing

plates and the eight screws (for plastic M4).

Fix it with the plate of the copier using a screw (flat-head M3).

When installing, remove the paper cassette.

Detail drawing

Detail drawing

Screw (flat-head M3)

DM-DE2 (Copier with one cassette + Multi-step cassette)

Put the copier on the multi-step cassette, and fix it with the four fixing

plates and the eight screws (for plastic M4).

Fix it with the plate of the copier using a screw (flat-head M3).

When installing, remove the first and second paper cassettes.

Detail drawing

Detail drawing

Screw (flat-head M3)

Detail drawing

DM-DE1 (Copier with 2 cassettes + Second cassette)

When installing, remove the second and third paper cassettes.

Detail drawing

Detail drawing

Detail drawing

DM-DE2 (Copier with 2 cassettes + Multi-step cassette)

When installing, remove the second and third paper cassettes.

Detail drawing

Detail drawing

Detail drawing

Detail drawing

– 3 –

Page 5

DM-DE2

5) Remove the connection gear lock.

DM-DE1, DM-DE2

After setting, pull out and remove the red tag in the direction indicated

by the arrow and remove the connection gear lock.

6) Connect the connector.

DM-DE1 (Copier with one cassette + Second cassette)

Optional interface harness

Pass the optional interface harness that is contained in the second

cassette through the back of the resin holder taking care to keep the

harness from contact with the high voltage wires, and then connect

the connector. (➀)

Be careful about the direction of the connector.

DM-DE2 (Copier with one cassette + Multi-step cassette)

Pass the optional interface harness that is contained in the multi-step

cassette through the back of the resin holder taking care to keep the

harness from contact with the high voltage wires, and then connect

the connector. (➀)

Be careful about the direction of the connector.

High voltage wires

Harness holder

(Copier with 2 cassettes + Multi-step cassette)

Connect the optional interface harness that is contained in the multistep cassette to the connector. (➀)

Fix the terminal section of the grounding wire at the option side using

the plate fixing screw. (➁)

High voltage wires

Harness holder

(Copier with 2 cassettes + Second cassette)

Connect the optional interface harness that is contained in the second

cassette to the connector.(➀)

Fix the terminal section of the grounding wire at the option side using

the plate fixing screw. (➁)

Be careful to the front and

the back sides.

Be careful to the front

and the back sides.

Be careful about the direction of the connector.

7) Attach the shielding plate and the terminal section of

the grounding wire.

DM-DE1 (Copier with one cassette + Second cassette)

DM-DE2 (Copier with one cassette + Multi-step cassette)

When attaching the shielding plate, pass the cassette interface harness through the notch. (➀)

Use the six screws to attach the shielding plate and tighten the terminal section of the grounding wire at the location shown in the

illustration. (➁)

(Use caution to ensure no wires are pinched by the shielding plate. )

A

A

Be careful about the direction

of the connector.

A

A

A

A

Notch

– 4 –

Page 6

DM-DE2

8) Remove the cassette packing fixtures.

DM-DE1, DM-DE2

Remove the pressure plate lock. Rotate the pressure plate lock in the

direction of the arrow to remove it while pressing down the pressure

plate of the paper tray.

9) Set the cassette side plate.

DM-DE1, DM-DE2

Squeeze the lock lever of the front guide and slide the front guide to

match the width of the paper.

10) Install the cassette rear edge plate.

DM-DE1, DM-DE2

Install the cassette edge plate to the position of the paper size to be

used.

11) Set the paper.

DM-DE1, DM-DE2

When setting the paper, do not exceed the height of the indication

label.

12) Check the center displacement.

DM-DE1

• Place a document on the document glass and make a copy using

a tray in the copier.

Then, make a copy using the tray in the installed optional paper

feed unit.

• If the center of the copy from the paper feed unit is displaced from

the copy from the tray in the copier, adjust the center according to

the procedure in the service manual.

DM-DE2

• Place a document on the document glass and make a copy using

a tray in the copier.

Then, make a copy using each tray in the installed optional paper

feed unit.

• If the center of the copy from each tray of the paper feed unit is

displaced from the copy from the tray in the copier, adjust the

center according to the procedure in the service manual.

Connect the power cord, turn the main switch ON, and

perform the following procedure.

