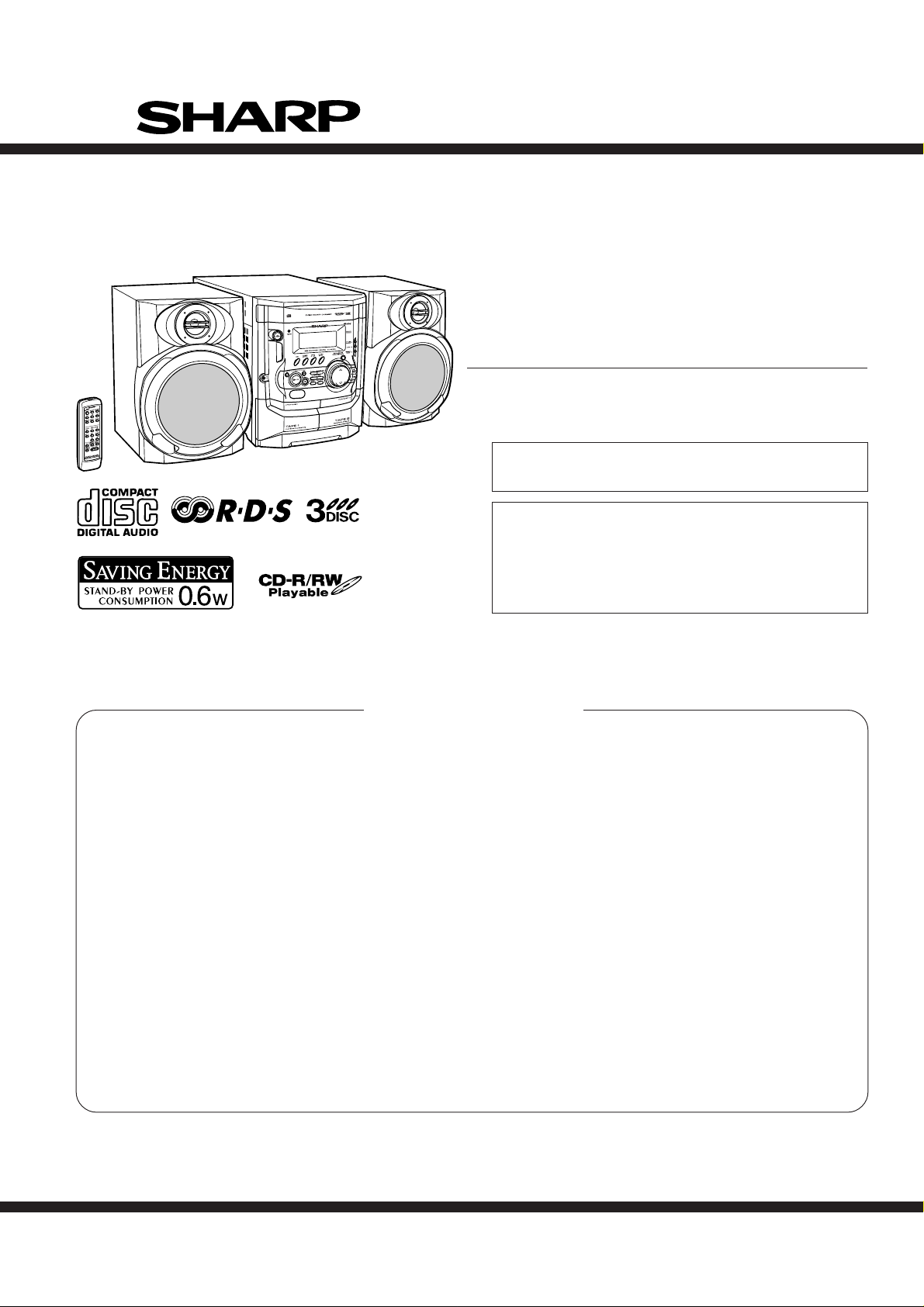

Page 1

CD-XP300H

SERVICE MANUAL

No. S2211CDXP300H

MINI COMPONENT SYSTEM

MODEL CD-XP300H

CD-XP300H Mini Component System consisting of CD-XP300H

(main unit) and CP-XP300H (speaker system).

• In the interests of user-safety the set should be restored to its

original condition and only parts identical to those specified be

used.

• Note for users in U.K.

Recording and playback of any material may require consent

which SHARP is unable to give. Please refer particularly to the

provisions of Copyright Act 1956, the Dramatic and Musical

Performers Protection Act 1956, the Performers Protection Acts

1963 and 1972 and to any subsequent statutory enactments and

orders.

CONTENTS

Page

SAFETY PRECAUTION FOR SERVICE MANUAL ........................................................................................................... 2

IMPORTANT SERVICE NOTES (FOR U.K. ONLY) .......................................................................................................... 2

SPECIFICATIONS ............................................................................................................................................................. 3

NAMES OF PARTS ........................................................................................................................................................... 4

OPERATION MANUAL ...................................................................................................................................................... 5

QUICK GUIDE (FOR U.K. ONLY)...................................................................................................................................... 8

DISASSEMBLY................................................................................................................................................................ 10

REMOVING AND REINSTALLING THE MAIN PARTS................................................................................................... 13

ADJUSTMENT ................................................................................................................................................................. 14

NOTES ON SCHEMATIC DIAGRAM .............................................................................................................................. 18

TYPES OF TRANSISTOR AND LED............................................................................................................................... 18

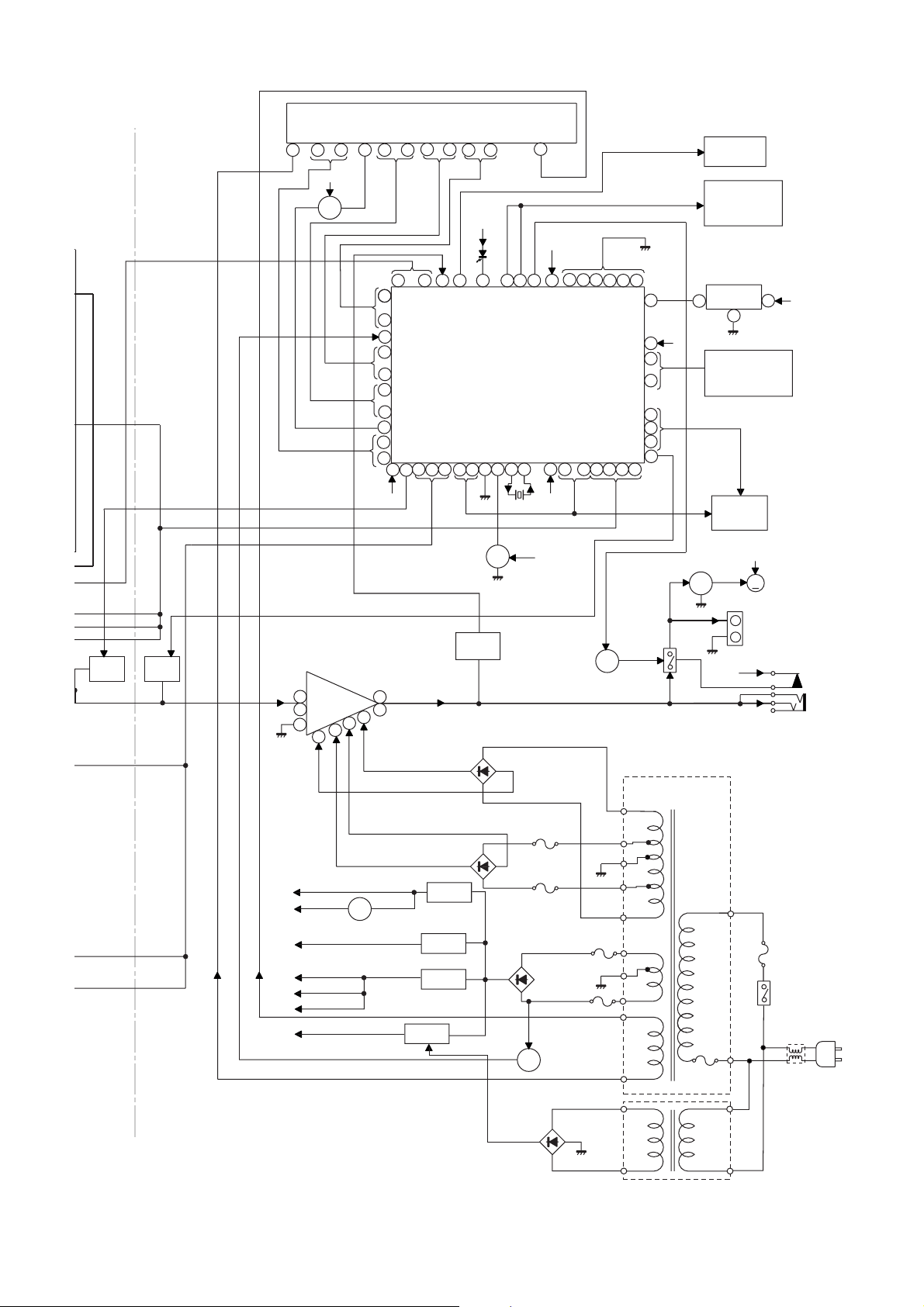

BLOCK DIAGRAM ........................................................................................................................................................... 19

SCHEMATIC DIAGRAM / WIRING SIDE OF P.W.BOARD............................................................................................. 22

VOLTAGE ........................................................................................................................................................................ 39

WAVEFORMS OF CD CIRCUIT...................................................................................................................................... 40

TROUBLESHOOTING..................................................................................................................................................... 41

FUNCTION TABLE OF IC................................................................................................................................................ 45

FL DISPLAY..................................................................................................................................................................... 51

WIRING OF PRIMARILY SUPPLY LEADS (FOR U.K. ONLY) ....................................................................................... 52

REPLACEMENT PARTS LIST/EXPLODED VIEW

PACKING METHOD (FOR U.K. ONLY)

SHARP CORPORATION

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

Page 2

CD-XP300H

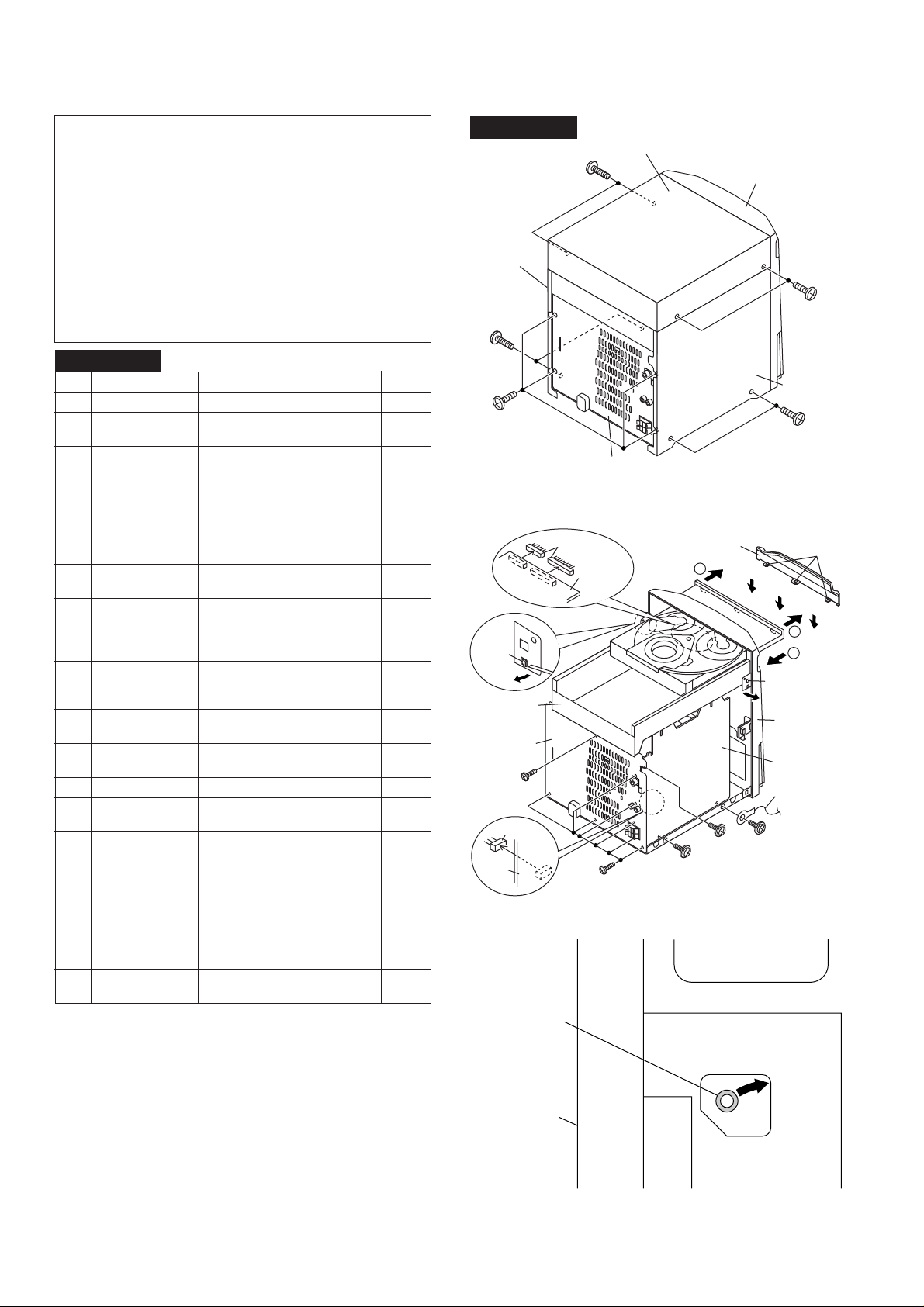

DISASSEMBLY

Caution on Disassembly

Follow the below-mentioned notes when disassembling

the unit and reassembling it, to keep it safe and ensure

excellent performance:

1. Take cassette tape and compact disc out of the unit.

2. Be sure to remove the power supply plug from the wall

outlet before starting to disassemble the unit.

3. Take off nylon bands or wire holders where they need to

be removed when disassembling the unit. After servicing

the unit, be sure to rearrange the leads where they were

before disassembling.

4. Take sufficient care on static electricity of integrated

circuits and other circuits when servicing.

