Page 1

Date: Jan. 17, 1995

COLOR IMAGE SCANNER: JX330

[Service information]

JX330 SERVICE DIALOGUE OPERATION METHOD

1.Model name: JX330/M/P

2.General: The service dialogue function has been added to the JX330 series.

3.Description: There are five types of dialogues in the service dialogue.

No. : CX-174

A Mechanical Function Test

B White Balance Test

C Shading ware form check

D Darknoize component wavefome check

E Control Board Check

Operation methods and details:

Set the DIP SW on the back of the scanner to suit for each dialogue mode. You can

use the service dialogue mode by turning on the DIP SW 7 and 8. Other DIP switches

are used for dialogue mode setting.

Notes:

Service dialogue can be only used in the models with the ROM versions since S081H.

This also can be operated in the main unit or the control PWB since October 1994

production.

SHARP CORPORATION Printer and Scanner Division

1/7

Orange

C

Page 2

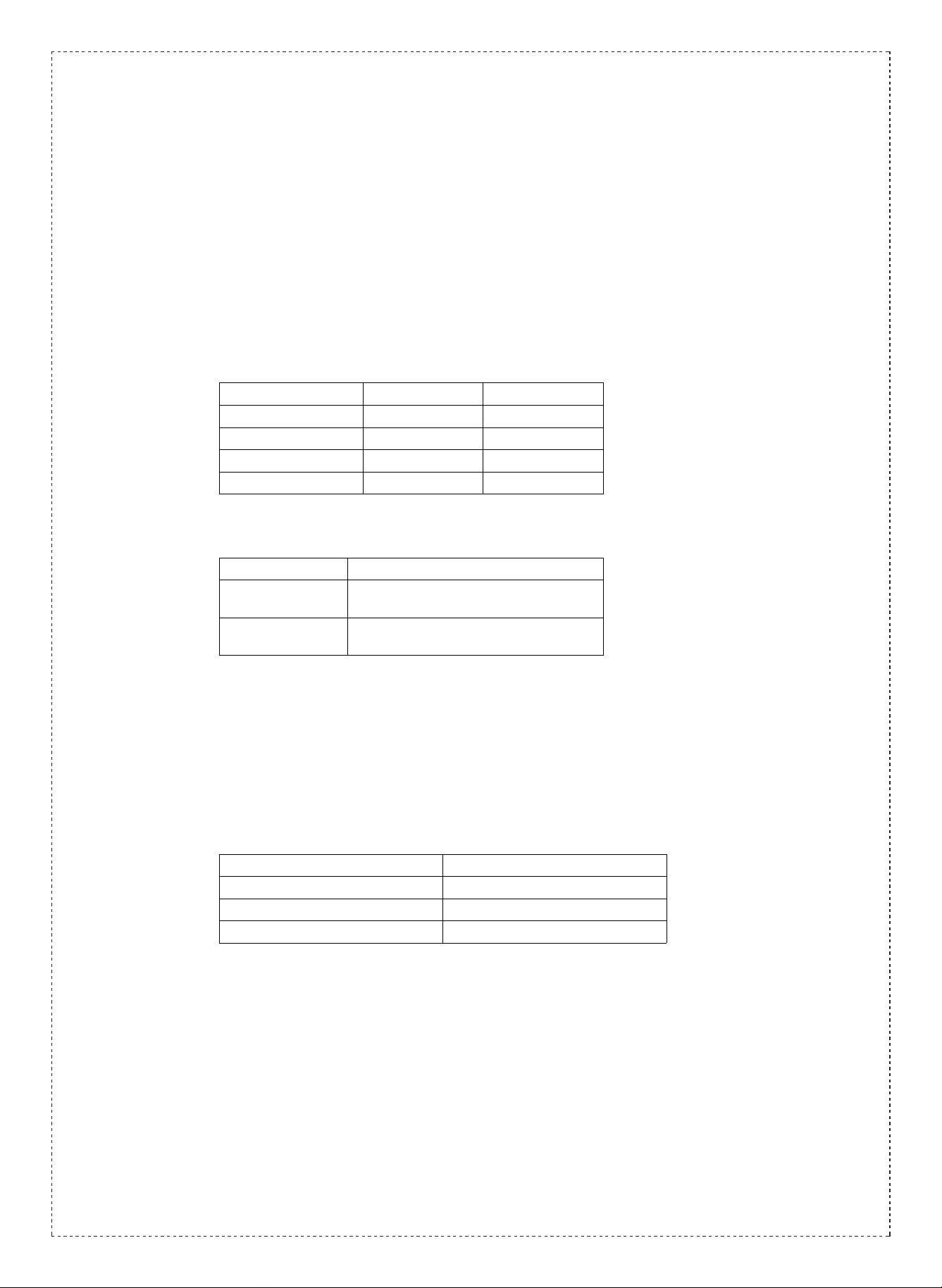

The P rocedure to Pe rform Service Diagnosic

A Mechanical Function Test

BWhite Balance Test

C Shading waveform check

D Darknoise com ponent wavefo rm check

E Control Boar d Check

A Mechanical Function Test

1) Turn the DIP SW 7 and 8 ON.

