Page 1

SERVICE MANUAL

COLOR MONITOR

SPECTRUM 4V SERIES

(D356P/PA)

41A50-087

Page 2

THESE DOCUMENTS ARE FOR REPAIR SERVICE INFORMATION ONLY. EVERY

REASONABLE EFFORT HAS BEEN MADE TO ENSURE THE ACCURACY OF THIS

MANUAL; WE CANNOT GUARANTEE THE ACCURACY OF THIS INFORMATION AFTER

THE DATE OF PUBLICATION AND DISCLAIMS LIABILITY FOR CHANGES, ERRORS OR

OMISSIONS,

MANUFACTURE DATA : JUNE. 1999

1

Page 3

TABLE OF CONTENTS

PAGE

1. SPECIFICATIONS ..................................................................................................... 2

2. PRECAUTION AND NOTICES ................................................................................ 3

2-1 SAFETY PRECAUTIONS .............................................................................. 3

2-2 PRODUCT SAFETY NOTICE ....................................................................... 3

2-3 SERVICE NOTES ........................................................................................... 4

2-4 HIGH VOLTAGE WARNING ....................................................................... 4

3. OPERATING INSTRUCTIONS ................................................................................ 5

4. ADJUSTMENT .......................................................................................................... 6

4-1 ADJUSTMENT CONDITIONS AND PRECAUTIONS ............................... 6

4-2 MAIN ADJUSTMENTS ................................................................................. 6

4-3 ADJUSTMENT METHOD ............................................................................. 6-7

5. CIRCUIT DESCRIPTION .......................................................................................... 8

6. TROUBLE SHOOTING CHART .............................................................................. 11

6-1 NO RASTER, CRT RELATIVE CIRCUIT PROBLEMS .............................. 11-12

6-2 ABNORMAL DISPLAY ................................................................................. 13

6-3 NO BLANKING .............................................................................................. 14

6-4 HOR. /OSC /DEF /HV CIRCUIT FAULT ...................................................... 14

6-5 ABNORMAL HORIZONTAL DEFLECTION .............................................. 15

6-6 ABNORMAL VERTICAL SCANNING ........................................................ 16

6-7 SIDE-PIN CUSHION DISTORTION ............................................................. 17

6-8 POOR FOCUS ................................................................................................. 17

6-9 NO SOUND (FOR 4VA/4VnA/4VlrA ONLY)............................................... 23

6-10 POWER SUPPLY TROUBLE SHOOTING CHART .................................... 18

7. MECHANICAL OF CABINET FRONT DIS-ASSEMBLY...................................... 19

8. PARTS LISTING ....................................................................................................... 20

9. BLOCK DIAGRAM (DEFLECTION) ....................................................................... 36

9-1 BLOCK DIAGRAM (SMPS) ........................................................................ 37

10. IC BLOCK DIAGRAMS............................................................................................ 38

11. PCB LAYOUT ............................................................................................................ 41

12. SCHEMATIC DIAGRAM ......................................................................................... 43

2

Page 4

1. SPECIFICATIONS FOR D356P COLOR MONITOR

1. CRT

35.5CM(14V) 90 Deflection, 29mm Neck, 0.28mm Dot Pitch, Non-Glare Screen

2. Viewable image Size: 33.5CM (13") diagonal

3. Display Color:Unlimited Colors

4. External Controls:

Power On/Off, UP/Down key, Function key: Contrast, Brightness, H-Size, H-center, V-Size, V-Center,

Pincushion, Trapezoid, volume (for 4VA/4VnA/4VlrA only)

5. Input Video Signal

Mode 1 Mode 2 Mode 3 Mode 4 Mode 5 Mode 6 Mode 7

RGB Analog RGB Analog RGB Analog RGB Analog RGB Analog RGB Analog RGB Analog

Horiz. Sync:

Vert. Sync:

TTL Level TTL Level TTL Level TTL Level TTL Leve l TTL Level TTL Leve l

Negative Negative Negative Negative Positive Positive Negative

TTL Level TTL Level TTL Level TTL Level TTL Leve l TTL Level TTL Leve l

Positive Negative Negative Negative Positive Positive Negative

6. Resolution

Horizontal:

Vertical :

Fh (KHz):

Fv (Hz) :

720 (H) 640 (H) 640 (H) 6 40 (H) 800 (H) 800 (H) 1024 (H)

400 (V) 480 (V) 480 (V) 4 80(V) 600(V) 600 (V) 768 (V)

31.5 31.5 37.5 43.3 46.8 53.7 48.4

70 60 75 85 75 85 60

7. Display Size

Horizontal: 250 mm

Vertical: 187 mm

8. Scanning Freq uencies

Horizontal:

Vertical:

30KHz ~ 54KHz

50 Hz ~ 120 Hz

9. Factory Preset Timings: 7

User Timings: 12

10. Misconvergence

Center: 0.3 mm Max.

Corner: 0.4 mm Max.

11. Video Bandwidth: 85 MHz

12. Power Source:

Switching Mode Power Supply

AC 100 ~240V, 50/60Hz Universal Type

13. Operating Temperature: 0 to 40 Ambient

3

Page 5

14. Humidity:

10 to 85 Relative, Non-Condensing

15

Weight: 11Kgs(Net), 12.8Kgs(Gross)

16. Dimensions Monitor:

Carton: 438(W) 394(H) 460(D)

Monitor:350(W) 352(H) 370(D)

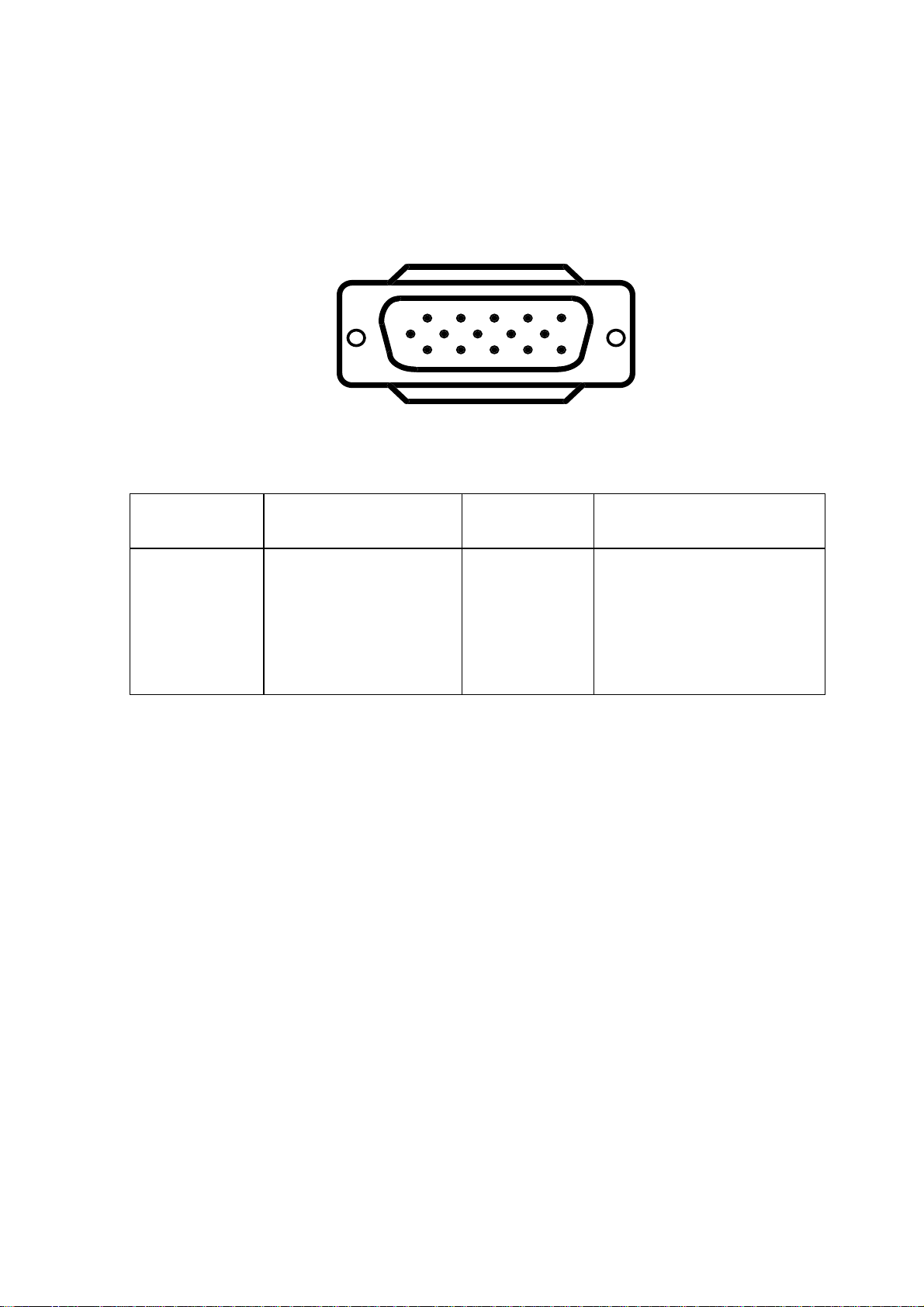

17. External Connection:

15 Pin D-type Connector

AC Power Cord

18. Speaker: (for 4VA/4VnA/4VlrA only)

Rate power: 1W (per channel)

Impedance:

16

19. Regulations: UL, CSA, DHHS, FCC-B, TÜV/GS, CE

TÜV/MPR-II (for 4Vlr/4VlrA only)

4

Page 6

2. PRECAUTIONS AND NOTICES

2-1 SAFETY PRECAUTIONS

1. Observe all caution and safety related notes located inside the display cabinet.

2. Operation of the display with the cover removed, may cause a serious shock hazard from the display power

supply. Work on the display should not be attempted by anyone who is not thoroughly familiar with

precautions necessary when working on high voltage equipment.

3. Do not install, remove or handle the picture tube in any manner unless shatterproof goggles are worn.

People who are not so equipped should be kept away while handling picture tube. Keep picture tube away

from the body while handling.

4. The picture tube is constructed to limit X-RAY radiation to 0.5 mR/HR. For continued p rotection, use the

designated replacement tube only, and adjust the voltages so that the designated maximum rating at the

anode will not be exceeded.

5. Before returning a serviced display to the c ustomer, a thorough sa fety test must be p erformed to verify that

the display is safe to operate without danger or shock. Always perform an AC leakage current check on the

exposed metallic parts of the cabinet, such as screw heads.

Test method for current leakage is described as follow.

(a) Plug the AC line cord directly into rated AC outlet (do not use a line isolation transformer during this

check).

(b) Use an AC voltmeter having 5000 ohms per volt or with more sensitivity in the following manner:

Connect a 1500 ohms 10 Watt resistor, paralleled by a 0.15UF, AC type capacitor between a known

good earth ground (water pipe, conduit, etc.) and the exposed metallic parts simultaneously. Measure

the AC voltage across the combination of 1500 ohms resistor and 0.15UF capacitor.

(c) Reverse the AC plug at the AC outlet and rep eat AC voltage meas urements for each exposed metallic

part.

(d) Voltage measured must not exceed 0.5 volts RMS. This corresponds to 0 .35 milliamp AC. Any value

exceeding this limit constitutes a potential shock hazard and must be corrected immediately.

2-2 PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in this chassis have special safety visual inspections and the protection

afforded by them cannot necessarily be obtained by using replacement components rated for higher voltage,

wattage, etc. Before replacing any of these components read the parts list in this manual carefully. The use of

substitute replacement parts which do not have the same safety characteristics as specified in the parts list may

create shock, fire, X-RAY radiation or other hazards.

2-3 SERVICE NOTES

1. When replacing parts or circuit boards, clamp the lead wires around terminals before soldering.

2. When replacing a high wattage resistor (more than 1/2W of metal oxide film resistor) in circuit board, keep

the resistor about 10 (1/2 in) away from circuit board.

3. Keep wires away from high voltage or high temp erature components.

4. Keep wires in their original position so as to reduce interference.

5

Page 7

2-4 HIGH VOLTAGE WARNING

Operation of monitor outside of cabinet or with back removed may cause a serious shock hazard. Work on this

model should only be performed by those who are thoroughly familiar with precautions necessary when working

on high voltage equip ment.

Exercise care when servicing this chassis with power applied. Many B plus and high voltage terminals are

exposed which, if carelessly contacted, can cause serious shock or result in damage to the chassis. Maintain

interconnecting ground lead connections between chassis and picture tube dag when operating chassis.

Certain HV failures can increase X-ray radiation. Monitor should not be operated with HV levels exceeding the

specified rating for the chassis type. The maximum operating HV specified for the chassis used in this monitor is

24.5KV

With a line voltage of 120/240 VAC. Higher voltage may also increase possibility of failure in HV supply.

It is important to maintain specified values of all components in the hor izontal and high voltage circuits and

anywhere else in the monitor that could cause a rise in high voltage or operating supply voltages. No changes

should be made to the original design of the monitor. Components shown in the shaded areas on the schematic

should be replaced with exact factory replacement parts. The use of unauthorized substitute parts may create a

shock, fire or other hazard.

To determine the presence of high voltage, use an accurate, high impedance, HV meter connected between

second anode lead and CRT dag grounding device. When servicing the High Voltage System, remove static

charge from it by connecting a 10K ohm resistor in series with an insulated wire (such as a test probe) between

picture tube dag and 2nd anode lead.(AC line cord disconnected from AC power outlet.)

The picture tube used in this monitor employs integral implosion protection. Replace with tube of the same type

number for c ontinue safety. Do not lift picture t ube by t he neck. H andle the p icture t ube only a fter disc harging

the high voltage completely.

1KV

±

6

Page 8

3. OPERATING INSTRUCTIONS

This procedure gives you instructions for installing and using the 4V Series display.

1. Position the display on the desired operation and plug the power cord into a co nvenient AC outlet. Threewire power cord must be shielded and is provided as a safety precaution as it connects the chassis and

cabinet to the electrical conduit ground. If the AC outlet in your location does not have provisions for the

grounded type plug, the installer should attach the proper adapter to ensure a safe ground potential.

2. Connect the 15-pin color display shielded signal cable to your signal system device and lock both screws

on the connector to ensure firm grounding. The connector information is as follow:

1

6

11 15

5

10

15 - Pin Color Display

Signal Cable

PIN NO. DESCRIPTION PIN NO. DESCRIPTION

1. RED 9. NC

2. GREEN 10. GND

3. BLUE 11. SYNC. GND

4. GND 12. SDA

5. GND 13. HORIZ. SYNC

6. GND-R 14.

VERT. SYNC (VCLK)

7. GND-G 15. SCL

8. GND-B

3. Apply power to the display by turning the power switch to the "ON" position and allow about thirty

seconds for display tube warm-up. The Power-On indicator lights when the display is on.

4. With proper signals feed to the display, a pattern or data should appear on the screen, adjust the brightness

and contrast to the most pleasing display.

5. This monitor has po wer sa vi ng func tio n fo llo wing t he V ESA DP MS . Be sure to co nnect t he s igna l cab le to

the PC.

6. If your 4V Series color display requires service, it must be returned with the power cord.

7

Page 9

4. ADJUSTMENT

4-1 ADJUSTMENT CONDITIONS AND PRECAUTIONS

1. Approximately 30 minutes should be allowed for warm up before proceeding.

2. Adjustments should be undertaken only on those necessary elements since most of them have been carefully

preset at the factory.

