Page 1

LASER PRINTER

(Multi-function printer)

Operation Manual

for printer operation and general information on multi functions

Page 2

Page 3

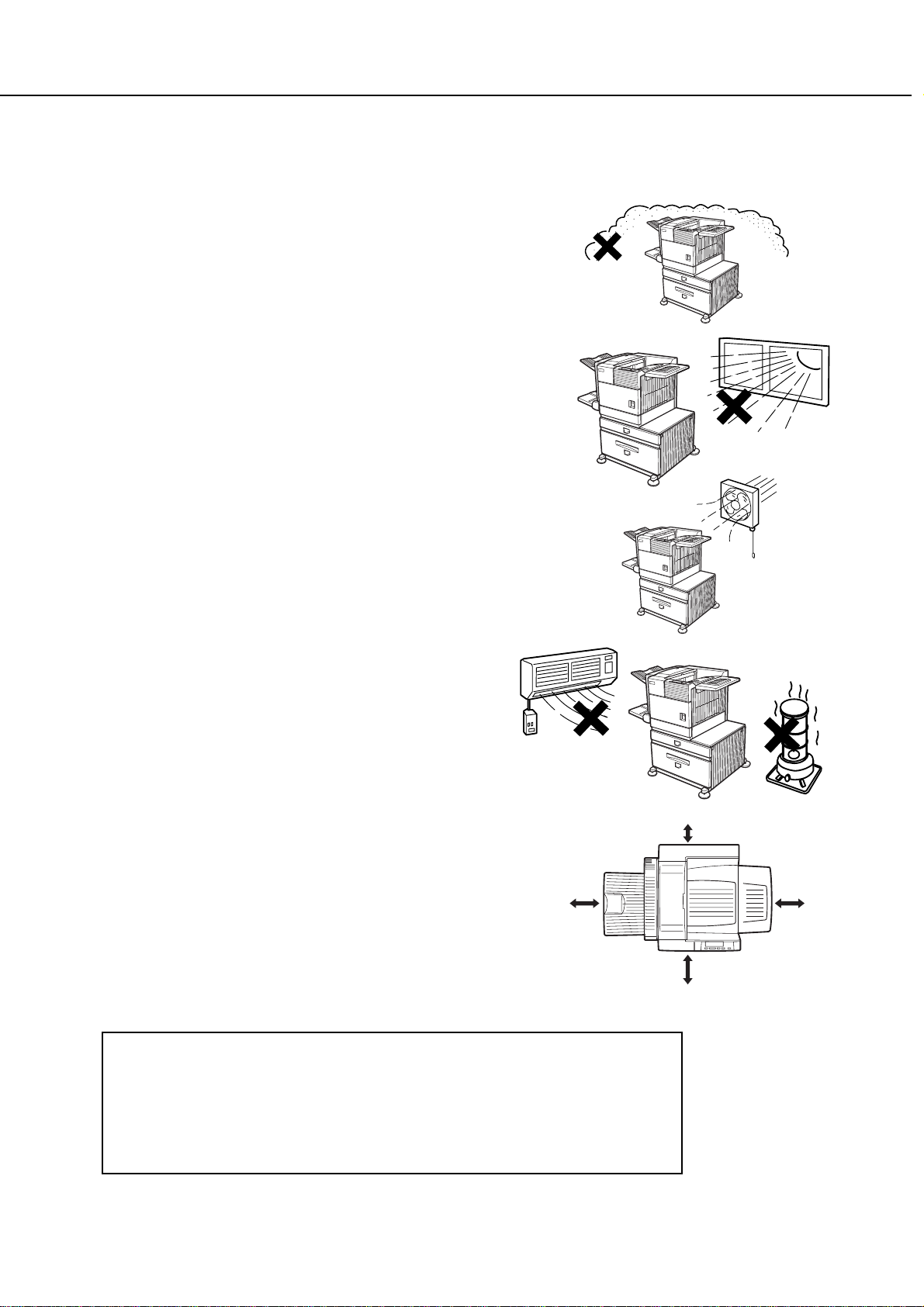

INSTALLATION REQUIREMENTS

Improper installation may damage this product. Please note the following during initial installation and whenever the

machine is moved.

1. The machine should be installed near an accessible

power outlet for easy connection.

2. Be sure to connect the power cord only to a power

outlet that meets the specified voltage and current

requirements. Also mak e certain the outlet is properly

grounded.

●

For the power supply requirements, see the name

plate of the main unit.

3. Do not install your machine in areas that are:

●

damp, humid, or very dusty

●

exposed to direct sunlight

●

poorly ventilated

●

subject to extreme temperature or humidity

changes, e.g., near an air conditioner or heater.

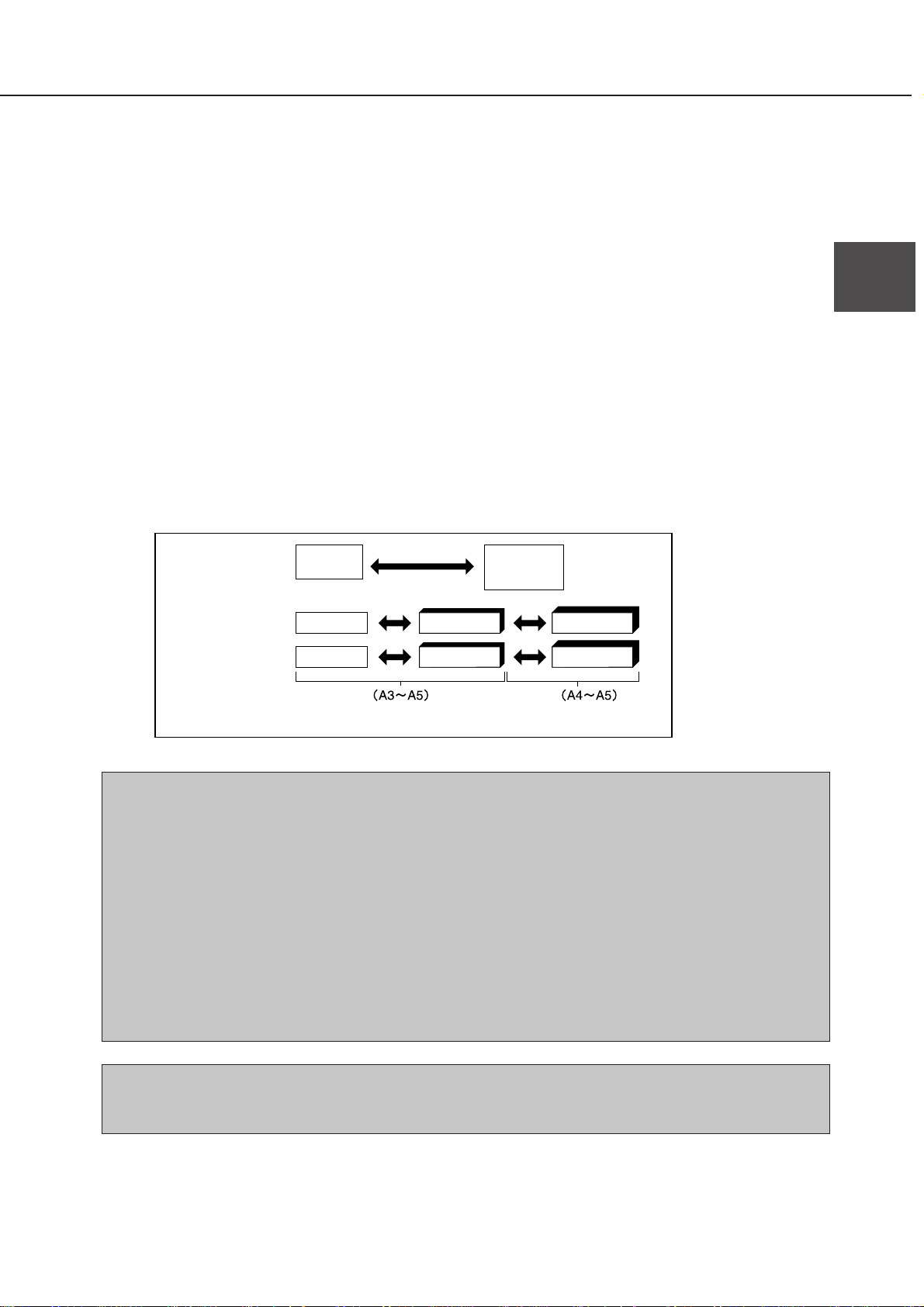

4. Be sure to allow the required space around the

machine for servicing and proper ventilation.

A small amount of ozone is produced within the copier

23-5/8"

(60cm)

during operation. The emission level is insufficient to cause any health hazard.

NOTE:

The present recommended long term exposure limit for ozone is 0.1 ppm (0.2 mg/m

calculated as an 8 hr. time-weighted av erage concentration.

However, since the small amount that is emitted may have an objectionable odor, it is

advisable to place the copier in a ventilated area.

11-13/16" (30cm)

23-5/8" (60cm)

3

)

23-5/8"

(60cm)

0-1

Page 4

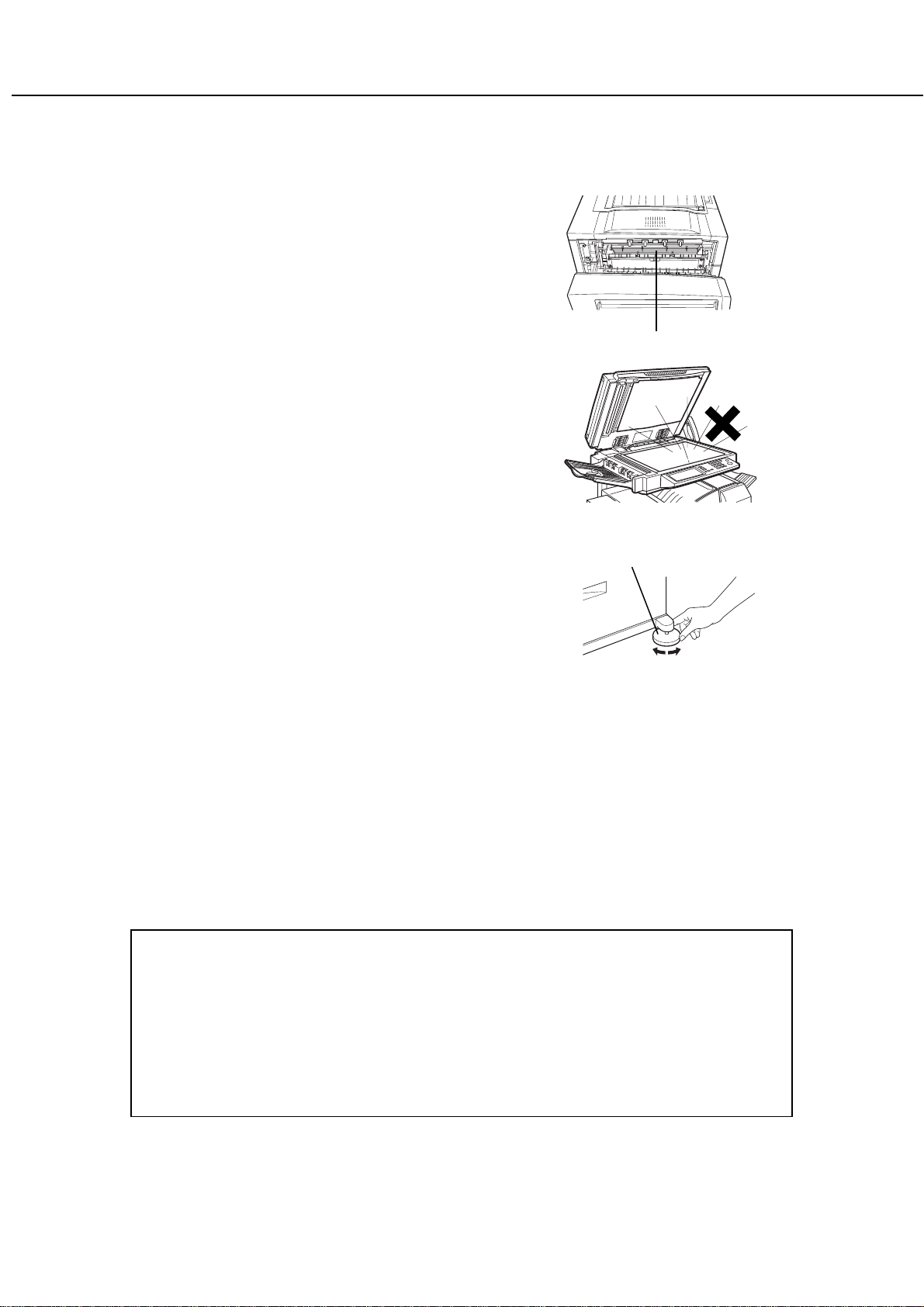

CAUTIONS

1. Do not touch the photoconductive drum. Scratches

or smudges on the drum will cause dirty printouts.

2. The fusing unit is extremely hot. Exercise care in

this area.

3. Do not look directly at the light source of a scanner

module. Doing so may damage your eyes.

4. Five installation adjusters are provided on a stand/

paper drawer which is provided as a peripheral unit.

When moving the machine with a stand/paper drawer ,

be sure to raise the installation adjusters. After

moving the machine, lower the five installation

adjusters until they reach the floor.

5. Do not make modifications to this machine. Doing

so may cause a fire or an electric shock.

6. When moving this machine, be sure to use two to

four persons. Since this machine is heavy, moving

it by yourself may cause an injury.

Fusing unit

Adjuster

7. When connecting this machine to a computer, be

sure turn off this machine and the computer in

advance.

8. When opening or closing the covers or paper trays

for misfeed remo val or loading paper, take care not

to get your fingers caught in the covers or trays.

9. Do not print anything which is prohibited from printing

by law. The following items are normally prohibited

from printing by national law. Other items may be

prohibited by local law.

●

Money ● Stamps

●

Bank drafts ● Checks ● Passports

●

Driver's licenses

CONTAINS MANGANESE DIOXIDE LITHIUM BATTER Y. MUST BE DISPOSED OF PR OPERLY.

CONT A CT YOUR SHARP DEALER OR SER VICER FOR INSTR UCTIONS.

This product utilizes tin-lead solder, and fluorescent lamp containing a small amount of mercury.

Disposal of these materials may be regulated due to environmental considerations.

For disposal or recycling information, please contact

your local authorities or the Electronics Industries

Alliance:www.eiae .org

●

Bonds

●

Stocks

"BA TTER Y DISPOSAL"

Lock Release

0-2

Page 5

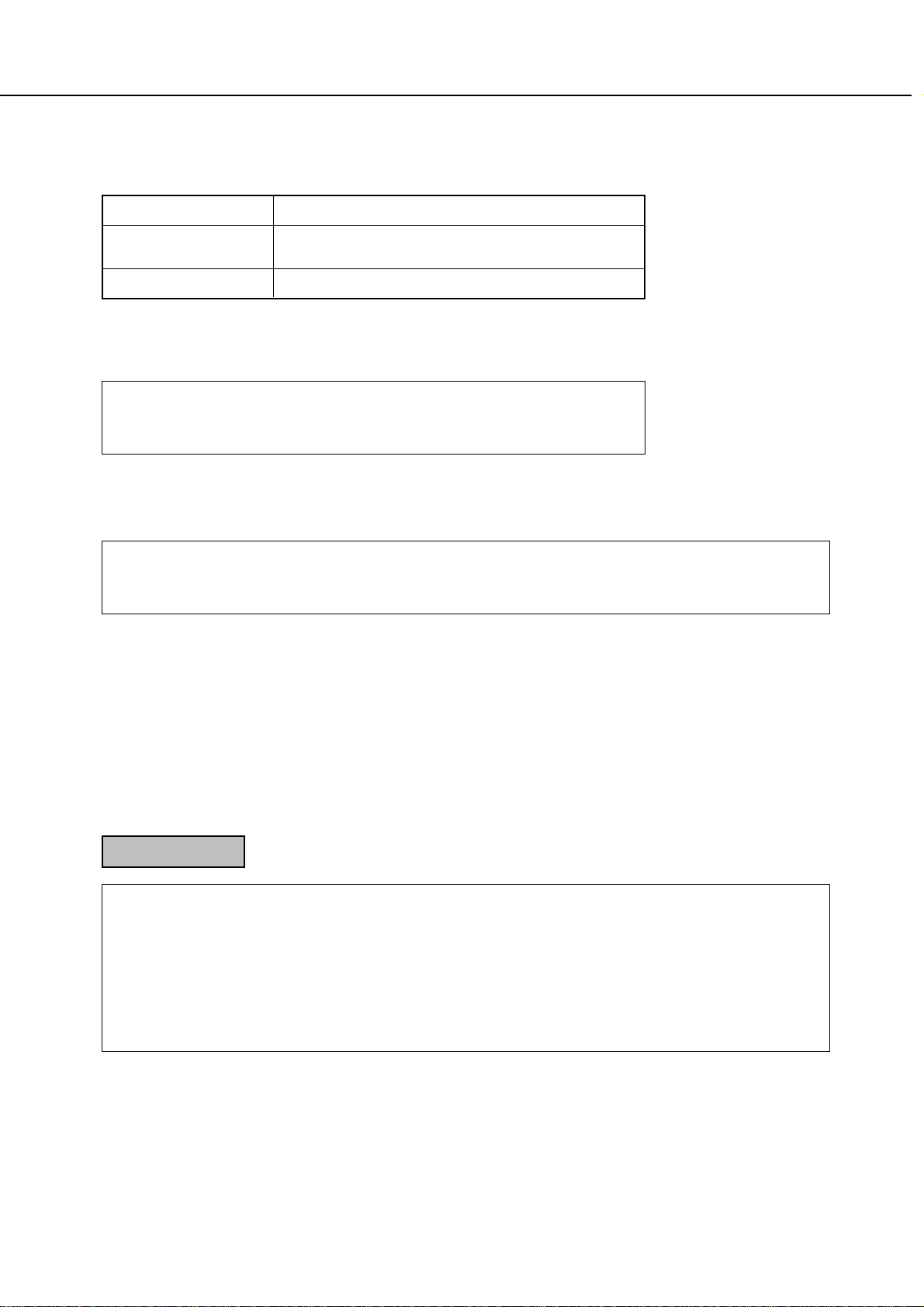

Cautions on laser

Wa v e length 785 nm ± 15 nm

Pulse times North America: (4.0 µs ± 4 ns)/7 mm

Europe: (5.4 µs ± 5.4 ns)/7 mm

Output power 0.25 mW - 0.50 mW

At the production line, the output power of the scanner unit is adjusted to 0.6

MILLIWATT PLUS 8 PCTS and is maintained constant by the operation of the

Automatic P ower Control (APC).

CAUTIONS

Caution

This product contains a low power laser device . To ensure continued safety do not remove any cov er or attempt

to gain access to the inside of the product. Refer all servicing to qualified personnel.

For North America:

SAFETY PRECAUTIONS

This Digital Equipment is rated Class 1 and complies with 21 CFR 1040.10 and 1040.11 of the

CDRH standards. This means that the equipment does not produce hazardous laser radiation. For

your safety, observe the precautions below.

●

Do not remove the cabinet, operation panel or any other covers.

●

The equipment's exterior covers contain several safety interlock switches. Do not bypass any

safety interlock by inserting wedges or other items into switch slots.

Caution

Use of controls or adjustments or performance of procedures other than those specified herein

may result in hazardous radiation exposure.

0-3

Page 6

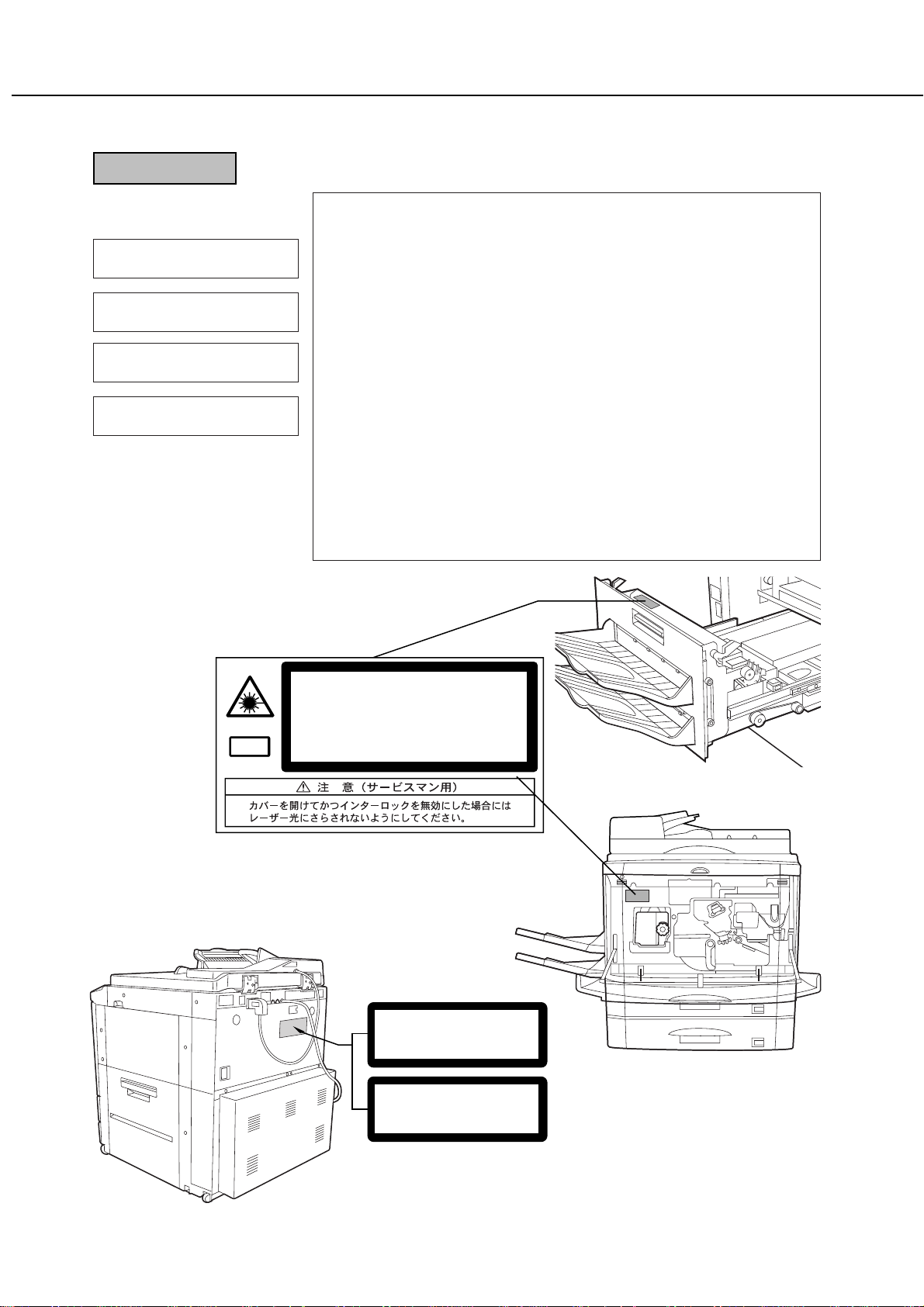

CAUTIONS

For Europe:

CLASS 1 LASER PRODUCT

LASER KLASSE 1

LUOKAN 1 LASERLAITE

KLASS 1 LASERAPPARAT

CAUTION

INVISIBLE LASER RADIATION

WHEN OPEN INTERLOCKS

DEFEATED. AVOID EXPOSURE

TO BEAM.

VORSICHT

UNSICHTBARE

LASERSTRAHLUNG WENN

ABDECKUNG GEÖFFNET UND

SICHERHEITSVERRIEGELUNG

ÜBERBRÜCKT. NICHT DEM

STRAHL AUSSETZEN.

ADVARSEL

USYNLIG LASERSTRÅLNING

VED ÅBNING, NÅR

SIKKERHEDSBRYDERE ER

UDE AF FUNKTION. UNDGÅ

UDSAETTELSE FOR

STRÅLNING.

VAROITUS!

LAITTEEN KÄYTTÄMINEN

MUULLA KUIN TÄSSÄ

KÄYTTÖOHJEESSA

MAINITULLA T AVALLA SAA TTAA

ALTISTAA KÄYTTÄJÄN

TURVALLISUUSLUOKAN 1

YLITTÄVÄLLE

NÄKYMÄTTÖMÄLLE

LASERSÄTEILYLLE.

VARNING

OM APPARATEN ANVÄNDS PÅ

ANNAT SÄTT ÄN I DENNA

BRUKSANVISNING

SPECIFICERATS, KAN

ANVÄNDAREN UTSÄTTAS FÖR

OSYNLIG LASERSTRÅLNING,

SOM ÖVERSKRIDER GRÄNSEN

FÖR LASERKLASS 1.

Laserstrahl

INVISIBLE LASER RADIATION WHEN OPEN AND INTERLOCKS DEFEATED.

AVOID EXPOSURE TO BEAM.

CAUTION

VORSICHT

ADVARSEL

ADVERSEL

VARNING

VARO!

UNSICHTBARE LASERSTRAHLUNG WENN ABDECKUNG GEÖFFNET UND

SICHERHEITSVERRIEGELUNG ÜBERERÜCKT. NICHT DEM STRAHL AUSSETZEN.

USYNLIG LASERSTRÅLING VED ÅBNING, NÅR SIKKERHEDSAFBRYDERE ER

UDE AF FUNKTION. UNDGÅ UDSAETTELSE FOR STRÅLNING.

USYNLIG LASERSTRÅLING NÅR DEKSEL ÅPNES OG SIKKERHEDSLÅS BRYTES.

UNNGÅ EKSPONERING FOR STRÅLEN.

OSYNLIG LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD OCH SPÄRRAR ÄR

URKOPPLADE. STRÅLEN ÄR FARLIG. BETRAKTA EJ STRÅLEN.

AVATTAESSA JA SUOJALUKITUS OHITETTAESSA OLET ALTTIINA NÄKYMÄTÖNTÄ

LASERSÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN.

