Page 1

1

AH/AY-X08CR

AH/AY-X10CR

AH/AY-X13CR

S3214AYX13CR/

SPLIT TYPE

ROOM AIR CONDITIONERS

In the interests of user-safety (Required by safety regulations in some

countries) the set should be restored to its original condition and only

parts identical to those specified should be used.

SER VICE MANU AL

Page

SPECIFICATIONS ............................................................................................................................................. 2

EXTERNAL DIMENSIONS .................................................................................................................................4

WIRING DIAGRAMS ......................................................................................................................................... 6

ELECTRICAL PARTS.........................................................................................................................................9

BLOCK DIAGRAM ............................................................................................................................................10

MICROCOMPUTER CONTROL SYSTEM .......................................................................................................12

FUNCTIONS .................................................................................................................................................... 19

FUNCTION AND OPERATION OF PROTECTIVE PROCEDURES ............................................................... 25

BREAKDOWN DIAGNOSIS PROCEDURE .................................................................................................... 27

REFRIGERATION CYCLE ............................................................................................................................. 30

PERFORMANCE CURVES ............................................................................................................................. 32

DISASSEMBLING PROCEDURE.................................................................................................................... 33

OPTION ........................................................................................................................................................... 41

REPLACEMENT PARTS LIST ........................................................................................................................ 42

REFRIGERANT PIPING INSTALLATION/SERVICE MANUAL FOR AIR CONDITIONERS USING R-410A.. 49

TABLE OF CONTENTS

INDOOR UNIT

AH-X08CR/10CR/13CR

AY-X08CR/10CR/13CR

OUTDOOR UNIT

AU-X08CR/10CR/13CR

AE-X08CR/10CR/13CR

MODELS

SHARP CORPORATION

New Refrigerant : R-410A

Page 2

2

AH/AY-X08CR

AH/AY-X10CR

AH/AY-X13CR

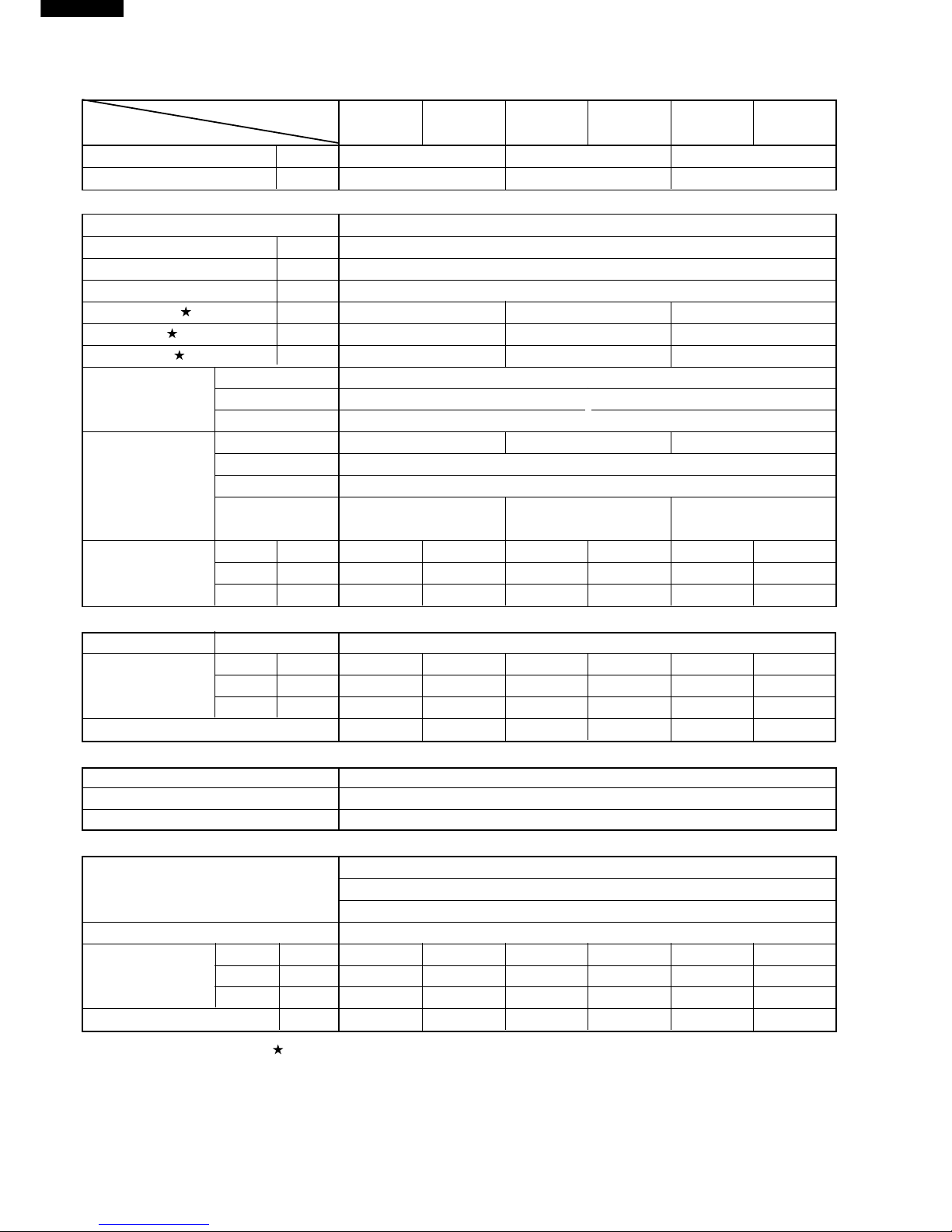

SPECIFICATIONS

MODEL

I

NDOOR UNIT

OUTDOOR UNIT

INDOOR UNIT

OUTDOOR UNIT

INDOOR UNIT

OUTDOOR UNIT

ITEMS AH-X08CR AU-X08CR AH-X10CR AU-X10CR AH-X13CR AU-X13CR

Cooling capacity

(Min. ~ Max.)

kW 2.2(0.9 _ 2.7) 2.8(0.9 _ 3.3) 3.6(0.9 _ 4.0)