– 5 –

Page 7

[4] EXTERNAL VIEW AND INTERNAL STRUCTURE

1. External view

3

1

No. Name No. Name No. Name

1 Paper feed tray 2 2-step paper feed right cover 3 1-step paper feed right cover

2

2. Internal structure

1

DM-DE2

11

3

2

1

6

5

4

9

10

8

Sensors and detectors

No. Code Name Type Function, operation Remark

1 DRS1 Door open/close sensor Photo transmission Detects door open/close.

2 PPD1 Paper entry sensor Photo transmission Detects paper transport.

3 CSS1 Paper empty sensor Photo transmission Detects paper presence/empty.

4 CASS1 Cassette detection SW Contact Detects cassette installation.

5 FSOL1 Transport solenoid DC solenoid Transports paper. (for clutch)

6 PSOL1 Paper feed solenoid DC solenoid Feeds paper. (For clutch)

7 PPD2 Paper entry sensor Photo transmission Detects paper transport. DM-DE2 only

8 CSS2 Paper empty sensor Photo transmission Detects paper in the cassette. DM-DE2 only

9 CASS2 Cassette detection SW Contact Detects cassette installation. DM-DE2 only

10 PSOL2 Paper feed solenoid DC solenoid Feeds paper. DM-DE2 only

11 PWB Interface PWB — — DM-DE2 only

7

– 6 –

Page 8

DM-DE2

[5] OPERATIONAL DESCRIPTION

1. Paper transport path

Transport roller

PF sensor

Copier

cassette

250-sheet paper

feed unit (upper)

250-sheet paper

feed unit (Lower)

2. Operational descriptions

The operations are controlled by the main body of the copier. the

paper feed roller (semi-circular roller) and the transport roller are

driven by the gear of the copier.

Paper is separated by the paper feed roller and the separation pawl,

and detected by the PF sensor, then transported to the Resist roller

by the transport roller.

Paper feed roller

To copier's PS

[6] DISASSEMBLY AND ASSEMBLY

1. Rear cover

1

2

1

2. Paper feed unit section

5

5

Copier

4

3

1

2

250-sheet paper feed unit

Paper lead edge

No. Name Operation

1 Paper feed roller Picks up paper.

2 Separation pawl Prevents against double feed of

paper.

3 Transport roller Transports paper.

4 Paper entry sensor Detects paper transport.

5 Resist roller Makes synchronization between the

paper lead edge and the image lead

edge.

