Page 1

SHARP

SERVICE MANUAL

S96M8CX6336l

111 Liilwiqf~ffU

PAL SYSTEM

COLOUR TELEVISION

f

l ELECTRICAL SPECIFICATIONS

l IMPORTANT SERVICE NOTES

l SERVICE ADJUSTMENT.

. TROUBLE SHOOTING TABLE

. CHASSIS LAYOUT DIAGRAM

. PRINTED WIRING BOARD ASSEMBLIES .....

. BLOCK DIAGRAMS

. SCHEMATIC DIAGRAMS AND

WAVEFORMS.

. REPLACEMENT PARTS LIST

CONTENTS

.............

..............

..................

..............

.............

.....................

.........................

..............

NC-6 CHASSIS

In the interests of user-safety (Required by safety regulations in some

countries) the set should be restored to its original condition and

only parts identical to those specified should be used.

ELECTRICAL SPECIFICATIONS a-w,

page

1

Aerial Input Impedance

Convergence

2

Focus

3

6

.ll

.13

.15

.19

.24

....................

Audio Power Output Rating

Intermediate Frequencies

Picture IF Frequency

Sound Carrier Trap

Adjacent Sound Carrier Trap

Power Input

Power Consumption

Speaker

Sweep Deflection

Tuning Ranges

..............

...........

...............

.............

...............

.................

..........

.....................

......................

10cm

......................

..............

75 ohm unbalanced

Self Converging System

Bi-potential electrostatic

2.OW

max.

36875MHz

31.375MHz

38.375MHz

240V AC 50Hz

12OW

Round Dynamic x 1 pc.

Magnetic

VHF Channels 0 thru 11

UHF Channels 28 thru 63

The

chassis in

power

receptacle, when servicing this

To

prevent electric

qualified service personnel.

this receiver is

shock, do

1

Specifications are subject to change without prior notice

WARNING

partially

not remove

hot.

chassis.

cover.

Use an

isolation

No

user

transformer

-

serviceable parts inside. Refer servicing

SHARP CORPORATION

between

the

line

cord plug and

1

to

Page 2

IMPORTANT SERVICE NOTES

Maintenance and repair of this receiver should be done by qualified

service

personnel only.

SERVICING OF HIGH VOLTAGE

SYSTEM AND PICTURE

TUBE

When

servrcrng

connectrng

is

a test probe) between picture tube tag and 2nd anode lead. (AC

ine cord should be disconnected from AC outlet.)

1. Picture tube in

2. Replace with tube of the same type number for continued safety.

3. Do not lift picture tube by the neck.

4. Handle the picture tube only when wearing shatter-proof goggles and

after discharging the high voltage completely.

the

hrgh

a 10k ohm

thus

voltage system, remove static charge from it by

Reststor

receiver employs integral Implosion protection.

in series wtth an Insulated wire (such

X-RAY

This

receiver IS designed so that any X-ray radiation IS kept to an

absolute minimum. Since certain malfunctions or

duce potentially hazardous rediation with prolonged exposure at close

range, the following precautions should be observed:

1.’

When repairing the circuit, be sure not to increase the high voltage to

more the

2. To keep the set in a normal operation, be sure to make it function

on

has been factory-adjusted to the above-mentioned high voltage.

.‘.

If there is a possibility that the high voltage fluctuates as a result

3. Do not substitute a picture tube with unauthorized types and/or

brands which may cause excess X-ray radiation.

30kV,

(at beam 1 .l

27.5kV _+

of the repairs, never forget to check for such high voltage after

the work.

1.5 kV (at beam 1.3

mA),

mA) In

for the set.

the case of the set. The set

servicing

may pro-

BEFORE RETURNING THE RECEIVER

Before returning the receiver to the user, perform the following safety

checks.

1. Inspect all lead dress to make certain that leads are not pinched or

that hardware is not lodged between the chassis and other metal

parts in the receiver.

2. Inspect all protective devices such as non-metallic control knobs,

insulating fishpapers, cabinet backs, adjustment and compartment

covers or shields, isolation resistor-capacity networks, mechinira!

insulators etc.

2

Page 3

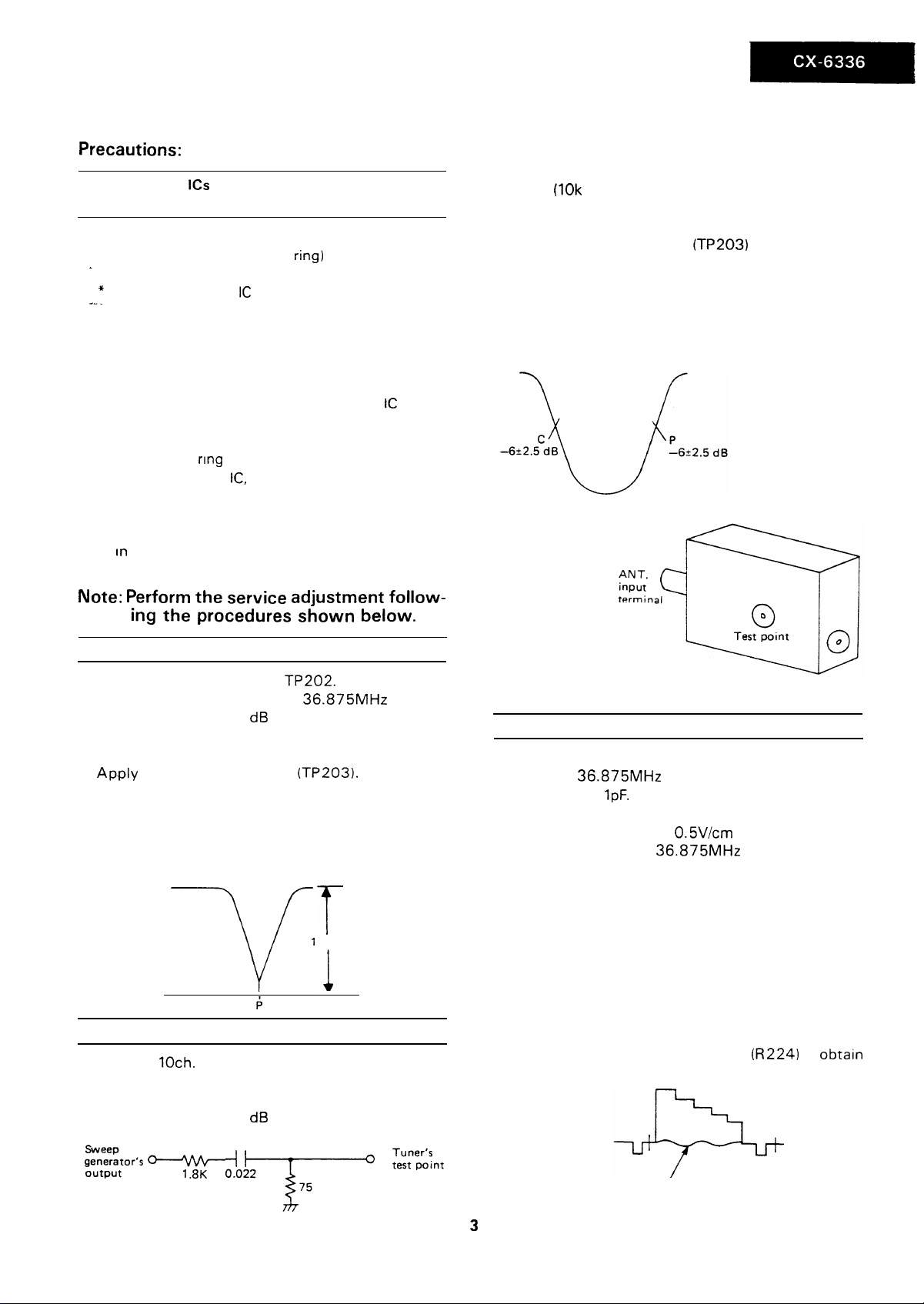

SERVICE ADJUSTMENT

Precautions:

How to prevent

tricity

1. When replacing or handling the IC, be sure to put on

your wrist a metal ring (earth

-

to ground.

