Page 1

DM-2000

CODE: 00ZDM2000/A1E

NETWORK LASER

SYSTEM

MODEL DM-2000

CONTENTS

[ 1 ] GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

[ 2 ] SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . 2 - 1

[ 3 ] CONSUMABLE PARTS . . . . . . . . . . . . . . . . . . . 3 - 1

[ 4 ] EXTERNAL VIEWS AND INTERNAL STRUCTURES . . . 4 - 1

[ 5 ] UNPACKING AND INSTALLATION . . . . . . . . . . . . . 5 - 1

[ 6 ] ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . 6 - 1

[ 7 ] SIMULATIONS . . . . . . . . . . . . . . . . . . . . . . . . 7 - 1

[ 8 ] FLASH ROM VERSION UP PROCEDURE . . . . . . . . . 8 - 1

[ 9 ] TROUBLE CODE LIST . . . . . . . . . . . . . . . . . . . . 9 - 1

[10] USER SETUP . . . . . . . . . . . . . . . . . . . . . . . . 10 - 1

[11] DISASSEMBLY AND ASSEMBLY . . . . . . . . . . . . . 11 - 1

[12] ELECTRICAL SECTION . . . . . . . . . . . . . . . . . . 12 - 1

Parts marked with “ ” are important for maintaining the safety of the set. Be sure to replace these parts with specified

ones for maintaining the safety and performance of the set.

This document has been published to be used

SHARP CORPORATION

for after sales service only.

The contents are subject to change without notice.

Page 2

DM-2000

Warning!

This product is a class A product.

If it is operated in households, offices or similar surroundings, it

can produce radio interferences at other appliances, so that the

user has to take adequate countermeasures.

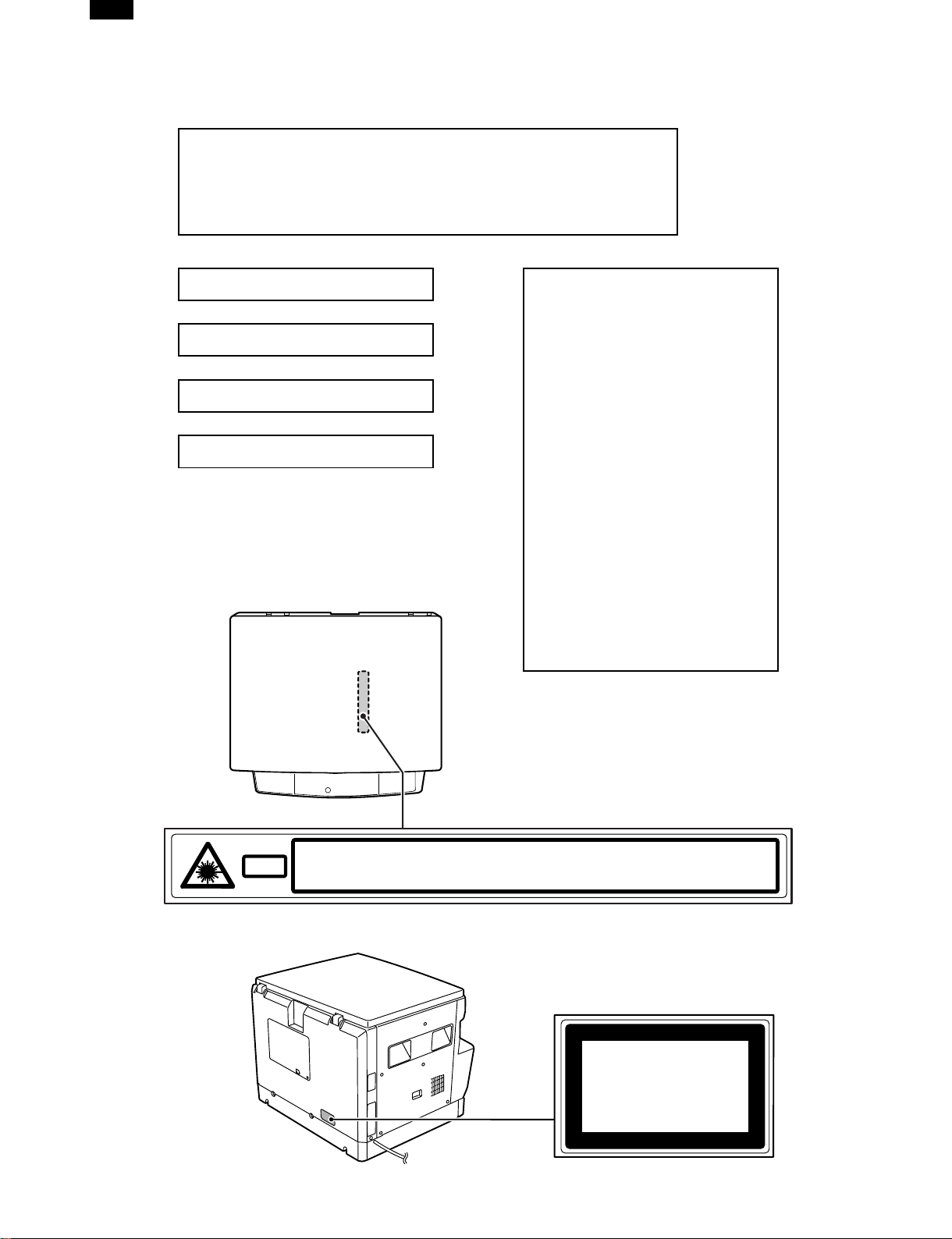

CLASS 1 LASER PRODUCT

LASER KLASSE 1

LUOKAN 1 LASERLAITE

KLASS 1 LASERAPPARAT

VAROITUS!

LAITTEEN KÄYTTÄMINEN

MUULLA KUIN TÄSSÄ

KÄYTTÖOHJEESSA MAINITULLA

TAVALLA SAATTAA ALTISTAA

KÄYTTÄJÄN

TURVALLISUUSLUOKAN 1

YLITTÄVÄLLE

NÄKYMÄTTÖMÄLLE

LASERSÄTEILYLLE.

VARNING

OM APPARATEN ANVÄNDS PÅ

ANNAT SÄTT ÄN I DENNA

BRUKSANVISNING

SPECIFICERATS, KAN

ANVÄNDAREN UTSÄTTAS FÖR

OSYNLIG LASERSTRÅLNING,

SOM ÖVERSKRIDER GRÄNSEN

FÖR LASERKLASS 1.

INVISIBLE LASER RADIATION WHEN OPEN AND INTERLOCKS DEFEATED.

CAUTION

AVOID EXPOSURE TO BEAM.

UNSICHTBARE LASERSTRAHLUNG WENN ABDECKUNG GEÖFFNET UND

VORSICHT

Laserstrahl

SICHERHEITSVERRIEGELUNG ÜBERERÜCKT. NICHT DEM STRAHL AUSSETZEN.

USYNLIG LASERSTRÅLING VED ÅBNING, NÅR SIKKERHEDSAFBRYDERE ER

ADVARSEL

UDE AF FUNKTION. UNDGA UDSAETTELSE FOR STRÅLING.

Disconnect the AC cord before servicing the unit.

USYNLIG LASERSTRÅLING NÅR DEKSEL ÅPNES OG SIKKERHEDSLÅS BRYTES.

ADVERSEL

VARNING

VARO!

UNNGÅ EKSPONERING FOR STRÅLEN.

OSYNLIG LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD OCH SPÄRRAR ÄR

URKOPPLADE. STRÅLEN ÄR FARLIG. BETRAKTA EJ STRÅLEN.

AVATTAESSA JA SUOJALUKITUS OHITETTAESSA OLET ALTTIINA NÄKYMÄTÖNTÄ

LASERSÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN.

CLASS 1

LASER PRODUCT

LASER KLASSE 1

Page 3

CONTENTS

DM-2000

[1] GENERAL ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 1 – 1

1. System configuration ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 1 – 1

2. Note for servicing ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 1 – 1

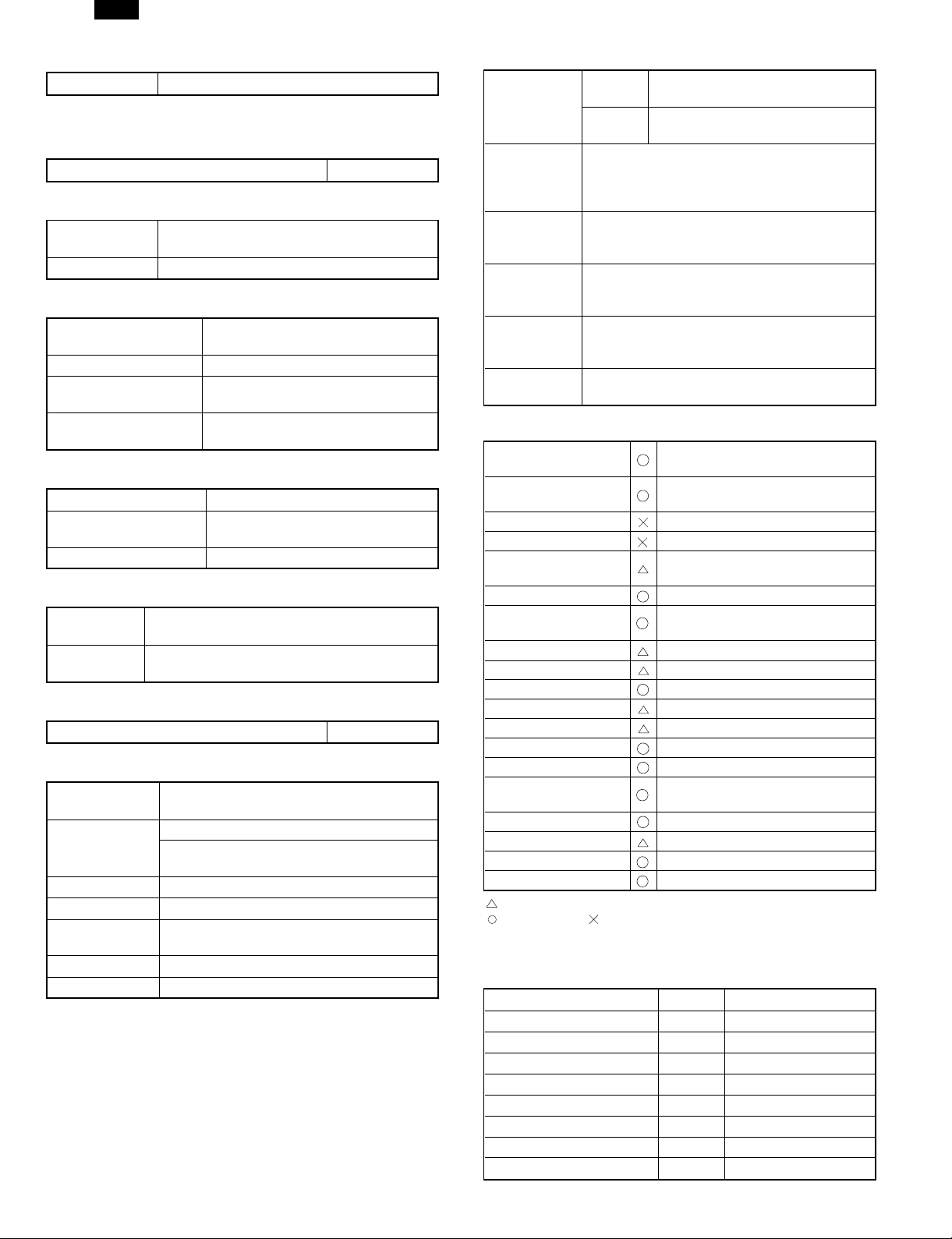

[2] SPECIFICATIONS ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 2 – 1

1. Copy mode ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 2 – 1

2. Specifications of printer section ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 2 – 3

[3] CONSUMABLE PARTS ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 3 – 1

1. Supply system table ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 3 – 1

2. Environment conditions ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 3 – 1

3. Production number identification ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 3 – 2

[4] EXTERNAL VIEWS AND INTERNAL

STRUCTURES ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 4 – 1

1. Appearance ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 4 – 1

2. Internal ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 4 – 1

3. Operation Section ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 4 – 2

4. Motor, solenoid, clutch ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 4 – 3

5. Sensor, switch ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 4 – 4

6. PWB unit ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 4 – 5

7. Cross sectional view ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 4 – 6

[5] UNPACKING AND INSTALLATION ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 5 – 1

1. Installing conditions ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 5 – 1

2. Removal of protective material and

fixing screw ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 5 – 1

3. Installing of developing cartridge ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 5 – 1

4. Removal and storage of fixing screw ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 5 – 2

5. Changing the copy paper size in the tray ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 5 – 2

6. Installing the printer driver ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 5 – 3

7. Expansion memory installation ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 5 – 7

8. Print server card installation ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 5 – 7

[10] USER SETUP ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅10 – 1

1. List of user programs ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 10 – 1

2. Setting the user programs ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 10 – 1

3. Configuration setting ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 10 – 4

4. Configuration report and test page ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 10 – 6

[11] DISASSEMBLY AND ASSEMBLY ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 11 – 1

1. High voltage section ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 11 – 1

2. Optical section ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 11 – 1

3. Fusing section ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 11 – 2

4. Paper exit section ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 11 – 5

5. MCU/Mother board/Printer control PWB ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 11 – 6

6. Optical frame unit ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 11 – 7

7. LSU ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 11 – 8

8. Tray paper feed section/Paper transport

section ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 11 – 8

9. Second Tray section ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 11 – 10

10. Manual multi paper feed section ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 11 – 11

11. Power section ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 11 – 13

[12] ELECTRICAL SECTION ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅12 – 1

1. Block diagram ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 12 – 1

2. Actual wiring diagram ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 12 – 2

[6] ADJUSTMENTS ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 6 – 1

1. Adjustment item list ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 6 – 1

2. Copier adjustment ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 6 – 1

[7] SIMULATIONS ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 7 – 1

1. Entering the simulation mode ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 7 – 1

2. Cancelling the simulation mode ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 7 – 1

3. List of simulations ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 7 – 1

4. Contents of simulations ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 7 – 2

[8] FLASH ROM VERSION UP PROCEDURE ⋅ ⋅ 8 – 1

1. MCU/E SORT ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 8 – 1

2. Printer control PWB firmware version up ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 8 – 2

[9] TROUBLE CODE LIST ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 9 – 1

1. Trouble code list ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 9 – 1

2. Details of trouble codes ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ ⋅ 9 – 2

Page 4

DM-2000

[1] GENERAL

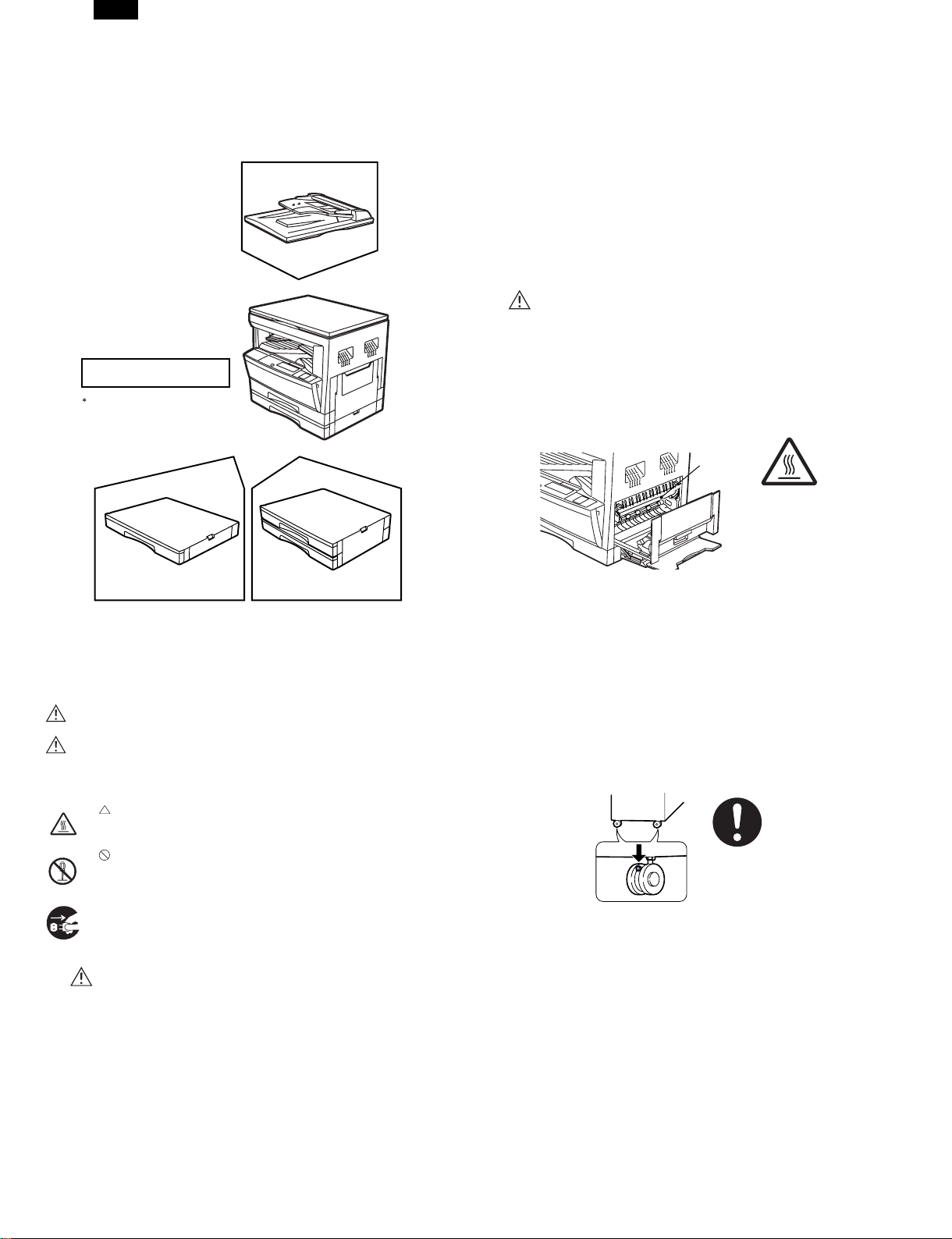

1. System configuration

A number of options are available for the DM System which allow you

to configure the system to meet your particular needs. The options include the following.

Single pass feeder

(DM-SP1)

Electronic sorting kit (DM-EB1)

Facsimile expansion kit (DM-FX1)*

This option is not used for the copier

operation.

