Page 1

AH-A07BE-C/09BE-C

AH-A07BE/09BE/12BE

AY-A07BE-C/09BE-C

AY-A07BE/09BE/12BE

1

INDOOR UNIT

AH-A07BE/A09BE/A12BE

AH-A07BE-C/A09BE-C

AY-A07BE/A09BE/A12BE

AY-A07BE-C/A09BE-C

OUTDOOR UNIT

AU-A07BE/A09BE/A12BE

AU-A07BE-C/A09BE-C

AE-A07BE/A09BE/A12BE

SHARP CORPORATION

TABLE OF CONTENTS

Page

SPECIFICATIONS .............................................................................................................................................2

EXTERNAL DIMENSIONS ................................................................................................................................4

WIRING DIAGRAMS .........................................................................................................................................6

ELECTRICAL PARTS........................................................................................................................................9

MICROCOMPUTER CONTROL SYSTEM ......................................................................................................13

FUNCTIONS ....................................................................................................................................................17

TROUBLESHOOTING OF THE CONTROL CIRCUIT ....................................................................................24

REFRIGERATION CYCLE ..............................................................................................................................29

PERFORMANCE CURVE ...............................................................................................................................31

DISASSEMBLING PROCEDURE....................................................................................................................33

REPLACEMENT PARTS LIST ........................................................................................................................41

SER VICE MANU AL

S4216AYA09BE/

SPLIT SYSTEM

ROOM AIR CONDITIONERS

In the interests of user-safety (Required by safety regulations in

some countries) the set should be restored to its original

condition and only parts identical to those specified should be

used.

MODELS

Page 2

2

AH-A07BE-C/09BE-C

AH-A07BE/09BE/12BE

AY-A07BE-C/09BE-C

AY-A07BE/09BE/12BE

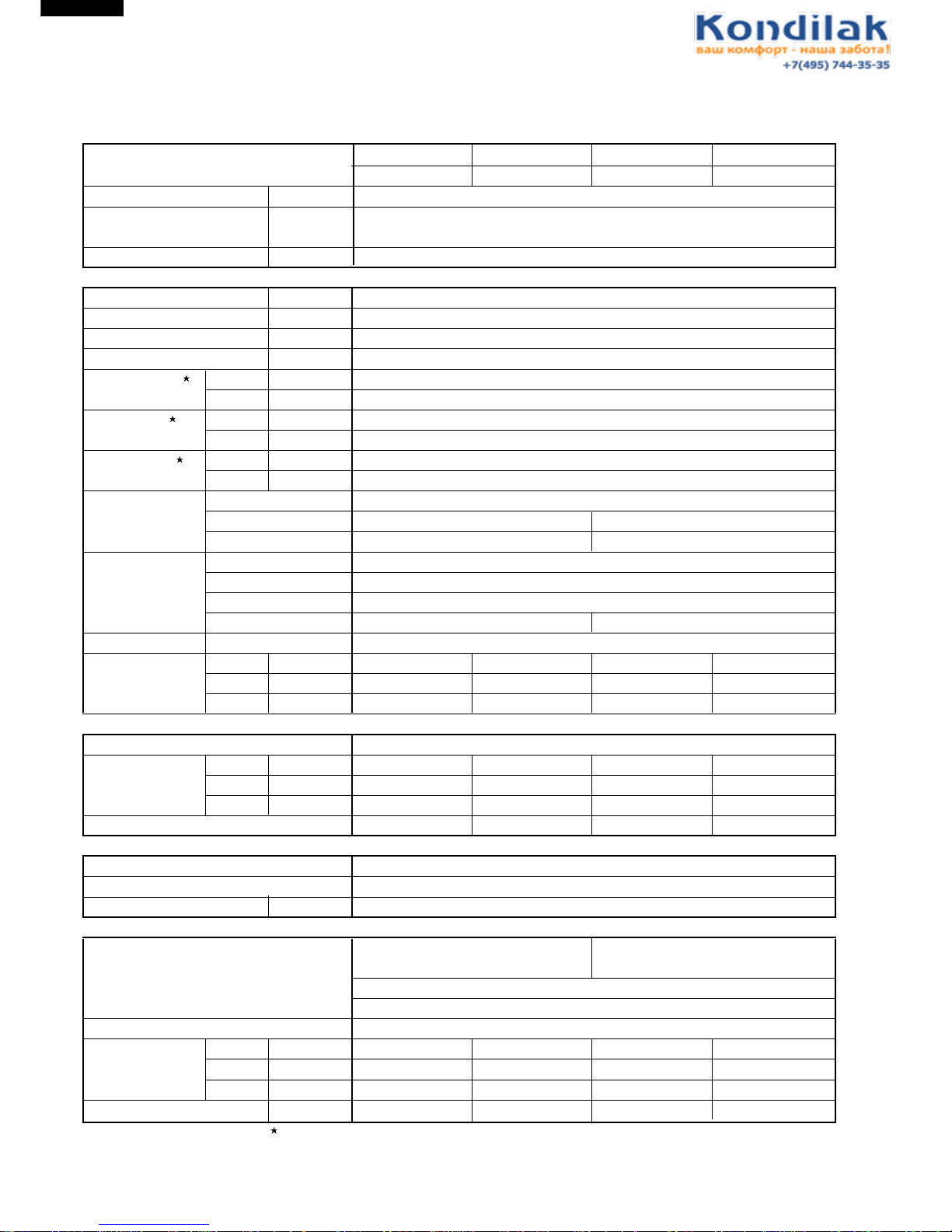

SPECIFICATIONS

ITEMS

INDOOR UNIT OUTDOOR UNIT INDOOR UNIT OUTDOOR UNIT

AY-A07BE AE-A07BE AY-A07BE-C AE-A07BE-C

Cooling capacity kW 2.1

Heat pump kW 2.4

Heating capacity

Moisture removal Liters/h 0.7

Electrical data

Phase – Single

Rated frequency Hz 50

Rated voltage range V 198 to 264

Rated voltage V 220 - 240

Rated current Cool A 3.1 - 3.0

Heat A 2.9 - 2.8

Rated input Cool W 650 - 690

Heat W 600 - 640

Power factor Cool % 95 - 96

Heat % 94 - 95

Compressor Type Hermetically sealed rotary type

Model QK134PA13A RH135VHST

Oil charge 300cc (SUNISO 4GSI) 300cc (DIAMOND MS56)

Refrigerant system

Evaporator Louver fin and Bare tube type

Condenser Corrugate fin and Grooved tube type

Control Capillary tube

Refrigerant volume 700g 650g

De-Ice system Micro computercontroled reverse systyem

Noise level High dB(A) 33 43 33 43

(at cooling) Med. dB(A) 29 – 29 –

Low dB(A) 27 – 27 –

Fan system

Drive Direct drive

Air flow quantity High m3/min. 7.2 21 7.2 21

Med. m3/min. 6.0 – 6.0 –

Low m3/min. 4.8 – 4.8 –

Fan Cross flow fan Propeller fan Cross flow fan Propeller fan

Connections

Refrigerant coupling Flare type

Refrigerant tube size Gas, Liquid 3/8", 1/4"

Drain piping mm O.D ø 18

Others

Safety device Compressor: Overload protector Compressor: Overload protector

(Internal)

Fan motor: Thermal fuse

Fuse, Micro computer control

Air filters Polypropylene net (Washable)

Net dimensions Width mm 815 720 815 720

Height mm 278 535 278 535

Depth mm 198 236 198 236

Net weight kg 9 30 9 30

Note: The condition of star( ) marked item are 'ISO5151' : 1994(E), condition T1.

Page 3

AH-A07BE-C/09BE-C

AH-A07BE/09BE/12BE

AY-A07BE-C/09BE-C

AY-A07BE/09BE/12BE

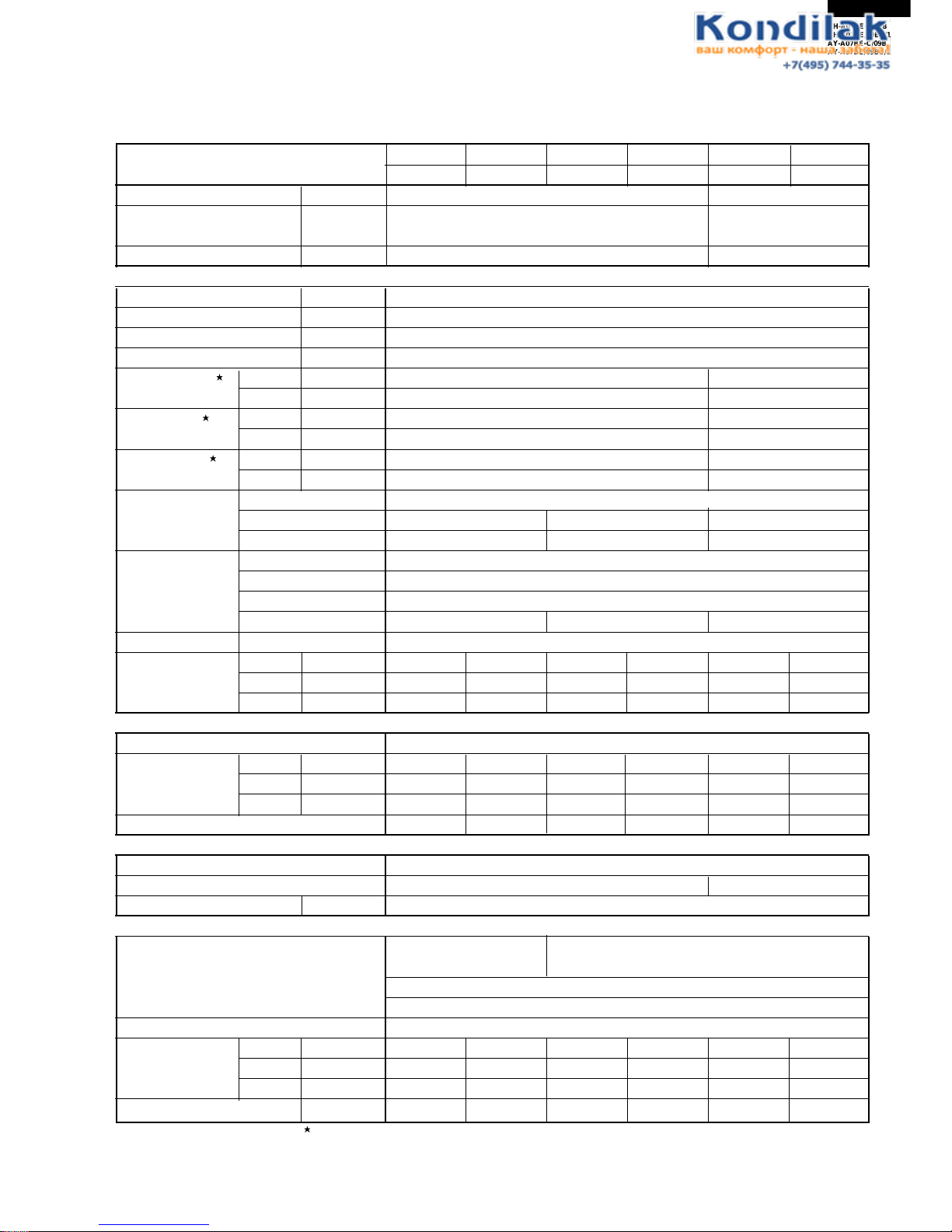

3

Overload

ITEMS

INDOOR UNIT

OUTDOOR UNIT

INDOOR UNIT

OUTDOOR UNIT

INDOOR UNIT

OUTDOOR UNIT

AY-A09BE AE-A09BE AY-A09BE-C AE-A09BE-C AY-A12BE AE-A12BE

Cooling capacity kW 2.64 3.5

Heat pump kW 3.1 4.0

Heating capacity

Moisture removal Liters/h 0.8 1.2

Electrical data

Phase – Single

Rated frequency Hz 50

Rated voltage range V 198 to 264

Rated voltage V 220 - 240

Rated current Cool A 3.8 - 3.6 5.0 - 4.8

Heat A 3.7 - 3.5 5.0 - 4.8

Rated input Cool W 820 - 850 1090 - 1120

Heat W 810 - 840 1080 - 1120

Power factor Cool % 98 - 98 99 - 97

Heat % 100 - 100 98 - 97

Compressor Type Hermetically sealed rotary type

Model QK164PA13A RH165VHET RH207VHET

Oil charge

300cc (SUNISO 4GSI) 300cc (DIAMOND MS56) 520cc (DIAMOND MS56)

Refrigerant system

Evaporator Louver fin and Grooved tube type

Condenser Corrugate fin and Grooved tube type

Control Capillary tube

Refrigerant volume 740g 690g 970g

De-Ice system Micro computercontroled reverse systyem

Noise level High dB(A) 36 43 36 43 38 48

(at cooling) Med. dB(A) 32 – 32 – 33 –

Low dB(A) 27 – 27 – 29 –

Fan system

Drive Direct drive

Air flow quantity High m3/min. 8.6 28 8.6 28 9.3 30

Med. m3/min. 6.8 – 6.8 – 8.4 –

Low m3/min. 5.3 – 5.3 – 7.4 –

Fan

Cross flow fan Propeller fan Cross flow fan Propeller fan Cross flow fan Propeller fan

Connections

Refrigerant coupling Flare type

Refrigerant tube size Gas, Liquid 3/8", 1/4" 1/2", 1/4"

Drain piping mm O.D ø 18

Others

Safety device Compressor: Compressor: Overload protector (Internal)

Overload protector

Fan motor: Thermal fuse

Fuse, Micro computer control

Air filters Polypropylene net (Washable)

Net dimensions Width mm 815 780 815 780 815 780

Height mm 278 540 278 540 278 540

Depth mm 198 269 198 269 198 269

Net weight kg 9 34 9 34 10 39

Note: The condition of star( ) marked item are 'ISO5151' : 1994(E), condition T1.

Page 4

4

AH-A07BE-C/09BE-C

AH-A07BE/09BE/12BE

AY-A07BE-C/09BE-C

AY-A07BE/09BE/12BE

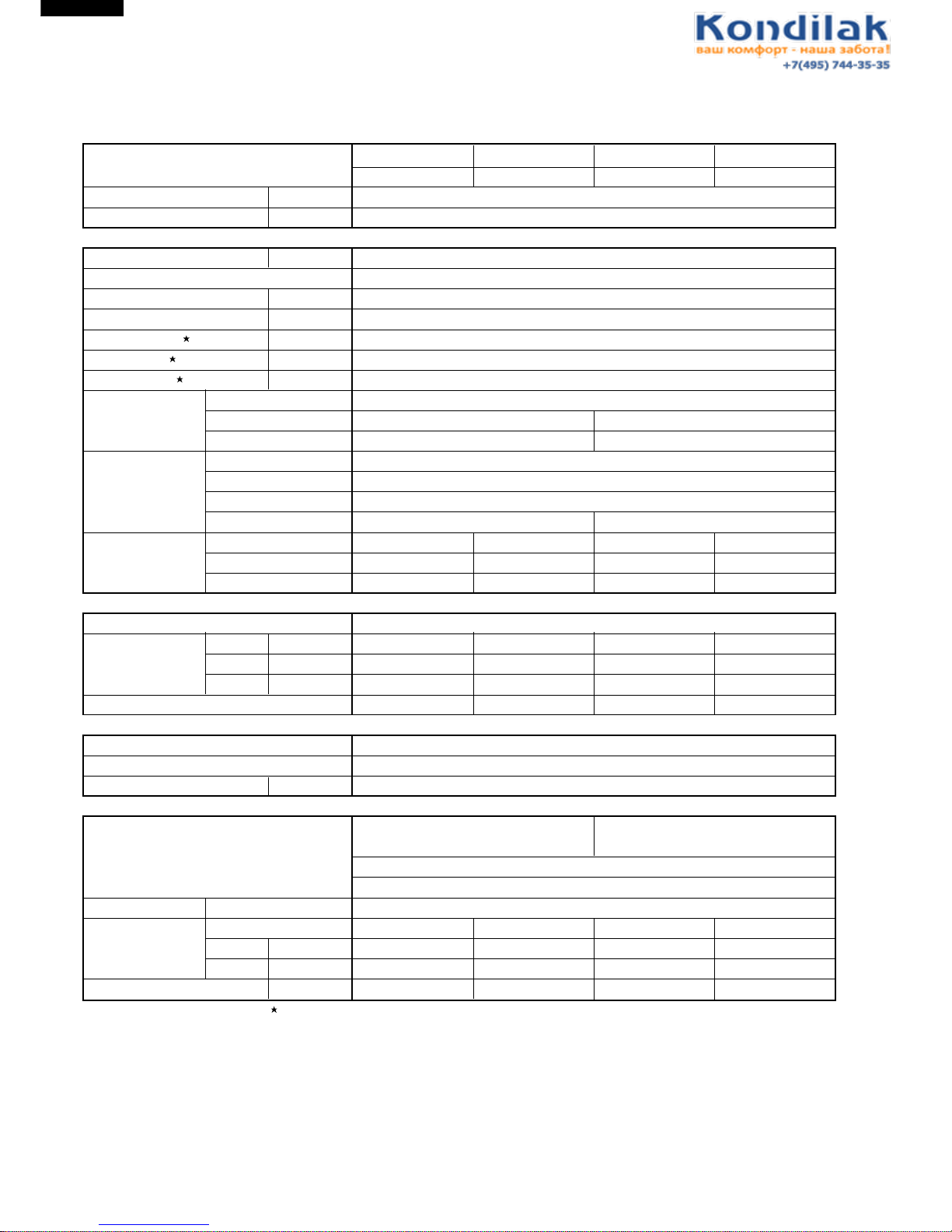

ITEMS

INDOOR UNIT OUTDOOR UNIT INDOOR UNIT OUTDOOR UNIT

AH-A07BE AU-A07BE AH-A07BE-C AU-A07BE-C

Cooling capacity kW 2.1

Moisture removal Liters/h 0.7

Electrical data

Phase – Single

Rated frequency Hz 50

Rated voltage range V 198 to 264

Rated voltage V 220 - 240

Rated current A 3.1 - 3.0

Rated input W 650 - 690

Power factor % 95 - 96

Compressor Type Hermetically sealed rotary type

Model QK134PA13A RH130VHST

Oil charge

300cc (SUNISO 4GSI) 300cc (

DIAMOND MS 56

)