Moisture removal Liters/h 0.6 0.7 1.3

Electrical data

Phase Single

Rated frequency Hz 50

Rated voltage range V 198 to 264

Rated voltage V 220 - 240

Rated current A 3.4 _ 3.1 4.3 _ 4.0 5.5 _ 5.1

Rated input W 730 930 1200

Power factor % 98 _ 98 98

_

97 99 _ 98

Type Hermetically sealed rotary type

Compressor Model DA89X1F-20F

Oil charge Ester oil VG68 370ml

Evaporator Bare tube type Grooved tube type Grooved tube type

Refrigerant system Condenser Louver Fin and Grooved tube type

Control Capillary tube

Refrigerant volume

640g 690g 660g

(R-410A)

Noise level

High dB(A) 33 43 36 43 38 48

(at cooling)

Med. dB(A) 29 – 32 – 33 Low dB(A) 27 – 27 – 29 -

Fan system

Drive Direct drive

Air flow quantity High m3/min. 7.5 28 8.7 28 9.3 30

(at cooling) Med. m3/min. 6.8 – 7.8 – 8.1 –

Low m3/min. 6.0 – 6.0 – 6.6 –

Fan

Cross flow fan Propeller fan Cross flow fan Propeller fan Cross flow fan Propeller fan

Connections

Refrigerant coupling Flare type

Refrigerant tube size Gas, Liquid 3/8", 1/4"

Drain piping mm O.D ø 18

Others

Compressor: Compressor thermistor

Safety device Fan motors: Thermal fuse

Fuse, Micro computer control

Air filters Polypropylene net (Washable)

Width mm 815 780 815 780 815 780

Net dimensions Height mm 278 540 278 540 278 540

Depth mm 198 269 198 269 198 269

Net weight kg 9 30 9 30 10 33

Note: The condition of star " " marked item are ‘ISO5151’ : 1994(E), condition T1.

Page 3

3

AH/AY-X08CR

AH/AY-X10CR

AH/AY-X13CR

MODEL

I

NDOOR UNIT

OUTDOOR UNIT

INDOOR UNIT

OUTDOOR UNIT

INDOOR UNIT

OUTDOOR UNIT

ITEMS AY-X08CR AE-X08CR AY-X10CR AE-X10CR AY-X13CR AE-X13CR

Cooling capacity

(Min. ~ Max.)

kW 2.2(0.9 _ 2.7) 2.8(0.9 _ 3.3) 3.6(0.9 _ 4.0)

Heating capacity

(Min. ~ Max.)

kW 3.2(0.9 _ 3.6) 3.7(0.9 _ 5.0) 4.8(1.0 _ 6.2)

Moisture removal(at cooling) Liters/h 0.7 0.8 1.3

Electrical data

Phase Single

Rated frequency Hz 50

Rated voltage range V 198 to 264

Rated voltage V 220 - 240

Cool A 3.4 _ 3.1 4.3 _ 4.0 5.5 _ 5.1

Rated current Heat A 4.2 _ 3.9 4.9 _ 4.5 6.8 _ 6.2

Cool W 730 930 1200

Rated input Heat W 910 1050 1480

Cool % 98 _ 98 98 _ 97 99 _ 98

Power factor Heat % 98 _ 97 97 _ 97 99 _ 99

Type Hermetically sealed rotary type

Compressor Model DA89X1F-20F

Oil charge Ester oil VG68 370ml

Evaporator Louver Fin and Grooved tube type

Refrigerant system Condenser Corrugate Fin and Grooved tube type

Control Capillary tube

Refrigerant volume

750g 770g 870g

(R-410A)

De-lce system Micro computer controled reversed systems

Noise level

High dB(A) 33 43 36 43 38 48

(at cooling)

Med. dB(A) 29 – 32 – 33 Low dB(A) 27 – 27 – 29 -

Fan system

Drive Direct drive

Air flow quantity High m3/min. 7.5 28 9.8 27.7 9.3 30

(at cooling) Med. m3/min. 6.8 – 8.2 – 8.1 –

Low m3/min. 6.0 – 6.1 – 6.6 –

Fan

Cross flow fan Propeller fan Cross flow fan Propeller fan Cross flow fan Propeller fan

Connections

Refrigerant coupling Flare type

Refrigerant tube size Gas, Liquid 3/8", 1/4"

Drain piping mm O.D ø 18

Others

Compressor: Compressor thermistor

Safety device Fan motors: Thermal fuse

Fuse, Micro computer control

Air filters Polypropylene net (Washable)

Width mm 815 780 815 780 815 780

Net dimensions Height mm 278 540 278 540 278 540

Depth mm 198 269 198 269 198 269

Net weight kg 9 33 10 33 10 37

Note: The condition of star " " marked item are ‘ISO5151’ : 1994(E), condition T1.

