Page 1

LASER PRINTER : JX-8200

Date

:

Jul. 3, 1998

1.ADDITION CARRIED OUT OF A CASSETTE RELEASE MYLAR SHEET.

2.ADDITION OF SEALANT CARRIED OUT TO THE FUSING THERMOSTAT.

3.CHANGE CARRIED OUT IN THE DAMPING RESISTANCE COEFFICIENT

OF THE PCU PWB.

No. : CLE-052

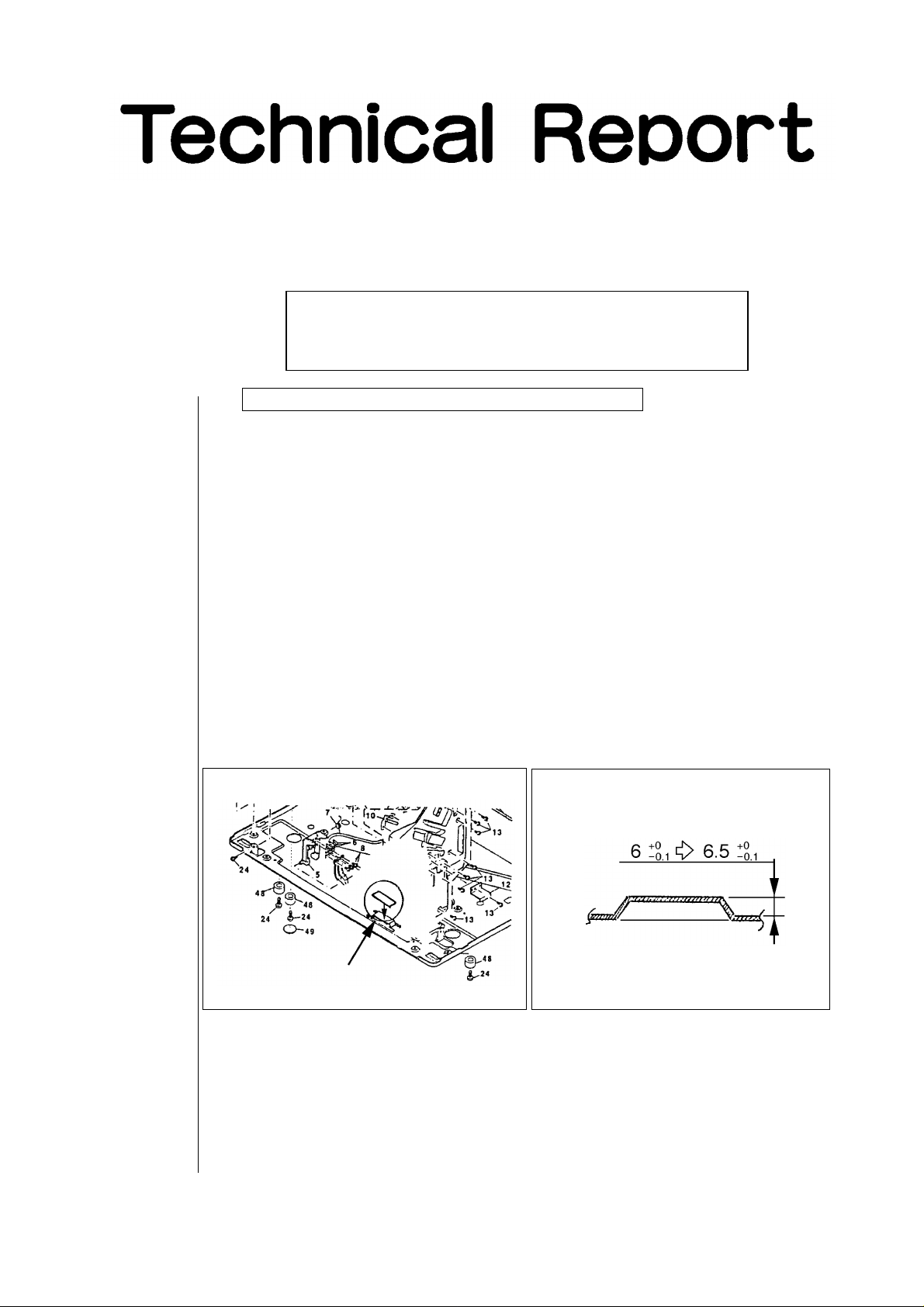

1. Addition carried out of a cassette release mylar sheet.

1.Model Name: JX-8200 (All destination)