CD-XP300H

STEP

10 Turntable 1. Hook........................ (K1) x2 11-3

11 Loading Tray 1.

12 CD Servo PWB 1. Screw ......................(M1) x2 11-5

13 CD Mechanism 1. Hook ........................ (N1) x2 11-6

Note 1: How to open the changer manually. (Fig. 10-3)

1. In this state, turn fully the lock lever in the arrow direction through

2. After that, push forward the loading tray.

REMOVAL

1 Top Cabinet 1. Screw ...................... (A1) x4 10-1

2 Side Panel 1. Screw ...................... (B1) x8 10-1

(Left/Right)

3 CD Tray Cover/ 1. Turn on the power supply,.. 10-2

CD Player Unit open the disc tray, take out

4 Rear Panel with 1. Screw ...................... (D1) x8 10-2

Fan Motor 2. Socket ..................... (D2) x1

5 Main PWB/ 1. Screw ...................... (E1) x4

RDS PWB 2. Socket ..................... (E2) x3 11-1

6 Front Panel 1. Screw .......................(F1) x2 11-1

7 Display PWB 1. Screw ....................(G1) x12 11-2

8 Tape Mechanism 1. Open the cassette holder. .. 11-2

9

Headphones PWB

(Note 2) 2. Hook........................ (M2) x1

the hole on the loading tray bottom.

the CD tray cover, and close.

(Note 1)

2. Screw ...................... (C1) x1

3. Hook........................ (C2) x3

4. Hook........................ (C3) x2

5. Socket ..................... (C4) x2

3. Flat Cable ............... (E3) x1

4. Flat Wire.................. (E4) x1

2. Hook.........................(F2) x2

3. Socket ......................(F3) x1

2. Flat Cable ...............(G2) x1

2. Screw...................... (H1) x5

1. Screw .......................(J1) x1 11-2

2. Cover ...................... (K2) x1

2.

3. Socket .....................(M3) x4

2. Hook........................ (N2) x2

PROCEDURE

Turn fully the lock lever in the

arrow direction

Push the loading tray backward

to engage the claw with the

groove and remove it in the

direction of the arrow

.

...

(L1) x6

FIGURE

10-2, 11-1

10-3

11-4

CD-XP300H

Side Panel

(Right)

(B1) x 2

ø3 x 10mm

(B1) x 4

ø3 x 10mm

(C3) x 1

Pull

CD Player

Unit

Rear

Panel

(C1) x 1

ø3 x 10mm

(D2) x 1

Main

PWB

Lock Lever

(A1) x 2

ø3 x 12mm

(C4) x 2

CD Servo

PWB

(D1) x 7

ø3 x 10mm

Top Cabinet

Rear

Panel

Figure 10-1

Figure 10-2

CD Tray Cover

1

(D1) x 1

(E1) x 1

ø3 x 10mm

ø3 x 10mm

Front

Panel

Side Panel

(Left)

(B1) x 2

ø3 x 10mm

(C3) x 1

Pull

Front

Panel

Main PWB

Lug Wire

(E1) x 1

ø3 x 10mm

(A1) x 2

ø3 x 12mm

(C2) x 3

1

2

Note 2:

1. After removing the connector for the optical pickup from the

connector, wrap the conductive aluminium foil around the front end

of the connector so as to protect the optical pickup from electrostatic damage.

Note 3:

1. Be careful not to break the claw of the CD mechanism.

2. When fining back the cam gear assembly, let it lock by front

movement.

CD Player Unit

(Bottom View)

Figure 10-3

– 10 –

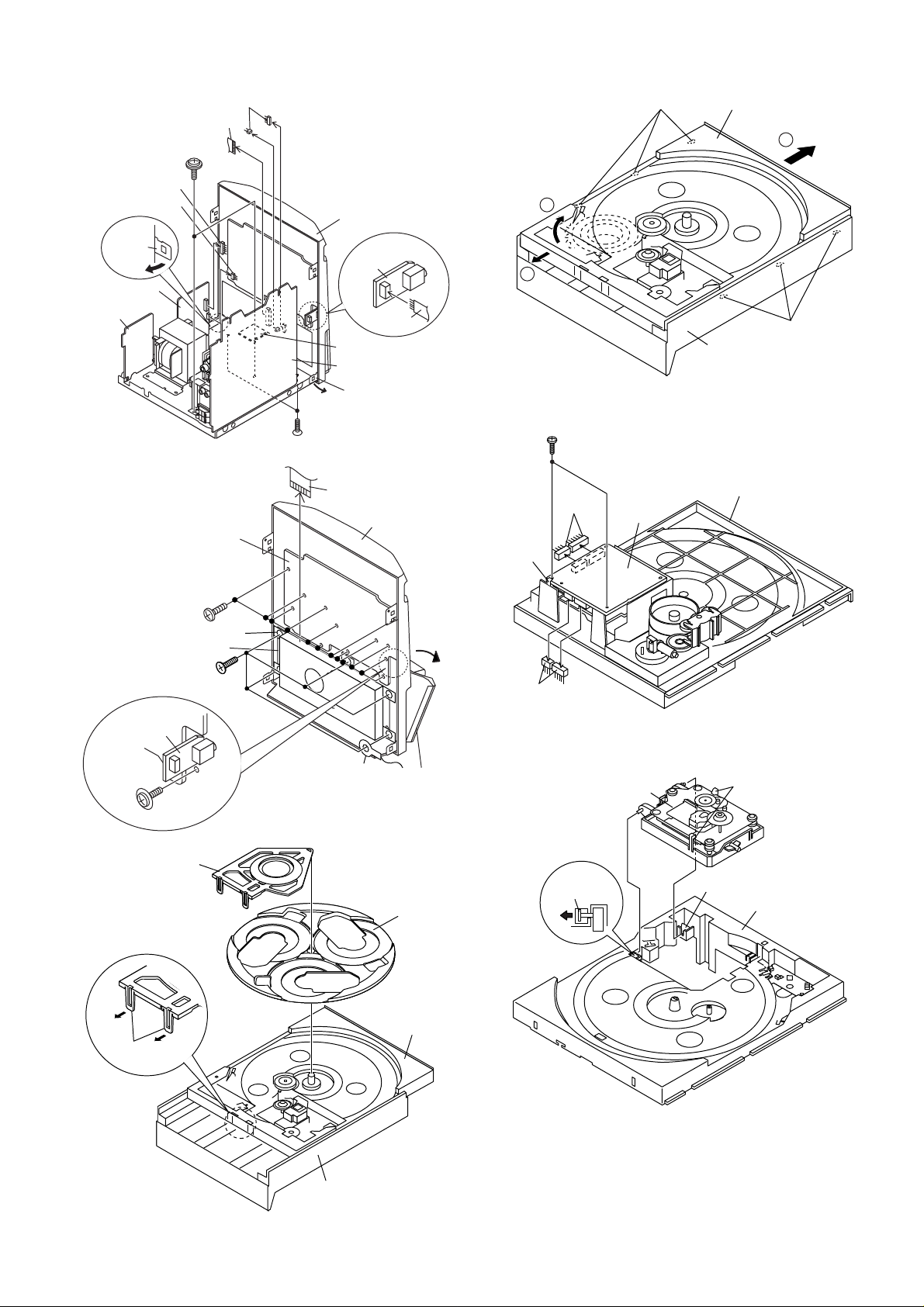

Page 3

(E2) x 1

(L1) x 3

3

(L1) x 3

Loading Tray

1

2

CD Player Unit

CD

Mechanism

(N2) x 2

(N1) x 1

(N1) x 1

Loading Tray

(F3) x 1

(F2) x 1

Pull

Power PWB

Transformer

PWB

(E1) x 2

ø3 x 10mm

Display PWB

(E2) x 2

(E3) x 1

Figure 11-1

Front

Panel

RDS PWB

Main PWB

(F2) x 1

Pull

(F1) x 2

ø3 x 10mm

(G2) x 1

Headphones

PWB

(E4) x 1

Front Panel

(M2) x 1

(M1) x 2

ø3 x 10mm

(M3) x 2

CD-XP300H

Figure 11-4

Loading

Tray

CD Servo

PWB

(G1) x 12

ø3 x 10mm

Mechanism Dust Cover

Tape Mechanism

(H1) x 5

ø3 x 10mm

Headphones

PWB

(J1) x 1

ø3 x 10mm

(K2) x 1

(K1) x 2

Figure 11-2

Open

(M3) x 2

Figure 11-5

Lug Wire

Cassette

Holder

Turntable

Loading

Tray

CD Player Unit

Figure 11-6

Figure 11-3

– 11 –

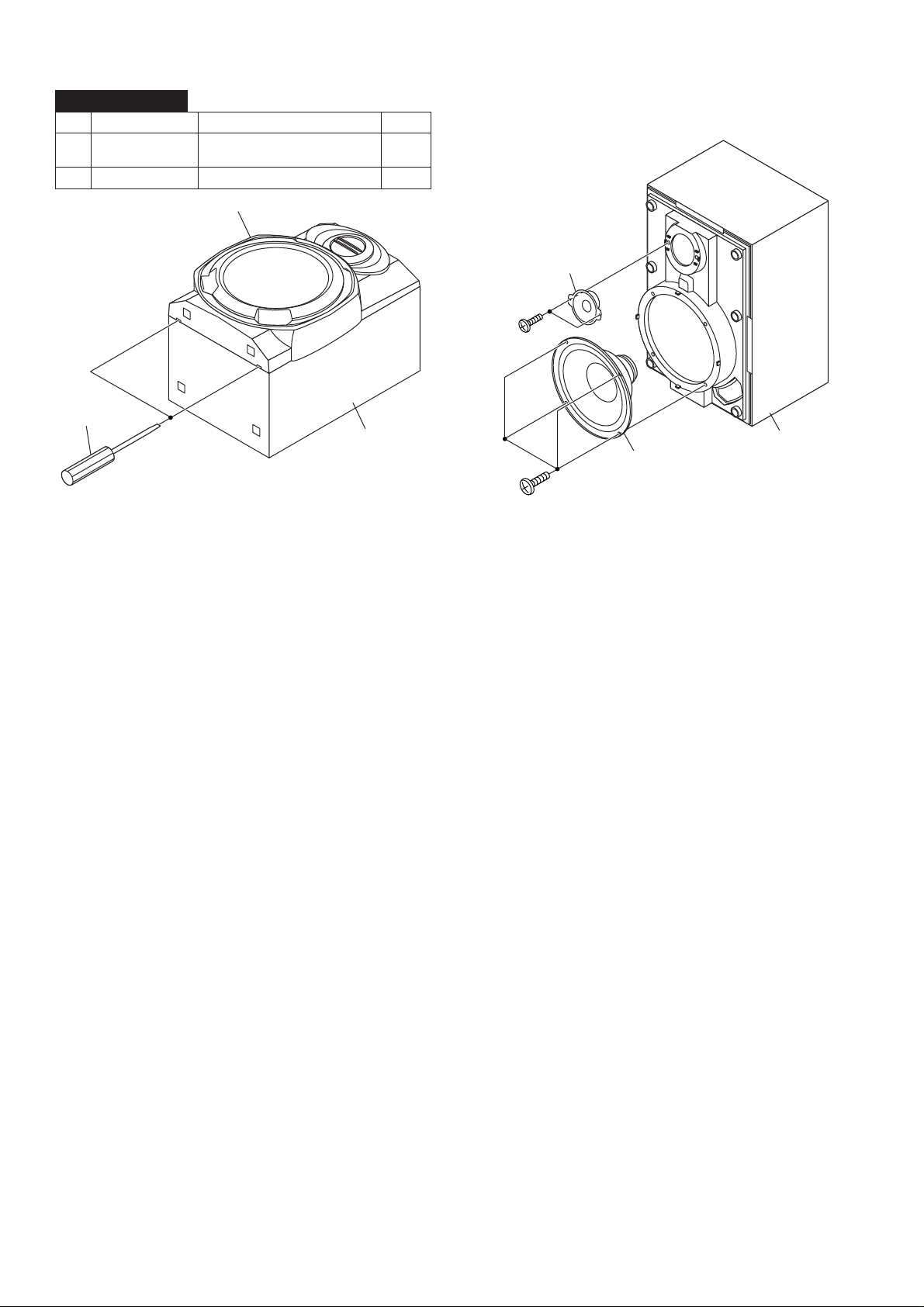

Page 4

CD-XP300H

CP-XP300H

STEP

Screwdriver

REMOVAL

1 Woofer 1. Front Panel ............. (A1) x1 12-1

2. Screw ...................... (A2) x4 12-2

2 Tweeter 1. Screw ...................... (B1) x2 12-2

Driver should

be pried away

from Speaker Box.