4-2 MAIN ADJUSTMENTS

NO. FUNCTION LOCATION DESIGNATION

1. 15V ADJ PCB - MAIN VR901

2. B + ADJ PCB - MAIN VR902

3. R.B. DRIVE CRT - BOARD VR801,802

4. R.G.B. CUT-OFF CRT - BOARD VR803,804,805

5. ABL ADJ PCB - MAIN VR701

6. UP KEY PCB - MAIN SW101

7. DOWN KEY PCB - MAIN SW102

8. FUNCTION KEY PCB - MAIN SW103

4-3 ADJUSTMENT METHOD

1. 15V, B + & HV protection voltage adjustment:

A. Chroma-2000 Signal generator or PC equivalent, set mode 1( VGA 640480) pattern 1.

B. Connect a DC voltage meter between TP 901 and ground, then adjust VR901 to be 15VDC.

C. Connect a DC voltage meter between TP 902 and ground, then adjust VR902 to be 90 VDC.

2. Factory preset timings adjustment:

A. When you turn on the monitor, the function LEDS will light up simultaneously for a while, then extinguish.

B. You can press t he up/func two keys simul t aneously, the most left four LEDS will light up for a while then

extinguish.

C. Then you can select o ne of the eight functio ns including Contra st, Brightness, H-SI ZE, H-CENTER, V-

SIZE, V-CENT ER, Pi ncushion and Tr apezo id Simply pr ess the functio n key and the LE D will b e light up

corresponding to the one selected, then press the up/down keys to get the factory presetting parameter value

to your satisfaction.

D. Then you wil l pre ss the up/f unctio n two keys si multa neous ly again, the mo st right four LE DS wi ll ligh t up

for a while then extinguish, the factory preset timings adjustment is finished.

3. White balance and luminance adjustment:

A. Bias (low light) adjustment:

(a) Set mode 5 ( 800600 Fh: 46.8KHz ) full white pattern.

(b) Adjust VR801, 802, 803, 804, 805, to make VR in the center position.

(c) Warm up more th an 20 minute.

(d) Brightness set to max. Contrast set to min. full white pattern, the n adjust FBT scr een VR to make Y=

1.0FL

(e) Brightness set to raster just cutoff, contrast set to 4FL, then adjust CRT board VR805 (B-Bias) VR803

(R-Bias) to make Y= 4

B. Gain (High light) adjustment:

(a) Set mode 5 ( 800600 Fh: 46.8KHz ) full white pattern.

(b) Brightness set to raster just cutoff and set the contrast to max.

(c) Adjust VR801, 802 to make color code x=281

C. Recheck item A&B to make sure both of them in spec.

0.2FL

±

0.2 FL, x= 281 ± 10, y= 311 ± 10

±

10, y=311 ± 10.

±

8

Page 10

D. Full white luminance:

(a) Set mode 5 ( 800600 Fh: 46.8K ) full white pattern.

(b) Image size : H:250

4mm, V:187±4mm.

±

(c) Brightness set to raster just cut off and set the contra st to max.

(d) Adjust VR701 to make sure white luminance at 25 FL.

4. Focus adjustment:

A. Set mode 2 ( 640480 Fh: 31.5KHz ) with character full page.

B. Adjust external brightness to raster cutoff and external contrast to max. , then adjust focus VR to make the

display be focused very well.

5. Purity adjustment

A. Be sure that the display is not being exposed to any external magnetic fields.

B. Ensure that the spacing between the Purity, Convergence, Magnet, (PCM), assembly and the CRT stem is

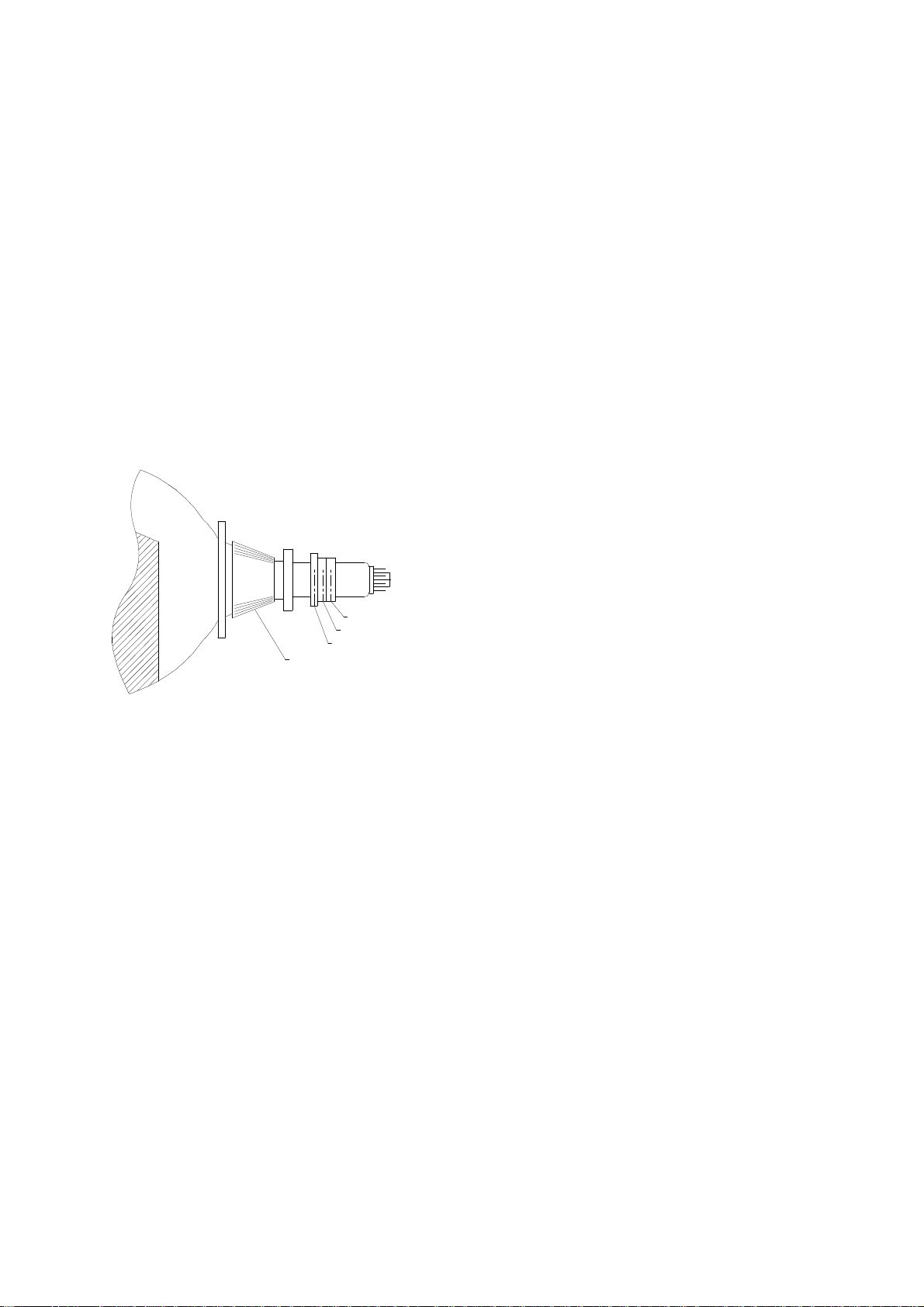

29 .(See below diagram)

C. P roduce a complete, red pattern on the display. Adjust the purity magnet rings on the PCM assembly to

obtain a complete field of the color red. This is done by moving the two tabs in such a manner that they

advance in an opposite direction but at the same time to obtain the same angle between the two tabs, which

should be approximately 180.

D. Check the complete blue and co mplete green patterns to observe their r espective color purity. make mino r

adjustments if needed.

RELATIVE PLACEMENT OF TYPICAL COMPONENTS

Purity Magnets

6-pole Convergence Magnets

4-pole Convergence Magnets

Deflection Yoke

6. Convergence adjustment

A. Produce a magenta crosshatch on the display.

B. Adjust the focus for the best overall focus on the display.

Also adjust the brightness to the desired condition.

C. Vertical red and blue lines are converged by varying the angle between the two tabs of the 4 pole magnets

on the PCM assembly. (See above diagrams)

D. Horizontal red and blue lines are converged by varying the two tabs together, keeping the angle between

them constant.

E. Produce a white crosshatch pattern on the display.

F. Vertical green and magenta lines are converged by varying the angle between the two tabs of the 6-pole

magnets.

G. Horizontal green and magenta lines are converged by varying the two tabs together, keeping the angle

between them constant.

9

Page 11

5. CIRCUIT DESCRIPTION

5-1 MICRO CIRCUIT

IC101 is CPU, This CPU has the following functions.

1. Detect timing mode by sensing the horizontal frequency, vertical frequency, the polarity of Hor. Sync and Ver.

Sync.

2. Keyboard scan control.

3. Geometry and volume (4VA/4Vn A/4VlrA only) control internal D/A converters and I

4. Cs capacitor switch control.

5. Power saving control.

When CPU detects timing, it takes data fro m E

volume (4VA/4VnA/4VlrA only) of this monitor.

If key is pressed, the CPU will do some job according to the key function. For example, if function key is pressed,

it can change different value to control screen geometry (H-SIZE, V-SIZE...etc.)

5-2 DEFLECTION CIRCUIT

Hor. sync. and Ver. sync. come from PC, go into the CPU (IC101). The output goes to the Hor. oscillation and Ver.

oscillation processor (IC401). The IC401 treats sync. Signal and output the drive signal to horizontal and vertical

output circuit. IC401 also generates some functions for geometry use, like, horizontal center, vertical size, by I

bus control, the geometry can be controlled. IC601 is a vertical output IC to supply the vertical scan. Q404, Q405,

Q406 and L405 are the horizontal size controls. Q403 is the horizontal deflection output, supply the horizontal

scan of the monitor. Q707 and Q601 generate the Blanking signal output to G1 of CRT.

Q703 Q704 and Q705 are mute control, brightness control and G1 DC voltage output.

²

PROM (IC102), then output voltage to control the geometry and

²

C bus control.

²

C

5-3 VIDEO CIRCUIT

IC801 is a video amplifier, clamping signal input from pin No. 11 to restore the DC voltage of video signal, the

signal output from IC801 pass through IC802 Video package amplifier stage LM2439, then go to the cut off DC

restore stage, The video output signal is about 40Vpp.

5-4 POWER SUPP LY

The design uses a discontinuous flyback topology operating in current-mode resulting in a multiple output

switcher with stack well. Faster diodes are used. The fast transient response of the control loop maintains picture

integrity. Very fast current limiting protects the switcher agains short circ uit s.

UC3842AM (IC901) is the current mode controller selected. It offers feed forward compensation, feedback error

amplifier, and low voltage lock out features. The 3842 draws very little current is start up mode. There is enough

power from the line bleeder to slowly charge a capacitor to the 16 volts needed to start the switcher.

The FET starts a cycle by allowing current to flow into the primary of the power transformer. As current ramps up

with time, the voltage across the current sense resistor (R929) also ramps to a point where the 3842 determines

that enough power is stored and turns off the FET. As the voltage on the transformer reverses, power is dumped

from the main power transformer through diodes into the different supplies. To keep RFI to a minimum and

reduce transistor heating, a turn-off snubber network is placed across the FET. Current from the secondary

windings are rectified and filtered to freate the desired voltages. Small high current capacitors quickly return

charging current to the source. Filter inductors remove high frequency noise.

10

Page 12

5-5 TRANSISTOR & DIODE CIRCUIT

LOCATION CIRCU IT FUNCTION DESCRIPTION

D901 ~ D904 Bridge Rectifier for AC Source

D909 Half-Wave Rectifier for Start CKT

D910 Clamp Diode for Snubber CKT

D919 Rectifier for Output Voltage

D921 Rectifier for Output Voltage

D922 Rectifier for Output Voltage

D923 Rectifier for Output Voltage

D925 Rectifier for Output Voltage

D927 Forward Bias when Q403 Turn-off to Protect B+ Block CKT

D929 B+ Feed Back Rectifier from F.B.T Pulse

Q904 Start CKT Amplifier Transistor

Q907, Q908 Use for Off-Mode to Cut-off 6.3V Supply Voltage

Q909, Q910 Use for Standy-By or Suspend Mode to Cut-off 15V Supply Voltage

Q912, Q920 Push-Pull Topology to Drive Q911

Q401 Turn-on at Power ON/OFF and Change Mode to Protect Hor.Block

Q402 HOR. Driver Transistor

Q407, Q408 As a Switcher for H-Size Correction CKT

Q410, Q426 H-Size Corection Mosfet (Q426 15" only)

