Page 1

AR-SS2

CODE : 00ZARSS2//A1E

20-BIN STAPLE

SORTER

MODEL AR-SS2

CONTENTS

[ 1 ] SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[ 2 ] UNPACKING AND INSTALLATION . . . . . . . . . . . . . . . . . . . . . 2-1

[ 3 ] EXTERNAL VIEW AND INTERNAL STRUCTURE . . . . . . . . . . 3-1

[ 4 ] DISASSEMBLY AND ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . 4-1

[ 5 ] ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

[ 6 ] DIAGNOSTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

[ 7 ] TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

[ 8 ] MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

[ 9 ] OPERATIONAL DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . 9-1

[10] ACTUAL WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

■ PARTS GUID E

Parts marked with “ ” are important for maintaining the safety of the set. Be sure to replace these parts with specified ones for

maintaining the safety and performance of the set.

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

Page 2

AR-SS2

[1] SPECIFICATIONS

Type

20-bin staple sorter (copier-mounted, hook type)

No. of bins

20 bins (incl. non-sort bin)

Loading method

Face up

Bin-shift, open-port system

Kinds of copy paper

With normal paper (64 to 105g/m2) or thick paper (106 to 200g/m2),

max. 2 sheets of covers, back covers, or insert papers can be sorted.

Special paper, 2nd original paper, OHP, postcards, labels

Capacity of each bin: 105g/m2 or equivalent

Non-sort mode

(1-bin only):

Sort mode: 50 sheets (A4, A4R, B5, B5R, A5, 8.5"x11",

Staple sort mode: 30 sheets (A4, A4R, B5, 8.5"x11", 8.5"x11"R)

Group mode: 30 sheets (A4, B5, A5, 8.5"x11", 5.5"x8.5", A4R,

Bin returning time (from 20 bin to 1 bin)

About 10 sec

Limitless function

Not provided

Bin specifying function

Not provided

Operation panel

Staple key

100 sheets (A4, A4R, B5, B5R, A5, 8.5"x11",

8.5"x11"R, 5.5"x8.5", 7.25"x10.25"R)

60 sheets (A3, B4, 11"x17", 8.5"x14", 8.5"x13",

12"x18")

8.5"x11"R, 5.5"x8.5")

25 sheets (A3, B4, 11"x17", 8.5"x14", 8.5"x13")

25 sheets (A3, B4, 11"x17", 8.5"x14", 8.5"x13")

B5R, 8.5"x11"R)

25 sheets (A3, B4, 11"x17", 8.5"x14", 8.5"x13")

Manual stapling: 30 sheets: A4, A4R, B5, 8.5"x11", 8.5"x11"R

Manual feed stapling:

(28 sheets of 105g/m2 + 2sheets of 200g/m2 or

max. thickness 5.5mm)

25 sheets: A3, B4, 11"x17", 8.5"x14", 8.5"x13"

(28 sheets of 105g/m2 + 2sheets of 200g/m2 or

max. thickness 5.5mm)

30 sheets: All sizes

Applicable staple

Staple: SF-SC11 (Cartridge: 5,000 staples)

Staple empty detection

Available (The staple empty display is lighted when the remaining

quantity of staples is 40 pcs or less after stapling.)

Auto staple positioning

Available (Auto staple positioning is started when the stapler unit

cover is closed after staples are supplied.)

Use environment

Temperature: Conforms to the conditions for the copier.

Humidity: Conforms to the conditions for the copier.

Power source

24V (Supplied from the copier)

Max. power consumption

About 60W

Weight

About 26.4kg

Dimensions (Width x Depth x Height)

417 x 594 x 624 mm

Staple position

6±2.5mm

Transport direction

Display section

Manual staple: Enable/disable (Enable when LED is ON)

Staple supply indication

Stapling system

Punching by the rotation cam

Auto stapling enable copy paper size

A3, A4, B4, B5, A4R, 11"x17", 8.5"x14", 8.5"x11", 8.5"x11"R, 8.5"x13"

Manual stapling enable copy paper size (Stapling by key

operation immediately after copying)

A3, A4, B4, B5, A4R, 11"x17", 8.5"x14", 8.5"x11", 8.5"x11"R, 8.5"x13"

Manual feed stapling enable copy paper size (Stapling by

paper insertion by the user)

All sizes

Number of sheets to be staped (64 to 105g/m2 or

equivalent)

Auto stapling: 30 sheets: A4, A4R, B5, 8.5"x11", 8.5"x11"R

(28 sheets of 105g/m2 + 2 sheets of 200g/m2 or

max. thickness 5.5mm)

25 sheets: A3, B4, 11"x17", 8.5"x14", 8.5"x13"

(28 sheets of 105g/m2 + 2 sheets of 200g/m2 or

max. thickness 5.5mm)

6±2.5mm

15˚

1 – 1

Page 3

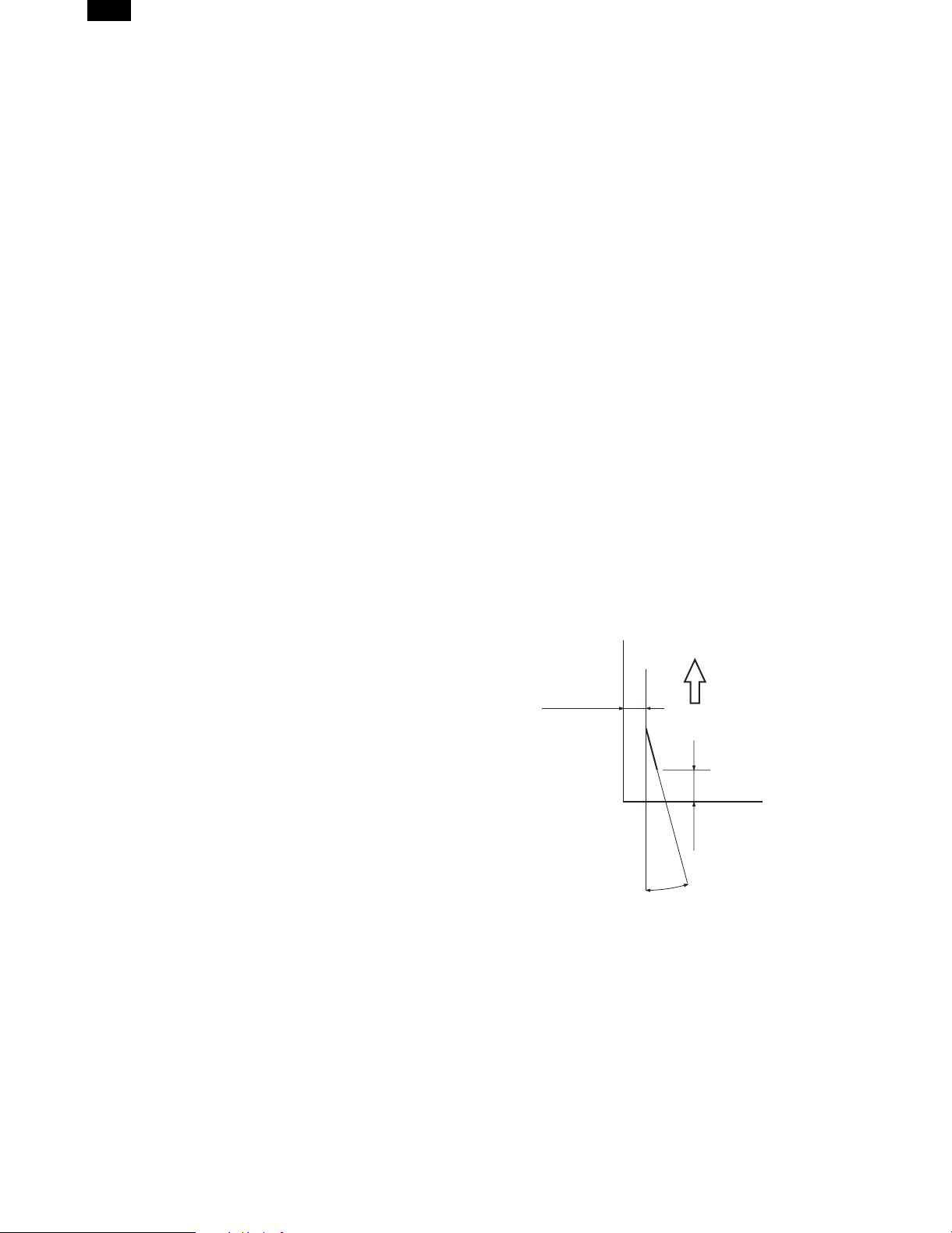

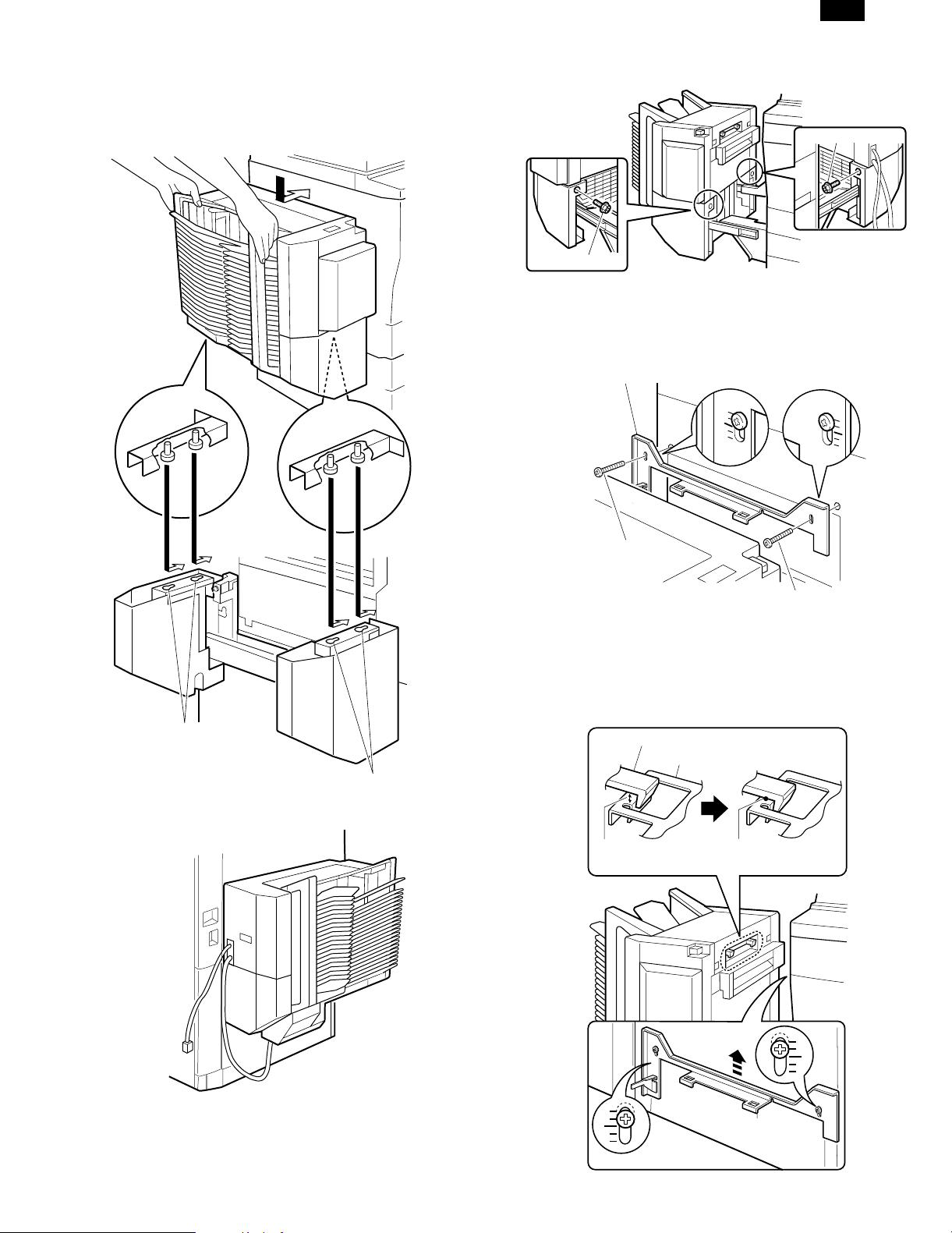

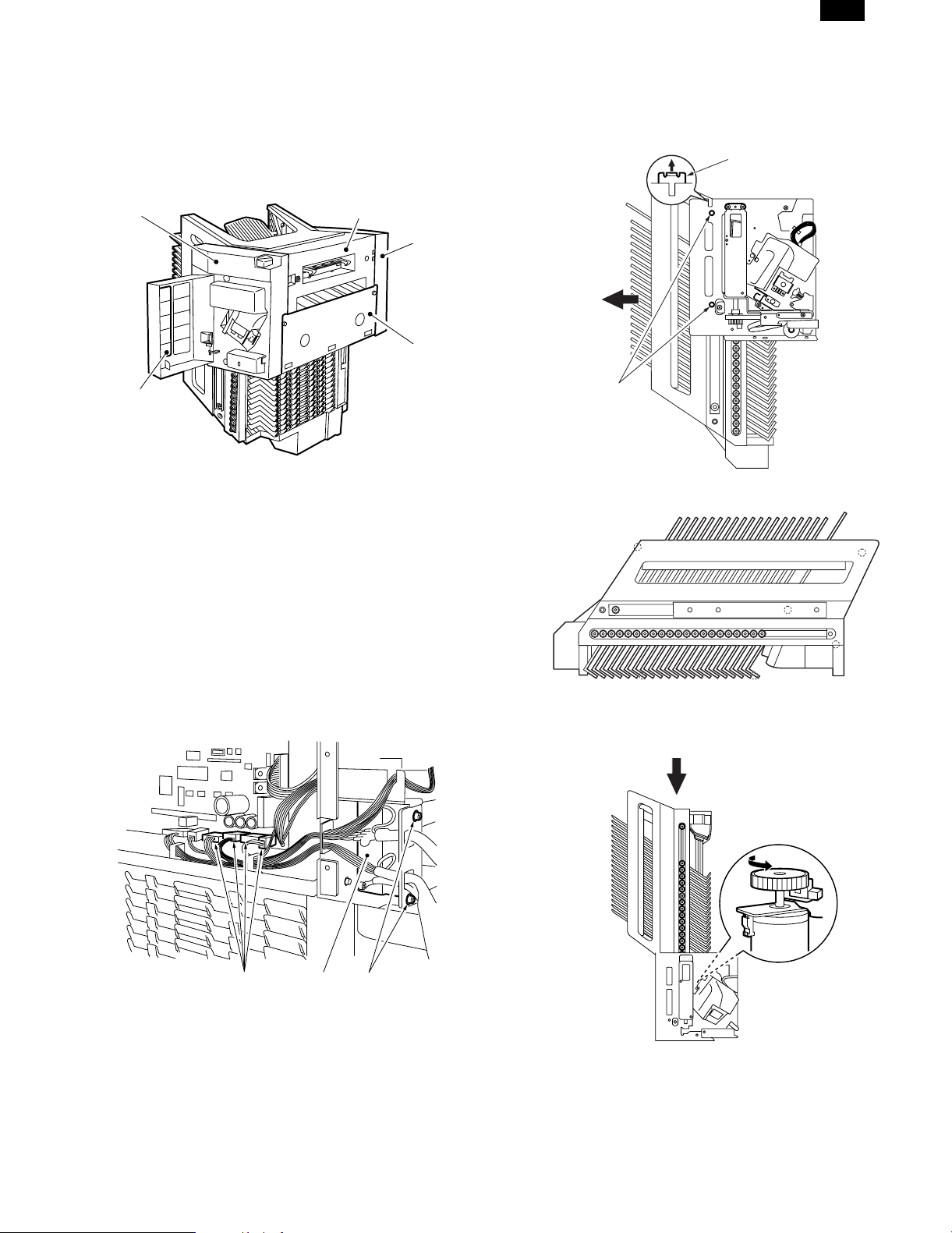

[2] UNPACKING AND INSTALLATION

1. Unpacking

AR-SS2

Remove the filament tape and remove the packing of each section.