PROCEDURE

(A1) x 1

Speaker Box

Figure 12-1

FIGURE

Tweeter

(B1) x 2

ø3 x 10mm

Speaker Box

Woofer

(A2) x 4

ø4 x 16mm

Figure 12-2

– 12 –

Page 5

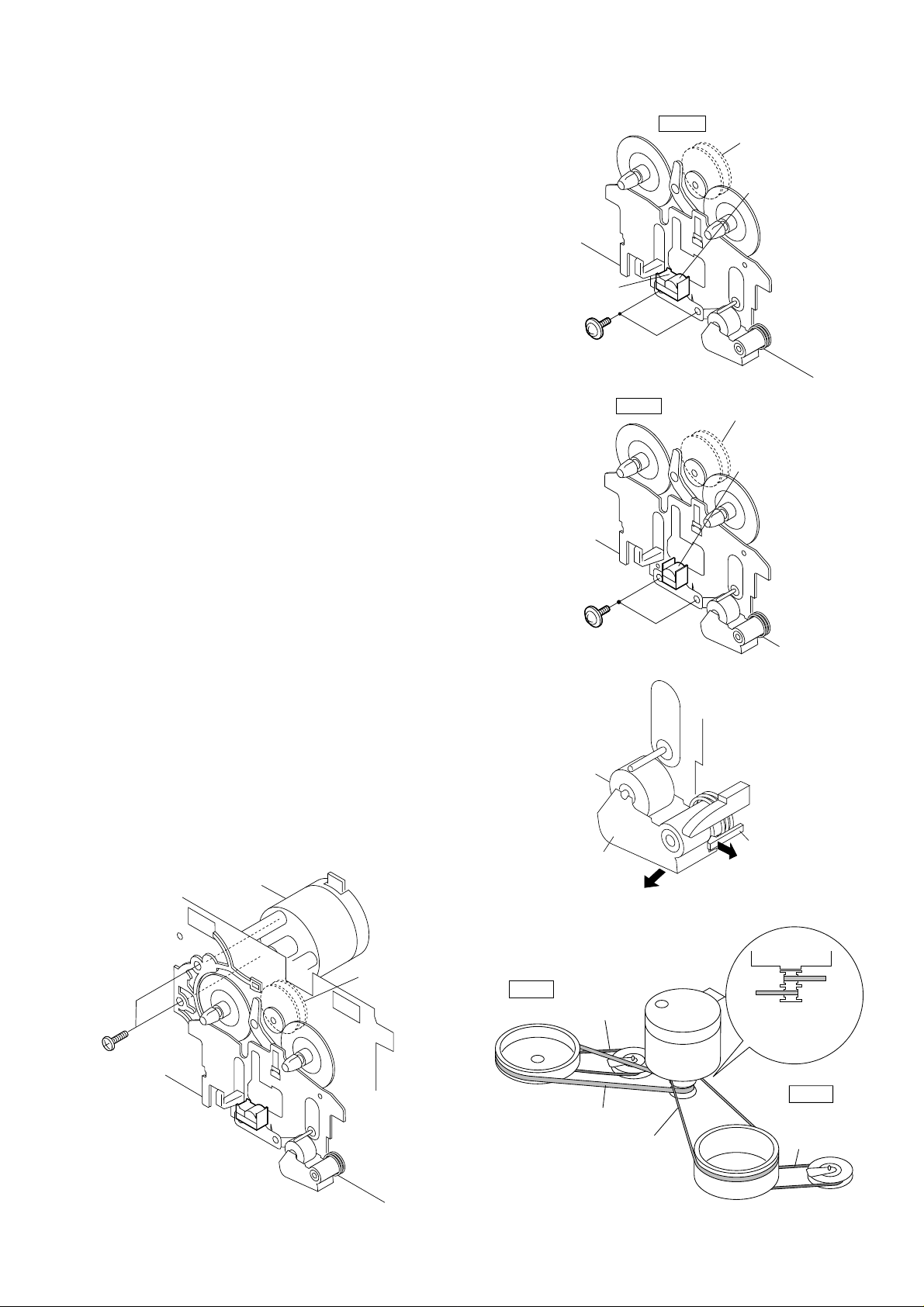

REMOVING AND REINSTALLING THE MAIN PARTS

TAPE 2

TAPE 1

Main Belt

(E1) x 1

TAPE 2

Main Belt

(D1) x 1

TAPE 1

Main Belt

(D1) x 1

Main Belt

(E1) x 1

FF/REW

Belt

(D2) x 1

FF/REW

Belt

(E2) x 1

Motor

Motor

TAPE MECHANISM SECTION

Perform steps 1 to 6 and 8 of the disassembly method to

remove the tape mechanism.

How to remove the record/playback and erase

heads (TAPE 2) (See Fig. 13-1)

1. When you remove the screws (A1) x 2 pcs., the recording/

playback head and three-dimensional head of the erasing

head can be removed.

How to remove the playback head (TAPE 1)

(See Fig. 13-2)

1. When you remove the screws (B1) x 2 pcs., the playback

head can be removed.

How to remove the pinch roller (TAPE 1/2)

(See Fig. 13-3)

1. Carefully bend the pinch roller pawl in the direction of the

arrow <A>, and remove the pinch roller (C1) x 1 pc., in the

direction of the arrow <B>.

Note:

When installing the pinch roller, pay attention to the spring

mounting position.

Erase Head

(A1) x 2

Ø2 x 9mm

Figure 13-1

TAPE 1

TAPE 2

CD-XP300H

Clutch Ass'y

Record/Playback

Head

Clutch Ass'y

Playback

Head

How to remove the belt (TAPE 2)

(See Fig. 13-4)

1. Remove the main belt (D1) x 1 pc., from the motor side.

2. Remove the FF/REW belt (D2) x 1 pc.

How to remove the belt (TAPE 1)

(See Fig. 13-4)

1. Remove the main belt (E1) x 1 pc., from the motor side.

2. Remove the FF/REW belt (E2) x 1 pc.

How to remove the motor (See Fig. 13-5)

1. Remove the screws (F1) x 2 pcs., to remove the motor.

Motor

Clutch Ass'y

(B1) x 2

Ø2 x 9mm

Pinch Roller

(C1) x 1

Figure 13-2

Pull

<B>

Figure 13-3

<A>

Pinch

Roller

Pawl

(F1) x 2

Ø 2.6 x 5mm

Figure 13-4Figure 13-5

– 13 –

Page 6

CD-XP300H

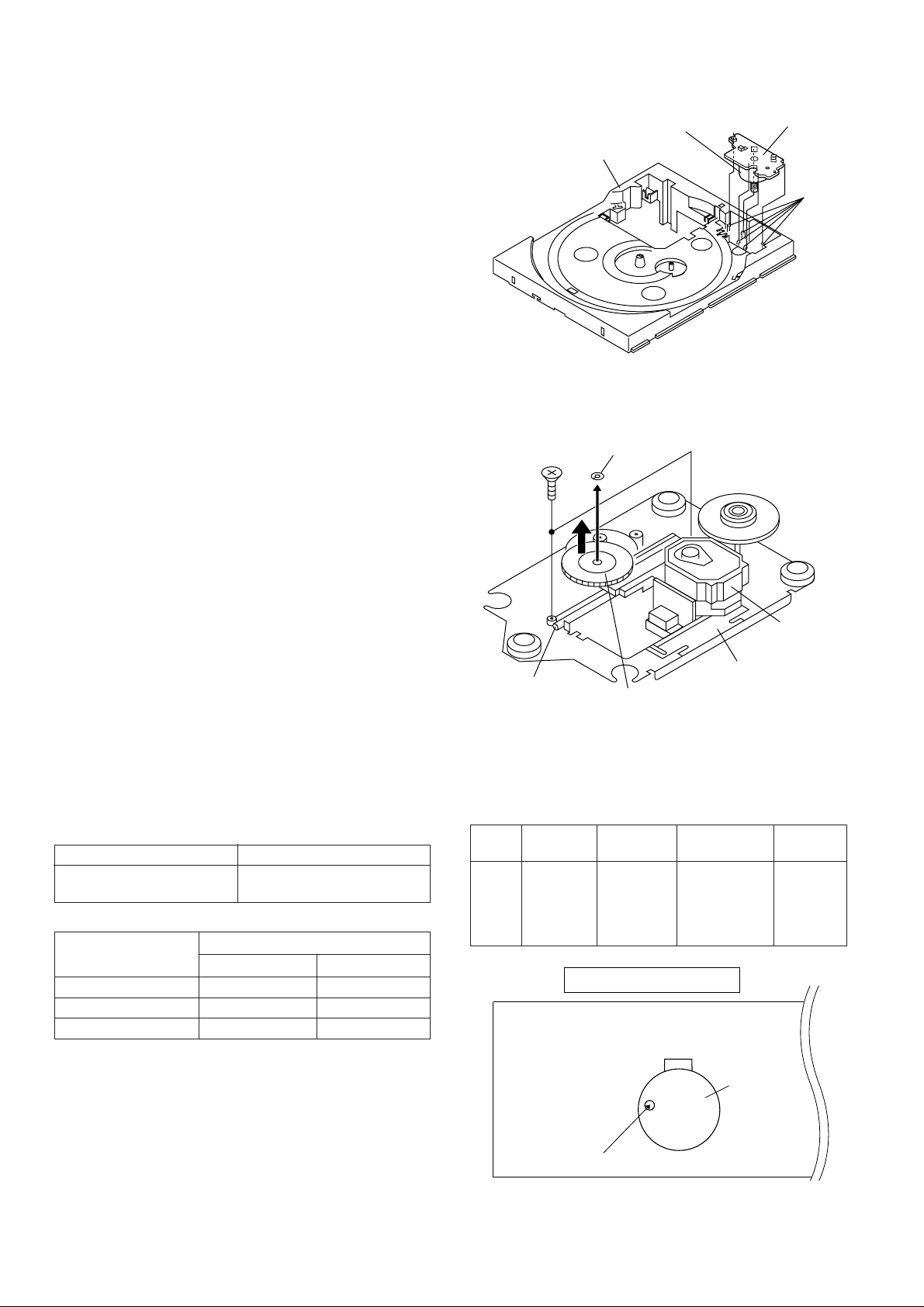

CD MECHANISM SECTION

Perform steps 1, 2, 3, 10, 11,12 and 13 of the disassembly

method to remove the CD mechanism.

How to remove the loading motor

(See Fig. 14-1)

1. Bend the hooks (A1) x 6 pcs., to remove the loading motor.

How to remove the pickup (See Fig. 14-2)

1. Remove the stop washer (B1) x 1 pc., to remove the gear

(B2) x 1 pc.

2. Remove the screws (B3) x 2 pcs., to remove the shaft

(B4) x 1 pc.

3. Remove the pickup.

Note

After removing the connector for the optical pickup from the

connector wrap the conductive aluminium foil around the front

end of connector so as to protect the optical pickup from

electrostatic damage.

(B3) x 2

ø2.6 x 6mm

Loading

Tray

Figure 14-1

Stop Washer

(B1) x 1

Loading

Motor

Loading

Motor PWB

(A1) x 6

ADJUSTMENT

MECHANISM SECTION

• Driving Force Check

Torque Meter Specified Value

Play: TW-2111 Tape 1: Over 80 g

• Torque Check

Torque Meter

Play: TW-2111 30 to 80 g.cm 30 to 80 g.cm

Fast forward: TW-2231 — 70 to 180 g.cm

Rewind: TW-2231 — 70 to 180 g.cm

Tape 2: Over 80 g

Specified Value

Tape 1

Tape 2

Pickup

Shaft

(B4) x 1

Gear

CD Mechanism

(B2) x 1

Figure 14-2

• Tape Speed

Test Tape

Normal MTT-111 Variable 3,000 ± 30 Hz Speaker

speed Resistor in Terminal

Adjusting

Point

motor. (Load

Specified

Value

TAPE MECHANISM

Instrument

Connection

resistance:

6 ohms)

– 14 –

Tape

Motor

Variable Resistor in motor

Figure 14-3

Page 7

CD-XP300H

T

T

EFBL

FDO

TE

Stopped

CH1=500 mV

DC 10:1

CH2=200 mV

DC 10:1

CH3=1 V

DC 10:1

500 ms/div

(500 ms/div)

NORM:20 kS/s

1

2

3

=Record Length=

Smoothing : ON CH1 : 0.000 V

CH2 : 0.000 V

Main : 100 K

Zoom : 2 k

Mode : SINGLE

Type : EDGE CH1

Delay : 0.0 ns

Hold off : 0.2 µs

CH3 : 0.00 V

CH4 : 0.00 V

BW : FULL

=Trigger==Filter= =Offset=

CH2

v/DIV

200 mV

1999/04/05 20:26:47

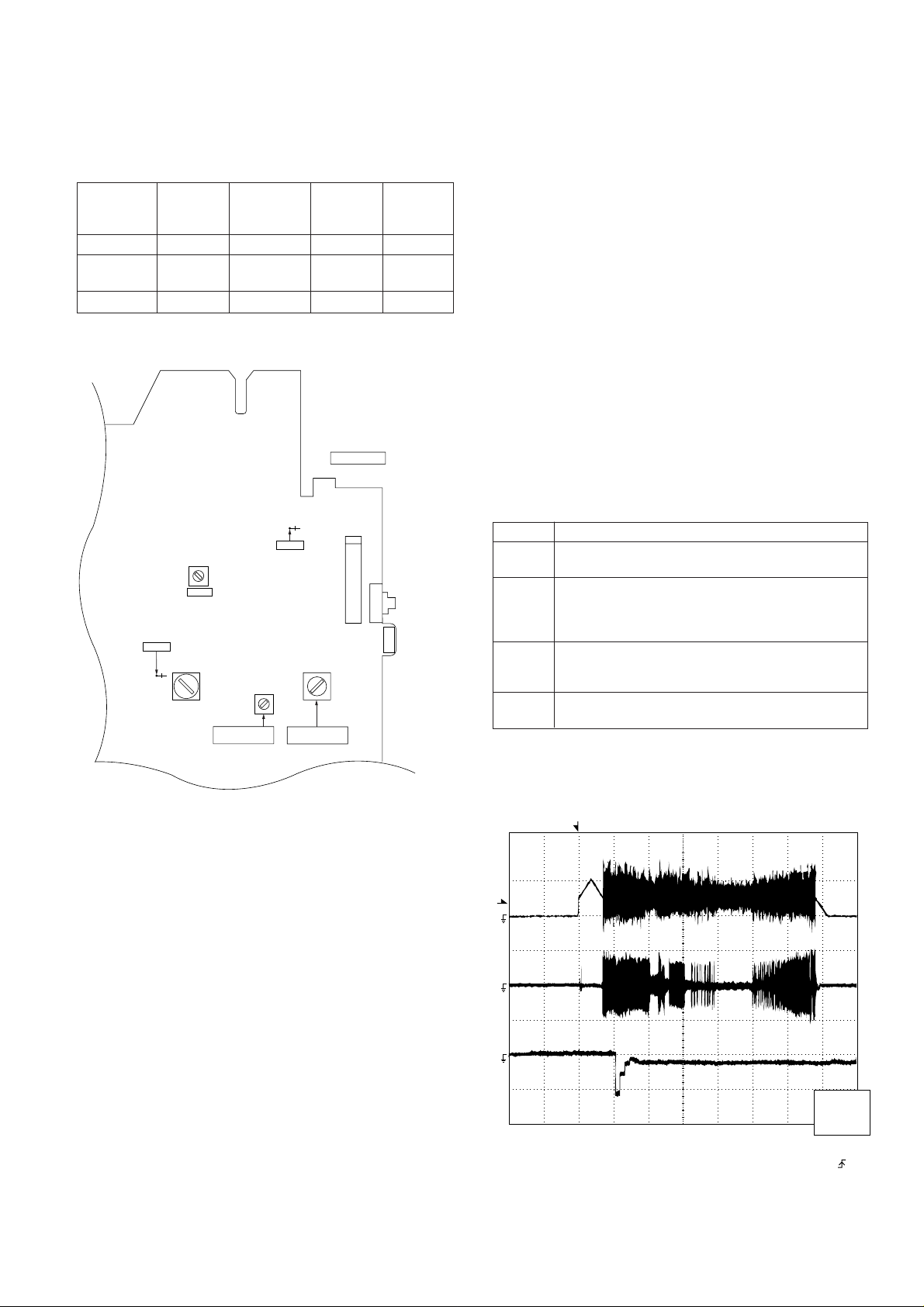

TUNER SECTION

fL: Low-range frequency

fH: High-range frequency

• AM IF/RF

Signal generator: 400 Hz, 30%, AM modulated

Test Stage

AM IF 450 kHz 1,620 kHz T351 *1

AM Band — 522 kHz (fL): T306 *2

Coverage 1.1 ± 0.1 V

AM Tracking 990 kHz 990 kHz (fL): T303 *1

*1. Input: Antenna Output: TP302

*2. Input: Antenna Output: TP301

Frequency Frequency

Display

T351

AM IF

TP302

L354

R357

T306

AM BAND

COVERAGE fL

R381

TP301

AM TRACKING

fL

Setting/

Adjusting

Parts

MAIN PWB

FE301

T303

Instrument

Connection

SO301

FM ANTENNA

TERMINAL

CNP301

AM LOOP

ANTENNA

CD SECTION

• Adjustment

Since this CD system incorporates the following automatic

adjustment functions, readjustment is not needed when

replacing the pickup. Therefore, different PWBs and pickups

can be combined freely.