Q404, Q405 As Differential Amp. to Drive Q406

Q406 Darlington Transistor for H-Size Control

Q703 As a Switcher to Mute Screen when Abnormal Qccurring

Q704, Q705 Unit Brightness Control CKT

Q601, Q707 Develop Blanking Signal

Q813, Q814 A Amplifier to Corection and Support Clamp Signal

11

Page 13

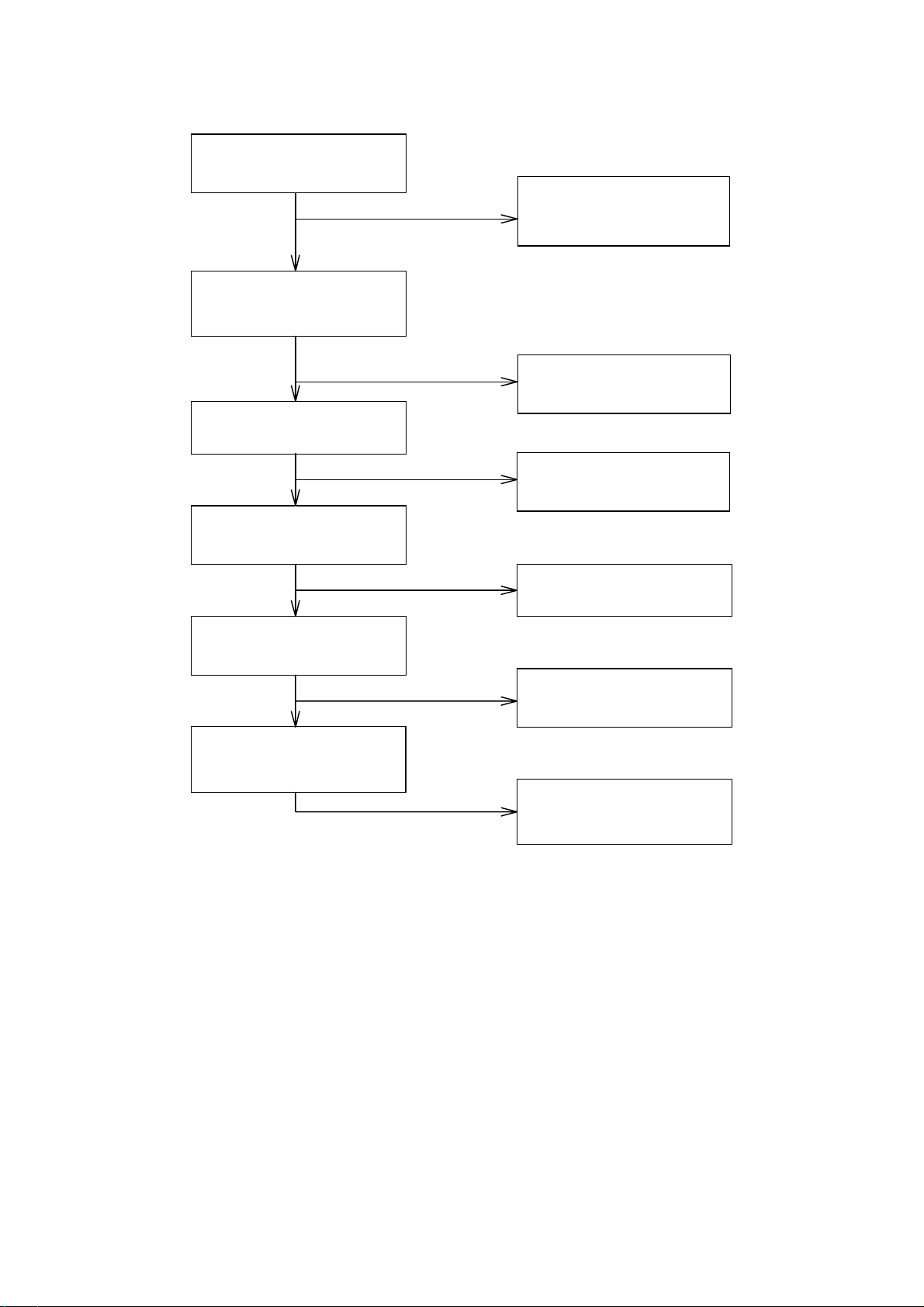

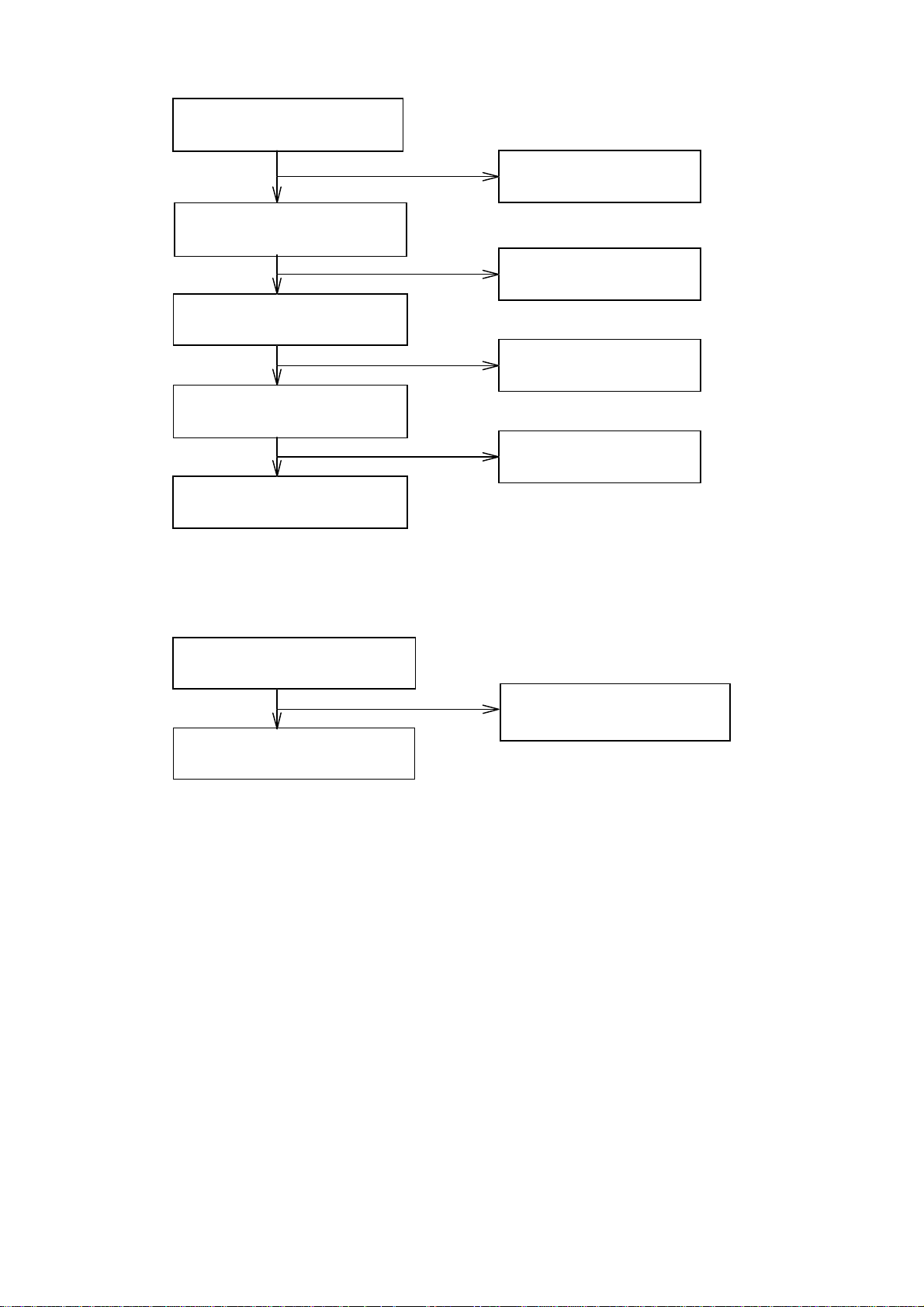

6-1 NO RASTER, CRT RELATIVE CIRCUIT PROBLEMS

90V, 12V

CHECK MAIN PC BOARD

6.TROUBLE SHOOTING CHART

NG

OK

CHECK THE HIGE VOLTAGE

OF CRT ABOUT 23.5 ~ 25KV

OK

CHECK THE VOLTAGE OF CRT

HEATER ABOUT 6.3V

OK

CHECK SCREEN VOLTAGE ABOUT

400V TO 600V

OK

BRIGHTNESS SET TO MAX.

THEN CHECK CRT G1 VOLTAGE

NG

NG

LESS THAN 300V

CHECK POWER SAVING CIRCUIT,

Q909, Q910

CHECK FAILSAFE CKT Q402, Q403

RELATIVE CKT.

CHECK CRT'S HEATER

RELATIVE CIRCUIT Q907, Q908

CHECK FBT. D706, R723, C713

NG

OK

CHECK VOLTAGE OF THE CRT

CATHODE ABOUT 60V TO 70V

NG

CHECK BRIGHTNESS CIRCUIT

Q703, Q704, Q705 RELATIVE CKT.

REFER ITEM 8-2

"ABNORMAL DISPLAY"

12

Page 14

2.ABNORMAL VIDEO LEVEL ON SCREEN

CHECK THE VOLTAGE OF IC801

PIN 2, 16 ABOUT 8V

NG

OK

CHECK THE SIGNAL INPUT OF R.G.B.

ABOUT 0.7Vpp

OK

CHECK IC801 PIN 11 ABOUT 10Vpp

NG

OK

CHECK THE VIDEO OUTPUT OF IC801

PIN 13, 15, 18 ABOUT 3Vpp

NG

OK

R.G.B. APPROACH STANDARD

3. ABNORMAL DDC (PLUG & PLAY)

CHECK 8V RELATIVE CIRCUIT

CHECK SIGNAL CABLE OR

INTERFACE CARD.

CHECK THE RELATIVE CIRCUIT

OF Q813, Q814 OR CLAMP.

CHECK IC801, Q813, Q814

CHECK IC101 PIN 5 VOLTAGE ABOUT 5V

NG

OK

CHECK SIGNAL CABLE

CHECK IC102 GOOD OR FAIL

13

Page 15

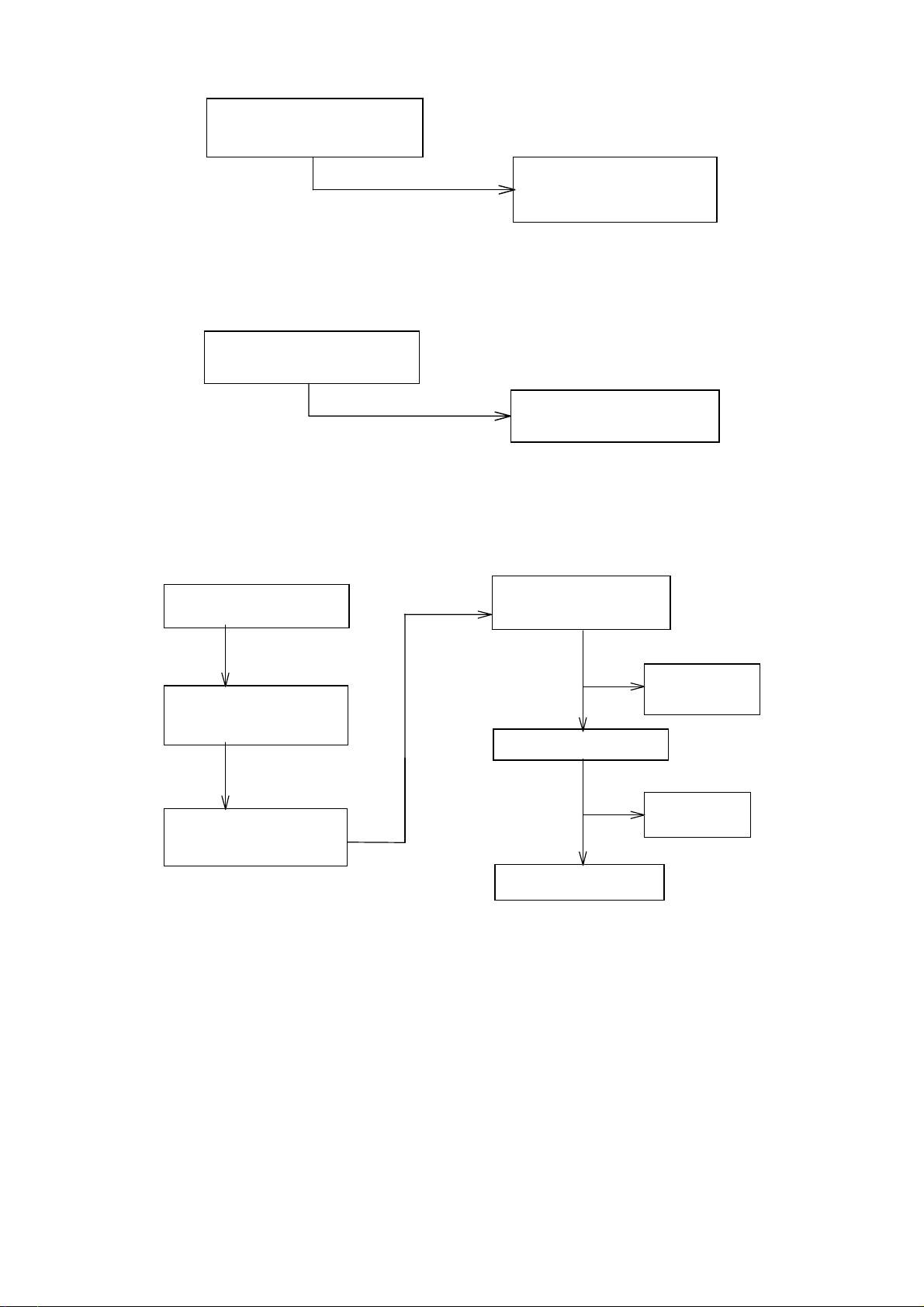

1.NO SIGNAL ON SCREEN

CHECK VIDEO IC VCC ABOUT 8V

6-2 ABNORMAL DISPLAY

NG

OK

CHECK THE OUTPUT VOLTAGE

OF IC801 PIN 13, 15, 18 ABOUT 3Vpp

NG

OK

CHECK THE B+ VOLTAGE OF

VIDEO PCB ABOUT 75V

NG

OK

CHECK THE VOLTAGE OF CRT

CATHODE ABOUT 40Vpp

NG

OK

CHECK THE VOLTAGE OF FBT SCREEN

ABOUT 400 TO 600V

LESS THAN 400V

CHECK THE 12V PIN

OF P802 CONNECTOR

CHECK THE RELATIVE CIRCUIT

OF Q813, Q814 & IC801

CHECK THE 80V RELATIVE CIRCUIT

OF SMPS ON MAIN PCB

CHECK THE IC802

RELATIVE CIRCUIT

CHECK FBT RELATIVE

CIRCUIT

EXCEED 600V

CHECK CRT RELATIVE

CIRCUIT OR REFER ITEM 7-1

14

Page 16

CHECK THE RELATIVE

CIRCUIT OF BLANKING

6-3 NO BLANKING

NG

OK

CHECK C836, R859 ON VIDEO PCB,

CHECK G1 RELATIVE CIRCUIT

FBT PIN 5 ON MAIN PCB

CHECK THE RELATIVE CIRCUIT

OF Q601 & Q707 ON MAIN PCB

6-4 HOR./OSC/DEF/HV CIRCUIT FAULT

1. NO RASTER (DISCONNECT WITH SIGNAL CABLE)

CHECK IC401 PIN 29 ABOUT 11.5 VDC

NG

OK

CHECK IC401 PIN 26 WAVE

FORM ABOUT 11.5Vpp

NG

OK

CHECK IC401 PIN 10 RELATIVE CIRCUIT

CHECK IC401 PIN 4 ~ 7, PIN 13

RELATIVE CIRCUIT

CHECK THE COLLECTOR VOLTAGE

OF Q402 ABOUT 30Vpp

NG

OK

CHECK THE COLLECTOR VOLTAGE

OF Q403 ABOUT 1250Vpp AT FH:31KHz

NG

CHECK Q402, T401

RELATIVE CIRCUIT

CHECK T401, T402, Q402, Q403,

D408, C418, C419, H-DY, B+

15

Page 17

6-5 ABNORMAL HORIZONTAL DEFLECTION

1. ABNORMAL HORIZONTAL SIZE

READJUST H-SIZE FUNCTION

NG

OK

CHECK FBT VOLTAGE ABOUT

90V AT FH=31KHz

CHECK THE HV OF CRT

ABOUT 24.5KV

CHECK THE RELATIVE CIRCUIT

OF Q404, Q405, & Q406

CHECK THE RELATIVE

CIRCUIT OF SMPS.

2. ABNORMAL HORIZONTAL RASTER CENTER

CHECK D418, D419, R457, R458, L404

3. ABNORMAL HORIZONTAL VIDEO CENTER

SET H-CENTER TO CENTER

NG

4. ABNORMAL HORIZONTAL LINEARITY

CHECK L401, Q408, Q410, C427

& DY IC101 PIN 29 (CS1)

CHECK IC401 PIN 4, 7

RELATIVE CIRCUIT

16

Page 18

6-6 ABNORMAL VERTICAL SCANNING

1. ABNORMAL VERTICAL SIZE

READJUST V-SIZE FUNCTION VALUE

CHECK THE IC601 ABOUT 11.8V PIN 6

NG

OK

CHECK VERT. OSC CIRCUIT

NG

OK

READJUST V-SIZE FUNCTION VALUE

2. VERTICAL CENTER

READJUST V-CENTER FUNCTION VALUE

NG

NG

CHECK D601, C606 RELATIVE CIRCUIT

CHECK THE VOLTAGE OF IC101

RELATIVE CIRCUIT

CHECK IC401 PIN 20, 21, 22, 23

RELATIVE CIRCUIT

CHECK IC401 & IC601 RELATIVE CKT

17

Page 19

6-7 SIDE-PIN CUSHION DISTORTION

READJUST SIDEPIN FUNCTION VALUE

READJUST FOCUS CONTROL

ADJUST VOLUME CONTROL

NG

CHECK IC401, Q404, Q405, Q406

RELATIVE CKT.

6-8 POOR FOCUS

NG CHECK FOCUS CONTROL UNIT, FOCUS

LEAD WIRE, CRT SOCKET & CRT

6-9 NO SOUND (FOR 5EA/5ElrA ONLY)

CHECK IC501

PIN 14 ABOUT 14V

OK

ENSURE THE SOUND SOURCE

IS POWER ON

OK

ENSURE THE SOURCE CABLE

CONNECTION

OK

NG

OK

CHECK IC501

NG

OK

SPEAKER FAILURE

CHECK POWER

SUPPLY CIRCUIT

IC501 FAILURE

18

Page 20

6-10 POWER SUPPLY TROUBLE SHOOTING CHART

BEFORE CHECK SW .REG. PLEASE REFER TO THE PO WER SUPPLY BLOCK DIAGRAM

POWER SUPPLY OUTPUT: (A) VARIABLE OUTPUT : 90V - 160V

(D EPENDING UPON H.SYNC FREQUENCY)

(B) CONSTANT OUTPUT : 6.3V, 15V, -12V, 75V

90V, 20V, 12V

CHECK MAIN PC BOARD

NG

OK

CHECK THE HIGE VOLTAGE

OF CRT ABOUT 23.5 ~ 25.5KV

NG

OK

CHECK THE VOLTAGE OF CRT

HEATER ABOUT 6.3V

NG

OK

CHECK SCREEN VOLTAGE ABOUT

400V TO 600V

LESS THAN 300V

OK

CHECK POWER SAVING CIRCUIT,

Q909, Q910

CHECK FAILSAFE CKT IC402

PIN 2 RELATIVE CKT.