2 – 1

Page 4

AR-SS2

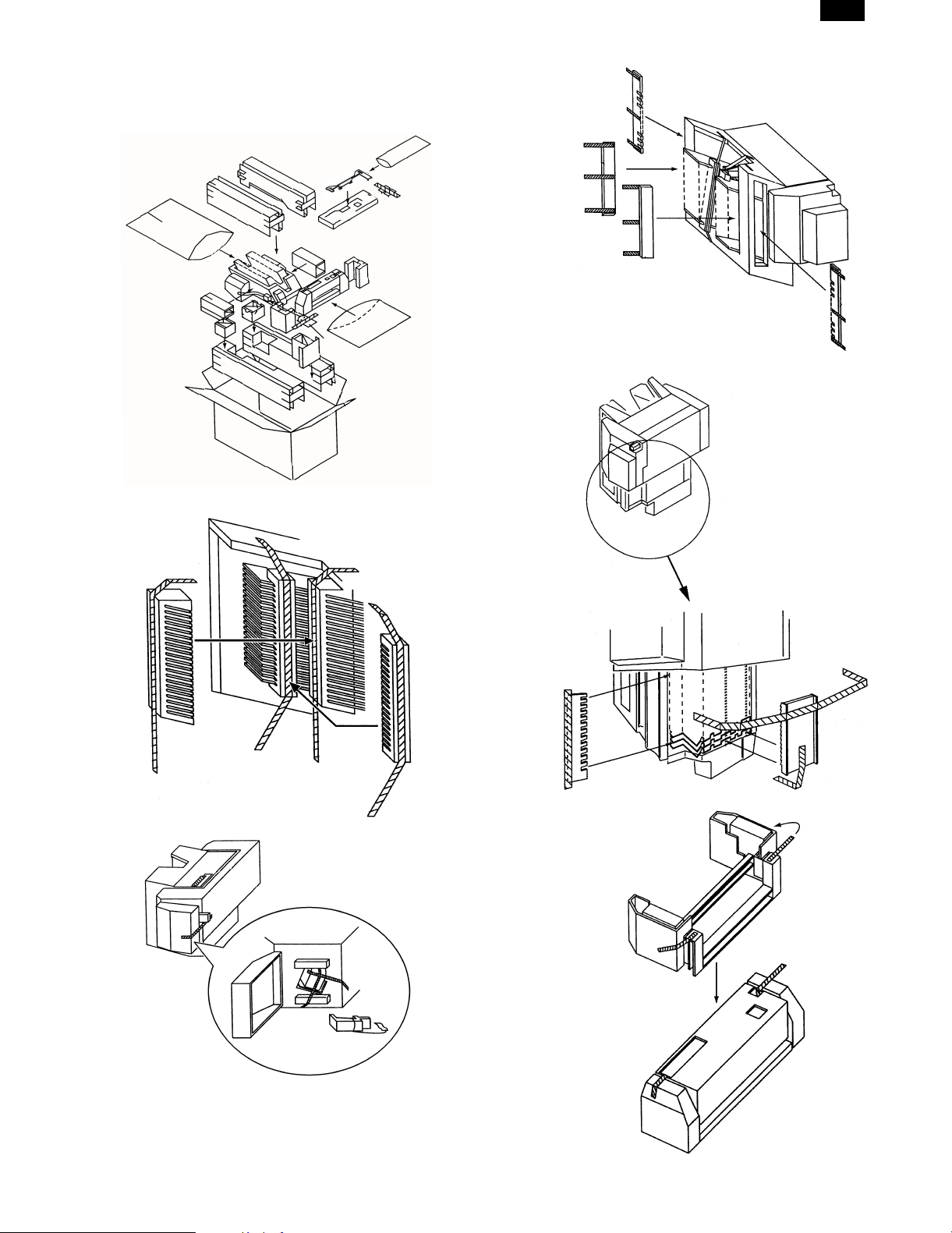

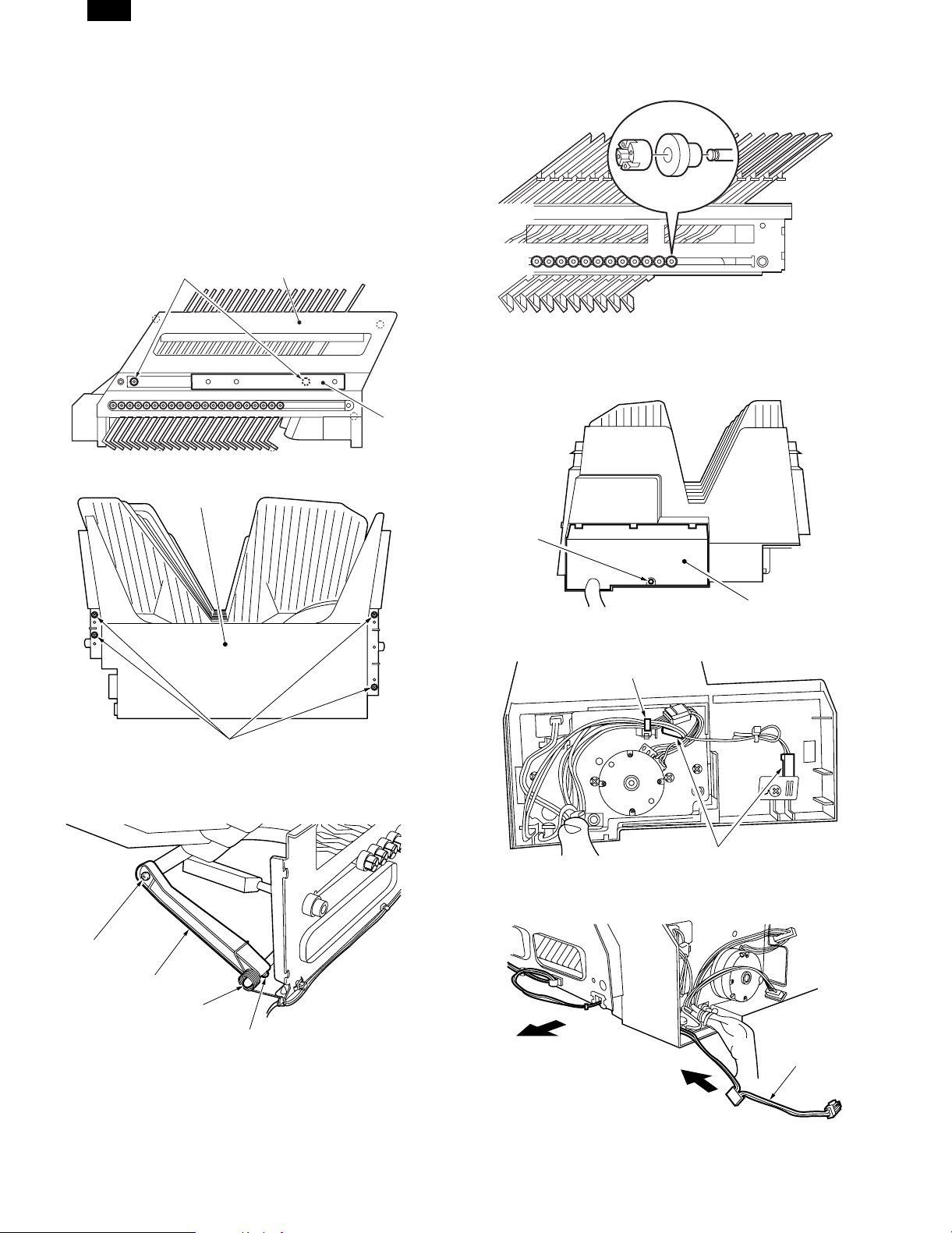

2. Installation

Packed items

1 Rail unit 1

2 Lock plate 1

3 Rail unit fixing screw 2

4 Mounting kit fixing screw (M4 x 18) 4

5 Sorter fixing screw (M4 x 10) 2

6 Stapler position label A (for the copier) 1

7 Stapler position label D (for the RADF) 1

2. Fix the rail unit fixing screw temporarily as shown in

the figure.

Cut-out

Rail unit fixing screws

1

2

3

6

4

7

5

Pull out the power plug of the copier from the

power outlet, and follow the procedures below.

Setting of the copier and the stapler sorter

1. Remove the notch sections of the copier, and install

the rail mounting plate fixing screw.

Use nippers to cut out the two cut-out sections on the upper side of

the left cabinet of the copier. Use a screwdriver to punch out the four

cut-out sections on the lower side. (There are 6 cut-out section in

total.)

Cut-out

3. Install the rail unit

Hang the rail unit on the upper rail unit fixing screws which were fixed

temporarily in procedure 2.

Tighten the mounting kit fixing screw in the position shown in the

figure.

Tighten the upper rail un it f ix in g sc r ew s whic h w ere temporarily fixe d.