Refrigerant system

Evaporator Louver fin and Bare tube type

Condenser Louver fin and Bare tube type

Control Capillary tube

Refrigerant volume 480g 470g

Noise level High dB(A) 33 43 33 43

(at cooling) Med. dB(A) 29 – 29 –

Low dB(A) 27 – 27 –

Fan system

Drive Direct drive

Air flow quantity High m3/min. 7.2 20 7.2 20

Med. m3/min. 6.0 – 6.0 –

Low m3/min. 4.8 – 4.8 –

Fan Cross flow fan Propeller fan Cross flow fan Propeller fan

Connections

Refrigerant coupling Flare type

Refrigerant tube size Gas, Liquid 3/8", 1/4"

Drain piping mm O.D ø 18

Others

Safety device Compressor: Overload protector Compressor: Overload protector

(Internal)

Fan motor: Thermal fuse

Fuse, Micro computer control

Air filters Polypropylene net (Washable)

Net dimensions Width mm 815 720 815 720

Height mm 278 535 278 535

Depth mm 198 236 198 236

Net weight kg 9 29 9 29

Note: The condition of star( ) marked item are 'ISO5151' : 1994(E), condition T1.

Page 5

AH-A07BE-C/09BE-C

AH-A07BE/09BE/12BE

AY-A07BE-C/09BE-C

AY-A07BE/09BE/12BE

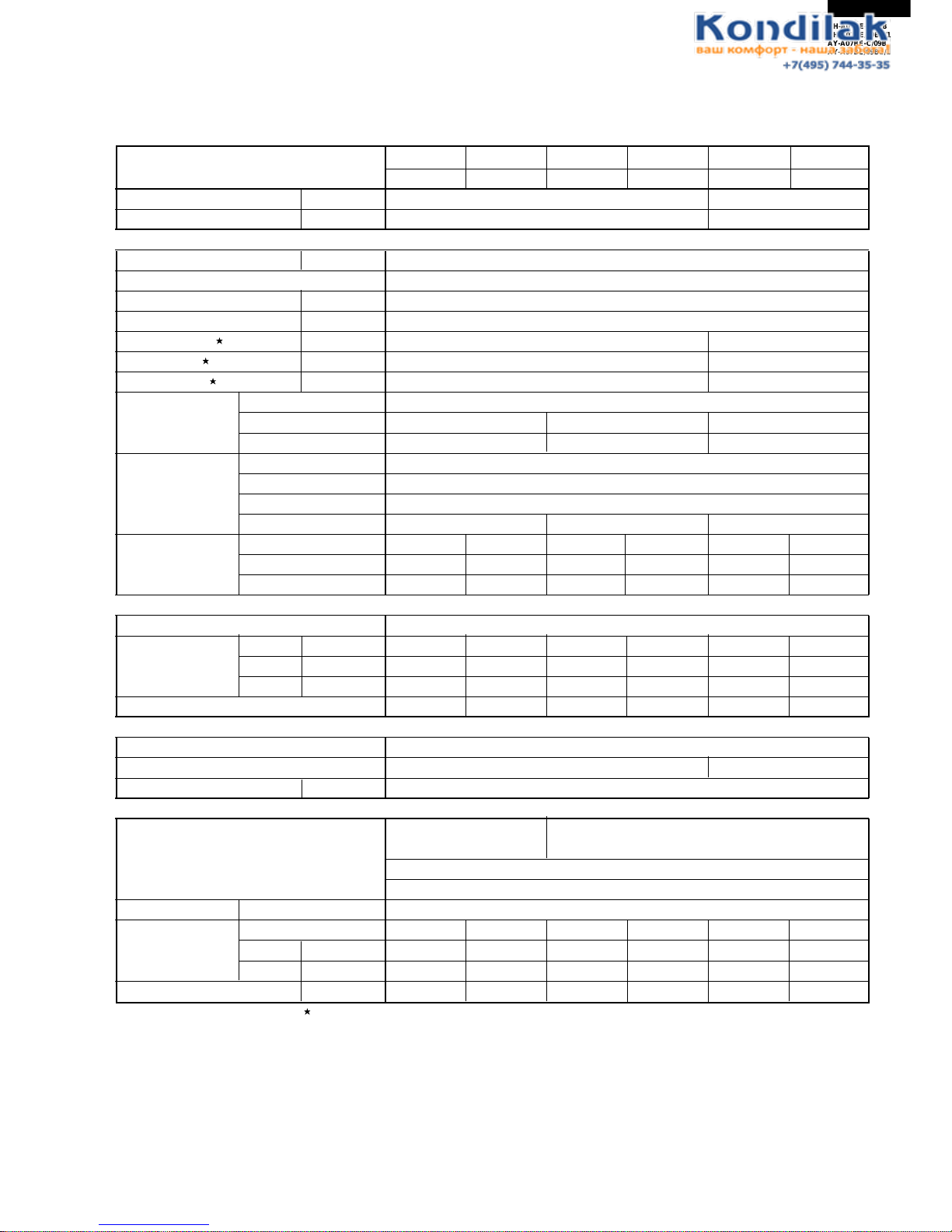

5

ITEMS

INDOOR UNIT

OUTDOOR UNIT

INDOOR UNIT

OUTDOOR UNIT

INDOOR UNIT

OUTDOOR UNIT

AH-A09BE AU-A09BE AH-A09BE-C AU-A09BE-C AH-A12BE AU-A12BE

Cooling capacity kW 2.64 3.5

Moisture removal Liters/h 0.8 1.2

Electrical data

Phase – Single

Rated frequency Hz 50

Rated voltage range V 198 to 264

Rated voltage V 220 - 240

Rated current A 3.8 - 3.6 5.0 - 4.8

Rated input W 820 - 850 1090 - 1120

Power factor % 98 - 98 99 - 97

Compressor Type Hermetically sealed rotary type

Model QK164PA13A RH154VHST RH207VHET

Oil charge

300cc (SUNISO 4GSI) 300cc (DIAMOND MS56) 520cc (DIAMOND MS56)

Refrigerant system

Evaporator Louver fin and Grooved tube type

Condenser Louver fin and Grooved tube type

Control Capillary tube

Refrigerant volume 550g 560g 870g

Noise level High dB(A) 36 43 36 43 38 48

(at cooling) Med. dB(A) 32 – 32 – 33 –

Low dB(A) 27 – 27 – 29 –

Fan system

Drive Direct drive

Air flow quantity High m3/min. 8.6 28 8.6 28 9.3 30.0

Med. m3/min. 6.8 – 6.8 – 8.4 –

Low m3/min. 5.3 – 5.3 – 7.4 –

Fan

Cross flow fan Propeller fan Cross flow fan Propeller fan Cross flow fan Propeller fan

Connections

Refrigerant coupling Flare type

Refrigerant tube size Gas, Liquid 3/8", 1/4" 1/2", 1/4"

Drain piping mm O.D ø 18

Others

Safety device

Compressor: Overload protector Compressor: Overload protector

(Internal)

Fan motor: Thermal fuse

Fuse, Micro computer control

Air filters Polypropylene net (Washable)

Net dimensions Width mm 815 780 815 780 815 780

Height mm 278 540 278 540 278 540

Depth mm 198 269 198 269 198 269

Net weight kg 9 33 9 33 10 38

Note: The condition of star( ) marked item are 'ISO5151' : 1994(E), condition T1.

Page 6

6

AH-A07BE-C/09BE-C

AH-A07BE/09BE/12BE

AY-A07BE-C/09BE-C

AY-A07BE/09BE/12BE

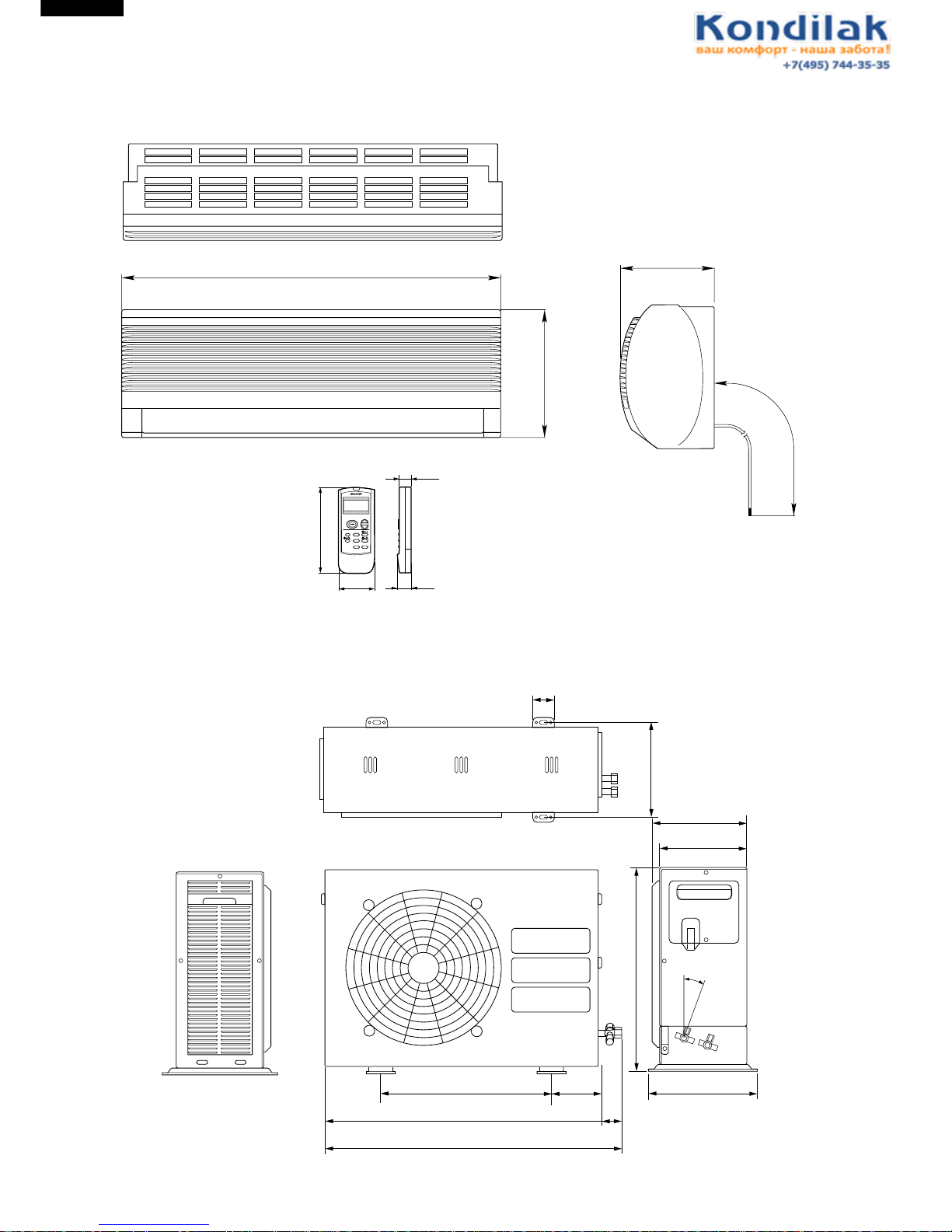

EXTERNAL DIMENSIONS

Figure E-1. INDOOR UNIT

Figure E-2. OUTDOOR UNIT FOR AE-A07BE/AE-A07BE-C AND AU-A07BE/AU-A07BE-C

Length unit (mm)