CHECK CRT'S HEATER

RELATIVE CIRCUIT Q907, Q908

CHECK FBT. D706, R723, C713

BRIGHTNESS SET TO MAX.

THEN CHECK CRT G1 VOLTAGE

NG

OK

CHECK VOLTAGE OF THE CRT

CATHODE ABOUT 60V TO 70V

NG

CHECK BRIGHTNESS CIRCUIT

Q703, Q704, Q705 RELATIVE CKT.

REFER ITEM 8-2

"ABNORMAL DISPLAY"

19

Page 21

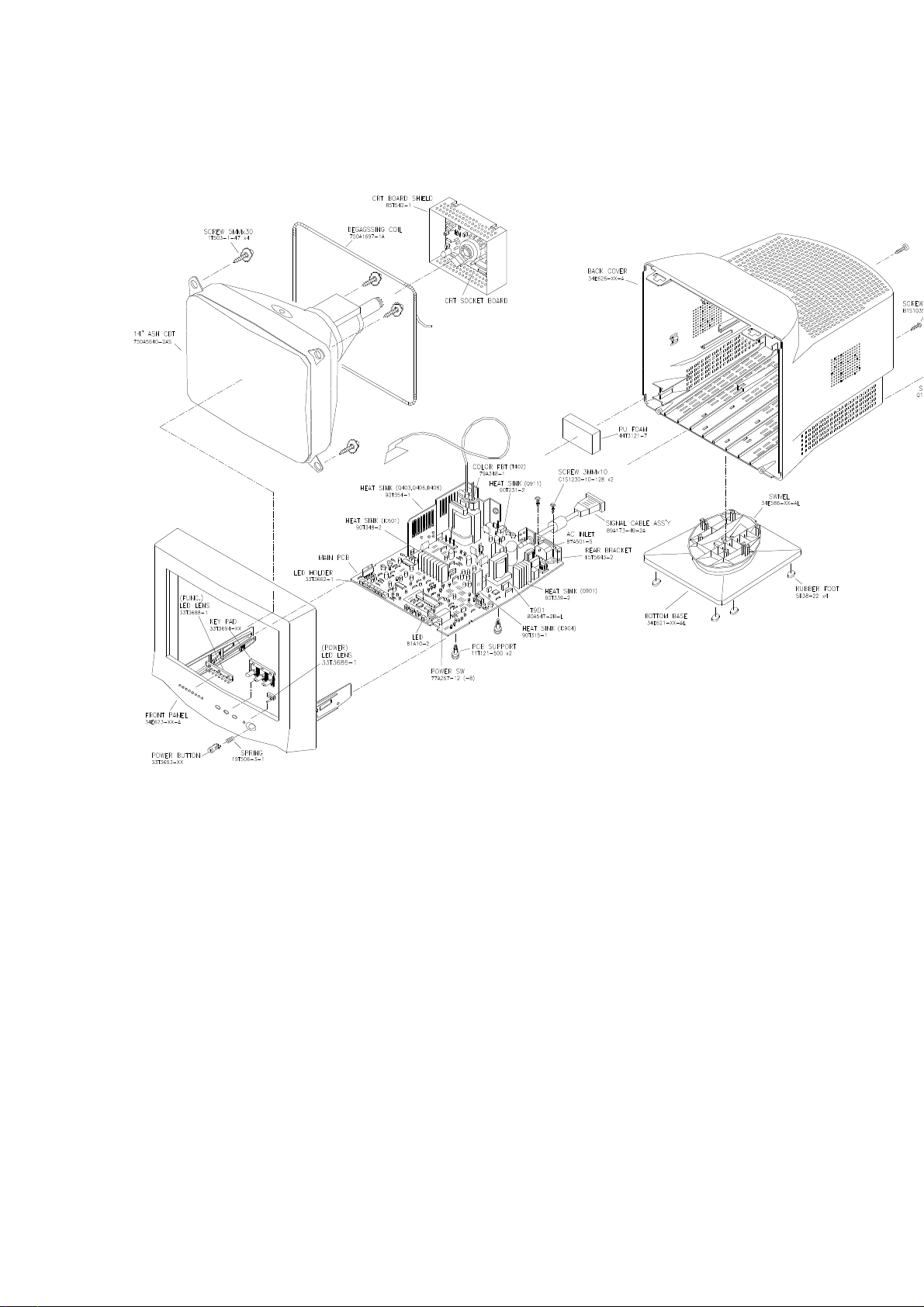

8. MECHANICAL OF CABINET FRONT DIS-ASSEMBLY

20

Page 22

PARTS LIST OF CABINET

LOCATION

D356P SPECIFICATION

(LOW RADIATION 110V)

CMC356PA CHAS ASS'Y

AUPC556NA AUDIO BOARD

1A 503- 1 - 47 SCREW

5A 38- 8 RUBBER WASHER

5A 6001- 1 RUBBER WASHER

9A 84- 23 TERMINAL LUG

11A 112- 1 WIRE MOUNTS

11A 6001- 1 WIRE MOUNT

15A 5663- 500 RETAINER SPEAKER

19A 403- 5 BUMPER STEEL SPRING

26A 800- 504 - 1 BARCODE

33A 3598- 1 ABS PLASTIC

33A 3697- 1 KEY PAD

33A 3698- 1 FUNC LED LENS

34A 625- 5 - A FRONT PANEL

40A 153- 63 CRT LABEL

40A 154- 501 - 1 HI-POT GROUNDING LABEL

40A 581- 26 - 659 LABEL

40A 581- 26 - 704 LABEL

!

!

!

CM1 95A 205R- 30 - 132 WIRE AS S ’ Y

40A 2006- 615 - 2C ID LABEL

41A 68- 563 WARRANTY CARD

41A 68- 576 WARRANTY CARD

41A 520- 615 - 1B MANUAL

44A 3121- 510 PU FOAM

44A 6528- 1 - EPS CUSHION

44A 6528- 2 EPS CUSHION

44A 6528- 615 - 2D CARTON

45A 76- 28 - R PE BAG

45A 77- 500 BARCODE RIBBON

45A 88- 1 - R PE BAG

71A 303- 9 - C SPPILER

85A 542- 1 SHIELD

89A 171- 25A POWER CORD

89A 173- 56 - 4 AUDIO CABLE

95A 91- 205 - 1 WIRE

95A 205R- 30 - 122 WIRE

95A 8013- 2 WIRE

B1A 1035- 10 - 128 SCREW

Q1A 330- 10 - 128 SCREW

Q1A 340- 16 - 128 SCREW

Q1A 1030- 10 - 128 SCREW

705A 356N- F34 - 01 CAB'T ASS'Y

705A 556T- C78 - 01 SPEAKER ASS’Y

750A 1697- 1G - D DEG. COIL UL/CSA

750A 5640- 2AS .28MM/CHUNGHWA

PARTS LIST OF AUDIO BOARD

LOCATION AUPC556NA SPECIFICATION

C507 67A 309- 101 - 3T 100uF +-20% 16V

EARPHON 88A 302- 5J PHONE JACK

H501 95A 8013- 5

P503-A 33A 3278- 4 4P PLUG

715A 602- 2 AUDIO PCB

R590 95A 90- 23 TIN COATED

R591 95A 90- 23 TIN COATED

505 WIRE ASS’Y

-

21

21

Page 23

PARTS LIST OF CHAS

LOCATION CMC356PA SPECIFICATION

CMP356PAAI MAIN PC BOARD ASS'Y

CRPC356P CRT BOARD ASS'Y

11A 121- 500 PC SUPPORT

15A 5640- 1

15A 5643- 3 BRACKET

33A 3662- 1 LED HOLDER

40A 581- 26

40A 581- 26

71A 55- 2 BEAD

71A 100- 7

!

(GND2) 95A 205- 30 - 082 WIRE ASS'Y

(LED1) 81A 10- 2 - S LED

(SW101) 77A 602- 1 - HJ TSVB-3B TACT SWITCH

(SW102) 77A 602- 1 - HJ TSVB-3B TACT SWITCH

(SW103) 77A 602- 1 - HJ TSVB-3B TACT SWITCH

AS1 95A 207T- 30 - 052 WIRE ASS'Y

AUDIO I 88A 302- 6J AUDIO JACK

C414 67A 305- 470 - 9 47uF +-20% 100V

C418 63A 210J- 392 - 8FC 3900PF +-5% 2KV

C419 63A 210J- 432 - 8FC 4300PF +-5% 2KV

C421 65A 1K- 102 - 1A 1000PF +-10% 1KV

C422 63A 100J- 225 - 59 2.2Uf +-5% 100V

!

!

C425 63A 210J- 334 - 3CC 0.33Uf +-5% 400V

C427 63A 210J- 364 - 2CC 0.36Uf +-5% 250V

C431 63A 210J- 104 - 2BC 0.1Uf +-5% 250V

C432 67A 215- 470 - 11J 47Uf 200V JAMICON

C440 65A 2K- 470 - 6B 47P 2KVF +-10% Y5U

C441 64A 44J- 224 - 1AT 0.22Uf 100V

C502 67A 305- 222 - 3M 2200Uf 16V

C603 67A 309- 471 - 3 470uF +-20% 16V

C605 67A 309- 221 - 6 220uF +-20% 35V

C606 67A 309- 102 - 3 1000uF +-20% 16V

C709 65A 1K- 561 - 5A 560PF 10% 1KV Y5P

C713 67A 309- 220 - 10 22uF +-20% 160V

C714 67A 305- 331 - 3 330Uf 20% 16V

C900 65A 305M- 472 - 2B 4700PF +-20% 400VAC/25 0VAC

C901 63A 107- 224 - 5S 0.22uF +-20% 250V

C902 63A 107- 104 - 5 0.1uF +-20% 250V

C907 67A 30- 151 - 14L 150uF +-20% 400V

C915 65A 2M- 103 - 3B 0.01uF +-20% 2KV Z5U

C923 65A 1K- 331 - 5A 330PF 1KV

C931 67A 305- 101 - 11J 100uF +-20% 200V

C936 67A 305- 102 - 4 1000uF +-20% 25V

C937 67A 305- 471 - 3 470uF +-20% 16V

C938 67A 305- 471 - 3 470uF +-20% 16V

C939 67A 305- 102 - 3 1000uF +-20% 16V

84A 33- 10 FUSE

89A 173- 49A

90A 345- 501

95A 90- 24 TIN COATED

B1A 1030- 10

B1A 1040- 8

M1A 1140- 6

M1A 1730- 11

Q1A 1135- 10

705A 356N- C57

705A 356N- C57

705A 356P- C56

705A 356P- C57

705A 356P- C87

705A 569D- C56

750A 5640- 356

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

A GND LUG

684 FAIL-SAFE LABEL

702 LABEL

H FERRITE CORE

2D SIGNAL CABLE

2 HEAT SINK

128 SCREW

128 SCREW

128 SCREW

128 SCREW

128 SCREW

02 Q901 ASS'Y

03 Q911 ASS'Y

01 IC601 ASS'Y

01 D408/Q403/Q406 ASS’Y

01 AC LINET INALWAYS

02 IC904 ASS'Y

ASP CRT ASS'Y

22

Page 24

LOCATION CMC356PA SPECIFICATION

C942 67A 309- 102 - 4 1000uF +-20% 25V

C950 65A 1K- 221 - 5A 220PF +-10% Y5P 1KV

C951 67A 215- 470 - 11J 47uF 200V JAMI CO N

C955 65A 1K- 221 - 5A 220PF+-10% Y5P 1KV

!

!

C963 65A 305M- 472 - 2B2 4700PF +- 20% 400VAC/250VAC

C964 65A 305M- 472 - 2B2 4700PF +- 20% 400VAC/250VAC

CN902 33A 3074- 1 2P PLUG

D1 93A 64- 11H - 52T DIODE IN4148

D901 93A 52- 41 - 52T DIODE IN5406

D902 93A 52- 41 - 52T DIODE IN5406

D903 93A 52- 41 - 52T DIODE IN5406

D904 93A 52- 41 - 52T DIODE IN5406

D919 93A 3040- 10 DIODE

D922 93A 3020- 6 - 52T STPR320

D923 93A 3020- 8 RG-4Z

F901 84A 7- 45 FUSE 2.5A 250V S-B/BEL

H802 95A 8013- 9 - 7 HARNESS 9P-9P 370MM

H803 95A 8013- 6 - 1 6-6P WIRE

HS1 95A 205T- 30 - 042 WIRE

IC101 56A 1125- 33 - X NT68P61A

IC102 56A 1133- 8 8 PIN AT24C04 EEPROM

IC104 56A 74LS- 14 - H 14 PIN IC 74LS14

IC401 56A 573- 1 TDA9111

!

IC501 56A 535- 1 TDA7057AQ

IC901 56A 379- 12 UC3842AM

JJ1 95A 201- 69 - 012 WIRE

L401 73A 147- 103 - L LINEARITY COIL

L404 73A 253- 70 1.5MH +-5% 0.3A

L405 73A 253- 68 - L 180UH +-10%

L901 73A 174- 2 - LA COIL 15MH MIN

L903 73A 259- 4 200UH +-5%

L906 73A 253- 90 - L CHOKE COIL

LED2 81A 2- 3 - 2B LED GREENBL-B2441J

LED3 81A 2- 3 - 2B LED GREENBL-B2441J

LED4 81A 2- 3 - 2B LED GREENBL-B2441J

LED5 81A 2- 3 - 2B LED GREENBL-B2441J

LED6 81A 2- 3 - 2B LED GREENBL-B2441J

LED7 81A 2- 3 - 2B LED GREENBL-B2441J

LED8 81A 2- 3 - 2B LED GREENBL-B2441J

LED9 81A 2- 3 - 2B LED GREENBL-B2441J

P401 33A 3192- 500 2 P PLUG

P402 33A 3192- 4 4 P PLUG

P403 33A 8009- 3 3 P PLUG

P503 33A 3278- 5 5 P PLUG

NR901 61A 58- 8 NTCR 15 OHM

!

PR901 61A 52- 22 - 3 220VAC 14 OHM PTCR

Q410 57A 600- 14 CEPF630

Q705 57A 690- 1 POWER AMP. 2SB649A/HITACH

Q907 57A 690- 2 PNP TR. BD140

Q909 57A 728- 3 HSB772P/HSB772E

R127 61A 152M- 910 - 64 91 OHM +-5% 2W

R426 61A 153M- 220 - 59 22 OHM +-5% 3W

R428 61A 153M- 688 - 59 0.68 OHM +-5% 3W

R456 61A 153M- 391 - 59 390 OHM +-5% 3W

R457 61A 153M- 330 - 59 33 OHM +-5% 3W

R458 61A 153M- 560 - 59 56 OHM +-5% 3W

R461 61A 153M- 151 - 59 150 OHM +-5% 3W

R501 61A 153M- 339 - 59 3.3 OHM 3W

R509 61A 153M- 339 - 59 3.3 OHM 3W

R510 61A 153M- 339 - 59 3.3 OHM 3W

R607 61A 208- 918 - 64 0.91 OHM +-5% 1W

R608 61A 152M- 100 - 64 10 OHM +-5% 2W

R723 61A 152M- 101 - 64 100 OHM +-5% 2W

R927 61A 153M- 333 - 59 33K OHM +-5% 3W

R929 61A 20K- 338 - GB1 0.33 OHM +-10% 2W

R955 61A 303- 228 - 64 0.22 OHM +-5% 1W

R989 61A 152M- 471 - 64 470 OHM +-5% 2W

23

Page 25

LOCATION CMC356PA SPECIFICATION

SS1 95A 207T- 30 - 052 WIRE

SW901 77A 267- 12 - HJ PWR SW

!