1

1

6

3

2

6

3

– 7 –

4

Page 9

DM-DE2

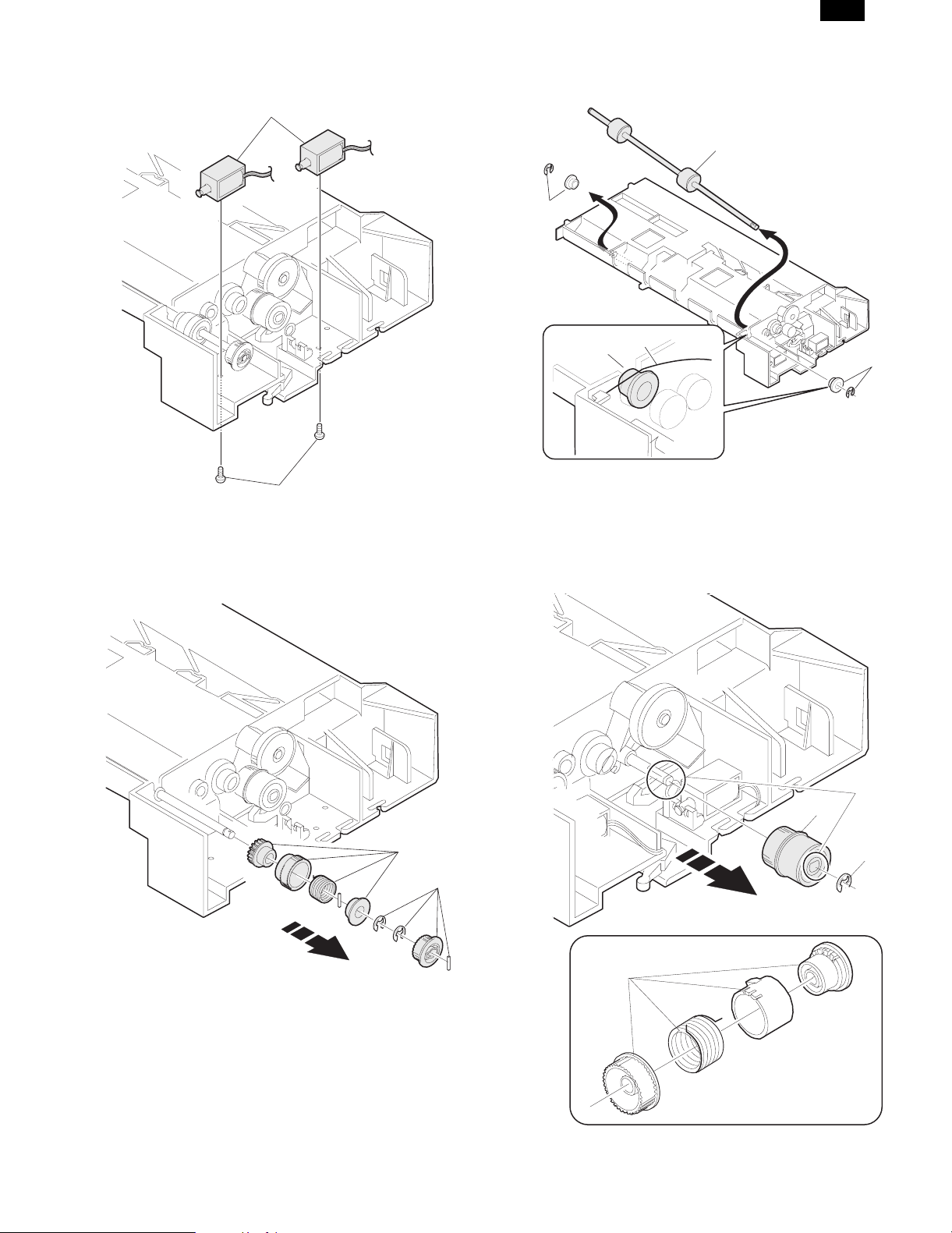

3. Paper feed solenoid, transport solenoid

2

1

4. Transport roller gear section

5. Transport roller

2

1

A

B

1

6. Paper feed roller clutch

NOTE: When asembling the paper feed roller cluch, fit and insert

section A (D cut) into the shaft as shown in the figure.

A

2

2

1

1

3

– 8 –

Page 10

DM-DE2

7. Paper feed roller

NOTE: Engage connection arm spring B with frame groove A and

connection arm groove C.

A

1

B

2

C

1

[7] MAINTENANCE

No. Name Work

item

1 Paper feed roller PA ass’y Cleaning F

2 Transport roller Cleaning F

2

[Note] For disassembly and assembly of the paper feed roller and

the transport roller, refer to [6] DISASSEMBLY AND ASSEMBLY.

When

service call

1

Remark

– 9 –

Page 11

[8] ELECTRICAL SECTION

DM-DE2

D

C

B

A

12345678

2 1

5V2

5V2

24V

5V2

24V

5V2

5V2

2nd/Multi step CS only

24V

Lower connection CS

CASS1

PPD1

DRS1

CSS1

PSOL1

FSOL1

PSOL2

CASS2

PPD2

Multi step CS only

CSS2

3

24V

5V2

5V1

5V1

IC1

Y1

Copier body

24V

Data selector

3

SELA

SELB

SELB

IC2

Driver array

PSOL1

FSOL1

PSOL2

5V1

IC3

Data selector

Y2

INTERFACE PWB

FSOL2

PSOL3

Y3

FSOL3

1. BLOCK DIAGRAM 1/1

8 7 6 5 4

D

C

B

– 10 –

A

Page 12

DM-DE2

D

2. ACTUAL WIRING DIAGRAM

12345678

1. 2nd CS TYPE DM-DE1

175778-2

1

CASS1

LGND

LGND

PPD1

5V2

LGND

DRS1

5V2

LGND

CSS1

2

1

2

3

1

2

3

1

2

35V2

GY

DF3-3S-2C

GY

OR

DF3-3S-2C

GY

OR

DF3-3S-2C

GY

OR

RD

BL

RD

BL

1

24V1

2

/PSOL1

1

24V1

2

/FSOL1

CASS1

PPD1

DRS1

CSS1

PSOL1

FSOL1

SELB

18

SELB

SELB

18415

19

SELC

SELC

19

A

5V2

5V120SELC

2 1

5V1

5V2

N.C.

N.C.

3

5V2

5V1

20

C

BR

GY

BR

OR

PL

LB

SMP-02V-NCSMR-02V-N

1

2

SMP-02V-BCSMR-02V-B

1

2

RD

BL

RD

BL

B

PHDR-20VS

TO 2ND OR MAIN BODY

(UPPER UN)

PGND

PSOL2Y1LGND

FSOL1

PSOL39FSOL37Y3

FSOL2

24VY224V

PSOL1

2

3

1

RDRDPK

123 4 56789

CASS1

13

LGND

9

16

11

14

15

PPD1

5V2

DRS1

CSS1

24V

24V

CN-B

(B16B-PHDSS)

10 16814

5

46

PK

GYGYGYBRPLPLPLOROR

PKPKPK

PK

21 22

PSOL1

FSOL1

FSOL2

PSOL2

PSOL3

PGND

FSOL3

CS INTERFACE PWB

2ND CS

1

24V1

/PSOL1

2

3

24V1

4

/FSOL1

5

N.C.

N.C.

6

N.C.

7

N.C.

8

N.C.

10

N.C.

12

CN-C

24V

24V

FSOL3

FSOL2

PSOL2

N.C.

PSOL3

2

1

N.C.