For description of this option, see its

separate manual.

cause an electric shock when touched. Do not leave the machine

with the cabinet removed. It is very dangerous for the user to

touch the inside of the machine.

5) Do not damage, brake, or work the power cord. Do not put a

heavy thing on the power cord. Do not pull or bend the power cord

extremely. Otherwise, the power cord may be damaged to cause

a fire or an electric shock.

6) Do not put a vessel with water in it on the machine. Do not put a

metal piece on the machine, which may drop into the machine,

causing a fire or an electric shock.

7) If water or a metal piece drops into the machine, turn off the power

switch, disconnect the power plug, then remove the dropped thing.

8) Do not use a wet hand to disconnect or insert the power plug and

to operate or service the machine. It may cause an electric shock.

B. CAUTION

1) Avoid installation on an unstable surface or a slant surface. Otherwise, it may drop from the surface, resulting in an injury. It is advisable to use the optional paper feed desk or the exclusive-use

desk.

2) Avoid installation in a humid or dusty place. Otherwise, a fire or an

elctric shock may be resulted.

3) The fusing section is very high. Be careful not to burn when servicing.

Fusing section

250-sheet paper feed unit

(DM-DE1)

2x250-sheet paper feed unit

(DM-DE2)

2. Note for servicing

Pictogram

This Service Manual uses some pictographs to assure safe operation.

Please understand the meanings of pictographs before servicing.

WARNING: If this WARNING should be ignored, a serious danger

CAUTION: If this CAUTION should be ignored, an injury or a

Meanings of pictographs

A. WARNING

1) Never use a power source of more than 15A, 100V.

Avoid complex wiring, which may lead to a fire or an electric

shock.

2) When any abnormality occurs, such as smoke or bad smell, do not

use the machine. If used in abnormal conditions, a fire or an

electric shock may be resulted.

3) Be sure to connect the grounding wire. If an electric leakage occurs without grounding, a fire or an electric shock may be resulted.

To protect the machine and the power unit from lightening,

grounding must be made.

4) When removing the cabinet of the machine, use an extreme care.

There is a high voltage section inside the machine which may

to life or a serial injury would be resulted.

damage to properties would be resulted.

This pictograph means that a care must be taken. In the

pictograph, the concrete content is drawn. (High temperature

in this example)

This pictograph means inhibition. The concrete content of

inhibition is shown in or near the pictograph. (Inhibition of disassembly in this example)

●This pictograph means a thing which must be done. (Dis-

connecting the power plug from the power outlet in this example)

4) When disconnecting the power plug from the power outlet, do not

pull the power cord. Otherwise, the cord may be damaged, resulting in exposed core or disconnection, causing a fire or an electric

shock.

5) Do not throw toner or a toner cartridge in a fire. Otherwise, toner

may pop and burn you.

6) When using the optional paper feed desk or the exclusive-use

desk, be sure to fix the adjusters on the floor, and lock the casters.

As shown in the figure, rotate the adjuster in the fixing direction

until it makes contact with the floor. Lock the casters to fix the

machine. (If the casters are not locked, the machine may gradually

move so that the SPF cable may be rubbed with the wall, causing

disconnection.

When moving the machine a little for reforming the office, turn the

adjuster to release lock of the casters. (After moving, lock the adjusters and casters to fix the machine.)

7) Do not see the light source and the laser beams. Otherwise the

eyes may be damaged.

8) When moving the machine, turn off the power switch and the

heater switch, and be sure to disconnect the power plug from the

power outlet. If not, the cord may be damaged to cause a fire or

an electric shock.

9) It is very dangerous to perform reception or printing during servicing. When servicing with the cabinet removed, pull out the

telephone line and the printer cable from the machine. (The laser

print function and the Fax function are options.)

10) There are some sharp edges inside the machine. Be careful not

to injure your fingers when servicing.

1 – 1

Page 5

DM-2000

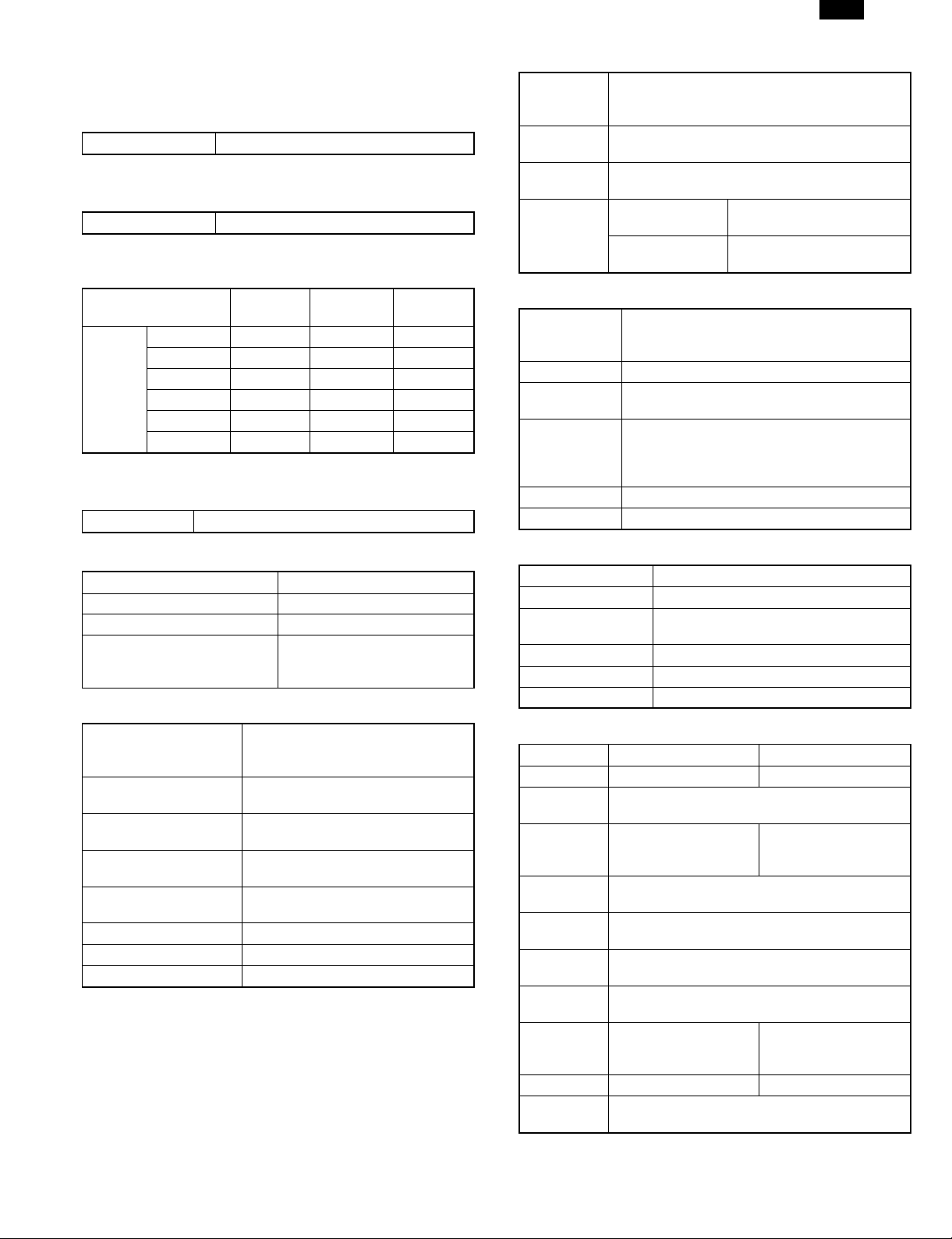

[2] SPECIFICATIONS

1. Copy mode

A. Type

Type Desk-top

B. Copy speed

(1) Basic speed

1 scan multi copy 20 sheets/min

Condition: Copy speed in the normal copy.

(2) Continuous copy speed (Sheets/min)

Paper size Normal

11" × 17" 10 10 10

8.5" × 14" 12 12 12

Inch

system

8.5" × 13" 12 12 12

8.5" × 11" 20 20 20

8.5" × 11"R 15 15 15

8.5" × 5.5" 20 20 20

C. First copy time

(1) Basic speed

First copy time 7.2 sec (8.5" × 11"/1st cassette/with OC)

Enlargement

(200%)

Reduction

(50%)

E. Paper feed

Max.: A3, 11" × 17"

Copy size

Paper feed

system

Paper feed

capacity

Remaining

quantity

detection

(1) Paper feed section of the copier

Paper feed

size

Side front Front 2 step

Paper feed

capacity

Detection

Weight 56 ∼ 80 g/m2 15 ∼ 21 lbs

Special paper Recycled paper

Min.: A6, 5.5" × 8.5" (For B6/A6 and 5.5" × 8.5",

Multi bypass tray only.)

2 cassette + Multi bypass tray

250 × 2 (Paper feed tray) + 100 (Multi bypass

tray)(56 ∼ 80 g/m2 equivalent)

Cassette section

Multi bypass tray

11" × 17", 8.5" × 14", 8.5" × 13", 8.5" × 11",

8.5" × 11"R, 8.5" × 5.5" (8.5" × 5.5" is only for

tray 1)

250 sheets (56 ∼ 80 g/m2 15 ∼ 21 lbs

equivalent)

Paper empty detection available, size detection

(by key input)

Detection size: 11" × 17", 8.5" × 14",

8.5" × 11", 8.5" × 11"R, 8.5" × 5.5"

Empty detection available,

size detection by key input

Only empty detection

available

D. Document

Max. document size 11" × 17"

Document reference position Left side center

Detection (Platen) Available

11" × 17", 8.5" × 14",

Detection size

(1) SPF/R-SPF

Standard/Option

Document load capacity

Document size

(Max. ∼ Min.)

Document replacement

speed

Document set/Paper

feed direction

Document weight 56 ∼ 90 g/m2, 15 ∼ 23.9 lbs

Document size detection On the document feed tray

Document mixture Copy mode: Not Available

8.5" × 11", 8.5" × 11"R,

8.5" × 5.5"

Option

SPF; DM-SP1

RSPF; Not available

30 sheets (56 ∼ 90 g/m2 15 ∼ 23.9

lbs equivalent)

11" × 17" ∼ 8.5" × 5.5"

16 sheets/min (8.5" × 11" normal

copy)

Face up, Center reference, Paper

feed from the top

(2) Manual paper feed section

Paper feed size 11" × 17" ∼ 5.5" × 8.5"

Paper feed capacity 100 sheets

Detection

Weight 56 ∼ 128 g/m2 15 ∼ 34 lbs

Special paper Recycled paper, OHP film, labels

Paper feed Single except for recycled paper

(3) Option paper feed unit

Model DM-DE1 DM-DE2

Paper feed

size

Capacity

(56 ∼ 80

g/m2)

Paper

weight

Dehumidifier

heater

Detection

Paper size

setting

External

dimensions

(W × D × H)

Weight About 5 kg About 10 kg

Special

paper

Size detection not available, paper empty

detection available

1-step paper feed unit 2-step paper feed unit

11" × 17", 8.5" × 14", 8.5" × 11",

8.5" × 11"R

About 250 sheets

× 1 step

56 ∼ 80 g/m2 15 ∼ 21 lbs

Paper empty detection, size detection

(by key input)

User setting (by key input)

590 × 571 × 88 mm 590 × 571 × 173.5 mm

Recycled paper

About 250 sheets

× 2 steps

None

2 – 1

Page 6

DM-2000

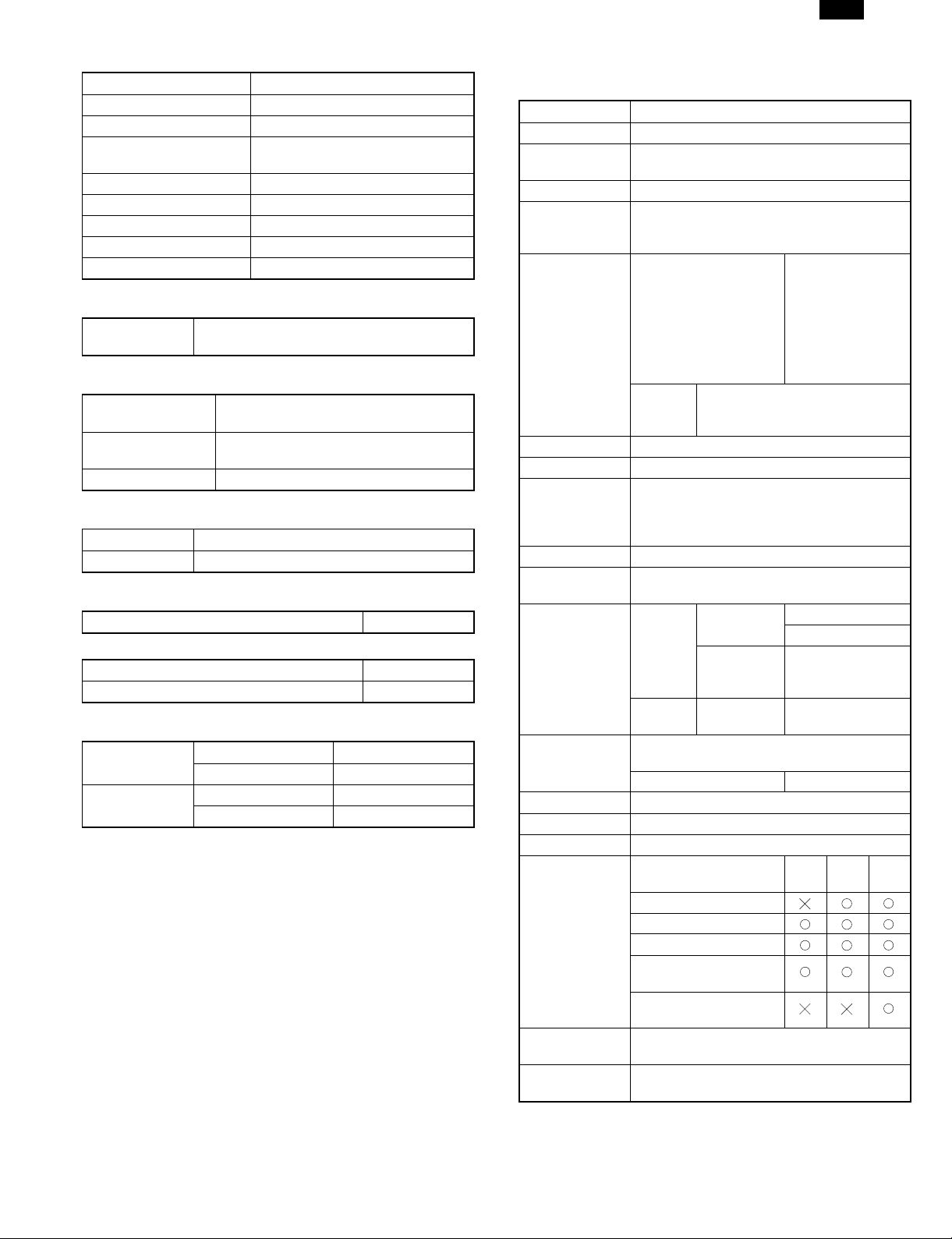

F. Job speed

S-S (1st step) 80% (document replacement rate)

Condition: With SPF

G. Multi copy

Max. number of multi copy 99 sheets

H. Warmup time

Warmup time

Pre-heat Available

Approx. 35 sec

(Condition: Standard condition)

I. Copy magnification ratio

Fixed magnification ratio

Zooming 50 ∼ 200%

Independent

zooming/vertical

Independent zooming

(horizontal)

50, 64, 77, 95, 100, 121, 129, 141,

200%

Available (50 ∼ 200%)

Available (50 ∼ 200%)

J. Print density

Density mode Auto/Manual/Photo

No. of manual

adjustment

Toner save mode Set by the user program

5 steps (Manual/Photo)

K. Void width

Void area

Image loss

Lead edge 1 ∼ 4 mm, rear edge 4 mm or less,

both side 4 mm or less

Max. 5/32" (4 mm) (leading and trailing edges)

Max. 5/32" (4 mm) (along other edges in total)

L. Auto duplex

Standard/Option Not installable

M. Paper exit/finishing

Paper exit

section capacity

Job separator

Full detection Available (Job separator)

Finishing Electronic sort board: Option (DM-EB1)

Electronic sort

capacity

Offset function Available (by the shifer)

Staple function None

Face down 250 sheets

Job separator, Standard provision

Upper: FAX/Printer, Lower: Copier

Upper: 100 sheets, Lower 150 sheets

8.5" × 11" standard document 60 sheets

(1) Electronic sort board (Option)

60 sheets of A4 (8.5" × 11")

standard documents

60 sheets of A4 (8.5" × 11")

standard documents

Electronic sort

Rotation copy

2 in 1, 4 in 1

Edge erase

Center erase

Margin shift

Sorting

Grouping

If there is paper of same size as the document,

the image is rotated to copy even though the

paper is set in the different direction from the

document direction.

Copies of 2 pages or 4 pages are integrated

into one surface. Divided by solid lines,

(Selectable by the user program.)

Images surrounding the document are erased

when copying. (Adjustable in 0 ∼ 20 mm (5 mm

step)/0" ∼ 1" (1/4" step) by the user program.)

The image at the center is erased when

copying. (Adjustable in 0 ∼ 20 mm (5 mm

step)/0" ∼ 1" (1/4" step) by the user program.)

Binding margin is made at the left edge of the

set documents.

N. Additional functions

APS

AMS

Duplex

Document count

Sorter

Independent zooming Vertical/Horizontal: 50 ∼ 200%

1 set 2 copy

Binding margin Shift width 9 mm/1/4"

Edge erase Adjustable 0 ∼ 20 mm/0" ∼ 1"

Black-white reversion Whole surface only

2 in 1, 4 in 1

Rotation copy

Memory copy Only one page memory installed.

Pre-heat function Conditions set by the user program

Auto power shut off

function

Auto tray switching

Message display (FAX/Printer extension)

User program

Total counter

: When an option is installed

: Available : Not available

(APS not available by flowing in

during use of SPF)

(AMS not available by flowing in

during use of SPF)

When the electronic sort board

installed.

Enlargement inhibited, inhibited

during the use of SPF

Conditions set by the user program

O. machine composition

(1) Option

Machine Model Power supply

250 sheets paper feed unit DM-DE1 Supplied by the copier.

500 sheets paper feed unit DM-DE2 Supplied by the copier.