T401 79A 167- 71A DRIVER X'FMR

T402 79A 355 4 - A FBT

T901 80A 356T 1 - L POWE R X'FMR

TP902 9A 211- 2 PIN

VR701 75A 335- 473 47K OHM +-30%

VR702 75A 335M- 204 - H 200K OHM METAL VR

VR901 75A 335- 101 100 OHM +-30%

!

VR902 75A 335- 223 22K OHM +-30%

X101 93A 22- 22 8.0000 MHZ/S.P.K.

PARTS LIST OF MAIN PC BOARD

LOCATION CMP356PAAI SPECIFICATION

6A 31- 4 BRASS

715A 684- G MAIN BOARD

C103 65A 450- 104 - 7T 0.1uF +80-20% Y5V 50V

C104 67A 309- 101 - 4T 100uF +-20% 25V

C105 65A 450- 104 - 7T 0.1uF +80-20% Y5V 50V

C106 67A 309- 330 - 7T 33uF +-20% 50V

C109 67A 60- 229 - 7T 2.2uF /50V

C110 67A 309- 109 - 7T 1.0Uf +-20% 50V

C113 67A 309- 101 - 4T 100Uf +-20% 25V

C130 65A 442- 100 - 13T 10PF +-5% 50V NPO

C160 65A 444- 101 - 5T 100 PF 10% 50V Y5P

C162 65A 444- 102 - 13T 1000 PF 10% 50V Z5P

C163 65A 444- 101 - 5T 100 PF 10% 50V Y5P

C164 65A 450- 104 - 7T 0.1uF +80-20% Y5V 50V

C403 64A 44J- 223 - 1AT 0.22uF +-2% 100V

C405 67A 309- 470 - 3T 47uF +-20% 16V

C406 65A 450- 104 - 7T 0.1uF +80-20% Y5V 50V

C407 65A 444- 101 - 5T 100 PF 10% 50V Y5P

C408 65A 444- 101 - 5T 100 PF 10% 50V Y5P

C410 65A 450- 104 - 7T 0.1uF +80-20% Y5V 50V

C411 67A 309- 470 - 3T 47uF +-20% 16V

C412 65A 442- 221 - 13T 220PF +-5% 50V

C413 65A 450- 104 - 7T 0.1uF +80-20% Y5V 50V

C415 64A 176J- 102 - 1T 0.001uF +-5% 100V

C417 64A 176J- 154 - 0T 0.15uF +-5% 63/50V

C423 65A 444- 332 - 5T 3300 PF 10% 50V Y5P

C430 95A 90- 23 TIN COATED

C433 67A 309- 100 - 7T 10Uf +-20% 50V

!

C434 67A 309- 220 - 7T 22Uf +-20% 50V

C435 64A 44J- 103 - 1AT 0.01Uf +-2% 100V

C436 67A 305- 470 - 7T 47Uf +-20% 50V

C437 67A 309- 220 - 3T 22Uf +-20% 16V

C439 67A 309- 109 - 7T 1.0Uf +-20% 50V

C442 64A 176J- 272 - 1T 2700PF +-5% 100V

C443 67A 309- 470 - 3T 47Uf +-20% 16V

C444 65A 450- 104 - 7T 0.1Uf +80-20% Y5V 50V

C445 95A 90- 23 TIN COATED

C446 65A 444- 101 - 5T 100PF10% Y5P 50V

C447 64A 45G- 102 - 1AT 0.001uF +-2% 100V

C448 64A 176J- 473 - 1T 0.047uF +-5% 100V

C449 64A 44J- 473 - 1AT 0.047uF +-2% 100V

C460 65A 450- 333 - 7T 0.033uF +-5% 50V

C463 64A 44J- 103 - 1AT 0.1uF +-2% 100V

C476 65A 450- 104 - 7T 0.1uF +80-20% Y5V 50V

C503 67A 309- 100 - 7T 10Uf +-20% 50V

C504 67A 309- 100 - 7T 10Uf +-20% 50V

C505 67A 309- 109 - 7T 1Uf +-20% 50V

24

Page 26

LOCATION CMP356PAI SPECIFICATION

C506 67A 309- 109 - 7T 1Uf +-20% 50V

C510 67A 176J- 472 - 1T 0.0047Uf +/5% 100V

C511 64A 176J- 472 - 1T 0.0047Uf +/5% 100V

C601 64A 44J- 104 - 1AT 0.1uF +-2% 100V

C602 65A 444- 331 - 5T 330PF10% Y5P 50V

C604 64A 176J- 224 - 0T 0.22uF +-5% 63V

C607 65A 444- 681 - 5T 680PF10% Y5P 50V

C608 65A 450- 104 - 7T 0.1uF +80-20% Y5V 50V

C609 64A 44J- 104 - 1AT 0.1uF +-2% 100V

C610 64A 176J- 474 - 0T 0.47uF +-5% 63V/50V

C611 65A 450- 104 - 7T 0.1uF +80-20% Y5V 50V

C612 67A 309- 470 - 3T 47uF +-20% 16V

C613 64A 44J- 154 - 1AT 0.15uF +-2% 100V

C614 65A 444- 101 - 5T 100PF10% Y5P 50V

C615 64A 44J- 103 - 1AT 0.01uF +-2% 100V

C705 67A 309- 220 - 7T 22uF +-20% 50V

C707 64A 176J- 223 - 2T 0.022uF +-5% 250V

C710 64A 176J- 224 - 1T 0.22uF +-5% 100V

C712 67A 60- 229 - 7T 2.2uF +-20% 50V

C914 67A 309- 479 - 7T 4.7uF +-20% 50V

C916 67A 305- 101 - 4T 100uF +-20% 25V

C917 67A 305- 229 - 7T 2.2uF +-20% 50V

C918 64A 44J- 332 - 1AT 330pF +-2% 100V

C920 64A 44J- 102 - 1AT 1000PF 100V

C921 64A 44J- 104 - 1AT 0.1uF +-5% 100V

!

!

C922 64A 176J- 104 - 1T 0.1uF +-5% 100V

C924 64A 44J- 332 - 1AT 330PF 100V

C925 67A 309- 100 - 7T 10uF +-20% 50V

C941 64A 176J- 104 - 0T 0.1uF +-5% 63V

C943 64A 176J- 222 - 1AT 2200PF 100V

C944 65A 450- 104 - 7T 0.1uF +80-20% Y5V 50V

C945 64A 44J- 104 - 1AT 0.1uF +-5% 100V

C946 64A 176J- 104 - 2T 0.1uF +-5% 250V MPE

C947 67A 309- 479 - 7T 4.7uF +-20% 50V

C961 64A 44J- 103 - 1AT 0.01uF +-5% 100V

C965 64A 44J- 103 - 1AT 0.01uF +-5% 100V

C995 64A 44J- 472 - 1AT 4700PF 100V

D101 93A 64- 11H - 52T DIODE IN4148

D102 93A 64- 11H - 52T DIODE IN4148

D103 93A 64- 11H - 52T DIODE IN4148

D104 93A 61- 11H - 52T DIODE IN4148

D125 61A 602- 102 - 52T 1K OHM 5% 1/6W

D402 93A 64- 11H - 52T DIODE IN4148

D404 93A 64- 11H - 52T DIODE IN4148

D403 93A 1002- 1T - 52T IN5817 1A/20V

D406 93A 60- 21P - 52T PS156R

D407 93A 60- 21P - 52T PS156R

D409 93A 64- 11H - 52T DIODE IN4148

D411 93A 64- 19G - 52T FAST RECPVERY

D412 93A 64- 11H - 52T DIODE IN4148

D414 93A 60- 38T - 52T FR103

D415 93A 60- 26T - 52T FR107

D418 93A 60- 21P - 52T PS156R

D419 93A 60- 21P - 52T PS156R

D420 93A 64- 11H - 52T DIODE IN4148

D450 93A 64- 11H - 52T DIODE IN4148

D460 93A 64- 11H - 52T DIODE IN4148

D601 93A 52- 47P - 52T IN4004

D602 93A 64- 11H - 52T DIODE IN4148

D603 93A 64- 11H - 52T DIODE IN4148

D701 93A 64- 11H - 52T DIODE IN4148

D702 93A 64- 11H - 52T DIODE IN4148

D704 93A 52- 47P - 52T IN4004

D706 93A 60- 21P - 52T PS156R

D710 95A 90- 23 TIN COATED

D721 95A 90- 23 TIN COATED

25

Page 27

LOCATION CMP356PAI SPECIFICATION

D909 93A 52- 1T - 52T 1A 600V IN4005

D910 93A 60- 21P - 52T PS156R

D911 93A 64- 31T - 52T SWITCH DIODE

D912 93A 64- 31T - 52T SWITCH DIODE

D913 93A 64- 11H - 52T DIODE IN4148

D914 93A 64- 11H - 52T DIODE IN4148

D925 93A 3020- 6 - 52T STPR320

D926 93A 64- 11H - 52T DIODE IN4148

D927 93A 64- 11H - 52T DIODE IN4148

D928 93A 64- 11H - 52T DIODE IN4148

D930 93A 1040- 2 - 52T F.R.D. UF4004

D995 93A 64- 11H - 52T DIODE IN4148

D929 93A 52- 47P - 52T DIODE IN4004

FB401 71A 55- 9 - T SHIELDED

FB501 95A 90- 23 TIN CO ATED

FB502 95A 90- 23 TIN CO ATED

!

