Page 1

1

AH-N45DP2

AU-N 45DP2

AH-N56DP2

AU-N 56DP2

INDOOR UNIT

AH-N45DP2

AH-N56DP2

OUTDOOR UNIT

MODELS

SERVICE MANUAL

S3314AHN56DP2

SHARP CORPORATION

In the interests of user-safety (Required by safety regulations in some

countries) the set should be restored to its original condition and only

parts identical to those specified should be used.

SPLIT SYSTEM

ROOM AIR CONDITIONERS

AU-N45DP2

AU-N56DP2

TABLE OF CONTENTS

Page

SPECIFICATIONS .............................................................................................................................................2

EXTERNAL DIMENSIONS ............................................................................................................................... 3

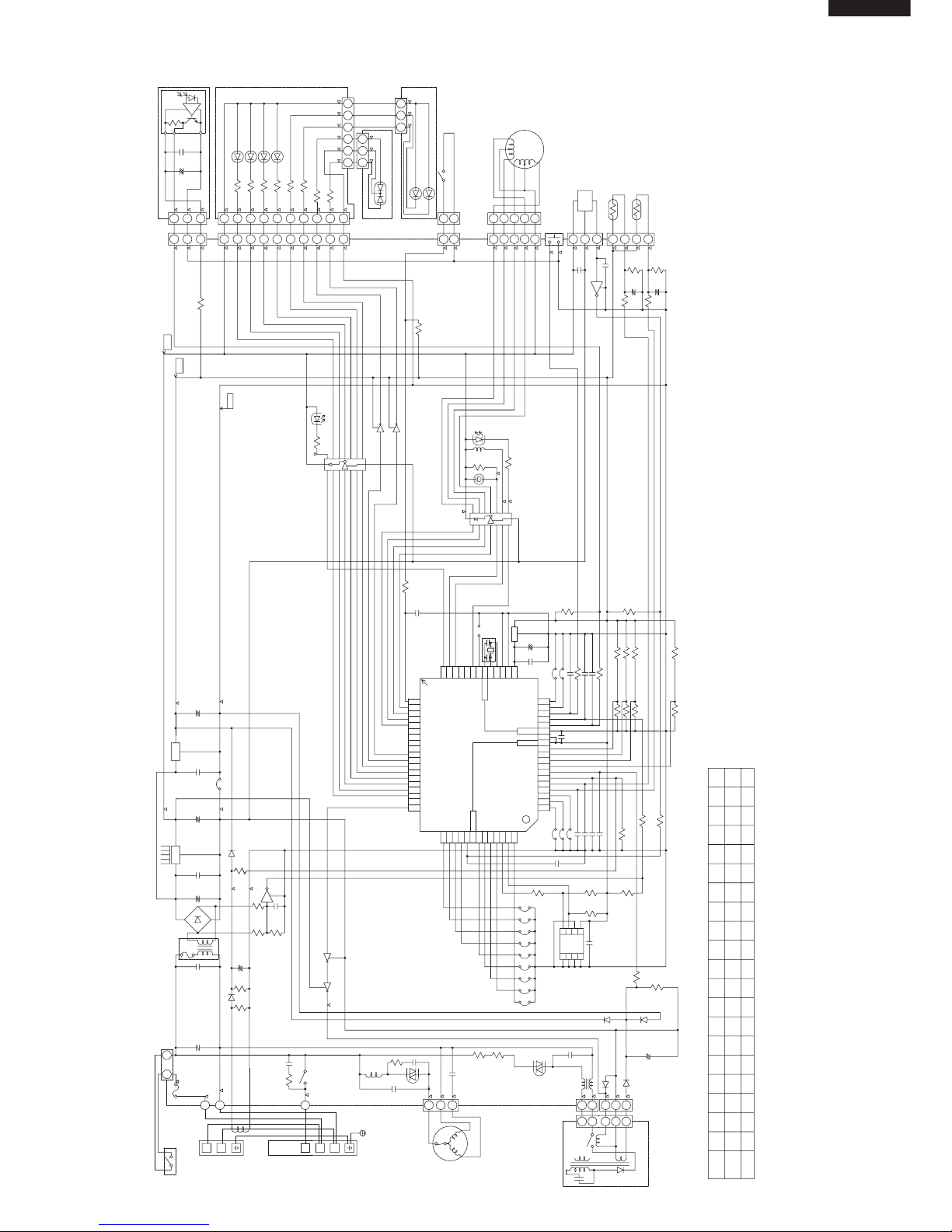

WIRING DIAGRAMS.........................................................................................................................................4

ELECTRICAL PARTS .......................................................................................................................................5

MICROCOMPUTER CONTROL SYSTEM .......................................................................................................6

FUNCTIONS ...................................................................................................................................................10

TROUBLESHOOTING GUIDE OF CONTROL CIRCUIT ................................................................................ 16

REFRIGERATION CYCLE ..............................................................................................................................20

PERFORMANCE CURVES ............................................................................................................................21

REFRIGERANT PIPE INSTALLATION WORKS .............................................................................................21

DISASSEMBLING PROCEDURE ................................................................................................................... 22

REPLACEMENT PARTS LIST ........................................................................................................................31

Page 2

2

AH-N45DP2

AU-N45DP2

AH-N56DP2

AU-N56DP2

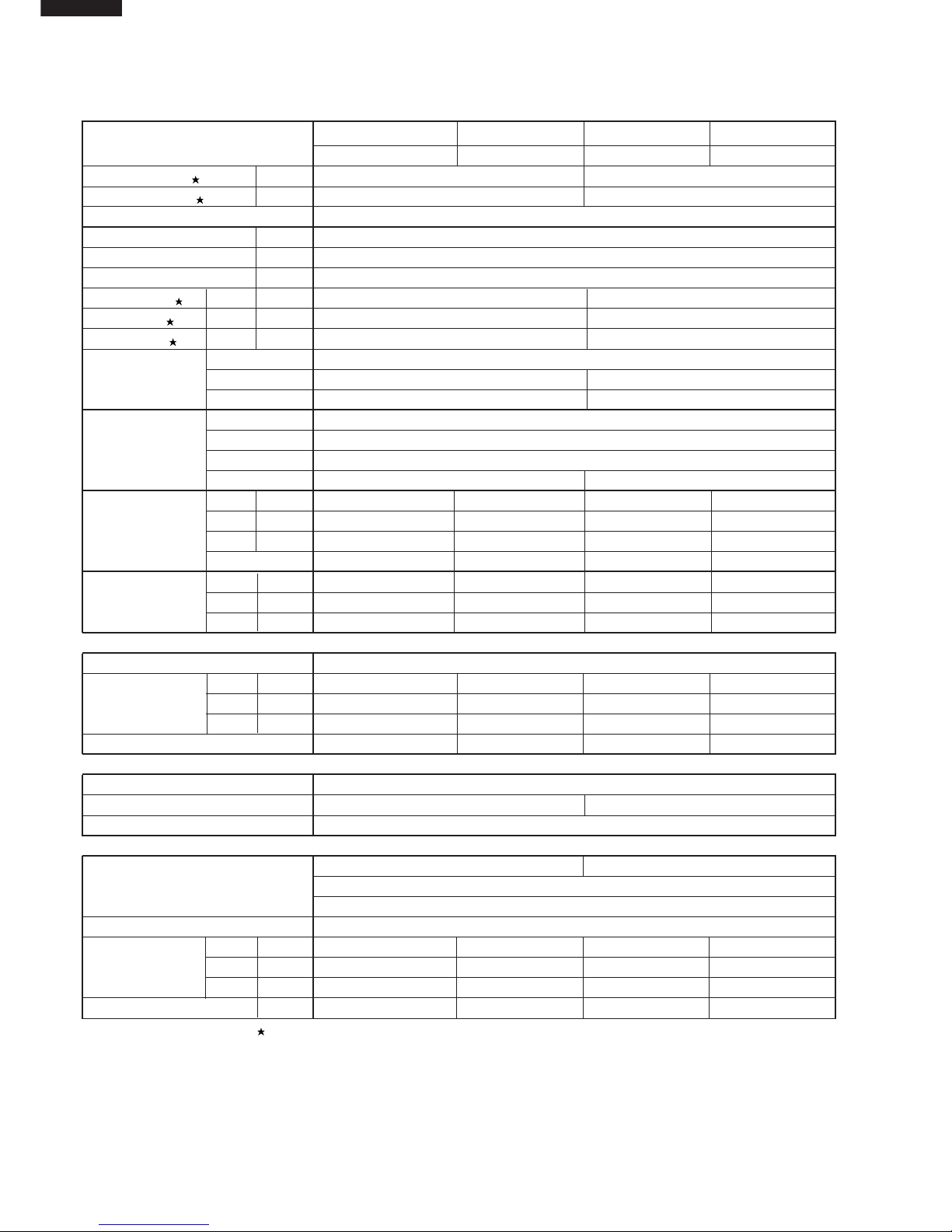

SPECIFICATIONS

ITEMS INDOOR UNIT OUTDOOR UNIT INDOOR UNIT OUTDOOR UNIT

AH-N45DP2 AU-N45DP2 AH-N56DP2 AU-N56DP2

Cooling capacity kW 5.0 6.3

Moisture removal Liters/h 1.9 2.5

Electrical data

Phase – Single

Rated frequency Hz 60

Rated voltage V 220

Rated current Cool A 8.5 10.7

Rated input Cool kW 1.82 2.29

Power factor Cool % 97 97

Compressor Type Hermetically sealed rotary type

Model PH28NNBT PH33NPBT

Oil charge 670cc (DIAMOND MS 32(N-1)) 900cc (DIAMOND MS 32(N-1))

Refrigerant system Evaporator Louver fin and Grooved tube type

Condenser Corrugate fin and Grooved tube type

Control Capillary tube

Refrigerant volume

1300g 1570g

Capillary tube size

Outer dia.

mm – 3.2 – 3.5

Inner dia.

mm – 2.0 – 2.2

Length mm – 400 – 800

Q'ty – 1 – 1

Noise level High dB(A) 40 52 44 54

(at cooling) Med. dB(A) 36 – 39 –

Low dB(A) 34 – 37 –

Fan system

Drive Direct drive

Air flow quantity High m3/min. 15.3 48 18.1 50

(at cooling) Med. m3/min. 13.4 – 15.0 –

Low m3/min. 11.3 – 13.7 –

Fan Cross flow fan Propeller fan Cross flow fan Propeller fan

Connections

Refrigerant coupling Flare type

Refrigerant tube size Gas, Liquid 1/2", 1/4" 5/8", 1/4"

Drain piping mm O.D ø 20

Others

Safety device

Compressor: Overload protector(Internal) Compressor: Overload protector(Internal)

Fan motors: Thermal protector (Internal)

Fuse, Micro computer control

Air filters Polypropylene net (Washable)

Net dimensions Width mm 1040 890 1040 890

Height mm 325 645 325 645

Depth mm 220 327 220 327

Net weight kg 16 51 16 60

Note: The condition of star ( ) marked item are ‘CNS 14464 B7291 : T1’.