SPF DM-SP1 Supplied by the copier.

Electronic sorting kit DM-EB1 Supplied by the copier.

Facsimile expansion kit DM-FX1 Supplied by the copier.

2 MB FAX memory AR-MM5

4 MB FAX memory AR-MM6

8 MB FAX memory AR-MM7

2 – 2

Page 7

DM-2000

P. Other specifications

Photoconductor type OPC (Organic Photo Conductor)

Photoconductor drum dia. 30 mm

Copy lamp Xenon lamp

Developing system

Charging system Saw teeth charging

Transfer system (+) DC corotoron

Separation system (–) DC corotoron

Fusing system Heat roller

Cleaning system Contact blade

Dry 2-component magnetic brush

development

Q. Package form

Body

Body/Accessories (NIC board is separately

packed.)

R. External view

External dimensions

(W × D × H)

Occupying area

(W × D)

Weight About 36.5 kg

590 × 531 × 552 mm (including Platen)

590 × 531 mm

(When the multi bypass tray is installed.)

S. Power source

Voltage AC120V ± 15%

Frequency 50/60Hz common

T. Power consumption

Max. power consumption About 1.5 KWh

∗ EnergyStar standard (The second level conformity)

Pre-heat About 60 Wh

Auto power shut off About 4.8 Wh

U. Digital performance

Resolution

Gradation

Reading 400 dpi

Writing 600 dpi

Reading 256 gradations

Writing Binary

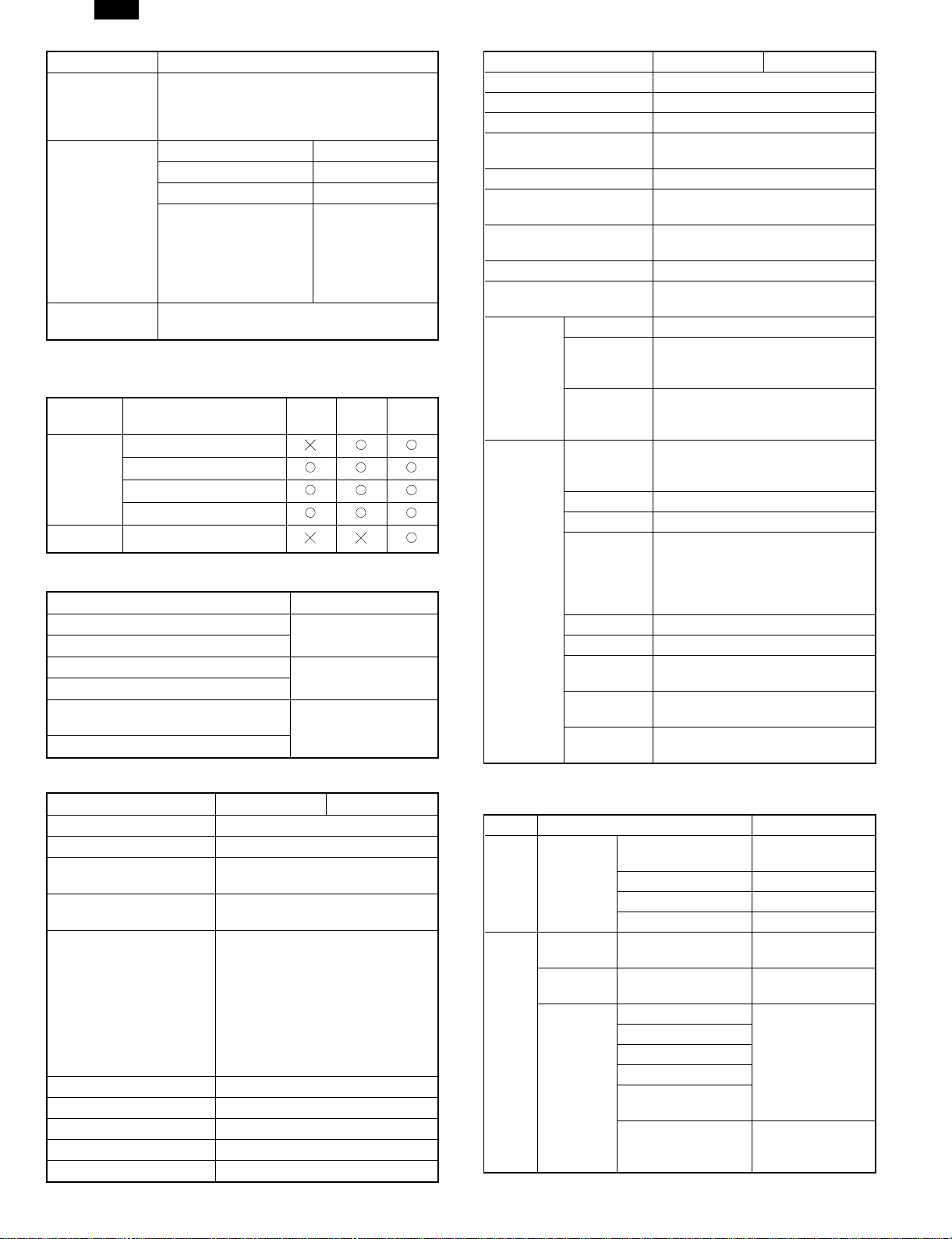

2. Specifications of printer section

A. Basic specifications

Item Contents

Print speed 20 PPM

Resolution

Toner save Available

Paper feed tray

Paper size

Paper exit Face down system

Shifter Available

Page

description

language

(standard)

Dot emulation None

Page protection

function

Interface

Interface cable

Interface select Auto

Emulation select Auto

Plug and play Conforming (only with Windows 95/98)

Printer driver

Network control

software

Built-in fonts

600 dpi, 300 dpi (1,200 dpi equivalent by

smoothing)

Multi bypass tray

Tray 1, Tray 2, Tray 3, Tray 4 (Depends on

the machine and the option installation.)

A3, B4, A4R,

B5R, A5, 11" ×

17", 8.5" × 14",

Multi bypass tray

Tray

1 ∼ 4

PCL6 emulation

PCL5e emulation

PostScript Level 2 emulation

Available

Standard

Option

Use IEEE1284 conforming parallel cable.

(shielded and grounded)

Max. length Within 3.0 m

Microsoft Windows 3.1

Microsoft Windows 95

Microsoft Windows 98

Microsoft Windows

NT4.0

Macintosh OS version

7.5 or later

Printer Administration Utility

Outline 45 fonts (PCL6 compatible)

Outline 35 fonts (PS2 compatible)

11" × 17", 8.5" × 14", 8.5" × 11",

8.5" × 11"R, 8.5" × 5.5", 8.5" ×

13"

IEEE1284

port

Expansion

slot

10/100

Base TX

8.5" × 11"R, 8.5"

× 5.5"R, 8.5" ×

13", 8.3" × 13",

7.25" × 10.5"R,

DL, C5, COM10

Compatibility mode

Nibble mode

Expansion slot for

Print Server Card

× 1

TCP/IP, IPX/SPX

PCL6PCL

5e

PS2

2 – 3

Page 8

DM-2000

Item Contents

Outline 31 fonts (PCL6 compatible) for

Screen font

Memory

Conforming PC

Windows

Outline 35 fonts (PS2 compatible) for

Windows

Standard 8 MB

Max. 136 MB

Expansion slot DIMM slot × 2

Expansion memory

(For details, refer to

the descriptions below.)

IBM PC-AT compatible

Apple Macintosh Computer

B. Printer driver specifications

(1) System

OS PCL6

Microsoft Windows 3.1

IBM

PC/AT

Macintosh

(2) Kinds of printer drivers

PCL5e for Windows 3.1/95/98

PCL5e for Windows NT4.0

PCL6 for Windows 95/98

PCL6 for Windows NT4.0

PostScript Level2 for Windows

3.1/95/98

PostScript Level2 for Windows NT4.0

Microsoft Windows 95

Microsoft Windows 98

Microsoft Windows NT4.0

OS 7.5 or lator

Printer driver name Name on PC screen

64 MB, 32 MB,

16 MB

(Commercially

available 168 pin

EDO DIMM 60ns

or faster used)

PCL5e

SHARP DM-2000

Series PCL5e

SHARP DM-2000

Series PCL6

SHARP DM-2000

Series PS2

PS2

Item PCL6 PCL5e

Smoothing On, Off

Resolution Settings 600 dpi, 300 dpi

Graphics Mode HP-GL/2 (Vector), Raster

Half Tone

Font Source Resident Fonts, Download Fonts

True Type Mode

Input Tray

Duplex Capability Yes, No

Installed RAM

Unit 0.01", 0.1 mm

Set

content of

custom

paper

Set

content of

water mark

Width

Length

Position

Size 6 ∼ 900

Angle ±90˚

Text

Edit Fonts Refer to the following Font List.

Edit Density 0 ∼ 255

Transparent

Text

On First

Page Only

As Outline

Only

Photo Images, Line Art, Scanned

Images

Download as True Type, Download

as bitmap font, Print as graphics

Two Trays, Three Trays, Four

Trays

8 MB, 24 MB, 40 MB, 56 MB, 72

MB, 88 MB, 104 MB, 136 MB

1000 to 2969

(In the case of 0.1 mm)

394 to 1169 (In the case of 0.01")

1480 to 4318

(In the case of 0.1 mm)

583 to 1700 (In the case of 0.01")

Depends on the paper size.

MAX Short –5.84" ∼ 5.84"

Long –8.5" ∼ 8.5"

TOP SECRET

CONFIDENTIAL

DRAFT

ORIGINAL

COPY

Yes, No

Yes, No

Yes, No (Only when Transparent

Text is OFF.)

(3) Set content

Item PCL6 PCL5e

Copies 1 to 999

Orientation Portrait, Landscape

Document Style

Paper Source

Paper Size

N-Up Printing 1-Up, 2-Up, 4-Up

Border On, Off

Fit to Page On, Off

Page Protection On, Off

Toner Save Mode On, Off

1-Sided, 2-Sided (Book), 2-Sided

(Tablet)

Auto, Tray 1, Tray 2, Tray 3, Tray

4, Bypass Tray

A3 (297 × 420 mm), B4 (257 ×

364 mm), A4 (210 × 297 mm), A5

(148 × 210 mm), B5 (182 × 257

mm), Ledger (11" × 17"), Letter

(8.5" × 11"), Legal (8.5" × 14"),

Executive (7.25" × 10.5"), Folio

(8.3" × 13"), Invoice (5.5" × 8.5"),

Foolscap (8.5" × 13"), DL, C5,

COM10, Custom Paper

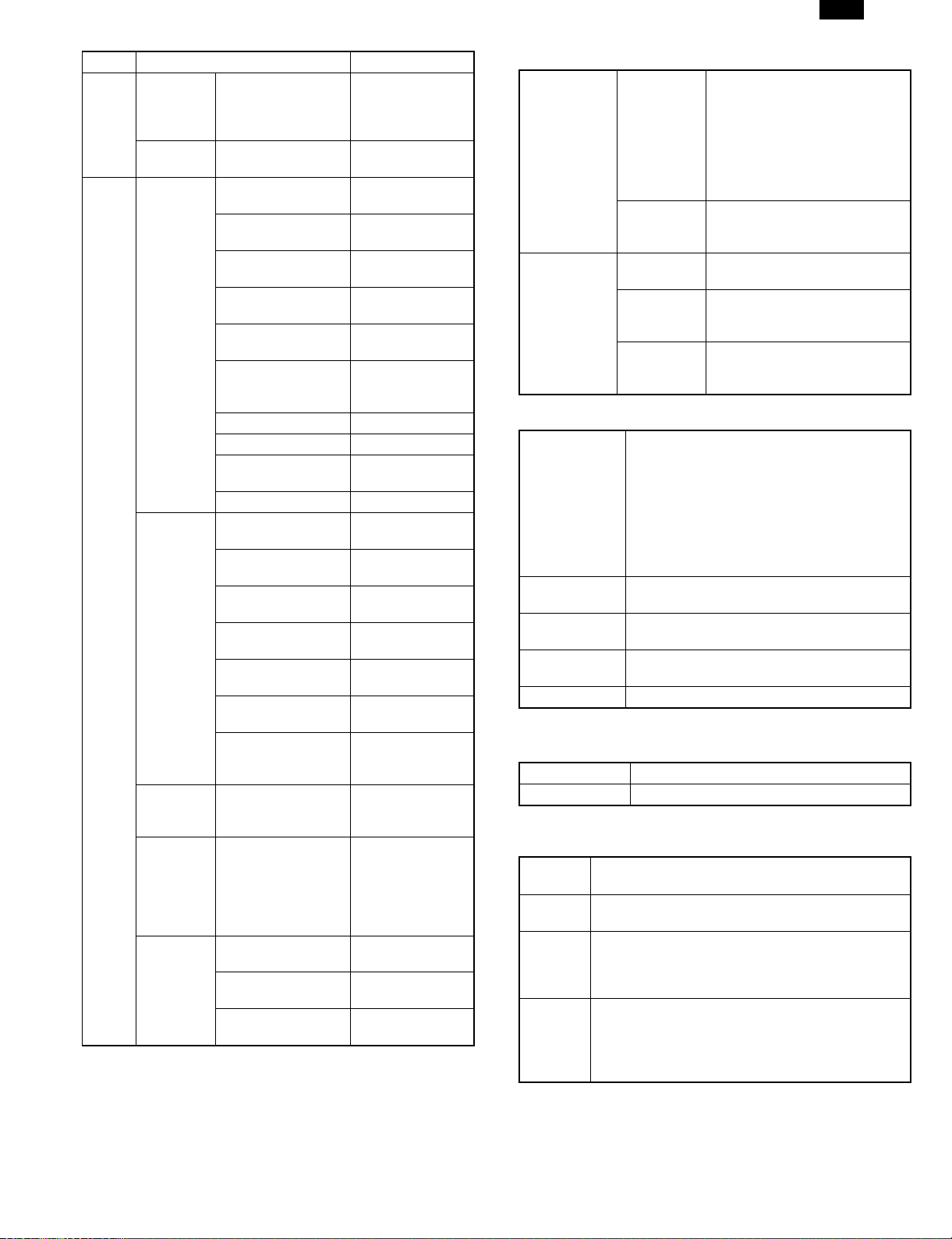

(4) LCD display

a. LCD message

Status LCD display Content

Online Online

Error

2 – 4

Data Loss

Error

Memory

Full

Out of

Paper

AUTO

PCL PCL

PS2 PS2

HEX HEX

Press ENTER

Press ENTER

Tray 1 <Paper Size>

Tray 2 <Paper Size>

Tray 3 <Paper Size>

Tray 4 <Paper Size>

Bypass

<Paper Size>

Tray <Paper Size>

Auto select to

emulation

When the paper

feed tray is

selected to other

than AUTO.

When the paper

feed tray is

selected to AUTO.

Page 9

Status LCD display Content

Toner empty

Error

User

setting

Check

Panel

Clear

Paper Path

Copies

Resolution

Smoothing

Toner Save

Main Menu

Network

Menu

PS2 Menu Print PS2 Error

Interface

Menu

Test

Printing

Menu

Page Protection

2-Sided Printing

Paper Source Tray select

Paper Size Paper size select

Orientation

Emulation Emulation setting

Set IP Address

Set Subnet Mask

Set Default Gateway

Enable TCP/IP

Enable Netware

Enable EtherTalk

Reset to Defaults

I/O Time Out

Configuration Page

PCL Font List

PS2 Font List

Drum replacement

Cover open

Service call error

Paper jam

Paper exit tray full

Printing of the set

quantity is made.

Printing at the set

resolution is made.

Smoothing

function setting.

Toner save mode

setting

Setting of page

protection function

Setting of duplex

function and

binding direction

Setting of print

direction

IP address

setting is made.

Subnet Mask

setting is made.

Default Gateway

setting is made.

Enable/Disable

TCP/IP

Enable/Disable

Netware

Enable/Disable

EtherTalk

Reset Print

Server Card to

default

Setting of printing

in case of PS

Error

If data reception

is not completed

within the set

time, it is judged

as a time out

error.

Configuration

page is printed.

PCL6 Font page

is printed.

PS2 Font page is

printed.

DM-2000

b. LED display

Indicates that the printer is offline and data cannot be

transferred or printed. Make

Extinguished

ON LINE light

Lit

Extinguished

DATA light

c. Operation keys

LINE key

MENU key

ITEM key

Left arrow key

Right arrow key

ENTER key Used to enter a new value.

∗ Invalid when the printer is on-line.

(5) Network board

10/100 Base TX TCP/IP, IPX/SPX, Ether Talk

10 Base T/2 TCP/IP, IPX/SPX, Ether Talk

(6) PC environment

a. In the case of IBM PC/AT or compatible computers

Computer

Type

Operating

System

CPU

RAM

Lit

Blinking

Changes between the on-line and off-line

modes.

When the printer is on-line, it can receive

data from the computer with which it is

connected.

When the printer is off-line, you can use

operation panel keys to make print settings.

Note, however, that you cannot make settings

if the “Data Remaining” message is displayed.

Used to show setting menus on the display in

sequence.∗

Used to show the setting items of the

selected menu in sequence.∗

Used to change the value of any item.∗

IBM PC/AT or compatible computer equipped with a

bi-directional parallel interface and CD-ROM drive

Windows 95, Windows 98, Windows NT4.0

Windows 3.1

Windows 95: 486SX or better

Windows 98: 486DX/66MHz or better (Pentium or

better is recommended.)

Windows NT4.0: 486/25MHz or better

Windows 95: 8 MB or more (12 MB or more is

recommended.)

Windows 98: 16 MB or more (32 MB or more is

recommended.)

Windows NT4.0: 16 MB or more

settings from the operation

panel in this mode. Note,

however, that you cannot make

settings if the “Data Remaining”

message is displayed.

Indicates that the printer is online and data can be transferred

and printed.

Indicates that there is no data

being received or processed.

Indicates that the printer is

receiving or processing print

data.

Indicates that there is print data

remaining in memory that has

not yet been printed.

2 – 5

Page 10

DM-2000

b. In the case of Macintosh

Computer

Type

Operating

System

CPU MC68040 or Power PC micro processor

RAM

Macintosh computer

Macintosh System 7.5 to 8.5

16MB or more for Power PC micro processor

machine

12MB or more for 68040 machine

Side set to the

paper feed port

Transport direction

ABC...

= Long side

Side set to the

paper feed port

Transport direction

= Short side

(7) Expansion memory

Memory expansion realizes the following effects.