10 16

8

5

3

9

7

6

SELA

PGND

LGND

13

12

17

11

15

BR

GY

BR

1011 12 13 1415 1617 1819 20

PGND

LGND

LGND

Y3Y2Y1

SELA

CN-A

(B22B-PHDSS)

(B20B-PHDSS)

Y3

Y2

LGND

LGND

PGND13PGND

N.C.

SELA

14

12

17

11

ELP-02V

1

AC100N

AC100L

2

FOR LOWER OPTION CS

ELR-02V

AC100N

AC100L

D

TO 2ND OR MAIN BODY

(UPPER UN)

WH

1

BK

2

ELP-02V

WH

BK

1

2

AC100N

C

ELR-02V

1

2AC100L

2nd CS UNIT

PPD1

DRS1

FSOL1

CASS1

HEATER DH1

JAPAN ONLY

PSOL1

CSS1

UNIT REAR VIEW

PWB

8 7 6 5 4

B

A

– 11 –

Page 13

DM-DE2

D

2. MULTI CS TYPE DM-DE2

12345678

UPPER UNIT

175778-2

1

CASS1

LGND

LGND

PPD1

LGND

DRS1

LGND

CSS1

CASS2

LGND

LGND

PPD2

5V2 3

GY

2

DF3-3S-2C

GY

1

2

OR

35V2

DF3-3S-2C

GY

1

2

OR

35V2

DF3-3S-2C

GY

1

2

OR

35V2

RD

BL

RD

BL

175778-2

1

2

DF3-3S-2C

GY

1

2

OR

CASS1

PPD1

DRS1

CSS1

PSOL1

FSOL1

LOWER UNIT

CASS2

PPD2

SELA

17

SELA

SELB

18

SELB

19

SELC

5V120SELC

5V1

5V2

5V2

A

2 1

N.C.

N.C.

3

C

BR

GY

BR

OR

PL

LB

1

2

1

2

SMP-02V-NCSMR-02V-N

1

24V1

2

/PSOL1

SMP-02V-BCSMR-02V-B

1

24V1

2

/FSOL1

SMR-08V-N SMP-08V-NC

BR

GY

GY

BR

OR

CASS2

1

1

LGND

2

2

LGND

3

3

PPD2

4

4

5V2

5

5

RD

BL

RD

BL

BR

BR

B

PHDR-20VS

TO 2ND OR MAIN BODY

(UPPER UN)

24VY224V

2

3

1

RDRDPK

123 4 56789

CASS1

13

9

LGND

24V

24V

16

PPD1

5V2

11

14

15

12

10

1

2

3

4

8

5

6

7

DRS1

CSS1

24V1

/PSOL1

24V1

/FSOL1

CASS2

PPD2

CSS2

24V1

/PSOL2

N.C.

CN-B

(B16B-PHDSS)

PGND

PSOL2Y1LGND

FSOL1

PGND

LGND

PSOL39FSOL37Y3

FSOL2

PSOL1

10 16814

13

12

11

5

46

PK

GYGYGYBRPLPLPLOROR

PSOL1

FSOL1

PSOL2

PKPKPK

21 22

FSOL2

PSOL3

PK

FSOL3

PGND

PGND

GY

LGND

BR

1011 12 13 1415 1617 1819 20

LGND

CN-A

(B22B-PHDSS)

CS INTERFACE PWB

MULTI CS

15

BR

Y3Y2Y1

CSS2

PSOL2

PPD1

DRS1

FSOL1

CASS1

PPD2

CASS2

1

LGND

2

CSS2

5V2

3

MULTI CS UNIT

CSS1

PSOL1

CSS2

PSOL2

DF3-3S-2C

GY

OR

RD

BL

PWB

GY

LGND

6

LB

CSS2

7

OR

5V2

8

SMR-02V-N SMP-02V-NC

RD

24V1

1

BL

/PSOL2

2

UNIT REAR VIEW

UPPER UNIT

LOWER UNIT

6

7

8

1

2

LB

RD

BL

ELP-02V

1

2

TO 2ND OR MAIN BODY

(UPPER UN)

AC100N

AC100L

ELP-02V

WH

BK

1 AC100N

AC100L

2

ELR-02V

1

2

UPPER CS

HEATER DH2

LOWER CS

1

ELP-02V

1 AC100N

AC100L 2

2

ELR-02V

HEATER DH3

JAPAN ONLY

8 7 6 5 4

D

C

B

A

– 12 –

Page 14

DM-DE2

q

COPYRIGHT C 1999 BY SHARP CORPORATION

All rights reserved.

Printed in Japan.

No part of this publication may be reproduced,

stored in a retrieval system, or transmitted,

in any form or by any means,

electronic, mechanical, photocopying, recording, or otherwise,

without prior written permission of the publisher.

SHARP CORPORATION

Digital Document Systems Group

Quality & Reliability Control Center

Yamatokoriyama, Nara 639-1186, Japan

1999 June Printed in Japan K

Loading...

Loading...