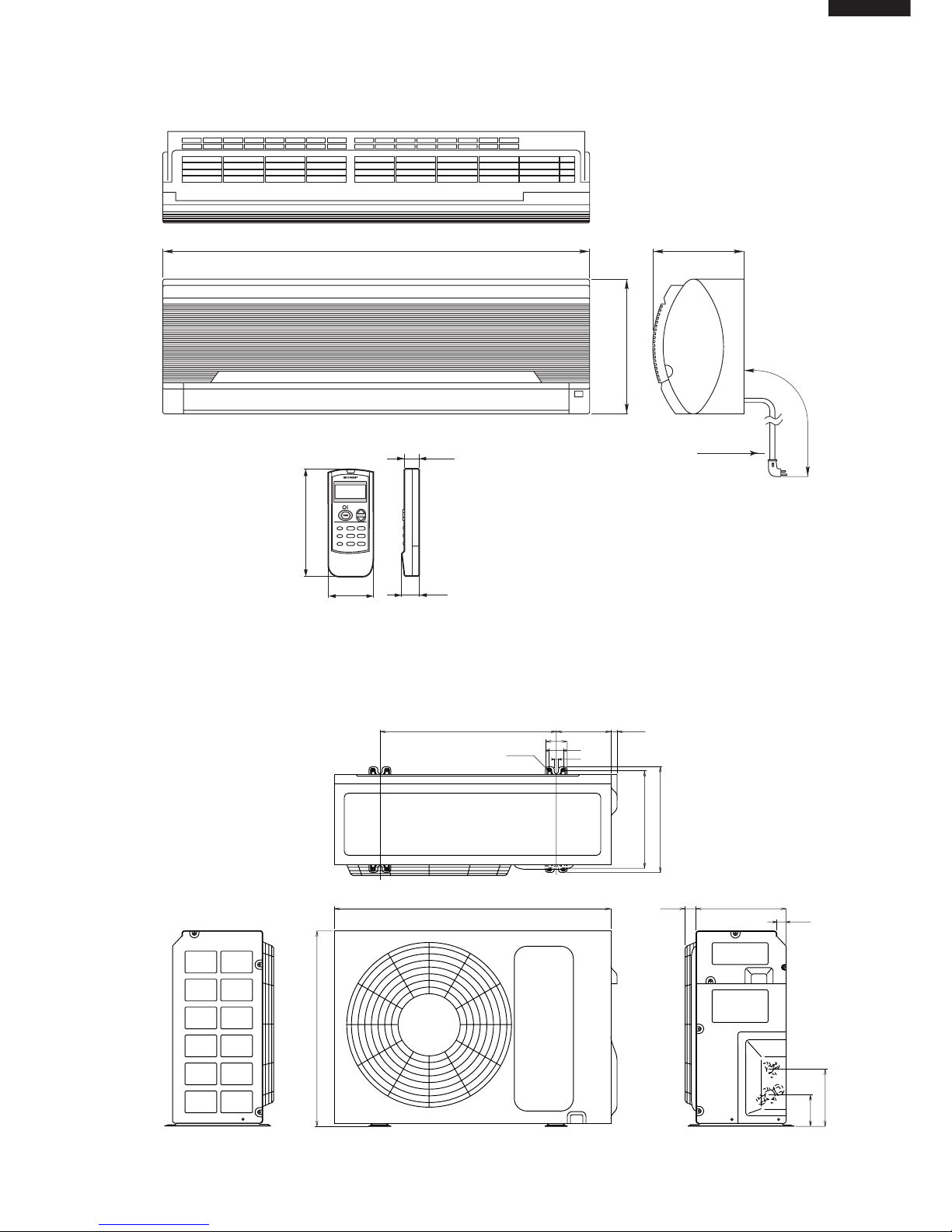

Page 3

3

AH-N45DP2

AU-N 45DP2

AH-N56DP2

AU-N 56DP2

570

645

202

122

320

342

890 29037

30

172

25

62

46.3

10.5

ø4.5

EXTERNAL DIMENSIONS

Figure E-1. INDOOR UNIT

Figure E-2. OUTDOOR UNIT

220

1600

Power supply cord

[Length unit : mm]

325

1040

Remote controller

58

18.5

22

140

TEMP.

INVERTER AIR CONDITIONER

TEMP.

MODE

FAN

TIMER

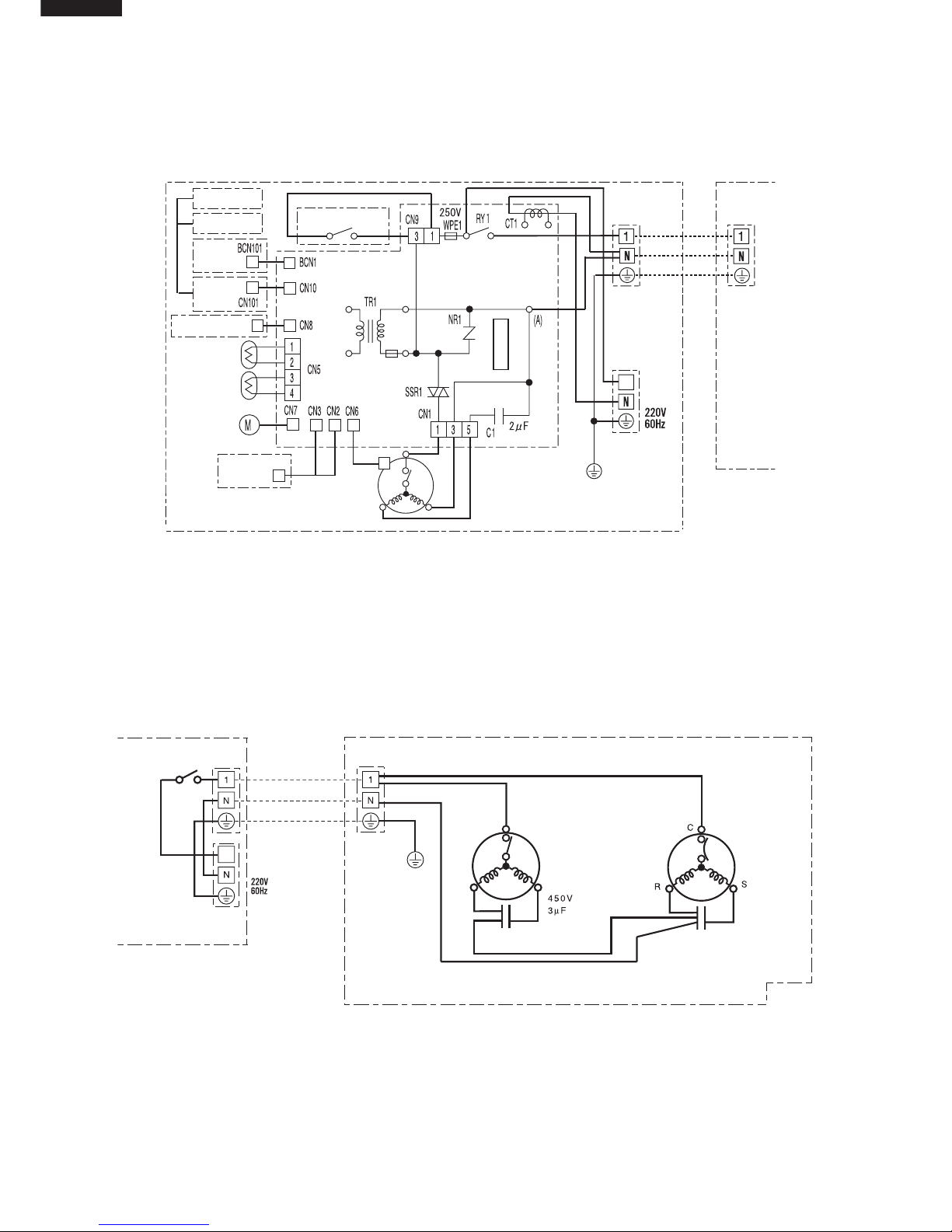

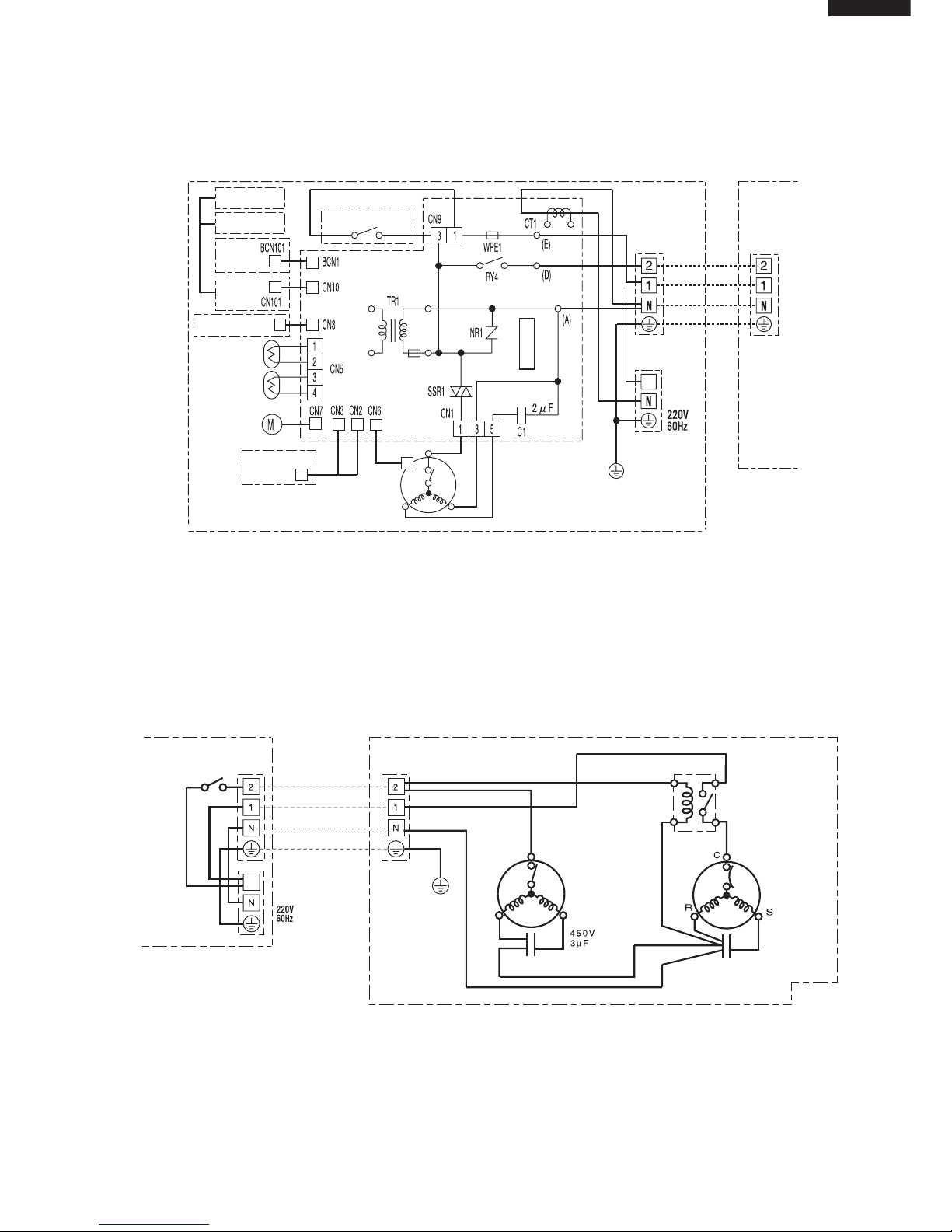

Page 4

4

AH-N45DP2

AU-N45DP2

AH-N56DP2

AU-N56DP2

WIRING DIAGRAMS

Figure W-1. Wiring Diagram for AH-N45DP2

Figure W-2. Wiring Diagram for AU-N45DP2

室内機

室外機

黒

藍

端子板

端子板

機

組

間

配

線

L

電源

單相

端子板

茶

藍

緑-黄

風扇馬達

電容器

回轉數

檢出信号

風扇馬達

紅

黒

藍

導風板

馬達

室温用

恒温器

熱交用

恒温器

控

制

基

板

受信基板

指示

基板1

指示基板2

指示基板3

電源變厭器

保險絲

内部温度控制器

内部

温度

控制器

In

Out

2.5或3A

400或430V

内部清洗按鈕2

内部清洗按鈕1

離子簇

産生器

注意!