2) Set the DIP SW 1 and 2 as shown in the table below depending what unit

you are testing. Each u nit can b e test ed separat ely.

Unit to b e Tested DIP SW1 DIP SW2

Main Body OFF OFF

ADF ON OFF

FSU OFF ON

FSU ON ON

3) Set the DIP SW 4 depending on how many times you want to repeat the

oper ati on of th e uni t.

DIP SW4 How Many Times to Repeat

OFF

ON

4) T ur n ot h er D I P SW ( 3 , 5, 6 an d 9) OFF .

5) Turn the Power Switch ON.

–– The Ready Lamp blinks for a minute.

6) While the Ready Lamp is blinking, turn the DIP SW 8 OFF.

7) While the Ready Lamp is blinking, turn the DIP SW 7 OFF.

–– The unit begins to operate and you can monitor the process of the

operation by observing blinking lamps.

Status of Unit Status of Lamp

Scanner Head Pausing Ready Lamp ON

Scanner Head Moving Ready Lamp OFF

Optional Unit S elected Option Lamp ON

–– The Error Lamp turns ON and the diagnostic program fails on the following occasion.

The operation repeats until the

Power Switch turns OFF.

The operation repeats 480

times then, automatically stops.

2/7

• You made the wrong setting.

• You performed 6) and 7) after the Ready Lamp stopped blinking (i.e.

after 1 m inute passed sinc e the Po wer Sw itch tur ned ON ).

• You did not connect the optional unit with the scanner despite the

setting was made for the use of the unit.

Page 3

8) Turn the Power Switc h OFF to stop the diagnostic program. If you have

turned DIP SW 4 ON, the unit stops automatically after repeating the

operation 480 times, then, the Ready Lamp, the Option Lamp and the Error

Lamp blink in sequence.

B White Balance Test

1) Turn the DIP SW 5, 7 and 8 ON.

2) Turn the DIP SW 1,2,3,4,6 and 9 OFF.

3) Turn the Power Switch ON.

–– The Ready Lamp blinks for a minute.

4) While the Ready Lamp is blinking, turn the DIP SW 8 OFF.

5) While the Ready Lamp is blinking, turn the DIP SW 7 OFF.

–– The white b alance i s check ed, then , sca nning st arts wit h the sca nner

head remaining in the s ame posi tion. If a regu lar-siz ed origi nal is o n

the original table, a part icular part of the or iginal i mage is d isplaye d

repeatedly.

Then, you can check the operation of the scanner head and the image date

input circuit (mainly the analog signal processor).

–– Ready Lamp blinks during the operation.

–– The Error Lamp turns ON and the diagnostic progra m fails o n the

follow in g occa sion .

• You made the wrong setting.

• The performed 4) and 5) after the Ready Lamp stopped blinking (i.e.

after 1 m inute passed sinc e the Po wer Sw itch tur ned ON ).

8) Turn the Power Switc h OFF to stop the diagnostic program. If you have

connected the FSU, the diagnostic program checks the FSU.

C Shading waveform check

(The video input circuit waveform check)

Use this diagnostic program to check the video input circuit (an analog circuit).

Check the waveform obtained by the program to detect any failure in the circuit.

1) Turn the DIP SW 1,5,7 and 8 ON.

2) Turn the DIP SW 2, 3, 4, 6 and 9 OFF.

3) Turn the Power Switch ON.

–– The Ready Lamp blinks for a minute.

4) While the Ready Lamp is blinking, turn the DIP SW 8 OFF.

5) While the Ready Lamp is blinking, turn the DIP SW 7 OFF.

–– The waveform is now obtained for signals generated when all lamps are ON.

The diagnostic program fails with the Error Lamp ON if;

• You made the wrong DIP SW setting

3/7

Page 4

• You performed 4) and 5) while the Ready Lamp was not blinking

6) Turn the Power Switch OFF to stop the diagnostic program.

If you have connected the FSU, the diagnostic program checks the FS U.

The TP9 Waveform

Voltage (V)

2.6V

0.7V

8µs

Output Shading Waveform

Time (µs)

D Darknoise component waveform check

(The video input circuit waveform check)

Use this diagnostic program to check the video input circuit (an analog circuit).