Rail unit

Mounting kit fixing screws

2 – 2

Page 5

AR-SS2

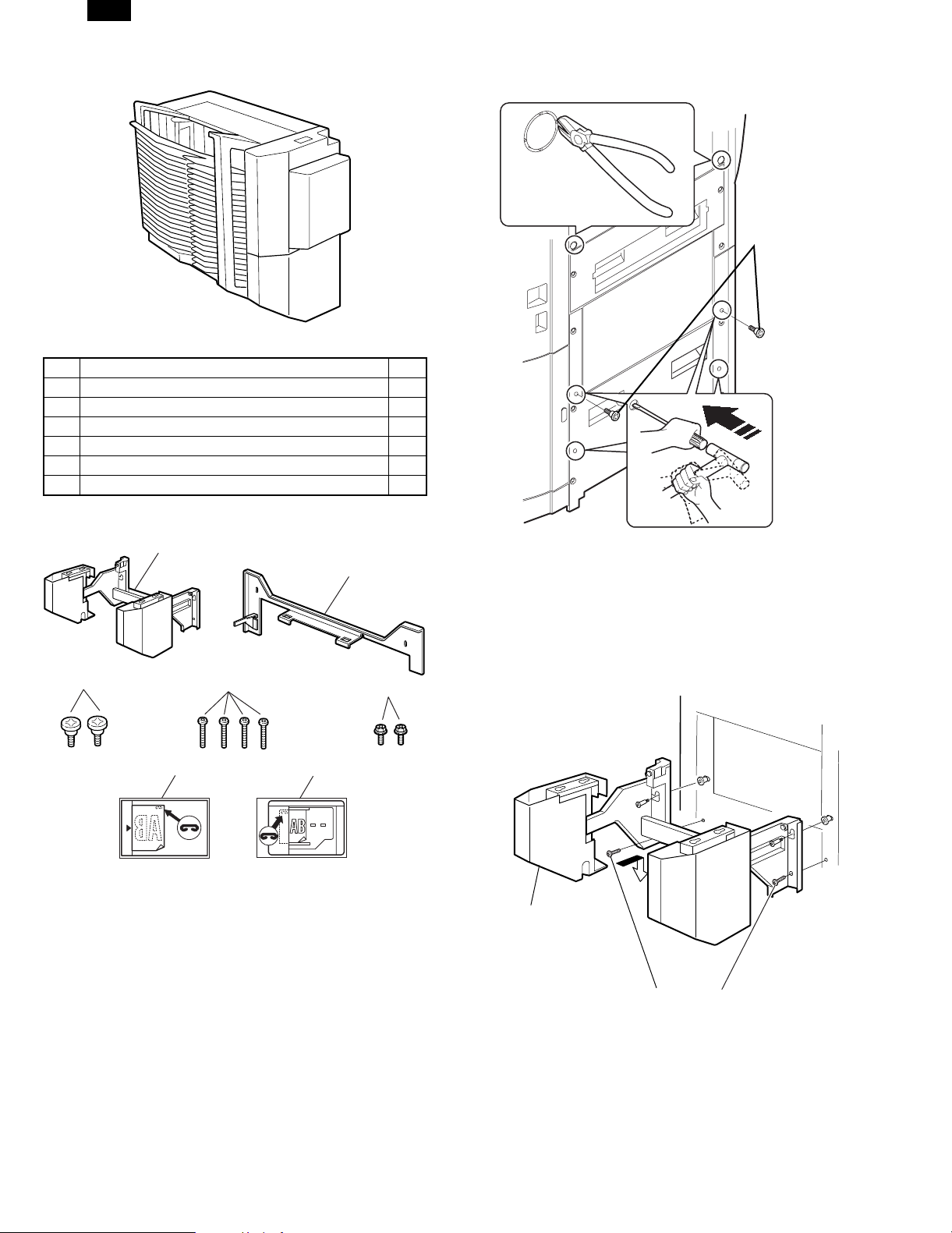

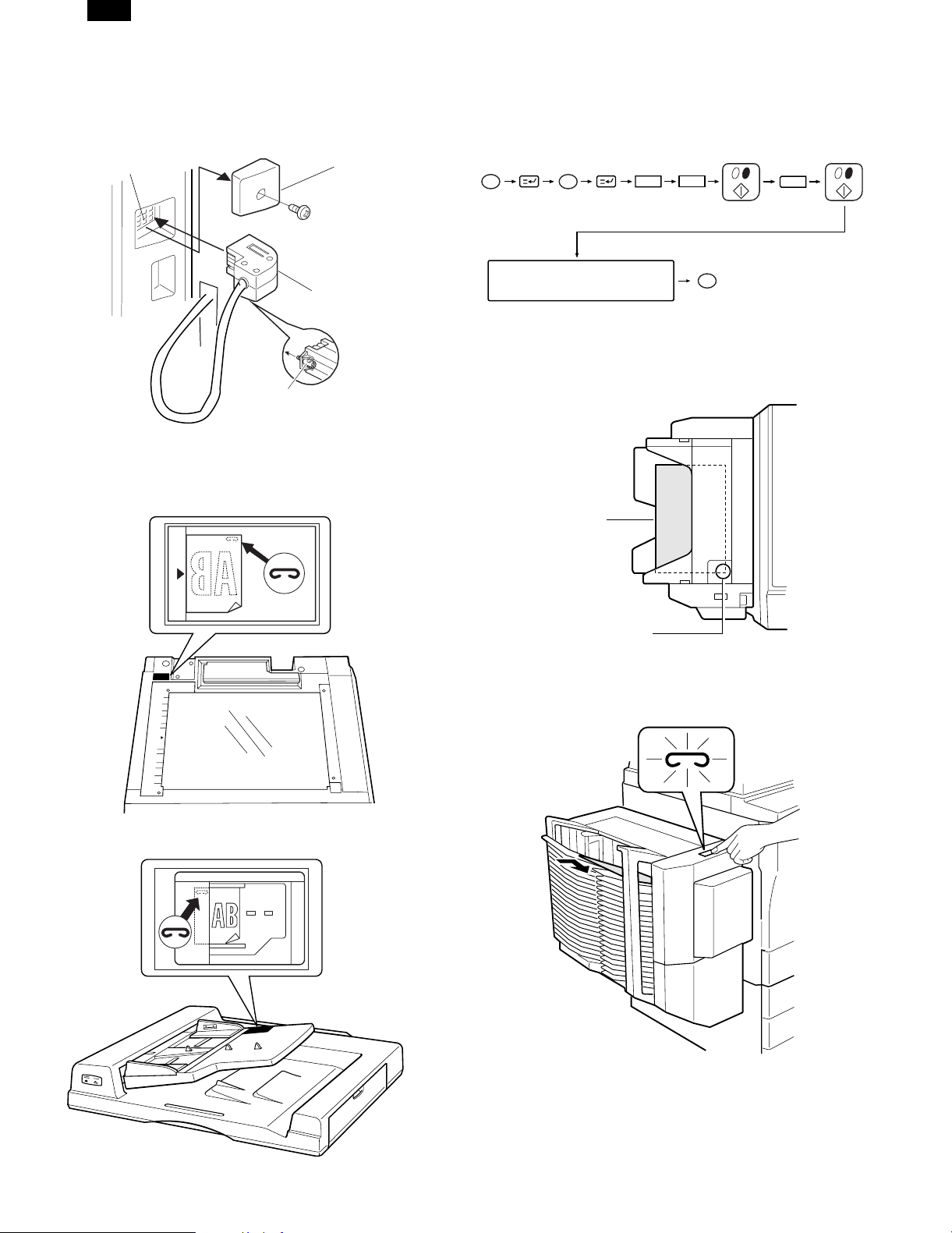

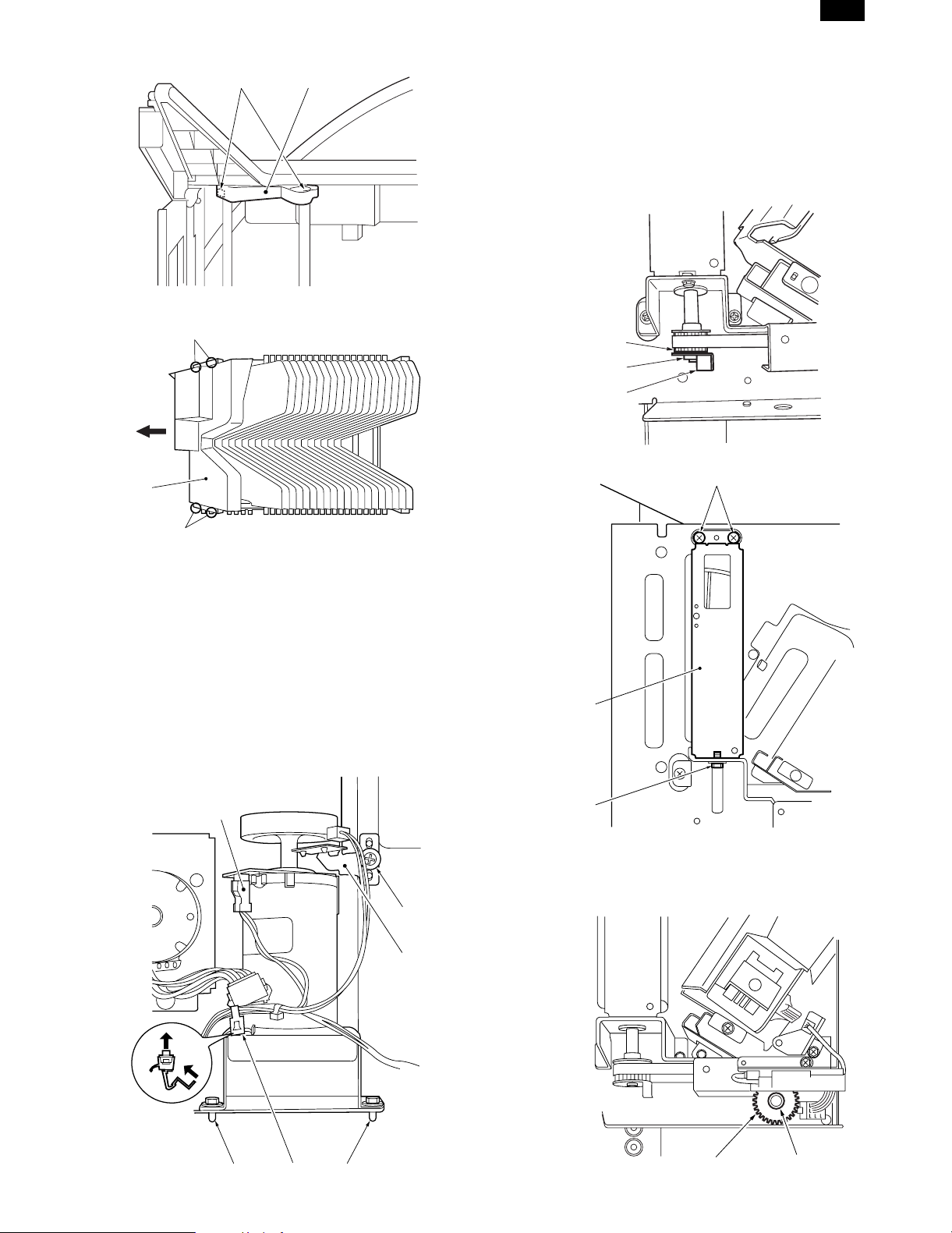

4. Fix the sorter to the rail unit.

[Note] When lifting the sorter, hold the sorter as shown in the figure

so as not to make contact with the sorter bin.

Insert the positioning screws on the lower side of the sorter into the

rail unit positioning holes, and slide the sorter inward.

Fix the sorter unit with the sorter fixing screws on the front and the

rear sides of the rail unit.

Sorter fixing screw

Sorter fixing screw

5. Install the lock plate and check that the staple sorter

is installed.

1) Fix the lock plate with two mounting kit fixing screws (M4 x 18 S

tight) with the sorter mounting plate lowered as shown in the

figure.

Lock plate

Positioning holes

Positioning holes

At that time, position the wiring of the sorter as shown in the figure.

Mounting kit fixing screw

Mounting kit fixing screw

2) Lock the staple sorter to the copier body, and check the clearance

between the sorter lock pawl and the lock plate. (Refer to Fig. 1)

3) Loosen two mounting kit fixing screws so that the sorter lock pawl

and the lock plate are in contact horizontally. Adjust the lock plate

height. One scale corresponds to about 2mm. (Refer to Fig. 2)

At that time, check that the paper exit cabinet of the copier can be

opened and closed.

Sorter lock pawl

Lock plate

Clearance

[Fig. 1]

Contact

[Fig. 2]

2 – 3

Page 6

AR-SS2

6. Connect the sorter connector.

Remove the sorter connector cover attached to the rear cabinet of the

copier.

Connect the sorter connector to the connector of the copier and

tighten the screw to fix the connector.

Connector of the copier

Sorter connector cover

Sorter connector

Screw

7. Attach the staple position label.

• Attach the staple position label as shown below.

Staple position label A (for the copier)

Insert the power plug of the copier into the power

outlet, turn on the power switch, and follow the

procedures below.

8. Set the mode.

• Set the mode with the key operation of the copier.

PC

Clear

Select the corresponding

number with the 10-key.

26

CA

The mode is set with the

above operations.

9. Check the operation of the staple sorter.

Align the paper to be stapled.

1

• The max. stapling capacity is 30 sheets. If the max. capacity is

exceeded, a malfunction may occur.

Copy (paper)

Staple position label D (for the RADF)

Stapling position

Set paper in the top bin, check the stapling position, and insert the

paper until it makes contact with the bin edge.

When the display lamp of the staple key is lighted, press the staple

key.

Remove the paper in the top bin, and check that stapling is made

properly.

If stapling is not made, repeat the above procedures.

With the above procedures, installation of the staple sorter is com-

pleted.

2 – 4

Page 7

AR-SS2

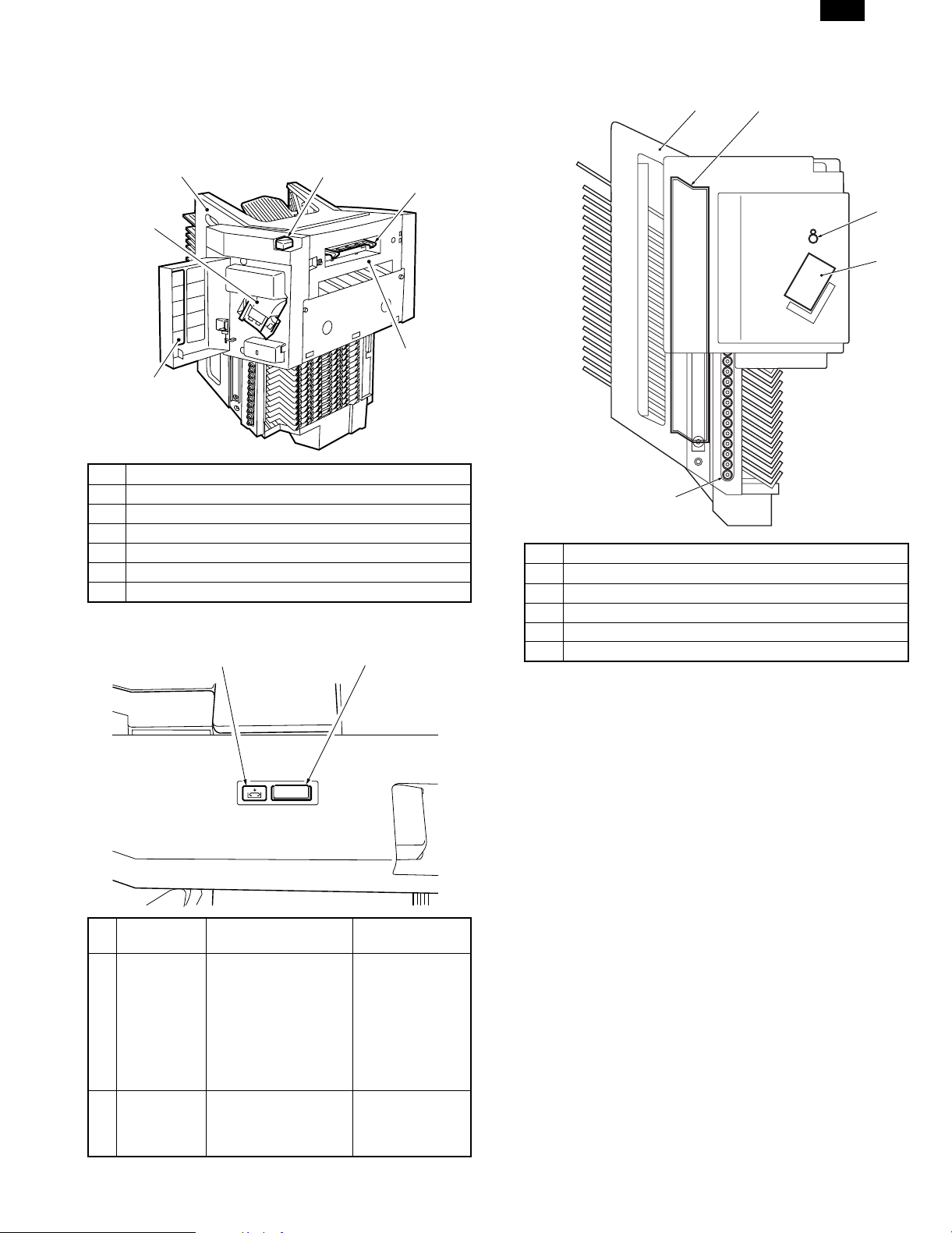

[3] EXTERNAL VIEW AND

INTERNAL STRUCTURE

1. Extern al par t s

1

3

2

No. Name

1 Bin unit

2 Stapler unit cover

3 Stapler unit

4 Transport guide unit

5 Latch lever

6 Latch

2. Operation panel

2

5

3. Cross section

1

6

4

3

No. Name

1 Bin unit

2 Guide bar

3 Roller

4 Stapler unit

1

5 Transport roller

2

5

4

No.

Key name Function Remarkl

1 Staple key • Press to start manual

stapling or manual

paper feed stapling.

• When pressed during

stapling, the

operation is stopped.

• Blinks when a staple

jam occurs.

2 Staple supply

display

Lights up when staplers

are exhausted.

During manual

paper feed

stapling,

interruption cannot

be made.

When the number

of remaining

staplers is 40 pcs

or less.