815

278

198

1100

Remote controller

58

18.5

22

140

INVERTER AIR CONDITIONER

430

720

775

143

55

245

535

278

236

228

20˚

58

Page 7

AH-A07BE-C/09BE-C

AH-A07BE/09BE/12BE

AY-A07BE-C/09BE-C

AY-A07BE/09BE/12BE

7

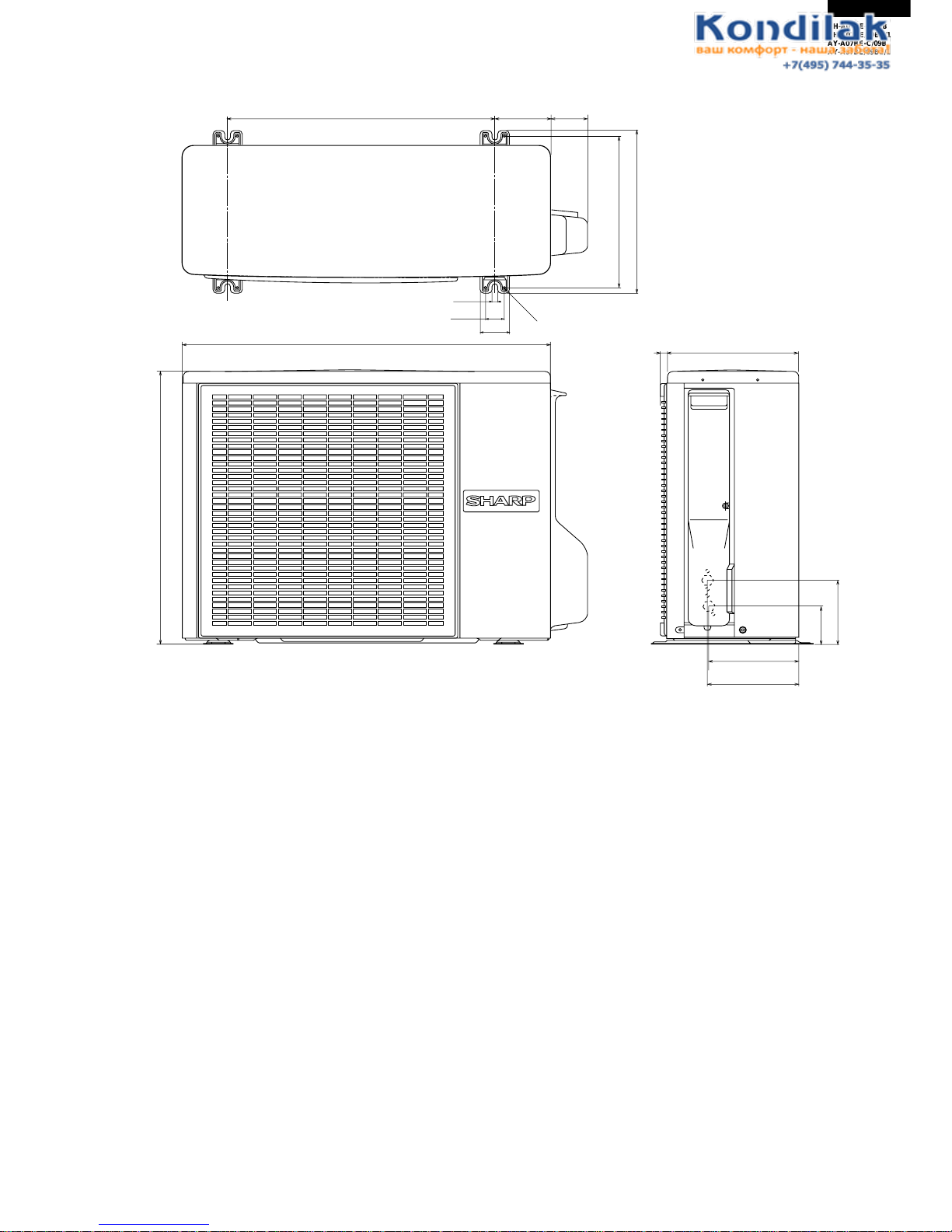

Figure E-3. OUTDOOR UNIT FOR AE-A09BE/AE-A09BE-C/A12BE AND AU-A09BE/AU-A09BE-C/A12BE

269

179.5

182.5

136

81

780

70

540

310

335

540

12

37.5

4.5

58

158

16

Page 8

8

AH-A07BE-C/09BE-C

AH-A07BE/09BE/12BE

AY-A07BE-C/09BE-C

AY-A07BE/09BE/12BE

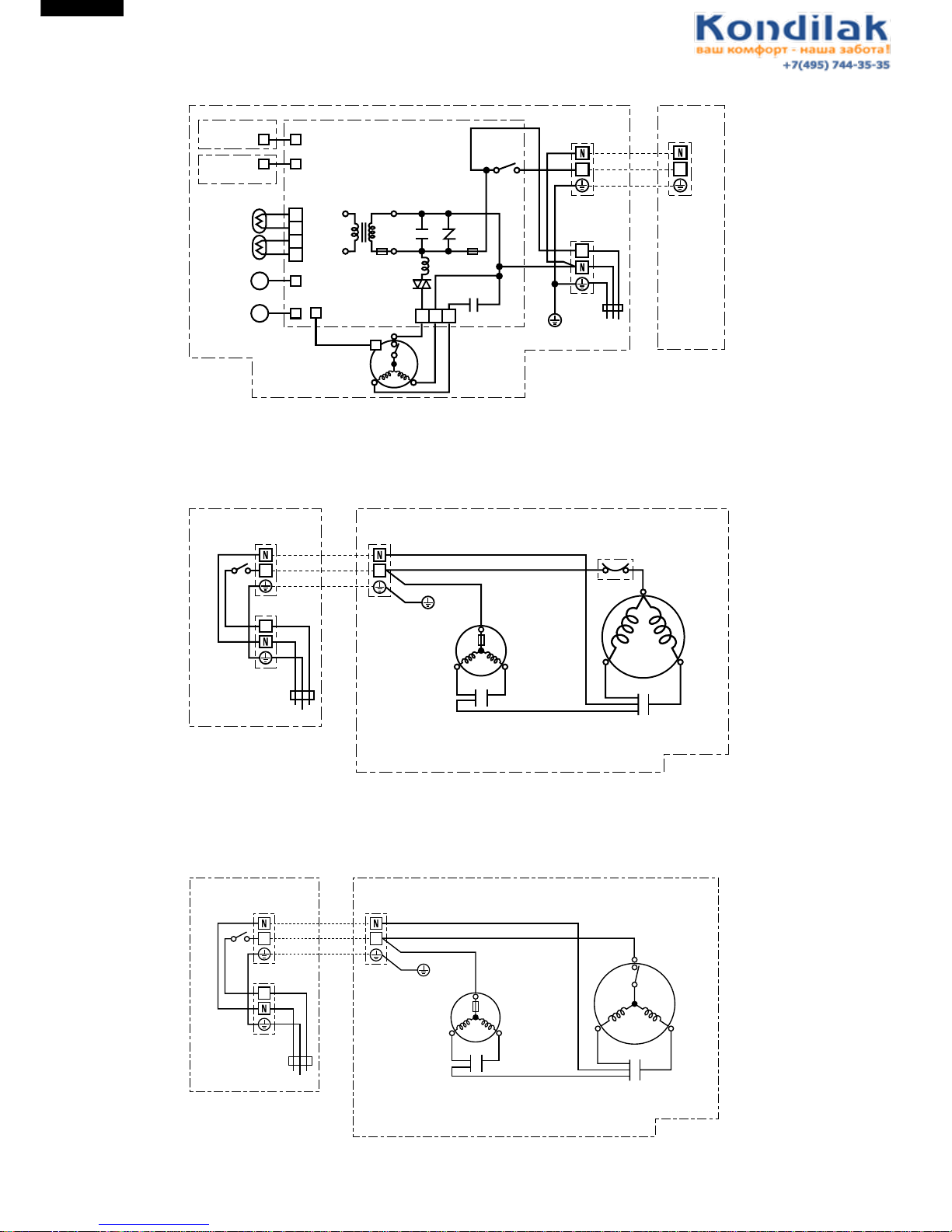

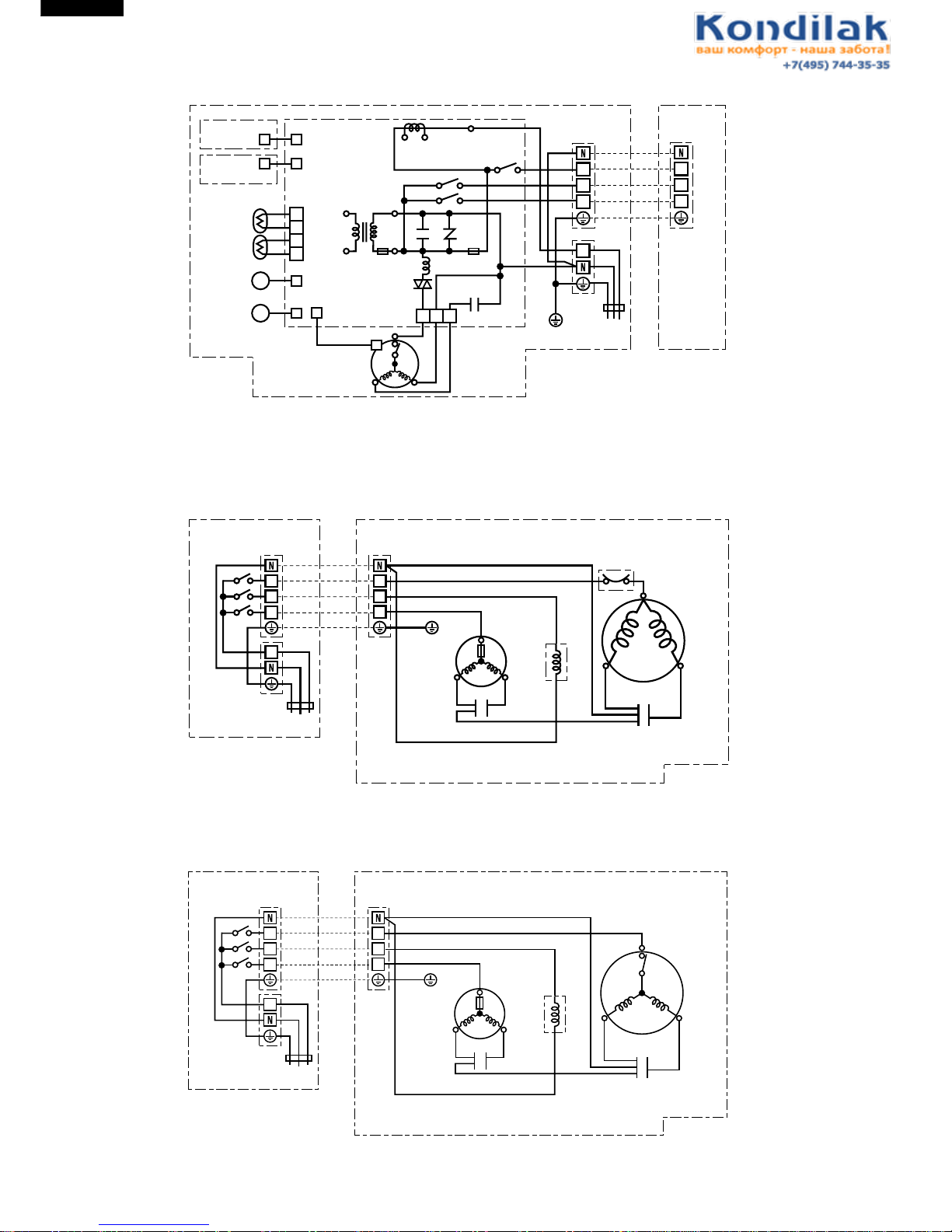

Figure W-1. Wiring Diagram for AH-A07BE/A07BE-C/A09BE/A09BE-C/A12BE

WIRING DIAGRAMS

Figure W-2. Wiring Diagram for AU-A07BE

Figure W-3. Wiring Diagram for AU-A07BE-C

INTERNAL

THERMOSTAT

TRANSFORMER

CONTROL BOARD UNIT

WPE1

IN

TEMP.FUSE

L

SSR

EVAPORATOR

BLBK

CN1

R

OUTDOOR

UNIT

TERMINAL

BOARD

FAN MOTOR

CAPACITOR

FAN

MOTOR

UNIT TO UNIT CORD

BK

BL

BR

: BLACK

: BLUE

: BROWN

R

G(Y

)

: RED

: GREEN-YELLOW

THERMISTOR

(PIPE TEMP.)

THERMISTOR

(ROOM TEMP.)

LOWER

LOUVER MOTOR

UPPER

LOUVER MOTOR

M

CN2

CN5

CN4

BCN2

BCN202

BCN201

RY1

BR

BR

BCN1

1

2

3

4

DISPLAY

UNIT

RECEIVER

UNIT

M

CN3

1 3 5

OUT

C1 NR1

3A

250V

INDOOR UNIT

BK

BL

BL

BL

G(Y

)

G(Y

)

TERMINAL BOARD 1

TERMINAL BOARD 2

POWER

SUPPLY

R.P.M SIGNAL

11

1

(N)

400(430)V 2µF

INTERNAL

THERMAL

FUSE

MOTOR PROTECTOR

OUTDOOR UNIT

TERMINAL BOARD

RUNNING

CAPACITOR

370V 25µF

FAN MOTOR

FAN MOTOR

CAPACITOR

400(450)V 1.5µF

COMPRESSOR MOTOR

C

BK

BL

BK

R

S

W

R

R

BL

CONTROL BOX

BK BL

UNIT TO UNIT CORD

BK

BR

R

BL

: BLACK

: BROWN

: RED

: BLUE

W

G(Y)

: WHITE

: GREEN YELLOW

1 1

INDOOR UNIT

TERMINAL BOARD 1

BR

BL

G(Y

)

BR

BL

G(Y

)

G(Y

)

TERMINAL BOARD 2

POWER SUPPLY

1

INTERNAL

THERMAL

FUSE

INTERNAL

MOTOR

PROTECTOR

OUTDOOR UNIT

TERMINAL BOARD

RUNNING

CAPACITOR

400V 25µF

FAN MOTOR

FAN MOTOR

CAPACITOR

400(450)V 1.5µF

COMPRESSOR MOTOR

C

BL

BK

R

S

W

R

R

BL

CONTROL BOX

BK BL

UNIT TO UNIT CORD

BK

BR

R

BL

: BLACK

: BROWN

: RED

: BLUE

W

G(Y)

: WHITE

: GREEN YELLOW

1 1

INDOOR UNIT

TERMINAL BOARD 1

BR

BL

G(Y

)

BR

BL

G(Y

)

G(Y

)