CLASS 1

LASER PRODUCT

LASER KLASSE 1

0-4

Page 7

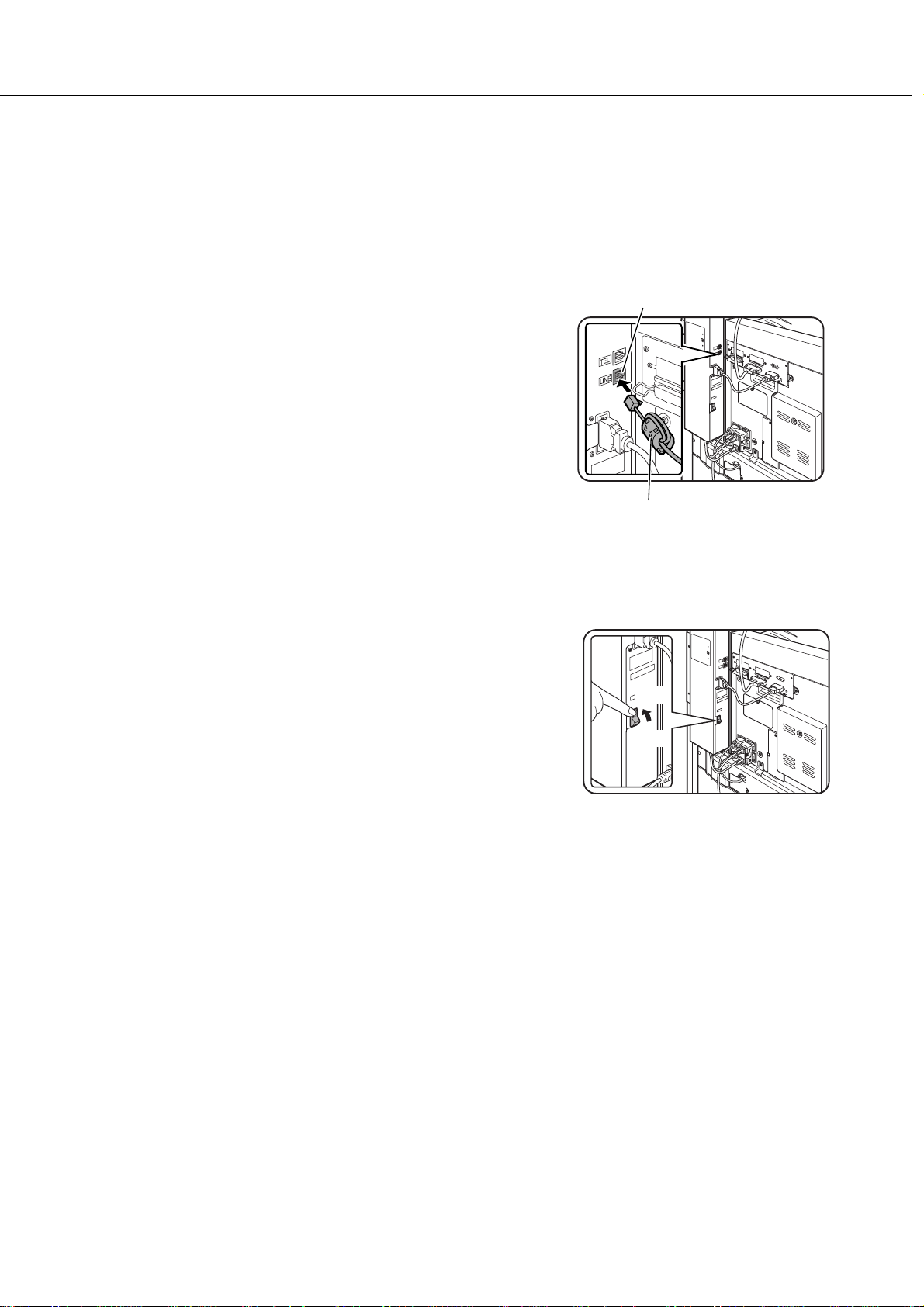

FACSIMILE FEATURE

TEL

LINE

TEL

LINE

When using this product as a facsimile by installing a facsimile expansion kit as a peripheral unit, refer to the following

items for proper use.

For the description of use of the facsimile feature, see the facsimile operation manual supplied with the facsimile

expansion kit.

Line connector

■■

■ Line connection

■■

For connection between this product and telephone line, be sure to

use the supplied connection cable. Connect the connecting cable so

that the terminal near the core is inserted to the line connector of the

facsimile expansion kit. Insert the other terminal (not the core side)

to the socket of the telephone line.

Core

■■

■ Fax power switch

■■

When using this product as a facsimile, keep always the fax power

switch on that is located on the facsimile expansion kit at the rear

side of this product. (Do not turn it off.) If the fax power switch is off,

the facsimile feature cannot be used.

ON

OFF

0-5

Page 8

CONTENTS

Page

INSTALLATION REQUIREMENTS . . . . . . . . . . . . 0-1

CAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0-2

CONTENTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0-5

CHAPTER 1

BEFORE USING THE PRODUCT

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAIN FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PART NAMES AND FUNCTIONS . . . . . . . . . . . . . . . .

●

Exterior* Interior . . . . . . . . . . . . . . . . . . . . . . . . . . .

●

Part names and functions of peripheral units . . . . .

●

Operation panel . . . . . . . . . . . . . . . . . . . . . . . . . . . .

●

Touch panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ADDING TONER . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LOADING PAPER . . . . . . . . . . . . . . . . . . . . . . . . . . . .

●

Loading paper in paper tray 1 . . . . . . . . . . . . . . . . .

●

Changing the paper size in paper tray 1 . . . . . . . . .

●

Paper available in paper trays . . . . . . . . . . . . . . . . .

●

Paper available in the bypass tray/multi

purpose drawer . . . . . . . . . . . . . . . . . . . . . . . . . . . .

●

Method of setting paper size and type . . . . . . . . . .

●

Setting from the operation panel of

a scanner module . . . . . . . . . . . . . . . . . . . . . . . . . .

●

Loading paper in the multi purpose drawer . . . . . . .

●

Changing paper size in the multi purpose

drawer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

●

Setting special paper in the multi purpose

drawer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

●

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

●

Loading paper in the stand/3 x 500 sheet

paper drawer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

●

Changing paper size in the stand/3 x 500

sheet paper drawer . . . . . . . . . . . . . . . . . . . . . . . . .

●

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

●

Loading paper in the stand/MPD & 2000

sheet paper drawer . . . . . . . . . . . . . . . . . . . . . . . . .

●

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INST ALLING PRINTER DRIVERS USING

THE PLUG & PLAY FUNCTION OR

ADD PRINTER WIZARD . . . . . . . . . . . . . . . . . . . . . . .

●

Before installation

SETTING THE PRINTER DRIVER . . . . . . . . . . . . . . .

●

Setting print conditions under Windows

(selecting and setting print conditions) . . . . . . . . . .

REMOTE OPERATION THROUGH NETWORK . . . . .

●

Environment required for accessing

Web screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

●

Accessing W eb screen and

displaying help. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

●

Items and outline of menu frame of

Web screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PRINT FUNCTIONS WHICH REQUIRING PRINT

STAR T OPERATION FR OM THE OPERATION

PANEL AND THEIR OPERATION METHOD . . . . . . . .

●

Print functions selectable in the "JOB CONTROL"

dialog box and their operation . . . . . . . . . . . . . . . . .

●

Printing method of hold job list . . . . . . . . . . . . . . . .

●

Setting from the operation panel of

a scanner module . . . . . . . . . . . . . . . . . . . . . . . . . .

●

Printer account control

CHAPTER 3

PRINTER BASIC SETTINGS

MAKING PRINTER CONFIGURA TION

SETTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

●

Operation procedure common to all printer

configuration settings (items that can be set

from the operation panel). . . . . . . . . . . . . . . . . . . . .

●

Initial settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

●

PCL settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

●

PS settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CUSTOM SETTINGS . . . . . . . . . . . . . . . . . . . . . . . . .

●

Operation procedure common to all custom

settings (items that can be set from the

operation panel) . . . . . . . . . . . . . . . . . . . . . . . . . . . .

●

Setting items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHAPTER 2

PRINTING FROM A COMPUTER

CONNECTING TO A COMPUTER . . . . . . . . . . . . . . .

SOFTWARE FOR WINDO WS . . . . . . . . . . . . . . . . . . .

INST ALLING PRINTER DRIVERS

AND PRINTER UTILITIES . . . . . . . . . . . . . . . . . . . . .

REMOVING PRINTER DRIVERS

AND PRINTER UTILITIES . . . . . . . . . . . . . . . . . . . . .

0-6

Page 9

CONTENTS

CHAPTER 4

TROUBLESHOOTING AND

MAINTENANCE

MISFEED REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . .

MACHINE TROUBLE? . . . . . . . . . . . . . . . . . . . . . . . .

USER MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . .

●

Cleaning the cabinet of the main unit . . . . . . . . . . .

●

Cleaning the paper feed section . . . . . . . . . . . . . . .

●

Cleaning the document glass and document

cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHAPTER 5

PERIPHERAL UNITS

DUPLEX MODULE . . . . . . . . . . . . . . . . . . . . . . . . . . .

●

Part names and functions . . . . . . . . . . . . . . . . . . . .

●

Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

●

Loading paper in the bypass tray . . . . . . . . . . . . . .

●

Setting the printer driver for your purpose . . . . . . . .

●

Setting the copier for your purpose . . . . . . . . . . . . .

●

Troubleshooting? . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAIL-BIN STACKER . . . . . . . . . . . . . . . . . . . . . . . . . .

●

Part names and functions . . . . . . . . . . . . . . . . . . . .

●

Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

●

Outline of mail-bin stacker. . . . . . . . . . . . . . . . . . . .

●

Using the mail-bin stacker. . . . . . . . . . . . . . . . . . . .

●

Misfeed removal in the mail-bin stacker . . . . . . . . .

FINISHER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

●

Part names and functions . . . . . . . . . . . . . . . . . . . .

●

Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

●

Outline of the finisher . . . . . . . . . . . . . . . . . . . . . . .

●

Quick reference table for stapling . . . . . . . . . . . . . .

●

Using the finisher functions. . . . . . . . . . . . . . . . . . .

●

Staple jam removal and staple cartridge

replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

●

Misfeed removal in the finisher . . . . . . . . . . . . . . . .

●

Troubleshooting? . . . . . . . . . . . . . . . . . . . . . . . . . . .

SADDLE STITCH FINISHER . . . . . . . . . . . . . . . . . . .

●

Part names and functions . . . . . . . . . . . . . . . . . . . .

●

Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

●

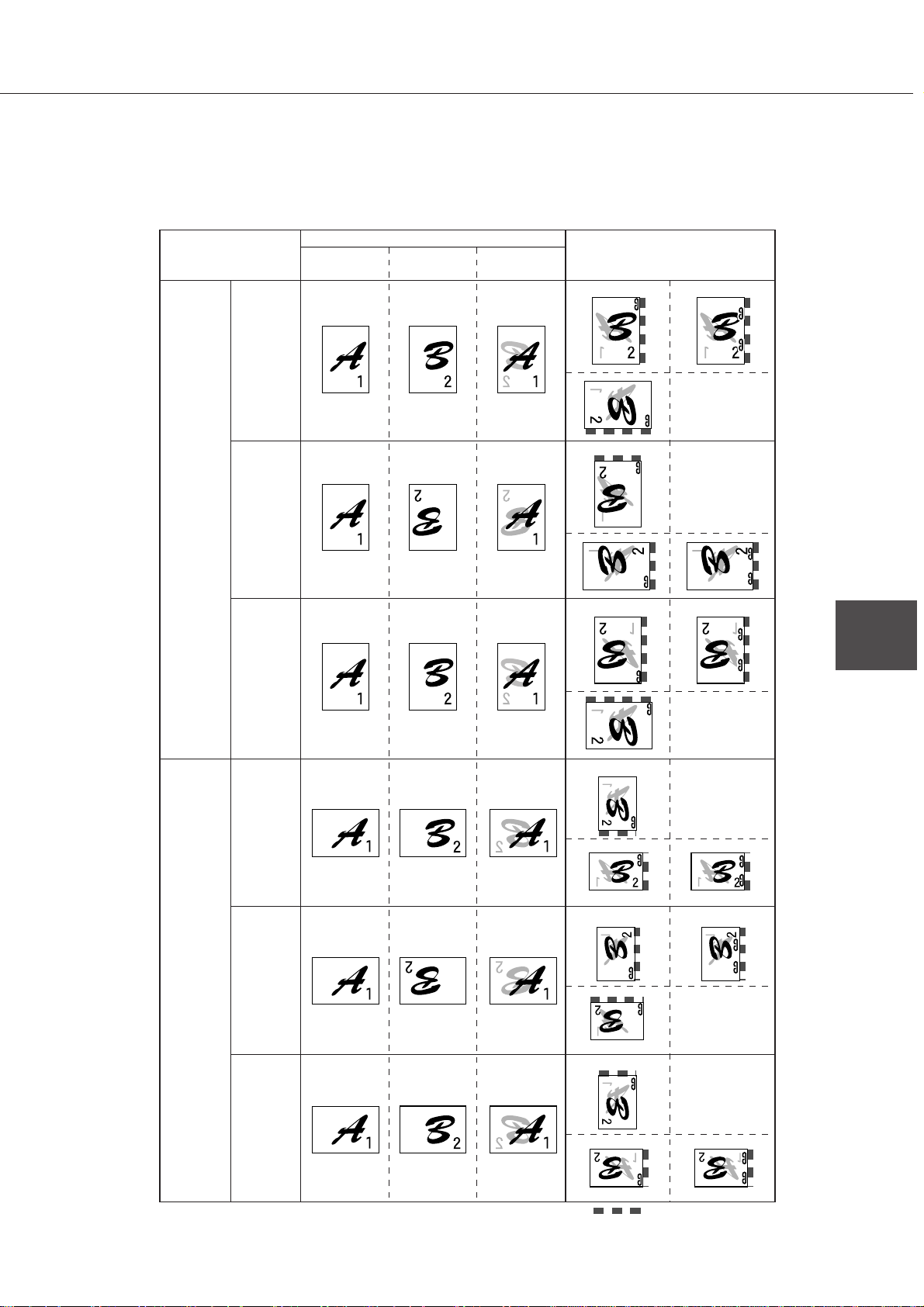

Outline of the finisher . . . . . . . . . . . . . . . . . . . . . . .

●

Quick reference table for stapling . . . . . . . . . . . . . .

●

Printed image and saddle stitch . . . . . . . . . . . . . . .

●

Using the finisher functions. . . . . . . . . . . . . . . . . . .

●

Staple jam removal and staple cartridge

replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

●

Misfeed removal in the finisher . . . . . . . . . . . . . . . .

●

Troubleshooting? . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHAPTER 6

KEY OPERATOR PROGRAMS

KEY OPERATOR PROGRAMS. . . . . . . . . . . . . . . . . .

●

Ke y operator program list . . . . . . . . . . . . . . . . . . . .

●

Using the key operator programs . . . . . . . . . . . . . .

●

Details of classification of setting items

(hierarchical structure) and supplementary

explanation of key operation . . . . . . . . . . . . . . . . . .

●

Description of programs . . . . . . . . . . . . . . . . . . . . .

CHAPTER 7

APPENDIX

PRINTER SPECIFICATIONS . . . . . . . . . . . . . . . . . . .

INTERFACE SPECIFICATIONS . . . . . . . . . . . . . . . . .

LIST OF COMBINATION OF

PERIPHERAL UNITS . . . . . . . . . . . . . . . . . . . . . . . . .

PRINT AREA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

0-7

Page 10

Page 11

CHAPTER 1

BEFORE USING THE PRODUCT

This chapter describes basic information that should be read before using

this product. Be sure to read this chapter before using this product.

Page

INTRODUCTION ................................................................................... 1-2

MAIN FEATURES .................................................................................. 1-5

PART NAMES AND FUNCTIONS ......................................................... 1-6

● Exterior ............................................................................................ 1-6

● Interior ............................................................................................. 1-7

● Part names and functions of peripheral units ................................. 1-8

● Operation panel .............................................................................. 1-11

● Touch panel .................................................................................... 1-15

LOADING PAPER .................................................................................. 1-18

● Loading paper in paper tray 1 ......................................................... 1-18

● Changing the paper size in paper tray 1 ........................................ 1-18

● Paper available in paper trays ........................................................ 1-19

● Paper available in the bypass tray/multi purpose drawer .............. 1-19

● Method of setting paper size and type ............................................ 1-20

● Loading paper in the multi purpose drawer .................................... 1-22

● Specifications .................................................................................. 1-22

● Loading paper in the stand/3 x 500 sheet paper drawer ............... 1-23

● Specifications .................................................................................. 1-23

● Loading paper in the stand/MPD & 2000 sheet paper drawer ....... 1-24

● Specifications .................................................................................. 1-24

ADDING TONER ................................................................................... 1-25

STORAGE OF SUPPLIES ..................................................................... 1-25

1-1

Page 12

INTRODUCTION

Read this operation manual carefully to use this product properly. Be sure to read “INSTALLATION REQUIREMENTS”

and “CAUTIONS” before using this product.

Be sure to keep this operation manual handy to refer to it any time.

This product is a multi-function printer that can be used as a local printer and a network printer as well as a copier,

network scanner, and a facsimile by installing various types of peripheral units (optional).

This operation manual describes the basic use of the product as a printer and also describes operation items common

to the printer and other features such as loading paper, misfeed removal, and user maintenance.

If you extend this product to use the copier feature, network scanner feature, facsimile feature or network printer

feature, relevant operation manuals are supplied. Read the respective manuals for using the features.

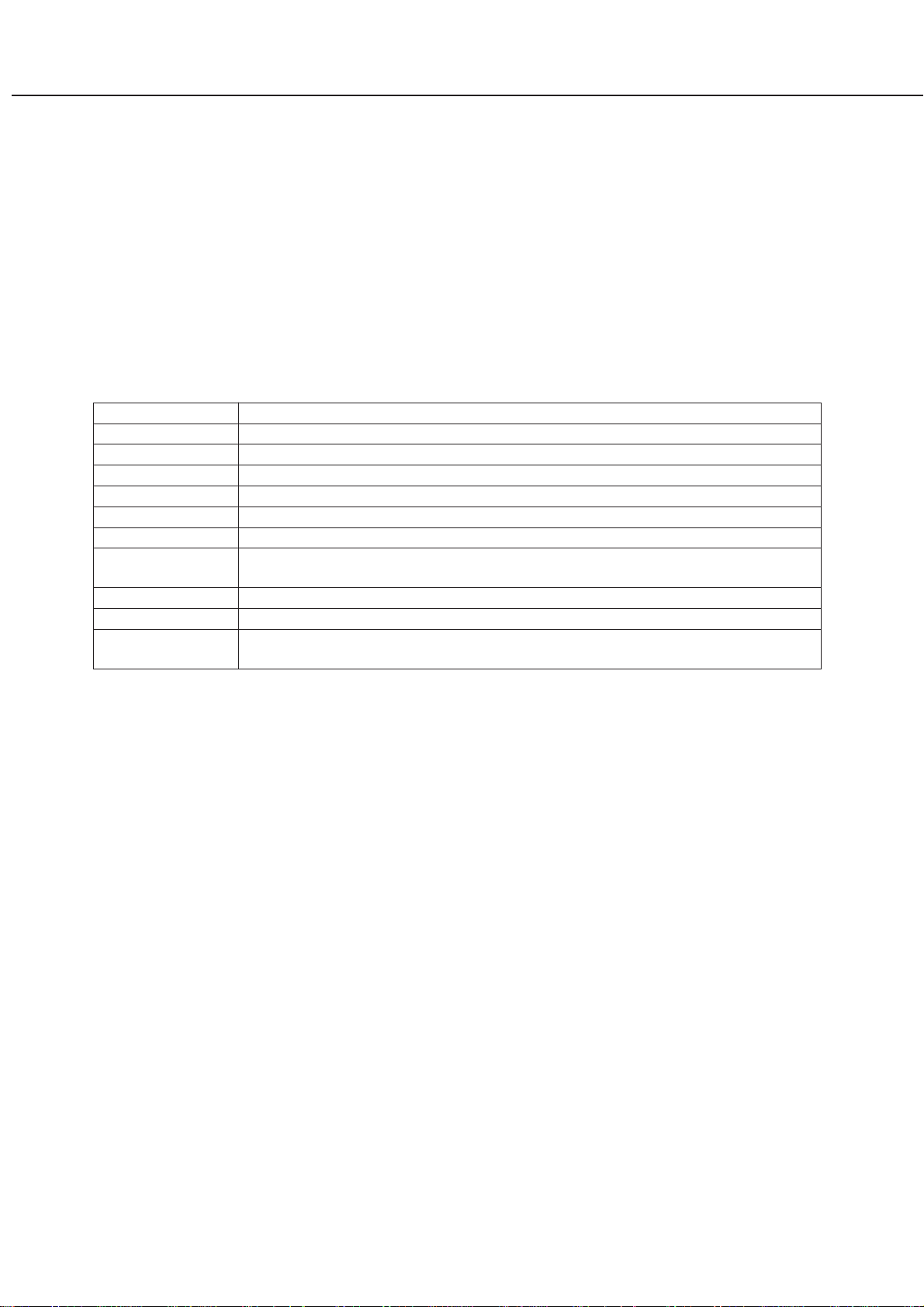

The following table shows the model names of the main units to which this operation manual applies and their product

configuration.

(As of end of April 2001)

Model name Product configuration

AR-P350 35 pages/minute printer

AR-P450 45 pages/minute printer

AR-M350 35 pages/minute printer (with a multi-function controller board)*1

AR-M450 45 pages/minute printer (with a multi-function controller board)*1

DM-3500 35 pages/minute printer

DM-3501 35 pages/minute network printer (with a print server card)*2

DM-3551 35 pages/minute network printer (with a multi-function controller board and a print

server card)*3

DM-4500 45 pages/minute printer

DM-4501 45 pages/minute network printer (with a print server card)*2

DM-4551 45 pages/minute network printer (with a multi-function controller board and a print

server card)*3

Although the peripheral units are basically optional, some units may be provided as standard components depending

on the model.

*1 A multi-function controller board required to extend the product to a multi-function printer that can be used as a

copier, facsimile, and a network scanner is provided as a standard component.

*2 A print server card required to extend the product to a network printer is provided as a standard component.

*3 A multi-function controller board and a print server card are provided as standard components.

1-2

Page 13

INTRODUCTION

Abbreviated names of peripheral units

The following unit is written with an abbreviated name without some exceptions to simplify the description in this

manual.

“B/W scanner module/DSPF”

The unit is written as “scanner module”.

NOTES

●

The scanner unit is a unit for scanning originals (automatic document feeder) when using the copier feature and

facsimile feature. In the touch panel messages in the scanner module, the “scanner module” is displayed as

“document feeder”.

●

To use a scanned image as image data on a computer, a network scanner expansion kit (peripheral unit) is needed

in addition to the network printer environment.