高厭電

蒸發器

CB806

L

電源

單相

機組間配線

端子板

緑-黄

紅

黒

内部温度控制器

風扇馬達

黒

藍

藍

風扇馬達電容器

藍

紅

白

運轉電容器

内部過載継電器

厭縮機

370

或

400V

35μF

控制接地

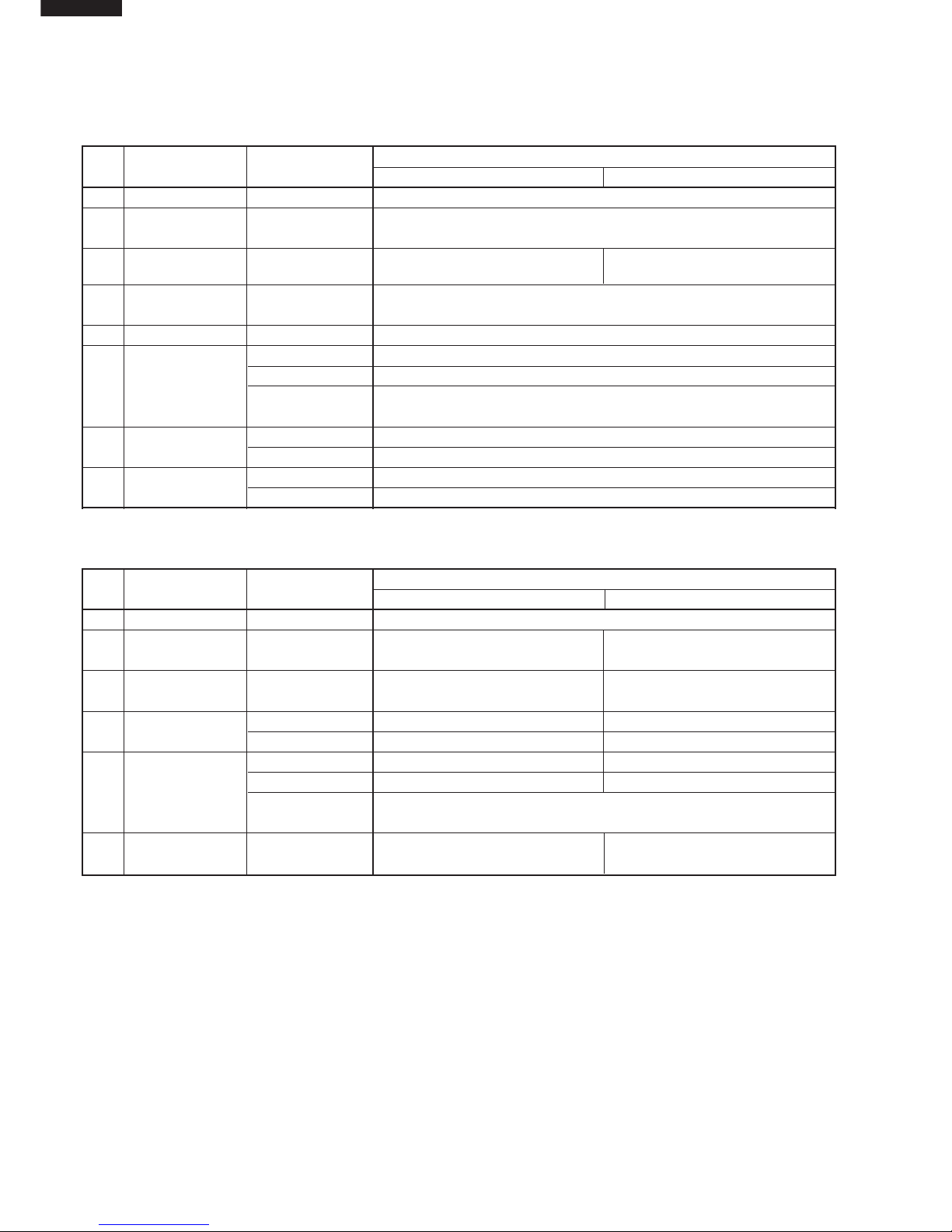

Page 5

5

AH-N45DP2

AU-N 45DP2

AH-N56DP2

AU-N 56DP2

Figure W-3. Wiring Diagram for AH-N56DP2

Figure W-4. Wiring Diagram for AU-N56DP2

室内機

室外機

端子板

端子板

機

組

間

配

線

茶

L

電源

單相

端子板

緑-黄

藍

藍

紅

茶

保險絲

控

制

基

板

風扇馬達

電容器

藍

黒

紅

回轉數

檢出信号

内部

温度

控制器

風扇馬達

導風板

馬達

室温用

恒温器

熱交用

恒温器

内部温度控制器

電源變厭器

指示

基板1

受信基板

指示基板3

指示基板2

2.5或3A

250V

400或430V

内部清洗按鈕1

内部清洗按鈕2

離子簇

産生器

注意!

高厭電

蒸發器

L

電源

單相

機組間配線

端子板

黄

茶

藍

緑-黄

内部温度控制器

風扇馬達

黒

藍

藍

風扇馬達電容器

藍

運轉電容器

白

紅

藍

紅

黒

内部過載継電器

厭縮機

継電器

CB807

370

或

400V

35μF

控制接地

Page 6

6

AH-N45DP2

AU-N45DP2

AH-N56DP2

AU-N56DP2

Part Part Name Items Specifications

No. AH-N45DP2 AH-N56DP2

1 Terminal Board Rating 300V 25A

2 Fan motor Rating 400V or 430V 2µF

Capacitor

3 Relay Rating RY1 AC250V 20A RY4 AC250V 5A

Coil Volt.; 12V Coil Volt.; 12V

4Printed Wiring Material Paper Base Phenolic Resin (UL 94V-0)

Board

5 Transformer Rating Pri 220 - 240VAC Sec. 16.8V DC 0.29A

6 Fan motor Rating 220 - 230VAC 60Hz 41W 4-Pole

Type MLB038

Thermal

Protector

Cut off 135±10˚C

(Internal)

7 Power Supply Rating 20A 250V 12AWG

Cord Type SJT12AWGSJT12 (12AWGX3)

8 Louver Motor Rating DC12V 250

Type MP35EA

Part Part Name Items Specifications

No. AU-N45DP2 AU-N56DP2

1 Terminal Board Rating 300V 25A

2 Fan motor Rating 450V 3µF 450V 3µF

Capacitor

3 Running Rating 370V or 400V 35µF 370V or 400V 35µF

Capacitor

4 Compessor Rating AC208 - 230V 60Hz 1250W AC208 - 230V 60Hz 1600W

Type PH28NNBT PH33NPBT

5 Fan motor Rating 220VAC 60Hz 63W 6-Pole 220VAC 60Hz 86W 6-Pole

Type MLB027 MLB028

Thermal protector Cut off 135˚C±5˚C

(Internal)

6 Relay Rating – AC250V 30A

Coil volt: 200 -240V

ELECTRICAL PARTS

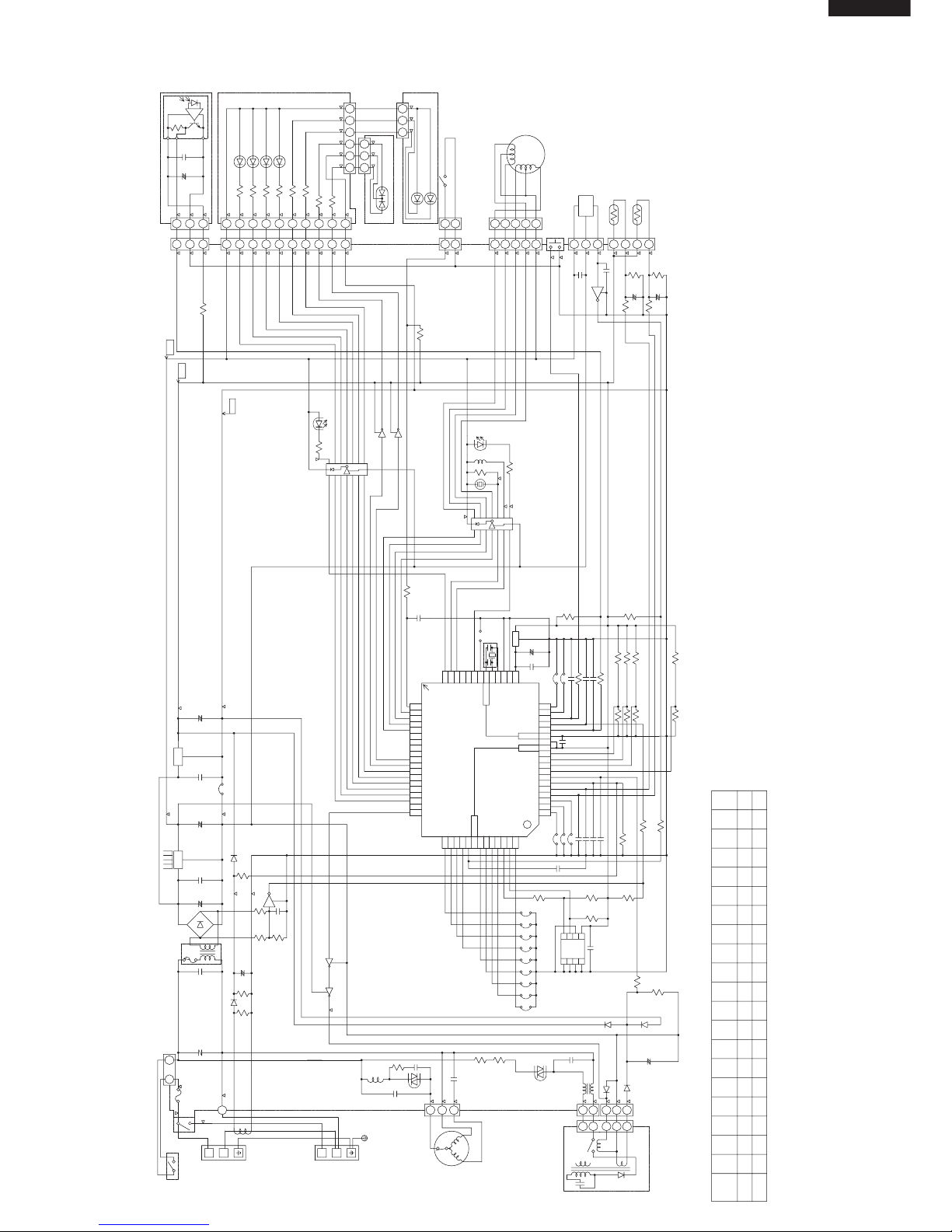

Page 7

7

AH-N45DP2

AU-N 45DP2

AH-N56DP2

AU-N 56DP2

MICROCOMPUTER CONTROL SYSTEM

Figure L-1. Electronic Control Circuit Diagram for AH-N45DP2

MODE

13K

R37

L2

NC

NC

56

L 1

9.1K

R45

1/2W

10K

D14

25V

47

µ

C29

+

NF1

6.8K

6.8K

R41

100

L1

SSR1

C31

1W

275V

0.033

µ

Q8 Q7

Q6

Q5

JP21

3

131

NR1

CN9

THERMOSTAT

INTERNAL

CN8

CN7

CN6

CN5

CN3

CN2

CN1

1

2

3

1

CLUSTER

R35

3.3K

R40

R39

10K

CLEANING

SWITCH 1

SWITCH 2

CLEANING

31

D8D9

3

2

1

2

3

3

2

2

0.01

µ

C22

16V

2

0.01µ

C10

16V

22K

R6

20K

Q2

1

R5

22K

R4

R27

2

1/2W

9

470

R30

SSR2

3

12V

5V

10

9

25V

C24

SW101

2

11

2

8

IC4

10K

R29

R28

1.8K

BZ1

RY1

SSR1

1/2W

470

IC5

8

9

Q1

16V

220µ

10K(F)

+

D6

25V

0.1µ

1

2

453

MOTOR

LOUVER

32154

123

HOLE

IC

FAN

MOTOR

2

3

JP3

JP2

JP1

NC

MB89537A

1

IC6

3

10K

13K

13K

25V

0.1

µ

1

µ

50V

IC1

(PATTERN SIDE)

400V

0.01µ

16V

JP5

JP4

1K

0.01

µ

OSC1

FRONT

P21

P22

P23

P24

P25

P26

P27X1X0

MOD1

MOD0

RST

32313029282726252423222120

Vcc

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

P45

P46

P47

AN0

AN1

AN2

AN3

AN4

AN5

AN6

AN7

AVR

P60

P61

P62

P63

P64

P31

P32

P33

P34

P35

P36

P37

P40

P41

P42

P43

P44

52535455565758596061626364

P30

NC

P00

P01

P02

P03

P04

P05

P06

P07

P10

P11

P12

P13

P14

P15

P16

P17

P20

49

50

51

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

AVcc

AVss

Vss

50V

1000p

+

680

10K 10K

10

µ

16V16V

10

µ

10k

(F)

10K

(F)

432

1

TH2

PIPE TEMP

15kΩ(25˚C).

TH1

ROOM TEMP

10kΩ(25˚C).