Page 4

4

AH/AY-X08CR

AH/AY-X10CR

AH/AY-X13CR

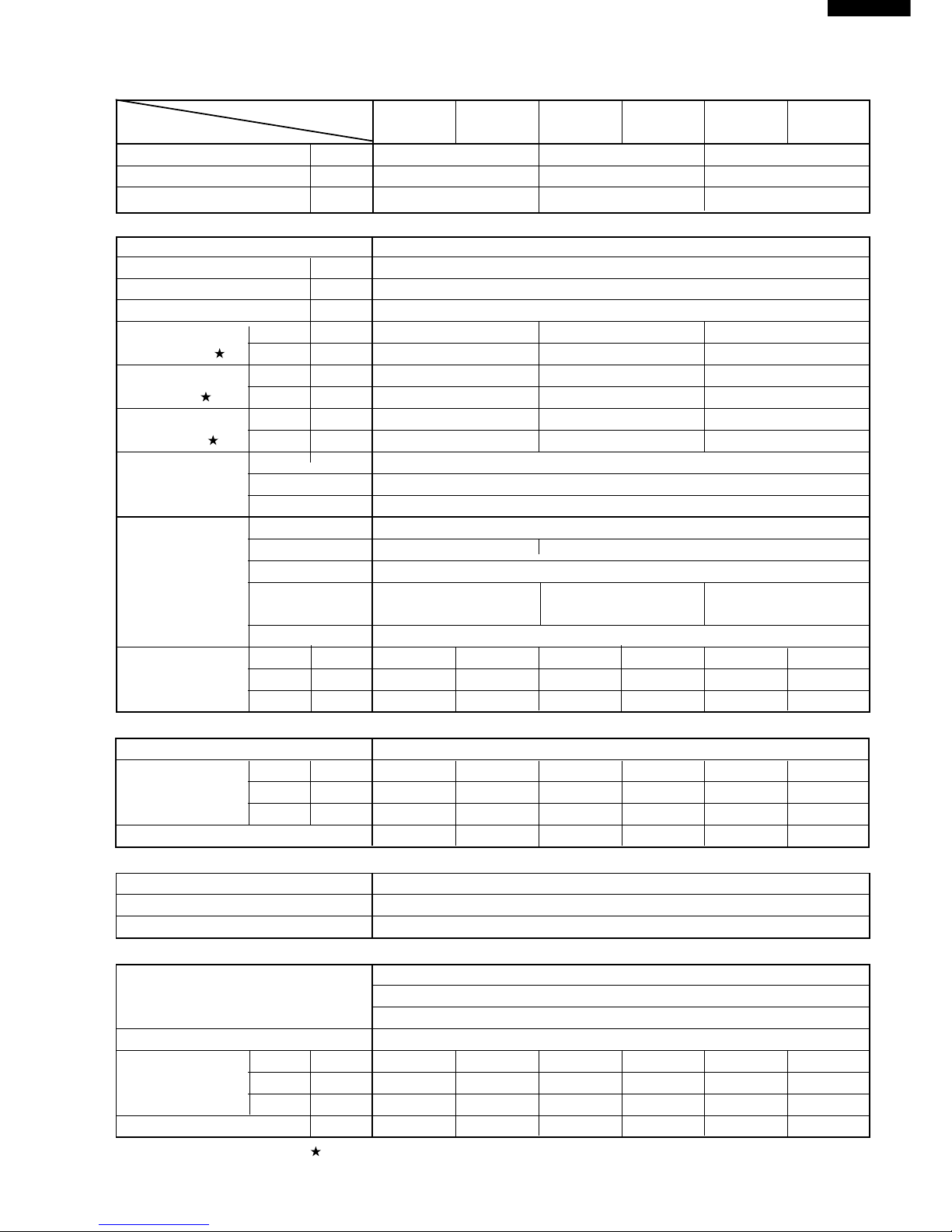

EXTERNAL DIMENSIONS

Figure E-1. INDOOR UNIT

Figure E-2. OUTDOOR UNIT

Length unit (mm)

815

278

198

1100

Remote controller

58

18.5

22

140

INVERTER AIR CONDITIONER

269

179.5

182.5

136

81

780

70

540

310

335

540

12

37.5

4.5

58

158

16

Page 5

5

AH/AY-X08CR

AH/AY-X10CR

AH/AY-X13CR

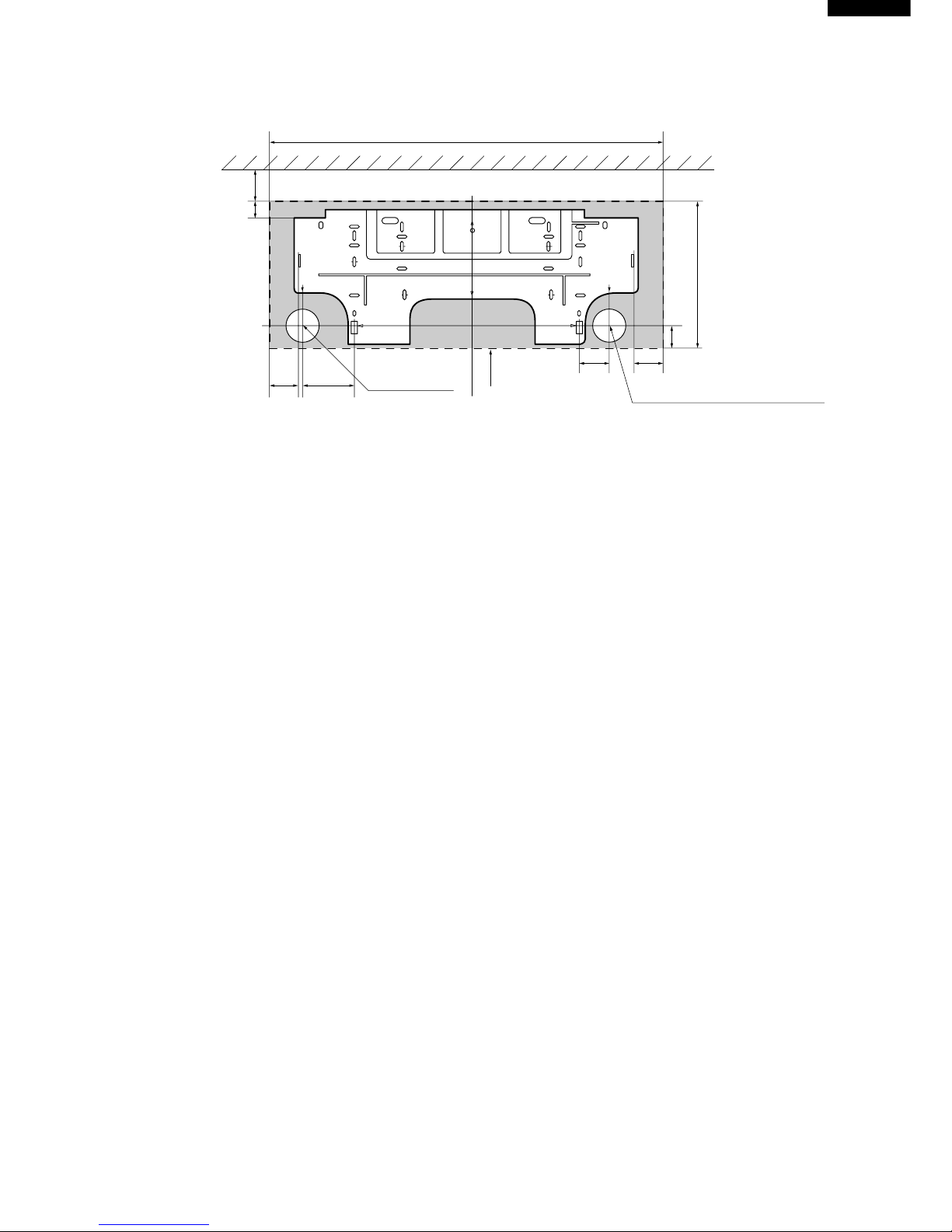

Figure E-3. INSTALLATION DIMENSIONS

815 (unit size)