Each time a disc is changed, these adjustments are

performed automatically. Therefore, playback of each disc

can be performed under optimum conditions.

Items adjusted automatically

(1) Offset adjustment (The offset voltage between the head

amplifier output and the VREF reference voltage is

compensated inside the IC.)

* Focus offset adjustment

* Tracking offset adjustment

(2) Tracking balance adjustment (waveform drawing

Fig.15-2 EFBL)

(3) Gain adjustment (The gain is compensated inside the IC

so that the loop gain at the gain crossover frequency will

be 0 dB.)

* Focus gain adjustment

* Tracking gain adjustment

CD ERROR CODE DESCRIPTION

Error

01

When Pickup set inner position, inner switch

cannot detect 'ON' level for 10 secs.

When tray moves to Open/Close, Open/Close switch

10*

cannot detect 'ON' level for 7 secs.

When disc table rotate to target position.

Clamp switch cannot detect 'ON' level for 7 secs.

When disc table set to Disc1 position for 1 st time,

11* "CLAMP SW", "DISC NO SW" and "OPEN/CLOSE"

cannot detect 'ON' level for 14 secs.

31

When it changes to CD function, DSP cannot read

initial data.

* 'CHECKING'

If Error is detected, 'CHECKING' will be display instead of 'ERCD**' display. 'ER-CD**' display will only be display when

error had been detected for the 5 th times.

Explanation

• FM IF

Notes:

1: Description of the "FM IF Adjustment" is not carried on this

Manual. It is because the IF coil in the FM front end section

has been best adjusted in the factory so that its further

adjustment is not needed at the field. When replacing the

FM front end assembly, no adjustment is needed either.

2: The parts in the FM front end section are prepared in a

complete unit, so you can't obtain each part individually.

Figure 15-1 ADJUSTMENT POINTS

Figure 15-2

– 15 –

Page 8

CD-XP300H

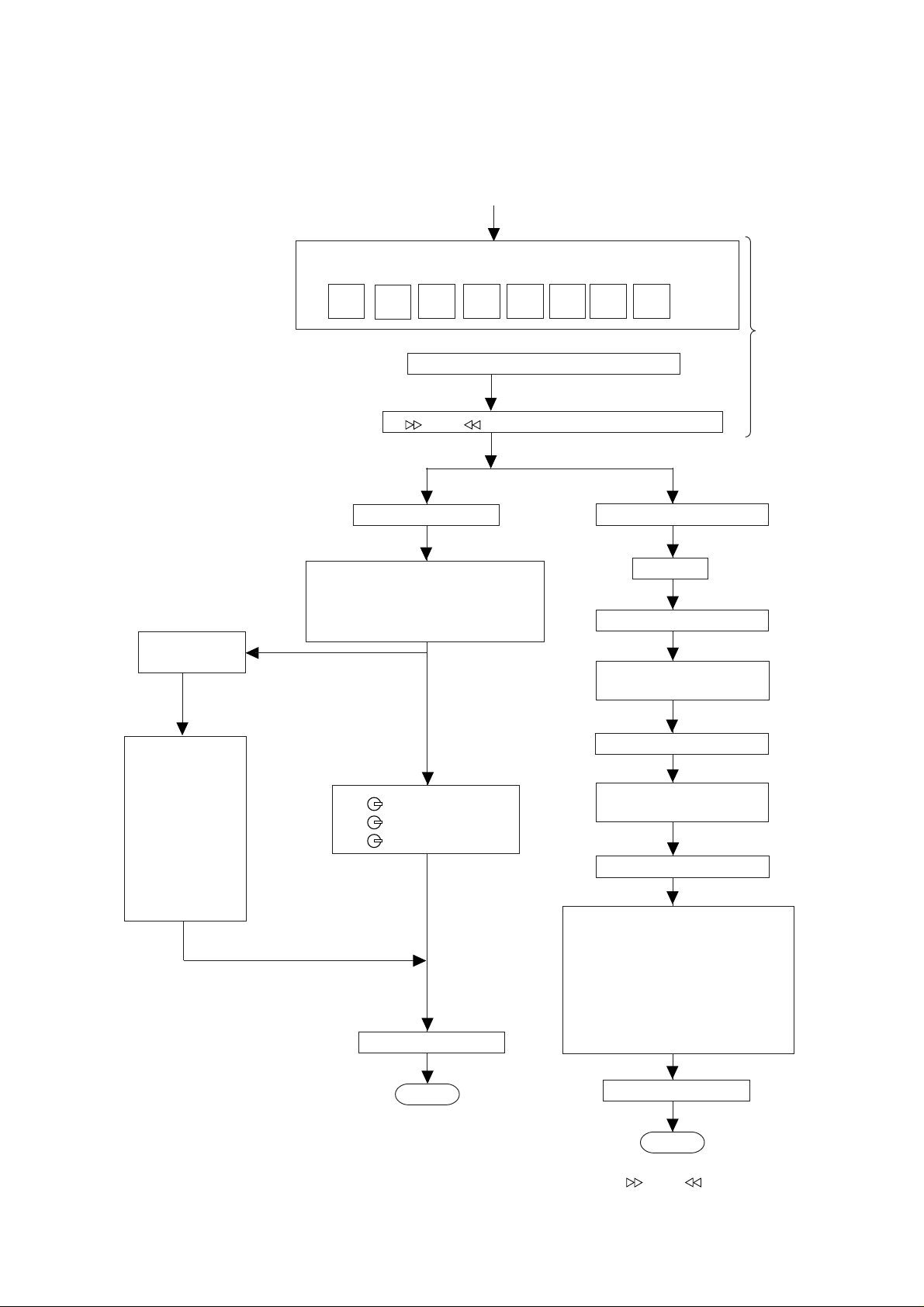

TEST MODE

• Setting the test mode

Any one of test mode can be set by pressing several keys as follows.

<X-BASS> + <CD> + <POWER> TEST: CD operation test.

Function: -CD test mode.

-Enter test mode.

C D T E S T

OPEN/CLOSE operation is using manual.

<< >>, << >> buttons make pick's slide possible.

IL isn't done

<<MEMORY>>

key input.

Adjustment result

automatically will

display as below.

for each 2 sec :

a) "FOFF_XX"

b) "TOFF_XX"

c) "TBAL_XX"

d) "TGAN_XX"

f) "FGAN_XX"

g) "RFLS_XX"

explanation:

a) Focus off set = "FOFF_XX"

b) Tracking off set = "TOFF_XX"

c) Tracking balance = "TBAL_XX"

d) Tracking Gain = "TGAN_XX"

f) Focus Gain = "FGAN_XX"

g) RF level shift = "RFLS_XX"

<<PLAY>> key input.

Do TOC IL. Do normal play.

When these following key is input

into PLAY key, track number can

be appoint directly.

<< 1>> key: Track 4

<< 2>> key: Track 9

<< 3>> key: Track 15

<<STOP>> key input.

STOP

<<MEMORY>> key input.

Laser ON.

<<MEMORY>> key input.

Tracking OFF play at that

specific point.

<<MEMORY>> key input.

Tracking ON play from

that specific point.

<<MEMORY>> key input.

Adjustment result automatically will

display as below for each 2 sec :

a) "FOFF_XX"

b) "TOFF_XX"

c) "TBAL_XX"

d) "TGAN_XX"

f) "FGAN_XX"

g) "RFLS_XX"

<<STOP>> key input.

VOL — Last memory

BAL — CENTER

P.GEQ — FLAT

X-BASS — OFF

To cancel : Power OFF

– 16 –

STOP

Sliding the PICKUP with

>>, << >> button

<<

must only be in STOP mode.

Page 9

Standard Specification of Stereo System Error Message Display Contents

Error Contents DISPLAY Notes

TAPE Mechanism Error. 'ER-TA**' 00: Tape Mechanism Error.

01: Initial Error.

02:

03:

CD Pickup Mechanism Error. 'ER-CD**' 01: PU-IN SW Detection NG.

02:

03:

04:

CD Changer Mechanism Error. 'ER-CD**' 10: Changer Error.

(*) 11: Initial Error.

12:

13:

CD DSP Communication Error 'ER-CD**' 31: DSP COMMUNICATION ERROR

Focus Not Match. 'NO DISC'

IL Time Over. 'NOT READ'

TUN PLL Unlock. 'ER-TU**' 00: TUN Error.

01: PLL Unlock.

02:

03:

CD-XP300H

(*) CHECKING:

If CD changer mechanism error is detected, 'CHECKING' will be display instead of 'ER-CD**' display 'ER-CD**' will only be display

when CD changer mechanism error had been detected for the 5 th times.

Speaker abnormal detection and +B PROTECTION display

In case speaker abnormal detection or +B PROTECTION had occurred, it can be check by pressing 'POWER', 'VIDEO' and 'XBASS' key twice. Display will show "S** B**". S is referring to speaker abnormal detection and B is referring to +B PROTECTION.

** is in hex valve.

+B PROTECTION is condition when irregular process occur on power supply line.

– 17 –

Page 10

CD-XP300H

NOTES ON SCHEMATIC DIAGRAM

• Resistor:

To differentiate the units of resistors, such symbol as K and

M are used: the symbol K means 1000 ohm and the symbol

M means 1000 kohm and the resistor without any symbol is

ohm-type resistor. Besides, the one with “Fusible” is a fuse

type.

• Capacitor:

To indicate the unit of capacitor, a symbol P is used: this

symbol P means pico-farad and the unit of the capacitor

without such a symbol is microfarad. As to electrolytic

capacitor, the expression “capacitance/withstand voltage”

is used.

(CH), (TH), (RH), (UJ): Temperature compensation

(ML): Mylar type

(P.P.): Polypropylene type

• Schematic diagram and Wiring Side of P.W.Board for this

model are subject to change for improvement without prior

notice.

• The indicated voltage in each section is the one measured

by Digital Multimeter between such a section and the chassis with no signal given.

1. In the tuner section,

indicates AM

indicates FM stereo

2. In the main section, a tape is being played back.

3. In the deck section, a tape is being played back.

( ) indicates the record state.

4. In the power section, a tape is being played back.

5. In the CD section, the CD is stopped.

• Parts marked with “ 1 ” ( ) are important for

maintaining the safety of the set. Be sure to replace these

parts with specified ones for maintaining the safety and

performance of the set.