“Duplex module”

This is a unit that allows printing onto two sides of paper. A single “duplex module” and a “duplex module/bypass tray”

are supplied. In this manual, both units are written as “duplex module” with some exception and description is made

mainly for the “duplex module/bypass tray”. The description for the bypass tray, therefore, is made only for the “duplex

module/bypass tray”. In the pages of “duplex module”, illustrations with an output tray are used. This output tray is

optional for both the duplex modules. (not included in the duplex modules)

1

1-3

Page 14

INTRODUCTION

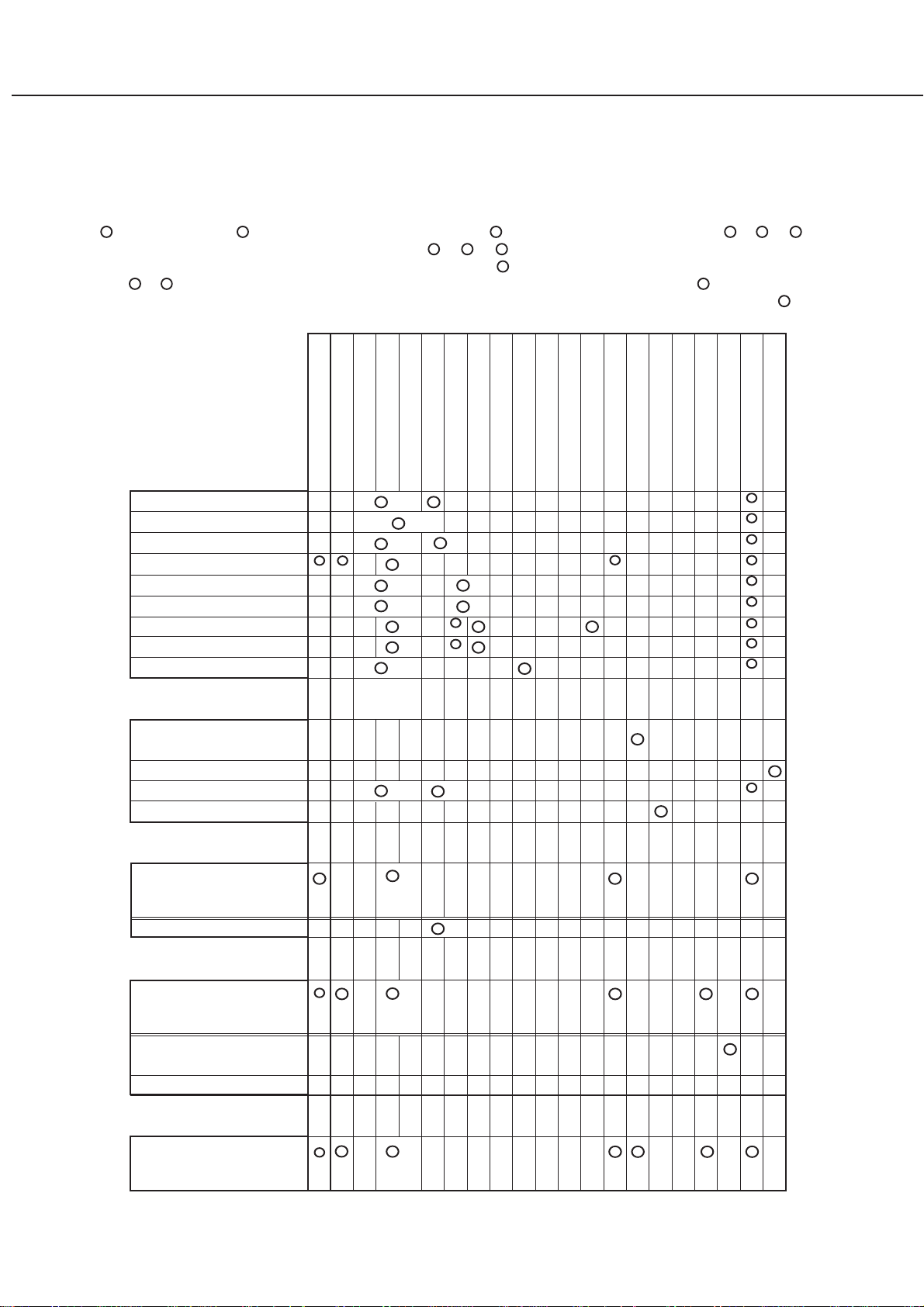

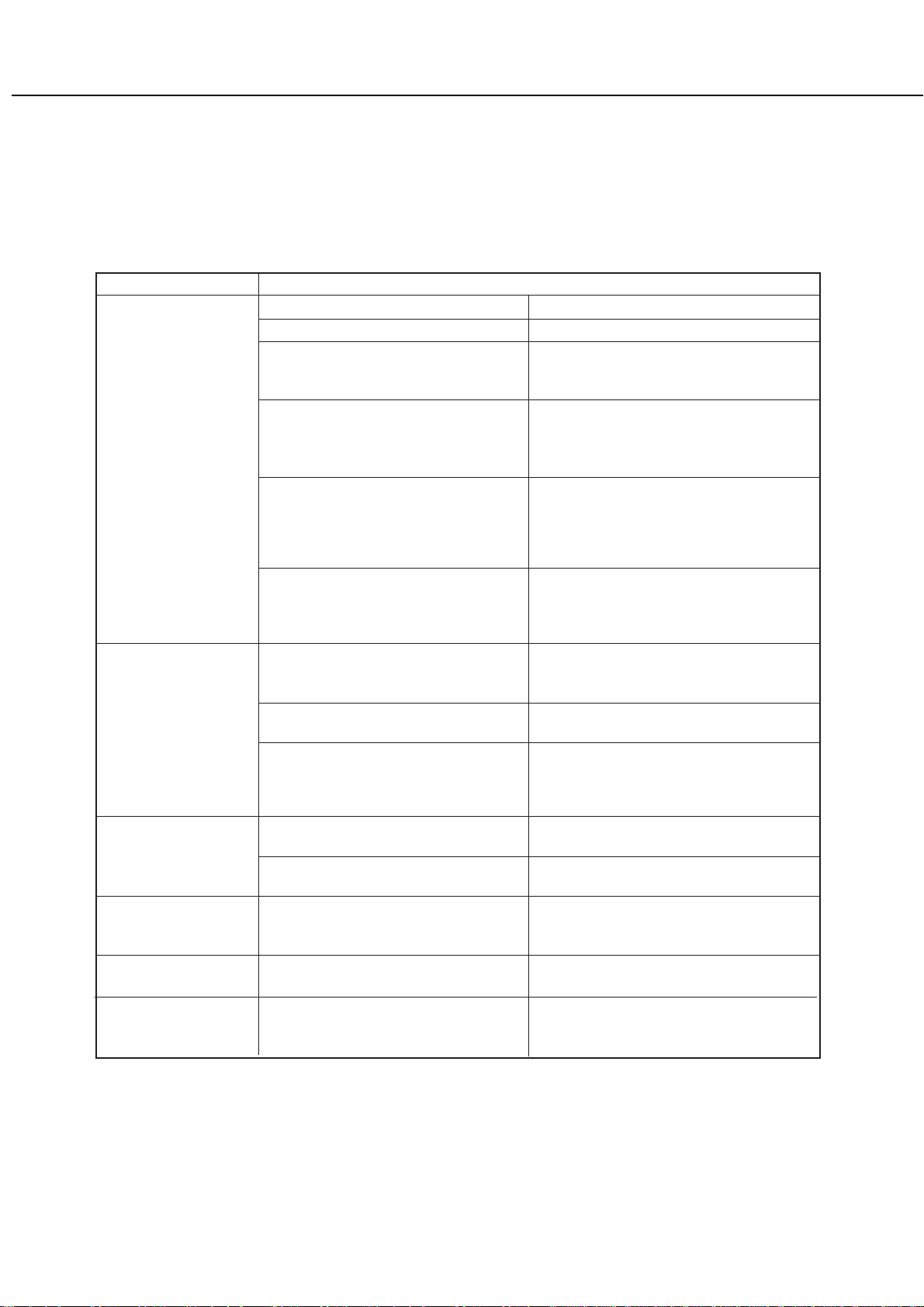

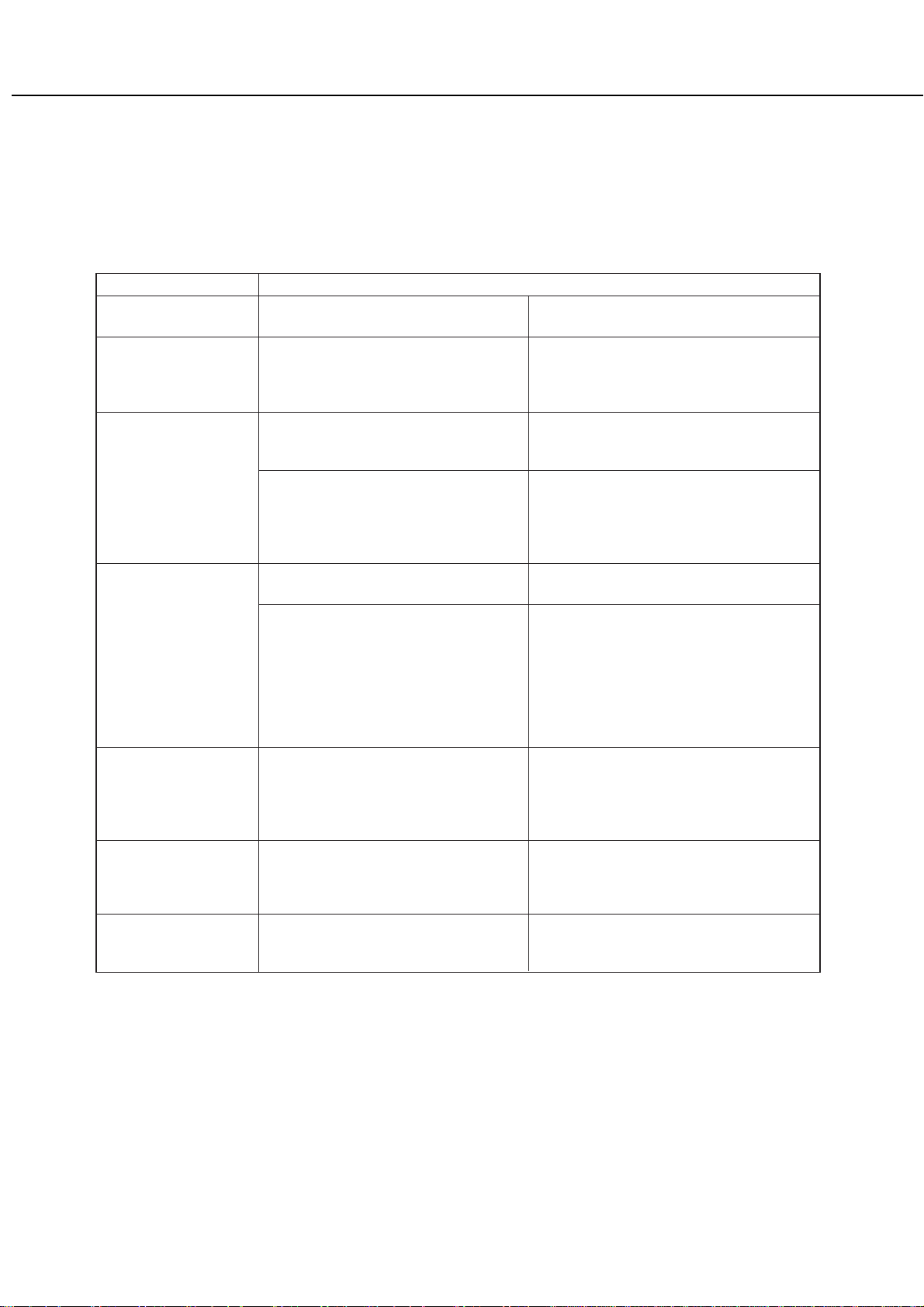

The following table shows the relation between the various functions described in this manual, copier operation manual,

facsimile operation manual, and network scanner operation manual and the required peripheral units. In each operation

manual, the optional peripheral units that are required for using each function is not particularly described. Refer to this

table as needed.

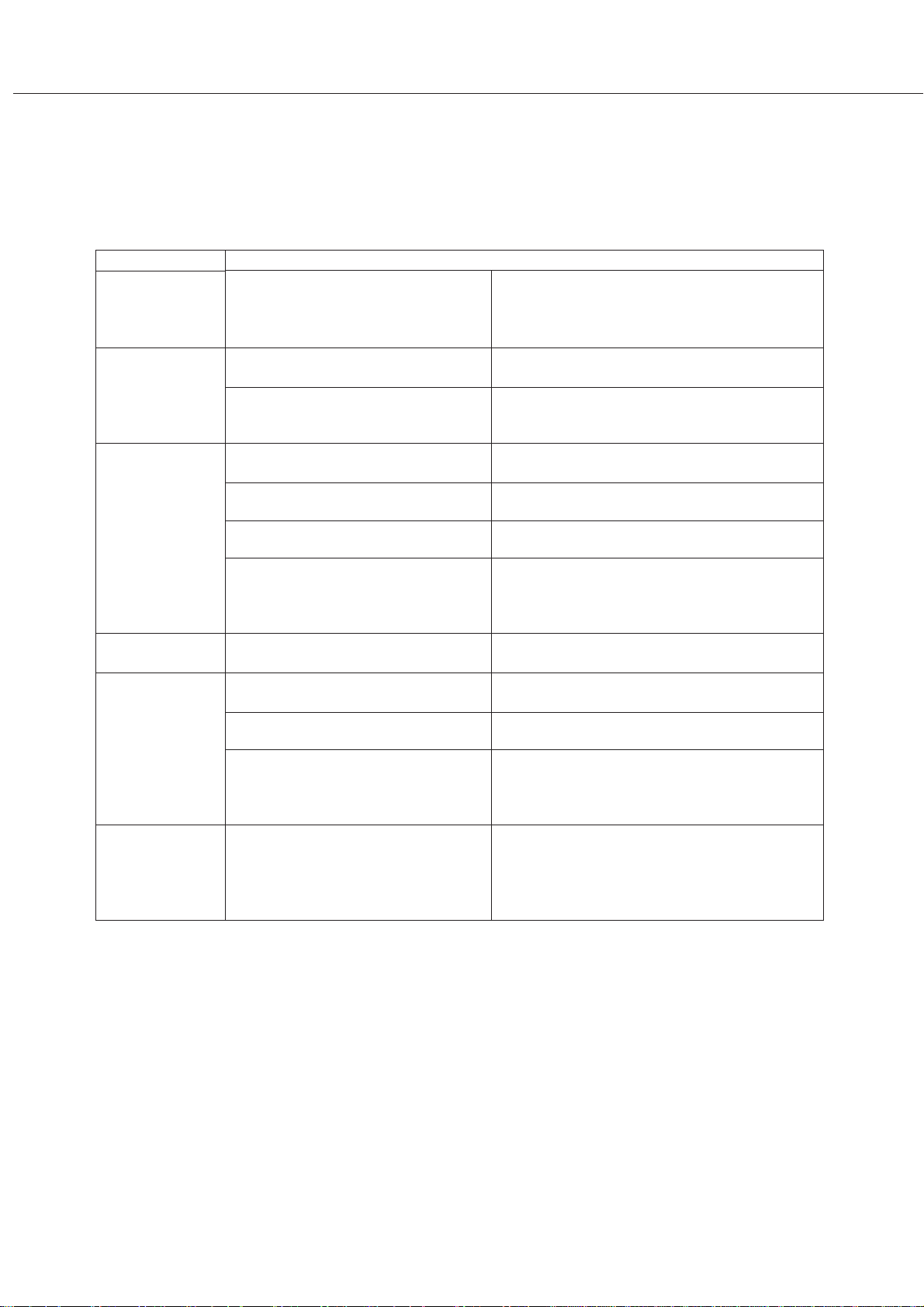

= Must be installed *1 = Any of the units must be installed. *2 = Must be installed together with or *1. *3

= Any of these units must be installed together with or *1. *4 = Required when a stand/3 x 500 sheet paper

drawer or a stand/MPD & 2000 sheet paper drawer is installed. *5 = Any of these units must be installed together

with or *1 but the multi purpose drawer is excluded when a saddle stitch finisher is installed. *6 = Any of these

units must be installed in addition to the peripheral units required at the minimum for using the copier feature. *7 =

Must be installed in addition to the peripheral units required at the minimum for using the facsimile feature.

Common to all features

Manual paper feeding

Print onto special paper

Two-sided print

Touch panel operation

Offset stack of printed sheets

Stapling of printed sheets

Center stapling of printed sheets

Punching of printed sheets

Mail bin stack of printed sheets

Printer feature

Network printer

Job retention function

Pamphlet print

PostScript3 compatibility

Copier feature

Peripheral units required at

the minimum for using the

copier feature

Pamphlet copy

Scanner rack

Multi purpose drawer

Stand/3 x 500 sheet paper drawer

Stand/MPD & 2000 sheet paper drawer

B/W scanner module/DSPF

✱2✱

1

✱

1

Duplex module/bypass tray

✱

3

✱

1

✱

3

✱

5

✱

5

✱

5

✱

3

✱

1

✱

3

✱

3

✱

✱

✱

3

✱

✱

1

1

✱

6

Duplex module

Saddle stitch finisher

Finisher

Mail-bin stacker

✱

1

✱

1

2

2

Exit tray

Upper exit tray extension

Punch module

✱

2

PS3 expansion kit

Print server card

Multi-function controller board

Facsimile expansion kit

Network scanner expansion kit

Power supply unit

Additional fax memory (8 MB)

✱

4

✱

4

✱

4

✱

2

✱

2

✱

2

✱

2

✱

2

✱

2

✱

2

Hard disk drive

Facsimile feature

Peripheral units required at

the minimum for using the

facsimile feature

Memory for original images of

xx sheets or more

Telephone call

Network scanner feature

Peripheral units required at the

minimum for using the network

scanner feature

1-4

✱

✱

1

✱

1

1

✱

7

✱

1

Page 15

MAIN FEATURES

Multi-function printer allowing extension of functions based on the purpose

This product is a multi-function printer that can be used as a local printer and a network printer as well as a copier,

a network scanner, and a facsimile by combining peripheral units. Various optional units for improving productivity

such as duplex modules for two-sided printing, additional paper feed units for large capacity paper stock, and paper

output units for sorting printed sheets are provided as peripheral units.

600 dpi high resolution printing

High definition and high quality printing with 600 dpi resolution can be performed. Also high image quality equivalent

to 1200 dpi can be output by using the soothing function.

Monochrome high-speed printing

High-speed printing of 35 pages/minute or 45 pages/minute can be performed for 8-1/2" x 11" or A4 size.

PostScript compatible

Installation of a PS3 expansion kit gives PostScript compatibility (PostScript level 3).

ENERGY STAR

As an ENERGY STA R® Partner, SHARP has determined that this product meets the ENERGY STA R® guidelines

for energy efficiency.

1

Energy saving feature

This product has the following two power save modes that conform the Energy

Star guidelines to conserve natural resources and to help reduce environmental

pollution.

Preheat mode

The machine will enter the preheat mode once the time set with a key operator program has elapsed without

any operation. In this mode, the fuser is maintained at a lower heat level thereby saving power.

Auto power shut-off mode

The machine will enter the auto power shut-off mode once the time set with a key operator program has

elapsed without any operation. In this mode, power to the display and the fuser is turned off and only the

lowest power is consumed. In this mode, power can be saved more than the preheat mode but more time is

needed to return to the operating state. This mode can be disabled using a key operator program.

If this product is used as a printer, when print data is received in the preheat mode or the auto power shut-off

mode, the mode will be automatically canceled and printing will start after the fuser temperature is restored to

the normal operating level.

If this product is used as a multi-function machine, the mode will be automatically canceled when print data or

facsimile data is received or when any key operation on the operation panel or original setting operation for

copying or facsimile transmission is performed.

1-5

Page 16

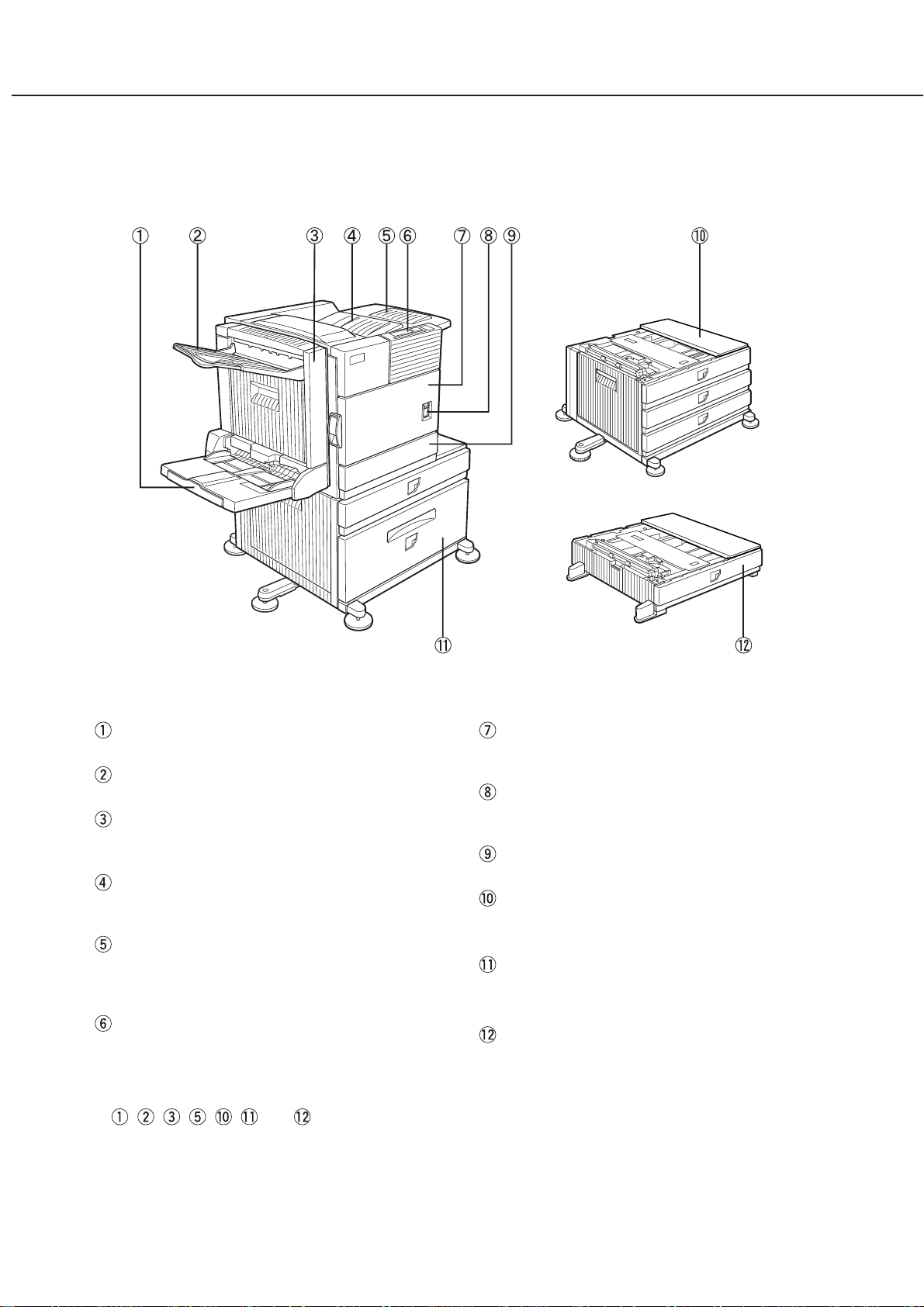

PART NAMES AND FUNCTIONS

Exterior

Bypass tray (part of duplex module/bypass tray)*1

Exit tray*1

Duplex module*1

Module for two-sided printing

Upper paper output area

Finished sheets are deposited here.

Upper exit tray extension*1

Extension table for preventing dropping of large paper

such as 11" x 17" and 8-1/2" x 14" (A3 and A4).

Operation panel (See page xxxx.)

*1 , , , , , , and are peripheral units. For description of these units, see page xx. The configuration

of peripheral units varies with the main unit model.

Front cover

Open to add toner and remove misfeeds.

Main switch (See page xxxx.)

Press to turn power on and off.

Paper tray 1

Stand/3 x 500 sheet paper drawer*1 (See page

xxxx.)

Stand/MPD & 2000 sheet paper drawer*1

(See page xxxx.)

Multi purpose drawer*1 (See page xxxx.)