TERMINAL BOARD 2

POWER SUPPLY

1

Page 9

AH-A07BE-C/09BE-C

AH-A07BE/09BE/12BE

AY-A07BE-C/09BE-C

AY-A07BE/09BE/12BE

9

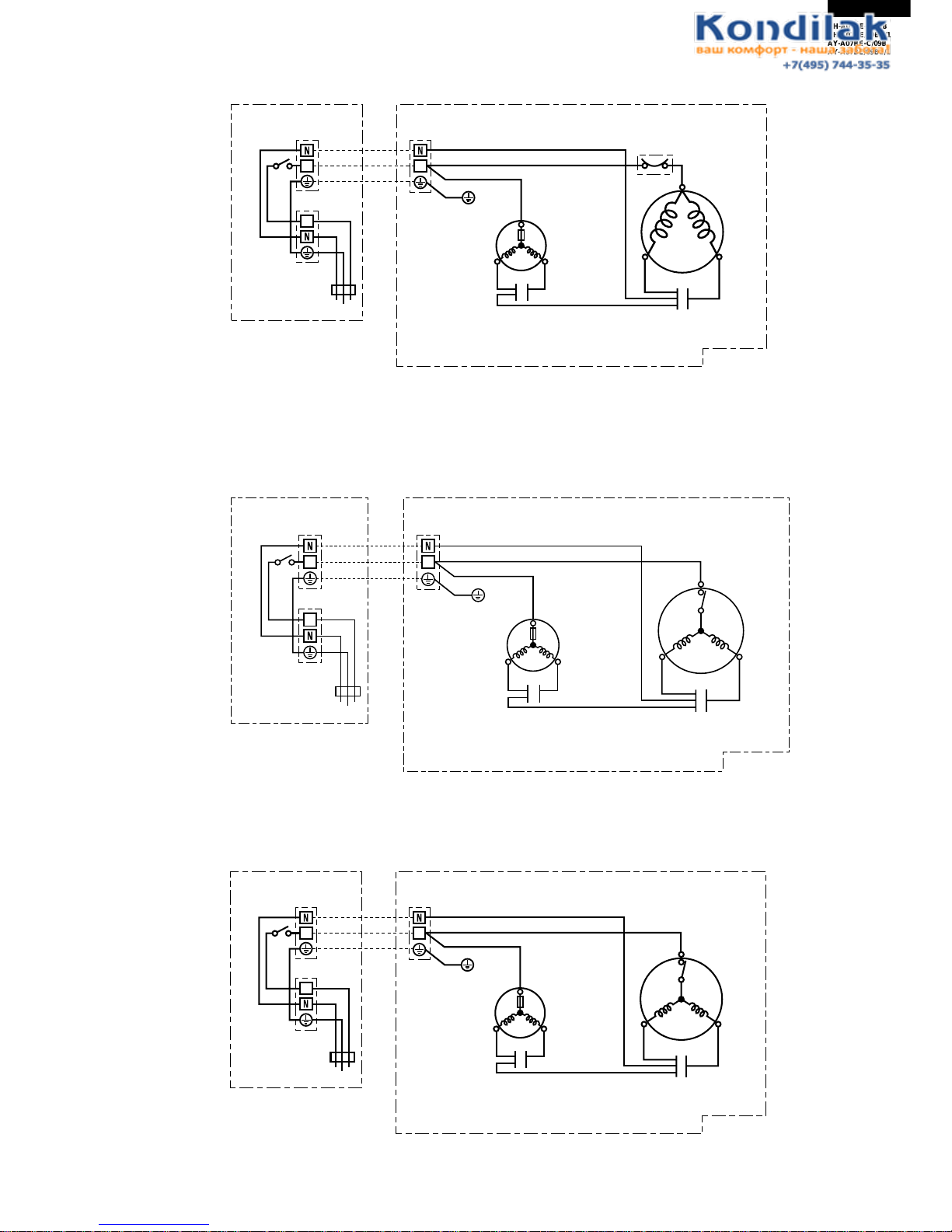

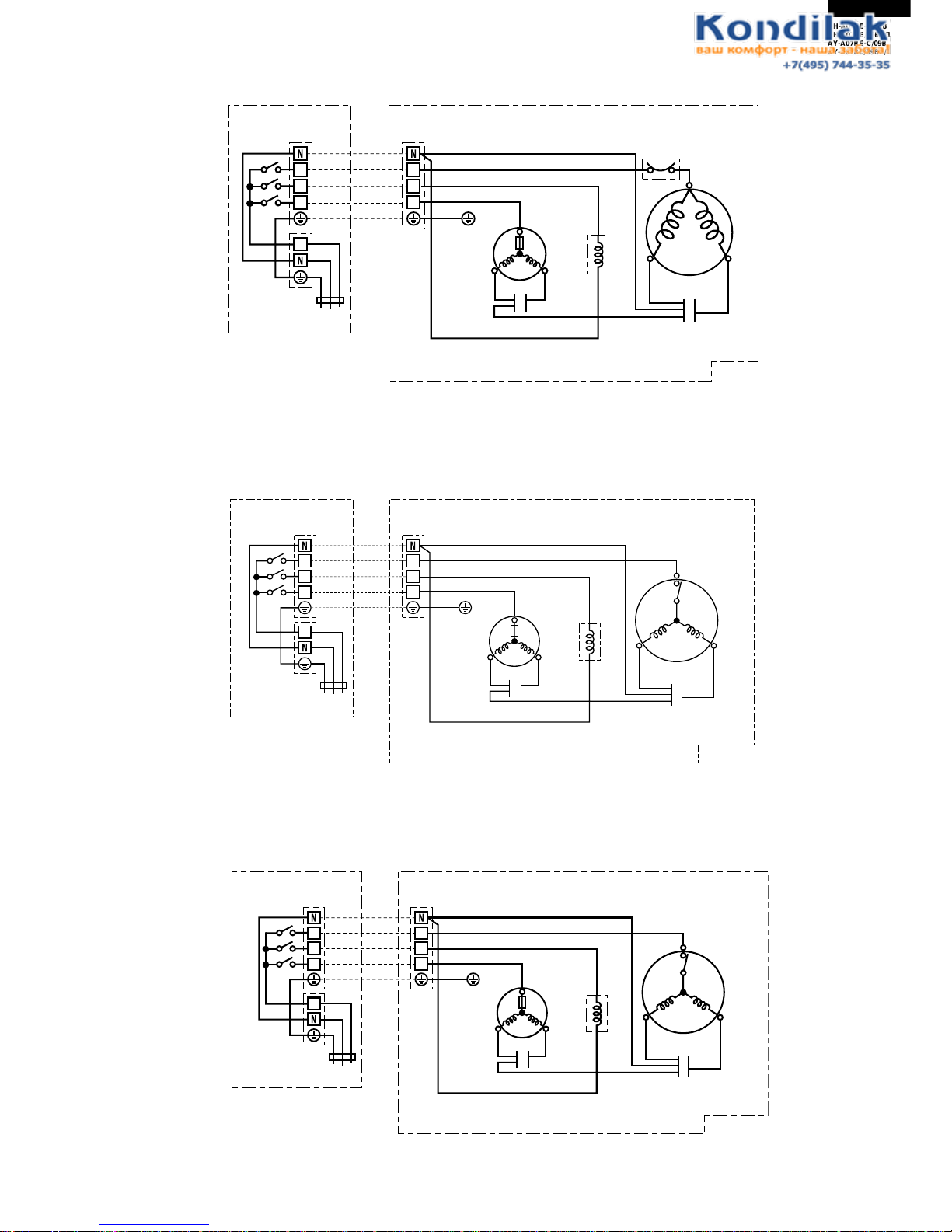

Figure W-4. Wiring Diagram for AU-A09BE

Figure W-5. Wiring Diagram for AU-A09BE-C

Figure W-6. Wiring Diagram for AU-A12BE

INTERNAL

THERMAL

FUSE

MOTOR PROTECTOR

OUTDOOR UNIT

TERMINAL BOARD

RUNNING

CAPACITOR

400V 30µF

FAN MOTOR

FAN MOTOR

CAPACITOR

400(450)V 1.5µF

COMPRESSOR MOTOR

C

BK

BL

BK

R

S

W

R

R

BL

CONTROL BOX

BK BL

UNIT TO UNIT CORD

BK

BR

R

BL

: BLACK

: BROWN

: RED

: BLUE

W

G(Y)

: WHITE

: GREEN YELLOW

1 1

INDOOR UNIT

TERMINAL BOARD 1

BR

BL

G(Y

)

BR

BL

G(Y

)

G(Y

)

TERMINAL BOARD 2

POWER SUPPLY

1

INTERNAL

THERMAL

FUSE

INTERNAL

MOTOR

PROTECTOR

OUTDOOR UNIT

TERMINAL BOARD

RUNNING

CAPACITOR

400V 25µF

FAN MOTOR

FAN MOTOR

CAPACITOR

400(450)V 1.5µF

COMPRESSOR MOTOR

C

BL

BK

R

S

W

R

R

BL

CONTROL BOX

BK BL

UNIT TO UNIT CORD

BK

BR

R

BL

: BLACK

: BROWN

: RED

: BLUE

W

G(Y)

: WHITE

: GREEN YELLOW

1 1

INDOOR UNIT

TERMINAL BOARD 1

BR

BL

G(Y

)

BR

BL

G(Y

)

G(Y

)

TERMINAL BOARD 2

POWER SUPPLY

1

INTERNAL

THERMAL

FUSE

INTERNAL

MOTOR

PROTECTOR

OUTDOOR UNIT

TERMINAL BOARD

RUNNING

CAPACITOR

400V 30µF

FAN MOTOR

FAN MOTOR

CAPACITOR

400(450)V 2µF

COMPRESSOR MOTOR

C

BL

BK

R

S

W

R

R

BL

CONTROL BOX

BK BL

UNIT TO UNIT CORD

BK

BR

R

BL

: BLACK

: BROWN

: RED

: BLUE

W

G(Y)

: WHITE

: GREEN YELLOW

1 1

INDOOR UNIT

TERMINAL BOARD 1

BR

BL

G(Y

)

BR

BL

G(Y

)

G(Y

)

TERMINAL BOARD 2

POWER SUPPLY

1

Page 10

10

AH-A07BE-C/09BE-C

AH-A07BE/09BE/12BE

AY-A07BE-C/09BE-C

AY-A07BE/09BE/12BE

Figure W-7. Wiring Diagram for AY-A07BE/A07BE-C/A09BE/A09BE-C/A12BE

Figure W-8. Wiring Diagram for AE-A07BE

Figure W-9. Wiring Diagram for AE-A07BE-C

INTERNAL

THERMOSTAT

TRANSFORMER

CONTROL BOARD UNIT

WPE1

TEMP.FUSE

L

SSR

EVAPORATOR

BLBK

CN1

R

OUTDOOR

UNIT

TERMINAL

BOARD

FAN MOTOR

CAPACITOR

FAN

MOTOR

UNIT TO UNIT CORD

BK

BL

BR

: BLACK

: BLUE

: BROWN

O

P

R

G(Y)

: ORANGE

: PURPLE

: RED

: GREEN-YELLOW

THERMISTOR

(PIPE TEMP.)

THERMISTOR

(ROOM TEMP.)

LOWER

LOUVER MOTOR

UPPER

LOUVER MOTOR

M

CN2

CN5

CN4

BCN2

BCN202

BCN201

RY2

RY1

RY3

BR

BCN1

1

2

3

4

DISPLAY

UNIT

RECEIVER

UNIT

M

CN3

1 3 5

C.T.

OUT

T1

C1 NR1

3A

250V

INDOOR UNIT

P

BK

BL

BL

BR

BL

O

G(Y

)

G(Y

)

TERMINAL BOARD 1

TERMINAL BOARD 2

POWER

SUPPLY

R.P.M SIGNAL

1

2

3

1

2

3

1

(A)

(B)

(N)

400(430)V 2µF

INTERNAL

THERMAL

FUSE

MOTOR PROTECTOR

OUTDOOR UNIT

TERMINAL BOARD

RUNNING

CAPACITOR

370V 25µF

FAN MOTOR

VALVE

COIL

FAN MOTOR

CAPACITOR

400(450)V 1.5µF

COMPRESSOR MOTOR

C

BK

BK

BL

R

S

W

R

R

BL

CONTROL BOX

BK

BK

BK

BL

UNIT TO UNIT CORD

BK

BR

R

BL

: BLACK

: BROWN

: RED

: BLUE

W

G(Y)

: WHITE

: GREEN YELLOW

1

2

1

2

3

INDOOR UNIT

TERMINAL

BOARD 1

POWER SUPPLY

BL

BR

BL

BR

G(Y

)

G(Y

)

G(Y

)

TERMINAL BOARD 2

3

1

INTERNAL

THERMAL

FUSE

INTERNAL

MOTOR

PROTECTOR

OUTDOOR UNIT

TERMINAL BOARD

RUNNING

CAPACITOR

400V 25µF

FAN MOTOR

VALVE

COIL

FAN MOTOR

CAPACITOR

400(450)V 1.5µF

COMPRESSOR MOTOR

C

BK

BK

BL

R

S

W

R

R

BL

CONTROL BOX

BK

BK

BL

UNIT TO UNIT CORD

BK

BR

R

BL

: BLACK

: BROWN

: RED

: BLUE

W

G(Y)

: WHITE

: GREEN YELLOW

CB574

1

2

1

2

3

INDOOR UNIT

TERMINAL

BOARD 1

POWER SUPPLY

BL

BR

BL

BR

G(Y

)

G(Y

)

G(Y

)

TERMINAL BOARD 2

3

1

Page 11

AH-A07BE-C/09BE-C

AH-A07BE/09BE/12BE

AY-A07BE-C/09BE-C

AY-A07BE/09BE/12BE

11

Figure W-10. Wiring Diagram for AE-A09BE

Figure W-11. Wiring Diagram for AE-A09BE-C

Figure W-12. Wiring Diagram for AE-A12BE

INTERNAL

THERMAL

FUSE

MOTOR PROTECTOR

OUTDOOR UNIT

TERMINAL BOARD

RUNNING

CAPACITOR

400V 30µF

FAN MOTOR

VALVE

COIL

FAN MOTOR

CAPACITOR

400(450)V 1.5µF

COMPRESSOR MOTOR

C

BK

BK

BL

R

S

W

R

R

BL

CONTROL BOX

BK

BK

BK

BL

UNIT TO UNIT CORD

BK

BR

R

BL

: BLACK

: BROWN

: RED

: BLUE

W

G(Y)

: WHITE

: GREEN YELLOW

1

2

1

2

3

INDOOR UNIT

TERMINAL

BOARD 1

POWER SUPPLY

BL

BR

BL

BR

G(Y

)

G(Y

)

G(Y

)

TERMINAL BOARD 2

3

1

INTERNAL

THERMAL

FUSE

INTERNAL

MOTOR

PROTECTOR

OUTDOOR UNIT

TERMINAL BOARD

RUNNING

CAPACITOR

400V 25µF

FAN MOTOR

VALVE

COIL

FAN MOTOR

CAPACITOR

400(450)V 1.5µF

COMPRESSOR MOTOR

C

BK

BK

BL

R

S

W

R

R

BL

CONTROL BOX

BK

BK

BL

UNIT TO UNIT CORD

BK

BR

R

BL

: BLACK

: BROWN

: RED

: BLUE

W

G(Y)

: WHITE

: GREEN YELLOW

CB572

1

2

1

2

3

INDOOR UNIT

TERMINAL

BOARD 1

POWER SUPPLY

BL

BR

BL

BR

G(Y

)

G(Y

)

G(Y

)

TERMINAL BOARD 2

3

1

INTERNAL

THERMAL

FUSE

INTERNAL

MOTOR

PROTECTOR

OUTDOOR UNIT

TERMINAL BOARD

RUNNING

CAPACITOR

400V 30µF

FAN MOTOR

VALVE

COIL

FAN MOTOR

CAPACITOR

400(450)V 2µF

COMPRESSOR MOTOR

C

BK

BK

BL

R

S

W

R

R

BL

CONTROL BOX

BK

BK

BL

UNIT TO UNIT CORD

BK

BR

R

BL

: BLACK

: BROWN

: RED

: BLUE

W

G(Y)

: WHITE

: GREEN YELLOW

1

2

1

2

3

INDOOR UNIT

TERMINAL

BOARD 1

POWER SUPPLY

BL

BR

BL

BR

G(Y

)

G(Y

)

G(Y

)

TERMINAL BOARD 2

3

1

Page 12

12

AH-A07BE-C/09BE-C

AH-A07BE/09BE/12BE

AY-A07BE-C/09BE-C

AY-A07BE/09BE/12BE

ELECTRICAL PARTS

For Models AY-A07BE/A07BE-C, AH-A07BE/A07BE-C, AE-A07BE/A07BE-C, AU-A07BE and AU-A07BE-C

DESCRIPTION MODEL REMARKS SITE

Compressor QK134PA13A 220 - 240V, 50Hz, 620W

AE/AU-A07BE

Compressor RH135VHST 220 - 240V, 50Hz, 650W AE-A07BE-C

Compressor RH130VHST 220 - 240V, 50Hz, 650W AU-A07BE-C

Indoor fan motor ML-A915 220 - 240V, 50Hz AY, AH

Outdoor fan motor ML-A592 220 - 240V, 50Hz AE, AU

Indoor fan motor capacitor – 400V, 2µF AY, AH

Outdoor fan motor capacitor – 400V, 1.5µF AE, AU

Running capacitor – 370V, 25µF

AE/AU-A07BE

Running capacitor – 400V, 25µF

AE/AU-A07BE-C

Transformer – Primary; AC 230V, 50Hz AY, AH

Secondary; AC16.7V, 50Hz

Fuse – 250V, 3A AY, AH

Reverse valve VK1100B, 1400B – AE

Reverse valve coil – 220 - 240V, 50/60Hz AE

For Models AY-A09BE/A09BE-C, AH-A09BE/A09BE-C, AE-A09BE/A09BE-C, AU-A09BE and AU-A09BE-C