FAN

MOTOR

2µ

135

2.7K(F)

D7

+

35V

1000µ

50V

0.1µ

7812

IC2

+

25V

47µ

7805

0.1µ

IC3

25V

10V

100µ

+

C7

D1?4

GND

22.6K(F)

3.3K

4

5

IC8

123

876

0.1µ

25V

16V

0.01µ

TR1

C1

C2

C3

C4

C5

C6 C8

C9

C11

C13

C14

C15 C17

C18

C19

C20

C21

C23

C25

R7

R8

R9

R10

R13

R14

R15

R16

R18

R19

R20

R21

R22

R23

R24

R25

R26

R32

R34

10K

16V

16V

16V

0.01µ

0.01µ

0.01µ

6.8K

R12

47K

R11

10MHz

JP10

JP11

JP12

JP13

JP18

10K

10K

0.01µ

16V

0.01

µ

16V

R17

3.3K

13K

C27

C12

SW1 : AUX.(TEST RUN)

C16

25V

0.1

µ

1

R31R33

+

+

C26

321

1

BCN1

2345678

R37

6

7

135

1K(F)

1

0.1µ

D12

3

R108

10

32

(TIMER)

LED102

LED101

(OPERATION)

1

12

BL

GR

LED107

(CLUSTER)

134256

9

R107

(FAN L)

(FAN M)

(FAN H)

(FAN AUTO)

LED106

LED105

LED104

LED103

3K

2.7K

R102

R101

1/2W

1/2W

C102

C101

0.1µ

25V

33µ

10V

+

IC101

BCN101

R103

R104

R105

R106

620

620

123

1

8765432

620

620

1/2W

1/2W

56

CN10

CN103

BCN102

CN102

CN101

275V

275V

0.1

µ

0.1

µ

275V

C28

8

6

SSR2

2W

2W

R1

R2

NC

NC

NC

NC

JP9

JP8

JP7

JP19

DEIC

E 1

DEIC

E 2

DRY

FAN

PIPE

1

PIPE

2

NONENONENONENONE

JP7 JP8 JP9

JP10 JP11 JP12 JP13

TEST

NONE

JP6

NONE 15K 15K 15K

JP18 JP19

LOUVOUT

FAN

CLUS

TER ER

R19 R21 R23

FAN2FAN1

HEAT COOL

MODE

R38

R38

ON

PWR

LESS

WIRE

AT

SWE-

KEEP

HOT

DEF.

SYMBOL

I

JP2 JP3 JP4 JP5JP1

IN

OUT

RY1

WPE1T250V

2.5A

1

N

BOARD

TERMINAL

L

N

PHASE

SINGLE

SUPPLY

POWER

TERMINAL

BOARD

A

BL

BK

BR

UNIT

OUTDOOR

TO

NONENONEUSE USE USE USE USE USENONE

47

CT1

BL

BL

Page 8

8

AH-N45DP2

AU-N45DP2

AH-N56DP2

AU-N56DP2

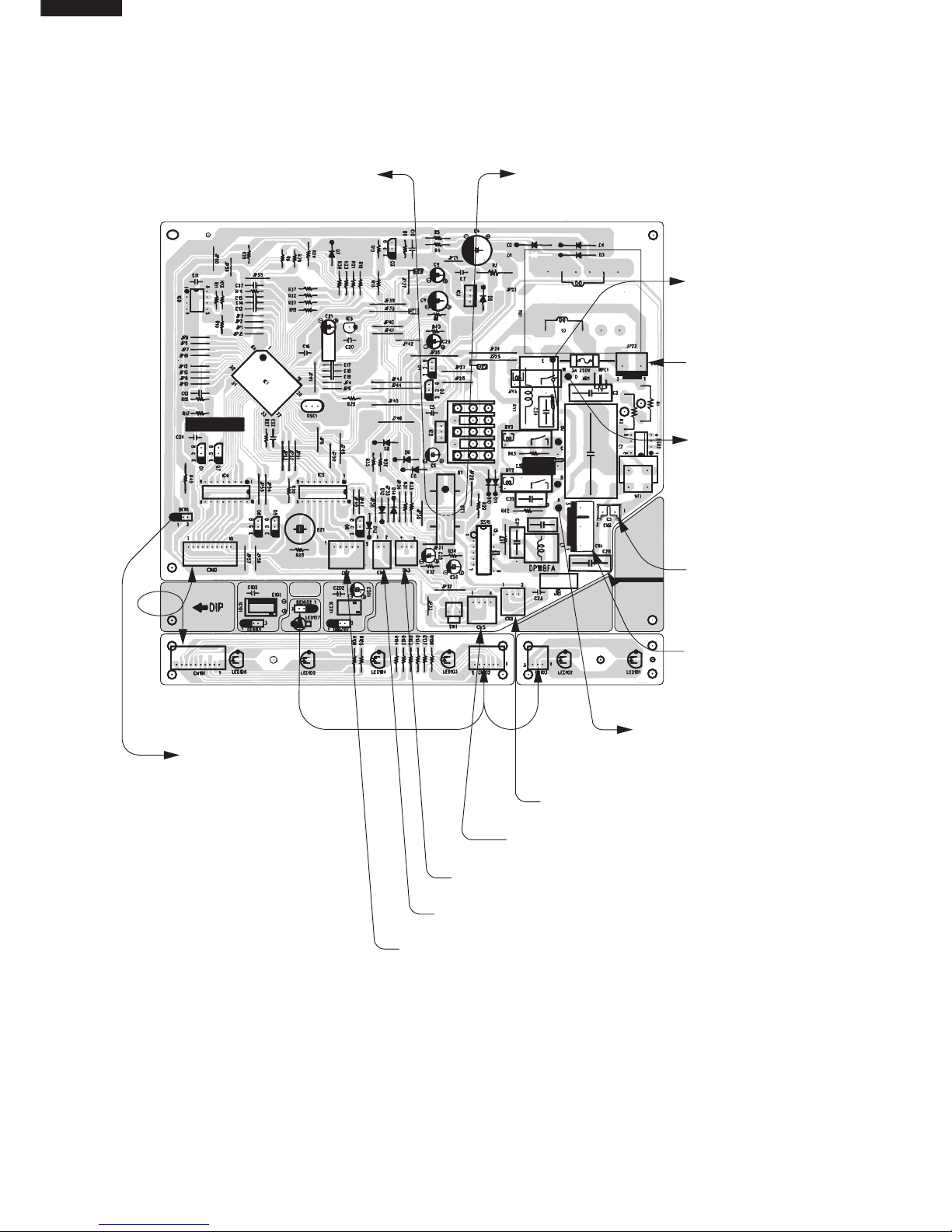

igure L-2. Printed Wiring Diagram for AH-N45DP2

2

FB441

2

FB441

2

2

FB441

2

FB441

2

TO TERMINAL

BOARD TOPN

TO TERMINAL BOARD

TOPN

TO TERMINAL BOARD

BOTTOMN

FROM TERMINAL

BOARD TOP1BLACK

FROM

TERMINAL

BOARD BOTTOM

LBROWN

FROM FAN MOTOR

FROM

FAN MOTOR

FROM CLUSTER GENERATOR

FROM

CLUSTER

GENERATOR

FROM CLEANING SWITCH 1

FROM

CLEANING

SWITCH 2

FROM THERMISTOR

FROM LOUVER MOTOR

BCN101(BCN201)

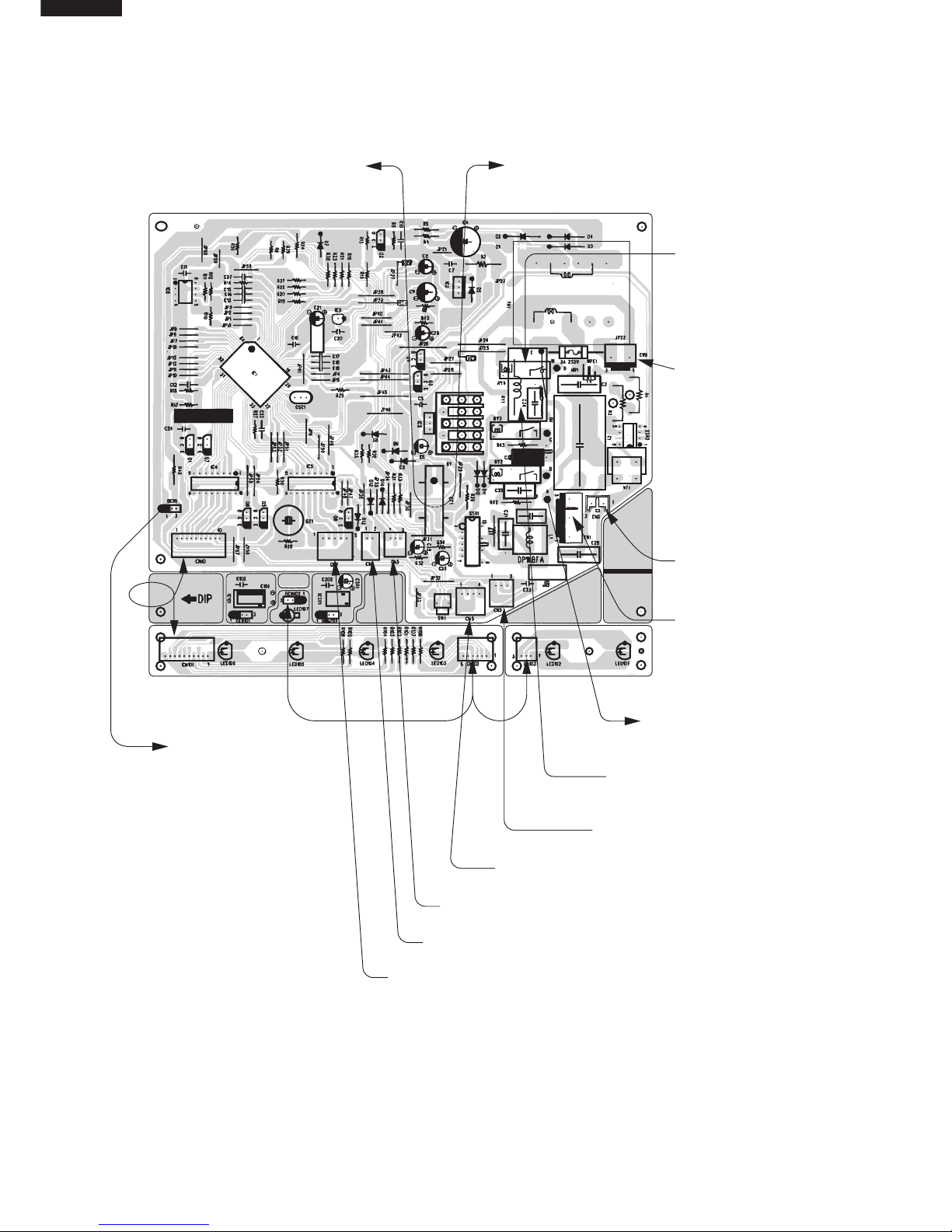

Page 9

9

AH-N45DP2

AU-N 45DP2

AH-N56DP2

AU-N 56DP2

Figure L-3. Electronic Control Circuit Diagram for AH-N56DP2

L2

R37

13K

MODEHOT

KEEP

SWE-

AT

WIRE

LESS

PWR

ON

DEIC

TEST

NONE NONE NONE NONE

JP13JP12JP11JP10

JP9JP8JP7

2

PIPE

1

PIPE

FAN

DRY

E 2

DEIC

E 1

NONE

JP6

COOLHEAT

FAN1 FAN2

R23R21R19

ERTER

CLUS

FAN

OUT LOUV

JP19

NONE 15K15K

JP18

MODE

L

R38

NONE USE USE USE USE USEUSENONE NONE

JP1 JP5JP4JP3JP2

I

SYMBOL

DEF.