1-6

Page 17

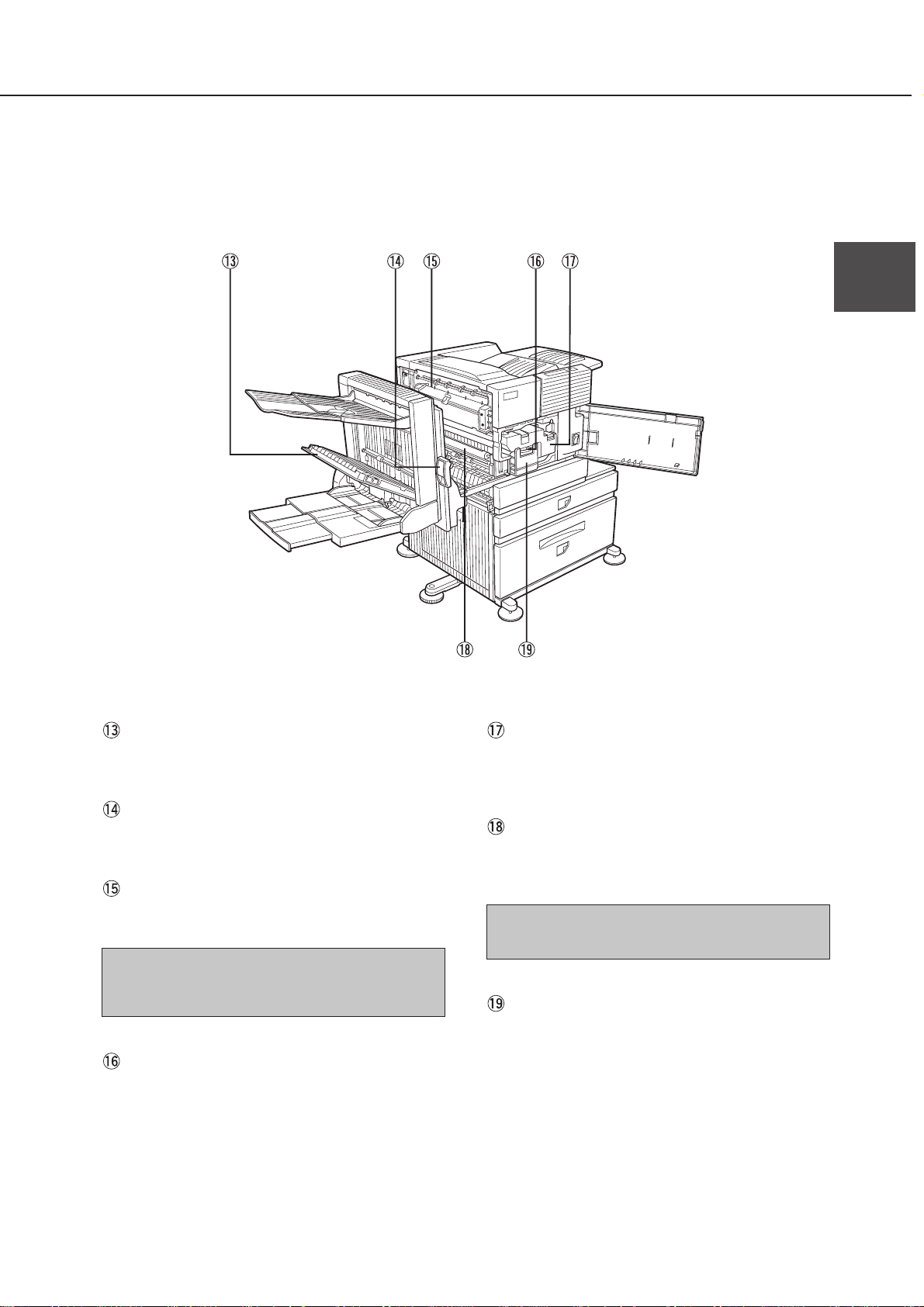

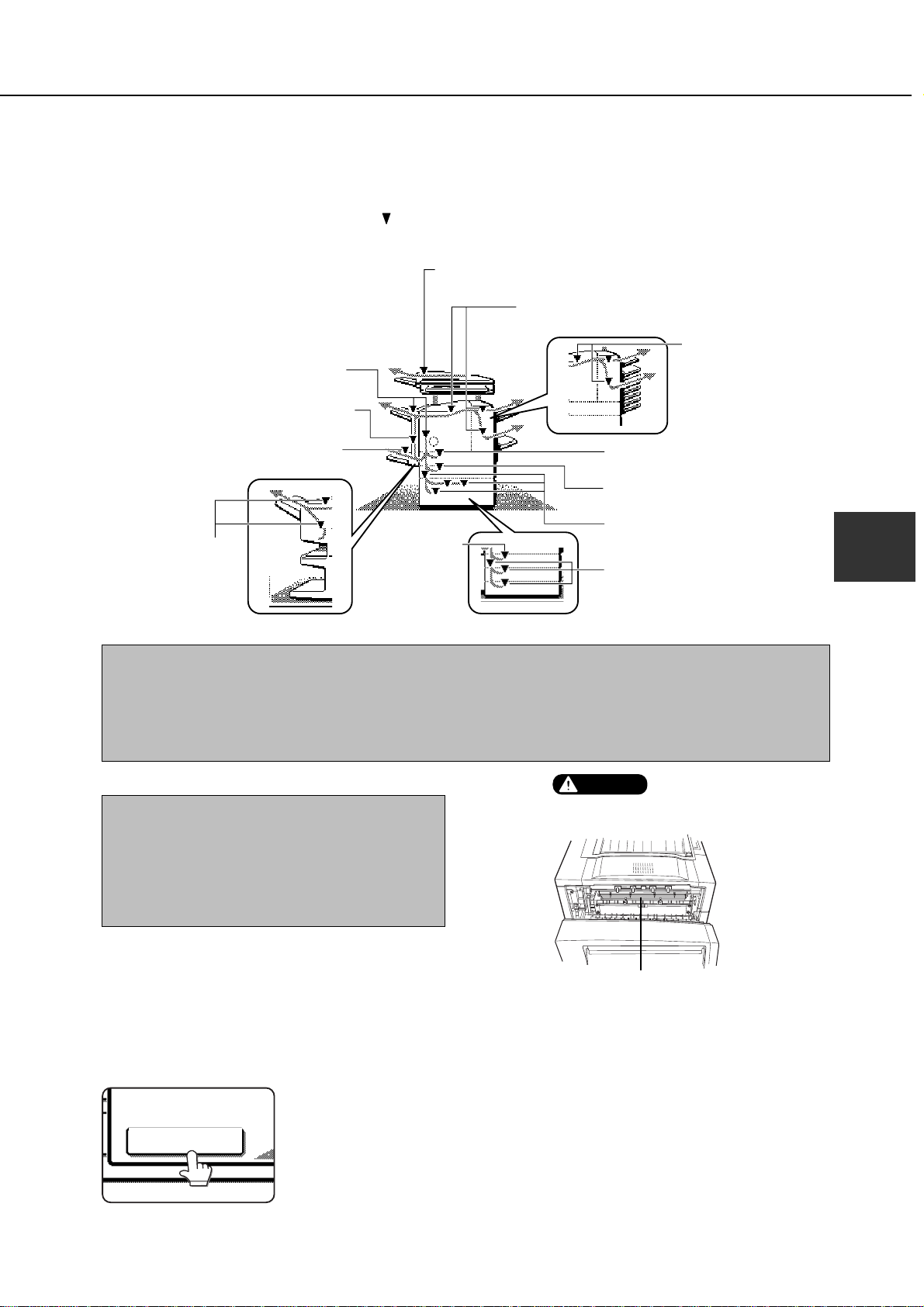

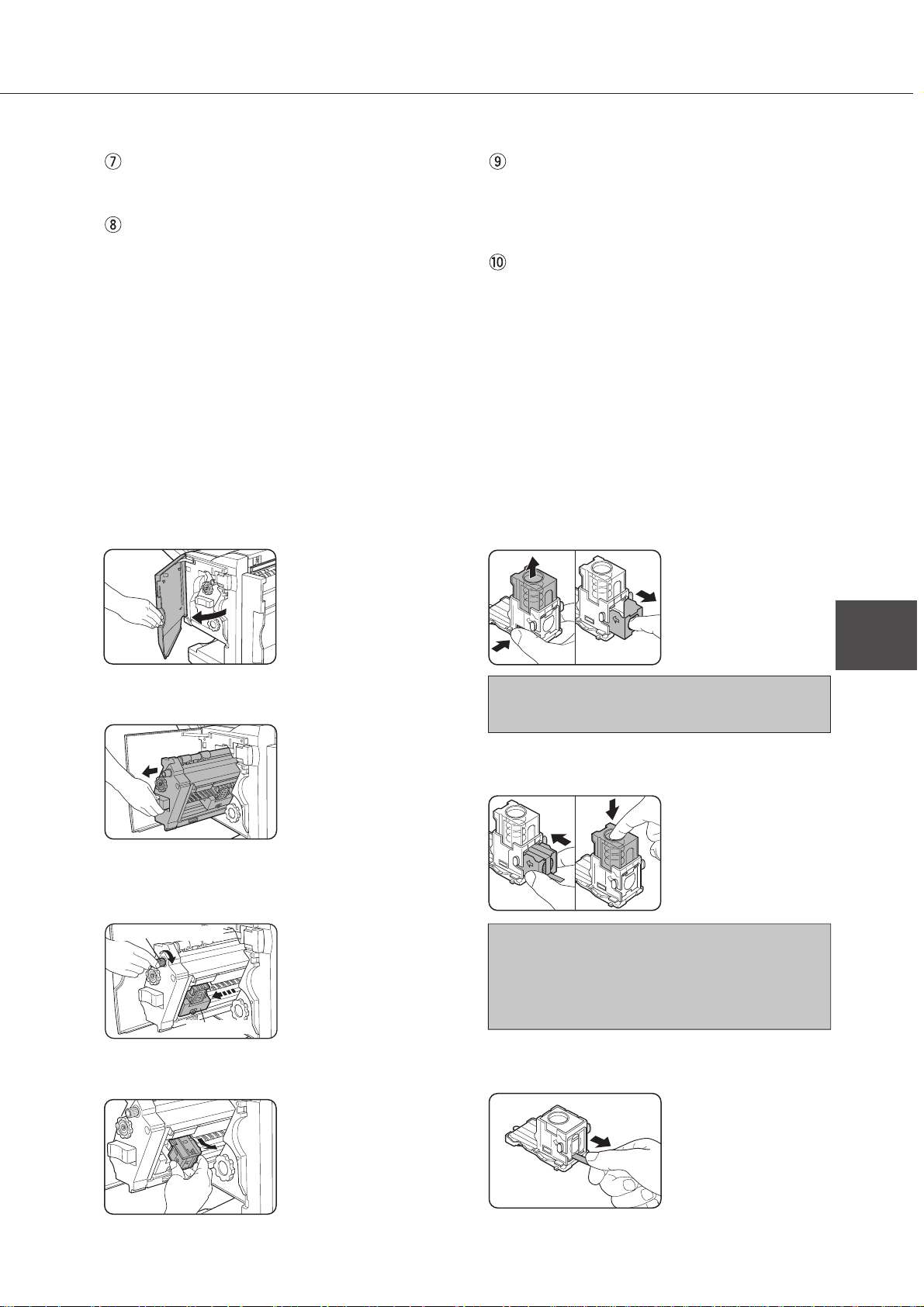

Interior

PART NAMES AND FUNCTIONS

1

Duplex module side cover

Open when a misfeed has occurred in the duplex

module.

Side cover open knob

Push up to open the side cover when a misfeed has

occurred in the fusing unit.

Fusing unit

Image that has been transferred on paper is fixed by

heating it in the fusing unit.

CAUTION

The fusing unit is hot. Take care in removing misfed

paper.

Developer cartridge* (See page xxxx.)

Container that contains developer. The cartridge must

be removed and replaced with a new one at the time

of replacement.

*2 For replacement and installation of each cartridge, see the separate manual “Supply Replacement Method.”

Toner cartridge* (See page xxxx.)

Container that contains toner. When toner is

exhausted, the cartridge must be removed and

replaced with a new one.

Photoconductive drum

A photoconductor is applied to the surface of the

photoconductive drum. Images are formed on the

photoconductive drum.

NOTE

Do not touch or damage the photoconductive drum.

Cartridge lock lever

When replacing the drum, toner or developer cartridge,

turn down this lever and pull it out.

1-7

Page 18

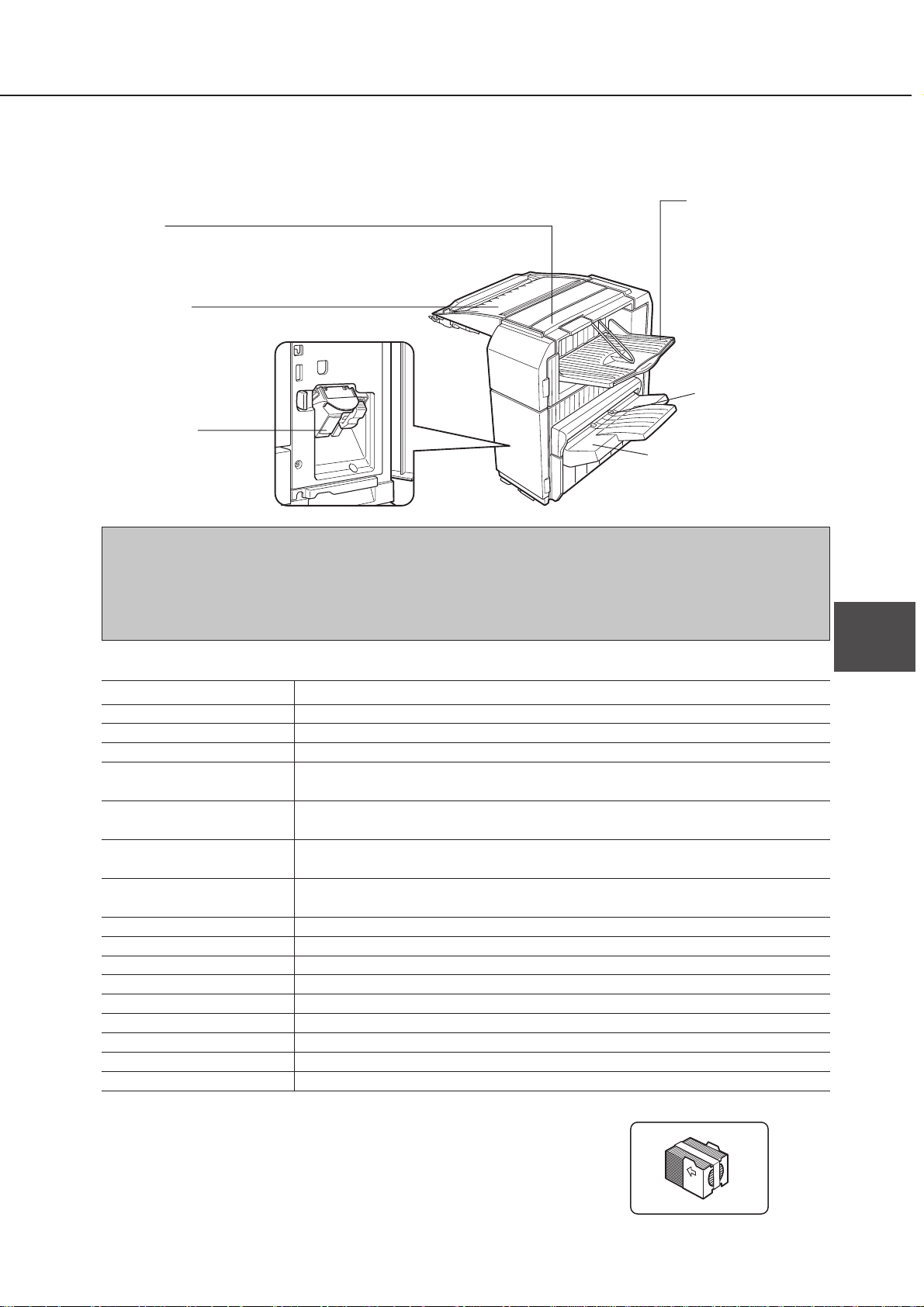

PART NAMES AND FUNCTIONS

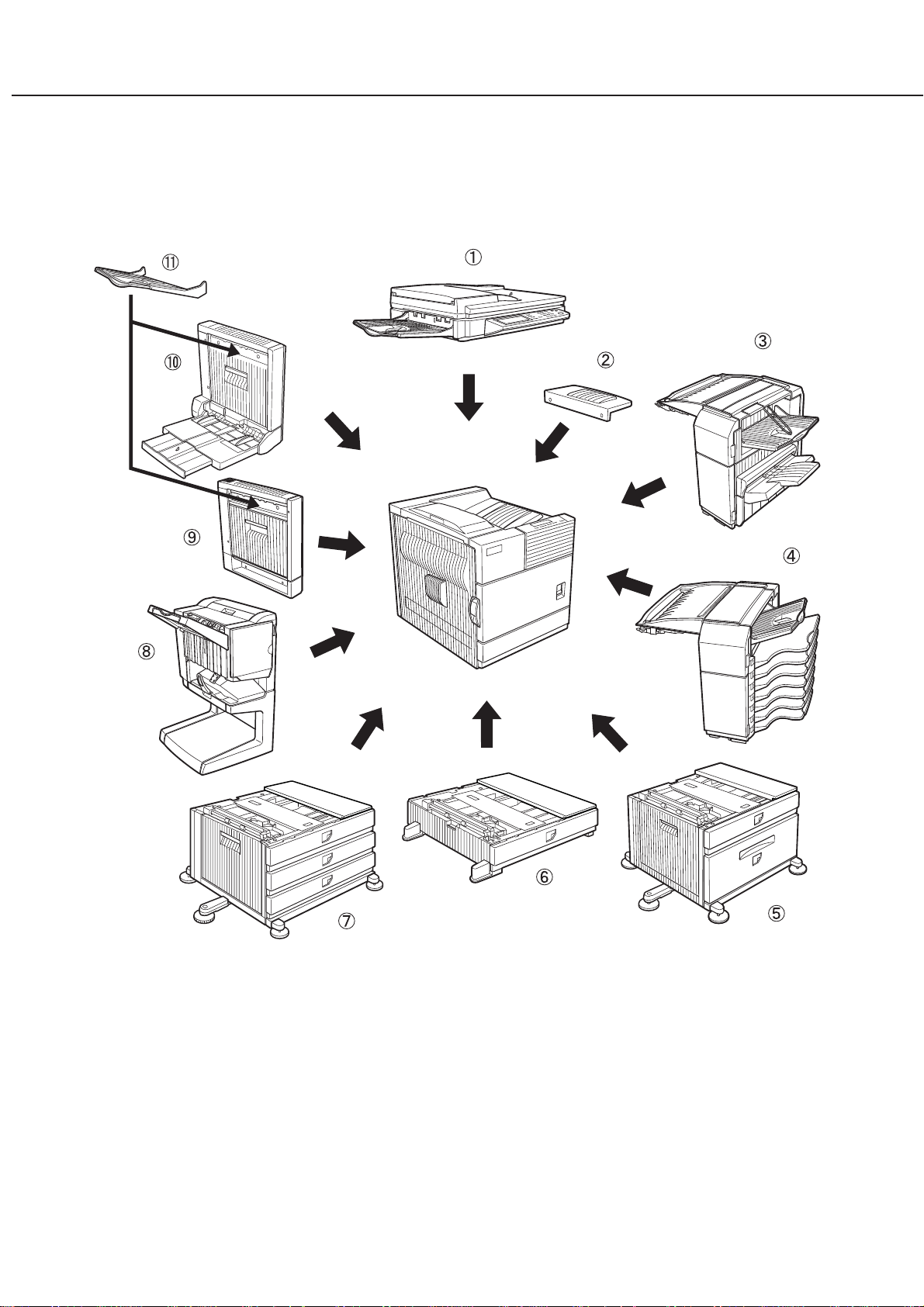

Part names and functions of peripheral units

1-8

Page 19

PART NAMES AND FUNCTIONS

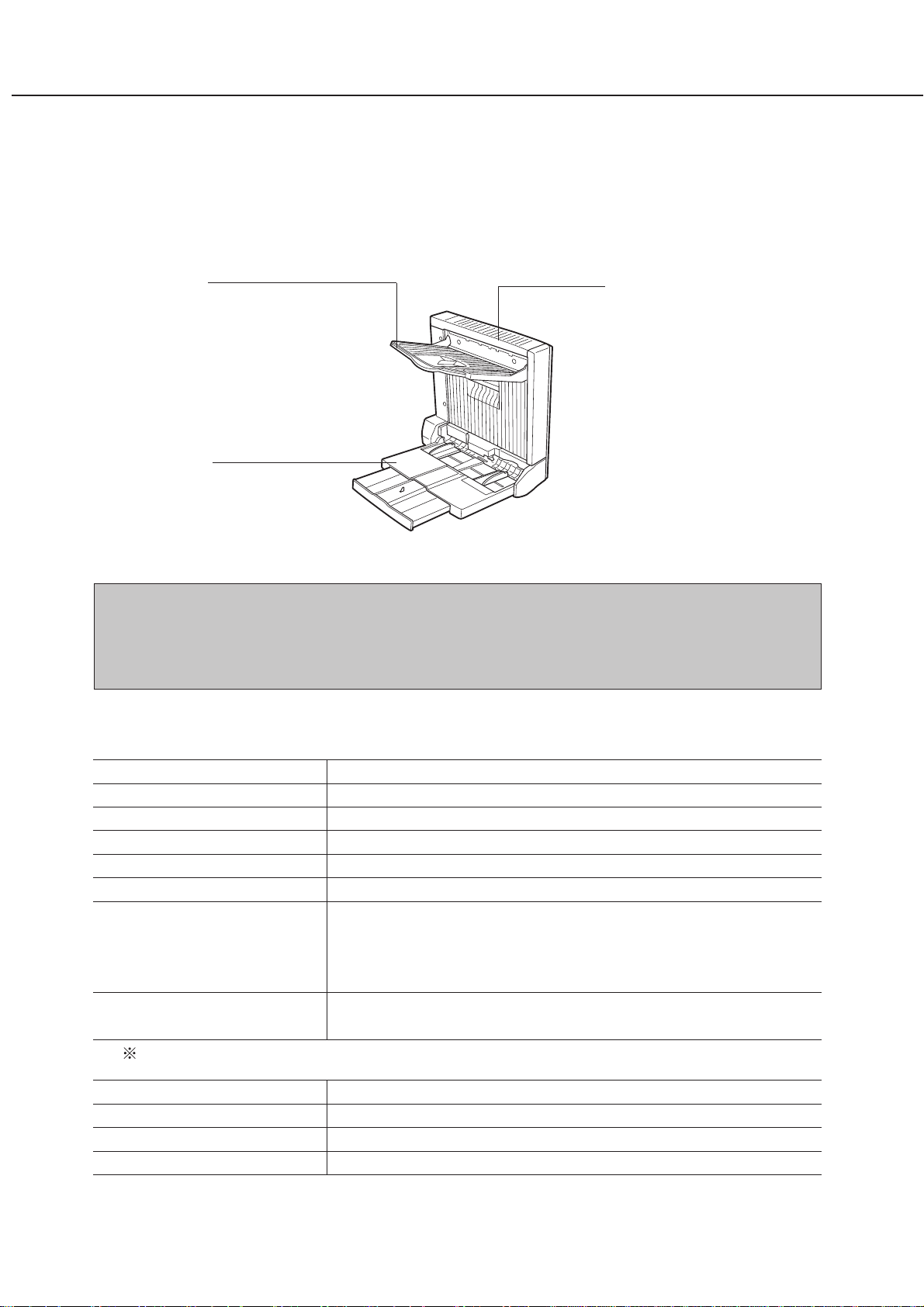

B/W scanner module/DSPF

This unit is a monochrome scanner that allows

automatic feeding of sheet originals and continuous

scanning. The B/W scanner module/DSPF (Dual

Single Pass Feeder) can scan two-sided sheet

originals and can scan both sides at a time. Also a

flat bed type document glass is provided in this unit

for scanning an original that cannot be fed such as a

book and thick original.

Upper exit tray extension

Mount this unit to the upper paper exit tray. This unit

is needed for output of 11" x 17" (A3) paper.

Finisher

Sorted output sheets or grouped output sheets by

page are offset stacked so that each set can be

taken out easily.

Also sorted output sheets can be stapled.

Mail-bin stacker

This unit is an output sheet sorting unit that contains

seven bins. When printed sheets are output in the

printer mode, a bin to which printed sheets are to be

deposited can be specified in the printer driver. The

bins can be classified by persons or by sections

depending on users so that the users deliver their

printed sheets to their specified bin. Sorted output

separated from the other users, therefore, can be

performed.

Output sheets in the copy and fax modes are

deposited in the top tray other than these seven bins.

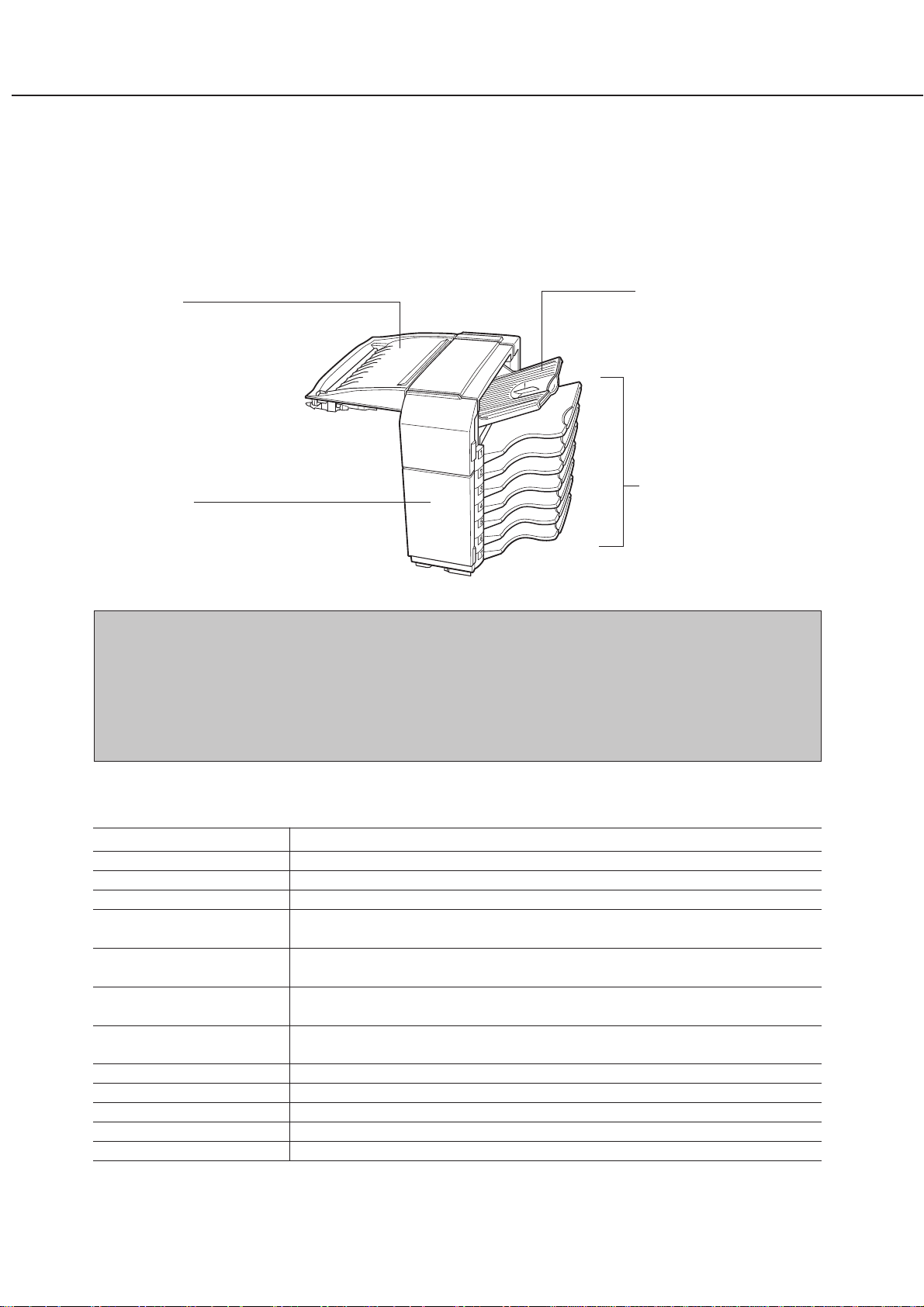

Stand/MPD & 2000 sheet paper drawer

This is a paper feed unit that contains two paper

trays. The upper tray is equivalent to the multi purpose

drawer. The lower tray holds approximately 2000

sheets of 20 lbs. (80 g/m

2

) paper.

Multi purpose drawer

Holds paper. Up to 500 sheets of 20 lbs. (80 g/m

paper can be loaded. Also special papers such as

envelopes (standard sizes only) and Japanese

postcard can be set.

Stand/3 x 500 sheet paper drawer

This is a paper feed unit that contains three paper

trays. The upper tray is equivalent to the multi purpose

drawer. Each of the lower two trays holds up to 500

sheets of 20 lbs. (80 g/m

Saddle stitch finisher

Sorted output sheets or grouped output sheets by

page are offset stacked so that each set can be

taken out easily. Also sorted output sheets can be

stapled at the edge or at the center for center-stapled

binding.

In addition, if a punch module is installed as a

peripheral unit, punch holes can be made in the

output sheets for filing.

Duplex module

Unit for automatic two-sided printing.

Duplex module/bypass tray

This module is equipped with a unit for automatic

two-sided printing and a bypass tray manual paper

feeding.

Exit tray

Mounted to the paper output port of a duplex module

or a duplex module/bypass tray.

2

) paper.

2

)

1

For installation of a peripheral unit, installation of some other peripheral units may be needed together and installation

of some peripheral units may not be possible together. See page xx, “COMBINATION OF PERIPHERAL UNITS.”

Peripheral units are basically optional but some units may be provided as standard units depending on the main unit

model.

1-9

Page 20

PART NAMES AND FUNCTIONS

■ Other peripheral units

●

Scanner rack

Rack required for installing a scanner module. The

height is fixed.

●

Power supply unit

For installation of some peripheral units, this unit is

required for supplying power to each unit.

●

Print server card

NIC (network interface card) for using the printer as

a network printer.

●

Multi-function controller board

Printer controller required for using the copier,

facsimile, and network scanner features.

●

PS3 expansion kit

Kit required for using the printer as a PostScript

compatible printer. (for PostScript level 3)

●

Hard disk drive

Extends the image storing capacity for the printer

and copier features (not for the facsimile feature).

Also this unit is required for using the job retention

function (see page xxxx) with which print data

received for the printer feature is held temporarily

instead of immediate output.

●

Facsimile expansion kit

Kit required for using the facsimile feature.

●

Additional fax memory (8 MB)

●

Network scanner expansion kit

Kit required for using the network scanner feature.

For installation of a peripheral unit, installation of some other peripheral units may be needed together and installation

of some peripheral units may not be possible together. See page xx, “COMBINATION OF PERIPHERAL UNITS.”

Peripheral units are basically optional but some units may be provided as standard units depending on the main unit

model.