2.General: There have been problems of the revolving plate not being able to be released when

the copy paper cassette is engaged. As a measure to alleviate this problem the action

described below has been carried out.

3.Description: A. Temporary: The addition of a cassette release mylar sheet has been carried out

to the frame base plate until the proper changes were able to be made

in the metal mold.

Cassette release mylar sheet PSHEP4628FCZZ

B. Permanent: A change has been carried out in the metal mold of the frame base plate.

Frame base plate LDAIU0011GCZ2 → LDAIU0011GCZ3

A. Temporary

[1. Temporary]

Cassette release mylar sheet

Cassette release mylar sheet

PSHEP4628FCZZ

PSHEP4628FCZZ

B. Permanent

[2.Permanent]

Change carried out in the

amount cut and elevated.

4.Action: A. Temporary: From 1998 January 9 production.

B. Permanent: From 1998 May production.

SHARP CORPORATION Reprography Division

1/3

Green

C

Page 2

2. Addition of sealant carried out to the fusing thermostat.

1.Model Name: JX-8200 (All destination)

2.General: The addition of the sealant has been carried out as a measure to improve the adhesive

performance of the tape used with the fusing thermostat.

3.Description: The fusing thermostat RDTCT0018GCZ1 → RDTCT0018GCZ2.

Added sealant

4.Action: From 1998 May production.