3 – 1

Page 8

AR-SS2

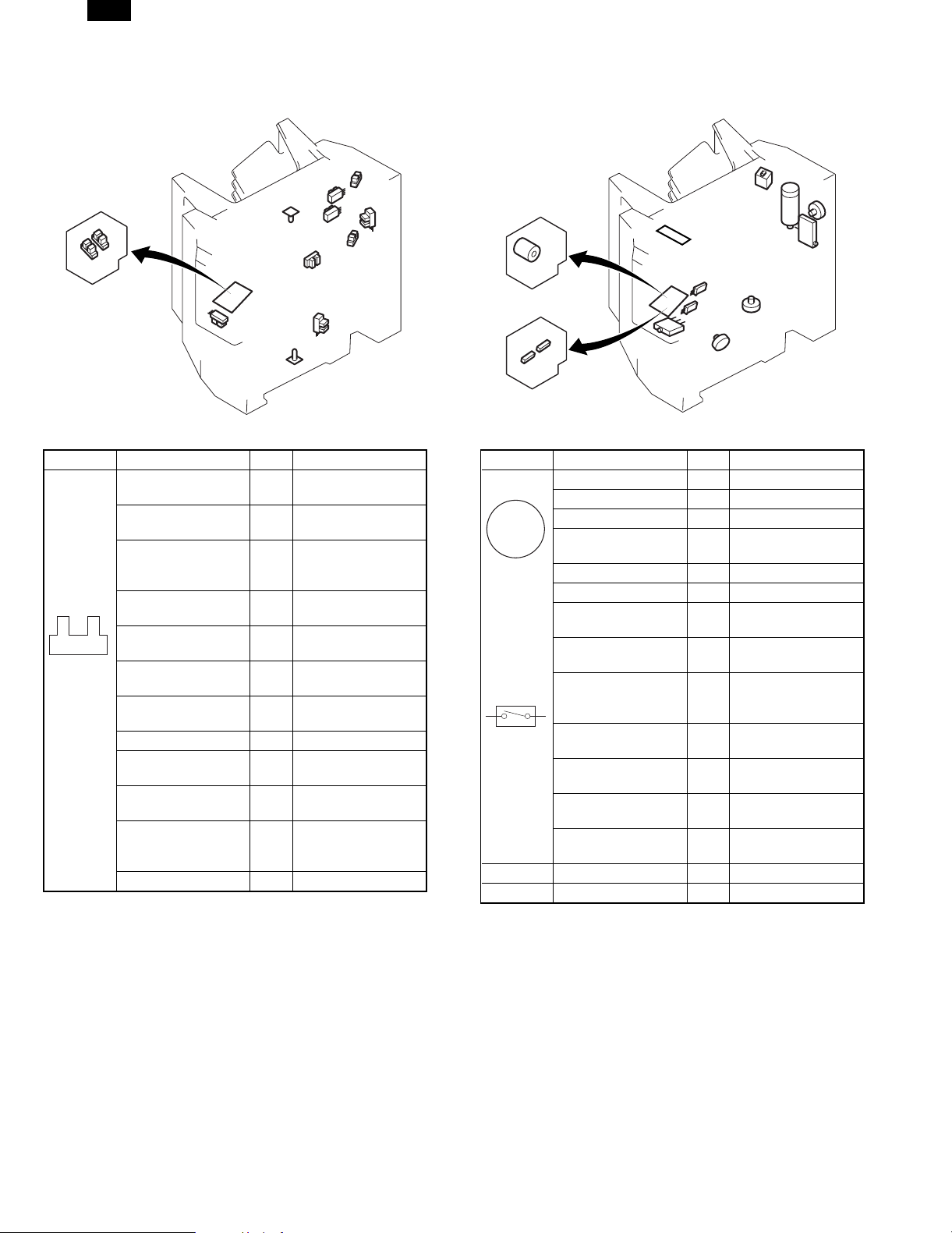

4. Sensors

PI5

PI4

PI9

PI8

PI7

Symbol Name Code Function

Sens or in bin (Light

emitting)

Sensor in bin (Light

receiving)

Bin unit shift motor

clock sensor PI1

Lead cam home

position sensor

Guide bar home

position sensor

Bin unit upper limit

sensor

Bin unit lower limit

sensor

Joint sensor PI6 Detects the joint.

Stapler unit cover

sensor

Staple home position

sensor

Staple ready sensor

Paper exit sensor PS1 Detects paper exit.

S1

PS1

PI3

S2

Detects paper in the

S1

bin (Light emitting)

Detects paper in the

S2

bin (Light receiving)

Detects clock signals

from the bin shift

motor.

Detects the lead cam

PI2

in the home position.

Detects the guide bar

PI3

in the home position.

Detects the bin unit at

PI4

the upper limit.

Detects the bin unit at

PI5

the lower limit.

Detects opening of

PI7

the stapler cover.

Detects stapling in

PI8

the home position.

Detects the first

PI9

staple at the

operation position.

PI2

PI1

PI6

5. Motors, switches, solenoids and PCBs

MS8

M1

M2

SW

M5

MS5

MS6

Symbol Name Code Function

Bin unit shift motor M1 Shifts the bin.

Paper feed motor M2 Feeds paper.

Guide bar drive motor M3 Drives the guide bar.

M

Stapler unit oscillation

motor

Stapler motor M5 Drives the stapler.

Joint switch MS1 Detects the joint.

Stapler unit cover

switch

Stapler safety

detection switch

Stapler unit oscillation

home position sensor MS4

No staple detection

switch

Cartridge detection

switch

Obstacle detection

switch

Manual staple switch

MS3

MS4

MS2

MS2

MS3

MS5

MS6

MS8

M3

M4

Drives the stapler unit.

M4

Detects opening of

the stapler cover.

Detects staplers

under the safety state.

Detects the stapler

unit in the oscillation

home position.

Detects stapler empty.

Detects the stapler

cartridge.

Detects an obstacle.

Manual stapling

SW

operation

1 Control panel PWB

2 Sorter controller PWB

MS1

3 – 2

Page 9

AR-SS2

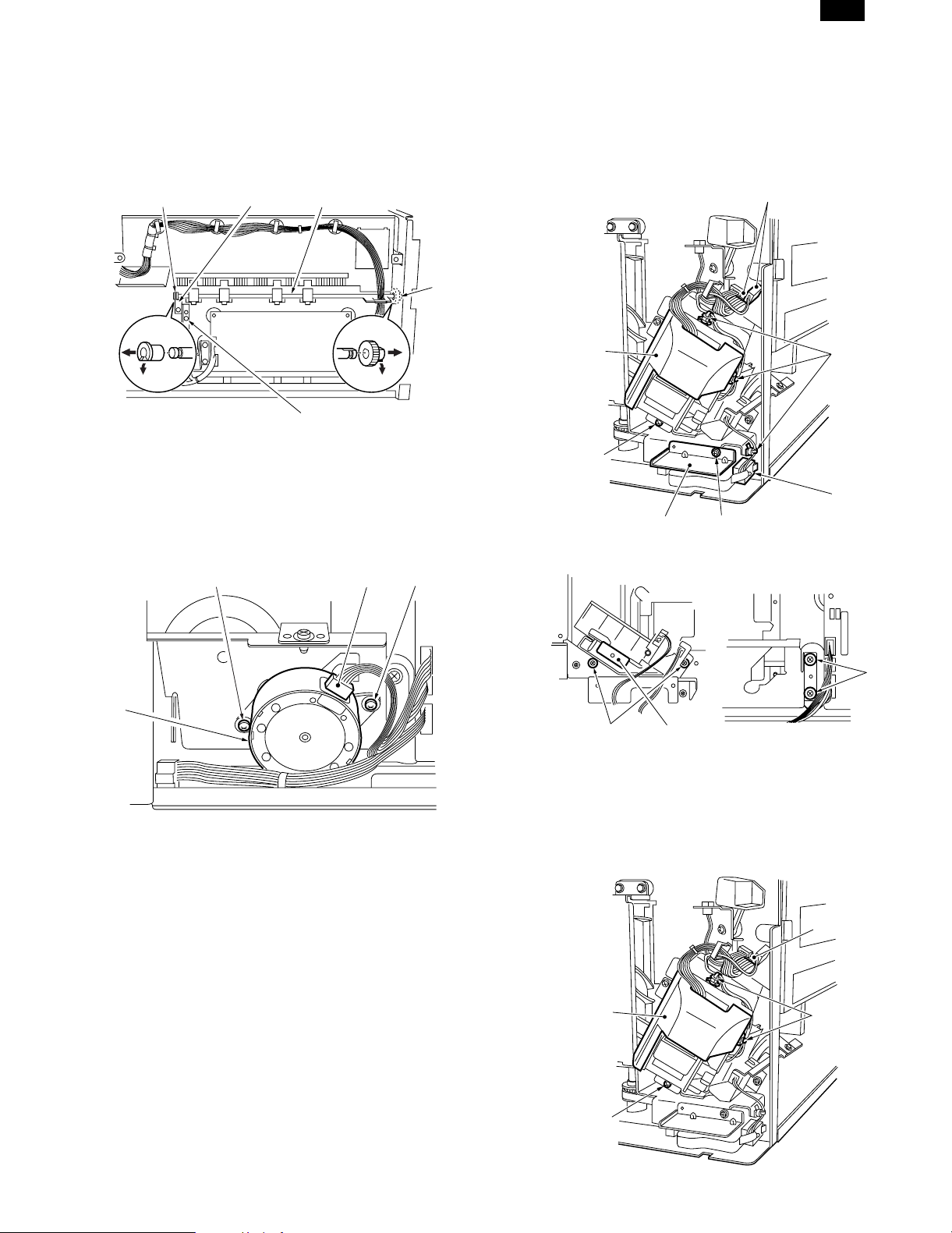

[4] DISASSEMBLY AND ASSEM BLY

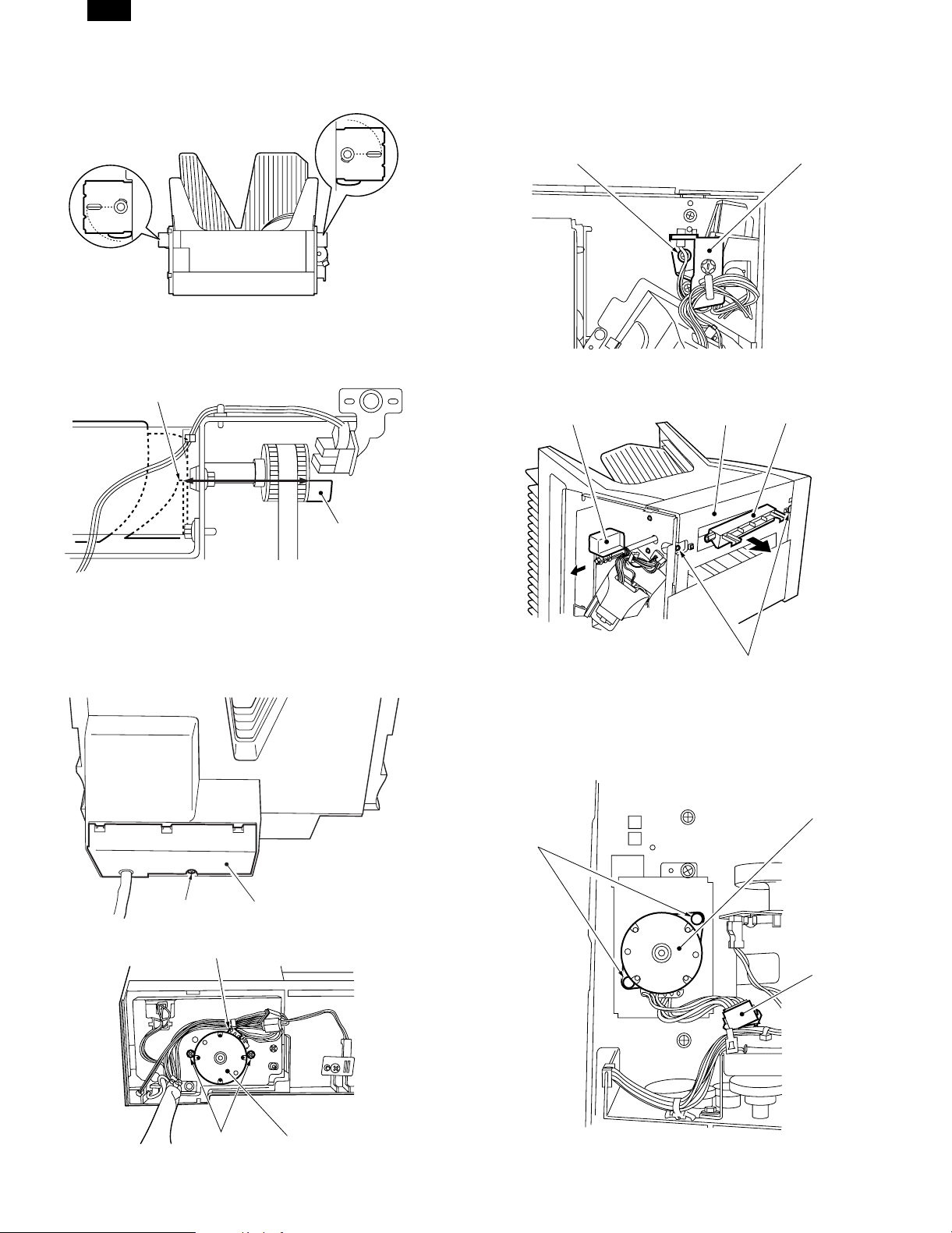

1. External fitting

To clean, check, or repair the machine, remove the cover of the

desired section in the following procedures.

For the covers that can be removed simply by removing the fixing

screws, the procedures are omitted.

1

4

1 Front cover (2)

2 Right cover (2)

3 Rear cover (2)

4 Stapler unit cover

5 Transport guide unit

Note When removing the front cover, be careful not to break the

connector that is at the back of the operation panel.

5

3

2

4) Remove the two screws (4) on the front side and the two on the

rear side.

5) Lift the projection (5) of the accuride rail and remove the bin unit in

the arrow direction.

Note: Bin unit weight: About 10kg

5

4

6) Set down the removed bin unit as shown below.

2. Bin unit

A. Bin unit removal

1) Remove the front cover, the right cover, and the rear cover.

2) Remove the four connectors (1) of the sorter controller PWB.

3) Remove the two screws (3) of the signal code plate (2), and

remove it.

1

2

3

Note: When assembling the bin unit, place the bin unit on the lead

cam from the upper side of the sorter body, rotate the clock

disc of the shift motor to engage the lead cam with the bin.

4 – 1

Page 10

AR-SS2

B. Bin removal

When removing the bin of this machine, remove the bin roller. If,

however, it is removed twice or more, the strength will be decreased

and it must be replaced. For replacement of first bin to 13th bin,

replace from the top. For replacement of the lower bins, replace from

the bottom.

1. Replacement of bins from the top

1) Remove the bin unit from the sorter and lay it on a work table.

2) Remove the two screws (2) and remove the accuride rail (1).

3) Remove the three screws on the front and the four screws on the

rear, and remove the bin front cover (3).

3

4) Remove the four screws (5) and remove the bin upper cover (4).

4

2

1

6) Remove the bin roller stopper (9) and the bin roller (10), and

remove the bin.

2. Replacement of bins from the bottom

1) Remove the screw (2) of the bin lower unit cover (1), and then

remove the bin lower unit cover.