1-10

Page 21

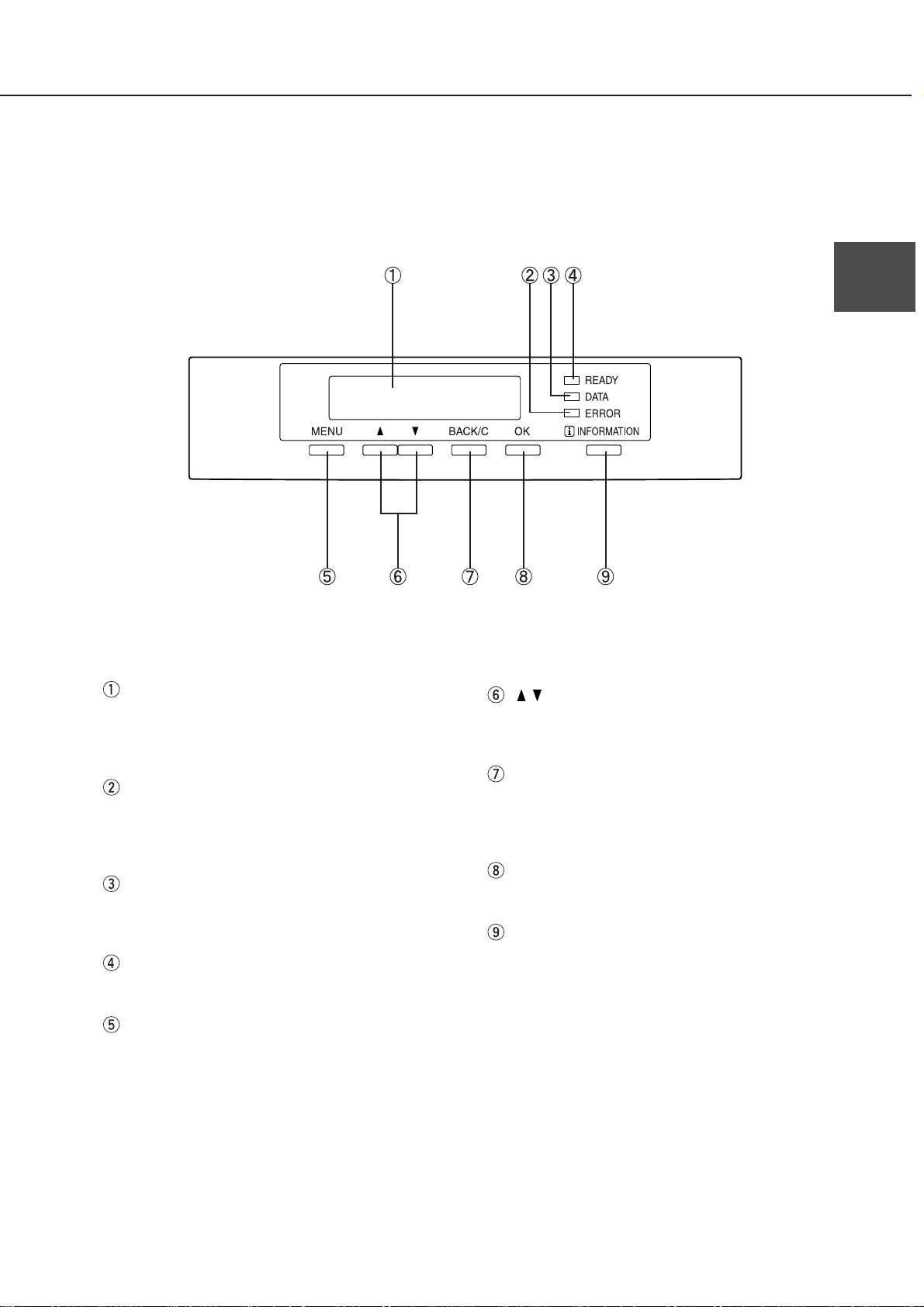

PART NAMES AND FUNCTIONS

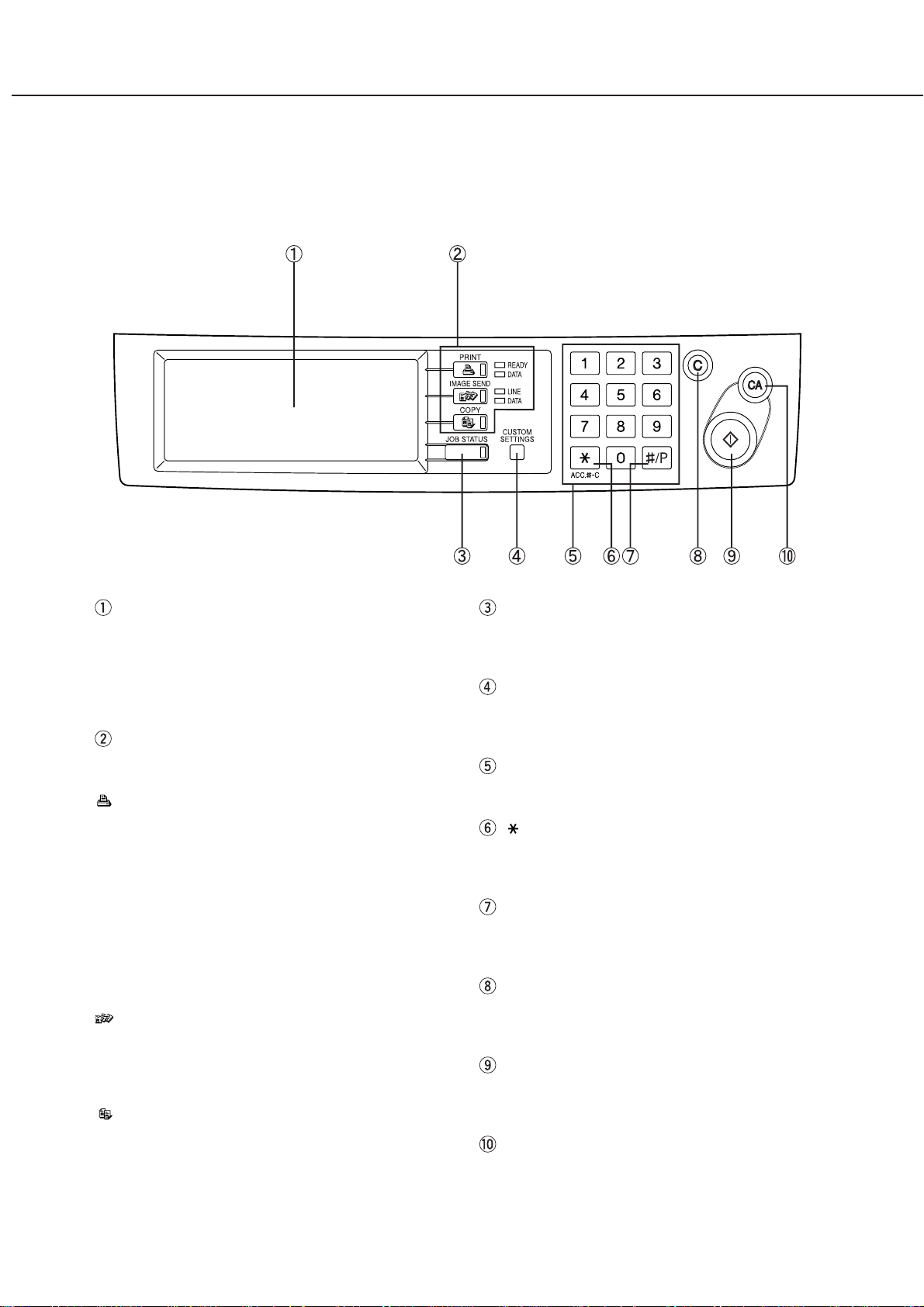

Operation panel

The display and indicators in the operation panel located on the front of the machine indicate the current status of the

printer. Also the keys on the operation panel allow settings required for printing.

1

Message display

Displays the printer current state.

[i] displayed in messages indicates the

[INFORMATIONS] key.

[ERROR] indicator

Lights up when paper or toner must be added or when

a misfeed has occurred. Blinks when an abnormal

condition has occurred in this machine.

[DATA] indicator

Lights up or blinks when print data is being received.

Also lights up when printing is being performed.

[READY] indicator

Printing can be executed when this indicator is lit.

[MENU] key

Press to select a menu group such as printer

configuration menu (page xxx), custom settings, and

execution of printing held by the retention function

(page xxx). Press also to return to the menu screen

from the setting screen of each menu group.

[ / ] keys

Press to select each menu or function or to set a

number.

[BACK/C] key

Use this key to return to the previous screen in each

menu selection, to cancel and delete the current job

or to delete a reserved job that has been selected.

[OK] key

Press to register the selected menu or function.

[INFORMATION] key

When [ i ] is displayed with a message indicating a

paper misfeed, requesting toner addition, etc., the

relevant operation procedure can be displayed by

pressing the [INFORMATION] key. If the

[INFORMATION] key or the [BACK/C] key is pressed

while the operation procedure is displayed, the

information mode will be canceled. If you press and

hold down this key while printing is being performed

or in the standby, the total number of printed pages

and quantity of toner remaining (as a percent) will be

displayed.

1-11

Page 22

PART NAMES AND FUNCTIONS

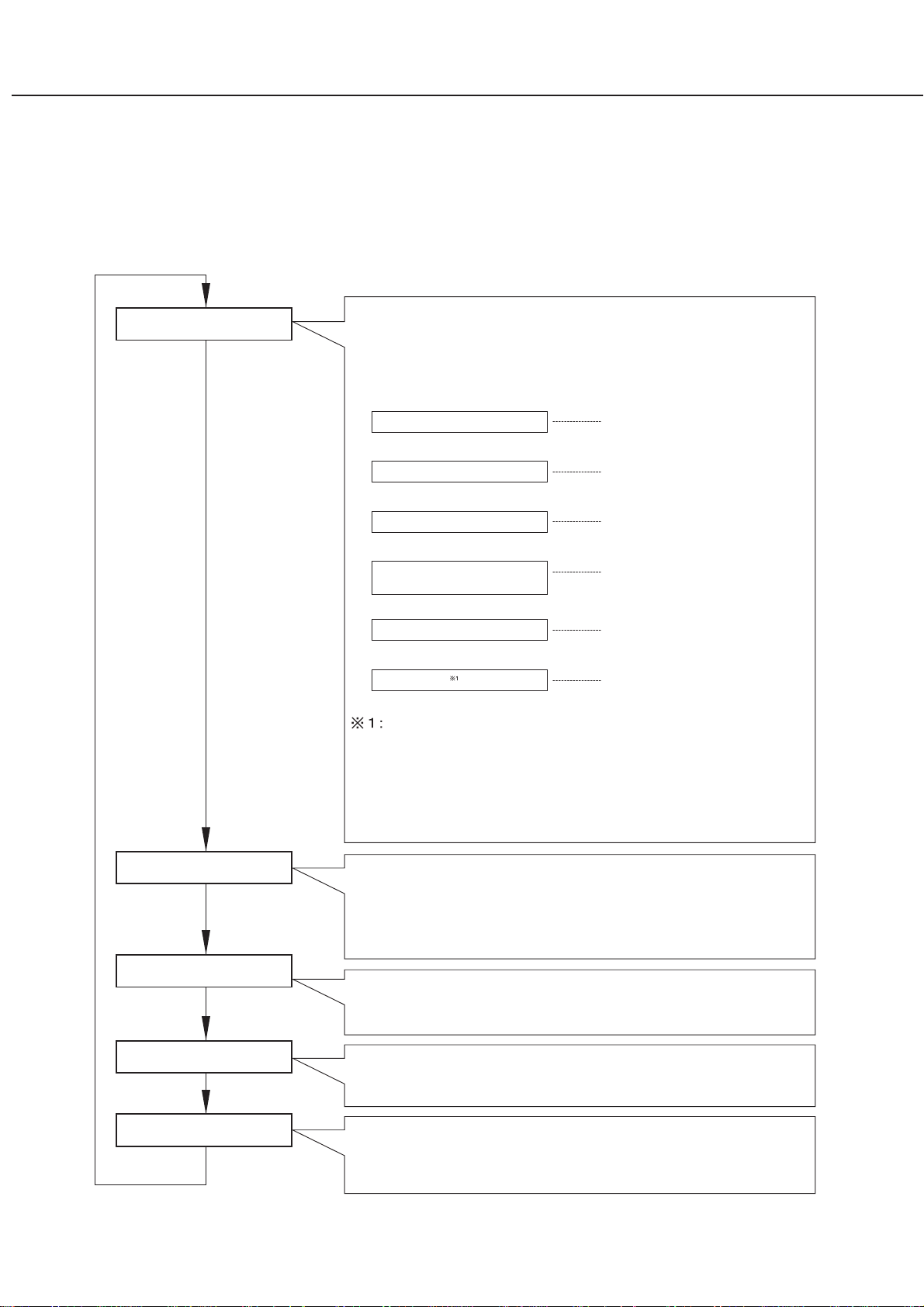

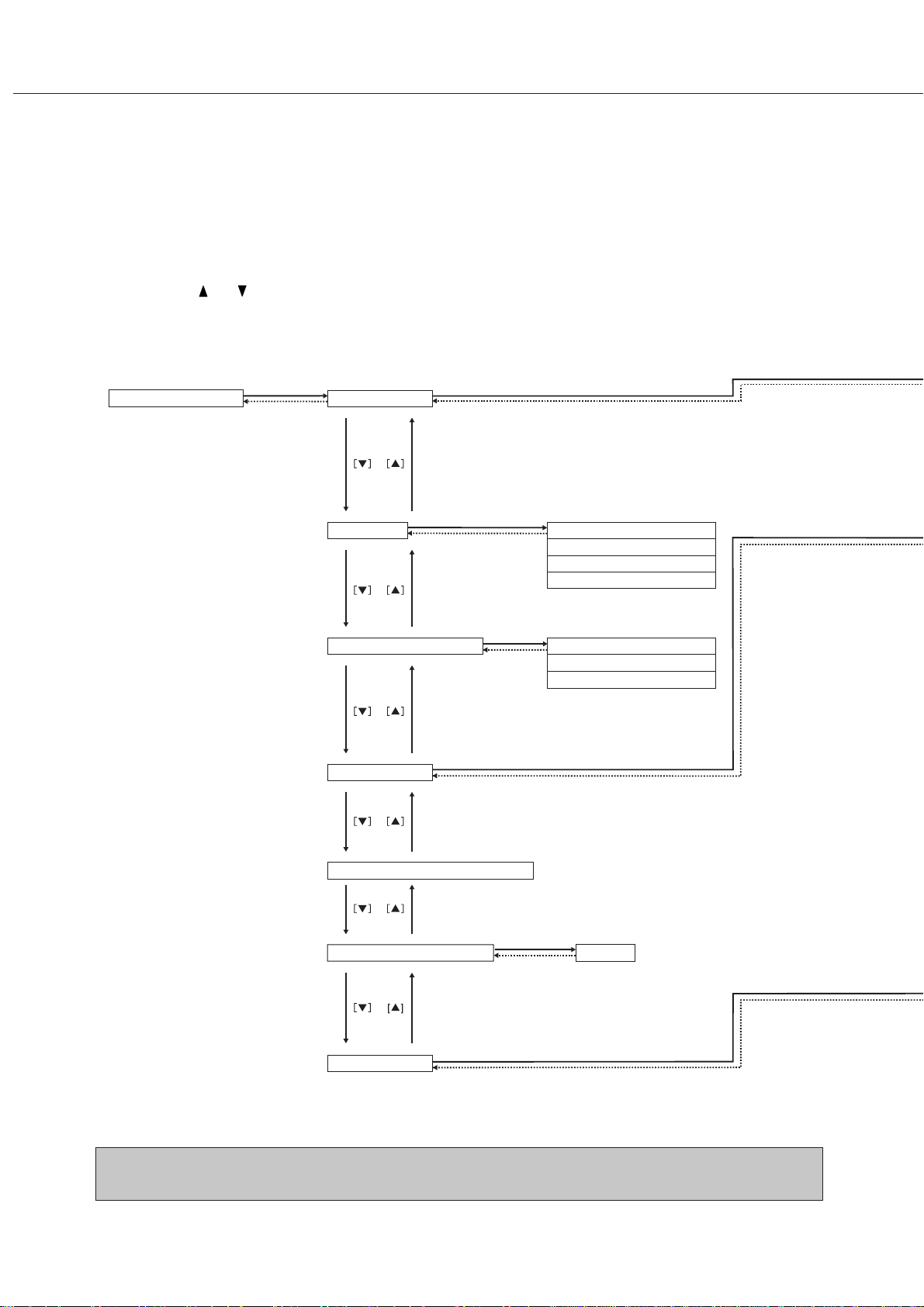

Menu group list and supplementary explanation of key operation (when

using the operation panel on the main unit)

The menu groups are classified into the following five groups as shown below. These menu groups are selected by

pressing the [MENU] key. If the [OK] key is pressed when the desired menu screen is displayed, a message indicating

required operation will appear.

READY.

[MENU] key

Job status screen

The message "WARMING UP" displayed when the power is turned on and

the list of the current job and the reserved jobs or the list of completed jobs

are displayed on the job status screen. Various messages are displayed on

the job status screen. Examples of messages are shown below.

(Display example)

WARMING UP.

READY.

FROM TRAY #

CHANGE THE TONER

CARTRIDGE.

PAPER JAM.

ADD PAPER.

[ADD PAPER] of status display

When the status display shows [ADD PAPER], the specified size

paper is not loaded. In this case, printing is suspended until paper

is loaded and another reserved job data will be printed if possible.

(If paper runs out during printing, another job data will not be

printed.) If you wish to change the paper size to resume printing,

see "Method of setting paper size and type" on page xxxx.

The printer is warming up to

allow printing.

The printer is ready to print.

The printer is currently executing

printing.

Toner runs out. Replace the

toner cartridge. (See page

xxxx.)

A misfeed has occurred. (See

page xxxx.)

Paper runs out. Load paper.

(See page xxxx.)

PRINT HOLD

[MENU] key

CONDITION SETTINGS

[MENU] key

CUSTOM SETTINGS

[MENU] key

KEY OPERATOR

PROGRAMS

[MENU] key

1-12

Print hold

If the job retention function is used from your computer, print data will

be stored in the printer as a hold job.

The job retention function can be used only if the printer is equipped

with a hard disk drive as a peripheral unit. (See page xxxx.)

Configuration settings

The printer configuration settings are used for basic printer settings.

(See page xxxx.)

Custom settings

Custom settings are used to make settings based on the conditions of

use of customers. (See page xxxx.)

Key operator programs

These are settings used by key operators (administrators of this

product). For the setting, see the "Key Operator's Guide". (See page

xxxx.)

Page 23

Canceling the current print job and deleting the print data on the printer

●

To cancel the current print job and delete the print data:

If you press the [BACK/C] key during printing, printing will be canceled and a confirmation message for deletion of

data will appear. To delete the data, press the [OK] key.

To cancel deletion, press the [BACK/C] key. Printing will resume.

●

To delete print data of a reserved job (that waits for printing):

Print data transmitted from computers will be stored in this printer (up to 99 jobs) and will be output sequentially. To

delete print data of a reserved job before starting printing, press the [ ] or [ ] key to display the desired data in the

message display. If you press the [BACK/C] key at this time, a confirmation message for deletion will appear. To

delete the data, press the [OK] key.

To cancel deletion, press the [BACK/C] key. Printing will resume.

1

1-13

Page 24

PART NAMES AND FUNCTIONS

When the printer is equipped with a scanner module as a peripheral unit, use the operation panel with a touch panel on

the scanner module.

[Touch panel]

Messages and keys are displayed here. Operation

can be performed by touching keys displayed here.

The display is switched depending on each function

in the print, copy, network scan, and fax modes. For

details, see page xxxx.

[Mode select] keys and indicators

Use to switch the display mode of the touch panel.

[PRINT] key/READY indicator/DATA indicator

Press to switch the display to the print mode. (See

next page.)

●

READY indicator

Printing can be performed when this indicator is

lit.

●

DATA indicator

Lights up or blinks when print data is being

received. Also lights up when printing is being

performed.

[IMAGE SEND] key/LINE indicator/DATA indicator

Press to switch the display to the network scan/fax

mode. (See page xxxx of the facsimile operation

manual.)

[COPY] key

Press to switch the display to the copy mode. (See

page xxxx.)

[JOB STATUS] key

Press to display the current job status. (See page

xxxx.)

[CUSTOM SETTINGS] key

Use to adjust the contrast of the touch panel or to

set key operator programs.

[Numeric] keys

Use to enter a number in various settings.

[ ] key ([ACC.#-C] key) (See page xxxx.)

Use when using the copier feature and the facsimile

feature.

[#/P] key (See page xxxx.)

Use when using the copier feature and the facsimile

feature.

[C] key

Use when using the copier feature and the facsimile

feature.

[Start] key (See page xxxx.)

Use when using the copier feature and the facsimile

feature.

[CA] key

Use when using the copier feature and the facsimile

feature.

1-14

Page 25

PART NAMES AND FUNCTIONS

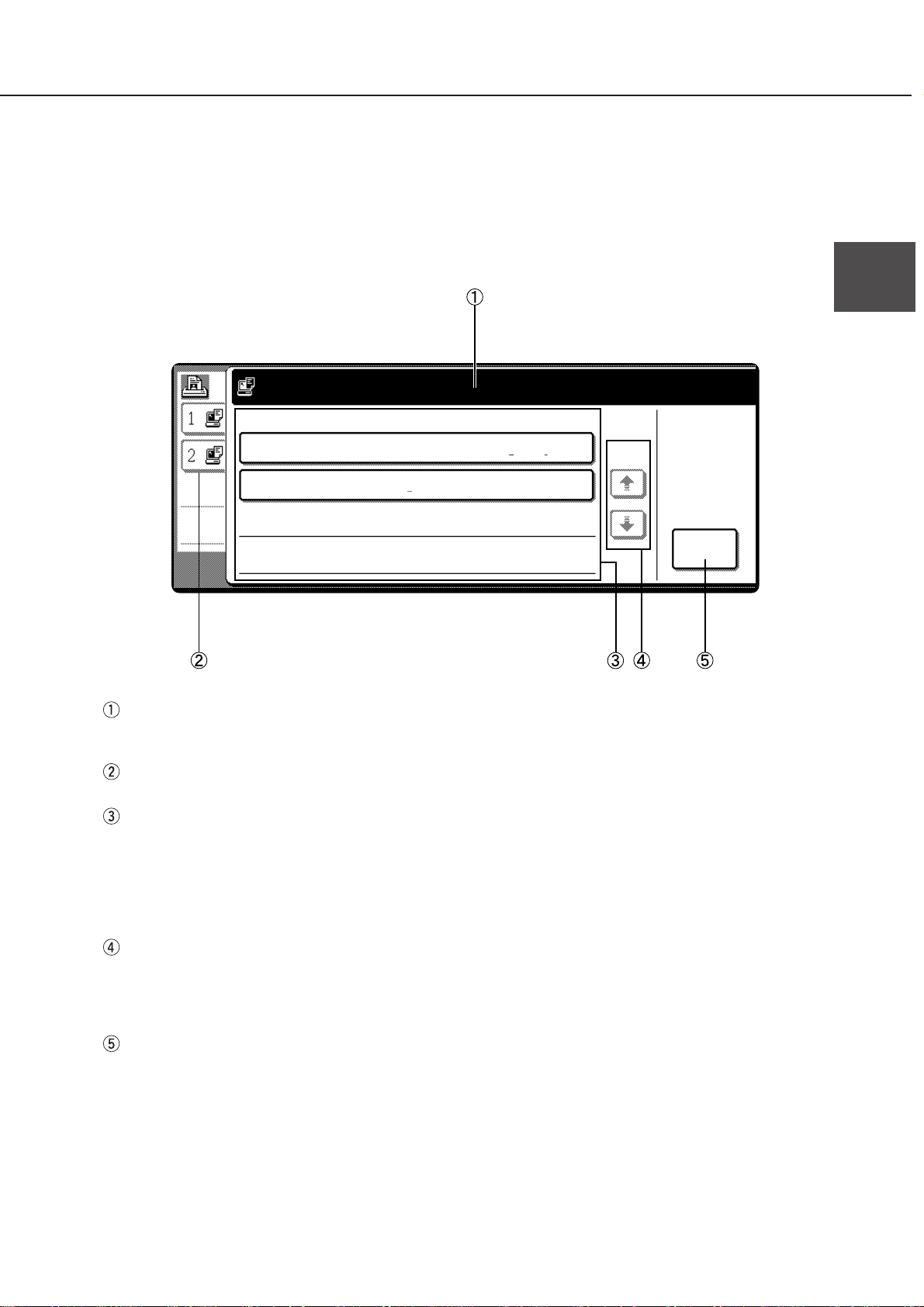

Touch panel

Print mode screen

This screen is displayed when the print mode is selected.

(The display varies with the mode. For the display in other modes, see respective operation manuals.)

SELECT JOB.

PRINT HOLD JOB LIST

1

Sharp 005

Sharp 006

Message display

Messages are displayed here.

Job status screen (See next page.)

Print hold job list

If the job retention function (see page xxxx) is used,

the list of stored print data is displayed here (up to

100 jobs). The job retention function can be used

only if the printer is equipped with a hard disk drive

as a peripheral unit.

Microsoft Word - Test001

EXCEL1

1/1

CONDITION

SETTINGS

[Display switching] keys

Use to switch the page of the print hold job list. If the

list is not contained in a page, succeeding pages

are prepared. Use these keys to switch the display.

[CUSTOM SETTINGS] key

Use to switch the display to the printer configuration

menu (see page xxxx).

