Page 1

SPECIFICATIONS

VOLTAGE

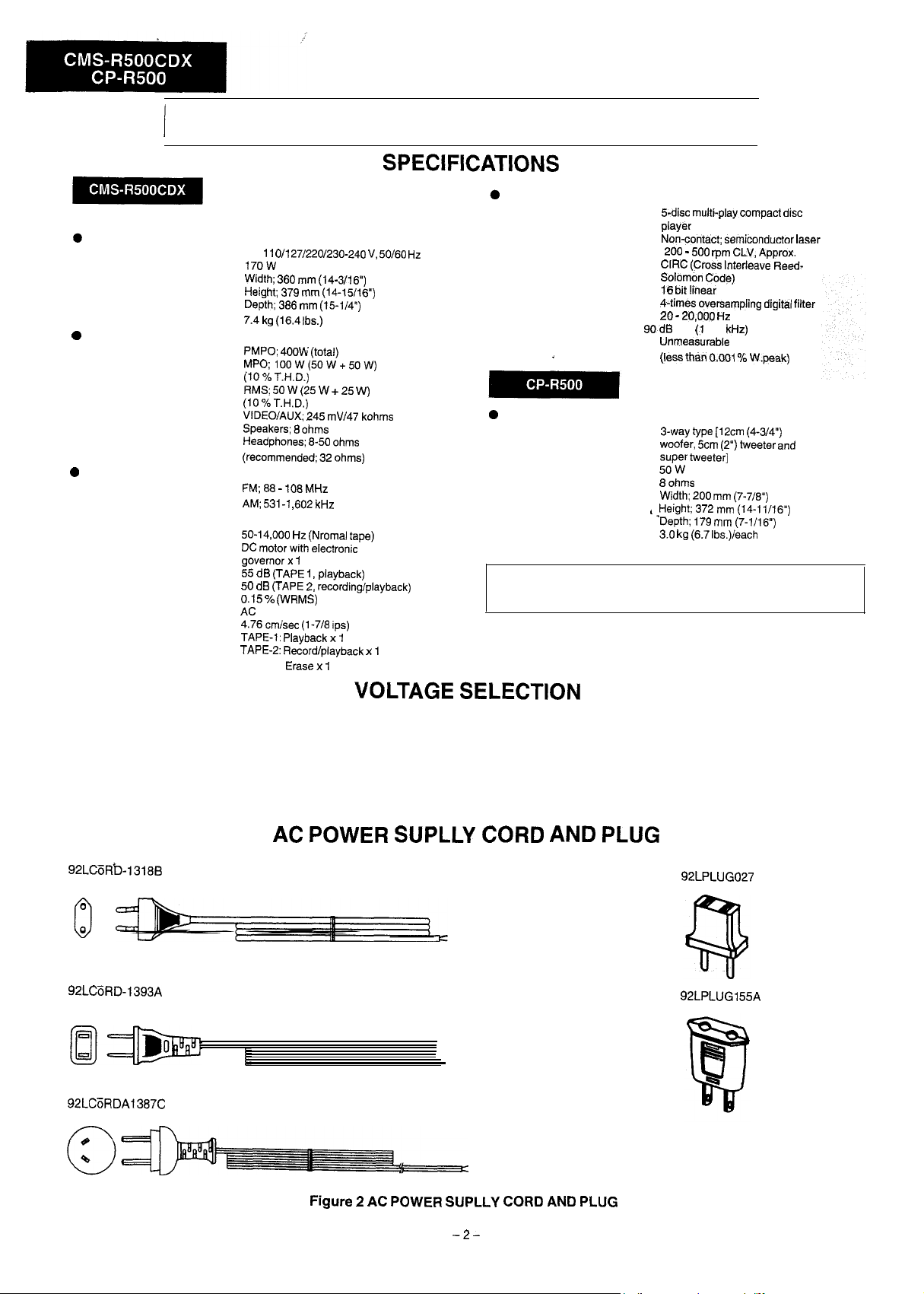

AC POWER SUPLLY CORD AND PLUG

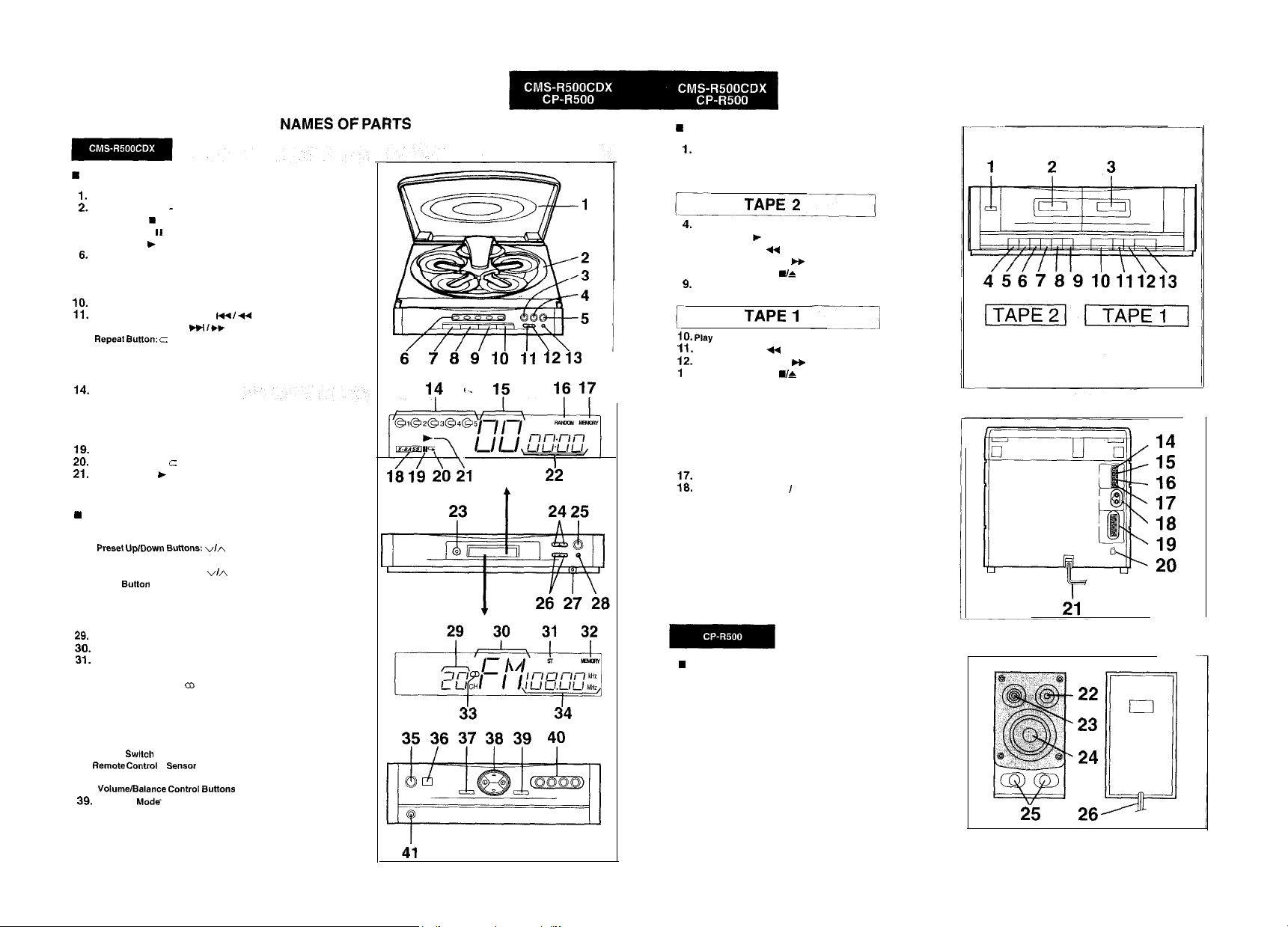

NAMES

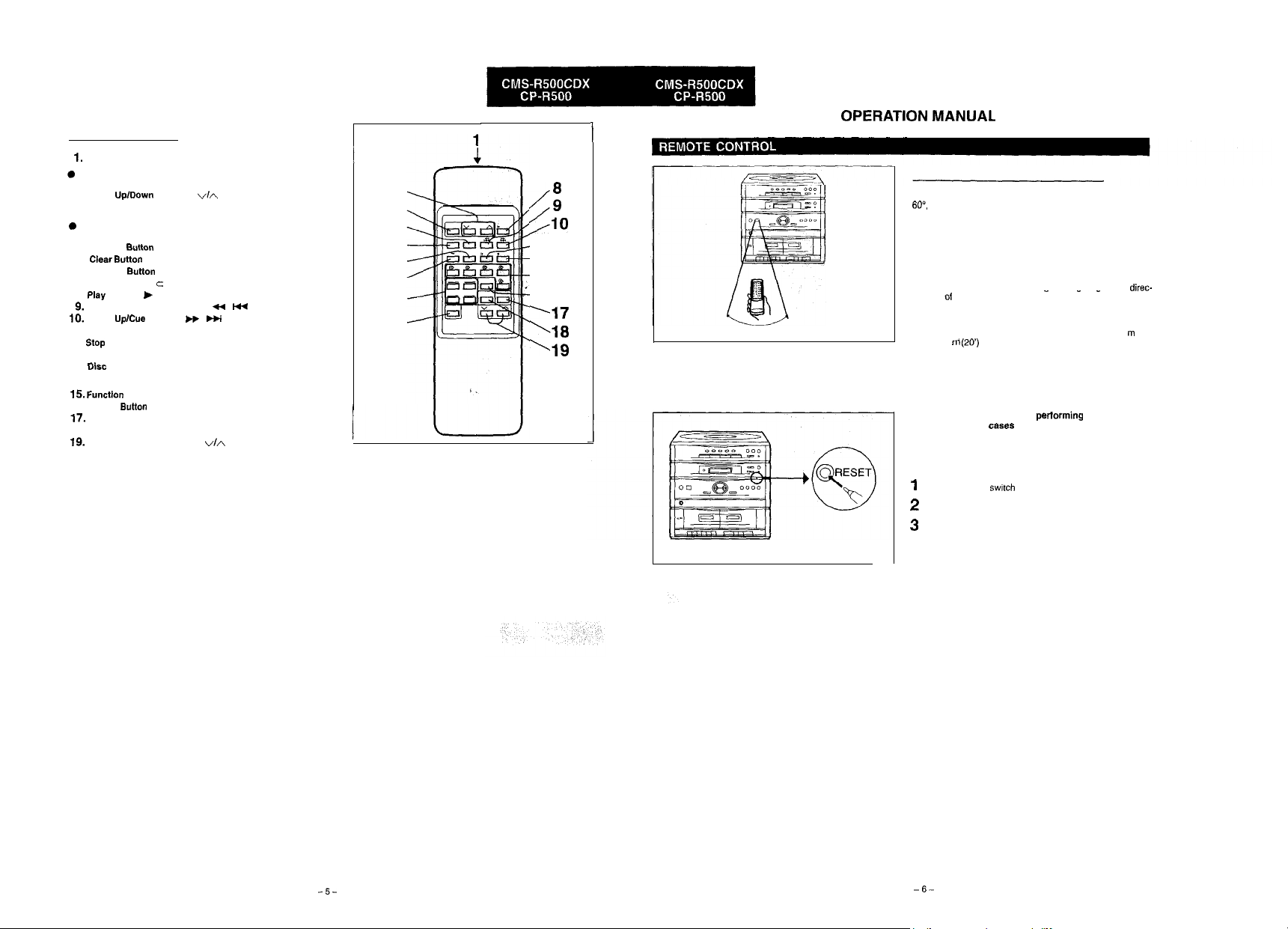

OPERATION

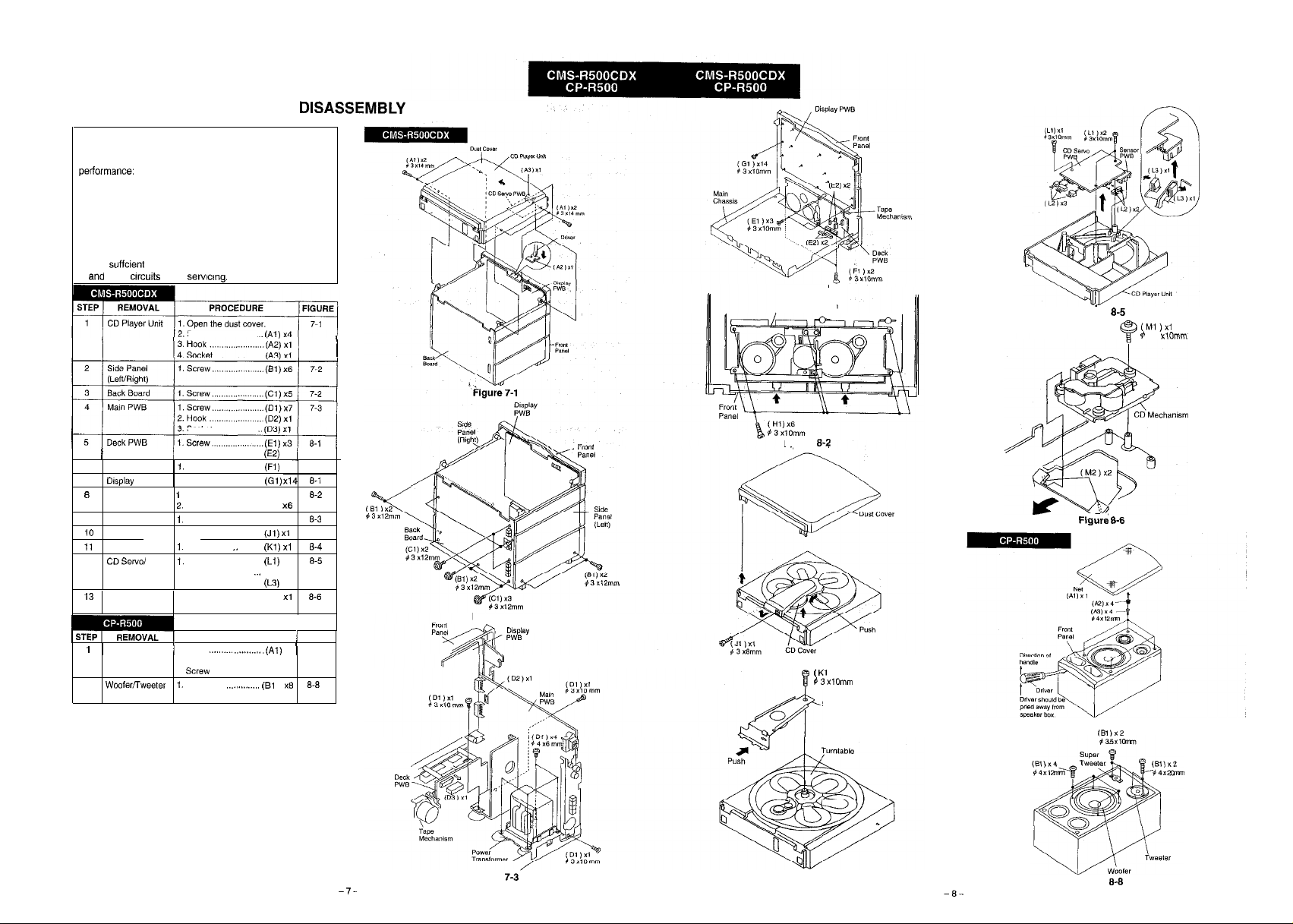

DISASSEMBLY

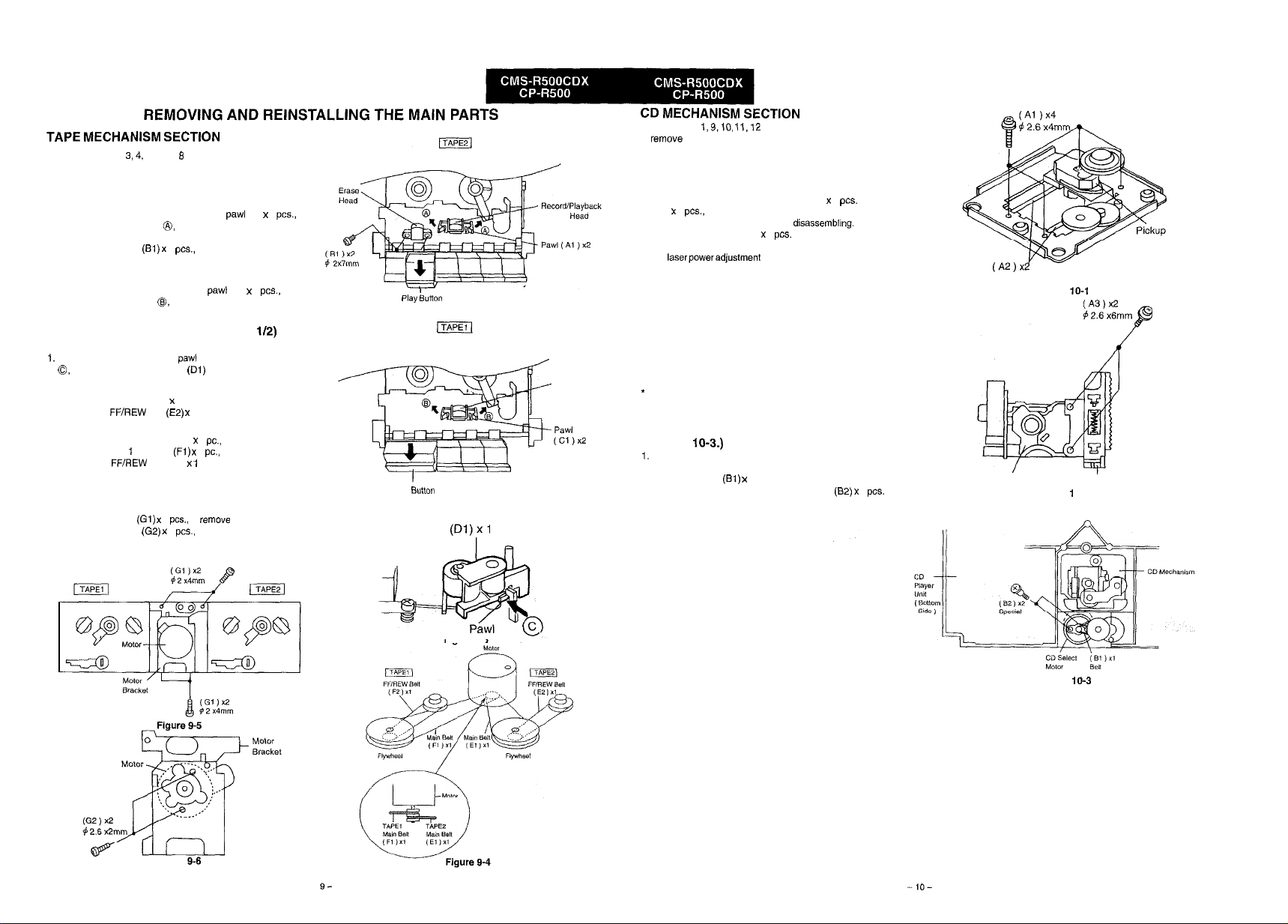

REMOVING AND REINSTALLING THE MAIN PARTS

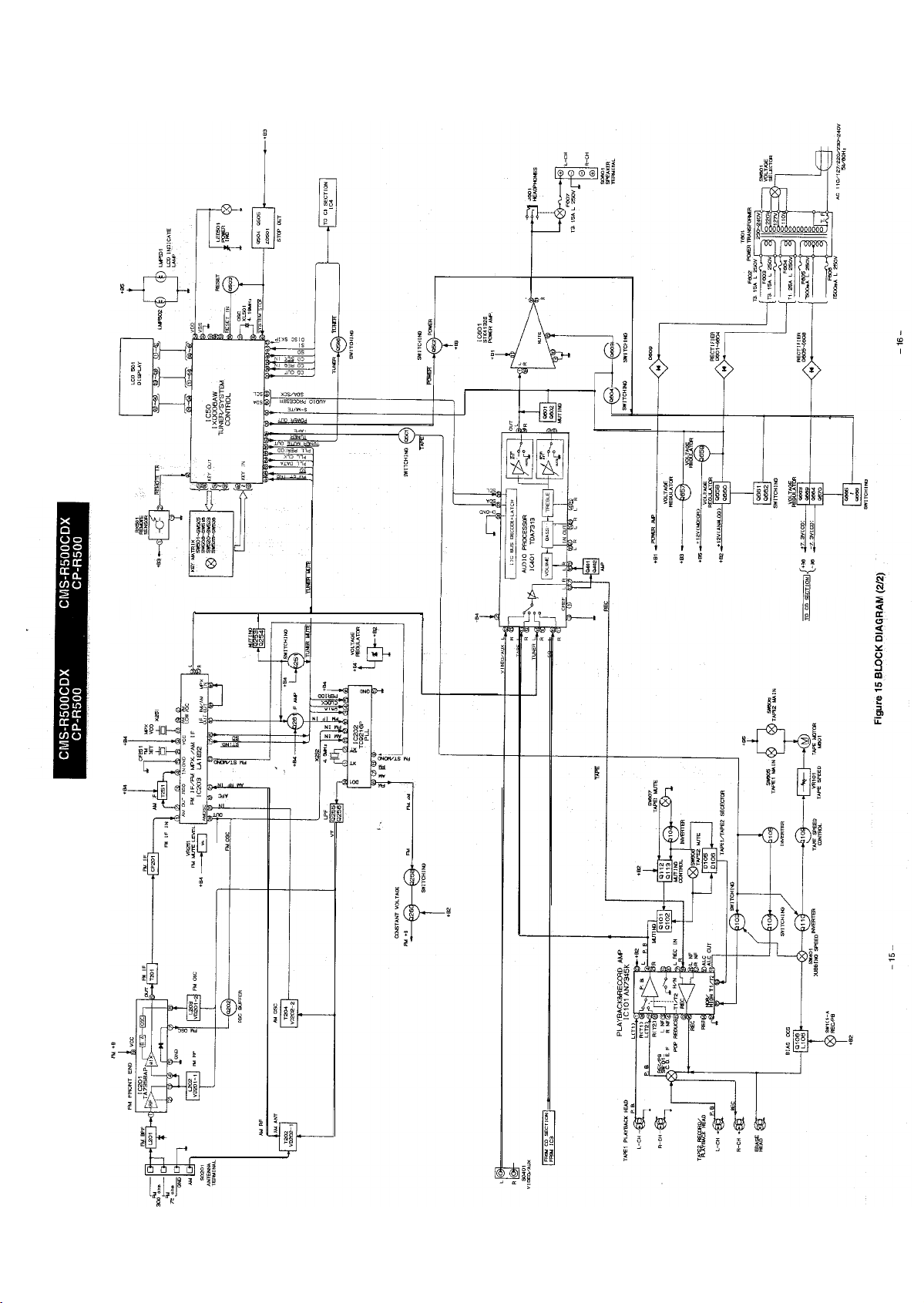

ADJUSTMENT

SCHEMATIC

WAVEFORMS OF CD CIRCUIT..

TYPES

NOTES ON

TROUBLESHOOTING

FUNCTION TABLE OF IC .

LCD SEGMENT

SELECTION

OF PARTS

OF TRANSISTOR

....

..............................................................................................................

.............

.............................

MANUAL

.............................................................................

DIAGRAM /WIRING SIDE OF

SCHEMATIC DIAGRAM

...............

......................

...................

(CD

............

........

LlST

.............................................................................................

.................

................................................................................

............................................................................................

.............................................................................................

..............................................................................

. . . . . . . . . .

..............................................................................

.............................

............................

SECTION)

.............................................................................................

.......................

............................................

.

. . .

.

.

. . . . .....

.......

. . . . . . . . . . . . . . . . . . . .

l

In the interests of user-safety the set should be restored to its

condition and only parts identical to those specified be used.

Page

2

3-5

7,

9,

10

33

34

34

35-39

40-44

2

2

6

..............................................................

..............

.

. . . . . ..-................. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

........................................................................

............................................................

......................................................................................................................

.

. .

.....

. ............................................................

...............................

Page 2

FOR A COMPLETE DESCRIPTION OF THE OPERATION OF THIS UNIT, PLEASE REFER

TO THE OPERATION MANUAL.

n

Compact disc stereo music system

General

Power source:

Power consumption:

Diemensions:

Weight:

Amplifier section

Output power:

Input terminal:

Output terminals:

Tuner section

Frequency range:

l

Cassette deck section

Frequency response:

Motor:

Signal/noise ratio:

Wow and flutter:

Bias and erasure system:

Tape speed:

Heads:

AC 27/220/230-240

(15-l/4”)

531-l

Record/playback

MHz

playback)

Compact disc player section

Type:

Signal readout:

Rotational speed:

Error correction:

Quantization:

Filter:

Frequency response:

Dynamic range:

Wow and flutter:

Speaker system

Type:

Maximum input power:

Impedance:

Dimensions:

Weight:

20,000

Height;

type

Approx.

Wpeak)

tweeter

(7-l/16”)

filter

Specifications for this model are subject to change without prior

notice.

The voltage selector is located on the AC voltage selector box.

If adjustment is necessary, use a screwdriver in order to turn the

selector in either direction until the correct voltage figure is

displayed in the window next to the adjustment screw.

Page 3

5-disc multi-play

Dust Cover

Disc Tray (Disc 1 - 5)

3.

Stop

4.

Pause Button:

5. Play Button:

Disc Number Select Buttons

7. Disc Skip Button

8.

Clear Button

9. Memory Button

Random Button

Track Down/Review Button:

12. Track Up/Cue Button:

13.

Disc Number Indicator

15.

Track Number indicator

16.

Random Indicator

17.

Memory Indicator

18. Extra Bass Indicator: X-SASS

Pause Indicator: II

Repeat Indicator:

Play Indicator:

22. Minutes and Seconds Indicator

compact disc player section

Button:

I

Stereo synthesizer tuner section

23. Stand-By Indicator

24.

25.

Band Selector Button

26. Tuning Up/Down Buttons:

27. Reset

28. Memory Button

/

Stereo double cassette deck section

Dubbing Speed Switch

2. TAPE 2) Cassette Compartment

3. TAPE 1) Cassette Compartment

Record Button:

5. Play Button:

6.

Rewind Button:

7. Fast Forward Button:

8. Stop/Eject Button:

Pause Button: II

Button: .

Rewind Button:

Fast Forward Button:

3. Stop/Eject Button:

n

Rear panel

14. FM 300 ohms Aerial Terminal

16. FM 75 ohms/ FM 300 ohms Aerial Terminal

16. FM/AM Aerial Earth Terminal

AM Aerial Terminal

Video (Audio Signal) / Auxiliary Input Sockets

18. Speaker Terminals

20. AC Voltage Selector

21.

AC Power Lead

l

Bend Indicator

FM Stereo Mode Indicator

32.

33. FM Stereo Indicator:

34.

n

35.

36.

37. Extra

38.

40. Function Selector Buttons

41. Headphones Socket

Indicator

Memory

Frequency

Station

Integrated stereo amplifier section

Power

Bass Button : X-BASS

Equalizer Mode Button

-3-

Speaker section

22. Tweeter

23.

Super Tweeter

24. Woofer

25.

Bass Reflex Ducts

26.

Speaker wire

-4-

Page 4

n

Names of controls

MANUAL

Remote Control Transmitter Window

Tuner control buttons

2. Preset

3. Band Selector Button

Buttons:

CD control buttons

4. Memory

5.

6.

Random

7. Repeat Button:

8.

Track Down/Review Button:

Track

Il.

Pause Button: II

12.

13.

Disc Number Select Buttons

14.

16. Power

Equalizer Mode Button

18.

Extra Bees Button : X-BASS

Volume Up/Down Buttons:

Button:

Button:

n

Skip Button

Selector Buttons

I

n

Proper use of the remote control

2

3

4

5

6

7

I

15

16

r-11

-12

-13

-14

60”

Aim the remote control at the remote control sensor within