REF. NO

SW1 OPEN/CLOSE ON—OFF

SW2 CLAMP ON—OFF

SW3 DISC NUMBER ON—OFF

SW4 PICKUP IN ON—OFF

SW701 ON/STAND-BY ON—OFF

SW702 FAST REWIND/PRESET DOWN ON—OFF

SW703 FAST FORWARD/PRESET UP ON— OFF

SW704 STOP ON—OFF

SW705 PLAY/REPEAT ON—OFF

SW711

SW712 TUNER (BAND) ON—OFF

SW713 TAPE ON—OFF

SW714 VIDEO/AUX ON—OFF

SW715 TIMER/SLEEP ON—OFF

CD

DESCRIPTION

POSITION

ON—OFF

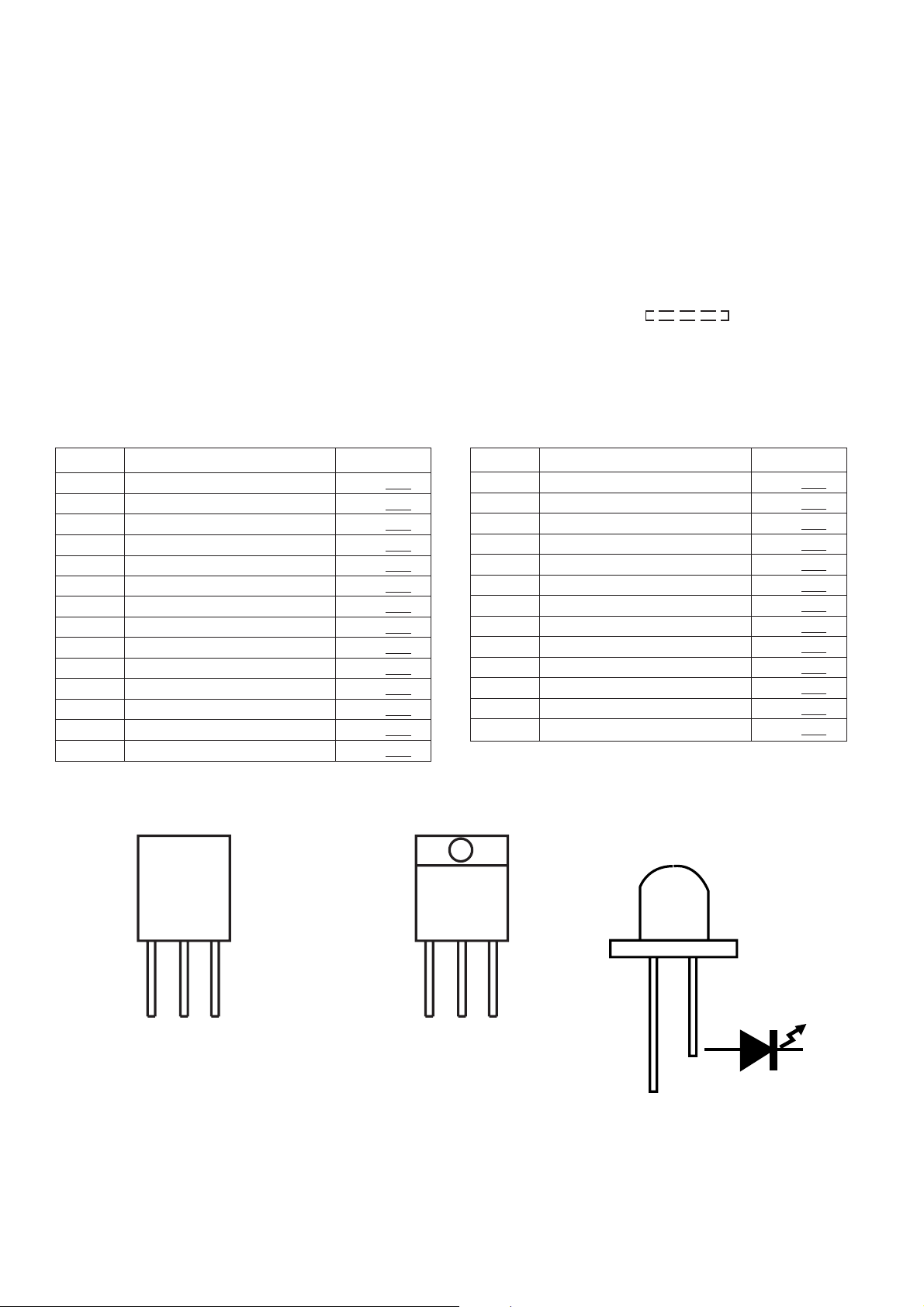

TYPES OF TRANSISTOR AND LED

FRONT

VIEW

REF. NO DESCRIPTION POSITION

SW716 TUNING/TIME UP ON—OFF

SW717 RECORD PAUSE ON—OFF

SW718 MEMORY/SET ON—OFF

SW719 TUNING/TIME DOWN ON—OFF

SW720 CLOCK ON—OFF

SW721 VOLUME UP ON—OFF

SW722 VOLUME DOWN ON—OFF

SW723 DISC SKIP ON—OFF

SW724 OPEN/CLOSE ON—OFF

SW725 EQUALIZER/X-BASS/DEMO ON—OFF

SW727 DISPLAY MODE ON—OFF

SW728 ASPM ON—OFF

SW729 PTY TI SEARCH ON—OFF

FRONT

VIEW

FRONT

VIEW

E C B

(S) (G) (D)

(1) (2) (3)

KRC102 M

KRC104 M

KTA1266 GR

KTA1273 Y

KTA1274 Y

KTC3199 GR

KTC3203 Y

2SC1845 F

2SC380 O

B C E

SLR342VCJKTC2026

– 18 –

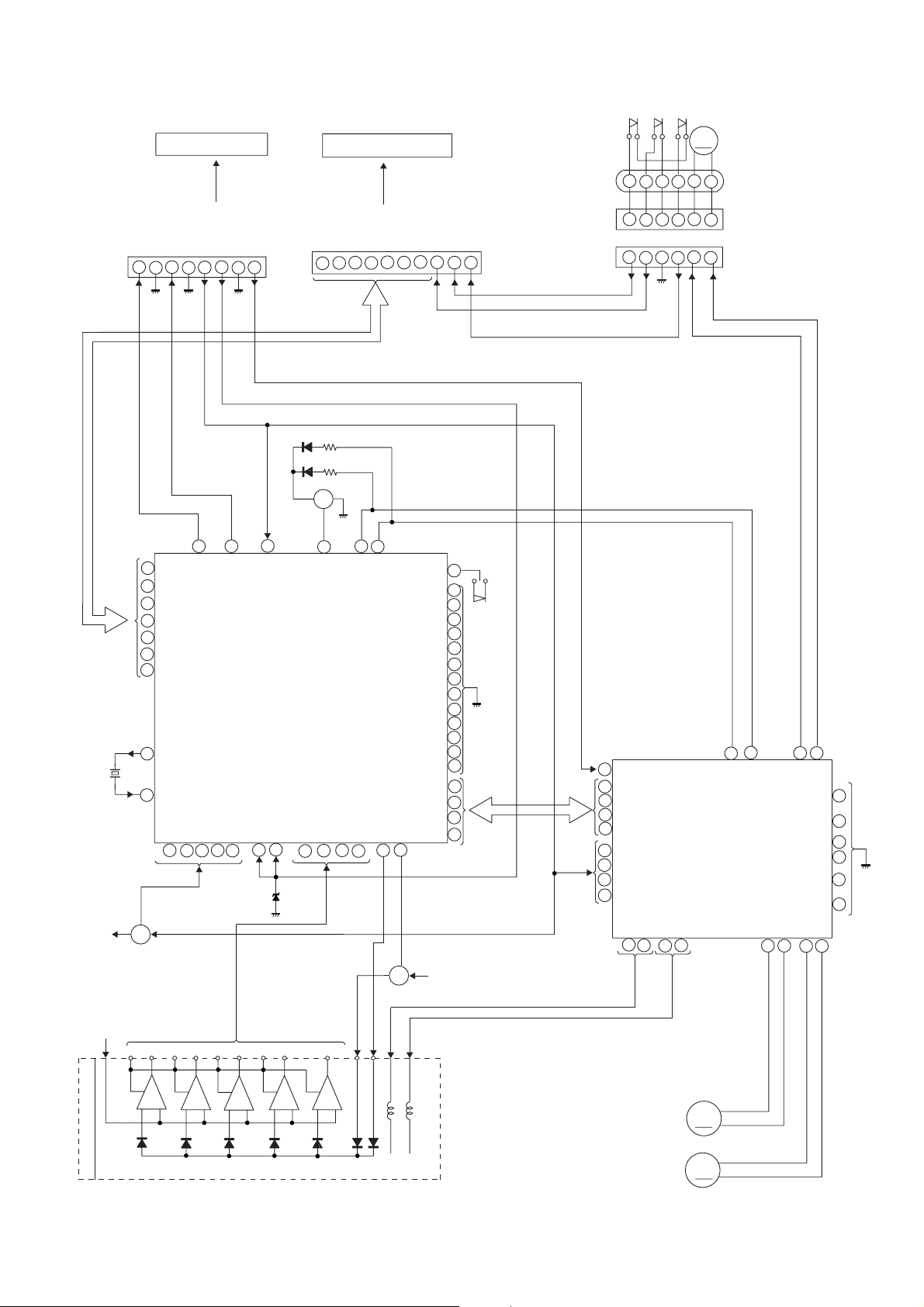

Page 11

TO MAIN SECTION

TO DISPLAY SECTION

SW1

OPEN/

CLOSE

SW2

CLAMP

SW3

DISC

NUMBER

316452

M

+–

CD-XP300H

M3

CD LOADING

MOTOR

BI4

CNP7

XL1

33.8688 MHz

A_GND

L-CH

R-CH

354

12

61

CE

62

CLK

63

DI

64

DO

65

WRQ

66

RES

67

DRF

XOUT

48

XIN

49

5

+3.3V(+B11)

D_GND

RFVDD

ADAVDD

18

+6.5V (+B4)

D_GND (DRIVER)

+5V (+B7)

+5V (+B8)

687

4245 68 25 70

VDD5

LCHO

RCHO

IC1

LC78645NE

CD SERVO

VDD

XVDD

77

38

47

VVDD

41

LVDD

46

RVDD

ZD1

3.3V

CLAMP SW

CD RES

CL

DI

DO

CE

DRF

WRQ

54

327168910

Q3

71

CONT5

FIN1 A

CONT4

FIN2 B

987

TIN1 E

10

CONT3

TIN2 F

79

CONT2

LDS

80

LDD

SLDO

SPDO

FDO

TDO

26

75

69

57

56

55

51

50

44

43

40

37

28

19

23

22

21

20

O/C

DISC NO

CNP8

SW4

PICKUP

IN

+5V

(+B7)

316452

316452

40

VCC4

25

17

2

1

18

VCC1

VCC2

24

23

VCC3

M63001FP

FOCUS/TRACKING/

SPIN/SLED

CNS4

CNP4

IC2

DRIVER

41 39 38

42

35

~~

29

22

21

14

8

+5V

(+B7)

Q2

CONSTANT

VOLTAGE

+3.3V

(+B11)

PICKUP UNIT

LASER

DRIVER

+3.3V(+B11)

Q1

FOCUS COIL

TRACKING COIL

Figure 19 BLOCK DIAGRAM (1/3)

– 19 –

4765

M2

SLED

MOTOR

M1

SPINDLE

MOTOR

M

M

162826 27

15

–

+

+

–

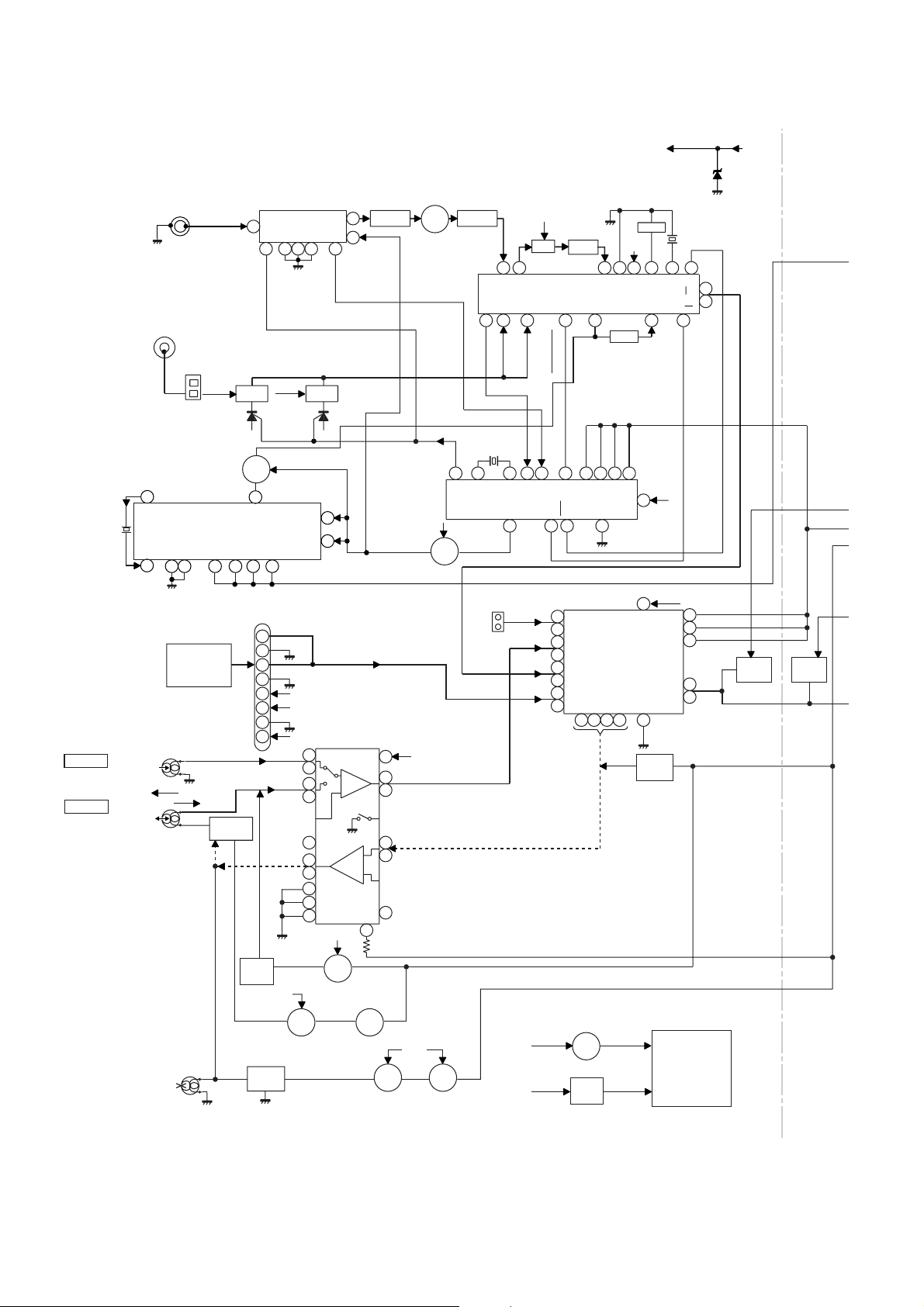

Page 12

CD-XP300H

MUTE

XT21

4.332 MHz

TAPE 1

PLAYBACK

HEAD

TAPE 2

RECORD/

PLAYBACK

HEAD

SO301A

FM ANTENNA

TERMINAL

AM LOOP

ANTENNA

CNP301

TRACKING

ICT21

LC72723

RDS DEORDER

8

X OUT

RST

VSSD

9

10

CD SERVO

SECTION

P.B.

AC BIAS

TEST

7

CNP7

FROM

REC.

14

13

Q101~

Q104

SWITCHING

X IN

L-CH

R-CH

L-CH

R-CH

ERASE

HEAD

FE301

FM FRONT END

3

7

3

11

1

24

2

23

6

T1/T2

REC

9

16

ALC

11

12

15

+B5

Q114

SWITCHING

1

5

P.B

T1/T2

SWITCHING

1

2

6

4

VT

AM

T303 T306

QT21

MPX IN

RDDA

15

BI601

Q105

Q106

BIAS OSC

AM BAND

COVERAGE

+B6

2

VDDA

VDDD

RDCL

RD-ID/

READY

16

R

1

2

L

3

4

+B7

5

+B8

6

7

+B4

8

L(T1)

R(T1)

L(T2)

R(T2)

POP

REDUCE

L REC

R REC

SWITCHING

+B5

Q112

Q111

L103

SWITCHING

CF301

IC302

LC72131

(TUNER)

VCC

SWITCHING

13

L

4

21

R

H/N

L

7

18

R

10

ALC

19

Q113

Q109

FM IF

AMP.