1-15

Page 26

PART NAMES AND FUNCTIONS

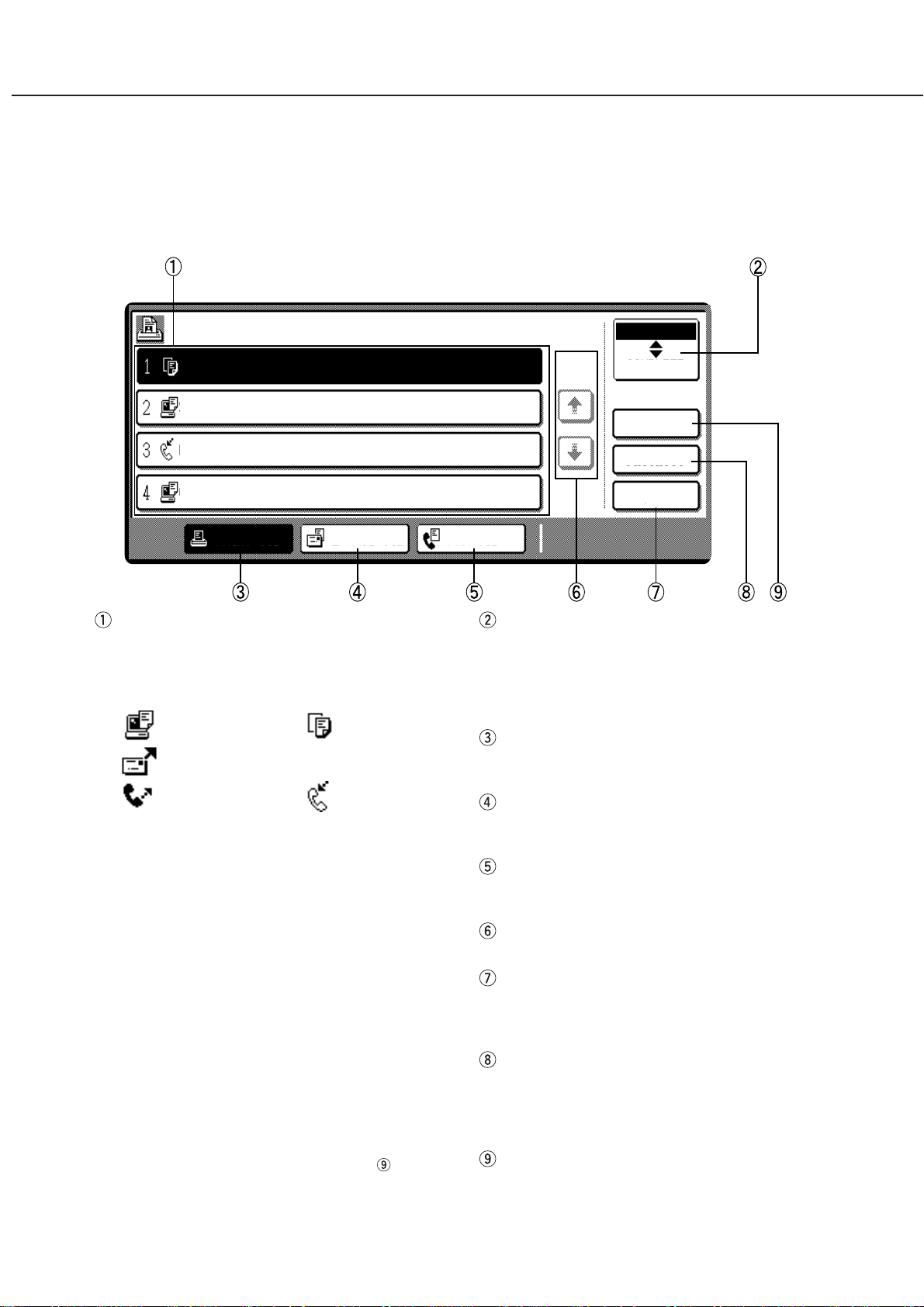

Job status screen (common to print, copy, network scan, and fax modes)

This screen is displayed when the [JOB STATUS] key on the operation panel is pressed.

A job list which indicates the current job and reserved jobs or a job list which indicates completed jobs is displayed.

You can check the contents of the jobs, give a reserved job the highest print priority in the print queue, and delete

a job that you wish to cancel. (The following screen indicates a job list which indicates the current job and reserved

jobs.)

JOB QUEUE

COPY

SHANE COFFEY

054234

CLIFF QUIROGA

SETS / PROGRESS

003 / 000

003 / 000

010 / 000

003 / 000

PRINT JOB E-MAIL JOB FAX JOB

Job list

A job list which indicates the current job and reserved

jobs or a job list which indicates completed jobs is

displayed. The icons at the top of each job indicate

the mode of each job.

Print mode Copy mode

Network scan mode

Fax mode Fax mode

(transmission job) (reception job)

When a job list which indicates the current job and

reserved jobs is displayed, the displayed jobs

themselves are operation keys. To cancel printing or

to give a job the highest print priority, touch the

relevant job key to select the job and execute the

desired operation using the keys described in 7, 8,

and 9.

STATUS

COPYING

WAITING

WAITING

WAITING

[Mode switching] key

Use to switch the job list between “JOB QUEUE”

and “COMPLETE”.

“JOB QUEUE”: Displays the list of the current job

“COMPLETE”: Displays the list of completed jobs.

[PRINT JOB] key

Use to display the print job list for all modes (print,

copy, network scan, and fax).

[E-MAIL JOB] key

Use to display the list of jobs that use the network

scanner feature.

[FAX JOB] key

Use to display the fax communication status and

the reserved transmission job status.

[Display switching] keys

Use to switch the page of the displayed job list.

JOB QUEUE

1/1

COMPLETE

DETAIL

PRIORITY

STOP/DELETE

and the reserved jobs.

*1: “PAPER EMPTY” in the job status display

When the job status display indicates “PAPER

EMPTY”, specified size paper is not loaded in any

tray. In this case, printing is suspended until paper

is loaded and another reserved job data will be printed

if possible. (If paper runs out during printing, another

job data will not be printed.) If you wish to change

the paper size because you cannot prepare the

specified size paper immediately, you can change

the size by touching the current job key to select it

and touch the [DETAIL] key described in

1-16

[STOP/DELETE] key

Use to cancel or delete the current job or delete the

selected reserved job. Reserved fax jobs, however,

cannot be deleted.

[PRIORITY] key

If you select a job among the reserved jobs in the

“JOB QUEUE” job list to which you wish to give the

highest priority and touch this key, the job will move

to the highest priority reserved job.

.

[DETAIL] ke

Use to display the detailed information of the selected

job. The paper size for printing can be changed from

the specified size.

Page 27

Using the touch panel

JOB QUEUE

SETS / PR

SHANE COFFEY

054234

CLIFF QUIROGA

COPY

003 / 00

010 / 00

003 / 00

003 / 00

1/13

COMPLETE

MULTI SHOT

DUAL PAGE

COPY

MULTI SHOT

DUAL PAGE

COPY

MULTI SHOT

DUAL PAGE

COPY

PART NAMES AND FUNCTIONS

■ How to use the touch panel

[Example 1]

You can easily set or

cancel a function by

touching a key on the

display with a finger. The

touch panel operation can

Beep

tone

[Example 2]

The beep tone of key touch can be disabled by a

key operator program. (See page xxxx of the Key

Operator’s guide.)

The touch panel (display) illustrated in this operation

panel is a conceptual illustration.

be confirmed with a beep

tone and highlighted

display.

If any key is disabled on

each screen, the key is

displayed gray. If you

press the key, two short

beeps will be sounded.

■ Selection of function

[Example 1]

1

If any key is highlighted in the initial setting of each

setting screen, the function will be registered when

you touch the [OK] key without additional operation.

[Example 2]

When using the copier

feature or the facsimile

feature, the functions

shown below which can

be set by only touching

the relevant key in the

special feature screen

can be canceled by

touching the key again

(canceling highlighted

display).

Copier feature Facsimile feature

Dual page copy

B/W reverse

Rotation copying in

two-sided copying

Centering

[Example 3]

Polling

Own number print

Page cutoff

When using the copier

feature or the facsimile

feature, if a special

function is set, the

corresponding function

icon will appear. If this

icon is touched, the

setting screen of the

function (or a menu

screen) will appear,

allowing the settings to be

checked or adjusted and

the function to be

canceled easily.

1-17

Page 28

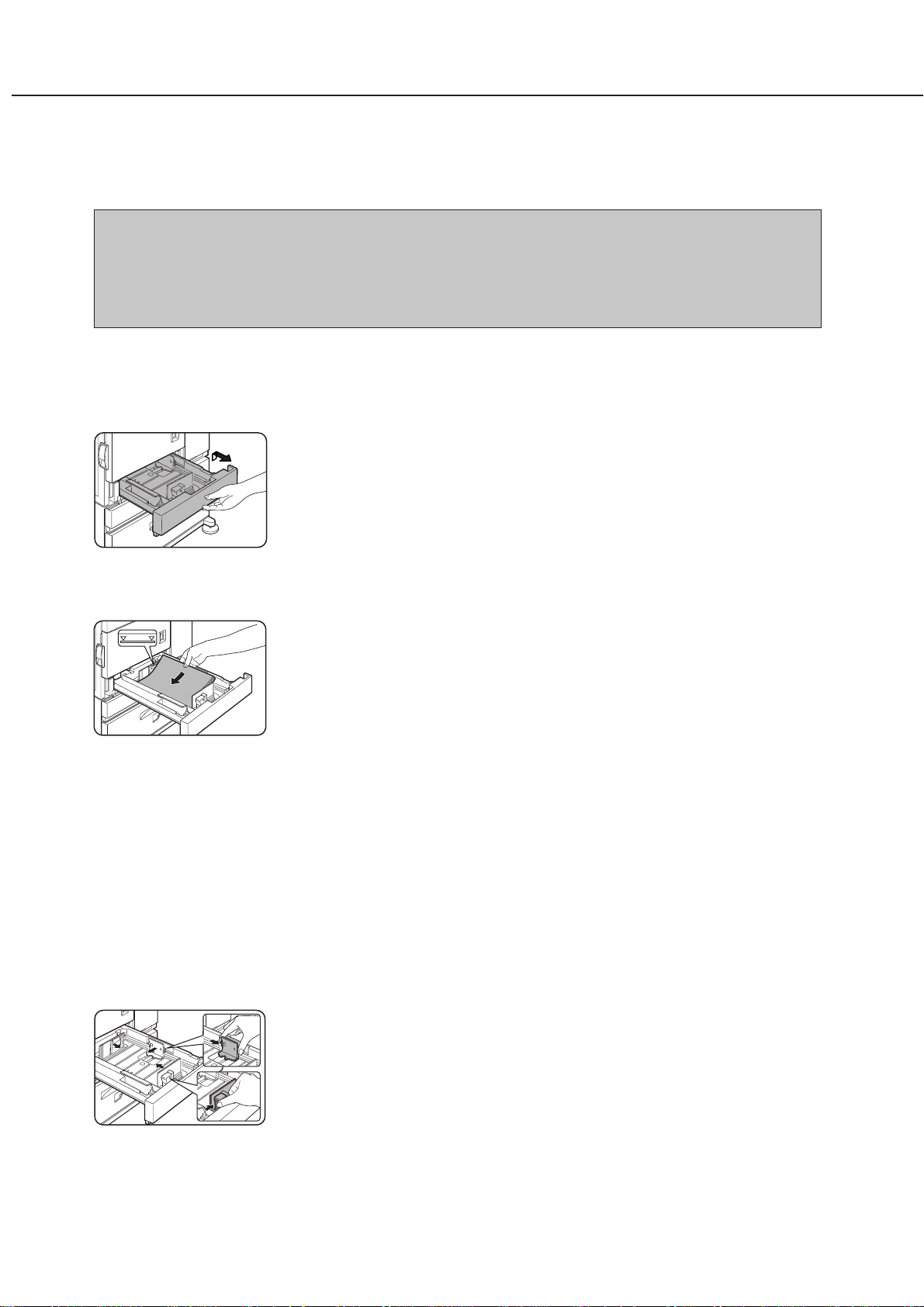

LOADING PAPER

When paper runs out during printing, a message indicating that paper runs out will appear.

Follow the procedure below to load paper.

NOTES

●

Do not use curled or folded paper. Doing so may cause a misfeed.

●

Use SHARP standard paper for paper tray 1. (See page xxxx.)

●

When you change the paper type in paper tray 1, set the paper type referring to “Method of setting paper size

and type” (page xxxx).

●

Do not place a heavy object or press down hard on a tray when the tray is pulled out.

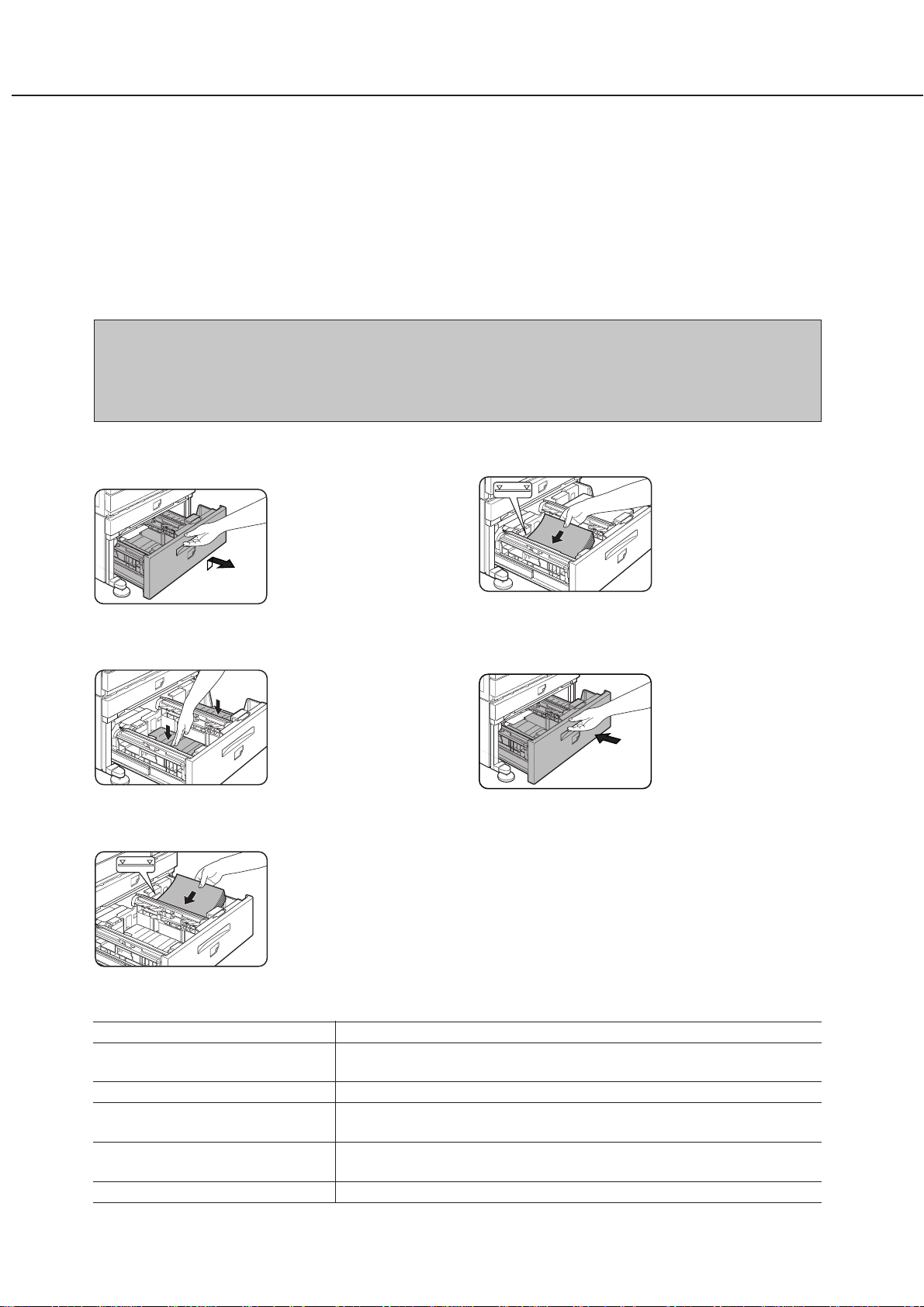

Loading paper in paper tray 1

Pull out paper tray 1.

1

Gently pull the tray out

until it stops.

Load paper into the tray.

Gently push paper tray 1.

3

Push the tray firmly all the way into the machine.

Set the paper type.

4

If you change the paper type, be sure to set the

paper type referring to “Method of setting paper

size and type” (page xxxx).

2

Do not load paper above

the maximum height line

(approximately 500

sheets of 20 lbs.

paper).

(80 g/m2)

Changing the paper size in paper tray 1

For paper tray 1, 8-1/2" x 11", A4 or B5 size paper can be set. Use the following procedure to change the size as

needed.

Loading of paper in paper tray 1 is now

complete.

5

Pull out paper tray 1.

1

If paper remains in the tray, remove it.

Adjust the guide plates A and B in the

tray to the length and width of the paper.

2

The guide plates A and B

are slidable. Adjust them

to the paper size to be

loaded while squeezing

their lock levers.

Load paper into the tray.

3

1-18

Gently push paper tray 1.

4

Push the tray firmly all the way into the machine.

Set the paper size.

5

Be sure to set the paper size and paper type

referring to “Method of setting paper size and type”

(page xxxx).

If this operation is not performed after the paper

size has been changed, printing will be made to

paper of a size other than the specified size and a

paper misfeed may occur.

Changing of paper size in paper tray 1 is

now complete.

6

Page 29

LOADING PAPER

Paper available in paper trays

Paper that can be used varies with the paper trays. Use SHARP standard paper in the following paper trays.

●

Paper tray 1

●

Stand/3 x 500 sheet paper drawer

●

Stand/MPD & 2000 sheet paper drawer

■ Paper that can be used

●

SHARP standard paper (See page xx.)

Use SHARP standard paper ranging from 5-1/2" x 8-1/2" (A5) to 11" x 17" (A3).

Paper available in the bypass tray/multi purpose drawer

Since the paper feeding method in the bypass tray and the multi purpose drawer varies with the paper type, be sure to

feed paper using the method adequate to the paper type. If the paper feeding method is not proper, a paper misfeed or

oblique feeding may occur.

■ Paper that can be used

●

SHARP standard paper

●

Ordinary paper other than SHARP standard paper

Paper size

Paper weight:

Continuous feeding

Single sheet feeding

2 2

.....

/m

Weight of a sheet of paper of 1 m

g

5-1/2" x 8-1/2" or

A5 (105 x 148 mm)

15 lbs.(52 g/m )

15 lbs.(52 g/m )

2

2

11" x 17" or A3

(297 x 420 mm)

28 lbs.(105 g/m )

*1

28 lbs.(105 g/m )

2

2

54 lbs.(205 g/m )

28 lbs.(105 g/m )

2

2

1

NOTES

●

Do not use paper that is not included in the range described above. Improper fusing (fusing strength of toner to

paper is weak and toner comes off if rubbed) and misfeeds may occur.

■ Envelope

●

Standard envelope sizes are only the following four: Monarch (MON), Commercial-10 (C10), DL, and C5.

■ Postcard

●

Double postcards can be used unless they have a fold. (Folded postcards cannot be used.)

●

Do not use unofficial postcards or picture postcards. They may cause misfeeds or smudges on printouts.

■ Special paper

●

For transparency film, letterhead paper, recycled paper, pre-printed paper, pre-punched paper, colored paper,

heavy paper, labels, and postcards, use SHARP recommended paper. Using paper that is not recommended by

SHARP may cause misfeeds and smudges on printouts.

●

Notebook paper

Do not use paper that has been cut manually. Paper misfeeds may occur.

NOTE

There are various types of special paper on the market and some of them cannot be used in this product. When

using such paper, contact your SHARP dealer.

1-19

Page 30

LOADING PAPER

Method of setting paper size and type

When the paper size or type is changed in a paper tray, set them referring to the following procedure.

When using the operation panel on the main unit:

For setting paper size and type from the operation panel with touch panel, see the next page.

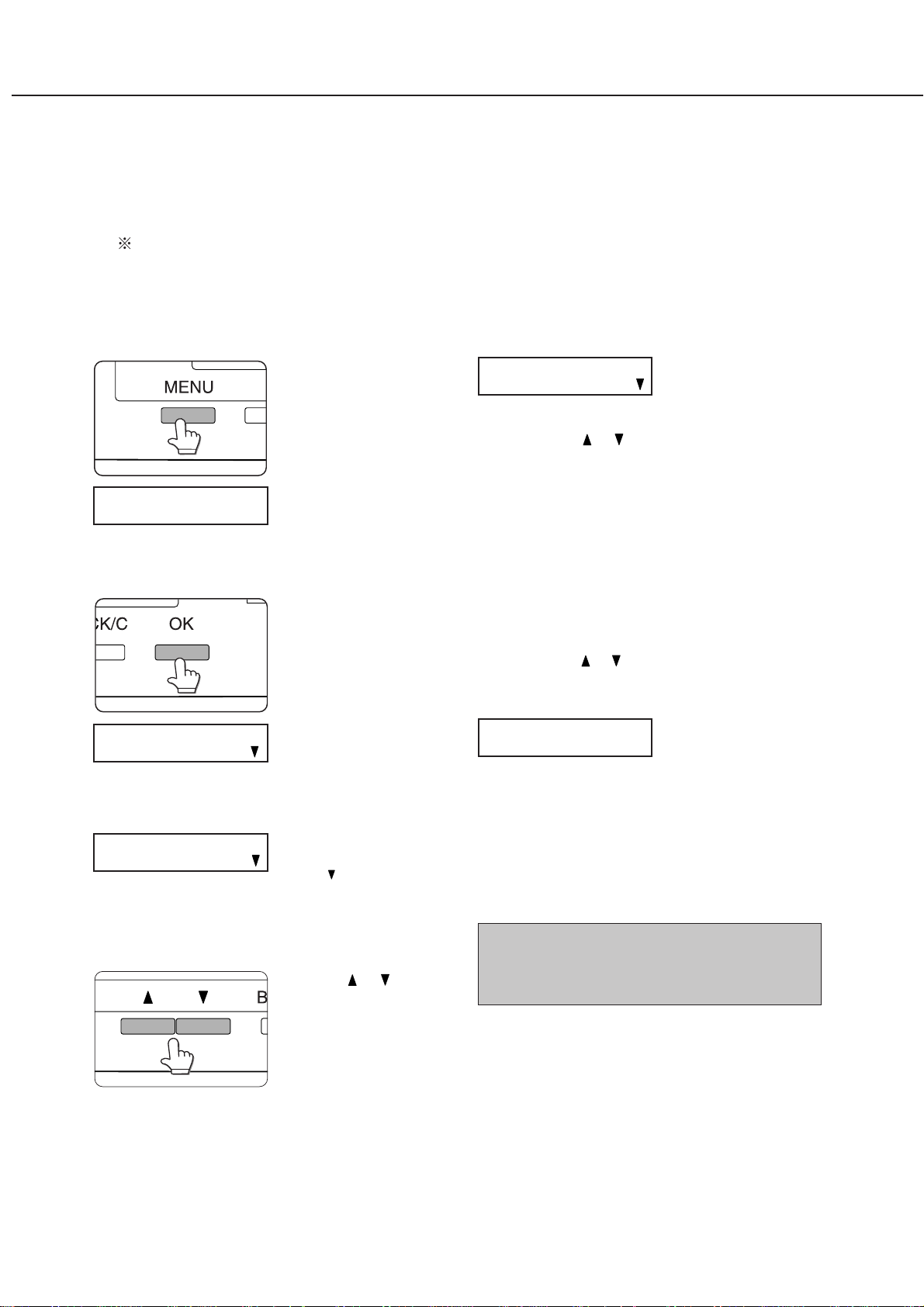

Press the [MENU] key repeatedly until

“CUSTOM SETTINGS” will appear in the

1

message display.

CUSTOM SETTINGS

Press the [OK] key.

2

When the [OK] key is

pressed,“TRAY SETTING”

will appear in the message

display.

TRAY SETTING

Ensure that the desired paper type for

printing is selected.

6

●

If TRAY 1 is selected,

LETTER

PLAIN

If the desired paper type for printing is not selected,

press the

When you wish to print onto special paper,

however, the paper tray must be TRAY 2 or

BYPASS.

Press the [OK] key.

or key on the operation panel.

the message shown to

the left will appear in the

initial condition.

7

Ensure that the desired paper size for

printing is selected.

8

If the desired paper size for printing is not selected,

press the or key on the operation panel after

checking the paper type.

●

If TRAY 1 has been

LETTER

OK?

selected, the message

shown to the left will

appear.

Press the [OK] key.

3

TRAY SETTING

TRAY1

Select the desired paper tray.

4

Press the [OK] key.

5

1-20

When the [OK] key is

pressed,“TRAY SETTING

TRAY1 ” will appear in

the message display.

Press the or key on

the operation panel

repeatedly until the

desired paper tray

appears.

Press the [OK] key to terminate the

setting.

9

NOTE

Special paper such as transparency film, labels, and

postcards can be set for tray 2 and the bypass tray.

Envelopes can be set only for tray 2.