*

Avoid touching the IC directly by hand as much as

--_

possible.

2. For the soldering iron and other jigs in use, be sure to

connect them to ground so that their potential is the

same as that of the PWB and/or IC.

3. The PWB cannot be connected to ground in some condition although you attempt to attach the rC to that

PWB. In this case, be sure to keep the PWB at the same

potential as ground by touching it by your hand on

which a metal nng is put.

4. When handling the

wear such clothes as not causing static electricity; the

ones of wool, silk or synthetic fiber should be avoided. This is Important in particular when handling the

IC In a dry environment.

ICs

from damages due to static elec-

ring1

that is connected

IC,

it is recommended for you to

__

3.

Connect the response lead to TP207.

4.

Connect a resistor of 100 ohms to both ends of

R235 (10k ohms).

Note: Keep the lead of the 100 ohm resistor as

short as possible.

5.

Apply AGC voltage to AGC

voltage so that the waveform on oscilloscope is 1

VP-P.

6.

Make sure that the overall waveform is as shown

in the figure below. If not, adjust it with the aid of

IF transformer of the tuner.

(TP203)

and adjust AGC

Note:

P-detector coil adjustment: T201

2. Connect the response lead of oscilloscope to

3.

4. Adjust AGC voltage so that the waveform on oscil-

5. Adjust T201 so that the waveform peak on oscillo-

Perform

ing

1. Connect sweep output to

l Sweep central frequency:

l Sweep output: 80

TP207.

Apply

AGC voltage to AGC

Note: The AGC voltage should not exceed 7V.

loscope becomes 1 Vp-p.

scope becomes aligned with P marker.

the service

adjustment

the procedures shown below.

TP202.

36.875MHz

dB

(TP203).

follow-

T

1

VP-P

T

i

Overall waveform

1. Receive

2. Connect sweep output to the tuner test point

through the specified jig.

l Sweep output: 70

loch.

signal.

dB

1

36.875 MHz

IF transformer

AFT adjustment: T202

1. Receive sequential colour bar signal.

2. Connect

capacitor of

3. Connect oscilloscope to TP207.

l Oscilloscope range:

4. Adjust the output of

the waveform beating on oscilloscope be observable.

5. Adjust the tuning control so that the waveform on

oscilloscope is free from beating.

l Set the band switch at VHF position and adjust

the tuning control.

6. Set the band switch at normal position and adjust

TP202 so that the waveform on oscilloscope is free

from beating.

l Turn on AFT switch.

Note: Set the RF AGC control

36.875MHz

1pF.

normal picture.

oscillator to TP202 across a

36.875MHz

0.5V/cm

AC

oscillator to have

(R224)

to

obtain

gztor’s e-4hk-+

output

,.8K &-g-o

~redds”t

Adjust for zero-beating.

3

Page 4

RF AGC cut-in adjustment: R224

1. Receive 10 ch. signal.

2. Set the signal input level at 52 + 1

dB.

3. Connect CR oscillator to TP204 across a capacitor

of lOpF/16V: This capacitor is to cut off DC supply.

l Oscillation frequency:

l Output voltage: 0.1 Vp-p (Output

1kHz

sine wave.

voltage availa-

ble at TP204)

4. Adjust R224 so that 1 kHz signal disappears from

TV screen.

5. Set the signal input level at 52 + 3 dB and check

that 1 kHz signal appears on TV screen.

If

1 kHz signal does not appear, set the input signal level at 52 dB again and follow the procedure

in step 4 again.

Sub-brightness adjustment: R421

1. Turn S501 on by tipping it rightwards in order to let

the raster be linear.

2. Set each control as follows:

l Screen control: at MIN position

l Sub-brightness control (R421): at MIN position

l R-bias control

l G-bias control

l B-bias control

l G-drive control

l B-drive control

l Contrast control: at MIN position

l Brightness control: at CENTER position

l Picture tone control: at CENTER position

l Colour control: at MIN position

(R862)

(R863)

(R864)

(R857-A)

(R857-B)

3. Receive lion head pattern signal.

4. Connect oscilloscope to TP850.

5. Adjust R421 so that the waveform on oscilloscope

is at 15 Vp-p.

12. Adjust each drive control for good white balance.

l Colour temperature:

7300OK

x=0.303

(

Y=O.310

)

13. Adjust brightness control and contrast control to

obtain a dark picture. If the white balance is disturbed, adjust the bias control to obtain good

white balance.

14. Again brighten the picture and adjust each drive

control for good white balance as in step 12 above.

Carrier wave-phase adjustment: R826

1. Receive sequential colour bar

signal.

2. Connect oscilloscope to K4 terminal (blue) and adjust synchronism of oscilloscope to obtain the

waveform as shown in the figure below.

minimum

3. Adjust the phase control so that the

l-l

part@of

B-Y

output waveform becomes minimum as shown in

the figure above.

Sub-colour adiustment: R817

1. Receive sequential colour bar signal.

2. Set each control as follows:

l Contrast control: at MAX position

l Brightness control: at CENTER position

l Colour control: at CENTER position

l Picture-tone control: at CENTER position

3. Connect oscilloscope to TP850.

4. Adjust R817 so that the white output (75%) and

red output will have the same level.

Background adjustment: Screen control R862 R863

R864

R857-A/B

6. Remove oscilloscope from TP850.

7. Adjust the screen control so that raster of red,

green, or blue appears dimly on screen.

8. Adjust the bias controls except for dimly appearing colour to let the picture on screen be white.

9. Adjust the screen control to obtain cut-off point

of CRT.

10. Turn S501 off by bringing it back to the center in

order to resume the normal raster.

11. Set the contrast control at MAX position.

Horizontal Size adjustment:

1.

Receive lion head pattern signal.

2. If the horizontal size is at less than 7% of

ning, insert the socket into the opening (2).

Vertical size adjustment: R525

3. Adjust R634 to have proper horizontal center.

4

overscan-

Page 5

Vertical linearity adjustment:

R520

-

Protector check

1. Receive lion head pattern signal.

2. Adjust R520 to obtain good vertical linearity.

Vertical

size

adjustment:

R525

,* .I --

3. Adjust R525 to have 10% of the vertical overscan.

Vertical center adjustment:

S502

--

1. If the vertical center of picture is 3mm higher than

the center of CRT, set

it is 3mm lower than the center of CRT, set

S502

at “down” position. If

S502

at “up” position.

1. Apply

.that

DC25V

to D605 (cathode side), and check

the protector remains inoperative.

2. Apply DC 30V to D605 (cathode side), and check

__ _

.

that the protector gets operative.