with no obstacles, and operate es shown.

Notes concerning use:

l

Replace the batteries if control distance decreases or

operation becomes erratic.

l

Periodically clean the transmitter window on the remote

control and the sensor on the main unit with a soft cloth.

l

Exposing the sensor on the main unit to strong light can

interfere with operation. Chanae the liahtina or the

tion

the unit:

l

Keep the remote control away from moisture, excessive

heat, shock, and vibrations.

l

The remote control’s usable range is between 0.2

and 6 away from the sensor.

Reset the microcomputer by pertorming the following

procedure for the cesee shown below:

l

To erase all of the stored memory contents, or

l

If the display does not function properly, or

l

The unit does not operate properly.

Disconnect the AC power lead from the AC socket.

Press the RESET button for at least 3 seconds.

(8”)

to STAND-BY.

Page 5

Caution on Disassembly

Follow the below-mentioned notes when disassembling the

unit and reassembling it, to keep its safety and excellent

1. Take cassette tape and compact disc out of the unit.

2. Be sure to remove the power supply plug from the wall outlet

before starting to disassemble the unit.

3. Take off nylon bands or wire holders where they need be

removed when disassembling the unit. After servicing the

unit, be sure to rearrange the leads where they were before

disassembling.

4. Take suffcient cars on static electricity of integrated circuits

other

when servcmg.

Screw

Figure 8-l

, Tape Mechanism

Figure 8-5

2.6

Socket

2. Socket..

6

Front Panel

7 Display

PWB

Tape Mechanism

9

Dust Cover

CD Cover

Turntable

12

Sensor PWB2.Socket..

CD Mechanism1.Screw

Front Panel

2

Super Tweeter

Screw..

1. Screw..

Open the cassette holder.

Screw..

See Rg.8.3.

1.

Screw..

Screw..

screw..

3 Hook

2. Hook

1. Net

2. Holder

3.

Screw

................... (EZ)

...................

........ ...........

................. (HI)

......... ..........

.....

.........

...................

...

....

.....

............... .......

(MP)

PROCEDURE

(A2) x4

x4

x2

x3 8-5

(L2) x5

x2

(Ml) xl

.(Al) xl

(A3) x4

)

x2

FIGURE

6-l

8-3

a-7

Figure 7-2

Figure 8-2

Figure 8-3

) xl

Stabilizer Bracket

Figure 6-7

Figure

Figure 6-4

Figure 6-6

Page 6

Perform steps 1, 2,

remove the tape mechanism.

5, 6 and 8 of the disassembly method to

How to remove the record/playback and erase

heads (TAPE 2) (See Fig. 9-l.)

1. Carefully band the record/playback head

the direction of the arrow

head upwards.

2. Remove the screws 2

and remove the record/playback

to remove the erase head.

(Al)

2

in

How to remove the playback head (TAPE 1)

(See Fig. 9-2.)

1. Carefully band the playback head

direction of the arrow

upwards.

and remove the playback head

(Cl)

2

in the

How to remove the pinch roller (TAPE

(See Fig. 9-3.)

Carefully bend the pinch roller

and remove the pinch roller

in the direction of the arrow

upwards.