Page 31

When using the operation panel with touch panel:

TOTAL COUNT

TRAY SETTINGS

TRAY 1

TRAY 2

TRAY 3

PLAIN / AUTO-INCH

RECYCLED / AUTO-INCH

TYPE / SIZE

PLAIN / 8 X11

1

/

2

TOTAL COUNT

TRAY SETTINGS

LOADING PAPER

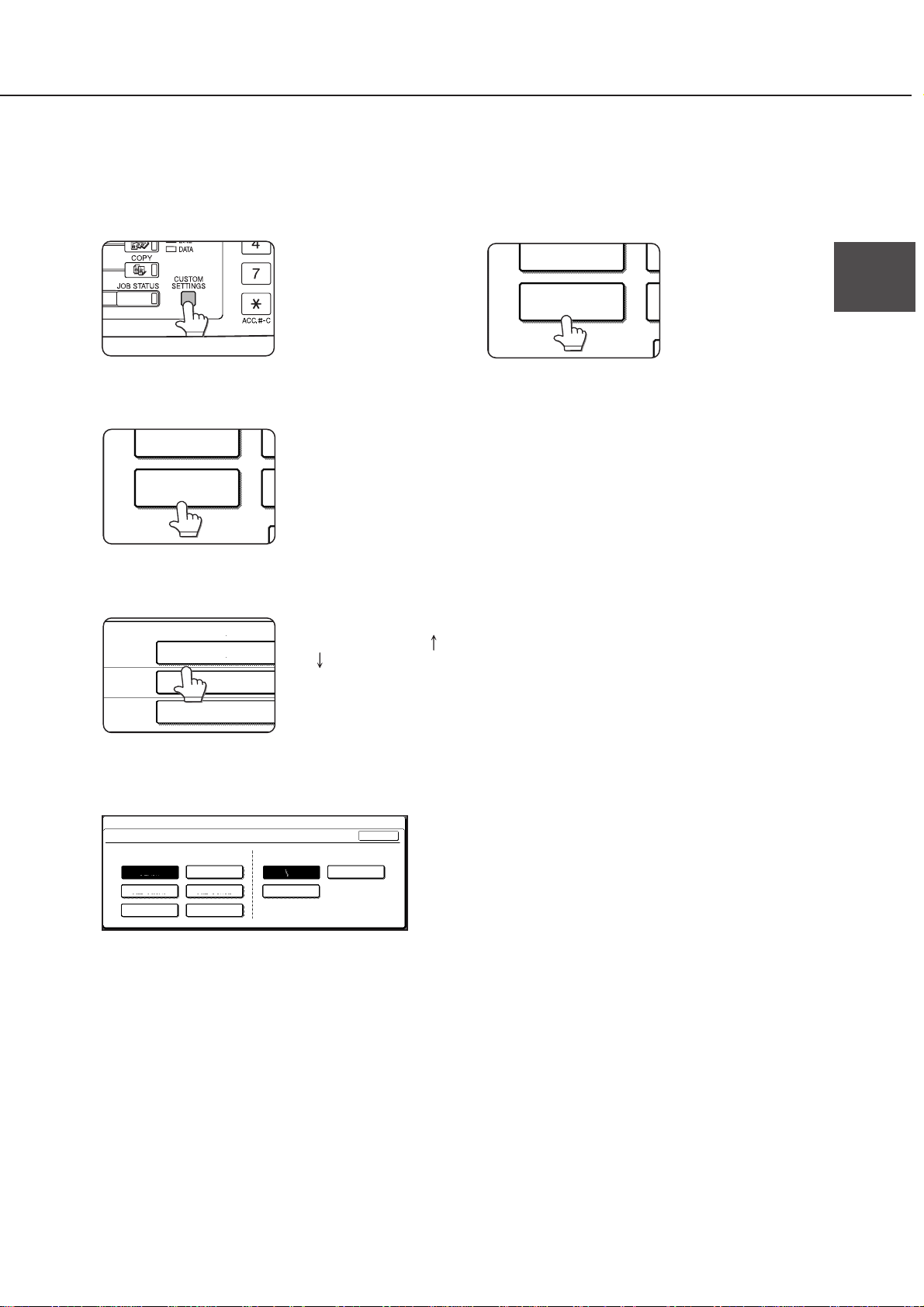

Press the [CUSTOM SETTINGS] key.

1

The custom setting menu

screen will appear.

Press the [TRAY SETTINGS] key.

2

The paper tray selection

screen will appear.

Select the paper tray for which setting is

to be made.

3

If the desired tray is not

displayed, touch the [ ]

or [ ] key to switch the

screen.

Touch the [OK] key to complete the setting.

5

1

4

●

If TRAY 1 has been selected in step 3:

CUSTOM SETTINGS

TRAY 1 TYPE/SIZE SETTING

Select the paper type and the paper size.

OK

TYPE SIZE

PLAIN

PRE-PRINTED

RECYCLED COLOR

The paper type and paper size with highlighted

display are selected. If the desired paper type and

paper size are not selected, select the desired type

and size by touching the relevant keys.

Special papers such as transparency film and

labels can be set for tray 2 and the bypass tray.

Envelopes can be set only for tray 2.

LETTER HEAD

PRE-PUNCHED

8 X11

B5

A4

1-21

Page 32

LOADING PAPER

Loading paper in the multi purpose drawer

The method of loading paper for the multi purpose drawer is the same for paper tray 1 in the main unit. Load paper

referring to steps 1 to 5 on page xxxx.

The following items, however, are different from paper tray 1.

●

Ordinary paper of standard sizes from 11" x 17" to 5-1/2" x 8-1/2"R (A3 to A5R) can be set.

●

Also certain types of special paper can be set.

For special papers that can be set, see “Paper available in the bypass tray/multi purpose drawer” on page xxxx. When

setting envelopes or postcards in the multi purpose drawer, read thoroughly the description of “Setting envelopes or

postcards” below.

■■

■ How to change the paper size

■■

If the paper size or paper type is changed when paper is set in the tray, the tray settings in the custom settings must

be changed. Be sure to change the setting referring to “Method of setting paper size and type” on page xxxx.

■■

■ Setting envelopes or postcards

■■

When setting envelopes or postcards in the multi purpose drawer, set them in the orientation shown below.

Notes common to setting of envelopes and postcards

●

Do not print onto two sides. A paper misfeed or improper printing may occur.

●

Be sure to write addresses after printing. Do not use envelopes or postcards on which printing has been performed

with a thermal transfer printer or an ink jet printer. Paper on which printing has been performed with a thermal

transfer printer with a ribbon cassette, particularly, may cause printed characters to come off or may cause

smudges on printouts.

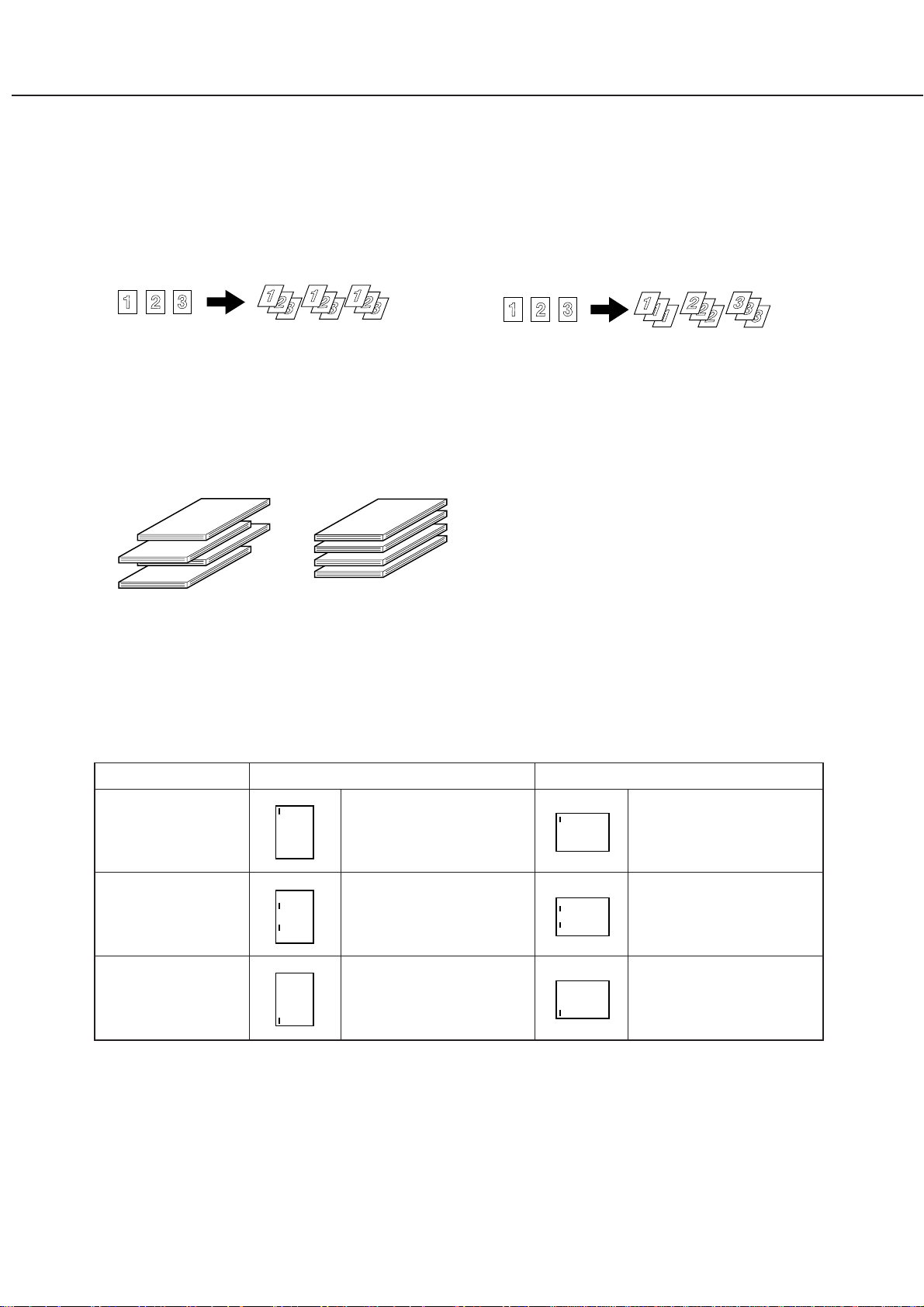

Example of setting postcards

Be sure to set the postcards face down and the upper

part located in the left.

Example of setting envelopes

For envelopes, only the address side can be printed on.

Be sure to set envelopes with the address side down

and the upper part located in the left.

Specifications

Note on setting postcards

●

Smooth out curled postcards before printing. Crumpling,

misfeeds or improper printing may occur.

Notes on setting of envelopes

●

For envelope sizes that can be used, see “Paper

available in the bypass tray/multi purpose drawer” on

page xxxx.

●

Do not use envelopes that have metal clasps, plastic

snappers, string closures, windows, linings, selfadhesive patches or synthetic materials. A paper

misfeed, improper fixing or failure may occur.

Name Multi purpose drawer

Paper size Max. 11" x 17" (A3), min. 5-1/2" x 8-1/2"R (A5R)

2

Paper capacity 500 sheets (20 lbs. (80 g/m

)) of paper, 100 envelopes, 100 postcards,

100 sheets of transparency film

Dimensions 23-1/32" (W) x 20-7/8" (D) x 4-1/2" (H) (585 mm (W) x 530 mm (D) x 114 mm (H))

Weight Approximately xxxx kg

Specifications are subject to change for improvement without notice.

1-22

Page 33

LOADING PAPER

Loading paper in the stand/3 x 500 sheet paper drawer

Upper paper tray:

The upper paper tray is equivalent to the multi purpose drawer. The method of loading paper and the paper that can be

used are the same as for the multi purpose drawer. Read the description of the multi purpose drawer (see page xxxx).

Middle and lower paper trays:

Up to 500 sheets of 11" x 17", 8-1/2" x 14", 8-1/2" x 11", 8-1/2" x 11"R, 7-1/4" x 10-1/2", A3, B4, A4, A4R, B5, and B5R

paper (20 lbs. (80 g/m

the main unit. See the description (page xxxx).

NOTE

If the paper size or paper type is changed when paper is set in a tray of the stand/3 x 500 sheet paper drawer, the tray

settings in the custom settings must be changed. Be sure to change the setting referring to “Method of setting paper size

and type” on page xxxx.

2

)) can be loaded in these trays. The method of loading paper is the same as for paper tray 1 in

Specifications

Name Stand/3 x 500 sheet paper drawer

Paper size Upper tray: Max. 11" x 17" (A3), min. 5-1/2" x 8-1/2"R (A5R), Middle/

lower trays: Max. 11" x 17" (A3), min. 7-1/4" x 10-1/2"R (B5R)

Paper weight 15 lbs. - 28 lbs. (56 - 105 g/m2)

Paper capacity (ordinary paper) 500 sheets (20 lbs. (80 g/m2)) each

Dimensions 23-1/32" (W) x 20-7/8" (D) x 15-29/32" (H) (585 mm (W) x 530 mm (D) x

404 mm (H))

Weight Approximately xxxx kg

1

1-23

Page 34

LOADING PAPER

Loading paper in the stand/MPD & 2000 sheet paper drawer

Upper paper tray:

The upper paper tray is equivalent to the multi purpose drawer. The method of loading paper and the paper that can be

used are the same as for the multi purpose drawer. Read the description of the multi purpose drawer (see page xxxx).

Lower paper tray:

The lower paper tray is a large capacity tray that holds 2,000 sheets of 8-1/2" x 11" or A4 paper (20 lbs. (80 g/m

the following procedure to load paper in the large capacity tray.

NOTE

If the paper size or paper type is changed when paper is set in the upper paper tray of the stand/MPD & 2000 sheet paper

drawer, the tray settings in the custom settings must be changed. (If the paper type is changed in the large capacity tray,

the tray settings must also be changed.) Be sure to change the setting referring to “Method of setting paper size and type”

on page xxxx.

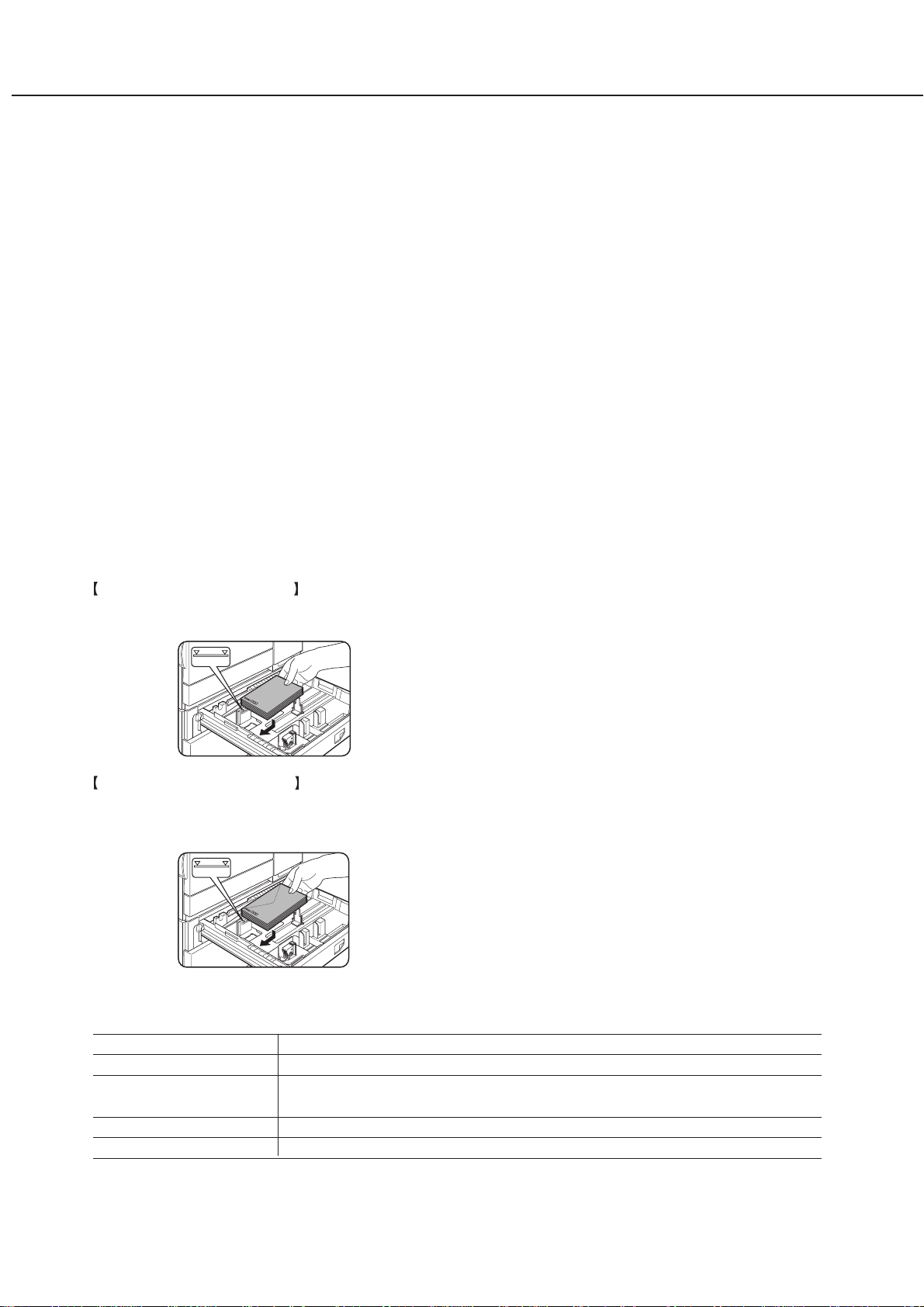

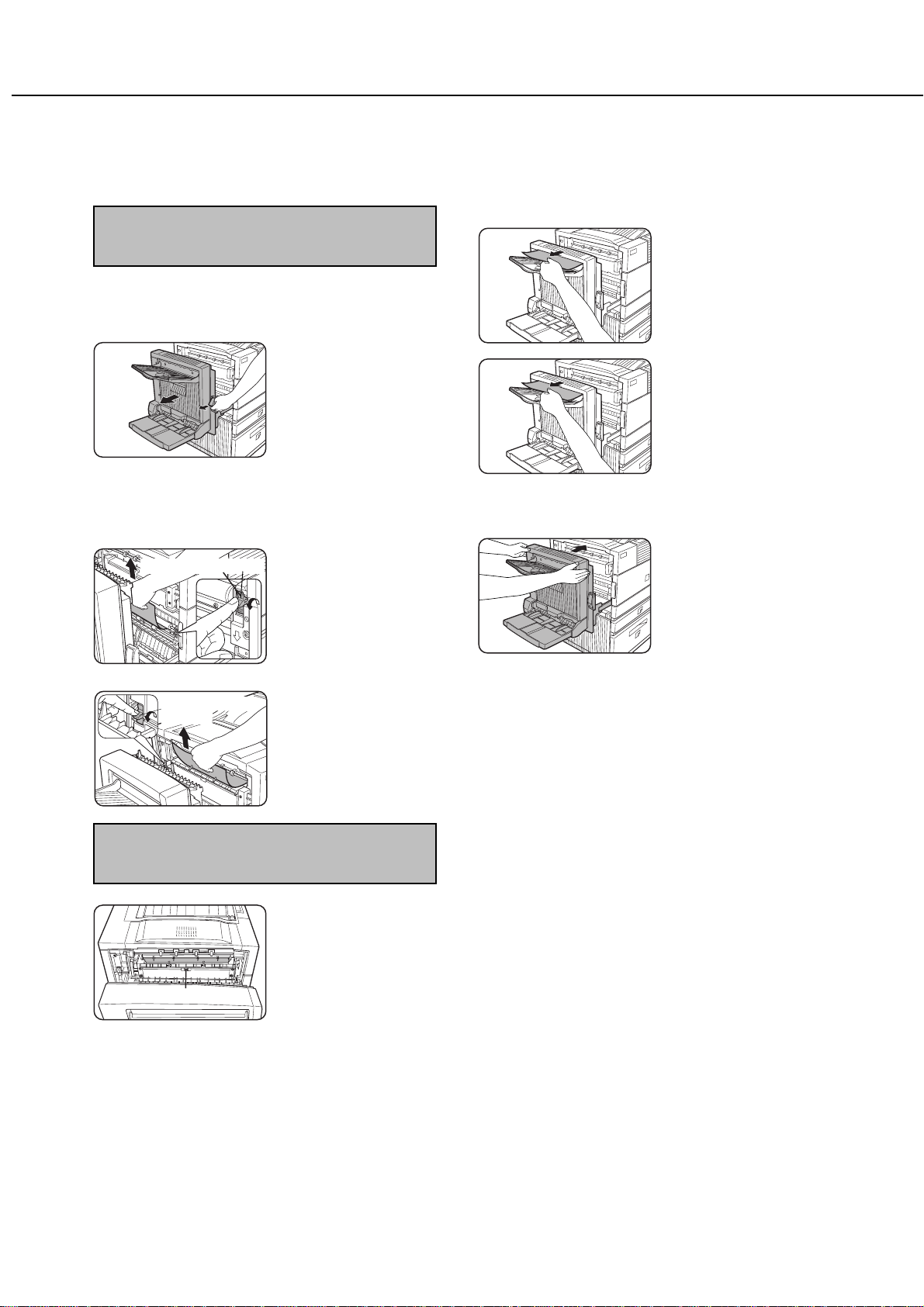

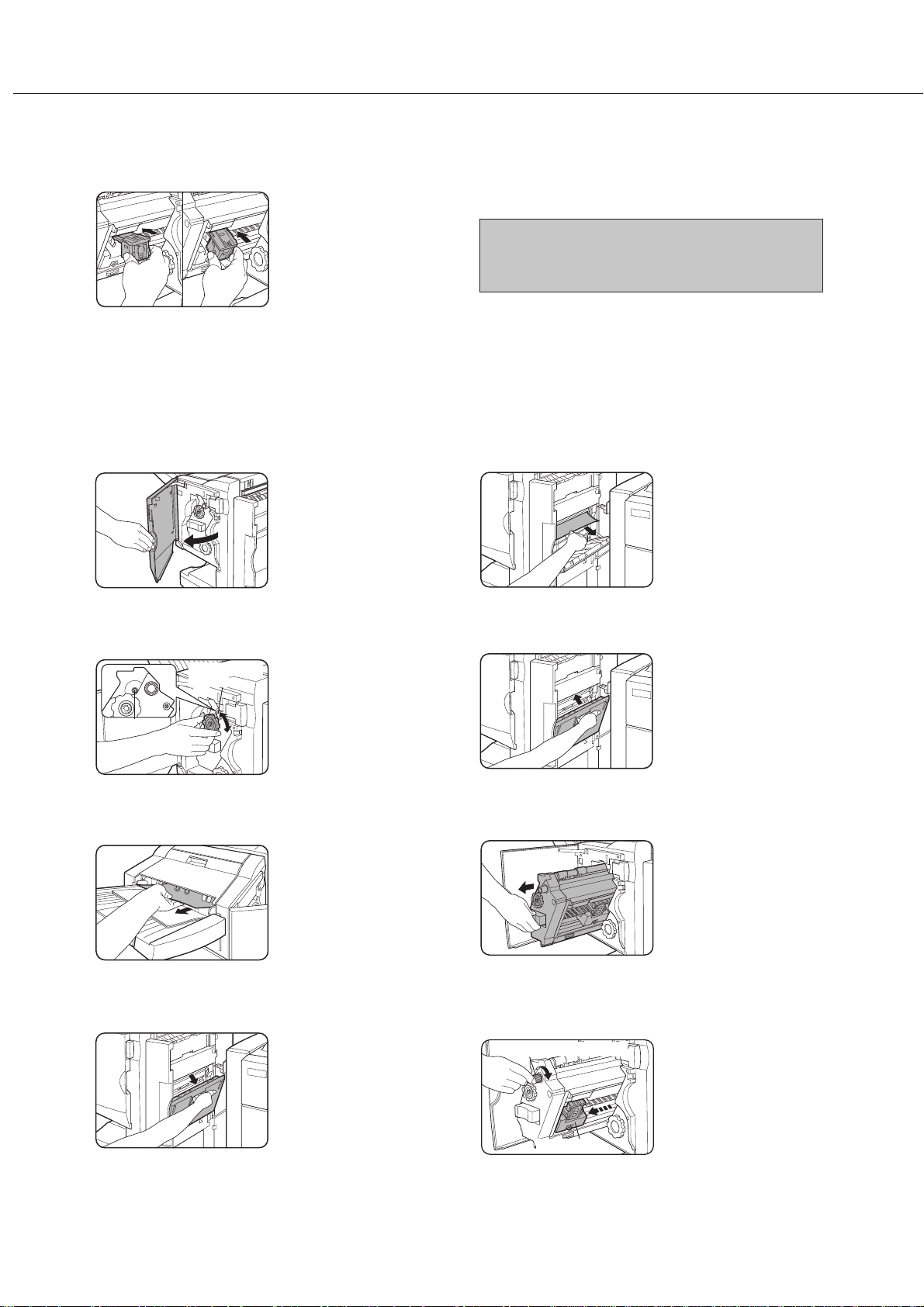

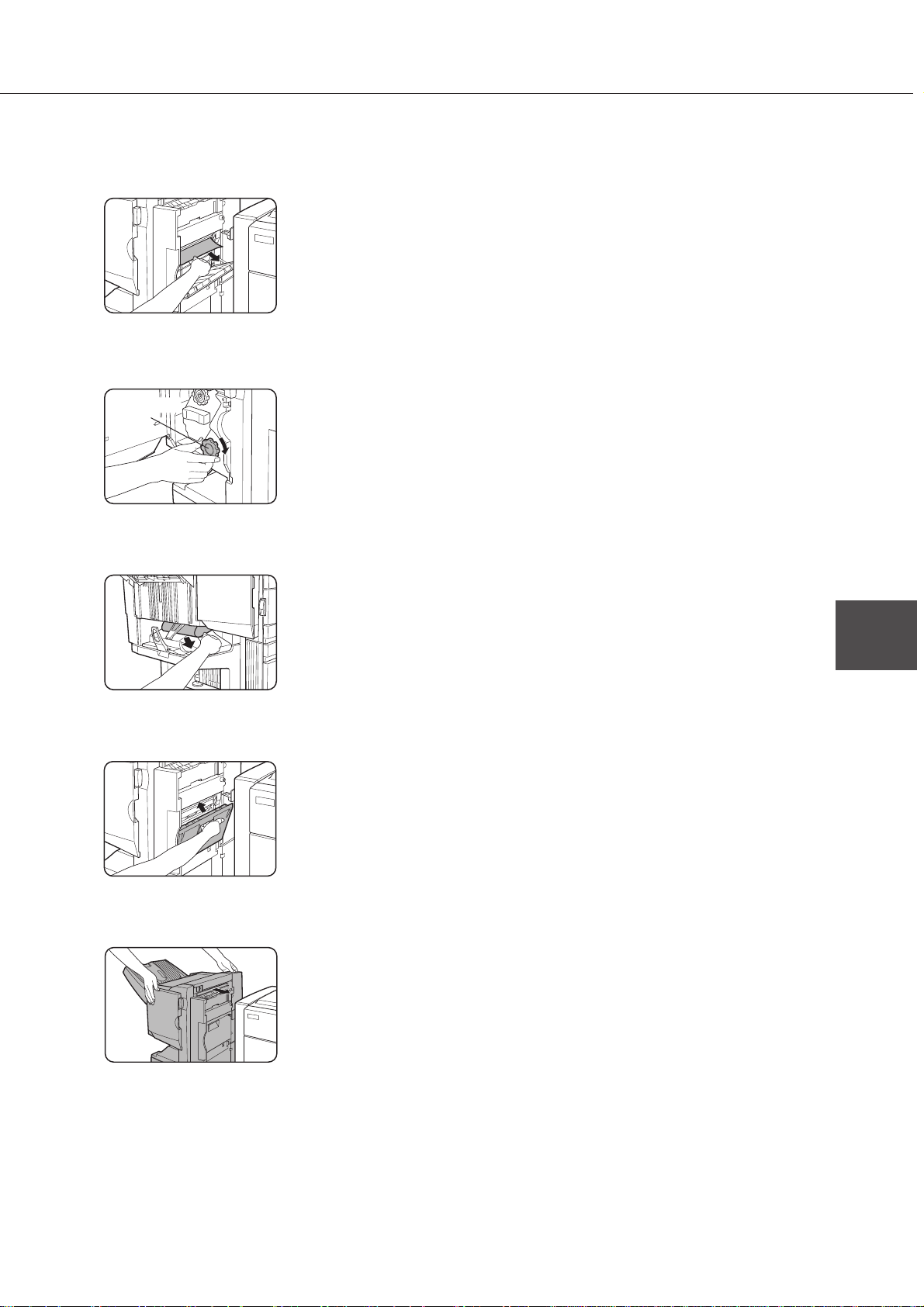

Pull out the large capacity tray.