3.-Connect

a resistor

(10k

ohms) between base of

Q603 and ground, and check that the protector

gets operative.

-

-

5

Page 6

_-

Checked Circuits

l Power Regulator Circuit

0

Horizontal Deflection Circuit

l Picture tube Bios Circuit

l Video Circuit

0 Picture tube

TROUBLE SHOOTING

r

When the power switch is push on,

is there caused a raster?

t

TABLE

: -! - _- : ..:- -__ I__ \

.

No

Are the Fuse

blown?

I

No

(F7001)

Yes

t

v

Replace the tuse

with new one

_ _.

Yes

_.

.- ^

t

,

Norma I

c

The tuse is ogain

.

blown out

Abnorma I

r-----

----1

Checked Circuits

l Horizontal Output Circuit

Check

R640 and Horizontal

Drive Circuit

I L606

L------------A

Q601, T601,

I

Normal

and R636

L---------a

.

NO HRIZONTAL SCANNING

Abnorma I

1

I------- -----

I

Check

1

R640 and- Horizontal

I Drive Circuit

L------------d

t

t

(2601, T601,

a------m--d

1

l

1

I

I

A bnormo I

l

OSC . Circuit

L----------d

w--m-

1

I

I

6

Page 7

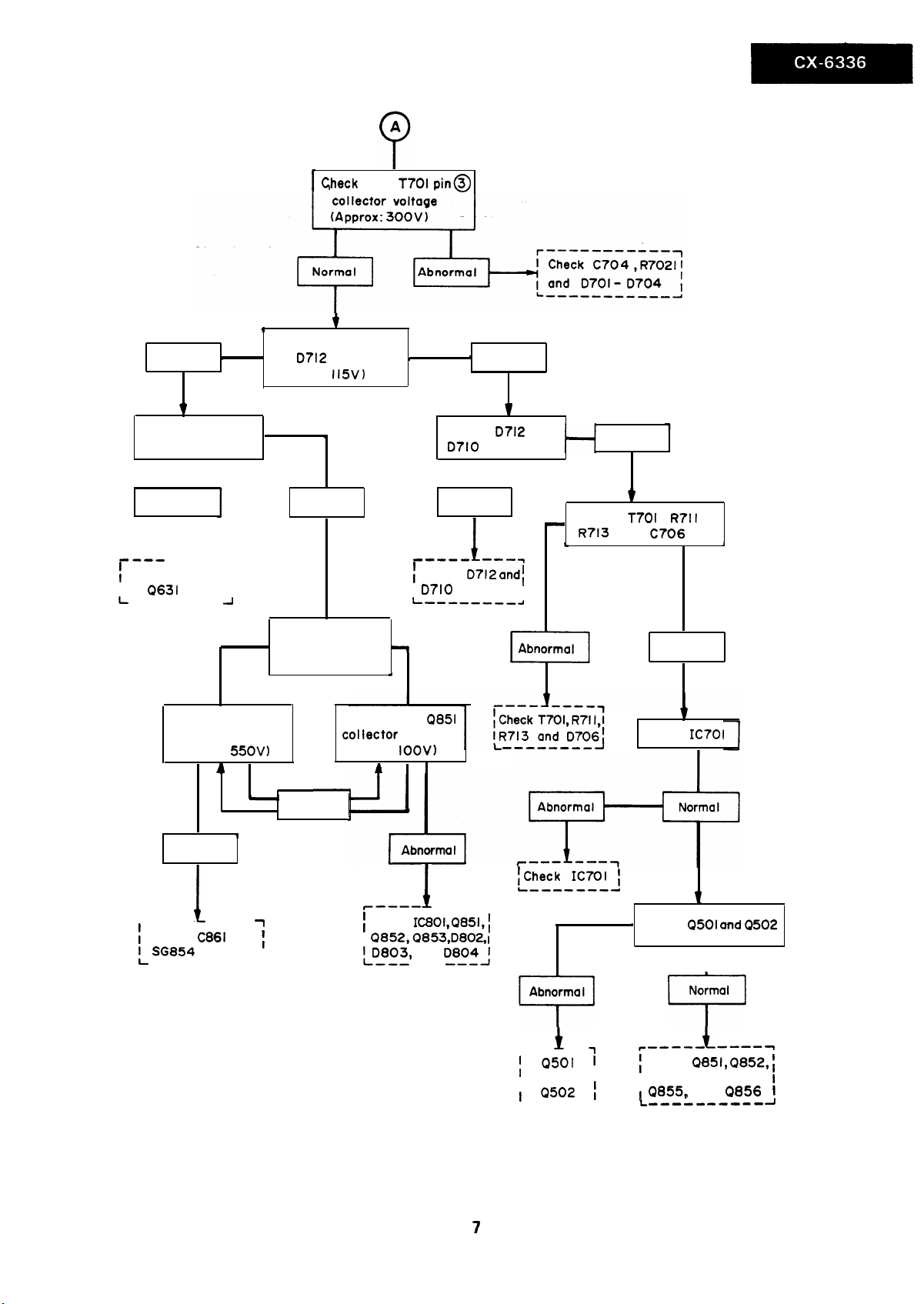

[ C,heck

for

T70l pin@)

Normal

1

Check for the CRT ,

heater vol toge

I

Abnormal

w--e

I

I

L

1

a----

Check

0631

--B-m---

Check for the

screen voltage

(Approx:

Abnormal

.

1

J

A

Normal

,

Check for the voltage

of

0712

(Approx:

,

I

I

Check for the Bias

circuit of picture

tube

55OV)

I

,

Norma I

t

cathode

ll5V)

/

*

Check for the

COI lector

(Approx: IOOV)

1

1

1

--e-e

Check 0712

I

I

D7lO

L

.

-

4

voltage Check

Check

0710

Abnorma I

--------a

Q85l

’

Abnormal

1

D712

I

L

m--y

andl

--------A

and

I

-

Check

c

Norma I

t

T70l

R713 and

,

C706

R7ll

I

Normal

1

IC7Ol

----- ----

I

Check

L SG854

I

C861

and

---------A

!Check IC701 1

L-------d

r-e--

1

1

I

i

Check IC8Ol,Q851,~

I

0852,0853,D802,l

lLD803,

I

-----

and

---------

D804J

.

Abnorma I

1

Check

7

i

-- --

r

; Q50l 1

I Q502 1

------a

1

----am-

i

Check

Q853,

Q855,

I

I

L

1

0501 und Q502

I

Normal

LT-’

t

-e-e-)

0851, Q852, i

0854,

and

----------

0856

.

1

A

7

Page 8

Checked Circuits

STF Amplifier Circuit

Sound Detector Circuit

Audio

Output

Circu 1

t

.

NO SOUND

1

,

1

Check

L301, C3lO

f

CF3OI

Check for the

Norma I

t

When the sound control

is set at MAX, does noise

increase

3

I

1

No, or very small

I

f.----- -a----,

C306, C307, f

and

i

Check

I

C317, R3lO,IC202

I

I and

L

-----------A

I

t

_I

C314,C315,

iC3Ot

pin@of

1

I

j

,

I

TC30l

(l2V)

1

Check

L703, 0714, t

1 C733) C735)

I and R730

-L

-------a---

c734,

f

I

J

Checked Circuits

0 Vertical Output Circuit

Check

and bias control

circuit.