FB503 95A 90- 23 TIN CO ATED

FB901 95A 90- 23 TIN CO ATED

FB902 95A 90- 23 TIN CO ATED

FB903 95A 90- 23 TIN CO ATED

FB904 71A 55- 9 - T SHIELD BEAD

FB905 95A 90- 23 TIN COATED

FB907 71A 55- 9 - T SHIELD BEAD

J001 95A 90- 23 TIN COATED

J003 95A 90- 23 TIN COATED

J004 95A 90- 23 TIN COATED

J005 95A 90- 23 TIN COATED

J006 95A 90- 23 TIN COATED

J008 95A 90- 23 TIN COATED

J009 95A 90- 23 TIN COATED

J010 95A 90- 23 TIN COATED

J011 95A 90- 23 TIN COATED

J012 95A 90- 23 TIN COATED

J013 95A 90- 23 TIN COATED

J014 95A 90- 23 TIN COATED

J015 95A 90- 23 TIN COATED

J016 95A 90- 23 TIN COATED

J019 95A 90- 23 TIN COATED

J020 95A 90- 23 TIN COATED

J021 95A 90- 23 TIN COATED

J022 95A 90- 23 TIN COATED

J023 95A 90- 23 TIN COATED

J024 95A 90- 23 TIN COATED

J025 95A 90- 23 TIN COATED

J026 95A 90- 23 TIN COATED

J027 95A 90- 23 TIN COATED

J028 95A 90- 23 TIN COATED

J029 95A 90- 23 TIN COATED

J030 95A 90- 23 TIN COATED

J032 95A 90- 23 TIN COATED

J033 95A 90- 23 TIN COATED

J034 95A 90- 23 TIN COATED

J036 95A 90- 23 TIN COATED

J037 95A 90- 23 TIN COATED

J038 95A 90- 23 TIN COATED

J039 95A 90- 23 TIN COATED

J041 95A 90- 23 TIN COATED

J042 95A 90- 23 TIN COATED

J043 95A 90- 23 TIN COATED

J044 95A 90- 23 TIN COATED

J045 95A 90- 23 TIN COATED

J046 95A 90- 23 TIN COATED

J049 95A 90- 23 TIN COATED

J050 95A 90- 23 TIN COATED

J051 95A 90- 23 TIN COATED

26

Page 28

LOCATION CMP356P AI SPECIFICATION

J052 95A 90- 23 TIN COATED

J053 95A 90- 23 TIN COATED

J054 95A 90- 23 TIN COATED

J057 95A 90- 23 TIN COATED

J058 95A 90- 23 TIN COATED

J061 95A 90- 23 TIN COATED

J062 95A 90- 23 TIN COATED

J063 95A 90- 23 TIN COATED

J064 95A 90- 23 TIN COATED

J065 95A 90- 23 TIN COATED

J066 95A 90- 23 TIN COATED

J067 95A 90- 23 TIN COATED

J068 95A 90- 23 TIN COATED

J069 95A 90- 23 TIN COATED

J070 95A 90- 23 TIN COATED

J071 95A 90- 23 TIN COATED

J072 95A 90- 23 TIN COATED

J073 95A 90- 23 TIN COATED

J074 95A 90- 23 TIN COATED

J075 95A 90- 23 TIN COATED

J077 95A 90- 23 TIN COATED

J078 95A 90- 23 TIN COATED

J079 95A 90- 23 TIN COATED

J080 95A 90- 23 TIN COATED

J081 95A 90- 23 TIN COATED

J082 95A 90- 23 TIN COATED

J083 95A 90- 23 TIN COATED

J084 95A 90- 23 TIN COATED

J085 95A 90- 23 TIN COATED

J086 95A 90- 23 TIN COATED

J087 95A 90- 23 TIN COATED

J088 95A 90- 23 TIN COATED

J089 95A 90- 23 TIN COATED

J090 95A 90- 23 TIN COATED

J091 95A 90- 23 TIN COATED

J092 95A 90- 23 TIN COATED

J093 95A 90- 23 TIN COATED

J094 95A 90- 23 TIN COATED

J095 95A 90- 23 TIN COATED

J096 95A 90- 23 TIN COATED

J097 95A 90- 23 TIN COATED

J098 95A 90- 23 TIN COATED

J099 95A 90- 23 TIN COATED

J100 95A 90- 23 TIN COATED

J101 95A 90- 23 TIN COATED

J102 95A 90- 23 TIN COATED

J103 95A 90- 23 TIN COATED

J104 95A 90- 23 TIN COATED

J105 95A 90- 23 TIN COATED

J107 95A 90- 23 TIN COATED

J108 95A 90- 23 TIN COATED

J109 95A 90- 23 TIN COATED

J110 95A 90- 23 TIN COATED

J111 95A 90- 23 TIN COATED

J112 95A 90- 23 TIN COATED

J113 95A 90- 23 TIN COATED

J114 95A 90- 23 TIN COATED

J115 95A 90- 23 TIN COATED

J116 95A 90- 23 TIN COATED

J117 95A 90- 23 TIN COATED

J118 95A 90- 23 TIN COATED

J120 95A 90- 23 TIN COATED

J121 95A 90- 23 TIN COATED

J123 95A 90- 23 TIN COATED

J125 95A 90- 23 TIN COATED

27

Page 29

LOCATION CMP356QAI SPECIFICATION

J127 95A 90- 23 TIN COATED

J130 95A 90- 23 TIN COATED

L101 73A 53- 339 - 10T 3.3UH +-10%

L402 95A 90- 23 TIN COATED

L403 95A 90- 23 TIN COATED

L406 95A 90- 23 TIN COATED

L907 95A 90- 23 TIN COATED

Q101 57A 446- 1 - T TR. 2SC1213AC

Q401 57A 419- P - T 2SC945P/NEC

Q402 57A 706- 2 - T 2N7000

Q404 57A 420- SG - T KSA733GC SAMSUNG

Q405 57A 420- SG - T KSA733GC SAMSUNG

Q408 57A 419- P - T 2SC945P/NEC

Q601 57A 419- Y - T TR. 2SC1815Y TOSHIBA

Q703 57A 419- P - T 2SC945P/NEC

Q704 57A 420- SG - T KSA733GC SAMSUNG

Q707 57A 419- Y - T TR. 2SC1815Y TOSHIBA

Q904 57A 594- 501 - T TR. 2N6517

Q908 57A 419- P - T 2SC945P/NEC

Q910 57A 419- P - T 2SC945P/NEC

Q912 57A 446- 1 - T 1213AC

Q914 95A 90- 23 TIN COATED

Q920 57A 727- 2 - T 2SA673C

R100 61A 602- 472 - 52T 4.7K OHM +-5% 1/6W

R101 61A 602- 102 - 52T 1K OHM +-5% 1/6W

R102 61A 602- 102 - 52T 1K OHM +-5% 1/6W

R103 61A 602- 102 - 52T 1K OHM +-5% 1/6W

R104 61A 602- 102 - 52T 1K OHM +-5% 1/6W

R105 61A 602- 102 - 52T 1K OHM +-5% 1/6W

R106 61A 602- 102 - 52T 1K OHM +-5% 1/6W

R107 61A 602- 102 - 52T 1K OHM +-5% 1/6W

R108 61A 602- 512 - 52T 5.1K OHM +-5% 1/6W

R109 61A 602- 512 - 52T 5.1K OHM +-5% 1/6W

R110 61A 602- 221 - 52T 220 OHM +-5% 1/6W

R111 61A 602- 221 - 52T 220 OHM +-5% 1/6W

R112 61A 602- 622 - 52T 6.2K OHM +-5% 1/6W

R113 61A 602- 103 - 52T 10K OHM +-5% 1/6W

R114 61A 602- 102 - 52T 1K OHM +-5% 1/6W

R116 61A 602- 472 - 52T 4.7K OHM +-5% 1/6W

R117 61A 602- 101 - 52T 100 OHM +-5% 1/6W

R118 61A 602- 103 - 52T 10K OHM +-5% 1/6W

R119 61A 602- 103 - 52T 10K OHM +-5% 1/6W

R122 61A 172- 221 - 52T 220 OHM +-5% 1/4W

R126 61A 172- 202 - 52T 2K OHM +-5% 1/4W

R132 61A 602- 102 - 52T 1K OHM +-5% 1/6W

R134 61A 602- 912 - 52T 9.1K OHM +-5% 1/6W

R135 61A 602- 152 - 52T 1.5K OHM +-5% 1/6W

R136 61A 602- 222 - 52T 2.2K OHM +-5% 1/6W

R137 61A 602- 272 - 52T 2.7K OHM +-5% 1/6W

R140 61A 602- 472 - 52T 4.7K OHM +-5% 1/6W

R143 61A 602- 101 - 52T 100 OHM +-5% 1/6W

R149 61A 602- 152 - 52T 1.5K OHM +-5% 1/6W

R156 61A 602- 103 - 52T 10K OHM +-5% 1/6W

R157 61A 602- 103 - 52T 10K OHM +-5% 1/6W

R160 61A 602- 221 - 52T 220 OHM +-5% 1/6W

R161 61A 602- 222 - 52T 2.2K OHM +-5% 1/6W

R165 61A 602- 222 - 52T 2.2K OHM +-5% 1/6W

R166 61A 602- 102 - 52T 1K OHM +-5% 1/6W

R172 61A 602- 102 - 52T 1K OHM +-5% 1/6W

R180 61A 602- 362 - 52T 3.6K OHM +-5% 1/6W

R185 93A 64- 11H - 52T DIODE 1N4148

R402 61A 172- 222 - 52T 2.2K OHM +-5% 1/4W

R403 61A 602- 101 - 52T 100 OHM +-5% 1/6W

R404 61A 602- 101 - 52T 100 OHM +-5% 1/6W

R405 61A 602- 101 - 52T 100 OHM +-5% 1/6W

28

Page 30

LOCATION CMP356PAI SPECIFICATION

R406 61A 602- 101 - 52T 100 OHM +-5% 1/6W

R408 61A 172- 304 - 52T 300K OHM +-5% 1/4W

R409 61A 172- 364 - 52T 360K OHM +-5% 1/4W

R410 61A 210- 472 - 52T 4.7K OHM +-1% 1/6W

R411 61A 602- 182 - 52T 1.8K OHM +-5% 1/6W

R414 61A 172- 242 - 52T 2.4K OHM +-5% 1/4W

R415 61A 172- 753 - 52T 75K OHM +-5% 1/4W

R416 61A 210- 183 - 52T 18K OHM +-1% 1/6W

R417 95A 90- 23 TIN COATED

R418 61A 210- 183 - 52T 18K OHM +-1% 1/6W

R420 61A 172- 472 - 52T 4.7K OHM +-5% 1/4W

R421 61A 172- 222 - 52T 2.2K OHM +-5% 1/4W

R422 61A 602- 101 - 52T 100 OHM +-5% 1/6W

R423 61A 602- 203 - 52T 20K OHM +-5% 1/6W

R425 61A 172- 221 - 52T 220 OHM +-5% 1/4W

R427 61A 175L- 220 - 52T 22 OHM +-5% 1/2W

R429 61A 175L- 100 - 52T 10 OHM +-5% 1/2W

R430 61A 172- 154 - 52T 150K OHM +-5% 1/4W

R431 95A 90- 23 TIN COATED

R433 61A 602- 222 - 52T 2.2K OHM +-5% 1/6W

R434 61A 602- 392 - 52T 3.9K OHM +-5% 1/6W

R435 61A 172- 122 - 52T 1.2K OHM +-5% 1/4W

R436 61A 602- 821 - 52T 820 OHM +-5% 1/6W

R440 61A 602- 562 - 52T 5.6KOHM +-5% 1/6W

R441 61A 175L- 913 - 52T 91K OHM +-5% 1/2W

R447 61A 172- 473 - 52T 47K OHM +-5% 1/4W

R448 61A 172- 202 - 52T 2K OHM +-5% 1/4W

R449 61A 172- 472 - 52T 4.7K OHM +-5% 1/4W

R450 61A 602- 563 - 52T 56K OHM +-5% 1/6W

R462 61A 602- 243 - 52T 24K OHM +-5% 1/6W

R470 61A 602- 133 - 52T 13K OHM +-5% 1/6W

R490 61A 210- 513 - 52T 51K OHM +-1% 1/6W

R497 61A 602- 561 - 52T 560K OHM +-5% 1/6W

R502 61A 210- 363 - 52T 36K OHM +-1% 1/6W

R503 61A 210- 303 - 52T 30K OHM +-1% 1/6W

R504 61A 602- 103 - 52T 10K OHM +-5% 1/6W

R505 61A 210- 363 - 52T 36K OHM +-1% 1/6W

R506 61A 210- 303 - 52T 30K OHM +-1% 1/6W

R507 61A 602- 103 - 52T 10K OHM +-5% 1/6W

R508 61A 210- 302 - 52T 3K OHM +-1% 1/6W

R520 95A 90- 23 TIN COATED

R601 61A 172- 243 - 52T 24K OHM +-5% 1/4W

R602 61A 172- 392 - 52T 3.9K OHM +-5% 1/4W

R603 61A 172- 123 - 52T 12K OHM +-5% 1/4W

R604 61A 172- 562 - 52T 5.6K OHM +-5% 1/4W

R605 61A 175L- 159 - 52T 1.5 OHM +-5% 1/2W

R606 61A 175L- 271 - 52T 270 OHM +-5% 1/2W

R609 61A 172- 564 - 52T 560K OHM +-5% 1/4W

R610 61A 172- 124 - 52T 120K OHM +-5% 1/4W

R611 61A 172- 563 - 52T 56K OHM +-5% 1/4W

R612 61A 172- 222 - 52T 2.2K OHM +-5% 1/4W

R613 61A 172- 102 - 52T 1K OHM +-5% 1/4W

R614 61A 172- 243 - 52T 24K OHM +-5% 1/4W

R707 61A 602- 472 - 52T 4.7K OHM +-5% 1/6W

R708 61A 602- 103 - 52T 10K OHM +-5% 1/6W

R709 61A 602- 103 - 52T 10K OHM +-5% 1/6W

R710 61A 602- 103 - 52T 10K OHM +-5% 1/6W

R711 61A 602- 103 - 52T 10K OHM +-5% 1/6W

R712 61A 602- 273 - 52T 27K OHM +-5% 1/6W

R713 61A 602- 562 - 52T 5.6K OHM +-5% 1/6W

R715 61A 602- 103 - 52T 10K OHM +-5% 1/6W

R720 61A 172- 104 - 52T 100K OHM +-5% 1/4W

R721 61A 175L- 102 - 52T 1K OHM +-5% 1/2W

R722 61A 602- 332 - 52T 3.3K OHM +-5% 1/6W

29

Page 31

LOCATION CMP356PAI SPECIFICATION

R724 61A 172- 105 - 52T 1MEG OHM +-5% 1/4W

R725 61A 204- 154 - 52T 150K OHM +-5% 1/2W

R726 61A 602- 102 - 52T 1K OHM +-5% 1/6W

R727 61A 175L- 823 - 52T 82K OHM +-5% 1/2W

R728 61A 172- 561 - 52T 560 OHM +-5% 1/4W

R729 61A 602- 470 - 52T 47 OHM +-5% 1/6W

R730 95A 90- 23 TIN COATED

R750 61A 204- 124 - 52T 120K OHM +-5% 1/2W

!

R901 61A 175L- 474 - 52T 470K OHM +-5% 1/2W

R922 61A 172- 273 - 52T 27K OHM +-5% 1/4W

R923 61A 172- 474 - 52T 470K OHM +-5% 1/4W

R924 61A 172- 474 - 52T 470K OHM +-5% 1/4W

R925 61A 172- 243 - 52T 24K OHM +-5% 1/4W

R926 61A 172- 183 - 52T 18K OHM +-5% 1/4W

R930 61A 172- 202 - 52T 2K OHM +-5% 1/4W

R931 61A 200- 109 - 52T 1 OHM +-1% 1/4W

R932 61A 172- 222 - 52T 2.2K OHM +-5% 1/4W

R933 61A 172- 361 - 52T 360 OHM +-5% 1/4W

R934 61A 172- 102 - 52T 1K OHM +-5% 1/4W

R935 61A 172- 334 - 52T 330K OHM +-5% 1/4W

R937 61A 172- 151 - 52T 150 OHM +-5% 1/4W

R938 61A 172- 220 - 52T 22 OHM +-5% 1/4W

R939 61A 172- 203 - 52T 20K OHM +-5% 1/4W

R940 61A 171- 393 - 52T 39K OHM +-2% 1/4W

R941 61A 172- 152 - 52T 1.5K OHM +-5% 1/4W

!