1

Gently pull the tray out until

it stops.

Press down the right and left paper feed

tables until they stop.

2

Gently push the large capacity paper tray

into the printer.

4

●

Load paper onto the left

paper feed table.

Push the tray firmly all the

way into the printer.

2

)). Use

Load paper onto the right and left paper

feed tables.

3

●

Load paper onto the right

paper feed table.

Set the paper type.

5

If you change the paper type in the tray, be sure to set

the paper type referring to “Method of setting paper

size and type” (page xx).

Loading of paper in the stand/MPD & 2000

sheet paper drawer is now complete.

6

Specifications

Name Stand/MPD & 2000 sheet paper drawer

Paper sizes Upper tray: Max. 11" x 17" (A3), Min. 5-1/2" x 8-1/2" (A5R), Lower tray:

8-1/2" x 11" (A4)

Paper weight 15 lbs. - 28 lbs. (56 - 105 g/m2)

2

Paper capacity (ordinary paper) Upper tray: 500 sheets (20 lbs. (80 g/m

lbs. (80 g/m2))

Dimensions 23-1/32" (W) x 20-7/8" (D) x 15-29/32" (H) (585 mm (W) x 530 mm (D) x

404 mm (H))

Weight Approximately xxxx kg

)), Lower tray: 2,000 sheets (20

1-24

Page 35

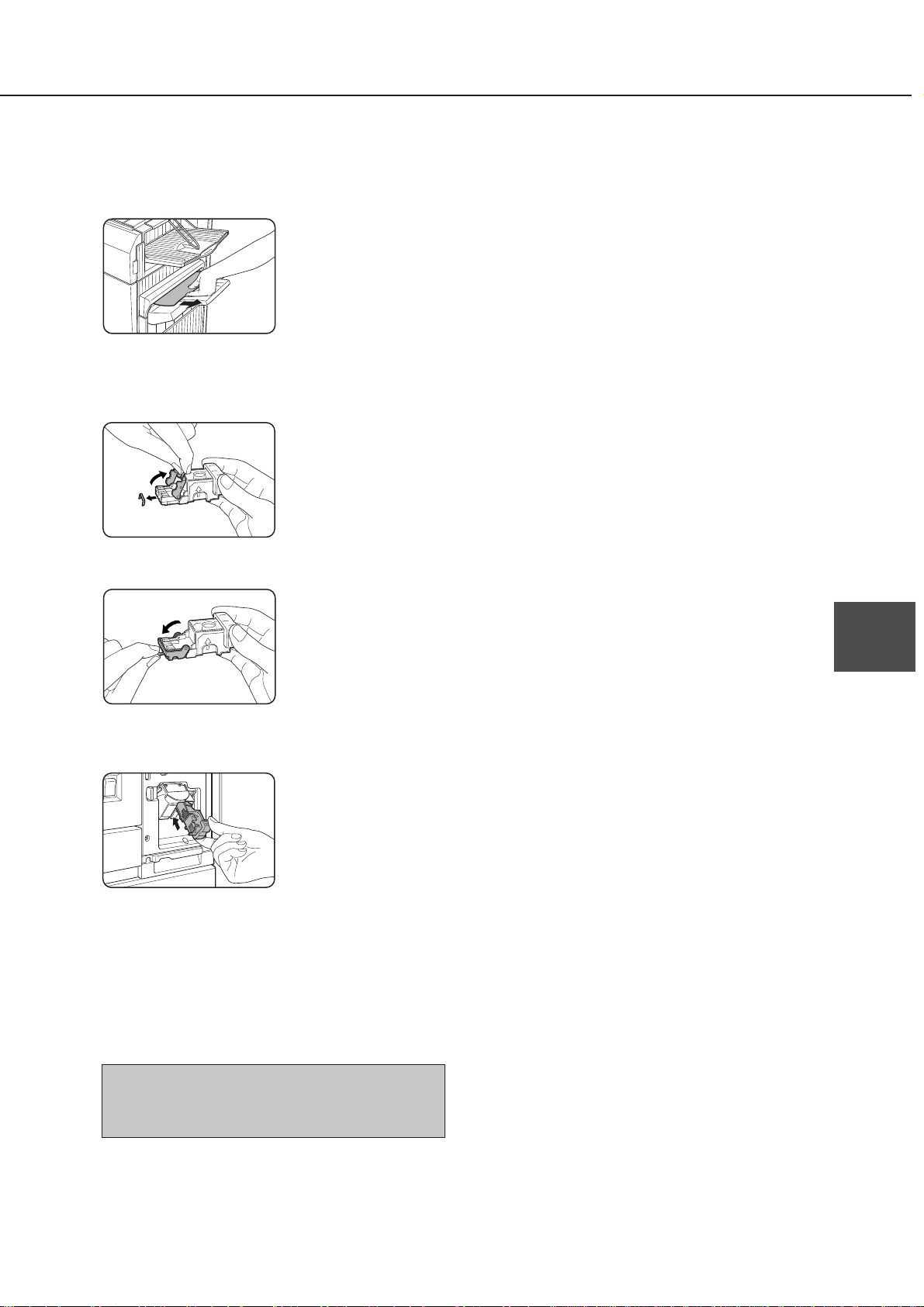

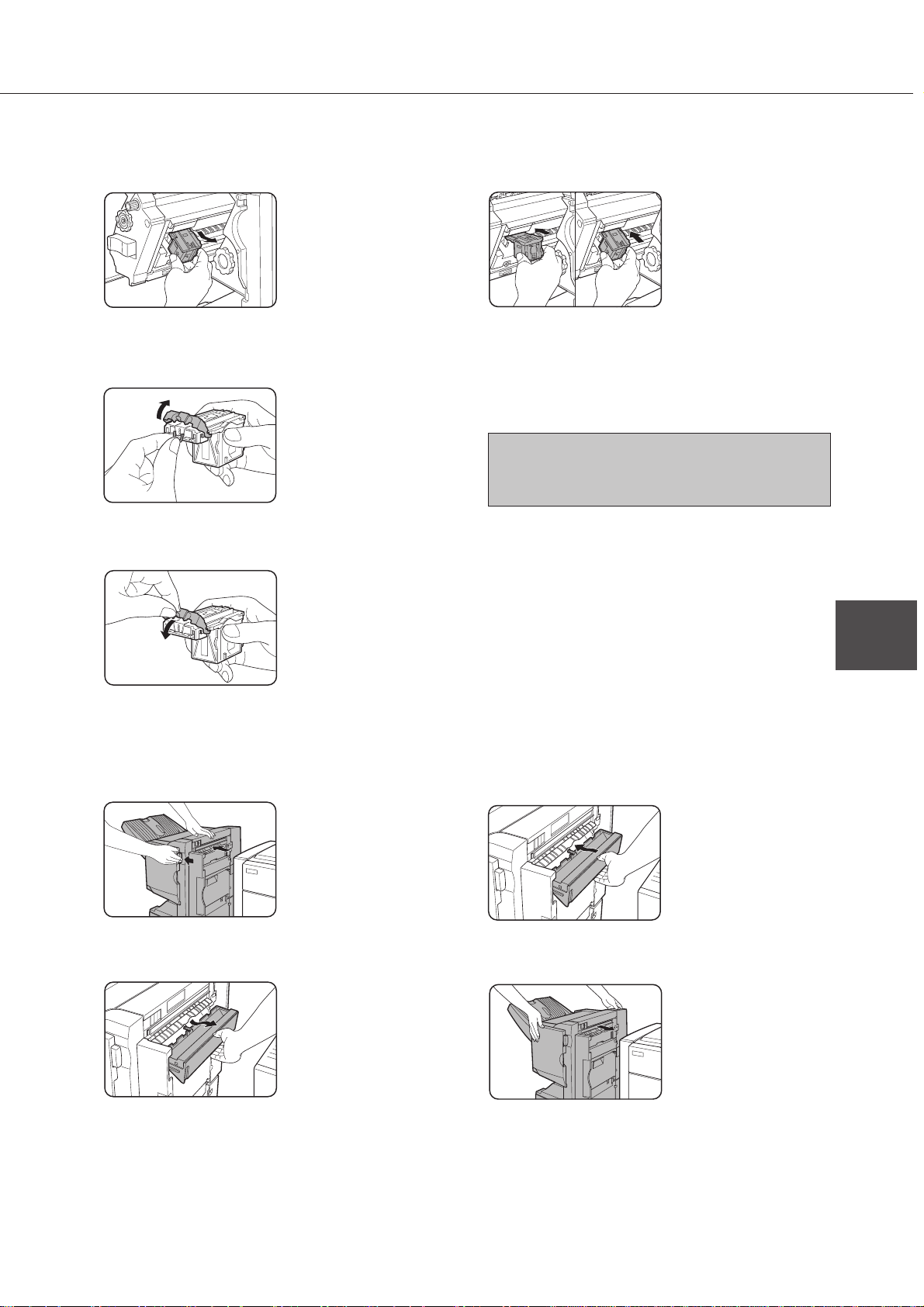

ADDING TONER

When toner runs out, a message indicating need to replace the toner cartridge will appear. Also depending on the

model, a message indicating need to replace the developer cartridge may appear.

For the procedure of replacement of these cartridges, see the separate manual "Supply Replacement Method."

STORAGE OF SUPPLIES

Standard supplies for this product that are to be replaced by the user are paper, toner cartridge, and staple cartridge for

the finisher.

For best copying results, be sure to use only Sharp Genuine Supplies which are designed,

engineered, and tested to maximize the life and performance of Sharp copiers. Look for the

Genuine Supplies label on the toner package.

GENUINE SUPPLIES

1

■ Proper storage

1 Store the supplies in a location that is:

●

clean and dry,

●

at a stable temperature,

●

not exposed to direct sunlight.

2 Store paper in the wrapper and lying flat.

●

Paper stored in packages standing up or out of

the wrapper may curl or become damp, resulting

in paper misfeeds.

1-25

Page 36

Page 37

CHAPTER 2

PRINTING FROM A COMPUTER

This chapter describes how to install and how to use the printer drivers

and printer utilities on a computer. This chapter also describes the job

retention function that allows print start operation from the operation

panel of the printer.

Page

CONNECTING TO A COMPUTER ........................................................ 2-2

SOFTWARE FOR WINDOWS ................................................................ 2-2

INSTALLING PRINTER DRIVERS AND PRINTER UTILITIES ............. 2-3

REMOVING PRINTER DRIVERS AND PRINTER UTILITIES ............... 2-3

INSTALLING PRINTER DRIVERS USING THE PLUG &

PLAY FEATURE OR ADD PRINTER WIZARD ..................................... 2-4

● Before installation ........................................................................... 2-4

SETTING THE PRINTER DRIVER ........................................................ 2-5

● Setting print conditions under Windows

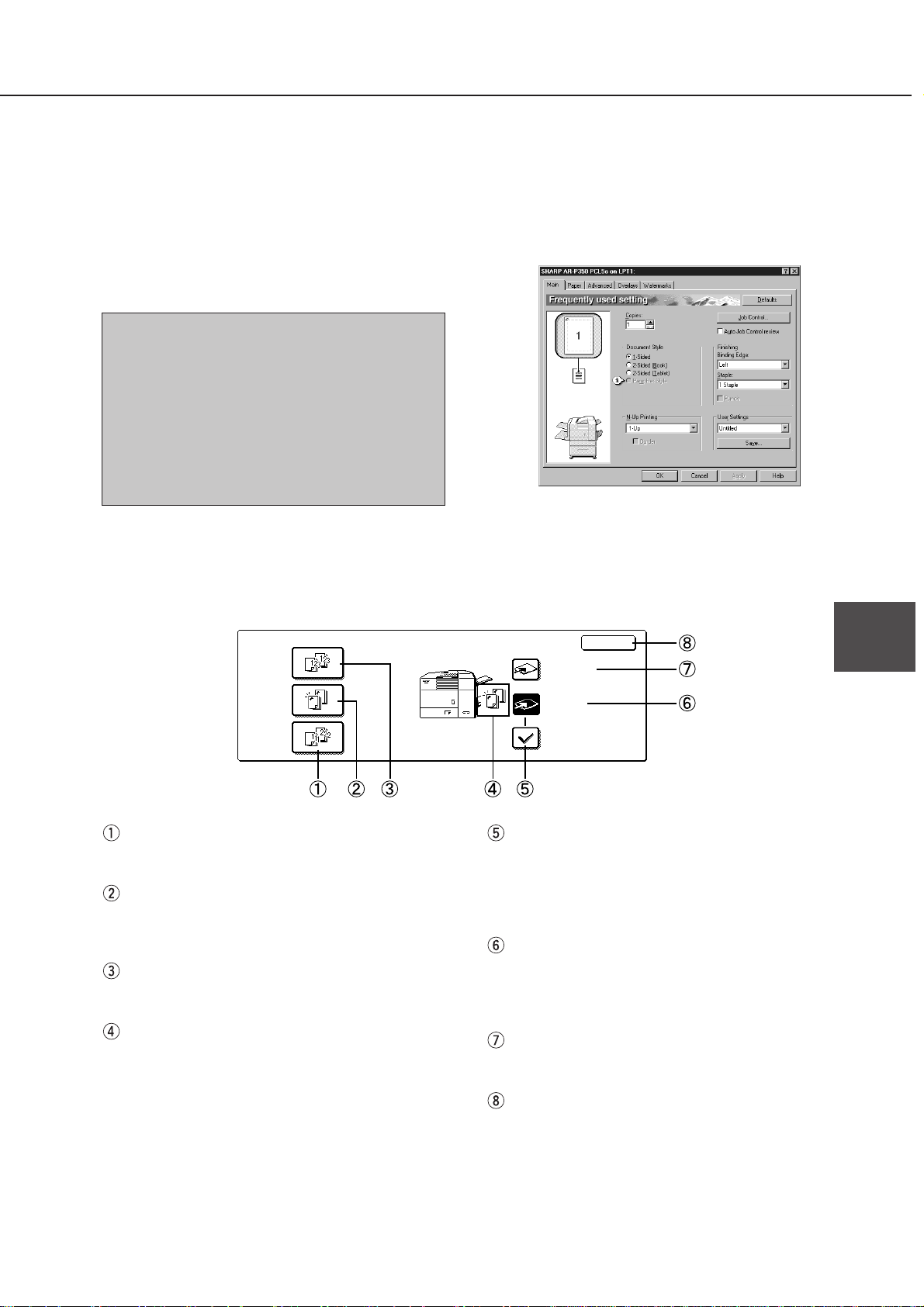

(selecting and setting print conditions) ........................................... 2-5

REMOTE OPERATION THROUGH NETWORK ................................... 2-6

● Environment required for accessing Web pages ........................... 2-6

● Accessing Web pages and displaying help .................................... 2-6

● Items and outline of menu frame of Web pages ............................. 2-7

JOB RETENTION FUNCTION WHICH ALLOWS PRINT START

OPERATION FROM THE OPERATION PANEL ..................................... 2-9

● Print functions selectable in the “JOB CONTROL”

dialog box and their operation ........................................................ 2-9

● Printing method of hold job list ........................................................ 2-10

● Printer account control .................................................................... 2-12

2-1

Page 38

CONNECTING TO A COMPUTER

1. Using this machine as a local printer

When using this machine as a local printer, connect your computer to the parallel interface connector of this

product as shown in the illustration.

For a connection cable, prepare a Centronics cable on the market that conforms to the following specifications.

The parallel interface of this machine conforms to IEEE-STD-1284-1993.

1

Connector type on this printer: 36-pin DDK 57LE-40360-730B (D29)

female connector or equivalent connector

For the specifications of the parallel interface

connector on the computer, see the computer

manual.

Parallel interface connector

2. Using this machine as a network printer

For using this machine as a network printer, a print server card is needed.

See the operation manual supplied with the print server card.

18

36 19

SOFTWARE FOR WINDOWS

When using this product in Windows environment, you must install a printer driver in your computer system. Use the

supplied CD-ROM for installation. For using this product, either connection through a parallel interface connector (see

page xxxx) between the computer and this machine (local printer) or network connection that uses a print server card

(network interface card) as a peripheral unit can be performed.

The print server card may be installed as a standard component or optional depending on the model. Contact your

SHARP dealer.

The following software for Windows is contained in the CD-ROM.

●

Printer drivers

●

Printer utilities

●

Installer

These are software for installing the printer drivers and printer utilities. If you use the Plug and Play feature or the

Add Printer wizard to install the driver without using the installer, specify directly the folder name referring to the

directory information of the PRINTER UTILITIES CD-ROM on page xxxx.

■■

■ Printer drivers

■■

●

PCL printer drivers (PCL5e and PCL6)

●

Optional PostScript printer driver (compatible to

PostScript level 3) and SHARP AR-xxxx PPD file

(PostScript Printer Description file)

1. Printer drivers

A printer driver is software designed to convert print data from any application into data understandable by the

printer so that the printer can print out the data. This product, therefore, can be used as a printer only after a printer

driver has been installed. If a printer driver is installed once, it is built into your computer system. You need not

install the driver each time you execute printing.

■■

■ Printer utilities

■■

●

Printer Administration Utility

●

Printer Status Monitor

●

Display Font

2. Printer utilities

Printer Administration Utility that allows setting and monitoring of printers on a computer and Printer Status Monitor

that allows monitoring of printer status and display and notification on a computer are provided for network

environment. (only in the Windows environment)

For use of Printer Administration Utility and Printer Status Monitor, see the help file. The details of use are written

in each help file.

Printer Administration Utility is software for system administrators.

2-2

Page 39

INSTALLING PRINTER DRIVERS AND PRINTER UTILITIES

Windows software

PCL printer drivers

Windows client

Printer Status

Monitor

Execute installation from the CD-ROM using the following procedure.

Start Windows.

Display font

Network administrator

Network Administration Utility

The following software can be installed from the installer

supplied in the CD-ROM :

●

PCL printer drivers (PCL5e and PCL6)

●

Display font

●

Printer Administration Utility

●

Printer Status Monitor

1

Insert the supplied CD-ROM into a CD-

ROM drive of your computer.

2

If your computer is configured for auto start

on the CD-ROM, the software license

agreement described in step 5 will appear.

(Steps 3 and 4 are not needed.)

On the [Start] menu, click “Run.”

3

NOTE

If you wish to install a printer driver or a printer

utility from a floppy disk, see the README file of

the CD-ROM. The method of copying printer drivers

and printer utilities from the CD-ROM to a floppy

disk and the method of use are described.

If you click the [README display] button, the

information of the specified software will be

displayed. When installing the Printer

Administration Utility and the Printer Status

Monitor, read the README display and

check to see if the computer system

requirements are satisfied.

NOTE

The Printer Administration Utility and the Printer

Status Monitor can be used only if this product is

used as a network printer.

2

Enter the CD-ROM drive and setup

command. Then click the [OK] button.

4

Example: If the CD-ROM drive is designated as

drive R, enter “R:\SETUP.EXE”.

Read the software license agreement and

click the [Next] button if you accept the

5

agreement.

The printer drivers and printer utilities that

can be installed from the CD-ROM will be

6

listed. Select the check boxes of the

desired drivers and utilities and click the

[Next] button.

Click the [Start] button.

7

The installation screen of the file selected with

a check box will appear. Follow the

instructions on your screen to install the

selected printer drivers and utilities.

When installation is complete, the message

“Setup has finished installing your

8

selected package(s).” will appear. Click the

[Close] button.

NOTE

Restart of your computer may be needed

depending on the system. Click [Yes] to restar t

the computer.

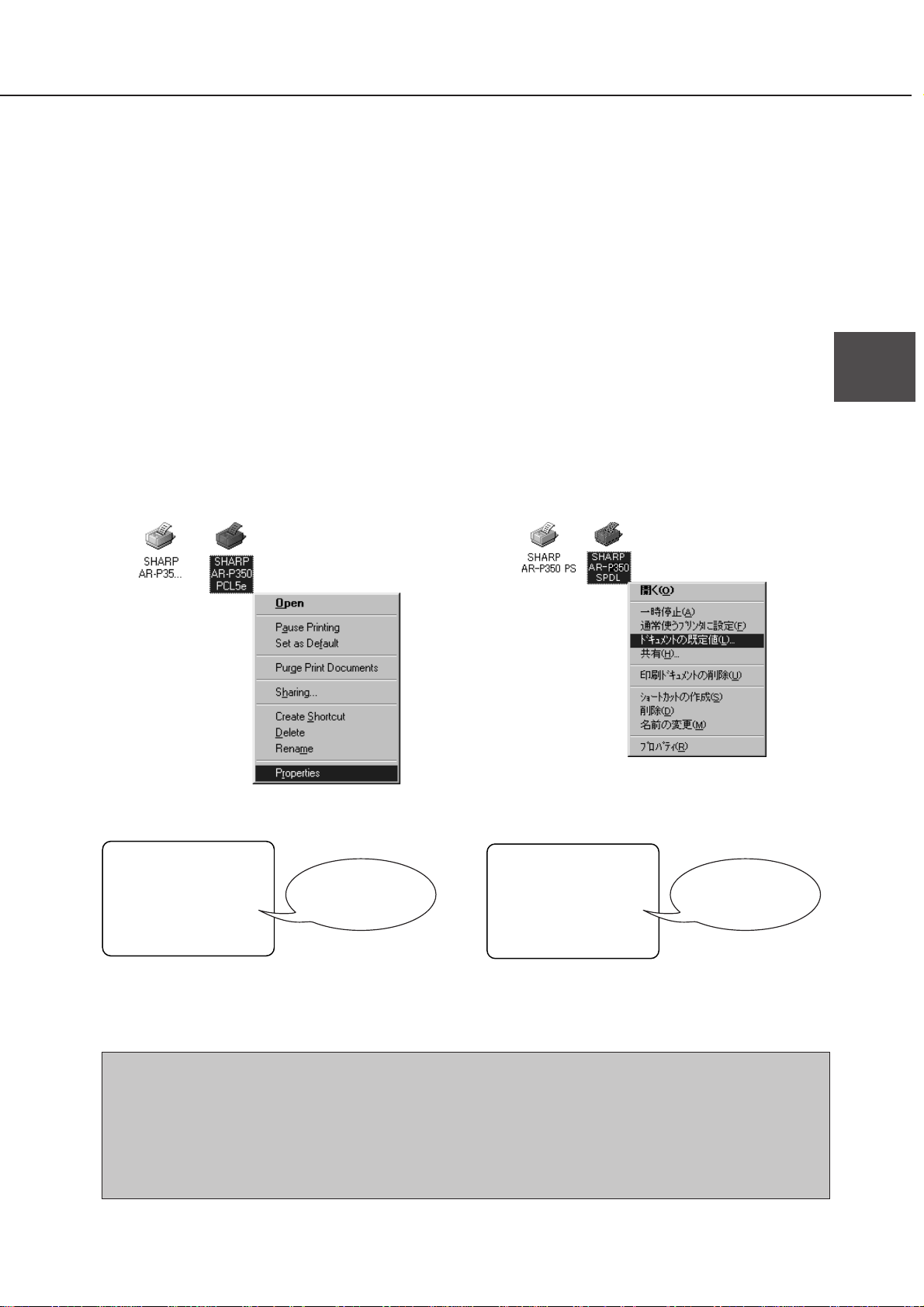

UNINSTALLING PRINTER UTILITIES

When uninstalling a printer driver that has been installed, right-click the printer to be deleted from “Printers” of “Control

Panel” and select [Delete]. When uninstalling the Printer Administration Utility or the Printer Status Monitor, use “Add/

Remove Programs” of “Control Panel”. Use the Windows standard operation for each case.

2-3

Page 40

INSTALLING PRINTER DRIVERS USING THE PLUG

& PLAY FEATURE OR ADD PRINTER WIZARD

Before installation

Before installing the printer drivers, check the following items.

●

Ensure that your computer system meets the following requirements.

Computer type:

IBM PC/AT or compatible computer

Hardware requirements of the operating system must

be satisfied.

When using the Plug and Play feature in the Windows 95/98 environment or using the Add Printer wizard to install

printer drivers, enter the directory name indicated below as a source directory.

Operating system:

Windows 95

Windows 98

Windows 2000

Windows NT 4.0

Windows Me

Path for using PCL5e driver under Windows 2000

Path for using PCL5e driver under Windows 2000

R:\AR-Tigeokamptor\Option\English\2k_pcl5e

R:\AR-Tigeokamptor\Option\English\2k_pcl5e

Path for using PCL6 driver under Windows 2000

R:\AR-Tigeokamptor\Option\English\2k_pcl6

Path for using PCL5e driver under Windows 95/98/Me

R:\AR-Tigeokamptor\Option\English\9x_pcl5e

Path for using PCL6 driver under Windows 95/98/Me

R:\AR-Tigeokamptor\Option\English\9x_pcl6

Path for using PCL5e driver under Windows NT

R:\AR-Tigeokamptor\Option\English\Nt_pcl5e

Path for using PCL6 driver under Windows NT

R:\AR-Tigeokamptor\Option\English\Nt_pcl6

■ Example of installation of a printer driver using the Add Printer wizard under Windows 98

The installation method of a printer driver under Windows 98 is shown below.