How to remove the belt (TAPE 2) (See Fig. 9-4.)

1. Remove the main belt (El)

2. Remove the FF/REW belt (E2)

1 pc., from the motor side.

1 pc.

How to remove the belt (TAPE 1) (See Fig. 9-4.)

1. Remove the tape 2 main belt (El)

2. Remove the tape

3. Remove the FF/REW belt (F2) pc.

main belt 1

1

from the motor side.

from the motor side.

How to remove the motor

(See Figs. 9-5 and 9-6.)

1. Remove the belt.

2. Remove the screws 4

3. Remove the screws (G2)

Note:

When mounting the motor, pay attention to the motor mounting

angle.

to remova the motor bracket.

2

to remove the motor.

69

Play

Figure 9-l

Figure 9-2

Pinch Roller

Playback Head

Perform steps

to remove the CD mechanism.

and 13 of the disassembly method

How to remove the pickup

(See Figs. 10-l and 10-2.)

1. After removing the CD mechanism according to the disassembling procedure, remove the screws, (Al)

(A2)

2

2. Fit a new pickup in reverse order of disassemblrng. After fitting,

lock it with the screw (A3)

3. Connect the connector and lead wire as it was.

4. The

ment of performance of pickup.

Note:

When replacing the pickup do not apply force to the turntable of

spin motor. Otherwise, the height of main chassis and turntable

may be varied.

and replace the pickup.

2

is not necessary owing to improve-

4

and shafts

After replacing the pickup

This new mechanism has been newly designed to enhance

remarkably its performance as compared to the former ones, so

that there is no need to adjust pickup posture,

After mounting the pickup, apply voltage to the slide motor, and

ascertain that it runs at DC 1.5 V or less.

How to remove the the CD select motor

(See Fig. 10-3.)

Refer to “Removing the turntable and remove the turntable”

(See Figs. 8-3, 8-4 and 8-5)

2. Remove the belt 1 pc.

3. Remove the select motor mounting screws 2

Shaft

Pickup

Fiaure IO-1

Rack Gear

Figure

O-2

Figure

Fiaure 9-3

Figure 10-3

Page 7

MECHANISM SECTION

l

Torque Meter

l

Torque Meter

Fast forward: TW-2231

l

55to120

Tape 1

Specified Value

Over

Over

Specified Value

Tape

l

Keeping the TUNING (DOWN) button and MEMORY button pressed,

turn on POWER. Then the frequency is initially set in the memory as

shown in Table. Call with the PRESET button to use itforadjustment and

check of tuner circuit.

2

Preset No.

FM

MHz

MHz

MHz

Signal generator:

Test

Stage Display

Frequency

MHz

40 kHz dev., FM modulated

Frequency Adjusting

MHz

Parts

AM

531

Instrument

Connection

Input: Pin 1 of

TUNER SECTION

Low-range frequency

High-range frequency

l

IF/RF

Signal generator: 400 Hz,

Test

Stage

Band

Tracking

l

1 Input: Antenna terminal

Input: Input is not connected.

Frequency

990

AM modulated

Frequency Specified

Display Value/

Adjusting

Point

531

990

T202

Output: Speaker terminal

Output: TP201

Instrument

Connection

l 1

Adjust the T201 so that an-output signal become maximum.

l

Signal generator: 1

Test Stage Frequency

Band

RF

96.00 MHz

Input: Input is not connected.

Input: Antenna

l

Mute

Signal generator: 1

40

dev., FM modulated

Frequency

Display

MHz

98.00 MHz

40

dev., FM modulated

Serringl

Adjusting Point Connection

Output: TP201

Output: Speaker terminal

Speaker

terminal

instrument

‘1

ANTENNA

TERMINAL

AM TRACKING

Page 8

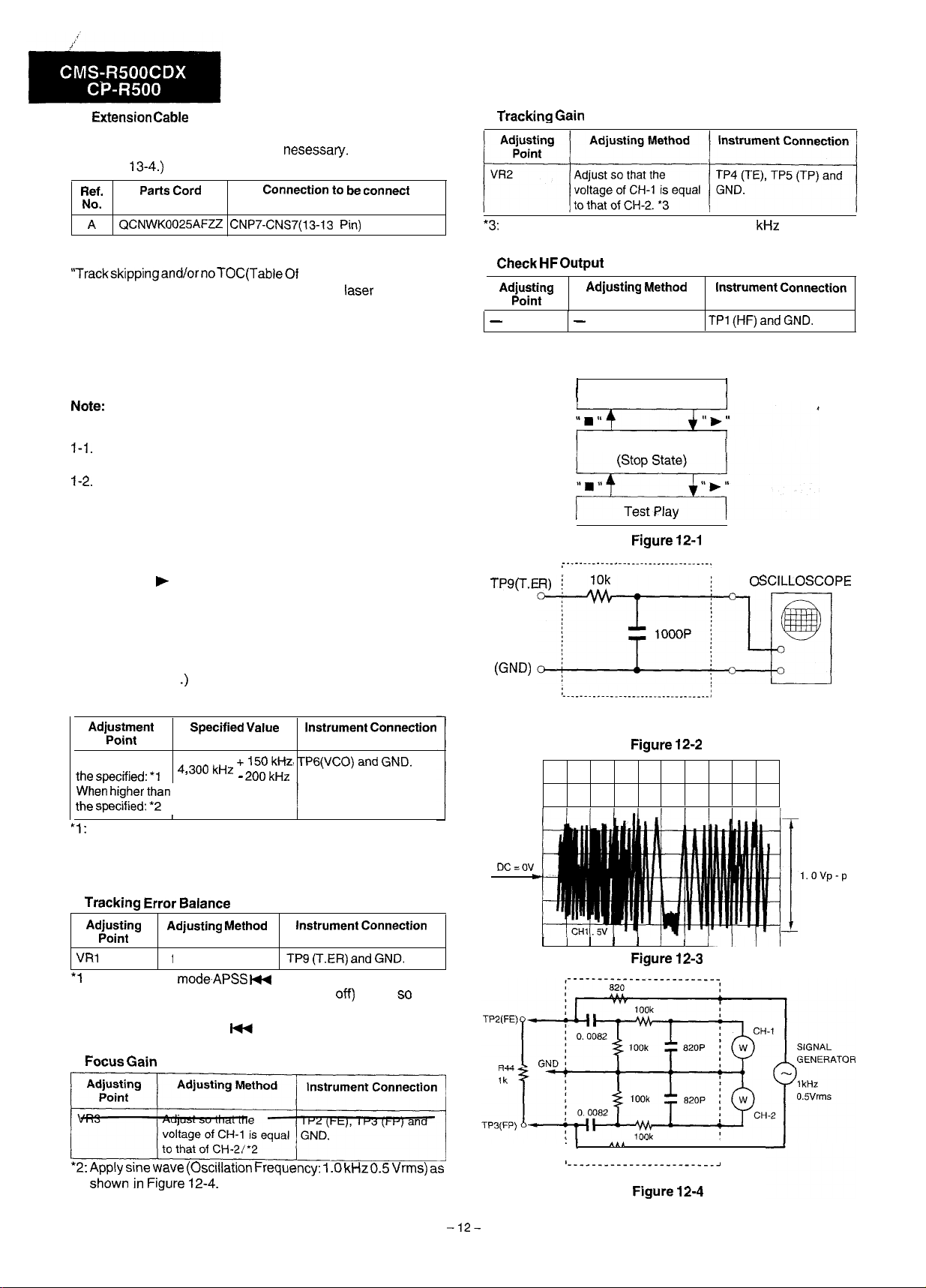

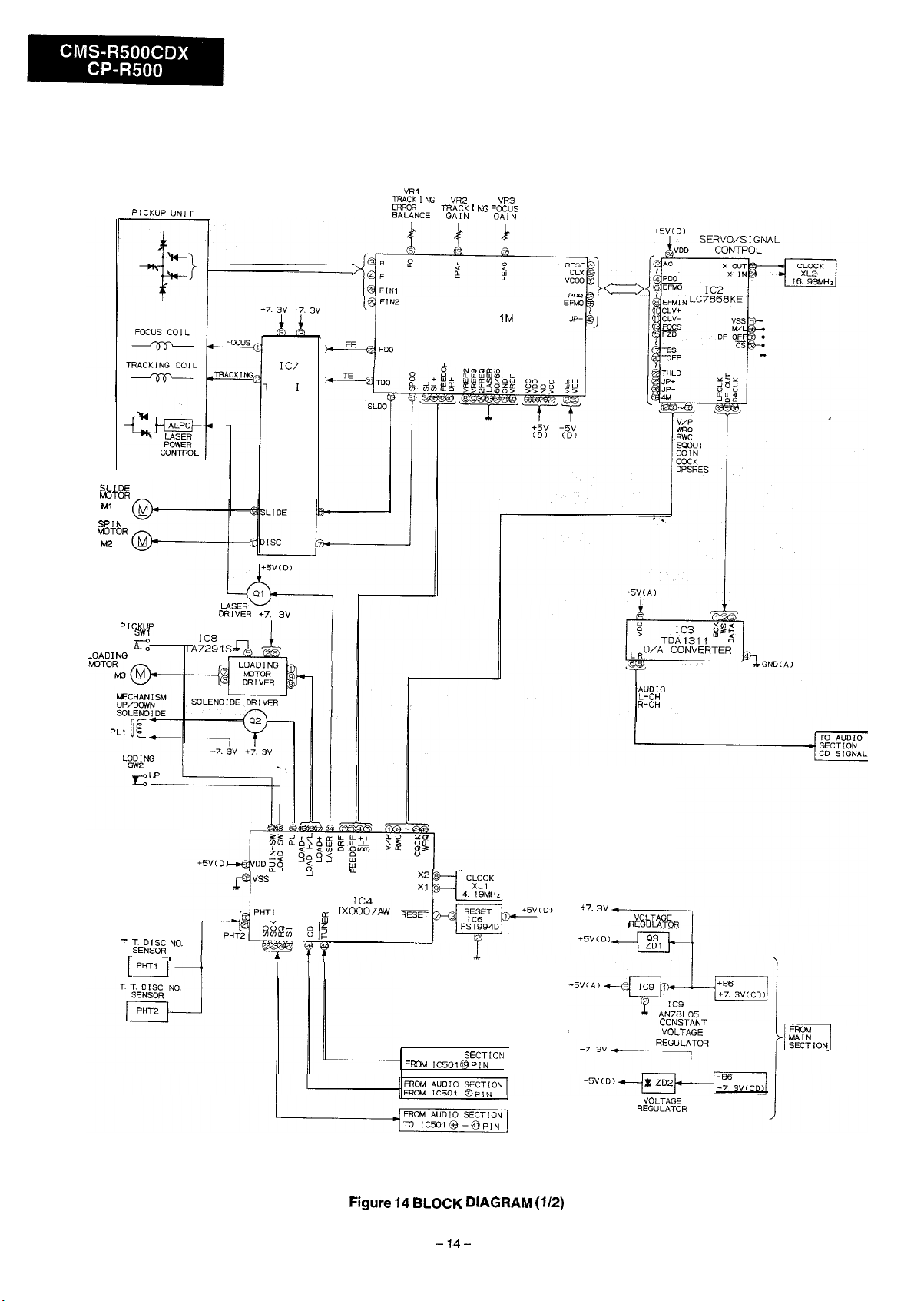

n

When performing adjustment or operation checks, use the extension cables as showm below, when nesessary.