R942 61A 172- 680 - 52T 68 OHM +-5% 1/4W

R951 61A 172- 100 - 52T 10 OHM +-1% 1/4W

R952 61A 172- 473 - 52T 47K OHM +-1% 1/4W

R953 61A 172- 303 - 52T 30K OHM +-5% 1/4W

R956 61A 172- 122 - 52T 1.2K OHM +-5% 1/4W

R957 61A 172- 473 - 52T 47K OHM +-5% 1/4W

R958 61A 172- 102 - 52T 1K OHM +-5% 1/4W

R959 61A 172- 333 - 52T 33K OHM +-5% 1/4W

R960 61A 172- 473 - 52T 47K OHM +-5% 1/4W

R962 61A 172- 220 - 52T 22 OHM +-5% 1/4W

R963 61A 175L 681 - 52T 680 OHM +-5% 1/2W

R966 61A 172- 302 - 52T 3K OHM +-5% 1/4W

R967 61A 172- 132 - 52T 1.3K OHM +-5% 1/4W

R968 61A 172- 244 - 52T 240K OHM +-5% 1/4W

R969 61A 172- 753 - 52T 75K OHM +-5% 1/4W

R972 61A 172- 183 - 52T 18K OHM +-5% 1/4W

R977 61A 175L 154 - 52T 150K OHM +-5% 1/2W

R980 61A 172- 221 - 52T 220 OHM +-5% 1/4W

R986 61A 172- 106 - 52T 10MEG OHM +-5% 1/4W

R988 61A 172- 223 - 52T 22K OHM +-5% 1/4W

R995 61A 602- 393 - 52T 39 OHM +-5% 1/6W

R996 61A 602- 103 - 52T 10K OHM +-5% 1/6W

ZD108 95A 90- 23 TIN COATED

ZD110 93A 39- 73 - 52T ZENER 5.6V

ZD403 93A 39- 54 - 52T 12.7V DIODE 1/2W

ZD404 95A 90- 23 TIN COATED

ZD420 93A 39- 522 - 52T TZX20B

ZD701 93A 39- 518 - 52T TZX8V2A

ZD702 93A 39- 515 - 52T TZX3VDC

ZD902 93A 39- 55T - 52T 0.5W ZD BZX55C30

ZD903 93A 39- 124 - 52T ZD 18-2

30

Page 32

PARTS LIST OF CRT PC BOARD

LOCATION CRPC356P SPECIFICATION

87A 3503- 500 CRT SOCKET

40A 581- 26 - 605 LABEL

705A 556P- R56 - 01 IC802 ASS’Y

C812 67A 305- 102 - 3 1000uF +-20% 16V

C835 65A 2Z- 103 - 4B 0.01UF +80% -20% 2K Z5V

C836 65A 1K- 221 - 5A 220PF +-10% Y5P 1KV

C837 67A 305- 470 - 10 47uF +-20% 160V

C861 65A 517M- 103 - 3A 0.01uF/500V +-20% Z5U

IC801 56A 539- 2 LM1279N

P801 33A 3278- 11A 11P PLUG B11B-XHA/JS

P802 33A 3278- 9 9P PLUG

P803 33A 3278- 6 6P PLUG

R807 61A 208- 390 - 64 39 OHM +-5% 1W

R859 61A 152M- 101 - 64 100 OHM 5% 2W

VR801 75A 334- 222 2.2K OHM 30%

VR802 75A 334- 222 2.2K OHM 30%

VR803 75A 334- 303 30K OHM 30%

VR804 75A 334- 303 30K OHM 30%

VR805 75A 334- 303 30K OHM 30%

PARTS LIST OF CRT AUTO INS. PC BOARD

LOCATION CRP356PAI SPECIFICATION

715A 694- B CRT BOARD

C801 67A 305- 100 - 7T 10uF +-20% 50V

C802 67A 305- 100 - 7T 10uF +-20% 50V

C803 67A 305- 100 - 7T 10uF +-20% 50V

C804 65A 450- 104 - 7T 0.1uF +80% -20% Y5V 50V

C805 65A 450- 104 - 7T 0.1uF +80% -20% Y5V 50V

C806 65A 450- 104 - 7T 0.1uF +80% -20% Y5V 50V

C807 67A 309- 100 - 7T 10uF +-20% 50V

C808 67A 309- 470 - 3T 47uF +-20% 16V

C809 65A 450- 104 - 7T 0.1uF +80% -20% Y5V 50V

C810 67A 305- 470 - 7T 47uF +-20% 50V

C811 65A 450- 104 - 7T 0.1uF +80% -20% Y5V 50V

C813 65A 450- 104 - 7T 0.1uF +80% -20% Y5V 50V

C814 65A 450- 104 - 7T 0.1uF +80% -20% Y5V 50V

C815 65A 450- 104 - 7T 0.1uF +80% -20% Y5V 50V

C816 65A 450- 104 - 7T 0.1uF +80% -20% Y5V 50V

C818 67A 305- 470 - 7T 47uF +-20% 50V

C819 65A 450- 104 - 7T 0.1uF +80% -20% Y5V 50V

C820 64A 44J- 104 - 1AT 0.1uF +-5% 100V

C828 67A 70- 478 - 9T 0.47Uf 100V NP

C829 67A 70- 478 - 9T 0.47Uf 100V NP

C830 67A 70- 478 - 9T 0.47Uf 100V NP

C831 64A 44J- 104 - 1AT 0.1uF +-5% 100V

C832 64A 44J- 104 - 1AT 0.1uF +-5% 100V

C833 64A 44J- 104 - 1AT 0.1uF +-5% 100V

C834 64A 46J- 104 - 1AT 0.1uF +-5% 100V

C838 65A 444- 102 - 13T 1000PF +-10% Z5P 50V

C840 65A 517K- 102 - 3T 1000PF +-10% Z5U 500V

C841 65A 517K- 102 - 3T 1000PF +-10% Z5U 500V

C842 65A 517K- 102 - 3T 1000PF +-10% Z5U 500V

31

Page 33

LOCATION CRP356PAI SPECIFICATION

D801 93A 64- 11H - 52T DIODE IN4148

D802 93A 64- 11H - 52T DIODE IN4148

D803 93A 64- 11H - 52T DIODE IN4148

D804 93A 64- 11H - 52T DIODE IN4148

D805 93A 64- 11H - 52T DIODE IN4148

D806 93A 64- 11H - 52T DIODE IN4148

D807 93A 64- 11H - 52T DIODE IN4148

D808 93A 64- 19G - 52T FAST RECOVERY DIODE

D809 93A 64- 19G - 52T FAST RECOVERY DIODE

D810 93A 64- 19G - 52T FAST RECOVERY DIODE

D811 93A 64- 19G - 52T FAST RECOVERY DIODE

D812 93A 64- 19G - 52T FAST RECOVERY DIODE

D813 93A 64- 19G - 52T FAST RECOVERY DIODE

D814 93A 64- 19G - 52T FAST RECOVERY DIODE

D815 93A 64- 19G - 52T FAST RECOVERY DIODE

D816 93A 64- 19G - 52T FAST RECOVERY DIODE

D817 93A 52- 1T - 52T 1A 600V IN4005

FB801 95A 90- 23 TIN COATED

FB802 95A 90- 23 TIN COATED

FB803 95A 90- 23 TIN COATED

J801 95A 90- 23 TIN COATED

J802 95A 90- 23 TIN COATED

J803 95A 90- 23 TIN COATED

J804 95A 90- 23 TIN COATED

J805 95A 90- 23 TIN COATED

J806 95A 90- 23 TIN COATED

J807 95A 90- 23 TIN COATED

J808 95A 90- 23 TIN COATED

J809 95A 90- 23 TIN COATED

J810 95A 90- 23 TIN COATED

L801 73A 54- 479 - 5T PEAKING COIL 4.7uF 5%

L805 73A 54- 478 - 10T PEAKING COIL

L806 73A 54- 478 - 10T PEAKING COIL

L807 73A 54- 478 - 10T PEAKING COIL

L808 73A 54- 479 - 5T PEAKING COIL 4.7uF 5%

Q813 57A 419- SG - T TR. KSC945GC

Q814 57A 742- 1 - T TR. 2SC1730

R801 61A 602- 750 - 52T 75 OHM +-5% 1/6W

R802 61A 602- 750 - 52T 75 OHM +-5% 1/6W

R803 61A 602- 750 - 52T 75 OHM +-5% 1/6W

R804 61A 602- 300 - 52T 30 OHM +-5% 1/6W

R805 61A 602- 300 - 52T 30 OHM +-5% 1/6W

R806 61A 602- 300 - 52T 30 OHM +-5% 1/6W

R808 61A 602- 103 - 52T 10K OHM +-5% 1/6W

R809 61A 172- 225 - 52T 2.2MEG OHM +-5% 1/4W

R810 61A 602- 101 - 52T 100 OHM +-5% 1/6W

R811 61A 602- 332 - 52T 3.3K OHM +-5% 1/6W

R812 61A 602- 132 - 52T 1.3K OHM +-5% 1/6W

R813 61A 602- 332 - 52T 3.3K OHM +-5% 1/6W

R814 61A 602- 332 - 52T 3.3K OHM +-5% 1/6W

R815 61A 602- 391 - 52T 390 OHM +-5% 1/6W

R816 61A 602- 391 - 52T 390 OHM +-5% 1/6W

R817 61A 602- 391 - 52T 390 OHM +-5% 1/6W

R818 61A 602- 100 - 52T 10 OHM +-5% 1/6W

R819 61A 602- 100 - 52T 10 OHM +-5% 1/6W

R820 61A 602- 100 - 52T 10 OHM +-5% 1/6W

R821 95A 90- 23 TIN COATED

R823 61A 602- 910 - 52T 91 OHM +-5% 1/6W

R824 61A 602- 910 - 52T 91 OHM +-5% 1/6W

R825 61A 602- 910 - 52T 91 OHM +-5% 1/6W

R826 95A 90- 23 TIN COATED

R840 61A 172- 102 - 52T 1K OHM +-5% 1/4W

R841 61A 172- 102 - 52T 1K OHM +-5% 1/4W

R842 61A 172- 102 - 52T 1K OHM +-5% 1/4W

R846 61A 602- 393 - 52T 39K OHM +-5% 1/6W

32

Page 34

LOCATION CRP356PAI SPECIFICATION

R847 61A 602- 393 - 52T 39K OHM +-5% 1/6W

R848 61A 602- 393 - 52T 39K OHM +-5% 1/6W

R849 61A 172- 105 - 52T 1MEG OHM +-5% 1/4W

R850 61A 172- 105 - 52T 1MEG OHM +-5% 1/4W

R851 61A 172- 105 - 52T 1MEG OHM +-5% 1/4W

R855 61A 175L- 560 - 52T 56 OHM +-5% 1/2W

R856 61A 175L- 560 - 52T 56 OHM +-5% 1/2W

R857 61A 175L- 560 - 52T 56 OHM +-5% 1/2W

R858 95A 90- 23 TIN COATED

R860 61A 172- 104 - 52T 100K OHM +-5% 1/4W

R861 61A 602- 822 - 52T 8.2 OHM +-5% 1/6W

R862 61A 602- 222 - 52T 2.2 OHM +-5% 1/6W

R863 95A 90- 23 TIN COATED

R864 61A 175L- 471 - 52T 470 OHM +-5% 1/2W

ZD801 93A 39- 519 - 52T TZX8V2B

PARTS LIST OF IC802 ASS'Y

LOCATION PARTS No. SPECIFICATION

90A 355- 2 HEAT SINK

M1A 1730- 8 - 128 SCREW

IC802 56A 551- 3 LM2439

L809 73A 54- 109 - 5T 1UH

L810 73A 54- 109 - 5T 1UH

L811 73A 54- 109 - 5T 1UH

PARTS LIST OF Q901 ASS'Y

LOCATION PARTS No. SPECIFICATION

5A 42 - 1 NYLON WASHER

12A 372- 1 SILICONE RUBBER

90A 339- 2 HEAT SINK

M1A 1730- 10 - 128 SCREW

!

Q901 57A 667- 7 IRFBC40 I.R. MOSFET

33

Page 35

PARTS LIST OF Q911 ASS'Y

LOCATION PARTS No. SPECIFICATION

5A 42 - 1 NYLON WASHER

12A 372- 1 SILICONE RUBBER

90A 315- 1 HEAT SINK

M1A 1730- 8 - 128 SCREW

Q911 57A 600- 504 MOS FET IRF634A

PARTS LIST OF IC601 ASS'Y

LOCATION PARTS No. SPECIFICATION

12A 372- 1 SILICONE RUBBER

90A 348- 3 HEAT SINK

M1A 1730- 10 - 128 SCREW

5A 42- 1 WASHER

IC601 56A 574- 1 TDA9302H

PARTS LIST OF AC LINET ASS'Y

LOCATION PARTS No. SPECIFICATION

87A 501- 5 RECEPTACLES 0714

96A 29- 6 - 190 H.S. TUBING

!

CN901 95A 205S- 354 - 043 WIRE

PARTS LIST OF Q403/Q406/D408 ASS'Y

LOCATION PARTS No. SPECIFICATION

5A 42 - 1 NYLON WASHER

32A 3028- 8 RUBBER

90A 354- 503 HEAT SINK

M1A 1730- 8 - 128 SCREW

M1A 1730- 10 - 128 SCREW

!

D408 93A 220- 11 - F DMV32B

Q403 57A 689- 6 2SC52967

Q406 57A 415- 3 TR. 2SD2025

PARTS LIST OF IC904 ASS'Y

LOCATION PARTS No. SPECIFICATION

90A 315- 1 HEAT SINK

M1A 1730- 6 - 128 SCREW

IC904 56A 133- 12 - STM 3 PIN 12V REG.L7812CV

34

Page 36

PARTS LIST OF CAB'T ASS'Y

LOCATION PARTS No. SPECIFICATION

12A 6000- 2 RUBBER FOOT

19A 506- 3 - 1 SPRING

33A 3686- 1 POWER BUTTON

34A 586- 1 - AL SWIVEL

34A 621- 2 - AL BASE

34A 626- 1 - 3A BACK COVER

45A 76- 31 - R BASE & SWIVEL

PARTS LIST OF SPEAKER ASS'Y

LOCATION PARTS No. SPECIFICATION

5A 38- 501 WASHER

95A 8013- 4 - 604 WIRE & HOUSING ASS’Y

SP501 78A 216- 23 - 5C 2W 16 OHM

SP502 78A 216- 23 - 5C 2W 16 OHM

35

Page 37

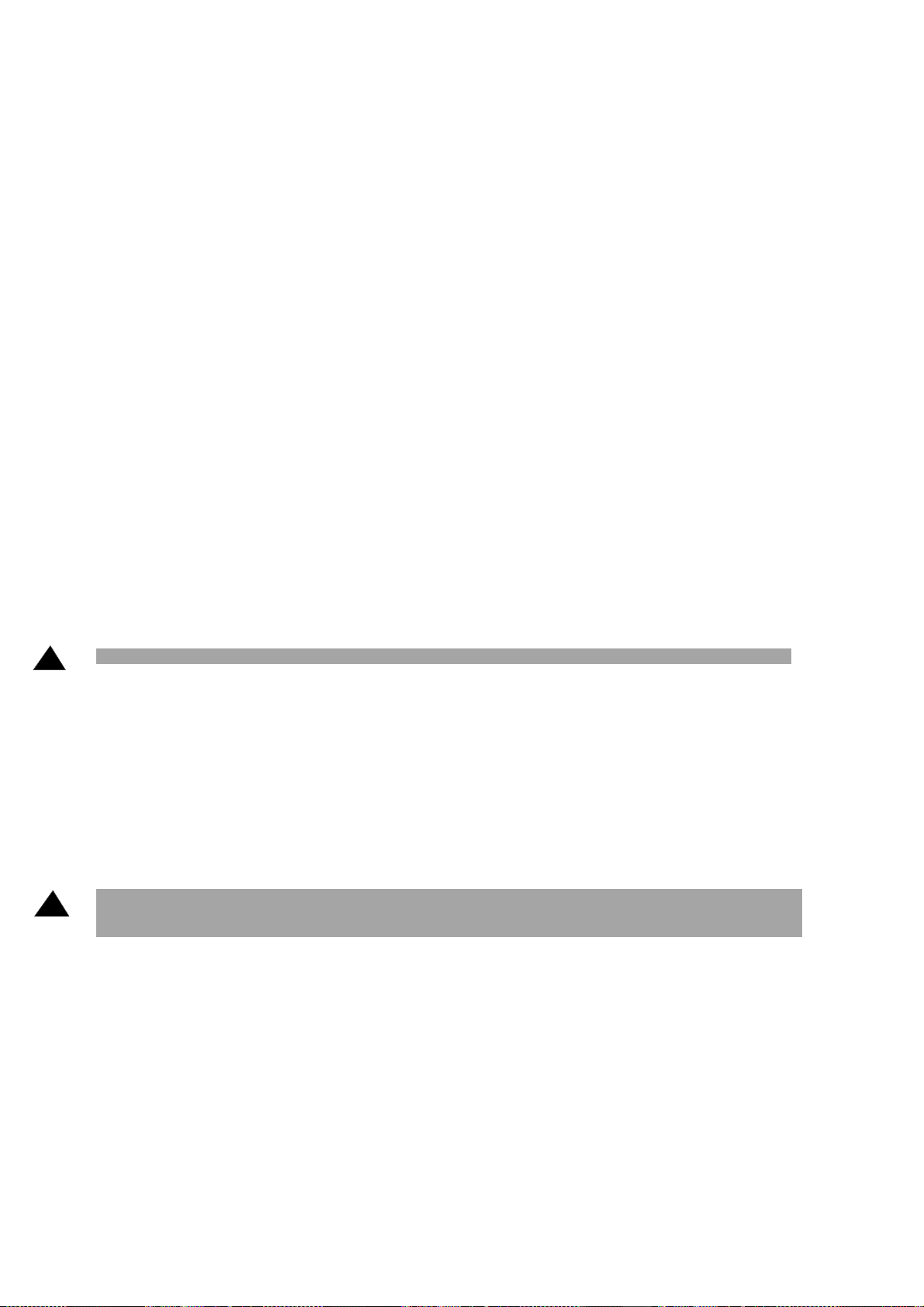

9. BLOCK DIAGRAM (DEFLECTION)

25KV

EHT

R

IC801

CRT

G

B

IC802

LM2439 O/P

LM1279N

PRE.AMP.

G1

HV

G2

FOCUS

HOR.O/P

Q403,T402(FBT)

Q402,T401

HOR. DRIVER

IC401

TDA9111

VERT.&HOR.OSC

X-RAY PROTECTION

Q404,Q405,Q406

POWER

SAVING

Q907,Q908

Q909,Q910

PINCUSHION &

H-SIZE CONTROL

Q601,Q707

BLANKING CIRCUIT

R

B

G

CABLE

SIGNAL

V

H

IC101

CONTROL

UP/DOWN

FUNCTION KEY

36

CPU

UM6861

WT6018

36

IC601

LED CONTROL

VERT.O/P

TDA9302H

Page 38

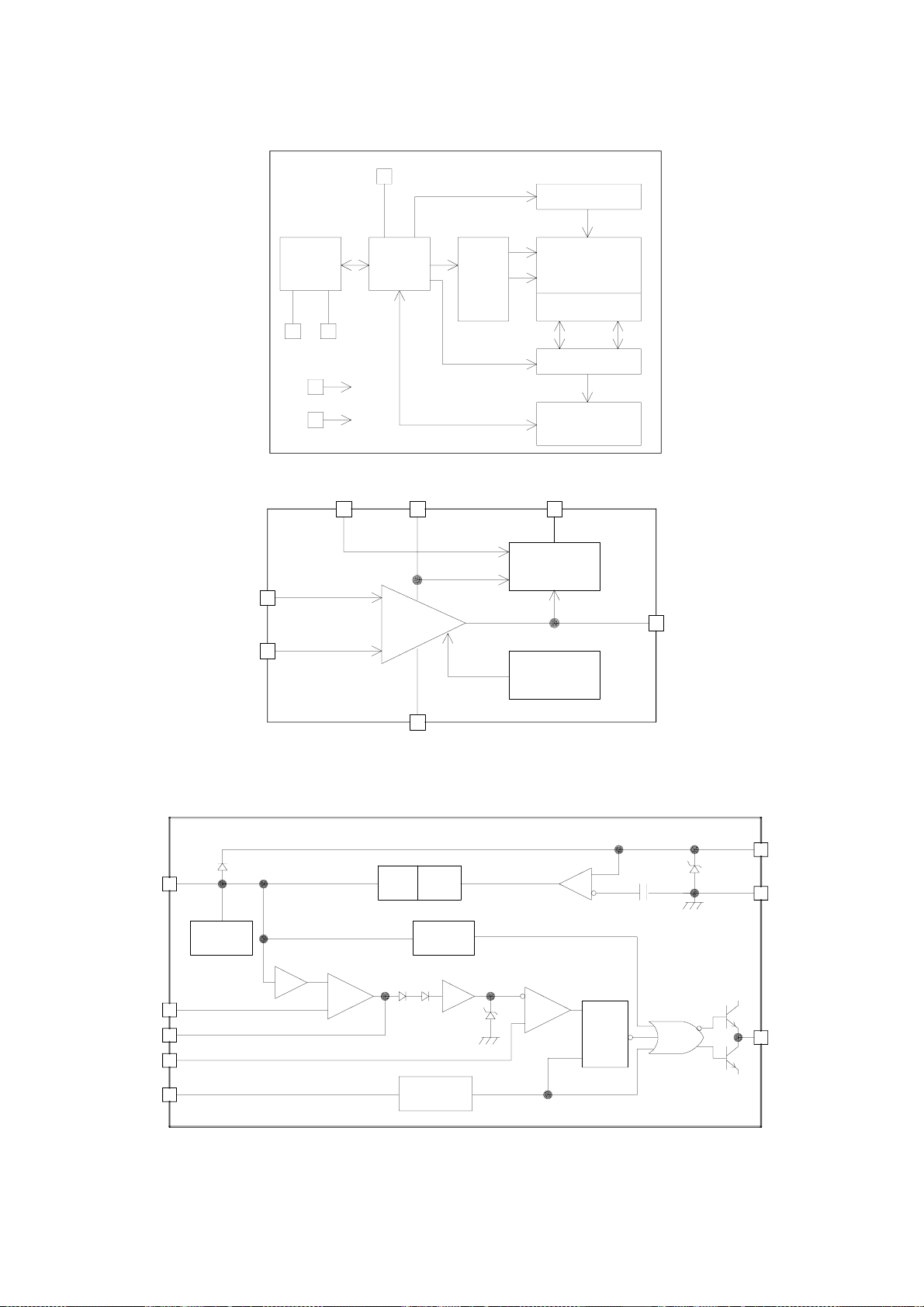

9-1. BLOCK DIAGRAM (SMPS)

+75V

-12V

12V

6.3V

R129

IC904

Q909

Q910

OUTPUTS

15V

OUTPUTS

T901

VIN

RECTIFIED

6.3V

&

SMOOTHED

RECTIFIED

&

SMOOTHED

Q908

Q907

75V

POWER

TRANSFORMER

LED1

R128

L906

&

RECTIFIED

START

C.K.T

D909,Q904

Q102

R125

SMOOTHED

VCC

R922,ZD902

12

34

5

26

IC101

VARI.