● Increased processing speed of outline fonts or complex graphic data.

● Shorter release time from a printing job of the computer.

● Allows high resolution printing.

● Complex data can be printed without data loss error or memory full

error.

Type

DIMM (60ns/EDO/168pin) (Use commercially

available one.)

Capacity 64 MB, 32 MB, 16 MB

Vendor Capacity Model name

Recommendable

product

Viking

Components

Kingston

Simple

Technology

Transcend

16 MB

32 MB

64 MB

16 MB

32 MB

64 MB

16 MB

64 MB

16 MB

32 MB

32 MB

64 MB

VE2641U2EN3-60

VE4641U4EN3-60

VE8641U4EN3-60

KTA4400/16

KTM4X64VN42-60EG

KTM8X64VN84-60EG

STI642004UD1-60VG

STI648104UD1-60VG

TS2MLE64V6PN

TS4MLE64V6TN

TS4MLE64V6UN

TS8MLE64V6VN

(8) Paper handling specifications

a. Paper feed direction

<1> Paper size and image transport direction

Paper Size Side set to the paper feed port

A3 Short side

B4 Short side

A4 Long side

A4R Short side

B5 Long side

B5R Short side

A5 Long side

A5R Short side

Ledger Short side

Legal Short side

Letter Long side

LetterR Short side

Invoice Long side

InvoiceR Short side

Foolscap Short side

Folio Short side

Executive Short side

COM-10 Short side

C5 Short side

DL Short side

ABC...

For paper feed of the multi bypass tray, the short side must be set

to the paper fed port regardless of paper size for making print data.

b. Paper feed port

Tray kind

Capacity

Bypass

Tray

100

sheets

Tray 1 Tray 2 Tray 3 Tray 4

250

sheets

250

sheets

250

sheets

250

sheets

A3

B4

A4

A4R

B5

B5R

A5

A5R

Ledger

Legal

Letter

LetterR

Invoice

InvoiceR

Foolscap

Folio

Executive

COM-10

C5

DL

Custom

∗ The number of trays supported depends on each model.

∗ When printing with the multi bypass tray, the printer board cannot

recognize the set paper direction, and therefore it regards that the

short side of paper would be set (vertical transport direction) to make

data.

c. Tray selection

Paper handling is controlled on the copier side. The printer board

sends the Video I/F command to the digital copier according to the

computer direction of the tray.

2 – 6

Page 11

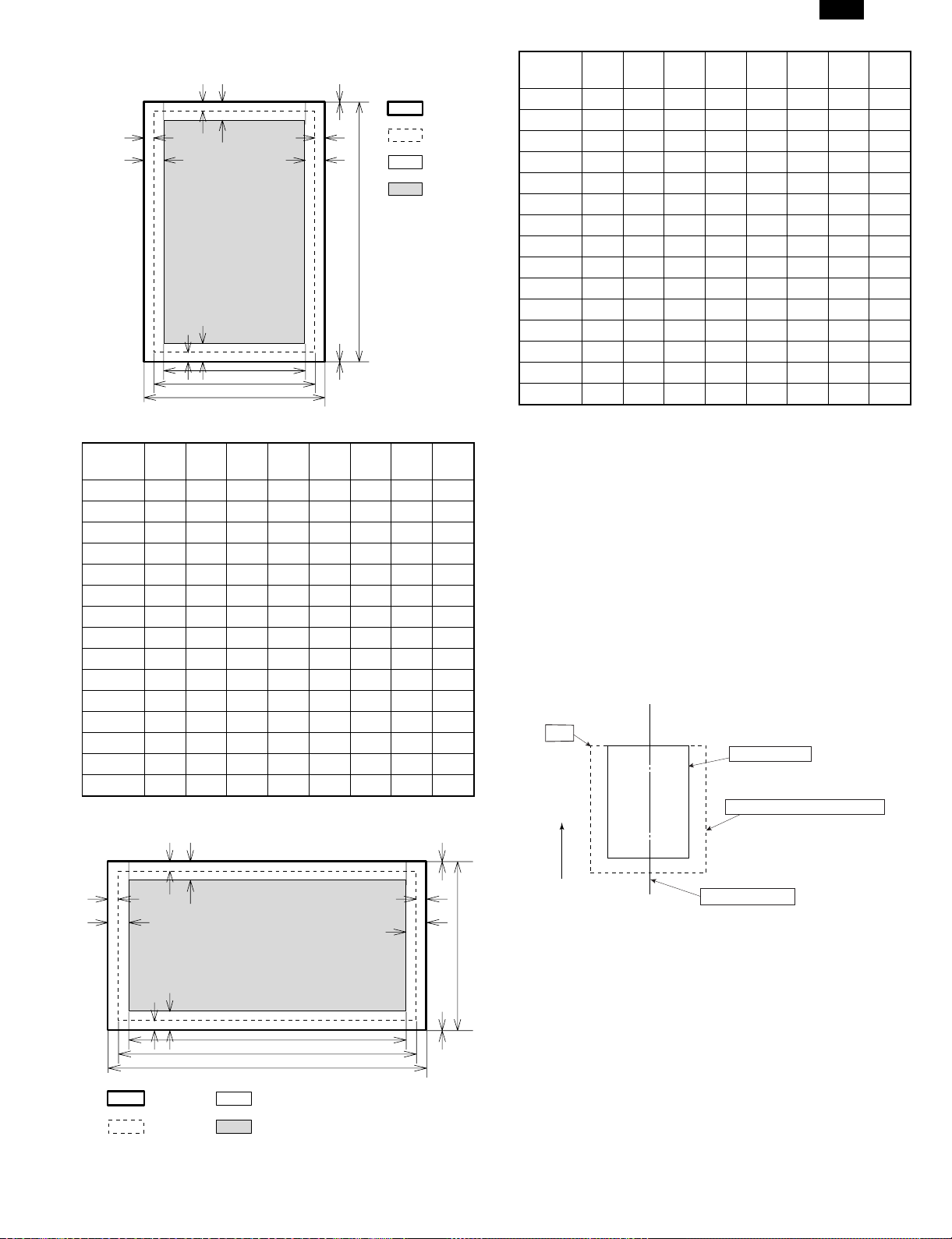

(9) Print Area

H

Physical

Page

EE

D

F

E

Paper

size

ABCDEFGH

F

C

G

A

E

D

B

H

Printable

Area

Logical

Page

HP/GL

Picture

Frame

A3 7014 9920 6730 142 100 300 6814 0

B4 6070 8597 5786 142 100 300 5870 0

A4 4960 7014 4676 142 100 300 4760 0

B5 4298 6070 5770 142 100 300 4098 0

A5 3508 4960 3224 142 100 300 3308 0

Ledger 6600 10200 6300 150 100 300 6400 0

Legal 5100 8400 4800 150 100 300 4900 0

Letter 5100 6600 4800 150 100 300 4900 0

Invoice 3300 5100 3000 150 100 300 3100 0

Foolscap 5100 7800 4800 150 100 300 4900 0

Folio 4980 7800 4680 150 100 300 4780 0

Executive 4350 6300 4050 150 100 300 4150 0

COM-10 2474 5700 2174 150 100 300 2274 0

C5 3826 5408 3542 142 100 300 3626 0

DL 2598 5196 2314 142 100 300 2398 0

(Unit: Dots/600DPI)

DM-2000

PAPER

SIZE

A3 9920 7014 9684 118 100 300 9720 0

B4 8597 6070 8361 118 100 300 8397 0

A4 7014 4960 6778 118 100 300 6814 0

B5 6070 4298 5830 118 100 300 5870 0

A5 4960 3508 4720 118 100 300 4760 0

Ledger 8400 5100 8160 120 100 300 8200 0

Legal 8400 5100 8160 120 100 300 8200 0

Letter 6600 5100 6360 120 100 300 6400 0

Invoice 5100 3300 2860 120 100 300 4900 0

Foolscap 7800 5100 7560 120 100 300 7600 0

Folio 7800 4980 7560 120 100 300 7600 0

Executive 6300 4350 6060 120 100 300 6100 0

COM-10 5700 2474 3460 120 100 300 5500 0

C5 5408 3826 5172 118 100 300 5208 0

DL 5196 2598 4960 118 100 300 4996 0

∗ Top Margin

The set value is received from the digital copier and data are made according to the set value.

∗ Left margin

Since the paper size sensor is not set, the digital copier does not know

the size and direction of paper inserted. Therefore, the left margin is

set according to the paper size indicated by the print data sent from the

computer, and printing is made. If the computer does not specify the

paper size or in the case of custom size, the left margin is set according to the default paper size.

(10) Print reference

This machine employs the center reference system.

Since the digital copier is not equipped with the paper size detection,

format is made not by the actual paper size, but by the paper size

specified by the computer, and center distribution is made.

Origin

Paper feed direction

ABCDEFGH

(Unit: Dots/600DPI)

ABCDEFGHIJKLMN

12345

abc

Actual paper size

Size specified by the host computer

EE

D

F

E

Physical

Page

Printable

Area

F

C

G

A

Logical

Page

HP/GL

Picture

Frame

H

E

D

B

H

Center reference line

2 – 7

Page 12

DM-2000

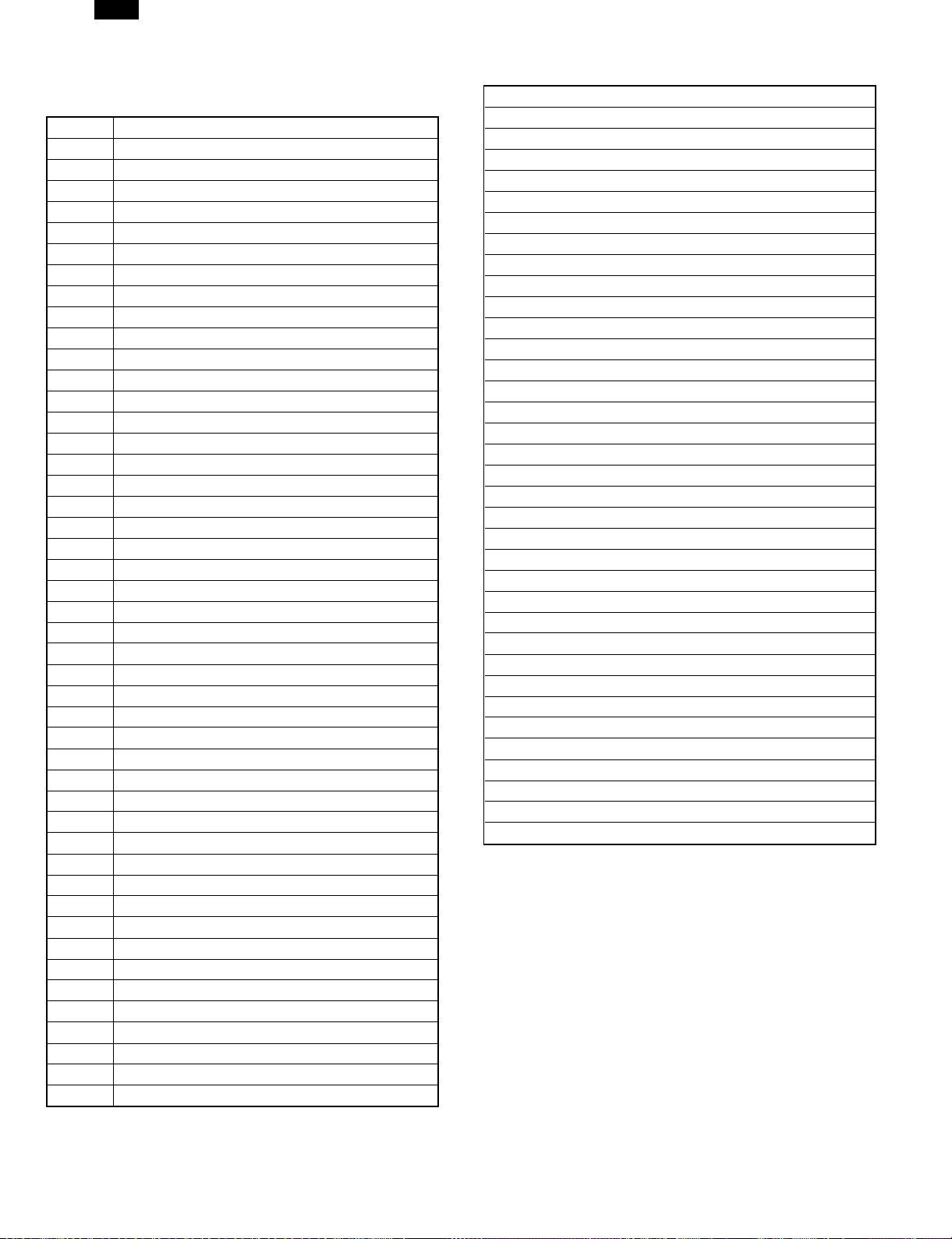

(11) Font

a. For PCL

TrueDoc Format 45 fonts

1 bitmap font

Font No. Font Name

0 Fixed Pitch 810 Courier Roman SWC

1 DutchTM 801 SWC

2 Dutch 801 Bold SWC

3 Dutch 801 Italic SWC

4 Dutch 801 Bold Italic SWC

5 Zapf Humanist 601 SWC

6 Zapf Humanist 601 Bold SWC

7 Zapf Humanist 601 Italic SWC

8 Zapf Humanist 601 Bold Italic SWC

9 Ribbon 131 SWC

10 Clarendon 701 Clarendon Condensed SWC

11 SwissTM 742 SWC

12 Swiss 742 Bold SWC

13 Swiss 742 Italic SWC

14 Swiss 742 Bold Italic SWC

15 Swiss 742 Condensed SWC

16 Swiss 742 Condensed Bold SWC

17 Swiss 742 Condensed Italic SWC

18 Swiss 742 Condensed Bold Italic SWC

19 Incised 901 SWC

20 Incised 901 Bold SWC

21 Incised 901 Italic SWC

22 Aldine 430 Original Garamond SWC

23 Aldine 430 Original Garamond Bold SWC

24 Aldine 430 Original Garamond Italic SWC

25 Aldine 430 Original Garamond Bold Italic SWC

26 Audrey Two SWC

27 Flareserif 821 SWC

28 Flareserif 821 Extra Bold SWC

29 Swiss 721 SWM

30 Swiss 721 Bold SWM

31 Swiss 721 Oblique SWM

32 Swiss 721 Bold Oblique SWM

33 Dutch 801 SWM

34 Dutch 801 Bold SWM

35 Dutch 801 Italic SWM

36 Dutch 801 Bold Italic SWM

37 Symbol SWA

38 Wingbats SWM

39 Fixed Pitch 810 Courier Bold SWC

40 Fixed Pitch 810 Courier Italic SWC

41 Fixed Pitch 810 Courier Bold Italic SWC

42 Fixed Pitch 850 Letter Gothic 12 pitch/text SWC

43 Fixed Pitch 850 Letter Gothic Bold 12 pitch/text SWC

44 Fixed Pitch 850 Letter Gothic Italic 12 pitch/text SWC

45 Line Printer

b. For PS2

Font Name

Dutch 801 SWA

DutchTM 801 Bold SWA

Dutch 801 Italic SWA

Dutch 801 Bold Italic SWA

SwissTM 721 SWA

Swiss 721 Bold SWA

Swiss 721 Oblique SWA

Swiss 721 Bold Oblique SWA

Fixed Pitch 810 Courier® SWA

Fixed Pitch 810 Courier Bold SWA

Fixed Pitch 810 Courier Italic SWA

Fixed Pitch 810 Courier Bold Italic SWA

Symbol SWA

Century 702 Century Schoolbook SWA

Century 702 Century Schoolbook Italic SWA

Century 702 Century Schoolbook Bold SWA

Century 702 Century Schoolbook Bold Italic SWA

Revival 711 ITC Bookman SWA

Revival 711 ITC Bookman Italic SWA

Revival 711 ITC Bookman® Demi SWA

Revival 711 ITC Bookman Demi Italic SWA

Swiss 721 Narrow Bold SWA

Swiss 721 Narrow Bold Oblique SWA

Swiss 721 Narrow SWA

Swiss 721 Narrow Oblique SWA

Geometric 711 ITC Avant Garde Gothic® Book SWA

Geometric 711 ITC Avant Garde Gothic Book Oblique SWA

Geometric 711 ITC Avant Garde Gothic Demi SWA

Geometric 711 ITC Avant Garde Gothic Demi Oblique SWA

Chancery 801 ITC Zapf Chancery® Medium Italic SWA

ITC Zapf Dingbats® SWA

Zapf Calligraphic 801 SWA

Zapf Calligraphic 801 Bold SWA

Zapf Calligraphic 801 Italic SWA

Zapf Calligraphic 801 Bold Italic SWA

2 – 8

Page 13

DM-2000

[3] CONSUMABLE PARTS

1. Supply system table

A. USA

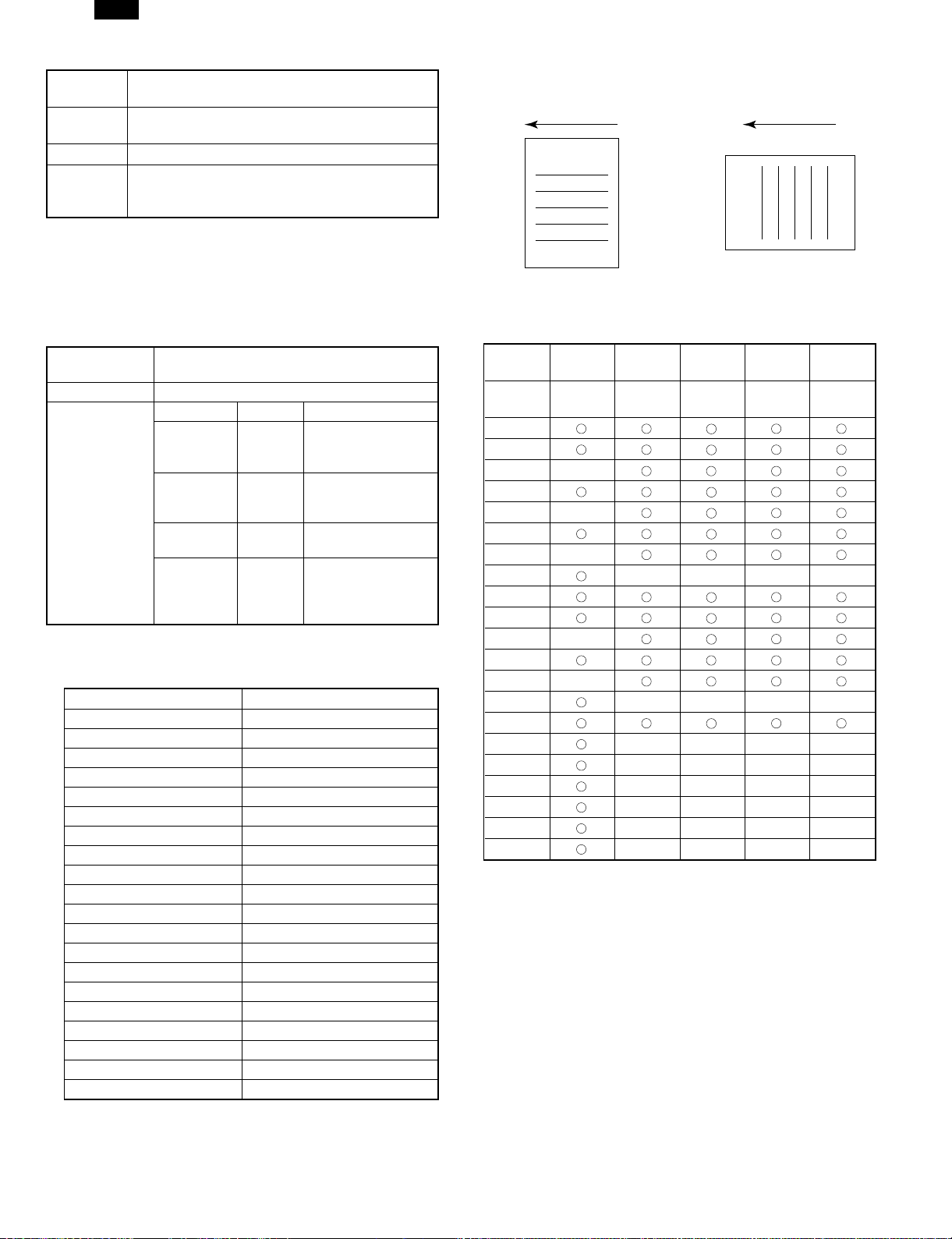

No. Name Content Life Product name Package Remark

1 Developer cartridge

(Black)

2 Drum cartridge Drum cartridge × 1 30K DM-200DR 4

Note: Maintenance parts other than mentioned above must be ordered through the parts department using the proper part number.