Q301

CF302

AM OSC OUT

+B6

T351

AM IF

21

AM MIX

21

AM OSC IN

AM RF IN

450 kHz

CF352

7

STEREO

FM MPX./AM IF

X352

4.5 MHZ

20 22 11

PLL

PB

REC

+B5

AOUT

+B5

FM

Q360

VIDEO/AUX IN

TUNER

X IN

JK690

L

R

X OUT

7

AUX

TAPE

CD

1615

MO/ST

FM/AM

10

9

9

L

R

16

10

L

R

15

11

L

R

14

12

PROCESSOR

L

R

13

IC101

AN7345K

PLAYBACK AND RECORD

/PLAYBACK AMP.

MOTOR

DRIVER

+B5

Q110

BIAS

+B3

+B3

Q706

Q707

Q708

SOLENOID

DRIVER

+B6

10.7 MHz

CF351

+B6

4

985

FM

GND

AM IF

L354

FM+B

MPX IN

162324

FM/AM

OUT

18

LOW PASS LOW

IC303

LA1832S

FM IF DET.

CLK

DO

DI

CE

5413

6

17

21

23

IC601

LC75341

AUDIO

7

81817

3

Q107

Q108

MUTING

ZD351

5.1V

X351

456 kHz

13

17

DET

VCO

14

MO/ST

PHASE

15

(FM/AM)

12

+B5

+B5

1

DI

2

CE

24

CLK

MECHANISM

21

4

TAPE

ASS'Y

R

L

–20dB

ATT

L

R

+B5

Q601

Q602

REC/PLAY

Q603

Q604

T1/T2

BIAS

SYSTEM

Figure 20 BLOCK DIAGRAM (2/3)

– 20 –

Page 13

+B5

51

Q705

~

12

+B9

FL701

FL DISPLAY

13

27

14

19

~

CD-XP300H

~

32

41

33

~

+B10

45

+B10

TO CD

SECTION

TAPE

MECHANISM

ASS'Y

0dB

T

Q601

Q602

REC/PLAY

Q603

Q604

MUTE

SYSTEM

SP DET.

IC901

STK41221

POWER AMP.

18

L

14

R

7

1

5

2

6

+B1

-B1

~

70

~

78

79

VLOAD

80

~

85

86

~

91

92

93

-

100

+B10

11

8

MICROCOMPUTER

VDD

12456 78

L-OUT

R-OUT

543859 62

5245 51

48

IC701

IX0524AW

SYSTEM

RESET

1 0 16 1 7 20 21222324

1112

9

XL700

4.194304 MHz

RESET

Q709

Q901~

Q904

D801

46

VDD

VDD

+B10

+B10

SP RELAY

ON-OFF

505549

–

Q905

40 25 13

AVDD

CLK

CEDIDO

FAN MOTOR

DRIVER

RL914

MAIN POWER

TRANSFORMER

39

34

33

~

31

37

26

15

41

+B10

PT801

RX701

REMOTE

1

SENSOR

2

KEY

SW701~SW705

SW711~SW725

SW727~SW729

TO CD

SERVO

SECTION

Q906

+B3

HEADPHONES

3

+B10

+B7

M4

M

FAN

MOTOR

SO901

SPEAKER

TERMINAL

JK701

T1/T2

BIAS

VF1

–VF

VF2

+B3

+B4

+B5

+B7

+B8

+B9

+B10

-B2

+B2

M_+13V

LD+7V

IC855

A+10V

D_5V

A_5V

SW_5V

UNSW_5.6V

KIA7812AP

VOLTAGE

REGULATOR

IC852

KIA7810AP

IC853

KIA7805AP

IC854

IC851

IC851~IC854

VOLTAGE REGULATOR

Figure 21 BLOCK DIAGRAM (3/3)

D802

AN78L05

– 21 –

F801

T4A L 125V

F802

T4A L 125V

T2A L 250V

D803, D804

F804

T2A L 250V

VOLTAGE

REGULATOR

Q801

D842~

D845

F803

T.F.

PT841

SUB POWER

TRANSFORMER

F805

T2.5A L 250V

RL841

L841

LINE

FILTER

AC POWER

SUPPLY CORD

AC 230 V, 50 Hz

Page 14

CD-XP300H

6

6

0

7

9

K

A

C652

220P

BI601

CNS601

1

TO CD

2

SERVO

PWB

3

P31 12 - D

4

CNP7

5

6

7

B

8

P26 1 - F

TO POWER SECTION

C

D

E

TAPE 1

PLAYBACK

HEAD

1

R-CH

2

L-CH

3

TAPE2

RECORD/

PLAYBACK

HEAD

F

R-CH

L-CH

ERASE

HEAD

1

2

3

4

5

6

7

G

1

2

3

4

5

6

7

8

8

19

12

11

14

1

2

3

20

1

2

3

1

2

3

4

5

6

7

CNP101

T1_R

A_GND

T1_L

M_GND

ERASE

T2_R2

A_GND

T2_R1

T2_L1

T2_L2

CNP102

R-CH

A_GND

L-CH

D_GND

D_5V

A_5V

D_GND(DRIVE)

LD+7V

LD+7V

D_GND

(DRIVE)

A_5V

D_5V

CD_D_GND

L_CH

A_GND

R_CH

CD_A_GND

FM SIGNAL

PLAYBACK SIGNAL

RECORD SIGNAL

CD SIGNAL

VIDEO SIGNAL

C102

560P

C101

560P

R619

R618

SYSTEM MUTE

330

330

C104

180P

C103

180P

Q603,604:

Q603

KTC3199 GR

Q604

KTC3199 GR

0V

0V

0V

0V

0V

0V

R617

2.2K

C637

0.001

C638

0.001

R616

2.2K

C640

1/50

Q102

2SC1845 F

0.7V

0.7V

Q104

2SC1845 F

Q103

2SC1845 F

0.7V

0.7V

Q101

2SC1845 F

R615

3.3K

R614

3.3K

+B

R620

22K

+B

R146

10K

9.3V

8.6V

Q112

9.3V

KTA1266 GR

Q112-114:

SWITCHING

R104

2.2K

R106

3.3K

R105

3.3K

R103

2.2K

Q101-106:SWITCHING

R613

390

Q601

KTC3199 GR

C635

0.001

C636

0.001

R610

2.2K

Q602

KTC3199 GR

R612

390

C639

1/50

+B

R147

10K

R148

4.7K

R109

4.7K

0V

R107

47K

R611

2.2K

R621

22K

Q113

KRC104 M

0V

2

0V

0V

2

Q114

KRC104 M

R112 15K

R102 1K

R101 1K

R108

47K

0V

0V

0V

R110

4.7K

Q105

KTC3199 GR

0V

0V

3.4V

3

1

3

3.4V

C106

560P

Q106

KTC3199 GR

C105

560P

R605 10K

R607 3.9K

R113 1K

R111 15K

C609 1/50

C607

0.1

C611 0.0022

C625

0.0022

R149 150

C141

100/16

L

PLAYBACK AND

PLAYBACK AMP.

C112

100/16

C114

0.033

R118

100K

C110

R114

330P

1K

R

C108

330P

24 23 22 21

1 2 3 4

L

C107

330P

C109

330P

R117

100K

C113

0.033

C605

0.1

C613 1/50

C615 4.7/50

C617 1/50

C619 1/50

C621 1/50

C623

1/50

R609

1.2K

IC101

AN7345K

RECORD/

R116

56

C116

560P

R120

3.9K

–

+

112K

Hich=T1

+

112K

–

R119

3.9K

C115

560P

C111

100/16

R115

56

AUDIO PROCESSOR

1

DI

CE

2

VSS

3

LOUT

4

LBASS

5

LTRE

6

LIN

7

LSEL0

8

L4

9

L3

10

L2

11

L1

12

R122

12K

R124

5.6K

C118

47/25

R123

5.6K

C117

47/25

R121

12K

R601 1K

C651

220P

IC601

LC75341

CCB

INTERFACE

+

+

C121

0.022

C119

R

0.0022

–

–

+

–

+

–

+

+

AUX

DECK

TUNER

CD

R150

68K

R126

4.7K

C143

3.3/50

R127

–

C120

0.0022

IC101

5 6 7

–

+

–

+

–

0V

R128

5.6K

18 19 20

R129

5.6K

C123

270P

4.7K

C124 270P

RBASS

RSEL0

Q108

KTC3199 GR

Hich=CHROME

R602 1K

C653

220P

24

CLK

VDD

23

VREF

C603 22/50

22

ROUT

21

20

C606

RTRE

0.1

19

C614 1/50

RIN

18

C616 4.7/50

17

C618 1/50

R4

16

R3

C620 1/50

15

R2

C622 1/50

14

C624 1/50

R1

13

C626

0.0022

R608

1.2K

REC_R

R138

R139

10K

10K

0.7V

R134

10K

R132

100

C130

0.0033

C132

R130 1.5K

C128

0.022

C126

22/50

16 17

–

+

56K

+

56K

–

8 9

10 11 12

C125

22/50

C131

47/25

R133

100

C127 0.022

R131 1.5K

C129 0.0033

C601

220/16

C608

0.1

KTC319

47/25

C133 22/50

RIPPLE

Nor/CrO2

ALC

ALC

R135

10K

C

0.

C

0.

R13

220

Q10

0.7V

C135 0.022

C134 220/10

13 14 15

Vcc

H

• NOTES ON SCHEMATIC DIAGRAM can be found on page 18.

1

23456

Figure 22 SCHEMATIC DIAGRAM (1/10)

– 22 –

Page 15

CD-XP300H

5

C130

C129

0

0033

2 1K

3

C603 22/50

C606

0.1

C614 1/50

C616 4.7/50

C618 1/50

C620 1/50

C622 1/50

C624 1/50

6

22

R608

1.2K

C601

220/16

C608

0.1

C602

0.022

C612

0.0022

C610

1/50

R606

3.9K

R603 1K

R604

10K

R642 10K

R644

22K

R643

22K

R641 10K

MAIN PWB-A1 (1/3)

R693

33K

CHASSIS

GND

22

26

28

23

24

29

27

30

25

35

34

33

32

31

L-CH

R-CH

JK690

VIDEO/

AUX IN

P25 8 - G

TO TUNER SECTION

C691

R691

390P

+B

+B

+B

+B

6.8K

R690

6.8K

C690

390P

A+10V

D_GND

TUN_R

A_GND

TUN_L

RDS_READY

RDS_RDCL

RDS_RDDA

RDS_RST

TUN_SM

CLK

R692

33K

CE

DI

DO

GR

56K

8

6K

E

.

0.0033

16

9

REC_R

R139

10K

R134

10K

C132

47/25

ALC

10 11 12

C131

47/25

R135

Q107

KTC3199 GR

0.7V

C133 22/50

C134 220/10

13 14 15

Vcc

RIPPLE

Nor/CrO2

ALC

10K

R136

220K

0V

C135 0.022

R137

220K

R158

220

0V

SWITCHING

47K

R143

22K

R144

C137

0.047

(ML)

+B

11.6V

Q109

KTA1266 GR

R142

82

(1/2W)

Q111

KTC3203 Y

+B

0V

C138

0.0082

(P.P.)

C139

0.039

(ML)

R140

47K

0V

L103

R141

4.7K

BIAS

OSC

0V

R145

4.7

330 µH

KRC104 M

11.6V

C140

47/25

2

Q110

CNP601

TUN_SM

RDS_RST

RDS_RDDA

RDS_RDCL

RDS_READY

SPAN

MIC IN

KARAOKE LATCH

CE

DO

CLK

DI

+B_PROTECT

LVL_DET

0V

3

BIAS

1

+B

M_GND

TAPE_A_GND

21

17 64151371810916

+B

A_GND(A-PRO)

A+10V

+B_PROTECT

TO POWER SECTION

D_GND

P26 1 - F

+B

M_+13V

SW_5V

UNSW_5.6V

SP_RLY

SP_DET

D_GND

S_MUTE

T_T1/T2

REC/PLAY

T_BIAS

M_+13V

A+10V

SW_5V

UNSW_5.6V

SP_DET

SP_RLY

–20dB

27

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

1

FFC701

TO

DISPLAY

PWB

P28 1 - E

CNP701

7

8 9 10 11 12

Figure 23 SCHEMATIC DIAGRAM (2/10)

– 23 –

Page 16

CD-XP300H

4

L CH OUT

R359

(UJ)

A

B

C

D

E

F

G

CHASSIS

GND

AM LOOP

ANTENNA

CHASSIS

GND

SO301A

FM

ANTENNA

TERMINAL

C302 0.001

L354

LOW PASS FILTER

C342

0.022

AM TRACKING

T303

C323

C338

0.022

0.001

AM ANTENNA

D301

DS1SS133

D302

DS1SS133

ANT

L341

GND

GND

1

1

2

2

CNP301

FM SIGNAL

COVERAGE fL

C345 0.022

C346 0.022

C321 100/16

L342

2.2 µH

R369 15

VCC

AM BAND

T306

AM OSC.

R345 4.7K

C347 0.022

C341

0.022

VT

GND

F OUT

FE301

FM FRONT END

C335

560P

C334

22P

(CH)

2

CF301

3

R344 470

R346

330

12345678

IF OUT

R348

R347

6.8K

1

680

R323

68K

C330

15P

VD301

SVC348S

C331

0.047

R336

TP301

R349 33

FM IF AMP.

Q301

2SC380 O

10K

R399

33

C348

0.01

C332

0.022

1

2

+B

3

CF302

C381

12P(CH)

4.5 MHz

C382

15P(CH)

R365

10K

R358

3.9K

AM OSC OUT

R351 5.6K

FM IF IN

123 456 78 9

C351 0.022

C350 0.022

C352 10/50

+B

C394

47/25

R381

10K

C393

1/50

VSS

AOUT

X OUT

X IN

CE

123456789

C383

47P

R374 1K

X352

R382

150

C397

0.022

C361 0.022

C362 3.3/50

C363 0.022

FM AFC

AM RF IN

AM OSC IN

REG

AM MIX OUT

T351

AM IF

C392

0.001

C380

10/50

R380

1.5K

PD

AIN

DO

CLK

DI

R378 1K

R372 1K

R373 1K

C364 2.2/50

R352

1K

C387

2.2K

R379

VDD

FM IN

FM/AM

IC302

LC72131

PLL(TUNER)

VSM

AM LOW CUT

AM IF IN

CF352

C389

0.022

0.001

C385

0.01

AM IN

IF

FM/AM

CONT

C367

1/50

FM/AM OUT

GND

SD

C353

L351

100 µH

1213141516171819202122

SD

IF IN

MO/ST

10 11

R350

2.7K

C366 0.001

C365 0.022

0.022

C386

330P

ST IND

R376

X351

456 kHz

STEREO

FM DET

R353

270

C354 0.022

CF351

R393

1K

R377

47K

1K

R386

22K

TP302

C399

+B

MPX IN

MPX VCO

VCC

10 11

C398

0.022

100/10

R395

47K

R360

4.7K

470K

R357

1K

R356

1/50

C368

IF OUT

PHASE

C357

2.2/50

C356

0.001

C355

15161718192021222324

C358

1/50

C374 0.015

27P

C369

1

R-CH OUT

22P

3.9K

R388

5.6K

R387

AM SIGNAL

H

• NOTES ON SCHEMATIC DIAGRAM can be found on page 18.