- _

r-----

0501,

-----

1

NO VERTICAL SCANNING

Waveform at Collector

of

Q503

is normal

,

Q502

-

1

?

Abnormo I

_

. .

. .

- -

.-

Page 9

Checked Circuits

l P-IF Circuit

l AGC Circuit

l Tuner Circuit

l

tB

Supply Circuit

IN0

PICTURE, NO SOUND

1

Norma I Abnormal

t

When band switch is

changed, does VT change?

Check tuner,

AGC and bias

control circuits

,

yet the reception is

Check for tuner

BU, BH, BL and B

(about

IZV)

I

I

Check for

f

l

Band Selector Circuit.

L-,------,--,,A

I

IC201,

and yet only the sound

changes remarkably.

b

%~?~~~~~~~~~

voltage at

pln@of IC202

Normal

i-’

I

I

1

Check IC201,l

;

T201,

l L2ll,L2lO, l

I and

CF202

I-

----e-

R233,;

I

J

the

IS

l2V

Abnormal

7

t

Normal

r

I Check tuner,

L2!rE!!t-~~--

----

. .

J

-- ----

bheck

CF2Ol

c--e-- ------

Check R220, R217,

i

I

1 R218

L---,-----,,d

t

l

and C235 I

1

I

Page 10

-

Checked Circuits

- 0

CHROMA Circuit

l VIDEO Circuit

r

NO COLOUR

I

Waveform at pin

5 of

IC801

0

normal ?

Waveform at

emi

tier (TP207)

of Q401 is

normal ?

is

Yes

I

I

Yes

No

1

Each termina I

voltage of tuner No

is nomal ?

(+B,BL,BH, BU)

Yes

Check XC20

and band

selector circuit.

I

I

Yes

Check Tuner and

control circuits.

10

Page 11

CHASSIS LAYOUT

CONTROL

UNIT

DUNTK4726WE

S?OOl

POWER SWITCH

POWER

SWITCH

DUNTK4727WE

SP301

SPEAKER

C

UNIT

I

!

j

REMOTE CONTROL

DUNTK4728WE

UNIT

CRT

SOCKET

UNIT

DUNTK4544WE

17

_-_

Xl?901

Itsol

-n

CF601

0

E202

TP205

u

SUB BRIGHT

TP207 0

0201

IC201

0401

0

R42la

IRG)

TP203

0

0

CF201

TP202

0203

0

TUNER

0

0

rl

C&O2

TP204

l

0202

00

R224

F

RF AGC

0

SCR601

ICJOI

1

LJ

TBOI

cl

(IT)

U

LeoI

Ll

0402

0801

l

l

1

======I

L

R826

Q603 u

a

rl

CS!zl

R525

V-SIZE

El

0604

R520

V-LINE

I

@iI

I

IK)

0

0503

0501

II

’

a

V-SENT

R508

so2

u

R629

0

0

R630

0 CL41

0

(HI

C728

DUNTK4543WE

1

I

2

I

3

I

4

I

s

I

6

11

Page 12

RB62 R-BIAS

RB63 G -BIAS

0853

a.

TPBSI

mm51

--

0854

.*

.-- -

RB57-B B-DRIVE

I

.LK)

<

- ._.

._

TA)

F700 I

T2A

tAB)

AAI

0

ICI03

a

ICI02

r-l

LJ

‘7

AA2

0

~

ICI01

L7001

(RG)

-

0105.

3i

(l-B)

0101

l

Cl01

R7001

/

a0102

1

/

I I

01007

(TA)

I

(TB)

n

u

ICI-I

SlOO5

0

cl

l-l

u

(Ml

0104

0

Al A3

0 0

51008

4CH 0

cl

SIOI

I

7CH

0

cl

-‘:“,‘,,

q q q q TU”E q

SlOO2

(-) (+I (-) (+)

SlOl5

L

/------p

5CH

8CH

SIOOI

R400l

2CH

S1006

q

SlOO9

q

s1012

cl

SlOO4

R300l

I

0

0

0

SlOO3

PICTURE

3CH

s1007

0

cl

SIOIO

6CH

0

q

SlOl3

9CH

0

cl

COLOR

I

CONT

1

f

BRIGHT

s-VOL

DUNTK4726WE 1

I

7

I

8

1

9

I

10

I

11

I

12

I

12

Page 13

PRINTED WIRING BOARD ASSEMBLIES

(All the

PWBs

h

ere are shown an viewed from their wiring sides.}

ec: g

=P

u

-t

x2--?

1

N

Y

yi

D-m%

070.

ii &

a

‘$‘W -

: “Z

u;;:,

S‘ g< _~ e%.._ -

1711

pF-&

-fp-.

I

3‘

SC

I

9738

-*r=f

c ra

+ I

,.~ .

2

I

i )

/

/

’

/

LTB

zi

c

_I

i

I

:

&I

t7.m

.

+

A_

65

C73‘

l

l

ih

t735..

, --.-..-

I

5

I

6

I

Mother

3

Unit

J

R 19 xi_,

B

.I;=; p’

1 5 y!;;:y:

J-4

r---:

4 f.

-----

:

t9

4

e 0711-.

* ik

i733

13

Page 14

CRT Socket Unit

57001

f! st

r-1

El

I

E&g e SW 5 B

89

2

Lt

:a;

pk 5

i

=Y

- Cl004

=u

9

El-

8

+~(-J0’oo7

...)

__ 5

3C”

s

1007

cl

9cH

SIC13

“0:

0

P

p

lOCH

51014

cl

16

- ,,“,a

“.

-

I

.‘

,s

-

0

1.

Power

Switch

Unit

Controi Unit

Channel Select

Unit

Page 15

DUNTK4543WE

(OPWBF4543CE)

BLOCK

DIAGRAI

TO

DUNTK

4547WE

(RG)

BAND-SELECTOR

d ICZOI

IX0260CE

I

RG)

AFT.-DRIVE AFT-SWITCH

- 0201

2SClBl5tGR) 2SK304

-

0202

-

t

!I

&--Qgyy-~-

) INVERTER 11 FILC0020CE 1

IBCE

FILTER

I

t ,

r

LIMITER

I

1

VIDEO DET

COIL

T201

CILDOI

SIF CF301

FILC0007CE

s

TUNER

VTUMF4EA-702/

PIF. AMP

1

1

I

SAW-FILTER

FILCOO94CE

R224

RF-AGC

I

+

-

RCILZO55lCE

F

115v

il

AUDIO -

ATT

IC202

IX0388CE

SPEAKER

r

AC240V

5oHz

1

1

I

2

SOUND OUTPUT

IC301

IX0365CE

RECnFIER

D701- 0704

DX0240CE

I

3

RECTIFIER

’ D714

DX0220CE

CHOPPER-TRANS

*

T7Ol

TRNZ0235CE

t

1

4

RECTIFIER

D710

DX0246CE

I

5

I

6

I

e

I

15

Page 16

ZK

DIAGRAM

ZiMP. I::o:,.

0652

2SA1015(Y)

H DELAY

UNIT

L801

9CILZ0551CE

AUTO

MATIC

COLOUR NOISE

/---

- SEP.

NTSC/

SWITCH

I

_ 2nd

AMP.