B. U.K.

No. Name Content Life Product name Package Remark

1 Developer cartridge

(Black)

2 Drum cartridge

Toner/developer cartridge

(Toner: 610 g, Developer: 395 g)

Postcard label

(TLABZ0025YSZZ)

Returned Operation Manual × 1

Vinyl bag × 1

Warranty Card × 1

Warranty Card × 1

Toner/developer cartridge

(Toner: 610 g, Developer: 395 g)

Returned Operation Manual × 1

Vinyl bag (TINSZ0031YSZZ) × 1

Drum cartridge × 1

× 1

× 1

× 1

15K DM-200TD 4 Life setting by A4 (8.5" ×

11") 6% documents

15K DM-200TD 4 Life setting by A4 6%

documents

30K DM-200DR 4

Note: Maintenance parts other than mentioned above must be ordered through the parts department using the proper part number.

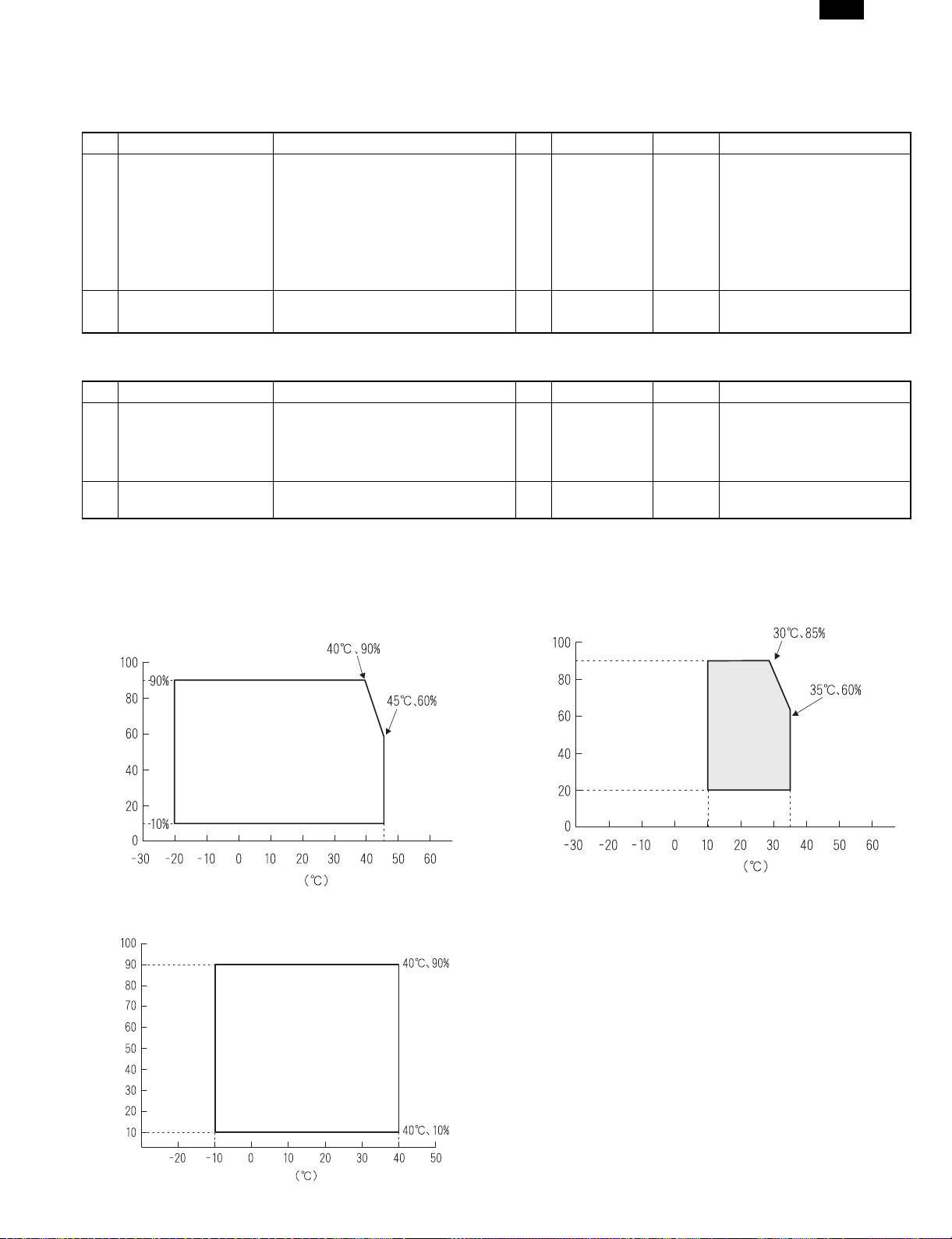

2. Environment conditions

A. Transport condition

(1) Transport conditions

Humidity (%)

Temperature

(2) Storage conditions (packed conditions)

B. Use conditions

Use environment

conditions

Humidity (%)

Temperature

C. Life (packed conditions)

Photoconductor drum (36 months from the production month)

Developer, toner (24 months from the production month)

Humidity (%)

Temperature

3 – 1

Page 14

DM-2000

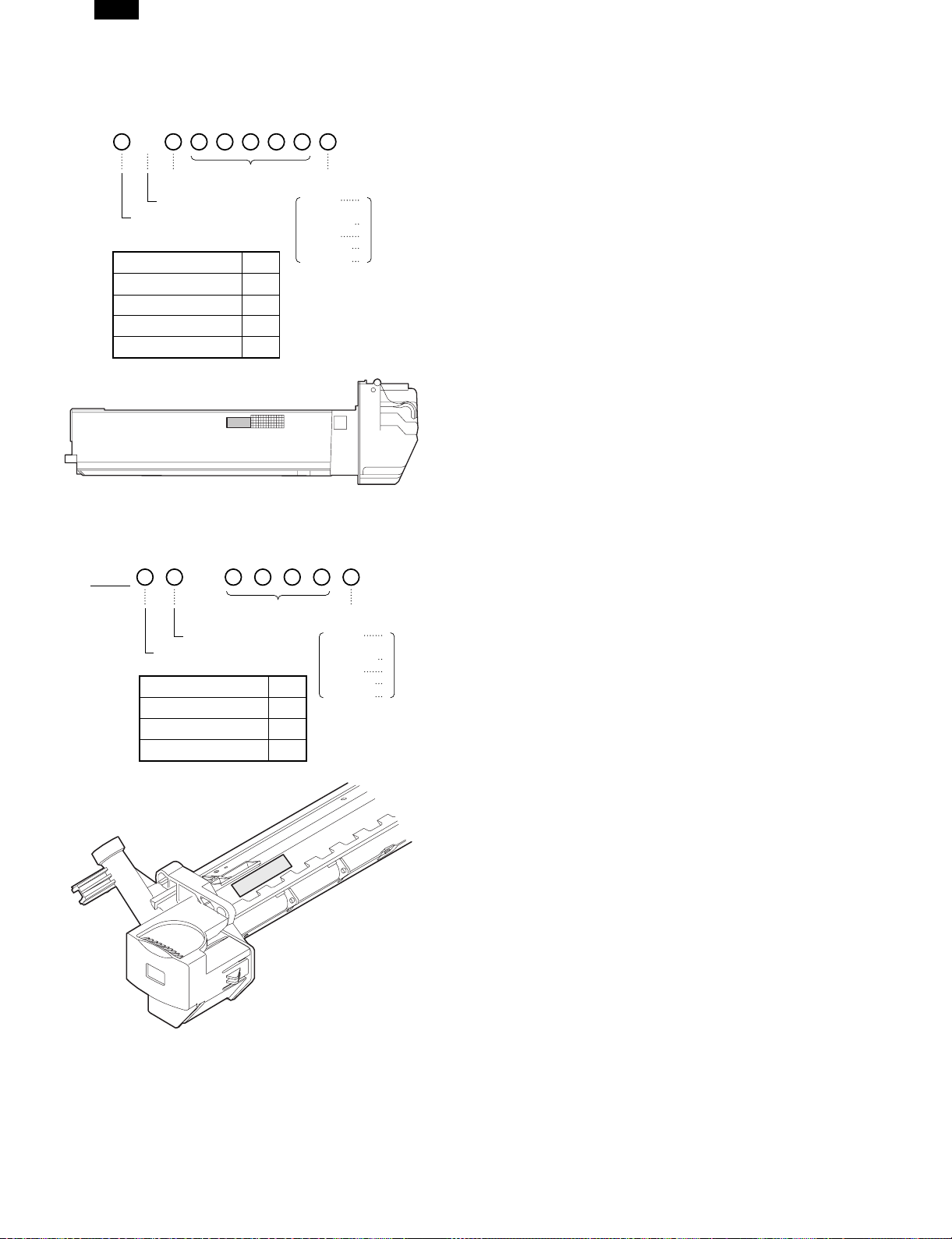

3. Production number identification

<Developing cartridge>

The label on the drum cartridge shows the date of production.

B

Destination

(∗)

Indicates production in China.

The end digit of production year

∗: Destination

Division No.

Serial number

(00001-99999)

Production

month

January

~

September

October

November

December

1

~

9

0

X

Y

Japan option 1

Ex option 2

Japan, same pack 6

Ex, same pack 7

<Drum cartridge>

The label on the drum cartridge shows the date of production.

Ver. A

1

Serial number (for each

month) (00001-99999)

Factory

The end digit of production year

Division No.

Ex production 1

Option 2

Same pack 3

Production

month

January

~

September

October

November

December

1

~

9

0

X

Y

3 – 2

Page 15

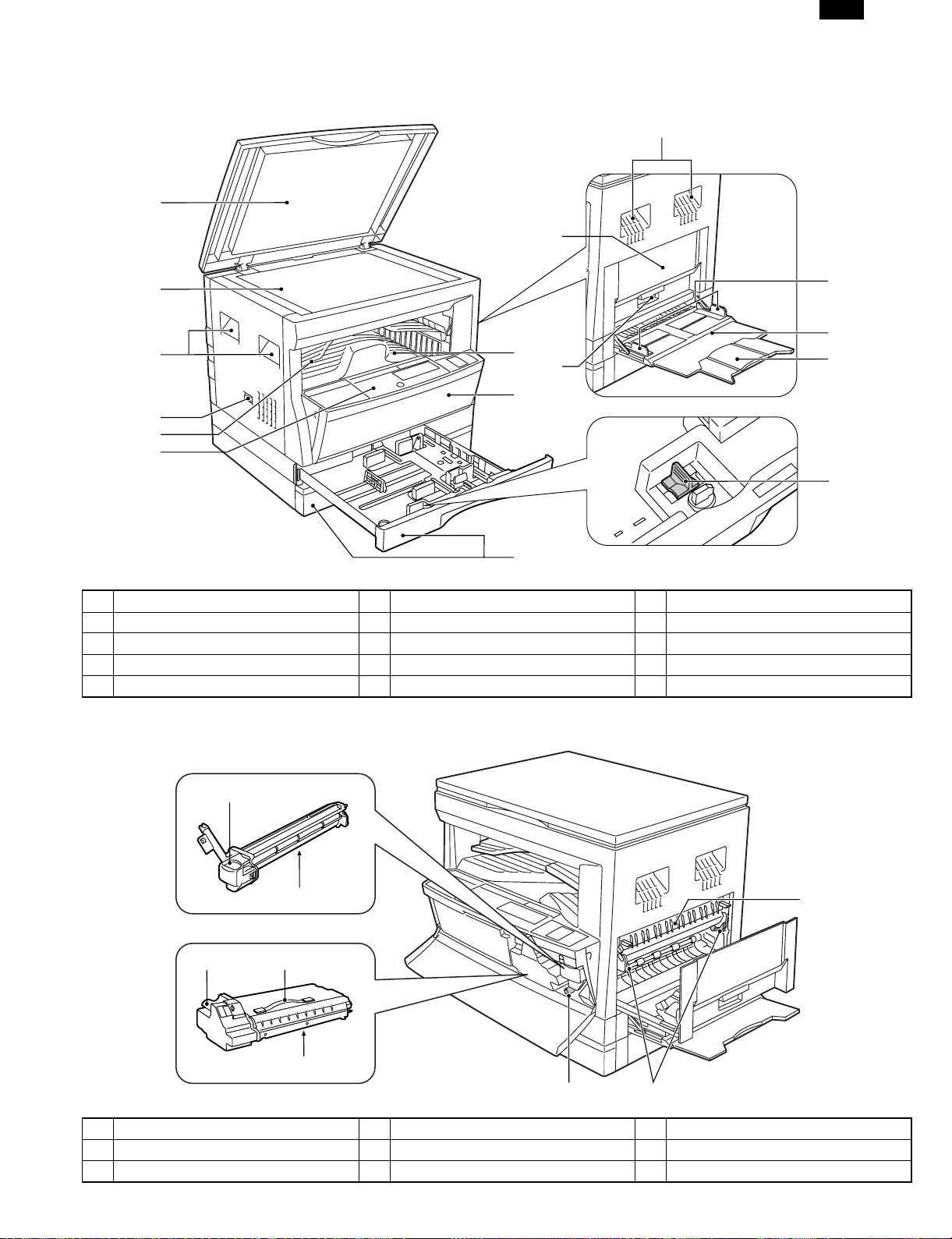

[4] EXTERNAL VIEWS AND INTERNAL STRUCTURES

1. Appearance

1

10

DM-2000

3

2

3

7

11

8

4

5

6

9

1 Platen cover 2 Original table 3 Handles

4 Power switch 5 Job separator tray 6 Operation panel

7 Paper output tray 8 Front cover 9 Paper trays

10 Side cover 11 Side cover handle 12 Bypass tray guides

13 Bypass tray 14 Bypass tray extension 15 Charger cleaner

12

13

14

15

2. Internal

1

2

3

4

5

6

1 Drum cartridge handle 2 Drum cartridge 3 TD cartridge lock release lever

4 TD cartridge strap 5 TD cartridge 6 Roller rotating knob

7 Fusing unit release levers 8 Paper guide

7

8

4 – 1

Page 16

DM-2000

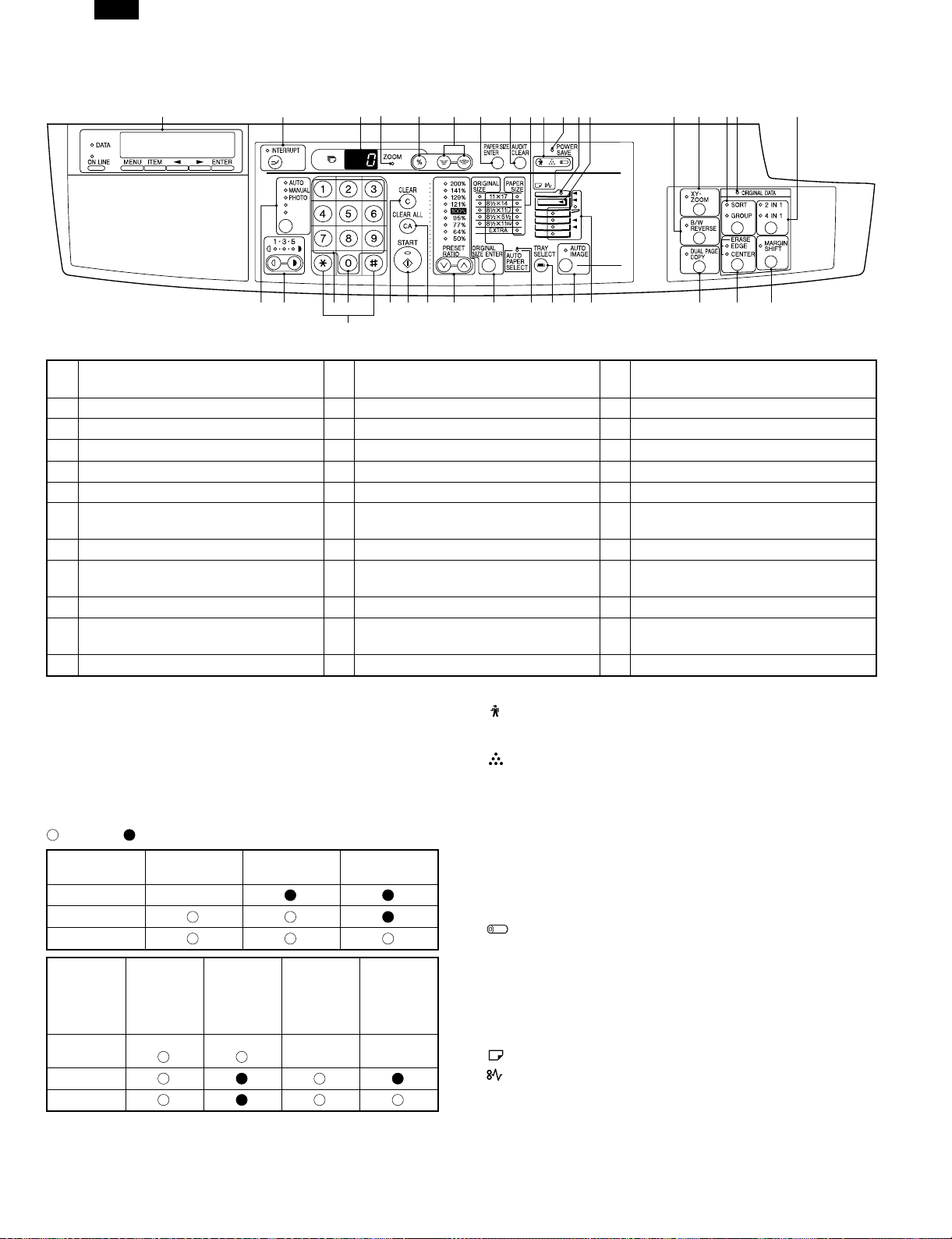

3. Operation Section

6

7

1

Operation panel and keys for printer

1

features

2345

21

19

20

Not used for the copier features.