1

23456

Figure 24 SCHEMATIC DIAGRAM (3/10)

– 24 –

Page 17

CF351

ILTER

TP302

X351

56 kHz

MPX VCO

FM DET

VCC

89

R353

270

C399

C398

0.022

+B

7

R395

47K

R360

4.7K

R386

22K

470K

R357

1K

R356

C374 0.015

1/50

C368

27P

C369

MPX IN

R-CH OUT

IF OUT

PHASE

C358

10 11 12

1/50

C357

2.2/50

C356

0.001

22P

C355

3.9K

R388

100/10

5.6K

R387

C373

0.015

C371 1/50

C372

1/50

(UJ)

1314151617

IC303

MO/ST

LA1832S

L-CH OUT

FM IF DET./FM

MPX./AM IF

(FM/AM)

PHASE

R355

3.3K

1/50

C370

L352

100 µH

C396

100/10

Q360

KTA1266 GR

R385

R359

1.8K

5.6K

+B

ZD351

DZ5.1BSB

C395 0.022

R391

R383

5.6K

C391

47/25

R384

5.6K

270

R392

270

+B

TUNER PWB-A1 (2/3)

R370

1K

C388

0.001

C384

0.001

CNP303

CD-XP300H

RDS PWB-A4

RT32

6.8K

RT31

10K

CT21

47/25

RT21

RT27

10K

1K

RT28

1K

CNS303

1

1

2

2

3

3

4

4

5

5

6

6

7

7

RT29

1K

RT30 1K

ICT21:

RDS DECORDER

CT23

22P(CH)

XT21 4.332 MHz

ICT21

LC72723

XIN

9

CT22

VSSD

10

0.022

VDDD

11

MODE

12

RST

13

RDDA

14

RDCL

15

RDS-ID/

READY

16

LT21

2.2 µH

CT24

47/25

ZDT21

DZ5.1BSB

XOUT

TEST

CIN

FLOUT

VSSA

VDDA

MPXIN

VREF

RT24

56K

10K

CT28

0.022

CT29

0.022

RT26

QT21

KTC3199 GR

CT30 0.022

CT31

47/25

CT32

47/25

RT23

390

56K

CT25

22P

(CH)

RT25

8

7

CT26

6

560P

5

CT27

4

0.022

3

2

1

LT22

2.2 µH

RT22

390

+B

+B

TUN_R

TUN_L

TUN_SM

RDS_RST

RDS_RDDA

RDS_RDCL

A_GND

D_GND

A+10V

DO

CLK

DI

CE

22 35343332313029282726252423

TO MAIN SECTION

P23 12 - C

7

8 9 10 11 12

RDS_READY

Figure 25 SCHEMATIC DIAGRAM (4/10)

– 25 –

Page 18

CD-XP300H

W

8

0

G

A

B

C

D

E

F

TO MAIN SECTION

G

C901

0.22/50

L_CH

1

2

3

4

6

7

8

9

10

11

P22 1 - C,P23 9 - H

12

13

14

15

16

17

18

19

20

21

+

–

18 17 16 15 14 13 12 11 10

C907

R903 1K

100P

C905

22/50

R907

R905

C906

560

C903

220P

R901

A_GND

R-CH

SP_DET

SP_RLY

M_+13V

560

R906

C904

220P

R902

56K

56K

LD+7V

A+10V

+B_PROTECT

D_5V

A_5V

SW_5V

CD_D_GND

UNSW_ 5.6V

A_GND (A-PRO)

M_GND

D_GND

CD_D_GND(DRIVE)

CD_A_GND

TAPE_A_GND

56K

22/50

C908

C909

0.1/50

C902

0.22/50

C910

3.3P(CH)

3.3P(CH)

R909

100/100

C913

R904

R911 56K

33K

C911

–

+

100P

R912

100

1K

Fusible

(1/4W)

C912

100/100

-B

R958

100

Fusible

(1/4W)

+B

+B

+B

+B

+B

+B

IC852,853:

VOLTAGE REGULATOR

+B

C861

0.047

(ML)

9 8 7 6 5 4 3 2 1

R913

0.22(3W)

+B

-B

R910

C914

100/100

1K

C915

100/100

IC855

KTC2026

SILICON

C863

22/50

R859 22K

ZD852

DZ8.2BSB

D857

DS1SS133

3 1

2

C860

47/25

D856

DS1SS133

+B

R916

0.22(3W)

R917

C917

0.022(ML)

DS1SS133

Q901

KTC3199 GR

SP_DET

+B

+B

R852

10K

0.1(3W)

C916

D906

DS1SS133

D905

KIA7812AP

REGULATOR

(ML)

R854 22K

C851 0.047

R853

22K

C857

47/25

VOLTAGE

R918

1.5K

R919

1.8K

Q902

KTC3199 GR

R920

1.8K

C919

0.022

R921

(ML)

1.5K

R922

0.1(3W)

-B

R908

1K

R860

220

C865

10/50

D852

DS1SS133

D851

DS1SS133

IC854

AN78L05

VOLTAGE REGULATOR

IC901

STK41221

POWER AMP.

100/50

C918 100/50

C920

3300/71

VH–

IC851

13 V

3 1

2

D858

DS1SS133

D859

C852 22/50

DS1SS133

IC852

KIA7810AP

3

2

C854

0.1

C853

(ML)

47/25

IC853

KIA7805AP

3 1

2

C858

0.022

C862

10/50

-B

ZD902

DZ150BSB

R927 22K

-B

R929

47K

D909

DS1N404S

-B

1

R858 220

DS1N404S

R925

1.5K

C921

4700/35

VL–

-B

+B

C864

0.1

(ML)

+B

C855

0.1(ML)

D855

DS1SS133

+B

C859

0.1(ML)

D853

+B

ZD903

DZ15BSB

R926

1.5K

R928

22K

C922

4700/35

D907 DS1SS133

C923

3300/71

VL+

+B

18V

C856

3300/35

+B

R930

47K

D910

DS1N404S

VH+

+B

Q904

KTC3199 GR

+B

+B

Q903

KTC3199 GR

C925

47/50

-B

LG2

CHASSIS GND

BI801

L902

0.29 µH

R934

56K

56K

R937

R935

56K

L901

0.29 µH

LG1

CHASSIS

1

2

3

4

5

6

7

8

9

10

DISPLAY P

P29 12 - D

CNS705

CNS8

TO

10

11 11

CNP

1

2

3

4

5

6

7

8

9

H

• NOTES ON SCHEMATIC DIAGRAM can be found on page 18.

1

23456

Figure 26 SCHEMATIC DIAGRAM (5/10)

– 26 –

Page 19

Q903

KTC3199 GR

C925

47/50

4S

R937

0.29 µH

R934

56K

56K

R935

56K

L901

0.29 µH

L902

R

L

C927

0.22

C929

0.22

R941

10

(1/2W)

+B

C926

0.22

C928

0.22

R938

10

(1/2W)

R939 10(1/2W)

R940 10(1/2W)

+B

R942 390(2W)

R943 390(2W)

D911

DS1SS133

0.2 V

Q905

KTC3199 GR

SP RELAY

ON-OFF

R944

1.5K

RL914

4.4 V

R946

47K

CD-XP300H

AMP. PWB-A1 (3/3)

FM SIGNAL

C930

47/50

Q906

M_+13.5V

SP_RLY

R-CH

GND

L-CH

C942

CNP971

FAN

MOTOR

DRIVER

HLD803

C943

0.001

0.001

2

1

1

5

+

+

–

–

2

1

CNS971

FW803

CNP705

R-CH

L-CH

L-CH GND

R-CH GND

+

M4

FAN

–

M

MOTOR

HEADPHONES

PWB-B2

C718

1

100P

2

3

4

L702

5

2.2µH

SO901

SPEAKER

TERMINAL

C719

100P

JK701

HEADPHONES

R948

+B

D912

DS1SS133

C931

10/50

0.29 µH

C935

0.022

C937

0.022

R953

6.8

4.7(1/2W)

L921

R949

R950

68K

C939

0.022

C941

0.022

R955

6.8

1K

KTC3203 Y

R

R1_OUT

C934

0.022

C936

0.022

R952

6.8

L

R947

15K

L920

0.29 µH

C938

0.022

C940

0.022

R954

6.8

R945

1.5K

L1_OUT

+B

+B

BI801

1

-B

2

3

4

5

6

7

8

9

10

11

DISPLAY PWB

LG2

CHASSIS GND

LG1

CHASSIS GND

CNS801

1

2

3

4

5

6

7

8

9

10

11

TO

P29 12 - D

CNS705

CNP802

-B

CNP801

1

VH–

2

-B

VL–

3

4

VL+

5

6

7

8

9

10

11

1

2

3

4

5

AC_RLY

VH+

SUB_B

+B

R801

220K

R804

–VF

VF1

P_IN

R803

47

VF2

12K

+B

+B

D803 DS1N404S

D804 DS1N404S

C806

0.1

C802 47/50

C801 100/35

ZD801

DZ6.2BSA

R805

47

R841 220K

D802

D3SBA60F

C807

0.1

C803

47/50

R806

47K

-B

R842 1K

TRANSFORMER PWB-A2

D801

D5SBA60F

+B

Q801

KTA1274 Y

VOLTAGE

REGULATOR

C809

0.1

ZD802

DZ6.2BSA

R802

47K

R808

2.2K

C808

0.1

ZD803

D805

DZ30BSB

C804

220/63

Q841

KTC3199 GR

R843

47K

C810

0.22(ML)

C811

0.22(ML)

F801

T4A L 250V

F802

T4A L 250V

F803

T2A L 250V

T2A L 250V

DS1N404S

D806

F804

C805

22/50

DS1N404S

C841

D842-845:DS1N404S

1000/6.3

C842

470/35

D845

D844

PT801

MAIN POWER

TRANSFORMER

T.F.

D842

C843

D843

HLD804B

0.047

1

(ML)

4

FW804

When Servicing, pay attention as the area

enclosed by this line ( ) is directly

connected with AC main voltage.

POWER PWB-A3

F805

T2.5A L 250V

RL841

D846

DS1SS133

1

HLD804A

4

PT841

SUB POWER

TRANSFORMER

L841

LINE

FILTER

K801

K802

C844

0.0047/250

AC POWER

SUPPLY CORD

AC 230 V, 50 Hz

7

8 9 10 11 12

Figure 27 SCHEMATIC DIAGRAM (6/10)

– 27 –

Page 20

CD-XP300H

5

G6

D

/

T

W

T

0

5

1

K

A

B

C

D

E

F

TAPE

MECHANISM

PWB-F

TAPE

MOTOR

-

M

+

G

SOLENOID

SOLENOID

PLAY

F. PLAY

CASSETTE

TO MAIN PWB

P23 12 - F

CNP601

PH

R794

1.5

F

P21

P20

P19

P18

P17

P16

P15

P14

P13

P12

P11

P10

C707

1/50

C706

47/25

R752

33

+B

FFC701

27

27

TUN SM

26

RDS-RST

25

RDS-RDDA

24

RDS-RDCL

23

RDS-READY

22

21

20

19

CE

18

DO

17

CLK

16

DI

15

+B_PROTECT

14

LVL_DET

13

D_GND

12

S_MUTE

11

T_T1/T2

10

REC/PLAY

9

T_BIAS

8

M_+13V

7

A+10V

6

SW_5V

5

UNSW5.6

4

SP_DET

3

SP_RLY

2

– 20dB

1

CNP701

1

FFC702

CNP702

1

T2_PLAY SW

1

2

3

4

5

6

7

8

1

GND

2

T2 RUN

3

+MTR

4

SOL2

5

SOL1

6

F_REC

7

T1 RUN

8

8

+B

D710

DS1SS133

45 41 40 39 31 38 37 36 35 34 33 32

R792

100K

+B

R772 10K

R770 10K

DS1SS133

R740 4.7K

Q705

KTC3199 GR

R738

47K

DS1SS133

DS1SS133

D709

D702

D701

R789

R793

1K

10K

C712

47/25

R788

10K

MOTOR

DRIVER

KTA1273 Y

+B

P09

30 29 28 27 19 18 17 16 15 14 13 12 11 1

R745 1K

R744 1K

R743 1K

R742 1K

R746 1K

R734 1K

R735 1K

R732 1K

FPA/FPB

Q706

KTA1273 Y

Q707

Q708

KTA1273 Y

Q707,708:

SOLENOID DRIVER

FL701

FL DISPLAY

P08

P07

81 82 83 84 85 86 87 88 89 90 91 92 93 94 9

80

S11

79

VLOAD

S13

78

77

S14

76

S15

S16

75

74

S17/DIST0

73

S18/DIST1

S19/DIST2

72

71

S20/DIST3

S21

70

69

DIST

68

67

66

65

64

63

RDS READY

62

RDS RDCL

61

RDS RDDA

60

RDS RST

59

58

57

56

55

54

53

52

51

+B

M_+13V

R777

10K

R778

10K

R779

10K

P06

S6S7S8

S9

S10

80

S12

MICROCOMPUTER

52

T1 RUN

T2 RUN

51

TIMER LED

VDD

AC_RLY

SP_

RLY

R730

1K

10K

R731

R729 560

R762

10K

R780

10K

P05

P04

P03

P02

IC701

IX0524AW

SYSTEM

T_SOL_B

SMUTE

T_SOL_A

T_MOTOR

R725 1K

R726 680

R727 680

R728 2.2K

P01

G08

G09

S1S2S3S4S5

G9G8G7

T2_PLAY SW

FPA/FPB S

PROTEC

LVL_DE

REMOCON

VSS

R733 1K

R724 1K

R765

4.7K

LED701

SLR342VCJ

G06

G07

VD

CD CLAMP SW

P_IN

SP DET

363738394041424344454647484950

R736 1K

R721 1K

R7

4.7

R76

10

H

• NOTES ON SCHEMATIC DIAGRAM can be found on page 18.