5

5) Remove the spring (7) and the screw (8), and then remove the

guide bar holder (5).

8

6

2

1

2) Remove the tie lap (3) and two connectors (4).

3

4

3) Pull out the sensor wiring (5) in the arrow direction.

7

8

5

4 – 2

Page 11

AR-SS2

4) Remove the two screws (7) of the guide bar holder (6).

67

5) Remove the four screws (9) and remove the bin lower unit (8).

When removing, separate the guide bar holder from the guide bar.

9

8

D. Lead cam

1. Lead cam removal

1) Turn on the power of the copier. Press SW2 on the sorter controller PWB to move the bin unit to the bottom.

Note: If two lead cams on the front and the rear sides are pressed

simultaneously, the bin unit falls suddenly. To prevent against

this, be sure to press them one at a time.

2) Remove the E-ring (1), the sensor flag (2), and the gear (3).

3

1

2

3) Remove the three screws (4), and remove the lead cam unit (5).

4

9

6) Remove the bin roller stopper and the bin roller, and remove the

bin.

Note: When assembling the bins, check the bin roller stopper lock

section. If it is broken, replace it. After assembling the bin unit,

check that all bin roller stoppers are in position.

C. Bin shift motor (M1) removal

1) Remove the rear cover.

2) Remove the screw (2) of the transport motor clock sensor mounting plate, and then remove the transport motor clock sensor

mounting plate (1).

3) Remove the connector (3), and pull out the tie lap(4) from the hole

in the plate.

4) Remove the two screws (5), and remove the bin shift motor.

3

2

1

5

4

2. Lead cam position adjustment

1) Remove the E-ring (2) of the lead cam drive gear (1) on the front

side.

455

4 – 3

1

2

Page 12

AR-SS2

2) Adjust engagement of the lead cam drive gear (1) so that the

upper blade tips of the lead cams on the front and the rear sides

are as shown in the figure below.

3) Attach the E-ring.

Note: When assembling the flag (1) for the lead cam home position

sensor, fit the teeth tips (2) of the lead cam with the phase of

the flag (1) as shown below.

2

3. Transport duide

A. Transport guide unit removal

1) Remove the front cover.

2) Remove the screw (2) and the latch lever holder (1).

2

3) Remove the latch lever (3) and the latch (4).

4) Remove the screw (5), and remove the transport guide unit (6).

3

6

1

4

1

E. Guide bar motor (M3) removal

1) Lift the bin unit to the top for easiness of work.

2) Remove the screw (1) and remove the bin lower unit cover (2).

3) Remove the connector (3) and two screws (4), and then remove

the guide bar motor (5).

1

2

3

5

B. Transport motor (M2) removal

1) Remove the rear cover.

2) Remove the connector (1) and two screws (2), and then remove

the transport motor (3).

3

2

1

4

5

4 – 4

Page 13

AR-SS2

C. Transport roller removal

1) Remove the right cover, the front cover, the transport guide unit,

the rear cover, and the transport motor.

2) Remove the transport roller bushing (1) and the gear (2).

3) Remove the screw (3), and remove the transport roller attachment

fixture (4).

4) Remove the transport roller (5).

1

4

5

2

3

4. Stapler oscillation unit

A. Stapler unit oscillation motor (M4) removal

1) Remove the right cover.

2) Remove the connector (1) and two screws (2), and remove the

stapler unit oscillation motor (3).

2

1

2

B. Stapler oscillation unit removal

1) Remove the right cover, the stapler unit oscillation motor, and the

front cover.

2) Remove the three connectors (1) and three tie laps (2).

3) Remove the screw (3), and remove the stapler unit (4).

4) Remove the screw (5), and remove the stapler cover switch unit

(6).

1

4

3

6

5) Remove the four screws (7), and remove the stapler oscillation

unit (8) toward you.

5

2

1

7

3

7

8

5. Stapler unit

A. Stapler unit removal

1) Remove the front cover.

2) Remove the connector (1) and two tie laps (2).

3) Remove the screw (3), and remove the stapler unit (4).

1

4

3

2

4 – 5

Page 14

AR-SS2

[5] ADJUSTMENTS

1. Electrical syst em

A. Process for major parts replacement

Major parts Process

• Sorter controller PWB 1) Bin paper sensor sensitivity

adjustment

2) Guide bar motor oscillation range

adjustment

3) Stapler oscillation motor oscillation

range adjustment (Staple position

adjustment)

• Bin paper sensor (S1,

2)

• Guide bar home

position sensor (PI3)

• Guide bar oscillation

motor (M3)

• Stapler oscillation

motor (M4)

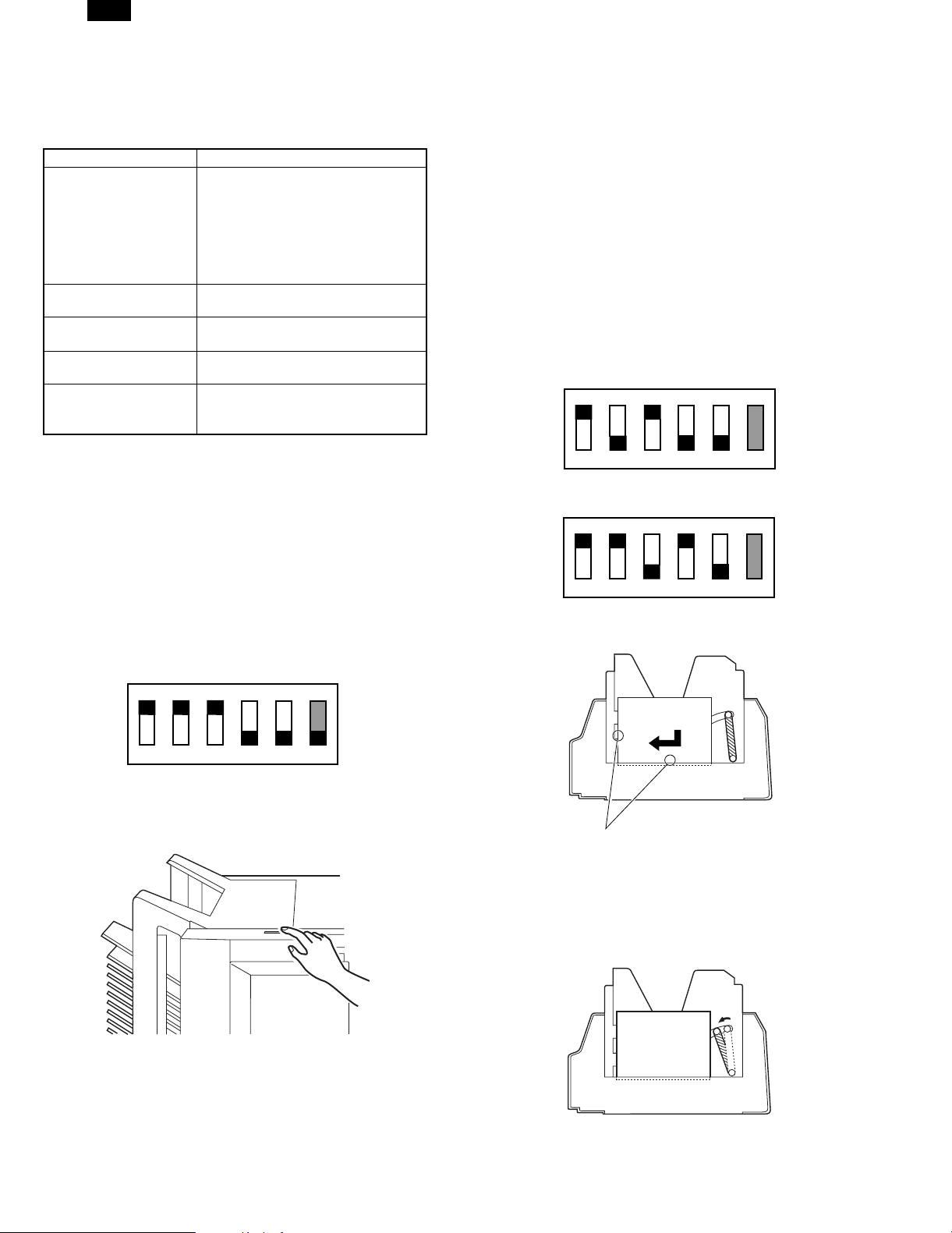

B. Bin paper sensor sensitivity adjustment

This adjustment must be performed when replacing the following

parts:

• Sorter controller PWB

• Bin paper sensor (S1, S2)

Note: To perform this adjustment, the bin unit must be assembled

completely in advance. If the adjustment is performed without

assembling the cover, etc., the sensor will receive external

lights, resulting in an error in adjustment.

<Operating procedure>

1) Remove all the paper in the bins.

2) Remove the right cover, and set the DIP switch on the sorter

controller PWB as shown below.

1) Bin paper sensor sensitivity

adjustment

1) Guide bar motor oscillation range

adjustment

1) Guide bar motor oscillation range

adjustment

1) Stapler oscillation motor oscillation

range adjustment (Staple position

adjustment)

5) When the manual staple key blinks, turn off and on the copier

power switch, check the status of the bin paper sensor (on the

light emitting side and the light receiving side) corresponding to

the error code, and perform the adjustment from procedure 1)

again.

6) After completion of the adjustment, return the DIP switch on the

sorter controller PWB to the original state.

C. Guide bar oscillation range adjustment

This adjustment is performed when the following parts are replaced.

• Sorter controller PWB

• Guide bar home position sensor (PI3)

• Guide bar oscillation motor (M3)

<Operating procedure>

1) Prepare one sheet of A4 or letter paper for copying.

2) Remove all the paper from the bins.

3) Remove the right cover, and set the DIP switch (SW1) on the

sorter controller PWB as shown below. (Note that the setup content differs depending on the copy paper size.)

ON

∗1

123456

(When A4 copy paper is used)

ON

∗1

123456

(When letter copy paper is used)

4) Place A4 or letter copy paper in the bin as shown below.

ON

123456

∗ Do not move No. 6, which is used only for selection of the com-

munication system with the copier.

3) Press the manual staple key on the operation section of the

machine.

4) Check the status of the manual staple key on the operation section of the machine.

ON: Adjustment completed.

Blinking: Adjustment error

In case of an adjustment error, the error code of F1-91 is dis-

played on the copier.

A4/Letter

Make close contact.

5) Operate the bin shift key (SW2, SW3) on the sorter controller

PWB to bring the guide bar into a slight contact with the copy

paper.

UP key (SW3): Moves the guide bar to the paper.

DOWN key (SW2): Moves the guide bar apart from the copy

paper.

Copy paper

6) Under the state of procedure 4), press the manual staple key on

the operation section of the machine. The guide bar returns to the

home position and the adjustment value is stored.

5 – 1

Page 15

AR-SS2

7) Check the status of the manual staple key.

ON: Adjustment completion

Blinking: Adjustment error

8) When the manual staple key blinks, check the installing condition

of the guide bar home position sensor, and perform the adjustment from procedure 4) again.

9) After completion of the adjustment, return the DIP switch (SW1)

on the sorter controller PWB to the original state.

D. Stapler unit oscillation position adjustment

(Staple position adjustment)

This adjustment is performed when the following parts are replaced.

• Sorter controller PWB

• Stapler unit oscillation motor

• Stapler oscillation unit

<Operating procedure>

1) Remove all the paper from the bins. Remove the right cover.

2) Set the DIP switch (SW1) on the sorter controller PWB as shown

below.

SW2 SW3

SW1LED

ON

1

123456

3) Place 5 sheets of A4 or letter paper in the first bin as shown

below.

4) Press the push switch (SW3) on the sorter controller PWB to shift

the stapler oscillation unit to the stapling position.

5) Press the push switch (SW2) on the sorter controller PWB and

press the manual staple key to staple and check the stapling

position.

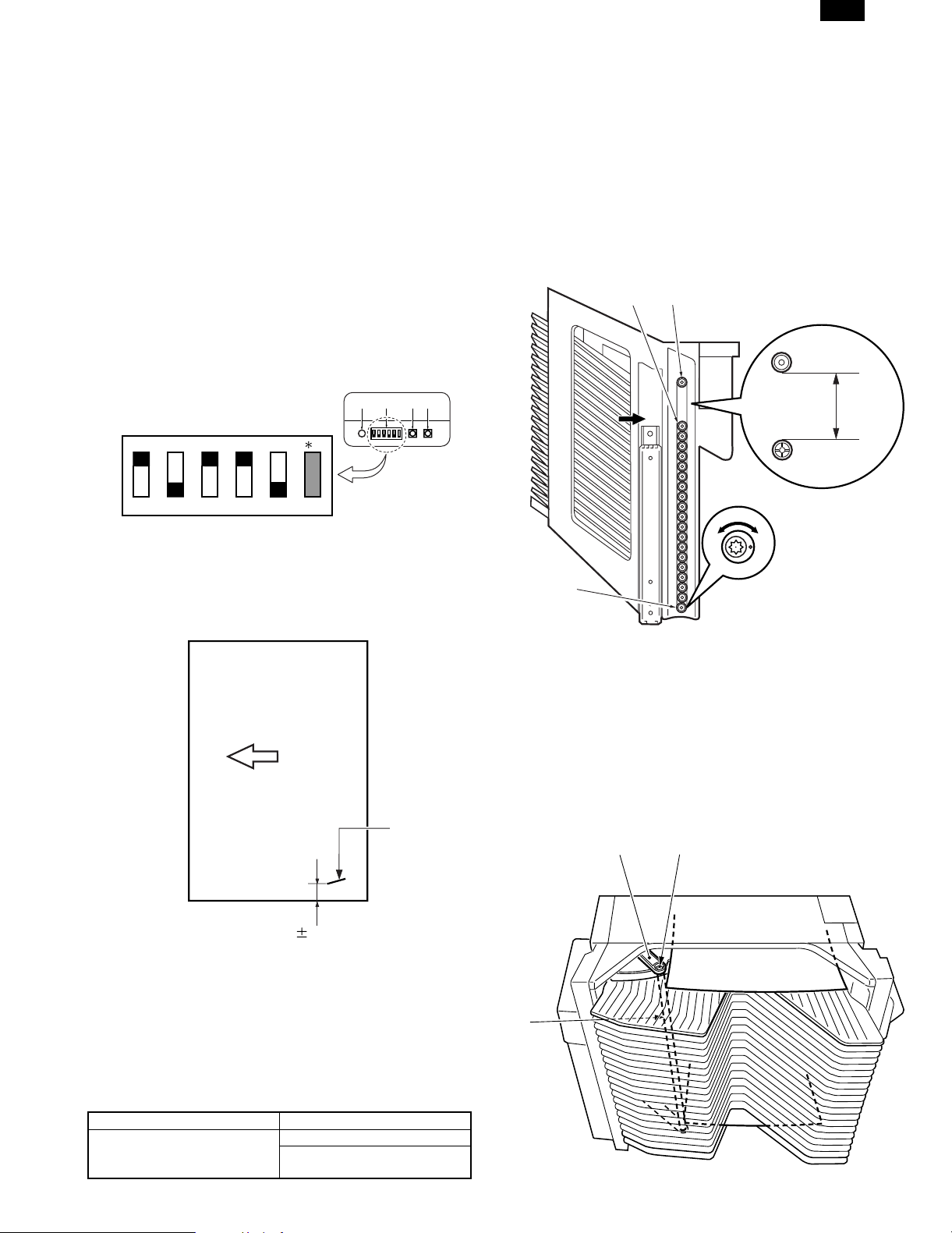

B. Bin roller height adjustment

The dummy roller lower is of eccentric shape so that you can adjust

the height of the bin roller this is so you can adjust the height at which

the bin roller and the lead cam tip t ouch.