Check the waveform obtained by the program to detect any failure in the circuit.

1) Turn the DIP SW 2, 5, 7 and 8 ON.

2) Turn the DIP SW 1, 3, 4, 6 and 9 OFF.

3) Turn the Power Switch ON.

–– The Ready Lamp blinks for a minute.

4) While the Ready Lamp is blinking, turn the DIP SW 8 OFF.

5) While the Ready Lamp is blinking, turn the DIP SW 7 OFF.

–– The waveform is now obtained for noises generated when all lamps are OFF.

The diagnostic program fails with the Error Lamp ON if;

• You made the wrong DIP SW setting.

• You performed 4) and 5) while the Ready Lamp was not blinking.

4/7

6) Turn the Power Switch OFF to stop the diagnostic program.

If you have connected the FSU, the diagnostic program checks the FS U.

Page 5

The TP10 Waveform

Voltage (V)

1.4V

0.7V

About 30ms

Enlarged

One wave-cycle consists of 256

small sawtooth patterns.

E Control Board Check

This diagnostic program checks :

• The device s such a s the I mage Proces sor, S CSI Co ntr oller and Gate A rray s

• Bus Lines on the Control Board

• Input/Output of signals in comm unications with the ADF

• Input/Output of signals in communications with the FSU

1) Turn the DIP SW 6, 7 and 8 ON.

2) Turn the DIP SW 1, 2, 3, 4, 5 and 9 OFF.

Time (ms)

3) Turn the Power Switch ON.

–– The Ready Lamp blinks for a minute.

4) While the Ready Lamp is blinking, turn the DIP SW 8 OFF.

5) While the Ready Lamp is blinking, turn the DIP SW 7 OFF.

–– The progr am simulates the scanning operation, creating automatically

particular image data (without actual scanning) and follows the steps

to process data until the data is sent to the interface unit.

–– If there is any defe ct in t he dev ices, the diagnost ic progra m detect s the

device that output unusual signal and shows you what device is

defec tiv e by c omb ina tio n s of b li nki ng la mps .

5/7

Page 6

During the operation, the Ready Lamp is blinking.

• If the operation finished successfully, the Ready Lamp stops

blinking and continues to be ON.

• If there is any problem:

1) The Er ror La mp bli n ks, an d then ,

2) Some of the Error, Ready and Opti on Lamps turn ON.

3) Some of the Error, Ready and Opti on Lamps turn ON in the

combination diff erent from above 2).

What lamps turns ON in steps 2) and 3) indicates the defect device.

Steps 1) to 3) are repeated until you finish the dia gnostic program.

–– The Error Lamp turns ON an d the diag nostic progra m fails o n the

follow in g occa sion .

• You made the wrong setting.

• You performed 4) and 5) after the Ready Lamp stopped blinking (i. e.

after 1 minute p assed since th e Power Switch t urned ON).

8) Turn the Power Switc h OFF to stop the diagnostic program. If you have

connected the FSU, the diagnostic program checks the control circuit of the

FSU.

6/7

Page 7

TROUBLE DISPLAY TABLE

LAMP CONDITION

ACTION 1 ACTION 2

BLINK A ERROR LAMP

R: READY LAMP ON

O: OPTION LAMP ON

E: ERROR LAMP ON

All lamps are off

E

E

E

E

E

E

O / E

O / E

O / E

O / E

O / E

O / E

R

R

R / E

R / E

R / E

R / O / E

R / O / E

R / O / E

R / O / E

ACTION 3

All lamps are off

E

O

O / E

R

R / E

R / O

E

O

O / E

R

R / E

R / O

E

O

E

O

O / E

E

O

O / E

R

7/7

DESCRIPTION

DIP SW trouble

B memory (IC22) databus trouble

C memory (IC27) databus trouble

Z memory (IC23) databus trouble

S memory (IC21) databus trouble

LL memory (IC35) databus trouble

LH memory (IC30) databus trouble

B memory (IC22) addressbus trouble

C memory (IC27) addressbus trouble

Z memory (IC23) addressbus trouble

S memory (IC21) addressbus trouble

LL memory (IC35) addressbus trouble

LH memory (IC30) addressbus trouble

Data transmission trouble from L memory (IC30, 35) to S (IC21) memory

Data transmission trouble from L memory (IC30, 35) to FIFO (IC38) memory

GATE ARRAY 1 (IC29) trouble

GATE ARRAY 2 (IC34) trouble

SCSI controller (IC36) trouble

LUT memory (IC34) trouble

EVEN memory (IC33) trouble

ODD memory (IC37) trouble

FIFO memory (IC38) trouble

Loading...

Loading...