DESCRIPTION MODEL REMARKS SITE

Compressor QK164PA13A 220 - 240V, 50Hz, 780W

AE/AU-A09BE

Compressor RH165VHET 220 - 240V, 50Hz, 800W

AE-A09BE

Compressor RH154VHST 220 - 240V, 50Hz, 750W

AU-A09BE

Indoor fan motor ML-A915 220 - 240V, 50Hz AY, AH

Outdoor fan motor ML-A916

220-240V,50Hz 220-230V,60Hz

AE, AU

Indoor fan motor capacitor – 400V, 2µF AY, AH

Outdoor fan motor capacitor – 400V, 1.5µF AE, AU

Running capacitor – 400V, 30µF

AE/AU-A09BE

Running capacitor – 400V, 25µF

AE/AU-A09BE-C

Transformer – Primary; AC 230V, 50Hz AY, H

Secondary; AC16.7V, 50Hz

Fuse – 250V, 3A AY, AH

Reverse valve VK1100B, 1400B – AE

Reverse valve coil – 220 - 240V, 50/60Hz AE

For Model AY-A12BE, AH-A12BE , AE-A12BE and AU-A12BE

DESCRIPTION MODEL REMARKS SITE

Compressor RH207VHET 220 - 240V, 50Hz, 1000W AE, AU

Indoor fan motor ML-A915 220 - 240V, 50Hz AY, AH

Outdoor fan motor ML-A917

220-240V,50Hz 220-230V,60Hz

AE, AU

Indoor fan motor capacitor – 400V, 2µF AY, AH

Outdoor fan motor capacitor – 400V, 2µF AE, AU

Running capacitor – 400V, 30µF AE, AU

Transformer – Primary; AC 230V, 50Hz AY, AH

Secondary; AC16.7V, 50Hz

Fuse – 250V, 3A AY, AH

Reverse valve VK2100B, 2400B – AE

Reverse valve coil – 220 - 240V, 50/60Hz AE

Page 13

AH-A07BE-C/09BE-C

AH-A07BE/09BE/12BE

AY-A07BE-C/09BE-C

AY-A07BE/09BE/12BE

13

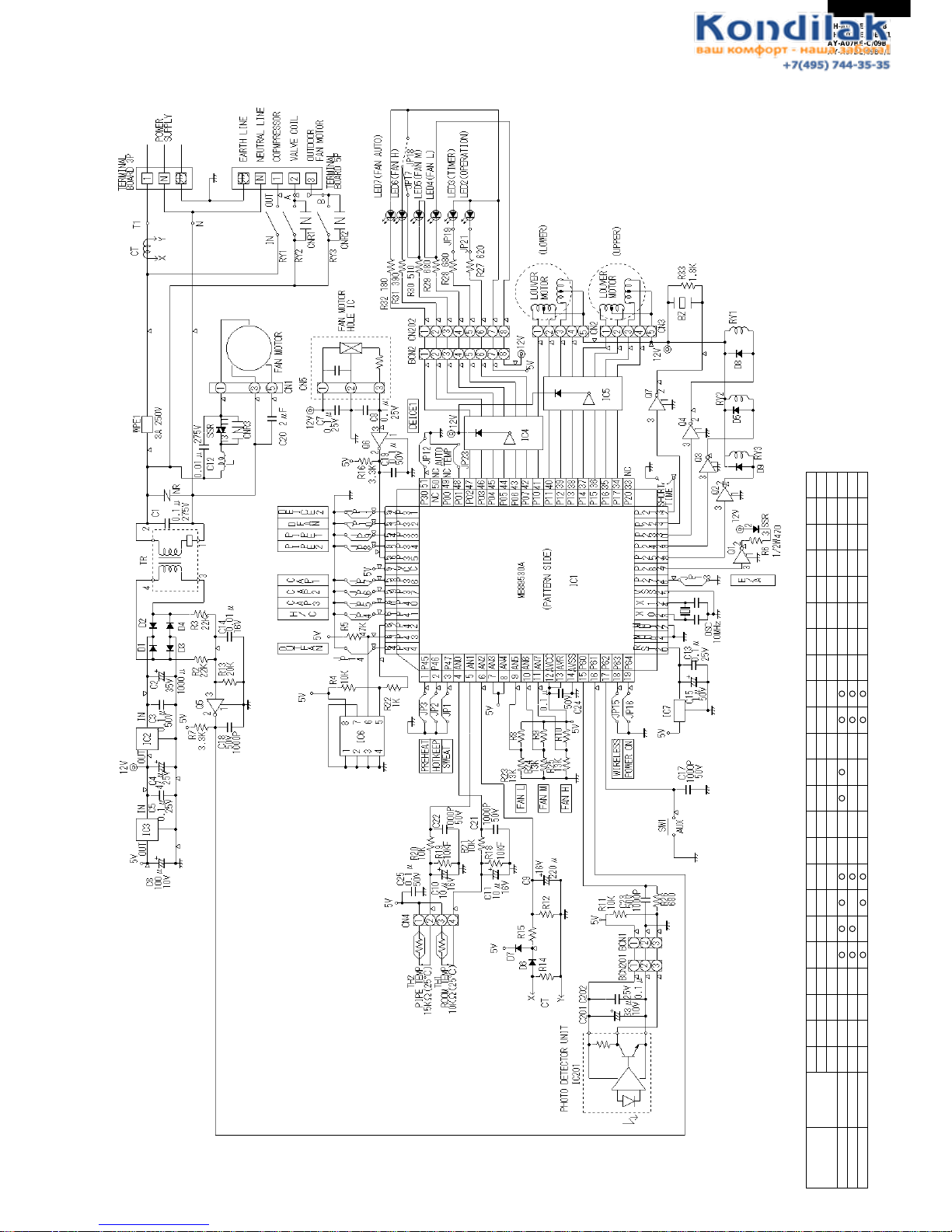

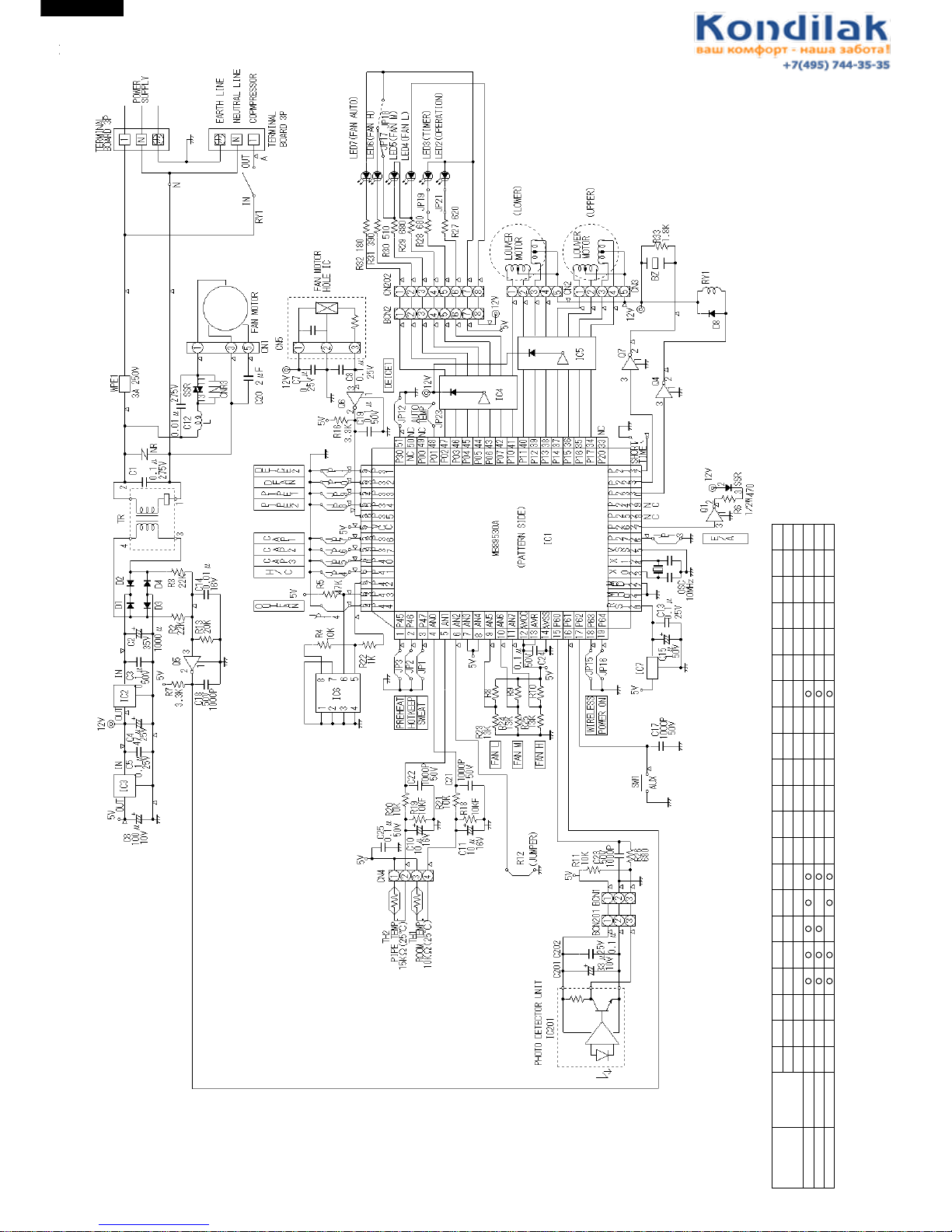

Figure L-1. Electronic Control Circuit Diagram for AY-A07BE/AY-A07BE-C/A09BE/A09BE-C/A12BE

MICROCOMPUTER CONTROL SYSTEM

AY-A07BE/A07BE-C

AY-A09BE/A09BE-C

AY-A12BE

PART CODE

DPWBFA210JBKZ

DPWBFA208JBKZ

DPWBFA211JBKZ

P47

SWEAT

JP1

NONE

NONE

NONE

P46

HOT KEEP

JP2

NONE

NONE

NONE

P45

REHEAT

JP3

NONE

NONE

NONE

P41

H/C

JP4

NONE

NONE

NONE

P40

CAP3

JP5

P37

CAP2

JP6

NONE

P36

CAP1

JP7

NONE

P34

PIPE 2

JP8

P33

PIPE 1

JP9

NONE

NONE

NONE

P32

D FAN

JP10

NONE

NONE

NONE

P31

DEICE 2

JP11

NONE

NONE

P30

DEICE 1

JP12

NONE

NONE

P27

EUROPE/ASIA

JP13

NONE

NONE

NONE

P44

OUT FAN

P63

WIRELESS

JP15JP14

P64

POWER ON

JP16

NONE

NONE

NONE

P01

SWEAT

JP23

NONE

NONE

NONE

AN5

FAN L

R8

15K

15K

15K

AN6

FAN M

R9

15K

15K

NONE

AN7

FAN H

15K

15K

15K

15K

CT

R12

6.8KF

6.8KF

6.8KF

CT

R14

2.7KF

2.7KF

2.7KF

CT

R15

1KF

1KF

1KF

Page 14

14

AH-A07BE-C/09BE-C

AH-A07BE/09BE/12BE

AY-A07BE-C/09BE-C

AY-A07BE/09BE/12BE

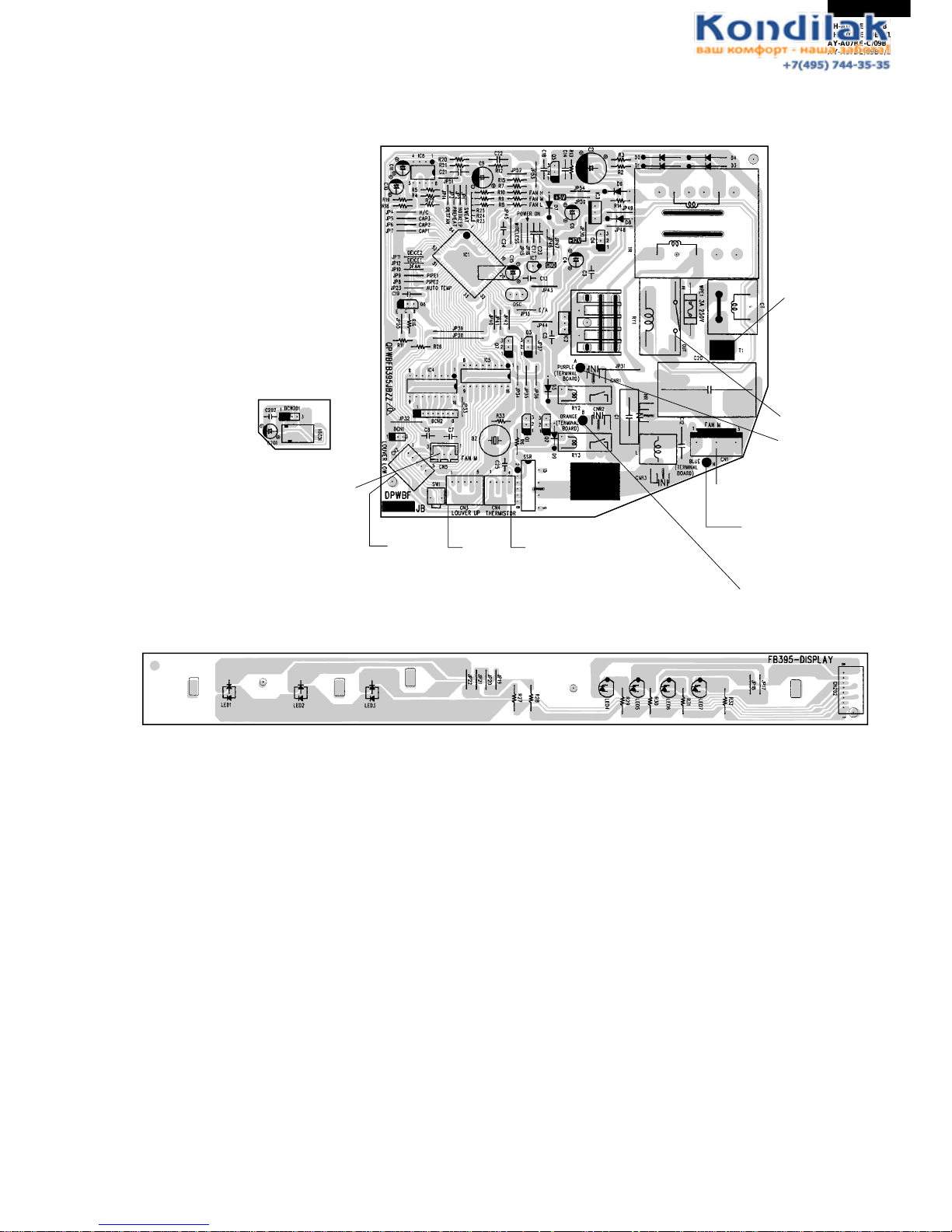

Figure L-2. Electronic Control Circuit Diagram for AH-A07BE/A07BE-C/A09BE/A09BE-C/A12BE

AH-A07BE/07BE-C

AH-A09BE/A09BE-C

AH-A12BE

PART CODE

DPWBFA212JBKZ

DPWBFA209JBKZ

DPWBFA213JBKZ

P47

SWEAT

JP1

NONE

NONE

NONE

P46

HOT KEEP

JP2

NONE

NONE

NONE

P45

REHEAT

JP3

NONE

NONE

NONE

P41

H/C

JP4

P40

CAP3

JP5

P37

CAP2

JP6

NONE

P36

CAP1

JP7

NONE

P34

PIPE 2

JP8

P33

PIPE 1

JP9

NONE

NONE

NONE

P32

D FAN

JP10

NONE

NONE

NONE

P31

DEICE 2

JP11

NONE

NONE

P30

DEICE 1

JP12

NONE

NONE NONE

NONE

P27

EUROPE/ASIA

JP13

NONE

NONE

NONE

NONE

NONE

NONE

P44

OUT FAN

P63

WIRELESS

JP15JP14

P64

POWER ON

JP16

NONE

NONE

NONE

P01

SWEAT

JP23

NONE

NONE

NONE

AN5

FAN L

R8

15K

15K

15K

AN6

FAN M

R9

15K

15K

NONE

AN7

FAN H

15K

15K

15K

15K

R12

JAMPER

JAMPER

JAMPER

Page 15

AH-A07BE-C/09BE-C

AH-A07BE/09BE/12BE

AY-A07BE-C/09BE-C

AY-A07BE/09BE/12BE

15

Fig. L-3 Printed Wiring Diagram for AY-A07BE/A07BE-C/A09BE/A09BE-C/A12BE

FROM

TERMINAL

BOARD

(POWER) " 1 "

FROM

TERMINAL

BOARD

(UNIT) " 1 "

FROM

TERMINAL BOARD

(UNIT) " N "

FROM

TERMINAL

BOARD

" 2 "

FROM

TERMINAL BOARD

" 3 "

FROM

THERMISTOR

FROM

LOUVER

(UPPER)

FROM

LOUVER

(LOWER)

INDOOR

FAN MOTOR

(R.P.M. SIGNAL)

INDOOR

FAN MOTOR

Page 16

16

AH-A07BE-C/09BE-C

AH-A07BE/09BE/12BE

AY-A07BE-C/09BE-C

AY-A07BE/09BE/12BE

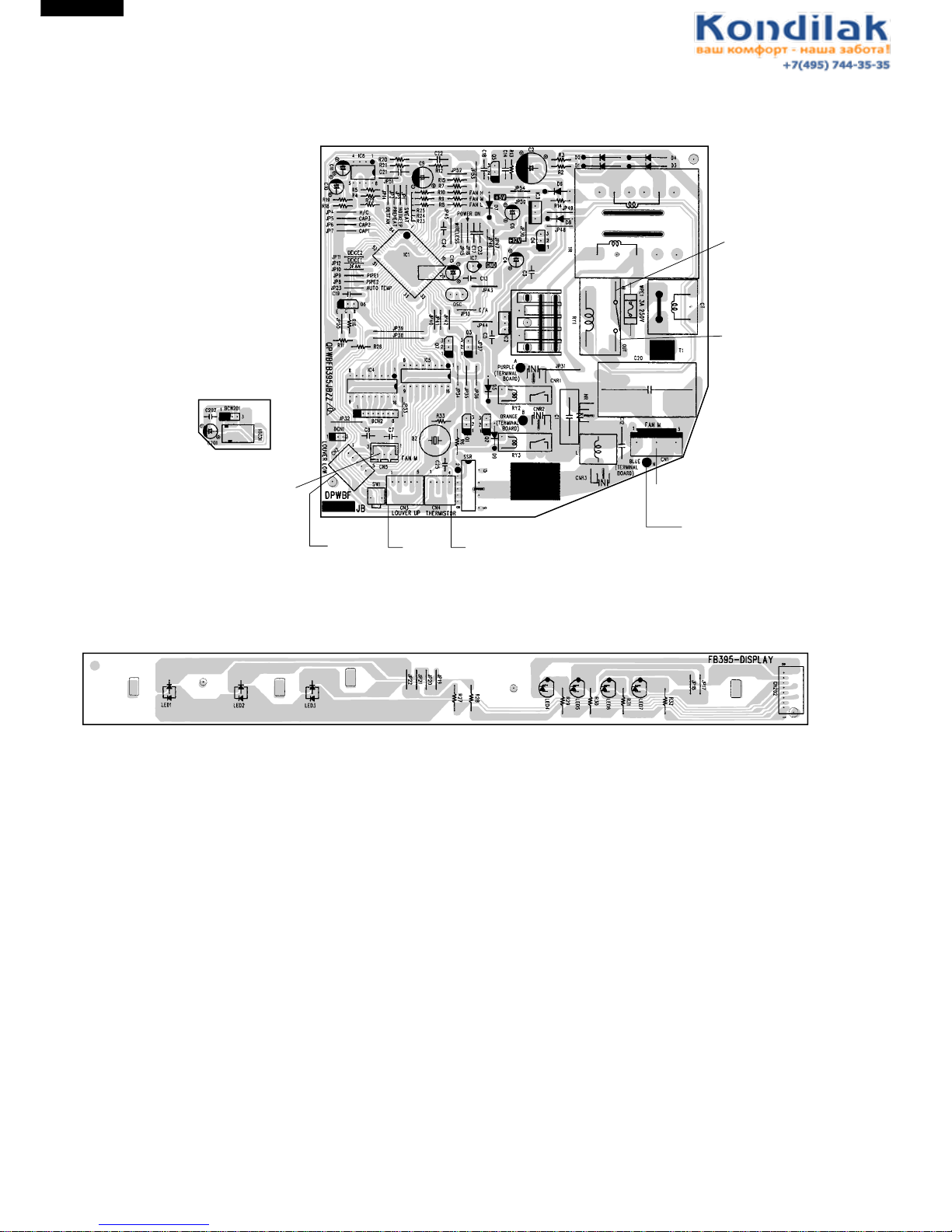

Fig. L-4 Printed Wiring Diagram for AH-A07BE/A07BE-C/A09BE/A09BE-C/A12BE

FROM

TERMINAL

BOARD

(POWER) " 1 "

FROM

TERMINAL

BOARD

(UNIT) " 1 "

FROM

TERMINAL BOARD

(UNIT) " N "

FROM

THERMISTOR

FROM

LOUVER

(UPPER)

FROM

LOUVER

(LOWER)

INDOOR

FAN MOTOR

(R.P.M. SIGNAL)

INDOOR

FAN MOTOR

Page 17

AH-A07BE-C/09BE-C

AH-A07BE/09BE/12BE

AY-A07BE-C/09BE-C

AY-A07BE/09BE/12BE

17

FUNCTIONS

AH-A07BE/A07BE-C/A09BE/A09BE-C/A12BE

are noty provided with the heating function

1. Temperature control characteristic

1-1 COOL operation

In the “COOL” mode, the thermostat circuit is

controlled by four thermostat lines (C1 thru C4).