1

23456

Figure 28 SCHEMATIC DIAGRAM (7/10)

– 28 –

Page 21

P06

1K

10K

P05

P04

P03

P02

P01

G06

G07

G08

IC701

SYSTEM

T_SOL_B

SMUTE

T_SOL_A

R725 1K

R726 680

R727 680

G09

S1S2S3S4S5

G9G8G7G6G5G4G3G2G1

VDD

T2_PLAY SW/

FPA/FPB SW

PROTECT

LVL_DET

SP DET

CD CLAMP SW

P_IN

REMOCON

VSS

R736 1K

R733 1K

R721 1K

R724 1K

19 18 17 16 15 14 13 12 11 10 98765 1

85 86 87 88 89 90 91 92 93 94 95 96 97 98 99

S6

S7

S12

IX0524AW

MICROCOMPUTER

2

T1 RUN

T2 RUN

1

T_MOTOR

TIMER LED

VDD

R728 2.2K

R729 560

G04

G05

-20dBATT

1

T-REC/PLAY

CD RESOUT

CD_WRQ

CD_DRF

CD CLK

28

29

30

DISC_NO SW

TUN SM

AVDD

AVREF

R720 1K

G02

G03

T-BIAS

T_T1/T2

RESET

VPP/IC

VDD

CD DI

CD DO

CD CE

CLK

DO

AVSS

KEY 1

KEY 0

R719 1K

G01

100

1

2

3

4

5

6

7

8

9

10

X2

11

X1

12

13

14

15

16

17

18

19

20

CE

21

22

DI

23

24

25

26

27

28

29

30

KEY 2

31323334353637383940414243444546

R718 1K

F

C703

0.022

R763 1K

R702 1K

R703 1K

R704 1K

R705 1K

R706 1K

R708 1K

C704 15P

XL700

4.194304 MHz

R769 1K

R709 1K

R710 1K

R711 1K

R712 1K

R713 1K

R714 1K

R715 1K

R716 1K

R717 100

R737 100

R739 1K

C720 0.022

R722 1K

C705

18P

R759

5.6K

C701

1/50

C702

220/10

R791

4.7K

CD-XP300H

DISPLAY PWB-B2

R795 1.5

+B

VF2

–VF

P_IN

VF1

D711

10

9

8

7

6

5

4

3

2

1

1

2

3

4

5

BI701

BI705

CNS701

10

9

8

7

6

5

4

3

2

1

CNS705

1

2

3

4

5

TO CD

SERVO

PWB

P31 12 - B

CNP8

TO

POWER

PWB

P27 7 - F

CNP802

DISC_NO SW

O/C_SW

CLAMP SW

+B

R747

4.7K

RES OUT

CD CLK

CD DI

CD DO

CD CE

DRF

WRQ(DSP)

AC_RLY CON

DS1SS133

D712

D714

DS1SS133

REMOTE SENSOR

C714

3.3/50

R782

100K

DS1SS133

RD25

3.9K

SW727SW725

DISPLAY

MODE

RD16

3.9K

SW717

RECORD

PAUSE

DS1SS133

RX701

123

RD26

5.6K

SW728

ASPM

RD17

5.6K

MEMORY

/SET

C716

+B

0.022

SW729

PTY TI

SEARCH

RD18

10K

SW719SW718 SW720SW716

TUNING

/TIME

DOWN

R783

100

C717

47/25

CLOCK

R773

10K

+B

R765

0

4.7K

LED701

SLR342VCJ

R761

10K

R756

4.7K

R768

10K

R767

10K

R766

10K

+B

KEY 2

KEY 1

KEY 0

5V BACK UP

VOLUME

RD10

SW701

ON/STAND-BY

+B

+B

RD20

RD19

680

UP

680

SW711 SW712 SW713

CD

RD01

680

RD21

820

SW722

VOLUME

DISC

DOWN

SKIP

RD11

RD12

820

TUNER

TAPE

(BAND)

RD02

820

SW702

FAST

REWIND/

PRESET DOWN

1K

1K

L701

100 µH

RD22

1.5K

SW724SW723SW721

OPEN/

CLOSE

RD13

1.5K

SW714

VIDEO

/AUX

RD03

1K

SW703

FAST

FORWARD

/PRESET UP

D713 DS1SS133

RESET

R781

Q709

47K

KRC102 M

C715

1

0.01

RD23

RD24

2.2K

EQUALIZER

/X-BASS/DEMO

RD14

2.2K

SW715

TIMER/

TUNING/

SLEEP

TIME UP

RD04

1.5K

SW704 SW705

STOP

UN_SW5V

32

D715

2.7K

RD15

2.7K

PLAY/

REPEAT

7

8 9 10 11 12

Figure 29 SCHEMATIC DIAGRAM (8/10)

– 29 –

Page 22

CD-XP300H

D

L

C

V

+

)

)

)

)

N

O

3

0

A

CD SERVO PWB-C

PICKUP UNIT

B

C

D

PICKUP

HPC1LX

TR+

TR–

FO+

FO–

CD MOTOR PWB-D

M1

SPINDLE

E

F

MOTOR

M2

SLED

MOTOR

SW4

PICKUP IN

GND

M

M

TR+

FO+

VCC

VREF

+

SPIN

–

+

SLIDE

–

PU-IN

E

A

B

F

C

TR–

VR

LD

CD SIGNAL

+B

7

7

6

6

5

5

4

4

3

3

2

2

1

1

CNS1B

1

1

2

2

3

3

4

4

5

5

PD

6

6

7

7

8

8

CNS2B

6

6

5

5

4

4

3

3

2

2

1

1

7

6

5

4

3

2

1

CNS1A

1

2

3

4

5

6

7

8

CNS2A

6

5

4

3

2

1

7

6

5

4

3

2

1

1

2

3

4

5

6

7

8

6

5

4

3

2

1

VCC

VREF

R6 22K

E

R5 8.2K

A

R4 8.2K

B

F

R3 22K

C

R1

8.2K

CNP1

C1

47/25

TR–

TR+

FO+

FO–

GND

PD

VR

LD

+B +B

CNP2

SP+

SP–

SL+

SL–

PUIN

GND

100/10

C40

220/6.3

R2

C39

MUTE

8.2K

C2

C38

0.01

0.01

21

VREF

20

STANDBY

19

R44

18

+

+B

R9

3.3

Q1

LASER DRIVER

KTA1266 GR

12K

SL–

VCC

SL+

SLDO

16

15

17

+

+

R7

47

+B

0.047

R10

47/25

C53

0.001

11

27K

TP3

+B

22P(CH)

100/10

100P(CH)

+B

GND

10

8

9

7

14

C52

0.001

C3

C4

0.001

12 13

IC2

M63001FP

FOCUS/TRACKING/

C5

C6

0.1

C50

C9

C12

C54

0.022

TR–

R12

330

TR+

6

0.0027

2

FO–

5

R11

10K

1

2

3

4

C8

5

6

7

TP1

8

TP2

9

10

C10

11

10/50

12

13

14

C11

15

0.22/50

16

17

+B

18

19

20

1K

R13

1

R14

1K

FO+

FD

4 3 2 1

R42

1.2K

80

LDD

EFMIN

RF

RFVDD

RSVSS

FIN1 A

FIN2 B

TIN1 E

TIN2 F

VREF

REF1

FE

TEC

TE

RFMON

JITTC

FDO

22

21

TO

SPIN/SLED DRIVER

CNP3

CNS3A

CNS3B

CNP3A

22

+

+

+

+

+

LD_M+

23

24

VCC2

25

SPO

26

SP+

27

SP-

28

VCC3

+B+B

29

30

31

32

33

C41

100/10

34

35

36

C46

100/10

37

38

M–

39

LD_M–

42

40

41

M+

VCC4

+B

+B

79 78

LDS

SPDO

R15

R41

77

FR

5

4

6

SLDO

232425

R16

1K

C34 100P(CH

C33 0.022

C32 100P(CH

C30 100P(CH

C57 56P(CH)

C28 100P(CH

C27 0.022

0.1

C36

C37

12K

680

R40

76

74

75

VVSS

VVDD

PCKIST

1

SLCO

2

SLCIST

LC78645

CD SERV

ADAVDD

18

ADAVSS

19

TDO

20

CONT5

CONT4

GPDAC

27

26

1K

R17 1K

R18 1K

DS1SS133

C35

0.22/50

0.047

680

R39

73

72

70

69

71

PDO2

PDO1

CONT2

CONT3

78

IC1

L

L

FSEQ

V/*P

DEFECT

SBCK/FG

32

31

30

28

29

R20

10K

R46

820

D2

32

Q

1

KRC1

VSS

MONI1

G

H

• NOTES ON SCHEMATIC DIAGRAM can be found on page 18.

1

23456

Figure 30 SCHEMATIC DIAGRAM (9/10)

– 30 –

Page 23

CD-XP300H

1K

61

CE

TEST

40

100/10

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

C22

0.01

C44

0.001

12

R38 1K

R37 1K

R36 1K

R35 1K

R34 1K

R33 1K

R32 1K

+B

R29

2.2K

R28

2.2K

11

10

XL1

33.8688 MHz

R43

220

ZD1

DZ3.3BSB

C16

330/6.3

+B

C23

10/25

R24

2.2K

0.0015

R26

10K

C25

R22

100

C24

R25

2.2K

C26

0.0015

R27

10K

+B

10/25

1

WRQ

2

DRF

CE

3

4

+B

+B

DO

5

DI

6

CLK

CD RES

7

CLAMP SW

8

9

O/C

10

DISC NO

CNP8

R-CH

1

A_GND

2

L-CH

3

D_GND

4

D_5V

5

A_5V

6

D_GND (DRIVER)

7

+6.5V

8

CNP7

CNS4

CNP4

1

1

2

2

3

3

4

4

5

5

6

6

CNS701

P29 12 - C

FROM DISPLAY PWB

CNS601

P22 1 - B

FROM MAIN PWB

CD LOADING

MOTOR PWB-E

BI4

1

2

3

4

5

6

OPEN/CLOSE

+

M

–

M3

CD LOADING

MOTOR

SW1

SW2

CLAMP

SW3

DISC

NUMBER

+B

R31

1K

+B

R23

+B

+B

220

+B

C42

0.01

C51

0.022

L1 0.82 µH

+B

+B

+B

+B

+B

0.022

CONSTANT

VOLTAGE

Q2

C18

100/10

KTC3203 Y

C48

(1/4W)

Fusible

R51

3.3

R47

100

ZD2

DZ3.9BSB

C34 100P(CH)

C33 0.022

C32 100P(CH)

C30 100P(CH)

C57 56P(CH)

C28 100P(CH)

C35

0.047

680

R39

72

70

71

PDO1

CONT2

IC1

V/*P

DEFECT

SBCK/FG

31

30

29

R20

10K

R46

820

D2

1

KRC102 M

+B

69 68

VSS

CONT3

DATA

BCK

LVSS

LCHO

LVDD

MONI1

FSEQ

33

32

Q3

R49

66

67

DRF

VDD5

378

60

59

43

42

41

MONI3

MONI2

35

34

9

C13

0.022

R45

820

DS1SS133

1

65

64

DO

*RES

*WRQ

ASDFIN

ASDACK

ASLRCK

16MOUT

FSX/16MIN

VSS

MONI5

MONI4

36

38

37

+B

D1

63 62

DI

LRCK

EFLG

XVSS

XOUT

XVDD

RVDD

RCHO

RVSS

VDD

C2F

39

C14

CLK

XIN

DOUT

C27 0.022

B

0.1

C36

C37

0.22/50

12K

R41

680

R40

77

76

74

73

75

78

FR

VVSS

PDO2

VVDD

PCKIST

5

D

1

SLCO

S

2

SLCIST

A

B

E

F

LC78645NE

CD SERVO

4

ADAVDD

18

ADAVSS

19

TDO

20

N

6

CONT5

CONT4

GPDAC

SLDO

27

26

232425

R16

1K

28

R17 1K

R18 1K

DS1SS133

32

• The numbers 1 to 12 are waveform numbers shown in page 40.

7

8 9 10 11 12

Figure 31 SCHEMATIC DIAGRAM (10/10)

– 31 –

Page 24

VOLTAGE

CD-XP300H

PIN

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

PIN

NO.

1

2

3

PIN

NO.

1

2

3

PIN

NO.

1

2

3

PIN

NO.

1

2

3

IC101

VOLTAGE

0 V

0 V

0.58 V

1.998 V

N.C.

1.303 V

0 V

0.587 V

3.54 V

3.48 V

0 V

0 V

7.03 V

4.2 V

0 V

3.45 V

0.587 V

0 V

2.00 V

N.C.

2.02 V

0.581 V

0 V

0 V

IC851

VOLTAGE

20.2 V

1.351 V

13.41 V

IC852

VOLTAGE

19.8 V

0 V

10.09 V

Q853

VOLTAGE

20.4 V

0 V

5 V

IC854

VOLTAGE

20.48 V

0.59 V

5.72 V

PIN

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

PIN

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

IC601

VOLTAGE

0 V

0 V

0 V

5 V

5 V

5 V

5 V

5 V

5 V

5 V

5 V

5 V

5 V

5 V

5 V

5 V

5 V

5 V

5 V

5 V

5 V

5 V

10.07 V

0 V

IC303

VOLTAGE

2.13 V

5.16 V

2.13 V

2.13 V

0 V

5.23 V

5.23 V

3.8 V

5.15 V

4.43 V

1.836 V

1.265 V

2.32 V

1.26 V

1.268 V

2.12 V

0 V

5.01 V

5.02 V

5.02 V

5.04 V

5.04 V

10.08 V

0 V

PIN

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

PIN

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

VOLTAGE

1.6 V

1.0 V

1.6 V

1.0 V

3.3 V

0 V

1.6 V

1.6 V

1.6 V

1.6 V

1.6 V

1.6 V

1.5 V

1.5 V

1.5 V