22

2 INTERRUPT key and indicator 3 Copy quantity display

23 24 25

26

4 ZOOM indicator 5 Copy ratio display key 6 Zoom keys

7 PAPER SIZE ENTER key 8 AUDIT CLEAR key 9 PAPER SIZE indicators

10 Alarm indicators ∗2 11 POWER SAVE indicator ∗1 12 SPF indicator

13 Output tray full indicator 14 B/W REVERSE key and indicator 15 XY-ZOOM key and indicator

16 SORT/GROUP key and indicators 17 ORIGINAL DATA indicator 18 2 IN 1 / 4 IN 1 key and indicators

AUTO/MANUAL/PHOTO key and

19

indicators

20 Light and dark keys and indicators 21 Numeric keys

22 Zero key 23 CLEAR key 24 START key and indicator

25 CLEAR ALL key 26

PRESET RATIO selector keys and

indicators

28 AUTO PAPER SELECT indicator 29 TRAY SELECT key 30 AUTO IMAGE key and indicator

Paper feed location/misfeed location

31

indicators

32 DUAL PAGE COPY key and indicator 33 ERASE key and indicators

34 MARGIN SHIFT key and indicator

891011

27 28

13

12

29

30 31

27

14

15 16 17

32

33 34

18

ORIGINAL SIZE ENTER key and

indicators

∗1

ON: Indicates that the machine is in the energy saving (pre-heat)

mode.

Blink: Indicates that the machine is in the process of resetting from the

energy saving mode or just after supplying the power. (During

warmup)

OFF: Indicates that resetting from the energy saving mode is com-

pleted and that the fusing temperature is in ready state.

The combinations of the above display lamps are as follows:

( = ON, = OFF)

Lamp

Pre-heat lamp Blink

Ready lamp

Other lamps

Lamp

Pre-heat

lamp

Ready lamp

Other lamps

Immediately after

power ON

Energy

saving mode

(Pre-heating)

Energy

saving mode

(Auto power

shut off)

Ready Copying

Resetting

from energy

saving mode

Blink Blink

Copy is

started during

resetting from

energy

saving mode

∗2

Maintenance lamp

When the set count number (set by the simulation) is reached,

the lamp lights up. The machine does not stop.

TD cartridge replacement required indicator

When toner density is lower than a specified level, the TONER

DEVELOPER CARTRIDGE REPLACEMENT indicator lights up

to warn the user.

If toner is not added after approximately 300 sheets are copied,

the indicator starts blinking and machine starts to supply toner.

(Toner Developer cartridge replacement indicator keeps lighting

up)

If toner density is not back to specific level after two minutes, the

READ indicator goes out and Toner Developer indicator starts

blinking, and the copier stops.

Photoconductor cartridge replacement lamp

When the copy count reaches 29,000 after installing a Photoconductor cartridge, the lamp lights up.

When 1,000 copies are made after that, the lamp blinks instead

of lighting. The machine does not stop.

Press and hold the clear key for 5 sec in the user simulation

mode to display the remaining life of the photoconductor cartridge

in 3 digits x 2 lines on the copy quantity display.