More than 50mm

E

Center of wall hole:

Leftward piping

Center of wall hole: Backward piping

Outline of indoor unit

55 95

80 55

AJ

IF

E

D

D

FA

C

J

H

I

GB

21

278 (unit size)

38

Ceiling

E

Page 6

6

AH/AY-X08CR

AH/AY-X10CR

AH/AY-X13CR

WIRING DIAGRAMS

Figure W-1. Wiring Diagram for AH-X08CR/X10CR/X13CR and AY-X08CR/X10CR/X13CR

BROWN

RY1

In Out

CB612-1

10

7

8

6

Temperature

Indicator

Blinking No.

Abnormal contents

AC overcurrent

Abnormal AC current

WPE1

250V

3A

INDOOR UNIT

UNIT

TO

UNIT

CORD

Power factor module(AF1) error

13

Overheat of the power module(IPM) or

short circuit of the power module(IPM) heat-sink thermistor

Open circuit of the power module(IPM) heat-sink thermistor

Rotation error of the compressor

OUTDOOR UNIT

N

1

2

TERMINAL BOARD

CONTROL BOARD UNIT

POWER

SUPPLY

TERMINAL BOARD 2

SINGLE

PHASE

N

1

2

CONTROL

BOARD

UNIT

M

M

FAN MOTOR

COMPRESSOR

N

1

TERMINAL BOARD 1

M

M

LOUVER

(LOWER)

SERIAL

SIGNAL

CIRCUIT

BLUE

BLUE

BLACK

S

RED

N

INTERNAL

THERMAL

FUSE

RECEIVER

BOARD UNIT

R.P.M.

SIGNAL

FAN MOTOR

CAPACITOR

430V 2.0µF

FAN MOTOR

LOUVER

(UPPER)

13

TH1

5

CN1

BCN1

BCN3

BCN2

CN2

CN3

TH2

YELLOW

ORANGE

CN6

CN7

DISPLAY

BOARD

UNIT

CN101

CN102

ROOM TEMP.

THERMISTOR

PIPE TEMP.

THERMISTOR

GREEN-YELLOW

TRANS1

SSR1

1

3

4

2

RED

BLUE

BLACK

C1

LED INDICATION FOR SELF-DIAGNOSIS

5

2

3

1

14

17

18

19

Short circuit of the outdoor thermistor

Overheat of the compressor

Open circuit of the outdoor thermistor

Power module(IPM) abnormality

Open circuit of serial signal line

Abnormal fan motor of indoor unit

Short circuit of serial signal line

CB612-2

<Indication of the abnormal condition>

LED indicator will blink,if the set

is in abnormal condition.

Page 7

7

AH/AY-X08CR

AH/AY-X10CR

AH/AY-X13CR

Figure W-2. Wiring Diagram for AE-X08CR/X10CR

+

-

+

-

N

1

2

INDOOR UNIT

TERMINAL

BOARD

CONTROL

BOARD

UNIT

POWER

SUPPLY

FAN

MOTOR

TERMINAL BOARD

UNIT TO UNIT CORD

SINGLE PHASE

220-240V 50Hz

BL

T2

BR

T3

RE

FC4

BULK HEAD

RE

T1

WPE1

C1

C2

C3

C4

C33

C34

15A

250V

SA1

RY1

T4

BCN11

CT1

The voltage is high at C8 (electronic capacitors) on outdoor unit.

For mentenance discharge at C8 to prevent electric shock.

In case that WPE101 has been fused, the voltage is kept high at C8.

CAUTION

BK

:

BLACK RE

:

RED YE

:

YELLOW

BL

:

BLUE WH

:

WHITE G:GREEN

BR

:

BROWN OR

:

ORANGE

GR

:

GRAY G

(

Y

):

GREEN-YELLOW

BL

GR

G

(

Y

)

G

(

Y

)

FAN

MOTOR

BL

PTC

MRY1

IN OUT

T6

T5

BK

TP

TN

YE

C8

OUTDOOR UNIT

POWER

TRANSISTOR

MODULE

(

QM101

)

TU TV TW

RE

WH

OR

COMPRESSOR

THERMISTOR

PIPE TEMP.

THERMISTOR

OUTDOOR

TEMP.

THERMISTOR

COMP. TEMP.

CN8

TH2

TH1

TH3

RE

OR

G

3

1

5

LED INDICATION OF SELF-DIAGNOSIS

ON OUTDOOR UNIT

LED BLINKING

LED turns on

Slow flashing

(

1 time for 2 seconds

)

Quick flashing

(

3 times for 2 seconds

)

Example: NO.2 Overheat of the compressor

1.0sec 0.6sec 0.6sec 1.0sec 0.6sec 0.6sec

CB565

123

4

10

NO. LED indication pattern

Mulfunction part or abnormal condition

Normal

Abnormal signal line

Overheat of the compressor

DC overcurrent of the power module

(

QM101

)

Short circuit of the thermistor

7

8

6

NO. LED indication pattern

Mulfunction part or abnormal condition

Open circuit of the thermistor

AC overcurrent

AC abnormal current

BK

1

2

3

4

5

6

NR1

NR2

CNR1

N

1

2

L3

L4

WPE33A250V

CN3

CONTROL BOARD UNIT

DIODE BRIDGE

DB1

BL

C5

WPE101

20A

250V

OR

FC1

C10

C

AM

CONTROL

BOX

FAN MOTOR

CAPACITOR

1.5µF 450V

C31

+

-

L1

WH

C8:1000µF 420V

BL

~

~

9

Power factor module(AF1) error

S

R

C(T)

FC5

AF1

LL+

I-

I+

ACTIVE

FILTER

O-

O+

WH

YE

BR

FC2

3

1

RY2

CNR2

4-WAY

VALVE

5

11

Overheat of the power module or

short circuit of the heat-sink thermistor

Open circuit of the heat-sink thermistor

Rotation error of the compressor

C36

C35

C37

C38

BK

1

3

THERMISTOR

HEAT-SINK

TEMP.