TO

PAL

CHROMA

DUNTK4726WE

t

i (IT) 1

T

I

-

(IT)

1

O(O) ]

I

4.43MHz

osc.

b

I

l--fKl--

P

DUNTK4544WE

(OPWBF4544CE)

- 0854

41

-

I

t--

‘-

-

-t-

g+l

R-OUTPUT

2SC3417

R-DRIVE

08.51

r

G-OUTPUT

0855

2SC3417

G-DRIVE

0852

2SCl815tGR)

I I -

R857 1 R863

G-DRIVE

/

H.V

9,

I I

f I I

I I

’ ’ !

CRT

Lt

f

;

V801

, I

I 1

t

t

1

G-BIAS

I

-II

I

Y--i-

J

DXOIOSTA

?J REGULATOR

0609

2SD313

I

la--J&J

2nd

VIDEO AMR

-1

r-l

I

I

L

--3

I

32tH OSC.

CF6Ol

FILAOO07CE

4

I-

I

J

I

H-DRIVE 2SA958iY)

0601

T60 I

TRNZ0193CE

HOR. OUTPUT

L

-III:

VERT DRIVE

0503

2SCl514

-

-.

L

VERT.-OUTPUT

Q501

2SC2168tY)

0502

,

tI-/L--,1

-

RS25

V-SIZE

R520

V-LINE.

s502

V-SENT.

VERT.

HOR.

TO

DUNTK4543WE

Di)(F.B.T.)(L4)

I

&

1-

(F)

:1x

1b.Y)

6

I

7

I

8

I

9

1

10

I

11

I

12

J

16

Page 17

TO

DUN’

A

DUNTK4726WE

T

AFT

c

KEY

MICRO

QIOL

2sc

VT-

ICI(

1x0

FT

t-1

TUN

(+I

TUN

t-1

Ich

2ch

5ch

6ch

7ch

+-I

0

r

V N U

0

r

l (TA)

L

1

8ch

9ch

loch

n I

(TB) r

1

(TB)

r-

KEY

I

I

I

i-

0 0

L

F

ninn7

“I”“,

11(

I

f-

DVAICAPC

rfivfu7bc ; +

R3nnl

F

t I

l

!!) l

1

0 II

1

1

,

R4001

e--w---

[ L.;

CO/NT

I

I

BdIGHT f

I

P--TONE

i

LB-,_-+

A

f

(IT)

I

TO

DUNTK4543WE

i

-

v

ADG COIL

I

v

-_

H

_ +“s- .-- .

: TO

+

DyNTK4543WE

__-

-

_:-

.

.*_

: -.

--

.

1

I

2

I

3

17

I

4

I

5

I

6

1

Page 18

_ _-

;:NTK4543WE

AFT

1

VT-AMP

KEY

IClOl

IX0605CE

MICRO PROCESSOR

VT

_

1

1

_.

@SClSlS (GWI

I

(2105

S - MUTE

J

-1

DUNTK4728WE.

I 1

TO

DUNTK4543WE

KEY

__

_

RESET

(A)

I.

TO

DUNTK4543WE

LINE - FILTER

A

AC240V

50Hz

(A81

DUNTK4727WE

I

7

I

8

I

9

I

18

10

=

--

I

11

1

12

__

z<_--

1

Page 19

B

C

DLNTK4544WE

D

lOPWBF4544CEZZl

7

- c321

+

116W

‘Urn

/ P

I I

IC3D

I

r

lX0365CE EdUW-AMP1

-OO(L2~K&3

E

.F

0

,WMTES

(K)

VxIIXEi 1 r

:Y,”

I 3mA

Ifocvm IKE

, ix1 +-I”.

I i f

1 I I

III ?

I f 1

t i 1

~VeDl

* : ;““““*

It

1;: ;

111 i

::: :

,a, --I

~

-.-A -

a:

_______-----___------------------------~---

~XTD’ IXOTJIQ tPDWEi?-RE6tUTORJ

CT39

I%02

it-

19

Page 20

SERVICE PRECAUTION:

-

-

-

The area enclosed by this line

connected with AC Mains Voltage.

(

When servicing the

area, connect an isolating transformer between TV receiver

and AC line to eliminate hazard of electric shock.

) is directly

DLNTK4543WE

R4411)

7

10 /

& h

s4 I :q &n7

&4,

I, /

4-l

!

-----_-_----

=WfER-ftE!3JL4TOFIP~

c73a -

I,% 2

c,,s Kzoo.?.cE

~:~

_-___ -----J

I

IZO 057cE

4

F870P

rCOI0 E

*- OEZ I

-cE>

1-1

C716

0015

RIVI

1

rl

7

I

8

I

9

I

10

1

11

I

12

I

20

Page 21

(BLACK)

cPr,mn

Th,

WC”ll

dloptwn I*

Lltermce

from

All !he

“Olh?~sr I”

All

mere ‘lpuror repr**on,

OI COloUr

NOlO

,

sqnolr

Ftsmrtor

1 I)

Restrl~“ce

121

All

IO,I,,W,

13)

AU

re,tstw,

: g--p @--csmenr

11)

corJocmnce

(21

All

cwoc~!ws

(31

AH

WLl--Uykv

aode

Doat

are shorn n ~01,s nmne

0th~

woe

CBLI - -Blue

(BR)

--B,orn

orlglm\ one tbeMIClorC

your.

coch

~om,we meo,u,ed wrh

WE

Y- we

dm.n n oh,,

Of0

I/6 t”OlI. UMs, otllarrne “Ned

ln4e.l orher*aa n0t.d.

or* CWQon.

@--Oxat Fen @--SIWY @--Uetot

d~~,orn n UF=IO-‘Fdwrwt,e mma P=“LIF=,O-‘~ F

“DMS

ore

ore 5OV.

LPFI--

lR1

--Red

uh,s otbrms noted

Polypro

COlhoda cot4”r

CY’)- - 1~101

IOR)--Dronpe

COPOC~~M OTC CWML. ,,a,,

OTC dworn n

tBKb--BUXk

F,m

mere

,000 MI

D~WW~~ ~T)IW

(TA)--- T~nloh,m

,WB--Wh,*

d,$arol ,,,,,I, ,,,c,o,

“Olt~pe Iaveh meoued

: K=

moy be 0

UPon receFdan

,.OOO.OOD

tG,--G,**”

n,gtl,

Coornp

R122

IS<

“‘w’

I-

L

C,,,.

IWP.

i

7

r-

I

I

,

p@

e-g

213

1.

:z is? *

::I

80

co5

RI3

R,,,

seuemcMKbdl(

I

I

I

113

RI19

(BLIIEI e

0

-_--.

.

z

lib

RB.3 Rl.8

:o”,

:I%,

m,..? RI.0

:z-al I :,%#,

I-i’

OlO5

2SC1Bl%GRl

b

1130

&

IoN

f

I

0

.301

1

E

I:

v

11

tV303

‘UN ‘.l

:r

K-y ,

‘4

a0 ; =

nL; \

y-$ 3

111

jiDm&r !

8)

I

I

I

/

;“;q-@+

,

! :

7

1

I

1 ~D~05~odiDi07kDIW “’ / / j

IrI

I

/

I

1

r

CXoo..T. x4

IXO605CE

ICIOI

RIO5

GZH-SELECTOR)

j

*

I

I

,st~)y

t

II

‘R

----

3cH

*y-Ii;

B

c

j

4

& /

! I

IDI-.