(See Fig.

l

CD SECTION

Contents) maybecaused

by a build up of dust other foreign matter on the

pickup lens.

Before attempting any adjustment make certain that the lens is

clean. If not, clean it as mentioned below.”

1. Turn the power off.

2. Gently clean the lens with a lens cleaning tissue and a small

amount of isopropyl alcohol.

Do not touch the lens with the bare hand.

1. Preparation for Adjustment

Remove the CD section from the main unit, and connect the

CD section to the main unit using a jig cable unit.

Test mode setting

With the PAUSE II button and STOP n button pressed, turn

on the power switch.

l-3. Test mode operation

When the test mode is entered, the CD mechanism will move

down.

When the

button is pressed once, the CD mechanism will

move up.

When it is pressed again, the CD mechanism will play. When

the n button is pressed during play, the CD mechanism will

stop.

When it is pressed again, the CD mechanism will move down.

(See Fig. 12-l

2. VCO Free-Run Frequency

When lower than

*I

Cut the R37 (39 kohms).

‘2: Cut the R38 (33 kohms).

3. Servo Unit

Follow the procedure stated below.

l

: When the play modeAPSS

of tracking error balance. (Tracking server

obtain symmetric waveform (Figure 12-3.) when DC is 0 V.

After adjustment APSS

(Tracking servo ON)

l

l

button is pressed, adjustment

Adjust

as to

button is pressed.

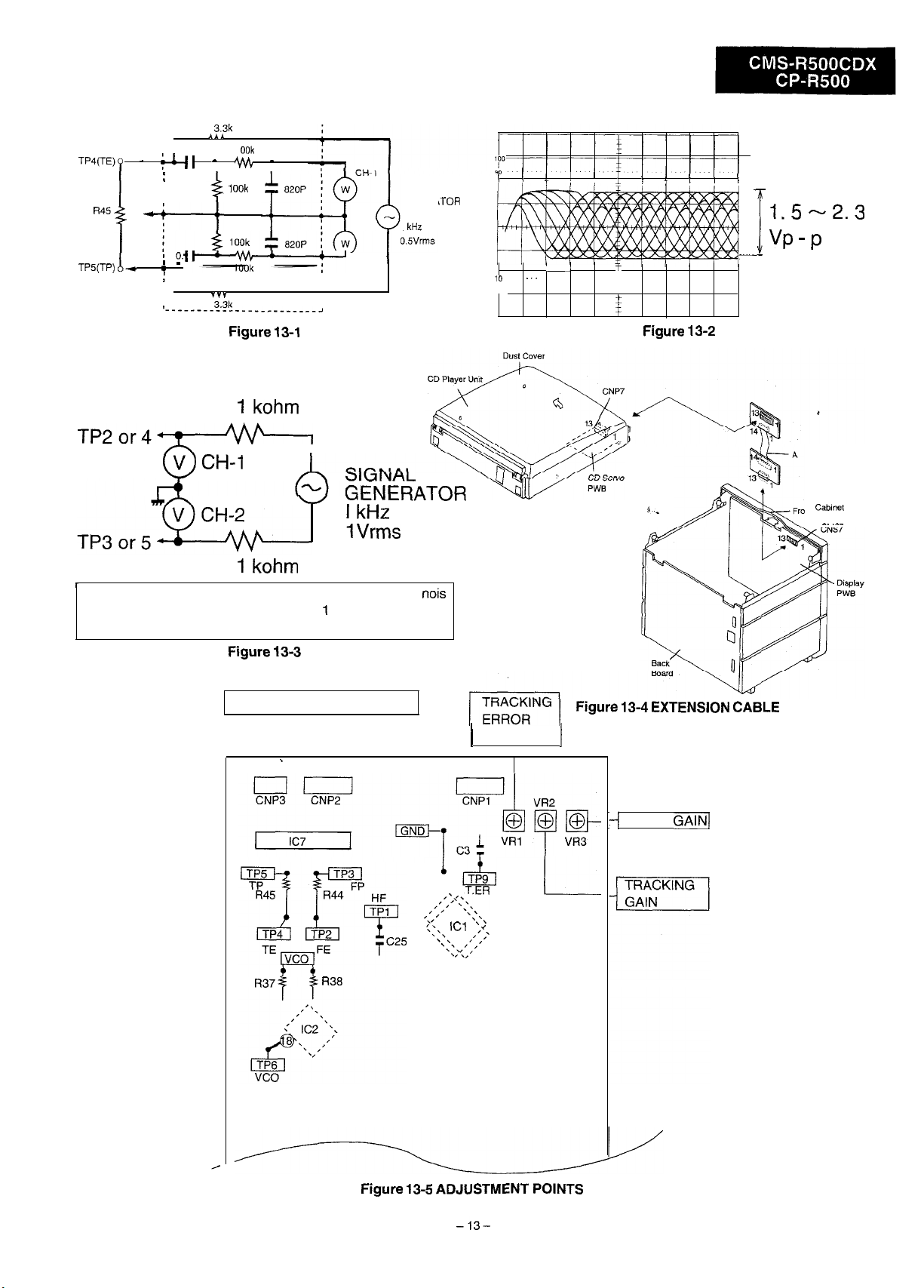

Apply sine wave (Oscillation Frequency: 1 .O kHz 0.5 Vrms) as

shown in Figure 13-I.

l

Make sure that waveform is as shown in Figure 13-2.

Test Mode Start

CD Mechanism Down

CD Mechniam Up

12-l

TRACKING ERROR

BALANCE ADJ. JIG

More than

wave (Oscillation

820

FOCUS GAIN ADJ. JIG

Page 9

-

0.0082

GND

lk

I

TRAC

KING GAIN ADJ. JIG

1

SIGNAL

GENERP

1 kHz

CH-2

I

The jig (BPF) are recommended to reduce high frequency nois

during alignment. As an alternative, two

be used to achieve the same results.

kohm resistors can

0%

nt

CD SERVO PWB (TOP VIEW)

BARANCE

I

FOCUS

Page 10

LASER

POWER

CONTROL

IN

LA6524

-RACK

/FOCUS

DR I VER

NC

FOCUS

ICI

LA921

SERVO AMP.

NG

CD CONTROL

MICROCOMPUTER

FRW AUDIO

SECTION

Page 11

Page 12

Page 13

Page 14

Page 15

1

2

3

I

-23-

4

5

6

Figure 23 WIRING SIDE OF P.W.BOARD (2/3)

7

9

10

11

12

Page 16

Page 17

Page 18

A

C

E

F

G

L

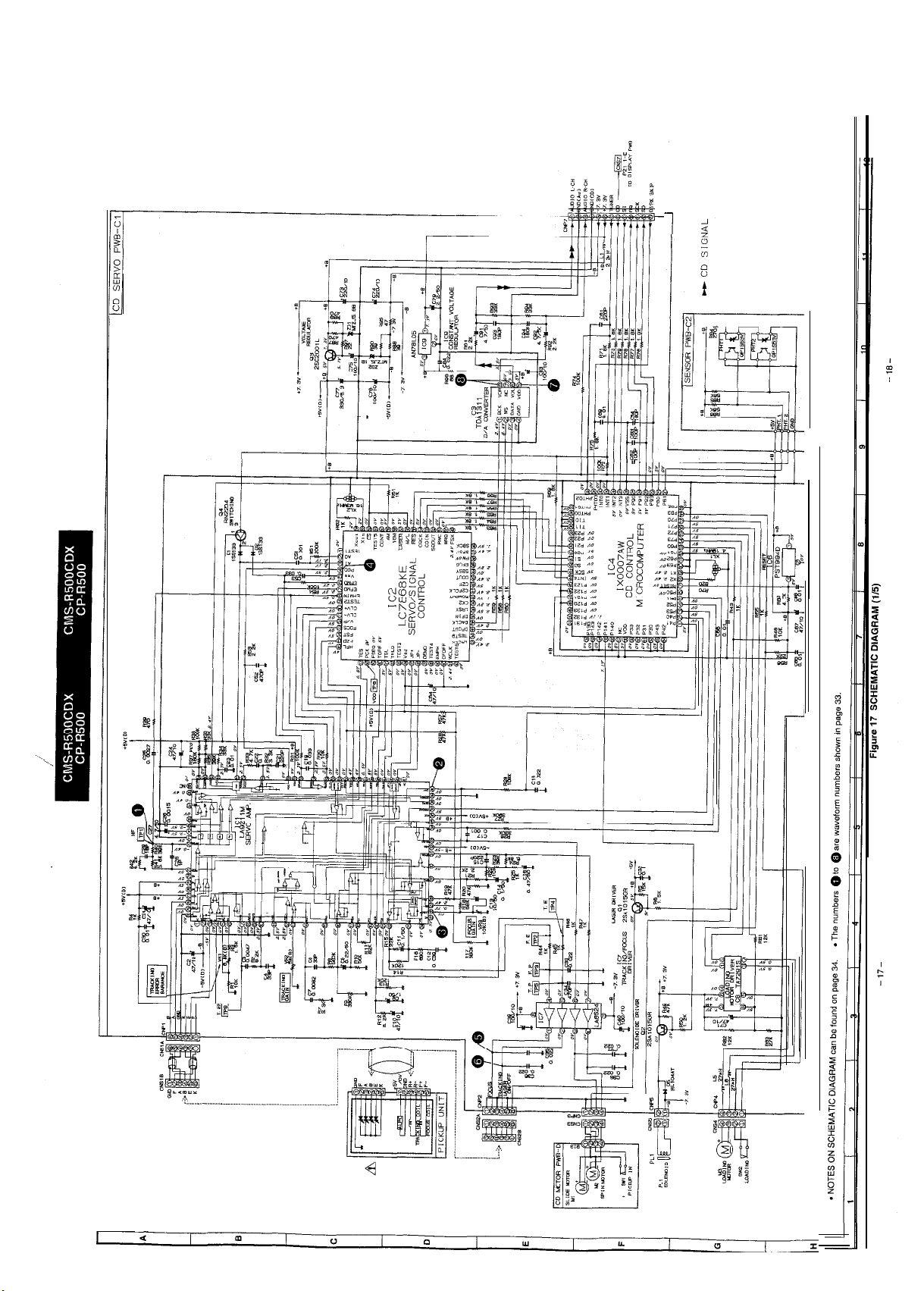

. NOTES ON SCHEMATIC DIAGRAM can be found on page 34.