CN7

41

YE

BL

CN12

CN13

BCN2

CN101

CN102

CN6

2

4

6

RE

WH

OR

POWER

TRANSISTOR

UNIT

NO.3 DC overcurrent of the power module

(

QM101

)

1.0sec 0.6sec 0.6sec 1.0sec 0.6sec

0.6sec

0.6sec

0.6sec

x 2times

x 3times

x 4times

x 5times

x 6times

x 7times

x 9times

x 11times

x 13times

x 14times

This circuit

is removed

about cooling

only models

CN4

Page 8

8

AH/AY-X08CR

AH/AY-X10CR

AH/AY-X13CR

Figure W-3. Wiring Diagram for AE-X13CR

+

-

+

-

N

1

2

INDOOR UNIT

TERMINAL

BOARD

CONTROL

BOARD

UNIT

POWER

SUPPLY

FAN

MOTOR

TERMINAL BOARD

UNIT TO UNIT CORD

SINGLE PHASE

220-240V 50Hz

BL

T2

BR

T3

RE

FC4

BULK HEAD

RE

T1

WPE1

C1

C2

C3

C4

C33

C34

20A

250V

SA1

RY1

T4

BCN11

CT1

The voltage is high at C8 (electronic capacitors) on outdoor unit.

For mentenance discharge at C8 to prevent electric shock.

In case that WPE101 has been fused, the voltage is kept high at C8.

CAUTION

BK

:

BLACK RE

:

RED YE

:

YELLOW

BL

:

BLUE WH

:

WHITE G:GREEN

BR

:

BROWN OR

:

ORANGE

GR

:

GRAY G

(

Y

):

GREEN-YELLOW

BL

GR

G

(

Y

)

G

(

Y

)

FAN

MOTOR

BL

PTC

MRY1

IN OUT

T6

T5

BK

TP

TN

YE

C8

OUTDOOR UNIT

POWER

TRANSISTOR

MODULE

(

QM101

)

TU TV TW

RE

WH

OR

COMPRESSOR

THERMISTOR

PIPE TEMP.

THERMISTOR

OUTDOOR

TEMP.

THERMISTOR

COMP. TEMP.

CN8

TH2

TH1

TH3

RE

OR

G

3

1

5

LED INDICATION OF SELF-DIAGNOSIS

ON OUTDOOR UNIT

LED BLINKING

LED turns on

Slow flashing

(

1 time for 2 seconds

)

Quick flashing

(

3 times for 2 seconds

)

Example: NO.2 Overheat of the compressor

1.0sec 0.6sec 0.6sec 1.0sec 0.6sec 0.6sec

CB566

123

4

10

NO. LED indication pattern

Mulfunction part or abnormal condition

Normal

Abnormal signal line

Overheat of the compressor

DC overcurrent of the power module

(

QM101

)

Short circuit of the thermistor

7

8

6

NO. LED indication pattern

Mulfunction part or abnormal condition

Open circuit of the thermistor

AC overcurrent

AC abnormal current

BK

1

2

3

4

5

6

NR1

NR2

CNR1

N

1

2

L3

L4

WPE33A250V

CN3

CONTROL BOARD UNIT

DIODE BRIDGE

DB1

BL

C5

WPE101

20A

250V

OR

FC1

C10

C

AM

CONTROL

BOX

FAN MOTOR

CAPACITOR

2.0µF 450V

C31

+

-

L1

WH

C8:1300

µ

F 420V

BL

~

~

9

Power factor module(AF1) error

S

R

C(T)

FC5

AF1

L

-

L

+

I

-

I

+

ACTIVE

FILTER

O

-

O

+

WH

YE

BR

FC2

3

1

RY2

CNR2

4-WAY

VALVE

5

11

Overheat of the power module or

short circuit of the heat-sink thermistor

Open circuit of the heat-sink thermistor

Rotation error of the compressor

C36

C35

C37

C38

BK

1

3

THERMISTOR

HEAT-SINK

TEMP.

CN7

41

YE

BL

CN12

CN13

BCN2

CN101

CN102

CN6

2

4

6

RE

WH

OR

POWER

TRANSISTOR

UNIT

NO.3 DC overcurrent of the power module

(

QM101

)

1.0sec 0.6sec 0.6sec 1.0sec 0.6sec

0.6sec

0.6sec

0.6sec

x 2times

x 3times

x 4times

x 5times

x 6times

x 7times

x 9times

x 11times

x 13times

x 14times

This circuit

is removed

about cooling

only models

CN4

Page 9

9

AH/AY-X08CR

AH/AY-X10CR

AH/AY-X13CR

Figure W-4. Wiring Diagram for AU-X08CR/X10CR

+

-

+

-

N

1

2

INDOOR UNIT

TERMINAL

BOARD

CONTROL

BOARD

UNIT

POWER

SUPPLY

FAN

MOTOR

TERMINAL BOARD

UNIT TO UNIT CORD

SINGLE PHASE

220-240V 50Hz

BL

T2

BR

T3

RE

FC4

BULK HEAD

RE

T1

WPE1

C1

C2

C3

C4

C33

C34

15A

250V

SA1

RY1

T4

BCN11

CT1

The voltage is high at C8 (electronic capacitors) on outdoor unit.

For mentenance discharge at C8 to prevent electric shock.

In case that WPE101 has been fused, the voltage is kept high at C8.

CAUTION

BK

:

BLACK RE

:

RED YE

:

YELLOW

BL

:

BLUE WH

:

WHITE G:GREEN

BR

:

BROWN OR

:

ORANGE

GR

:

GRAY G

(

Y

):

GREEN-YELLOW

BL

GR

G

(

Y

)

G

(

Y

)

FAN

MOTOR

BL

PTC

MRY1

IN OUT

T6

T5

BK

TP

TN

YE

C8

OUTDOOR UNIT

POWER

TRANSISTOR

MODULE

(

QM101

)

TU TV TW

RE

WH

OR

COMPRESSOR

THERMISTOR

PIPE TEMP.