1/2W

R4547

TO

OUTDOOR

UNIT

BR

E

A

BOARD

TERMINAL

2

POWER

SUPPLY

SINGLE

PHASE

N

L

TERMINAL

BOARD

N

1

2.5A

250VTWPE1

8765432

BCN1

1

123

C26

+

+

R33 R31

1

0.1µ

25V

C16

SW1 : AUX.(TEST RUN)

C12

R37

C27

13K

3.3K

R17

16V

0.01µ

16V

0.01µ

10K

10K

JP18

JP13

JP12

JP11

JP10

10MHz

R11

47K

R12

6.8K

0.01µ

0.01µ

0.01µ

16V

16V

16V

10K

R34

R32

R26

R25

R24

R23

R22

R21

R20

R19

R18

R16

R15

R14

R13

R10

R9

R8

R7

C25

C23

C21

C20

C19

C18

C17C15

C14

C13

C11

C9

C8C6

C5

C4

C3

C2

C1

TR1

0.01µ

16V

25V

0.1µ

678

321

IC8

5

4

3.3K

22.6K(F)

GND

D1?4

C7

+

100µ

10V

25V

IC3

0.1µ

7805

47µ

25V

+

IC2

7812

0.1µ

50V

1000µ

35V

+

D7

2.7K(F)

531

2µ

MOTOR

FAN

123

4

(F)

10K

(F)

10k

10µ

16V 16V

10µ

10K10K

680

+

1000p

50V

Vss

AVss

AVcc

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

51

50

49

P20

P17

P16

P15

P14

P13

P12

P11

P10

P07

P06

P05

P04

P03

P02

P01

P00

NC

P30

64636261605958575655545352

P44

P43

P42

P41

P40

P37

P36

P35

P34

P33

P32

P31

P64

P63

P62

P61

P60

AVR

AN7

AN6

AN5

AN4

AN3

AN2

AN1

AN0

P47

P46

P45

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

Vcc

20212223242526272829303132

RST

MOD0

MOD1

X0X1P27

P26

P25

P24

P23

P22

P21

F

R

O

N

T

OSC1

SSR1

0.01µ

1K

JP4

JP5

16V

0.01µ

400V

(PATTERN SIDE)

IC1

50V

1µ

0.1µ

25V

13K

13K

10K

3

IC6

1

MB89537A

NC

JP1

JP2

JP3

3

2

MOTOR

FAN

IC

HOLE

321

4

5

123

LOUVER

MOTOR

35421

0.1µ

25V

D6

+

10K(F)

220µ

16V

Q1

9

8

IC5

470

1/2W

SSR1

RY4

BZ1

1.8K

R28

R29

10K

IC4

8

2

11

2

SW101

C24

25V

9

10

5V

12V

3

SSR2

R30

470

9

1/2W

2

R27

R4

22K

R5

1

Q2

20K

R6

22K

16V

C10

0.01µ

2

16V

C22

0.01µ

2

1

2

3

3

2

1

2

3

D9 D8

13

CLEANING

SWITCH 2

SWITCH 1

CLEANING

10K

R39

R40

3.3K

R35

CLUSTER

1

3

2

1

CN1

CN2

CN3

CN5

CN6

CN7

CN8

INTERNAL

THERMOSTAT

CN9

NR1

131

3

JP21

Q5

Q6

Q7Q8

6

7

135

820(F)

0.1µ

D12

56

56

1/2W

1/2W

620

620

2345678

1

321

620

620

R106

R105

R104

R103

BCN101

IC101

+

10V

33µ

25V

0.1µ

C101

C102

1/2W

1/2W

R101

R102

2.7K

3K

LED103

LED104

LED105

LED106

(FAN AUTO)

(FAN H)

(FAN M)

(FAN L)

R107

9

65 243 1

(CLUSTER)

LED107

GR

BL

21

1

(OPERATION)

LED101

LED102

(TIMER)

23

10

R108

3

CN103

BCN102

CN102

CN10

CN101

275V

275V

0.1µ

R2

R1

2W

2W

SSR2

6

8

C28

275V

0.1µ

JP9

JP8

JP7

JP19

R38

NC

NC

NC

NC

L1

100

R41

1W

C31

0.033µ

275V

6.8K

6.8K

NF1

D14

+

C29

47µ

25V

10K

275V

RY4

R44

0.01µ

C34

1W

D

NC

NC

47K 5.1K

RE

BL

CT1

BL

BL

BR

TH1 PIPE

TEMP.

10kΩ(25˚C)

TH2 PIPE

TEMP.

15kΩ(25˚C)

Page 10

10

AH-N45DP2

AU-N45DP2

AH-N56DP2

AU-N56DP2

igure L-4. Printed Wiring Diagram for AH-N56DP2

2

FB441

2

FB441

2

2

FB441

2

FB441

2

TO TERMINAL BOARD

TOPN

TO TERMINAL BOARD

TOPN

TO TERMINAL BOARD

BOTTOMN

TO TERMINAL

BOARD TOP

2

TO TERMINAL

BOARD BOTTOM

L

FROM FAN MOTOR

FROM

FAN MOTOR

FROM CLUSTER GENERATOR

FROM

CLUSTER

GENERATOR

FROM CLEANING SWITCH 1

FROM

CLEANING

SWITCH 2

FROM THERMISTOR

FROM LOUVER MOTOR

BCN101(BCN201)

Page 11

11

AH-N45DP2

AU-N 45DP2

AH-N56DP2

AU-N 56DP2

Microcomputer (IC1)

IC1 is a CMOS, one chip, 8-bit microcomputer.

Microcomputer port allocation is as follows.

Pin Terminal Input

No. Name Output Function

1 P45 IN –

2 P46 IN HOOT KEEP

3 P47 IN SWEET

4 AN0 IN ROOM TEMP.

5 AN1 IN PIPE TEMP.

6 AN2 IN CT

7 AN3 IN CLUSTER SENS.

8 AN4 IN MODEL

9 AN5 IN LOUVER SET

10 AN6 IN FAN SET COOL

11 AN7 IN FAN SET HEAT

12 AVCC IN 5V

13 AVR IN 5V

14 AVSS IN 0V

15 R60 IN WIRELESS SIGNAL

16 R61 IN AC CLOCK

17 R62 IN SW1

18 R63 IN WIRELESS HEDDER

19 R64 IN POWER ON

20 RST IN RESET SUGNAL

21 MOD0 IN 0V

22 MOD1 IN 0V

23 X0 IN OSILLATION

24 X1 IN OSILLATION

25 VSS IN 0V

26 P27 IN –

27 P26 OUT FAN MOTOR A CONTROL

28 P25 OUT

OUTDOOR FAN M. CONTROL

29 P24 OUT VALVE CONTROL

30 P23 OUT COMPRESSOR CONTROL

31 P22 OUT BUZZER

32 P21 OUT

CLUSTER GENERATOR CONTROL

Pin Terminal Input

No. Name Output Function

33 P20 IN CLEANING SW1

34 P17 OUT LOUVER MOTOR

35 P16 OUT LOUVER MOTOR

36 P15 OUT LOUVER MOTOR

37 P14 OUT LOUVER MOTOR

38 P13 NC –

39 P12 NC –

40 P11 NC –

41 P10 NC –

42 P07 OUT LED 107 (GREEN)

43 P06 OUT LED 107 (BLUE)

44 P05 OUT LED 101

45 P04 OUT LED 102

46 P03 OUT LED 103

47 P02 OUT LED 104

48 P01 OUT LED 105

49 P00 OUT LED 106

50 N5 NC –

51 P30 OUT

CLUSTER POLARITY CONTROL

52 P31 IN DEICE 2

53 P32 IN DRY FAN

54 P33 IN PIPE 1

55 P34 IN PIPE 2

56 P35 IN INDOOR FAN MOTOR R.P.M.

57 VCC IN 5V

58 P36 IN CLUSTER SET

59 P37 IN –

60 P40 IN TEST

61 P41 IN DEICE 1

62 P42 IN/OUT EEPROM

63 P43 IN/OUT EEPROM

64 P44 IN OUT FAN

Page 12

12

AH-N45DP2

AU-N45DP2

AH-N56DP2

AU-N56DP2

FUNCTIONS

1. Temperature control characteristic

1-1 COOL operation

In the “COOL” mode, the thermostat circuit is

controlled by four thermostat lines (C1 thru C5).

Figure H-1

1-2 DRY operation

In the “DRY” mode, the thermostat circuit is

controlled by three thermostat lines (D1 thru D3).

Figure H-2

2. Operation modes

2-1 COOL operation

The compressor turns on or off, at the thermostat

lines C4 and C5. The outdoor fan motor is also

controlled with the compressor.

Figure H-3

2-2 DRY operation

On the switch on, the compressor always starts to

operate for 2 minutes with fan speed "DL" .

The microcomputer reads the room temperature 2

minutes after this first compressor operation.

This room temperature is set as the preset

temperature automatically.

The preset temperature ranges from 18˚C to

32˚C. When the room temperature is below 18˚C,

the preset temperature is set to 18˚C, and when

the room temperature is over 32˚C, the preset

temperature is set to 32˚C.

Dry operation is divided into three zones (Cooling

zone, Dehumidifying zone and Circulating zone)

by thermostat lines (D1 to D3), and the

compressor and the fan motor are controlled in

each zone as shown in Table H-1.

18

32

C1

C2

C3

C4

17.5

18.5

19.5

19.0

20.5

31.5

33.0

32.5

33.5

34.5

Preset temperature (˚C)

Room temperature (˚C)

C5

Room temperature(˚C)

Preset temperature (˚C)

18

32

D1

D2

D3

17.5

18.5

19.5

31.5

32.5

33.5

Room temperature

Preset temperature

Room

temperature

transition

C4

C5

States 1 & 3 : Compressor ON

State 2 : Compressor OFF

1

2

3

Room temperature

Preset temperature

Room

temperature

transition

D3

D2

D1

States 1 & 5 : Cooling zone

States 2 & 4 : Dehumidifying zone

States 3 : Circulating zone

3

4

5

1

2

Figure H-4

Page 13

13

AH-N45DP2

AU-N 45DP2

AH-N56DP2

AU-N 56DP2

Fan

switch

DL

Fan

speed

Fan switch

(AUTO)

AH-

N45DP2

(r.p.m.)

750 830

780 860

820 960

840 980

940 1030

1000 1120

1050 1210

AH-

N56DP2

DH

DRY

COOL

CL

COOL

SOFT

CAL

CM

COOL

LOW

CAH

CH

COOL

HIGH

Table H-1

Compressor

Cooling zone

Dehumidifying zone

Circulating zone

Fan speed

ON "DH"

"DL"

"DL" or OFF

ON

OFF

3. Fan speed

Fan speeds are given by the indoor fan motor,

"DL"~"HH" which are available in the following

operation mode.

Table H-2

4. Freeze preventive

When the indoor pipe temperature falls below 0˚C

during cool operation or dry operation, the

compressor is turned off.

5. Test run

If the "AUX" button on the unit is pressed for 5

seconds or more during operation, cool test

operation starts. The operation LED (red) flickers

during test run.

To put the system in the heating test run mode,

start the cooling operation and select the heating

mode on the remote control. In cool and heat

mode continuous compressor on operation is

performed. In dry mode the operation is in

dehumidifying zone. In fan only mode the indoor

fan motor runs continusly.

6. Timer

6-1 ON/OFF TIMER

When the unit operates during one hour after the

OFF-time is set, thermostat setting is

automatically shifted (+1˚C in cool operation and

dry operation, -3˚C in heat operation, 16˚C 32˚C). When the ON-timer is set in heat operation

and cool operation, operation starts before 0 to 30

minutes(depends on the room temperature) so

that preset temperature is obtaind at set time.

6-2 ONE-HOUR TIMER

When ONE-HOUR timer is set, the unit turns off

automatically after one hour. The one hour timer

operation has priority over other time operation,

such as the TIMER ON and TIMER OFF. If the

ONE-HOUR TIMER button is pressed again

during operation, the unit will operate additionally

for another one hour.

7. Automatic air conditioning

automatic air conditioning is selected, the

operation mode and preset temperature are set

automatically according to the room temperature

on starting operation.

Table H-3

Room temperature

Preset temperature

Room

temperature

transition

C3

C2

C1

States 1 & 5 :"CAH"

States 2 & 4 : "CM"

States 3 : "CAL"

a. COOL operation

3

4

5

1

2

When DRY mode is selected by the micro

computer with AUTO operation, the fan speed

lamps on the indoor unit panel will indicate

identically with the fan speed symbols on the

remote control dispaly, as the FAN speed setting

is changed accordingly. Despite, the actual fan

speed will not change, as it is determined

automatically by the micro computer.

8. Automatic fan speed

When the automatic fan speed is selected in cool

or heat operation, the fan speed is automatically

changed by the thermostat lines C1 to C3 in cool

operation, and H1 to H4 in heat operation.