1-3 HEAT operation

In the “HEAT” mode, the thermostat circuit

is controlled by six thermostat lines (H01 thru

H4).

Figure Y-1

1-2 DRY operation

In the “DRY” mode, the thermostat circuit is

controlled by three thermostat lines (D1 thru

D3).

Figure Y-3

2. Operation modes

2-1 COOL operation

The compressor turns on or off, at the

thermostat lines C3 and C4. The outdoor fan

motor is also controlled with the compressor.

Figure Y-4

Figure Y-2

Room temperature

Preset temperature

Room

temperature

transition

C3

C4

States 1 & 3 : Compressor ON

State 2 : Compressor OFF

1

2

3

18

32

C1

C2

C3

C4

17.5

18.5

19.5

20.5

31.5

32.5

33.5

34.5

Preset temperature (˚C)

Room temperature (˚C)

Room temperature(˚C)

Preset temperature (˚C)

18

32

D1

D2

D3

17.5

18.5

19.5

31.5

32.5

33.5

Preset temperature (˚C)

H4

H3

H2

H1

H02

H01

17

19

21

22

24

26

31.5

32.5

34.0

35.0

36.0

37.0

18 32

Room temperature(˚C)

Page 18

18

AH-A07BE-C/09BE-C

AH-A07BE/09BE/12BE

AY-A07BE-C/09BE-C

AY-A07BE/09BE/12BE

Figure Y-5

2-2 DRY operation

On the switch on, the compressor always starts

to operate for 2 minutes with fan speed “DL” .

The microcomputer reads the room temperature

2 minutes after this first compressor operation.

This room temperature is set as the preset

temperature automatically.

The preset temperature ranges from 18˚C to

32˚C. When the room temperature is below

18˚C, the preset temperature is set to 18˚C,

and when the room temperature is over 32˚C,

the preset temperature is set to 32˚C.

Dry operation is divided into three zones

(Cooling zone, Dehumidifying zone and

Circulating zone) by thermostat lines (D1 to

D3), and the compressor and the fan motor

are controlled in each zone as shown in Table

Y-1.

Room temperature

Preset temperature

Room

temperature

transition

D3

D2

D1

States 1 & 5 : Cooling zone

States 2 & 4 : Dehumidifying zone

States 3 : Circulating zone

3

4

5

1

2

Room temperature

Preset temperature

Room

temperature

transition

States 1 & 3 : Compressor ON

States 2 : Compressor OFF/(ON)

(Hot-keep function)

H1

H2

3

1

2

Compressor

Cooling zone

Dehumidifying zone

Circulating zone

Fan speed

ON "DH"

"DL"

"DL" or OFF

ON

OFF

Table Y-1

2-3 Heat operation

The compressor turns on or off, at State 2 ,

turns on continuously at State 1 & 3 .

Figure Y-6

3. Fan speed

Fan speeds are given by the indoor fan motor, "DL"~"HH" which are available in the following operation mode.

Table Y-2

Fan switch

DL

Fan speed

Fan switch (AUTO)

07BE/07BE-C TYPE

AY AH AY AH AY AH

(r.p.m.)

630 630 690 690 750 750

710 710 740 740 840 840

710 710 760 760 840 840

750 750 790 790 860 860

830 830 910 910 930 930

900 900 990 990 970 970

950 950 1090 1090 1010 1010

700 750 850

830 920 920

850 950 950

900 1000 1000

950 1050 1040

990 1100 1080

09BE/09BE-C TYPE

12BE TYPE

DH

DRY

COOL

CL

COOL SOFT

CAL

CM

COOL LOW

CAH

CH

COOL HIGH

HUL

HL

HEAT SOFT

HEAT

HAL

HM

HEAT LOW

HAH

HH

HEAT HIGH

Page 19

AH-A07BE-C/09BE-C

AH-A07BE/09BE/12BE

AY-A07BE-C/09BE-C

AY-A07BE/09BE/12BE

19

OFF OFF

ON

ON

U1

U2

U1

U2

U2'U2'

Within 3 minutes Over 3 minutes

Figure Y-8

Figure Y-7

5. Preheat air flow

This function is intended to prevent cold air from being

discharged when the heating operation starts or when

defrosting.

When the indoor pipe temperature is below 29˚C at the

begining of the heat operation or after defrosting, the

indoor fan motor stays.

When the indoor pipe temperature gets higher than

29˚C, the fan motor is turned on at speed “HUL” after

compensation of starting.

When the indoor pipe temperature exceeds 35˚C, the

specified fan speed is restored. When the indoor pipe

temperature falls below 30˚C, the fan speed shifts

down to “HUL”. And, when the indoor pipe temperature

falls below 23˚C, the fan motor turns off. Then, over

29˚C , it turns on again at speed “HUL”.

4. Hot-Keep

This function automatically controls the on-off operation

of the indoor fan motor in accordance during the

heating operation, thereby preventing the air conditioner

from delivering a cold air when the compressor is off.

When the room temperature exceeds the thermostat

line “H1”, the compressor is turned off, and the indoor

fan motor is turned off after rotating at “HUL” for 30

seconds. 3 minutes and 10 seconds after turning off the

compressor, the indoor fan motor is turned on for 3

minutes and 20 seconds. At 10 seconds after turning

on the compressor, the indoor fan motor is turned on.

The next compressor OFF time is for 3, 8 or more than

8 minutes according to the room temperature (the time

increases with a rise of room temperature) when 3

minutes elapse after turning on the compessor.

6. Overheating protection system

When overloading occurs during the heating operation,

this system controls the outdoor fan motor according to

the indoor pipe temperature to prevent the overloading

of the compressor and restrain the rise in high pressure.

When the indoor pipe temperature exceeds U1˚C, the

outdoor fan motor is turned off, and when the indoor

pipe temperature falls U2˚C, the outdoor fan motor

turns on.

If 3 minutes elapse after turning off outdoor fan motor,

the outdoor fan motor is turned on, when the indoor

pipe falls U2' ˚C,

Pipe temperature(˚C)

24

29

30

35

OFF

UL UL UL

OFFPreset

Fan speed

Figure Y-9

Table Y-3

Compressor

ON

OFF

Indoor

fan motor

30sec.

time

UL

ON

OFF

3 min.

3 min.

10sec.

UL

30sec.

10sec.

Thermo off

HH

HAH

HM

HAL

HL

HUL

53˚C53˚C

52˚C52˚C

U1

AY-A07BE

AY-A07BE-C

AY-A09BE

AY-A09BE-C

AY-A12BE

U2'

49˚C

53˚C

52˚C

49˚C

53˚C

52˚C

49˚C

49˚CU2

54˚CU2

53˚CU'2

50˚CU2

54˚CU2

53˚CU2'

50˚CU2

Fan speed

LIne

MODELS

Page 20

20

AH-A07BE-C/09BE-C

AH-A07BE/09BE/12BE

AY-A07BE-C/09BE-C

AY-A07BE/09BE/12BE

7. Current control

This system, in order to prevent overcurrent during

heating operation, controls the outdoor fan motor and

changes the indoor fan motor speed by detecting total

current. When the current exceeds P2, the outdoor fan

motor is automatically turned off, and when the current

falls below P4, the outdoor fan motor is turned on.

When the current exceeds P3 and the indoor fan speed

shifts down because of cold air (5. Preheat air flow), the

changes in the indoor fan speed shifts up as follows,

from "off" to "HUL", or from "HUL" to "HL". And when

the current falls bellow P5, the indoor fan speed shift up

is canceled.

Figure Y-10

8. Freeze preventive

When the indoor pipe temperature falls below 0˚C

during cool operation or dry operation, the compressor

is turned off.

9. Defrost

The defrost timer (integrating the operation time of

compressor) counts time with microcomputer during

heat operation.

Frost of outdoor pipe is estimated by indoor pipe

temperature (TH2), room temperature (TH1), indoor

fan speed and operation state of compressor.

In the defrost operation, first the compressor is turned

off, the fan speed is set to “HUL” and the outdoor fan

motor is turned off.

30 seconds later the indoor fan motor is turned off, 60

seconds later the reverse valve is turned off, and the

compressor is turned on. In the end of defrosting, the

compressor is turned off, the outdoor fan motor is

turned on, 60 seconds later the reverse valve is turned

on, and the compressor is turned on, starting heat

operation. At this time, the indoor fan motor is turned

off or the fan speed is set to “HUL” if preheat air flow

function is effective.

Figure Y-11

Figure Y-12

10. Delayed operation of the reverse valve

When the heat operation is shut down or the operating

mode is switched from heat to cool or dry, or vice versa,

the reverse valve is switched after 3 minutes.

11. Test run

If the "AUX" button on the unit is pressed for 5 seconds

or more during operation, cool test operation starts.

The operation LED (red) flickers during test run.

To put the system in the heating test run mode, start the

cooling operation and select the heating mode on the

remote control. In cool and heat mode continuous

compressor on operation is performed. In dry mode the

operation is in dehumidifying zone. In fan only mode

the indoor fan motor runs continusly.

12.Timer

12-1 ON/OFF TIMER

When the unit operates during one hour after

the OFF-time is set, thermostat setting is

automatically shifted (+1˚C in cool operation

and dry operation, -3˚C in heat operation, 16˚C

- 32˚C). When the ON-timer is set in heat

operation and cool operation, operation starts

before 0 to 30 minutes(depends on the room

temperature) so that preset temperature is

obtaind at set time.

12-2 ONE-HOUR TIMER

When ONE-HOUR timer is set, the unit turns

off automatically after one hour. The one hour

timer operation has priority over other time

operation, such as the TIMER ON and TIMER

OFF. If the ONE-HOUR TIMER button is

pressed again during operation, the unit will

operate additionally for another one hour.

Outdoor

Fan motor

OFF

Indoor

Fan motor

Shift UP

Compressor

OFF

Time

Input current

Current transition

P1 5.1A 6.6A 10.0A

P2 4.3A 5.3A 8.0A

P3 3.9A 4.7A 7.2A

P4 3.3A 3.8A 6.1A

P5 3.0A 3.4A 3.5A

AY-A07BE

AY-A07BE-C

AY-A09BE

AY-A09BE-C

AY-A12BE

Switch ON

Heating

Heating

Heating

Min.

40min.

Max.

8min.

(AY--A07BE/A07BE-C)

9min.

(AY--A09BE/A09BE-C/A12BE)

Min.

30min.

Max.

8min. (AY--A07BE/A07BE-C)

9min. (AY--A09BE/A09BE-C/A12BE)

DefrostDefrost

Defrost start

Compressor

Reverse

Valve

Outdoor

Fan Motor

Indoor

Fan Motor

Preheat Air

Flow Control

30sec.

MAX. 9min.

(AY-A09BE/A09BE-C/A12BE)

MAX. 8min.

(AY-A07BE/A07BE)

60sec.

60sec.

ON

OFF

ON

OFF

ON

OFF

ON

OFF

60sec.

HUL

Page 21

AH-A07BE-C/09BE-C

AH-A07BE/09BE/12BE

AY-A07BE-C/09BE-C

AY-A07BE/09BE/12BE

21

ON

OFF

ON

OFF

ON

ON

ON

OFF

ON ON OFF

OFF ON OFF

ON ON ON

OFF

ON/UL/OFF

ON

ON UL/OFF ON

OFF OFF OFF

ON

L/UL

UL/D

OFF D/OFF

OFF

OFF

OFF

Mode

Compressor

Outdoor

Fan Motor

Cooling

Circulating

Normal

Preheat

Air Flow

Control

ON Defrost

Indoor

Fan Motor

Valve

Coil

C

O

O

L

H

E

A

T

D

R

Y

Cooling

Circulating

Dehumidiflying

Room temperature

Preset temperature

Room

temperature

transition

C3

C2

C1

States 1 & 5 :"CAH"

States 2 & 4 : "CM"

States 3 : "CAL"

a. COOL operation

3

4

5

1

2

Room temperature

Preset temperature

Room

temperature

transition

States 1 & 7 : "HAM"

States 2 & 6 : "HM"

States 3 & 5 : "HAL"

States 4 : "HUL", "HL", OFF

H1

H2

1

H4

H3

6

5

4

7

2

3

b. HEAT operation

13. Automatic air conditioning

When automatic air conditioning is selected, the

operation mode and preset temperature are set

automatically according to the room temperature on

starting operation.

Table Y-4

When DRY mode is selected by the micro computer

15. Outputs in each operation mode

Table Y-5

16. Power on start

If the connecting wire "POWER ON" (JP16) is cut on

the PWB ass'y, when the power is supplied by turning

on a circuit breaker, the air conditioner automatically

starts of operation in "AUTO".

(Refer to Figure L-2. Printed Wiring Board.)

17. AUTO RESTART

Power failure occurs during operation, the unit will

retart in the same operation mode as before after

power recovery.

(Refer to Figure L-2. Printed Wiring Board.)

18.Test mode

Keep pushing the "AUX." buttons and supply the

power, the system will go to the test mode. In this

mode, the output of operation is switched by pushing

the ""AUX." button in the unit or the "OI" button in the

remote controller. Normal outputs are shown in Table

Y-6 and Y-7.

with AUTO operation, the fan speed lamps on the

indoor unit panel will indicate identically with the fan

speed symbols on the remote control dispaly, as the

FAN spped setting is changed accordingly. Despite,

the actual fan speed will not change, as it is determined

automatically by the micro computer.

14. Automatic fan speed

When the automatic fan speed is selected in cool or

heat operation, the fan speed is automatically changed

by the thermostat lines C1 to C3 in cool operation, and

H1 to H4 in heat operation.

Figure Y-13

Figure Y-14

Room temperature

at operation start

Operation

Mode

Preset

Temperature

Above 28˚C

Below 21˚C

26˚C

26˚C 28˚C

24˚C 26˚C

21˚C 24˚C

25˚C

24˚C

Room temperature

at operation start

23˚C

COOL

DRY

HEAT

Page 22

22

AH-A07BE-C/09BE-C

AH-A07BE/09BE/12BE

AY-A07BE-C/09BE-C

AY-A07BE/09BE/12BE

19.Diagnosis procedure

When indoor fan motor is out of order or compressor lock occurs, the compressor, indoor fan motor, outdoor fan

motor, and louver are all stopped and the operation LED(red) turns on or off syncronously with the timimg of the

timer LED.

When the thermistor for room temperature or pipe temperature is open or short state, the operation LED turns on

or off syncrnoously with the timing of the timer LED by pushing continously for more than 5 seconds "AUX."

button during suspension of operation.

Timing chart of Timer LED and Operation LED of DIAGNOSIS PROCEDURE.

When "OI" button the remote controller or "AUX." button in the unit is pushed, the unit is free from DIAGNOSIS

PROCEDURE.

Indoor

fan motor

Comp.-lock

Thermistor

short state

Thermistor

open state

Timer

LED

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

Operation

LED

Operation

LED

Operation

LED

Operation

LED

1sec. 1sec.