THERMISTOR

OUTDOOR

TEMP.

THERMISTOR

COMP. TEMP.

CN8

TH2

TH1

TH3

RE

OR

G

3

1

5

LED INDICATION OF SELF-DIAGNOSIS

ON OUTDOOR UNIT

LED BLINKING

LED turns on

Slow flashing

(

1 time for 2 seconds

)

Quick flashing

(

3 times for 2 seconds

)

Example: NO.2 Overheat of the compressor

1.0sec 0.6sec 0.6sec 1.0sec 0.6sec 0.6sec

CB567

123

4

10

NO. LED indication pattern

Mulfunction part or abnormal condition

Normal

Abnormal signal line

Overheat of the compressor

DC overcurrent of the power module

(

QM101

)

Short circuit of the thermistor

7

8

6

NO. LED indication pattern

Mulfunction part or abnormal condition

Open circuit of the thermistor

AC overcurrent

AC abnormal current

BK

1

2

3

4

5

6

NR1

NR2

CNR1

N

1

2

L3

L4

WPE33A250V

CN3

CONTROL BOARD UNIT

DIODE BRIDGE

DB1

BL

C5

WPE101

20A

250V

OR

FC1

C10

C

AM

CONTROL

BOX

FAN MOTOR

CAPACITOR

1.5µF 450V

C31

+

-

L1

WH

C8:1000

µF 420V

BL

~

~

9

Power factor module(AF1) error

S

R

C(T)

FC5

AF1

L

-

L

+

I

-

I

+

ACTIVE

FILTER

O

-

O

+

WH

YE

BR

FC2

5

11

Overheat of the power module or

short circuit of the heat-sink thermistor

Open circuit of the heat-sink thermistor

Rotation error of the compressor

C36

C35

C37

C38

BK

1

3

THERMISTOR

HEAT-SINK

TEMP.

CN7

41

YE

BL

CN12

CN13

BCN2

CN101

CN102

CN6

2

4

6

RE

WH

OR

POWER

TRANSISTOR

UNIT

NO.3 DC overcurrent of the power module

(

QM101

)

1.0sec 0.6sec 0.6sec 1.0sec 0.6sec

0.6sec

0.6sec

0.6sec

x 2times

x 3times

x 4times

x 5times

x 6times

x 7times

x 9times

x 11times

x 13times

x 14times

Page 10

10

AH/AY-X08CR

AH/AY-X10CR

AH/AY-X13CR

Figure W-5. Wiring Diagram for AU-X13CR

+

-

+

-

N

1

2

INDOOR UNIT

TERMINAL

BOARD

CONTROL

BOARD

UNIT

POWER

SUPPLY

FAN

MOTOR

TERMINAL BOARD

UNIT TO UNIT CORD

SINGLE PHASE

220-240V 50Hz

BL

T2

BR

T3

RE

FC4

BULK HEAD

RE

T1

WPE1

C1

C2

C3

C4

C33

C34

20A

250V

SA1

RY1

T4

BCN11

CT1

The voltage is high at C8 (electronic capacitors) on outdoor unit.

For mentenance discharge at C8 to prevent electric shock.

In case that WPE101 has been fused, the voltage is kept high at C8.

CAUTION

BK

:

BLACK RE

:

RED YE

:

YELLOW

BL

:

BLUE WH

:

WHITE G:GREEN

BR

:

BROWN OR

:

ORANGE

GR

:

GRAY G

(

Y

):

GREEN-YELLOW

BL

GR

G

(

Y

)

G

(

Y

)

FAN

MOTOR

BL

PTC

MRY1

IN OUT

T6

T5

BK

TP

TN

YE

C8

OUTDOOR UNIT

POWER

TRANSISTOR

MODULE

(

QM101

)

TU TV TW

RE

WH

OR

COMPRESSOR

THERMISTOR

PIPE TEMP.

THERMISTOR

OUTDOOR

TEMP.

THERMISTOR

COMP. TEMP.

CN8

TH2

TH1

TH3

RE

OR

G

3

1

5

LED INDICATION OF SELF-DIAGNOSIS

ON OUTDOOR UNIT

LED BLINKING

LED turns on

Slow flashing

(

1 time for 2 seconds

)

Quick flashing

(

3 times for 2 seconds

)

Example: NO.2 Overheat of the compressor

1.0sec 0.6sec 0.6sec 1.0sec 0.6sec 0.6sec

CB568

123

4

10

NO. LED indication pattern

Mulfunction part or abnormal condition

Normal

Abnormal signal line

Overheat of the compressor

DC overcurrent of the power module

(

QM101

)

Short circuit of the thermistor

7

8

6

NO. LED indication pattern

Mulfunction part or abnormal condition

Open circuit of the thermistor

AC overcurrent

AC abnormal current

BK

1

2

3

4

5

6

NR1

NR2

CNR1

N

1

2

L3

L4

WPE33A250V

CN3

CONTROL BOARD UNIT

DIODE BRIDGE

DB1

BL

C5

WPE101

20A

250V

OR

FC1

C10

C

AM

CONTROL

BOX

FAN MOTOR

CAPACITOR

2.0µF 430V

C31

+

-

L1

WH

C8:1300

µ

F 420V

BL

~

~

9

Power factor module(AF1) error

S

R

C(T)

FC5

AF1

L

-

L

+

I

-

I

+

ACTIVE

FILTER

O

-

O

+

WH

YE

BR

FC2

5

11

Overheat of the power module or

short circuit of the heat-sink thermistor

Open circuit of the heat-sink thermistor

Rotation error of the compressor

C36

C35

C37

C38

BK

1

3

THERMISTOR

HEAT-SINK

TEMP.