Figure H-5

Room temperature

at operation start

Operation

Mode

Preset

Temperature

Above 28˚C 26˚C

26˚C ~ 28˚C

24˚C ~ 26˚C

Below 24˚C

25˚C

24˚C

Room temperature

at operation start

COOL

DRY

Page 14

14

AH-N45DP2

AU-N45DP2

AH-N56DP2

AU-N56DP2

Timer LED

(Yellow)

ON OFF

Judgement Normal

(Generator OK)

Failure

(Check circuit)

1) Cluster generator checking (STEP 1)

9. Outputs in each operation mode

Table H-4

10. Power on start

If the connecting wire JP5 is shorten on the PWB

ass'y, when the power is supplied by turning on a

circuit breaker, the air conditioner automatically

starts of operation in "AUTO".

(Refer to Figure L-2.and Figure L-4. Printed

Wiring Board.)

11. AUTO RESTART

Power failure occurs during operation, the unit will

restart in the same operation mode as before after

power recovery.

12. Test mode

Keep pushing the "AUX." buttons and supply the

power, the system will go to the test mode. In this

mode, the output of operation is switched by

pushing the "AUX." button in the unit or the

"

" button in the remote controller.

Normal outputs are shown in Table Y-6 and Y-7.

13. Plasma cluster

Plasma cluster ion mode

SSR2 : ON

Relay (Cluster unit inside) : OFF

Minus ion mode

SSR2 : ON

Relay (Cluster unit inside) : ON

ON

OFF

ON

OFF

ON ON OFF

OFF ON OFF

ON

ON ON

L/UL

UL/D

OFF D/OFF

OFF

OFF

OFF

Mode

Compressor

Outdoor

Fan Motor

Cooling

Circulating

Indoor

Fan Motor

Valve

Coil

C

O

O

L

D

R

Y

Cooling

Circulating

Dehumidiflying

Page 15

15

AH-N45DP2

AU-N 45DP2

AH-N56DP2

AU-N 56DP2

Table H-6

AH-N56DP2

7

~

42˚C ON -2

~

45˚C ON

~

7˚C , 42˚C

~

OFF

~

-2˚C , 45˚C

~

OFF

0.3V

~

4.5V ON

~

0.3V , 4.5V

~

ON 0.3V

~

4.5V ON

~

0.3V , 4.5V

~

ON

~

0.3V , 4.5V

~

OFF 0.3V

~

4.5V OFF

~

0.3V , 4.5V

~

OFF 0.3V

~

4.5V OFF

OFF ON

ON OFF

STEP

No

Buzzer

Lam

p

s Cluster

Outdoor

Indoor

Fan

Louver

RED YELLOW FAN SOFT FAN LOW FAN HIGH FAN AUTO CLUSTER Power Selector

02

Room temp. Pipe temp.

ON ON ON ON BLUE OFF OFF OFF OFF OPEN

11

FEED BACK CIRCUIT CT INPUT(AN2 input voltage)

BLUE ON OFF ON

1000

rpm

OFF

OFF

OFF

OPEN

FLICK

21

Power On Start(JP5) Wireless(JP4) MODEL SELECTION(AN4 input voltage)

GREEN ON ON OFF

31

Sweat(JP3) Hot Keep(JP2) Out Fan(JP18) TEST(JP8) Cluster(JP19) Dry Fan(JP11)

OFF OFF OFF OFF

41

DEICE 1 DEICE 2 Louver Collection(AN5 input voltage)

OFF OFF OFF OFF

51

Pipe 1 Pipe 2 Cooling mode FAN speed Collection(AN6 input voltage)

OFF OFF OFF OFF OFF

61

EEPROM Micro SW Heating mode FAN speed Collection(AN6 input voltage)

OFF OFF OFF OFF OFF

ON

71 OFF OFF

EEPROM VERSION(UPPER 4bit)

OFF OFF OFF OFF OFF

OFF OFF OFF OFF

OFF OFF OFF81 OFF OFF CLOSE

OFF OFF OFF OFF

OFF OFF

EEPROM VERSION(LOWER 4bit)

ON

ON

ON

ON

ON

OFF

ON

ON

ON

ON

OFF

OFF

OFF

OFF

ON

OFF

OFF

OFF

OFF

OFF

ON

ON

ON

ON

AH-N45DP2

7

~

42˚C ON -2

~

45˚C ON

~

7˚C , 42˚C

~

OFF

~

-2˚C , 45˚C

~

OFF

0.3V

~

4.5V ON

~

0.3V , 4.5V

~

ON 0.3V

~

4.5V ON

~

0.3V , 4.5V

~

ON

~

0.3V , 4.5V

~~

0.1V, 4.9V

~

OFF OFF 0.3V

~

4.5V OFF

~

0.3V , 4.5V

~

OFF 0.3V

~

4.5V OFF

OFF ON OFF ON ON

OFF ON ON ON

OFF ON ON ON

OFF OFF ON ON

OFF ON ON ON

OFF

OFF

OFF

ON

OFF

ON

Sweat(JP3)

DEICE 1

Pipe 1

ON

OFF

ON

OFF ON

ON OFF

OFF OFF

FAN HIGH FAN AUTO

Cluster

STEP

No

Buzzer

Lamps

RED YELLOW FAN SOFT FAN LOW CLUSTER Power Selector

OFF

Outdoor

Indoor

Fan

Louver

BLUE OFF OFF OPENOFF02

Room temp. Pipe temp.

ON ON ON ON

OFF OFF

OFF

OFF

OFF

OFF

EEPROM VERSION(UPPER 4bit)

OFF

81 OFF OFF

OFF OFF OFF

EEPROM VERSION(LOWER 4bit)

OFF

OFF OFF

OFF OFF OFF

11

FEED BACK CIRCUIT CT INPUT(AN2 input voltage)

BLUE ON OFF ON

1000

rpm

OFF

OFF

OPEN

FLICK

21

Power On Start(JP5) Wireless(JP4) MODEL SELECTION(AN4 input voltage)

GREEN ON ON OFF

31

Hot Keep(JP2) Out Fan(JP18) TEST(JP8) Cluster(JP19) Dry Fan(JP11)

OFF OFF

41

DEICE 2 Louver Collection(AN5 input voltage)

OFF OFF OFF OFF OFF

51

Pipe 2 Cooling mode FAN speed Collection(AN6 input voltage)

OFF OFF OFF

61

EEPROM Micro SW Heating mode FAN speed Collection(AN6 input voltage)

OFF OFF OFF

ON

71 OFF

CLOSE

OFF OFF OFF OFF

OFF OFFOFF

ON

OFF

NONE

USE

ON

OFF

NONE

USE

AN3 ( 1)

0.1V

~

4.9V ON

~

0.1V, 4.9V

~

OFF

0.1V

~

4.9V ON

AN3 ( 1)

Page 16

16

AH-N45DP2

AU-N45DP2

AH-N56DP2

AU-N56DP2

TROUBLESHOOTING GUIDE OF CONTROL CIRCUIT

measure the secondary voltage

of transformer.

YES

NO

YES

NO

The machine does not function

at all with remote controller and

switch on the indoor unit.

Using a tester, measure the

voltage between anodes of D1

and D2 on PWB ass'y.

Is the measured value

approx. 17.5 Vac ?

Replace the PWB with a new

one.

Is the WPE1

open circuit ?

Replace the fuse and varistor

with new ones.

Replace the transformer with

a new one.

YES

NO

Check the cleaning

switch 2(1),CN9, CN8

and lead wires.

Replace the cleaning switch 2(1).

(or reset connector)

Page 17

17

AH-N45DP2

AU-N 45DP2

AH-N56DP2

AU-N 56DP2

YES

NO

NO

YES

The machine does not function

with remote controller

Push button " " on the

wireless remote controller.

Is transmitting

indicator of the remote

controller active ?

Is indicator lamp of

indoor unit proper ?

Replace the

PWB with a

new one.

Does beep sound

from the indoor unit ?

Using a tester,

measure the voltage

between terminals

of resistor R26

on the PWB ass'y.

Push the button

" ".

Are batteries of the

wireless remote controller

proper ?

Replace the batteries

with new ones.

Replace the wireless

remote controller.

When the signal is

received, does the voltage

change ?

Replace the PWB with a new

one.

PWB is normal.

Inspect the outdoor unit.

NO

YES

NO

YES

Replace the photo

detector unit with a new

one.

NO

YES

Page 18

18

AH-N45DP2

AU-N45DP2

AH-N56DP2

AU-N56DP2

The room is not cooled at all

or not cooled.

The compressor does not operate.

Measure resistances of TH1 and TH2.

Push the button "AUX." on

the indoor unit, for more than 5 sec.

Is the voltage

between terminal "N" and

"1" of the terminal board the

power supply voltage ?

Are the resistances

conformed Fig. 1 ?

Replace the thermistor ass'y

with a new one.

NO

YES

YES

NO

Replace the PWB ass'y with a new one.

Fig. 1

Using a tester, measure voltage at

the terminals on the terminal board.

100

80

60

40

20

0

-10 0 10 20 30 40

Resistance

Thermistor

Room temperature

Heat exchange

Color

Yellow

Orange

To measure the resistance, first remove

the connector as shown at right.

Room temperature

thermistor TH1

Tester

Connector

No. 3 to 4

No. 1 to 2

Fig. 1 Temperature properties of indoor thermistors

K

Heat exchange thermistor

TH2 (orange)

25°C resistance 15 K

Room temperature

thermistor TH1 (yellow)

25°C resistance 10 K

Heat exchange

thermistor TH2

Tester

4

1

CN4

The control circuit is normal.

The compressor may be defective.

The running capacitor may be

defective.

Refrigerant may be leaked.

The outdoor fan motor may be

defective.

The outdoor fan motor capacitor

may be defective.

Page 19

19

AH-N45DP2

AU-N 45DP2

AH-N56DP2

AU-N 56DP2

For AH-N56DP2 / AU-N56DP2

The room is not cooled at all

or not cooled.

The compressor does not operate.

Measure resistances of TH1 and TH2.

The control circuit is normal.

The compressor may be defective.

The running capacitor may be

defective.

Refrigerant may be leaked.

The outdoor fan motor may be

defective.

The outdoor fan motor capacitor

may be defective.

Push the button " AUX." on

the indoor unit, for more than 5 sec.

Is the voltage

between terminal of black

lead wire on the relay in the outdoor unit

and terminal "N" on the terminal board the

power suuply voltage ?

Are the resistances

conformed Fig. 1 ?

Replace the thermistor

ass'y with a new one.

NO

YES

YES

NO

Replace the PWB ass'y with a new one.

Using a tester, measure voltage at

the terminals on the terminal board.

Replace the relay in the outdoor unit with

a new one.

Is the voltage

between terminal " N " and

" 2 " in the outdoor unit

the power supply

voltage ?

YES

NO

Page 20

20

AH-N45DP2

AU-N45DP2

AH-N56DP2

AU-N56DP2

Cycle temperature and service port pressure

REFRIGERATION CYCLE

Figure R-1. Refrigeration Cycle for AH-N45DP2 / AH-N56DP2

1

2

Capillary tube

3

Outdoor unit

Condenser

Evaporator

Indoor unit

Compressor

Flare coupling Flare coupling

4

3-way

valve

2-way

valve

Accumulator

Indoor side

Outdoor side

Temperature (˚C) Temperature (˚C)Relative humididity (%) Relative humididity (%)

27 47 35 40

Cooling

ISO condition

Dimension of Capillary tube

AH-N45DP2 AH-N56DP2

Cooling Cooling

Model

NO. Condition

Based on 'ISO 5151 : 1994(E), condition T1' (at 220V refrigerant pipes length 7.5m)

1

2

3

4

Service port pressure

83˚C 81˚C

40˚C 37˚C

11˚C 11˚C

7˚C 4˚C

0.46MPa 0.46MPa

O.D. I.D. L

Capillary tube

ø 3.5 ø 2.2 800

O.D. I.D. L

Capillary tube

ø 3.2 ø 2.0 400

AH-N45DP2 AH-N56DP2

Page 21

21

AH-N45DP2

AU-N 45DP2

AH-N56DP2

AU-N 56DP2

Figure P-1. At Cooling for AH-N45DP2

Figure P-2. At Cooling for AH-N56DP2

REFRIGERANT PIPE INSTALLATION WORKS

Refrigerant pipe length and level difference between the indoor and outdoor units.

The shorter refrigerant pipe, the highter the machine capabillity. Keep the pipe line as short as possible.

If actual pipe length exceeds 7.5m, and refrigerant (R22) 15g per 1m.