1

2

Figure

29 SCHEMATIC

I-

DIAGRAM

I NVERTER

9

11

12

Page 19

Page 20

HF

0

FRF

FE

0.

STOP-PLAYBACK

PLAYBACK

l

Resistor.

To differentiate the units of resistors, such symbol as K and M

are used: the symbol K means 1000 ohm and the symbol M

means 1000 kohm and the resistor without any symbol is ohm-

type resistor.

l

Capacitor:

To indicate the

P means micro-micro-farad and the unit of the capacitor without

such a symbol is microfarad. As to electrolytic capacitor, the

expression “capacitance/withstand voltage” is used.

STOP-PLAYBACK

DATA

0

(ML): Mylar type

l

Schematicdiagram and Wiring

are subject to change for improvement without prior notice.

REF. NO

SW2

SW101

SW401

SW501

CD-MEMORY

the one with “Fusible” is a fuse type.

of capacitor, a symbol P is used: this symbol

Temperature compensation

DESCRIPTION

L

RECORD/PLAYBACK

DUBBING SPEED

POSITION

OFF

OFF

PLAYBACK

OFF

OFF

OFF

OFF

OFF

OFF

OFF 1

DIAGRAM

The indicated voltage in each section is the one measured by

Digital Multimeter between such a section and the chaws with

no signal given.

In the tuner section,

indicates AM and

in the FM ST mode.

2. In the main section, a tape is being played back.

3. In the deck section, a tape is being played back.

indicates the record state.

4. In the power section, a tape is being

5. In the CD

indicates CD playback.

l

Parts marked with

thesafetyoftheset. Besureto replacetheseparts withspecified

ones for

the CD is stopped.

the safety and performance of the set.

FM MONO

played

back.

are important for maintaining

FRF

FOCUS COIL

0.

PLAYBACK

(DC)

-33-

BAND

SW517

SW518

SW520 CD

PRESET DOWN

PRESET UP

RN1202

OFF

OFF

OFF

OFF

L

GR RN1207

K

RN2202

C

RN2204

GR

Figure 34 TYPES OF TRANSISTOR

I

SR

BCE

Page 21

When the CD section dose not operate When the objective lens of the optical pickup is dirty, this section may not operate. Clean the

objective lens, and check the playback operation. When this section does not operate even

items. Remove the cabinet and follow the troubleshooting instructions.

“Track skipping

Before attempting any adjustment make certain that the lens is clean. If not, clean it as mentioned below.”

Turn the power off.

2. Gently clean the lens with a lens cleaning tissue and a small amount of isopropyl alcohol.

Do not touch the lens with the bare hand.

Turn the power switch on the unit to ON.

no TOC(Table Of Conetents) may

above step is taken, check the following

by a build up of dust other foreign matter on the laser pickup lens.

When the CD mode is entered, does the LCD change from

displaying “CD” to the function display “01 O:OO”?

Does the CD mechanism move down? Does the turntable

rotate?

Does the spin motor run?

When the disc is initialized, is TOC read?

Is TOC set to the playback mode?

Is there any audio

output

Check the item of “The CD microcomputer circuit

No

No

No

No

No

No

ates improperly”.

. . Check the item of “The CD mechanism moves up or down

improperly”.

Check the item of “The turntable operates improperly”.

Check the item of “The mechanism up operation is not

being detected”.

Check the item of ‘The spin motor does not run.”

Check the item of “The disc does not playback.”

Check the audio circuit.

OK

Page 22

l

Turn the power switch to ON.

Check the power circuit voltage.

Is the oscillating circuit

operating normally?

Check to see that the reset circuit of the control microcomputer

(lC4) is operating normally.

Is the drive signal of the LCD

Are the connector and PWB pattern damaged?

Is one of the motor drive output pins 15and 17of microcomputer

held “I-“?

of the control microcomputer (IC4)

Normal

being

output from the

Yes

Normal

OK

odown4mpreperly.

1

Defective replace faulty parts.

control

Check the XL1 and peripheral circuits and replace faulty

No

parts.

Check the reset circuit (IC6) and peripheral circuits and

The microcomputer (IC4) is defective. Replace it.

The microcomputer (IC4) is defective. Replace.

Is there any output between

the loading motor rotating?

Belt slip: Clean the pulley belt.

Replace the belt.

Are the plunger suction output pin 55 of microcomputer (IC4)

held “L”?

Is +B(7.5

The plunger and suction mechanism are defective.

Replace the plunger or the drive mechanism.

being output to pin

Yes

The motor drive

The loading motor (M3) is defective. Replace.

The turntable shutter, sensor

No

No

(PHT

The microcomputer (IC4) is defective. Replace.

The plunger driver circuits (Q2) are defective. Replace.

are defective. Replace.

input terminal state of

microcomputer

(IC8) is defective. Replace.

and sensors

1 2 3 4

Pin 21

Pin 22 H L H

H H L H H

H L

Page 23

l

Has the mechanism up detection input pin 18 of

microcomputer (IC4) changed to

Has the motor drive output of microcomputer (IC4) been turned

OFF (pins 15 and 17: “H”)?

Yes

The motor drive

motor M2 is defective. Replace it.

is defective. Replace’.

The mechanism up switch or detection mechanism is

No

defective. Replace.

The microcomputer (IC4) is defective. Replace.

is defective. Replace it.

is defective. Replace it.

is defective. Replate it.

l

Is the disc initialized? Does the laser diode go on?

Does the tracking servo operate normally?

Is the EFM signal of pin 72 of ICI flat? (Lower side)

Is the tracking error signal (

Yes

Yes

Normal

A: Check the item of “The laser diode goes on.”

B: Check the item of “The laser diode does not go on.”

Check if the objective lens of the

No

No

pickup is dirty.

If it is dirty, clean it.

Does the spin motor run normally? Check the waveform of

pins 10

Is there any dropout part in the EFM signal of pin 72 of ICI?

Replace the disc or change the program.

Is the tracking signal being out-

put from the pickup main unit?

and 11 (CLV-) of

Normal

Yes

IC2 is defective.

No

Replace it.

The pickup is

defective.

Yes

Is the tracking coil drive output being output from the tracking -- IC7 is defective.

driver output (pin 2 of

Yes

The pickup connecting connector is broken.

The pickup tracking coil is broken.

No

The PWB negative pattern is damaged.

Replace the

Page 24

When the CD Mecahnism moves up without loading disc, does the pickup lens move

up and down?

the EFM signal of pin 72 of

being output?

No

l

Pickup height error

l

Laser diode output error

NO

Are the voltages at pins 8 and 3 of the focus

driver (IC7) +7.5V and -7.5V, respectively?

Yes

Is the high/low level repetition output for

leading the focus servo of pin 13 of

being output?

Yes

of

Is the DRF disc

reflection

signal

pin 40 of the servo signal control

at a high level?

Yes

shown below?

Pin 40

DRF

Pin 26

FEAO

The servo amplifier

The servo amplifier

) is defective.

is defective.

is defective.

Is the high/low repetition output being

output from pin 22 of

The focus error

Replace it.

Yes

Is the high/low repetition output being

output from pin 1 of

Check connectors

and

is defective.

Yes

Check to see that the focus circuit is normal and check the

distribution connector.

The focus driver (IC7) is defective. Replace it.

Page 25

(IC4) at a low level?

Yes

emitter voltage

Yes

The laser diode is defective.

Check the powercircuit.

No

Is the pickup returned to the innermost part?

Is the pickup in switch

Check if pins 4 (SLM+) and 5

Check pin 33 of servo A

Check pin 9 of the slide

Check if there is voltage at CNP3,

turned to ON?

No

and Ml.

Yes

Replace the pickup.

IS

pin

of

at a low

level?

Yes

IC4 is defective. Replace it.

IC4 is defective. Replace it.

The servo AMP.

The slide motor driver (IC7) is defective. Replace it.

is defective.

Replace it.

is defective. Replace it.

Is there audio output?

Is there audio output fro

Checking the D/A circuit.

Yes

I

l

No

Check sound coupling capacitors

(R-CH).

(L-CH) and C92

Page 26

Tuner/System Control

this

terminal

asterisk

terminal

Page 27

CLOCKED

I

Tuner/System Control

A

PROGRAM

ROM

PR

OGRAM

MEMORY

q

GENERAL

DATA

REG.

BITS

I I

CPU

CLOCK

Page 28

terminal

asterisk

terminal

Page 29

unit, the terminal with asterisk mark (*) is (open) terminal which is connected to the outside.

In this

CD Control Microcomputer

TIO

1

s

I NTTO

I NTERRUPT

CD Control Microcomputer

ROM

PROGRAM

MEMORY

2160X.3

TS

MEMORY

BITS

P73

I

CLOCK

OUTPUT

CONTROL

CLOCK

CLOCK STAND BY

GENERATOR

Xl x2

Page 30

OK

Page 31

Page 32

Page 33

Page 34

IC6

REPLACEMENT PARTS LIST

“HOW TO ORDER REPLACEMENT PARTS”

To have your order filled promptly and correctly, please furnish the following information.

NOTE:

Parts marked with “A” are Important for maintaining the safety of the set. Be sure to replace these parts

for maintaining the safety and performance of the set.