4sec.

Page 23

AH-A07BE-C/09BE-C

AH-A07BE/09BE/12BE

AY-A07BE-C/09BE-C

AY-A07BE/09BE/12BE

23

Table Y-6 [AY-A07BE/A07BE-C/A09BE/A09BE-C/A12BE]

1110987654321

ON ON

OFF

OFF ON ON OFF ON OFF OFF OFF OFF

OFF ON OFF ON OFF ON ON ON OFF

ON ON OFF ON OFF ON ON ON OFF

ON ON OFF OFF OFF OFF OFF OFF OFF

OFF ON OFF OFF OFF OFF OFF OFF OFF

OFF OFF ON ON OFF ON ON ON OFF

OFF

CLOSE

OFF OFF OFF OFF OFF OFF OFF

ON ON ON ON ON ON ON ON OFF

ON OFF ON OFF ON OFF ON OFF ON

OFF ON ON ON OFF OFF OFF OFF

OFF

ON

OFF

ON

ON

OFF

OFF

OFF

ON

ON

OFF

OFF

OFF

ON

ON

ON

OFF

OFF

OFF

ON

ON

OFF

OFF

OFF

ON

ON

ON

ON

ON

OFF

CLOSE

ON

OFF

ON

OFF

ON

ON

ON

ON

ON

OFF

CLOSE

ON

OFF

ON

OFF

OFF OFF

OFF

ON

ON

OFF

OFF

ON

OFF

ON

OFF

ON

OFF

OFF

ON

ON

OFF

OFF

ON

OFF

ON

OFF

ON

OFF

OFF

ON

OFF

ON

OFF

OFF

ON

OFF

ON

ON

ON

OFF

ON

OFF

ON

OFF

OFF

ON

OFF

ON

ON

ON

OFF

OFF

OFF

ON

ON

OFF

OFF

ON

OFF

ON

OFF

OFF

OFF

OFF

ON

ON

OFF

OFF

ON

OFF

ON

OFF

OFF

OFF

OFF

OFF

ON

ON

OFF

OFF

ON

OFF

ON

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON

ON

OFF

OFF

OFF

OFF

ON

ON

OFF

OFF

ON

OFF

ON

OFF

OFF

OFF

OFF

ON

ON

OFF

OFF

ON

OFF

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON

OFF

OFF

OFF

OFF

OFF

ON

OFF

ON

ON

FLICK

ON

ON

ON

OPEN

OFF

ON

OFF

OFF

RED

YELLOW

FAN SOFT

FAN LOW

Lamps

Louver

Indoor fan

Outdoor fan

4-way valve

Compressor

FAN HIGH

AUTO

RED

YELLOW

Lamps

Louver

Indoor fan

Outdoor fan

4-way valve

Compressor

AUTO

RED

YELLOW

Lamps

Louver

Indoor fan

Outdoor fan

4-way valve

Compressor

AUTO

Step

AY-A07BE

AY-A07BE-C

AY-A09BE

AY-A09BE-C

AY-A12BE

1

2

ON

ON

ON

ON

OPEN

OFF

ON

OFF

OFF

1

2

ON

ON

ON

ON

OPEN

OFF

ON

OFF

OFF

1

2

3

ON

OFF

OFF

OFF

OFF

ON

OFF

ON

ON

FLICK

3

ON

OFF

OFF

OFF

OFF

ON

OFF

ON

ON

FLICK

3

ON

OFF

OFF

OFF

OFF

ON

OFF

ON

ON

OFF

ON

OFF

OFF

OFF

OFF

ON

OFF

ON

ON

ON

OFF

4

1

2

3

: 7˚C Room temp. 42˚C ON

: 7˚C (Room temp.) or (Room temp.) 42˚C OFF

: –2˚C Pipe temp. 45˚C ON

: –2˚C (Pipe temp.) or (Pipe temp.) 45˚C OFF

: 0.31V (AN2 input voltage) 4.47V ON

: 0.31V (AN2 input voltage) or (AN2 input voltage 4.47V) OFF

4

: When Power on start is effective, 4-way valve is OFF.

ON

4

ON

4

FAN SOFT

FAN LOW

FAN HIGH

FAN SOFT

FAN LOW

FAN HIGH

Page 24

24

AH-A07BE-C/09BE-C

AH-A07BE/09BE/12BE

AY-A07BE-C/09BE-C

AY-A07BE/09BE/12BE

Table Y-7 [AH-A07BE/A07BE-C/A09BE/A09BE-C/A12BE]

1110987654321

ON ON

OFF

OFF

OFF OFF ON ON ON OFF OFF OFF OFF

OFF ON OFF ON OFF ON ON ON OFF

ON ON OFF ON ON ON ON ON OFF

ON ON OFF OFF OFF OFF OFF OFF OFF

OFF ON OFF OFF OFF OFF OFF OFF OFF

OFF OFF ON ON ON ON ON ON OFF

OFF

CLOSE

OFF OFF OFF OFF OFF OFF OFF

ON ON ON ON ON ON ON ON OFF

OFF

ON

OFF

ON

ON

OFF

OFF

OFF

ON

OFF

OFF

ON

ON

ON

OFF

OFF

OFF

ON

OFF

OFF

OFF

ON

ON

ON

ON

OFF

CLOSE

ON

OFF

OFF

ON

ON

ON

ON

OFF

CLOSE

ON

OFF

OFF OFF

ON

ON

ON

OFF

OFF

ON

OFF

ON

OFF

ON

ON

ON

OFF

OFF

ON

OFF

ON

OFF

OFF

ON

OFF

ON

OFF

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

OFF

ON

OFF

ON

OFF

OFF

OFF

ON

ON

OFF

OFF

ON

OFF

ON

OFF

OFF

ON

ON

OFF

OFF

ON

OFF

ON

OFF

OFF

OFF

ON

ON

OFF

OFF

ON

OFF

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON

OFF

OFF

OFF

ON

ON

OFF

OFF

ON

OFF

ON

OFF

OFF

ON

ON

OFF

OFF

OFF

ON

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON

ON

FLICK

ON

ON

ON

OPEN

OFF

OFF

RED

YELLOW

Lamps

Louver

Indoor fan

Compressor

AUTO

RED

YELLOW

Lamps

Louver

Indoor fan

Compressor

AUTO

RED

YELLOW

Lamps

Louver

Indoor fan

Compressor

AUTO

Step

AH-A07BE

AH-A07BE-C

AH-A09BE

AH-A09BE-C

AH-A12BE

1

2

ON

ON

ON

ON

OPEN

OFF

OFF

1

2

ON

ON

ON

ON

OPEN

OFF

OFF

1

2

ON

OFF

OFF

OFF

OFF

OFF

ON

ON

FLICK

ON

OFF

OFF

OFF

OFF

OFF

ON

ON

FLICK

ON

OFF

OFF

OFF

OFF

ON

OFF

ON

OFF

ON

OFF

OFF

OFF

OFF

ON

OFF

ON

OFF

1

2

: 7˚C Room temp. 42˚C ON

: 7˚C (Room temp.) or (Room temp.) 42˚C OFF

: –2˚C Pipe temp. 45˚C ON

: –2˚C (Pipe temp.) or (Pipe temp.) 45˚C OFF

FAN SOFT

FAN LOW

FAN HIGH

FAN SOFT

FAN LOW

FAN HIGH

FAN SOFT

FAN LOW

FAN HIGH

Page 25

AH-A07BE-C/09BE-C

AH-A07BE/09BE/12BE

AY-A07BE-C/09BE-C

AY-A07BE/09BE/12BE

25

TROUBLESHOOTING GUIDE OF CONTROL CIRCUIT

measure the secondary voltage

of transformer.

YES

NO

YES

NO

The machine does not function

at all with remote controller and

switches on the indoor unit.

Using a tester, measure the

voltage between anodes of D1

and D2 on PWB ass'y.

Is the measured value

approx. 17.0 Vac ?

Replace the PWB with a new

one.

Is the 3.0A fuse down ?

Replace the fuse and varistor

with new ones.

Replace the ftransformer with

a new one.

Page 26

26

AH-A07BE-C/09BE-C

AH-A07BE/09BE/12BE

AY-A07BE-C/09BE-C

AY-A07BE/09BE/12BE

YES

NO

NO

YES

The machine does not function

with remote controller

Push butt "OI" on on the wireless

remote controller.

Is transmitting

indicator of the remote

controller active ?

Is indicator lamp of

indoor unit proper ?

Replace the

PWB with a

new one.

Does beep sound

from the indoor unit ?

Using a tester,

measure the voltage

between terminals

of resistor R11

on the PWB ass'y.

Push the button "OI".

Are batteries of the

wireless remote controller

proper ?

Replace the batteries

with new ones.

Replace the wireless

remote controller.

When the signal is

received, does the voltage

change ?

Replace the PWB with a new

one.

PWB is normal.

Inspect the outdoor unit.

NO

YES

NO

YES

Replace the photo

detector unit with a new

one.

NO

YES

Page 27

AH-A07BE-C/09BE-C

AH-A07BE/09BE/12BE

AY-A07BE-C/09BE-C

AY-A07BE/09BE/12BE

27

The room is not cooled at all

or not cooled.

The compressor does not operate.

Measure resistances of TH1 and TH2.

The control circuit is normal.

The compressor may be defective.

The running capacitor may be defective.

Refrigerant may be leaked.

The outdoor fan motor may be defective.

The outdoor fan motor capacitor may be defective.

Push the button "AUX." on

the indoor unit, for more than 5 sec.

Is the voltage

between terminal "N" and

"1" of the terminal board the

power supply voltage ?

Are the resistances

conformed Fig. 1 ?

Replace the thermistor ass'y with a new one.

NO

YES

YES

NO

Replace the PWB ass'y with a new one.

Fig. 1

Using a tester, measure voltage at

the terminals on the terminal board.

100

80

60

40

20

0

-10 0 10 20 30 40

Resistance

Thermistor

Room temperature

Heat exchange

Color

Yellow

Orange

To measure the resistance, first remove

the connector as shown at right.

Room temperature

thermistor TH1

Tester

Connector

No. 3 to 4

No. 1 to 2

Fig. 1 Temperature properties of indoor thermistors

K

Heat exchange thermistor

TH2 (orange)

25°C resistance 15 K

Room temperature

thermistor TH1 (yellow)

25°C resistance 10 K

Heat exchange

thermistor TH2

Tester

4 1 CN4

Page 28

28

AH-A07BE-C/09BE-C

AH-A07BE/09BE/12BE

AY-A07BE-C/09BE-C

AY-A07BE/09BE/12BE

The room is not heated at all or not heated.

The compressor does not operate.

The control circuit board is normal.

Refrigerant may be leaked.

The running capacitor may be defective.

The outdoor fan motor may be defective.

The outdoor fan motor capacitor may be defective.

The compressor may be defective.

The thermistor may be defective.

Is the voltage

between terminal "N" and

"1" of the terminal board the

power supply voltage ?

NO

Replace the PWB ass'y with a new one.

Push the button of "TEST RUN" on the

indoor unit, and wait 3 minutes.

Using a tester, measure voltages at the

terminals on the terminal board.

Select HEAT MODE with remote controller.

And then start operation.

Is the voltage

between terminal "N" and

"2" of the terminal board the

power supply voltage ?

Is the voltage

between terminal "N" and

"3" of the terminal board the

power supply voltage ?

YES

YES

YES

NO

NO

NO

Page 29

AH-A07BE-C/09BE-C

AH-A07BE/09BE/12BE

AY-A07BE-C/09BE-C

AY-A07BE/09BE/12BE

29

REFRIGERATION CYCLE

Figure R-1. Refrigeration Cycle for AH-A07BE/A07BE-C/A09BE/A09BE-C/A12BE

Figure R-2. Flow of Refrigerant for

AY-A09BE/A09BE-C/A12BE

Figure R-3. Flow of Refrigerant for

AY-A07BE/A07BE-C

1

2

Capillary tube

3

Outdoor unit

Condenser

Evaporator

Indoor unit

Compressor

Flare coupling Flare coupling

Silencer

4

3-way

valve

2-way

valve

Accumulator

s

1

4

C

2

Capillary

tube A

Capillary

tube B

Capillary

tube C

(2 pieces)

Accumulator

3

Strainer

Heating Cooling

Outdoor unit

Condenser

Evaporator

Indoor unit

Reverse valve

Comp-

ressor

Flare coupling Flare coupling

3-way

valve

2-way

valve

Silencer

Coil

s

1

4

C

2

Capillary

tube A

Capillary

tube B

Accumulator

3

Strainer

Heating Cooling

Outdoor unit

Condenser

Evaporator

Indoor unit

Reverse valve

Comp-

ressor

Flare coupling Flare coupling

3-way

valve

2-way

valve

Silencer

Coil

Page 30

30

AH-A07BE-C/09BE-C

AH-A07BE/09BE/12BE

AY-A07BE-C/09BE-C

AY-A07BE/09BE/12BE

Indoor side

Standard conditions:

Dry-bulb Temp. (˚C) Relative Humidity (%)

27Cooling 47

Outdoor side

Dry-bulb Temp. (˚C) Relative Humidity (%)

35 40

AH-A07BE / AH-A07BE-C / AH-A09BE / AH-A09BE-C / AH-A12BE

Temperature at each part and pressure in 3-way valve

Model

1

2

3

4

3-way valve

pressure (MPaG)

76˚C

44˚C

11˚C

8˚C

0.53

76˚C

40˚C

13˚C

7˚C

0.49

81˚C

42˚C

12˚C

10˚C

0.5

Dimension of Capillary tube

AH-A07BE/A07BE-C

AH-A09BE/A09BE-C

AH-A07BE/A07BE-C

AH-A09BE/A09BE-C

AH-A12BE

Model

ø2.7

ø2.7

ø2.7

O.D

ø1.4 ø1.5

ø1.6

400

600

I.D L

O.D

I.D L

O.D

I.D L

500

Capillary tube

AH-A09BE/A09BE-CAH-A07BE/A07BE-C AH-A12BE

Indoor side

Standard conditions:

Dry-bulb Temp. (˚C) Relative Humidity (%)

20Heating

Outdoor side

Dry-bulb Temp. (˚C) Relative Humidity (%)

787

27Cooling 47 35 40

AY-A07BE / AY-A07BE-C / AY-A09BE / AY-A09BE-C / AY-A12BE

Temperature at each part and pressure in 3-way valve

NO.