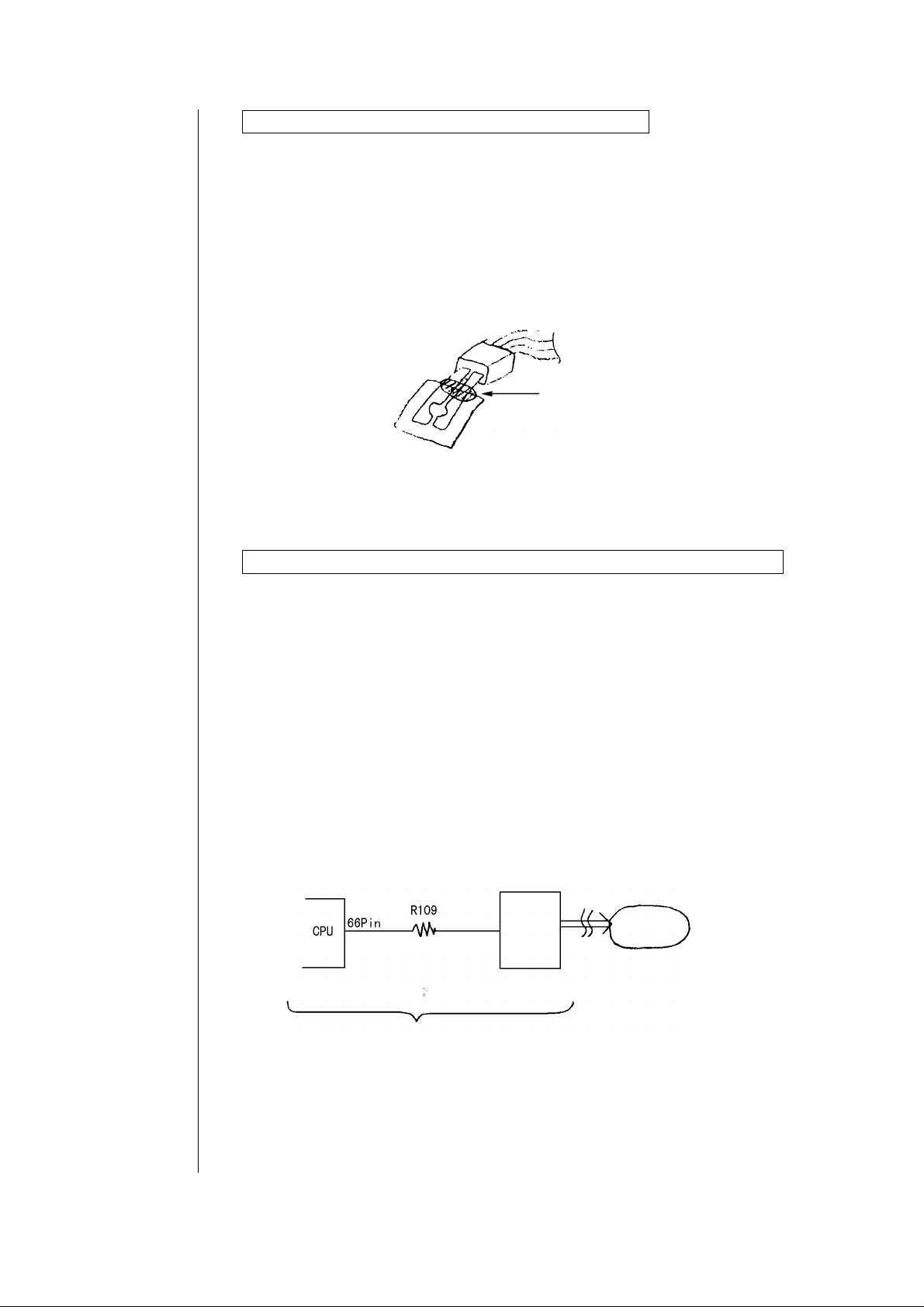

3. Change carried out in the damping resistance coefficient of the PCU PWB.

1.Model Name: JX-8200 (All destination)

2.General: The damping resistance of the main signal line upper of the drive between the CPU and

the gate array in the PCU PWB has been changed from 10 kΩ to 100Ω. This action has

been carried out as a measure to improve the movement stability of the main motor,

which is controlled by the PCU PWB, and as a measure to improve noise conditions.

3.Description: A change has been carried out in R109 in the PCU PWB from 10 kΩ to 100Ω.

The 10 kΩ resistor VRS-TS2AD103J- → 100Ω resistor VRS-TS2AD101JPCU PWB CPWBX0089GC57 → CPWBX0089GC62

Damping resistance

10 kΩ

↓

!00

PCU PWB

Gate

array

Main motor

4.Action: Running change from 1998 March production.

2/3

Page 3

Ref.

Model

No.

name

1

2 ---- RDTCT0018GCZ1 RDTCT0018GCZ2 AR Fusing thermostat '98/5

JX-8200 All

3

<Interchange>

1. Interchangeable. 4. Not interchangeable.

2. Current type can be used in place of new type.

New type cannot be used in place of current type.

3. Current type cannot be used in place of new type.

New type can be used in place of current type.

Parts marked with " " is important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

Version P/G No.

---- ---- PSHEP4628FCZZ AC Cassette release mylar '98/1/9 6 Temporary

7 -50

21 -53 VRS-TS2AD103J- VRS-TS2AD101J- AA 100Ω resistor (R109)

21 -901

Current parts New parts

Parts code Parts code

LDAIU0011GCZ2 LDAIU0011GCZ3 AZ Frame base plate '98/5

CPWBX0089GC57 CPWBX0089GC62

CPWBX0089GC56 CPWBX0089GC61

Price

rank

BZ PCU PWB unit

5. Interchangeable if replaced with same types of

related parts in use.

6. Others.

Parts name

∗ Running change from 1998 March production.

Effec-

tive

time

∗

Inter-

change-

ability

3

Note

Permanent

1 location

for R109

3/3

Loading...

Loading...