PERFORMANCE CURVES

MODEL

AH-N56DP2

PIPE SIZE

GAS

LIQUID

STANDARD PERMISSIBLE

LENGTH

STANDARD LEVEL

DIFERENCE

1/2"

5/8"

1/4"

1/4"

15m 10m

15m 10m

AH-N45DP2

4.5

5.0

5.5

Cooling capacity (kW)

1500

Power input(W)

12

Outside air temp.(˚C)

Inside Outlet air temp.(˚C)

30 31 32 33 34 35 36 37 38 39 40

13

14

15

16

2000

Indoor air temp. : 27˚C

Indoor humidity : 47RH%

Indoor fan speed : Hi

Pipe length : 7.5m

2500

6.0

6.5

Cooling capacity (kW)

2000

Power input(W)

11

Outside air temp.(˚C)

Inside Outlet air temp.(˚C)

30 31 32 33 34 35 36 37 38 39 40

12

13

14

15

2000

Indoor air temp. : 27˚C

Indoor humidity : 47RH%

Indoor fan speed : Hi

Pipe length : 7.5m

Page 22

22

AH-N45DP2

AU-N45DP2

AH-N56DP2

AU-N56DP2

DISASSEMBLING PROCEDURE

FOR INDOOR UNIT MODEL [AH-N45DP2 / AH-N56DP2]

CAUTION:DISCONNECT THE UNIT FROM THE POWER SUPPLY BEFORE ANY SERVICING

1. Open the Opne panel, remove 2 Air Filters.

2. Open the Louver frame.unlook the hooks,and pull

the unit.

3. Remove 6 screws fixing the Front panel.

4. Remove the screw fixing the Cord holder.

Page 23

23

AH-N45DP2

AU-N 45DP2

AH-N56DP2

AU-N 56DP2

5. Close the Open panel. pushing the nail of the

Front panel, and lift the Front panel up.

6. Remove the unit-to-unit wiring from the Terminal

board.

7. Remove a screw fixing the Control box cover.

8. Cut the fixing band and Remove the Cover B.

9. Remove a screw fixing the ground wire.

Page 24

24

AH-N45DP2

AU-N45DP2

AH-N56DP2

AU-N56DP2

10. Remove the Thermistor of the Evaporator.

11. Remove Connectors.

12. Cut the fixing band and Remove the Holder.

13. Remove 2 screws fixing the Control box and

remove it.

Page 25

25

AH-N45DP2

AU-N 45DP2

AH-N56DP2

AU-N 56DP2

14. Remove a screw fixing the drain pan and pull

Drain pan toward you.

15. Remove the Drain cover from the Evaporator.

16. Remove 3 screws fixing the Evaporator.

17. Remove the Evaporator from the Cabinet.

18. Remove 4 screws fixing the Side cover R, and

pull up the Cross flow fan.

19. Loose a screw fixing Cross flow fan.

Page 26

26

AH-N45DP2

AU-N45DP2

AH-N56DP2

AU-N56DP2

The Electric Control box.

1. Remove the screw fixing the Receiving filter.

2. Remove the 2 Switch and Photo detector unit.

3. Remove a screw fixing the Cord holder.

4. Remove a screw fixing the Cord holder and 2

screws fixing the Terminal board.

5. Remove 2 screws fixing the Transformer and pull

the Control board unit.

The DRAIN PAN and related

Page 27

27

AH-N45DP2

AU-N 45DP2

AH-N56DP2

AU-N 56DP2

The DRAIN PAN and related

1. Remove the screw fixing the Drain pan on both

side.

2. Turn left the Drain hose.

The LOUVER FRAME UNIT and related

1. Remove the screw fixing the FRAME GUIDE on

both side and take off the LOUVER UNIT.

2. Remove 2 screws fixing Cover-L and Cover-R

and take off them.

Page 28

28

AH-N45DP2

AU-N45DP2

AH-N56DP2

AU-N56DP2

1

2

3. Remove the connector of Louver motor and take

off the Wire and Holder.

4. Push the one of the Vertical louver.

How to remove the DISPLY COVER.

1 Push the center of the Front panel under

the Display cover.

2 Slide it to one side.

How to remove the Hi Voltage UNIT.

1. Remove 2 screws fixing Holder.

2. Take off the HIGH VOLTAGE UNIT ASS’Y from

the HOLDER

3. Remove the connector of HIGH VOLTAGE UNIT

ASS’Y

Page 29

29

AH-N45DP2

AU-N 45DP2

AH-N56DP2

AU-N 56DP2

FOR OUTDOOR UNIT MODEL AU-N45DP2 / AU-N56DP2

DISASSEMBLING PROCEDURE OF THE CONTROL BOX

1. Loose 3 screws fixing the control cover.

2. Loose 1 screw fixing the side cover.

3. Loose 8 screws fixing the side cover R.

4. Loose 2 screws fixing the cabinet (left side).

5. Loose 1 screw fixing the cabinet (rear side).

6. Loose 3 screw fixing the cabinet (right side).

7. Loose 1 screw fixing the cabinet (front side).

8. Loose 7 screws fixing the rear cabinet.

Page 30

30

AH-N45DP2

AU-N45DP2

AH-N56DP2

AU-N56DP2

9. Loose 1 screw fixing the rear cabinet (left side).

10. Cut nylon band.

11. Loose 1 screw fixing the control box.

12. Remove the terminal cover.

13. Remove 3 terminals.

14. Loose 3 screws fixing the bulkhead.

DISASSEMBLING PROCEDURE OF THE FAN

1. Loose the fan nut and fan can take out.

2. Loose 2 screw fixing the fan motor angle

3. Cut the nylon band and loose 4 screws fixing the

fan motor.

Page 31

31

AH-N45DP2

AU-N 45DP2

AH-N56DP2

AU-N 56DP2

REF. NO. PART NO. DESCRIPTION Q'TY CODE

CABINET AND UNIT PARTS

1- 1 CMOT-A415JBKZ Fan moter sub assembly 1 BR

1- 3 GWAK-A270JBFA Front panel 1 BA

1- 4 CHLD-A067JBK0 Bearing assembly 1 AL

1- 5 DCHS-A437JBKZ Cabinet sub assembly 1 BF

1- 6 NFANCA091JBEZ Cross flow fan 1 BD

1- 7 DSRA-A245JBKZ Drain pan sub assembly 1 BD

1- 8 CWAK-C200JBKZ Louver Frame assembly 1 BE

1- 9 MJNTPA093JBFA Louver link 3 AK

1-10 MLOV-A326JBFA Vertical louver 12 AE

1-11 MLOV-A327JBRA Horizontal louver 1 AN

1-12 QW-VZE168JBZZ Lead wire (for Louver motor) 1 AH

1-13 LHLD-A197JBFP Louver holder 2 AC

1-14 NBRG-A026JBFA Louver bushing 1 AB

1-15 PCOV-A752JBFA Receving filter 1 AC

1-16 PHOS-A033JBEZ Drain hose 1 AP

1-17 PPACGA026JBEZ O ring 1 AC

1-18 PCOV-A750JBFZ Drain cover 1 AF

1-19 RMOT-A099JBEZ Louver motor 1 AT

1-20 CWAK-C201JBKZ Front panel assembly 1 BE

1-21 FCOV-A104JBFA Cover R 1 AE

1-22 FCOV-A105JBFA Cover L 1 AE

1-23 PCOV-A745JBRA Display cover 1 BB

1-24 HDEC-B145JBRA Display panel 1 AP

1-25 PFILMA163JBEA Air filter 2 AK

1-26 DHLD-A010JBKZ Tube holder assembly 1 AK

1-27 HPNL-A568JBFA Open panel 1 BA

1-28 PPLT-A278JBFZ Side cover L 1 AK

1-29 PPLT-A277JBFZ Side cover R 1 AH

1-30 PSHE-A200JBEZ Evaporator sheet 1 AD

1-31 LSPR-A021JBEZ Sheet spring 4 AE

1-32 LHLD-A550JBRA Display cover 1 BE

1-33 PGID-A103JBFA Frame guide 2 AU

1-34 DCOV-A204JBKZ Cluster cover ass’y 1 AE

1-35 LHLD-A536JBFA Holder 1 AM

1-36 LHLD-A277JBF0 Tube holder 1 AD

1-37 PCOV-A819JBEZ Cover 1 AA

1-38 PCOV-A820JBEZ Cover B 1 AB

1-39 LHLD-A548JBFA Holder 1 AM

1-40 LHLD-A549JBFA Holder 1 AM

1-41 QW-VZE167JBZZ Lead wire 1 AM

1-42 PFPFPC205JBEZ Filter insulator 2 AA

1-43 TSPC-E396JBRA Name label [AH-N45DP2] 1 AE

1-43 TSPC-E397JBRA Name label [AH-N56DP2] 1 AE

1-44 TLABCB734JBRZ Wiring diagram [AH-N45DP2] 1 AD

1-44 TLABCB735JBRZ Wiring diagram [AH-N56DP2] 1 AD

CONTROL BOX PARTS

2- 1 RTHM-A300JBE0 Thermistor 1 AN

2- 2 PBOX-A378JBFA Control box 1 AX

2- 3 PCOV-A744JBWZ Control box cover 1 AS

2- 4 LHLD-A500JBFZ Thermistor holder 1 AC

2- 5 PCOV-A300JBF0 Thermo holder cover 1 AB

2- 6 CPNL-A414JBKZ Control box cover 1 AK

2- 7 CKITTA002JBKZ High voltage unit (Plasma cluster unit) 1 BA

2- 8 LHLD-A537JBFA LED holder 1 AM

2- 9 LHLD-A542JBFA Holder 2 AM

2-10 DPWBFA315JBKZ Control board unit [AH-N45DP2] 1 BQ

2-10 DPWBFA316JBKZ Control board unit [AH-N56DP2] 1 BQ

2-11 QACC-A164JBE0 Power supply cord 1 AY

2-12 QTANZA006JBZZ Terminal board (3pin) 1 AN

2-13 QTANZA002JBZZ Terminal board (3pin) [AH-N45DP2] 1 AN

2-13 QTANZA001JBZZ Terminal board (4pin) [AH-N56DP2] 1 AQ

2-14 FCOV-A106JBFA Receiving filter 1 AC

2-15 PCOV-A742JBFA LED holder 2 AC

2-16 LHLD-A618JBFA Cord holder 1 AN

2-17 LHLD-A539JBFA Cord holder 1 AE

2-18 LHLD-A540JBFA Holder 1 AM

2-19 QSW-MA008JBZZ Switch 1 AK

2-20 QSW-MA147WRZZ Micro switch A 1 AG

2-21 RC-HZA421JBZZ Fan motor capacitor (C1) 1 AP

2-22 RH-IXA691JBZZ Microcomputer (IC1) 1 AU

2-23 RH-IZA149JBE0 Integrated circuit (IC2) 1 AE

2-24 RIC--A022BDE0 Integrated circuit (IC3) 1 AE

REPLACEMENT PARTS LIST [AH-N45DP2 / AH-N56DP2]

Page 32

32

AH-N45DP2

AU-N45DP2

AH-N56DP2

AU-N56DP2

REF. NO. PART NO. DESCRIPTION Q'TY CODE

2-25 RIC--A025BDE0 Integrated circuit (IC4, IC5) 2 AE

2-26 RH-IZA140JBE0 Integrated circuit (IC6) 1 AE

2-27 VHIBR24C01A-6 Integrated circuit (IC8) 1 AF

2-28 RRMCUA001JBZZ Photo detector unit (IC101) 1 AK

2-29 RH-VXA002JBZZ Varistor (NR1) 1 AF

2-30 RTRN-A181JBE0 Current transformer (CT1) 1 AN

2-31 VHRS201D01/-6 Solid state relay (SSR1) 1 AK

2-32 VHRPR33MF11-6 Solid state relay (SSR2) 1 AX

2-33 RTRN-A287JBZZ Transformer (TR1) 1 AT

2-34 RRLYDA004JBZZ Relay (RY1) [AH-N45DP2] 1 AG

2-35 RRLYDA008JBZZ Relay (RY4) [AH-N56DP2] 1 AH

2-36 QFS-GA053JBZZ Fuse (WPE1) 1 AE

CYCLE PARTS

3- 1 CPIPCA723JBKZ Tube assembly [AH-N45DP2] 1 BA

3- 1 CPIPCA729JBKZ Tube assembly [AH-N56DP2] 1 BA

3- 2 PSEN-A042JBKZ Flare nut assembly (1/4") 1 AL

3- 3 PSEN-A043JBKZ Flare nut assembly (3/8") [AH-N45DP2] 1 AD

3- 3 PSEN-A048JBKZ Flare nut assembly (1/2") [AH-N56DP2] 1 AP

3- 4 PVLV-A222JBEZ Flare union (1/4") 1 AG

3- 5 PVLV-A223JBEZ Flare union (3/8") [AH-N45DP2] 1 AL

3- 5 PVLV-A238JBEZ Flare union (1/2") [AH-N56DP2] 1 AM

3- 6 DEVA-A188JBKZ Evaporator sub assembly [AH-N45DP2] 1 CA

3- 6 DEVA-A203JBKZ Evaporator sub assembly [AH-N56DP2] 1 BW

ACCESSORY PARTS

4- 1 CRMC-A607JBEZ Remote control 1 BA

4- 2 UBATUA027JBE0 Battery pack 1 AE

4- 3 LHLD-A535JBFA Cord holder

(for covering the terminal board of indoor unit)