CN7

41

YE

BL

CN12

CN13

BCN2

CN101

CN102

CN6

2

4

6

RE

WH

OR

POWER

TRANSISTOR

UNIT

NO.3 DC overcurrent of the power module

(

QM101

)

1.0sec 0.6sec 0.6sec 1.0sec 0.6sec

0.6sec

0.6sec

0.6sec

x 2times

x 3times

x 4times

x 5times

x 6times

x 7times

x 9times

x 11times

x 13times

x 14times

Page 11

27

AH/AY-X08CR

AH/AY-X10CR

AH/AY-X13CR

BREAK DOWN DIAGNOSIS PROCEDURE

Self-diagnostic procedure using display mode

If the timer lamp blinks during operation, the problem can be diagnosed using the following table.

: Blinks at 2-second intervals : OFF : ON : Blinks 3 times at 0.2-second intervals

The error of outdoor unit

Display by indoor unit operation lamp

Displayed in a pattern which comes on at the same

time as the timer lamp

4 seconds off

What to check, procedure

Display by

outdoor

unit lamp

LED 1

Diagnosis

Solution

Condition

of indoor

and

outdoor

unit

Normal

Twice

3 times

4 times

5 times

6 times

7 times

DC overcurrent error

AC overcurrent error

Normal

Overheat of the power

module or short circuit

of the heatsink

thermistor.

1. Check the circuit in the power transistor module.

2. Is the outdoor fan revolving ?

1. Is the discharge outlet of the outdoor unit clogged ?

1. Measure the resistance of heatsink thermistor TH6 on the heatsink

in outdoor unit.

2. Check rotation of the fan motor in outdoor unit.

3. Is the power supply voltage at least 198V at full power operation ?

1. Measure the resistance of thermistor TH2 on the outdoor unit

(see Figure 3).

1. Replace power transistor

module

1. Clear the discharge outlet.

11 times Power factor module error

1. CHeck wiring of power factor module.

1. Replace the power factor module.

1. Reattach.

2. Reattach CN101 and CN102,

otherwise replace power transistor

module assembly or outdoor control

board assembly.

9 times

14 times

13 times

Rotation errot of the

compressor

1. Has not if escaped from the compressor CN6 ?

2. Is the power supplied of 15V and 6V supplied to the IPM PWB.

1. Replace the heatsink thermistor.

Open circuit of the

heatsink thermistor.

1. Are the connectors of the heatsink thermistor in outdoor unit well

attached ?

2. Measure the resistance of thermistor TH6 on the heatsink.

(See Figure 3).

Overheat of the comp-

ressor error

(protector operating) or

outdoor compressor

thermistor TH1 short

1. Reattach.

2. Replace the heatsink thermistor.

1. Replace the outdoor control board

assembly

(Current transformer wire break.)

1. Reattach.

2. Replace the outdoor thermistor

assembly.

1. Replace the outdoor thermistor

assembly.

1. Clear the discharge outlet.

2. Assure power supply voltage.

3. Refill to rated amount.

4. Replace the outdoor ther-mistor

assembly.

5. Replace the indoor control board

assembly or only TH2.

1. Can voltage be detected at the current transformer on the outdoor

unit control board?

1. Is the connector of the outdoor unit thermistors well attached ?

(see Figure 3).

2. Measure the resistance of thermistors TH1 and TH2 on the

outdoor unit (see Figure 3).

1. Is the discharge outlet of the outdoor unit clogged ?

2. Is the power supply voltage at least 198 V at full power operation ?

3. Check for refrigerant leaks at the tubing connections.

4. Measure the resistance of compressor thermistor TH1 on the

outdoor unit (see Figure 3).

5. Measure the resistance of heat exchanger pipe thermistor TH2 on

the indoor unit (see Figure 1).

AC abnormal current

error

Open circuit of the

outdoor thermistor error

Short circuit of the

outdoor thermistor error

2. Reattach CN3, otherwise replace

the fan motor of outdoor unit.

3. Assure power supply voltage.

Page 12

28

AH/AY-X08CR

AH/AY-X10CR

AH/AY-X13CR

Note: 1. Normal : Only the timer lamp blinks. Error : Displayed by blinking of run

lamp (above table).

2. If the power plug is removed from the outlet or the breaker is switched to

"OFF", the self-diagnostic memory will be erased.

3. Example of outdoor unit LED 1 blinking :

: Blinks at 2-second intervals : OFF : ON : Blinks 3 times at 0.2-second intervals

The error of indoor unit

Display by indoor unit operation lamp

Displayed in a pattern which comes on at the same

time as the timer lamp

4 seconds off

What to check, procedure

Display by

outdoor

unit lamp

LED 1

Diagnosis

Solution

Condition

of indoor

and

outdoor

unit

Serial short

Serial open

1. Check the wiring between units.

1. Check the wiring between units.

1. Check the wiring between units.

2. Check the fuse in the outdoor unit.

3. Indoor control board.

4. Outdoor control board.

1. Rewire.

1. Rewire.

Indoor fan out of order

1. Is the fan motor locked ?

2. Is the wiring connector firmly fitted ?

3. Is the speed signal applied to the motor ?

Outdoor power supply

does't turn on.

Wiring mistake.

1. Rewire.

2. Replace the fuse, replace the

outdoor board assembly.

3. Replace the board.

4. Replace the board.

1. Replace fan motor

2. Reattach.

3. Replace the indoor control board

assembly.

1

sec.

1

sec.

0.6

sec.

1

sec.

1

sec.

1

sec.

1

sec.

1

sec.

1

sec.

Overheat of the compressor

0.6

sec.

1

sec.

0.6

sec.

1

sec.

0.6

sec.