INTEGRATED CIRCUITS

J Servo Amp.,LA9211M

J CD Control Microcomputer,

J Reset.PST994D

J Tracking/Focus Driver,

J Loading Motor Driver,

J PLL.TC9216P

J FM IF

J Audio Processor,TDA7318

J

TRANSISTORS

J

J

J

J Stlicon,NPN,ZSC535 C AC

J Digital,PNP.RNZZOZ AB

J Sillcon,NPN,ZSC1740 SR

J

J

J Digital.PNP,RNZZOZ

J

J

J Silicon.NPN.ZSC1740 SR

J

Silican.NPN.‘ZSCZOOl L

J Silicon~NPN;ZSDZOlZ

Q251

Q604

Q658.659

Q660

RH-

RH-

1. MODEL NUMBER

3. PART NO.

PARTS-DELIVERY SECTION

Control,

LA6524

Playback Amp.,AN7345K

AM IF,LA1832

Control,

GR AB

CODE

AQ

AN

AY

AC

AH

AG

AE

AM

AG

AL

AR

AX

AY

AB

AB

AC

AD

AB

A0

AD

2. REF. NO.

4. DESCRIPTION

Q661

Q664

Q667

Q669

D5

LED501

VD202

ZD653

ZD655.656

CF251

T204

T251

J

TRANSFORMERS

DESCRIPTION

J

J Sflicon,NPN,2SD2012

J Silicon,PNP,ZSBL375

J

J

J

DIODES

J

J Sllicon,RL104AT

J

J

J

J

J

J

J

J

J

Variable Capacitance,

Variable Capacitance.

J Zener.6.2V.MTZJ6.2C

FILTERS

J FM Detector

J FM IF

J AM IF

J Power

specified ones

GR

CODE

A6

AD

AF

A8

A8

AB

AB

AA

AA

AB

AC

AD

AA

AA

AA

AA

AA

AA

AG

AA

AE

AE

AS

AC

AC

AA

AB

AC

AA

AD

AH

AD

AD

AC

AF

VA2

VR251

x251

x252

XL1

XL2

XL501

There are two types of capacitors

other by reading their Part Numbers.

The capacitance error of each capacitor is indicated by the symbol given at

13th digit of the Part Number

(Tubular type ceramic capacltar is

(Tubular type

NO.

c3 VCTY,#,lCX472K J 0.0047 pF,16V AA

c4

C6

c7

L6

Ceramic

A symbol “c”

. Semiconductor type capacitor:

A symbol “T”

NO.

VP-CH27QKQQQQ J 27

VARIABLE RESISTORS

capacitor;

“K” is given at the 3rd digit of its Part Number like “VCC

gwen at the 3rd diglt of its Part Number

capacitor is identified by the symbol MF(MN)

otherwise specified,

this MF(MN)

COILS

J 2.2

J 27

J 1.8 mH.Choke

J

mH,Choke

J 330

J FM Oscillation

J 100

J

mH,Choke

J 100 ,zH,Choke

J 2.2

J

[Tracking Error

J 5 kohms

[Tracking Gain1

J

kohm

[Focus Gain1

J

VIBRATORS

CAPACITORS

“D”

this TV(TQ/CY) does not mean the lead

J 33

J 47

Speed1

kohm

Mute Level1

Crystal,456

MHz

and they can be identified from

not mean the lead wire)

capacitors are

sF,SOV.Electroiytic

“z”

by the symbol TV(TQ/CY)

“M”

type.Q260

AB

A0

AC

AB

AB

AF

AA

AD

AB

AB

AB

A0

AB

AB

AB

AD

AK

AD

AG

AD

the par

AA

AA

AA

AA

AB

AB

AB

AB

AA

AA

AB

AA

AA

AA

AA

AA

AA

AB

AB

AB

A0

AA

AA

AA

AA

AA

AB

AA

AA

AB

AA

AB

AA

AB

AB

AB

AB

AA

AA

AA

AA

AA

AA

AB

AA

AB

AA

AA

AA

AA

AA

AA

AA

AA

AB

AA

A0

AA

AA

AB

AA

AB

AB

Cl6

C24

C25

C27

c31

C32

c34

c51

c52

C61

C65

C67

c71

c77

c79

c91.92

c93.94

Cl60

0.47 pF,SOV,Electrolytic

J 0.001 /1F,50”

J 0.022 #F,6.3V

J 220

J

J

J 47

J 0.022

J 470

J 0.001 pF,50V

J 220

J 330 pF,&3V,Electrolytic

J

J 330

J 560

flF.SOV,Ekctrolytic

J

J 0.01 pF.16V

J 0.001 fiF,SOV

J 0.0033 uF.16V

J

sF,StiV,Electrolytic

J 22 uF.16V.Electrolvtic

J O.O& pF.16V

J

220

J

33

J

470

J

47

J

0.0039 pF,lOOV.

Polypropylene

J

0.027 pF,SOV,Mylar

J

47 /rF,16V,Electrolytlc

J

2.2 flF,50V,Electrolytic

Page 35

Cl72

c212

C213

C214

C215

C216

C217

C218

C225

C226

C232

C234

C235

C236

C252

C256

C257

C258

c259

C261

C262

C263

C264

C265

C266

C275

C281

C282

C285

C286

C287

c292

c293

c294

c295

C296

C297

C298

c299

PART NO.

J

J 18 pF (CH),SOV

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J 8.2 pF

J

J

J 18 pF (UJ),SOV

J 18 pF (CH),SOV

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J 12 pF

J 15 pF

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

RC-GZA475AFlH

J

J

J

DESCRIPTION

J

0.022

22

0.01 /1F,16V

4.7

15 pF (CH),SOV

33

0.0047 ,~F,16v

10

0.001

0.022

0.001

0.022

10

0.022

100

8.2 pF (UJ),SOV

22

0.022

0.001

0.022

0.047 pF,5OV

0.022

470

0.022 ,uF,25V

0.022

10

0.022

22

0.001

2.2

1

0.022 ,uF,25V

120

0.022

3.3

0.022

22

0.001

1

1

0.015

22

0.1

0.022

0.01

330

0.022

0.022

47

0.001

0.33 ,uF,SOV,Electrolytic

47

0.022 /1F,25V

100

56

100

0.022

10

47

0.0018

4.7

0.22

100

CODE REF.NO.

AA

C421

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AB

C516

AA

AA

AA

AA

c529

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AB

AA

C631

AA

AA

C634

AB

C655

AB

AA

AA

AA

AB

C662

AA

C663

AB

C664

AB

C665

AA

AB

AB

AB

AB

AA

AA

AA

(Unless otherwise specfifed, resistors are

AA

AA

AA

AA

AA

AB

R3

AA

R4

AA

R5

AB

R6

AA

R7

AB

R8

AA

AB

AA

AB

AB

AA

R15

AB

R16

AB

R17

AA

PART NO.

1

100

J O.OOlpF,5OV

J 470

J 3.3

0.01

100

0.01

J

J 330

J

10

RC-GZA476AFlV J 47

10

100

J 2.2

100

10

10

RC-GZA336AFlC J 33

3300

1000

RESISTORS

J 0

J

1

J 15

J 56

J 8.2

120 kohms,l/8W

22 kohms,l/8W

680 ohms,l/8W

J 680

Ivory

DESCRIPTION

type.)

CODE

AB

AB

AB

AA

AA

AA

AA

AB

AA

AB

AA

AB

AA

AA

AA

AA

AA

AA

AA

AB

AB

AA

AA

AA

AB

AB

AB

AB

AB

AB

AB

AA

AA

AA

AB

AA

AA

AB

AB

AB

AB

AG

AD

AF

AF

AB

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

Page 36

REF.NO.

R22

R23

R24

R25

R26

R27

R28

R29

R30

R32

R33

R34

R35

R36

R37

R38

R39

R40

R42

R43

R48

R49

R50

R53

R54

R55

R56

R57

R63

R64

R69

R70

R71

R72

R73

R74

R75

R83

R84

R87

R95

R97

R120

PART NO.

VRD-MNZBDIOZJ

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J 10

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

J

68

47

2.2

10

39

6.8

330

390

47

100

10

100

3.3

4.7

33

39

33

180

100

470

39

5.6

8.2

1

1

47

1.2

200

2.2

100

1

22

47

1

1.8

1.8

1.8

1.8

820

1.8

100

1.8

100

1.8

1.8

4.7

12

27

270

56

470

39

470

39

2.2

33

47

22

68

1

56

100

3.9

100

5.6

3.9

3.9

1

DESCRIPTION

CODE REF.NO.

AA

AA

AA

AA

AA

R133

AA

R134

AA

AA

AA

AA

R142

AA

R143

AA

AA

AA

AA

R153

AA

AA

R154

AA

R155

AA

R158

AA

R159

AA

R160

AA

AA

AA

R164

AA

AA

AA

AA

AA

R170

AA

R179

AA

AA

R201

AA

R202

AA

R203

AA

R204

AA

R205

AA

R206

AA

R207

AA

R208

AA

R209

AA

R210

AA

R219

AA

R220

AA

R223

AA

R224

AA

R251

AA

R252

AA

R253

AA

R254

AA

R255

AA

R256

AA

R258

AA

R259

AA

R260

AA

AA

AA

AA

R267

AA

R268

AA

AA

R279

AA

R280

AA

R281

AA

R282

AA

R283

AA

R284

AA

R285

AA

R286

AA

R293

AA

PART NO.

VRD-MNZBDIOZJ

3 J

J

6.8

J

560

J 100

J

10

J

680

J

470

J

3.3

J

27

J

10

J

4.7

J

10

J

10

J

4.7

J

10

J

27

J

100

J

47

J

22

J

22

J

68

J

6.8

J

2.7

J

1

J

4.7

J

4.7

J

10

J

33

J

1

J

5.6

J

10

J

10

J

22

J

100

J

33

J

10

J

47

J

680

J

270

J

1.2

J

4.7

J

100

J

4.7

J

68

J

100

J

6.8

J

2.7

J

270

J

10

J

3.3

J

3.3

J

6.8

J

1.8

J

4.7

J

27

J

3.3

J

10

J

1

J

33

J

1

J

2.2

J

2.7

J

10

J

150

J

5.6

J

12

J

10

J

47

J

390

J

5.6

DESCRIPTION

CODE

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

Page 37

REF.NO.

R295

R296

R297

R298

R417

R418

R451

R452

R523

R532

R533

R534

R537

R538

R539

R540

R541

R551

R613

R614 ,

R615

R616

R617

R620

R625

R626

R629

R630

R632

R639

R665

R668

R669

R670

R671

PART NO. *

J 5.6

J 470

J 560

J 820

J 5.6

J

J 100

J 1.2

J 5.6

J 2.7

J 47

J 1.2

J 1.2

J 8.2

J

JJ330

J 2.7

J 5.6

J 56

J 56

JJ560

J 560

J

J 150

J 220

J 39

J 220

J 3.3

1JJ

J

J 22

J

J

1

1

10

1

1

1

100

1

10

1

1

1

1

10

1

100

330

100

1

10

1

DESCRIPTION

CODE

AP

AP

AP

AP

AP

AP

AP

AP

AA

AP

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AB

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AB

AA

AA

AA

AA

REF.NO.