Paper required indicator

Misfeed indicator

4 – 2

Page 17

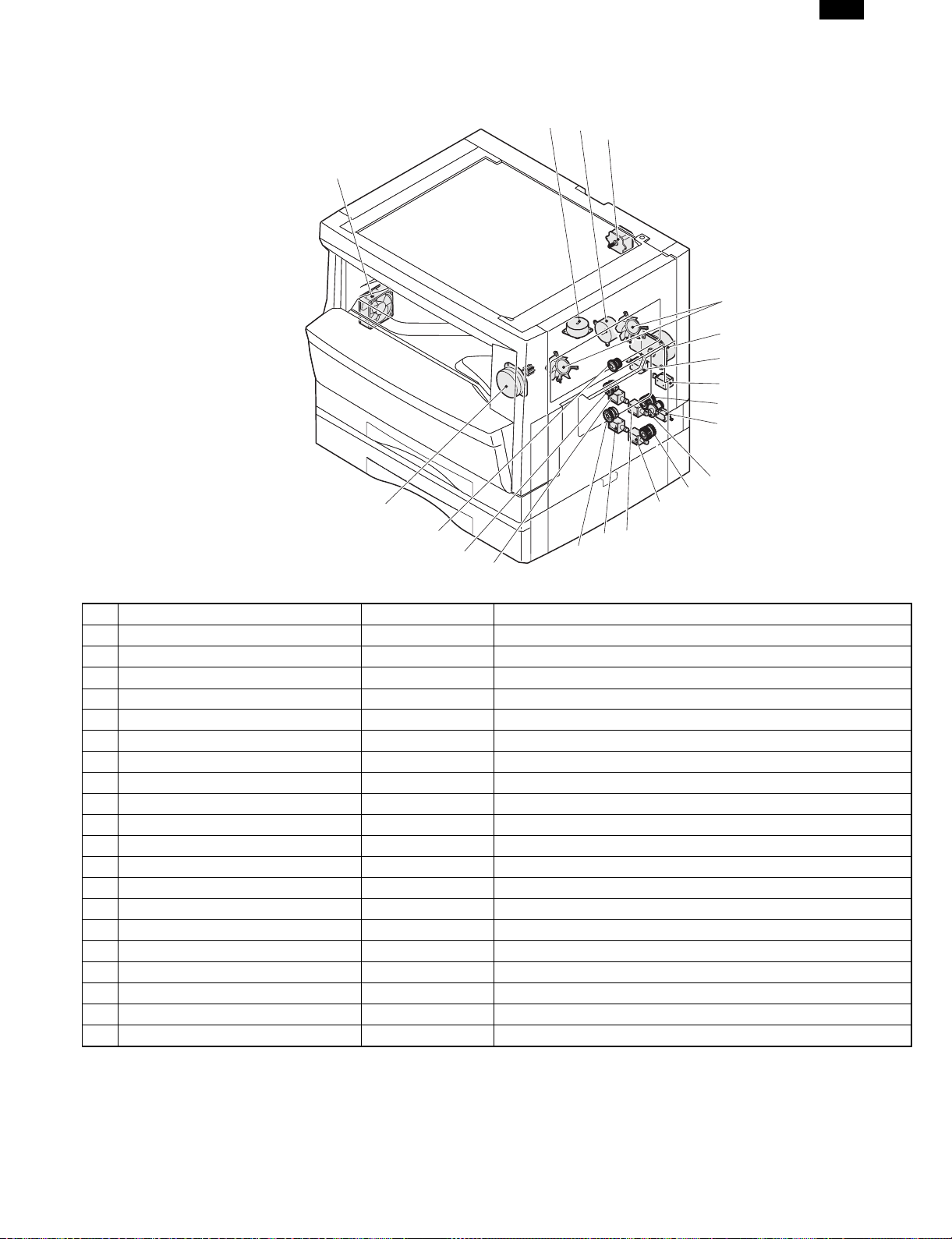

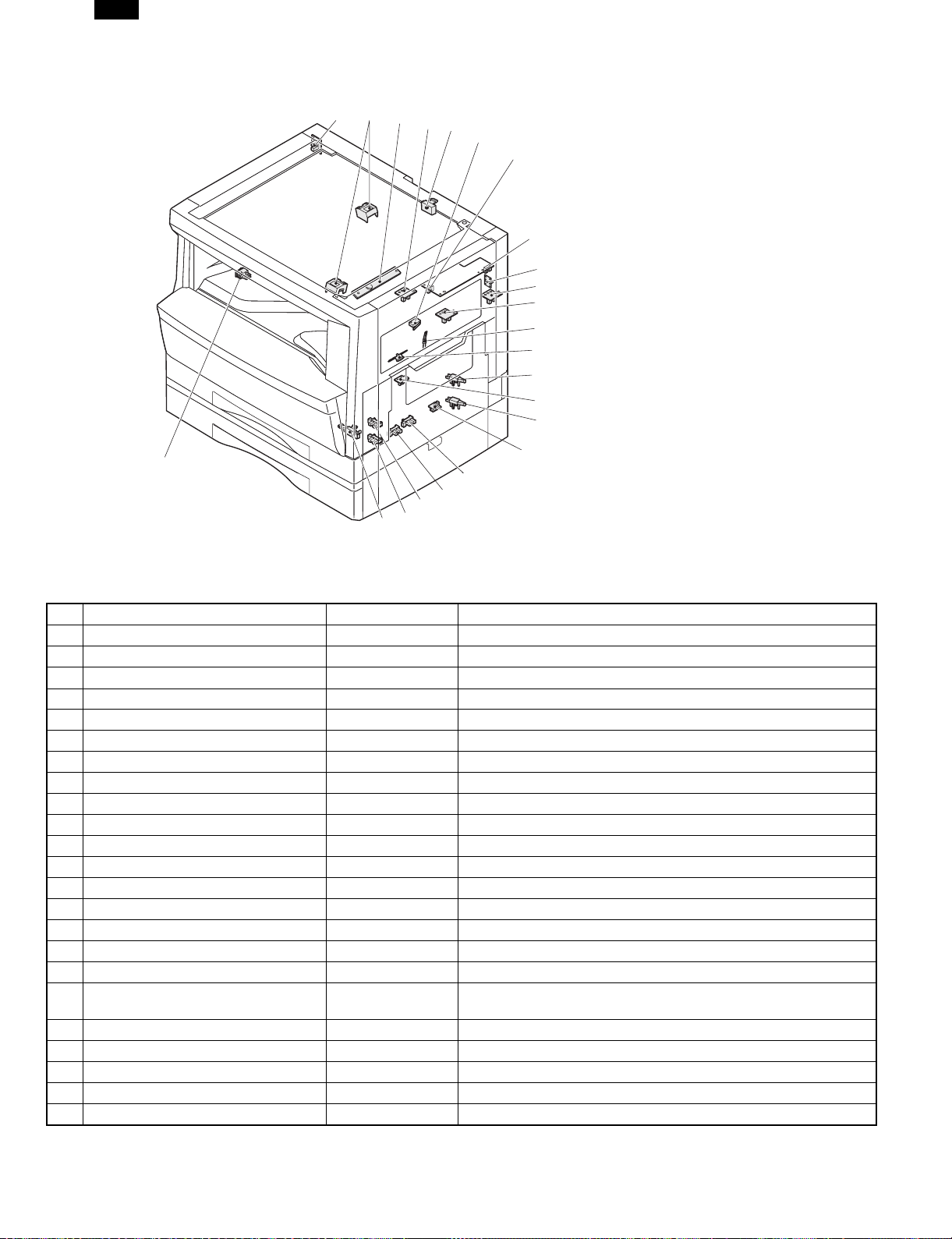

4. Motor, solenoid, clutch

DM-2000

2

3

4

1

5

6

7

8

9

10

11

12

20

13

19

18

17

No. Name Code Function, operation

1 Exhaust fan motor VFM Cools the inside of the machine.

2 Shifter motor SHTM Shifts the paper exit tray.

3 Toner motor TM Toner supply

4 Mirror motor MRM Drives the optical mirror base (scanner unit).

5 Cooling fan motor CFM Cools the inside of the machine.

6 Main motor MM Drives the machine.

7 Paper feed solenoid CPFS1 Solenoid for paper feed from cassette

8 Resist roller solenoid RRS Resist roller rotation control solenoid

9 Manual paper feed clutch MPFC Drives the manual paper feed roller.

10 Manual paper feed solenoid MPFS Manual paper feed solenoid

11 Manual paper transport clutch MPTC Drives the manual paper transport roller.

12 Second tray transport clutch CPFC2 Drives the second tray transport roller.

13 Second tray transport solenoid FSOL2 Second tray transport solenoid

14 First tray transport solenoid FSOL1 First tray transport solenoid

15 Second tray paper feed solenoid PSOL2 Second tray transport solenoid

16 Paper feed clutch CPFC2 Drives the cassette paper feed roller.

17 First tray paper feed solenoid PSOL1 First tray transport solenoid

18 First tray paper feed clutch CPFC1 Drives the first tray transport roller.

19 PS clutch RRC Drives the resist roller

20 Job separator Motor LFTM Drives the Job-separator

16

15

14

4 – 3

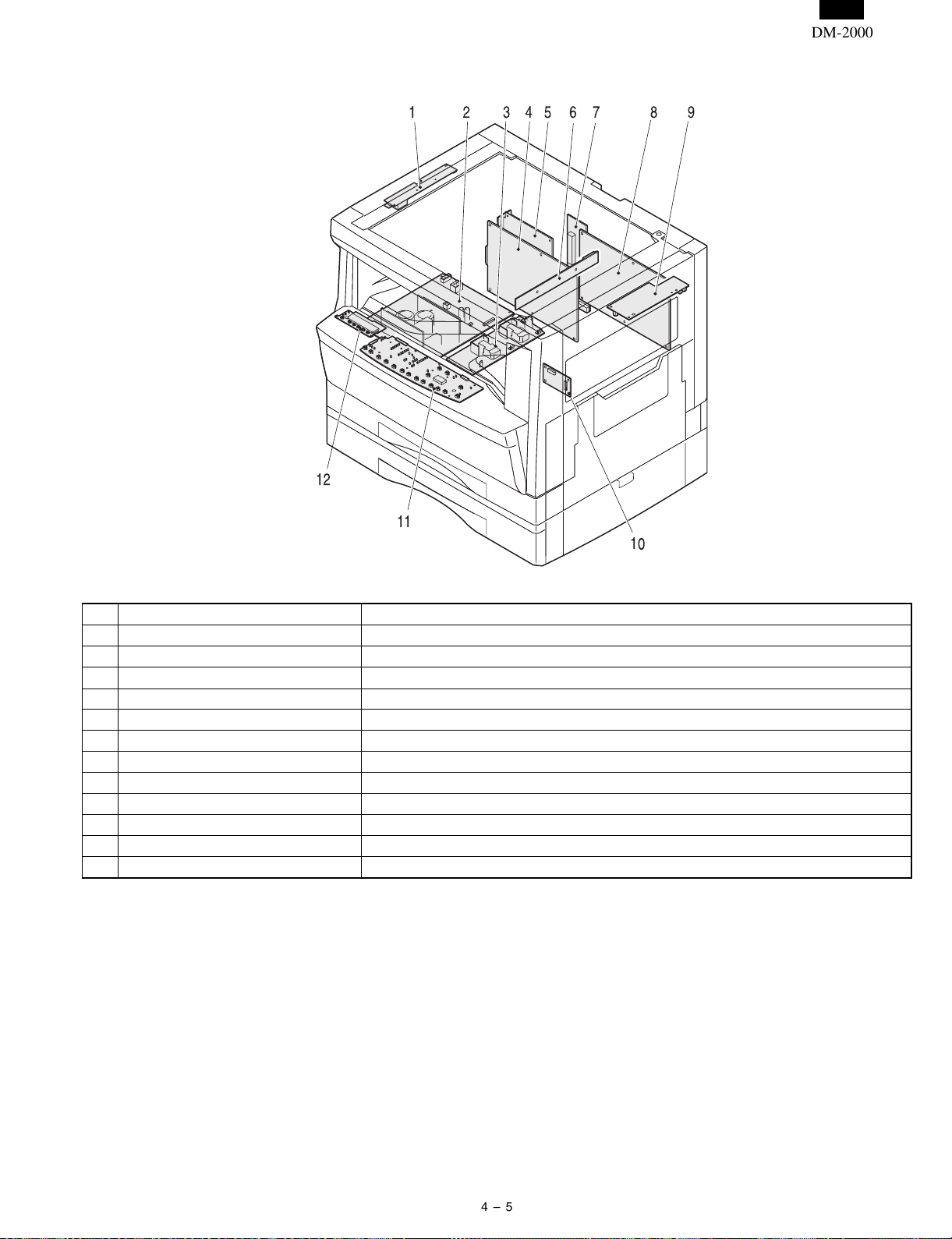

Page 18

DM-2000

5. Sensor, switch

23

123

20

21

22

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

No. Name Code Function, operation

1 Mirror home position sensor MHPS Detects the mirror (scanner unit) home position.

2 Document size sensor DSIN Paper size detection

3 Toner density sensor TCS Toner quantity detection

4 Paper exit sensor (paper exit side) POD1 Detects paper exit.

5 OC open/close sensor DOC COVER OC and SPF open close detection

6 Right door switch DSWR Side door open/close detection

7 Paper full sensor P FULL Paper exit tray section full detection <For JOB separator>

8 Lift sensor LFTHP Paper feed tray lift up detection <For JOB separator>

9 Lower limit sensor JTRAY Job separator tray lower limit detection

10 Paper exit sensor (DUP side) PDPX Paper transport detection

11 Shifter home position sensor SFTHP Shifter home position detection

12 Thermistor RTH Fusing section temperature detection

13 Thermostat Fusing section abnormally high temperature detection

14 1st tray detection switch CSD1 1st tray detection

15 Paper in PIN Paper transport detection

16 2nd tray detection switch CSD2 2nd tray detection

17 Manual sensor MPED Manual transport detection

Second cassette door open/close

18

sensor

19 Second cassette paper entry sensor PPD2 Paper transport detection

20 First tray paper empty sensor CSS1 First tray paper empty detection

21 Second tray paper empty sensor CSS2 Second tray paper empty detection

22 Drum reset switch DRST New drum detection switch

23 Power switch MAIN SW Turns ON/OFF the main power source.

DRS2 Second cassette door open/close detection

4 – 4

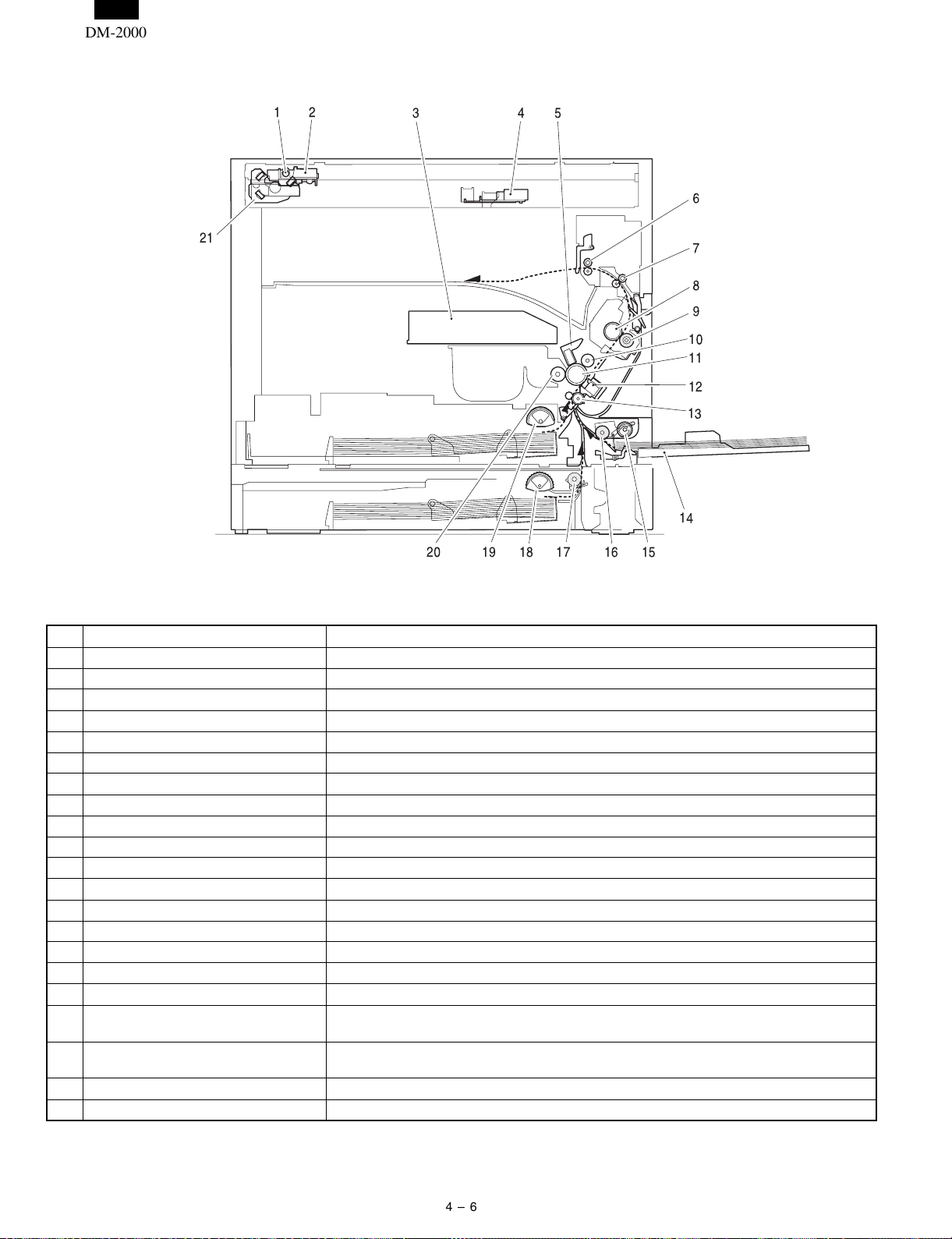

Page 19

6. PWB unit

DM-2000

12

1234965

11

78

10

No. Name Function, operation

1 Copy lamp Inverter PWB Copy lamp control

2 Power PWB AC power input/DC power control

3 High voltage PWB High voltage control

4 Printer control PWB Printer control

5 Network Board Network system interface

6 CCD sensor PWB Image scanning

7 Motor PWB

8 Main PWB (MCU) Machine control/Image process

9 Paper exit interface PWB Paepr exit, finishing control

10 Tray interface PWB Paper tray control

11 Operation main PWB Operation panel input/Display, operation panel section control

12 LCD PWB Printer and FAX status display

4 – 5

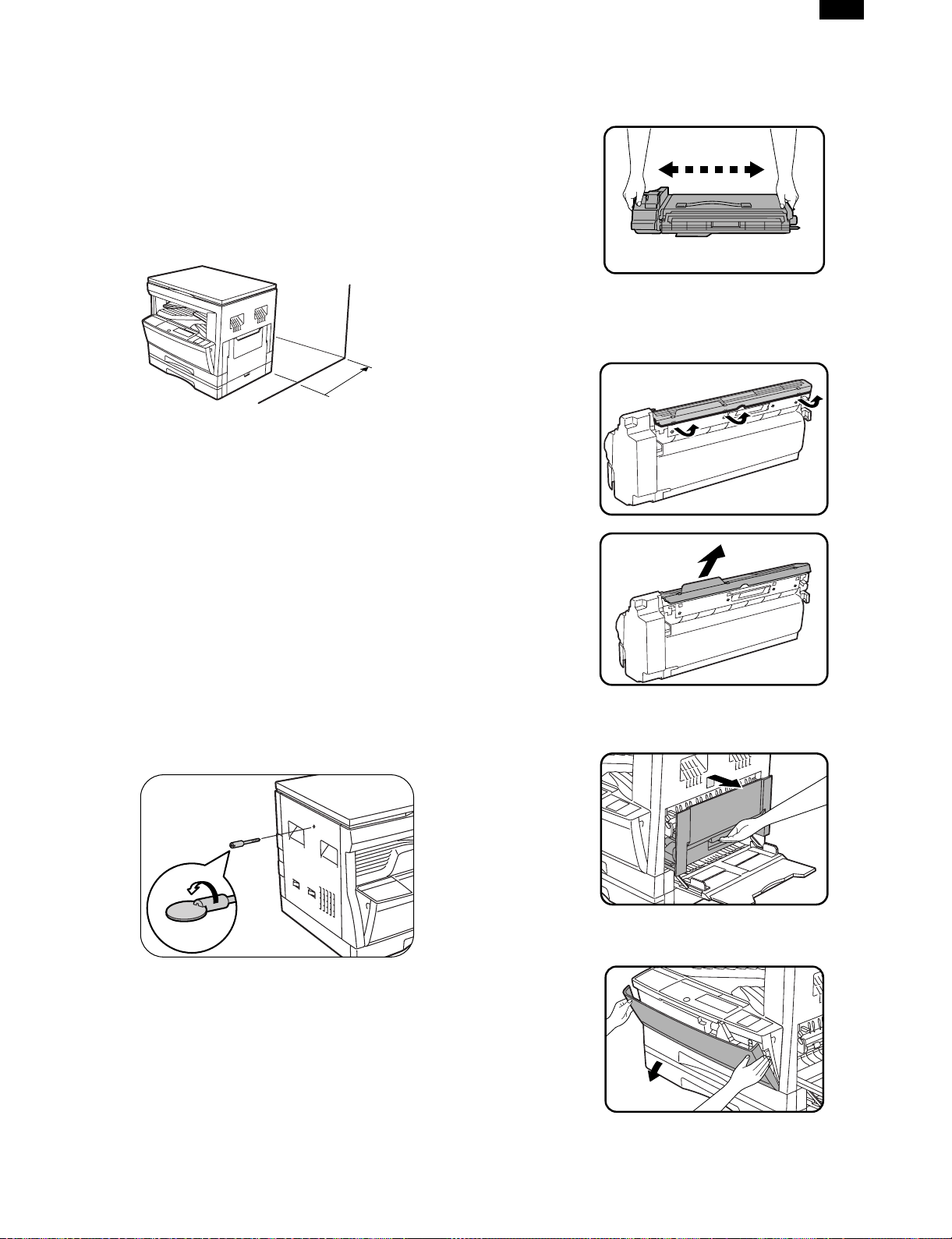

Page 20

DM-2000

7. Cross sectional view

12 3 45

6

21

7

8

9

10

11

12

13

14

15

1617181920

No. Name Function/Operation

1 Copy lamp Image radiation lamp

2 Copy lamp unit Operates in synchronization with No. 2/3 mirror unit to radiate documents sequentially.

3 LSU unit Converts image signals into laser beams to write on the drum.

4 Lens unit Reads images with the lens and the CCD.

5 MC holder unit Supplies negative charges evenly on the drum.

6 Paper exit roller Used to discharge paper.

7 Transport roller Used to transport paper.

8 Upper heat roller Fuses toner on paper (with the teflon roller).

9 Lower heat roller Fuses toner on paper (with the silicon rubber roller).

10 Waste toner transport roller Transports waste toner to the waste toner box.

11 Drum unit Forms images.

12 Transfer charger unit Transfer images (on the drum) onto paper.

13 Resist roller Takes synchronization between the paper lead edge and the image lead edge.

14 Manual paper feed tray Manual paper feed tray

15 Manual paper feed roller Picks up paper in manual paper feed.

16 Manual transport roller Transports paper from the manual paper feed port.

17 2nd tray paper transport roller Transports paper from the 2nd tray

2nd tray paper feed roller (semi-circuit

18

roller)

1st tray paper feed roller (semi-circular

19

roller)

20 MG roller Puts toner on the OPC drum.

21 No. 2/3 mirror unit Reflects the images from the copy lamp unit to the lens unit.

Picks up paper from 2nd tray

Picks up paper from the 1st tray

4 – 6

Page 21

DM-2000

[5] UNPACKING AND INSTALLATION

1. Installing conditions

1) Copier installation

Do not install your copier in areas that are:

● damp, humid, or very dusty

● exposed to direct sunlight

● poorly ventilated

● subject to extreme temperature or humidity changes, e.g., near

an air conditioner or heater.

● Be sure to allow the required space around the machine for servicing and proper ventilation.

4" (10 cm)

2) Power source

● Use an exclusive-use power outlet. If the power plug of this

machine is inserted into a power outlet commonly used with

other illumination units, flickers of the lamp may be result. Use

a power outlet which is not used commonly with any illumination

units.

● Avoid complex wiring.

3) Grounding wire connection.

● To avoid danger, be sure to connect a grounding wire. If no

grounding wire is connected and a leakage occurs, a fire or an

electric shock may be result.

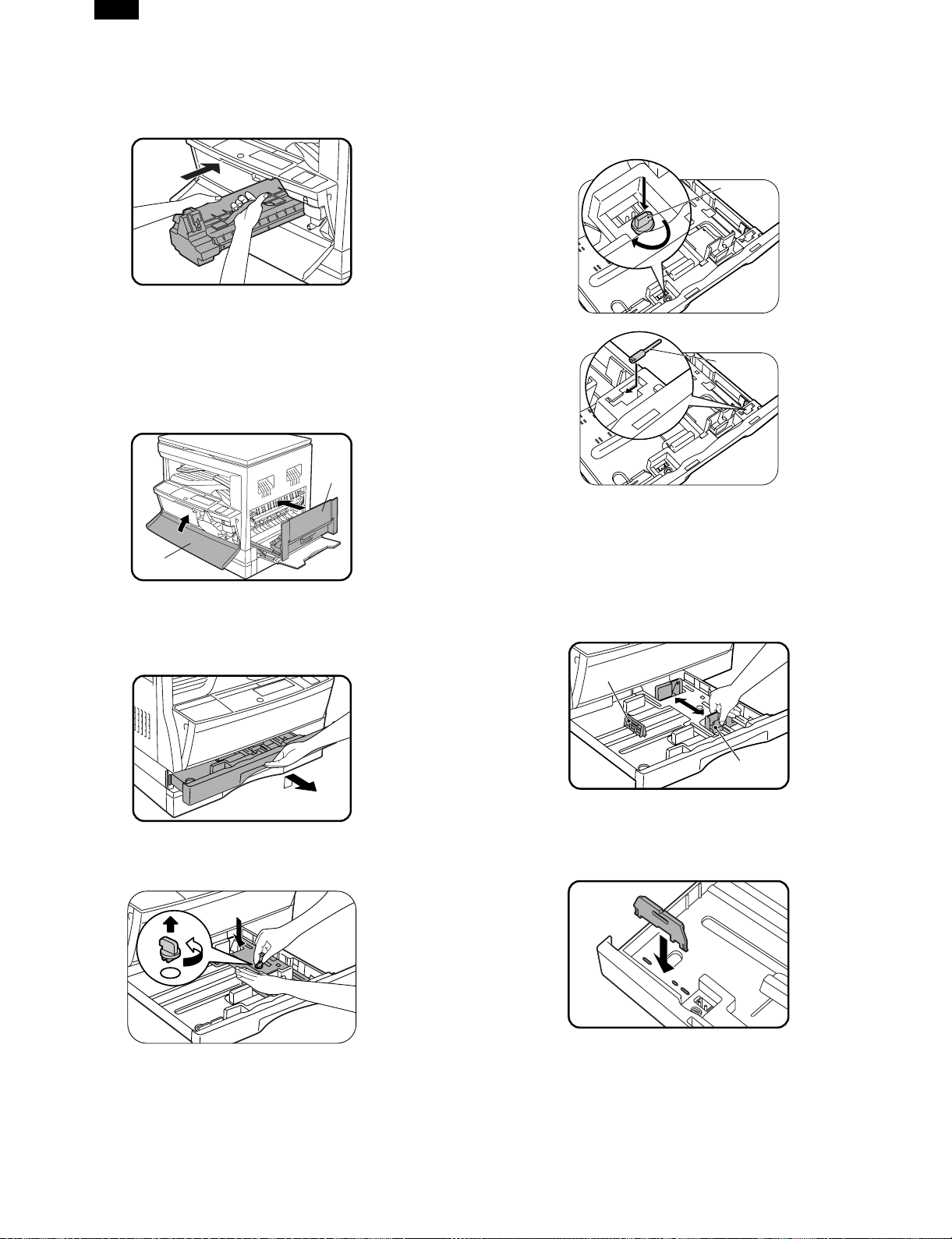

3. Installation of developing cartridge

1) Remove the new TD cartridge from the bag. Hold the cartridge on

both sides and shake it horizontally four or five times.

4 or 5 times

2) Remove the protective cover from the TD cartridge by unlatching

three cover hooks from the holes on the cartridge and then pulling

the cover in the direction indicated by the arrow in the illustration.

2. Removal of protective material and

fixing screw

1) Remove all tapes and protective material.

● Remove all tapes, then open the document cover and remove

the protective material of sheet shape

2) Remove the fixing screw.

● Use a coin to remove the fixing screw.

● The fixing screw is required when transporting the machine.

Keep it in the tray. (Refer to the later description.)

3) Open the bypass tray. Lift slightly on the side cover and slide the

cover out until it stops.

4) Push gently on both sides of the front cover to open the cover.

5 – 1

Page 22

Front guide

Left guide

DM-2000

5) Gently insert the TD cartridge along the guides until it locks in

place.

Note: If dirt or dust is adhered to the TD cartridge, remove it

before installing the cartridge.

6) Close the front cover by pushing both sides with your hands and

then close the side cover by pressing the handle on the cover.

The indicator will go out.

Cautoion: When closing the covers, be sure to close the front

cover securely and then close the side cover. If the

covers are closed in the wrong order, the covers may

be damaged.

B

3) Store the fixing pin and the fixing screw in the tray.

● Store the fixing screw which was removed in the above procedure 2 and the fixing screw which was removed in procedure 2

of 2.

● Removal of protective material and fixing screw in the storage

place in the tray.

Pressure

plate

lock

Screw

A

4. Removal and storage of fixing screw

1) Gently lift and pull out the paper tray until it stops.

2) Hold the paper pressure plate and turn the fixing screw in the

arrow direction.

5. Changing the copy paper size in the

tray

1) Gently lift and pull out the paper tray until it stops.

2) Push the pressure plate down until it locks in place.

3) Squeeze the lock lever of the front guide and slide the front guide

to match the width of the paper.

4) Move the left guide to the appropriate slot as marked on the tray.

● When using 11" ×17" copy paper, store the left guide in the slot

at the left front of the paper tray.

5) Load copy paper into the tray.

6) Place the appropriate label to indicate the selected paper size into

the recess on the right front side of the paper tray.

7) Push the paper tray firmly back into the DM System.

8) Turn the power switch on.