0

1

0

2

0

fitf

a

-GJ-pJ

0

&)I

I

4

^

^

a

& BI

F

I

I

- 0 6

E

I

I I

x-l

“I /

OIW~-D1cm6

1SSIIsiw

1(100.?

6 CI

t

cDE 7

I

r I,

P

L

_I -1

// :9

/

/1r707-

’

IllI/

X6

$1

RmcM

R1003

R1Ms

Rmcm

’ III

WIT

A

_-------_

Ft,o

i

I

No645cEI

3T~mEDl

-1

51007

5,006

-

5mos

SW

51010

-

5,017

‘CM

51012

w

StOl.

‘0%

D1007

PXO!WCE

I

I

I I.

~

/

i

r----i

-_-__d

9lh’

, I&

a:‘oi.

~~~~~Zi~l

III

RID6

Q-

m D

j-y-++/Gj j 1 1 ~I+q

. .

I L

wy-i>,

M,,

-YG%F3+1-1

..

-3-l

/ “’ ?i&b43BS-,

; / +-+-y-F*;

i.l I

* g9-

iI !\ 0 coo

-0

I

!

%

u

’

:

1-j

p::,

1

z

::!?

q

ill I

/

ff-y-q&Yh

(

I

I.

7

h

Ezi

-I

i,i’rpy]/

j2*p!

lKz

’

T-

0

m

<a

b-1

I D!??-- 1

) 1

‘,yy 1 j

I /

I II J j 1 /

I l4-wi IA’ ’ I WI

,2:&&i A/ / AT+

EXooslGE

I

ICI02

IXO439CE

IMEMDRY~

dllE~ml~l~ /

DWTK472BWE

tOFWSF472BCEZZl

A

j

I

&r

iI

ji \

.Y3V

CICImf

a-

ll

I

Izv

UT,

I

I

iI/

I

li

:

21

lNO304cT)

DWTK4727WE

lDPWBF4727CEZf~

Page 22

DESCRIPTION OF SCHEMATIC DIAGRAM AND WAVEFORMS

PARTS

MARKED

MAINTAINING THE SAFEN

PLACE THESE PARTS WITH SPECIFIED ONES

ING

THE

SAFETY

CAUTION:

This

circuit diagram is original

slight difference from

All the voltages

meter.

All

these figures represent

reception of colour signals.

Waveform Measurement Conditions

1.

Upon receiving

2. m indicates wave form

and measured from point indicated to

WITH *A

AND

in each

EBU

- (

OF THE

PERFORMANCE OF THE

yours.

point

are

the

colour bar signal of

check

) ARE IMPORTANT FOR

SET.

one,

therefore there may

measured

voltage

points

chassis

BE SURE TO

FOR MAINTAIN-

SET.

be

wrth

digital multi

levels measured upon

70 dS in

(See

field intensity.

chart, waveforms

ground).

RE-

NOTE:

RESISTOR

11)

Resistance values are

K=

1,000 M=

(21

All resistores

(31

All resistores

@ . . . . . .

@ . . . . . .

a

@. . . . .

CAPACITOR

Capacitance

(1)

p=uuF=

(21

All capacitors

All capacitore

(31

/MU . . . . . .

(TA). . . . . .

DIODE

Diode

are,

colour.

(BL) . . . . . .

(Yl. . . . .

(G). . . . .

I,i?OO,OOO

are

are Carbon,

Solid

Oxide

Film

.

Metal Coating

values are

10-12F

are

are Ceramic,

Mylar

.

Tantalum

shown

parts

BLUE

.

YELLOW

.

GREEN

shown

in

ohms:

l/8 watt, unless otherwise noted.

unless other wise noted.

. . . . . .

Cement

8

@ . . . . . .

Special

shown

in u=

10e6F otherwise noted

5OV, unless otherwise

unless otherwise noted.

IPf) . . . . . . . Polypro

name other Diode

(BR) . . . . . .

(WI . . . . . .

(ORI. . . . .

Film

BUCK

WHITE

.

ORANGE

noted.

are

shown cathode

@ 48OVPp

(1OOV

@ l.GVp-p

(0.2V

@ 4.8Vp-p

(2V

20psec)

10usec)

20psec)

@

8.OVp-p

(2V1

@

B.OVp-p

(0.W 20wec)

@! 1.14vpp

(0.2V

@ 1.4vp-p

Ousec)

20ysec) (0.1 V 1

(0.2V 20rrsec)

@ 4.ovp-p

(0.5V

@ O.GVp-p

2OjSec)

Ol.rsec)

11 9.2vpp

i0

(2V 20psec)

/

@ 96Vp-p

(2OV

5msec)

@ 2.ovp-p

10.2V 20usec) (0.1 V20ctsec)

@ 12ovp-p

(2OV

2Opsec)

@ toovp-p

(2OV

5msec)

@ 0.84Vp-p

@ 114vp-p

(2OV

@ 152vp-p

(2OV 1

20psec)

Opsec)

@ 0.7vp-p

(0.1

v

@ 112vp-p

(2OV 20ysec)

2Owx)

7

22

Page 23

TUNER

A

VTUMF4EA-7021

F

I

t

1

c

R

I

{\

:!

1

VS2SD313F//lE

VS2SC2168Y12E

,

LEYITTER

L--‘LLECTW

VS2SClBISGW-I

VS2SCl906NlE

VSZSA950~

RH-IX0439CEZZ

RI-I-IX0412CEZZ

VSZSDl556//2E

SOLID STATE DEVICE BASE DIAGRAM

VS2SC1514-

VS2SC2271-EIA

RH

- PXOI49CEZZ

I-

-EMITTER

COLLECTOR

RMPTE0043CEZZ

/ZE

RMPTCOl50CEZZ

8

7i-7

RH

-1X0260CEZZ

I

c

ii

RH-

IX0731CEZZ

YP

h

t345

RH

- !XC703CEZZ

%y+

L i : _ L

23.5

5

VS2SK304CO/- I

VHSSF3H42// - I

-GATE

RH- IX0368CEZZ

30

nnnnnnnnnn

RH- IXO767CEZZ

6

-..

_ - _-

16

I

I

-

-

-

-

-

:

CIITHOGE

Rr-IX0249CEZZ

ANODE

4z3.5 GI G9IO0,z0

23

c

(

c

L

L

4,

-

Page 24

PARTS LIST

PARTS REPLACEMENT

Replacement parts which have these special safety characteristics

identified in this manual; electrical components having such

tures are identified by A in the Replacement Parts Lists.

The use of a substitute replacement part which

same safety characteristics as the factory recommended replacement parts shown in this service manual may create shock, fire or

other hazards.

“HOW TO ORDER REPLACEMENT PARTS”

To have your order filled promptly and correctly, please furnish the

following informations.

1. MODEL NUMBER

3. PART NO. 4. DESCRIPTION

NOTE: THE PARTS HERE SHOWN ARE SUPPLIED AS

AN ASSEMBLY BUT NOT IN DEPENDENTLY.