When the bin roller is replaced or reassembled, check the standard

dimensions and change and adjust the installing angle of the dummy

roller lower if necessary.

1) Adjustment procedure

Stand up the bin unit straight. Measure the distance between the

upper dummy roller (1) and the bin roller (2). If the distance is too

large, rotate the lower dummy roller (3) counterclockwise. If the

distance is too small, turn it clockwise. Turn and adjust so that the

distance is about 97.8mm.

1

2

97.8mm

3

Transport direction

Staple

6 2.5mm

6) If the stapling position is outside the specified range, adjust the

stapling position with the push switch (SW3).

Press the staple key of the sorter. The stapler oscillation unit

returns to the home position and the adjustment value is stored.

7) Return the DIP switch (SW1) to the original state and install the

right cover.

2. Mechanical system

A. Process for major parts replacement

Major parts Process

Bin, bin roller 1) Bin roller height adjustment

2) Guide bar parallelism

adjustment

3. Guide bar parallelism adjustment

When the bin unit is disassembled or the top screw of the guide bar is

removed, adjust the guide bar parallelism.

1) Adjustment procedure

Set B5 paper or A4R paper in the 1st bin and in the 20th bin.

Push the guide bar (1) manually in the alignment direction to press

it onto the paper.

Check contact conditions of the guide bar and the paper in the 1st

bin and the 20th bin. If they are not parallel, loosen the screw (3)

of the guide bar holder (2).

2

1

3

5 – 2

Page 16

AR-SS2

[6] DIAGNOSTICS

1. PWB

SW2 SW3

SW1LED

2. List of DIP switch functions

The functions of the DIP switch (SW1) on the sorter controller PWB

are as follows:

Purpose DIP switch setup Content

Normal copy state • When all are set to OFF, the machine returns to the normal mode.

ON 1

123456

Transport motor (M2) • When the manual staple key (SW) is pressed, the transport motor (M2)

ON

1

rotates forward (in the paper transport direction). To stop the motor,

press the manual staple key (SW) again.

123456

Sensor adjustment mode (Bin

paper sensor)

Guide for operation range

adjustment mode (When A4

size is used)

ON

123456

ON

• When the manual staple key (SW) is pressed, adjustment of the bin

1

paper sensors (S1, S2) is performed. (For details, refer to page 5-1)

Adjustment complete: Manual staple key (SW) ON

Adjustment error: Manual staple key (SW) blinking

In case of an adjustment error, check which sensor is malfunctioning by

the error code.

Error code F1-91: S1, S2 error

• For details, refer to page 5-1.

1

123456

Guide bar operation range

adjustment mode (When letter

size is used)

ON

• For details, refer to page 5-1.

1

123456

Guide bar operation text • When the manual staple key (SW) is pressed, the guide bar operates.

ON

1

The operation of A4R -> B5 -> Letter R -> A4R is repeated. When the

manual staple key is pressed again, the guide bar returns to the home

position.

123456

Stapler unit oscillation position

adjustment

ON

• For details, refer to page 5-2.

1

123456

∗1: Do not move No. 6 of DIP switch, which is used only for selection of the communication system with the copier.

(ON: Now IPC communication / OFF: Old IPC communication)

6 – 1

Page 17

AR-SS2

3. Self diagnostics

This machine is provided with the self diagnostics function of the

machine state by the CPU (Q1) on the sorter controller PWB. It

performs diagnostics occasionally and displays an error message or

code on the copier when any abnormality is found.

A. Stack over alarm

Abnormality Copier operation Reset

Overload

(When the capacity

per bin is exceeded

during copying)

B. Stapler alarm

Abnoamality Copier operation Reset

Staple jam • Staple sort mode:

Stapler safety

mechanism

operating ( foreign

material is in the

stapler)

Staple capacity

over (The load

quantity per bin

exceeds the max.

stapling capacity

(30 sheets) in the

staple sort mode.)

Mixed paper sizes

(horizontal

direction)

No staple • Staple sort mode:

C. Jam

Abnormality Copier function

Transport delay jam

Refer to page 9-8.

Transport remaining jam

Refer to page 9-8.

Power ON jam

Refer to page 9-8.

Door open jam

Refer to page 9-8.

■ Reset

After processing a jam, turn on the joint switch (MS1)

• Standby state (Start

key OFF)

Alarm display is

made when the copy

start key is pressed.

Copying is disabled.

• Other mode

Normal operations

• Staple sort mode:

Alarm display is

made when the copy

start key is pressed.

Copying is disabled.

• Other mode

Normal operations

• Staple sort mode:

Alarm display is

made when the copy

start key is pressed.

Copying is disabled.

• Other mode

Normal operations

• Staple sort mode:

Alarm display is

made when the copy

start key is pressed.

Copying is disabled.

• Other mode

Normal operations

Alarm display is

made when the copy

start key is pressed.

Copying is disabled.

• Other mode

Normal operations

Operation stop

Operation stop

No operation

Operation stop

Remove all the

paper in the bins.

Remove the

jammed staple and

close the stapler

unit.

Open and close

the stapler unit

cover.

Remove all the

paper from the bins.

Remove all the

paper from the bins.

Set a new staple

cartridge.

D. Error

Sub

code

Content The power source (+24V) is not supplied.

Description

• The +24V power is not supplied to the sorter

80

Detail

control PWB.

• The breaker is shut off.

• The +24V power detection circuit trouble

• The +24V line in the sorter control PWB is

checked.

Content Staple unit oscillation motor (M4) lock

• When the stapler unit moves from the

oscillation home position, the stapler unit

oscillation home position switch is kept ON

after 50 pulses.

• When the stapler unit moves to the oscillation

home position, the stapler unit oscillation home

87

Detail

position switch is kept OFF for 2 sec.

• Stapler unit oscillation motor trouble

• Stapler unit oscillation home position switch

trouble

• Circuit breaker operation

• Stapler unit oscillation mechanism trouble

• Sorter controller PWB trouble

• Check the operations of the stapler shift motor

and the sensor with SIM 3-1/2.

Content Bin shift motor lock (M1)

• The operation is not completed in the time

which is 4 times greater than the specified time

after starting the bin shift motor.

• When driving the bin shift motor, the signal

from the shift motor lock sensor is not detected

for 250msec.

89

Detail

• When shifting to the home position, the

operation is not completed in 20 sec.

• Bin shift motor trouble

• Lead cam home position trouble

• Bin shift mechanism trouble

• Circuit breaker operation

• Sorter control PWB trouble

• Check the operation of the bin shift motor and

the sensor with SIM 3-1/2.

Content Bin paper sensor automatic adjustment trouble

• The sensor output abnormality in the sensor

91

Detail

detection level adjustment

• Bin paper sensor trouble

• Sorter control PWB trouble

• Check the sensor output with SIM 3-2.

Content • Manual staple key abnormality

• When copying is started with the bin in the

home position and while the manual staple key

94

Details

is kept pressed in a mode other than the

non-sort mode, and when pressing of the

manual staple key is detected for 5 sec.

• Manual staple key trouble

• Operation PWB trouble

6 – 2

Page 18

AR-SS2

[7] TROUBLESHOOTING

1. Troubleshooting procedures

A. F1-91/Display ON

Cause/

Trouble position

Cable 1 Check that the cable between the sorter controller

Cable 2 Check that the cable between the bin paper

Installation of bin paper

sensor light emitting side

(S1) and light receiving

side (S2)

Bin paper sensor light

emitting side (S1) and light

receiving side (S2)

Sorter controller PWB NO Replace the sorter controller PWB, and perform the bin paper

B. F1-87/Display ON

Cause/

Trouble position

Circuit breaker 1 Check that the circuit breaker on the sorter

24V power is not supplied 2 Set the tester range to 50VDC. Check that the

Stapler unit oscillation

motor (M4)

Stapler unit oscillation

motor home position

switch (MS4)

Sorter controller PWB Replace the sorter controller PWB, and perform the bin paper

Procedure Check item Result Process

PWB and the bin unit is properly connected.

sensor light emitting side (S1) and the light

receiving side (S2) is properly connected.

3 Check that the bin paper sensor light emitting side

(S1) and the light receiving side (S2) are properly

installed.

4 When the bin paper sensor light emitting side (S1)

and the light receiving side (S2) are replaced and

the bin paper sensor sensitivity adjustment is

performed, the trouble is canceled.

Procedure Check item Result Process

controller PWB is operating.

voltage between J1-1 (+) and J1-2 (–) on the

sorter controller PWB is about 24V.

3 Check that there are pulse outputs at connector

J12-2 to -5 on the sorter controller PWB at the

operating timing of the stapler unit oscillation

motor.

Check that J12-1 is +24V.

4 Set the tester range to 50VDC. Check that the

voltage between the sorter controller PWB J6-3

(+) and the case (–) is about 24V (when the joint

and the coupler are closed). Check that the

voltage between J6-4 (+) and the case (–) is

about 24V when the stapler oscillation unit is in

the home position, and 0V when it is not.

NO Connect properly.

NO Connect properly.

NO Connect properly.

When the bin paper sensor light emitting side (S1) and the light

receiving side (S2) are installed again, perform the bin paper

sensor sensitivity adjustment. (For the procedure, refer to page

5-1)

YES Replace the bin paper sensor light emitting side (S1) and the

light receiving side (S2) and perform the bin paper sensor

sensitivity adjustment. (For the procedure, refer to page 5-1)

sensor sensitivity adjustment, the guide bar motor oscillation

range adjustment, and the stapler motor oscillation motor

oscillation range adjustment. (For the procedures, refer to pages

5-1 to 5-2)

YES Remove the cause of the circuit breaker operation, and press the

circuit breaker.

NO Check 24V of the copier.

YES Check the wiring to the stapler unit oscillation motor. If it is

normal, replace the stapler unit oscillation motor.

YES Stapler unit oscillation motor home position switch (MS4)

sensor sensitivity adjustment, the guide bar motor oscillation

range adjustment, and the stapler oscillation motor oscillation

range adjustment. (For the procedures, refer to pages 5-1 to 5-2.)

C. F1-89/Display ON

Cause/

Trouble position

Cable 1 Check that the cable between the bin shift motor

Circuit breaker 2 Check that the circuit breaker (CB1) on the sorter

24V power is not supplied 3 Set the tester range to 50VDC. Check that the

Bin shift motor (M1) 4 Check that the voltage between the connector

Sorter controller PWB NO Replace the sorter controller PWB, and perform the bin paper

Procedure Check item Result Process

and the sorter controller PWB is properly

connected.

controller PWB is operating.

voltage between the sorter controller PWB J1-1

(+) and J1-2 (–) is about 24V.

J8-1 and J8-2 on the bin shift motor driver PWB is

about 24V at the operating timing of the bin shift

motor (M1).

NO Connect properly.

YES Remove the cause of the circuit breaker operation, and press the

circuit breaker.

NO Check the 24V power of the copier.

NO Check the wiring to the bin shift motor. If it is normal, replace the

bin shift motor.

sensor sensitivity adjustment, the guide bar motor oscillation

range adjustment, and the stapler oscillation motor oscillation

range adjustment. (For the procedures, refer to pages 5-1 to 5-2.)

D. F1-94 display ON

Cause/

Trouble position

The manual staple key is

pressed when starting

copying.

Key 2 Press a key and check that the switch on the

Operation PWB 3 Check the cable connection between the sorter

Procedure Check item Result Process

1 Check that there is anything on the key or not. NO Start copying in a mode other than the non-sort mode with the

bin in the home position to check that the operation is performed

normally or not.

NO Properly connect the cable.

operation PWB is pressed or not.

YES Replace the operation PWB.

control PWB and the operation PWB.

7 – 1

Page 19

[8] MAINTENANCE

1. Periodic replacement parts

There is no part which must be replaced periodically.

2. Consumable parts life

The following part may deteriorate or require replacement during the warranty period. Replace it if it is deteriorated or broken.

AR-SS2

No. Part name Part number

1 Stapler 0GZ4A12553000 1 Stapling 300,000 times One staple cartridge allows about

No. of part

used

Reference of life Remark

5,000 stampling.

3. Periodic services list

This machine has no part which requires periodic servicing.

8 – 1

Page 20

AR-SS2

[9] OPERATIONAL DESCRIPTIONS

1. Outline

This machine performs sorting and stapling of copy paper according

to the operation mode set by the copier.

Stapling is made also by the operation of the keys on this machine.

There are following four operation modes;

1. Non-sort mode

2. Sot mode

3. Group mode

4. Staple sort mode

2. Details

The basic operations in each mode are described below.

A. Non-sort mode

If the sort/group mode is not set, all copy paper is discharged to the

1st bin.

1) Press the copy start key of the copier.

↓

2) Copy paper is discharged to the 1st bin.

↓

↓

↓

↓

↓

↓

Non-sort mode (10 black/white sheets)

Copier resist

Paper exit sensor

Transport motor

Bin shift motor

Lead cam sensor

Bin lower limit sensor

Guide bar oscillation motor

Guide bar HP motor

Parrallel section HIGH

Pin HP LOW

↓

↓

↓

3) Copying of the set quantity is completed.

↓

4) Discharging of th e set qua ntity is comp leted and the o perat ion

is completed.

Forward rotation

Transport (Transport)

Alignment (Alignment)

Shift (Up)

Staple oscillation (Shifted to the stapling position.)

Staple (Staple)

Reverse rotation

Transport (Not)

Alignment (Save)

Shift (Down)

Staple oscillation (Shifted to HP.)

Staple (Staple jam reset)

• Sort mode (B/W, color): Discharged from the 2nd bin.

The other modes: Discharged from the 1st bin.