1AE

4- 4 XTTSD40P20000 Tapping screw (for fixing the cord holder) 1 AA

4- 5 LX-NZA207JBEZ Special nut (for fixing long screw steadily) 10 AE

4- 6 TINS-A767JBRZ Installation manual 1 AF

4- 7 PPLTNA061JBWZ Mounting angle 1 AT

4- 8 XTTSD45P30000 Long screw 8 AA

4- 9 TINS-A768JBRZ Operation manual 1 AE

4-10 XTTSF40P20000 Tapping screw (for fixing the remote controller holder) 1 AB

4-11 LHLD-A484JBFA Holder 1 AE

4-12 TGANJB557JBRZ Warranty card 1 AF

SCREWS

5- 1 LX-BZA075JBE0 Special screw (for earth) 1 AA

PACKING PARTS

6- 1 CPADBA047JBKZ Packing pad assembly 2 AN

6- 2 SPADBA162JBEZ Packing pad (sheet) 1 AL

6- 3 SPAKCB320JBEZ Packing case [AH-N45DP2] 1 AV

6- 3 SPAKCB321JBEZ Packing case [AH-N56DP2] 1 AV

HOW TO ORDER REPLACEMENT PARTS

To have your order filled prompty and correctly, please furnish the following information.

1. MODEL NUMBER 2. REF. NO.

3. PART NO. 4. DESCRIPTION

Page 33

33

AH-N45DP2

AU-N 45DP2

AH-N56DP2

AU-N 56DP2

A

B

C

D

E

F

G

H

A

123456

123456

B

C

D

E

F

G

H

INDOOR UNIT AH-N45DP2 / AH-N56DP2

1-43

1-44

1-27

1-24

1-23

1-25

1-26

1-18

2-3

2-2

2-28

2-10

2-14

2-11

2-19

2-20

1-39

1-40

2-6

1-38

1-29

1-1

1-7

2-9

2-9

2-15

1-10

1-33

1-15

1-21

1-19

1-12

1-10

1-10

1-33

1-35

2-15

1-41

2-7

1-9

1-8

1-22

1-14

1-13

1-13

1-11

1-9

1-9

1-16

1-17

2-18

2-8

1-32

1-34

2-13

2-12

2-17

2-16

1-28

1-5

4-7

3-6

1-31

1-30

3-1

5-1

3-4

2-5

2-1

1-37

1-6

1-4

2-4

3-5

3-3

3-2

1-42

1-31

1-31

1-31

1-42

1-36

6-3

6-2

6-1

4-2

4-9

4-8

4-4

4-5

4-6

4-12

4-10

4-1

4-3

1-20

1-3

4-11

Page 34

34

AH-N45DP2

AU-N45DP2

AH-N56DP2

AU-N56DP2

REF. NO. PART NO. DESCRIPTION Q'TY CODE

CABINET AND UNIT PARTS

1- 1 LSUB-A024JBPZ Motor angle sub 2 AP

1- 2 CMOTLB027JBEZ Fan motor [AU-N45DP2] 1 BU

1- 2 CMOTLB028JBEZ Fan motor [AU-N56DP2] 1 BS

1- 3 NFANPA108JBFA Propeller fan 1 BA

1- 4 LANGKA145JBPZ Motor angle 1 AV

1- 5 PSKR-A242JBWZ Bulkhead 1 AT

1- 6 GPLTMA060JBTA Right side cover 1 AS

1- 7 CFTA-B310JBKZ Control cover assembly [AU-N45DP2] 1 BA

1- 7 CFTA-A311JBKZ Control cover assembly [AU-N56DP2] 1 AW

1- 8 GCAB-A221JBTA Rear cabinet 1 BE

1- 9 GCAB-A189JBTA Cabinet 1 BG

1-10 GGADFA028JBTA Fan guard 1 AZ

1-11 PSEL-C280JBEZ Bulkhead insulator C 1 AE

1-12 PSPF-A827JBEZ Compressor cover 1 AS

1-13 PSEL-C017JBEZ Cabinet seal 1 AC

1-14 TSPC-E398JBRZ Name label [AU-N45DP2] 1 AE

1-14 TSPC-E399JBRZ Name label [AU-N56DP2] 1 AE

1-15 TLABBA100JBRA SHARP badge 1 AE

1-16 CCHS-A777JBTZ Base pan assembly 1 BE

1-18 PSEL-C264JBEZ Bulkhead insulator B 1 AD

1-19 LBSHCA022JBF0 Bushing 1 AE

1-20 PFPFPC111JBEZ Corner insulator 1 AC

1-21 PSEL-B643JBE0 Insulator No.9 1 AC

1-22 PSEL-C275JBEZ Insulator 1 AD

1-23 PSEL-C278JBEZ Insulator 1 AC

1-24 PSEL-C282JBEZ Cushion 1 AD

1-25 PSEL-C370JBEZ Insulator 1 AC

1-26 PSEL-C378JBEZ Insulator 1 AB

1-27 PSEL-C379JBEZ Insulator 1 AB

1-28 PSEL-C380JBEZ Insulator 1 AC

1-29 PSEL-A191JBE0 Condenser seal 1 AA

1-30 PFTA-A095JBFA Side cover 1 AN

CONTROL BOX PARTS

2- 1 RRLYJA088JBZZ Relay [AU-N56DP2] 1 BA

2- 2 LHLD-A544JBFA Cord clamp holder 1 AG

2- 3 QW-IZA031JBZZ Compressor cord 1 AT

2- 4 RC-HZA472JBZZ Running capacitor 1 AX

2- 5 RC-HZA404JBZZ Fan motor capacitor 1 AU

2- 6 QTANZA002JBZZ Terminal board [AU-N45DP2] 1 AN

2- 6 QTANZA001JBZZ Terminal board [AU-N56DP2] 1 AQ

2- 7 LHLD-A539JBFA Cord clamp 1 AE

2- 8 PBOX-A379JBWZ Control box 1 AR

2- 9 LBNDKA047JBW0 Capacitor clamp 1 AH

2-10 TLABCB806JBRZ Wiring diagram [AU-N45DP2] 1 AE

2-10 TLABCB807JBRZ Wiring diagram [AU-N56DP2] 1 AE

CYCLE PARTS

3- 1 PCMPRA294JBE0 Compressor [AU-N45DP2] 1 CP

3- 1 PCMPRA392JBEZ Compressor [AU-N56DP2] 1 CH

3- 2 PCON-A511JBPZ Condenser 1 CB

3- 3 DVLV-A606JBKZ 2 Way valve assembly 1 AR

3- 4 LX-NZA250JBEZ Flare nut 1 AE

3- 5 MSPRPA018JBE0 Terminal cover holder 1 AK

3- 6 PCAP-A075JBFZ Bonnet 1 AC

3- 7 DVLV-A607JBKZ 3 Way valve assembly [AU-N45DP2] 1 AX

3- 7 DVLV-A608JBKZ 3 Way valve assembly [AU-N56DP2] 1 AZ

3- 8 LX-NZA280JBEZ Flare nut [AU-N45DP2] 1 AG

3- 8 LX-NZA286JBEZ Flare nut [AU-N56DP2] 1 AH

3- 9 CPIPCA817JBKZ Discharge tube ass’y [AU-N45DP2] 1 AT

3- 9 CPIPCA818JBKZ Discharge tube ass’y [AU-N56DP2] 1 AY

3-10 PCAP-A089JBEZ Bonnet [AU-N45DP2] 1 AX

3-10 PCAP-A090JBEZ Bonnet [AU-N56DP2] 1 AE

3-11 CCPY-A161JBKZ Capillary tube assembly [AU-N45DP2] 1 AR

3-11 CCPY-A139JBKZ Capillary tube assembly [AU-N56DP2] 1 BF

3-12 PCOV-A379JBE0 Terminal cover 1 AF

3-13 CPIPCA794JBKZ Suction tube ass’y [AU-N45DP2] 1 AX

3-13 CPIP-A054JBKZ Suction tube ass’y [AU-N56DP2] 1 AZ

3-14 GLEG-A094JBE0 Compressor cushion rubber 4 AG

3-15 PSEL-B173JBE0 Terminal gasket 1 AE

3-13 CPIPCA794JBKZ Suction tube ass’y [AU-N45DP2] 1 AX

3-13 CPIP-A054JBKZ Suction tube ass’y [AU-N56DP2] 1 AZ

REPLACEMENT PARTS LIST [AU-N45DP2 / AU-N56DP2]

Page 35

35

AH-N45DP2

AU-N 45DP2

AH-N56DP2

AU-N 56DP2

REF. NO. PART NO. DESCRIPTION Q'TY CODE

HOW TO ORDER REPLACEMENT PARTS

To have your order filled prompty and correctly, please furnish the following information.

1. MODEL NUMBER 2. REF. NO.

3. PART NO. 4. DESCRIPTION

SCREWS, NUT AND BOLT

6- 1 LX-BZA072JBE0 Special screw 4 AB

6- 2 LX-NZ0128JBE0 Special nut 1 AB

6- 3 LX-BZA140JBE0 Special screw 24 AB

6- 4 LX-BZA292JBE0 Special screw 19 AC

6- 5 LX-BZA166JBE0 Special screw 1 AB

6- 6 LX-NZA048JBE0 Special nut 4 AA

6- 7 XCPSD40P25000 Tapping screw 1 AC

6- 8 XCTSD40P12000 Tapping screw [AU-N45DP2] 2 AA

6- 8 XCTSD40P12000 Tapping screw [AU-N56DP2] 4 AA

6- 9 XCTSD40P40000 Tapping screw 2 AA

6-10 LX-BZA075JBE0 Special screw 1 AA

PACKING PARTS

7- 1 CPADBA050JBKZ Bottom pad assembly 1 AM

7- 2 CPADBA051JBKZ Packing pad assembly 1 AM

7- 3 SPAKCB322JBEZ Packing case [AU-N45DP2] 1 AX

7- 3 SPAKCB323JBEZ Packing case [AU-N56DP2] 1 AX

Page 36

36

AH-N45DP2

AU-N45DP2

AH-N56DP2

AU-N56DP2

A

B

C

D

E

F

G

H

A

123456

123456

B

C

D

E

F

G

H

'2003. 03

OUTDOOR UNIT AU-N45DP2 / AU-N56DP2

6-4

6-4

6-4

6-4

6-4

6-4

6-3

6-4

6-3

6-4

2-10

1-7

1-14

6-4

6-4

6-5

1-24

3-2

1-6

1-30

1-20

1-22

1-4

6-3

6-3

6-3

1-1

1-1

1-3

1-2

6-4

6-2

6-3

1-8

1-23

6-3

1-26

1-13

1-25

1-29

1-16

6-1

3-7

3-8

3-10

1-28

3-11

1-12

6-3

6-3

6-3

6-3

1-21

1-10

1-9

2-2

2-7

2-6

6-8

6-7

1-27

1-19

1-5

1-18

1-11

6-10

2-8

2-4

2-5

2-1

6-8

2-9

6-3

3-4

3-3

3-6

1-15

7-3

7-1

7-2

F

ro

n

t s

id

e

3-14

6-6

3-5

3-12

3-15

2-3

3-1

3-13

3-9

Loading...

Loading...