TRANSFORMER

Q901

POWER

F.B

O/P

2

6

&

7

CONTROL

8

MOSFET

3

IC901

PWM O/P

VARIABLE)

(70V-170V

OUTPUT

Q911

Is

4

B+

&

SMOOTHED

RECTIFIED

POWER

MOSFET

R929

IC401

B+ PWM CONTROL

FROM

H.O.T

H-SYNC

Q912,Q914,Q920

H-SYNC

CONTROL

C.K.T

C.K.T

DEGAUSSING

37

POWER

ON/OFF

SWITCH

LINE

FILTER

90V-264V

AC INPUT

Page 39

IC101

UM6861/WT6018

10. IC BLOCK DIAGRAMS

DEGAUSS V-I/P

BRIGHT

CONTRAST

RESET_

VCC

GND

OSC0

OSC1

SCL

SDA

WRITE PROTECT

STAND BY/SUSPEND

H.W DDC

SENSE

KEY SELECT

10

11

12

13

14

15

1

2

3

5

6

7

8

40

H-I/P

39

N.C

38

N.C

374

N.C

36

N.C

35

OFF MODE

34

H-OUT

33

V-OUT

329

N.C

31

MUTE

30

CS1

29

CS0

28

AUDIO

27

LED DETECT

26

IC802

LM2439

9

8

7

6

5

4

3

2

1

Vin 1

VBB

Vin 2

Vin 3

GND

VCC

Vout 3

Vout 2

Vout 1

LED9

LED8

LED7

LED6

16

17

18

19

SCL

25

SDA

24

LED2/UP KEY

23

LED3/DOWN KEY

22

LED4/SELECTLED5

2120

38

Page 40

WP

7

IC102 24C04

HV GENERATOR

I/O

CONTROL CONTROL

LOGIC LOGIC

65

SCLSDA

8

VCC

4

VSS

26 3

1

7

MEMORY

IC601 TDA9302H

-

POWER

AMPLITIER

+

XDEC

EEPROM ARRAY

(128X8)

PAGE LATCHES

YDEC

SENSE AMP

R.W CONTROL

FLYBACK

GENERATOR

5

THERMAL

PROTECTION

Vref 8

F.B

COMP.

Is

Ct/Rt

2

1

3

4

INTERNAL

BIAS

1/2 Vref

ERR

AMP

4

IC901 3842

5V

Vref

OSCILLATOR

SET/

RESET

LOGLC

1/3

1V

U.V.L.O.

C.S.

COMP

R

PWM

LATCH

S

36V

VCC

7

GND

5

O/P

6

39

Page 41

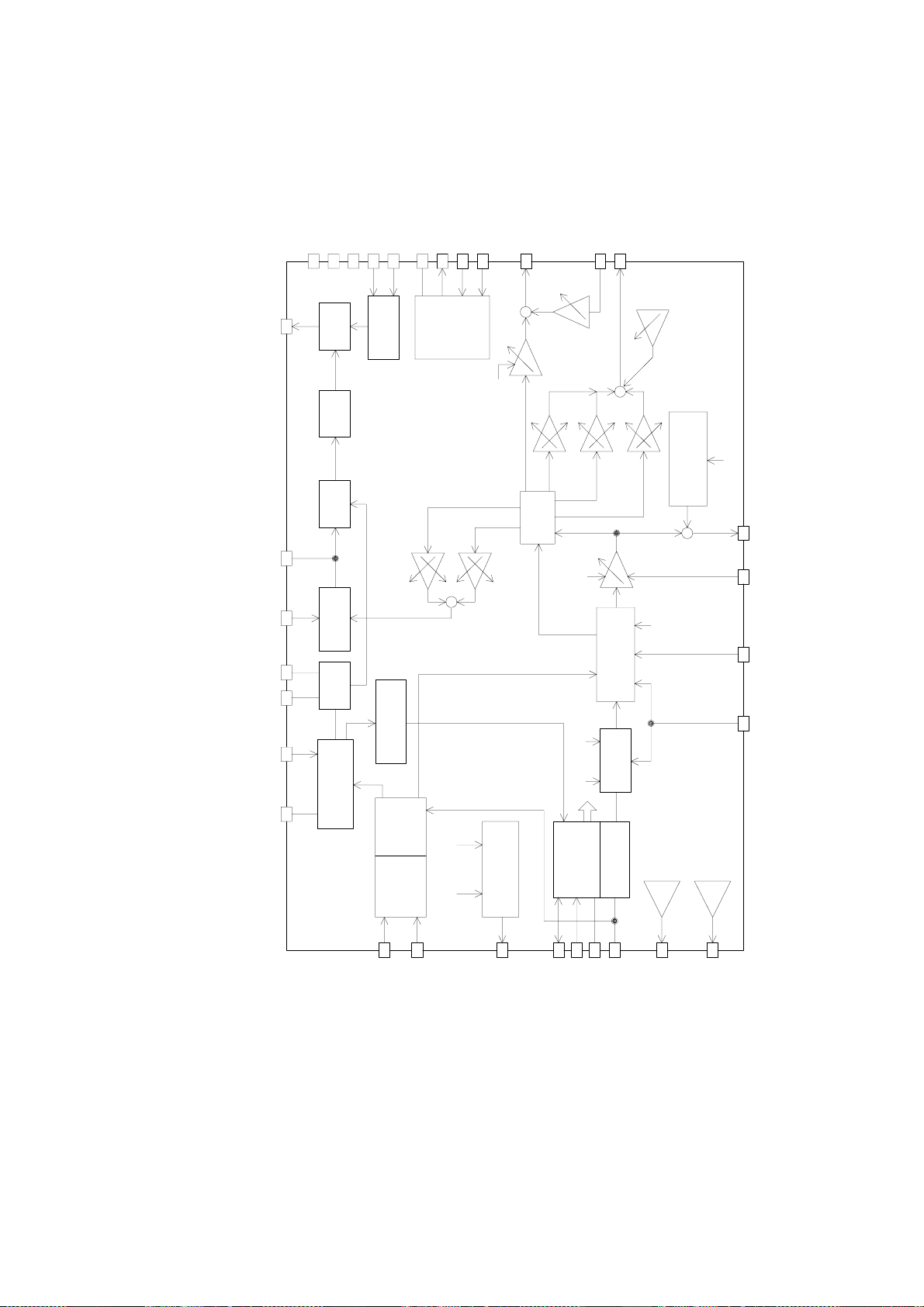

IC401

TDA9111

26

HOUT

4

PLL2C

12

HFLY

5

C0

6

R0

8

HPOSITION

7

PLL1F

VGND

HGND

BGND

11

19

17

HOUT

BUFFER

H-DUTY

(7 bits)

PHASE

SHIFTER

PHASE

COMPARATOR

VCO

COMPARATOR

PHASE/FREQUENCY

H-PHASE(7 bits)

Vcc

XRAY

29

25

SAFETY

PROCESSOR

7bits

Spin Bal

LOCK/UNLOCK

IDENTIFICATION

SYNC

SELECT

SYNC INPUT

COMP

14

B+

CONTROLLER

2

X

PROCESSOR

(1 bit)

B+OUT

28

(lntemal

+

HFLY

VSYNC

Isense

REGIN

15

16

7bits)

Reference

VAMP

2

X

HORIZONTAL MOIRE

FOCUS

10

+

7 bits

GEOMETRY

7 bits

Key Bal

GENERATOR

7BITS+ON/OFF

2

X

Amp &

4

X

TRACKING

Keystone

2X7 bits

4

X

E/Wpcc

7 bits

VAMP

7 bits

7 bits

7 bits

2

I C INTERFACE

EWOUT

HFOCUSCAP

9

24

+

Keyst.

7 bits

VERTICAL

DSCILLATOR

RAMP GENERATOR

S AND C

CORRECTION

RESET

GENERATOR

Hsize

DC

X

7 bits

VPOS

CANCEL

VERTICAL MOIRE

+

7 bits

Vref

VSYNC

7 BITS+ON/OFF

Vref

23

18

20

22

Vout

BREATH

Vagccap

Vcap

1

H/HVIN

2

VSYNCIN

40

3

HMOIRE

31

SDA

30

SCL

27

GND

32

5V

13

HREF

21

Vref

Page 42

11 PCB LAYOUT

11-1 MAIN PCB LAYOUT

FUNCT

DOWN

(LED1)

LED8

SW101

LED9

(SW103)

SW103

(SW102)

SW102

(SW101)

UP

R107

R106

R105

R104

R103

R101

D103

D101

LED1

<LED1>

J065

VR902

C913

R172

R132

J047

SYNC_

GND

R969

R973

J064

R967

J033

R972

R489

C961

R968

R670

D929

R966

C947

Q401

E

C

B

R419

D401

D412

J024

J050

J053

D603

J042

J026

A

J025

J027

10

9

C160

C163

Q501

E

H802

C

1

1

B

R520

R521

C113

R963

C104

J127

R948

R961

R947

R943

1

IC906

IC903

4

R970

R903

R429

R416

C413

R424

R427

R423

R417

R433

C414

R499

J046

J052

C604

J051

J093

R606

R435

C607

C606

J009

R603

C601

IC601

R601

R602

C605

J118

J072

J088

J044

J043

R426

R608

C935

R523

L905

J028

C934

ZD501

Q909

B

C

C937

J041

D928

IC103

ZD110

IC904

OUT

COM

B

C

E

Q101

IN

R126

VR903

J005

R933

R940

Q904

R932

R934

VR901

14.5VADJ

R611

R402

J101

L402

R430

IC401

R431

C446

C614

L406

C403

R410

C435

J057

C110

D104

R112

R118

R120

R180

R161

C108

R121

C103

C107

+

ZD103

R108

R109

ZD104

81

R117

R143

R183

R181

R182

R125

R128

C405

R497

C406

C408

C906

C407

B

32

1

5

D403

R472

D423

IC402

1

8

J032

C109

R113

J004

J030

R116

ZD101

5

R100

10

15

IC101

61

CNAA

J008

D125

C164

SW901

R941

C410

R403

R404

C411

C404

LED7

D411

J023

LED6

J058

LED5

R421

LED4

R407

R432

LED3

LED2

R406

R405

R102

R119

R147

R166

R146

R148

C106

J071

J116

L101

J040

X101

J015

ZD102

D102

C105

IC102

J014

J013

J012

J011

Q102

E

C

B

J006

R609

J062

C610

R418

R422

C612

C611

C433

C613

C434

27

22

10

C441

C943

J054

B

C412

C447

C443

R412

R411

C444

FB401

C437

J128

D160

C130

IC104

C162

J066

J036

J035

J034

J037

J029

J021

401

C161

C101

35

J019

J020

R124

30

J131

J018

25

J016

J017

2120

D126

R129

R122

R135

R157

R185

R959

R985

R988

D938

C940

6

10

C968

T903

5

1

R942

D914

C924

C965

R614

R610

C609

17

D927

R462

J063

16

C449

C409

C945

D402

J115

1

14

J038

R162

R420

R114

R141

D701

J022

R115

R123

R149

CONT

R160

CLP

12V

R140

GND

R136

SDA

R165

SCL

R137

VS

HS

R156

R110

R111

R134

J085

J002

R958

B

C

E

Q910

R964

R

A

K

C954

SYNC+

R904

C440

C445

BEC

C442

D407

C417

T401

D460

ZD420

R607

R604

J067

R605

C602

2

1

7

6

C603

D602

C615

J117

C608

J078

J073

J130

C939

J075

J076

L907

C938

E

J061

R957

ZD905

IN COMOUT

ZD108

R127

TP901

C914

R921

C

B

E

R926

ZD902

R924

R925

Q403

D406

C416

D405

R428

D450

D404

C415

D

G

S

C420

Q402

J108

G

D

S

C424

D416

Q407

Q411

E

C

B

D601

R445

C468

D417

D604

C436

R615

B

Q601

C

E

R612

J069

C714

R613

R442

R443

R447

D923

J092

C931

L903

C942

D930

D921

D922

16

14

J124

C969

FB903

T901

C936

1

1

C916

C921

D912

D911

8

C917

R922

ZD903

R936

R935

1

C962

R923

C919

C918

C419

R425

D409

R446

J081

R460

C438

D422

J070

R728

R444

R955

15

2

2

R931

R996

IC901

R995

J068

J126

J100

J080

5

4

3

2

S

D

G

Q426

C426

D463

B

C

E

Q409

R453

Q408

B

C

E

C439

E

C

B

ZD703

Q707

R448

J077

J039

D704

J059

C930

13

14

12

13

11

4

3

4

3

R938

R937

D995

C995

D909

C920

CMPC-D356P/D556P

715A684-1

2

1

3

D413

FB402

C418

P401

J074

1

C430

L401

D421

R471

C429

C428

D415

R451

R449

ZD702

C707

R713

ZD403

C731

J079

L906

R989

D919

C955

12

11

9

10

5

6

6

5

R939

FB904

C923

D913

R930

R401

TP404

D408

J132

R461

R456

J084

C423

C427

R457

R729

R495

R715

R712

B

C

E

Q705

D925

FB907

R954

C949

9

10

8

7

8

7

R927

SG

J003

(GND1)

J007

TP403

C450

P402

ZD410

C480

R480

J134

D410

J133

1

12

10

9

ZD701

R956

C907

8

11

7

6

5

L404

C712

J091

C713

R724

J104

C431

J045

R727

R458

C709

Q703

D710

D702

E

C

B

C476

R707

R708

R980

J090

J094

Q914

E

C

B

Q907

Q912

C

B

CN903

R953

C

B

Q920

D955

C925

E

E

C

C

B

B

Q903

Q905

C964

80V

1

C705

R760

D721

HT

R709

6

J098

R730

GND

R510

J109

J099

J096

R509

R501

J095

E

C

B

C908

R986

D420

R408

C926

R952

2

1

B

R951

C

R981

E

D939

Q908

RY901

J123

J125

CN902

2

13

PR901

D904

D903

D902

D901

DEG.COIL

C905

NR901

2

C425

3

4

R450

D706

C432

S

C711

J087

D

G