9 – 1

Page 21

AR-SS2

B. Sort mode

When the sort mode is set, alignment of copy pages is automatically

performed.

B/W mode Color mode

4) Copying of the specified quantity is completed.

↓

Black/white mode Color mode

1) Press the copy start key of the copier .

↓↓

↓

2) The guide bar is oscillated from the paper exit center to the half

of the paper size +8mm.

↓

Copy paper exit direction

↓

↓

↓

↓

↓

↓

↓

Guide bar

↓

↓

↓

↓

5) The orig in al is ch anged and reverse sort in g is performed.

↓

3) Every time paper is discharged, the guide bar oscillates to

press the paper to the regulation plate to align paper and the

bin is shifted by one.

↓

↓↓

Discharged copy paper

↓

↓

↓

↓

↓

↓

↓

↓

↓

↓

When the number of copy sets is 1 to 19, copies are discharged

from the 2nd bin.

When the number of copy sets is 20, copies are discharged from

the1st bin.

Sort mode (black/white, 2 originals, 3 copies)

Copier resist

Paper exit sensor

Transport motor

Bin shift motor

Lead cam sensor

Bin lower limit sensor

Guide bar oscillation motor

Guide bar HP motor

Sort mode (color, 2 originals, 3 copies)

Copier resist

Paper exit sensor

Transport motor

Bin shift motor

Lead cam sensor

Bin lower limit sensor

Guide bar oscillation motor

Guide bar HP motor

↓

↓

↓

6) The operation is repeated until all the originals are completed.

7) After comple tion o f copying , the gu ide bar returns to the h ome

position.

8) When copying is stopped, the bin which is not closed isshifted.

↓

↓

↓

↓

9 – 2

Page 22

AR-SS2

C. Group mode

When the group mode is set, the copies of an original set are discharged to one bin.

1) Press the copy start key of the copier.

↓

2) The guid e bar is oscillated f rom t h e pa per exit center to t he hal f

of paper size +6mm.

↓

↓

Paper exit center

↓

↓

↓

↓

3) Every time paper is discharged, the guide bar oscillates to

press the paper to the regulation plate to align paper and the

bin is shifted by one.

↓

Copy paper exit direction

Bin

Guide bar

6mm

Paper size

Discharged copy paper

5) The or iginal is changed and th e bin is shift ed by one.

↓

↓

↓

↓

↓

↓

6) The operation i s repeated until all the originals are completed.

↓

7) After completion of copying, the guide bar returns to the home

position.

Copies are loaded from the 1st bin to the 20th bin sequentially.

When the original exceeds 20 pages, loading is returned to the1st

bin without reverse sorting.

↓

↓

↓

↓

4) Copying of the specified quan tity is completed.

↓

Group mode (black/white, 3 originals, 2 copies)

Copier resist

Paper exit sensor

Transport motor

Bin shift motor

Lead cam sensor

Bin lower limit sensor

Guide bar oscillation motor

Guide bar HP motor

9 – 3

Page 23

AR-SS2

D. Staple sort mode

When the staple mode is set, stapling is automatically performed after

sorting the copies.

1) The sa me operatio ns as the sort mod e are performed an d all

copied papers are discharged to the bins.

↓

↓

↓

↓

↓

↓

2) The guide bar oscillates.

↓

↓

↓

Discharged paper

4) The stapler unit staples the paper.

↓

5) The guide bar, the paper holding arm, and the stapler unit are

separated from the paper.

↓

6) The bin is shifted by one.

↓

↓

↓

↓

↓

7) Proc edures 3 to 6 are repeated for al l paper in the bins, and the

operation is completed.

Note: The staple sort mode is valid only when the RADF is used. In

the book mode, the staple sort mode can be set, but automatic

stanpling cannot be performed.

Paper holding arm

↓

3) The guide bar aligns the paper.

The stapler unit is shifted to the stapling position.

At the same time, the paper holding arm holds discharged

paper.

↓

Discharged paper

↓

↓

↓

↓

Stapler unit

Paper holding arm

Paper

Bin

Bin supporting arm

9 – 4

Page 24

AR-SS2

Staple sort mode (Black/white, 2 originals, 3 copies)

Copier resist

Paper exit sensor

Transport motor

Bin shift motor

Lead cam sensor

Bin lower limit sensor

Guide bar oscillation motor

Guide bar HP motor

Staple motor

Stapler oscillation motor

Stapling HP sensor

Stapler oscillation HP sensor

Staple sort mode (Color, 2 originals, 3 copies)

Copier resist

Paper exit sensor

Transport motor

Bin shift motor

Lead cam sensor

Bin lower limit sensor

Guide bar oscillation motor

Guide bar HP motor

Staple motor

Stapler oscillation motor

Stapling HP sensor

Stapler oscillation HP sensor

9 – 5

Page 25

AR-SS2

3. Operations of each section

A. Transport drive system

(1) Outline

The transport system transports paper discharged from the copier to

the bin by the transport roller. The transport roller is driven by the

transport motor (M2).

The paper transport status is detected by the paper exit sensor (PS1)

on the sorter controller PWB.

The transport motor is a stepping motor of 4-phase control. The

transport speed is controlled with the number of pulses of pulse signals A, A*, B, and B* of the motor driver IC (Q23).

Transport motor

Transport

motor drive

signal

M2

Paper

detection

PS1

Paper exit sensor

signal

(2) Transport speed control

1) Outline

The transport speed is controlled by the transport motor (M2) and the

torque limiter. The transport motor changes the transport speed

depending on the paper size, and it keeps a fixed speed during

transporting without control of the transport speed.

The transport speed of this machine is higher than the process speed

of the copier. When copy paper is at the fusing section of the copier

and the transport roller of this machine at the same time, the transport

roller speed is reduced by the torque limiter.

2) Process speed

The process speed is the speed from when the copy paper is

received from the copier to when it is taken into the sorter completely.

It is the same as the process speed of the copier.

Transport roller

Sorter controller PWB

3) Taking in, paper exit speed

This is the transport speed after discharging of the copy from the

fusing section of the copier. It varies depending on the paper size.

Paper size Transport speed

A4, 8.5"x11" 625mm/sec

A4-R, 8.5"x11"R 675mm/sec

B4, 8.5"x14" 700mm/sec

Fixed paper other than the above 575mm/sec

Unfixed paper 700mm/sec

(3) Stack over

1) Outline

The capacity of bins in each mode is limited as shown below. If the

capacity is exceeded, the stack over error occurs.

Non-sort mode Max. capacity

A3, B4, 11"x17", 8.5"x13", 8.5"x14" , 12"x18 " 1st bin: 60 sheets

A4, B5, A5, A4-R, B5-R, 8.5"x11",

8.5"x1 1" R , 5.5"x8.5", 7.2 5" x 10 . 25 " R

100 sheets

Staple sort mode Max. capacity

A3, B4, 11"x17", 8.5"x13", 8.5"x14" 25 sheets

A4, B5, A4-R, 8.5"x11", 8.5"x11"R 30 sheets

Sort mode Max. capacity

A3, B4, 11"x17", 8.5"x13", 8.5"x14" 25 sheets

A4, B5, A5, A4-R, B5-R, 8.5"x11",

8.5"x1 1" R , 5.5"x8.5"

50 sheets

Group mode Max. capacity

A3, B4, 11"x17", 8.5"x14", 8.5"x13" 25 sheets

A4, B5, A5, 8.5"x11", 5.5"x8.5", A4R, B5R,

8.5"x11"R

30 sheets

(4) Paper jam

When the sorter detects a jam, it sends the jam signal (SJAM) to the

copier. Then the copier stops copying and displays "Paper feed

check" on the display section.

After completion of removing the jam, press the copy start key again,

and the jam-corrected number of copies are automatically made and

discharged to the bins.

When, on the other hand, a jam occurs in the copier, all the copy

papers under transportation in the sorter are discharged to the

specified bins and the operation is stopped.

Note: When a paper jam is detected in the sorter, separate the sorter

from the copier (the joint sensor is turned OFF), and remove

the jammed paper. Then reset the sorter to the copier, and the

trouble will be canceled.

1) Transport delay jam

The paper exit sensor does not detect the paper in 300msec of

transport time (which varies depending on the copier) after reception

of the paper exit signal from the copier.

Torque limiter

9 – 6

Page 26

AR-SS2

Copier paper exit signal

Transport motor (M2)

a

Paper exit sensor (PI1)

Normal Abnormal

Jam signal (SJAM)

300msec transport time (Varies depending on the model)

2) Transport remaining jam

The paper does not pass over the paper exit sensor within the

transport time of 2 sheets of copy paper after the paper exit sensor

(PS1) detects the paper.

Transport motor (M2)

Paper exit sensor (PI1)

Jam signal (SJAM)

a: Copy paper length x 2 (mm) + copier’s paper exit speed (mm/sec)

a Normal Abnormala

3) Power ON jam (Jam paper remaining detection)

When the power switch of the copier is turned on, if the paper exit

sensor is ON, the SJAM signal is generated.

4) Door open jam

When the sorter is separated from the copier during operation, the

SJAM signal is generated.

■ After removing the above jam error, press the copy start key, and

the remaining quantity of copies are automatically made by the

jam correction function. ON the other hand, when a jam occurs in

the copier, all the copy papers transporting in the sorter are discharged to the specified bin and the sorter is stopped.

B. Bin unit drive system

(1) Outline

The bin unit drive system is composed of the following drive systems.

• Bin drive system

• Guide bar drive system

The bin is driven by the bin shift motor (M1), and moved up and

down.

The guide bar is driven by the guide bar motor (M3) to align the

discharged copy paper.

(2) Bin unit

1) Bin unit composition

The bin unit is composed as shown below.

The both sides of each bin are provided with the roller from the

outside of the bin frame. The dummy rollers on the upper and the

lower sides are integrated with the bin unit and fixed to the both ends

of the bin frame.

The lower dummy roller is of eccentric shape to adjust the bin roller

height.

Guide bar

M3

PI1

S1

S2

PI3

Shift motor clock signal

LED lighting signal

Lower limit detection signal

PI5

Upper limit detection signal

PI4

Bin shift motor drive signal

M1

Lead cam position detection signal

PI2

Guide bar oscillation motor drive signal

Bin paper detection signal

Guide bar home position detection signal

Sorter controller PWB

9 – 7

2) Lead cam function

The lead cam is attached to be engaged with the bin unit roller. It is

driven by the bin shift motor (M1) which can rotate forward and

reverse.

Lead cam

Bin shift motor

Drive belt

Lead cam drive

toward you

Page 27

AR-SS2

When the lead cam rotates and the roller moves up and down along

the lead cam, the bin connected with the bin frame and the roller is

moved up and down.

Roller

Bin

Lead cam

Roller

If, however, all the grooves in the lead cam were slanted, the lead

cam would be rotated by the weight of the bin unit when the bin unit is

stationary. To prevent against this, the groove has the horizontal

section as shown below. The lead cam home position sensor detects

the position so that the roller comes at the horizontal section when

the bin unit is stationary.

3) Bin shift motor control

The bin shift motor control circuit is shown below.

The bin shift motor (M1) is a DC motor, and controlled by the drive

circuit to move the bin unit up and down.

The up/down moving speed of the bin unit is detected and controlled

by the shift motor clock sensor.

The stop position of the bin unit is detected by the lead cam home

position sensor.

When the stapler unit is not in the home position, the +24V power is

interrupted by the stapler home position switch to stop the bin shift

motor in order to prevent against a crash of the bin unit and the

stapler unit.

An overrun is prevented by the bin unit upper limit sensor and the

lower limit sensor.

The current detection circuit is provided to detect an overcurrent when

the bin unit is interrupted by a foreign material. It stops the bin unit at

that time.

Horizontal section

Lead cam home

position sensor (PI2)

9 – 8

Page 28

AR-SS2

Sorter controller PWB

Q1

CPU

Stapler home

position switch

NO

+24V

BMUP

BMDWN

PWM

MS4

Current

detection

circuit

Bin unit upper

limit sensor

PI4 PI5

Drive circuit

Bin unit lower

limit sensor

Bin shift motor

LCHP

M1

PI2

Lead cam home

position sensor

PI1

Shift motor

clock sensor

Obstacle

detection

switch MS8

MS8

4) Bin shift motor rotation control

The bin shift motor that drives the lead cam is controlled depending

on the copy speed data sent from the copier.

The microcomputer on the sorter controller PWB controls the bin shift

motor as follows:

• Paper exit: The bin roller is moved to the parallel section of the

lead cam and stopped there.

• Transport: The bin is shifted by one.

The microcomputer on the sorter controller PWB controls the rpm of

the bin shift motor so that the bin is shifted by one during the

transport interval of copy paper.

Bin shift motor (M1)

Lead cam home

position sensor (PI2)

Roller position

on the lead cam

Bin

Horizontal

section

Stop

Up/Down

Slant

section

Horizontal

section

Stop

Slant

section

Up/Down

Horizontal

section

Stop

(3) Guide bar control

1) Outline

The guide bar is in the bin unit. It oscillates as shown below.

The guide bar has the following functions:

The guide bar is driven by the guide bar oscillation motor (M3).

The guide bar home position sensor (PI3) detects that the guide bar

is in the home position.

Guide bar

Guide bar home

position sensor

(PI3)

Guide bar home position signal

Guide bar

oscillation motor

(M3)

Guide bar oscillation

motor drive signal

9 – 9

Sorter controller PWB

Page 29

AR-SS2

2) Alignment operation

The alignment operation of the guide bar is performed every time

when copy paper is discharged. When stapling is made, it holds copy

paper.

Guide bar

Paper size

3) Guide bar oscillation motor (M3) control

The control circuit of the guide bar oscillation motor (M3) is shown

below.

The guide bar oscillation motor is a stepping motor of 4-phase control.

The sorter controller PWB sends drive pulses (GBMA, GBMA∗,

GBMB, GBMB∗) to the motor driver.

The motor driver controls the output timing of the pulse signals (A,

A∗, B, B∗) according to each signal to turn ON/OFF the guide bar

oscillation motor and switch the rotating direction.

When the guide bar oscillation motor (M3) is held, the output timing of

the pulse signals (A, A∗, B, B∗) is fixed.

The fuse (ICP2) breaks the power supply circuit when an overcurrent

flows through the circuit to stop the guide bar oscillation motor (M3).

Sorter controller PWB

+24V

Guide bar

drive motor

M3

PI3

Guide bar home

position sensor

Q1

CPU

GBMA

GBMA*

GBMB

GBMB*

Q34

Motor

driver

A

A

B

B

ICP2

∗

∗

GBHP

(4) Bin paper sensor

1) Outline

The bin paper sensor is composed of the LED and the photo transistor. It detects paper in the bin.