R691

R692

R693

CNP3

CNP4

CNP5

CNP7

CNP103

CNP104

CNS4

CNS7

CNS103

CNS104

LCD501

Ml

M2

M3

M601

RX501

so401

SO601

SW1

SW401

SW501

SW502

SW503

SW504

PART NO.

J

10

DESCRIPTION

J 68

OTHER CIRCUITRY PARTS

J Connector

J Plug,GPin

J

J

J

J

J

Part of

J

J

J

J

J

J Fuse,T3.15A L 250V

J Jack,Headphones

J Lamp

[Loading]

l/-l

J Receiver,Remote Control,

J

J

J

[Pickup In]

[Loading]

[Record/Playback]

[Dubbing Speed]

[Fast Forward]

[Rewind]

[Random]

L 250V

L 250V

L

Type

Type

Type

Type

Type

Type [Repeat]

Type

CODE

AA

AA

AA

AA

AA

AA

AA

AA

AF

AL

AD

AC

AB

AB

AA

AG

AB

AB

AB

AC

AC

AF

AL

AG

AD

AG

AF

AH

AD

AF

AF

AD

AD

AD

AD

AK

AV

AD

AP

AT

AS

AP

AM

AK

AK

AF

AG

AC

AC

AG

AF

AC

AC

AC

AC

Page 38

SW505

SW508

PART NO.

DESCRIPTION

Type [Play]

Type

CODE

AC

AC

[CD-Memory]

SW509

AC

[Tuning Down]

SW510

Type

AC

[Tuning Up1

SW511

AC

[Tuning-Memory]

SW512

SW513

SW514

SW515

SW516

SW517

Type [Clear]

Type [Power]

Type

AC

AC

AC

AC

AC

AC

[Preset Down]

SW518

Type

AC

[Preset Up]

SW520

SW521

SW522

SW523

SW525

Type

Type [Tuner]

Type [Tape]

Type

AC

AC

AC

AC

AC

[Balance-Left]

SW526

Type

AC

[Balance-Right]

SW527

Type

AC

[Disc Skip]

SW528

SW529

SW530

SW531

SW532

SW533

SW534

Type [Disc

Type [Disc

Type [Disc

AC

AC

AC

AC

AC

AC

AC

[Volume-Down]

SW535

Type

AC

[Equalizer Mode]

[Voltage

Type

Type

Selector]

Type

AC

AQ

SW536 AC

SW541

J

SW605 AE

[Tape 1 Main]

SW606 AE

Type

[Tape 2 Main]

SW607 AB

[Tape 1 Mute]

SW608

AB

[Tape 2 Mute]

DECK MECHANISM PARTS

1

2

3

4

5

6

10

12

13

14

15

J Joint

J Spring,Latch Plate AA

J Head,Erase

Plate

Lock

AC

AC

AB

AB

AB

AA

AA

AG

AA

AA

Lever

16

17

AA

AG

REF.NO.

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

40

41

42

43

45

46

47

48

50

51

52

53

54

55

56

58

63

64

66

67

68

69

70

71

72

501

503

504

505

506

508

509

510

511

SW605

SW606

SW607

SW608

301

PART NO.

J

J idler Lever Ass’y

J Lever,Main Lock

J Lever,AS Killer

J

J Lever,Record

J Lever,P-Kick

J

J Spring,Operate Lever

J Spring,Pause Killer

J Take-up Reel Ass’y

PCUSZO 162AFZZ

J Prevent Vibration Rubber

LX-WZ9064AFZZ J

J

J

LX-WZ9063AFZZ J

J

J Screw,dZmn P-Kick Lever

J Motor with Pulley [Tape]

CD MECHANISM PARTS

J

DESCRIPTION

Joint

Lock

1

21

Lever

Killer Lever

Stop Lever

[Tape

11

J Screw+$ZX4mm

J

J Screw,dZXSmm

Type

[Tape

Main]

[Tape 2 Main]

[Tape 1 Mute]

[Tape 2 Mute]

11

46XO.5mm

CODE

AG

AG

AA

AC

AB

AB

AC

AA

AB

AA

AB

AB

AA

AA

AB

AB

AB

AB

AB

AB

AF

AG

AA

AA

AC

AE

AB

AM

AD

AA

AA

AA

AA

AA

AA

AG

AA

AA

AA

AA

AA

AA

AA

AA

AA

AK

AA

AB

AA

AA

AA

AA

AA

AA

AA

AP

AE

AE

AB

AB

AA

Page 39

302

303

304

305

306

308

701

702

703

M2

201

202

203

204

205

206

207

208

209

210

211

212

213

214

215

217

218

220

221

222

8223

8223

8223

224

225

226

227

228

229

230

231

232

233

234

235

236

237

REF.NO.

1

2

3

1

2

1

2

PART NO.

CABINET PARTS

DESCRIPTION

J

J

J Gear,Rack,Fix

J

J

J Cushion

J Pickup Unit

J Screw,dPX3mm

J Screw,+2.6XGmm

J Motor with Gear

J Motor with Chassis

Front Panel

(Not Replacement Item)

J

J

J

[Tape

11

Cassette Holder

(Not Replacement Item)

J

[Tape

J Cassette Holder Ass’y

Cassette Holder

(Not Replacement Item)

J

J Spring,Cassette Up.

J Damper

J Knob,CD

J Knob,CD Disc

J Knob,Tuner

J Knob,Power

J Knob,X-BASS

J

J

J

J Knob,Function

J

J Main Chassis

J Bracket,Main PWB

J

J

J

J AC Power Supply Cord

[For Taiwan]

[For Saudi Arabia]

J AC Power Supply Cord

[For Australia]

J Gear,Driving

J Cam,Driving Gear

J Gear,Driving Gear Cam

J

J

J Cushion,Arm

J

J

J

Turntable

[Tape 21

Cover

Player Base

Bottom

Lock

CODE

AC

AB

AB

AB

AC

AC

BF

AA

AA

AA

AP

AT

AY

AC

AH

AA

AL

AD

AL

AD

AA

AD

AC

AF

AC

AC

AC

AD

AD

AC

AD

AE

AT

AF

AA

AD

AM

AM

AP

AC

AF

AC

AC

AE

AB

AH

AB

AB

AC

AD

AC

AW

AF

REF.NO.

238

239

240

241

242

243

244

245

246

247

248

249

250

251

252

253

254

255

256

257

258

259

260

261

262

263

265

266

267

268

269

270

271

601

602

603

604

605

606

607

608

609

610

611

612

614

615

616

617

618

619

620

621

622

623

PART NO.

DESCRIPTION

CODE

1

(Not Replacement Item)

2

J

Holder

AA

AK

1

(Not Replacement Item)

2

3

J Cu.shion,Stabilizer AD

J Stabilizer AE

J

AC

AA

J Heat Sink

J

J LCD Sheet

J Back Board

J Side Panel

J

J Hinge Ass’y

AR

AE

AE

AK

AN

AG

AH

AW

1

Dust Cover

(Not Replacement Item)

2

Hing

JBTN-0008AWSA J

[Tape

[Tape 21

J

[Tape

Forward

AC

AC

AV

AB

AB

AB

AB

[Tape

JBTN-0012AWSA J

JBTN-0013AWSA J

JBTN-0014AWSA J

JBTN-0015AWSA J

JBTN-0016AWSA J

JBTN-0017AWSA J

J Lever,Record

[Tape

[Tape 21

[Tape 21

[Tape

[Tape

Forward

11

[Tape

AB

AB

AB

AB

AB

AB

AB

AB

Button

AB

J Fuse Holder

J Magnet

J Spring,Lock Lever

J Bushing,AC Power Supply

AA

AE

AB

AD

AD

Cord

J Bracket,Heat Sink

J Heat Sink

1

J

J

J

J

J

J

J

J

J

J Screw,+43X25mm

J Screw,d2.6mm

J Washer,d3mm

J Screw,d3X

J

AF

AC

AC

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AB

AA

AA

AA

AB

-57-

Page 40

624

PART NO.

DESCRIPTION

J

ACCESSORIES/PACKING PARTS

J Packing

J Packing Case

T i NSTOOO

J Operation Manual

[For Thailand

[Except for Thailand]

T

NSZ0049AWZZ

J Operation Manual

[For Russian Only1

J AM Loop Antenna

Accessories

Dust Cover

J Polyethylene Bag,

AC Plug Adaptor

[Except for Australia]

J FM Antenna

[For Australia Only]

[For Saudi Arabia]

J Adaptor,AC Plug

[Except for Saudi

Arabia]

J Remote Control

J Battery Lid,Remote

Control

CODE

AA

AS

AF

AP

AF

AK

AA

AB

AB

AA

AD

AB

AD

AG

AX

REF.NO.

707

708

709

710

711

712

PART NO.

PACKING PARTS

DESCRIPTION

J Speaker Cord

J

J

J

J

Non-Polar

J Woofer

J Packing

Bottom,Speaker

J Sheet,Speaker

J Polyethylene Bag,Speaker

CODE

AG

AA

AA

AC

AC

AB

AD

BA

AT

AF

AH

AD

AD

P.W.B. ASSEMBLY (Not Replacement Item)

J Main/Power

(Combined Ass’y)

PWB-B 32Ll%B1862DPLS J Display

[For Australia Only]

PWB-Cl9

J CD Servo/Sensor

[For Australia Only]

PWB-D

J CD Motor (PWB Only)

[For Australia Only]

PWB-E

OTHER SERVICE PART

A

J Extension Cable,

SPEAKER BOX PARTS

701 92LPFPAlR500

J Front Panel Ass’y AW

Front Panel

(Not Replacement Item)

2

702

1

J Net Frame Ass’y

Net Frame

(Not Replacement Item)

2

703

704

705

J Badge,SHARP

J Speaker Box Ass’y

J Port Cushion

J Bracket,Tweeter

Australia Only]

Ass’y)

AB

Australia Only]

BE

(1%13Pin)

AD

AU

AC

AY

AD

AD

Writer and Editor: Quality

Reliability Control Center of Communication

Printed in Japan

Audio Systems Group, Sharp Corp.

Loading...

Loading...