5 – 2

Page 23

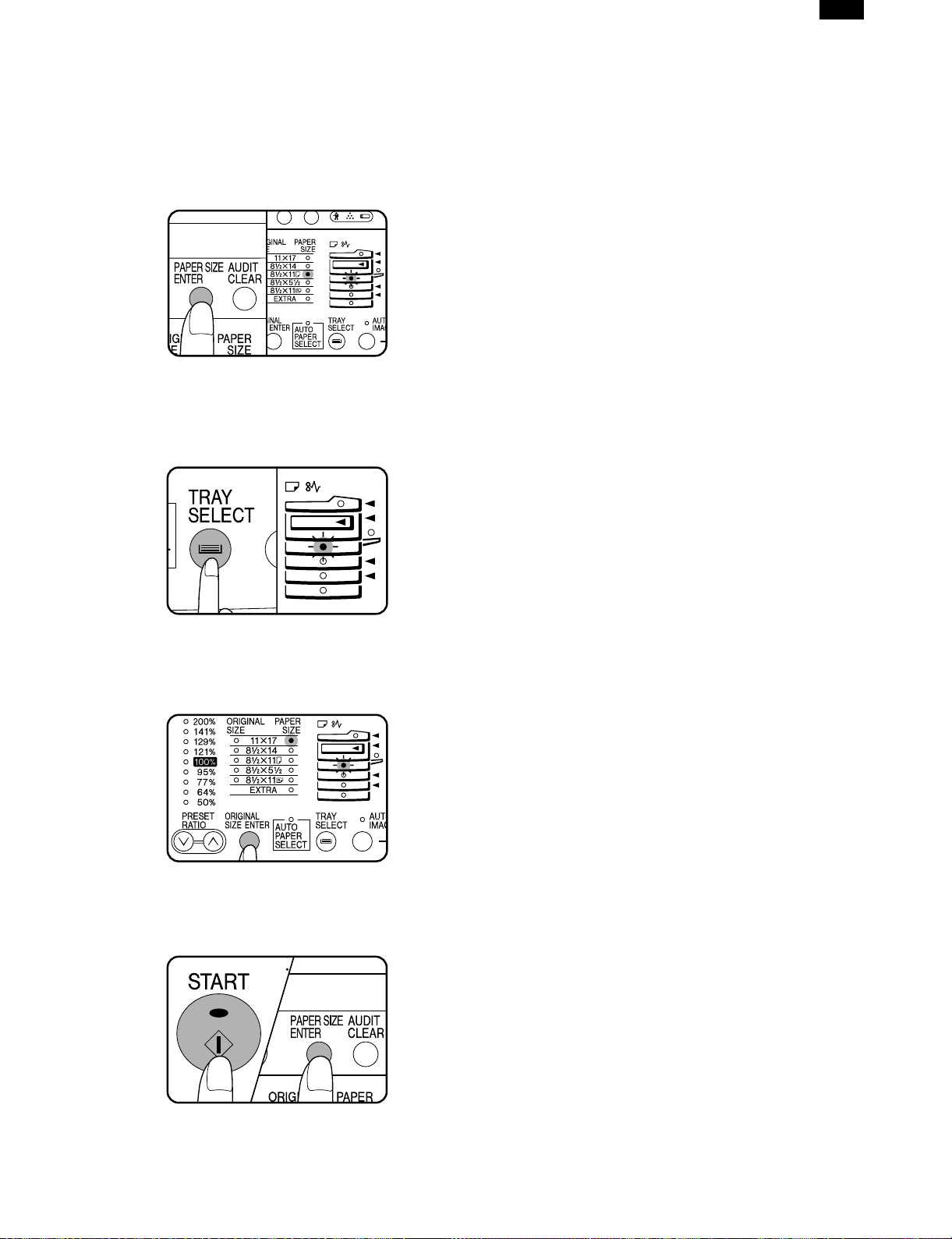

9) To set the selected paper size, press the PAPER SIZE ENTER

key.

● The selected paper feed location indicator will blink and the corresponding paper size (which is currently set) indicator will light

up steadily. All other indicators will go out.

Note: For paper size setting, ensure that the COPY mode has

been selected. However, if copying, printing or facsimile

printing is being performed, paper size setting cannot be

made even in the COPY mode.

10) Use the TRAY SELECT key to select the paper tray of which the

paper size has been changed.

● Each time the TRAY SELECT key is pressed, a paper tray will

be indicated with a blinking paper feed location indicator.

11) Use the ORIGINAL SIZE ENTER key to select the paper size

which is set.

● Each time the ORIGINAL SIZE ENTER key is pressed, a paper

size will be indicated with a paper size indicator.

DM-2000

6. Installing the printer driver

To use this printer with your computer, you must install the printer

driver.

Install the printer driver using the supplied SHARP Software CD-ROM.

This kit is supplied with the following printer drivers:

● PCL6 for Windows 95/98

● PCL6 for Windows NT 4.0

● PCL5e for Windows 95/98

● PCL5e for Windows NT 4.0

Note: ● It is recommended that you install the PCL6 printer driver. If

you have a problem printing from older software using the

PCL6 driver, remove it and install the PCL5e driver.

● The printer driver data in the CD-ROM can be copied to floppy disks.

1. Double-click “My Computer”, “Dm2000” and “Makedisk”.

2. Double-click “Makedisk.exe”.

3. Follow the on-screen instructions.

Before installation, make sure that:

● You read the README.TXT file which is contained on the SHARP

Software CD-ROM. This file contains the information and restrictions

for using the printer.

● The printer is connected properly with the computer or network.

● The printer is loaded with paper.

● The printer is turned on and on-line (the ON LINE light is lit).

● You quit all application software that is running on your computer.

● Your computer meets the following hardware and software require-

ments:

Computer Type

Operating System Windows 95, Windows 98, Windows NT 4.0

CPU Windows 95: 486SX or better

RAM Windows 95: 8 MB or more (12 MB or

This procedure uses the following drive name in examples:

Drive R: CD-ROM drive (holds the CD-ROM containing the printer

Change the drive name as required according to your environment.

IBM PC/AT or compatible computer equipped

with a bi-directional parallel interface and CDROM drive

Windows 98: 486DX/66 MHz or better

(Pentium or better is

recommended.)

Windows NT 4.0: 486/25 MHz or better

more is recommended.)

Windows 98: 16 MB or more (32 MB or

more is recommended.)

Windows NT 4.0: 16 MB or more

drivers)

12) Press the START key and then the PAPER SIZE ENTER key.

● To change the paper size setting of another tray, repeat steps

10) to 11) after pressing the START key.

A. Installing onto Windows 95

This printer is compatible with plug & play. If your computer is incompatible with plug & play or if you want to use this printer as a network

printer, refer to “Installing onto Windows 95/98 without Using the Plug

& Play Function”.

1) Turn the computer on and start Windows 95.

Note: Depending on which version of Windows you are using, the

display examples in this step may differ from those on your

system.

● Either the “Update Device Driver Wizard” window or the “New

Hardware Found” window may appear automatically.

Note: If neither the “Update Device Driver Wizard” window nor

the “New Hardware Found” window appear, refer to “Installing Windows 95/98 without Using the Plug & Play

Function”.

5 – 3

Page 24

DM-2000

● If the “Update Device Driver Wizard” window appears, click the

[Next] button and proceed to step 2).

● If the “New Hardware Found” window appears, perform the fol-

lowing steps:

<1> Choose “Driver from disk provided by hardware manufac-

turer” and click the [OK] button.

<2> When the “Install From Disk” window appears, insert the

SHARP Software CD-ROM into the CD-ROM drive, type

R:\English\WinXX and click the [OK] button.

<3> Choose the appropriate printer driver from those listed below

and click the [OK] button.

● PCL6 Printer Driver:SHARP DM-2000 Series PCL6

● PCL5e Printer Driver:SHARP DM-2000 Series PCL5e

Note: It is recommended that you install the PCL6 printer driver.

If you have a problem printing from older software using

the PCL6 driver,remove it and install the PCL5e driver.

<4> Proceed to step 5).

2) Search for the printer driver by clicking [Other Locations...] button.

3) Insert the SHARP Software CD-ROM into the CD-ROM drive, type

R:\English\WinXX and click the [OK] button.

4) After Windows finds the printer driver, click the [Finish] button to

continue the installation.

Note: In this step the PCL6 printer driver is installed automat-

ically. If you want to install the PCL5e printer driver, refer

to “Installing onto Windows 95/98 without Using the Plug &

Play Function”.

5) Set the printer name.

<1> If you want to change the printer name, enter a new name

in the space provided.

<2> If the program displays, “Do you want your Windows-based

programs to use this printer as the default printer?”, check

“Yes”.

<3> Click the [Next] button.

6) Print a test page by clicking the [Finish] button.

Note: If you check “No” and click the [Finish] button, the printer

does not print a test page after the installation.

● The printer driver installation begins.

● If the “Insert Disk” window appears, perform the following steps:

<1> Click the [OK] button.

<2> When the “Copying Files” window appears, type

R:\English\WinXX and click the [OK] button.

7) When the test page is printed properly, click the [Yes] button.

● The printer is ready for printing.

B. Installing onto Windows 98

This printer is compatible with plug & play. If your computer is incompatible with plug & play or if you want to use this printer as a network

printer, refer to “Installing onto Windows 95/98 without Using the Plug

& Play Function”.

1) Turn the computer on and start Windows 98.

● The “Add New Hardware Wizard” window appears automat-

ically, click the [Next] button.

Note: If the “Add New Hardware Wizard” window does not ap-

pear in this step, refer to “Installing onto Windows 95/98

without Using the Plug& Play Function”.

5 – 4

2) Display a list of all the printer drivers by checking “Display a list

of all the drivers in a specific location, ...” and clicking the [Next]

button.

Page 25

3) Click the [Have Disk...] button.

4) Insert the SHARP Software CD-ROM into the CD-ROM drive, type

R:\English\WinXX, and click the [OK] button.

5) Choose the appropriate printer driver from those listed below and

click the [Next] button.

● PCL6 Printer Driver: SHARP DM-2000 Series PCL6

● PCL5e Printer Driver: SHARP DM-2000 Series PCL5e

Note: It is recommended that you install the PCL6 printer driver.

If you have a problem printing from older software using

the PCL6 driver,remove it and install the PCL5e driver.

DM-2000

C. Installing onto Windows 95/98 without Using the

Plug & Play Function

Computers using Windows 95 or Windows 98 that are compatible with

plug & play can install the printer driver automatically. However, if your

computer is incompatible with plug & play, or if you want to use this

printer as a network printer, follow the procedure in this section.

The following steps use Windows 98 in display examples.

1) Turn the computer on and start Windows 95/98.

2) Click the Start menu, point to “Settings”, and choose “Printers”.

3) When the “Printers” window appears, double-click the “Add

Printer” icon.

4) Click the [Next] button.

5) If the screen for choosing the connection method appears, choose

the connection method and click the [Next] button.

Note: This screen appears only when the computer is connected

to a network.

● When the printer is directly connected to the computer, choose

“Local printer”.

Otherwise, choose “Network printer”.

If you choose “Network printer” you must specify a network path

or queue name.

Contact your network administrator for details.

The following steps use the example of a local printer.

6) After Windows finds the printer driver, click the [Next] button to

continue the installation.

7) Print a test page by clicking the [Finish] button.

Note: If you check “No” and click the [Finish] button, the printer

does not print a test page after the installation.

● The printer driver installation begins.

8) When the test page is printed properly, click the [Yes] button.

● The printer is ready for printing.

6) Click the [Have Disk...] button.

7) Insert the SHARP Software CD-ROM into the CD-ROM drive, type

R:\English\WinXX, and click the [OK] button.

8) Choose the appropriate printer driver from those listed below and

click the [Next] button.

● PCL6 Printer Driver: SHARP DM-2000 Series PCL6

● PCL5e Printer Driver: SHARP DM-2000 Series PCL5e

Note: It is recommended that you install the PCL6 printer driver.

If you have a problem printing from older software using

the PCL6 driver,remove it and install the PCL5e driver.

5 – 5

Page 26

DM-2000

9) Choose the port and click the [Next] button.

Note: This screen appears only if you selected “Network printer”

in step 5).

D. Installing onto Windows NT 4.0

1) Turn the computer on and start Windows NT.

2) Click the Start menu, point to “Settings”, and choose “Printers”.

3) When the “Printers” window appears, double-click the “Add

Printer” icon.

4) Choose “My Computer” or “Network printer server” and click the

[Next] button.

● The following steps use “My Computer” as an example.

For more information about using this printer as a network

printer, refer to the Windows NT 4.0 networking documentation.

5) Check the checkbox for the port you are using and click the [Next]

button.

10) Set the printer name.

<1> If you want to change the printer name, enter a new name

in the space provided.

<2> If the program displays, “Do you want your Windows-based

programs to use this printer as the default printer?”, check

“Yes”.

<3> Click the [Next] button.

11) Print a test page by clicking the [Finish] button.

Note: If you check “No” and click the [Finish] button, the printer

does not print a test page after the installation.

● The printer driver installation begins.

6) Click the [Have Disk...] button.

7) Insert the SHARP Software CD-ROM into the CD-ROM drive, type

R:\English\WinNT and click the [OK] button.

12) When the test page is printed properly, click the [Yes] button.

● The printer is ready for printing.

8) Choose the appropriate printer driver from those listed below and

click the [Next] button.

● PCL6 Printer Driver: SHARP DM-2000 Series PCL6

● PCL5e Printer Driver: SHARP DM-2000 Series PCL5e

Note: It is recommended that you install the PCL6 printer driver.

If you have a problem printing from older software using

the PCL6 driver,remove it and install the PCL5e driver.

5 – 6

Page 27

9) Set the printer name.

<1> If you want to change the printer name, enter a new name

in the space provided.

<2> If the program displays, “Do you want your Windows-based

programs to use this printer as the default printer?”, check

“Yes”.

<3> Click the [Next] button.

10) Make the appropriate settings for your environment.

● When using print sharing, choose “Shared” and enter a share

name. If necessary for your environment, select Windows 95

from the list of operating systems.

● If you are not using shared printing, choose “Not shared”.

DM-2000

7. Expansion memory installation

Memory expansion realizes the following effects.

● Increased processing speed of outline fonts or complex graphic data.

● Shorter release time from a printing job of the computer.

● Allows high resolution printing.

● Complex data can be printed without data loss error or memory full

error.

Extend the pawls, insert an expansion memory, and engage the pawls

with the notches.

8. Print server card installation

Remove the dummy cover, insert the print server card into the connector of the printer PWB and fix it with the screw of the dummy cover. At

that time, cut off the notched section in the rear cabinet with nippers.

(Use nippers so that the cut surface is flat.)

Dummy cover

After making the settings on this screen, click the [Next] button.

11) Print a test page by clicking the [Finish] button.

Note: If you check “No” and click the [Finish] button, the printer

does not print a test page after the installation.

● The printer driver installation begins.

12) When the test page is printed properly, click the [Yes] button.

● The printer is ready for printing.

E. Changing Printer Configuration Settings

After installing the printer driver use the procedure in this section to

change the printer configuration settings. Also refer to the print driver

help for more information.

1. Click the Start menu, point to “Settings”, and choose “Printers”.

2. Right-click the appropriate printer and choose “Properties” fromthe menu.

3. Click the Configuration tab and change the printer settings.

5 – 7

Page 28

DM-2000

[6] ADJUSTMENTS

1. Adjustment item list

Section Adjustment item Adjustment procedure/SIM No.

A Process section

B Mechanism section

C Image density adjustment (1) Copy mode SIM 46-1

(1) Developing bias voltage output adjustment

(2) Grid bias voltage adjustment

(1) Image lead edge position adjustment SIM 50-1/SIM 50-10

Main scanning direction (FR direction)

(2)

distortion balance adjustment

Main scanning direction (FR direction)

(3)

distortion adjustment

Sub scanning direction (scanning direction)

(4)

distortion adjustment

Main scanning direction (FR direction)

(5)

magnification ratio adjustment

Sub scanning direction (scanning direction)

(6)

magnification ratio adjustment

(7) Off center adjustment

OC (SPF) open/close detection position

(8)

adjustment

(9) Original sensor adjustment SIM 43-3

No. 2/3 mirror base unit installing position

adjustment

Copy lamp unit installing position adjustment

Rail height adjustment

Winding pulley position adjustment

SIM 48-1

a OC mode in copying (SIM 48-2)

b SPF mode in copying (SIM 48-5)

a OC mode (SIM 50-13)

b SPF mode (SIM 50-16)

2. Copier adjustment

A. Process section

(1) Developing bias voltage adjustment

Note: ● Use a digital multi-meter with an internal resistance of 10 MΩ

or more.

1) Set the digital multi-meter range to DC700V.

2) Put the test rod of the digital multi-meter on the developing bias

voltage output check pin.

3) Turn on the power.

4) Adjust the adjustment volume VR31 so that the output voltage is

within the specified range shown below.

(2) Grid bias voltage adjustment

Note: ● Use a digital multi-meter with an internal resistance of 10MΩ

or more.

1) Set the digital multi-meter range to DC700V.

2) Put the test rod of the digital multi-meter on the grid bias voltage

output check pin.

3) Turn on the power.

4) Adjust the adjustment volumes (VR51, VR52) so that the output

voltage is within the specified range. (The voltage is outputted in

the grid bias high output mode during warming up, and in the grid

bias low output mode after completion of warming up.)

5) Adjust the adjustment volume VR51/VR52 so that the output voltage is within the specified range shown below.

<Adjustment specification>

Mode Specification

Developing bias voltage DC-400 ± 8V VR31

<Adjustment specification>

Mode Specification

Grid bias LOW DC-400 ± 20V VR52

Grid bias HIGH DC-525 ± 10V VR51

6 – 1

Page 29

B. Mechanism section

(1) Image lead edge position adjustment (SIM 50-1/SIM 50-10)

a. OC image lead edge position adjustment

Note: In advance to this adjustment, the sub scanning magnification

ratio adjustment must be performed.

1) Set a scale on the OC table as shown below.

DM-2000

8) Measure the image loss R of the copied image. Enter the set

value of the image scanning lead edge position (Exposure display

<AUTO> ON) again.

● 1 step of the set value corresponds to about 0.127 mm shift.

● Calculate the set value from the formula below.

99 - R/0.127 (mm) = Image loss set value <R: Image loss measurement value (mm)>

5mm

0mm

5

10

2) Make a copy.

3) Check the copy output. If necessary, perform the following adjustment procedures.

4) Execute SIM 50-1.

5) Set the OC lead edge position set value (Exposure display

<AUTO> ON) to “99.”

The OC image scanning start position is shifted inside the document edge.

6) Set the main cassette lead edge void adjustment value (Exposure

display <PHOTO> ON) * to “1.”

The lead edge void becomes the minimum.

7) Set the print start position value (Exposure display <EXP1> ON)

to “99” and make a copy.

The print start position is shifted inside the document edge.

5mm

5

4mm

10

*The dimension varies depending on the model.

* The scanning edge is set.

(A line may be printed by scanning the document edge.)

Example: 99 - 4/0.127 = 99 - 31.5 = about 67

Note: If the set value is not obtained from the above formula, per-

form the fine adjustment.

9) Measure the distance H between the paper lead edge and the

image print start position. Set the image print start position set

value (Exposure display <EXP1> ON) again.

● 1 step of the set value corresponds to about 0.127 mm shift.

● Calculate the set value from the formula below.

99 - H/0.127 (mm) = Image print start position set value <H: Print

start position measurement value (mm)>

0mm

5