Condition

Cooling Heating Cooling Heating Cooling Heating

Model

1

2

3

4

3-way valve

pressure (MPaG)

0.54 1.51 0.52 1.54 0.52 1.62

41˚C

70˚C

12˚C

7˚C

74˚C

3˚C

32˚C

3˚C

75˚C

43˚C

13˚C

8˚C

74˚C

2˚C

32˚C

3˚C

41˚C

78˚C

14˚C

11˚C

73˚C

3˚C

32˚C

4˚C

Dimension of Capillary tube

AY-A12BE

Model

ø2.7

ø2.7

O.D

ø1.6

ø1.6

150

I.D L

O.D

I.D L

O.D

I.D L

150

Capillary tube C

ø2.7

ø2.7

ø2.7

ø1.4 ø1.5

ø1.6

700

700

700

Capillary tube B

ø2.7

ø2.7

ø2.7

ø1.4 ø1.5

ø1.6

600

500

400

Capillary tube A

AY-A09BEAY-A07BE AY-A12BE

REFRIGERANT PIPE LENGTH 7.5m

REFRIGERANT PIPE LENGTH 7.5m

Model

O.D

I.D L

O.D

I.D L

Capillary tube C

ø2.7

ø2.7

ø1.4 ø1.5700

700

ø2.7

ø1.6

150

Capillary tube B

ø2.7

ø2.7

ø1.4 ø1.5500

400

Capillary tube A

AY-A09BE-CAY-A07BE-C

Page 31

AH-A07BE-C/09BE-C

AH-A07BE/09BE/12BE

AY-A07BE-C/09BE-C

AY-A07BE/09BE/12BE

31

25 30 35 40

2.4

2.6

2.8

3.0

3.2

12

14

16

600

700

800

900

Cooling capacity(kW)

Outside air temp.(˚C)

Input(W)

Outlet air temp.(˚C)

25 30 35 40

3.2

3.4

3.6

3.8

4.0

10

12

14

900

1000

1100

1200

Cooling capacity(kW)

Outside air temp.(˚C)

Input(W)

Outlet air temp.(˚C)

25 30 35 40

3.2

3.4

3.6

3.8

4.0

10

12

14

900

1000

1100

1200

Cooling capacity(kW)

Outside air temp.(˚C)

Input(W)

Outlet air temp.(˚C)

25 30 35 40

2.0

2.2

2.4

2.6

10

12

14

500

600

700

800

Cooling capacity(kW)

Outside air temp.(˚C)

Input(W)

Outlet air temp.(˚C)

PERFORMANCE CURVES

NOTE: 1) Indoor fan speed: Hi

2) Vertical adjustment louver "45˚", Horizontal adjustment louver "front"

3) Indoor air temp. : Cooling 27˚C, Heating 20˚C

4) Power source : 220V, 50Hz

Figure P-1. At Cooling for AH-A07BE/A07BE-C Figure P-2. At Cooling for AH-A09BE/A09BE-C

Figure P-3. At Cooling for AH-A12BE

Figure P-4. At Cooling for AY-A07BE/A07BE-C

Figure P-5. At Cooling for AY-A09BE/A09BE-C Figure P-6. At Cooling for AY-A12BE

25 30 35 40

2.0

2.2

2.4

2.6

10

12

14

500

600

700

800

Cooling capacity(kW)

Outside air temp.(˚C)

Input(W)

Outlet air temp.(˚C)

25 30 35 40

2.4

2.6

2.8

3.0

3.2

12

14

16

600

700

800

900

Cooling capacity(kW)

Outside air temp.(˚C)

Input(W)

Outlet air temp.(˚C)

Page 32

32

AH-A07BE-C/09BE-C

AH-A07BE/09BE/12BE

AY-A07BE-C/09BE-C

AY-A07BE/09BE/12BE

Figure P-7. At Heating for AY-A07BE/A07BE-C Figure P-8. At Heating for AY-A09BE/A09BE-C

Figure P-9. At Heating for AY-A12BE

-5 0 7510

1.5

2.0

2.5

3.0

35

30

40

400

500

600

700

Heating capacity(kW)

Outside air temp.(˚C)

Input(W)

Outlet air temp.(˚C)

-5 0 5 7 10

2.5

2.0

3.0

3.5

35

40

45

600

700

800

900

Heating capacity(kW)

Outside air temp.(˚C)

Input(W)

Outlet air temp.(˚C)

-5 0 5 7 10

2.5

3.0

3.5

4.0

4.5

5.0

35

40

45

800

900

1000

1100

1200

Heating capacity(kW)

Outside air temp.(˚C)

Input(W)

Outlet air temp.(˚C)

Page 33

AH-A07BE-C/09BE-C

AH-A07BE/09BE/12BE

AY-A07BE-C/09BE-C

AY-A07BE/09BE/12BE

33

DISASSEMBLING PROCEDURE

FOR INDOOR UNIT

CAUTION : DISCONNECT THE UNIT FROM THE POWER SUPPLY BEFORE ANY SERVICING

1. Open the opne panel, and remove 2 air filters.

2. Remove 4 screws fixing the front panel.

3. Remove the screw fixing the cord clamp.

Note: During reassembly, install the holder after

installing the front panel. THis will make it

easier to assemble the front pane.

4. Close the open panel. Pushing the nail of the front

pane.

5. Pull the front panel up.

6. Remove the unit-to-unit wiring from the terminal

board.

7. Remove a screw fixing the control box cover, and

remove it.

8. Remove a screw fixing the ground wire.

Note: During reassembly, take care for the

direction of the lead wire.

Page 34

34

AH-A07BE-C/09BE-C

AH-A07BE/09BE/12BE

AY-A07BE-C/09BE-C

AY-A07BE/09BE/12BE

9. Remove the thermostat of the evaporator.

10. Remove 4 connectors.

11. Remove the thermistor holder from the evaporator.

12. Remove the display from the drain pan.

13. Remove the screw fixing the pipe holder.

14. Remove 3 screws fixing the control box, and remove

the control box.

15. Remove a screw fixing the drain pan.

16. Pull drain pan toward you.

CN1

CN6

CN3

CN2

Page 35

AH-A07BE-C/09BE-C

AH-A07BE/09BE/12BE

AY-A07BE-C/09BE-C

AY-A07BE/09BE/12BE

35

17. Remove the drain cover from the evaporator.

Note: During reassembly, verify that the dew on

the pipe is led to the drain pan.

18. Remove 4 screws fixing the evaporator.

19. Remove the evaporator from the cabinet.

20. Remove 2 screws fixing the motor cover, and pull up

the fan.

21. Loose a screw fixing fan.

[Cautionary points for assembling the fan]

a. When inseting the motor shaft into the metal fan

boss, take care to prevent injuring the inner surface of

the metal fan boss.

b. Before fastening the motor shaft and fan, insert the

motor shaft into contact with the bottom of the metal

fan boss.

Fan motor

Motor shaft

Fan boss

Cross flow fan

Page 36

36

AH-A07BE-C/09BE-C

AH-A07BE/09BE/12BE

AY-A07BE-C/09BE-C

AY-A07BE/09BE/12BE

How to remove the display cover

1

2

1. Push the center of display cover from the back.

2. Slide the display cover to the right.

How to assemble the display cover

1. Slide the left end of the display cover through 3 hooks

on the front panel along the guide from the center of

the front panel.

2. After the left half is inseted completely, press the

display cover and snap in the 3 hooks on the right.

How to remove the control box.

1. Remove the photo detector unit.

(Press and spread the upper hook, and the photo

detector unit will be ready for removal.)

2. Remove the screw fixing the terminal board.

3. Remove a screw fixing the cord holder.

4. Remove 2 screws fixing the board (transformer.

5. Pull the board.

Page 37

AH-A07BE-C/09BE-C

AH-A07BE/09BE/12BE

AY-A07BE-C/09BE-C

AY-A07BE/09BE/12BE

37

Drain pan and related

1. Remove 3 screws fixing motors.

2. Turn the cap area of the drain hose counterclockwise,

and remove it from the drain pan.

During installation, turn the drain hose to the state of

the “engagement position”.

After reinstallation, verify that it is securely fastened.

How to remove the horizontal louver

Slightly pull down the hinge area, defelect thge louver,

and unhook it from the hinge. Remove the shaft from

each of the left and right sides.

Drain pan

Drain Hose

Groove

Projection

To disconned To reconnect

Page 38

38

AH-A07BE-C/09BE-C

AH-A07BE/09BE/12BE

AY-A07BE-C/09BE-C

AY-A07BE/09BE/12BE

FOR OUTDOOR UNIT [AU-A09BE/A09BE-C/A12BE, AE-A09BE/A09BE-C/A12BE]

CAUTION : DISCONNECT THE UNIT FROM THE POWER SUPPLY BEFORE ANY SERVICING

1. Loose a screw fixing the side cover.

2. Loose a screw fixing the cord clamp.

3. Loose the unit-to-unit cord.

4. Loose 4 screws fixing the top panel.

5. Loose 5 screws fixing the front panel.

6. Cut 3 nylon bands.

Right side view Left side view

Front view

7. Remove 5 terminals. [AE-A09BE/A09BE-C/A12BE]

Remove 3 terminals. [AU-A09BE/A09BE-C/A12BE]

AE-A09BEA09BE-C/A12BE AU-A09BEA09BE-C/A12BE

Fan motor 3 3

Reverse valve 2 0

Right side view Left side view

Page 39

AH-A07BE-C/09BE-C

AH-A07BE/09BE/12BE

AY-A07BE-C/09BE-C

AY-A07BE/09BE/12BE

39

8. Remove the terminal cover.

9. Remove 3 terminals.

10. Loose 4 screws fixing the control box.

11. Take out the control box.

DISASSEMBLING PROCEDURE OF THE FAN

1. Loose the fan nut and fan can take out.

2. Fan motor is secured by 4 screws.

Loose

Page 40

40

AH-A07BE-C/09BE-C

AH-A07BE/09BE/12BE

AY-A07BE-C/09BE-C

AY-A07BE/09BE/12BE

1

Left side cover

Condenser

Right side cover

Cabinet

Fan motor Bulkhead

Propeller fan

Compressor

AE-A07BE/A07BE-C

Fan guard

2

3

1

1

3

AU-A07BE/A07BE-C

FOR OUTDOOR UNIT MODEL AE-A07BE/A07BE-C AND AU-A07BE/A07BE-C

CAUTION: DISCONNECT THE UNIT FROM THE POWER SUPPLY BEFORE ANY SERVICING

1 Remove the four (4) screws holding the terminal

cover and right side cover. Then take them out.

2 Remove the three (3) screws holding the left side

cover and take it out.

3 Remove the another screws holding the cabinet

and take it out.

NOTE: Number as shown in following

figure is the moval order.

Fig. D-1. OUTDOOR UNIT

Page 41

AH-A07BE-C/09BE-C

AH-A07BE/09BE/12BE

AY-A07BE-C/09BE-C

AY-A07BE/09BE/12BE

41

REF. NO. PART NO. DESCRIPTION Q'TY CODE

REPLACEMENT PARTS LIST [AH/AY-A07BE/A07BE-C/A09BE/A09BE-C/A12BE]

CABINET AND UNIT PARTS

1- 1 CMOT-A397JBKZ Fan motor sub assembly 1 BG

1- 2 PGUMSA046JBE0 Damper rubber 1 AD

1- 3 CHLD-A067JBK0 Bearing assembly 1 AL

1- 4 DCHS-A399JBKZ Cabinet assembly[except for AY-A12BE, AH-A12BE] 1 BD

1- 4 DCHS-A401JBKZ Cabinet assembly [AY-A12BE, AH-A12BE] 1 BC

1- 5 NFANCA089JBEZ Cross flow fan 1 BD

1- 6 DSRA-A234JBKZ Drain pan sub assembly 1 BB

1- 7 CMOTLA915JBEZ Fan motor 1 BK

1- 8 MJNTPA082JBFA Louver link 2 AC

1- 9 MLOV-A299JBFA Vertical louver 12 AC

1-10 MLOV-A297JBFA Horizontal louver A 1 AK

1-11 MLOV-A298JBFA Horizontal louver B 1 AK

1-12 QW-VZE022JBZZ Fan motor wire 1 AM

1-13 LHLD-A197JBFP Louver holder 2 AX

1-14 NBRG-A026JBFA Louver bushing 2 AB

1-15 LHLD-A476JBFZ Display cover 1 AK

1-16 PHOS-A025JBE0 Drain hose 1 AL

1-17 PPACGA010JBE0 O ring 1 AB

1-18 PGID-A097JBFZ Drain cover 2 AF

1-19 RMOT-A061JBE0 Louver motor 2 AS

1-20 PGUMMA110JBE0 Drain cap 1 AD

1-21 CWAK-C108JBKZ Front panel assembly

[AY-A07BE/A07BE-C/A09BE/A09BE-C/A12BE]

1BK

1-21 CWAK-C109JBKZ Front panel assembly

[AH-A07BE/A07BE-C/A09BE/A09BE-C/A12BE]

1BL

1-22 PPLT-A212JBFZ Side cover R 1 AL

1-23 PPLT-A213JBFZ Side cover L 1 AL

1-24 PCOV-A637JBRA Display cover 1 BC

1-25 PFILMA145JBEA Air filter 2 AL

1-26 DHLD-A010JBKZ Tube holder assembly 1 AK

1-27 HPNL-A520JBFB Open panel 1 AR

1-28 TSPC-D666JBRA Name label [AH-A07BE] 1 AF

1-28 TSPC-E055JBRA Name label [AH-A07BE-C] 1 AF

1-28 TSPC-D662JBRA Name label [AH-A09BE] 1 AE

1-28 TSPC-E056JBRA Name label [AH-A09BE-C] 1 AC

1-28 TSPC-D667JBRA Name label [AH-A12BE] 1 AE

1-28 TSPC-D663JBRA Name label [AY-A07BE] 1 AC

1-28 TSPC-E053JBRA Name label [AY-A07BE-C] 1 AC

1-28 TSPC-D658JBRA Name label [AY-A09BE] 1 AC

1-28 TSPC-E054JBRA Name label [AY-A09BE-C] 1 AD

1-28 TSPC-D664JBRA Name label [AY-A12BE] 1 AC

1-29 PFPFPB901JBEZ Cabinet insulator[except for AY-A12BE, AH-A12BE] 1 AH

1-30 QW-VZE013JBZZ Lead wire (upper) 1 AG

1-31 GWAK-A257JBFA Front panel 1 AX

1-32 PCOV-A614JBFZ Drain cover 1 AG

1-33 TLABCB408JBRZ Wiring diagram [AY-A07BE/A07BE-C/A09BE/A09BE-C/A12BE] 1 AC

1-33 TLABCB413JBRZ Wiring diagram [AH-A07BE/A07BE-C/A09BE/A09BE-C/A12BE] 1 AC

1-34 QW-VZD893JBZZ Lead wire (lower) 2 AG

1-35 LHLD-A303JBFA Tube cover 1 AD

1-36 PSEL-C125JBEZ Panel insulator 1 AF

1-37 HDEC-B108JBEZ Sheet 2 AF

1-38 HDEC-B112JBEZ Sheet 1 AN

1-39 PSEL-C055JBEZ Evaporator seal [AH-A12BE, AH-A12BE] 1 AC

1-40 PSHE-A126JBE0 Evaporator seal 1 AG

1-41 LSPR-A007JBE0 Seet spring 2 AD

1-42 PSEL-C136JBEZ Insulator [AY-A12BE, AH-A12BE] 1 AC

1-43 PFPFPB962JBEZ Insulator 1 AC

1-44 PFPFPB967JBEZ Insulator 1 AC

CONTROL BOX PARTS

2- 1 RTHM-A300JBE0 Thermistor 1 AP

2- 2 PBOX-A342JBFZ Control box 1 AQ

2- 3 PBOX-A341JBFZ Terminal cover 1 AH

2- 4 LHLD-A500JBFZ Thermistor holder 1 AC

2- 5 PCOV-A300JBF0 Thermistor holder cover 1 AB

2- 6 HPNLCA776JBFA Control box cover 1 AG

2- 7 HPNLCA777JBEA Control panel 1 AD

2- 8 PCOV-A618JBFA LED holder 1 AE

2- 9 PCOV-A640JBFA LED holder B 1 AK

2-10 DPWBFA212JBKZ Control board unit [AH-A07BE/A07BE-C] 1 BK

2-10 DPWBFA209JBKZ Control board unit [AH-A09BE/A09BE-C] 1 BK

2-10 DPWBFA213JBKZ Electric control board [AH-A12BE] 1 BK

2-10 DPWBFA210JBKZ Control board unit [AY-A07BE/A07BE-C] 1 BL

2-10 DPWBFA208JBKZ Control board unit [AY-A09BE/A09BE-C] 1 BL

2-10 DPWBFA211JBKZ Control board unit [AY-A12BE] 1 BL

2-11 QACC-A158JBE0 Power supply cord 1 AT

2-12 QTANZA002JBZZ Terminal board(3 pin) 1 AN

2-13 QTANZA002JBZZ Terminal board(3 pin)

[AH-A07BE/A07BE-C/A09BE/A09BE-C/A12BE]

1AN

2-13 QTANZA003JBZZ Terminal board(5 pin)

[AY-A07BE/A07BE-C/A09BE/A09BE-C/A12BE]

1AR

Page 42

42

AH-A07BE-C/09BE-C

AH-A07BE/09BE/12BE

AY-A07BE-C/09BE-C

AY-A07BE/09BE/12BE

REF. NO. PART NO. DESCRIPTION Q'TY CODE

2-14 PCOV-A609JBWZ Control box cover 1 AC

2-15 PCOV-A611JBWZ Control box cover 1 AF

2-16 PCOV-A610JBWZ Terminal cover 1 AE

2-17 VHLGPIU28RR-1 Photo detector unit (IC201) 1 AK

2-18 QFS-GA027JBE0 Fuse 3A 250V 1 AD

2-19 RH-IXA664JBZZ Microcomputer (IC1) 1 AU

2-29 RH-IZA149JBE0

Integrated circuit (IC2)

1AE

2-21 RIC--A022BDE0

Integrated circuit (IC3)

1AE

2-22 RIC--A025BDE0

Integrated circuit(IC4,IC5) [AH-A07BE/A07BE-C/A09BE/A09BE-C/A12BE]

2AE

2-23 VHIBR24C01A-6 E2PROM (IC6) 1 AF

2-24 RH-IZA140JBE0 Integrated circuit (IC7) 1 AE

2-25 RH-VZA020JBE0

Varistor (CNR1,CNR2.CNR3)[AY-A07BE/A07BE-C/A09BE/A09BE-C/A12BE]

3AE