2 times

OFFONOFF

Page 13

32

AH/AY-X08CR

AH/AY-X10CR

AH/AY-X13CR

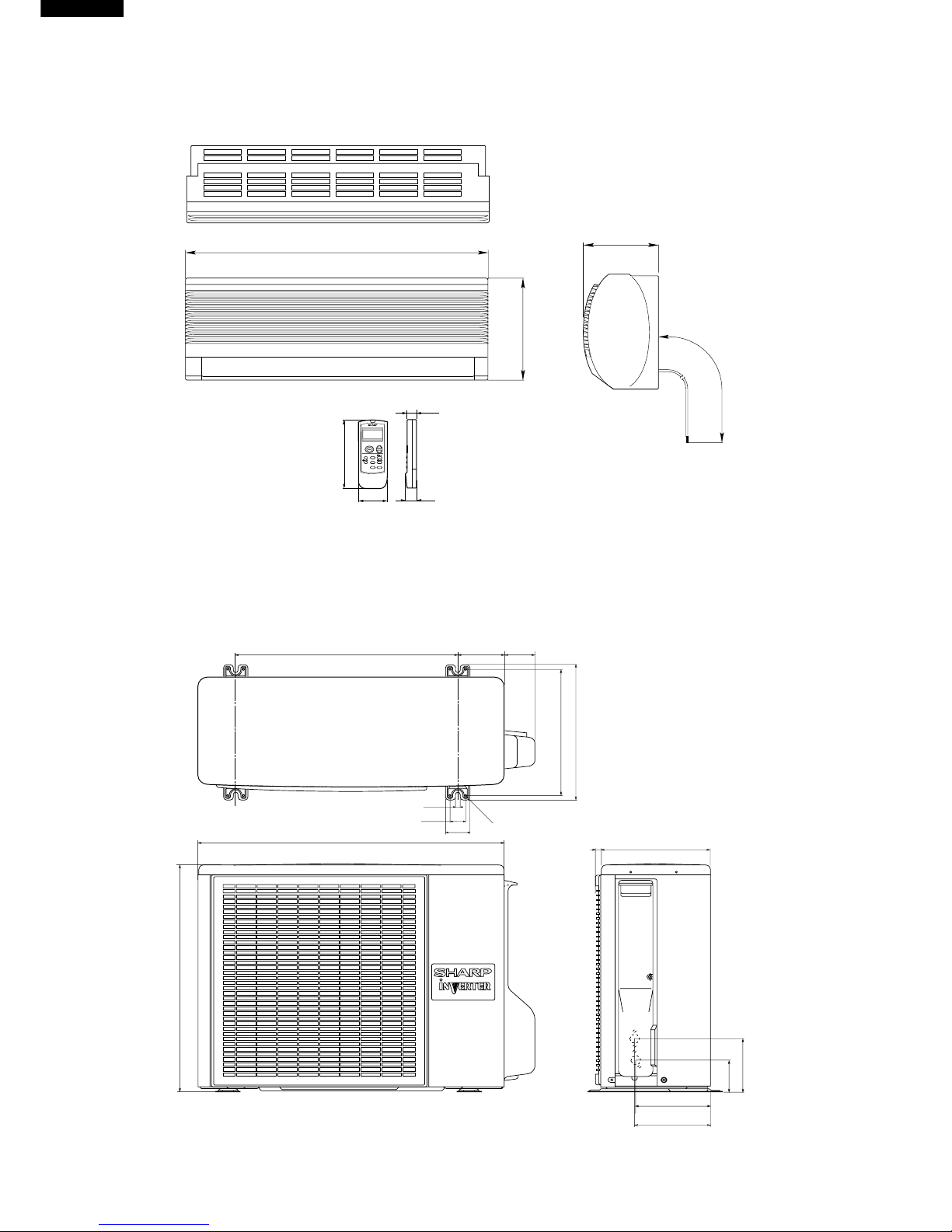

PERFORMANCE CURVES

NOTE: 1) Indoor fan speed: Hi

2) Vertical adjustment louver "45˚", Horizontal adjustment louver "front"

3) Indoor air temp. : Cooling 27˚C, Heating 20˚C

Figure P-1. At Cooling for AH-X08CR

Figure P-2. At Cooling for AH-X10CR

Figure P-3. At Cooling for AH-X13CR Figure P-4. At Cooling for AY-X08CR

Figure P-5. At Cooling for AY-X10CR

Figure P-6. At Cooling for AY-X13CR

25 30 35 40

2.0

2.2

2.4

2.6

10

12

14

600

700

800

900

Cooling capacity(kW)

Outside air temp.(˚C)

Input(W)

Outlet air temp.(˚C)

(Running frequency: 50HZ)

25 30 35 40

2.4

2.6

2.8

3.0

3.2

12

14

16

700

800

900

1000

(Running frequency: 62Hz)

Cooling capacity(kW)

Outside air temp.(˚C)

Input(W)

Outlet air temp.(˚C)

25 30 35 40

3.2

3.4

3.6

3.8

4.0

10

12

14

1000

1100

1200

1300

(Running frequency: 81Hz)

Cooling capacity(kW)

Outside air temp.(˚C)

Input(W)

Outlet air temp.(˚C)

25 30 35 40

2.0

2.2

2.4

2.6

10

12

14

600

700

800

900

Cooling capacity(kW)

Outside air temp.(˚C)

Input(W)

Outlet air temp.(˚C)

(Running frequency: 51Hz)

25 30 35 40

2.4

2.6

2.8

3.0

3.2

12

14

16

700

800

900

1000

(Running frequency: 63Hz)

Cooling capacity(kW)

Outside air temp.(˚C)

Input(W)

Outlet air temp.(˚C)

25 30 35 40

3.2

3.4

3.6

3.8

4.0

10

12

14

1000

1100

1200

1300

(Running frequency: 83Hz)

Cooling capacity(kW)

Outside air temp.(˚C)

Input(W)

Outlet air temp.(˚C)

Page 14

33

AH/AY-X08CR

AH/AY-X10CR

AH/AY-X13CR

Figure P-7. At Heating for AY-X08CR Figure P-8. At Heating for AY-X10CR

Figure P-9. At Heating for AY-X13CR

-5 0 7510

2.4

2.8

3.2

3.6

35

40

45

700

800

900

1000

(Running frequency: 68Hz)

Heating capacity(kW)

Outside air temp.(˚C)

Input(W)

Outlet air temp.(˚C)

-5 0 5 7 10

2.5

3.0

3.5

4.0

30

35

40

45

800

900

1000

1100

(Running frequency: 79Hz)

Heating capacity(kW)

Outside air temp.(˚C)

Input(W)

Outlet air temp.(˚C)

-5 0 5 7 10

3.0

3.5

4.0

4.5

5.0

5.5

30

35

40

45

1200

1300

1400

1500

1600

(Running frequency: 96Hz)

Heating capacity(kW)

Outside air temp.(˚C)

Input(W)

Outlet air temp.(˚C)

Loading...

Loading...