b

VTUMF4EA- 7021

INTEGRATED CIRCUITS

IC201

IC202

IC301

,IC701

lcaol

RH- i

RH- i

RH- i

RH- i

RH- i

X0260CEZZ

X03aaCEZZ

X0365CEZZ

X0731CEZZ

X0787CEZZ

2. REF. NO.

VHFUHF Tuner

doeqnot

have the

Ref. No.

Q402

0501

0502

0503

0601

fea-

Q602

0604

BSCR601 VHSSF3H42/ / -

0201,

VS2SA950dl

VS2SC2 16BY/

VS2SA95BYl

VS2SCI 514VS2SC2271VS2SDI 556/ /

VS2SD313Fi

VHDlSSllSII-

401,

402.

404

I

406,

503,

504,

506

I

508,

602,

606,

611

I

613,

651,

652,

705

D202 RH-

BF

AF

AQ

AK

AT

AT

D502,

A

608,

D603,

80605

D609

AD610

80701

A

704

.

0707

0710

D712

D802

XR801

604

804

RH601,

607,

706,

714

RH-

RH-

RH-

RH-

RH-

I

RH-

RH-

RHRH-

I

RCRSB003 1 CEZZ Crystal

Part No.

I - 1

/ 1 E

/ 2E

/ 1 E

2SA950

2E

2SC216B(Y)

2SA95B(Y)

2SC1514

ElA 2SC2271

2E

2SDI556

2SD313(F)

1

SF3H42

DIODES

1 AB

EX0056GEZZ

DX0220CEZZ

EXOI

39GEZZ Zener Diode

EX0034CEZZ

DX0105TAZZ

EXOI

69GEZZ Zener Diode

DX0240CEZZ

EX0060GEZZ

DX0246CEZZ

EXOl

52CEZZ Zener Diode .

EX0072GEZZ

Zener Diode

Zener Diode

Zener Diode

Zener Diode

PACKAGED CIRCUIT

Description Code

AD

AF

AC

AE

AC

AP

AE

AG

AB

AB

AA

AC

AD

AA

AB

AA

AD

AE

AA

AK

TRANSISTORS

0201,

Q202

Q203

0401,

>

603,

vs2scla15GW-

801

VS2SK304CDi

VS2SC1906ii

VS2SAlOl 5Yi

652 L211

1

2SClB15IGR)

- 1 2SK 304 AC

IE

2SC 1906 AC

1 E

2SAl015(Y)

A0

AC

24

L204,

206

L205,

609

L209

L210

VP- DF

VP-

VP-

VP- XF

VP-

lR2MOOOO l.2pH

DF6BOKOOOO

CF6BOKOOOO

120KOOOO

XF4R7KOOOO 4.7pH

COILS

6BpH

6BpH

12pH

AB

A%

AB

AB

AB

Page 25

t?ef.No.

Part No.

Description

Code Ref. No.

Part No.

Description

Code

L301

L302,

303

L403

L404

1L602 VP- L K l~OOKOOOO 10pH

1L603, VP- MK 1 OOKOOOO

I

608

L604

L605

L606

L607

L610

L701

L702

L703

L801

L802

VP- XF

VP- CF

VP - DF R

RCi LZ0488CEZZ

RCi LP0097CEZZ

RCi

RCi

VP- CF

VP-

VP-

RCi

VP- CF

RCi LZ0551CEZZ IH-DL

VP- DF

180KOOOO

2R2MOOOO 2.2pH

39MOOOO

LP0070CEZZ

LZ0422CEZZ

390KOOOO

XF2R7MOOOO

CFR33MOOOO 0.33pH

LP0069TAZZ

3R3KOOOO 3.3/~H

102KOOOO ImH

18pH AB

0.39rH

Video Delay AH

1OpH

3gpH AB 727

2.7~H

47pH

Unit

CERAMIC FILTERS

CF201

CF202

CF301

CF302

CF601’

RF i L

COO94CEZZ

RFi LC0020CEZZ 5.5MHz

RF I

LC0007CEZZ

RFi LC0097CEZZ

RFi LA0007CEZZ

SAW Filter AK

SIF Filter

SIF Detector

32fH Osc.

Trap

TRANSFORMERS

T201

T202

T601

hT602

,T701

T801

RCi

LDOl 18CEZZ

RCi LD0099CEZZ

RTRNZOI

RTRNF

RTRNZ0235CEZZ

RCi

93CEZZ Horizontal Drive

1625CEZZ Flyback

LVOl

39CEZZ Band Pass Trans. AE

P-DET

AFT

Trans.

Regulator Trans.

CONTROLS

R224

R421

R520

R525

R634

R817,

826 Carrier Wave-

RVR-

B51

RVR- B 5

RVR-

B51

RVR-

851

RVRRVR-

B51

37CEZZ 5k(B) RF-AGC AB

139CEZZ

34CEZZ

31CEZZ

B5141CEZZ

38CEZZ

20k(B)

lk(B)

200k(B)

50k(B) Horizontal-Center AD

IOk

Sub-Brightness AB

Vertical-Line AD

Vertical-Size

Sub Colour

Phase

CAPACITORS

c222

c303

c317,

617

C318

c319

C321

c409

c503

c507

C512

c513

c515

C516

VCSATAlVEl05K

RC-

EZOI

30CEZZ 330

VCEAGAI

VCEAGAl

RC-

VCEAGAlCW477M

VCFYSB2AB224K

VCCSPA2HL470K

-VCEAGA2CW336M

VCFYSB2EB104K

VCSATA 1 VE 684K 0.68 35V

VCEAGH2CW227M

VCFYSB2EB223K

CWl07M

EWI 07M 100 25V Electrolytic AD

EZ0077CEZZ

1 35v

16V

100 16V Electrolytic AB

470

470 16V

0.22 IOOV Mylar

33

0.1

220

0.022 250V

25V

47p

500V Ceramic AA

160V Electrolytic AD

250V Mylar AC

16OV

Tantalum AD

Electrolytic AC

Electrolytic AD

Electrolytic AC

Tantalum AC

Electrolytic

Mylar

C602

C604

AB

C615

AB

C616

C619

AB

C620,

AB

AE 725,

AD 733

AG

AB AC625,

AB 626

AF

AB

AE C631

AB C632

AE

AE

629,

634,

C622,

C627

C630

C633

AC701,

-A 702,

730,

739

AC704

AI= AC706,

AE

A 707

c709

c710

c711

C716

AD

C718,

AE

AG

BH

AT

AD

AB

726

C720

C724

C728 RCc729

C732

c734

C738

C811

R416

R425

AR506

R508

R511

R529,

640

R530

R605

R619

AR620

AR628,

A 730

R629,

AD

AH AR636

AC

630,

713

R631

R649

VCCSPA2HL470K

VCEAGAlCW337M

RC-

EZOl 11CEZZ

VCEAGAlAWl07M

VCKYPAZHB

VCKYPA2HB 102K

RC-

VCFPPD3CA682J

VCEAAH2EW226M

VCEAGAl EW337M

VCKYPA2HB271K

VCFPPD2DB434J

VCFYSB2GB393K

RC-

RCRC- KZ007 1 CEZZ

VCEAGAI

VCKYPA2HB272K

VCEAGAI

VCEAAA2EW475M

RC-

KZ0057CEZZ

RC-

VCKYPA2HB222K

RC-

VCKYPH3DB561K

RCRC-

VCEAGAlCW227M

101 K

KZOOI GCEZZ

KZ0029CEZZ

EZO169CEZZ

HW107M

EW227M

KZ0035CEZZ 220~

EZOO69CEZZ

EZ0107CEZZ

EZOl 12CEZZ

KZ0024CEZZ

RESISTORS

VRSVRS-

RR-