This machine executes the paper detection level correction automatically and periodically to prevent against malfunctions due to light

quantity change in each sensor.

Note: When the sensor light receiving section (S2) is exposed to

external lights during correction of the paper detection level,

an erroneous correction value is stored. In such a case,

"E525" is displayed on the operation panel of the copier during

the normal operation.

LED(S1)

Bin unit

Photo transistor (S2)

Sorter controller PWB

Bin paper sensor

Light

emitting

section

Light

receiving

section

+5V

Q16

(5) Other sensors

1) Bin unit lower limit sensor (Home position sensor)

The bin unit returns to the home position when the copy start key is

pressed ON or when all the paper in the bins are removed.

In that case, the actuator section integrated with the bin unit passes

over the bin unit lower limit sensor (PI4) to turn on the sensor, sending signals to the CPU of the sorter controller PWB.

When the bin unit is falling further from the home position, the lead

cam home position sensor turns OFF to detect the lower limit. The

sorter controller PWB immediately stops the bin shift motor (M1) drive

and displays the error code on the operation panel of the copier at the

same time.

2) Bin unit upper limit sensor

The bin unit upper limit detection is performed by the actuator section

integrated with the bin unit and the bin unit upper limit sensor (PI5).

When any abnormality occurs and the bin unit moves up further from

the 20th bin, the actuator section passes over the upper limit sensor

to turn on the sensor, sending signals to the CPU of the sorter controller PWB. It immediately stops the bin shift motor (M1) drive and

displays the error code on the operation panel of the copier at the

same time.

■ Reset

Turn off the copier power and turn on again.

Lower limit

sensor (PI4)

Upper limit

sensor (PI5)

9 – 10

Actuator section

Page 30

AR-SS2

C. Stapler unit drive system

(1) Outline

The stapler unit staples paper discharged into the bins.

The stapling is driven by the stapler motor (M5).

The stapler unit oscillation is performed by the stapler unit oscillation

motor (M4).

The stapler unit home position is detected by the stapler unit oscillation home position switch (MS4) and the stepping motor is driven by

the specified number of pulses to move the stapler unit to the oscillation position.

During oscillation, the stapler presses the paper holding lever to hold

paper during stapling.

PI9

PI8

MS5

MS6

Stapler motor

M5

Staple empty detection signal

Cartridge empty detection signal

Stapler operation home

position detection signal

Staple cue detection signal

Stapler motor

drive signal

Sorter controller circuit PWB

MS3

Stapler unit oscillation home

position detection signal

MS4

Stapler safety detection signal

Stapler unit oscillation motor

drive signal

M4

9 – 11

Page 31

AR-SS2

(2) Stapler unit

1) Outline

The staple unit composition is shown in the figure below.

Stapling is driven by the stapler motor (M5). Stapling is made by the

rotation of the cam. The staple home position sensor (PI8) detects

one cycle of stapling.

The cartridge empty detection switch (MS6) detects the staple

cartridge empty. The staple empty detection switch (MS5) detects

staple empty in the cartridge.

Staple cue

sensor

PI9

Stapling home

position sensor

PI8

MS5

Stapler motor

Cartridge empty

detection switch

MS6

Staple empty

detection switch

2) Stapler motor (M5) control

a. Outline

The block diagram below shows the stapler motor control circuit.

The stapler motor is a DC motor. This circuit has the following

functions.

• ON/OFF control of the stapler motor

• Rotating direction control of the stapler motor

• Overcurrent protection of the stapler motor

Stapler safety switch

Stapler motor

M5

NO

+24

R156

Q47

Q4

MS3

Sorter controller PWB

R15

Q48

Q50

R164

R158

Q52

Q51

The stapler safety switch is provided in the power supply path to

the stapler motor (M5).

When a material of about 5.5mm or greater enters the staple

section, the stapler safety switch (MS3) cuts off the power source

for driving the stapler motor (M5).

+5V

Q56

Q43

Q43

12

11

R16

Q54

R159

R160

+5V

R161

+5V

R162

SPMCW

SPMCCW

Current

detection

circuit

R16

9 – 12

Q56

D32

D33

+5V

Q55

R173

Page 32

AR-SS2

b. Stapler motor ON/OFF control

ON/OFF and the rotation direction of the stapler motor are controlled by the combination of the following two signals.

1. Stapler motor forward rotation signal (SPMCW∗)

2. Stapler motor reverse rotation signal (SPMCCW∗)

Stapler motor rotating direction SPMCW∗ SPMCCW∗

Forward 1 0

Reverse 0 1

Stop 1 0

c. Stapler motor overcurrent protection

When the stapler motor starts rotation, the current detection circuit

detects the current flowing through the stapler motor.

When an overcurrent is detected, the current detection circuit

turns on Q54 and Q55 to control the stapler motor drive.

3) Stapler motor staple jam control

When a staple jam occurs in the stapler unit, the stapler motor (M5) is

controlled as follows.

1) An overload is applied to the stapler motor by a staple jam.

↓

2) The stapler does not return to the home position within about

0.6sec after starting stapling.

↓

3) The stapler mo tor is rotated in reverse to re turn to the home

position of stapling.

↓

4) An alarm is made to the copier.

4) Safety switch (MS3)

When your finger enters the stapling position, the actuator is lowered

to turn off the safety switch. When the safety switch is turned off, the

stapler motor (M5) power is cut off and the signal is sent to the CPU

to turn off the drive signal of the stapler motor (M5) to stop stapling.

5) Staple em pt y detection

The staple empty detection in the staple cartridge is made by the

staple empty detection switch (MS5) provided in the stapler.

The staples in the staple cartridge are pushed up by the spring and

the plate. the staples are also pushed toward the tip of the stapler.

When there are staples in the cartridge, the staple empty detection

switch (MS5) is pushed by the staples and the sorter controller

detects presence of the staples.

When the staples are exhausted (when the remaining quantity of the

staples becomes about 40 pcs.), the staple detection switch (MS5) is

opened (MS5: normal open), and the sorter controller detects staple

empty. At the same time, the sorter controller displays the staple

supply display.

When staple empty is detected, stapling is stopped. When, however,

staple empty is detected during continuous stapling, stapling is

stopped after completion of the job.

Staple feed roller

Staple empty

detection switch

Cartridge empty

detection switch

MS6

MS5

Staple

Plate

Spring

Staple cartridge

Actuator

Safety switch (MS3)

MS6

MS5

(3) Stapler unit oscillation control

1) Outline

When the bin is shifted, the stapler unit oscillates as shown below so

that the stapler unit does not make contact with the paper in the bin.

Oscillation is performed by the stapler unit oscillation motor (M4).

When the stapler unit reaches the stapling position, the drive power is

supplied to the stapler motor.

To detect the home position, the stapler home position switch (MS4)

is provided.

9 – 13

Page 33

AR-SS2

Save positionStapling position

Copy paper

Oscillation home

position sensor (MS4)

Stapler oscillation motor (M4)

2) Stapler unit oscillation position detection

The stapler unit home position is detected by the stapler unit home

position switch (MS4).

The stapler unit home position switch (MS4) detects that the stapler

unit is in the home position.

The stapling position is determined by the pulse number to drive the

stapler unit oscillation motor (M4).

Oscillation home position detection switch

Stapling position

Stapler cover switch

Sorter controller PWB

SPSWHA

SPSWHA

SPSWHB

SPSWHB

Q1

CPU

b. Operation

The microcomputer on the sorter controller PWB receives a command of the staple mode from the copier. The microcomputer (Q1)

sends the drive pulses (SPSWHA, SPSWHA∗, SPSWHB,

SPSWHB∗) to the driver circuit.

The motor driver circuit drives the stapler unit oscillation motor

(M4) according to the signal.

When the stapler unit oscillation motor is held, the output timing of

the pulse signals (A, A∗, B, B∗) is fixed.

∗

∗

NO

+24V

Q44

Motor

driver

MS2

Stapler unit

ICP3

oscillation motor

∗

A

B

∗

B

+24V

NO

Stapler unit home

position switch

M4

MS4

(4) Paper holding

1) Outline

Paper holding is performed during stapling. The paper holding arm

presses paper by the stapler roller when the staple unit oscillates. At

the same time, the stapler unit bin supporting arm supports the bin

from the bottom to stable stapling operation.

Home position

Stapler oscillation motor

3) Stapler unit oscillation motor control

a. Outline

The stapler unit oscillation motor (M4) control circuit is shown in

the figure below.

The stapler unit oscillation motor is a stepping motor of 4-phase

control. By controlling the outputs of pulse signals (A, A∗, B, B∗),

the stapler unit oscillation motor (M4) ON/OFF and its rotating

direction are switched.

The power supply circuit of the stapler oscillation motor (M4) is

provided with the stapler cover switch (MS2) and the fuse (ICP3).

The stapler cover switch cuts off the power supply circuit when the

stapler cover is opened. The fuse (ICP3) cuts off the power supply

circuit when an overcurrent flows through the circuit. The stapler

unit oscillation motor (M4) is stopped in that manner.

Paper holding arm

Staple roller

Paper holding arm

Paper

Bin

9 – 14

Bin supporting arm

Page 34

AR-SS2

(5) Stapling timing (3 originals, 3 copies)

<Stapler oscillation unit>

Stapler oscillation

motor (M4)

Stapler unit oscillation home

position switch (MS4)

<Stapler unit>

Stapler motor (M5)

Stapling home

position sensor (PI7)

<Bin unit>

Bin shift motor (M1)

Lead cam center

position sensor (PI2)

: Motor reverse rotation

Stapling request signal from the copier (AFSTRQ)

4. Electric circuit operations

A. Composition of functions

The functions of this machine are largely classified into the following

six blocks: the transport drive system, the bin unit drive system, the

stapler unit drive system*, the guide bar drive system, and the control

system.

Operation

section

B. Outline of the electric circuit

The electrical control of this machine is made by the sorter controller.

The major rolls of the IC on the sorter controller are as follows:

Code Role

Q1 Sequence control

Q3 Contains the sequence program.

Q2 Sensor adjustment values, and operation modes.

Q4 Control of communication with the copier

Sorter controller PWB

Sensor

Q1 CPU

Switch

Operation

Section

Q3

RAM

Q2

ROM

Q4

communication

IC

Motor

Bin unit

drive system

Guide bar

drive

system

Transport

drive system

Stapler

unit drive

system

Control

system

Copier

9 – 15

Page 35

C. Tray controller input/output

Sorter controller input (1/2)

AR-SS2

Sorter controller PWB

Stapler motor

M5

Guide bar oscillation motor

M3

Bin shift motor

M1

J201

1

2

3

4

J110

1

2

11

10

9

8

6

5

3

4

2

1

1

2

3

4

1

2

4

3

5

6

J111

1

2

J102

1

2

3

4

J7

1

2

3

4

J9

1

A

2

3

B

4

A

5

6

B

J8

1

2

For details, refer to page 9-12.

+24V

For details, refer to page 9-8.

∗

∗

For details, refer to page 9-8.

Transport motor

M2

Stapler unit oscillation motor

M4

1

2

4

3

5

6

1

2

3

4

5

J116

J112

1

2

3

4

5

+24V

6

5

3

4

2

1

3

A

4

5

B

6

A

7

8

B

J12

5

A

4

B

3

A

2

B

1

For details, refer to page 9-7.

∗

∗

+24V

∗

For details, refer to page 9-15.

∗

9 – 16

Page 36

AR-SS2

Sorter controller output (2/2)

Sorter controller PWB

NO

Staple empty detection

NO

Cartridge empty

detection

+5V

Stapling home position

sensor

+5V

Staple cue sensor

MS5

MS6

PI8

PI9

COM

COM

11

J201

7

8

9

7

8

9

11

5

4

3

1

7

8

J102

9

11

11

J7

7

SPEMP

8

SPCART

9

SPLHP

SELFP

"1" when staple empty

"1" when cartridge empty

"0" when stapling is in the home

position.

"0" when staple cue is completed.

MS3

NO COM

Obstacle detection

Bin unit upper limit sensor

Bin unit lower limit sensor

Joint sensor

Operation panel

PI4

PI5

PI6

3

2

1

3

2

1

3

2

1

J301

+24V

J103

1

2

33 3223

1

2

J104J202

12

13

IBUTU

+5V

J11

1

2

3

+5V

4

5

6

+5V

J13

1

2

3

SPLSU

"0" when an obstacle is detected.

BUL

0" when the bin unit reaches

the upper limit

"0" when the bin unit reaches

BLL

the lower limit.

SOP

"1" when connected with the copier.

"0" when manual stapling

9 – 17

Page 37

D. Copier/sorter communication

1) Outline

The copier and the sorter are exchanging the status signals by IPC

(communication IC).

This machine is provided with a new IPC and the old IPC communication functions as well to allow selection depending on the copier

connected.

Selection is made by the DIP switch (SW1) No. 6 on the sorter

controller PWB.

SW1-6 ON OFF

Communication

system

Old IPC

communication

Bin paper sensor

1

2

S1 (Light receiving section)

Bin paper sensor

2

1

S2 (Light receiving section)

J203

1

2

J204

2

1

New IPC

communication

4

3

J108

2

1

1

2

3

4

AR-SS2

These signals are written into the RAM on the sorter controller PWB

and outputted according to the control signal from the CPU (Q1).

A serviceman cannot check if the status signal is properly transferred

or not. When, however, an error in signal transfer occurs, the self

diagnostics function of the copier functions to display the error code

on the operation section of the copier. (Code: F1-70)

Sorter controller PWB

+5V

J4

1

2

BIN LED

3

PA CHE

4

"1" when LED emits light. (Blinking)

"1" when there is paper in the bin.

Guide bar home position sensor

1

2

3

PI3

Joint switch

MS1

NO

NO

NO

COM

Bin shift motor clock sensor

3

2

1

PI1

Lead cam home position sensor

3

2

1

PI2

Stapler unit cover switch

MS2

COM

Stapler unit home position switch

MS4

COM

Stapler unit cover sensor

3

2

1

PI7

S3

J301

1

2

4

J115

1

2

3

4

5

6

7

J202 J104

4

1

3

2

1

4

+5V

6

7

8

1

2

1

3

2

4

5

6

1

2

3

4

5

6

7

1

2

4

1

2

3

4

3

2

1

1

4

2

3

4

1

STYGHP

+24V

J10

JOI SW "1" when connected to the copier.

+5V

J5

SHIFT CLK

+5V

CUMH

+24V

J6

SPLOPN

+24V

SPUHP

+5V

J14

SPLOPN "1" when the stapler unit cover is closed.

J3

SPLED "1" when stapling is enabled.

HARI LED

"1" when the guide bar is in the home position.

Pulses corresponding to the shift

motor rotating speed