RRVRSRR-

VRSVRS-

VRS-

VRDRR-

RR-

VRN-

RR-

VRS-

PV3ABl02J

VV3AB681

XZ0091CEZZ

WZ0090CEZZ

VV3DB392J

WZ0065CEZZ 3.9k

VV3DB562J

VV3LB472J 4.7k

VV3DB 103J

RA2BE 103J

XZ0090CEZZ

WZ0082CEZZ

VV3AB2R7J

XZ0092CEZZ

VV3DB222J

47p

330 16V Electrolytic AC

1000

100

100~

0.001 500V Ceramic AA

0.01 Ceramic AC

0.0068

22

330

270~

0.43 200V Metalized AE

0.039 400V Mylar

0.01

330 4oov Electrolytic AT

0.0022

100

0.0027 500V Ceramic AA

220

4.7

0.0015 2kV Ceramic AD

0.0022 500V Ceramic AA

220

10

560~

330 25V

0.001 2kV Ceramic

220

lk

J 680

18

150

3.9k

5.6k

1

12

470

2.2k

500V Ceramic AA

6.3V

500V Ceramic AA

1.6kV

250V Electrolytic AD

25V Electrolytic AC

500V Ceramic AA

5ov Electrolytic AC

25V

250V Electrolytic AB

2kV Ceramic AB

16OV

2kV

1w

1W

1/2w

low

2W Oxide Film AA

5W Cement AD

2W Oxide Film AA

3W

10k 2W Oxtde Film AA

IOk

5w

2.7

1W

ll2W

2W Oxide Film AA

Electrolytic AC

Electrolytic AB

1ov

Metalized AE

Polyester

Polyester

Ceramic AC

Ceramic AC

Electrolytic AC

Electrolytrc

16OV

Electrolyttc

Ceramic

Electrolytic AC

Electrolytic AC

16V

Oxide Film AA

Oxide Film AA

Fuse

Resistor

Cement

Oxide Film AB

1/8W Carbon

1/2w

Fuse

Resistor

Cement AD

Metal AA

Coating

Fuse

Resistor

AC

AG

AF

AC

AC

AB

AC

AA

AB

AB

25

Page 26

ef.No.

Part No.

Description

Code Ref. No.

Part No. Description

Code

AR

703.

A

704

R

710

R

711 RR-

VRC-

VRS-

SV2HCl

WZ0099CEZZ

UA2HG825K 8.2M

OOJ 100 112w Oxide Film AA AC858

1 5w Cement AD AC861 RC-

1/2W Solid AA

SWITCHES

501 QSW- BOO1 5CEZZ Service AC

502

OS W -

B 0 0 2 0 C E Z Z Vertical Center AE

MISCELLANEOUS

B601,

8701

B703,

RBL N- 001 OCEZZ Ferrite Bead

602,

603,

702

RBLN- 0030CEZZ Ferrite Bead

RBL N- 0041 CEZZ Ferrite Bead

704, ASG854

705,

706

AC

AC A 853,

AB A 855

C864,

865

R865,

866,

867

ASG851,

A 852,

CAPACITORS

VCEAAH2EW226M

KZOO23CEZZ

VCKYPA2HB 102K

RESISTORS

VRS-

VV3DB123J

MISCELLANEOUS

QSoCV0814CEZZ

QSPGC0022CEZZ

QSPGC0020CEZZ

22

0.0047

0.001 500V Ceramrc AA

Spark Gap

Spark Gap

250

12k 2W Oxide Film * AA

CRTSocket

Electrolytrc AD

Ceramic

AD

AG

AC

AB

TRANSISTORS

1851,

!854,

852,

853

855,

856

VS2SC1815GW-

VS2SC3417;

1

2SC1815(GR)

IlE

2SC3417

DIODES

1852,

853,

855

VHDlSSllS!!-1

COILS

851 VP- CF 68 1 KOOOO

852 VP- XF 1 OOKOOOO 10pH

I

854

680rH

CONTROLS

857-A/

RVR-

B5083CEZZ 500k(B)x2

-B

862 RVR863,

864

B4567CEZZ

5k(B)

Green Drive/

Blue

Dnve

Red Bias

Green Bias

Blue Bias

AB

AC

01001

D1007

I

006

VHDISSI 19,

RH-

PXOl

64CEZZ Channel LED

)I - 1

CONTROLS

RVR-

AR3001

AR4001 RVR-

AB

AS1001

I

1014

AS101 5 QSW- BOO1 88CEZ Band Select

AB

Q4032CEZZ

G4013CEZZ

MISCELLANEOUS

RR MCUO 1 6 OC E Z Z

QSW-

K0030CEZZ

SWITCH

AS7001

AC

AC

QSW-

P0370CEZZ

Power Switch

INTEGRATED CIRCUITS

IClOl

ICI02

RH- II

RH- ii

X0605CEZZ

X0439CEZZ

lSS119

Remote Control Receiver

I

AB

AN

AF

AG

AR

AB

AD

AK

AS

AQ

26

Page 27

Ref .No.

IC103

IC104

DlOl,

102

D105 RH-

108

D104 RH-

;:1::::::‘:,;~

VHDlSSllSII-

I

R

MP T P 0 0 2 8 C E Z Z Positive Coefficient

Part No.

TRANSISTORS

DIODES

1 AB

EX0044TAZZ

EX0051GEZZ

RD8.2

PACKAGED CIRCUITS

I

ZenerDiode

Description

Code Ref. No.

AP

AE

F

AC

AB

AB

AB

AA

Part No.

C C AB A 5 1 6 6 C E S 0 Front Cabinet Ass’y

Not Available

GLEGP9007CEZZ

C WAK P 1 1 3 6 C E 3 7 Front Frame Ass’y

Not Avairable Front Frame

GDoRF 1572CESA

HBDGB

HBDGD301

Hi ND M 2 4 8 3 C E S A Indication Metal

Hi

Hi

HPNLCl

HPNLCOl GOCESA

CCABBl 650WEVl BackCabinetAss’y

JBTNJ BTN- 1354CESA Button, Channel

J KNBP

1058AF

GCESA

NDM2485CESA

NDP2379CESA

563CESA Indication Panel

Not Available

1321CESC

1099CESA

Leg

Door

SA Badge “SHARP”

Badge “LINYTRON”

Decoration Metal

Indication LED

Punching Plate

Button,Power

Knob

Description

Front Cabinet

Back Cabinet

Code

-

AC

BB

-

AL

AD

AE

AD

AF

AD

AW

AR

-

AC

AE

AC

LlOl

L102

L104,

105

L106

,L7001

Cl09

LC7001

c7003

iR7001

,F7001

VP-

MK560KOOOO

VP- XF 1 ROM0000

VP- XF

VP- XF

R

C i L F 0 0 9 0 C E Z Z

5R6KOOOO

120KOOOO 12/~H

56pH

1pH

5.6pH

Line Filter

CAPACITORS

RESISTOR

RR-

WZ0096CEZZ

6.8

low

Cement

MISCELLANEOUS

QFS-

C2022TAZZ

QF S H D 1 0 0 2 C E Z Z Fuse Holder (2 Used)

QACCL 5001CEZZ AC Cord

Fuse, T2A

AB

AB

AB

AB

AL

AB

AG

AD

AE

AE

AA

AP

SP301

AP

27

Page 28

SHARP

T5652-S

Printed in Japan

MW.KY

Loading...

Loading...